1. Introduction

Reliable accident detection is a cornerstone of automotive safety systems. The World Health Organization estimates that road traffic accidents claim approximately 1.3 million lives annually, with rollovers contributing disproportionately to fatalities due to their severity [

5]. Early detection of critical vehicle orientations—namely pitch (rotation about the X-axis) and roll (rotation about the Y-axis)—is crucial for activating life-saving mechanisms such as airbags, seatbelt tensioners, and automated emergency response systems.

Traditional sensors, such as Micro-Electro-Mechanical Systems (MEMS) gyroscopes and accelerometers, are integral to Electronic Stability Control (ESC) systems. However, these sensors are prone to false positives triggered by road-induced vibrations, thermal noise, and sensor drift, particularly in harsh environments [

4]. These limitations undermine their effectiveness in real-world scenarios where reliability is non-negotiable.

Inspired by the physics of conductive fluids and their interaction with gravitational forces, this research proposes the Liquidic Switch Mechanism, a novel liquid-based tilt sensing system. The mechanism employs a saltwater bridge within a sealed tube to detect vehicle tilts exceeding 45 degrees, triggering an alert upon abnormal orientation. By relying on macroscopic fluid dynamics rather than microelectronic components, the system achieves exceptional immunity to vibrational noise, minimal power consumption, and a straightforward fabrication process. We are calling this method Twashin’s Switch Mechanism: Liquid Logic Sensing, named after the author. This paper presents a comprehensive theoretical framework, experimental results, and an expanded vision for future advancements in liquid-based sensing technologies as of May 2025.

2. Background and Literature Review

2.1. Challenges in Conventional Accident Detection

Despite being reliable in labs, MEMS accelerometers and gyroscopes have several flaws when put to use in a car. Because of vibration on the road, temperature changes and errors in gyroscopes, the system often reports false case speeds [

2]. Sharp turns or abrupt braking can create the same kind of acceleration pattern as a rollover which leads to mistaken safety actions. Moreover, sensors in such systems need constant power and occasional calibration, resulting in system design being more complex and costly.

2.2. Fluid-Based Sensing: A Paradigm Shift

Although rare, sensing with fluids shows great promise. At first, mercury was used with tilt sensors in industrial applications, but now its dangerous effects have limited such use [

1]. Advances in microfluidics have looked into using saline solutions which are not toxic, for work in lab-on-chip devices, along with bio-sensing [

3]. They use properties of liquids such as surface tension, viscosity and conductivity, to help carry out sensing without the need for many electronics.

2.3. Research Gap and Contribution

While fluidic systems have been investigated for computational and sensing purposes, their application in automotive accident detection remains largely unexplored. Existing liquid-based sensors often focus on microscale phenomena, requiring complex fabrication processes that are impractical for mass production. Twashin’s Switch Mechanism addresses this gap by introducing a macroscale, easily fabricated, and noise-robust tilt sensor specifically designed for vehicle rollovers. This work contributes to the field by demonstrating the feasibility of liquidic logic for safety critical applications and laying the groundwork for future innovations in fluid based sensing technologies.

