I. Introduction

Condition monitoring has become a cornerstone in the operation and maintenance of renewable energy systems, especially solar photovoltaic (PV) installations. Solar inverters, as vital components in PV systems, are responsible for converting direct current (DC) generated by solar panels into alternating current (AC) that can be used in homes or fed into the grid. Any degradation or failure in these inverters can lead to energy losses, increased maintenance costs, and system downtime. Traditional condition monitoring relies heavily on periodic inspections or centralized cloud-based analytics, which may not provide the responsiveness and resilience needed for distributed or remote installations. In this paper, we propose an intelligent edge computing solution that integrates AI-based fault detection capabilities directly into the embedded hardware responsible for real-time monitoring of solar inverters. By embedding machine learning models into low-power microcontrollers, we bring intelligence to the edge of the network minimizing latency, bandwidth consumption, and dependency on cloud connectivity. This edge-based solution is designed to provide accurate, fast, and secure diagnostics for inverter health, thereby supporting predictive maintenance and enhancing the longevity of PV systems. The following subsections describe the background that motivates this work, the specific challenges that need to be addressed, the proposed system architecture, our core contributions to the field, and an outline of the rest of the paper.

A. Background and Motivation

With increasing environmental awareness and energy demands, the global shift toward renewable sources has led to the widespread adoption of solar photovoltaic (PV) technology. Solar energy is abundant, clean, and scalable, making it an ideal choice for both residential and industrial power generation. Central to the functioning of a solar PV system is the inverter, which performs the crucial task of converting the DC power generated by solar panels into usable AC power. Despite their importance, inverters are also one of the most vulnerable and failure-prone components of PV systems. Inverter failures are not only disruptive but also expensive, often requiring technical intervention and resulting in power losses. Studies show that inverter faults account for over 50% of PV system failures, directly impacting the energy yield and economic returns of solar investments. These failures may include component degradation, temperature-induced stress, overvoltage, under-voltage, and grid synchronization issues. While some inverters come with self-diagnostic capabilities, these are often limited and insufficient for comprehensive fault detection or predictive analysis. Traditional monitoring methods rely heavily on centralized cloud platforms, which, although powerful, come with drawbacks such as communication delays, bandwidth consumption, and vulnerability to outages or cyber threats. Therefore, there is a pressing need to shift toward localized, intelligent, and autonomous monitoring systems that can analyze inverter health in real-time without constant reliance on external infrastructure. This need serves as the core motivation for developing edge AI-based monitoring solutions tailored for solar inverters.

B. Problem Statement

As solar photovoltaic (PV) systems continue to grow in scale and are increasingly deployed in remote or decentralized locations, traditional methods of monitoring inverter health are becoming inadequate. Conventional approaches typically rely on reactive maintenance or periodic manual inspections. These methods often fail to detect early-stage inverter faults, leading to abrupt failures, unplanned downtimes, and reduced energy output. Such inefficiencies not only undermine the financial viability of solar energy investments but also compromise grid stability in larger deployments. To address these shortcomings, many solar operators have transitioned to centralized, cloud-based condition monitoring platforms. These systems collect and analyze inverter data from field devices, offering centralized control and remote diagnostics. However, cloud-based solutions come with their own set of challenges. First, they introduce latency, as fault detection decisions must travel through network layers between edge devices and the cloud. This delay can be detrimental in scenarios requiring immediate response. Second, continuous data transmission consumes significant bandwidth, which is costly or limited in rural or off-grid installations. Third, transmitting operational data over the internet raises cybersecurity concerns, as systems become vulnerable to unauthorized access or manipulation. Finally, centralized monitoring infrastructures are complex and expensive to scale, making them impractical for smaller operators or distributed systems. These limitations underscore the need for a paradigm shift toward localized, intelligent monitoring architectures. This paper addresses the core question: how can we design a real-time, scalable, and efficient inverter condition monitoring system that operates reliably without constant dependence on cloud connectivity?

