Submitted:

03 October 2025

Posted:

06 October 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Test Methods

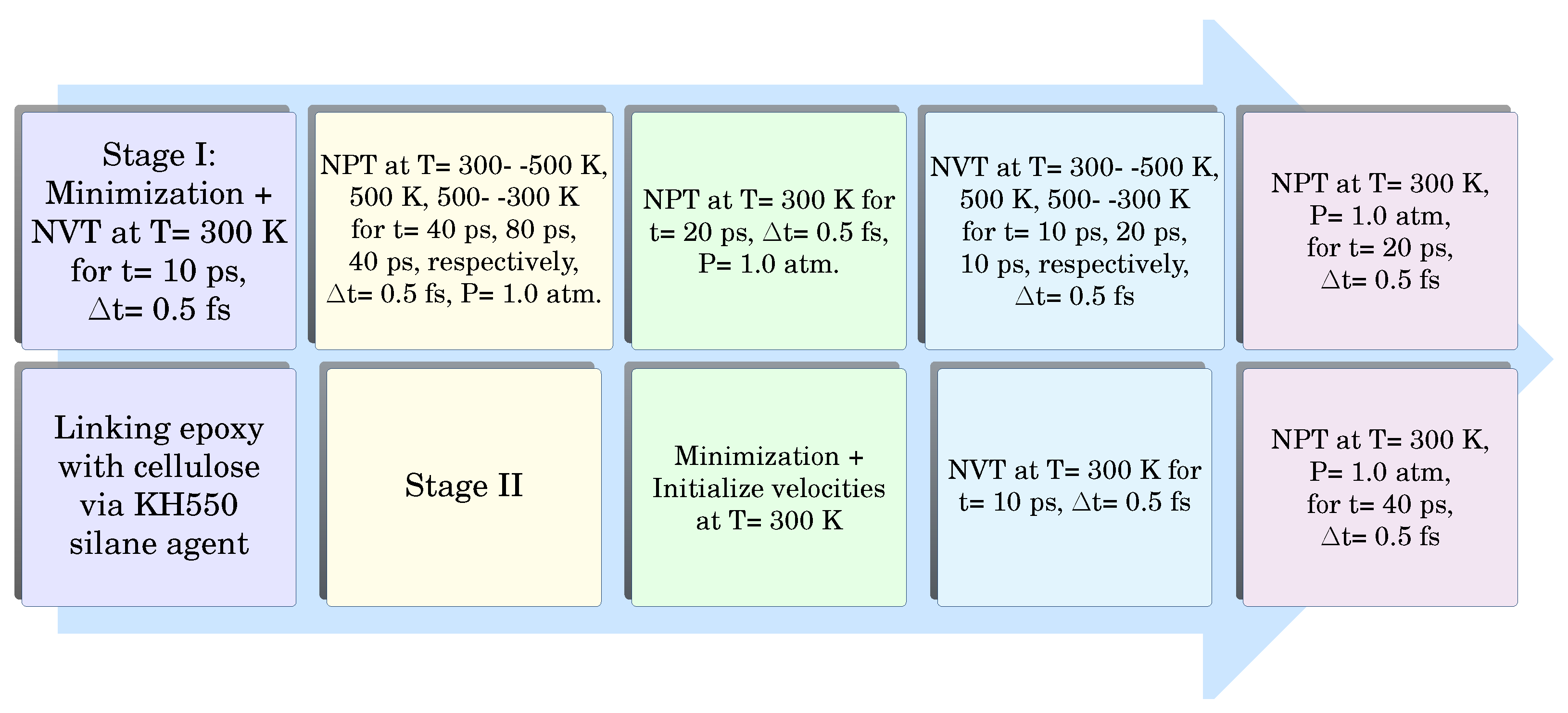

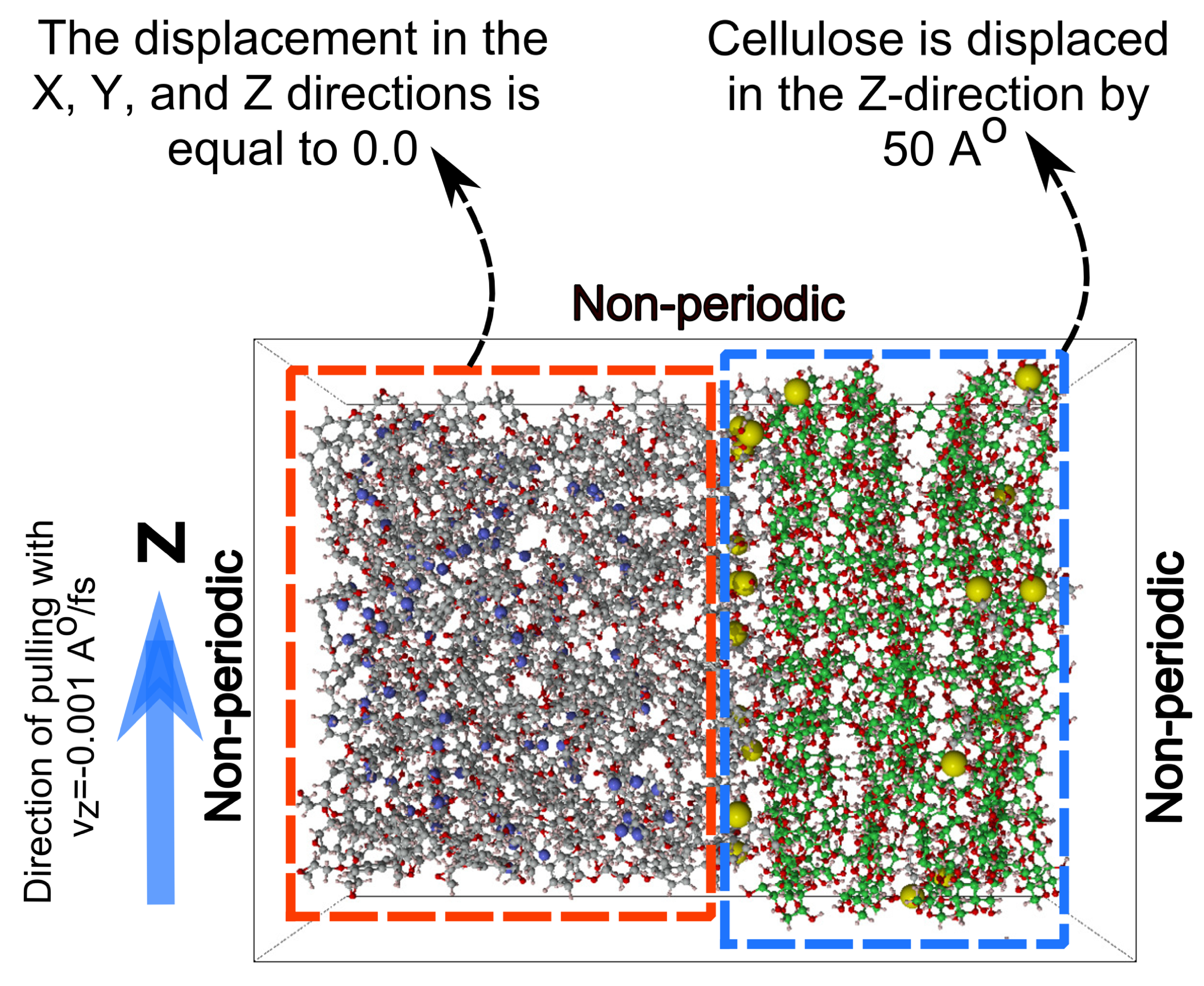

2.1. Molecular Dynamics Simulation

