1. Introduction

In recent years, terms and public policies such as “technological innovation” “green and low-carbon development” “high-quality development” and “new quality productivity” have become key driving forces for the transformation and upgrading of the cement and concrete industry, especially in developing countries and territories, such as in China. Due to the depletion of natural sand, limitation imposed on sand quarry for environment and ecosystem protection, and transportation cost, manufactured sand, as the fundamental replacement of natural sand, is increasingly used material in infrastructure construction. Using manufactured sand as a replacement of natural sand is beneficial both environmentally and economically. China produces approximately 18 billion tons of sand and gravel annually, with 17.42 billion tons in 2022 [

1,

2,

3,

4], accounting for 40% of global demand and dominating the aggregate market. In 2023, consumption of manufactured sand was 12.2 billion tons in China, accounting for nearly 72% of all sand aggregates [

3]. The quality of sand and gravel aggregates directly affects the quality, safety and efficiency of engineering construction, and plays an important role in national economy and people’s livelihood, as well as the high-quality development. The utilization of manufactured sand instead of natural sand in concrete preparation is the future trend in civil engineering materials.

Manufactured sands refer to artificial aggregates obtained through a series of processes, including soil removal, mechanical crushing, and screening to acquire rock particles with a size smaller than 4.75 mm. The characteristics of manufactured sands vary due to the influence of different rock types and crushing methods. In comparison to natural sands, manufactured sands typically exhibit irregular shape with rough surface and sharp edges.

With the intensification of ecological and environmental protection efforts and the rapid development of infrastructure construction, natural sand and gravel resources are facing depletion [

3]. Vigorously developing manufactured sand and gravel has become the inevitable path for the safe and high-quality development of the sand and gravel industry (as the upstream of concrete industrial chain) under the new situation. However, due to factors such as sand-making process and the quality of base/raw materials, manufactured sand and gravel have problems such as uneven quality, inconsistent properties/performance indicators, low production levels, inadequate quality controls, and incompatibility with other concrete raw materials, which seriously affect the transformation and upgrading as well as green development of the sand and gravel industry [

5,

6,

7]. In response to these issues, it is urgent to further carry out relevant technology research to enhance the quality and supply capacity of manufactured sand, so as to providing support for the healthy, orderly and high-quality development of infrastructure construction in China (as a typical representative of developing countries and territories).

Currently, the production process of manufactured sands is currently divided into two types: dry process and wet process. Compared with the dry sand-making process, the water-washed wet sand-making process basically emits no dust, and the manufactured sand produced has a low mud/clay/silt/powder content, high cleanliness and excellent quality, which is more in line with the requirements of green environmental protection and clean production. However, in order to meet environmental requirements and reduce production costs, in the wet sand-making process, flocculants are usually used to purify the sand-washing water for recycling, which inevitably results in the flocculants being mixed into the finished/final manufactured sand. Once the flocculants remaining in the manufactured sand is excessive or overdose, it is bound to affect the performance of ready-mixed concrete proportioning with manufactured sand [

8,

9,

10,

11,

12,

13,

14]. A considerable amount of flocculants adhering to the surface of manufactured sand can have adverse effects on the concrete mixture, such as a reduction in strength. In other word, the presence of harmful chemical substances and flocculants in water-washing manufactured sand can be one of the potential reasons for affecting the performance of concrete made with manufactured sand. Therefore, on the one hand, it is necessary to accurately detect and strictly control the content of residual flocculants in final manufactured sand products to keep it within the allowable/acceptable range. On the other hand, it is necessary to explore the external manifestations and internal mechanisms of the influence of flocculants on the concrete performance. This study focuses on the rapid detection approach for residual flocculant content in washed machine-made sand and the main influences of the residual flocculants on the properties/performance of ready-mixed concrete prepared with manufactured sand, which are the hot issues in the production, quality inspection and application of manufactured sand. Through a series of experimental investigations, the means and basis for the water-washed wet sand-making process and the quality control of concrete were provided.

2. Materials and Methods

2.1. A Brief Literature Review

According to incomplete statistics, washing 1 m

3 of sand requires 2.0-3.5 tons of water, and the price of large-scale sand washing equipment ranges from tens to hundreds of thousands. Moreover, multiple water treatment steps require strict control, the process is complicated, it occupies a larger area, and there is a higher risk of pollution. In order to reduce production costs and meet environmental protection requirements, water-washed manufactured sand production enterprises/companies usually use flocculants to purify the sand-washing water for recycling and reuse. In this way, 0.1-0.2 tons of water is consumed to produce one cubic meter of sand. Compared with the non-recycling method of sand-washing water, at least 90% of the fresh water can be saved. Although the problem of sewage discharge is well solved, there will be residual flocculant in the recovered water, and the amount of residual flocculant will increase due to the repeated use of water. In the actual production of sand-making enterprises/companies, the control accuracy of the additive amount of flocculants is often rather limited, and the addition dosage is highly arbitrary. Generally, the residual concentration of flocculant in the final manufactured sand is probably not detected at all. This has posed a variety of issues that may affect product quality of downstream users of manufactured sand, especially ready-mixed concrete and prefabricated concrete elements enterprises [

9,

10,

11].

Specifically speaking, the flocculants remained in manufactured sand may impair the workability, mechanical properties as well as long-term durability of the resulting concrete. Some studies show that the research on residual flocculants in manufactured sand is in its infancy, urgently needs to be deepened and extended, and in accordance with “Chinese characteristics” [

9,

10,

11,

12,

13,

14,

15,

16,

17,

18]. You et al. [

11] studied the effects of different types (PAM-1, 2 and 3 versus PAC) and amounts of flocculants on the initial workability and compressive strength of concrete at different ages. The test results show that PAM-3 has the greatest influence on the performance of concrete. When the content of PAM-3 exceeds 0.48 g/15L, the compressive strength of concrete will be reduced. When the content of PAM-1 and PAM-2 is less than 0.24 g/15L, it has no obvious influence on concrete performance. When PAC content is less than 1.8 g/15L, it has no obvious influence on concrete performance. Increasing the amount of concrete admixture can alleviate the adverse effect of the flocculant on concrete to a certain extent.

The existing studies basically take the manufactured sand without flocculants as the reference/control group, and through intentionally adding the flocculants instead of the residual flocculants in the manufactured sand, setting a series of concentrations of flocculants artificially, to investigate the influences of flocculant concentration on the behavior/properties of cement paste, mortar or concrete [

9,

10,

11,

12,

13,

14]. Finally, based on the test results under specific boundary conditions, the concentration threshold of a specific flocculant in a specific cement-based material system is speculated. Although this method can explore the influence law of flocculant concentration on the performance of concrete mixed with manufactured sand and determine the allowable range of the flocculant content accordingly, it cannot directly detect the residual flocculant content of water-washed manufactured sand, which is not conducive to the rapid evaluation of the quality of washed manufactured sand, nor can it adjust the real-time proportion of manufactured sand concrete in a timely manner to ensure the quality and performance stability of the concrete. Therefore, this study proposes a method for rapidly detecting the content of residual flocculants in water-washed manufactured sand and determining its qualified threshold to affect the properties of concrete.