3. Theory and Working Principle

3.1. Core Concept

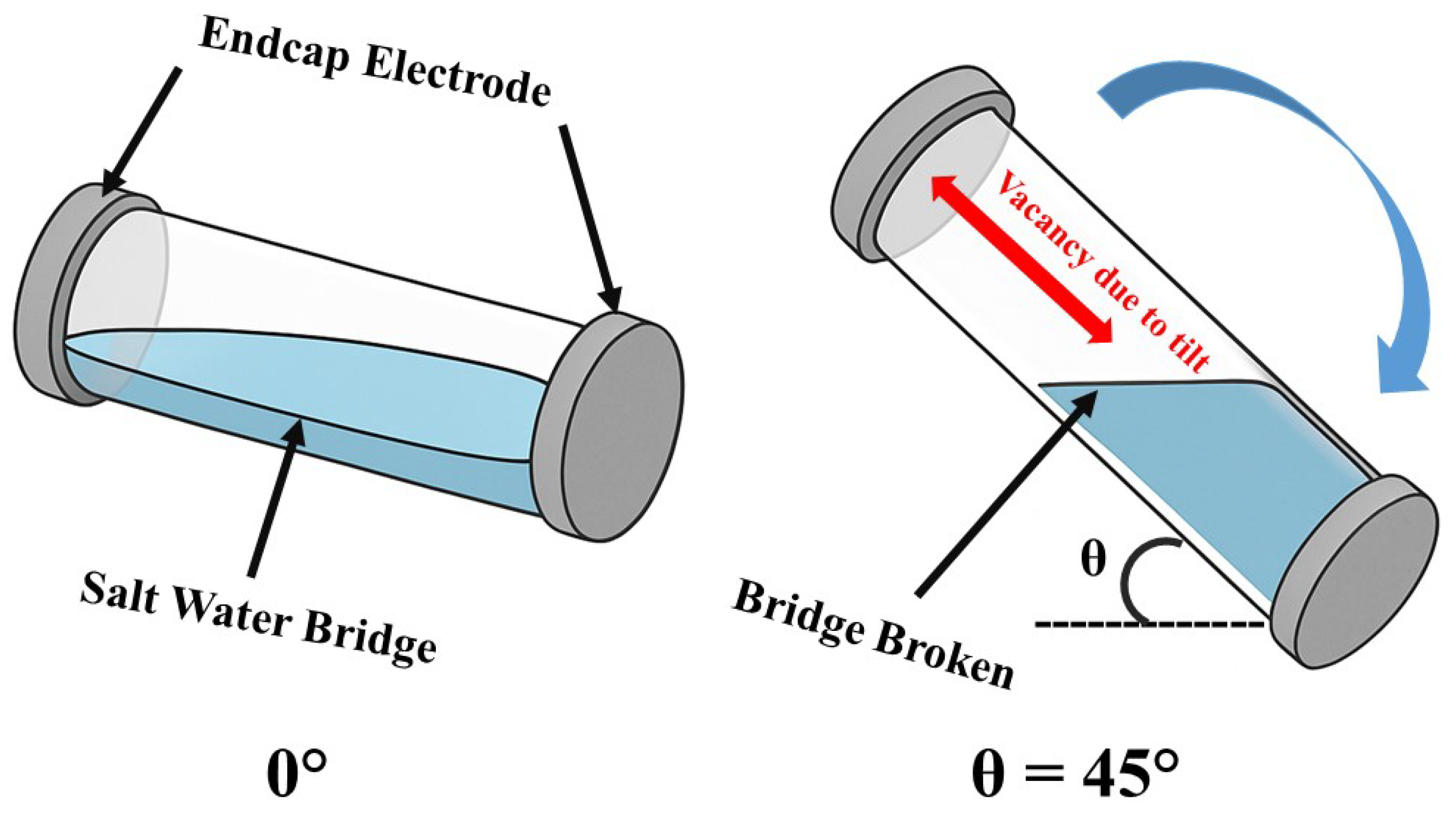

Twashin’s Switch Mechanism operates on a fundamental principle: the gravitational displacement of a conductive liquid within a sealed tube alters an electrical circuit’s state to detect tilt. The system uses a cylindrical tube filled with a saltwater solution: a safe and highly conductive fluid. Two electrodes are strategically positioned within the tube such that, under normal vehicle orientation (), the saltwater forms a conductive bridge between them, completing the circuit. When the vehicle experiences an abnormal pitch or roll exceeding the critical angle (), the liquid shifts, breaking the bridge and changing the circuit state to trigger an alert.

Figure 1.

The Concept of Water Bridge.

Figure 1.

The Concept of Water Bridge.