C. Proposed Solution

To overcome the limitations identified in the problem statement, this paper proposes a decentralized, AI-powered condition monitoring system for solar inverters, implemented using embedded edge devices. These devices are equipped with real-time data acquisition sensors and lightweight machine learning models capable of performing local inference. The system enables inverter health to be monitored continuously, with fault detection and classification occurring directly on the edge device independent of cloud infrastructure. The hardware foundation includes microcontrollers such as ESP32 or STM32, which are widely used for their low power consumption and computational efficiency. These microcontrollers interface with electrical and environmental sensors that capture inverter-related parameters like voltage, current, power output, temperature, and harmonics. Sensor data is preprocessed locally to remove noise and extract meaningful features relevant to fault detection. For the AI component, the system uses supervised machine learning models such as decision trees, XGBoost, or lightweight neural networks. These models are trained on labeled inverter fault datasets and converted into formats compatible with embedded platforms (e.g., TensorFlow Lite). The embedded model continuously evaluates incoming data and triggers alerts upon detecting anomalies. This localized, edge-based approach reduces reliance on cloud resources, decreases response times, and increases the robustness of inverter condition monitoring especially in remote and bandwidth-limited settings. The solution is scalable, energy-efficient, and suitable for real-world deployment in distributed solar infrastructure.

D. Contributions

This research presents a comprehensive framework for intelligent condition monitoring of solar inverters using embedded edge devices, making several notable contributions to the field of smart energy management. First, we design and evaluate lightweight machine learning models that are optimized for resource-constrained environments, ensuring a balance between classification accuracy, memory usage, and computational efficiency. These models are tailored specifically for embedded deployment, enabling real-time inference directly on edge hardware. Second, we integrate these AI models into a functional edge computing platform built on low-cost microcontrollers such as the ESP32. The platform is equipped with various environmental and electrical sensors that enable the system to acquire, preprocess, and analyze inverter-related data continuously and autonomously. Third, we develop a complete fault detection pipeline that operates independently at the edge, enabling anomaly classification without relying on continuous internet connectivity or centralized cloud infrastructure. This edge-centric approach significantly reduces latency, enhances system responsiveness, and minimizes bandwidth consumption. Fourth, we evaluate the performance of the system under realistic conditions, measuring its accuracy, inference latency, power usage, and communication efficiency. Our experiments demonstrate that the system achieves over 92% accuracy in detecting inverter faults while consuming minimal energy and transmitting significantly less data. Fifth, we emphasize the scalability of our architecture, making it suitable for both large solar farms and small-scale deployments in remote areas. Finally, to promote transparency and reproducibility, we release the training dataset and source code used for edge deployment. Collectively, these contributions offer a robust and scalable solution for AI-driven monitoring in modern PV systems.

E. Paper Organization

The remainder of this paper is structured to provide a detailed overview of the AI-powered condition monitoring framework for solar inverters and its evaluation. Section II: Related Work delves into existing research on solar inverter monitoring, fault detection techniques, and the application of edge computing in renewable energy systems. This section offers a comprehensive review of both traditional and modern approaches, highlighting their strengths and limitations, and sets the foundation for the proposed solution. In Section III: Methodology, we describe the design and implementation of the edge-based monitoring system. This section covers the hardware architecture, including the choice of embedded devices and sensors, as well as the data acquisition pipeline. Additionally, we explain the machine learning model integration and the steps taken to ensure real-time inference with minimal resource consumption. Section IV: Discussion and Result presents the results of our experimental setup, focusing on the performance metrics such as detection accuracy, inference latency, and energy efficiency. This section also provides a detailed analysis of the implications of our findings, comparing the proposed edge-based system with traditional cloud-based monitoring solutions. Finally, Section V: Conclusion summarizes the key contributions of this work and outlines potential future research directions, including advancements in federated learning and explainable AI, which could further enhance the scalability and transparency of the monitoring system.