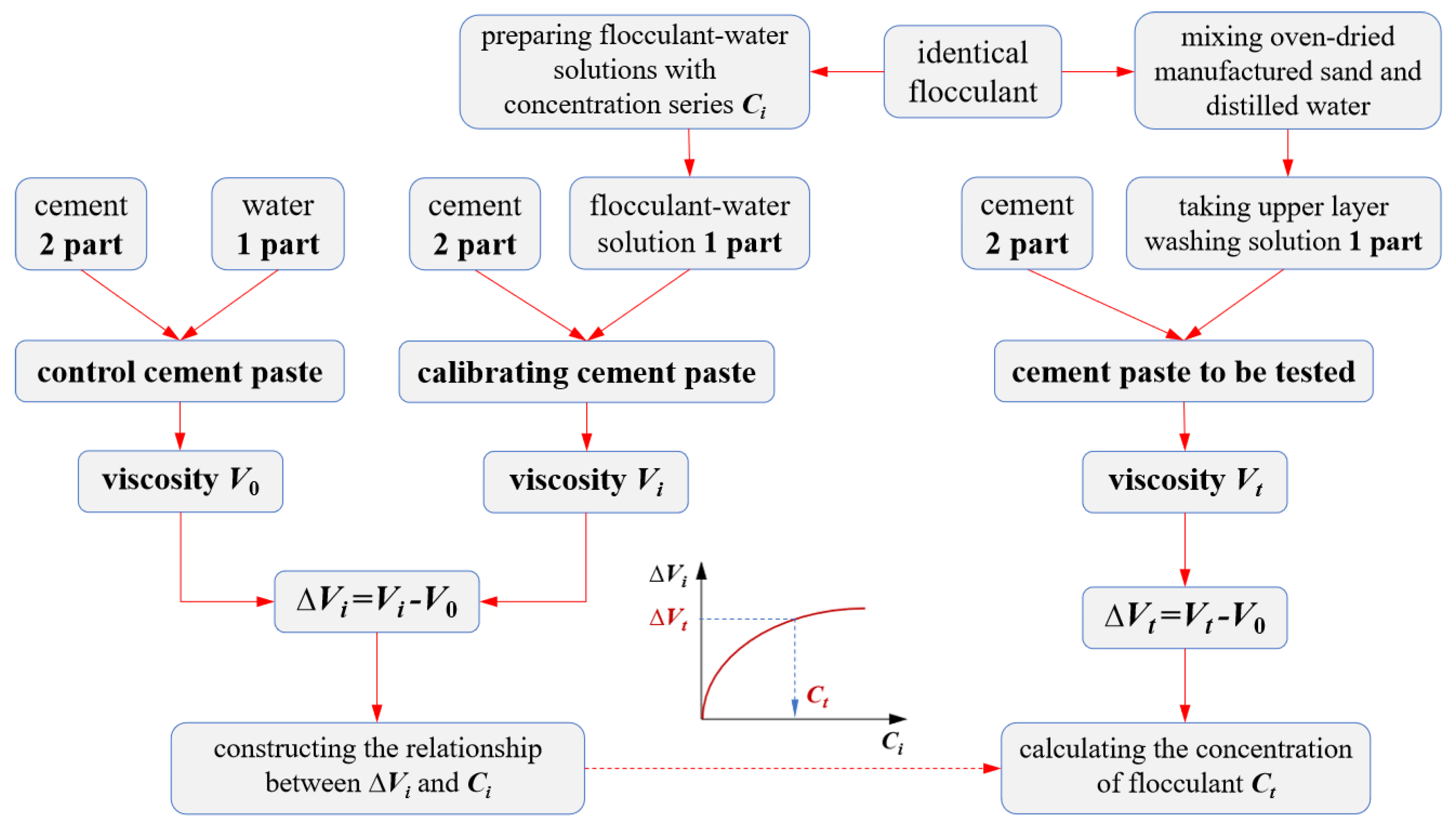

2.2. Detection of the Residual Flocculants Content in Manufactured Sand

Flocculants are agents that make fine and subfine solids or colloids suspended in the solution form large loose flocs through bridging, thus achieving solid-liquid separation. Flocculants are basically divided into three categories: (i) mineral supplements such as PAC, (ii) synthetic organic polymers, and (iii) flocculants found in nature. Compared to inorganic flocculants, organic flocculants have higher molecular weight and stronger flocculation ability, and can achieve efficient flocculation effects at low doses [

15,

16]. Therefore, organic flocculants were the most commonly used flocculants currently. Since the flocculants can affect the viscosity of the liquid phase, a quantitative relationship between the Stormer viscosity of the cement paste and the concentration of the flocculant was established, and several flocculant concentrations were set up to verify the reliability of this quantitative relationship (that is, the concentration of the flocculant was calculated based on the measured viscosity data according to the quantitative relationship, thereby obtaining the concentration difference from the actually prepared flocculant). By measuring the viscosity value of the cement paste prepared from the soaking solution of manufactured sand of unknown concentration, and based on the established quantitative relationship between the Stormer viscosity and the concentration of the flocculant, the concentration of the flocculant in the soaking solution of manufactured sand was inversely obtained (as shown in

Figure 1).

Since the quantitative relationship between the viscosity of the cement paste and the concentration of the flocculant was highly dependent on the type of flocculant, for different flocculants, this relationship should be obtained separately through experiments, and the selected cement must also come from the same batch. Once an excessive amount of flocculant was added to the water, the solution may stratify after standing still. To this end, measures should be taken to ensure the uniformity and stability of the aqueous solution of the flocculant used for preparing cement paste. Considering that the concentration of the prepared flocculant aqueous solution was too low (generally no higher than 0.01%), in order to improve the test accuracy, the amount of solution prepared should be appropriately increased.

2.3. Determination of the Threshold Content for Residual Flocculants in Manufactured Sand

The aqueous solution of flocculant and the washed manufactured sand, cement, admixtures, coarse aggregates and admixtures were prepared in accordance with the specific concentration sequence to prepare mortar and concrete. The flowability of mortar and the workability (slump and slump flow) of concrete and their time- dependence were determined respectively. Then, the quantitative relationship between the workability indicators of mortar and concrete and the content of flocculant was established. Based on the perspectives of concrete production and construction, an acceptable loss value of slump/slump flow caused by residual flocculants was proposed, and the safe threshold of flocculant content is determined finally. It should be noted that the manufactured sand selected for the test should be representative, and the influence of the mining source, parent rock and particle gradation should be taken into account. A series of tests should be conducted for different manufactured sands respectively, and the corresponding safety threshold of residual flocculant content may be very different. The test indicators of concrete included slump flow and its loss over time, the emptying time of the inverted slump cone (referred to as the inverted emptying time), and the cubic compressive strength.

2.4. Materials

The cement (OPC) was P·O 42.5 cement produced by Tongxiang Canal Cement Co., LTD in Zhejiang, China. The fly ash (FA) was from Heye Building Materials Co., LTD in Hangzhou, China. The granulated blast furnace slag powder (GBFS) was from Zhongtian New Materials Co., LTD in Changzhou, China. The metakaolin (MK) was from Lingdong Chemical Co., LTD in Shanghai, China. The chemical compositions of these four cementitious materials are shown in

Table 1.

The sand (SS) used for the test complied with the Chinese ISO standard. The coarse aggregate used for concrete tests was granite crushed stone, including two specifications of 5-15 mm (SG) and 5-25 mm (LG), and its properties complied with the requirements of the current Chinese national standard GB/T 14685 “Pebbles and Crushed Stones for Construction”. There were also two types of fine aggregates, which were machine-made coarse sand (MS) and natural fine sand (NS). The former adopted grade I manufactured sand with a fineness modulus of 3.1. The latter was river sand with a fineness modulus of 0.80. The properties of the two fine aggregates both complied with the requirements of the current Chinese national standard GB/T 14684 “Sand for Construction”. The admixture (SP) selected was the PCA-2 polycarboxylate superplasticizer produced by Subote New Materials Co., Ltd. in Jiangsu, China, with a water reduction rate of 26% and a solid content of 17.5%. The water (W) used for mixing the cement paste, mortar and concrete was distilled water and tap water from the local municipal water supply network respectively.

There were mainly two types of flocculants, with polyacrylamide (PAM) as the primary one and polyaluminium chloride (PAC) as the secondary one [

8,

9,

10,

11,

12]. The more commonly used PAM was taken as the research object in this study. The PAM used in the experiment was provided by four water-washed manufactured sand factories, all of which were products used in the actual production process. The codes of these four types of PAM were named as PAM-A, PAM-B, PAM-C and PAM-D respectively, and all of them were anionic products. Among them, the relative molecular mass of PAM-B was 1600×10

4, and those of PAM-A, PAM-C and PAM-D were all 1800×10

4.

2.5. Mixture Proportions

The research on flocculants was carried out respectively on cement paste, mortar and concrete. The Mixture Proportionss of these three types of research subjects are shown in

Table 2 and

Table 3. To make the expression concise, each raw material was represented by a pre-given capital letter code. A small amount of metakaolin was added to the cement paste. The purpose was to prevent the paste from bleeding and ensure the stability and uniformity of the paste state during the test process. To match the engineering application, the Mixture Proportions of the concrete was the same as that of a ready-mixed concrete enterprise, and the codes were C30, C35, and C45, which corresponded one-to-one with the strength grades of these concretions respectively.

