1. Introduction

Expansive soil is a special type of soil primarily composed of clay minerals such as montmorillonite, which have strong hydrophilic properties. It exhibits significant characteristics of swelling when absorbing water and shrinking when losing water. In road engineering projects in expansive soil areas, the repeated swelling and shrinking behavior causes the development and expansion of fissures in the subgrade soil, which weakens the strength and stability of the soil and ultimately leads to problems such as subgrade heaving and cracking. Therefore, effective improvement of expansive soil is essential for its reuse in road construction. Researchers in both academia and engineering have conducted extensive studies on how to improve the swelling and shrinkage properties of expansive soil, enhance its strength, and increase its bearing capacity. Existing research can be roughly divided into two categories: physical improvement methods and chemical improvement methods. Physical improvement methods typically involve incorporating materials such as coconut shell fibers [

1], glass fibers [

2], or coarse granular materials like waste glass powder [

3], marble powder [

4], and waste tire textile fibers [

5] into the soil to improve its particle grading, cohesion, and bonding, thereby enhancing the soil's physical and mechanical properties. Chemical improvement methods primarily involve adding materials like cement [

6], sugarcane bagasse ash [

7], lime, and fly ash [

8] to alter the mineral composition or structure of the soil, achieving improvement. However, some chemical additives, such as sulfates and organic substances, may cause environmental pollution and even lead to the degradation of soil properties after treatment. Long-term use may result in soil performance failure [

9].

In recent years, the use of environmentally friendly biomaterials and natural fibers has gradually become a new trend in expansive soil improvement research, offering effective solutions for the sustainable improvement of expansive soil. Guar gum and palm fibers, as natural materials, have shown significant ecological and sustainable benefits in the improvement of expansive soil. Guar gum, a polysaccharide biopolymer, possesses high viscosity and stability and can maintain its chemical structure under certain temperature and pH conditions; while palm fibers have high tensile strength and corrosion resistance. Studies have shown that guar gum and palm fibers exhibit good effects in improving the properties of expansive soil. For example, Hamza M et al. [

10] found through UCS and CBR tests that the UCS and CBR values of expansive soil significantly increased with the increase in guar gum content and curing time. Guar gum forms a hydrogel, which covers the pores and enhances the cementation of the soil, effectively reducing the swelling and shrinkage of the soil and improving its strength. Keshav N et al. [

11] also demonstrated that when the guar gum content was 1.5%, the soil strength increased by 100%, further confirming the effectiveness of guar gum as an environmentally friendly additive. Vydehi KV et al. [

12] found that both guar gum and xanthan gum significantly improved the unconfined compressive strength (UCS) and consolidation properties of expansive soil at different dosages. Other studies have shown that the improvement effect of guar gum on expansive soil increases with the dosage [

13] and can effectively improve the soil's compressibility and anti-disintegration properties [

14]. Additionally, the incorporation of palm fibers also significantly improves the strength, ductility, and energy absorption capacity of the soil [

15]. A review by Medina-Martinez CJ et al. [

16] pointed out that the appropriate addition of natural fibers significantly improves the shear strength of expansive soil.

Although the aforementioned studies have demonstrated that the use of guar gum or natural fibers alone can effectively improve the physical and mechanical properties of expansive soil, single improvement methods have certain limitations. Therefore, this paper proposes a composite improvement technique using guar gum and palm fibers, aiming to reduce the soil-water interaction through the cementing effect of guar gum while utilizing the reinforcing effect of palm fibers to inhibit crack propagation, thereby offering an economical and environmentally friendly composite improvement solution. First, the optimal dosage of guar gum is determined through disintegration tests to evaluate its effect on the water stability of expansive soil. Then, based on the optimal dosage of guar gum, different amounts of palm fibers are incorporated, and the effects of palm fibers on the strength and deformation failure characteristics of guar gum-treated soil are analyzed through unconfined compressive strength tests and triaxial compression tests. Finally, through microscopic mechanism analysis, the improvement mechanism and failure mechanism of the guar gum-palm fiber composite treatment on expansive soil are revealed, providing a theoretical basis for engineering management in expansive soil areas.

2. Materials and Methods

2.1. Expansive Soil

The expansive soil used in this experiment was sourced from the third section of the engineering project located along Enhu Road (Yongwu Road - Jinlun Road) in Nanning, Guangxi. The sampling depth was approximately 2.8 meters, with soil colors ranging from gray-white to brown, and a relatively high clay content. Its primary mineral composition consists of montmorillonite and illite. According to the "Highway Soil Test Code" (JTG 3430-2020) [

17], the expansive soil was crushed and sieved using a 2 mm mesh. Its basic physical properties were determined through laboratory tests, with the relevant data presented in

Table 1. Based on the free expansion rate classification, this soil is categorized as medium-expansive soil. It exhibits significant water absorption expansion and shrinkage upon water loss, demonstrating distinct engineering hazards.

2.2. Guar Gum

Guar gum is a water-soluble polymer that appears as a milky white powder (as shown in

Figure 1(a). Its molecular structure is linear, as illustrated in

Figure 1(b), and contains hydroxyl (-OH) and carboxyl (-COOH) groups. The aqueous solution of guar gum exhibits high viscosity and demonstrates excellent water resistance and stability. Its chemical structure remains stable under certain temperature and pH conditions.

2.3. palm Fiber

The palm fiber used in this study is derived from natural mountain palm fibers from Yichang, Hubei, and has a brownish color (as shown in

Figure 2). The properties of the fiber are presented in

Table 2. Palm fiber is known for its high toughness, corrosion resistance, and insect-repellent characteristics. Additionally, it has a high tensile strength along the grain direction.

2.4. Experimental Design

2.4.1. Sample Preparation

The soil samples used in the experiment are divided into three categories: expansive soil, guar gum-improved expansive soil (hereinafter referred to as guar gum-improved soil), and palm fiber-improved expansive soil (hereinafter referred to as composite-improved soil). Among these, the guar gum-improved soil is used to determine the optimal dosage of guar gum, defined as the mass ratio of dry guar gum to dry expansive soil. The composite-improved soil is used to determine the optimal dosage of palm fiber, defined as the mass ratio of dry palm fiber to the soil sample (which includes both dry expansive soil and dry guar gum). The experimental design of this study is based on the “Highway Geotechnical Testing Specifications” (JTG 3430-2020) [

17]. The mixing ratios in the experimental design are shown in

Table 3. For simplicity, all ratios are represented using simple codes. For example, G1P0.4L3 indicates a guar gum content of 1%, a palm fiber content of 0.4‰, and a palm fiber length of 3mm. Other ratios are similarly represented.

In the experiment, air-dried expansive soil is crushed and sieved, then uniformly mixed after passing through a 2mm sieve. Water is added according to the maximum dry density (ρ

d max) and optimum moisture content (w

0) specified in

Table 1 to prepare the soil mix, and the required water amount is calculated. First, an appropriate amount of air-dried soil is placed in a mixing bowl, and guar gum are added and thoroughly mixed. Subsequently, water is gradually sprayed into the mixing bowl using a spray bottle. During the mixing process, any clumped soil samples are manually broken apart, and spraying continues until the optimum moisture content is reached. For the preparation of soil samples containing guar gum and palm fiber, the guar gum is first thoroughly mixed with the air-dried soil sample. Then, water is added to achieve 2% below the optimum moisture content. Palm fibers are added, and the mixture is thoroughly stirred again. The well-mixed soil samples are then placed in sealed bags and left to rest for 48 hours for conditioning.

The disintegrated samples are compacted in layers using standard molds to form cubic samples with side lengths of 50mm, with a compaction degree set to 90%. The samples for the unconfined compressive strength test are cylindrical, with a diameter of 50mm and height of 100mm. The samples are prepared using the layer-by-layer compaction method. First, the required amount of soil is calculated based on the 90% compaction degree and added in five layers to a compaction mold. After each layer is added, a compaction hammer is used to compact the soil to the target depth. After all compaction steps are completed, the compaction mold is placed in an electric demolding machine for removal. The samples for the triaxial compression test are cylindrical, with a diameter of 39.1mm and a height of 80mm, and are also prepared using the layer-by-layer compaction method. The compaction procedure is repeated until the soil sample is level with the top port of the triaxial apparatus. The prepared samples are cured for 0 and 14 days, respectively. For the samples cured for 14 days, after demolding, they are wrapped with cling film and placed in a moisture-retaining chamber for curing at a constant temperature of 20°C.

2.5. Experimental Methods

1)Disintegration rate test: In the specimen maintenance process, the specimen is first placed on a 10 cm × 10 cm metal mesh, which is then suspended from the hook of a force gauge using a thin string. The assembly is then submerged in a transparent glass water tank with a water level of 20 cm. During the disintegration process, the force gauge readings are automatically collected by a computer once every second, and a camera simultaneously captures images to document the state of the specimen in the water. The test is terminated when the force gauge reading drops to zero or stops changing. The disintegration rate, denoted by η, is used to characterize the disintegration properties of expansive soil and is calculated using the following formula:

where η is the disintegration rate (%), m₀ is the mass of the specimen before disintegration (g), and m is the mass of the specimen after stable disintegration (g).

2)Unconfined compressive strength test: The test is conducted using an XS (082) F-type universal testing machine, with a loading rate set to 3 mm/min. During the test, when the axial stress curve reaches its peak or stabilizes, additional strain of 3%-5% is applied until the test is stopped. If the stress-strain curve does not exhibit a peak or the axial stress does not stabilize, the test is stopped when the axial strain reaches 20%.

