Submitted:

20 June 2025

Posted:

23 June 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Calculating Emissions from a Facility Operating Normally

2.2. Estimating Fugitive Emissions

2.3. Maintenance Emissions

2.4. Large Upset Emissions

2.5. Comparison with Observed Emissions

3. Results

3.1. Emissions from a Facility Operating Normally

3.1.1. Prototypical Facility Type 1

3.1.2. Prototypical Facility Type 2

3.1.3. Note of Caution with Data

| Type | Number platforms surveyed | Average # fugitives | Average Total Emission (kg h-1) | Average Emission per Leak (kg h-1) |

| Fixed Leg | 43 | 12 | 7.7 | 0.64 |

| FPSO | 1 | 4 | 11.9 | 2.99 |

| Semi-Submersible | 3 | 18 | 28.3 | 1.57 |

| Spar | 3 | 16 | 20.8 | 1.30 |

| Tension Leg | 4 | 15 | 21.4 | 1.42 |

| ID | Lat (°N) | Lon (°W) | Lease number | Distance (nm) | Depth (ft) | Store Tank | C&P | Type | PTF type | OP (bbl/h) | GP (kg/h) | Study | Q (kg/h) | Loss (%) |

| 20043 | 28.97 | 90.00 | 00128 | 13 | 85 | Y | N | Fixed | 1 | 4 | 256 | 1 | 7.46 | 3 |

| 22486 | 29.15 | 89.90 | N/A* | 7 | 55 | Y | N | Fixed | 1 | 0 | 0 | 1 | 8.25 | - |

| 23103 | 29.14 | 91.17 | G01359 | 5 | 15 | N | N | Caisson | 1 | 0 | 52 | 1 | 8.46 | 18 |

| 22630 | 28.93 | 90.47 | G03236 | 10 | 60 | N | N | Fixed | 1 | 0 | 1819 | 1 | 10.85 | 1 |

| 20035 | 29.01 | 89.84 | G31418 | 19 | 111 | N | N | Fixed | 1 | 53 | 8941 | 1 | 10.97 | 0.1 |

| 1531 | 29.56 | 93.42 | G01240 | 14 | 42 | N | N | Fixed | 1 | 4 | 170 | 1 | 11.46 | 7 |

| 2006 | 28.96 | 90.02 | 00180 | 14 | 92 | N | N | Fixed | 1 | 3 | 176 | 1 | 14.01 | 9 |

| 717 | 29.13 | 91.18 | G23740 | 5 | 12 | N | N | Caisson | 1 | 0 | 218 | 1 | 15.36 | 8 |

| 2275 | 29.34 | 92.99 | 00133 | 23 | 55 | N | N | Fixed | 1 | 4 | 150 | 1 | 17.05 | 12 |

| 10237 | 29.52 | 94.15 | 00346 | 10 | 41 | N | N | Fixed | 1 | 0 | 160 | 1 | 18.22 | 12 |

| 10500 | 29.13 | 94.55 | G25937 | 17 | 58 | N | N | Fixed | 1 | 1 | 2074 | 1 | 25.01 | 1 |

| 31012 | 28.92 | 90.35 | G05006 | 9 | 62 | N | N | Fixed | 1 | 0 | 61 | 1 | 35.06 | 61 |

| 21517 | 29.19 | 91.62 | G06093 | 17 | 22 | N | N | Fixed | 1 | 16 | 261 | 2 | 46.55 | 19 |

| 1088 | 28.74 | 88.83 | G01865 | 30 | 2850 | Y | Y | MTLP | 2 | 1 | 1247 | 1 | 5.83 | 1 |

| 21895 | 29.08 | 88.70 | G23851 | 18 | 340 | Y | Y | Fixed | 2 | 2 | 6405 | 1 | 8.06 | 0.5 |

| 10082 | 29.18 | 94.52 | G19931 | 15 | 54 | N | Y | Fixed | 2 | 28 | 2107 | 1 | 8.94 | 0.1 |

| 2574 | 28.12 | 90.53 | G02445 | 0 | 391 | Y | Y | Fixed | 2 | 247 | 427 | 1 | 9.33 | 2 |

| 22593 | 28.91 | 89.51 | N/A* | 5 | 143 | Y | Y | Fixed | 2 | 0 | 0 | 1 | 12.43 | - |

| 21429 | 28.46 | 91.08 | 00830 | 62 | 130 | Y | Y | Fixed | 2 | 0 | 0 | 3 | 14.00 | - |

