Submitted:

01 September 2025

Posted:

02 September 2025

You are already at the latest version

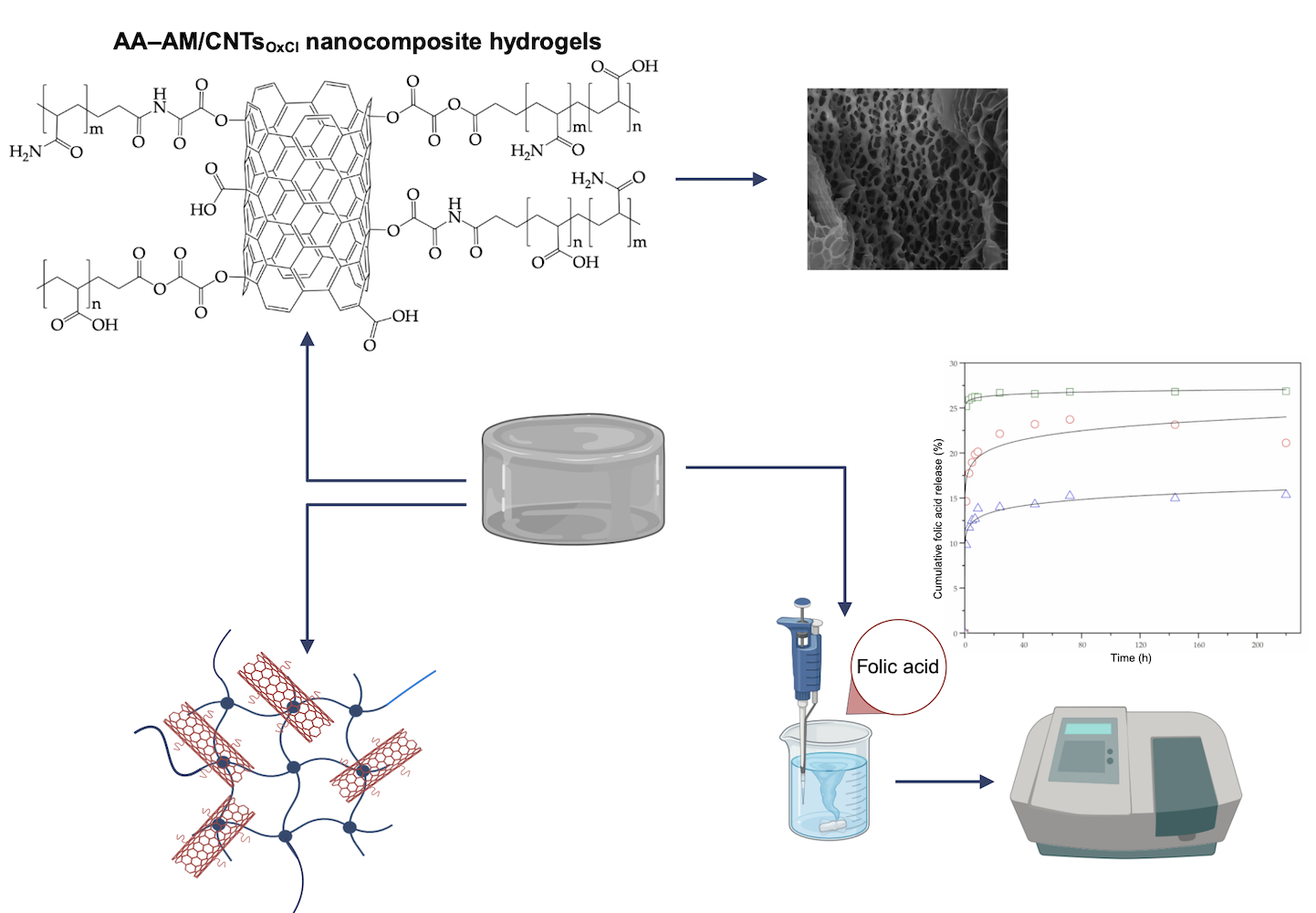

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

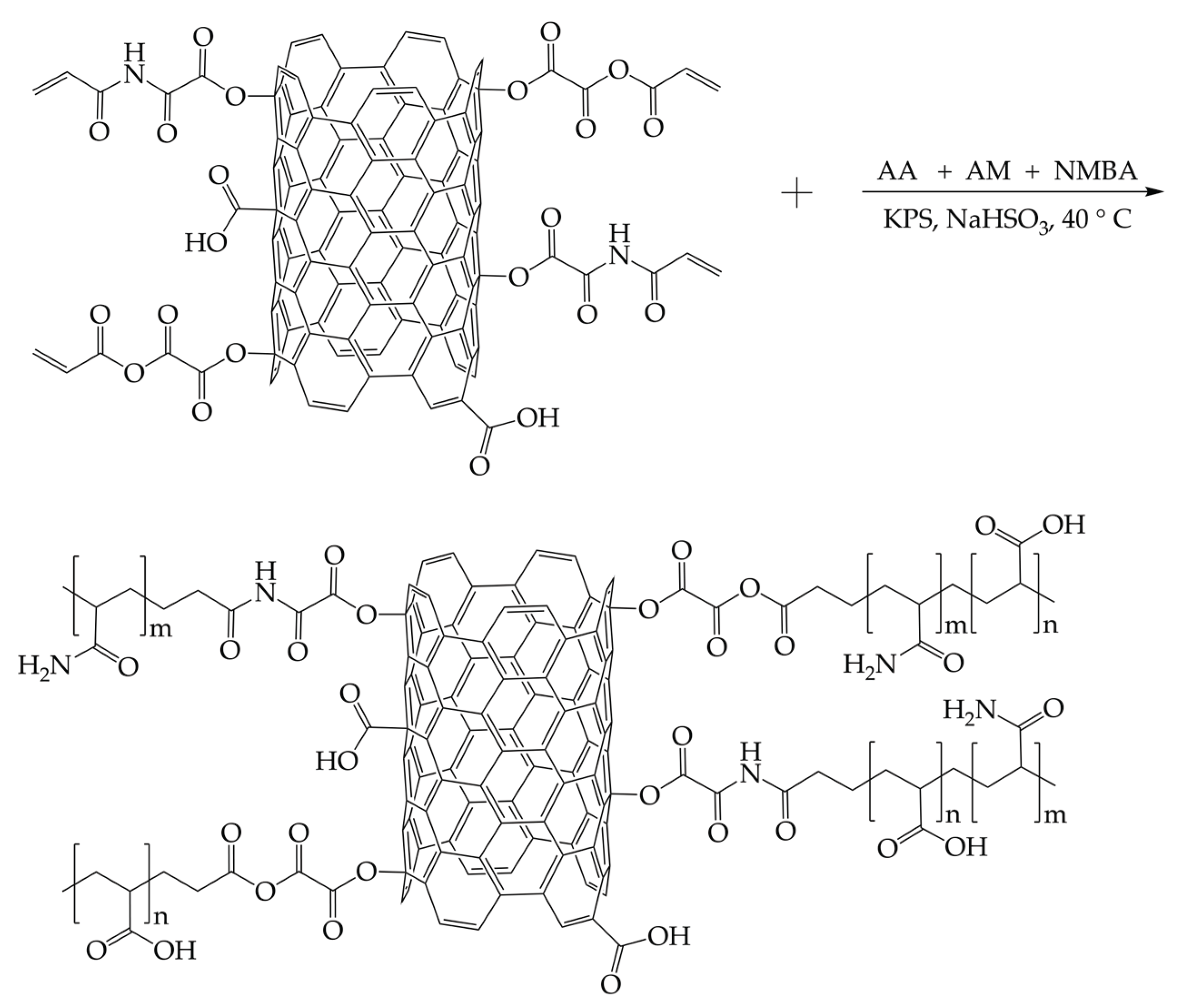

2.2. Synthesis, Purification, Partial Oxidization, and Chemical Functionalization of CNTs

2.4. Synthesis and Purification of the AM–AA Hydrogels and AM–AA/CNTsOxCl Nanocomposite Hydrogels

2.5. CNTs, AM–AA Hydrogels, and AM–AA/CNTsOxCl Nanocomposite Hydrogels Characterization

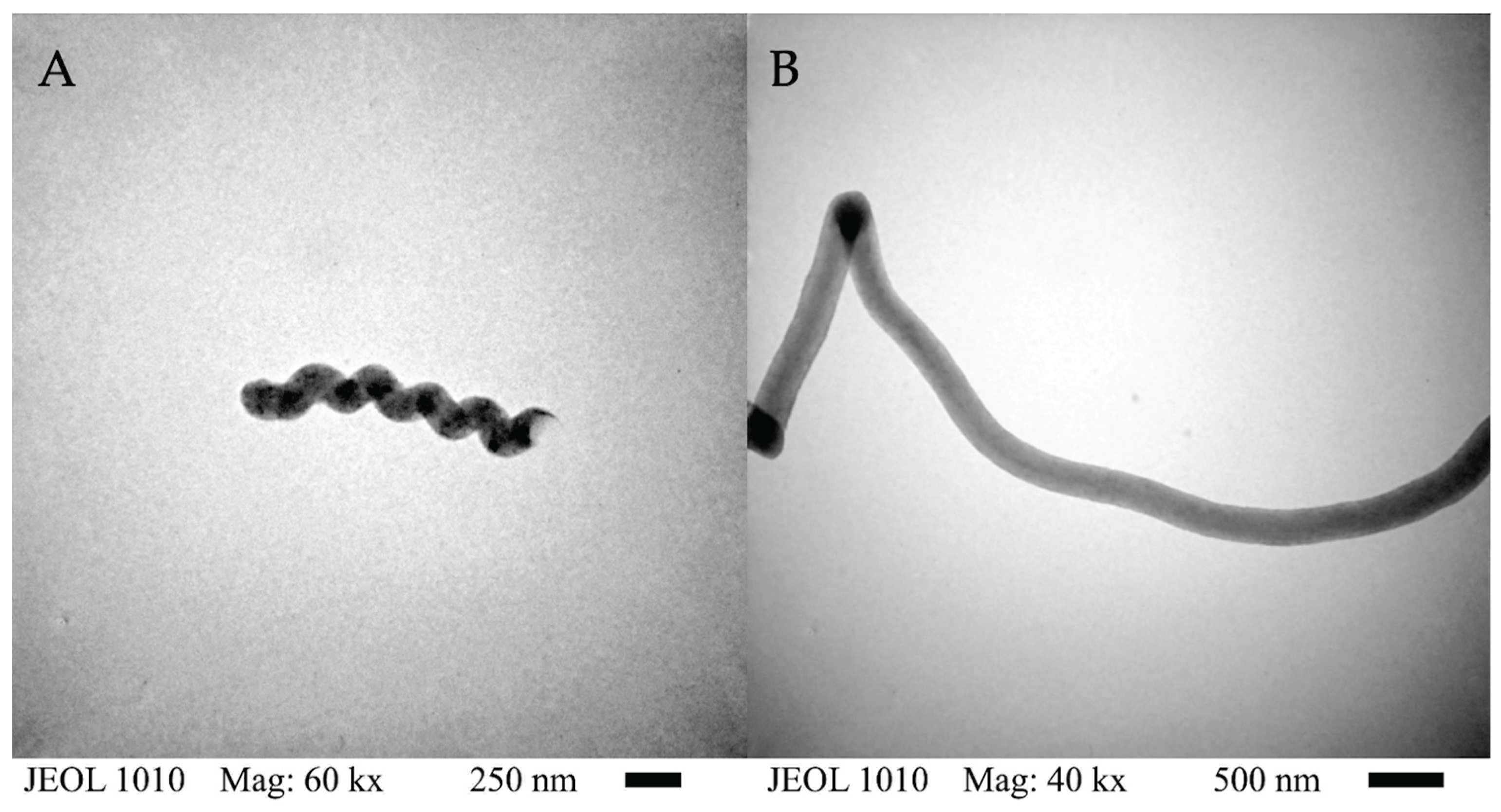

2.5.1. Transmission Electron Microscopy (TEM)

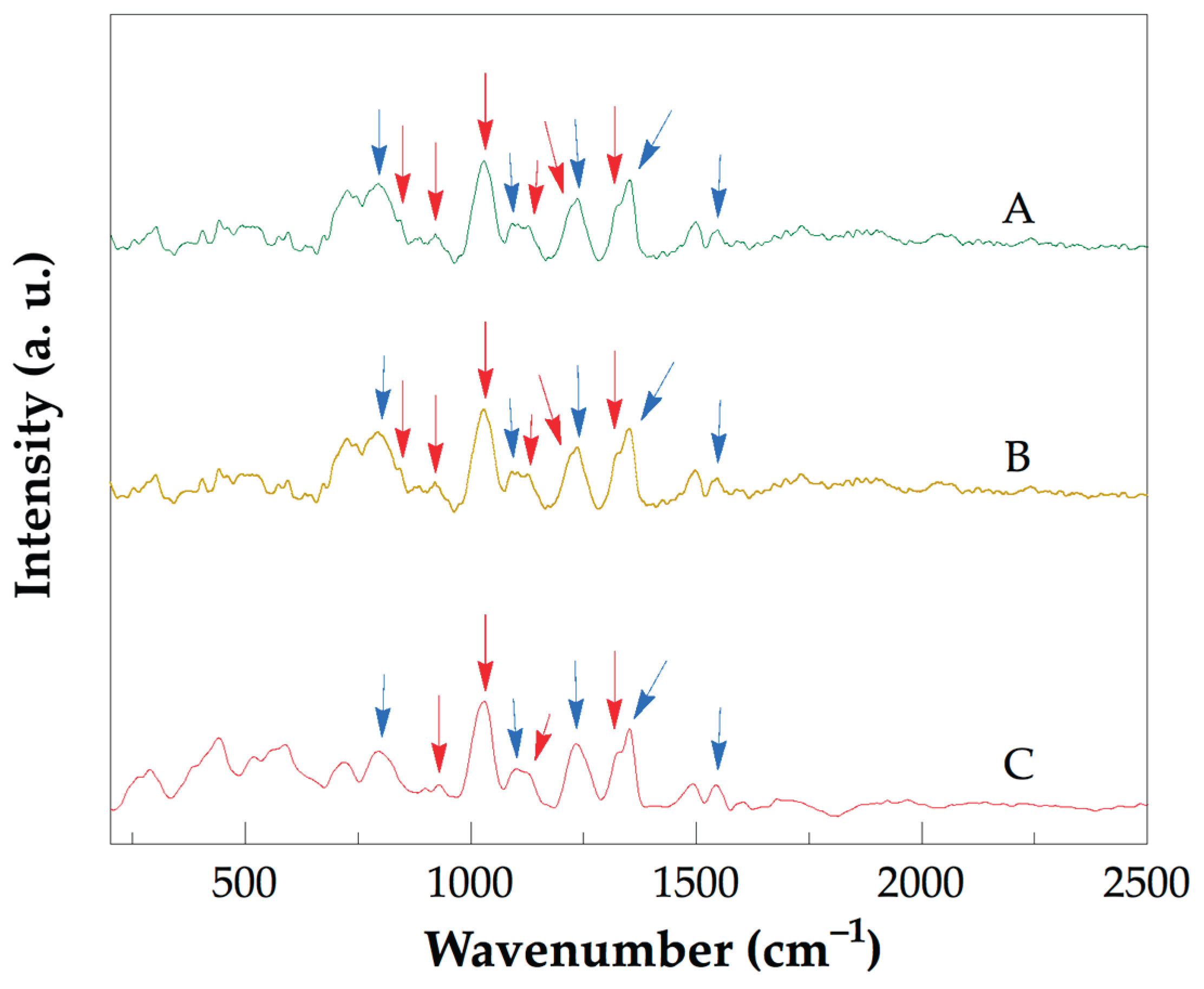

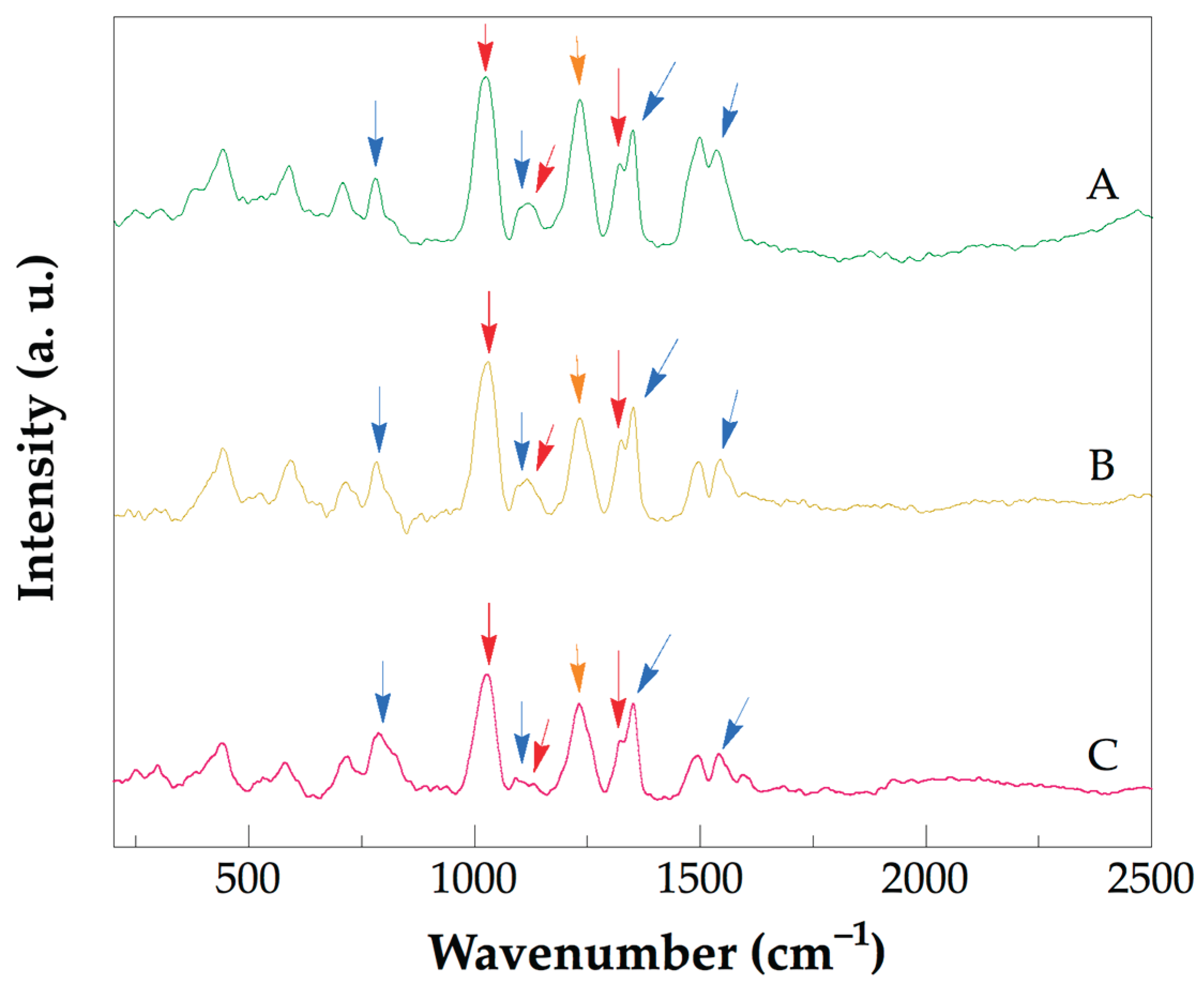

2.5.2. Raman Spectroscopy

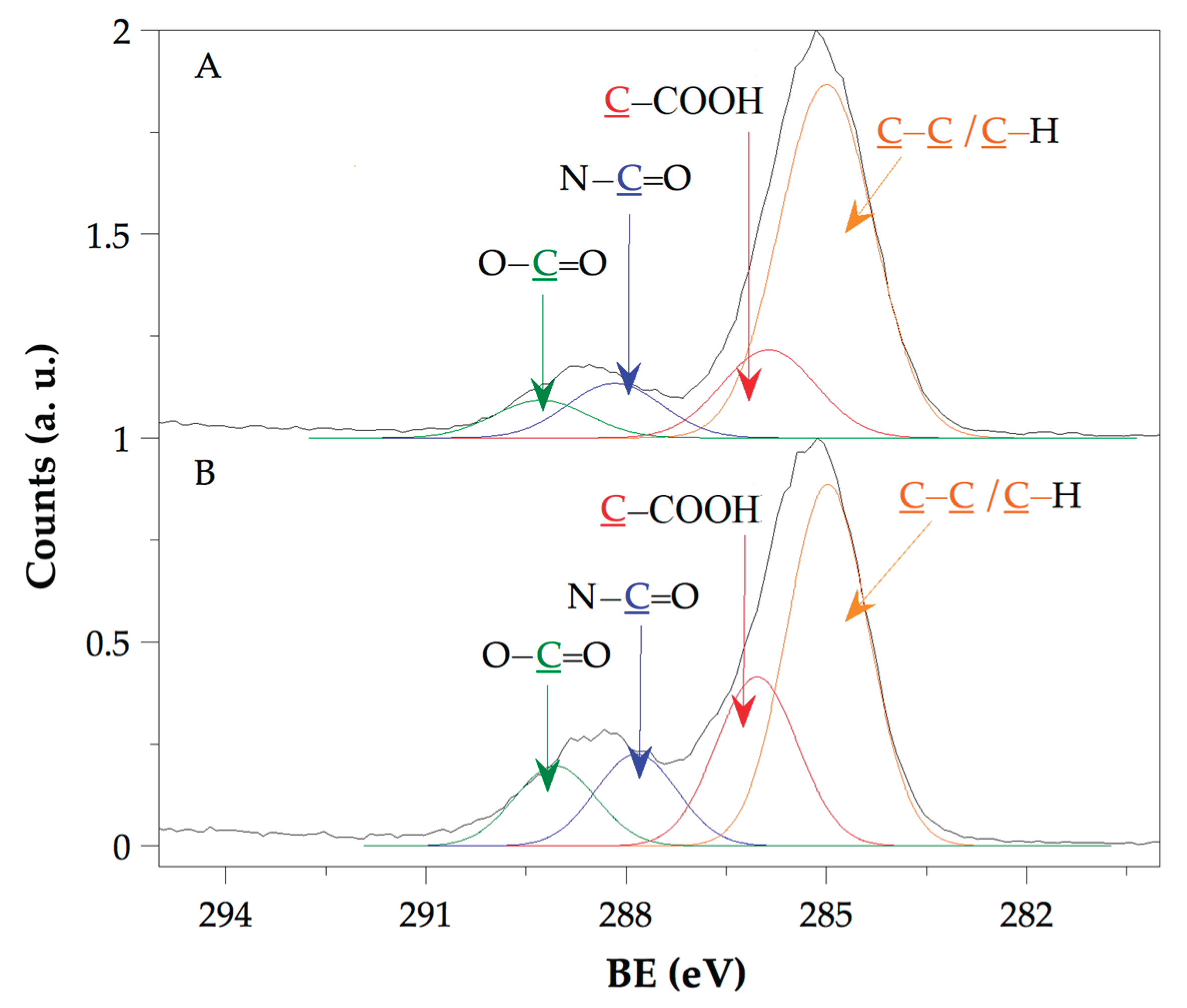

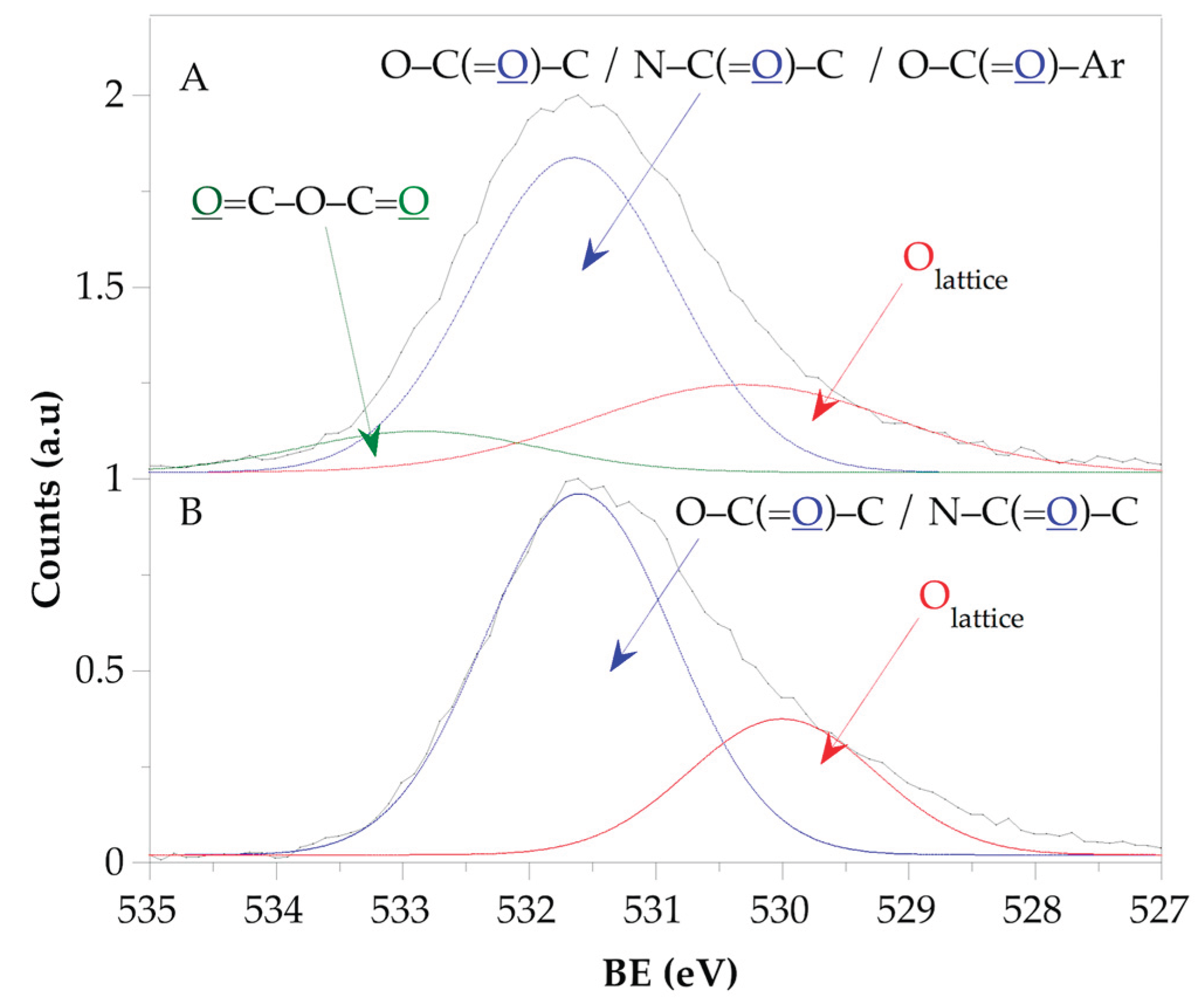

2.5.3. X–Ray Photoelectron Spectroscopy (XPS)

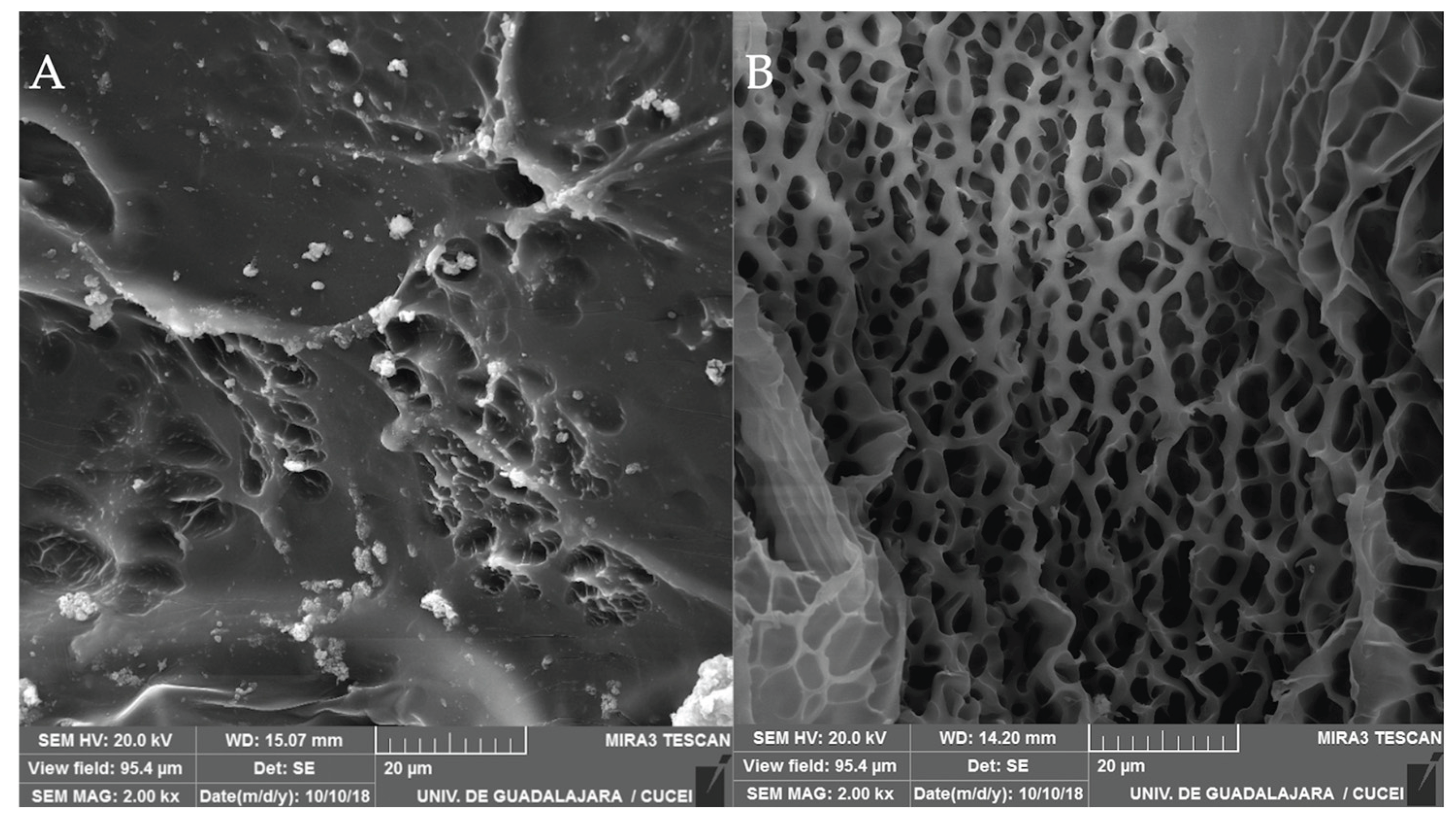

2.5.4. Field–Emission Scanning Electron Microscopy (FE–SEM)

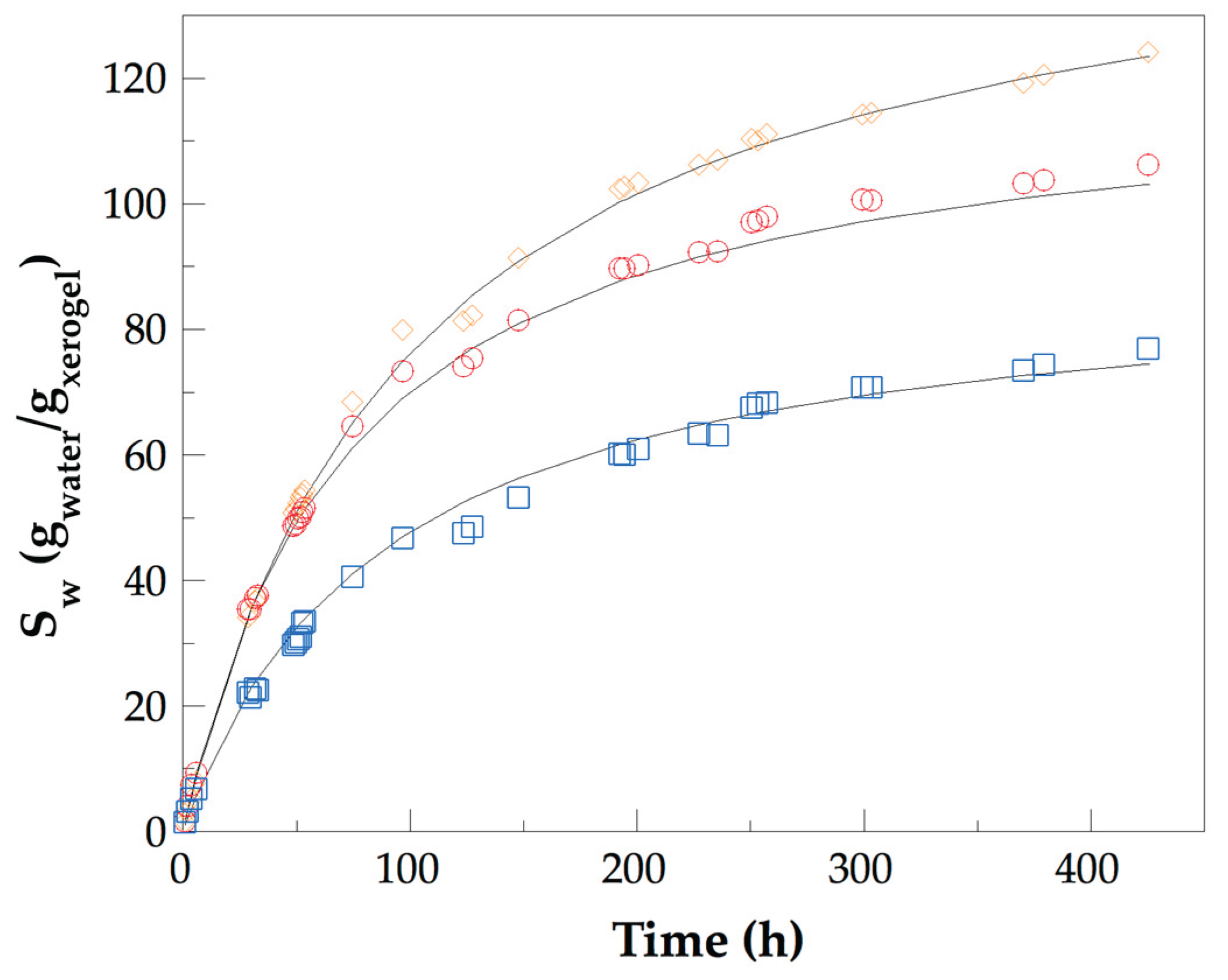

2.5.5. Swelling Tests

2.5.6. Mechanical Tests

2.5.7. UV–Vis Spectroscopy

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | acrylamide |