3)Triaxial compression strength test: The test follows the “Highway Soil Test Code” (JTG 3430-2020) [

17] for consolidated undrained tests. The TSZ-2 type fully automated triaxial testing apparatus is used. The shear strain rate is set to 0.08 mm/min, and the confining pressures are set at 100 kPa, 200 kPa, and 300 kPa. The data acquisition system automatically records and processes the test data.

4)Scanning electron microscopy (SEM) test: The KYKY-EM6200 digital scanning electron microscope and GVC-1000 ion sputtering instrument are used for observation. First, the specimens from the disintegration, unconfined compressive strength, and triaxial compression tests are air-dried and placed on a hammering mat, then crushed using a roller. The crushed soil samples are then placed in the ion sputtering instrument for metal powder coating. Finally, the scanning electron microscope is used to observe the microstructure of the soil samples.

3. Result Analysis

3.1. Effect of Guar Gum Content on Disintegratio

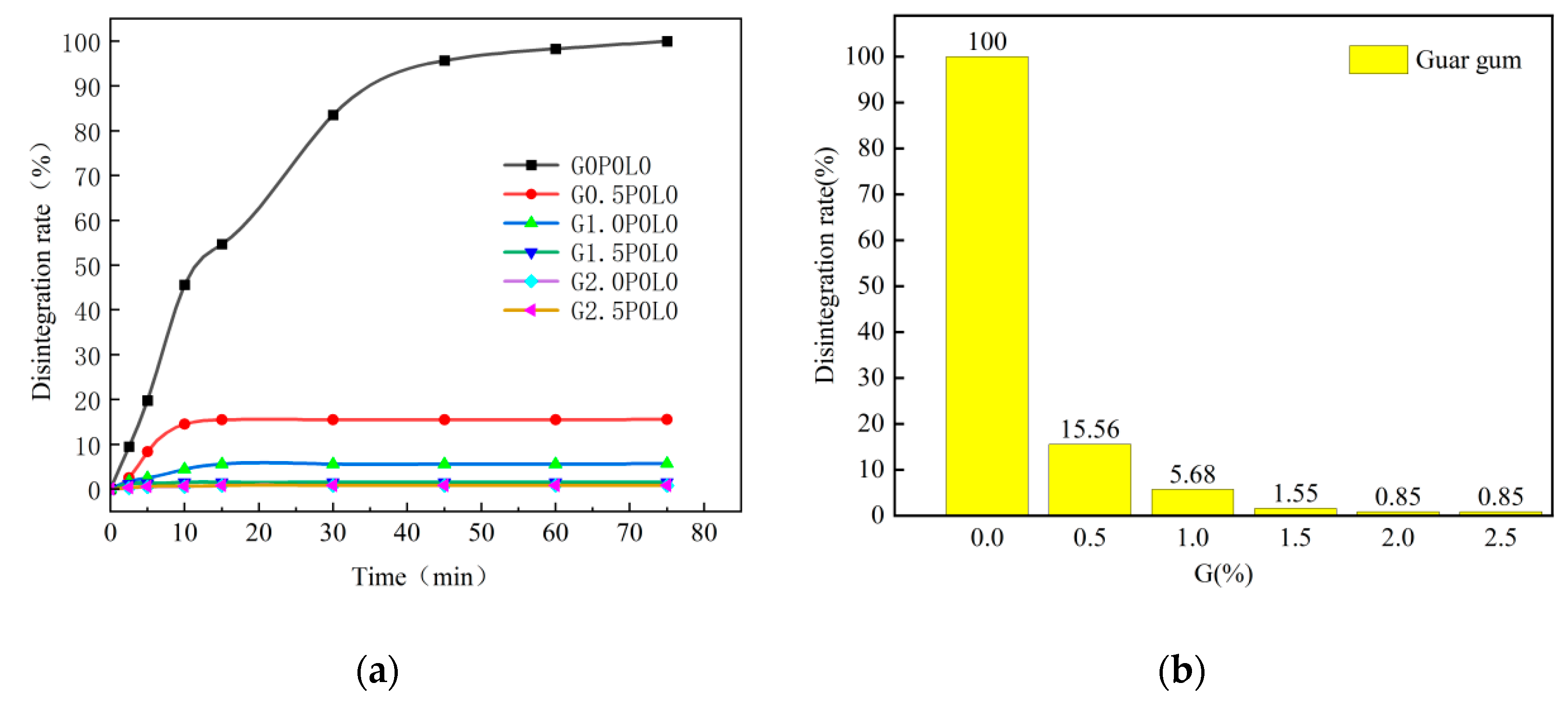

When expansive soil comes into contact with water, disintegration can lead to the collapse of the soil structure, a sharp decrease in strength, and other adverse effects, which directly impact the long-term safety of engineering projects. The disintegration test results of expansive soil modified with different guar gum contents are shown in

Figure 3 and

Figure 4.

As seen in

Figure 3, the G0P0L0 sample exhibited a rapid disintegration rate, with a disintegration rate exceeding 90% after 45 minutes of static water immersion, indicating extremely poor water stability. After adding guar gum to the expansive soil, the disintegration of the soil was significantly suppressed, particularly in the G1.5P0L0, G2.0P0L0, and G2.5P0L0 samples. The disintegration rate of the modified expansive soil was significantly reduced, even to less than 5%. The disintegration stability time of these samples was relatively short, with the disintegration rate of the G2.0P0L0 and G2.5P0L0 samples being as low as 0.85%, suggesting that when the guar gum content reached 2%, the disintegration improvement effect of the expansive soil tended to saturate, and the water stability reached its optimal level.

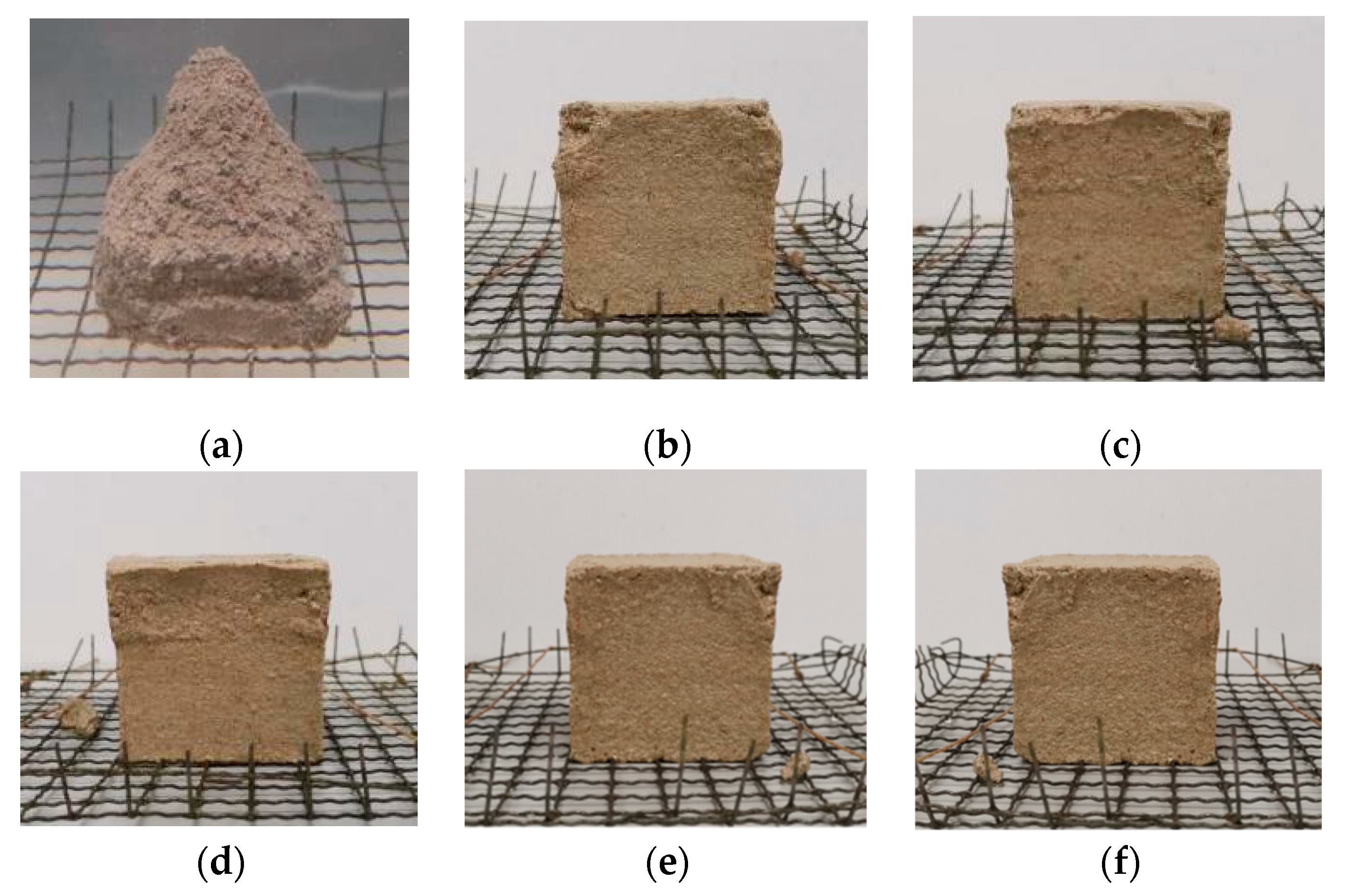

Figure 4 shows the photographs of the samples after static water immersion to the point of disintegration stability for both unmodified soil and soil modified with different guar gum contents. As can be observed from the Figure, compared to the G0P0L0 sample in

Figure 4(a), the guar gum-modified soil samples showed a significant improvement in disintegration resistance. In

Figure 4(b), the G0.5P0L0 sample showed slight soil detachment at the top corner, with fine cracks appearing along the edges. The G1P0L0 sample in

Figure 4(c) exhibited slight damage at the top edges and corners, but was overall more intact than the G0P0L0 sample shown in

Figure 4(b). In

Figure 4(d), the G1.5P0L0 sample displayed minor soil detachment at one top corner, with no significant detachment observed at other locations, though slight deformation was present. In

Figure 4(e), the G2P0L0 sample only showed slight soil detachment at one top corner, and the surface of the sample after disintegration stabilization was relatively smooth, without visible cracks. The G2.5P0L0 sample in

Figure 4(f) appeared almost identical to the G2P0L0 sample in

Figure 4(e), with a smooth surface and no significant differences.

