Submitted:

17 June 2025

Posted:

19 June 2025

You are already at the latest version

Abstract

Keywords:

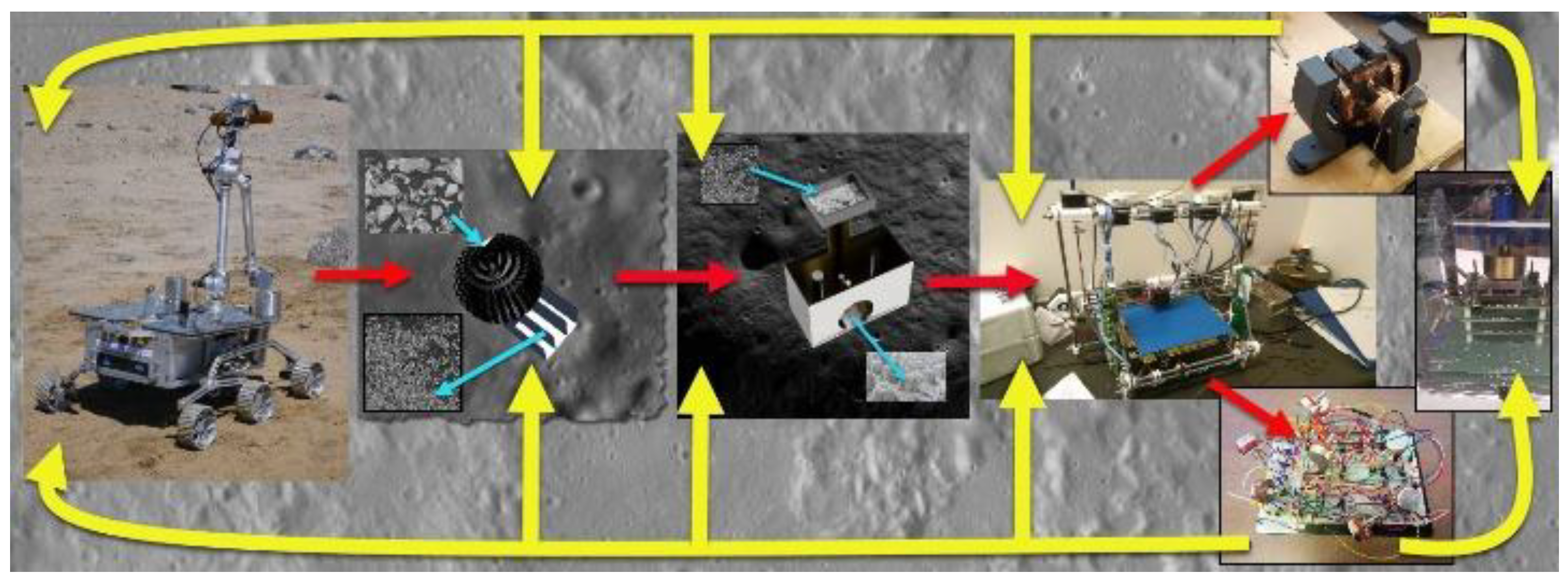

1. Introduction

2. Additive Manufacturing

3. 3D Printing Electric Motors

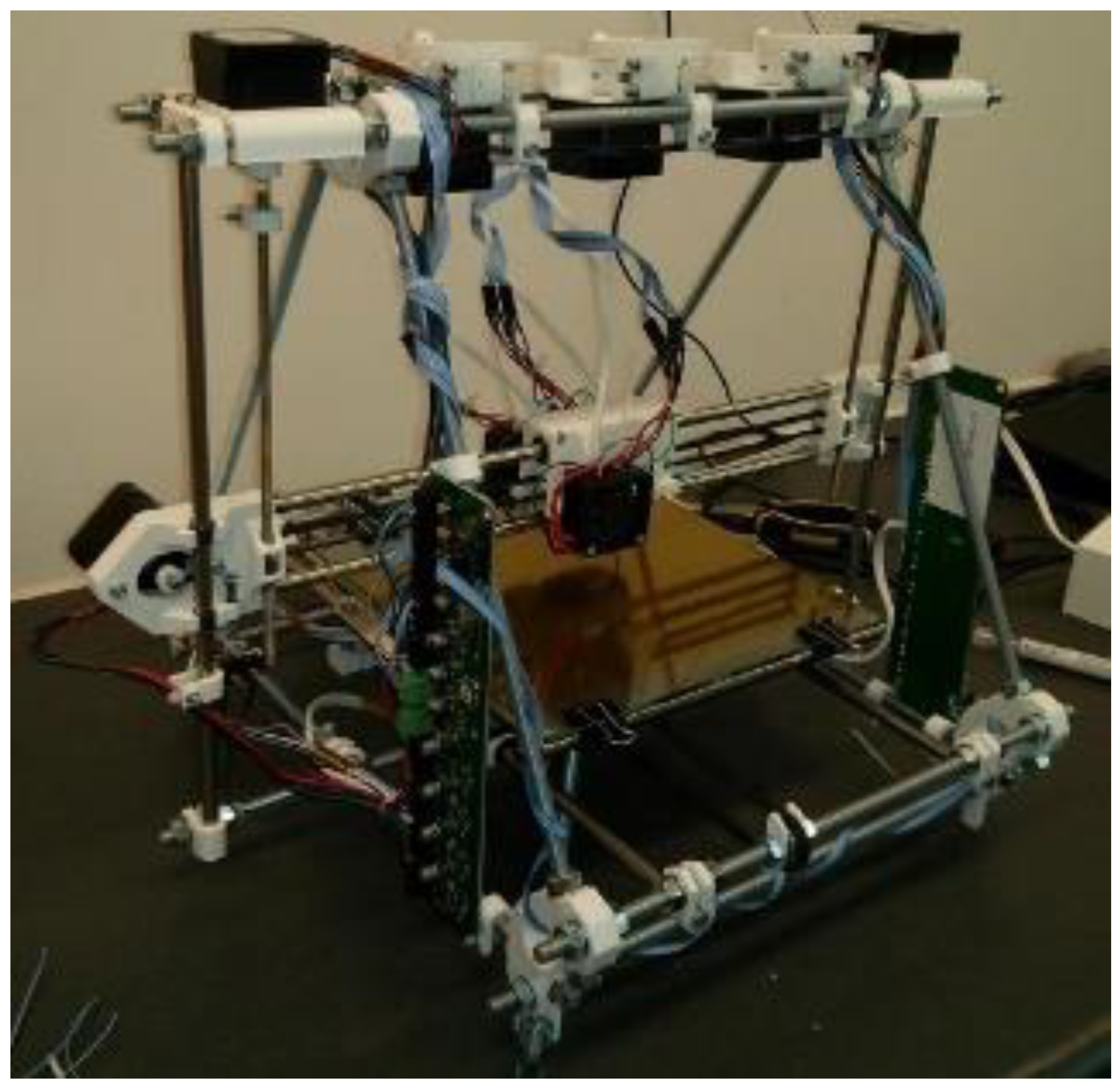

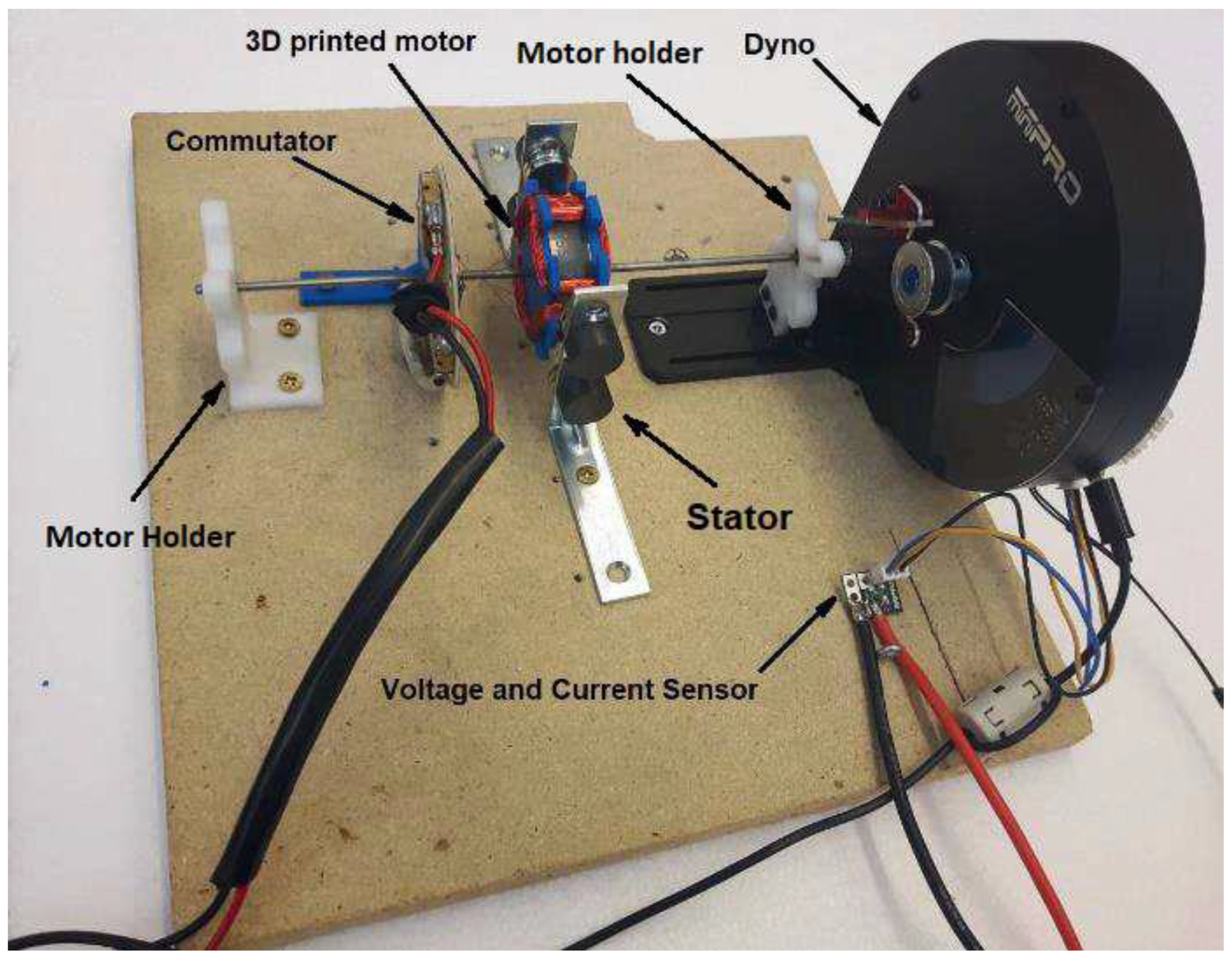

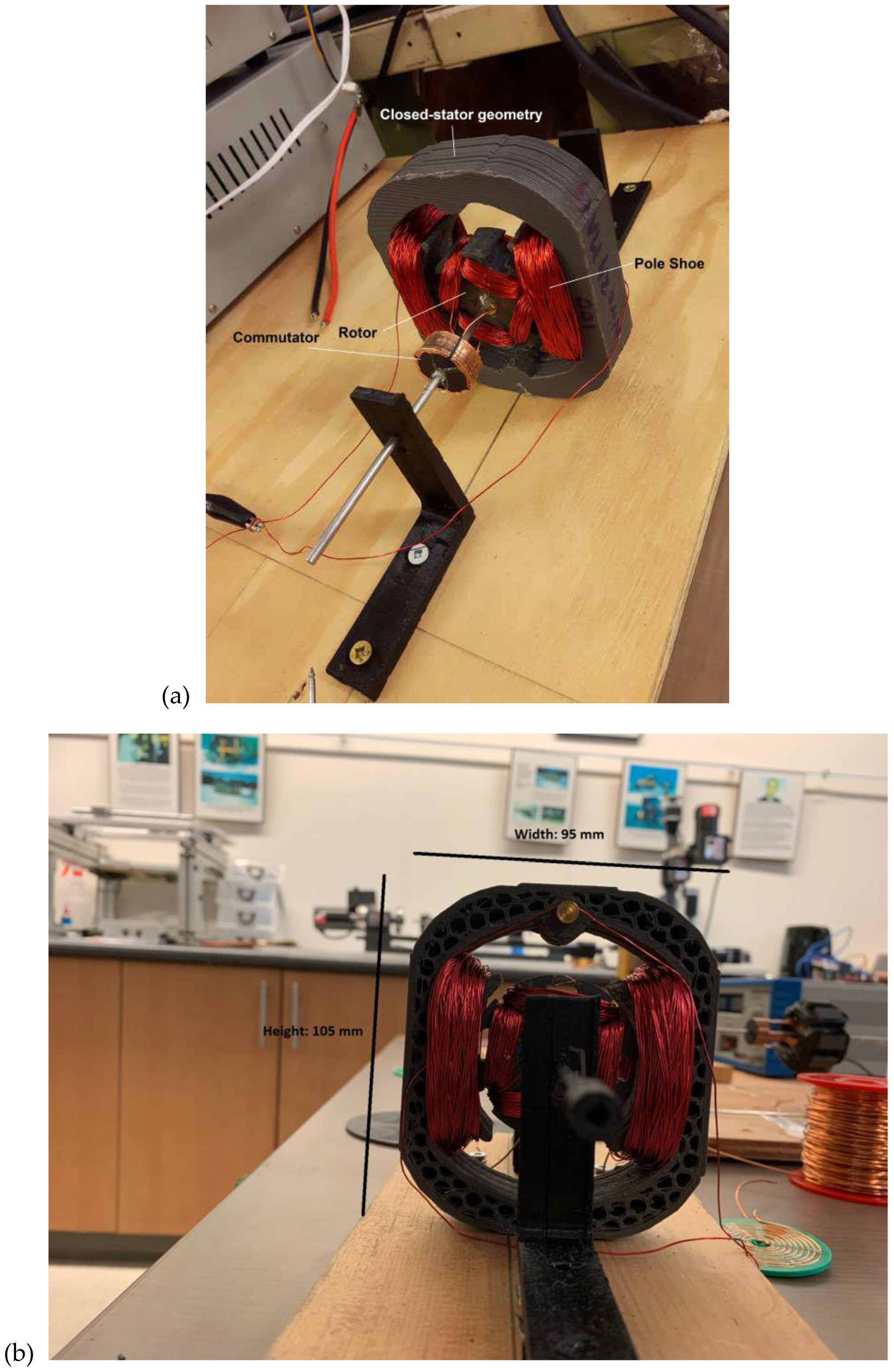

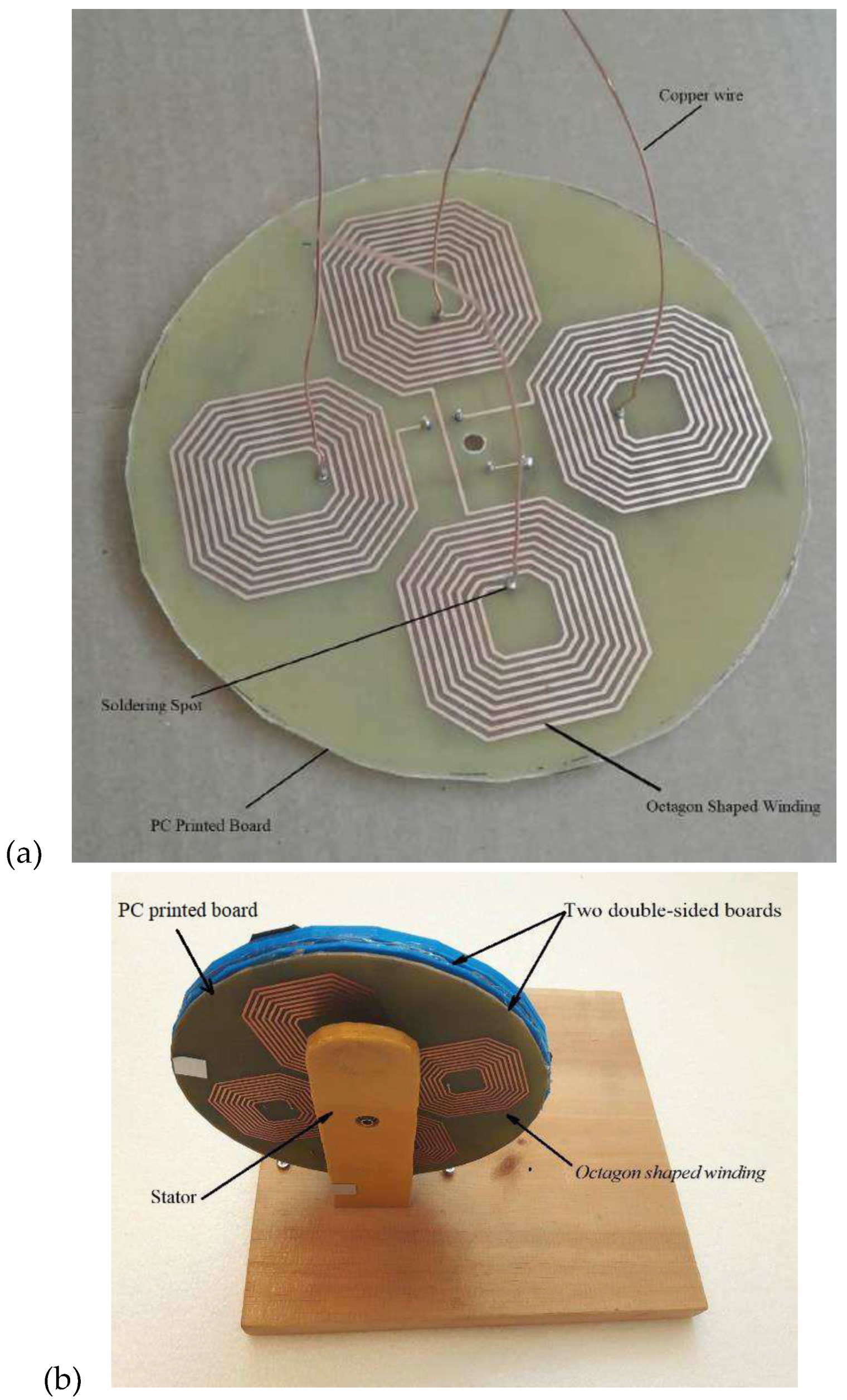