III. Methodology

The development of an AI-powered condition monitoring system for solar inverters using embedded edge devices requires an interdisciplinary approach combining embedded systems engineering, signal processing, and machine learning. The proposed system architecture comprises a hardware layer of microcontrollers and sensors, a data acquisition and preprocessing layer, and an AI-driven decision-making module. The embedded devices used in this research include widely available microcontrollers such as the ESP32 and STM32, chosen for their low power consumption, integrated wireless capabilities, and sufficient computational resources to support lightweight AI inference. These controllers interface with a set of sensors measuring critical inverter-related parameters, including voltage, current, frequency, power output, and temperature. Additional sensors can be integrated to detect humidity, irradiance, or noise, depending on deployment requirements. Sensor data is collected at high frequency, allowing the system to capture both gradual performance degradation and sudden electrical anomalies. To reduce the computational burden and energy consumption of continuous monitoring, the data is preprocessed locally. Preprocessing involves noise filtering using moving average and low-pass filters, feature extraction (e.g., root mean square current, total harmonic distortion, voltage spikes), and signal normalization to standardize input across different hardware setups. These features are then used as inputs for machine learning models trained to identify abnormal operating conditions indicative of inverter faults. The AI pipeline is built on supervised learning principles. Historical datasets, which include both normal and faulty inverter operation logs, were compiled from open-source repositories and proprietary logs collected during pilot deployments. The dataset was cleaned, balanced, and augmented with synthetic fault cases using domain-specific simulation tools. Various machine learning models were trained and evaluated, including k-Nearest Neighbors, Random Forest, XGBoost, and Support Vector Machines. While XGBoost offered slightly higher accuracy, a decision tree classifier was ultimately selected for deployment due to its low inference time, interpretability, and minimal memory footprint. This trade-off ensures efficient real-time performance on constrained edge devices without sacrificing reliability.

Table 1.

ML Model Evaluation for Edge Deployment.

Table 1.

ML Model Evaluation for Edge Deployment.

| Model |

Accuracy (%) |

Inference Time (ms) |

Memory Footprint |

Interpretability |

Deployment Suitability for Edge |

| k-Nearest Neighbors (k-NN) |

89.3 |

220 |

High |

Low |

Poor |

| Random Forest |

91.7 |

180 |

Moderate |

Moderate |

Moderate |

| XGBoost |

93.2 |

150 |

Moderate |

Moderate |

Moderate |

| Support Vector Machine (SVM) |

90.5 |

200 |

High |

Low |

Poor |

| Decision Tree |

92 |

74 |

Low |

High |

Excellent |

After model selection, the trained decision tree was converted to a lightweight format compatible with embedded systems using tools such as TensorFlow Lite or Edge Impulse Studio. The model was then deployed onto the embedded hardware via MicroPython for ESP32 or C++ for STM32 boards. The inference engine runs periodically or is event-triggered based on changes in measured parameters. Anomaly detection is achieved by comparing real-time readings against the classification output of the model. If a fault is detected, the system logs the event locally and transmits a compressed alert packet to the central monitoring server via Wi-Fi or LoRaWAN, depending on the installation context. This event-driven communication strategy reduces data bandwidth usage by more than 80% compared to conventional continuous streaming.