By comparing the five different guar gum-modified expansive soils, it was observed that when the guar gum content exceeded 2%, there was almost no change in the disintegration amount. This is because the gel-like substances produced during the hydration reaction of guar gum filled the pores between soil particles and formed a strong cemented structure between the particles, significantly enhancing the soil’s resistance to disintegration. Considering all factors, a guar gum content of 2% was found to be the optimal proportion. Therefore, in subsequent experiments, the guar gum content will be fixed at 2%.

3.2. The Effect of Palm Fiber Content and Length on UCS

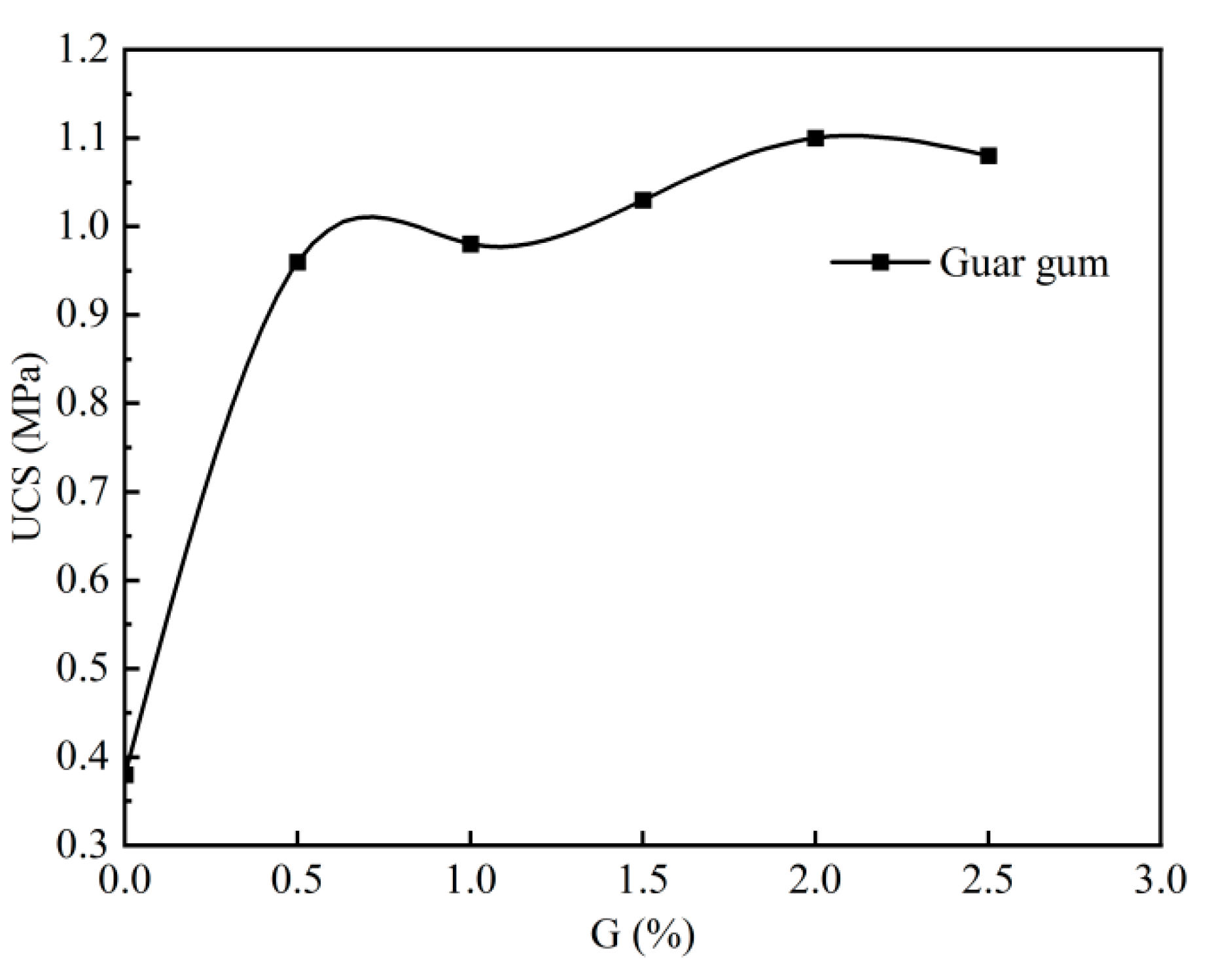

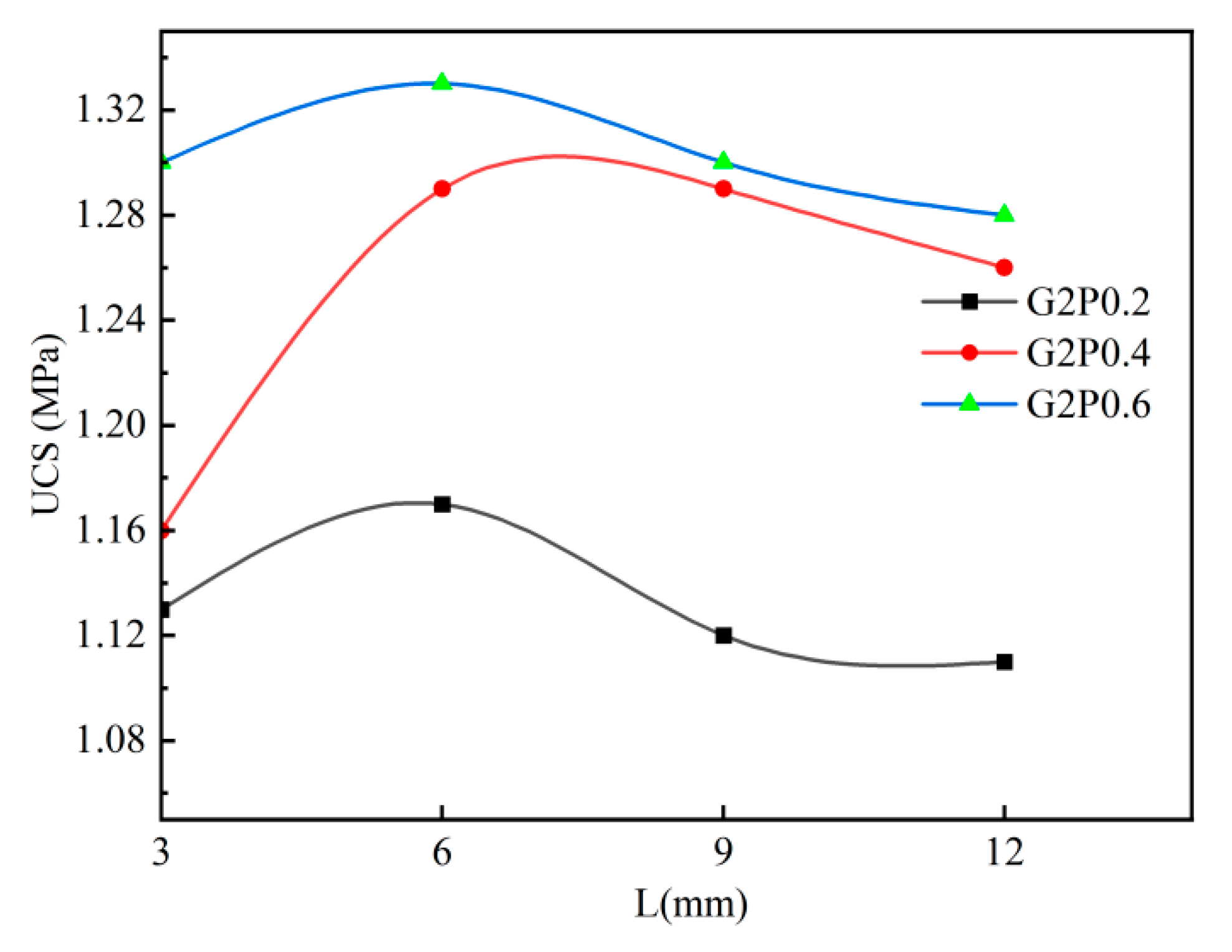

Figure 5 and

Figure 6 show the stress-strain curves for the unconfined compressive strength tests of pure soil, guar gum-modified soil, and composite-modified soil. From

Figure 5, it is evident that guar gum significantly enhances the unconfined compressive strength of expansive soil. With an increase in the guar gum content, the compressive strength of the modified soil shows a noticeable improvement. When the guar gum content reaches 2%, the unconfined compressive strength of the G2P0L0 sample reaches its maximum value of 1.10 Mpa, which is a 187.18% increase compared to pure soil. This phenomenon indicates that the addition of guar gum effectively enhances the soil’s resistance to failure and deformation.

