Submitted:

06 August 2025

Posted:

06 August 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

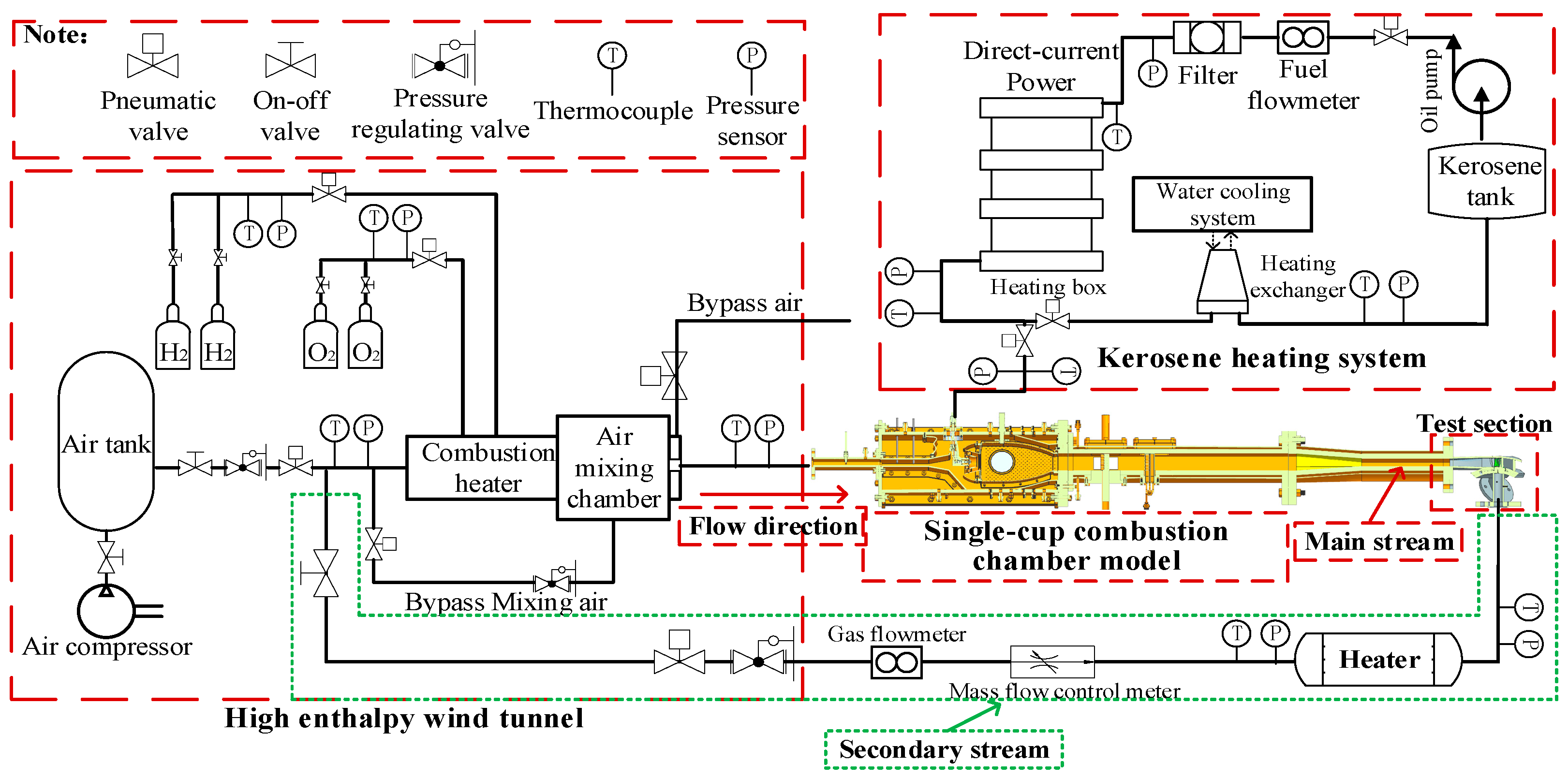

2. Experimental System and Conditions

2.1. Experimental System

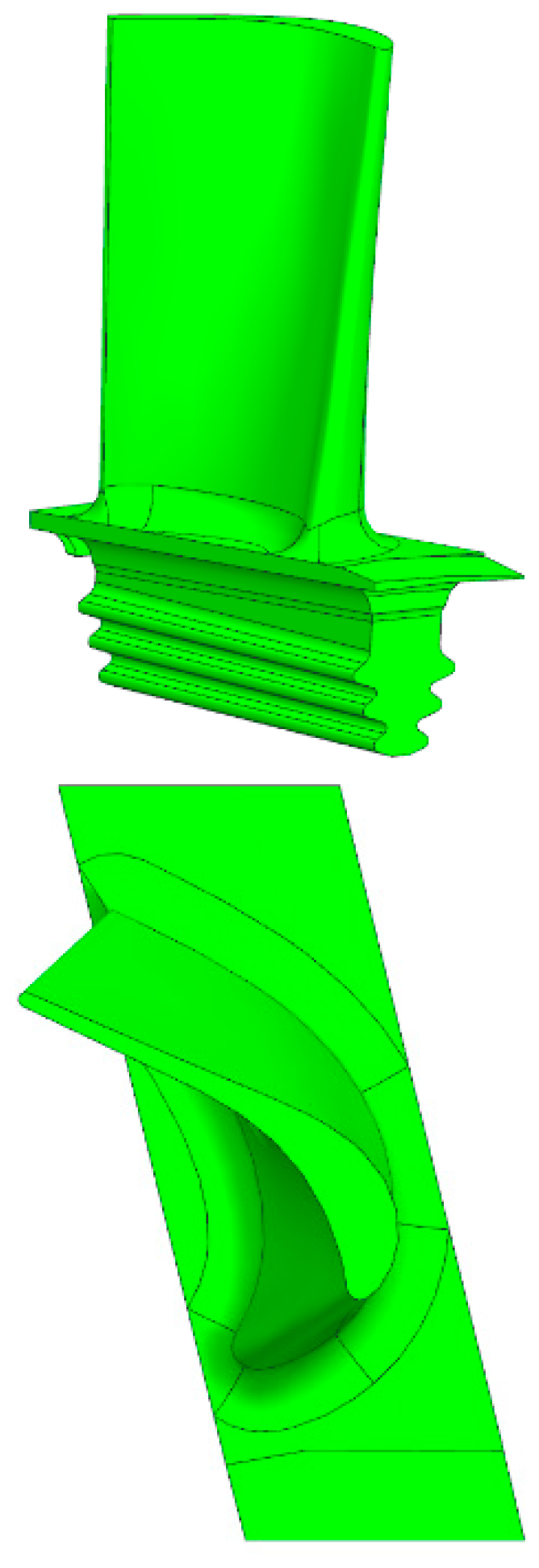

2.2. Test Blade

3. Numerical Simulation

3.1. Computational Model and Boundary Conditions

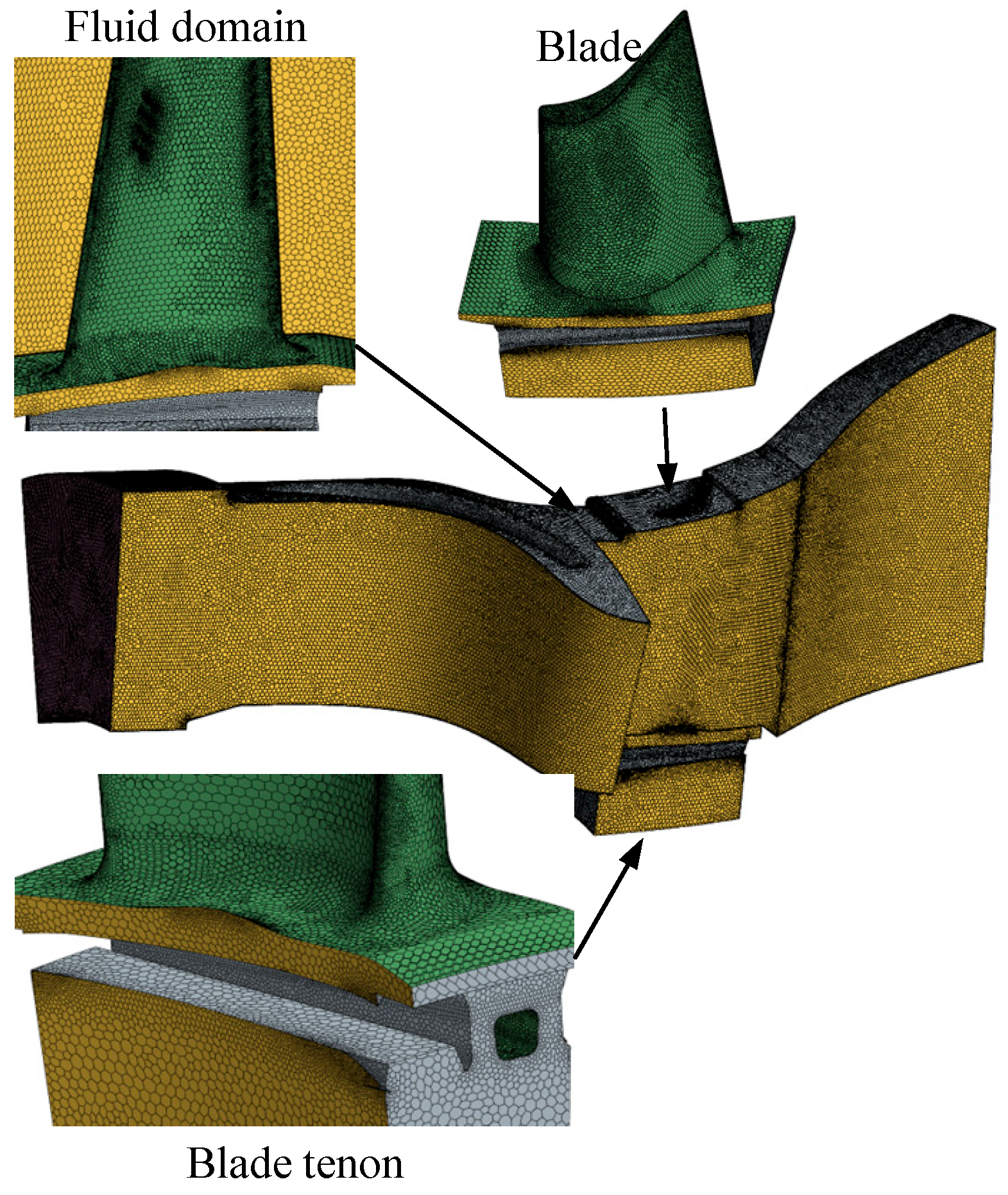

3.2. Mesh

3.3. Mesh Independence

3.4. Numerical Calculation Conditions

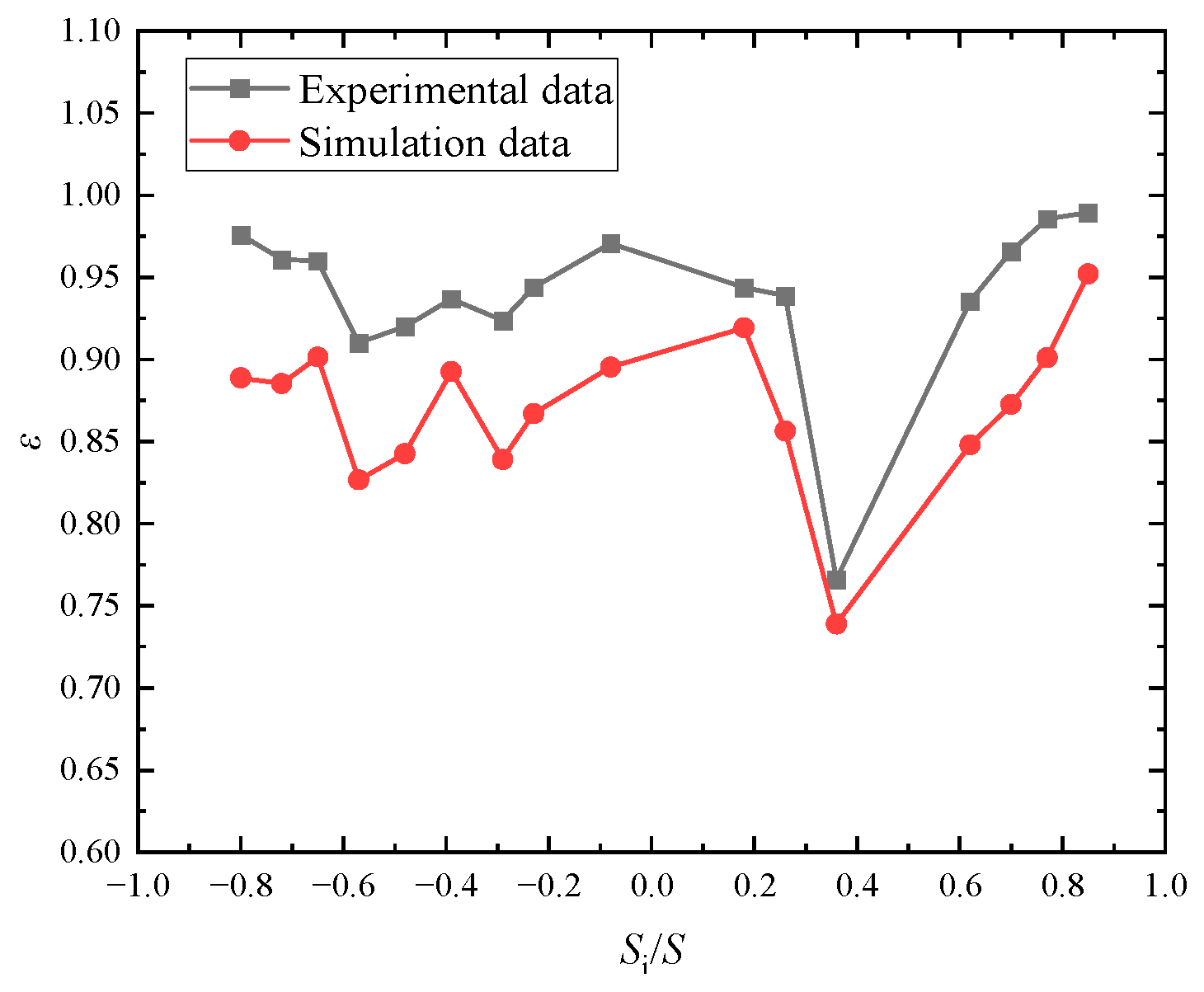

3.5. Validation of the Simulation Results

4. Numerical Results and Discussion

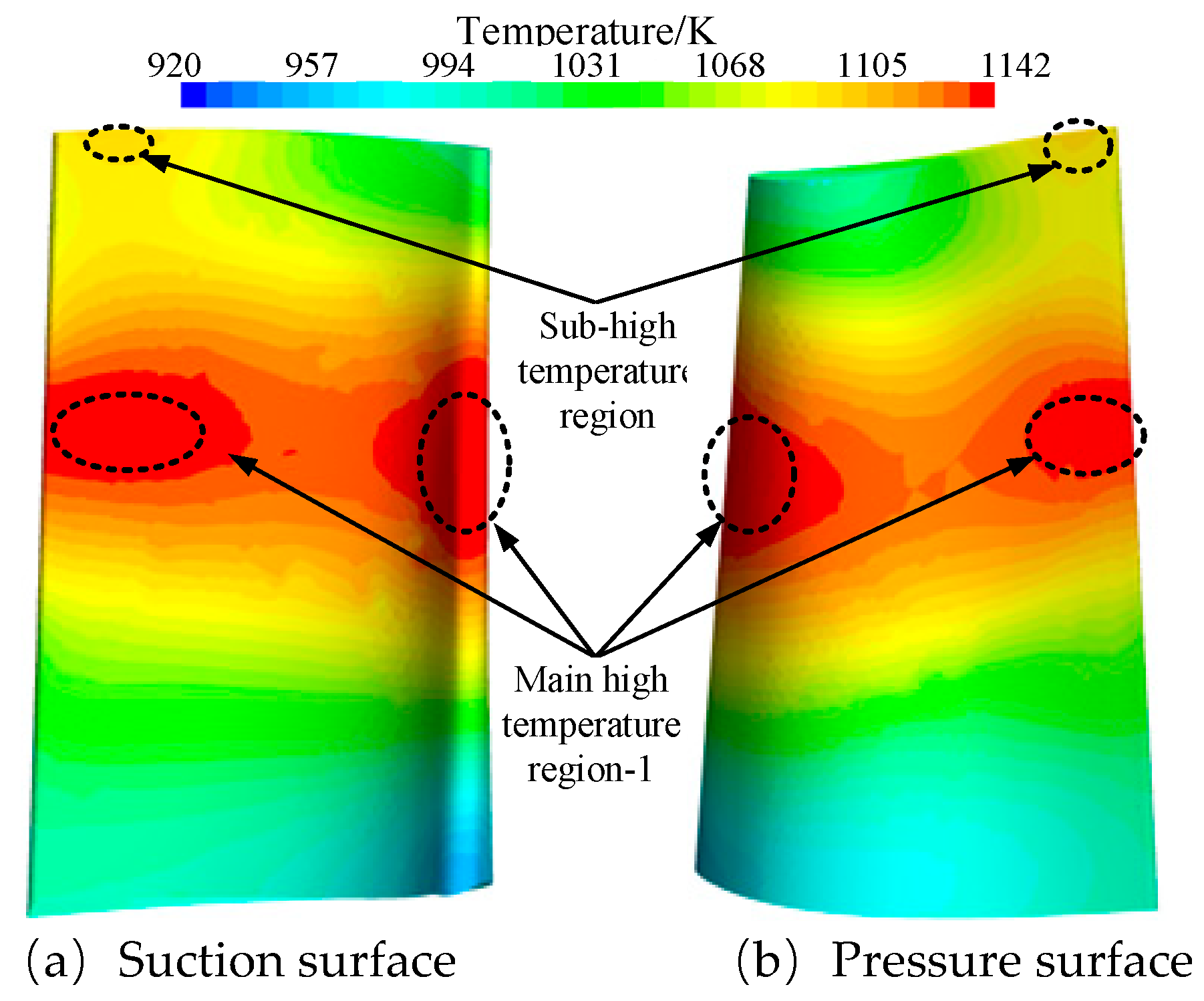

4.1. Temperature Field of the Original Turbine Blade

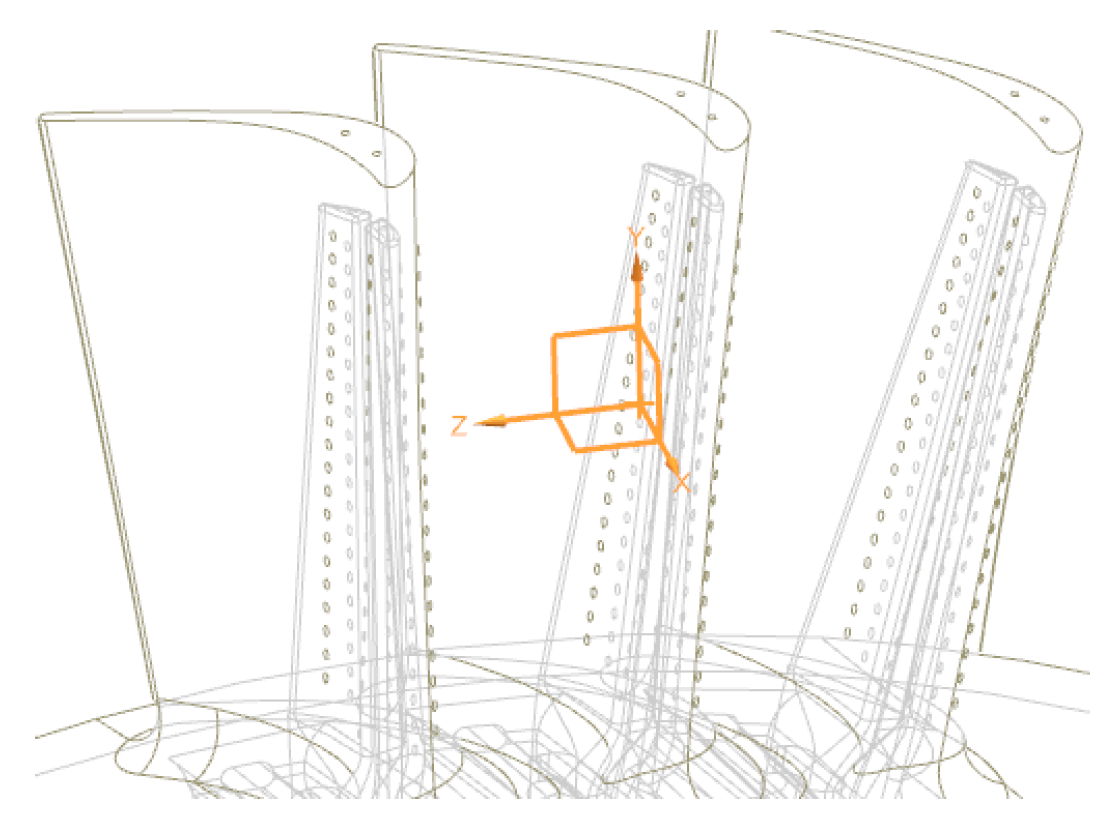