| AA | acrylic acid |

| CNTs | carbon nanotubes |

| CVD | chemical vapor deposition |

| TEM | transmission electron microscopy |

| XPS | X–ray photoelectron spectroscopy |

| FE-SEM | field-emission scanning electron microscopy |

| SWCNTs | single–walled carbon nanotubes |

| MWCNTs | multi–walled carbon nanotubes |

| DDS | drug delivery systems |

| UCST | upper critical solution temperature |

| PPy | polypyrrole |

| 5-FU | 5–fluorouracil |

| NIR | near–infrared |

| PAAm | polyacrylamide |

| PAAc | polyacrylic acid |

| IPN | interpenetrating network |

References

- Chai, Q.; Jiao, Y.; Yu, X. Hydrogels for Biomedical Applications: Their Characteristics and the Mechanisms behind Them. Gels 2017, 3, 6.

- Seliktar, D. Designing Cell–Compatible Hydrogels for Biomedical Applications. Science 2012, 336, 1124–1128.

- Delcea, M.; Möhwald, H.; Skirtach, A.G. Stimuli–responsive Lbl capsules and nanoshells for drug delivery. Adv Drug Del. Rev. 2011, 63, 730–747.

- Sennakesavan, G.; Mostakhdemin, M.; Dkhar, L.K.; Seyfoddin, A. Acrylic acid/acrylamide based hydrogels and its properties – A review. Polym. Degrad. Stab. 2020, 180, 109308.