Further analysis reveals that when the guar gum content is optimized at 2%, the palm fiber content and length significantly affect the unconfined compressive strength.

Figure 6 illustrates the variation in compressive strength for guar gum-palm fiber composite-modified soil. The results show that, with a fixed palm fiber length, as the palm fiber content increases, the compressive strength of the composite-modified soil gradually increases. Conversely, when the palm fiber content is fixed, the change in palm fiber length exhibits a trend of first increasing and then decreasing. Notably, when the palm fiber content is 0.6% and the fiber length is 6 mm, the unconfined compressive strength of the G2P0.6L6 sample reaches its maximum value of 133.2 kPa, which is a 20.9% increase compared to the G2P0L0 sample. This indicates that the proper combination of palm fiber content and length contributes to further enhancing the compressive strength of the modified soil.

The composite modification effect ”f gu’r gum and palm fiber primarily manifests in enhancing the physical structure and compressive capacity of expansive soil. Guar gum, with its strong adhesiveness, can form a network structure in the soil, enhancing the bonding force between particles. Particularly when the content is 2%, this network structure optimizes the soil’s microstructure, improving stability and compressive strength. Palm fiber, as a natural fiber, effectively enhances the compressive strength of the soil by serving as a framework support to help distribute external loads. The synergistic effect of guar gum and palm fiber in composite-modified soil exhibits clear complementarity, with guar gum enhancing soil cohesion and palm fiber strengthening structural integrity. Together, they significantly improve the compressive performance of expansive soil.

However, the improvement in compressive strength has an optimal dosage limit. Once the optimal palm fiber content is exceeded, the distribution of the palm fibers in the soil may become uneven, weakening the reinforcement effect and thus affecting the strength performance of the composite-modified soil. Based on the above experimental results, the optimal composite-modified soil mix is determined to be 2% guar gum, 0.6% palm fiber content, and a palm fiber length of 6 mm.

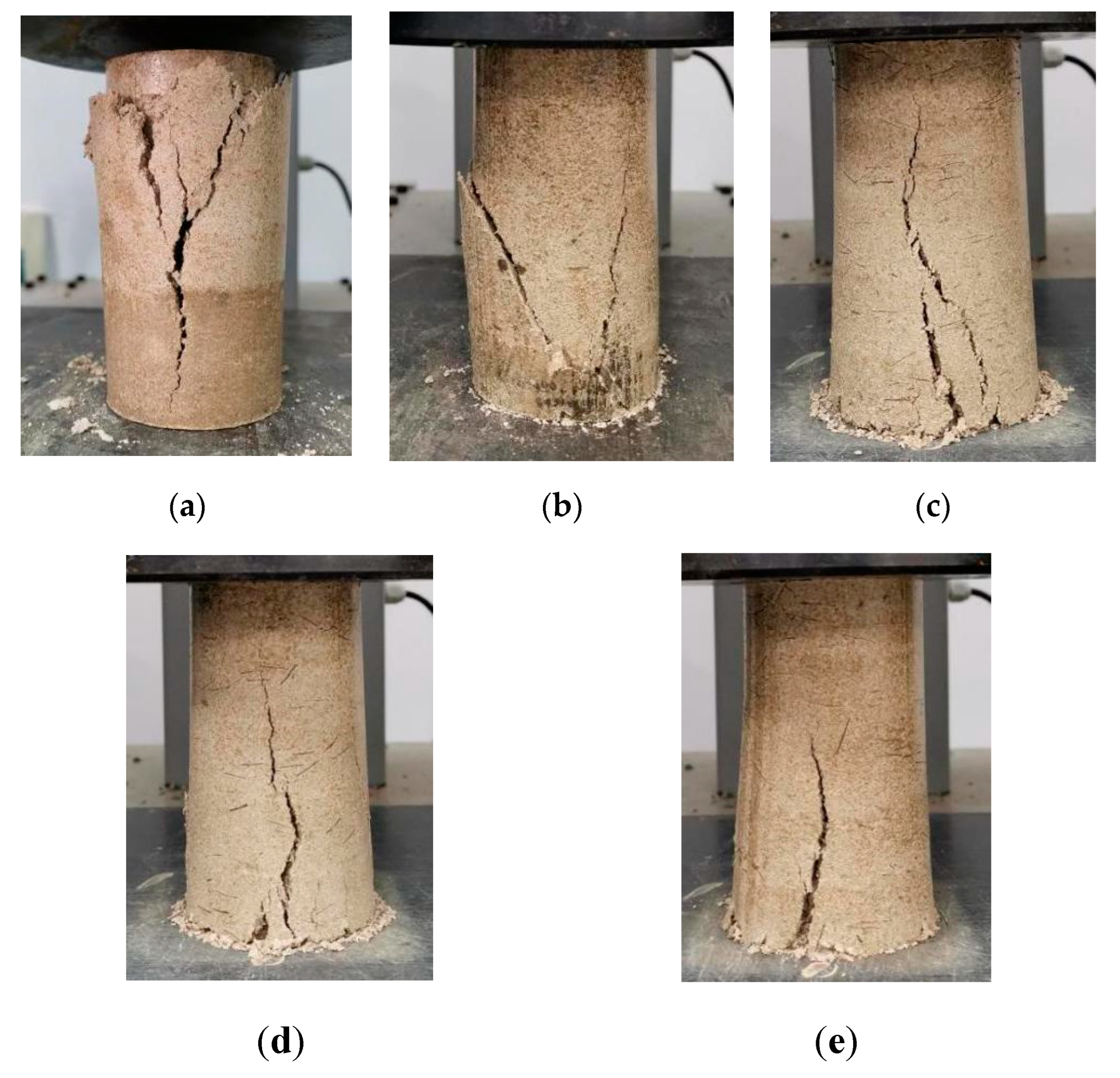

3.2.1. Failure Modes of Improved Expansive Soil Samples

Figure 7(a)–7(b) show the failure modes of the unmodified soil sample, guar gum-modified soil sample, and guar gum-palm fiber composite-modified soil sample under unconfined compressive strength testing. The G0P0L0 sample experienced structural failure under axial stress, with a small amount of soil particles collapsing. A deep “Y”-shaped crack appeared on the surface of the sample, accompanied by numerous fine cracks around the crack, which penetrated the entire sample. In contrast, the G2P0L0 sample’s surface cracks did not penetrate the entire sample, but instead formed a shear failure surface. This failure surface started from the center of the sample, slanted inward toward the bottom of the sample, and, together with other cracks, formed a “V”-shaped failure surface. This indicates that the addition of guar gum effectively improved the unconfined compressive strength of the expansive soil. Guar gum undergoes a hydration reaction in the expansive soil, generating a high-viscosity gel that fills the voids between particles and covers the soil particles’ surfaces, enhancing the bonding between particles. As a result, the internal structure of the soil transitions from a loose state to a more compact structure, improving the overall integrity and stability of the soil.

From

Figure 7(c)–7(e), it can be observed that the failure mode of the guar gum-palm fiber composite-modified soil sample differs from that of the unmodified soil and guar gum-modified soil samples. This sample did not exhibit “Y”-shaped cracks or inclined shear failure surfaces, but instead formed irregular vertical cracks. When the palm fiber length was 6 mm, as the palm fiber content increased, the vertical crack length in the compressed sample gradually shortened, and the crack width also gradually decreased. This suggests that as the palm fiber content increases, the contact area between the soil and the palm fiber expands, and the fibers play a good interlocking role between the particles inside the soil. The addition of guar gum mainly affects the failure mode of the compressed sample, while the addition of palm fiber primarily influences the crack propagation length and width[

15]. Palm fiber significantly enhances the cracking resistance of expansive soil.