4.2. Design of the Blade Film Cooling Structure

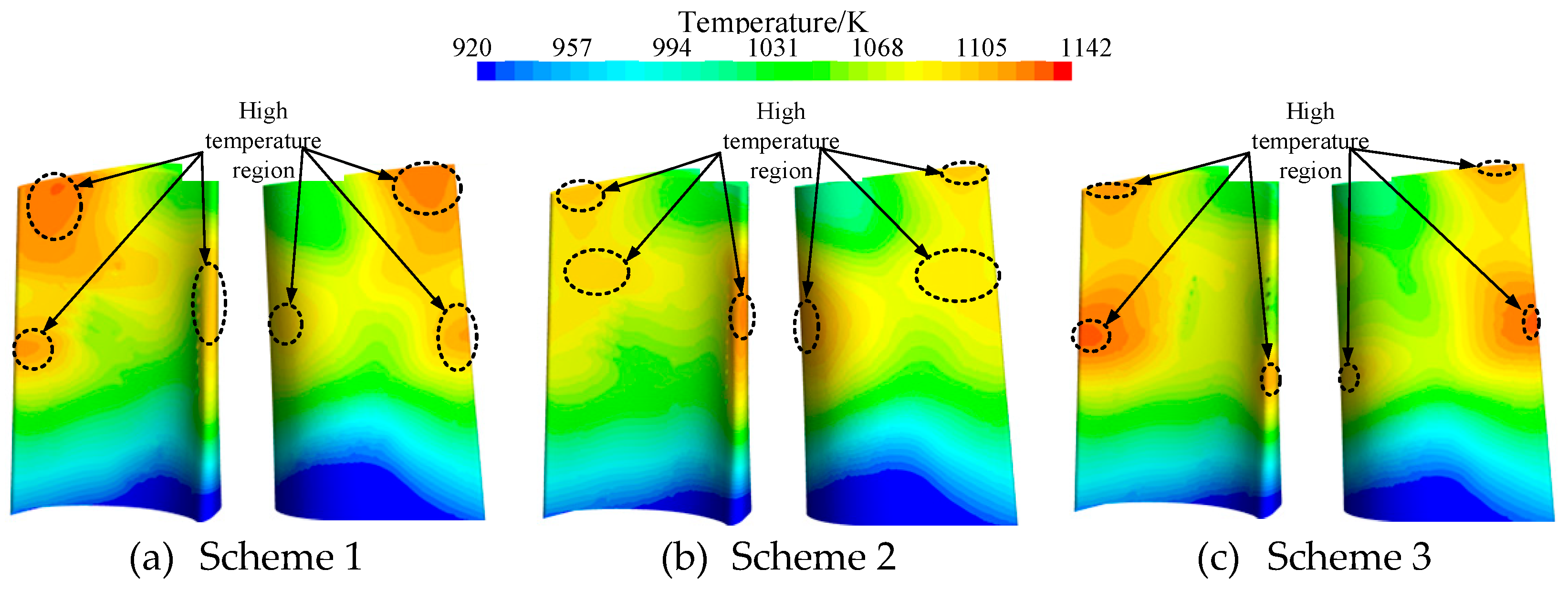

4.3. Surface Temperature Distribution of the Blade

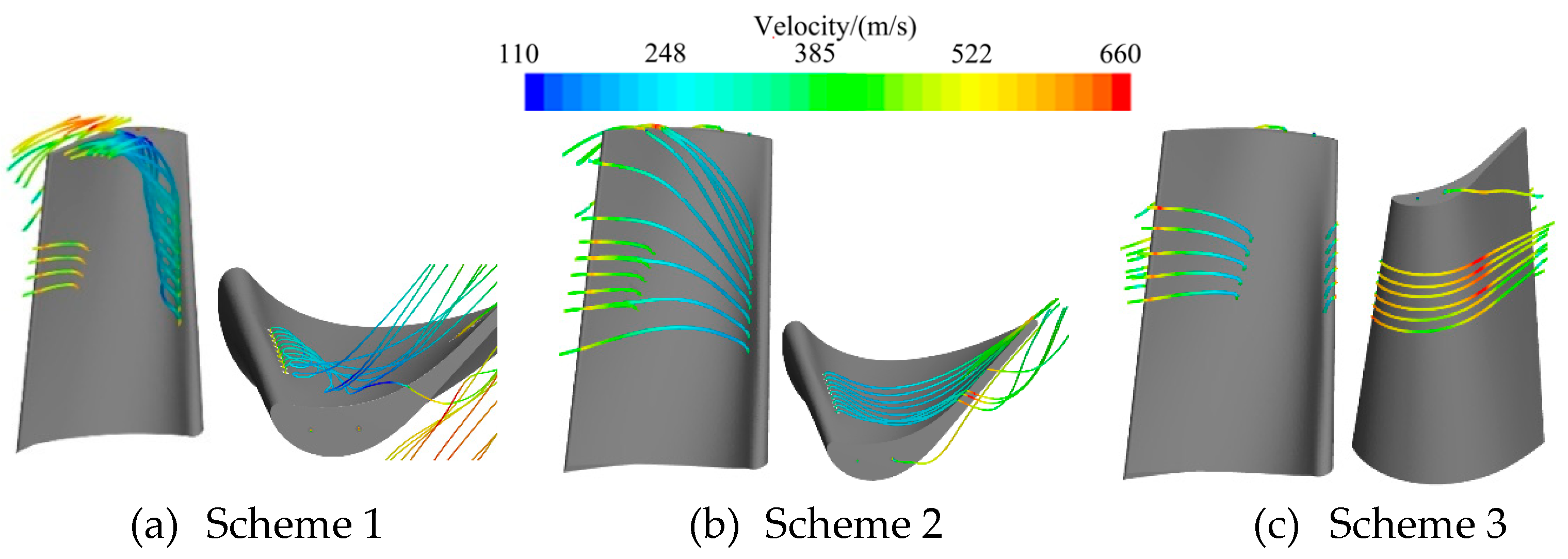

4.4 Film Hole Flowline Distribution Characteristics

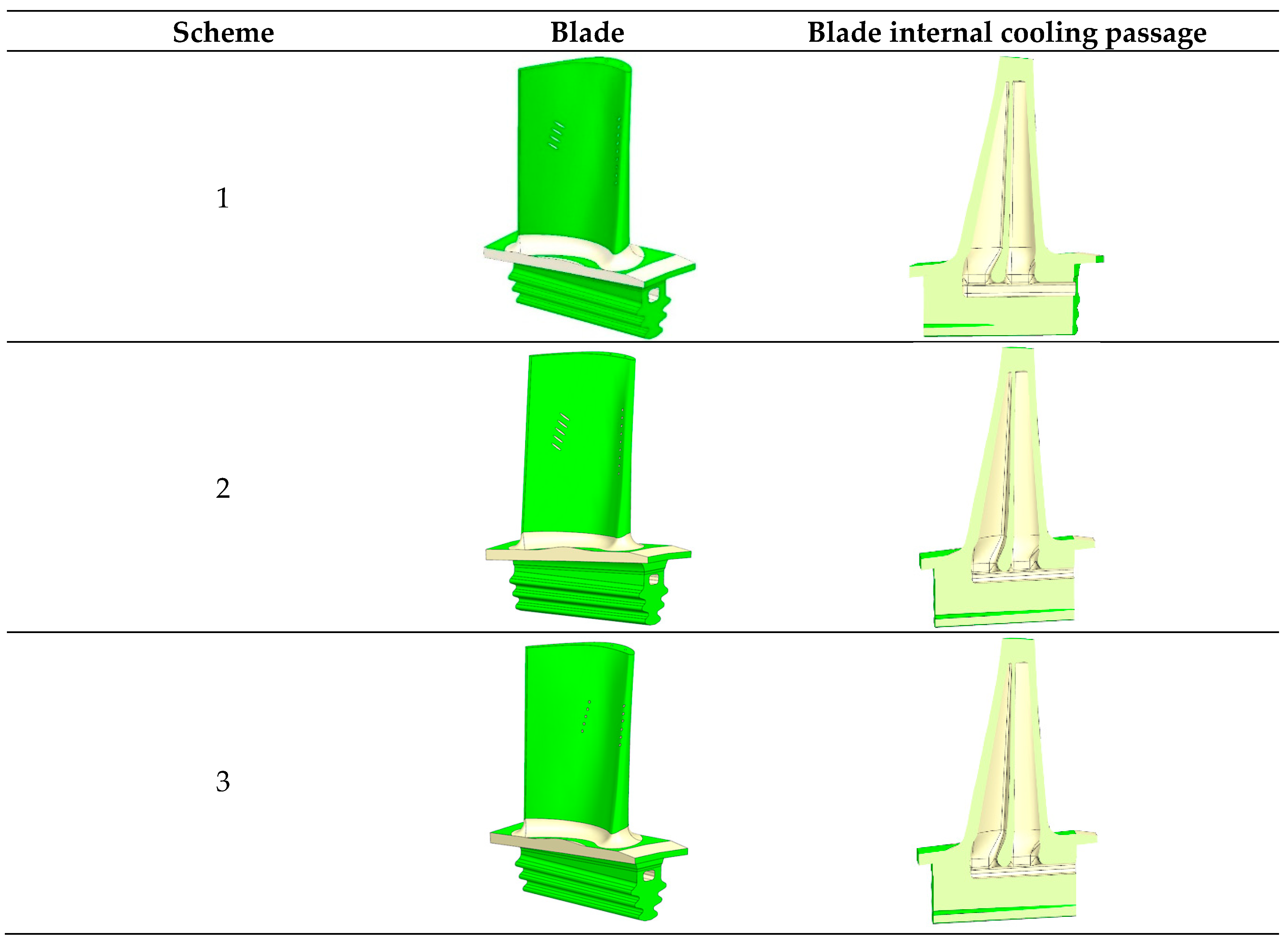

4.5. Final Experimental Blade Scheme

5. Experimental Results and Analysis

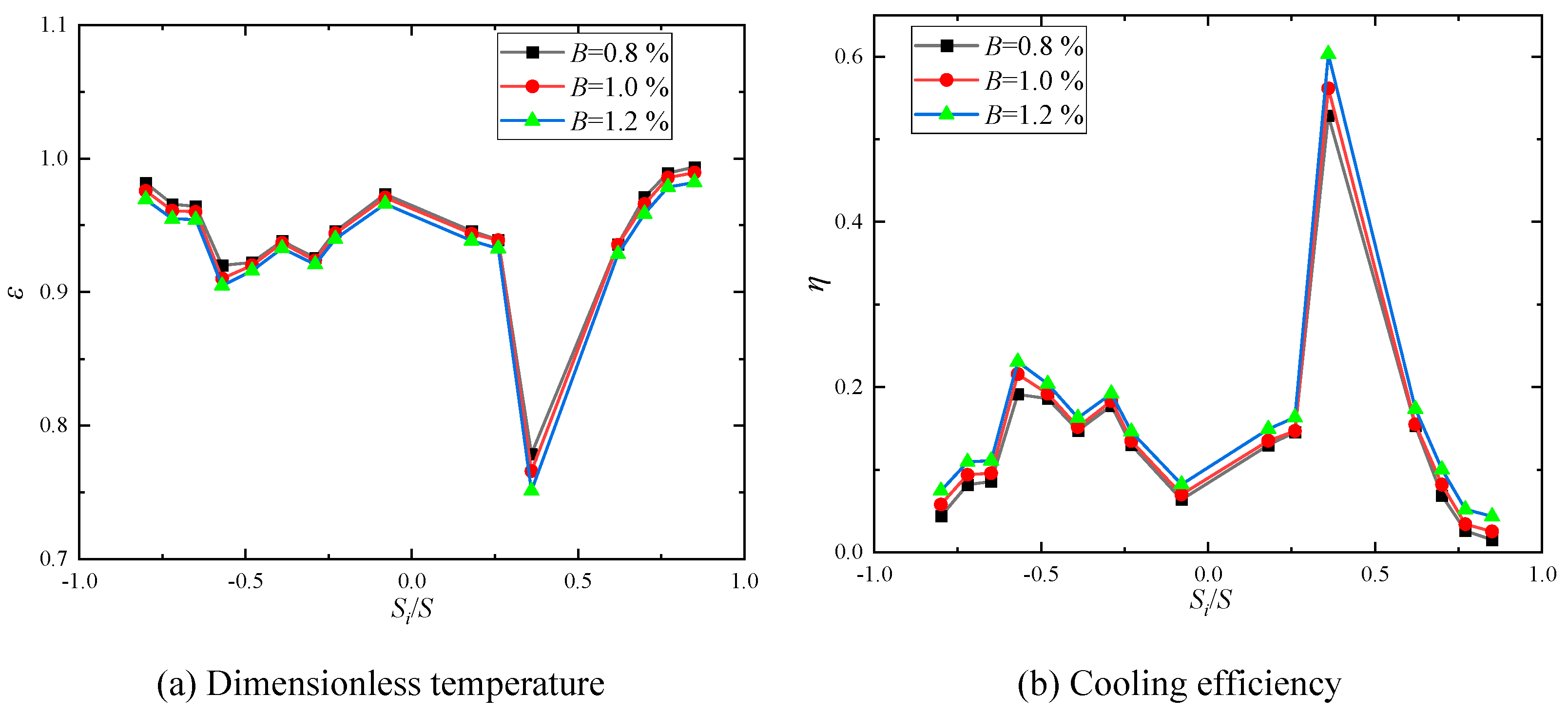

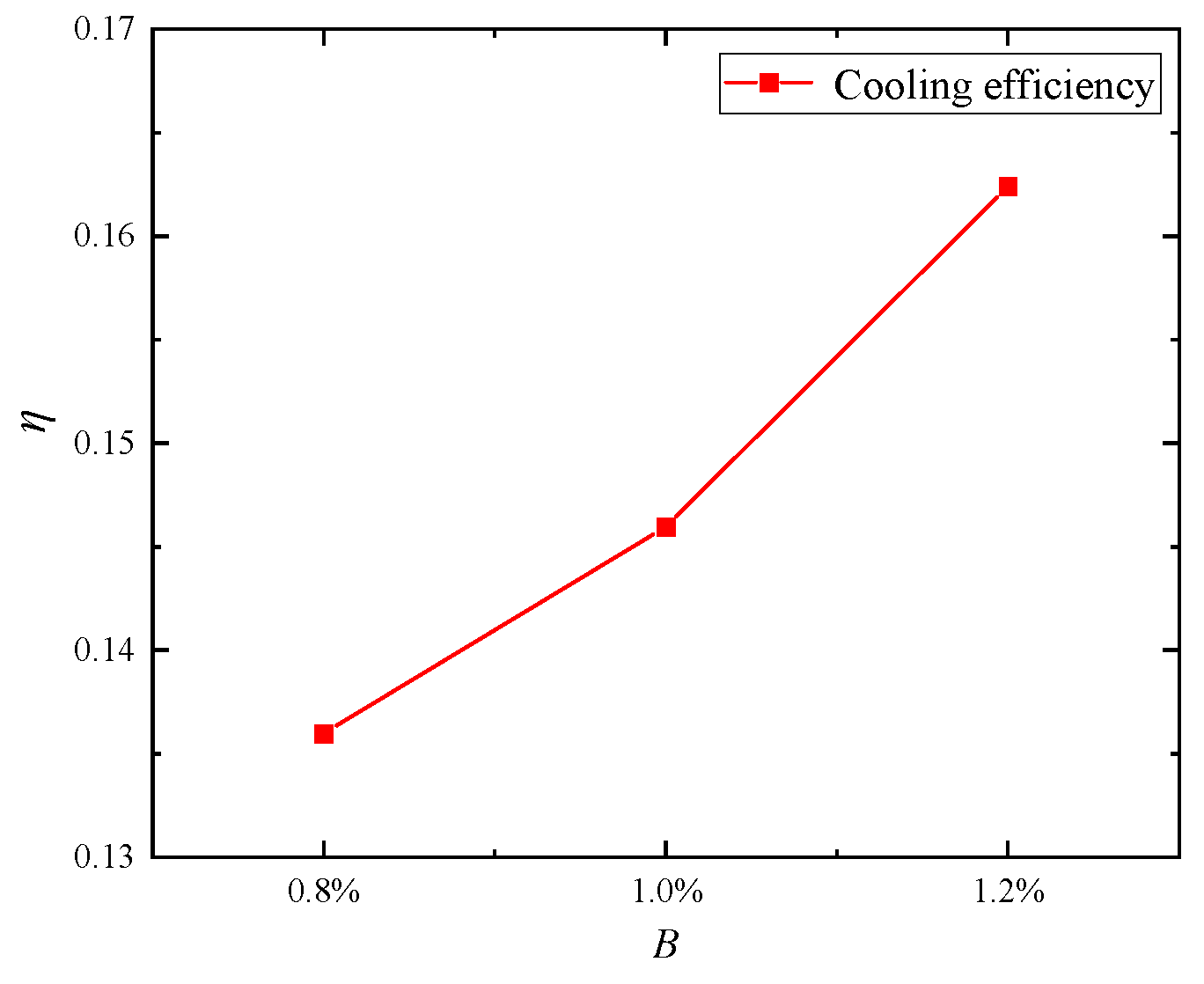

5.1 Effect of B on Cooling Performance

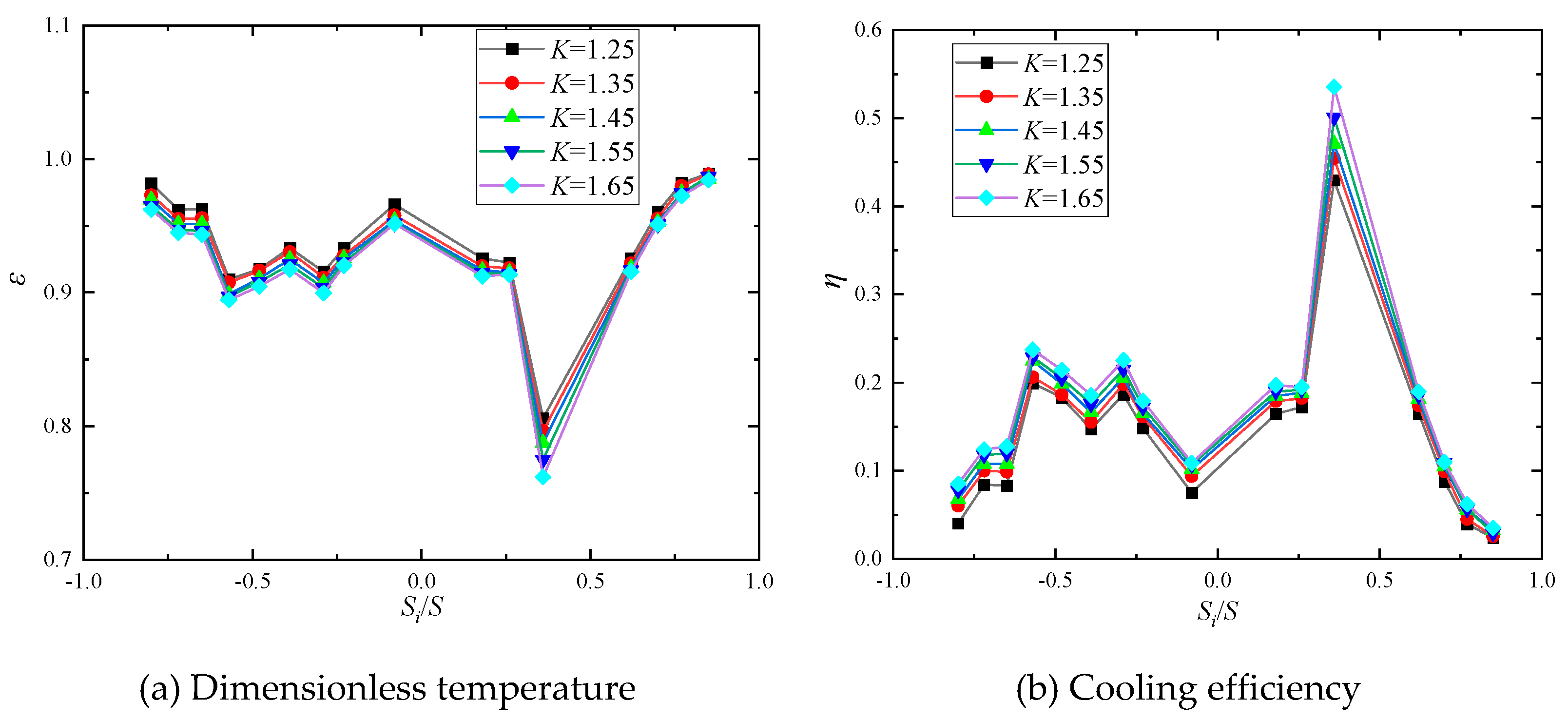

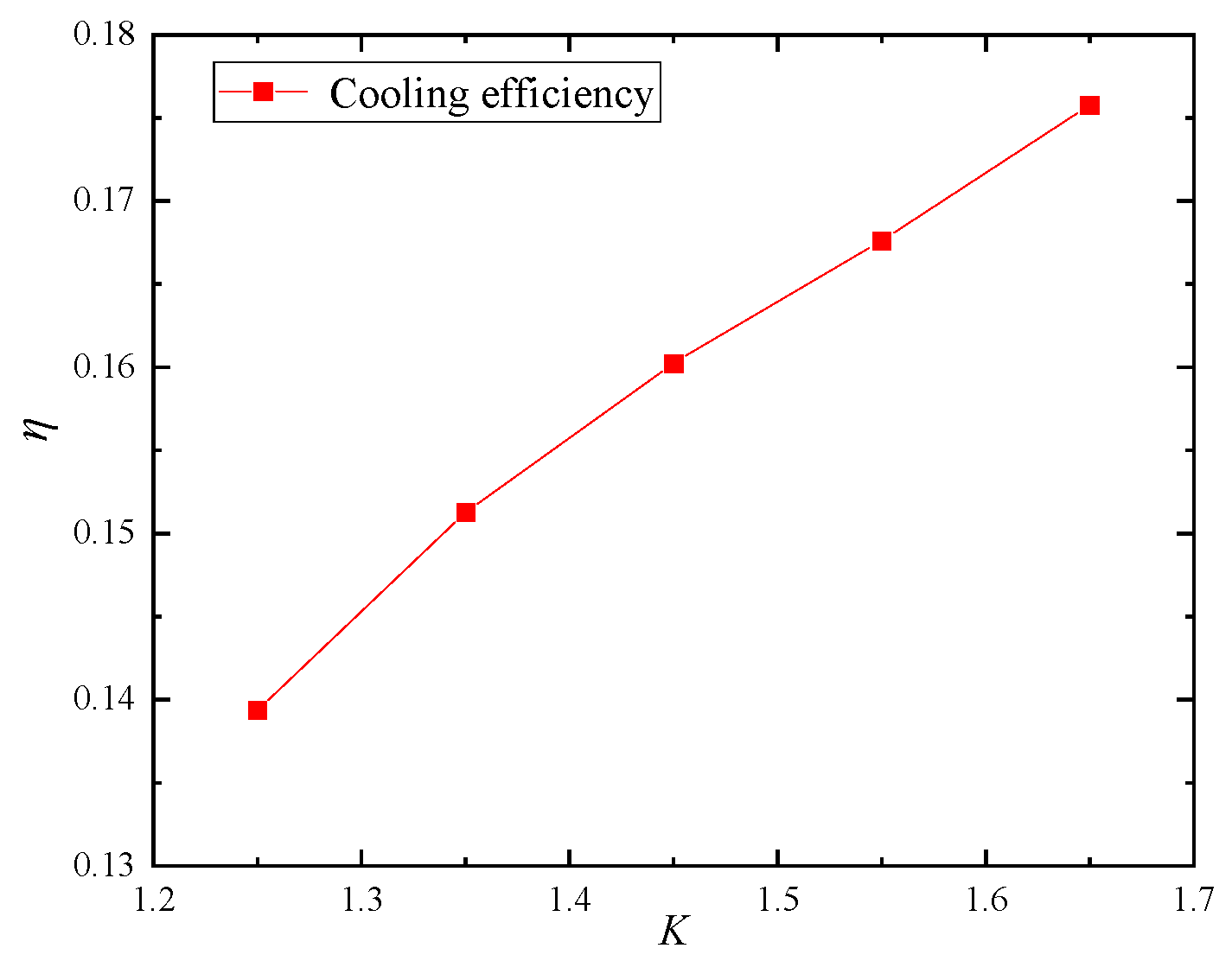

5.2 Effect of K on Cooling Performance

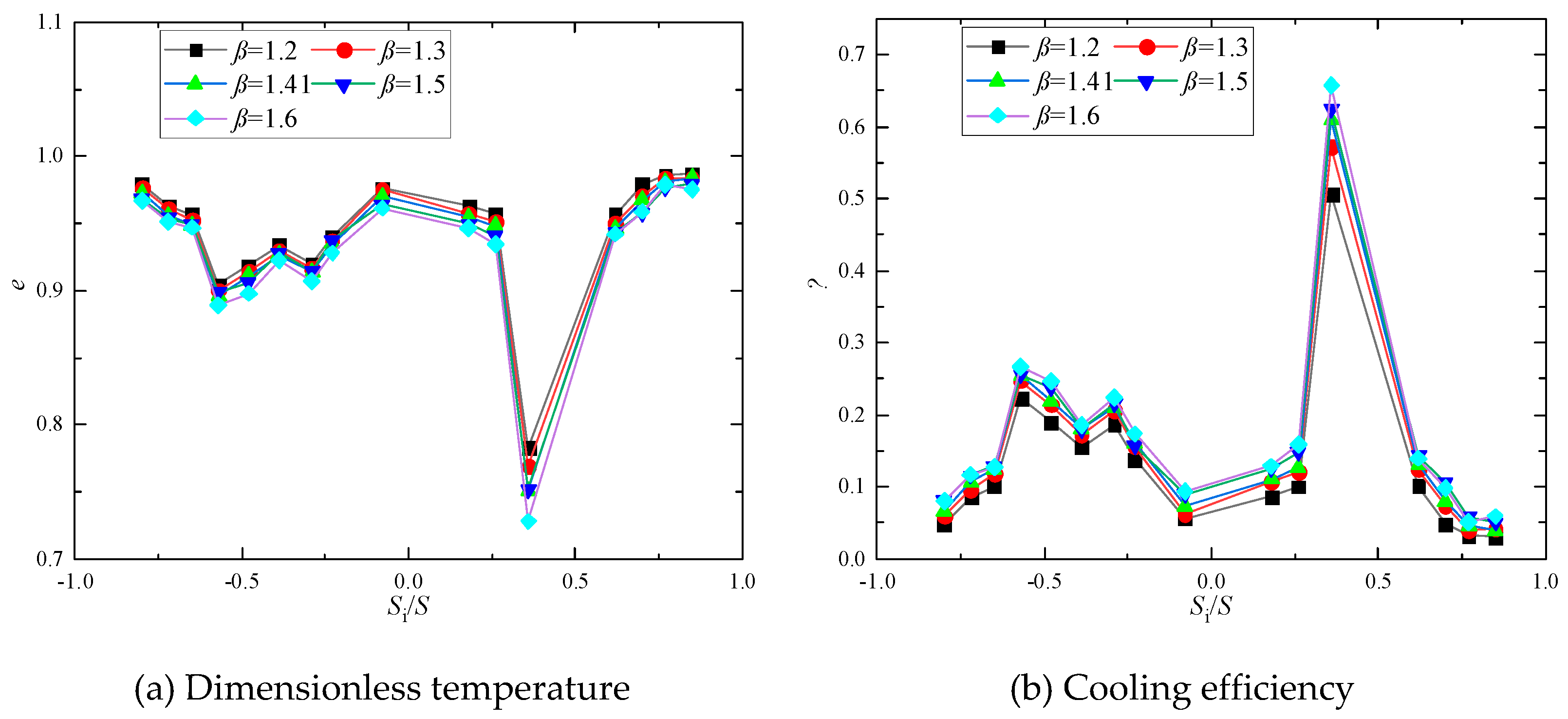

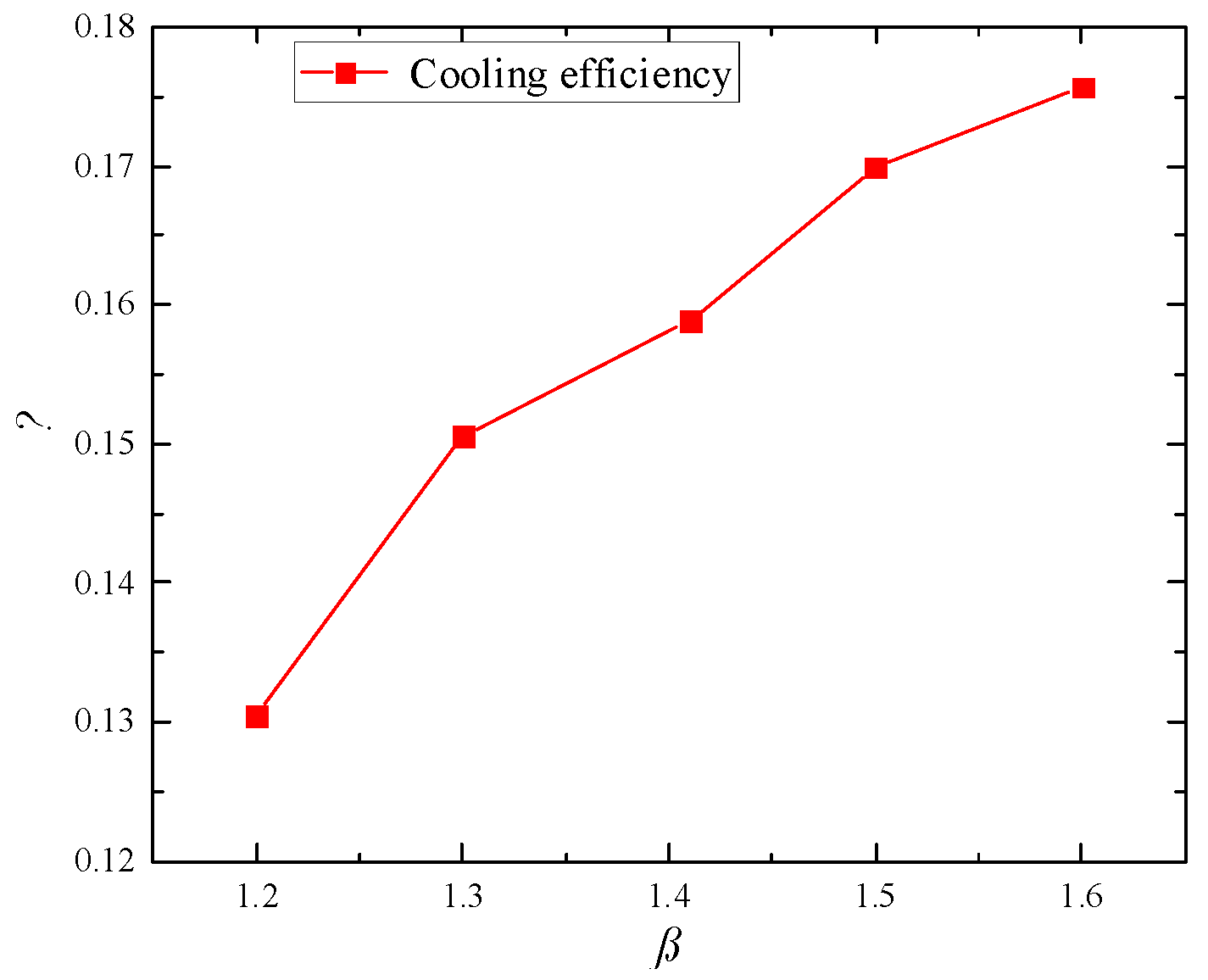

5.3. Effect of β on Cooling Performance

6. Conclusions