The “water” in each mixture proportions was actually the aqueous solution of the flocculant, and according to different test purposes, the corresponding concentration series of the flocculant aqueous solution was set. After repeated cleaning, it was assumed that the content of flocculant in the manufactured sand was zero, and other raw materials didn’t contain flocculant either. The reason for adopting the method of actively adding flocculants was to precisely control the content (or concentration) of flocculants, so as to accurately grasp the influence law of flocculant content on the performance of cement-based materials.

2.6. Experimental Procedures

The pure water (such as distilled water) was replaced with PAM aqueous solutions of different concentrations (0.001%-0.1%, also known as PAM equivalent concentration) prepared in advance. The cement paste was prepared in accordance with the provisions of the current Chinese national standard GB/T 8077 “Test Methods for Homogeneity of Concrete Admixtures”, and the Stormer viscosity (KU) of the cement paste was tested using a Stormer viscometer. The average value of three consecutive and stable test results was taken as the KU value of the cement paste. The difference in KU values between the cement paste doped with PAM (experimental group) and the cement paste not doped with PAM (control group) was defined as the KU difference value. The corresponding relationship between the KU value or KU difference of the cement paste established through experiments and the PAM concentration of the cement paste (mixing water) was built to determine the numerical fitting formula of PAM content and cement paste viscosity, so as to reverse calculate the PAM concentration based on the KU value or KU difference of the cement paste. The reason Stormer viscosity was chosen as the characteristic index of the rheological performance of the cement paste was that the determination method of Stormer viscosity was simple, fast and convenient for practical application compared with other indicators.

Referring to the current Chinese national standard GB/T 17671 “Test Method for Strength of Cement Mortar (ISO Method)”, the fluidity and compressive strength at 3 days and 28 days of mortar mixed with water solutions of different PAM concentrations were detected, in order to investigate the influence of PAM content on the fluidity and strength of cement mortar. Referring to the current Chinese national standards GB/T 50080 “Standard Test Methods for Properties of Ordinary Concrete Mixtures” and GB/T 50081 “Standard Test Methods for Physical and Mechanical Properties of Concrete”, water was replaced with PAM aqueous solution, and the concrete was mixed to make specimens to investigate the influence of PAM concentration in the mixing water on the properties of concrete.

Whether it was the cement paste test, the mortar test or the concrete test, the corresponding control groups (or reference objects) were all pure water-prepared paste, mortar or concrete, that is, PAM was not actively added.

3. Results and Discussion

3.1. Relationship Between the Viscosity of the Cement Paste and the Concentration of PAM

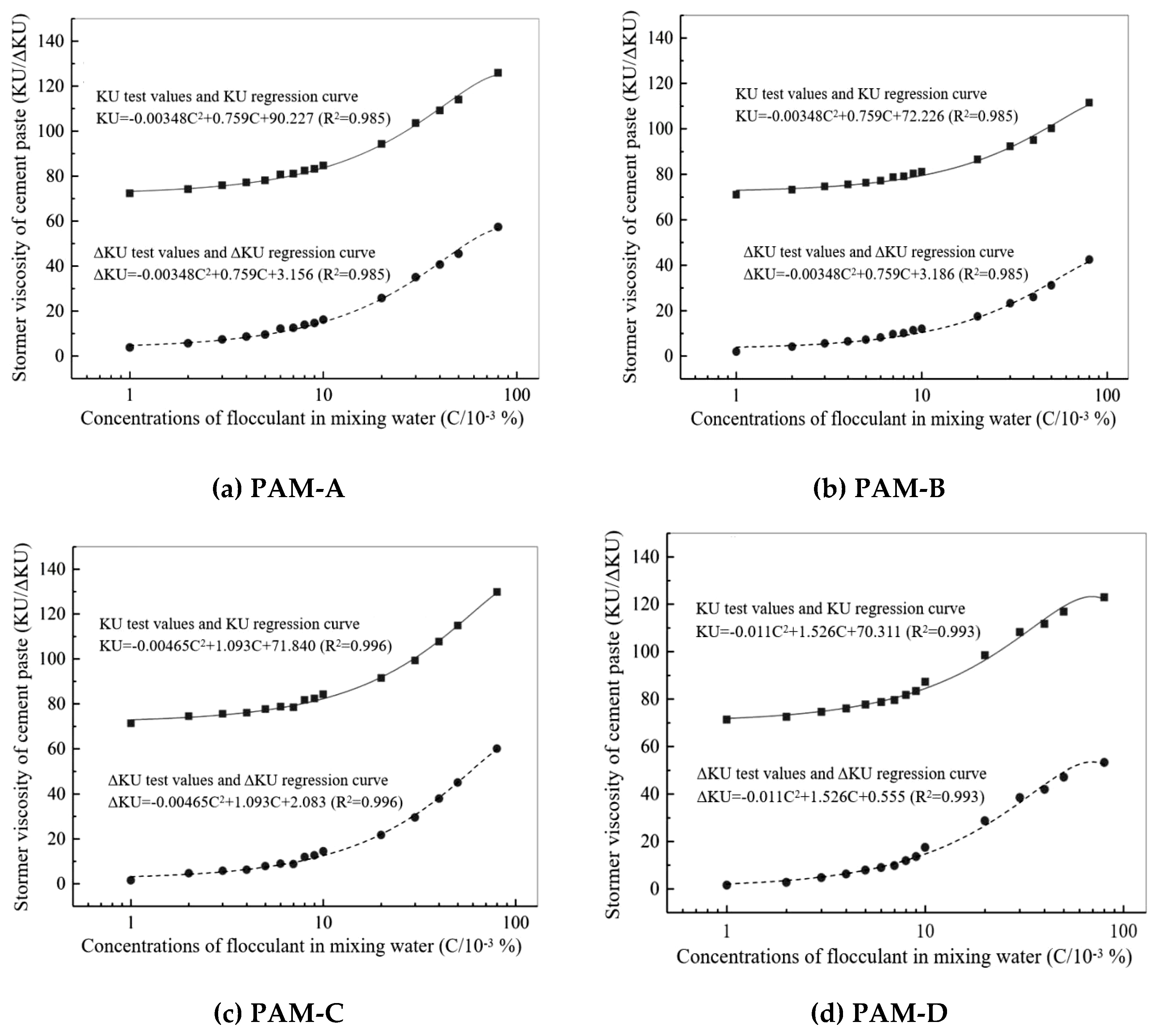

Taking the cement paste as the object, a series of experiments were conducted to investigate the effects of the flocculant aqueous solution concentration and flocculant type on the rheological performance characteristic index of cement-based materials, which was the Stormer viscosity. As shown in

Figure 2, the relationship between the Stormer viscosity of the cement paste with the active addition of four types of PAM and the concentration of PAM (aqueous solution) is presented respectively.

It can be found that the four types of PAM and their concentrations all had different degrees of influence on the viscosity of the cement paste [

10,

12,

19], and the influence can be clearly reflected by the Stormer viscosity. As the concentration of PAM in the mixing water increases, the viscosity of the PAM aqueous solution was bound to increase, but it cannot be distinguished by the naked eye. Only when the PAM content reached a relatively high level (such as 0.005%), the viscosity of the PAM aqueous solution can increase to be distinguishable to the naked eye. With the increase of PAM concentration, the KU value of the cement paste became larger, and there was a clear positive correlation between PAM concentration and the KU value or KU difference of cement paste viscosity. The correlation between them can be fitted by a quadratic function. For either type of PAM, the fitting correlation coefficient (R2) can reach above 0.99.

Bessaies-Bey et al. [

20,

21] held that PAM adsorption-type additives belonged to hydrophilic groups. They adsorbed cement particles through long-chain structures, causing the cement particles to bond and aggregate with each other to form flocs, thereby increasing the viscosity of the cement slurry. With the increase of PAM content, the viscosity of the aqueous solution increased. Meanwhile, the special structure of PAM also promoted the formation of more flocs, resulting in an increase in the viscosity of the cement paste and a decrease in fluidity.

From the KU difference analysis, compared with PAM-A, C and D with a molecular weight of 1800×10

4, PAM-B with a molecular weight of 1600×10

4 had a smaller influence on the viscosity of the cement paste. That is to say, the larger the molecular weight of PAM, the higher the viscosity of its aqueous solution and the stronger its adsorption capacity for fine particles. This was consistent with the rule that the larger the molecular weight of PAM used in water-washed manufactured sand, the greater the influence on the workability of concrete [

17,

22,

23].