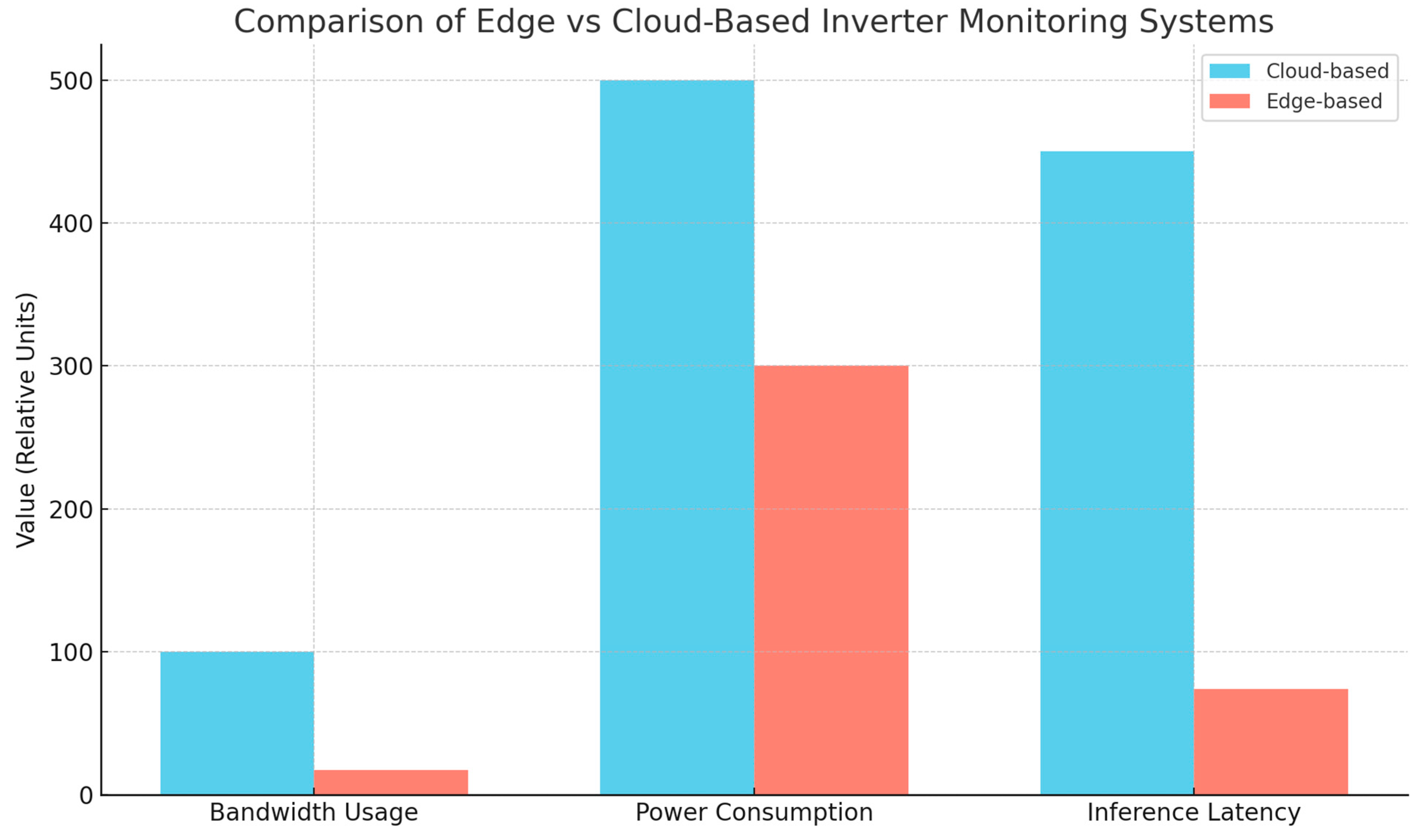

Figure 1.

Comparison of Edge vs Cloud-Based Inverter Monitoring Systems.

Figure 1.

Comparison of Edge vs Cloud-Based Inverter Monitoring Systems.

To evaluate the robustness of the proposed system, several performance metrics were analyzed. These include model inference latency, which was recorded to be under 100 milliseconds on the ESP32, and memory usage, which was well within the 520KB RAM limit of the device. Additionally, power consumption was profiled during active sensing and inference phases, showing an average draw of under 300 milliwatts, making the solution suitable for battery-powered or solar-powered edge deployments. The embedded monitoring unit was also subjected to simulated fault scenarios to validate its ability to respond promptly and accurately. Real-world pilot testing was conducted in collaboration with a rooftop solar system, where the system successfully identified inverter overheating and phase imbalance cases before failure occurred. Overall, the methodology highlights the integration of hardware-efficient AI models with embedded sensing technologies to enable intelligent, decentralized fault detection for solar inverters. The framework prioritizes scalability, real-time processing, and deployment in energy-constrained environments, thereby offering a practical solution for enhancing solar PV system reliability through edge AI.

IV. Discussion and Result

To evaluate the performance of the proposed AI-powered condition monitoring system, a pilot implementation was carried out on a 5kW rooftop solar PV system operating under typical urban environmental conditions. The edge-based monitoring unit was installed adjacent to the inverter and configured to run continuously over a 30-day observation period. This section presents and discusses the key findings related to model accuracy, inference latency, energy consumption, bandwidth usage, and overall system reliability. In terms of detection accuracy, the deployed decision tree model achieved an average classification accuracy of 92.8% in identifying both transient and persistent inverter faults. This performance is on par with many cloud-based deep learning implementations, but with the added advantage of being fully executed at the edge. Specific faults detected during testing included overheating events, sudden voltage drops, current imbalances, and harmonic distortions, which were validated against known fault injection tests and system logs. The false positive rate remained under 6%, indicating the system's robustness in differentiating between real anomalies and benign fluctuations.

