1. Introduction

Face turning is a widely used machining process for generating flat surfaces that are perpendicular to the rotational axis of a workpiece. It is commonly applied to components such as flanges, piston end faces, punches, and other parts requiring high flatness and surface uniformity. The key parameters that govern the face turning process include cutting speed (

vc), depth of cut (

ap), and feed rate (

fr). Among these, cutting speed plays a critical role, exerting a highly variable and difficult-to-control influence on cutting force, the formation of built-up edges, and the resulting surface quality as it strongly depends on the characteristics of the material being machined [

1,

2,

3]. Unlike cylindrical turning, where the cutting diameter remains constant, face turning involves a continuous change in cutting diameter (D

w) along the radial feed direction. As a result, the cutting speed varies depending on the position of the insert’s nose on the workpiece surface and is no longer a fixed value. It is calculated using the following equation:

Here,

Dw represents the instantaneous diameter at the cutting point, and

n is the spindle speed. As the cutting tool moves radially toward the center of the workpiece, the effective diameter decreases, leading to a corresponding reduction in cutting speed. Conversely, at the outer edge of the workpiece, the cutting speed is significantly higher due to the larger diameter. This variation in cutting speed across the face area results in inconsistencies in the cutting mechanism and surface quality. In particular, when machining near the center, the cutting speed can become very low, often leading to increased surface roughness and degraded surface quality.

While face turning is commonly encountered in practical machining tasks, especially for producing flat surfaces on rotational parts, it has received less in-depth research compared to cylindrical, conical, or thread turning. This is partly due to its relatively specific application scope and the complexities introduced by the variation in cutting speed across the machined surface. In components such as pipe flanges, where the center contains a large hole, the reduction in cutting speed near the center is acceptable, allowing surface quality to be maintained. However, for solid shafts or punch tip that require machining all the way to the center, the issue becomes more critical, as the cutting speed near the center approaches zero, often resulting in poor surface finish and inconsistent cutting behavior.

Ultrasonic-assisted turning (UAT) has been demonstrated to effectively improve surface finish and reduce cutting forces, particularly for machining difficult-to-cut materials such as nickel-based alloys [

4,

5], composite materials [

6,

7,

8], and even low-carbon steels [

9]. The fundamental principle of UAT involves superimposing high-frequency ultrasonic vibration onto the cutting tool, resulting in an intermittent cutting mechanism that contributes to the observed improvements. When the vibration is applied in the direction of the cutting speed, the instantaneous cutting speed

vins oscillates around the conventional cutting speed

vc, with an amplitude of 2π

Af, where

A is the vibration amplitude and

f is the vibration frequency [

10]. This relationship is described by the following equation:

If the conventional cutting speed is lower than 2π

Af, there will be time intervals during which the instantaneous cutting speed becomes zero or negative, resulting in intermittent cutting. This phenomenon can significantly reduce cutting forces and enhance surface quality; however, the material removal rate (MRR) is reduced due to the lower cutting speed, leading to longer machining times [

11,

12]. Most recent studies apply UAT within low cutting speed region to maximize reductions in cutting forces and surface roughness [

13,

14,

15]. Nevertheless, this restricts its applicability in industrial settings, where productivity is a critical factor. Recent research has begun to explore UAT at cutting speeds exceeding the critical threshold 2π

Af, but these studies have primarily focused on cylindrical turning [

16] or face turning at low spindle speeds [

17,

18], without specifically addressing surface quality in high-speed ultrasonic-assisted face turning

Therefore, this work aims to investigate the effect of ultrasonic vibration applied in the direction of cutting speed on surface homogeneity during face turning of C45 steel workpiece, within a spindle speed range of up to 1300 rpm. In particular, the experiments focus on evaluating improvements in surface roughness and structural characteristics near the central region of the workpiece, where machining quality is often significantly degraded due to extremely low cutting speeds.