The subsequent experiments analyzed the influence of flocculants on the various properties of cement mortar and concrete. PAM-B, which had a smaller impact on the cement paste and a stable fitting trend, was selected for the experimental investigation.

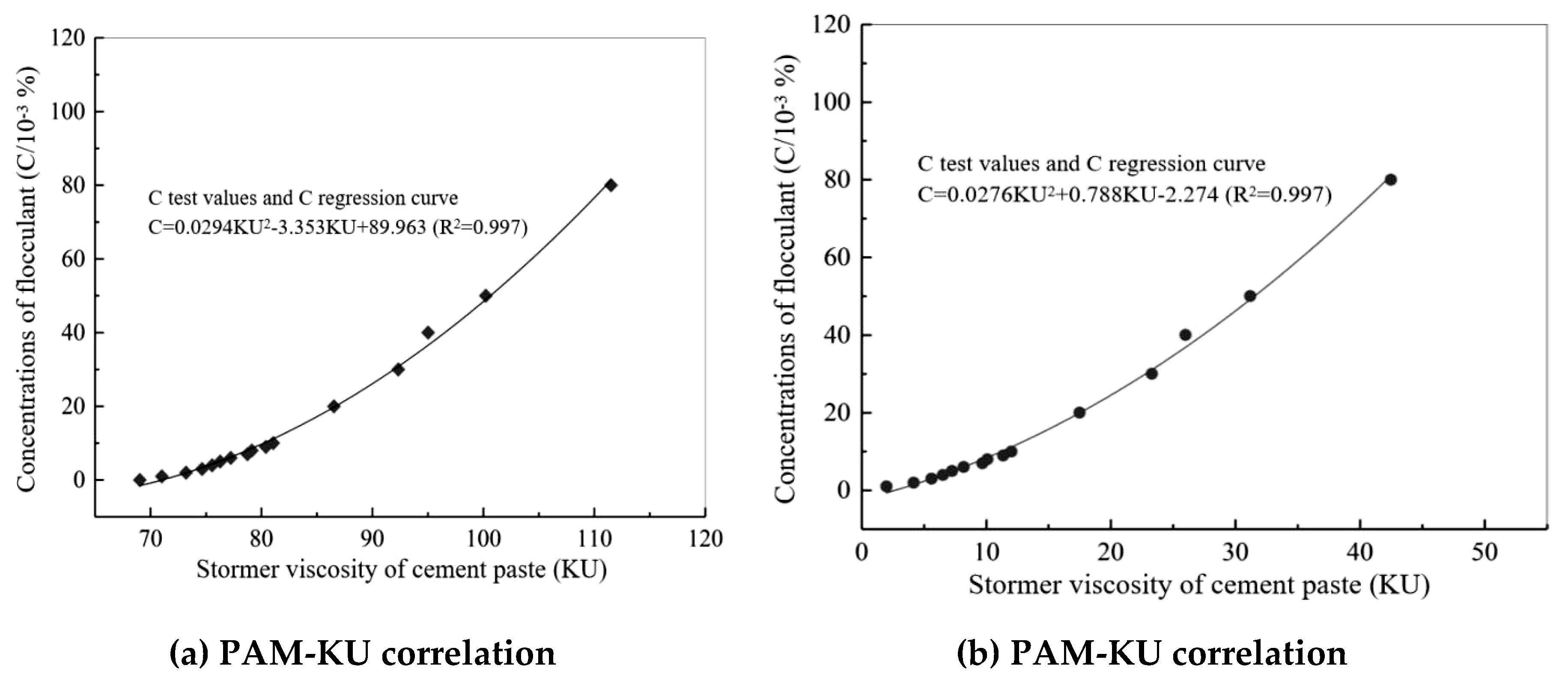

Figure 2b shows that the concentration of PAM was closely related to the KU value /KU difference of the cement paste. As shown in

Figure 3, within the controllable range, the relationship between the KU value /KU difference of the viscosity of cement paste with PAM-B and the concentration of PAM was reverse-fitted. The correlation coefficients were all above 0.99, showing a very obvious correlation, and the relationship formula was verified.

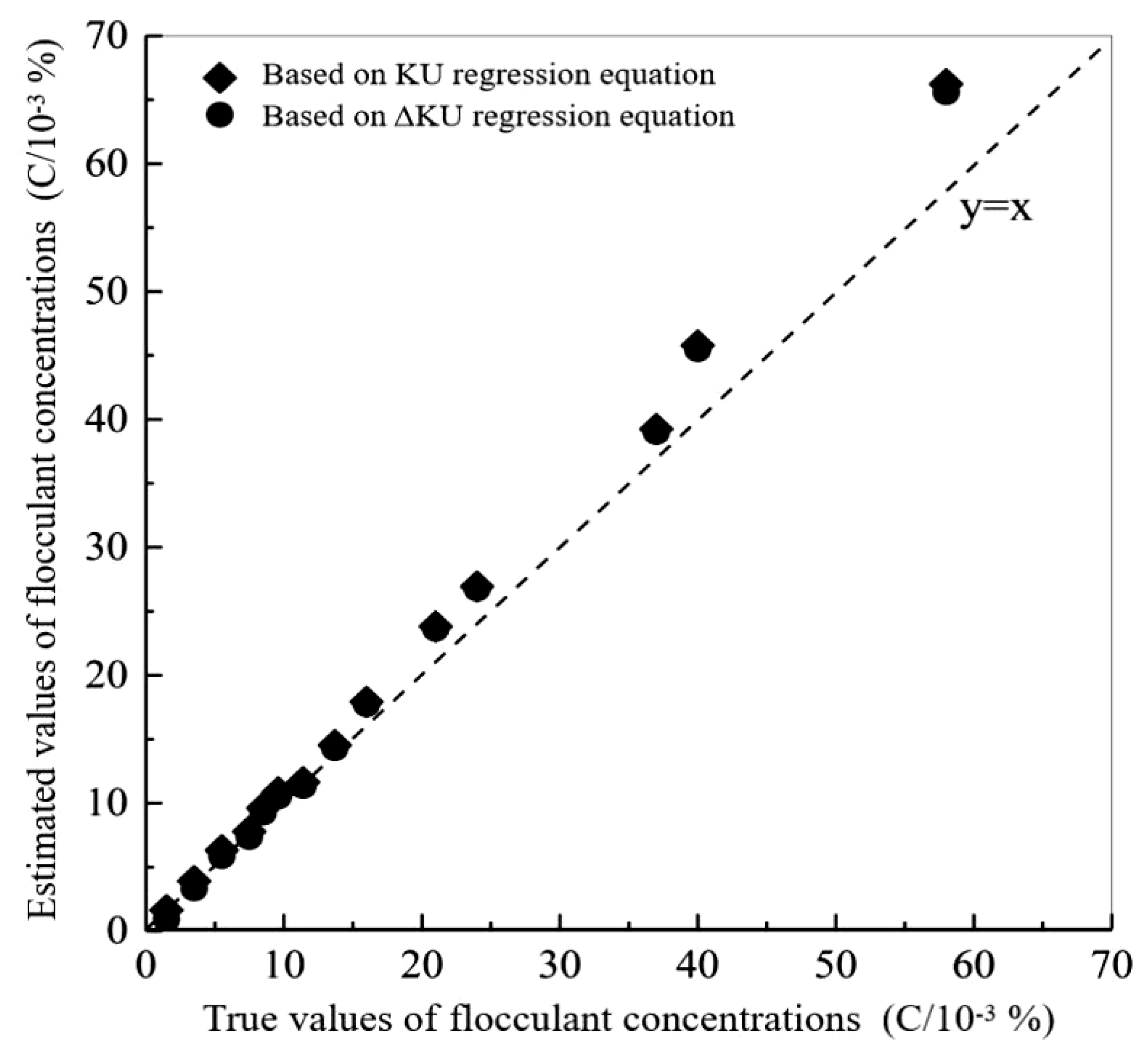

Different PAM concentration solutions were randomly prepared. The KU value and KU difference of the cement paste were measured by the aforementioned method. The two values were substituted into the corresponding fitting formulas. The deviation degree between the speculated value and the true value was compared to verify the feasibility of the rapid determination method of PAM solution concentration. The test results are shown in

Figure 4. The smaller the PAM concentration, the closer the estimated concentration value was to the actual value, and the smaller the deviation between them. Therefore, this rapid determination method was effective and feasible.