| 1899 | 27.30 | 90.14 | G20084 | 175 | 4375 | Y | Y | TLP | 2 | 457 | 3754 | 3 | 15.00 | 0.4 |

| 1482 | 28.94 | 88.91 | G28351 | 30 | 667 | N | Y | Fixed | 2 | 11 | 820 | 1 | 18.43 | 2 |

| 1279 | 28.09 | 90.74 | G22762 | 60 | 447 | N | Y | Fixed | 2 | 4 | 117 | 1 | 21.36 | 20 |

| 1076 | 28.09 | 90.67 | N/A* | 65 | 460 | Y | Y | Fixed | 2 | 0 | 0 | 1 | 22.22 | - |

| 24129 | 28.10 | 90.20 | G12136 | 66 | 775 | Y | Y | Fixed | 2 | 213 | 4403 | 1 | 37.57 | 1 |

| 24209 | 28.83 | 89.56 | N/A* | 6 | 252 | Y | Y | Fixed | 2 | 0 | 0 | 3 | 48.00 | - |

| 22380 | 28.89 | 89.06 | G02177 | 7 | 300 | Y | Y | Fixed | 2 | 30 | 1303 | 1 | 49.36 | 4 |

| 24199 | 28.17 | 89.22 | G07963 | 52 | 2933 | Y | Y | TLP | 2 | 852 | 18916 | 3 | 50.00 | 0.3 |

| 67 | 27.78 | 90.52 | G05911 | 60 | 2590 | Y | Y | Spar | 2 | 49 | 1370 | 3 | 52.00 | 4 |

| 23848 | 28.78 | 89.24 | G05052 | 13 | 467 | Y | N | Fixed | 2 | 0 | 0 | 1 | 57.95 | - |

| 251 | 27.69 | 90.28 | G07049 | 86 | 3294 | Y | Y | MTLP | 2 | 58 | 2616 | 3 | 58.00 | 2 |

| 2103 | 29.38 | 91.75 | G02625 | 7 | 13 | N | Y | Fixed | 2 | 24 | 392 | 3 | 63.00 | 17 |

| 20375 | 29.09 | 88.73 | G01294 | 17 | 325 | Y | Y | Fixed | 2 | 8 | 179 | 1 | 64.29 | 39 |

| 2247 | 28.91 | 90.42 | G24956 | 9 | 60 | Y | Y | Fixed | 2 | 26 | 2695 | 1 | 94.21 | 4 |

| * facility not on active lease. | ||||||||||||||

3.2. Fugitive Emissions

3.3. Observed Emissions

3.3.1. Prototypical Type 1 Facilities

3.3.2. Prototypical Type 2 Facilities

4. Discussion and Conclusions

4.1. Calculated Bottom-Up Emission Estimates

4.2. Measured Emissions

4.3. Recognizing Real Large Emission Events and Quantification Best Practices

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- OGMP Oil and Gas Methane Partnership 2.0—Key Benefits. Available online: https://www.ogmpartnership.org/key-benefits (accessed on 17 June 2025).

- Cheniere Converting Measurements Into Measurement Informed Inventories: Lessons from Cheniere’s. QMRV Research Series. Global Methane Initiative, Geneva March 20, 2024. Available online: https://www.globalmethane.org/documents/2024Forum/Oil%20&%20Gas%20Sessions/3%20-%20The%20Role%20of%20Technologies%20in%20Improving%20Measurements%20and%20Enhancing%20Inventories%20to%20Enable%20Faster%20Action/8%20-%20George_MRV_Oil%20&%20Gas.pdf (accessed on 17 June 2025).

- Statistica Number of Offshore Rigs Worldwide as of January 2018 by Region. Available online: Https://Www.Statista.Com/Statistics/279100/Number-of-Offshore-Rigs-Worldwide-by-Region/ (accessed on 28 December 2021).

- EIA Offshore Production Nearly 30% of Global Crude Oil Output in 2015. Available online: https://www.eia.gov/todayinenergy/detail.php?id=28492 (accessed on 28 December 2021).

- EIA Natural Gas Explained. Available online: https://www.eia.gov/energyexplained/natural-gas/use-of-natural-gas.php (accessed on 12 October 2021).

- BSEE Bureau of Safety and Environmental Enforcement (BSEE) Data Center. Available online: https://www.data.bsee.gov/Main/Default.aspx (accessed on 4 February 2025).

- Speight, J. Processing Gas from Tight Formations. In Shale Oil and Gas Production Processes; Elsevier, 2020; pp. 451–518 ISBN 978-0-12-813315-6.