3.3. Triaxial Compression Strength Test

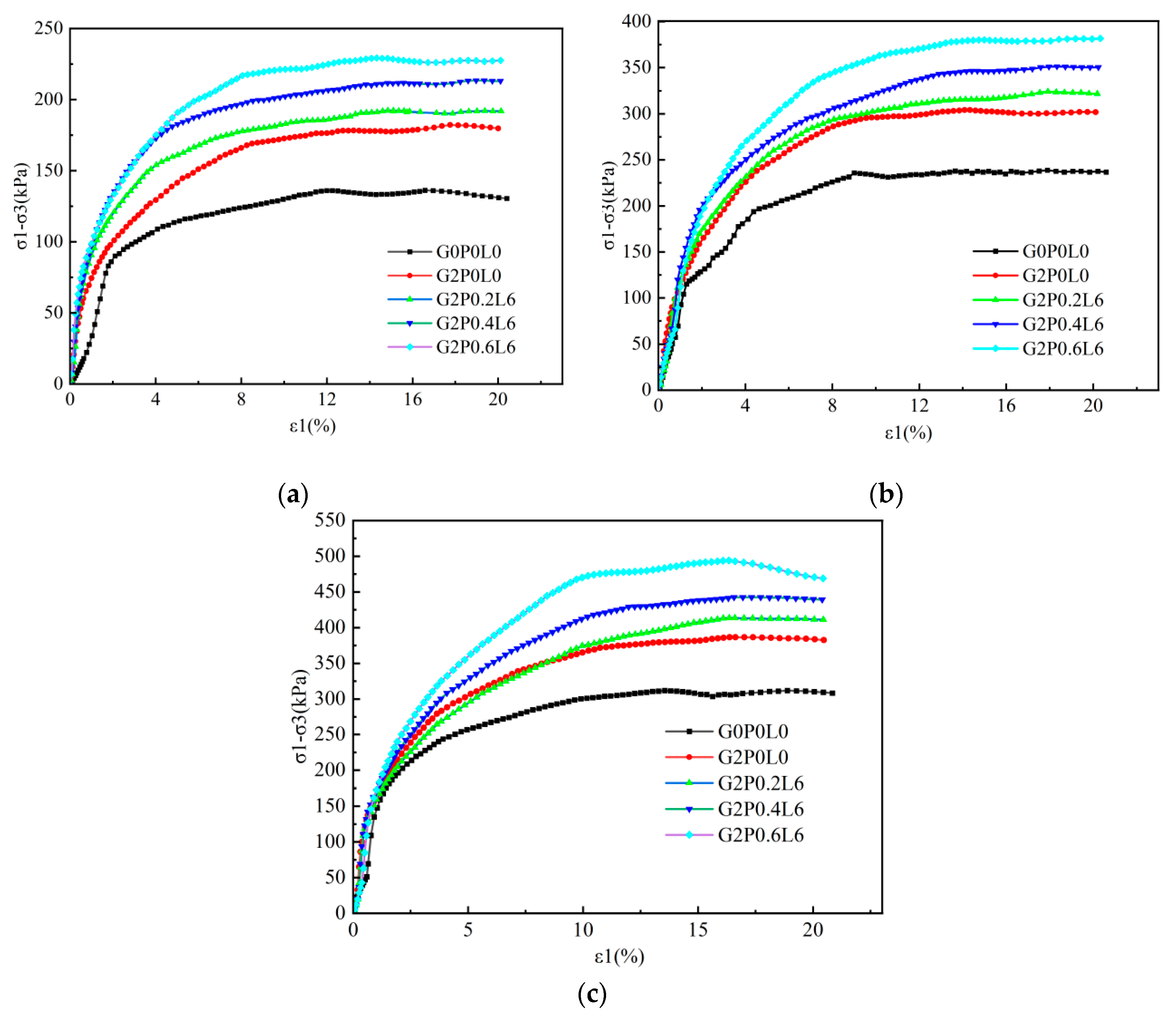

3.3.1. Stress-Strain Relationship Curve of Improved Expansive Soil

Figure 8(a) to 8(c) analyze the influence of guar gum and palm fiber content on the stress-strain evolution of improved expansive soil. Under the same confining pressure conditions, both the stress-strain curves of the untreated soil and the improved soil exhibit strain-hardening characteristics. Specifically, the stress-strain relationship curves of the 2% guar gum-improved soil and the guar gum-palm fiber composite improved soil are both higher than that of the untreated soil. As the confining pressure and palm fiber content increase, the curves progressively shift upward, and the difference in principal stress at the same strain continues to increase. When the confining pressure is 300 kPa, the peak principal stress difference of the G0P0L0 sample is 311.34 kPa, while the peak principal stress difference of the G2P0L0 sample is 386.85 kPa, which is an increase of 24.25% compared to the G0P0L0 sample. Among the composite improved soils, the sample with the highest peak principal stress difference is G2P0.6L6, reaching 492.47 kPa, an increase of 27.30% compared to the G2P0L0 sample. In summary, with the increase in palm fiber content, the peak principal stress difference gradually increases, significantly enhancing the shear strength of the improved soil[

18].

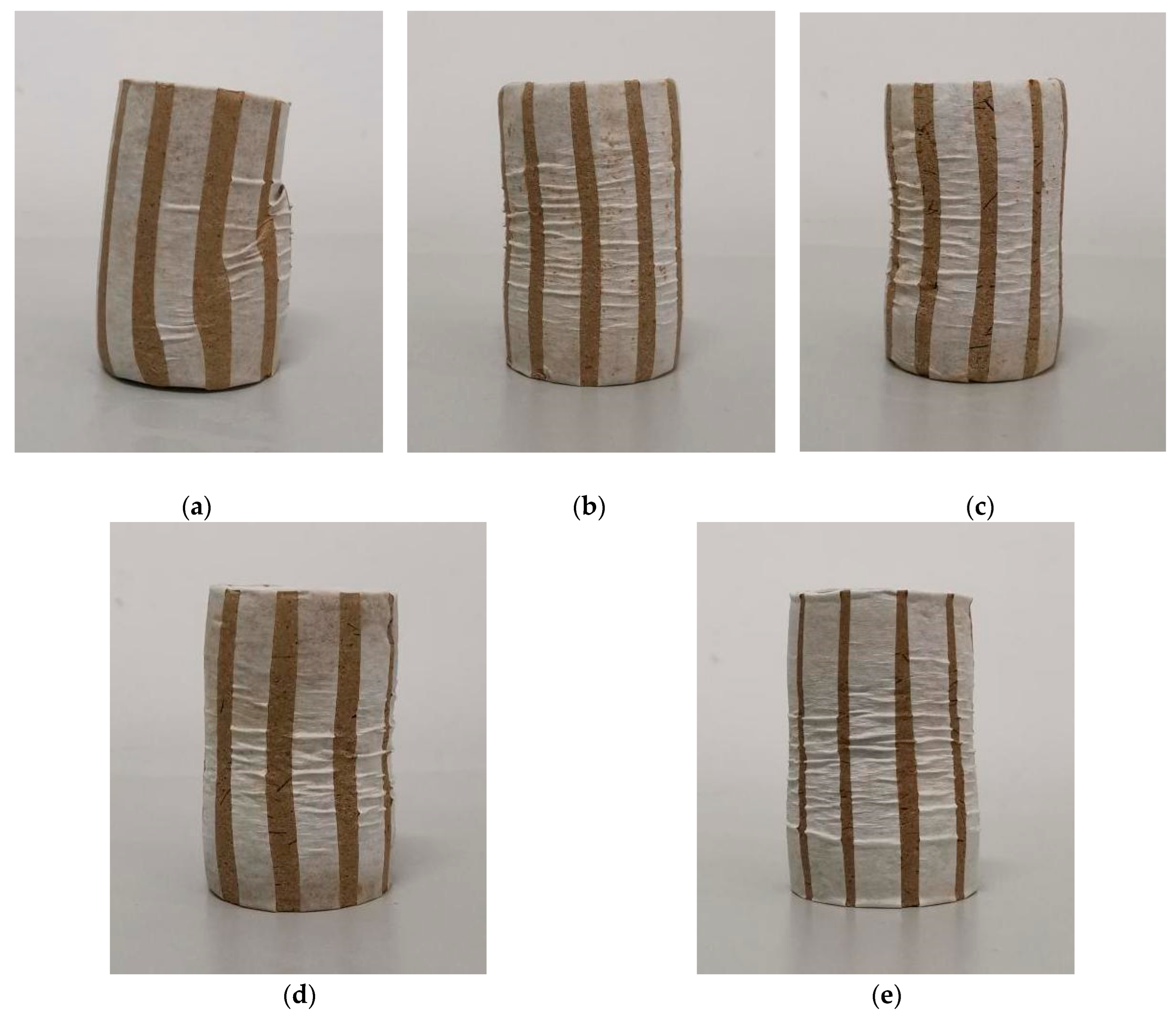

3.3.2. Shear Failure Modes of Improved Expansive Soil Samples in Triaxial Compression Test

Figure 9 illustrates the shear failure modes of untreated expansive soil, guar gum-improved expansive soil, and composite improved expansive soil samples during the triaxial compression test. As shown in the Figure, the G0P0L0 sample exhibits a shear brittle failure mode, while the G2P0L0 sample and the guar gum-palm fiber composite improved soil sample demonstrate bulging failure. Under the same guar gum content conditions, the shear failure deformation of the G2P0L0 sample is significantly lower than that of the G0P0L0 sample. Moreover, as the palm fiber content increases, the deformation of the improved expansive soil gradually decreases, with the G2P0.6L6 sample exhibiting the least degree of bulging failure. Xu J et al. [

19] also indicated that the incorporation of fibers can transform the failure mode of the sample from brittle failure to plastic failure.

This indicates that the addition of guar gum fills the voids between soil particles with the gel-like substance produced by the hydration reaction, enhancing the bonding between particles and thereby increasing the soil's cohesion, thus altering the failure mode of the soil sample. The incorporation of palm fiber, on the other hand, plays a reinforcement role. The palm fibers are encapsulated within the soil particles and gel-like substances, further enhancing the bonding between particles and improving the overall integrity of the soil structure. A single palm fiber restricts the misalignment slip between soil particles, and there is an interaction force between palm fibers. When two palm fibers intertwine, the interaction force between them restricts their movement. If multiple palm fibers form a fiber network, they create a fiber-soil contact interface, thereby enhancing the overall structure of the soil. Due to the good toughness of palm fibers, they are less prone to breakage under external forces and are difficult to pull out, effectively transferring external loads to the fiber network, making the soil subjected to more uniform stress and improving its stability. Furthermore, the friction between fibers and soil particles increases the internal friction angle of the improved soil, significantly enhancing its shear resistance.