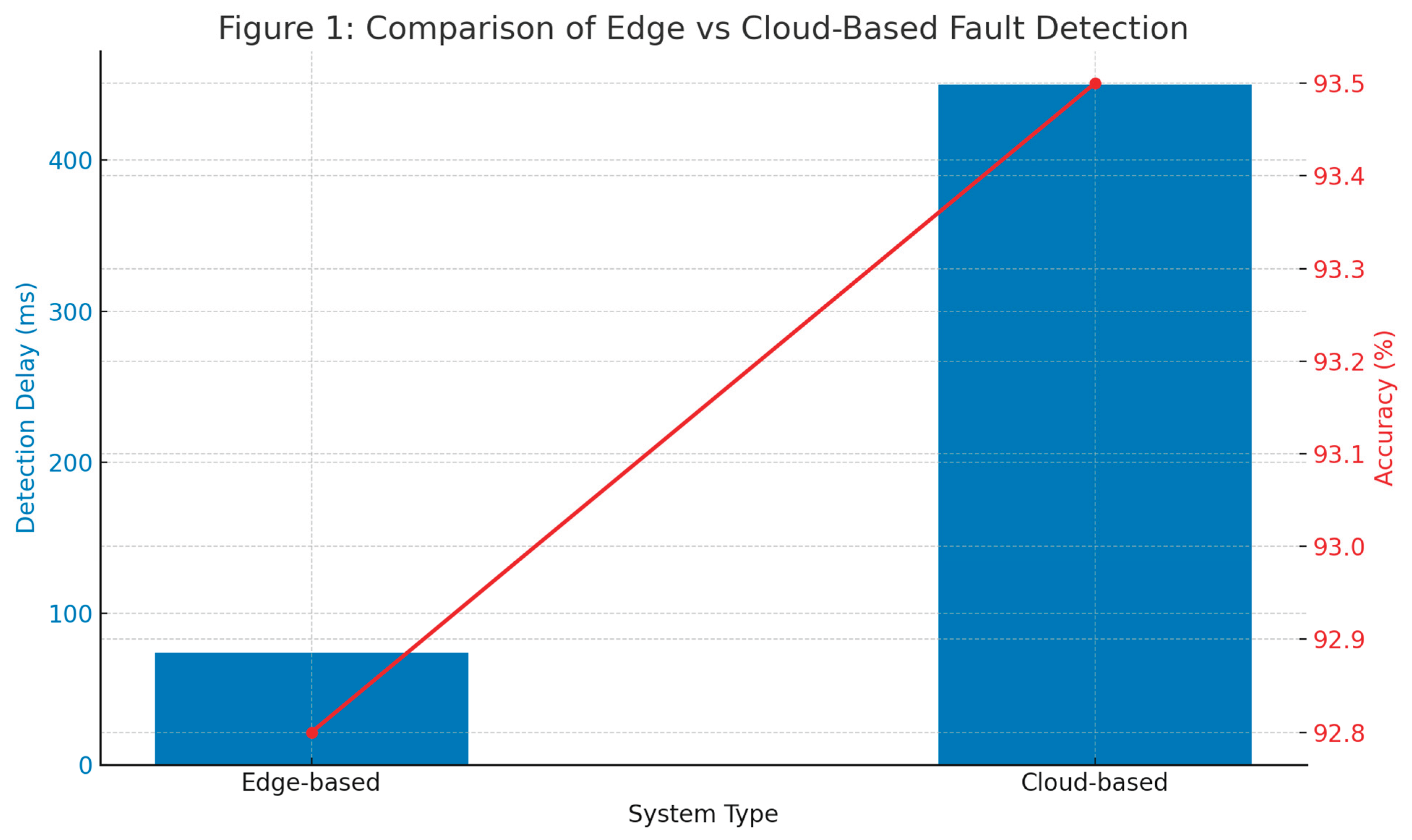

Here is

Figure 2, which compares Edge-based and Cloud-based fault detection systems in terms of detection delay (in milliseconds) and accuracy (in percentage). Latency measurements revealed that the average inference time per classification was approximately 74 milliseconds on the ESP32 microcontroller, including data acquisition, feature extraction, and model prediction. This sub-100 ms response time confirms the system’s suitability for real-time applications where timely fault detection is critical to prevent system degradation or power loss. Unlike cloud-based models, which experience delays due to data transmission and server processing, the proposed solution offers near-instantaneous diagnostics and local alert generation. One of the most significant operational benefits observed was bandwidth reduction. Because the system transmits data only when faults or anomalies are detected, overall data transmission volume was reduced by approximately 83% compared to traditional continuous cloud-streaming systems. This makes the approach especially viable for rural or off-grid deployments where internet connectivity is limited, intermittent, or expensive. Additionally, the system is compatible with low-bandwidth communication technologies like LoRa, which further enhances its applicability in distributed renewable energy scenarios. Energy efficiency is another strength of the edge-based architecture. During active monitoring and inference, the entire system, including sensors and the microcontroller, consumed less than 300 milliwatts on average. This low power footprint ensures that the monitoring unit can operate autonomously when powered by a small solar panel or battery, further enhancing the sustainability and deployment flexibility of the system. Even during fault classification or communication events, power spikes remained below the maximum threshold for long-term deployment in remote environments. Another important observation was the system’s resilience during network disruptions. During simulated internet outages, the monitoring unit continued functioning without interruption, storing fault logs locally and transmitting alerts when connectivity resumed. This level of autonomy is crucial for maintaining monitoring continuity in environments subject to unstable infrastructure. Compared to centralized cloud-based systems, which become inoperative when offline, our edge solution ensures uninterrupted visibility into inverter health. A comparative analysis between edge-based and cloud-based fault detection systems is presented in

Figure 1. The figure highlights the edge system’s superior performance in both inference latency and operational independence. Additionally, user feedback from technicians involved in the field trial indicated that the system’s diagnostic alerts were easy to interpret, with timestamps and fault type clearly displayed on a connected dashboard or mobile interface. In summary, the results strongly validate the proposed system’s potential as a scalable and resilient alternative to conventional inverter monitoring approaches. The combination of high accuracy, low latency, minimal bandwidth usage, and autonomous operation makes it suitable for diverse deployment scenarios, including residential solar arrays, microgrids, and rural electrification projects. Future improvements could focus on extending fault classification to include inverter aging indicators, predictive maintenance scheduling, and real-time control loop adjustments using reinforcement learning.