- Standard Handbook of Petroleum and Natural Gas Engineering; Lyons, W.C., Plisga, G.J., Lorenz, M.D., Eds.; Third edition.; Elsevier : GPP: Amsterdam ; Boston, 2016; ISBN 978-0-12-383846-9.

- Ayasse, A.K.; Thorpe, A.K.; Cusworth, D.H.; Kort, E.A.; Negron, A.G.; Heckler, J.; Asner, G.; Duren, R.M. Methane Remote Sensing and Emission Quantification of Offshore Shallow Water Oil and Gas Platforms in the Gulf of Mexico. Environ. Res. Lett. 2022, 17, 084039. [Google Scholar] [CrossRef]

- Foulds, A.; Allen, G.; Shaw, J.T.; Bateson, P.; Barker, P.A.; Huang, L.; Pitt, J.R.; Lee, J.D.; Wilde, S.E.; Dominutti, P.; et al. Quantification and Assessment of Methane Emissions from Offshore Oil and Gas Facilities on the Norwegian Continental Shelf. Atmos. Chem. Phys. 2022, 22, 4303–4322. [Google Scholar] [CrossRef]

- Gorchov Negron, A.M.; Kort, E.A.; Chen, Y.; Brandt, A.R.; Smith, M.L.; Plant, G.; Ayasse, A.K.; Schwietzke, S.; Zavala-Araiza, D.; Hausman, C.; et al. Excess Methane Emissions from Shallow Water Platforms Elevate the Carbon Intensity of US Gulf of Mexico Oil and Gas Production. Proc. Natl. Acad. Sci. U.S.A. 2023, 120, e2215275120. [Google Scholar] [CrossRef] [PubMed]

- Gorchov Negron, A.M.; Kort, E.A.; Conley, S.A.; Smith, M.L. Airborne Assessment of Methane Emissions from Offshore Platforms in the U.S. Gulf of Mexico. Environ. Sci. Technol. 2020, 54, 5112–5120. [Google Scholar] [CrossRef] [PubMed]

- Hensen, A.; Velzeboer, I.; Frumau, K.F.A.; van den Bulk, W.C.M.; van Dinter, D. Methane Emission Measurements of Offshore Oil and Gas Platforms; TNO: Petten, 2019; p. 94. [Google Scholar]

- Irakulis-Loitxate, I.; Gorroño, J.; Zavala-Araiza, D.; Guanter, L. Satellites Detect a Methane Ultra-Emission Event from an Offshore Platform in the Gulf of Mexico. Environ. Sci. Technol. Lett. 2022, 9, 520–525. [Google Scholar] [CrossRef]

- Khaleghi, A.; MacKay, K.; Darlington, A.; James, L.A.; Risk, D. Methane Emission Rate Estimates of Offshore Oil Platforms in Newfoundland and Labrador, Canada. Elem Sci Anth 2024, 12, 00025. [Google Scholar] [CrossRef]

- MacLean, J.-P.W.; Girard, M.; Jervis, D.; Marshall, D.; McKeever, J.; Ramier, A.; Strupler, M.; Tarrant, E.; Young, D. Offshore Methane Detection and Quantification from Space Using Sun Glint Measurements with the GHGSat Constellation. Atmos. Meas. Tech. 2024, 17, 863–874. [Google Scholar] [CrossRef]

- Nara, H.; Tanimoto, H.; Tohjima, Y.; Mukai, H.; Nojiri, Y.; Machida, T. Emissions of Methane from Offshore Oil and Gas Platforms in Southeast Asia. Scientific Reports 2015, 4. [Google Scholar] [CrossRef] [PubMed]

- Pühl, M.; Roiger, A.; Fiehn, A.; Gorchov Negron, A.M.; Kort, E.A.; Schwietzke, S.; Pisso, I.; Foulds, A.; Lee, J.; France, J.L.; et al. Aircraft-Based Mass Balance Estimate of Methane Emissions from Offshore Gas Facilities in the Southern North Sea. Atmos. Chem. Phys. 2024, 24, 1005–1024. [Google Scholar] [CrossRef]

- Riddick, S.N.; Mauzerall, D.L.; Celia, M.; Harris, N.R.P.; Allen, G.; Pitt, J.; Staunton-Sykes, J.; Forster, G.L.; Kang, M.; Lowry, D.; et al. Methane Emissions from Oil and Gas Platforms in the North Sea. Atmospheric Chemistry and Physics 2019, 19, 9787–9796. [Google Scholar] [CrossRef]