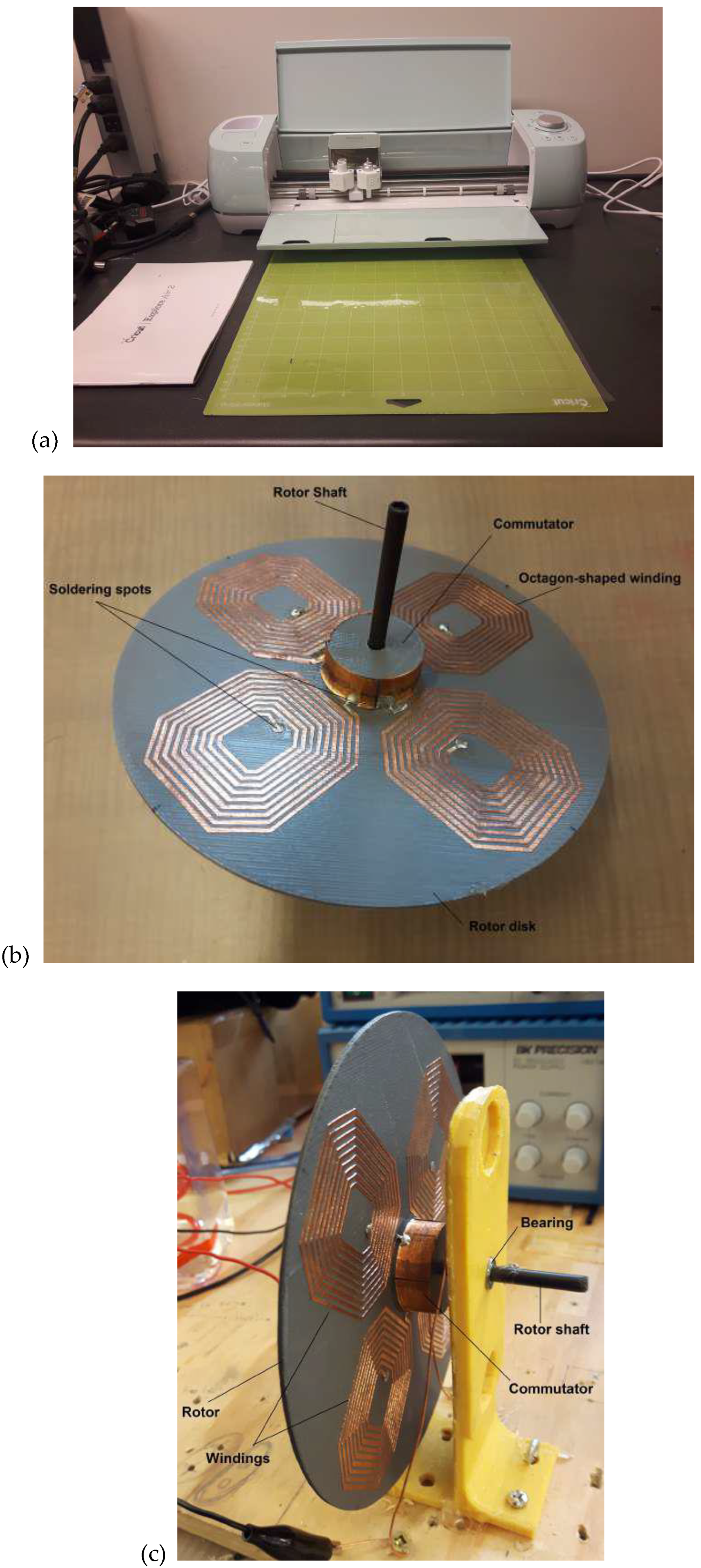

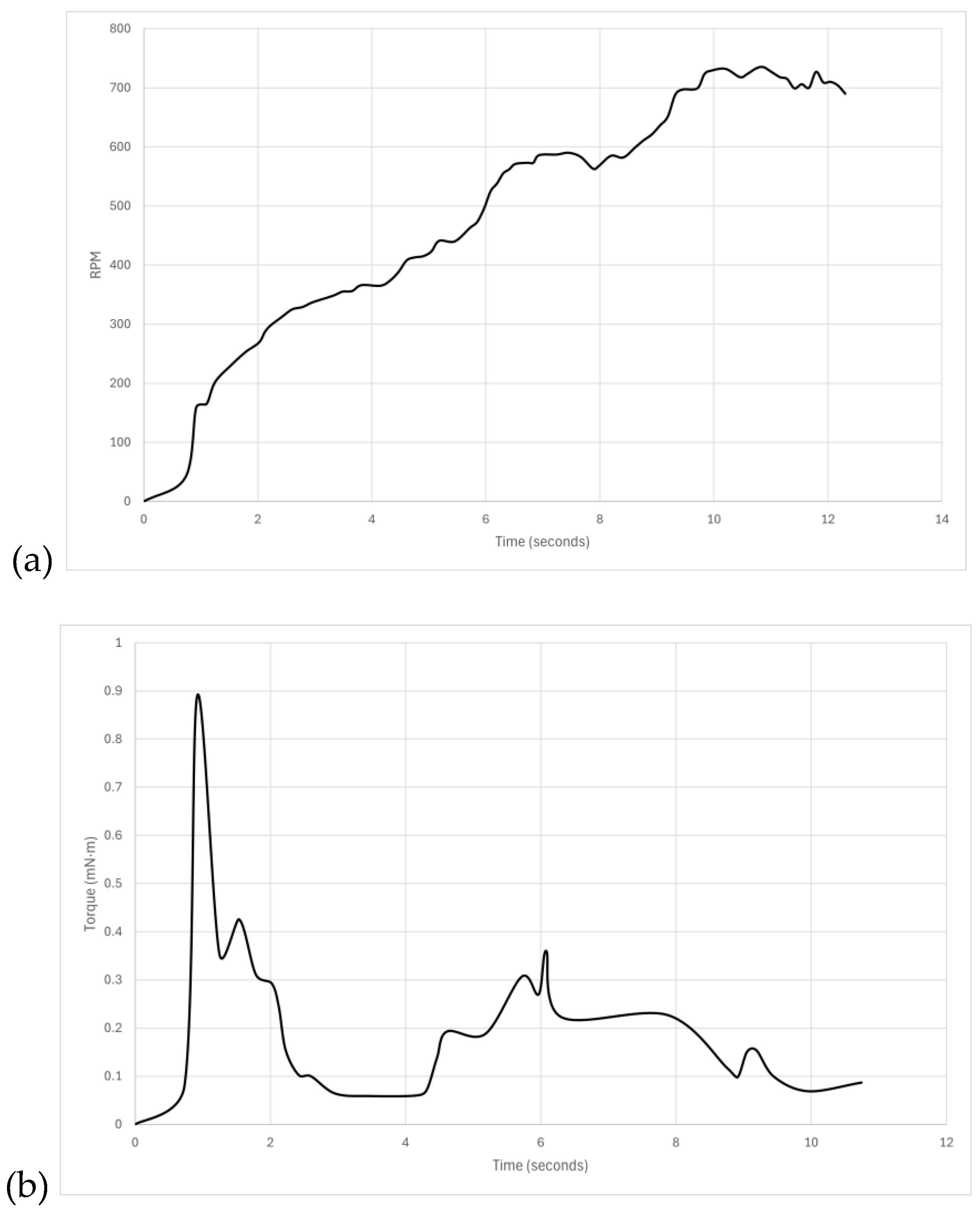

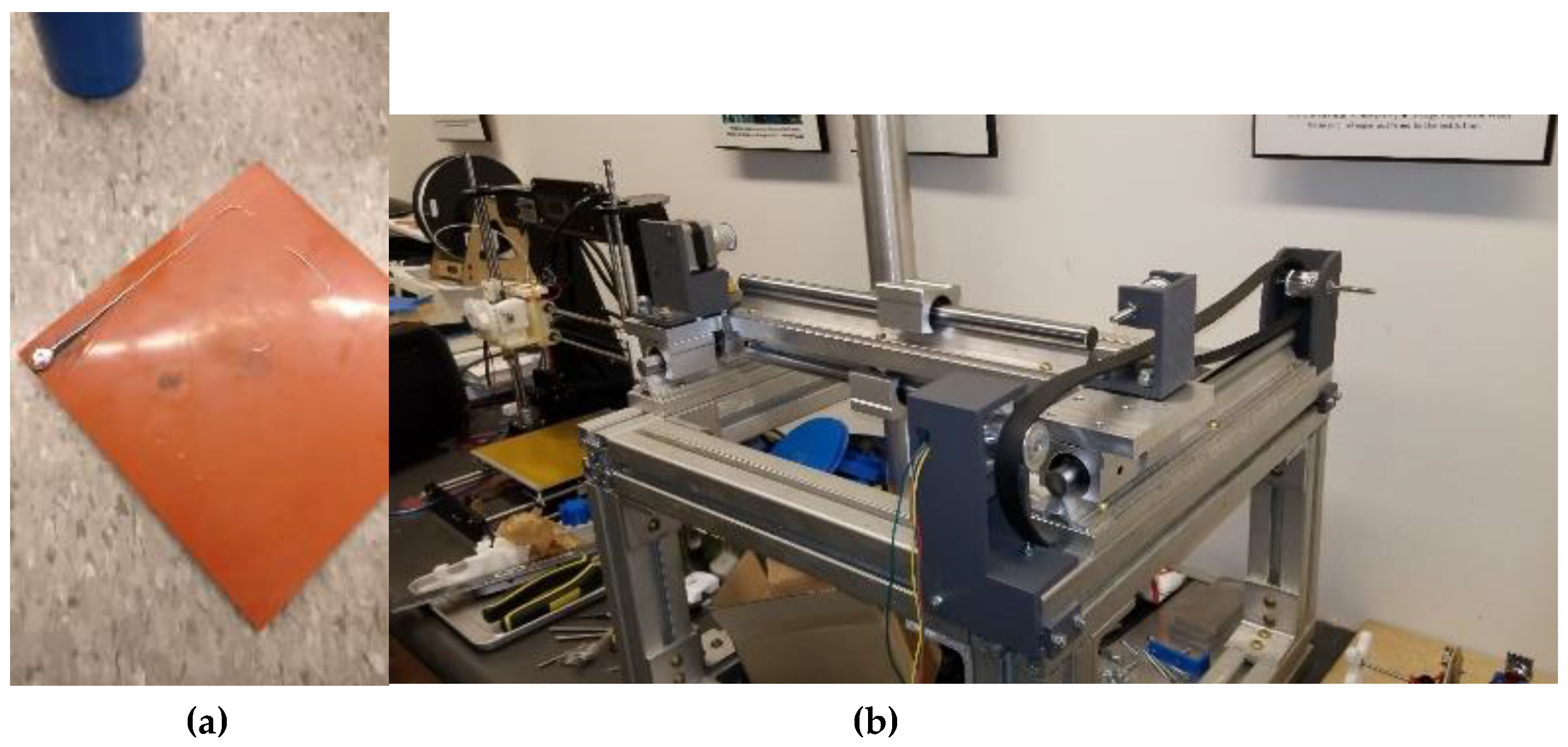

3.1. Motor Testing Apparatus

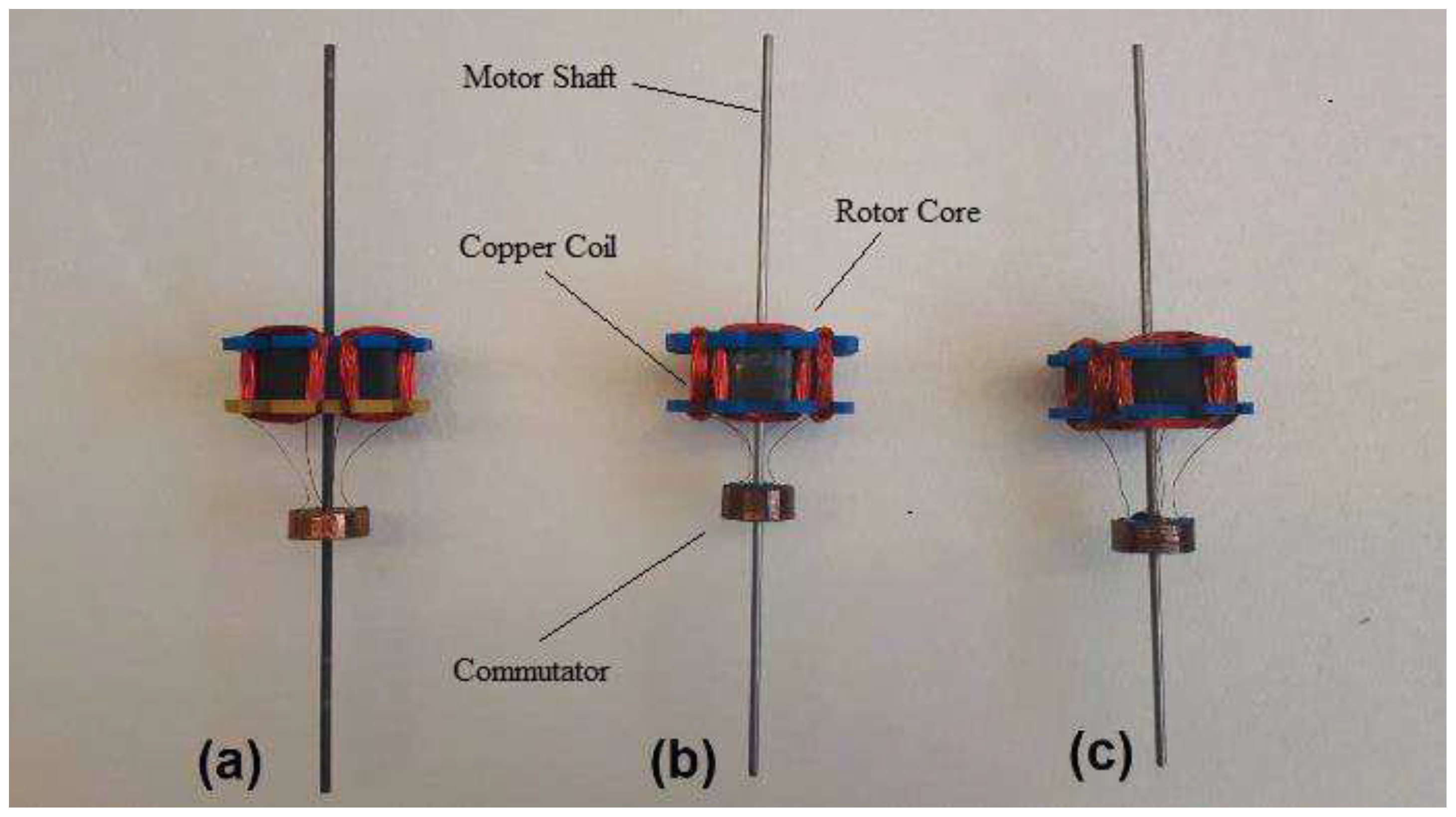

3.2. 3D Printing Soft Magnets for Rotors

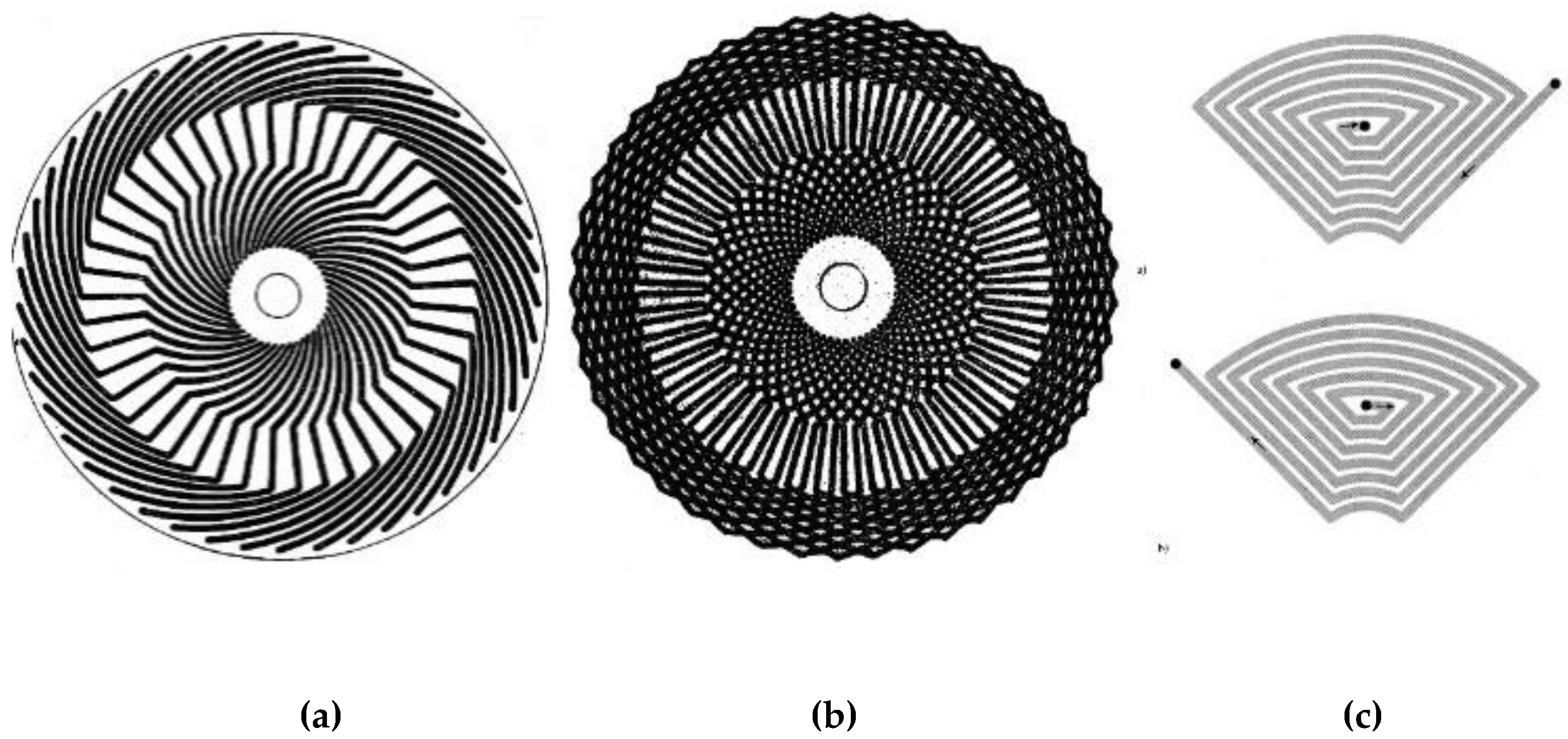

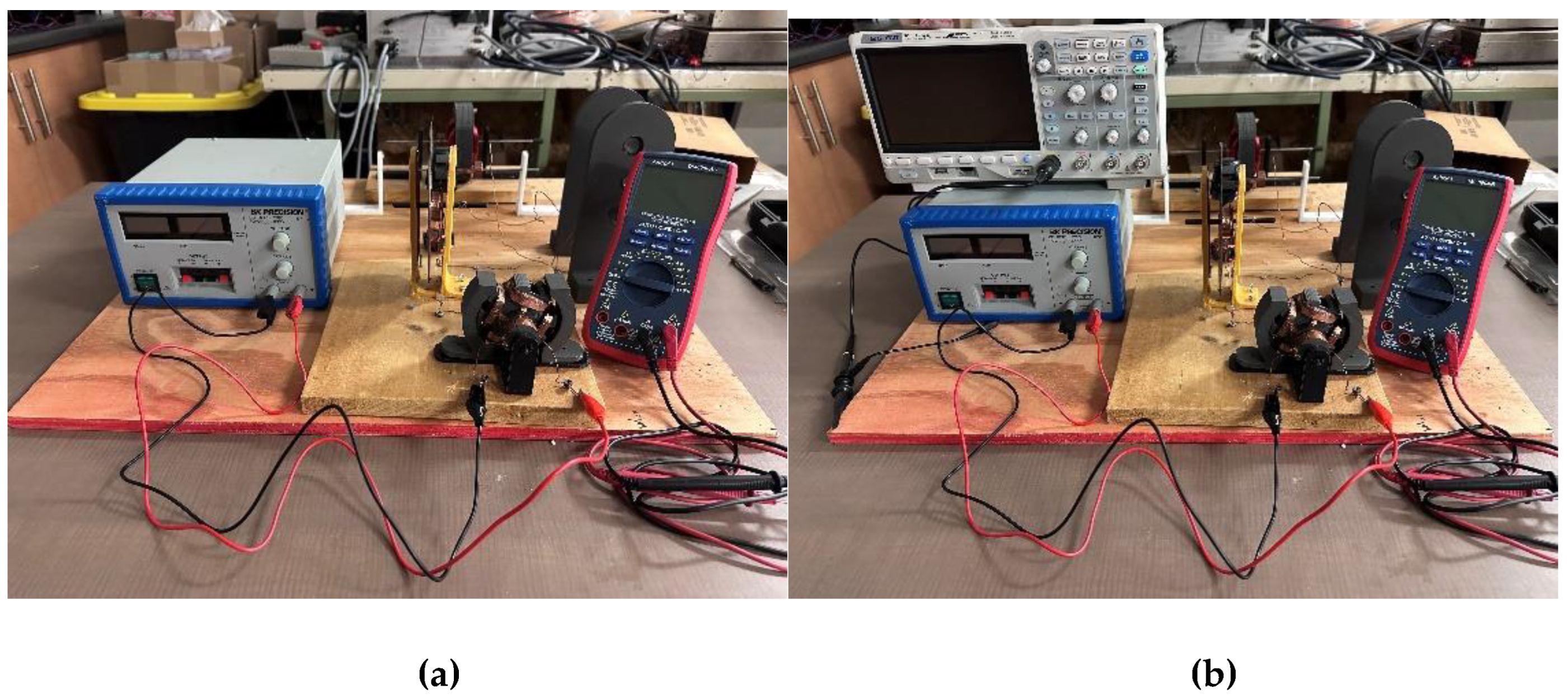

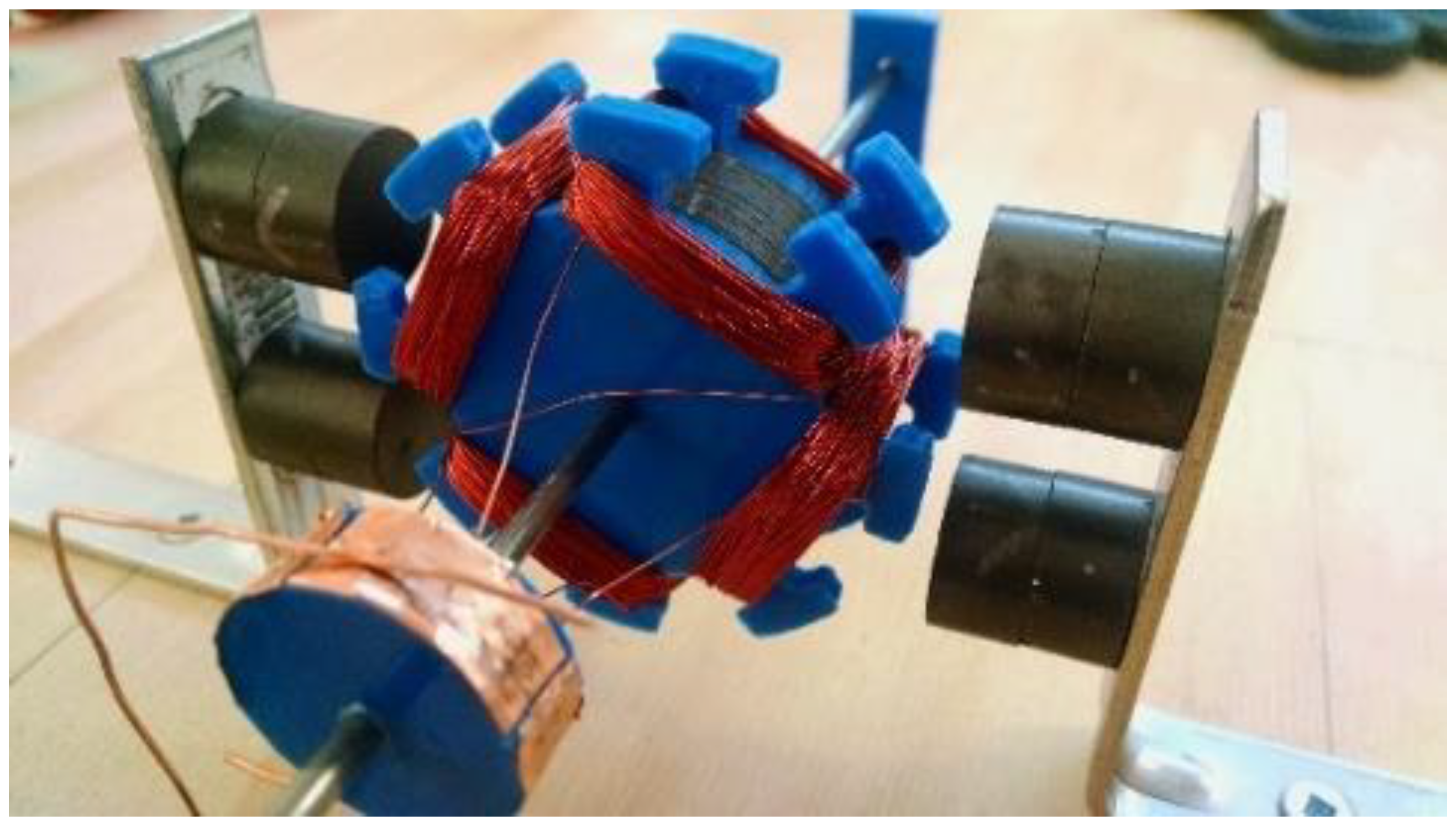

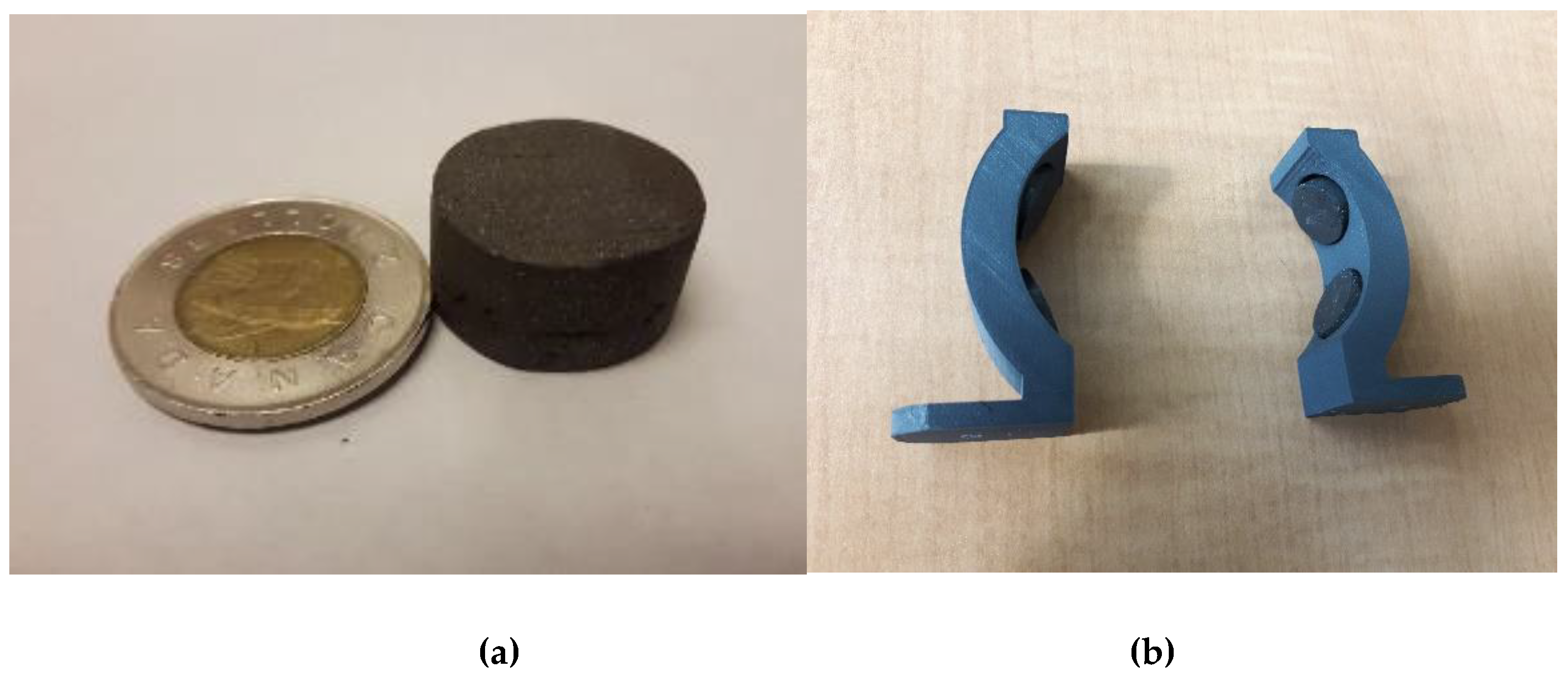