- Taylor, M.J.; Tomlins, P.; Sahota, T.S. Themoresposive Gels. Gels 2017, 3, 4.

- Alzari, V.; Ruiu, A.; Nuvoli, D.; Sanna, R.; Martinez, J.I.; Appelhans, D.; Voit, B.; Zschoche, S.; Mariani, A. Three component terpolymer and IPN hydrogels with response to stimuli. Polymer 2014, 55, 5305–5313.

- Marcelo, G.; Areias, L.R.P.; Viciosa, M.T.; Martinho, J.M.G.; Farinha, J.P.S. PNIPAm–based microgels with a UCST response. Polymer 2017, 116, 261–267.

- Bajpai, A.K.; Shukla, S.K.; Bhanu, S.; Kankane, S. Responsive polymers in controlled drug delivery. Prog. Polym. Sci. 2008, 33, 1088–1118.

- Zhou, X.; Weng, L.; Chen, Q.; Zhang, J.; Shen, D.; Li, Z.; Shao, M.; Xu, J. Investigation of pH sensitivity of poly(acrylic acid–co–acrylamide) hydrogel. Polym. Int. 2003, 52, 1153–1157.

- Ding, C.; Guo, Z.; Xiong, J.; Wu, D.; Tao, Y.; Qin, Y.; Kong, Y. Rational design of a multi–responsive drug delivery platform based on SiO2@PPy@poly(acrylic acid–co–acrylamide). React. Funct. Polym. 2019, 137, 88–95.

- Ray, D.; Mohapatra, D.K.; Mohapatra, R.K.; Mohanta, G.P.; Sahoo, P.K. Synthesis and colon–specific drug delivery of a poly(acrylic–co–acrylamide)/MBA nanosized Hydrogel. J. Biomater. Sci. Polymer Ed. 2008, 19, 1487–1502.