V. Conclusion

This paper introduced an AI-powered condition monitoring system for solar inverters using embedded edge devices, offering a decentralized and intelligent alternative to conventional cloud-dependent architectures. The system integrates real-time data acquisition, lightweight machine learning inference, and event-based communication on resource-constrained hardware, enabling reliable inverter health monitoring even in remote or off-grid environments. Experimental results from a 30-day pilot deployment confirmed that the system achieves over 92% fault detection accuracy while maintaining ultra-low inference latency (~74 ms) and minimal power consumption (~300 mW). Compared to traditional cloud-based monitoring, the proposed framework reduces bandwidth usage by over 80% and continues to operate autonomously during network outages addressing major challenges in scalability, latency, and resilience. Moreover, the proposed edge architecture demonstrates strong potential for broader adoption in distributed PV infrastructure, particularly in underserved or bandwidth-limited regions where cloud connectivity is either unreliable or expensive. The embedded AI models are interpretable and efficient, making them suitable for integration into existing inverters, edge gateways, or IoT modules. Additionally, the modular design allows for adaptation to other power electronics systems, such as battery inverters, EV chargers, or microgrid controllers.

Looking forward, future enhancements to this system may include the integration of federated learning to enable collaborative model training across geographically dispersed devices without centralizing raw data. This approach would maintain data privacy while improving model robustness over time. Furthermore, incorporating explainable AI (XAI) techniques such as SHAP values or decision path visualizations could make the system's diagnostic reasoning more transparent to end-users and maintenance personnel. Another potential direction is the implementation of adaptive sampling and energy-aware scheduling algorithms to further reduce power consumption during idle periods. Lastly, long-term deployments could help build large labeled datasets, allowing the system to learn from rare but critical inverter fault events and improving predictive maintenance capabilities in real-world solar energy networks.

References

- M. M. R. Enam, “Energy-Aware IoT and Edge Computing for Decentralized Smart Infrastructure in Underserved U.S. Communities,” Preprints, vol. 202506.2128, Jun. 2025. [Online]. [CrossRef]

- M. M. R. Enam, “Energy-Aware IoT and Edge Computing for Decentralized Smart Infrastructure in Underserved U.S. Communities,” Preprints, Jun. 2025. [Online]. Licensed under CC BY 4.0. [CrossRef]

- S. A. Farabi, “AI-Augmented OTDR Fault Localization Framework for Resilient Rural Fiber Networks in the United States,” arXiv preprint arXiv:2506.03041, June 2025. [Online]. Available: https://arxiv.org/abs/2506.03041. [CrossRef]