2. Experimental Setup and Results

2.1. Experimental Setup

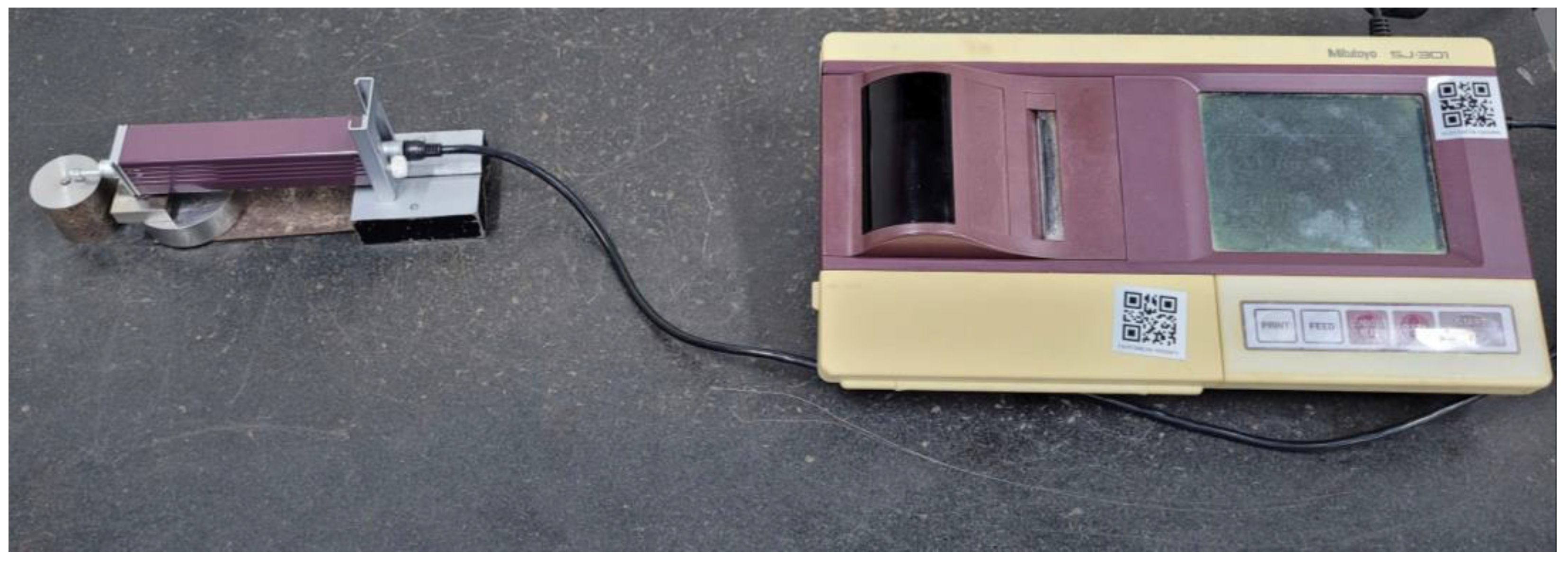

To investigate the effect of ultrasonic vibration on surface integrity in face turning, a series of experiments were conducted on a retrofitted conventional lathe (OKK Ramo). The experimental setup consisted of a vibration module delivering longitudinal ultrasonic excitation at 20 kHz frequency and 10 µm amplitude directly coupled to the turning insert. C45 steel shafts were used as workpiece material, while carbide inserts with a nose radius of 0.8 mm were selected from Dormer Pramet to ensure consistency across tests. The cutting parameters (spindle speed, feed rate, and depth of cut) were varied systematically as listed in

Table 1. Surface roughness was measured using a 2D roughness tester (Mitutoyo SJ-301), and surface integrity was observed via digital microscope (Keyence VHX 7000). Each roughness and vibration measurement were repeated three times to ensure repeatability.

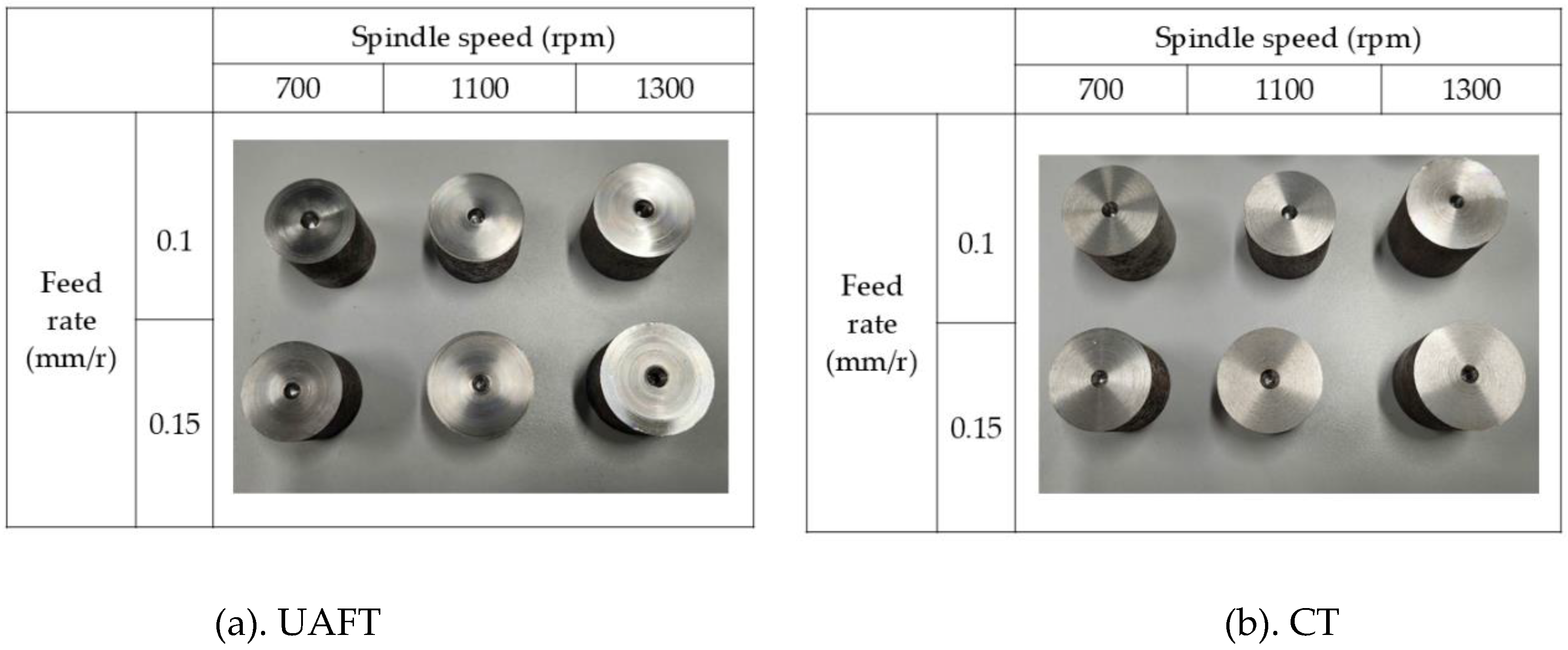

After the face turning process was completed, the samples were sectioned as illustrated in

Figure 1, and surface roughness was measured as shown in

Figure 2.