- Thippeswamy, M.; Puttagiddappa, M.G.; Thippaiah, D.; Satyanarayan, D.N. Poly(acrylamide–co–acrylic acid) synthesized, moxifloxacin drug–loaded hydrogel: Characterization and evaluation studies. J. Appl. Pharm. Sci. 2021, 11, 074–081.

- Chavda, H.V.; Patel, C.N. Effect of crosslinker concentration on characteristics of superporous hydrogel. Int. J. Pharm. Investig. 2011, 1, 17–21.

- Syduzzaman, M.; Islam Saad, M.S.; Piam, M.F.; Talukdar, T.A.; Shobdo, T.T.; Pritha, N.M. Carbon nanotubes: structure, properties and applications in the aerospace industry. Results Mater. 2025, 25, 100654.

- Yu, M.–F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640.

- Yu, M.–F.; Files, B.S.; Arepalli, S.; Ruoff, R.S. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys. Rev. Lett. 2000, 84, 5552.

- Bellingeri, R.; Mulko, L.; Molina, M.; Picco, N.; Alustiza, F.; Grosso, C.; Vivas, A.; Acevedo, D.F.; Barbero, C.A. Nanocomposites based on pH–sensitive hydrogels and chitosan decorated carbon nanotubes with antibacterial properties. Mat. Sci. Eng. C–Mater. 2018, 90, 461–467.