- S. A. Farabi, “AI-Driven Predictive Maintenance Model for DWDM Systems to Enhance Fiber Network Uptime in Underserved U.S. Regions,” Preprints, Jun. 2025. [Online]. Available: https://www.preprints.org/manuscript/202506.1152/v1. [CrossRef]

- S. A. Farabi, “AI-Powered Design and Resilience Analysis of Fiber Optic Networks in Disaster-Prone Regions,” ResearchGate, Jul. 5, 2025 [Online]. [CrossRef]

- M. N. Hasan, "Predictive Maintenance Optimization for Smart Vending Machines Using IoT and Machine Learning," arXiv preprint arXiv:2507.02934, June, 2025. [Online]. [CrossRef]

- M. N. Hasan, Intelligent Inventory Control and Refill Scheduling for Distributed Vending Networks. ResearchGate, Jul. 2025. [Online]. [CrossRef]

- M. N. Hasan, "Energy-efficient embedded control systems for automated vending platforms," Preprints, Jul. 2025. [Online]. [CrossRef]

- S. R. Sunny, “Lifecycle Analysis of Rocket Components Using Digital Twins and Multiphysics Simulation,” ResearchGate, [Online]. [CrossRef]

- Sunny, S. R. (2025). AI-Driven Defect Prediction for Aerospace Composites Using Industry 4.0 Technologies (Preprint - v1.0, July 2025.). Zenodo. Energy-Efficient Embedded Control Systems for Automated Vending Platforms. [CrossRef]

- Mahmudul Hasan Mithun, Md. Faisal Bin Shaikat, Sharif Ahmed Sazzad, Masum Billah, Sadeques Salehin, Al Maksud Foysal, Arafath Jubayer, Rakibul Islam, Asif Anzum, Atiqur Rahman Sunny (2024). "Microplastics in Aquatic Ecosystems: Sources, Impacts, and Challenges for Biodiversity, Food Security, and Human Health - A Meta Analysis", Journal of Angiotherapy, 8(11),1-12,10035. [CrossRef]

- Faisal Bin Shaikat, Rafiqul Islam, Asma Tabassum Happy, Shown Ahmed Faysal. “Optimization of Production Scheduling in Smart Manufacturing Environments Using Machine Learning Algorithms” , LHEP, Vol.2025, ISSN 2632-2714.Lett.Phys.

- Islam, R., Faysal, S. A., Shaikat, F. B., Happy, A. T., Bakchi, N., & Moniruzzaman, M. (2025). Integration of Industrial Internet of Things (IIoT) with MIS: A framework for smart factory automation. Journal of Information Systems Engineering and Management, 10. [CrossRef]

- Happy, A. T., Hossain, M. I., Islam, R., Shohel, M. S. H., Jasem, M. M. H., Faysal, S. A., Shaikat, M. F. B., Sunny, A. R. (2024). "Enhancing Pharmacological Access and Health Outcomes in Rural Communities through Renewable Energy Integration: Implications for chronic inflammatory Disease Management", Integrative Biomedical Research (Former Journal of Angiotherapy), 8(12),1-12,10197. [CrossRef]

- Shaikat, Faisal Bin. (2025). AI-Powered Hybrid Scheduling Algorithms for Lean Production in Small U.S. Factories. [CrossRef]

- Shaikat, Faisal Bin. (2025). Energy-Aware Scheduling in Smart Factories Using Reinforcement Learning. [CrossRef]

- Shaikat, Faisal Bin. (2025). Secure IIoT Data Pipeline Architecture for Real-Time Analytics in Industry 4.0 Platforms. [CrossRef]

- Shaikat, Faisal Bin. (2025). Upskilling the American Industrial Workforce: Modular AI Toolkits for Smart Factory Roles. [CrossRef]

- Md Faisal Bin Shaikat. Pilot Deployment of an AI-Driven Production Intelligence Platform in a Textile Assembly Line Author. TechRxiv. July 09, 2025. [CrossRef]

- R. Islam, S. Kabir, A. Shufian, M. S. Rabbi and M. Akteruzzaman, "Optimizing Renewable Energy Management and Demand Response with Ant Colony Optimization: A Pathway to Enhanced Grid Stability and Efficiency," 2025 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 2025, pp. 1-6. [CrossRef]

- M. S. Rabbi, "Extremum-seeking MPPT control for Z-source inverters in grid-connected solar PV systems," Preprints, 2025. [Online]. [CrossRef]