3.3. 3D Printing Dual Excitation Motors

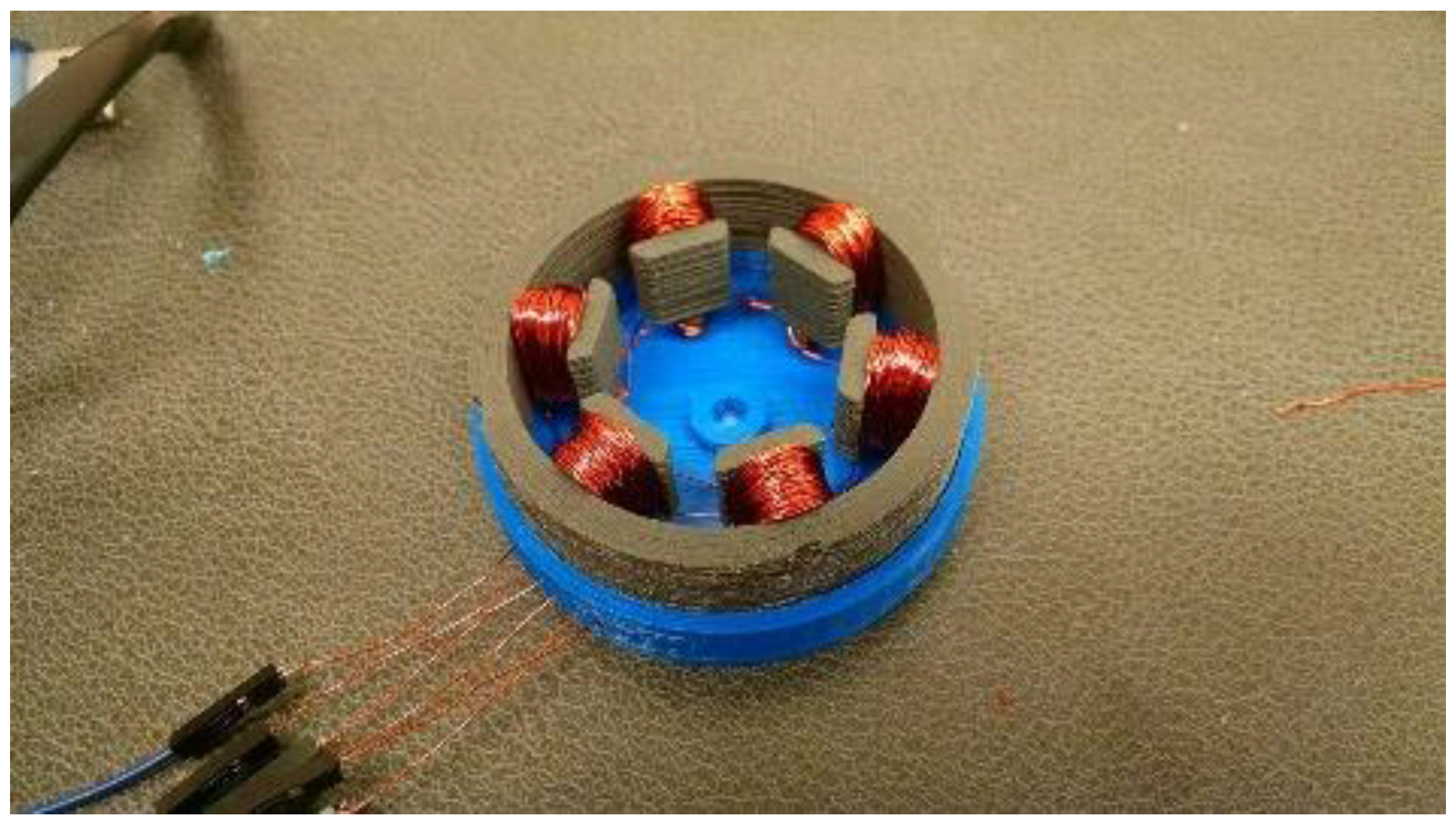

3.4. 3D Printing Permanent Magnets for Stators

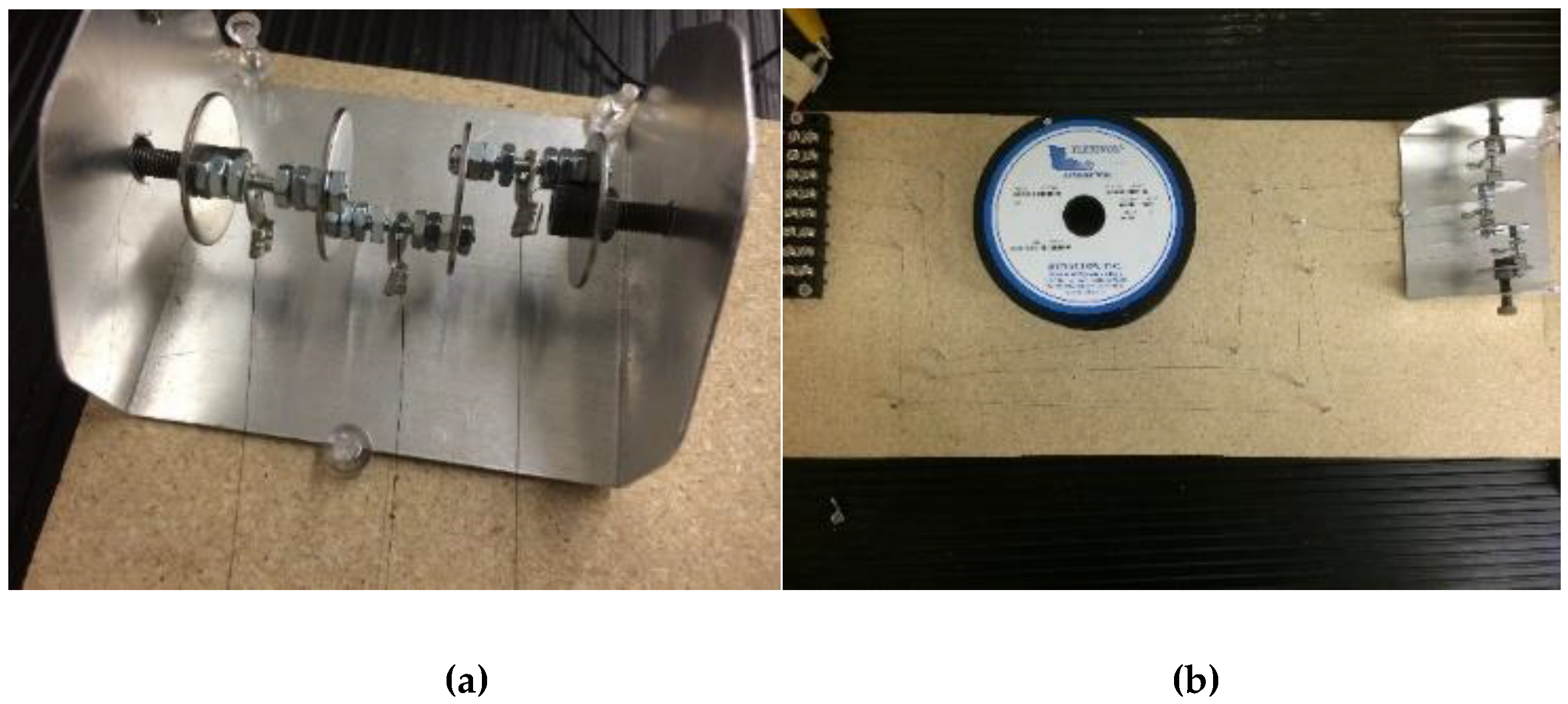

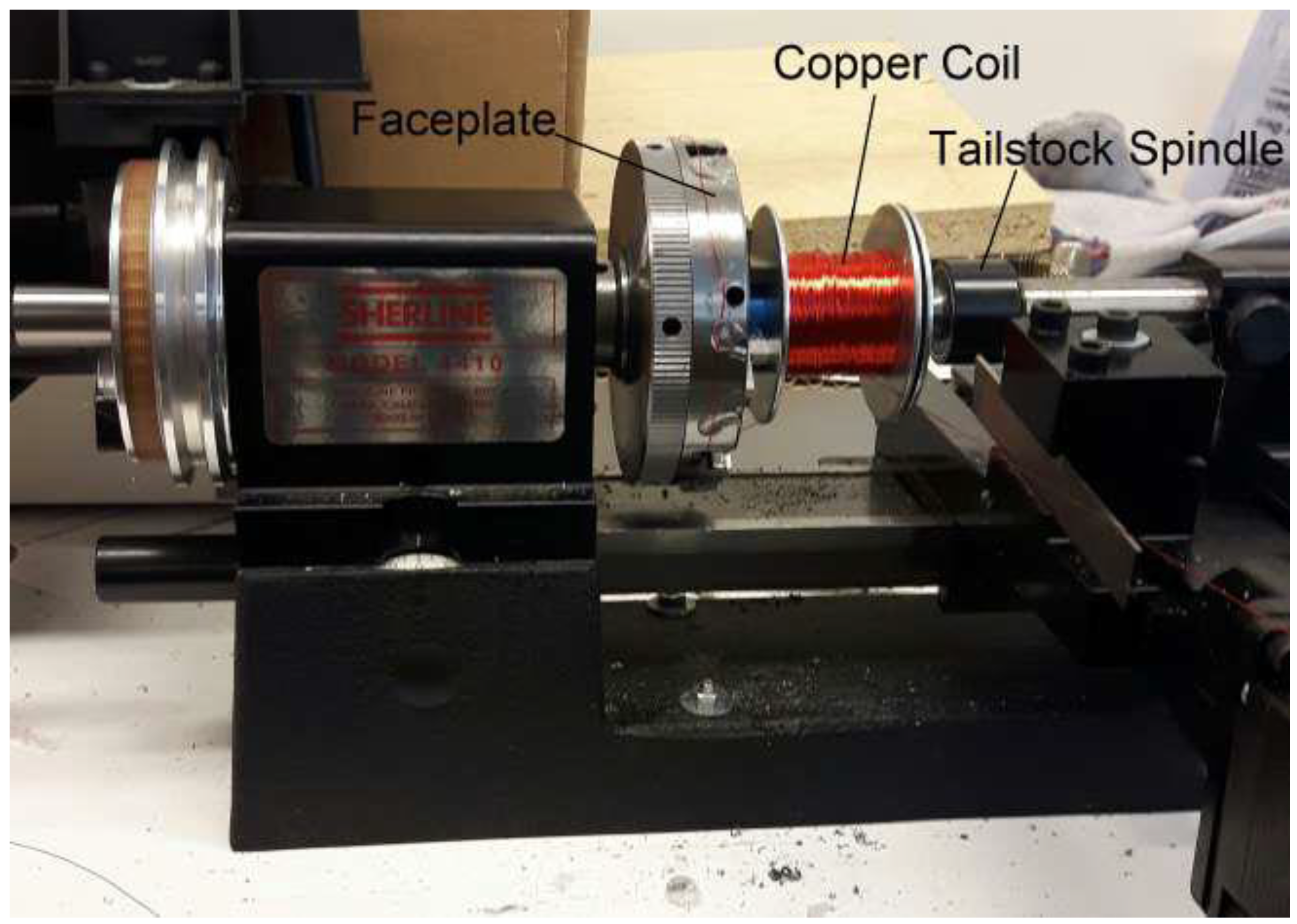

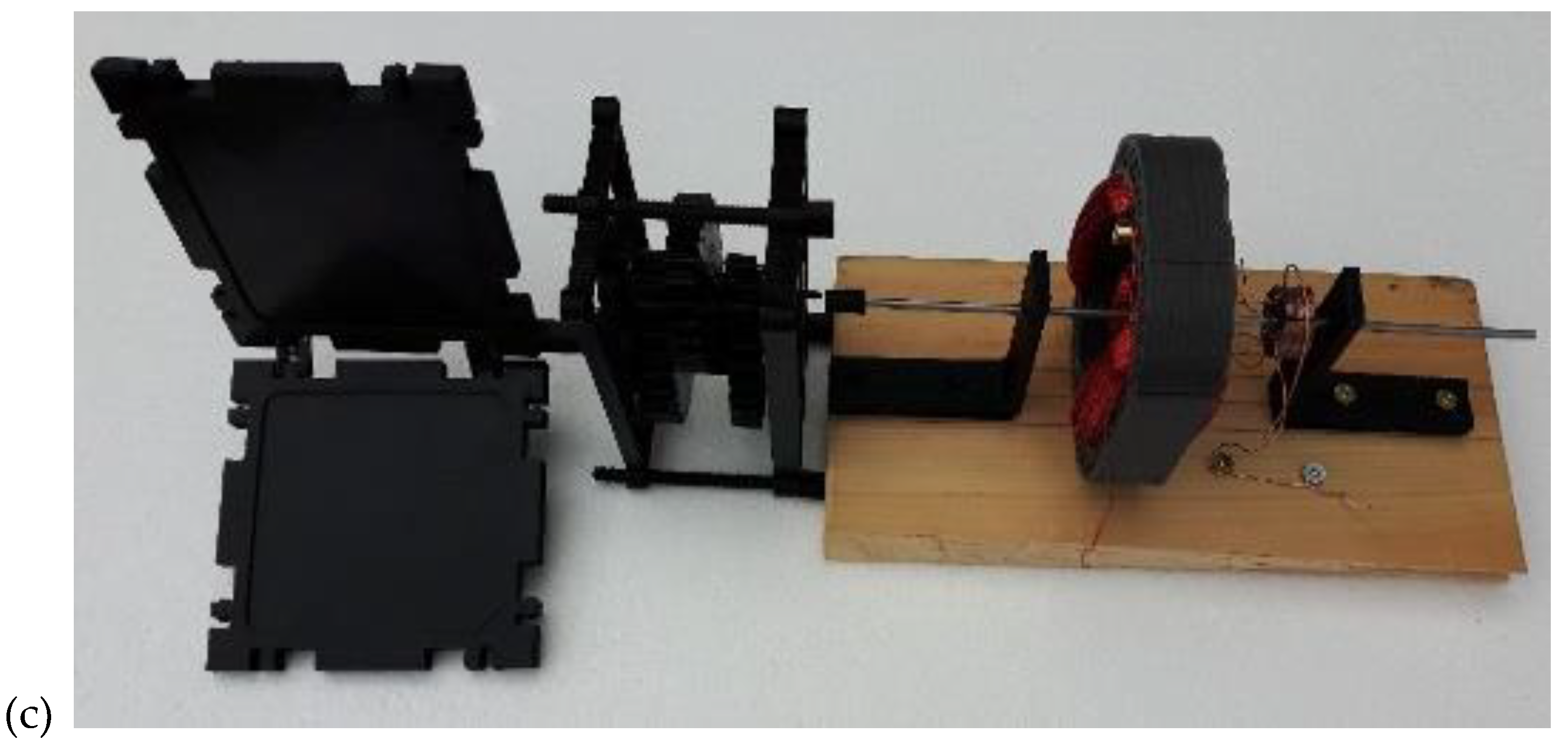

3.5. Challenge of 3D Printing Wire Coils

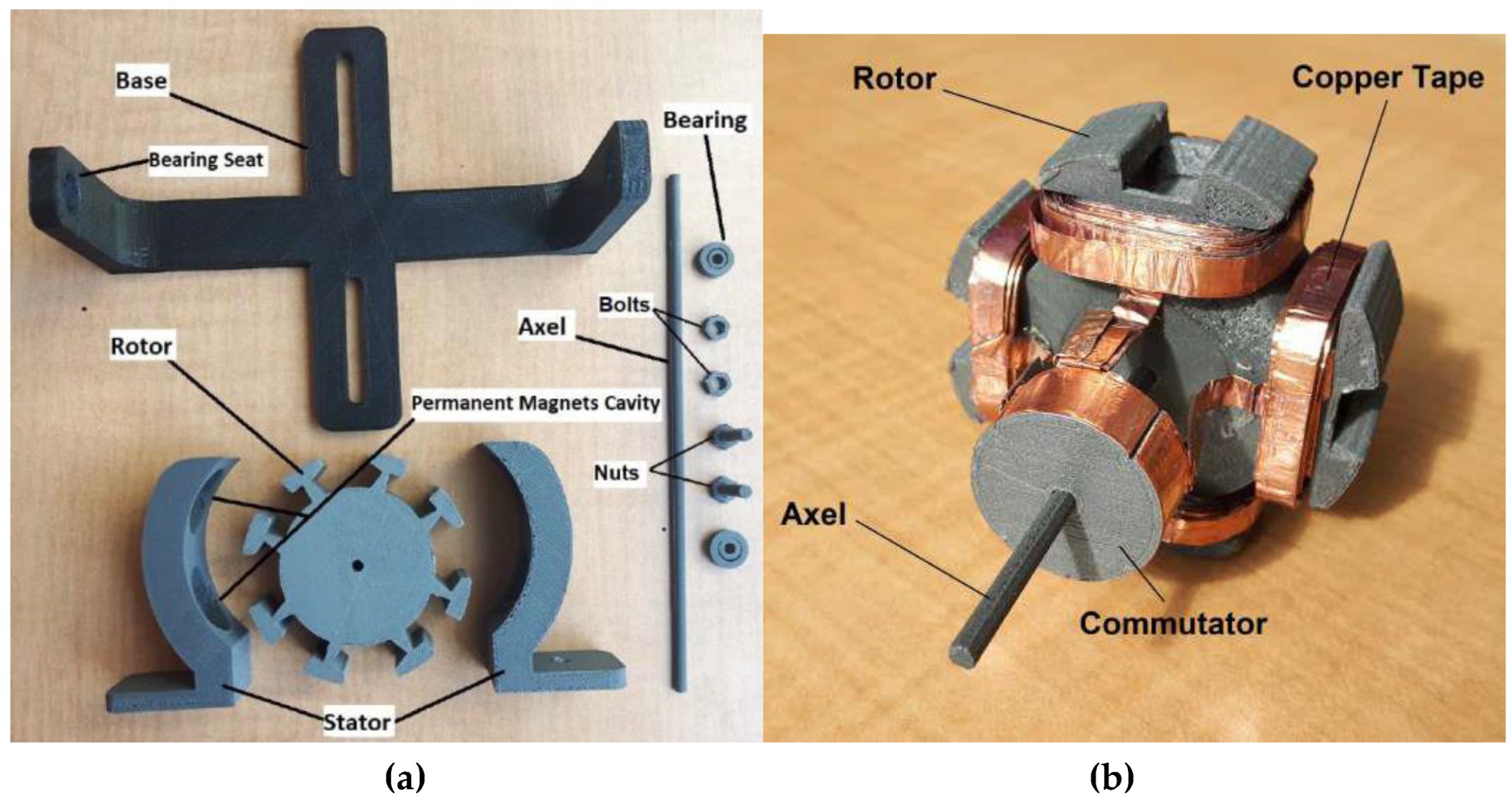

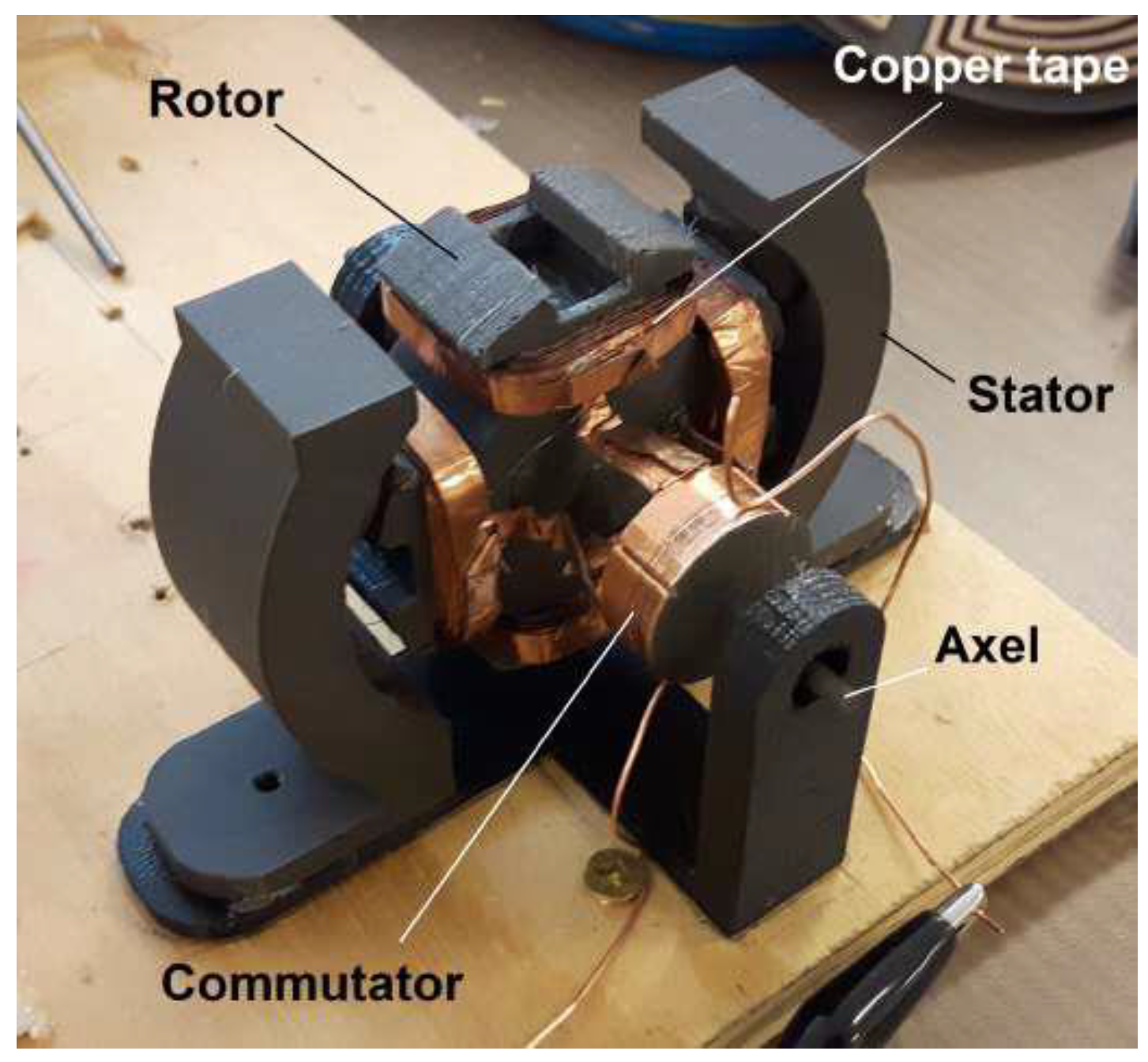