- Feng, H.; Zheng, T.; Wang, X.; Wang, H. Poly(acrylamide)–MWNTs hybrid hydrogel with extremely high mechanical strength. Open Chem. 2016, 14, 150–157.

- Takada, T.; Morikawa, Y.; Kikuchi, Y.; Miyamoto, D.; Hayasaka, Y.; Abe, S. Mechanical and swelling properties of polyacrylamide/polyacrylic acid composite hydrogels: The effects of network structure and carbon nanotube reinforcement. Carbon Rep. 2024, 3, 29–36.

- Kanca, Y.; Özdemir, R.; Dini, D.; Özkahraman, B. Multi–walled carbon nanotube reinforced polyacrylamide–acrylic acid nanocomposite hydrogels with superior mechanical and tribological performance as focal cartilage substitute. Polym. Eng. Sci. 2025, 65, 3988–4005.

- Narmani, A.; Rezvani, M.; Farhood, B.; Darkhor, P.; Mohammadnejad, J.; Amini, B.; Rafahi, S., Goushbolagh, N.A. Folic acid functionalized nanoparticles as pharmaceutical carriers in drug delivery systems. Drug Dev. Res. 2019, 80, 404–424.

- Fuster, M.G.; Wang, J.; Fandiño, O.; Víllora, G.; Paredes, A.J. Folic acid–decorated nanocrystals as highly loaded trojan horses to target cancer cells. Mol. Pharmaceutics 2024, 21, 2781–2794.