3.3.3. The Effect of Guar Gum and Palm Fiber Content on the Shear Strength Parameters of Modified Expansive Soil

Shear strength is one of the important mechanical properties of soil. In geotechnical engineering, the stability of expansive soil slopes, foundation pits, and underground structures is controlled by the soil's shear strength. Therefore, selecting and applying the shear strength parameters of soil correctly is crucial for engineering practice.

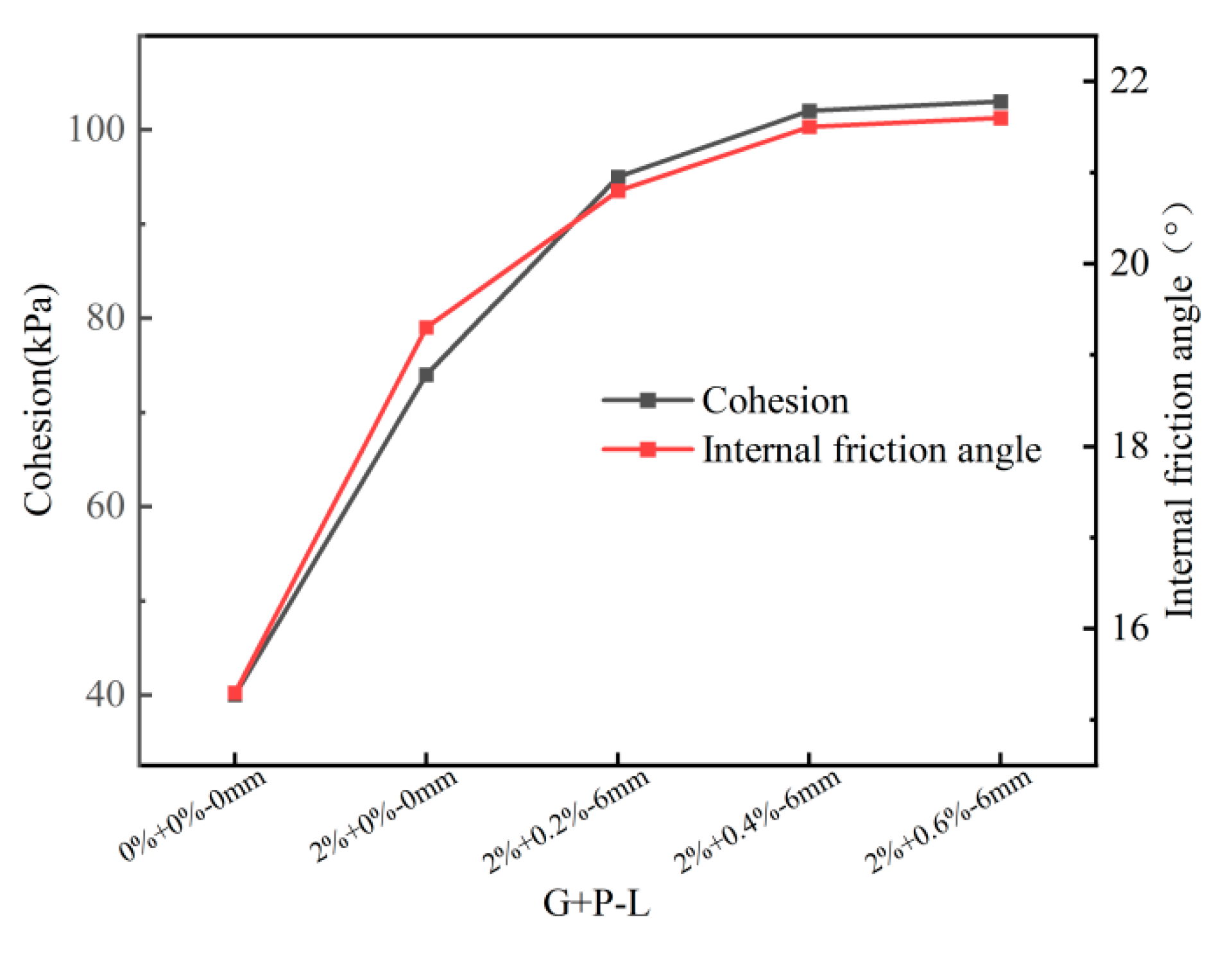

Figure 10 presents the relationship curves between the content of guar gum, palm fiber, and the shear strength parameters (cohesion and internal friction angle) of modified expansive soil.

From the Figure, it can be seen that the cohesion and internal friction angle of the G2P0L0 sample significantly increased compared to the natural expansive soil, with a rapid rate of increase. When the guar gum content is 2%, the shear strength parameters of the composite modified expansive soil increase with the increase in palm fiber content, but the growth rate gradually slows down. When the palm fiber content reaches 2% + 0.6% - 6mm, the increase in shear strength parameters tends to level off, indicating that the modification effect is approaching saturation. The cohesion and internal friction angle of the G2P0.6L6 sample reached 103.56 kPa and 21.68°, respectively, showing an improvement of 52.1% and 12.4% compared to the G2P0L0 sample. The experimental results show that the differences in the triaxial shear strength of the composite modified soil with different palm fiber contents are related to both cohesion and internal friction angle, with a larger influence from cohesion. This phenomenon is consistent with the study by Widianti A et al. [

20].

The reason for the change in the relationship curves of the shear strength parameters of the modified expansive soil is as follows: Guar gum itself has a thickening effect. After being added to the soil, the gel-like products formed through hydration reactions can agglomerate the soil particles together, creating a cohesive structure. At the same time, some of the gel-like products fill the voids between soil particles, significantly reducing the soil's porosity and increasing its compaction. Moreover, the addition of gel-like products reduces the thickness of the water film between particles, making the distance between particles smaller, thus enhancing the mechanical interlocking between particles. This is reflected in the rapid increase in the cohesion and internal friction angle of guar gum-modified soil.

When palm fibers are added to expansive soil, a fiber network is formed within the soil. The soil particles and the hydration products of guar gum surround the palm fibers, and through interface friction and stress transfer mechanisms, the displacement of particles is restricted. The toughness of the palm fiber itself improves the soil's resistance to deformation. As the palm fiber content increases, the distance between adjacent palm fibers within the soil gradually decreases, forming a "fiber-rich zone." This leads to a reduction in the contact area between soil particles, weakening the interparticle bonding force, reducing the mechanical interlocking and frictional resistance, and thus affecting the shear strength of the soil. Previous studies have shown [

21,

22] that there is a critical value for the fiber content, and once this value is exceeded, the strength improvement of the soil gradually approaches saturation, which is consistent with the experimental results in this paper. Therefore, the growth of shear strength parameters gradually slows down. The relationship curve in the Figure indicates that when the palm fiber content is 0.6%, the increase in shear strength parameters is small, suggesting that this content is close to the optimal amount of palm fiber. Combining the results of the disintegration test and the unconfined compressive strength test mentioned earlier, it can be concluded that the optimal mix for modifying expansive soil is 2% guar gum and 0.6%-6mm palm fiber.