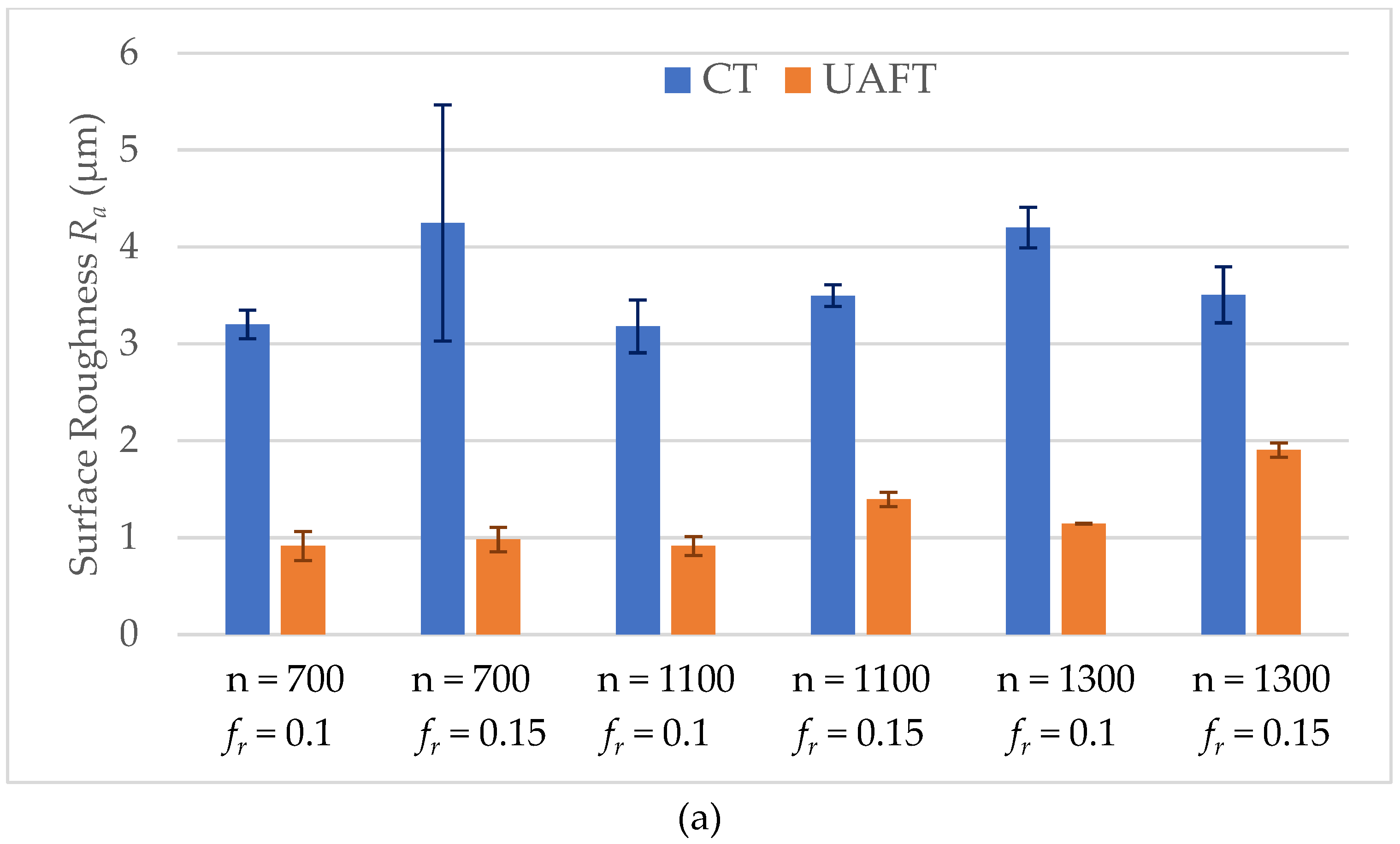

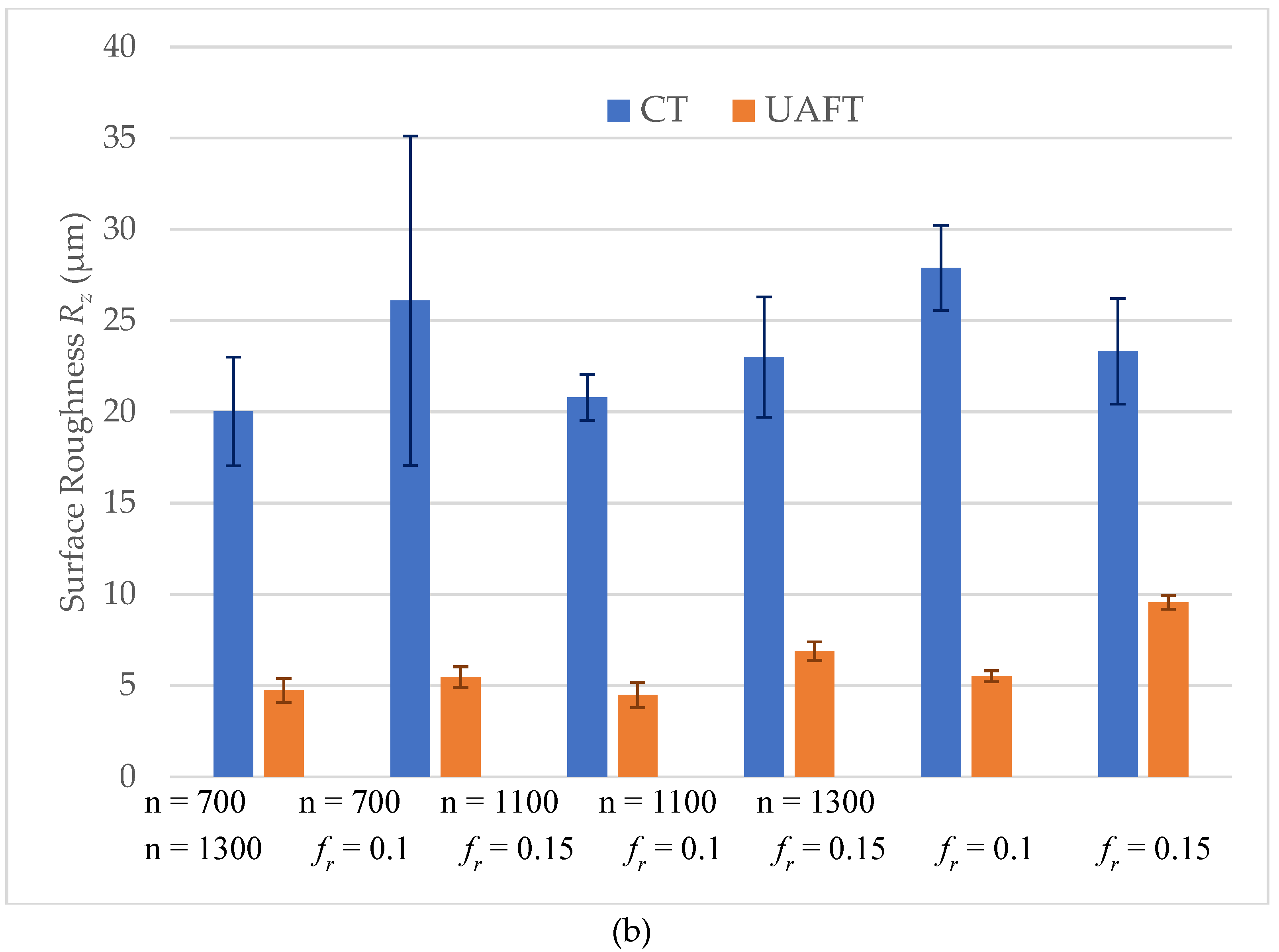

2.2. Surface Roughness

The resulting

Ra and

Rz values are presented in

Figure 3. From the graphs, the following observations can be made: In the conventional turning (CT) method, surface roughness exhibited minimal variation with spindle speed in the range of 700 to 1300 rpm. This is because roughness was measured in the radial direction, which is perpendicular to the tool path. Since the actual cutting speed gradually decreases from the outer diameter toward the center, and the speeds within this range are insufficient to overcome built-up edge (BUE) formation - the primary cause of poor surface finish of medium carbon steel [

19,

20]. In the ultrasonic-assisted face turning (UAFT) method, surface roughness was strongly influenced by both cutting speed and feed rate. When the cutting speed was lower than the critical speed (defined as v

critical = 2π

Af), a significant reduction in roughness was observed [

7,

13,

21,

22]. However, when the cutting speed exceeded this threshold, the improvement in roughness compared to CT became marginal, although the resulting surface finish remained acceptably fine [

23].

The lowest mean

Ra value obtained in the UAFT method was 0.91 µm, corresponding to the cutting parameters of n = 700 rpm and

fr = 0.1 mm/rev, representing a 71% reduction compared to the equivalent value in CT. However, the standard deviation remained relatively high at 0.15 μm, as the cutting speed at this level was entirely within the typical BUE formation zone. At low cutting speeds (typically below 60 m/min), the temperature at the rake face falls within the steel's "blue-brittle" range, where ductility is reduced and shear failure is more likely [

24]. Under high shear stress and hydrostatic pressure, material begins to accumulate on the rake face, forming an initial BUE layer. As cutting continues, new material slides along the tool but partially adheres, causing the BUE to gradually thicken. Once the adhesive limit is exceeded, the BUE detaches and may transfer to the machined surface, leading to increased roughness. Although UAFT effectively mitigates BUE, the phenomenon remains a rapidly recurring cyclic process at low speeds, which compromises the uniformity of the surface finish.

Conversely, at n = 1300 rpm and fr = 0.1 mm/rev, although Ra did not reach the minimum, the standard deviations of Ra and Rz were only 0.006 µm and 0.30 µm, respectively. These low variations indicate a highly consistent surface quality at high spindle speeds, primarily due to the significant reduction in the BUE phenomenon due to both high cutting speeds and assisted vibration.