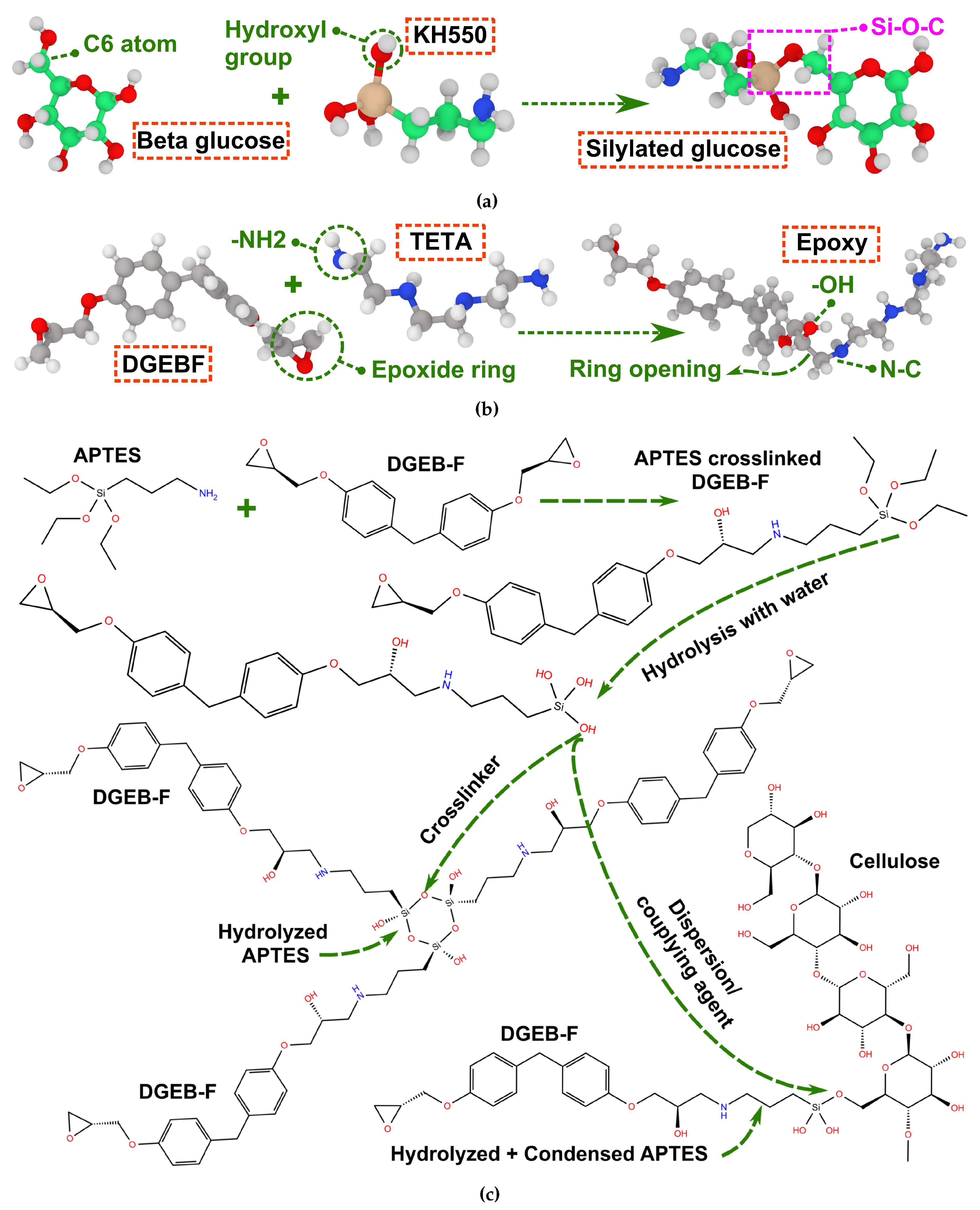

2.2. Reinforcing Epoxy with Silylated Cellulose

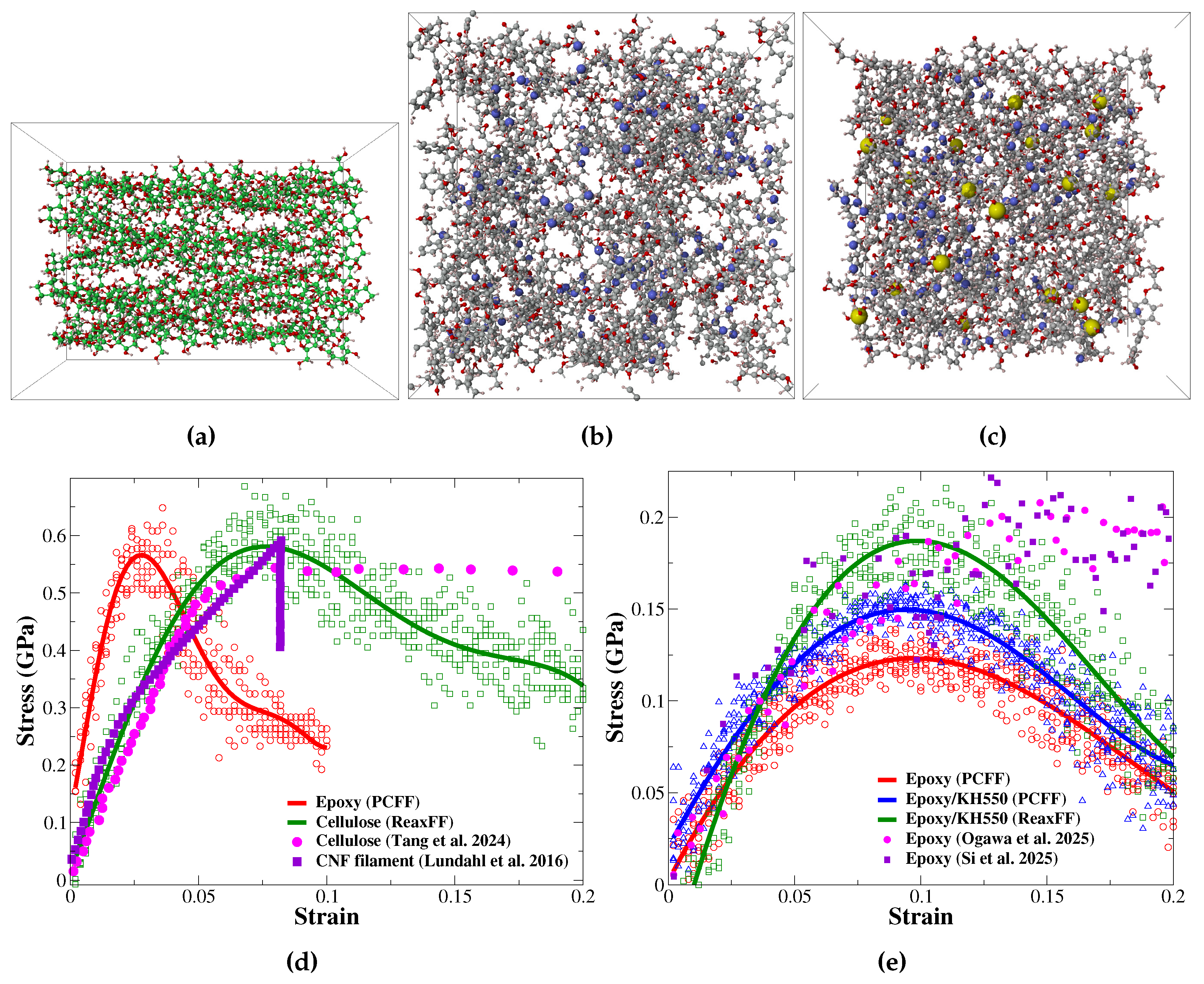

3. Results and Discussion

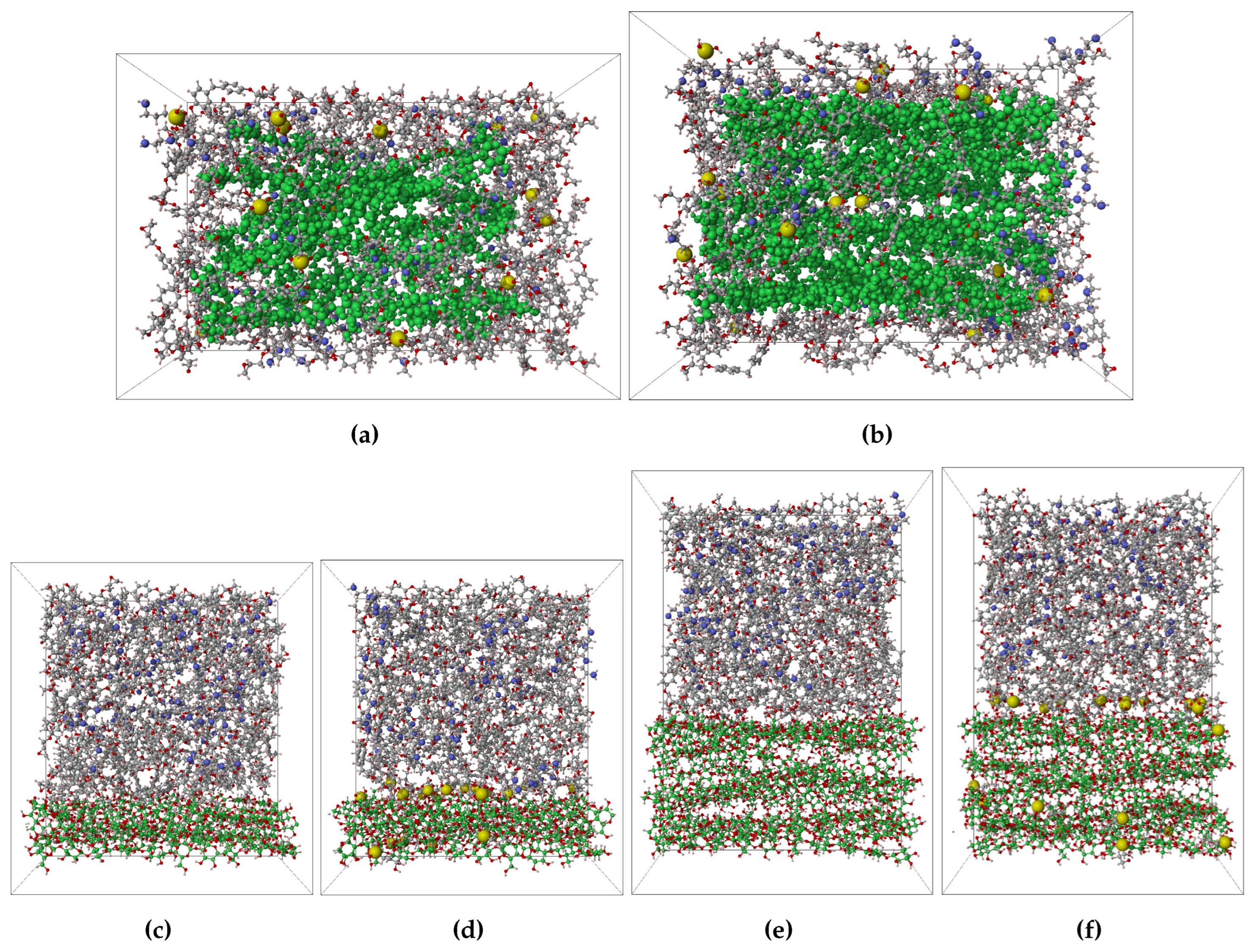

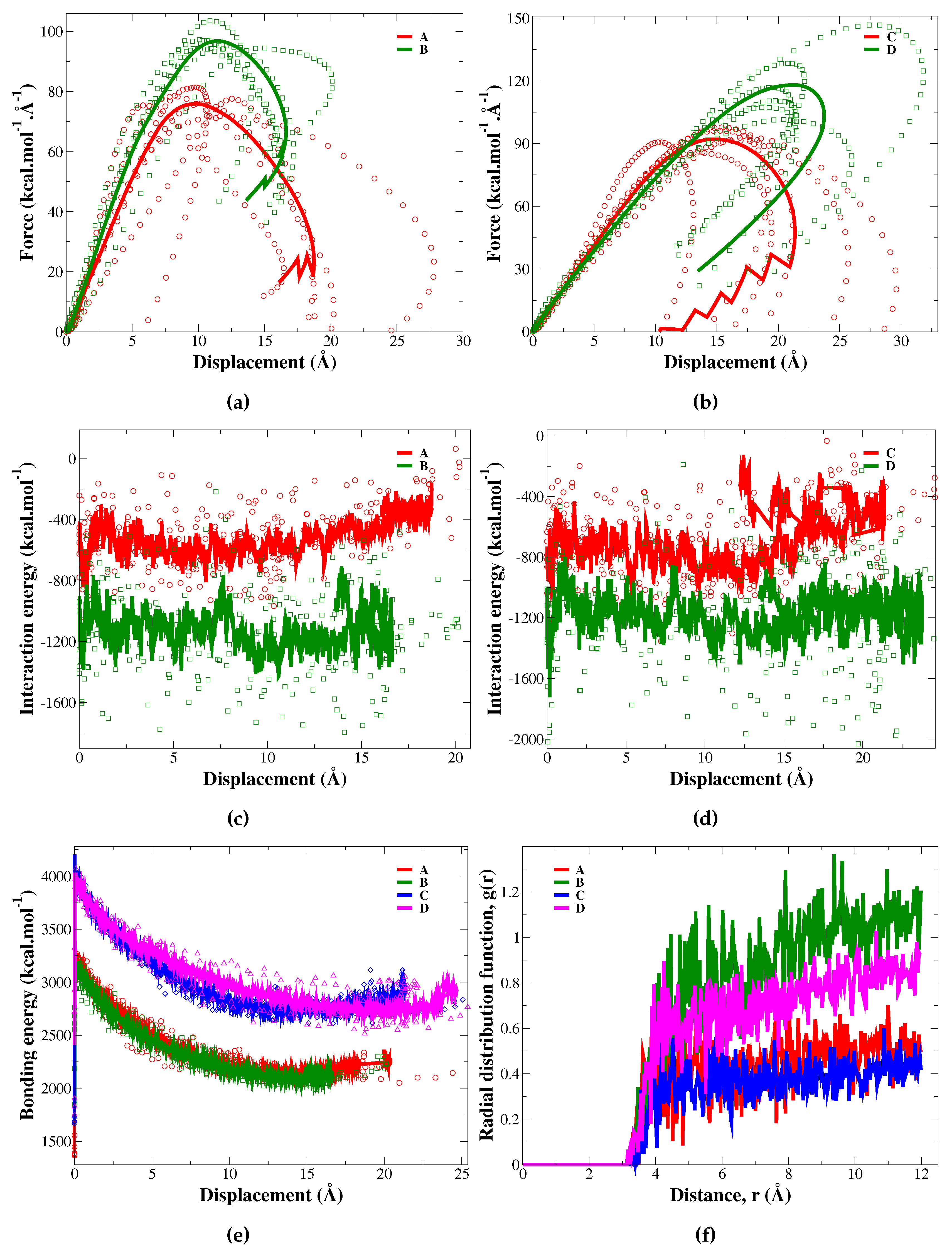