- Rúan–Esparza, L.; Soto, V.; Gómez–Salazar, S.; Rabelero, M.; Ávalos–Borja, M.; Luna–Bárcenas, G.; Prokhorov, E.; Nuño–Donlucas, S.M. Poly[ethylene–co–(acrylic acid)]–based nanocomposites: Thermal and mechanical properties and their structural characteristics studied by Raman spectroscopy. Polym. Compos. 2011, 32, 1181–1189.

- Torres–Ávalos, J.A.; Cajero–Zul, L.R.; Vázquez–Lepe, M.; López–Dellmary, F.A.; Martínez–Richa, A.; Barrera–Rivera, K.A.; López–Serrano, F.; Nuño–Donlucas, S.M. Synthesis of poly(methacrylic acid–co–butyl acrylate) grafted onto functionalized carbon nanotube nanocomposites for drug delivery. Polymers 2021, 13, 533.

- Xia, R.; Li, M.; Zhang, Y.; Qian, J.; Yuan, X. Surface modification of MWCNTs with BA–MMA–GMA terpolymer by single–step grafting technique. J. Appl. Polym. Sci. 2011, 119, 282–289.

- Silva–Jara, J.M.; Manríquez–González, R.; López–Dellamary, F.A.; Puig, J.E.; Nuño–Donlucas, S.M. Semi–continuous heterophase polymerization to synthesize nanocomposites of poly(acrylic acid)–functionalized carbon nanotubes. J. Macromol. Sci. Part A 2015, 52, 732–744.

- Cajero–Zul, L.R.; López–Dellmary, F.A.; Gómez–Salazar, S.; Vázquez–Lepe, M.; Vera–Graziano, R.; Torres–Vitela, M.R.; Olea–Rodríguez, M.A.; Nuño–Donlucas, S.M. Evaluation of the resistance to bacterial growth of star–shaped poly(e–caprolactone)–co–poly(ethylene glycol) grafted onto functionalized carbon nanotubes nanocomposites. J. Biomater. Sci. Polym. Ed. 2019, 30, 163–189.

- Katime, I.; Velada, J. L.; Novoa, R.; Díaz de Apodaca; E.; Puig, J.; Mendizábal, E. Swelling kinetics of poly(acrylamide)/poly(mono–n–alkyl itaconates) hydrogels. Polym Int. 1996, 40, 281–286.

- Salvetat, J.–P.; Bonard, J.–M.; Thomson, N.H.; Kulik, A.J.; Forró, L.; Benoit, W.; Zuppiroli, L. Mechanical properties of carbon nanotubes. Appl. Phys. A 1999, 69, 255–260.

- Gómez–Vázquez, D.; Cajero–Zul, L.R.; Torres–Ávalos, J.A.; Sandoval–García, K.; Cortés–Ortega, J.A.; López–Dellamary, F.A.; Soltero–Martínez, J.F.A.; Martínez–Richa, A.; Nuño–Donlucas, S.M. Homogeneous hydrogels made with acrylic acid, acrylamide amd chemically functionalized carbon nanotubes. J. Macromol. Sci. Part A 2019, 56, 417–428.

- Li, C.; Chou, T.–W. Elastic moduli of multi–walled carbon nanotubes and the effect of van der Waals forces. Compos. Sci. Technol. 2003, 63, 1517–1524.

- Sivaganga, K.C.; Varughese, T. Physical properties of carbon nanotubes. In Handbook of carbon nanotubes, 1st ed.; Abraham, J., Thomas, S., Kalarikkal, N., Eds.; Springer: Cham, Switzerland, 2022: pp. 283–297.

- Thomsen, C.; Reich, S. Double resonant Raman scattering in graphite. Phys. Rev. Lett. 2000, 85, 5214.

- Brown, S.D.M.; Jorio, A.; Dresselhaus, M.S.; Dresselhaus, G. Observationsof the D–band feature in the Raman spectra of carbon nanotubes. Phys. Rev. B 2001, 64, 073403.

- Costa, S.; Borowiak–Palen, E.; Kruszyńska, M.; Bachmatiuk, A.; Kaleńczuk, R.J. Characterization of carbon nanotubes by Raman spectroscopy. Mater. Sci.–Pol. 2008, 26, 433–441.

- Heise, H.M.; Kuckuk, R.; Ojha, A.K.; Srivastava, A.; Srivastava, V.; Asthana, B.P. Characterisation of carbonaceous materials using Raman spectroscopy: a comparison of carbon nanotube filters, single– and multi–walled nanotubes, graphitised porous carbon and graphite. J. Raman Spectrosc. 2009, 40, 344–353.

- Fantini, C.; Usrey, M.L., Strano, M.S. Investigation of electronic and vibrational properties of single–walled carbon nanotubes functionalized with diazonium salts. J. Phys. Chem. C 2007, 111, 17941–17946.

- Gupta, M.K.; Bansil, R. Laser Raman spectroscopy of polyacrylamide. J. Polym. Sci., Polym. Phys. Ed. 1981, 19, 353–360.

- Amorim da Costa, A.M.; Amado, A.M. Cationic hydration in hydrogelic polyacrylamide–phosphoric acid network: A study by Raman spectroscopy. Solid State Ion. 2001, 145, 79–84.

- Dong, J.; Ozaki, J.; Nakashima, K. Infrared, Raman, and near–infrared spectroscopic evidence for the coexistence of various hydrogen–bond forms in poly(acrylic acid). Macromolecules 1997, 30, 1111-1117.

- Todica, M.; Stefan, R.; Pop, C.V.; Olar, L. IR and Raman investigation of some poly(acrylic) acid gels in aqueous and neutralized state. Acta Phys. Pol. A 2015, 128, 128-135.

- Liu, S.; Zhang, M.; Huang, B.; Wu, N.; Ouyang, S. Raman spectroscopy for the competition of hydrogen bonds in ternary (H2O–THF–DMSO) aqueous solutions. Molecules, 2019, 24, 3666.

- Herrera–Gomez, A.; Bravo–Sanchez, M.; Ceballos–Sanchez, O.; Vazquez–Lepe, M.O. Practical methods for background substraction in photoemission spectra. Surf. Interface Anal. 2014, 46, 897–905.

- Dietrich, P.M.; Henning, A.; Holzweber, M.; Thiele, T.; Borcherding, H.; Lippitz, A.; Schedler, U.; Resch–Genger, U.; Unger, W.E.S. Surface analytical study of poly(acrylic acid)–grafted microparticles (beads): characterization, chemical derivatization, and quantification of surface carboxyl groups. J. Phys. Chem. C 2014, 118, 20393–20404.

- Beamson, G.; Briggs, D. High Resolution XPS of Organic Polymers: The Scienta ESCA300 Database, 1st ed.; Wiley: Chichester, UK, 1992; pp. 110–111.

- Uchida, E.; Uyama, Y.; Iwata, H.; Ikada, Y. XPS analysis of the poly(ethylene terephthalate) film grafted with acrylamide. J. Polym. Sci., Part A: Polym. Chem. 1990, 28, 2837–2844.

- Mukherjee, S.; Mondal, M.H.; Mukherjee, M.; Doyle, B.P.; Nannarone, S. Onset kinetics of thermal degradation of ultrathin polyacrylamide films. Macromolecules 2009, 42, 7889–7896.

- González–Iñiguez, K.J.; Figueroa–Ochoa, E.B.; Martínez–Richa, A.; Cajero–Zul, L.R.; Nuño–Donlucas, S.M. Synthesis of poly(L–lactide)–poly(–caprolactone)–poly(ethylene glycol) terpolymer grafted onto partially oxidixed carbon nanotube nanocomposites for drug delivery. Polymers 2024, 16, 2580.

- Deng, Y.; Xu, Y.; Nie, L.; Huang, Y. Crosslinked polymer coatings of poly(acrylic acid–co–acrylamide)/polyethyleneimine (P(AA–co–Aam)/PEI) on titanium alloy with excellent lubrication performance for artificial joints. Coatings 2024, 14, 28.

- Khokhra, R.; Bharti, B.; Lee, H.–N.; Kumar, R. Visible and UV photo–detection in ZnO nanostructured thin films via simple tuning of solution method. Sci. Rep. 2017, 7, 15032.

- Briggs, D.; Beamson, G. XPS studies of the oxygen 1s and 2s levels in a wide range of functional polymers. Anal. Chem. 1993, 65, 1517–1523.