- Valverde, A.; Irakulis-Loitxate, I.; Roger, J.; Gorroño, J.; Guanter, L. Satellite Characterization of Methane Point Sources by Offshore Oil and Gas PlatForms. In Proceedings of the IV Conference on Geomatics Engineering; 12 January 2024; MDPI; p. 22. [Google Scholar]

- Yacovitch, T.I.; Daube, C.; Herndon, S.C. Methane Emissions from Offshore Oil and Gas Platforms in the Gulf of Mexico. Environ. Sci. Technol. 2020, 54, 3530–3538. [Google Scholar] [CrossRef] [PubMed]

- Riddick, S.N.; Mbua, M.; Laughery, C.; Zimmerle, D.J. A Review of Offshore Methane Quantification Methodologies. Atmosphere 2025, 16, 626. [Google Scholar] [CrossRef]

- Riddick, S.N.; Mauzerall, D.L. Likely Substantial Underestimation of Reported Methane Emissions from United Kingdom Upstream Oil and Gas Activities. Energy Environ. Sci. 2023, 16, 295–304. [Google Scholar] [CrossRef]

- EPA Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990-2016. Https://Www.Epa.Gov/Ghgemissions/Inventory-Us-Greenhouse-Gas-Emissions-and-Sinks-1990-2016. Last Accessed 5th May 2023. US EPA 2018.

- US EPA U.S. Environmental Protection Agency, AP-42: Compilation of Air Emissions Factors, 2018. Available online: https://www3.epa.gov/ttn/chief/ap42/ch13/final/C13S05_02-05-18.pdf. (accessed on 25 October 2022).

- US EPA US Environmental Protection Agency. Methane Emissions from the Natural Gas Industry, Volume 3: General Methodology. Available online: https://www.epa.gov/sites/default/files/2016-08/documents/3_generalmeth.pdf (accessed on 6 December 2024).

- Riddick, S.N.; Mbua, M.; Santos, A.; Hartzell, W.; Zimmerle, D.J. Potential Underestimate in Reported Bottom-up Methane Emissions from Oil and Gas Operations in the Delaware Basin. Atmosphere 2024, 15, 202. [Google Scholar] [CrossRef]

- Varon, D.J.; Jacob, D.J.; Hmiel, B.; Gautam, R.; Lyon, D.R.; Omara, M.; Sulprizio, M.; Shen, L.; Pendergrass, D.; Nesser, H.; et al. Continuous Weekly Monitoring of Methane Emissions from the Permian Basin by Inversion of TROPOMI Satellite Observations. Atmos. Chem. Phys. 2023, 23, 7503–7520. [Google Scholar] [CrossRef]

- Riddick, S.N.; Cheptonui, F.; Yuan, K.; Mbua, M.; Day, R.; Vaughn, T.L.; Duggan, A.; Bennett, K.E.; Zimmerle, D.J. Estimating Regional Methane Emission Factors from Energy and Agricultural Sector Sources Using a Portable Measurement System: Case Study of the Denver–Julesburg Basin. Sensors 2022, 22, 7410. [Google Scholar] [CrossRef] [PubMed]

- Zavala-Araiza, D.; Alvarez, R.A.; Lyon, D.R.; Allen, D.T.; Marchese, A.J.; Zimmerle, D.J.; Hamburg, S.P. Super-Emitters in Natural Gas Infrastructure Are Caused by Abnormal Process Conditions. Nat Commun 2017, 8, 14012. [Google Scholar] [CrossRef] [PubMed]

- BOEM Bureau of Ocean Energy Management (BOEM) OCS Emissions Inventory—2017. Available online: https://www.boem.gov/environment/environmental-studies/ocs-emissions-inventory-2017 (accessed on 4 February 2025).

- Vaughn, T.L.; Bell, C.S.; Pickering, C.K.; Schwietzke, S.; Heath, G.A.; Pétron, G.; Zimmerle, D.J.; Schnell, R.C.; Nummedal, D. Temporal Variability Largely Explains Top-down/Bottom-up Difference in Methane Emission Estimates from a Natural Gas Production Region. Proceedings of the National Academy of Sciences 2018, 115, 11712–11717. [Google Scholar] [CrossRef] [PubMed]

| Prototypical facility type | Average number of producing well heads per facility | Average Water Production (Mbbl y-1 well-1) |