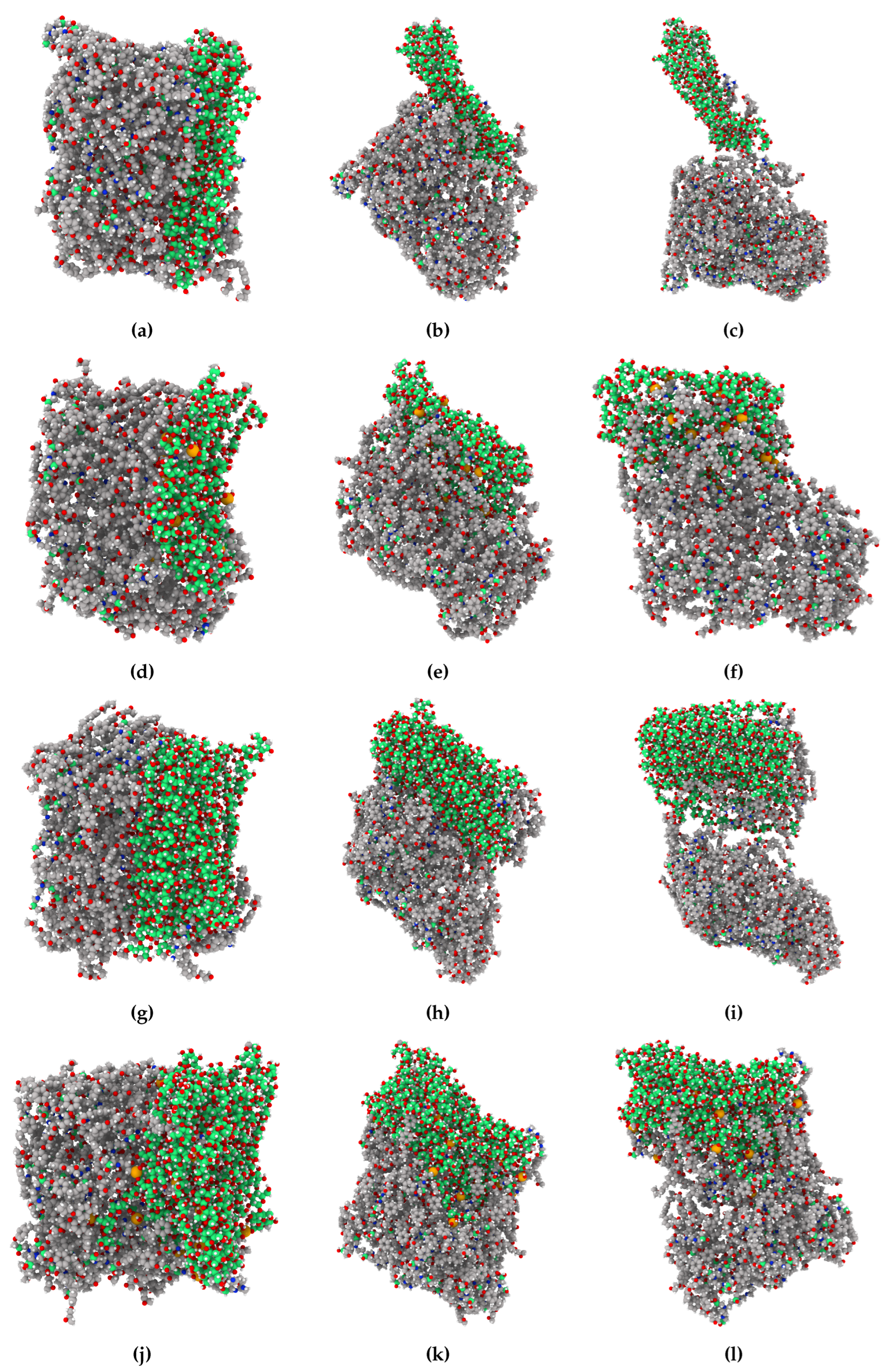

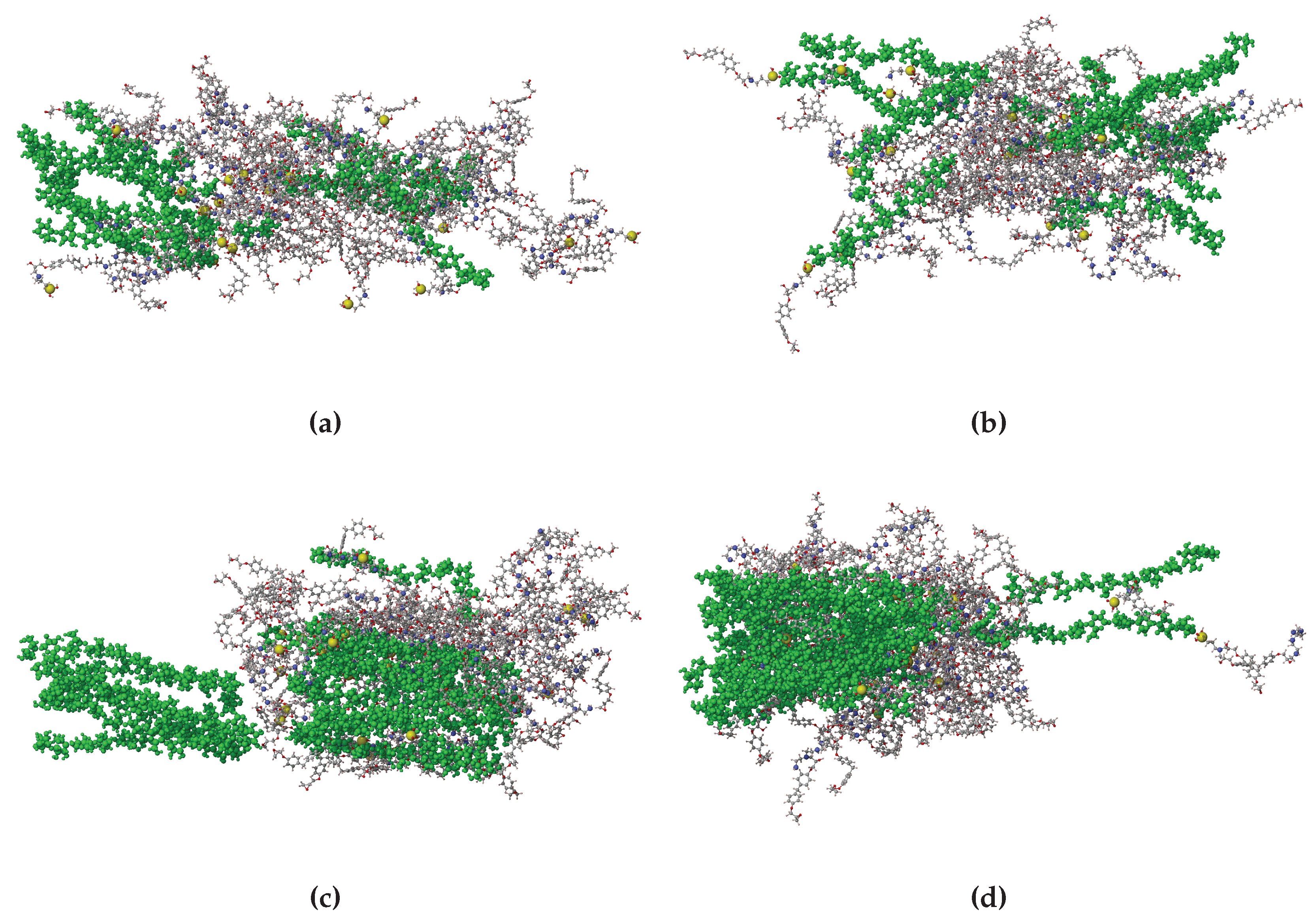

3.1. The Effect of Silylation Treatment on the Interfacial Adhesion

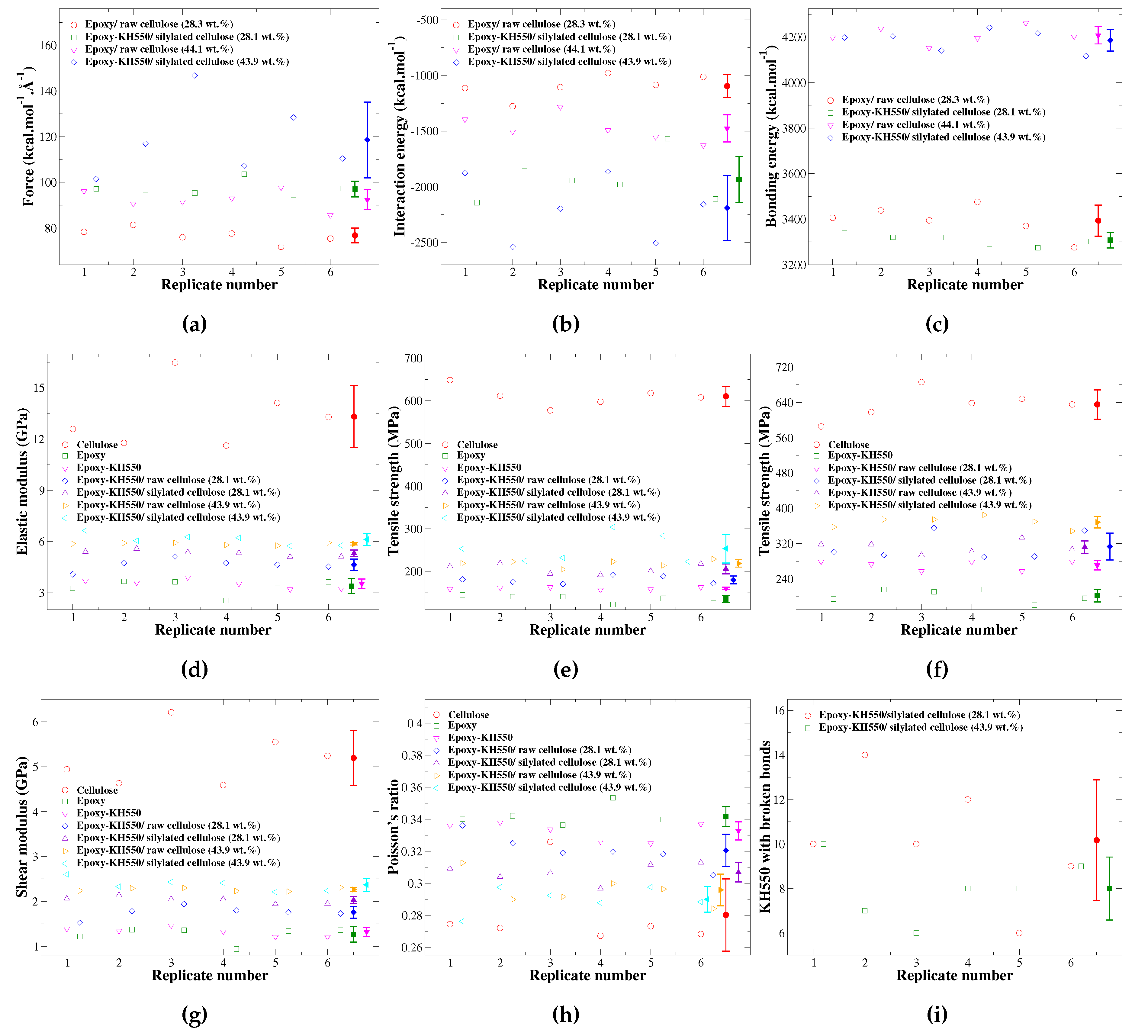