3.2. Influence of PAM Concentration on the Performance of Mortar

The presence of flocculants in manufactured sand has always been a problem in its application. According to the experimental results in

Section 3.1, with the increase of the concentration of PAM solution, both the viscosity and consistency of the cement slurry increased. Similarly, this phenomenon can also be verified in mortar and concrete, and can be used as the basis for determining the safe threshold of residual flocculant content in manufactured sand.

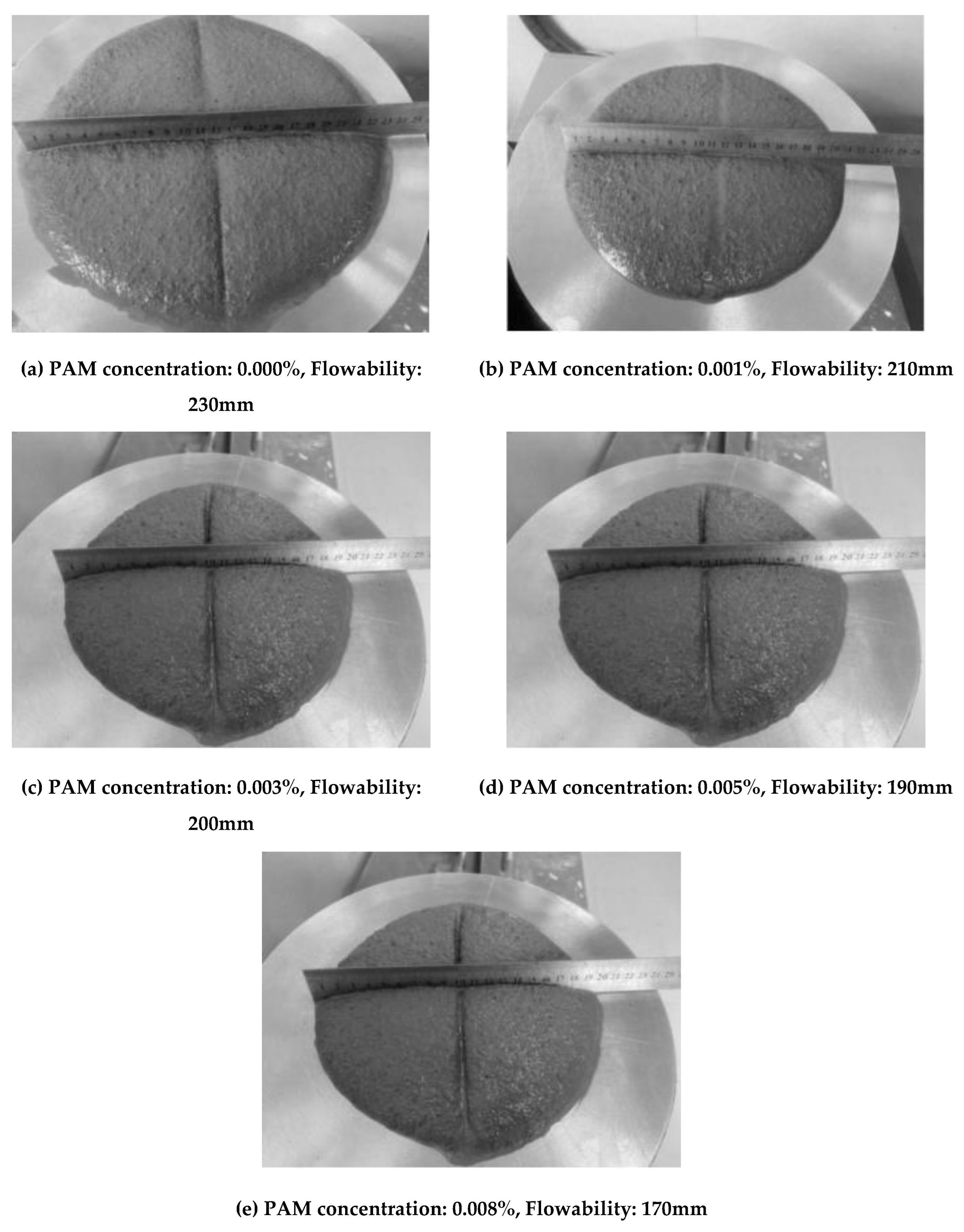

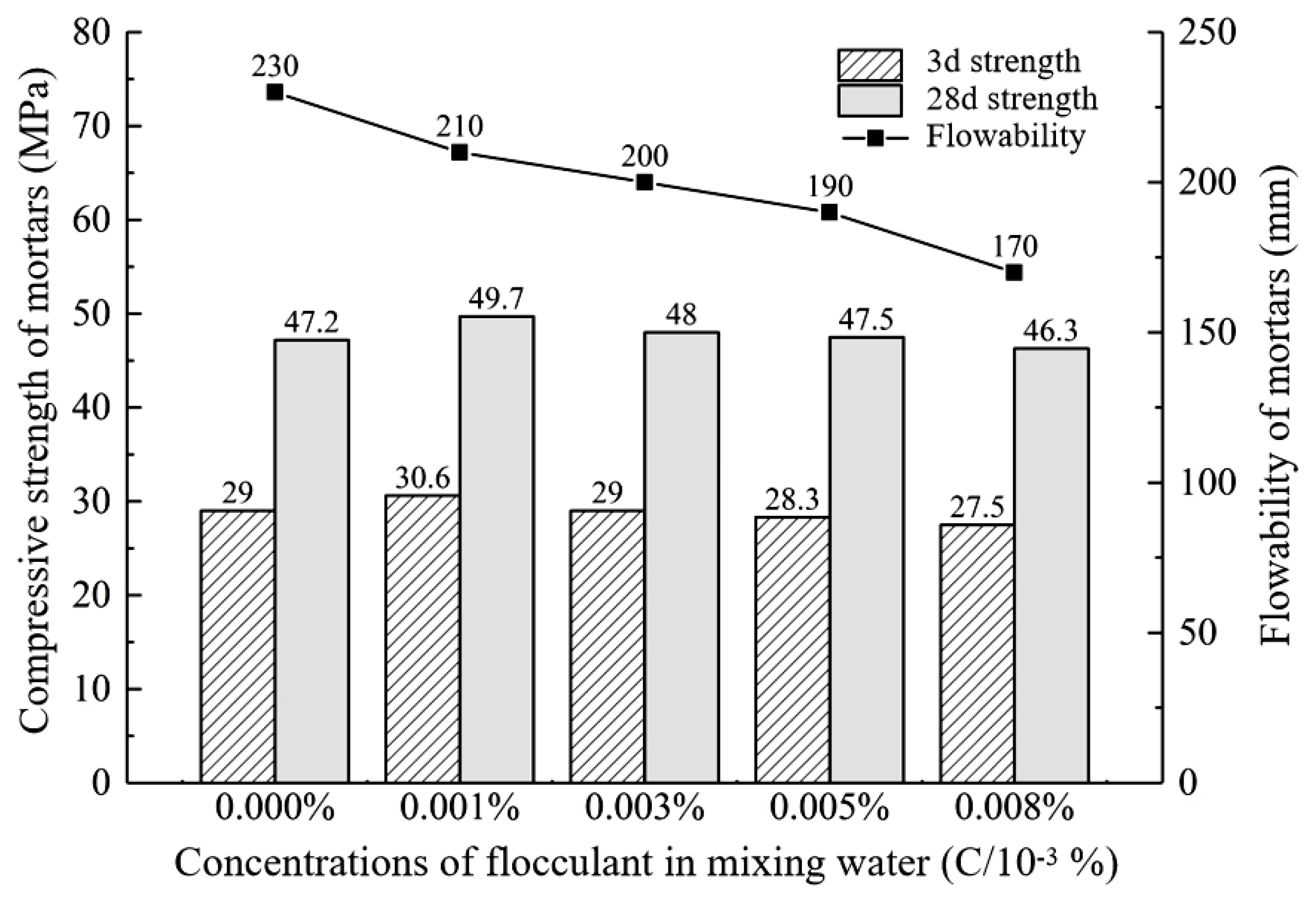

Cement mortar was prepared by using PAM solutions of different concentrations. The fluidity and mechanical properties of the cement mortar were tested, and the influence of PAM solutions of different concentrations on the performance of the mortar was analyzed. The test results are shown in

Figure 5 and

Figure 6.