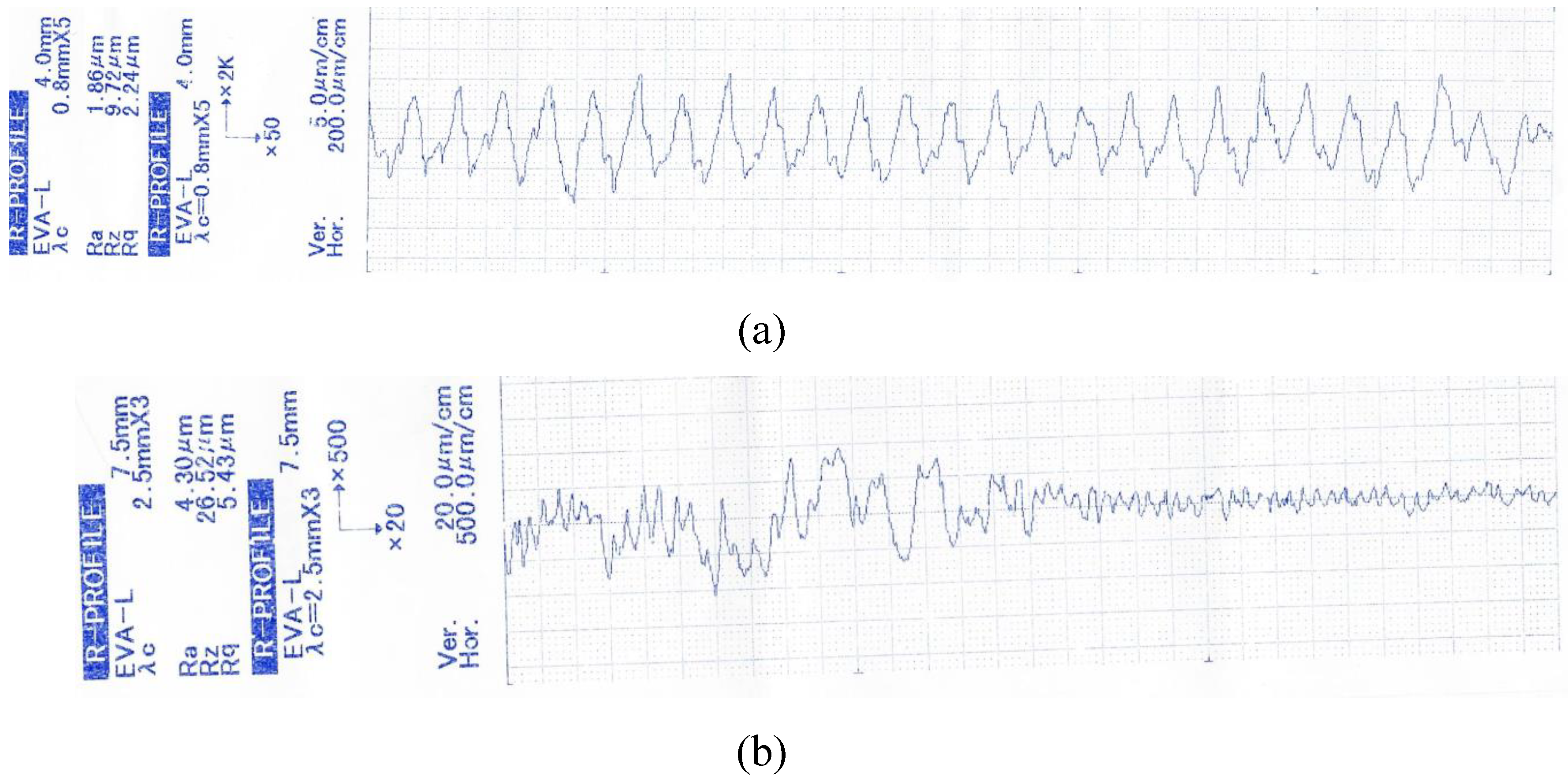

An important observation lies in the ratio between

Ra and

Rz, which serves as an indicator of the surface texture characteristics. In conventional turning (CT), this ratio fluctuated around 15–16.3%, whereas in ultrasonic-assisted face turning (UAFT), it ranged from 17.9% to 20.3%. This suggests that surface asperities generated by CT tend to exhibit more irregular and sharper peaks, leading to a relatively higher

Rz compared to

Ra. In contrast, UAFT tends to produce more uniform and rounded peak formations, resulting in a higher

Ra/

Rz ratio. This inference is further supported by the roughness profiles shown in

Figure 4 and is consistent with the findings of Thomas M. et al. [

25], where a ratio of

Rmax/

Ra = 4.4 corresponds to a saw-tooth profile composed of regular, periodic peaks—indicative of stable cutting without built-up edge (BUE) formation. Conversely, when the surface profile appears more random and irregular, a higher ratio of R

max/

Ra = 6.3 is observed, reflecting the presence of significant BUE effects. These results highlight that analyzing the relationship between

Ra and

Rz (or

Rmax) provides not only a quantitative measure of surface roughness but also valuable insight into the underlying cutting mechanisms and stability of the machining process.

Notably, in

Figure 4(b), where the roughness probe scanned from the center outward in a CT sample, the first half (corresponding to lower cutting speeds) exhibits an unstable and irregular roughness pattern. In contrast, the second half (corresponding to higher cutting speeds) shows more periodic and consistent peak formation. In comparison,

Figure 4(a) for the UAFT sample demonstrates uniformly spaced roughness peaks across the entire profile. The distance between successive peaks closely matches the feed rate

fr, implying that the BUE formation was effectively suppressed even in regions with low cutting speed, thereby confirming the stabilizing effect of ultrasonic assistance.