3.2. The Structural Reinforcing Effect of Cellulose at High Loadings

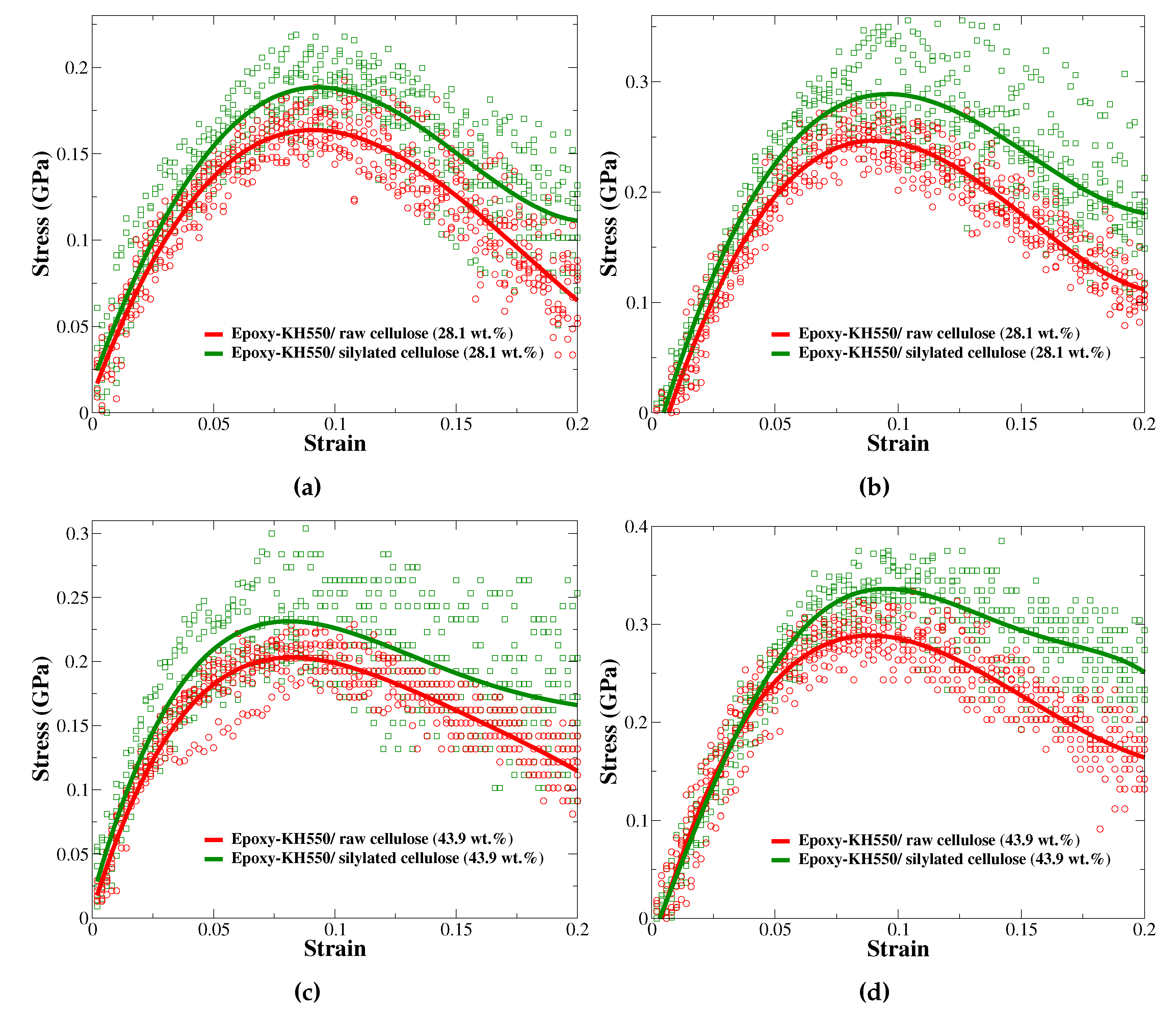

3.3. The Effect of Cellulose Silylation on the Mechanical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ren, Z.; Guo, R.; Zhou, X.; Bi, H.; Jia, X.; Xu, M.; Wang, J.; Cai, L.; Huang, Z. Effect of amorphous cellulose on the deformation behavior of cellulose composites: molecular dynamics simulation. Rsc Advances 2021, 11, 19967–19977. [Google Scholar] [CrossRef] [PubMed]