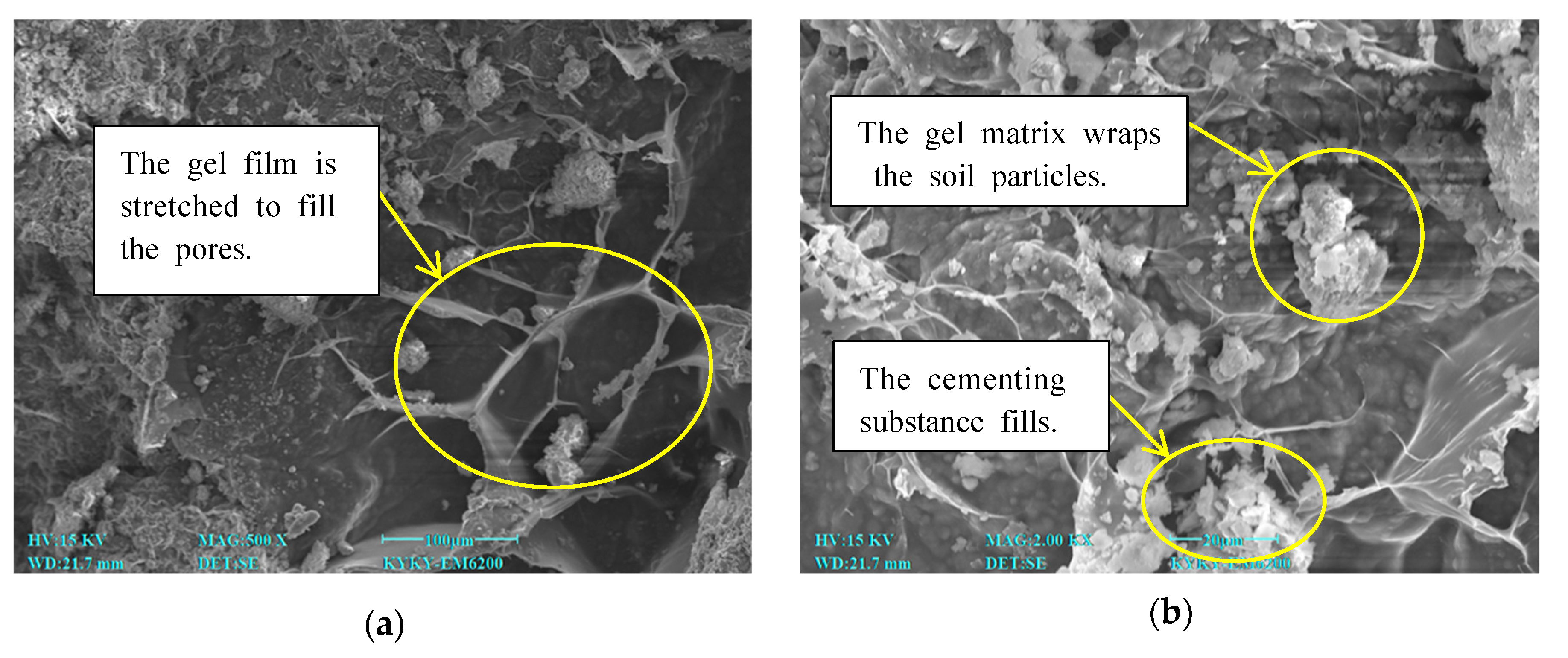

3.4. Mechanism Analysis of Guar Gum-Improved Soil

Figure 11 illustrates the microscopic structural characteristics of the gel formed after guar gum hydration, which wraps and cements the expansive soil. After guar gum is mixed with soil, the gel matrix generated by the hydration reaction forms a gel film (as shown in

Figure 11a) through stretching. This film fills the pores of the soil, preventing the internal water film from further thickening. Meanwhile, part of the gel, under the action of hydrogen bonds, combines with the cations on the soil particle surface, wrapping around the surface of the soil particles. This binds the soil particles together, forming a cemented structure and filling the pores between the particles (as shown in

Figure 11b). This structural change reduces the pore space between particles, increases the bonding strength, and thus makes the soil structure more compact. Acharya R et al. [

23] also pointed out that guar gum, as a biopolymer, has effects such as filling, wrapping, and cementing the microstructure of the stabilized surface soil. The wrapping effect of guar gum on the soil particles prevents the particles wrapped by the hydrated guar gum products from coming into contact with external moisture, thereby inhibiting the lubricating effect of water molecules on the soil particles and effectively controlling the misalignment and sliding between particles. On a macroscopic scale, this results in improved cohesion and friction resistance of the soil. Meanwhile, the cementing effect of guar gum between soil particles improves the bonding strength between the particles, allowing for better transmission of internal stress under external loads, leading to more uniform stress distribution on the particles, thereby enhancing the soil's resistance to disintegration and compressive strength.

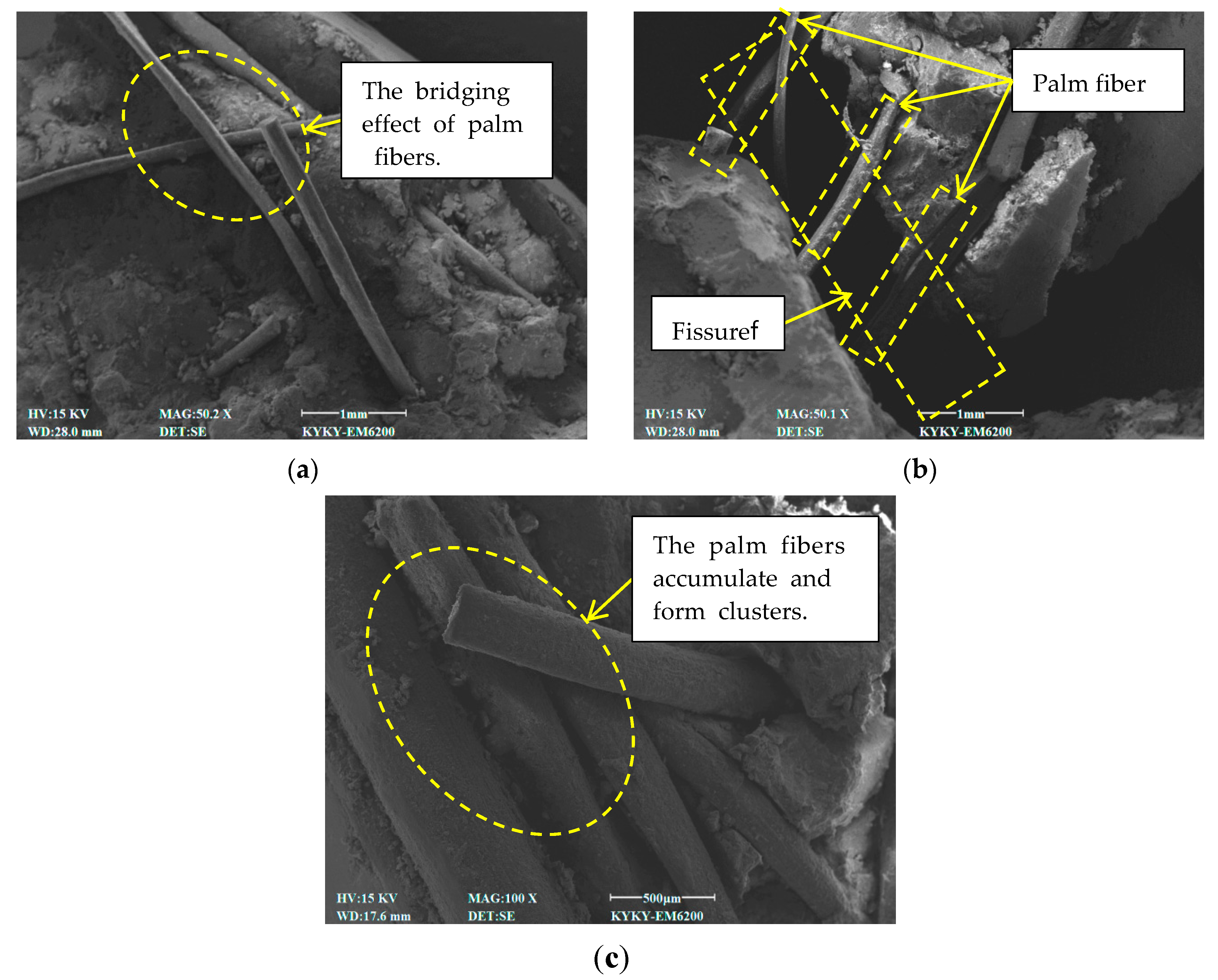

3.5. Mechanism of Guar Gum-Palm Fiber Composite Improvement of Expansive Soil

Figure 12 presents the microscopic structural characteristics of guar gum-palm fiber composite improved expansive soil. As shown in the Figure, when the palm fiber content is 0.4% and the fiber length is 6 mm, the reinforcing effect of the fiber promotes an intricate interweaving of fibers within the soil, forming a stable three-dimensional reinforcement structure. This structure forms a solid fiber-soil interface with the soil particles, making it difficult for the palm fibers to be pulled out, thus effectively suppressing the misalignment and slip of the soil particles. When the soil is subjected to compression, the palm fibers share part of the load through a “bridging effect” (as shown in

Figure 12a), thereby delayg the destruction and deformation of the soil structure. When the soil structure is severely damaged, cracks may develop between the soil particles, and the fibers will connect the soil mass on both sides of the crack [

24] (as shown in

Figure 12b). At this point, in the frictional resistance between the fibers and the soil particles helps to suppress the crack’s expansion and maintain the structural integrity of the soil sample after failure. On a macroscopic level, this results in a significant improvement in the soil’s compressive strength and deformation resistance. However, if the length or content of the palm fibers is excessive, it may lead to the aggregation of fibers within the soil (as shown in

Figure 12c), increasing the contact area between the fibers [

25]. In this case, the mechanical interlocking force and frictional resistance between the soil particles will decrease, resulting in a reduction in the soil’s strength and structural stability. Therefore, to maximize the reinforcing effect of the fibers, the length and content of the fibers should be strictly controlled.

4. Discussion

The study has demonstrated that guar gum and palm fiber are both effective in improving the properties of expansive soil. The results indicate that the combination of these materials significantly enhances the water stability, compressive strength, shear strength, and failure modes of the soil. Furthermore, the micro-improvement mechanisms highlighted by scanning electron microscope analysis provide valuable insights into how guar gum and palm fiber work synergistically to reinforce soil properties.

Based on the findings, the following conclusions can be drawn:

Guar gum can effectively improve the water stability of expansive soil. With the increase in guar gum content, the disintegration resistance of the samples significantly improves. When the guar gum content reaches 2%, the disintegration rate of the sample reaches the threshold of 0.85% and virtually no further disintegration occurs. Therefore, it is recommended that the guar gum content in practical applications be 2%.

Both guar gum and guar gum-palm fiber composite materials can enhance the unconfined compressive strength of expansive soil, with the guar gum-palm fiber composite material showing the best improvement. Under the condition of a fixed palm fiber content, the compressive strength of the soil initially increases and then decreases as the palm fiber length increases. When the palm fiber content is 0.6% and the length is 6mm, the unconfined compressive strength of the composite improved soil increases the most, with a 20.9% higher compressive strength compared to expansive soil improved with 2% guar gum.