2.3. Surface Topography

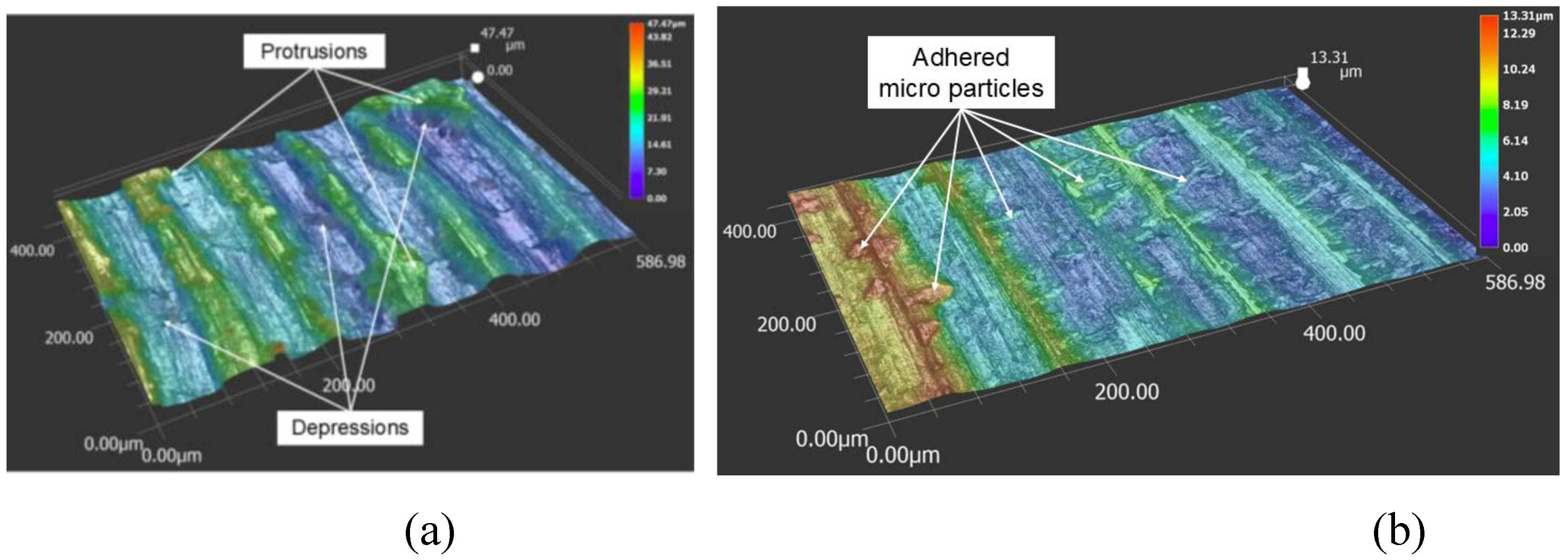

Microscopic observations using the Keyence VHX-7000 digital microscope further support the previously discussed findings. In the CT method at a spindle speed of n = 1300 rpm, the surface near the center of the workpiece (

Figure 5a) exhibits distinct tool marks corresponding to the feed rate (

fr). However, the peak-to-valley height is considerably large, and the surface displays protrusions and depressions irregularly distributed along the cutting direction, indicative of material adhesion and unstable chip formation. These characteristics suggest the presence of a built-up edge (BUE), which contributes to increased surface roughness and the formation of surface irregularities.

Toward the outer region of the workpiece (

Figure 5b), the height of the surface asperities is significantly reduced. Nevertheless, abnormal surface features oriented along the cutting speed direction are observed—commonly referred to as “adhered micro particle” by R. Tan [

26]. This phenomenon is typically associated with lateral material deformation along the cutting edge and frequently occurs in conventional turning at high cutting speeds.