- Jakob, M.; Mahendran, A.R.; Gindl-Altmutter, W.; Bliem, P.; Konnerth, J.; Müller, U.; Veigel, S. The strength and stiffness of oriented wood and cellulose-fibre materials: A review. Progress in Materials Science 2022, 125, 100916. [Google Scholar] [CrossRef]

- Sirviö, J.A.; Lakovaara, M. A fast dissolution pretreatment to produce strong regenerated cellulose nanofibers via mechanical disintegration. Biomacromolecules 2021, 22, 3366–3376. [Google Scholar] [CrossRef]

- Subbotina, E.; Montanari, C.; Olsén, P.; Berglund, L.A. Fully bio-based cellulose nanofiber/epoxy composites with both sustainable production and selective matrix deconstruction towards infinite fiber recycling systems. Journal of Materials Chemistry A 2022, 10, 570–576. [Google Scholar] [CrossRef]

- Adusumali, R.B.; Reifferscheid, M.; Weber, H.; Roeder, T.; Sixta, H.; Gindl, W. Mechanical properties of regenerated cellulose fibres for composites. Macromolecular Symposia 2006, 244, 119–125. [Google Scholar] [CrossRef]

- Low, I.; McGrath, M.; Lawrence, D.; Schmidt, P.; Lane, J.; Latella, B.; Sim, K. Mechanical and fracture properties of cellulose-fibre-reinforced epoxy laminates. Composites Part A: Applied Science and Manufacturing 2007, 38, 963–974. [Google Scholar] [CrossRef]

- Mader, A.; Kondor, A.; Schmid, T.; Einsiedel, R.; Müssig, J. Surface properties and fibre-matrix adhesion of man-made cellulose epoxy composites – Influence on impact properties. Composites Science and Technology 2016, 123, 163–170. [Google Scholar] [CrossRef]

- Hameed, N.; Bavishi, J.; Parameswaranpillai, J.; Salim, N.; Joseph, J.; Madras, G.; Fox, B. Thermally flexible epoxy/cellulose blends mediated by an ionic liquid. RSC Advances 2015, 5, 52832–52836. [Google Scholar] [CrossRef]

- Saba, N.; Mohammad, F.; Pervaiz, M.; Jawaid, M.; Alothman, O.; Sain, M. Mechanical, morphological and structural properties of cellulose nanofibers reinforced epoxy composites. International Journal of Biological Macromolecules 2017, 97, 190–200. [Google Scholar] [CrossRef]

- Yusuf, J.; Sapuan, S.; Rashid, U.; Ilyas, R.; Hassan, M. Thermal, mechanical, and morphological properties of oil palm cellulose nanofibril reinforced green epoxy nanocomposites. International Journal of Biological Macromolecules 2024, 278, 134421. [Google Scholar] [CrossRef]

- Masoodi, R.; El-Hajjar, R.; Pillai, K.; Sabo, R. Mechanical characterization of cellulose nanofiber and bio-based epoxy composite. Materials & Design (1980-2015) 2012, 36, 570–576. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, Y. Dispersion characterizations and adhesion properties of epoxy composites reinforced by carboxymethyl cellulose surface treated carbon nanotubes. Powder Technology 2022, 404, 117505. [Google Scholar] [CrossRef]

- Adil, S.; Kumar, B.; Panicker, P.S.; Pham, D.H.; Kim, J. High-performance green composites made by cellulose long filament-reinforced vanillin epoxy resin. Polymer Testing 2023, 123, 108042. [Google Scholar] [CrossRef]

- Tüfekci, M. Nonlinear dynamic mechanical and impact performance assessment of epoxy and microcrystalline cellulose-reinforced epoxy. Polymers 2024, 16, 3284. [Google Scholar] [CrossRef] [PubMed]

- Nair, S.S.; Dartiailh, C.; Levin, D.B.; Yan, N. Highly toughened and transparent biobased epoxy composites reinforced with cellulose nanofibrils. Polymers 2019, 11, 612. [Google Scholar] [CrossRef]

- Nair, S.S.; Kuo, P.Y.; Chen, H.; Yan, N. Investigating the effect of lignin on the mechanical, thermal, and barrier properties of cellulose nanofibril reinforced epoxy composite. Industrial Crops and Products 2017, 100, 208–217. [Google Scholar] [CrossRef]

- Nissilä, T.; Hietala, M.; Oksman, K. A method for preparing epoxy-cellulose nanofiber composites with an oriented structure. Composites Part A: Applied Science and Manufacturing 2019, 125, 105515. [Google Scholar] [CrossRef]

- Kim, H.C.; Panicker, P.S.; Kim, D.; Adil, S.; Kim, J. High-strength cellulose nanofiber/graphene oxide hybrid filament made by continuous processing and its humidity monitoring. Scientific Reports 2021, 11, 13611. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I. Mechanical properties and water absorption behaviour of recycled cellulose fibre reinforced epoxy composites. Polymer Testing 2012, 31, 620–628. [Google Scholar] [CrossRef]

- Voicu, S.I.; Thakur, V.K. Aminopropyltriethoxysilane as a linker for cellulose-based functional materials: New horizons and future challenges. Current Opinion in Green and Sustainable Chemistry 2021, 30, 100480. [Google Scholar] [CrossRef]

- Liu, F.; Huang, L.; Wang, B.; Hu, Z.; Zhang, C.; Lu, F. Molecular dynamics simulation study of the mechanical properties of silane coupling agent-enhanced glass fiber/epoxy resin interfaces. Polymer Composites 2025. [Google Scholar] [CrossRef]

- Khanjanzadeh, H.; Behrooz, R.; Bahramifar, N.; Gindl-Altmutter, W.; Bacher, M.; Edler, M.; Griesser, T. Surface chemical functionalization of cellulose nanocrystals by 3-aminopropyltriethoxysilane. International Journal of Biological Macromolecules 2018, 106, 1288–1296. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Guo, J.; Ren, H.; Jin, J.; He, H.; Jin, P.; Wu, Z.; Zheng, Y. Research progress of nanocellulose-based food packaging. Trends in Food Science & Technology 2024, 143, 104289. [Google Scholar] [CrossRef]

- Kono, H.; Uno, T.; Tsujisaki, H.; Matsushima, T.; Tajima, K. Nanofibrillated bacterial cellulose modified with (3-aminopropyl)trimethoxysilane under aqueous conditions: Applications to poly(methyl methacrylate) fiber-reinforced nanocomposites. ACS Omega 2020, 5, 29561–29569. [Google Scholar] [CrossRef] [PubMed]

- Lu, T.; Jiang, M.; Jiang, Z.; Hui, D.; Wang, Z.; Zhou, Z. Effect of surface modification of bamboo cellulose fibers on mechanical properties of cellulose/epoxy composites. Composites Part B: Engineering 2013, 51, 28–34. [Google Scholar] [CrossRef]

- Rajan, R.; Rainosalo, E.; Thomas, S.P.; Ramamoorthy, S.K.; Zavašnik, J.; Vuorinen, J.; Skrifvars, M. Modification of epoxy resin by silane-coupling agent to improve tensile properties of viscose fabric composites. Polymer Bulletin 2018, 75, 167–195. [Google Scholar] [CrossRef]

- Rajan, R.; Rainosalo, E.; Ramamoorthy, S.K.; Thomas, S.P.; Zavašnik, J.; Vuorinen, J.; Skrifvars, M. Mechanical, thermal, and burning properties of viscose fabric composites: Influence of epoxy resin modification. Journal of Applied Polymer Science 2018, 135, 46673. [Google Scholar] [CrossRef]