- 1)

- Within the experimental conditions, as the mass flow ratio increases, the cooling efficiency gradually improves. When the mass flow ratio increases from 0.8% to 1.2%, the overall cooling efficiency on the blade surface rises from 0.136 to 0.162, representing a 19.12% improvement. However, the increase in flow ratio has no significant effect on the distribution of surface cooling efficiency or the dimensionless temperature distribution on the blade surface. Since the variation range of secondary flow in this study is relatively small, the influence of the mass flow ratio on overall cooling efficiency is limited.

- 2)

- With an increase in the temperature ratio between the secondary flow and the mainstream gas, the overall cooling efficiency of the blade increases. When the temperature ratio K = 1.25, the cooling efficiency is 0.139; when K = 1.65, the efficiency reaches 0.176, indicating an increase of 26.62%.

- 3)

- The pressure ratio has a greater influence on the blade's overall cooling efficiency compared to the mass flow and temperature ratios. When the pressure ratio β = 1.2, the cooling efficiency of the blade surface is 0.130, while at β = 1.6, it increases to 0.176, representing a 35.38% improvement.

- 4)

- The cooling structure of the turbine blade was optimized based on numerical simulation methods and manufactured using additive manufacturing technology. Experimental results show that the blade's overall cooling performance meets the design requirements.