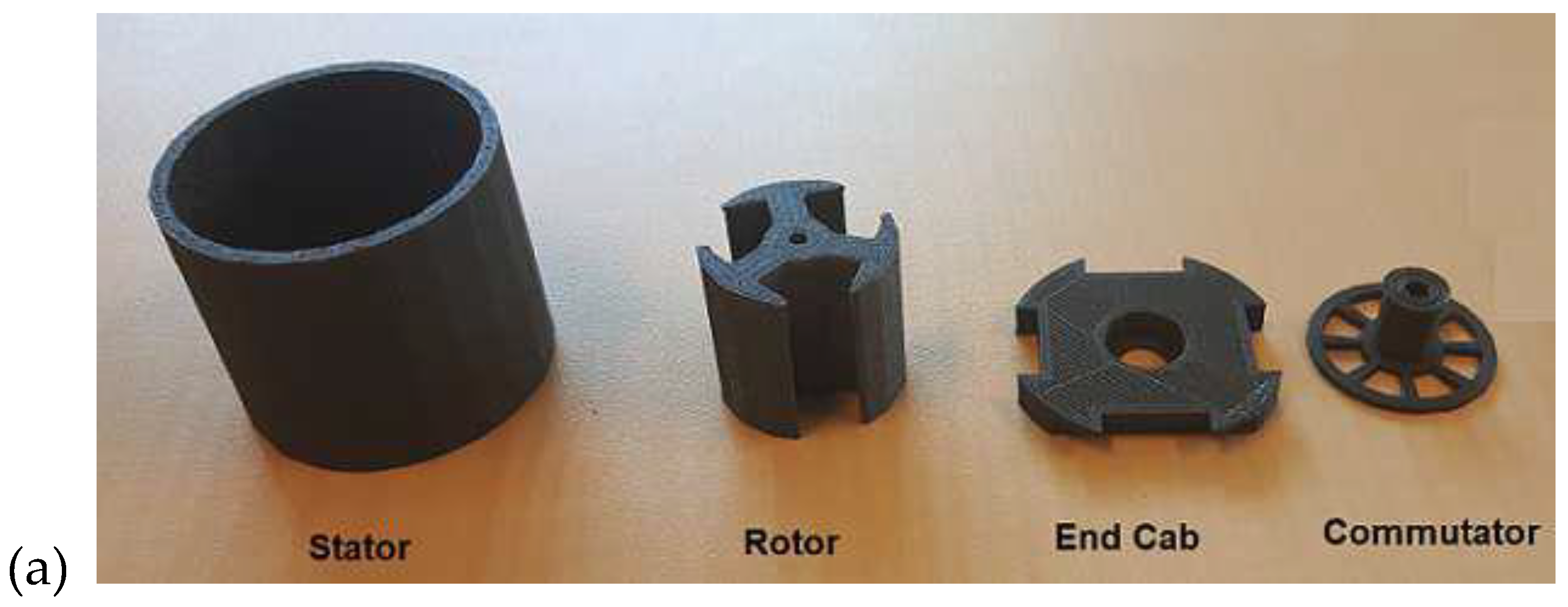

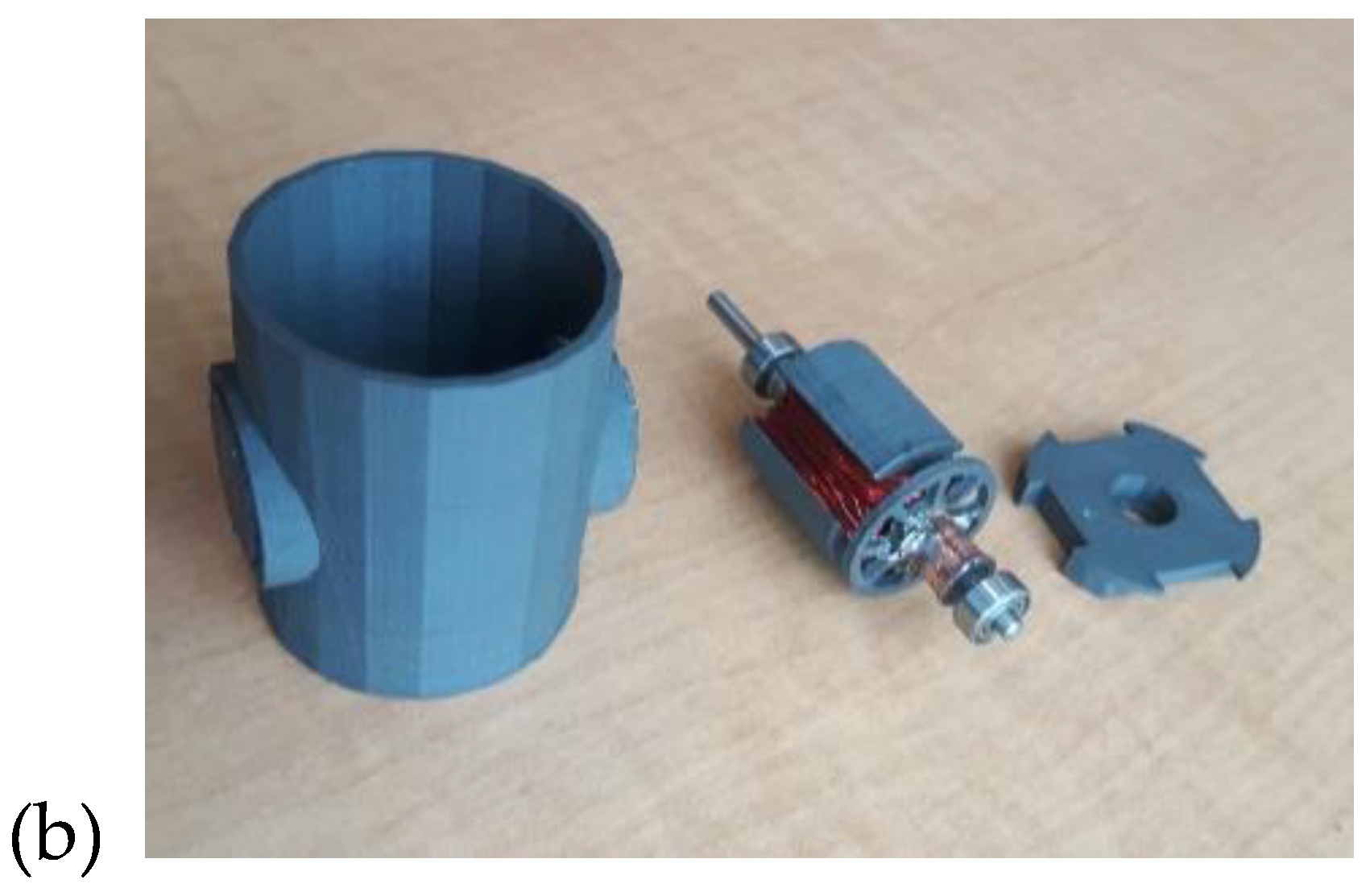

3.6. Assembly of Fully 3D Printed DC Motor

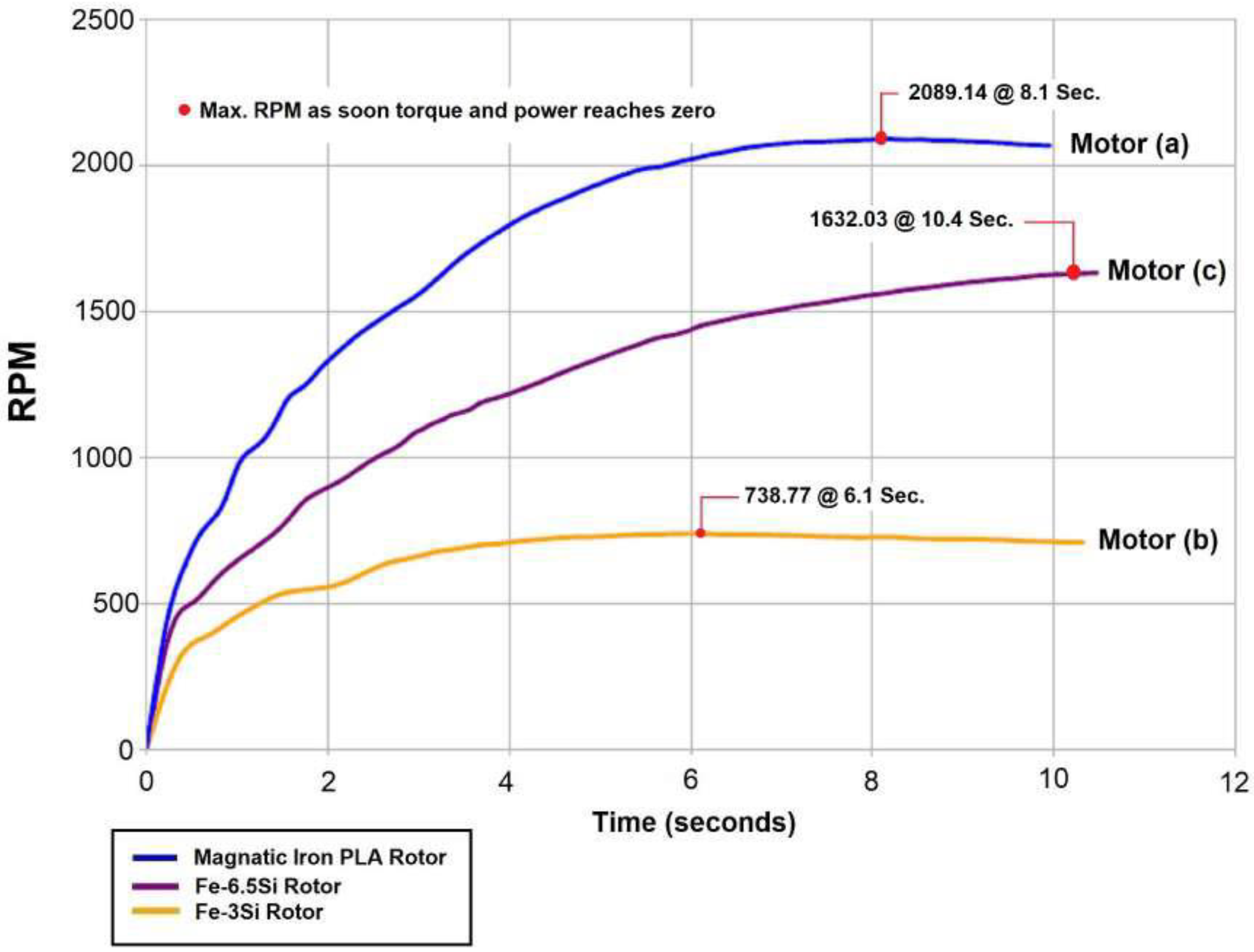

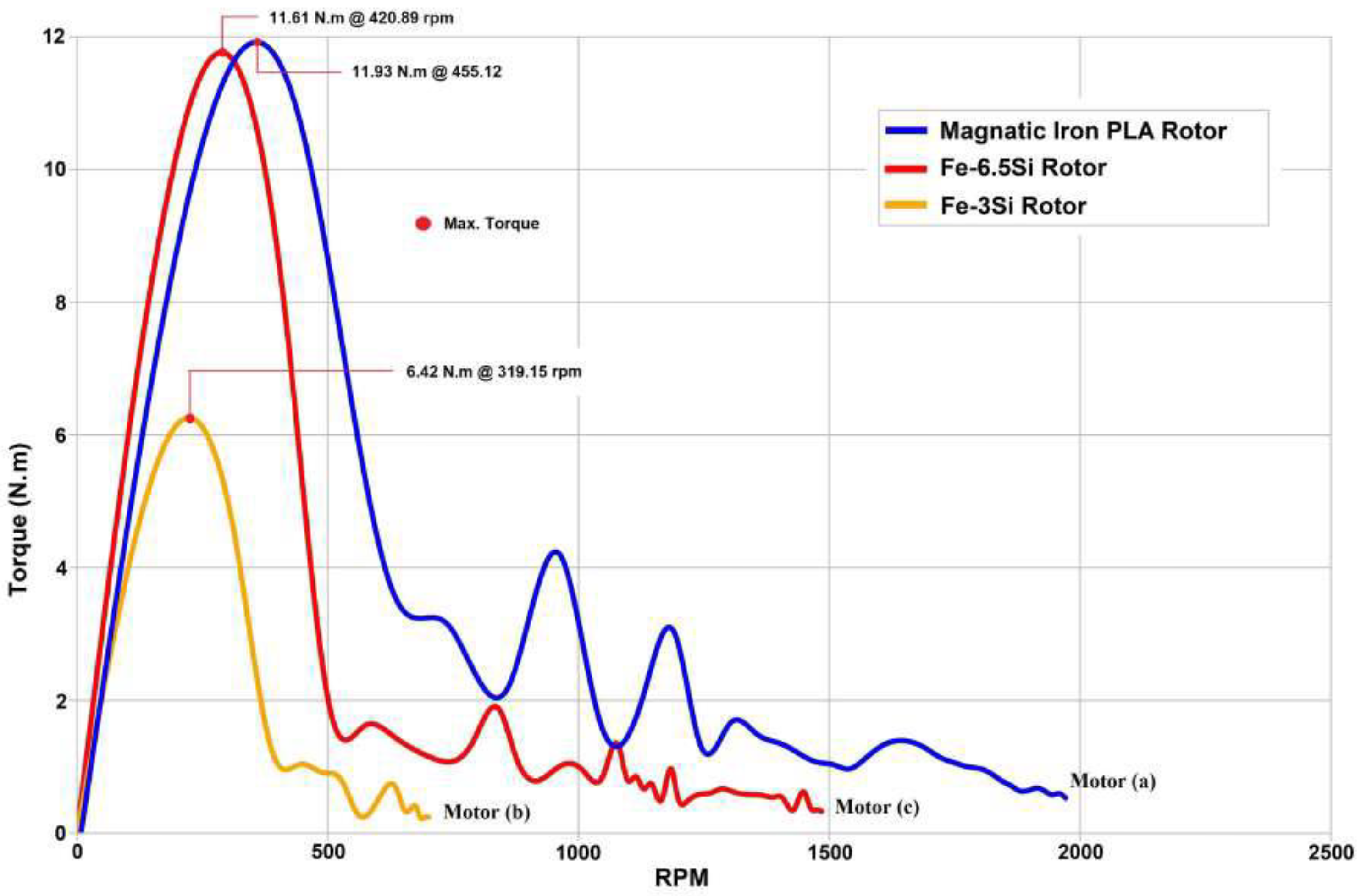

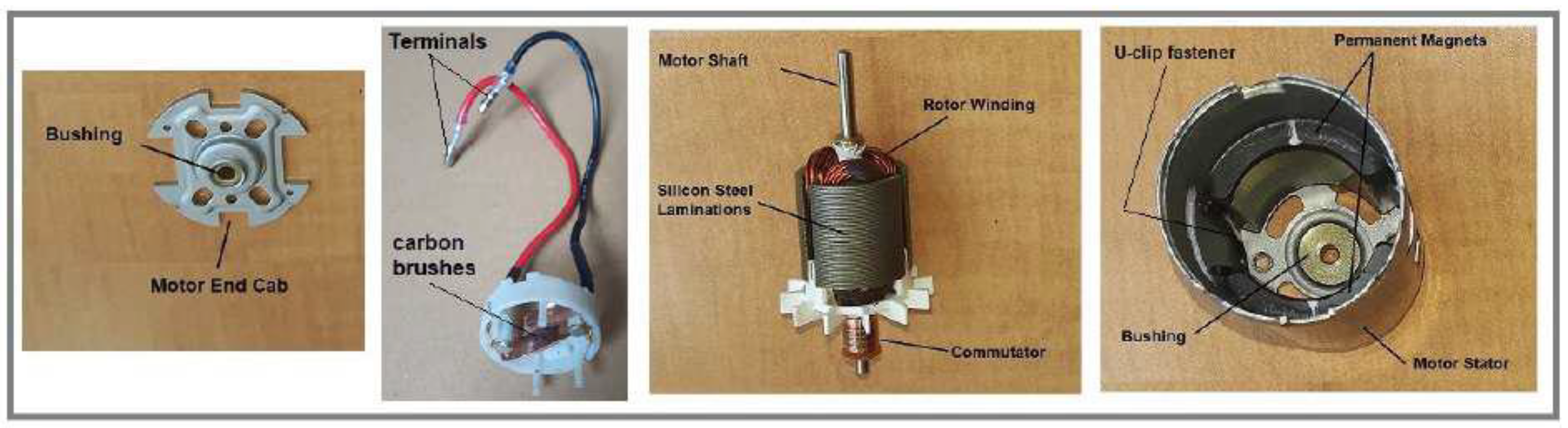

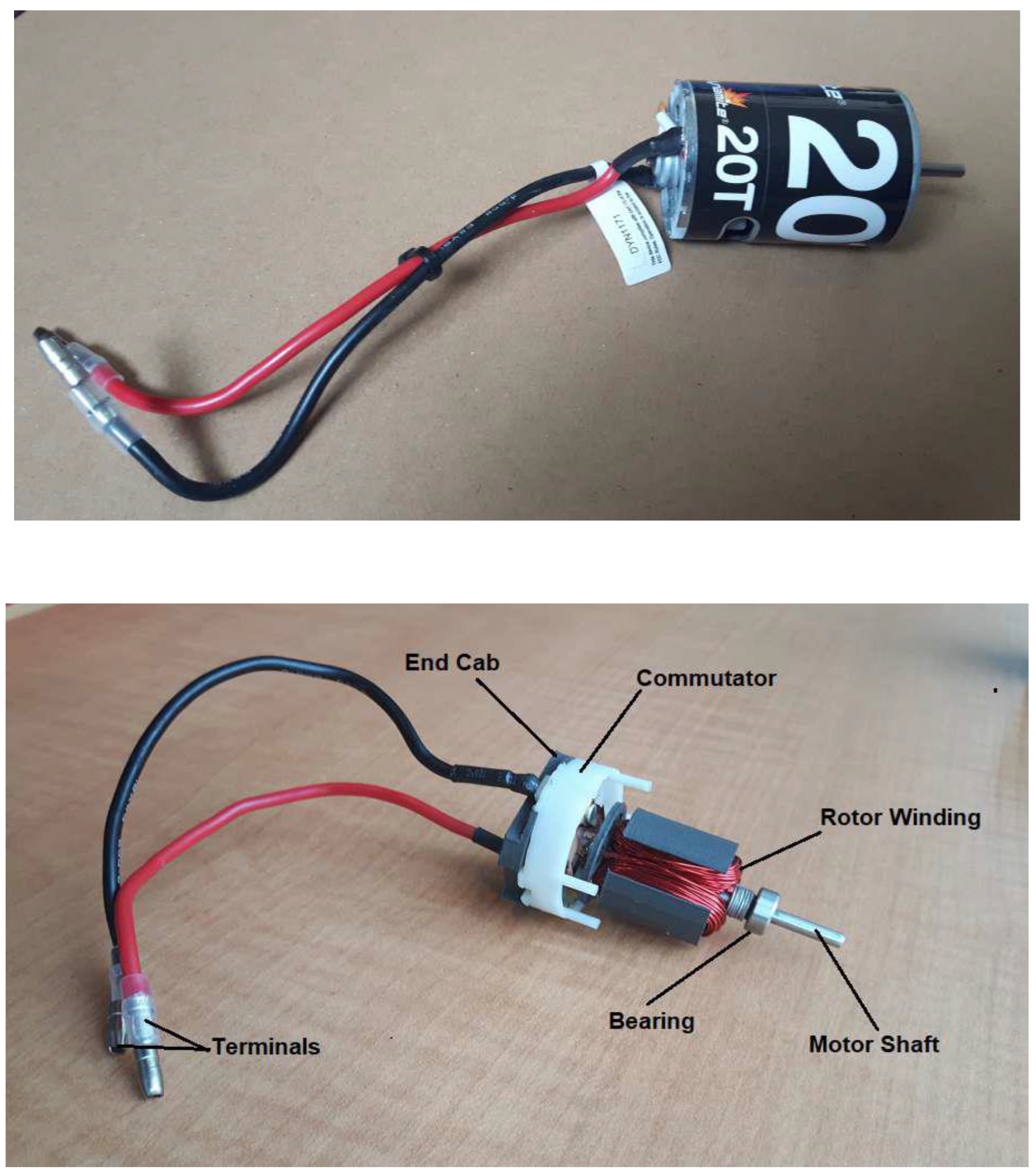

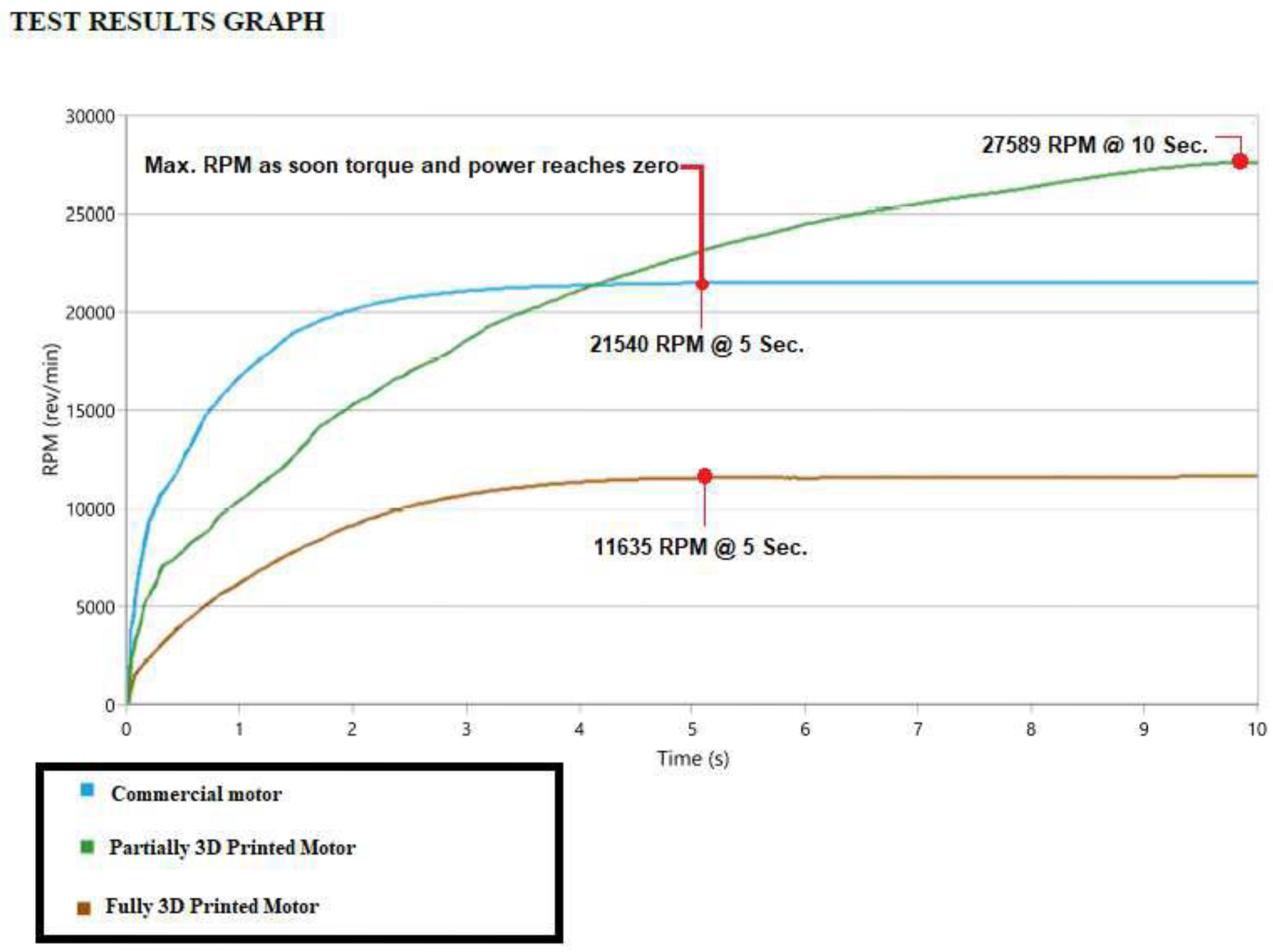

3.7. Benchmarking a Partially 3D Printed Motor

4. Future Developments

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Burkes A, von Neumann J. Theory of Self-Reproducing Automata; University of Illinois Press: Champaign, IL, USA, 1966. [Google Scholar]

- Langton C. Self-reproduction in cellular automata. Physica 1984, 10D, 135–144. [Google Scholar]

- Ellery A. Are self-replicating machines feasible? AIAA J Spacecraft & Rockets 2016, 53, 317–327. [Google Scholar]

- Jones R, Haufe P, Sells E, Iravani P, Olliver V, Palmer C, Bowyer A. RepRap – the replicating rapid prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Ellery A (2024) “Vertical closure constraints on self-replicating machines” Proc Living Machines Conf (Lecture Notes in AI), Chicago, USA.

- Ellery A. Are there biomimetic lessons from genetic regulatory networks for developing a lunar industrial ecology? Biomimetics J 2021, 6, 50. [Google Scholar] [CrossRef] [PubMed]

- Moses M, Ma H, Wolfe K, Chirikjian G. Architecture for universal construction via modular robotic components. Robotics & Autonomous Systems 2014, 62, 945–965. [Google Scholar]

- Ellery A, Elaskri A (2025) “3D printing modules for self-assembling space systems” in press with Progress in Aerospace Sciences.