- Bamer, F.; Ebrahem, F.; Markert, B. Athermal mechanical analysis of Stone-Wales defects in two-dimensional silica. Computational Materials Science 2019, 163, 301–307. [Google Scholar] [CrossRef]

- Bamer, F.; Ebrahem, F.; Markert, B.; Stamm, B. Molecular mechanics of disordered solids. Archives of Computational Methods in Engineering 2023, 30, 2105–2180. [Google Scholar] [CrossRef]

- Mostafavi, S.; Bamer, F.; Markert, B. Molecular dynamics simulation of interface atomic diffusion in ultrasonic metal welding: Effect of crystal orientation and sliding velocity. The International Journal of Advanced Manufacturing Technology 2022, 118, 2339–2353. [Google Scholar] [CrossRef]

- Liu, T.; Li, K.; Zhou, A.; Yu, Z.; Qin, R.; Zou, D. Atomic insight into the functionalization of cellulose nanofiber on durability of epoxy nanocomposites. Nano Research 2023, 16, 3256–3266. [Google Scholar] [CrossRef]

- Al-Maharma, A.; Markert, B.; Bamer, F. Silylation Treatment of C/Sic Reinforced Cellulose Nanocomposites to Mitigate the Adverse Impact of Moisture on the Mechanical Performance, [https://ssrn.com/abstract=4855671]. [CrossRef]

- Wang, Y.; Kiziltas, A.; Blanchard, P.; Walsh, T.R. Probing functionalized cellulose/polypropylene interfacial properties at the molecular scale. ACS Sustainable Chemistry & Engineering 2025, 0, null. [Google Scholar] [CrossRef]

- ou Ruan, H.; hao Wang, W.; Umemoto, T.; ze Song, Y.; Kumada, A.; Sato, M. Tailoring multi-scale interactions at resin-layer interfaces for simultaneous enhancement of electrical and mechanical strength in aramid paper laminates. Composites Part A: Applied Science and Manufacturing 2025, 198, 109146. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, J.; Song, Y.; Jia, D.; Sun, G.; Wang, C. Effect of alkali treatment and silane functionalization on cellulose fibers: Experimental investigation, mechanism and molecular dynamics simulation. Applied Surface Science 2026, 716, 164716. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. Journal of Computational Physics 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Design, M. Material Exploration Design Analysis (MedeA) Release 3.6. https://www.materialsdesign.com, 2023. Accessed: 24 December 2024.

- Vashisth, A.; Ashraf, C.; Zhang, W.; Bakis, C.E.; van Duin, A.C.T. Accelerated ReaxFF simulations for describing the reactive cross-linking of polymers. The Journal of Physical Chemistry A 2018, 122, 6633–6642. [Google Scholar] [CrossRef]

- Newsome, D.A.; Sengupta, D.; Foroutan, H.; Russo, M.F.; van Duin, A.C.T. Oxidation of silicon carbide by O2 and H2O: A ReaxFF reactive molecular dynamics study, Part I. The Journal of Physical Chemistry C 2012, 116, 16111–16121. [Google Scholar] [CrossRef]

- Zhang, X.; Tschopp, M.A.; Horstemeyer, M.F.; Shi, S.Q.; Cao, J. Mechanical properties of amorphous cellulose using molecular dynamics simulations with a reactive force field. International Journal of Modelling, Identification and Control 2013, 18, 211–217. [Google Scholar] [CrossRef]

- Mileo, P.G.M.; Krauter, C.M.; Sanders, J.M.; Browning, A.R.; Halls, M.D. Molecular-scale exploration of mechanical properties and interactions of poly(lactic acid) with cellulose and chitin. ACS Omega 2023, 8, 42417–42428. [Google Scholar] [CrossRef] [PubMed]

- Haque, E.; Kalaitzidou, K.; Wu, X. A molecular dynamics study of the effects of silane and cellulose nanocrystals at a glass fiber and epoxy interphase. Cellulose 2024, 31, 11243–11258. [Google Scholar] [CrossRef]

- Jiang, K.; Yan, Z.; Fang, W.; Zhang, Y. Molecular dynamics simulation on tensile behavior of cellulose at different strain rates. Advances in Materials Science and Engineering 2023, 2023, 7890912. [Google Scholar] [CrossRef]

- Uppal, N.; Pappu, A.; Gowri, V.K.S.; Thakur, V.K. Cellulosic fibres-based epoxy composites: From bioresources to a circular economy. Industrial Crops and Products 2022, 182, 114895. [Google Scholar] [CrossRef]

- Anderson, O.L. A simplified method for calculating the debye temperature from elastic constants. Journal of Physics and Chemistry of Solids 1963, 24, 909–917. [Google Scholar] [CrossRef]

- Zhao, H.; Chang, A.; Wang, Y. Structural, elastic, and electronic properties of cubic perovskite BaHfO3 obtained from first principles. Physica B: Condensed Matter 2009, 404, 2192–2196. [Google Scholar] [CrossRef]

- Chen, W.; Lickfield, G.C.; Yang, C.Q. Molecular modeling of cellulose in amorphous state. Part I: model building and plastic deformation study. Polymer 2004, 45, 1063–1071. [Google Scholar] [CrossRef]

- Lundahl, M.J.; Klar, V.; Wang, L.; Ago, M.; Rojas, O.J. Spinning of cellulose nanofibrils into filaments: A review. Industrial & Engineering Chemistry Research 2017, 56, 8–19. [Google Scholar] [CrossRef]

- Tang, J.; Wu, L.; Fan, X.; Dong, X.; Li, X.; Xie, Y.; Li, J.; Rao, J.; Li, T.; Gan, W. Superstrong, sustainable, origami wood paper enabled by dual-phase nanostructure regulation in cell walls. Science Advances 2024, 10, eado5142. [Google Scholar] [CrossRef]

- Si, J.S.; Wu, N.; Wen, M.J.; Chen, D.P.; He, Y.L.; Zhang, J.W.; Duan, K. Reactive machine learning force field for crosslinked epoxy. Chinese Journal of Polymer Science 2025. [Google Scholar] [CrossRef]

- Ogawa, M.; Morimura, A.; Haba, I.; Yonezu, A. Coarse-grained molecular dynamics simulations of nano-deformation behavior of epoxy adhesives’ interface during atomic force microscopy (AFM) mechanical testing. Polymer 2025, 320, 128071. [Google Scholar] [CrossRef]

- Gong, Y.; Zhang, L.; He, J.; Liu, B.; Wang, L.; Ao, Y.; Liu, Y.; Shang, L. Improving processability and mechanical properties of epoxy resins with biobased flame retardants. Polymer International 2024, 73, 646–657. [Google Scholar] [CrossRef]

- Hobbiebrunken, T.; Fiedler, B.; Hojo, M.; Tanaka, M. Experimental determination of the true epoxy resin strength using micro-scaled specimens. Composites Part A: Applied Science and Manufacturing 2007, 38, 814–818. [Google Scholar] [CrossRef]

- Cho, J.; Luo, J.; Daniel, I. Mechanical characterization of graphite/epoxy nanocomposites by multi-scale analysis. Composites Science and Technology 2007, 67, 2399–2407. [Google Scholar] [CrossRef]

- Santmarti, A.; Liu, H.W.; Herrera, N.; Lee, K.Y. Anomalous tensile response of bacterial cellulose nanopaper at intermediate strain rates. Scientific Reports 2020, 10, 15260. [Google Scholar] [CrossRef]

- Research, D.E.S. Schrödinger Release 2021-2: Desmond Molecular Dynamics System; www.schrodinger.com: New York, NY, 2021.