It can be clearly seen from

Figure 5 that as the concentration of the PAM solution increased from 0.000% to 0.008%, the flowability of cementitious sand decreased from 230 mm to 170 mm, and the surface of the cementitious sand changed from slightly slurry to rough and dull, indicating that the free water was adsorbed by the flocculant. This was because the chemical structure of PAM contained hydrophilic amide groups, which formed strong hydrogen bonds with water molecules, locking in and reducing the free water in the mortar, lowering the lubricity of the mortar on the aggregates, thereby achieving the effects of water locking and thickening, and further affecting the fluidity of the mortar [

10,

15,

16,

17,

24]. It can be seen that PAM had a significant thickening and adsorption effect on water and water reducing agents, verifying the phenomenon of inter-molecular bridging adsorption and molecular chain entanglement of PAM on cement, water reducing agents, water, etc.

As can be seen from

Figure 6, with the increase of PAM concentration, the strength of the mortar at 3 days and 28 days showed a trend of first increasing and then decreasing. When the PAM concentration was 0.001%, the strength of the mortar was the highest at 3 days and 28 days. When the concentration of PAM added was less than 0.003%, the strength was all higher than that of benchmark mortar. This was because PAM can lock in the excess free water through the entanglement of molecular chains. The PAM chain hydrates filled the internal pores of the mortar, which can increase the viscosity and density of the mortar, improve the encapsulation property of the mortar, and slightly increase the bonding strength between the cementitious material and the fine aggregate. On the contrary, for the mortar prepared with a high concentration of PAM solution, the fine sand particles and free water were locked by the PAM molecular chain, resulting in agglomeration [

10,

12,

17,

25], forming a separator with the cementitious material. The homogeneity and fluidity were poor, which would delay or even not participate in the hydration reaction, forming sand clusters and voids without adhesion. This enabled it to remain inside and reduced the density and strength of the mortar.

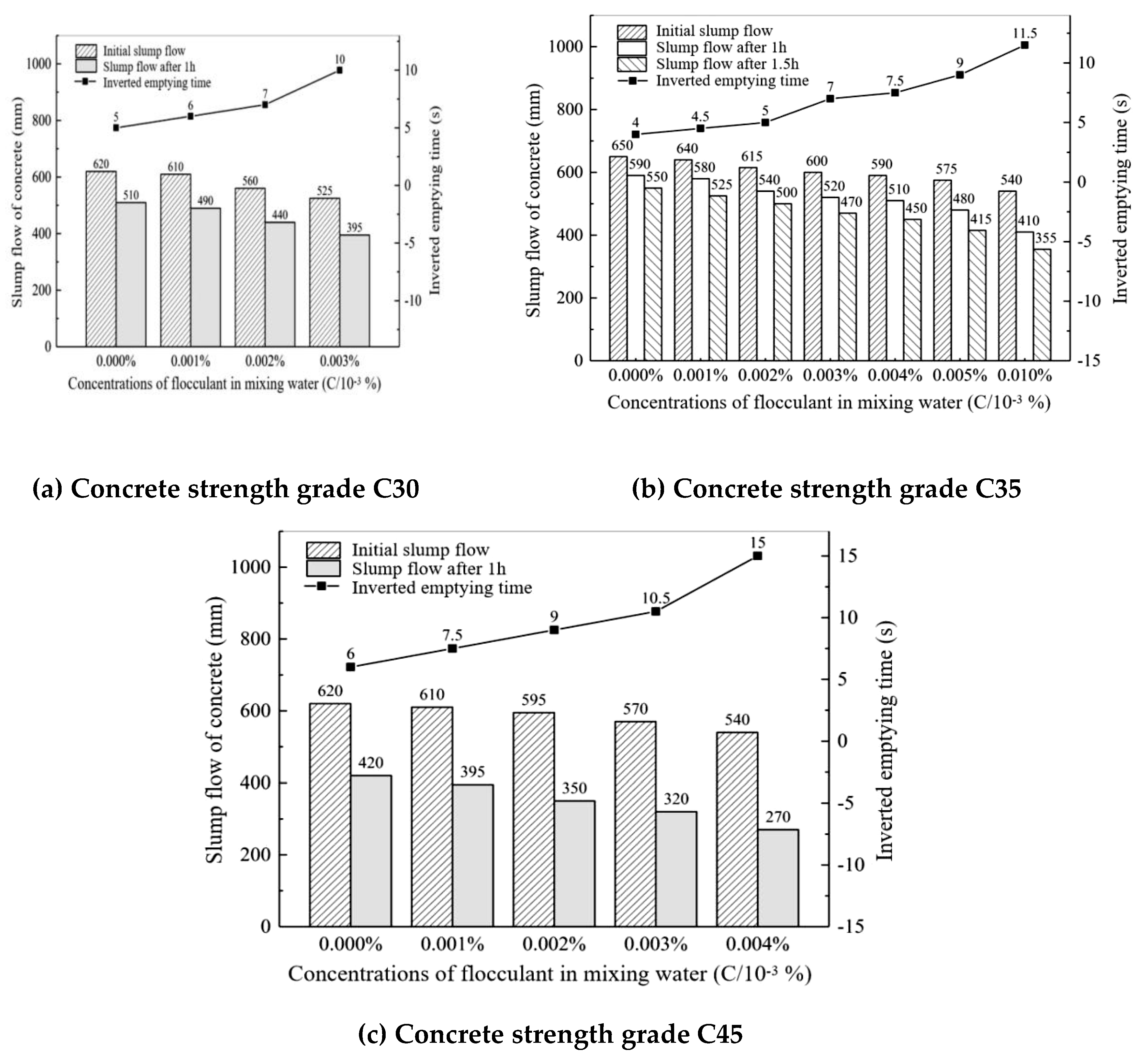

3.3. Influence of PAM Concentration on the Performance of Concrete

It can be seen from

Figure 7 that PAM has a significant influence on the workability and compressive strength of concrete. It can be concluded from the out-machine expansion degree, slump loss variation and inverted emptying time that the higher the concrete strength grade and PAM concentration, the more obvious the influence on the workability of concrete [

12,

17,

18]. The concentration of PAM was inversely proportional to the expansion degree and directly proportional to the inverted emptying time. When the concentration of PAM was greater than 0.002%, the inverted emptying time was significantly prolonged and the slump loss was significantly increased. This was mainly because the gelation particles and water reducing agent were adsorbed and electro-neutralized by PAM. Under the interaction of adsorption bridging [

26,

27,

28,

29,

30,

31,

32], the electric repulsion force on the colloid surface was reduced. The diffusion surface on the particle surface was weakened, thus gradually losing stability. The cementitious particles were bridged, aggregated and lost activity by the high-molecular long chains [

31,

33], which increased the internal yield stress of the concrete and promoted the mortar to have stronger encapsulation and poorer fluidity.