- Ellery A. Bio-inspired strategies are adaptable to sensors manufactured on the Moon. Biomimetics J 2024, 9, 496. [Google Scholar]

- Ellery A. Bootstrapping neural electronics from lunar resources for in-situ artificial intelligence applications. Proc 42nd SGAI Int Conf on Artificial Intelligence - Lecture Notes in Artificial Intelligence 2022, 13652, 83–97. [Google Scholar]

- Chafik A, Gaber J, Tayane S, Ennaji M, Bourgeois J,El Ghazawi T. From conventional to programmable matter systems: a review of design, materials and technologies. ACM Computing Surveys 2024, 56, article 210. [Google Scholar]

- Greco C, Kotak P, Pagnotta L, Lamuta C. Evolution of mechanical actuation: from conventional actuators to artificial muscles. Int Materials Reviews 2022, 67, 575–619. [Google Scholar] [CrossRef]

- Exley T, Johnson D, Jafari A. Novel variable impedance actuator utilizing adjustable viscoelastic properties of thermos-responsive polycaprolactone. Robotics Reports 2023, 1, 57–66. [Google Scholar] [CrossRef]

- Jani M, Leary M, Subic A, Gibson M. Review of shape memory alloy research, applications and opportunities. Materials & Design 2014, 56, 1078–1113. [Google Scholar]

- Gul Z, Sajid M, Rehman M, Siddiqui U, Shah I, Kim K-H, Lee J-W, Choi H. 3D printing for soft robotics – a review. Science & Technology of Advanced Materials 2018, 19, 243–262. [Google Scholar]

- Nespoli A, Besseghini S, Piiaccio S, Villa E, Viscuso S. High potential of shape memory alloys in developing miniature mechanical devices: a review in shape memory alloy mini-actuators. Sensors & Actuators A 2010, 158, 149–160. [Google Scholar]

- Nespoli A, Besseghini S, Piiaccio S, Villa E, Viscuso S. High potential of shape memory alloys in developing miniature mechanical devices: a review in shape memory alloy mini-actuators. Sensors & Actuators A 2010, 158, 149–160. [Google Scholar]

- Wagner M, Ocana-Pujol J, Hadian A, Clemens F, Spolenak R. Filament extrusion-based additive manufacturing of NiTi shape memory alloys. Materials & Design 2023, 225, 111418. [Google Scholar]

- Elahinia M, Moghaddam S, Andani T, Amerinatanzi A, Bimber B, Hamilton R. Fabrication of NiTi through additive manufacturing: a review. Progress in Materials Science 2016, 83, 630–663. [Google Scholar] [CrossRef]

- Lu H, Yang C, Luo X, Ma H, Song B, Li Y, Zhang L. Ultrahigh performance TiNi shape memory alloy by 3D printing. Materials Science & Engineering A 2019, 763, 138166. [Google Scholar]

- Haberland C, Elahinia M, Walker J, Meier H, Frenzel J. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Materials & Structures 2014, 23, 104002. [Google Scholar]

- Yao T, Wang Y, Zhu B, Wei D, Yang Y, Han X. 4D printing and collaborative design of highly flexible shape memory alloy structures: a case study for a metallic robot prototype. Smart Materials & Structures 2021, 50, 015018. [Google Scholar]

- Jaiganesh V, Christopher A, Mugilan E. Manufacturing of PMMA cam shaft by rapid prototyping. Procedia Engineering 2014, 97, 2127–2135. [Google Scholar] [CrossRef]

- Wu X, Huang W, Ding Z, Tan H, Yang W, Sun K. Characterisation of the thermoresponsive shape memory effect in poly(ether ether ketone) (PEEK). J Applied Polymer Science 2014, 2014, 39844. [Google Scholar]

- Grassi G, Sparrman B, Paoletti I, Tibbits S. 4D soft materials. Proc 2021 DigitalFutures 2022, 201–210. [Google Scholar]

- Conrad S, Speck T, Tauber F. Multi-material FDM 3D printed arm with integrated pneumatic actuator. Lecture Notes in AI 2022, 13548, 27–31. [Google Scholar]

- Faris O, Tawk C, Hussain I. SoPCAS finger: a three-dimensional printed soft finger with pneumatic chambers for simultaneous actuation, sensing and controlled grasping. ,Robotics Reports 2024, 2.1, 32–42. [Google Scholar]

- Kumar S, Chen P-Y, Ren H. Review of printable flexible and stretchable tactile sensors. Research 2019, 2019, 3018568. [Google Scholar]

- Robinson S, O’Brien K, Zhao H, Peele B, Larson C, MacMurray B, van Meerbeek I, Dunham S, Shepherd R. Integrated soft sensors and elastomeric actuators for tactile machines with kinaesthetic sense. Extreme Mechanics Letters 2015, 5, 47–53. [Google Scholar] [CrossRef]

- Othman W, Lai Z-H, Abril C, Barajas-Gamboa J, Corcelles R, Kroh M, Qasaimeh M. Tactile sensing for minimally invasive surgery: conventional methods and potential emerging tactile technologies. Frontiers in Robotics & AI 2022, 8, article 705662. [Google Scholar]

- Cui H, Yao D, Hensleigh R, Lu H, Calderon A, Xu Z, Davaria S, Wang Z, Mercier P, Tarazanga P, Zheng X. Design and printing of proprioceptive three-dimensional architected robotic metamaterials. Science 2022, 376, 1287–1293. [Google Scholar] [CrossRef]

- Ge O, Sakhaei H, Dunn C, Fang N, Dunn M. Multimaterial 4D printing with tailorable shape memory polymers. Scientific Reports 2016, 6, 31110. [Google Scholar] [CrossRef]

- Rafsanjani A. Turning materials into robots. Science 2022, 376, 1272–1273. [Google Scholar] [CrossRef]

- Aubin C, Heisser R, Pretz O, Timko J, Lo J, Helbling F, Sobhani S, Gat A, Shepherd R. Powerful, soft combustion actuators for insect-scale robots. Science 2023, 381, 121–1217. [Google Scholar]

- Hawkes E, Xiao C, Peloquin R-A, Keeley C, Begley M, Pope M, Niemeyer G. Engineered jumpers overcome biological limits via work multiplication. Nature 2022, 604, 611–657. [Google Scholar]

- Bergbreiter S. Jumping robot bests biology. Nature 2022, 604, 627–629. [Google Scholar] [CrossRef]

- Moses M, Chirikjian M (2011) “Design of an electromagnetic actuator suitable for production by rapid prototyping” Proc ASME Int Design Engineering Technical Conf & Computers and Information in Engineering Conf, DETC2011-48602.

- Bugeja C. Printable motor. IEEE Spectrum 2018, 18–19. [Google Scholar]

- Burr R. Printed motor: a new approach to intermittent and continuous motion devices in data processing equipment. Proc IRE-AIEE-ACM Computer Conf 1960, 6.5, 325–342. [Google Scholar]

- Gyani G; Parkash O. Design and technological aspects of printed motor armatures. IEE-IERE Proc – India 1977, 64–68. [Google Scholar]

- Gambetta D; Ahfock A. Designing printed circuit stators for brushless permanent magnet motors. IET Electrical Power Applications 2009, 3, 482–490. [Google Scholar] [CrossRef]

- Maamer B, Tounsi F, Kaziz S, Jaziri N, Boughamoura A. Halbach cylinder-based system for energy harvesting from rotational motion for high power density. Sensors & Actuators A: Physical 2022, 337, 113428. [Google Scholar]

- Kim Y, Yuk H, Zhao R, Chester S, Zhao X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef]

- Paranthaman P, Shafer C, Elliott A, Siddel D, McGuire M, Springfield R, Martin J, Fredette R, Ormerod J. Binder jetting: a novel NdFeB bonded magnet fabrication process. J Minerals, Metals & M Materials Society 2016, 68, 1978–1982. [Google Scholar]

- Ki L, Tirado A, Conner B, Chi M, Elliott A, Rios O, Zhou H, Paranthaman P. Novel method combining additive manufacturing and alloy infiltration for NdFeB magnet fabrication. J Magnetism & Magnetic Materials 2017, 438, 163–167. [Google Scholar]

- Pham T, Do T, Jwon P, Foster S. Additive manufacturing of high performance ferromagnetic materials. Proc IEEE Energy Conversion Congress & Exposition 2018, Portland, 4303–4308. [Google Scholar]

- Han L, Maccarri F, Filho I, Peter N, Wei Y, Gault B, Gutfleisch O, Li Z, Raabe D. Mechanically strong and ductile soft magnet with extremely low coercivity. Nature 2022, 608, 310–316. [Google Scholar] [CrossRef] [PubMed]

- Elaskri A, Ellery A (2018) “Developing techniques to 3D print electric motors” Proc Int Symp Artificial Intelligence Robotics and Automation in Space, Madrid, Spain.

- llery A, Elaskri A (2025) “3D printing modules for self-assembling space systems” in press with Progress in Aerospace Sciences.

- Li L, Tirado A, Nlebedim I, Rios O, Post B, Kinc V, Lowden R, Lara-Curzio E, Fredette R, Ormerod J, Lograsso T, Paranthaman P. Big area additive manufacturing of high performance bonded NdFeB magnets. Nature Scientific Reports 2016, 6, 36212. [Google Scholar] [CrossRef]

- Nlebedim I, Ucar H, Hatter C, MCallum R, McCall S, Kramer M, Paranthaman P (2017) “Studies on in-situ magnetic alignment of bonded Nd-Fe-B alloy powders” J Magnetism & Magnetic Materials 422, 168-173 Nlebedim I, Ucar H, Hatter C, MCallum R, McCall S, Kramer M, Paranthaman P (2017) “Studies on in-situ magnetic alignment of bonded Nd-Fe-B alloy powders” J Magnetism & Magnetic Materials 422, 168-173.

- Li L, Jones K, Sales B, Pries J, Nlebedim I, Jin K, Bei H, Post B, Kesler M, Rios O, Kune V, Fredette R, Ormerod J, Williams A, Lograsso T, Paranthaman P. Fabrication of highly dense isotropic NdFeB nylon bonded magnets via extrusion-based additive manufacturing. Additive Manufacturing 2018, 21, 495–500. [Google Scholar] [CrossRef]

- Hamitsch R, Belmann R, Stephan R. Small axial flux motor with permanent magnet excitation and etched airgap winding. IEEE Trans Magnetics 1994, 30, 592–594. [Google Scholar] [CrossRef]

- Moreels D, Lijnen P. Turning the electric motor inside out. IEEE Spectrum 2019, 42–45. [Google Scholar]

- Guedes-Pinto P. Axial flux motor for an electrified world. IEEE Spectrum 2022, 38–43. [Google Scholar]

- Sochol R, Sweet E, Glick C, Wu S-Y, Yang C, Restaino M, Lin L. 3D printed microfluidics and microelectronics. Microelectronic Engineering 2018, 189, 52–68. [Google Scholar] [CrossRef]

- Elaskri A, Ellery A. 3D printed electric motors as a step towards self-replicating machines. Proc Int Symp Artificial Intelligence, Robotics and Automation in Space 2020, paper no 5020. [Google Scholar]

- Canada J, Kim H, Velasquez-Garcia F. Three-dimensional soft magnetic cored solenoids via multi-material extrusion. Virtual & Physical Prototyping 2024, 19, e2310046. [Google Scholar]

- Ellery A. Are 3D printers universal constructors? In Proc ASCE Earth & Space Conf; Florida International University: Miami, FL, USA, 2024; p. paper 3666. [Google Scholar]

- Hasanov S, Alkunte S, Rajeshirke M, Gupta A, Huseynov O, Fidan I, Alifui-Segbaya F, Rennie A. Review on additive manufacturing of multi-material parts: progress and challenges. J Manufacturing & Materials Processing 2022, 6, 4. [Google Scholar]

- Hofmann D, Kolodziejska J, Otis R, Liu Z-K, Borgonia J-P. Compositionally graded metals: a new frontier of additive manufacturing. J Materials Research 2014, 29, 1899–1910. [Google Scholar] [CrossRef]

- Shahbazi M, Jager H, Ettelaie R, Mohammadi A, Kashi A. Multimaterial 3D printing of self-assembling smart thermo-responsive polymers into 4D printed objects: a review. Additive Manufacturing 2023, 71, 103598. [Google Scholar] [CrossRef]

- Tan W, Choong C, Kuo N, Low Y, Chua K. 3D printed electronics: processes, materials and future trends. Progress in Materials Science 2022, 27, 100945. [Google Scholar]

- Sowade E, Polomoshnov M, Willert A, Baumann R. Toward 3D printed electronics: inkjet-printed vertical metal wire interconnects and screen-printed batteries. Advances in Engineering Materials 2019, 21, 1900568. [Google Scholar] [CrossRef]

- Lin z, Li T, Yang S, Ji B, Wang Z. Revolutionising flexible electronics with liquid metal innovations. Device 2024, 2, 100331. [Google Scholar] [CrossRef]

- Kim C, Sullivan C, Hillstrom A, Wicker R. Intermittent embedding of wire into 3D prints for wireless power transfer. Int J Precision Engineering & Manufacturing 2021, 22, 919–931. [Google Scholar]

- Rafiee M, Farahani R, Therriault D. Multi-material 3D and 4D printing: a survey. Advanced Science 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Xu S, Ahmed S, Momin M, Hossain A, Zhiu T. Unleashing the potential of 3D printing soft materials. Device 2023, 1, 100067. [Google Scholar] [CrossRef]

- Hardin J, Grabowski C, Lucas M, Durstock M, Berrigan D. All-printed multilayer high voltage capacitors with integrated processing feedback. Additive Manufacturing 2019, 27, 327–333. [Google Scholar] [CrossRef]

- Yan A, Yuan X, Li Z, Yang J, Ren K, Dong S. 3D printed flexible, multilayered ceramic-polymer composite grid with integrated structural self-sensing function. Sensors & Actuators A Physical 2921, 332, 113187. [Google Scholar]

- MacCurdy R, Katzschmann R, Kim Y, Rus D. Printable hydraulics: a method for fabricating robots by 3D co-printing solids and liquids. Proc IEEE Int Conf Robotics & Automation 2016, 3878–3885. [Google Scholar]

- Bartlett N, Tolley M, Overveide J, Weaver J, Mosadegh B, Bertoldi K, Whitesides G, Wood R. 3D printed functionally graded soft robot powered by combustion. Science 2015, 349, 161–165. [Google Scholar] [CrossRef]

- Zheng B, Xie Y, Xu S, Meng A, Wang S, Wu Y, Yang S, Wan C, Huang G, Tour J, Lin J. Programmed multimaterial assembly by synergized 3D printing and freeform laser induction. Nature Communications 2024, 15, 4541. [Google Scholar] [CrossRef]

| Permanent magnetic material | BHmax | Coercive force (kA/m) |

|---|---|---|

| NdFeB | 10-40 | 750-2000 |

| Ferrite | 3.5 | 100-300 |

| Alnico 1 or 2 | 5.5 | 37-45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).