- Wang, X.; Tang, C.; Wang, Q.; Li, X.; Hao, J. Selection of optimal polymerization degree and force field in the molecular dynamics simulation of insulating paper cellulose. Energies 2017, 10, 1377. [Google Scholar] [CrossRef]

- Tang, Y.; Tang, C.; Hu, D.; Gui, Y. Effect of aminosilane coupling agents with different chain lengths on thermo-mechanical properties of cross-linked epoxy resin. Nanomaterials 2018, 8, 951. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, L.; Huang, W.; Rao, X.; Lu, Y.; Zhang, W.; Pan, S.; Yu, M. Molecular dynamics simulation of epoxy resin properties at different C=N contents. AIP Advances 2023, 13, 095013. [Google Scholar] [CrossRef]

- Watowich, S.J.; Meyer, E.S.; Hagstrom, R.; Josephs, R. A stable, rapidly converging conjugate gradient method for energy minimization. Journal of Computational Chemistry 1988, 9, 650–661. [Google Scholar] [CrossRef]

- Sayadi, S.; Brouillette, F. Silylation of phosphorylated cellulosic fibers with an aminosilane. Carbohydrate Polymers 2024, 343, 122500. [Google Scholar] [CrossRef]

- Martínez, L.; Andrade, R.; Birgin, E.G.; Martínez, J.M. PACKMOL: A package for building initial configurations for molecular dynamics simulations. Journal of Computational Chemistry 2009, 30, 2157–2164. [Google Scholar] [CrossRef]

- R, S.K.; Muralidharan, N.D. Mechanical characteristics study of chemically modified kenaf fiber reinforced epoxy composites. Journal of Natural Fibers 2022, 19, 2457–2467. [Google Scholar] [CrossRef]

- Suarsana, I.K.; Suryawan, I.; Suardana, N.; Winaya, S.; Soenoko, R.; Suyasa, B.; Sunu, P.W.; Rasta, I. Flexural strength of hybrid composite resin epoxy reinforced stinging nettle fiber with silane chemical treatment. AIMS Materials Science 2021, 8, 185–199. [Google Scholar] [CrossRef]

- Barari, B.; Ellingham, T.K.; Qamhia, I.; Pillai, K.M.; El-Hajjar, R.; Turng, L.S.; Sabo, R. Mechanical characterization of scalable cellulose nano-fiber based composites made using liquid composite molding process. Composites Part B: Engineering 2016, 84, 277–284. [Google Scholar] [CrossRef]

- Barari, B.; Omrani, E.; Dorri Moghadam, A.; Menezes, P.L.; Pillai, K.M.; Rohatgi, P.K. Mechanical, physical and tribological characterization of nano-cellulose fibers reinforced bio-epoxy composites: An attempt to fabricate and scale the ‘Green’ composite. Carbohydrate Polymers 2016, 147, 282–293. [Google Scholar] [CrossRef]

- Yang, J.P.; Chen, Z.K.; Yang, G.; Fu, S.Y.; Ye, L. Simultaneous improvements in the cryogenic tensile strength, ductility and impact strength of epoxy resins by a hyperbranched polymer. Polymer 2008, 49, 3168–3175. [Google Scholar] [CrossRef]

- Yang, J.; He, X.; Wang, H.; Liu, X.; Lin, P.; Yang, S.; Fu, S. High-toughness, environment-friendly solid epoxy resins: Preparation, mechanical performance, curing behavior, and thermal properties. Journal of Applied Polymer Science 2020, 137, 48596. [Google Scholar] [CrossRef]

- Mi, X.; Liang, N.; Xu, H.; Wu, J.; Jiang, Y.; Nie, B.; Zhang, D. Toughness and its mechanisms in epoxy resins. Progress in Materials Science 2022, 130, 100977. [Google Scholar] [CrossRef]

- Ansari, F.; Galland, S.; Johansson, M.; Plummer, C.J.; Berglund, L.A. Cellulose nanofiber network for moisture stable, strong and ductile biocomposites and increased epoxy curing rate. Composites Part A: Applied Science and Manufacturing 2014, 63, 35–44. [Google Scholar] [CrossRef]

- Rangaraj, R.; Sathish, S.; Mansadevi, T.L.D.; Supriya, R.; Surakasi, R.; Aravindh, M.; Karthick, A.; Mohanavel, V.; Ravichandran, M.; Muhibbullah, M.; et al. Investigation of weight fraction and alkaline treatment on Catechu Linnaeus/Hibiscus cannabinus/Sansevieria Ehrenbergii plant fibers-reinforced epoxy hybrid composites. Advances in Materials Science and Engineering 2022, 2022, 4940531. [Google Scholar] [CrossRef]

| Material | Molecular formula | Matrix composition | Cellulose (wt.%) | Number of atoms |

|---|---|---|---|---|

| Cellulose | C1200O1000H2040 | Cellulose chains: 20 | - | 4240 |

| Epoxy | C2394N152O456H2964 | Diglycidyl ether bisphenol F molecules: 114, TETA molecules: 38 |

- | 5966 |

| Epoxy/ cellulose (28.3 wt.%) | C2994N152O956H3984 | 28.3 | 8086 | |

| Epoxy/ cellulose (44.1 wt.%) | C3594N152O1456H5004 | 44.1 | 10206 | |

| Epoxy-KH550 | Si20C2330N140O500H2960 | Diglycidyl ether bisphenol F molecules: 110, TETA molecules: 30, KH550 molecules: 20 |

- | 5950 |

| Epoxy-KH550/ cellulose (28.1 wt.%) | Si20C2930N140O1000H3980 | 28.1 | 8050 | |

| Epoxy-KH550/ cellulose (43.9 wt.%) | Si20C3530N140O1500H5000 | 43.9 | 10170 |

| Material | Pulling force () |

Interaction energy () |

Bonding energy () |

|---|---|---|---|

| Epoxy/ raw cellulose (28.3 wt.%) | 76.8±3.4 | -1095.3±108.7 | 3393.4±71.7 |

| Epoxy-KH550/ silylated cellulose (28.1 wt%) | 97.1±3.6 | -1934.4±217.7 | 3307.8±36.1 |

| Epoxy/ raw cellulose (44.1 wt.%) | 92.5±4.5 | -1475.7±127.6 | 4208.1±39.9 |

| Epoxy-KH550/ silylated cellulose (43.9 wt.%) | 118.6±17.4 | -2190.8±307.1 | 4186.1±50 |

| Material | Elasticity (GPa) | Strength, ReaxFF (MPa) | Strength (MPa) | Shear modulus (GPa) | Poisson’s ratio |

|---|---|---|---|---|---|

| Cellulose | 13.31±1.90 | 635.31±34.84 | 610.31±24.63 | 5.19±0.65 | 0.28±0.02 |

| Epoxy-KH550 | 3.53±0.28 | 202.31±14.93 | 160.43±2.83 | 1.32±0.10 | 0.33±0.01 |

| Epoxy-KH550/ raw cellulose (28.1 wt.%) | 4.64±0.36 | 271.04±11.37 | 180.02±9.48 | 1.76±0.14 | 0.32±0.01 |

| Epoxy-KH550/ silylated cellulose (28.1 wt.%) | 5.31±0.19 | 313.43±32.17 | 205.86±12.50 | 2.03±0.08 | 0.31±0.01 |

| Epoxy-KH550/ raw cellulose (43.9 wt.%) | 5.87±0.08 | 312.08±14.75 | 218.69±8.93 | 2.27±0.04 | 0.30±0.01 |

| Epoxy-KH550/ silylated cellulose (43.9 wt.%) | 6.12±0.36 | 368.49±13.86 | 253.48±35.35 | 2.37±0.15 | 0.29±0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).