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| β | Pressure ratio |

| K | Temperature ratio |

| B | Flow ratio |

| TBC | Thermal barrier coating technology |

| mc | Secondary flow mass flow rate |

| mg | Mainstream gas mass flow rate |

| Tc | Secondary flow temperature |

| Tg | Mainstream gas temperature |

| pc | Total pressure at the secondary air inlet |

| Cascade gas inlet total pressure | |

| pout | Cascade gas outlet static pressure |

| Tw | Turbine blade surface temperature |

| S | Total arc-length of the blade outer surface at the 50% span section |

| ΔSi | Arc-length corresponding to measurement point i |

| ε | Blade surface dimensionless temperature |

| η | Cooling effectiveness |

References

- Kong, X., Zhang, Z, Zhu, J., et al. Research Progress on Cooling Structure of Aeroengine Air-Cooled Turbine Blade. Journal of Propulsion Technology, 2022, 43, 6-28. [CrossRef]

- Zeng, Q., Chen, X. Combustor Technology of High Temperature Rise for Aero Engine. Progress in Aerospace Sciences. 2023, 140. 100927. [CrossRef]

- Nourin, F. N., Amano, R. S. Review of Gas Turbine Internal Cooling Improvement Technology. Journal of Energy Resources Technology. 2020, 143, 080801. [CrossRef]

- Zhu, H., Xie, G., Zhu, R., et al. Comparisons on Flow Characteristics and Film Cooling Performance of Cylindrical and Sister Holes with/without internal coolant crossflow. International Journal of Thermal Sciences. 2022, 182, 107791. [CrossRef]

- Ye, L., Liu, C. l., Liu, H. y., et al. Experimental and Numerical Study on the Effects of Rib Orientation Angle on Film Cooling Performance of Compound Angle Holes. International Journal of Heat and Mass Transfer. 2018, 126, 1099-1112. [CrossRef]

- Chen, G., Liu, Y., Rao, Y., et al. Numerical Investigation on Conjugate Heat transfer of Impingement/Effusion Double-wall Cooling with Different Crossflow Schemes. Applied Thermal Engineering. 2019, 155, 515-524. [CrossRef]

- Zhang, M., Wang, N., Han, J. C. Internal Heat Transfer of Film-cooled Leading Edge Model with Normal and Tangential Impinging Jets. International Journal of Heat and Mass Transfer. 2019, 139, 193-204. [CrossRef]