- Zhang, N.; Xiong, Y. Lattice oxygen activation for enhanced electrochemical oxygen evolution. J. Phys. Chem. C 2023, 127, 2147–2159.

- Hepworth, S.J.; Leach, M.O.; Doran, S.J. Dynamics of polymerization in polyacrylamide gel (PAG) dosimeters: (II) modeling oxygen diffusion. Phys. Med. Biol. 1999, 44, 1875–1884.

- Linert, W.; Lukovits, I. Aromaticity of carbon nanotubes. J. Chem. Inf. Model. 2007, 47, 887–890.

- Zhang, K.; Feng, W.; Jin, C. Protocol efficiently measuring the swelling rate of hydrogels. MethodsX 2020, 7, 100779.

- Aydınoğlu, D. Investigation of pH–dependent swelling behavior and kinetic parameters of novel poly(acrylamide–co–acrylic acid) hydrogels with spirulina. e–Polymers 2015, 15, 81–93.

- ImageJ. Available online: https://imagej.net/ij/ (accessed on 12 July 2024).

- Zhang, Y.; Huo, M.; Zhou, J.; Zou, A.; Li, W.; Yao, C.; Xie, S. DDSolver: An add–in program for modeling and comparison of drug dissolution profiles. AAPS J. 2010, 12, 263–271.

- Langenbucher, F. Linearization of dissolution rate curves by the Weibull distribution. J. Pharm. Pharmacol. 1972, 24, 979–981.

- Costa, P.; Sousa Lobo, J.M. Modelling and comparison of dissolution profiles. Eur. J. Pharm. Sci. 2001, 13, 123–133.

- Corsaro, C.; Neri, G.; Mezzasalma, A.M.; Fazio, E. Weibull modeling of controlled drug release from Ag–PMA nanosystems. Polymers 2021, 13, 2897.

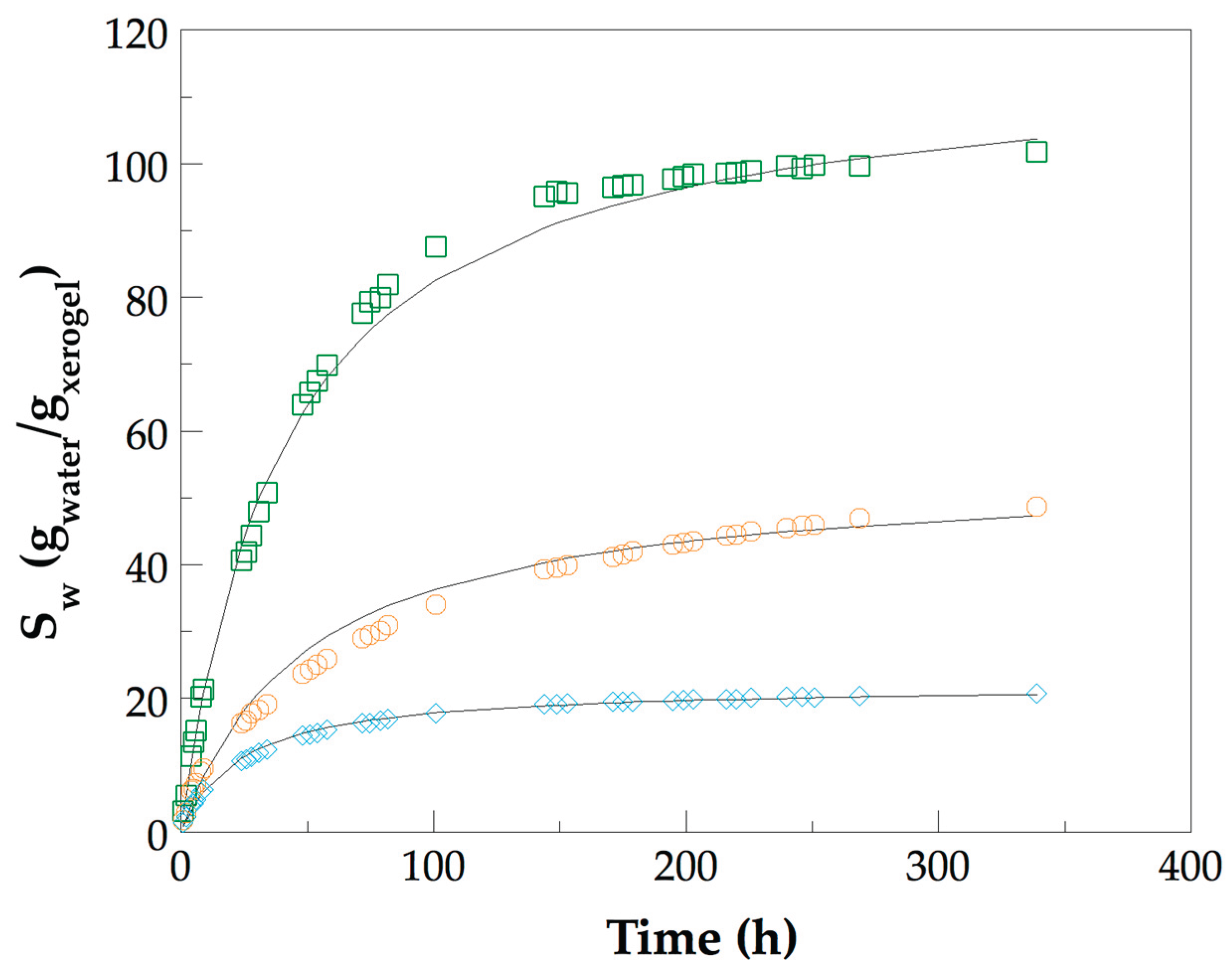

), Hydro 2 (

), Hydro 2 ( ), and Hydro 3 (

), and Hydro 3 ( ).

).