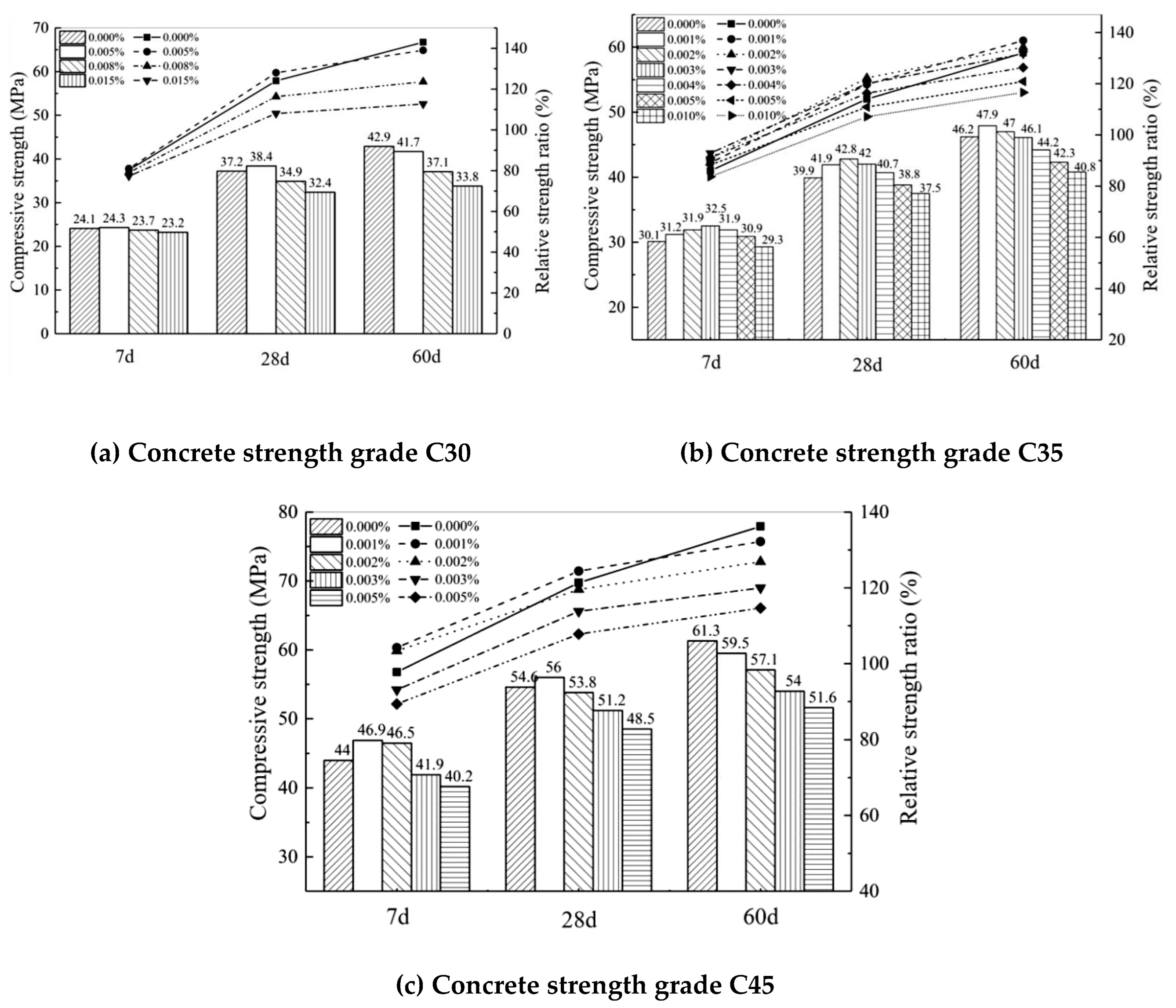

It can be seen from

Figure 8 that with the increase of PAM concentration, the compressive strength of concrete showed a trend of rising first and then decreasing, and the strength enhancement amplitude in later also slowed down with the increase of PAM concentration. In three groups of comparative tests with different strength grades, after adding a higher concentration of PAM solution, the workability of concrete gradually deteriorated, but it had an enhancing effect on the early strength growth. However, when the curing age of concrete reached 60 days, the strength improvement trend of the control group with PAM concentration not more than 0.002% was significantly better than that of the others. This indicated that the high-concentration PAM solution inhibited the increase of concrete strength. It can be obtained through experiments that adding a small amount of PAM component to concrete can improve the cohesion and water retention of concrete, increase the internal yield force of concrete, and enhance the early compressive strength of concrete [

33,

34,

35,

36].

4. Conclusions

Based on the above experimental research, the following conclusions can be drawn:

The type, molecular weight of PAM and the its concentration in the mixing water directly affected the Stormer viscosity of the cement paste. The viscosity of the cement paste showed a good positive correlation with the concentration of PAM. The experimental results showed that the correlation calibration formula can be used to determine the residual PAM concentration in manufactured sand by measuring the Stormer viscosity of the cement paste. This method can determine the residual PAM content in water-washed manufactured sand accurately and rapidly.

The influence of active/passive introduction of PAM on the performance of concrete was related to its content. When the concentration of PAM was less than 0.003%, PAM can play a role in thickening and water retention, improving the encapsulation property of the paste and enhancing the strength of concrete. When the PAM concentration was more than 0.003%, the workability and later strength of concrete would be negatively affected to varying degrees. The influence laws of PAM on the workability of concrete, mortar and cement paste have good consistency.

Before the water-washed manufactured sand is used to mix concrete, it is recommended to use the method proposed in this study to rapidly detect the PAM content in the sand filtrate, and set an acceptable upper limit of PAM concentration based on its influence on the properties of concrete. If necessary, measures such as controlling the moisture content of manufactured sand and secondary flushing can be taken to reduce the PAM concentration to ensure the quality of manufactured sand concrete.

Author Contributions

Conceptualization, C.H. Jiang and X.H. Gan.; methodology, C.H. Jiang; software, Z.F. Chen; validation, C.H. Jiang; formal analysis, Z.F. Chen; investigation, C.H. Jiang and Z.F. Chen; writing—original draft preparation, Z.F. Chen; writing—review and editing, Z.F. Chen and C.H. Jiang; visualization, Z.F. Chen; supervision, C.H. Jiang and X.H. Gan; project administration, X.F. Gan; funding acquisition, C.H. Jiang. All authors have read and agreed to the published version of the manuscript.” Please turn to the CRediT taxonomy for the term explanation. Authorship must be limited to those who have contributed substantially to the work reported.

Funding

This research was funded by GENERAL SCIENTIFIC RESEARCH PROGRAM OF DEPARTMENT OF EDUCATION OF ZHEJIANG PROVINCE, grant number Y202250417, TEACHING REFORM AND RESEARCH PROGRAM OF ZHEJIANG HIGHER VOCATIONAL EDUCATION, grant number jg20230178, GENERAL SCIENTIFIC RESEARCH PROGRAM OF DEPARTMENT OF HOUSING AND URBAN-RURAL DEVELOPMENT OF ZHEJIANG PROVINCE, grant number 2024K056 and NATIONAL NATURAL SCIENCE FOUNDATION OF CHINA, grant number 22376163. The APC was funded by GENERAL SCIENTIFIC RESEARCH PROGRAM OF DEPARTMENT OF EDUCATION OF ZHEJIANG PROVINCE.

Data Availability Statement

Data will be made available on request.

Acknowledgments

Thanks to Yulei Zhu, Xiaoqing Ding and other colleagues for their assistance in the experiment. Thanks to them, my experiment can be successfully completed. Thanks to Xuehong Gan and Xuehui Zou for his guidance and help in the preparation of this manuscript, which has greatly improved my study, scientific research and thinking. I would like to express my heartfelt thanks and deep respect to them. During the preparation of this manuscript/study, the author(s) used DeepSeek-R1 (© 2025 DeepSeek, English edition, All rights reserved. Website:

https://www.deepseek.com/en) for the purposes of literature retrieval. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| WWMS |

water-washed manufactured sand |

| W |

Mixing water for cement paste, mortar and concrete |

| WRA |

Water-reducing agent (Superplasticizer) |

| FA |

Fly ash |

| OPC |

Ordinary Portland cement |

| GBFS |

Ground granulated blast furnace slag (powder) |

| LG |

larger gravel |

| SG |

smaller gravel |

| MS |

manufactured sand |

| NS |

natural sand |

| MK |

Metakaolin (powder) |

| SS |

Chinese ISO standard sand |

| KU |

Stormer viscosity |

| ΔKU |

Stormer viscosity difference |

| C |

Concentrations of flocculant in mixing water |

Appendix A

Appendix A.1

Stormer viscosity is a consistency indicator of liquid measured by Stormer-Type Viscometer as shown in

Figure A1. Stormer-Type Viscometer stands as a precise tool for measuring the viscosity of both Newtonian and non-Newtonian fluids, adhering to the stringent ASTM D562 standard “Standard Test Method for Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using a Stormer-Type Viscometer”. This test method covers the measurement of Krebs Unit (KU) viscosity to evaluate the consistency of paints and related coatings using the Stormer-type viscometer. This test method provides values that are useful in specifying and controlling the consistency of paints, such as consumer or trade sales products.The authors used the test method in the cement-based materials.

Figure A1.

A commercially available Stormer viscometer

Figure A1.

A commercially available Stormer viscometer

The Stormer viscometer with the paddle-type rotor as illustrated in

Figure A1. The stroboscopic timer can be removed and the instrument used without it but with a sacrifice of speed and accuracy. The stroboscopic timer gives the 200 r/min reading directly. Container—500-mL (1-pt), 85 mm (33⁄8 in.) in diameter. Thermometer—An ASTM Stormer Viscosity thermometer having a range from 20 to 70°C. Stopwatch—or suitable timer measuring to 0.2 s. Weights—a set covering the range from 5 to 1000 g.