Average Gas Production (MMscf y-1 well-1) |

Average Gas Production (kg h-1 facility-1) |

Average Oil Production (Mbbl y-1 well-1) |

| 1 | 2.6 | 114 | 87 | 480 | 25 |

| 2 | 4.0 | 357 | 411 | 3,495 | 566 |

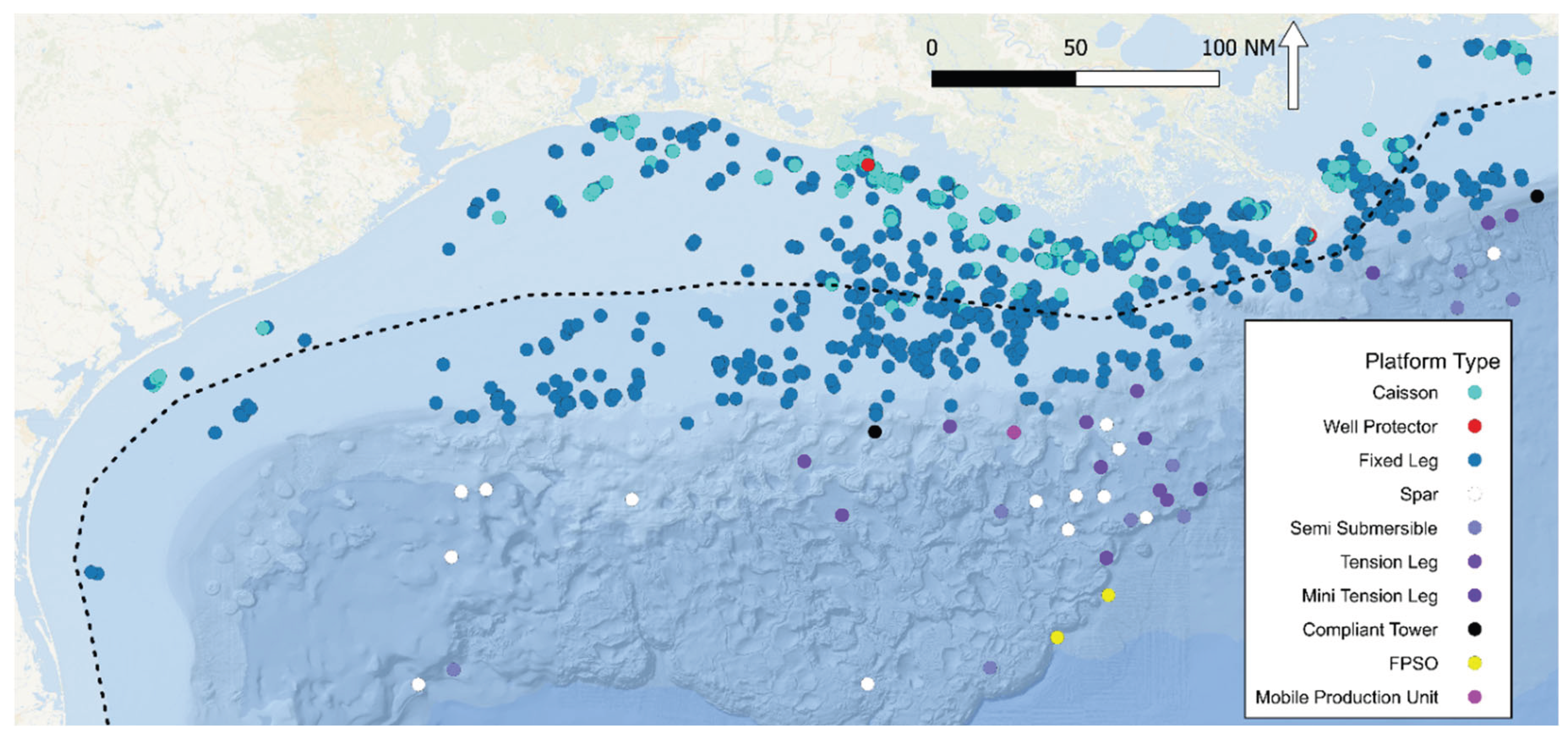

| Platform type | Count | Average Install Date | Average Deck Count | Manned 24 Hours per day (%) | With a Compressor (%) | With a Generator (%) | With Production Equipment (%) | With a Storage Tank (%) |