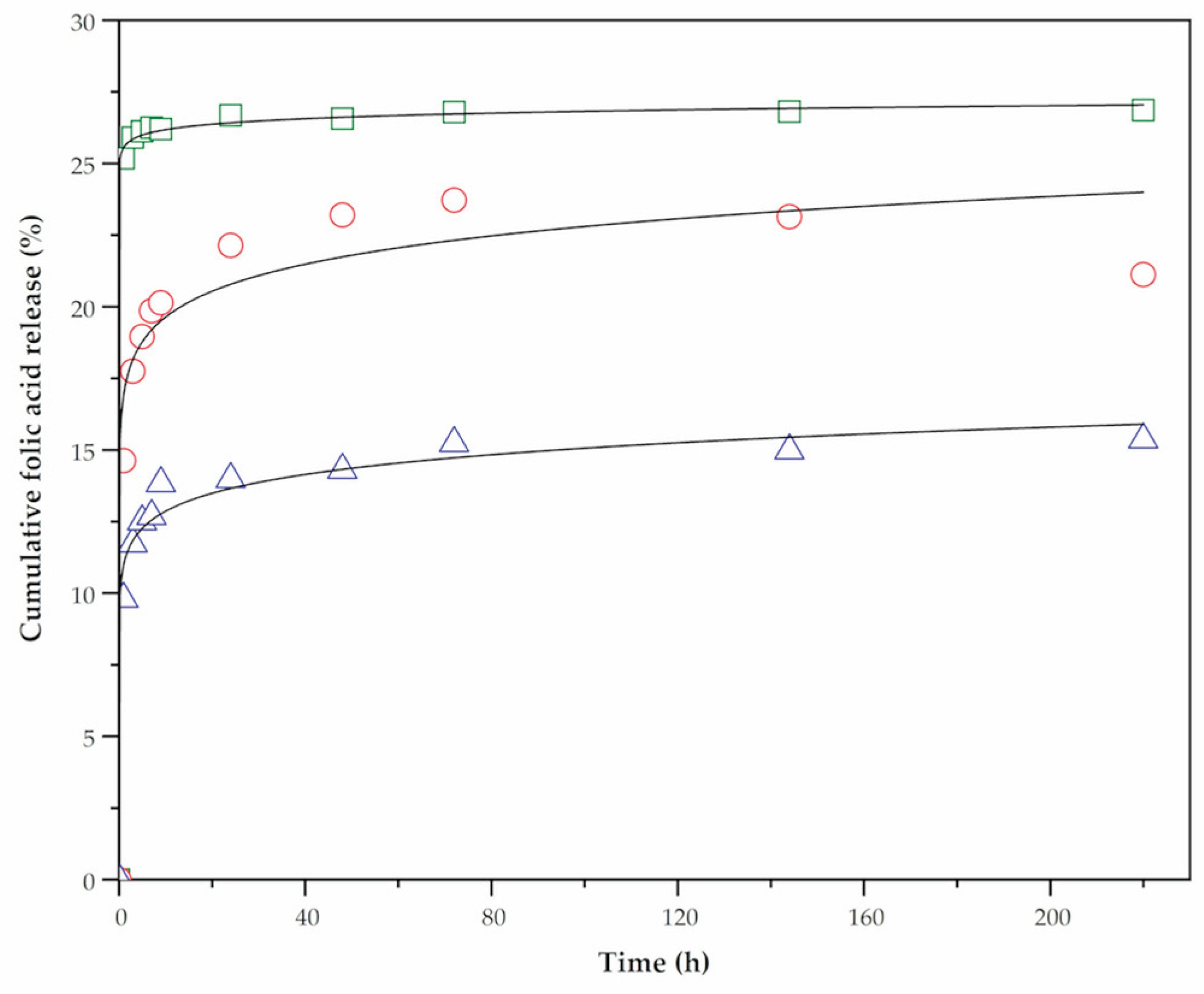

), Nano Hydro 2 (

), Nano Hydro 2 ( ), and Nano Hydro 3 (

), and Nano Hydro 3 ( ).

).

), Nano Hydro 2 (

), Nano Hydro 2 ( ), and Nano Hydro 3 (

), and Nano Hydro 3 ( ).

).

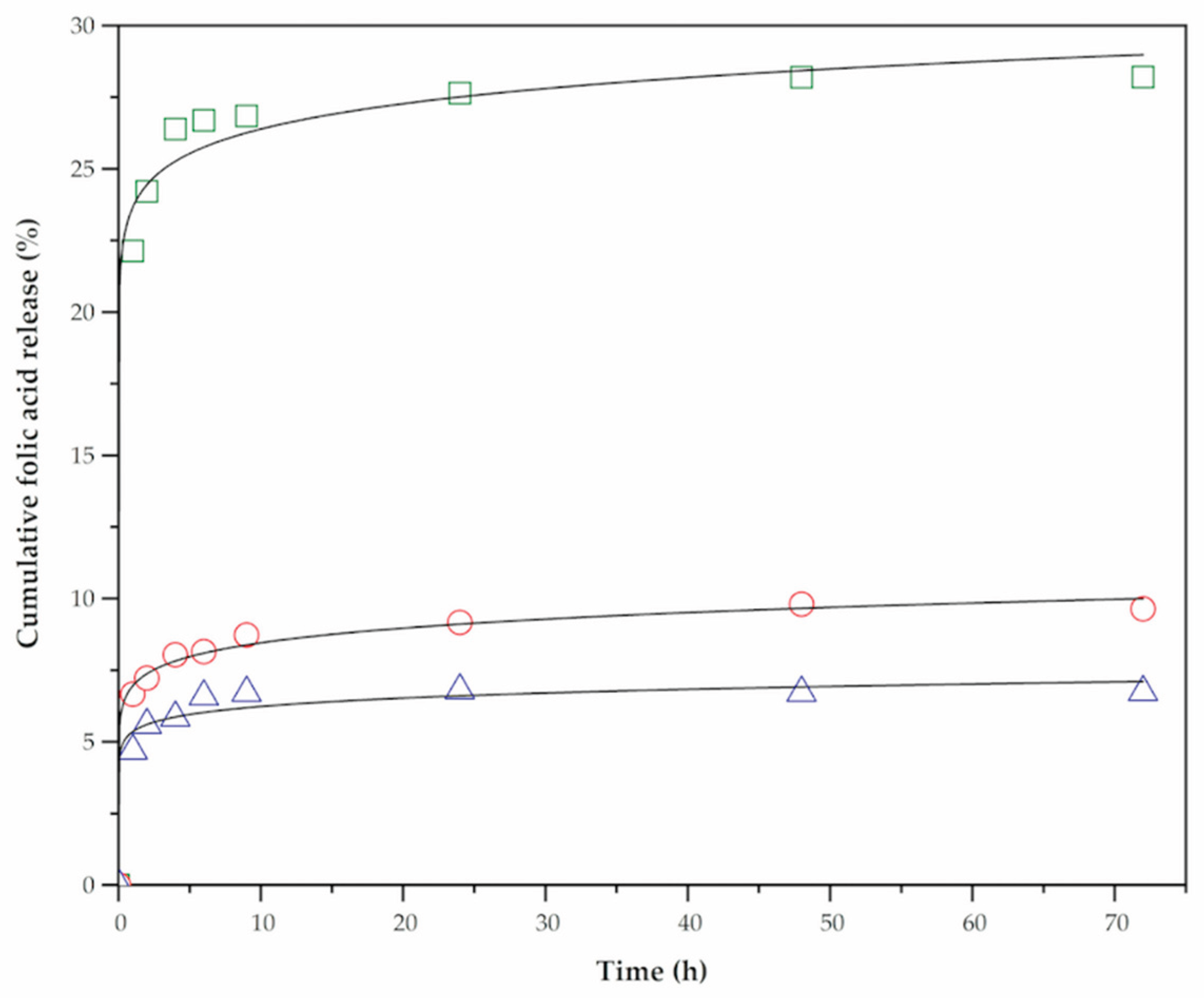

), and Hydro 3 (

), and Hydro 3 ( ).

).

), and Nano Hydro 3 (

), and Nano Hydro 3 ( ).

).

| Samples | AM | AA | NMBA | Na2SO3 | KPS | CNTsOxCl | H2O |

|---|---|---|---|---|---|---|---|

| Hydro 1 | 9 | 1 | 0.1 | 0.05 | 0.05 | 0 | 89.8 |

| Hydro 2 | 8 | 2 | 0.1 | 0.05 | 0.05 | 0 | 89.8 |

| Hydro 3 | 7 | 3 | 0.1 | 0.05 | 0.05 | 0 | 89.8 |

| Nano Hydro 1 | 9 | 1 | 0.1 | 0.05 | 0.05 | 0.1 | 89.7 |

| Nano Hydro 2 | 8 | 2 | 0.1 | 0.05 | 0.05 | 0.1 | 89.7 |

| Nano Hydro 3 | 7 | 3 | 0.1 | 0.05 | 0.05 | 0.1 | 89.7 |

| Samples | D-band (cm-1) |

G-band (cm-1) |

G’-band (cm-1) |

G-band area (u. a.) |

ID/IG |

|---|---|---|---|---|---|

| CNTspoxi | 1233 | 1485 | 2436 | 19.49 | 0.81 |

| CNTsOxCl | 1235 | 1466 | 2461 | 41.43 | 1.56 |

| Samples |

|

|

k |

| Hydro 1 | 77.0 | 74.4 | 1.0 |

| Hydro 2 | 106.3 | 103.1 | 1.5 |

| Hydro 3 | 124.2 | 123.4 | 1.7 |

| Nano Hydro 1 | 20.6 | 20.5 | 1.0 |

| Nano Hydro 2 | 48.6 | 47.3 | 1.1 |

| Nano Hydro 3 | 101.3 | 103.6 | 2.9 |

| Samples |

E (Pa) |

Coefficient of determination (R2) |

|---|---|---|

| Hydro 1 | 6560 | 0.994 |

| Hydro 2 | 7602 | 0.994 |

| Hydro 3 | 8796 | 0.994 |

| Nano Hydro 1 | 9220 | 0.996 |

| Nano Hydro 2 | 10350 | 0.990 |

| Nano Hydro 3 | 10595 | 0.983 |

| Samples | Parameters of the Weibull model | Coefficient of determination (R2) | ||

|---|---|---|---|---|

| Hydro 1 | 0.96 | 8.0 | 0.057 | 0.993 |

| Hydro 2 | 0.98 | 4.9 | 0.054 | 0.973 |

| Hydro 3 | 0.96 | 3.3 | 0.009 | 0.999 |

| Nano Hydro 1 | 0.99 | 16.6 | 0.042 | 0.987 |

| Nano Hydro 2 | 0.75 | 13.1 | 0.074 | 0.997 |

| Nano Hydro 3 | 0.97 | 3.4 | 0.037 | 0.998 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).