The addition of palm fiber can improve the shear strength of guar gum-treated soil. As the palm fiber content increases, the stress-strain curve of the composite improved soil gradually rises. The two shear strength indicators, cohesion and internal friction angle, both increase as the palm fiber content rises. When the ratio is 2% guar gum and 0.6%-6mm palm fiber, the increase in the two shear strength indicators levels off, with increases of 52.1% and 12.4%, respectively, compared to pure guar gum-treated soil. However, further increasing the palm fiber content is detrimental to the improvement of the soil’s shear strength.

Guar gum and palm fiber have a significant impact on the failure modes of the expansive soil samples. Under axial pressure, the guar gum-improved soil exhibits a “V”-shaped failure, with cracks not penetrating the sample; while the composite improved soil shows irregular vertical cracks, and as the content increases, the cracks gradually shorten. Under shear failure, both guar gum-improved soil and guar gum-palm fiber composite improved soil show bulging failure, and the deformation gradually decreases with the increase in palm fiber content.

Scanning electron microscope analysis of the micro-improvement mechanism of guar gum-palm fiber improved soil reveals that the gel matrix generated by the hydration reaction of guar gum can enhance the bonding strength of soil particles through stretching, wrapping, and filling, thus improving the water stability and mechanical properties of expansive soil. The reinforcement effect of palm fiber further enhances the mechanical properties of the improved soil.

This composite improvement method can not only effectively increase the bearing capacity and deformation ability of expansive soil, but also is environmentally friendly and has broad potential for promotion. However, this study is limited to expansive soil in Nanning, Guangxi,China, and the results are applicable only under conventional conditions. Therefore, the identified optimal ratio has certain limitations, and further research and verification are needed for specific situations.

Author Contributions

Conceptualization, J.C. and A.C.; methodology, A.C.; formal analysis, A.C.; investigation, X.J.; data curation, Y.X., X.L. and S.L.; writing—original draft preparation, Y.H. and J.C.; writing—review and editing, J.C.; project administration, J.C.; funding acquisition, J.C.

Funding

This research was funded by the Guangxi Natural Science Foundation Project, grant number 2022GXNSFAA035485; the Science and Technology Base and Talent Special Project, grant number GUIKE AD21220051.

Data Availability Statement

Data are available upon request to the corresponding author.

Acknowledgments

The authors thank the Guangxi Natural Science Foundation Project and the Science and Technology Base and Talent Special Project for the opportunity to provide funding for research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tiwari, N.; Satyam, N.; Puppala, A.J. Strength and durability assessment of expansive soil stabilized with recycled ash and natural fibers. Transportation Geotechnics 2021, 29, 100556. [Google Scholar] [CrossRef]

- Rabab’ah, S.; Al Hattamleh, O.; Aldeeky, H.; Alfoul, B.A. Effect of glass fiber on the properties of expansive soil and its utilization as subgrade reinforcement in pavement applications. Case Studies in Construction Materials 2021, 14, e00485. [Google Scholar] [CrossRef]

- Blayi, R.A.; Sherwani, A.F.H.; Ibrahim, H.H.; Faraj, R.H.; Daraei, A. Strength improvement of expansive soil by utilizing waste glass powder. Case Studies in Construction Materials 2020, 13, e00427. [Google Scholar] [CrossRef]

- Jain, A.K.; Jha, A.K. Geotechnical behaviour and micro-analyses of expansive soil amended with marble dust. Soils and Foundations 2020, 60, 737–751. [Google Scholar] [CrossRef]

- Narani, S.; Abbaspour, M.; Hosseini, S.M.M.; Aflaki, E.; Nejad, F.M. Sustainable reuse of Waste Tire Textile Fibers (WTTFs) as reinforcement materials for expansive soils: With a special focus on landfill liners/covers. Journal of Cleaner Production 2020, 247, 119151. [Google Scholar] [CrossRef]

- Cai, Y.; Xu, L.; Liu, W.; Shang, Y.; Su, N.; Feng, D. Field Test Study on the dynamic response of the cement-improved expansive soil subgrade of a heavy-haul railway. Soil Dynamics and Earthquake Engineering 2020, 128, 105878. [Google Scholar] [CrossRef]

- Dang, L.C.; Khabbaz, H.; Ni, B.-J. Improving engineering characteristics of expansive soils using industry waste as a sustainable application for reuse of bagasse ash. Transportation Geotechnics 2021, 31, 100637. [Google Scholar] [CrossRef]

- Ma, B.; Cai, K.; Zeng, X.; Li, Z.; Hu, Z.; Chen, Q.; He, C.; Chen, B.; Huang, X. Experimental study on physical-mechanical properties of expansive soil improved by multiple admixtures. Advances in Civil Engineering 2021, 2021, 5567753. [Google Scholar] [CrossRef]

- Barman, D.; Dash, S.K. Stabilization of expansive soils using chemical additives: A review. Journal of Rock Mechanics and Geotechnical Engineering 2022, 14, 1319–1342. [Google Scholar] [CrossRef]

- Hamza, M.; Nie, Z.; Aziz, M.; Ijaz, N.; Fang, C.; Ghani, M.U.; Ijaz, Z.; Noshin, S.; Salman, M. Geotechnical properties of problematic expansive subgrade stabilized with guar gum biopolymer. Clean Technologies and Environmental Policy 2023, 25, 1699–1719. [Google Scholar] [CrossRef]

- Keshav, N.; Prabhu, A.; Kattimani, A.; Dharwad, A.; Kallatti, C.; Mahalank, S. Enhancing the properties of expansive soil using biopolymers—xanthan gum and guar gum. In Proceedings of the Proceedings of the Indian Geotechnical Conference 2019: IGC-2019 Volume IV, Springer; 2021:129-35.

- Vydehi, K.V.; Moghal, A.A.B. Effect of biopolymeric stabilization on the strength and compressibility characteristics of cohesive soil. Journal of Materials in Civil Engineering 2022, 34, 04021428. [Google Scholar] [CrossRef]

- Vydehi, K.V.; Moghal, A.A.B. Compressibility characteristics of Guar gum-treated expansive soil. In Proceedings of the Ground Improvement and Reinforced Soil Structures: Proceedings of Indian Geotechnical Conference 2020 Volume 2, Springer; 2021:339-45.

- Xu, X.; Chu, H.; Wang, Q.; Li, J.; Yuan, X.; Niu, C.; Lei, H.; Yu, Z. Dispersion, mechanical, hydrophysical properties and mechanistic analysis of improved dispersive soil using guar gum. Bulletin of Engineering Geology and the Environment 2025, 84, 1–19. [Google Scholar] [CrossRef]

- Anandha Kumar, S.; Sujatha, E.R.; Pugazhendi, A.; Jamal, M.T. Guar gum-stabilized soil: A clean, sustainable and economic alternative liner material for landfills. Clean technologies and environmental policy 2021, 1–19. [Google Scholar] [CrossRef]

- Medina-Martinez, C.J.; Sandoval-Herazo, L.C.; Zamora-Castro, S.A.; Vivar-Ocampo, R.; Reyes-Gonzalez, D. Natural fibers: an alternative for the reinforcement of expansive soils. Sustainability 2022, 14, 9275. [Google Scholar] [CrossRef]

- Standard. Test Methods of Soils for Highway Engineering. JTG 3430—2020. Transportation Ministry of the People's

Republic of China; 2020.

- Hu, Q.; Song, W.; Hu, J. Study of the mechanical properties and water stability of microbially cured, coir-fiber-reinforced clay soil. Sustainability 2023, 15, 13261. [Google Scholar] [CrossRef]

- Xu, J.; Wu, Z.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Triaxial shear behavior of basalt fiber-reinforced loess based on digital image technology. KSCE Journal of Civil Engineering 2021, 25, 3714–3726. [Google Scholar] [CrossRef]

- Widianti, A.; Diana, W.; Alghifari, M. Shear strength and elastic modulus behavior of coconut fiber-reinforced expansive soil. In Proceedings of the IOP Conference Series: Materials Science and Engineering 1144. IOP Publishing; 2021; p. 012043. [Google Scholar]

- Chen, J.; Mu, J.; Chen, A.; Long, Y.; Zhang, Y.; Zou, J. Experimental Study on the Properties of Basalt Fiber–Cement-Stabilized Expansive Soil. Sustainability 2024, 16, 7579. [Google Scholar] [CrossRef]

- Khattak, M.J.; Alrashidi, M. Durability and mechanistic characteristics of fiber reinforced soil–cement mixtures. The International Journal of Pavement Engineering 2006, 7, 53–62. [Google Scholar] [CrossRef]

- Acharya, R.; Pedarla, A.; Bheemasetti, T.V.; Puppala, A.J. Assessment of guar gum biopolymer treatment toward mitigation of desiccation cracking on slopes built with expansive soils. Transportation Research Record 2017, 2657, 78–88. [Google Scholar] [CrossRef]

- Consoli, N.C.; Casagrande, M.D.; Prietto, P.D.; Thomé, A.n. Plate load test on fiber-reinforced soil. Journal of geotechnical and geoenvironmental engineering 2003, 129, 951–955. [Google Scholar] [CrossRef]

- Yixian, W.; Panpan, G.; Shengbiao, S.; Haiping, Y.; Binxiang, Y. Study on strength influence mechanism of fiber-reinforced expansive soil using jute. Geotechnical and Geological Engineering 2016, 34, 1079–1088. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).