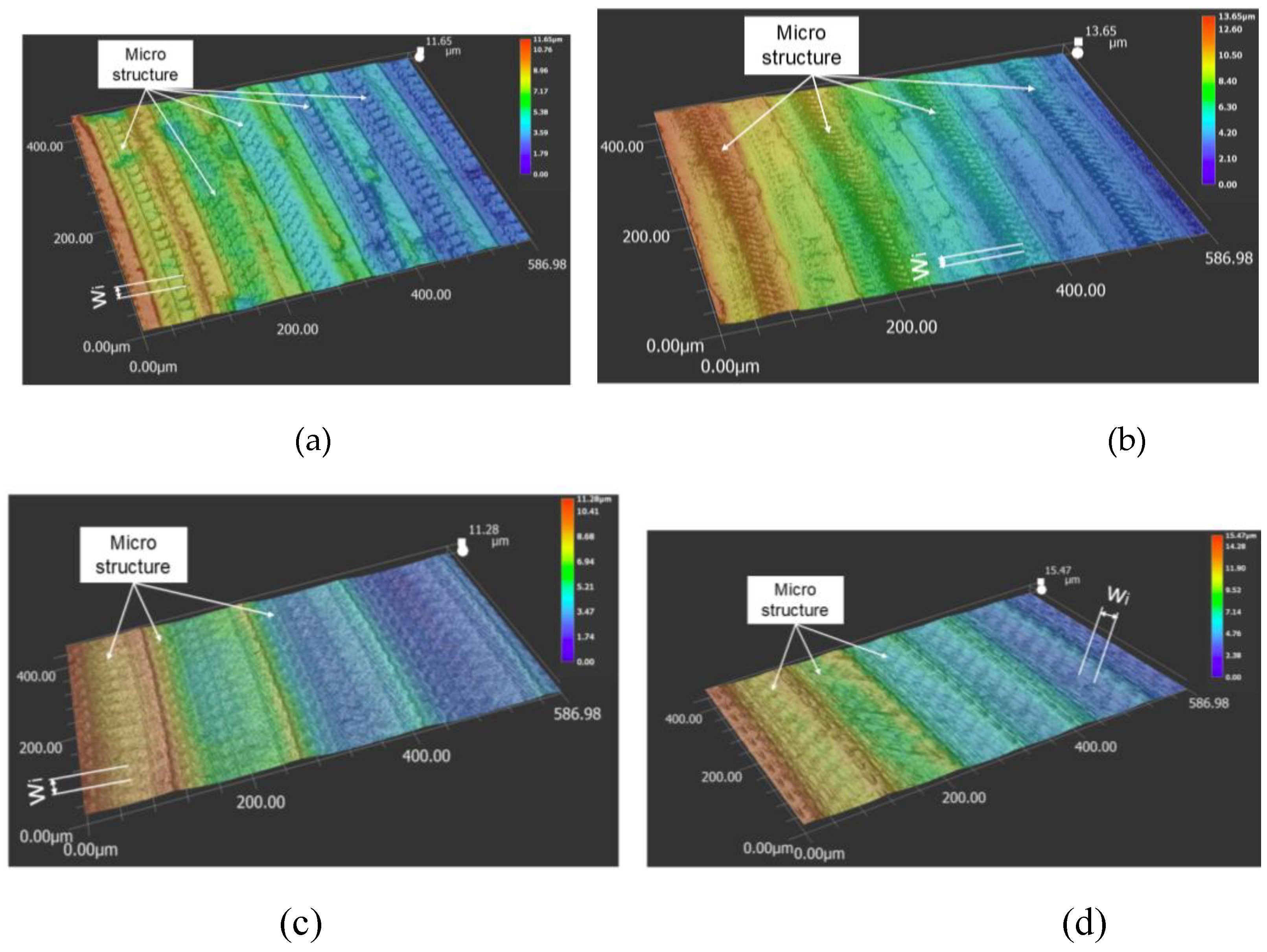

In contrast, surface observations of the samples machined using UAFT (

Figure 6) show no signs of adhered micro particles. The peak-to-valley height is smaller than in CT and approaches the theoretical value calculated by the formula [

27]:

(3)

where Ra Arithmetic Mean Height, fr is the feed rate, and Rc is the tool nose radius.

Additionally, theoretical and experimental studies, such as the one conducted in [

23], have demonstrated that the ultrasonic vibration introduces periodic structures on the surface, with a wavelength given by:

Here,

represents the wavelength of the periodic structures formed on the machined surface by UAFT along the cutting direction, expressed in µm, and was found to exhibit negligible deviation from experimental results reported in [

23]. In this equation

, denotes the cutting speed (in m/min), and

f is the frequency (in Hz) of the assisted ultrasonic vibration.

3. Conclusions

The effect of ultrasonic vibration applied in the cutting speed direction on surface quality during face turning of C45 steel was systematically investigated. The experimental results revealed that ultrasonic assistance significantly improved surface roughness, particularly in the area near the center of the workpiece where the cutting speed is extremely low. The lowest Ra value obtained in UAFT was 0.91 µm at a spindle speed of 700 rpm and a feed rate of 0.1 mm/rev, representing a reduction of up to 71% compared to CT.

The improvement in surface quality at low cutting speeds is especially noteworthy, as CT under such conditions typically results in severe surface degradation, with high Ra and Rz values primarily due to the formation of BUE. However, with the application of ultrasonic vibration, BUE formation was significantly suppressed. Surface topography observations indicated that, in the UAFT method, roughness peaks appeared at regular intervals corresponding to the feed rate, and the machined surfaces exhibited uniform microstructures, attributed to the modulation of instantaneous cutting speed by ultrasonic vibration.

Funding

This research received no external funding.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors would like to thank the Precision Engineering & Smart Measurements Laboratory at Hanoi University of Science and Technology for their support in conducting the turning operations as well as the surface roughness and vibration amplitude measurements.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| A |

Ultrasonic vibration amplitude (µm) |

| f |

Frequency of ultrasonic vibration (Hz) |

| fr |

Feed rate in Conventional Turning (CT) (mm/rev) |

| Ra |

Arithmetic Mean Height (µm) |

| Rz |

Ten-point Mean Height (µm) |

| vc |

Cutting speed in Conventional Turning (m/min) |

| vins |

Instantaneous cutting speed with ultrasonic vibration assistance |

| vcritical |

Critical cutting speed (m/min) |

| n |

Spindle speed of lathe (rev/min) |

| ap |

Depth of cut |

| Rc |

Nose radius of turning insert |

| wi |

The wavelength of the periodic microstructure |

Abbreviations

The following abbreviations are used in this manuscript:

| UAFT |

Ultrasonic Assisted Face Turning |

| CT |

Conventional Turning |

| |

|

| |

|

References

- P. Muñoz-Escalona, Z. Cassier. Influence of the critical cutting speed on the surface finish of turned steel. Wear. 1998, 218(1), 103–109. [Google Scholar] [CrossRef]

- Esteves Correia, J. Paulo Davim. Surface roughness measurement in turning carbon steel AISI 1045 using wiper inserts. Measurement. 2011, 44(5), 1000–1005. [Google Scholar] [CrossRef]

- D. Frăţilă & C. Caizar. Investigation of the Influence of Process Parameters and Cooling Method on the Surface Quality of AISI-1045 during Turning. Materials and Manufacturing Processes. 2012, 27, 1123–1128. [Google Scholar]

- Kang, R.; Zhang, P.; Wei, Z.; Dong, Z.; Wang, Y. Experimental Study on Ultrasonic Assisted Turning of GH4068 Superalloy. Materials 2023, 16, 3554. [Google Scholar] [CrossRef] [PubMed]

- Navneet Khanna, Jay Airao, Chandrakant K. Nirala, Grzegorz M. Krolczyk. Novel sustainable cryo-lubrication strategies for reducing tool wear during ultrasonic-assisted turning of Inconel 718. Tribology International. 2022, 174, 107728. [Google Scholar] [CrossRef]

- Rachele Bertolini, Ghiotti Andrea, Nageswaran Tamil Alagan, Stefania Bruschi. Tool wear reduction in ultrasonic vibration-assisted turning of SiC-reinforced metal-matrix composite. Wear. 2023, 523, 204785. [Google Scholar] [CrossRef]