- Zhang, M., Wang, N., and Han, J. C. Overall Effectiveness of Film-cooled Leading Edge Model with Normal and Tangential Impinging Jets. International Journal of Heat and Mass Transfer. 2019, 139, 577-587. [CrossRef]

- Jia, G., Zhang L., Lu C., et al. Film Cooling Performance with Internal Coolant Channel Crossflow. Journal of Aerospace Power. 2015, 30, 823-830. [CrossRef]

- Rao, Y., Chen, P., Wan, C. Experimental and Numerical Investigation of Impingement Heat Transfer on the Surface with Micro W-shaped Ribs. International Journal of Heat and Mass Transfer. 2016, 93, 683-694. [CrossRef]

- Kalghatgi, P., Acharya, S. Flow Dynamics of a Film Cooling Jet Issued From a Round Hole Embedded in Contoured Crate. Journal of Turbomachinery, 2019, 141, 081006. [CrossRef]

- Zhang, Z.; Zeng, W.; Bian, X., et al. Effects of Thermal Barrier Coating on Temperature and Stress of Turbine Rotor Blade. Journal of Propulsion Technology. 2023, 5, 218-231. [CrossRef]

- Zhu, J., Zhao, C., Qiu, L. Thermal Protection Effectiveness of Thermal Barrier Coatings in Turbine Blade Applications. Journal of Aerospace Power. 2019, 34, 2503-2508. [CrossRef]

- Haydt, S., Lynch, S. Cooling Effectiveness for a Shaped Film Cooling Hole at a Range of Compound Angles. Journal of Turbomachinery, 2019, 141, 041005. [CrossRef]

- Haydt, S., Lynch, S. Flowfield of a Shaped Film Cooling Hole Over a Range of Compound Angles. ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, June 11–15, 2018, GT2018-75728. [CrossRef]

- Haydt, S., Lynch, S., Lewis, S. The Effect of a Meter-Diffuser Offset on Shaped Film Cooling Hole Adiabatic Effectiveness. Journal of Turbomachinery. 2017, 139, 091012. [CrossRef]

- Haydt, S., Lynch, S., Lewis, S. The Effect of Area Ratio Change Via Increased Hole Length for Shaped Film Cooling Holes With Constant Expansion Angles. Journal of Turbomachinery. 2018, 140, 051002. [CrossRef]

- Gao, Z., Narzary, D. P., Han, J.C. Film Cooling on a Gas Turbine Blade Pressure Side or Suction Side with Axial Shaped Holes. International Journal of Heat and Mass Transfer. 2008, 51, 2139-2152. [CrossRef]

- Narzary, D. P., Liu, K. C., Rallabandi, A. P., et al. Influence of Coolant Density on Turbine Blade Film-Cooling Using Pressure Sensitive Paint Technique. Journal of Turbomachinery. 2011, 134, 895-908. [CrossRef]

- Jeong, J. Y., Kwak, J. S., Park, J. S., et al. Measurement of Film Cooling Effectiveness for the First-Stage Vane and Endwall of a Gas Turbine With Fan-Shaped Holes. ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition. Charlotte, North Carolina, USA. June 26–30, 2017. GT2017-63896. [CrossRef]

- Zhang, X. Application of Metal Additive Manufacturing in Aero-engine. Journal of Aerospace Power, 2016, 31, 10-16. [CrossRef]

- Yu, Z., Guo, Y., Sun, H., et al. Recent Progress in Structural Integrity of Novel Materials and Advanced Techniques. Acta Aeronautica et Astronautica Sinica. 2024, 45, 29888. [CrossRef]

- Zhang, X., Tao, C., Liu, C., et al. Investigation of Processing Methods and Development of Gas Holes of Engine Blade. Materials Reports. 2013, 27, 117-120. [CrossRef]

- Sambhav, K., Tandon, P., Kapoor, S. G., et al. Mathematical Modeling of Cutting Forces in Microdrilling. Journal of Manufacturing Science and Engineering. 2013, 135, 014501. [CrossRef]

- Peng, L., Taiping, Y., Sheng, L., et al. Direct Laser Fabrication of Nickel Slloy Samples. International Journal of Machine Tools and Manufacture. 2005, 45, 1288-1294. [CrossRef]

- Dinda, G. P., Dasgupta, A. K., Mazumder, J. Texture Control During Laser Deposition of Nickel-based Superalloy. Scripta Materialia. 2012, 67, 503-506. [CrossRef]

- Tabernero, I., Lamikiz, A., Martínez, S., et al. Evaluation of the Mechanical Properties of Inconel 718 Components Built by Laser cladding. International Journal of Machine Tools & Manufacture. 2011, 51, 465-470. [CrossRef]

- Acharya, R., Bansal, R., Gambone, J. J., et al. Modeling of Solidification and Microstructure Evolution in the Scanning Laser Epitaxy (SLE) Process for Additive Manufacturing With Nickel-Base Superalloy Powders. ASME 2013 International Mechanical Engineering Congress and Exposition. San Diego, California, USA. November 15–21, 2013. IMECE2013-66807. [CrossRef]

- Doubrovski, Z., Verlinden, J. C., Geraedts, J. M. P. Optimal Design for Additive Manufacturing: Opportunities and Challenges. ASME 2011 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Washington, DC, USA. August 28–31, 2011. DETC2011-48131. [CrossRef]

- LUO, J. Research of External film cooling Performance of Turbine Blade with Different Internal Cooling Structures. Northwestern Polytechnical University. 2014, 17-37. [CrossRef]

- Dong, S. Comprehensive Simulation Design Platform for Turbine Cooling Blades. 1 July 2025. Available online: http://www.lgsim.com/wllqypzhfzsjpt.

- Moffat, R. J. Describing the Uncertainties in Experimental Results. Experimental Thermal and Fluid Science. 1988, 1, 3-17. [CrossRef]

- Walters, D. K., Leylek, J. H. Impact of Film-Cooling Jets on Turbine Aerodynamic Losses. Journal of Turbomachinery. 1999, 122, 537-545. [CrossRef]

- Na, S., Zhu, B., Bryden, M., et al. CFD Analysis of Film Cooling. 44th AIAA Aerospace Sciences Meeting and Exhibit. Reno, Nevada. January, 9-12, 2006. AIAA 2006-22. [CrossRef]

| Parameters | Measuring instrument | Range | Uncertain/% |

| Blade surface temperature | K thermocouple | 273~1000 K | 0.5 |

| Total inlet/outlet temperature |

K thermocouple | 273~1000 K | 0.5 |

| Total inlet/outlet pressure |

Pressure sensor A | 0.5~1.5 MPa | 0.5 |

| Inlet/outlet static pressure |

Pressure sensor B | 0.1~5.0 MPa | 0.5 |

| Secondary flow | Mass flowmeter | 0.1~100 g/s | 1.0 |

| Mass flow control meter | 0.1~5.0 g/s | 0.05 |

| Mesh/106 | 1.0 | 3.0 | 5.0 | 9.0 |

| Average blade temperature/K | 1018.9 | 1024.8 | 1025.3 | 1025.6 |

| Parameters | Value |

| 1.34 MPa | |

| Tg | 1284.6 K |

| mg | 0.585 kg/s |

| pc | 0.8 MPa |

| Tc | 708.5 K |

| Position | Scheme 1 | Scheme 2 | Scheme 3 |

| Leading Edge | 9 | 9 | 6 |

| Trailing Edge | 4 | 5 | 5 |

| Blade tip | 2 | 2 | 1 |

| Blade internal cooling channel | 2.2×2.0 mm | 2.2×1.5 mm | 2.2×1.5 mm |

| Position | Scheme 1 | Scheme 2 | Scheme 3 |

| Leading Edge | 41° | 39° | 35° |

| Trailing Edge | 30° | 30° | 45° |

| Blade tip | 90° | 88° | 88° |

| Scheme | Maximum temperature on the surface of turbine blade/K | Average temperature of blade body and tenon/K | Total cooling air flow/g•s-1 |

| 1 | 1087.8 | 890.6 | 4.57 |

| 2 | 1082.4 | 893.2 | 3.47 |

| 3 | 1098.3 | 902.4 | 2.00 |

| Parameter | Value |

| B | 0.8%, 1.0%, 1.2% |

| K | 1.25, 1.35, 1.45, 1.55, 1.65 |

| β | 1.2, 1.3, 1.41, 1.5, 1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).