- M. S. Rabbi, "Design of Fire-Resilient Solar Inverter Systems for Wildfire-Prone U.S. Regions" Preprints, 2025. [Online]. Available: https://www.preprints.org/manuscript/202507.2505/v1. [CrossRef]

- M. S. Rabbi, "Grid Synchronization Algorithms for Intermittent Renewable Energy Sources Using AI Control Loops" Preprints, 2025. [Online]. Available: https://www.preprints.org/manuscript/202507.2353/v1. [CrossRef]

- A. A. R. Tonoy, "Mechanical properties and structural stability of semiconducting electrides: Insights for material design in mechanical applications," Global Mainstream Journal of Innovation, Engineering & Emerging Technology, vol. 1, no. 1, pp. 18–35, Sep. 2022. [Online]. [CrossRef]

- A. R. Tonoy and M. R. Khan, "The role of semiconducting electrides in mechanical energy conversion and piezoelectric applications: A systematic literature," Journal of Scholarly Research and Innovation, vol. 2, no. 1, pp. 1–23, Dec. 2023. [Online]. [CrossRef]

- M. A. Khan and A. A. R. Tonoy, "Lean Six Sigma applications in electrical equipment manufacturing: A systematic literature review," American Journal of Interdisciplinary Studies, vol. 5, no. 2, pp. 31–63, Dec. 2024. [Online]. [CrossRef]

- A. A. R. Tonoy, M. Ahmed, and M. R. Khan, "Precision mechanical systems in semiconductor lithography equipment design and development," American Journal of Advanced Technology and Engineering Solutions, vol. 1, no. 1, pp. 71–97, Feb. 2025. [Online]. [CrossRef]

- S. Rana, A. Bajwa, A. A. R. Tonoy, and I. Ahmed, "Cybersecurity in industrial control systems: A systematic literature review on AI-based threat detection for SCADA and IoT networks," ASRC Procedia: Global Perspectives in Science and Scholarship, vol. 1, no. 1, pp. 1–15, Apr. 2025. [Online]. [CrossRef]

- A. Bajwa, A. A. R. Tonoy, and M. A. M. Khan, "IoT-enabled condition monitoring in power transformers: A proposed model," Review of Applied Science and Technology, vol. 4, no. 2, pp. 118–144, Jun. 2025. [Online]. [CrossRef]

- A. R. Tonoy, “Condition Monitoring in Power Transformers Using IoT: A Model for Predictive Maintenance,” Preprints, Jul. 28, 2025. [Online]. [CrossRef]

- A. R. Tonoy, “Applications of Semiconducting Electrides in Mechanical Energy Conversion and Piezoelectric Systems,” Preprints, Jul. 28, 2025. [Online]. [CrossRef]

- H. Tao, G. Han and M. Zou, "The System Analysis of Solar Inverter Based on Network Controlling," 2010 International Conference on Challenges in Environmental Science and Computer Engineering, Wuhan, China, 2010, pp. 243-246. [CrossRef]

- P. P. Waghmare, S. Y. Gadgune and P. S. Rajmane, "Solar Energy Integration Using Grid Forming Inverter," 2023 IEEE Engineering Informatics, Melbourne, Australia, 2023, pp. 1-5. [CrossRef]

- A. Desai, I. Mukhopadhyay and A. Ray, "Performance Analysis of String and Central Inverter based Ideally Designed Utility scale Solar PV Plant," 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 2020, pp. 2412-2417. [CrossRef]

- S. Asapu, L. Juttiga, D. Bhuvaneswari, S. S. Adabala, P. Apireddi and A. Bale, "Implementation of Seven-Level Asymmetrical Multilevel Inverter for Solar PV Application," 2024 International Conference on Distributed Computing and Optimization Techniques (ICDCOT), Bengaluru, India, 2024, pp. 1-5. [CrossRef]

- A. Desai, V. Shah, I. Mukhopadhyay and A. Ray, "Annual performance of Multiple MPPT based String Inverter under Partial Shadowing: Observations at Utility scale Solar PV Plants," 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 2020, pp. 2438-2443. [CrossRef]

- R. R. R and P. K. Abraham, "Sine Wave Inverter with Three Stage Battery Charger for Solar Photovoltaic Application," 2021 IEEE Madras Section Conference (MASCON), Chennai, India, 2021, pp. 1-5. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).