- Bo Zhang, Guangjun Chen, Zhuang Chen, Gaofeng Hu, Yingxin Lv, Haiyu Li. Ultrasonic elliptic vibration assisted turning SiCp/Al composite surface morphology. Journal of Manufacturing Processes. 2025, 141, 1071–1083. [Google Scholar] [CrossRef]

- Liu, C. , Wang, W., Xiong, Y. et al. Experimental investigation on tool wear in ultrasonic vibration-assisted turning of SiCf/SiC ceramic matrix composite. Int J Adv Manuf Technol. 2023; 125, 3081–3101. [Google Scholar]

- Anh Tuan, Bui; et al. Investigation of surface topography in ultrasonic-assisted turning of C45 carbon steel. Jpn. J. Appl. Phys. 2024, 63, 016501. [Google Scholar]

- Schubert, A. Nestler, S. Pinternagel, H. Zeidler. Influence of ultrasonic vibration assistance on the surface integrity in turning of the aluminium alloy AA2017. Materials. Science & Engineering Technology. 2011, 42, 658–665. [Google Scholar]

- Neelesh, K. Jain, Vijay K. Jain. Modeling of material removal in mechanical type advanced machining processes: a state-of-art review. International Journal of Machine Tools and Manufacture, 2001, 41 (11), 1573- 1635. [Google Scholar]

- Raman Kumar, Paramjit Singh Bilga, Sehijpal Singh. Multi objective optimization using different methods of assigning weights to energy consumption responses, surface roughness and material removal rate during rough turning operation. Journal of Cleaner Production. 2017, 164, 45–57. [Google Scholar] [CrossRef]

- Xu, Y. , Gao, F., Zou, P. et al. Theoretical and experimental investigations of surface roughness, surface topography, and chip shape in ultrasonic vibration-assisted turning of Inconel 718. Journal of Mechanical Science and Technology. 2020, 34 (9), 3791–3806. [Google Scholar]

- Mohsen Khajehzadeh, Omid Boostanipour, Mohammad Reza Razfar. Finite element simulation and experimental investigation of residual stresses in ultrasonic assisted turning. Ultrasonics, 2020, 108, 106208. [Google Scholar] [CrossRef] [PubMed]

- Varun Sharma, Pulak M. Pandey. Optimization of machining and vibration parameters for residual stresses minimization in ultrasonic assisted turning of 4340 hardened steel. Ultrasonics. 2016, 70, 172–182. [Google Scholar] [CrossRef] [PubMed]

- Zhichao Yang, Lida Zhu, Guixiang Zhang, Chenbing Ni, Bin Lin. Review of ultrasonic vibration-assisted machining in advanced materials. International Journal of Machine Tools and Manufacture, 2020, 156, 103594.

- Matin Mirzabagherian, Saeid Amini, Masuod Bayat. Investigation of the Effects of Ultrasonic-Assisted Face Turning with CO2 Cooling on Cutting Forces, Residual Stress, and Surface Quality. International Journal of Lightweight Materials and Manufacture 2025.

- S. Amini, H. Nouri Hosseinabadi, S.A. Sajjady. Experimental study on effect of micro textured surfaces generated by ultrasonic vibration assisted face turning on friction and wear performance. Applied Surface Science. 2016, 390, 633–648. [Google Scholar] [CrossRef]

- Lubis, S. Y. , Djamil, S., & Zebua, Y. K. Effect of cutting speed in the turning process of AISI 1045 steel on cutting force and built-up edge (BUE) characteristics of carbide cutting tool. Sinergi. 2020, 24, 171. [Google Scholar]

- Gómez-Parra, M. Álvarez-Alcón, J. Salguero, M. Batista, M. Marcos. Analysis of the evolution of the Built-Up Edge and Built-Up Layer formation mechanisms in the dry turning of aeronautical aluminium alloys. Wear, 2013, 302, 1209–1218. [Google Scholar] [CrossRef]

- Puga, Hélder, José Grilo, and Vitor H. Carneiro. Ultrasonic assisted turning of Al alloys: influence of material processing to improve surface roughness. Surfaces, 2019; 2, 326–335.

- S. A. Sajjady, H. Nouri Hossein Abadi, S. Amini, R. Nosouhi. Analytical and experimental study of topography of surface texture in ultrasonic vibration assisted turning. Materials & Design. 2016, 93, 311–323. [Google Scholar]

- Nguyen, T. T. , Vu, T. T., & Nguyen, T. D. Surface Topography in Cutting-Speed-Direction Ultrasonic-Assisted Turning. Micromachines. 2024, 15, 668. [Google Scholar]

- Childs, T. H. C. Towards simulating built-up-edge formation in the machining of steel. CIRP Journal of Manufacturing Science and Technology. 2011, 4(1), 57–70. [Google Scholar] [CrossRef]

- Thomas, M. , Beauchamp Y., Youssef A. Y. and Masounave J. An experimental design for surface roughness and built-up edge formation in lathe dry turning. International Journal of Quality Science. 1997, 2, 167–180. [Google Scholar]

- Tan, R. , Zhao, X., Zhang, S., Zou, X., Guo, S., Hu, Z., & Sun, T. Study on ultra-precision processing of Ti-6Al-4V with different ultrasonic vibration-assisted cutting modes. Materials and manufacturing processes. 2019, 34, 1380–1388. [Google Scholar]

-

Geoffrey Boothroyd; Winston A. Knight. Fundamentals of Machining and Machine Tools. 2nd ed, CRC Press: New York, USA, 1988; p. 168.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).