| Caisson | 253 | 1992 | 1.7 | 1 | 2 | 4 | 72 | 2 |

| Well Protector | 6 | 1983 | 1.0 | 0 | 0 | 0 | 50 | 0 |

| Fixed Leg | 806 | 1982 | 2.3 | 23 | 38 | 47 | 84 | 28 |

| Spar Platform | 17 | 2005 | 3.4 | 94 | 100 | 100 | 100 | 65 |

| Semi-Submersible | 15 | 2014 | 1.7 | 93 | 93 | 93 | 93 | 73 |

| Tension leg | 14 | 2003 | 2.5 | 100 | 100 | 100 | 100 | 93 |

| Mini Tension Leg | 3 | 2003 | 3.3 | 100 | 100 | 100 | 100 | 67 |

| Compliant tower | 2 | 1999 | 3.5 | 100 | 100 | 100 | 100 | 100 |

| FPSO | 2 | 2013 | 0.0 | 100 | 100 | 100 | 100 | 100 |

| Mobile Prod. Unit | 1 | 2009 | 3.0 | 100 | 100 | 100 | 100 | 100 |

| Equipment | Description | EPA Emission factor | Emission (kg h-1) | Updated emission factors from measurement studies | Emission (kg h-1) |

| Gas Outlet | Pipelines to shore | N/A | 0 | 0 | |

| Oil/Condensate | Pipelines to refinery onshore | N/A | 0 | 0 | |

| Separators | 1 high pressure, 2 low pressure | 969 kg/separator/y | 0.3 | 969 kg/separator/y | 0.3 |

| Water Treatment |

Water stored in the gravity base structure. | 51 kg/Mbbls water | 0.1 | 0.415 g CH4 m-3 water[23] | - |

| Gas Flaring | Flaring gas to control emissions from loading operations and emergency releases. Destruction efficiency of 98%. | 5 g bbl-1 | 0.01 | 5.4 g bbl-1 [23] | 0.011 |

| Gas Venting | Vents from Chemical Injector pumps (CI) and dehydrators (D). | CI 1519 kg/pump/y D 0.7 kg MMscf-1 |

0.5 0.01 |

CI 1577 kg pump-1 y-1 [30] D 181 kg CH4 MMm-3 NG [30] |

0.52 0.13 |

| Pneumatic Controllers |

Intermittent bleed | 1,386 kg/controller/y | 0.5 | 4643 kg/controller/y [30] | 1.67 |

| Fugitives | AVO LDAR only, plus methane detectors for manned facilities | 7.7 kg/h | 7.7 | 7.7 kg/h | 7.7 |

| Total | 9.17 | 10.3 |

| Equipment | Description | Emission factor | Emission (kg h-1) | Updated emission factors | Emission (kg h-1) |

| Gas Outlet | Pipelines transport gas back to shore | N/A | 0 | N/A | 0 |

| Oil/Condensate | Stored in atmospheric tanks inside the vessel hull, usually with vapor recovery. Shuttle/transportation tankers then offload and bring the oil to port. | N/A | 0 | N/A | 0 |

| Separators | 10 separators. High pressure separators, then condensate stabilization. | 968.5 kg/separator/y | 1.1 | 968.5 kg/separator/y | 1.1 |

| Hydrocarbon Storage Tanks | Oil tanks built into hull of vessel. Methane from flashing, working, and standing losses goes to vapor recovery. | 188 kg Mbbl-1 | 11.9 | 0.36 kg CH4 bbl-1 [23] | 23.3 |

| Water Storage Tanks | Water treated and then discharged or reinjected. Methane from flashing, working, and standing losses goes to vapor recovery. | 51 kg/Mbbls water | 2.1 | 0.415 g CH4 m-3 water [23] | 0.03 |

| Gas Flaring | Flare efficiency is assumed to be 98%. | 5 g bbl-1 | 0.3 | 5.4 g bbl-1 [23] | 0.32 |

| Gas Venting | Vents from Chemical Injector pumps (CI) and dehydrators (D). | CI 1519 kg/pump/y D 0.7 kg/MMscf |

0.7 0.03 |

CI 1577 kg pump-1 y-1 [30] D 181 kg CH4 MMm-3 NG [30] |

0.52 0.96 |

| Pneumatic Controllers | Generally, air instruments. | 1,386 kg/controller/y | 0.7 | 4643 kg/controller/y [30] | 2.3 |

| Compressors | Centrifugal. Dry gas seals. Assume similar to midstream compressors. | 16,118 kg/y | 1.8 | 58.3 kg CH4 y-1 [23] | 6.7 |

| Fugitives | AVO LDAR only, plus methane detectors for manned facilities | 23.4 kg/h | 23.4 | 23.4 kg/h | 23.4 |

| Total | 42.2 | 58.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).