Appendix A.2

Figure A2 indicates the flocculant (PAM) powder specimen, the flocculant-water solutions with different concentrations and the flocculating effect on commercially manufactured sand. It is obvious that a higher concentration of flocculant in water results in better flocculating effect to suspended solids (e.g., mud/clay/silt/powder) in the manufactured sand. However, the higher concentration of flocculant leads to higher risk of sand-washing water pollution and more residual in final manufactured sand.

Figure A2.

Left image: A PAM flocculant powder specimen used in this study and aqueous solutions of the PAM flocculant with different concentrations; Right image: Commercially manufactured sand soaked in pure water, 0.006% and 0.01% aqueous solutions of the PAM flocculant for one hour, respectively.

Figure A2.

Left image: A PAM flocculant powder specimen used in this study and aqueous solutions of the PAM flocculant with different concentrations; Right image: Commercially manufactured sand soaked in pure water, 0.006% and 0.01% aqueous solutions of the PAM flocculant for one hour, respectively.

Polyelectrolytes act through a combination of cell surface charge neutralization and particle bridging to form flocs. The effectiveness of polyelectrolyte flocculants is influenced by the following factors: the molecular mass or chain length of the polymer, the charge density on the molecule and also the dose used. Salts of aluminum and iron are the most widely used flocculant because of their efficacy, availability, safety and relatively low cost. A combination of flocculants is sometimes more effective than any one flocculant. The overall degree of flocculation was improved and the dosage of the inorganic flocculant was reduced by using the two flocculants together.

References

- Zhang C.H., Song S.M., Liu F. Review on the present situation of preparing sand aggregate from mine waste rock. Fly Ash Comprehensive Utilization 2023, 86, 55-63.

- Zhuang S.R., Torres A, Chen R.S. Trends, challenges, and mitigation strategies for the use of sand and gravel resources in China. Journal of East China Normal University (Natural Science Edition) 2022, 23, 137-147. [CrossRef]

- Han Z. Research on design, performance and mechanism of high performance concrete based on manufactured sand morphology. Lanzhou: Lanzhou University of Technology, 2023.

- Bendixen M., Best J., Hackney C., et al. Time is running out for sand. Nature 2019, 571: 29-31. [CrossRef]

- Goncalves P., Tavares M., Filho T., et al. Comparison of natural and manufactured fine aggregates in cement mortars. Cement and Concrete Research 2007, 37, 924-932. [CrossRef]

- Yu L.J., Tong X. Optimization of key components of impact crusher based on “rock bed” mechanism. Mechanics of Advanced Materials and Structures 2020, 29, 321-329. [CrossRef]

- Cortes D.D., Kim H.K., Palomino A.M., et al. Rheological and mechanical properties of mortars prepared with natural and manufactured sands. Cement and Concrete Research 2008, 38, 1142-1147. [CrossRef]

- Chen J.L. The current situation and prospects of China’s manufactured sand and gravel industry. China Concrete 2011, 22, 62-64.

- Peng W.B., Zhang R.H., Wu X. Experimental study on the preparation of poor concrete with high-quality manufactured sand. China Concrete 2021, 32, 56-60.

- Wu J.Z., Shan G.C., Chen J., et al. Application of flocculant in manufactured sand and its effect on the dispersion of plasticizer. New Building Materials 2021, 48, 53-55.

- Feng W.K., Xie Y.C., Xu Q., et al. Influence of flocculant in manufactured aggregate on the quality of ready-mixed concrete. Ready-mixed Concrete 2020, 26, 22-26.

- Yang L., Li C.H. Effect of flocculant (PAM) on performance of cement (cementitious material) paste and concrete. China Concrete 2021, 32, 80-83.

- Duan S.S. A brief discussion on the application of manufactured sand in concrete. Ready-mixed Concrete 2017,11, 2-7.

- Feng A.L., Qin W.Z., Wang Z.Y. Comparison of some kinds of wadding congeal that influence the property of non-scattering concrete. Petroleum Engineering Construction 2002, 4, 6-10, 2.

- Yu X. Cao T.C., Bai L.L., et al. Effect of polyacrylamide on the properties of cement stabilized sand. Journal of Hebei University of Engineering (Natural Science Edition) 2023, 40,65-70.

- Ye C.F. Effect of polyacrylamide on properties of steel slag concrete. China Concrete and Cement Products 2023, 8, 88-92.

- Meng Q.C., Mao Y.L., Zhang J.G., et al. Effect of flocculant in circulating washing crushed sand on concrete performance. China Concrete 2022, 49, 65-68.

- Yin J.L. Study on the effect of flocculants in washed manufactured sand on the performance of concrete. China Concrete 2023, 50, 14-18.

- Yang G.S., Du S.P., Luo X.D., et al. Effect of flocculants on workablity and strength of C30 strength class concrete. Ready-mixed Concrete 2019, 11, 53-56.

- Bessaies-Bey H., Baumann R., Schmitz M., et al. Effect of polyacrylamide on rheology of fresh cement pastes. Cement and Concrete Research 2015, 76, 98-106. [CrossRef]

- Bey H.B., Khaya K.H., Palacios M., et al. Viscosity modifying agents: Key components of advanced cement-based materials with adapted rheology. Cement and Concrete Research 2022, 152, 106646. [CrossRef]

- Lai Z.F., Wang W.J., Leng F.G., et al. Study on the effect of sulfonation β-cyclodextrin as an impedance flocculant in concrete. New Building Materials 2023, 50, 74-77.

- Zhang D.L., Yi P., Zhang X., et al. Study on perparation of underwater anti-dispersion concrete with construction waste. New Building Materials 2023, 50, 38-41.

- Xie W.X. Exploration of stable use of manufactured sand in concrete. Guangdong Building Materials 2022, 38, 11-12, 14.

- Zhang Y.A. Analysis on the influence of washing sand with flocculant on concrete performance. New Technology & New Products of China 2022, 27, 123-125.

- Shi L.P., Su Q.J. Study on the effect of compound flocculants on the settlement of fine coal slime waste. Coal Processing & Comprehensive Utilization 2024, 33, 26-30, 36.

- Zhu F.R. Study on preparation and flocculation efficiency of inorganic-organic hybrid polymer flocculant. Daqing: Northeast Petroleum University 2023: 1-14.

- Wang Z.Y., Li L., He Y.L., et al. Molecular dynamics simulation of PAM and PCE adsorption sites on sodium montmorillonite surface. Journal of Materials Science and Engineering 2023, 41, 397-403.

- Chen Z.Q., Xia L.S., Wang Q.C., et al. Preparation of an inorganic-orgainc macromolecular compound flocculant and study of its properties. Journal of University of South China (Science and Technology Edition) 2004, 18, 28-31.

- Zhu Y.P., Wang P. , Guo H.P. , Lou R.R. , Ye W.D., Liu Y., Liu K. Effect of dry process manufactured sands dust on the mechanical property and durability of recycled concrete. Journal of Building Engineering, 2024, 87, Article No. 108942. [CrossRef]

- Wu B., Zhang T. Preparation of recycled sand from WRSG and compressive and flexural behavior of recycled aggregate concrete. Construct. Build. Mater. 2024, 414, Article No. 134944. [CrossRef]

- Bayesteh H., Sharifi M., Haghshenas A. Effect of stone powder on the rheological and mechanical performance of cement-stabilized marine clay/sands. Construct. Build. Mater. 2020, 262, Article No. 120792. [CrossRef]

- Lu L., Yang Z.X., Lin Y. Partial replacement of manufactured sands with homologous granite powder in mortar: the effect on porosity and capillary water absorption. Construct. Build. Mater. 2023, 376, Article No. 131031. [CrossRef]

- Li H.J., Huang F.L., Cheng G.Z. Effect of granite dust on mechanical and some durability properties of manufactured sands concrete. Construct. Build. Mater. 2016, 109, 41-46. [CrossRef]

- Ding X.X., Li C.Y., Xu Y.Y. Experimental study on long-term compressive strength of concrete with manufactured sands. Construct. Build. Mater. 2016, 108, 67-73. [CrossRef]

- Jiang Z.W. Production of manufactured sands Green High-Performance Concrete with Manufactured Sands. Construct. Build. Mater. 2022, 114, 13-46.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).