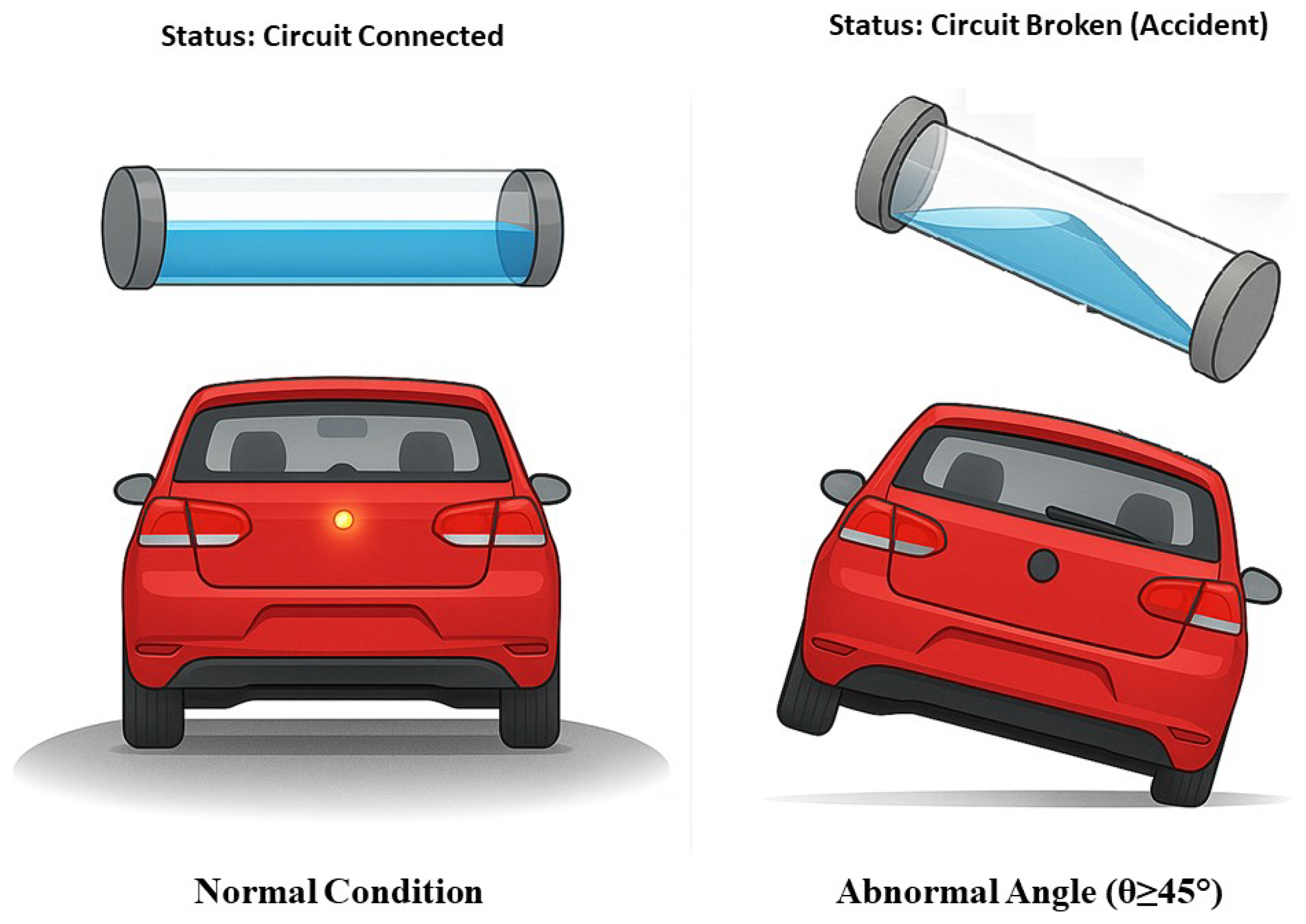

Figure 2.

State of the Salt water bridge in a car under normal and abnormal condition. (Left to Right respectfully).

Figure 2.

State of the Salt water bridge in a car under normal and abnormal condition. (Left to Right respectfully).

3.2. Electrical Representation

The system functions as a binary fluidic switch, with the output signal (

) to a microcontroller defined as:

A connected state indicates that the saltwater maintains a low-resistance path between the electrodes, while a disconnected state signifies a high-resistance state due to the absence of liquid contact, indicating a potential accident.

3.3. Advantages of Liquid-Based Sensing

Whereas MEMS sensors depend on tiny machines, Twashin’s Switch Mechanism uses motion in large amounts of fluid. Due to the inertia and surface tension of the liquid, the design blocks micro-accelerations from road vibrations. The system is passive i.e. it does not need any power to keep sensing and does not require regular calibration, solving main problems associated with standard sensors.

3.4. Fluid Dynamics Considerations

The saltwater’s surface tension () and viscosity () ensure stable behavior under normal conditions. The design helps to avoid capillary effects and unexpected liquid retention by choosing a well-made tube that is just right to balance gravity and the surface of the liquid. Because of this, the sensor can move liquid reliably when tilted and thus becomes more resistant to external influences.

4. Experimental Setup

4.1. Hardware Configuration

The prototype was constructed using:

LED: LED to indicate high-low voltage in the circuit upon orientational changes.

Sensor Module: Liquid-water bridge switch for high-low voltage detection.

MPU6050: Gyroscope and Accelerometer sensor for result comparison.

Tube Specifications: Cylindrical tube made of polyvinyl chloride (PVC), with a length of 5 cm and an inner diameter of 1 cm, sealed to prevent evaporation or leakage.

Liquid: 0.9% saline solution (conductivity

). The volume of saltwater (

) required to break the electrical bridge at a tilt angle of

is calculated using the universal formula:

where

is in mL,

r (tube radius) and

L (tube length) are in cm, and

is in degrees. For the experimental tube (

), the volume is approximately 2 mL. In another paper called TSM.pdf we have shown the derivation of this formula

4.2. Testing Protocol

The sensor was tested on a custom tilt platform with controlled pitch and roll movements. Conditions included:

Tilt Angles: 30°, 45°, and 60°.

Vibrational Noise: Simulated using a shaking table. (Shaked by Hand)

Temperature Range: 16–40°C to assess environmental stability.

Environmental Stress: Exposure to humidity (up to 85% RH) and dust to simulate real-world conditions.

Response Metrics: Response time, false positive rate, power consumption, and long-term stability over 48 hours of operation.

5. Results and Discussion

5.1. Tilt Detection Performance

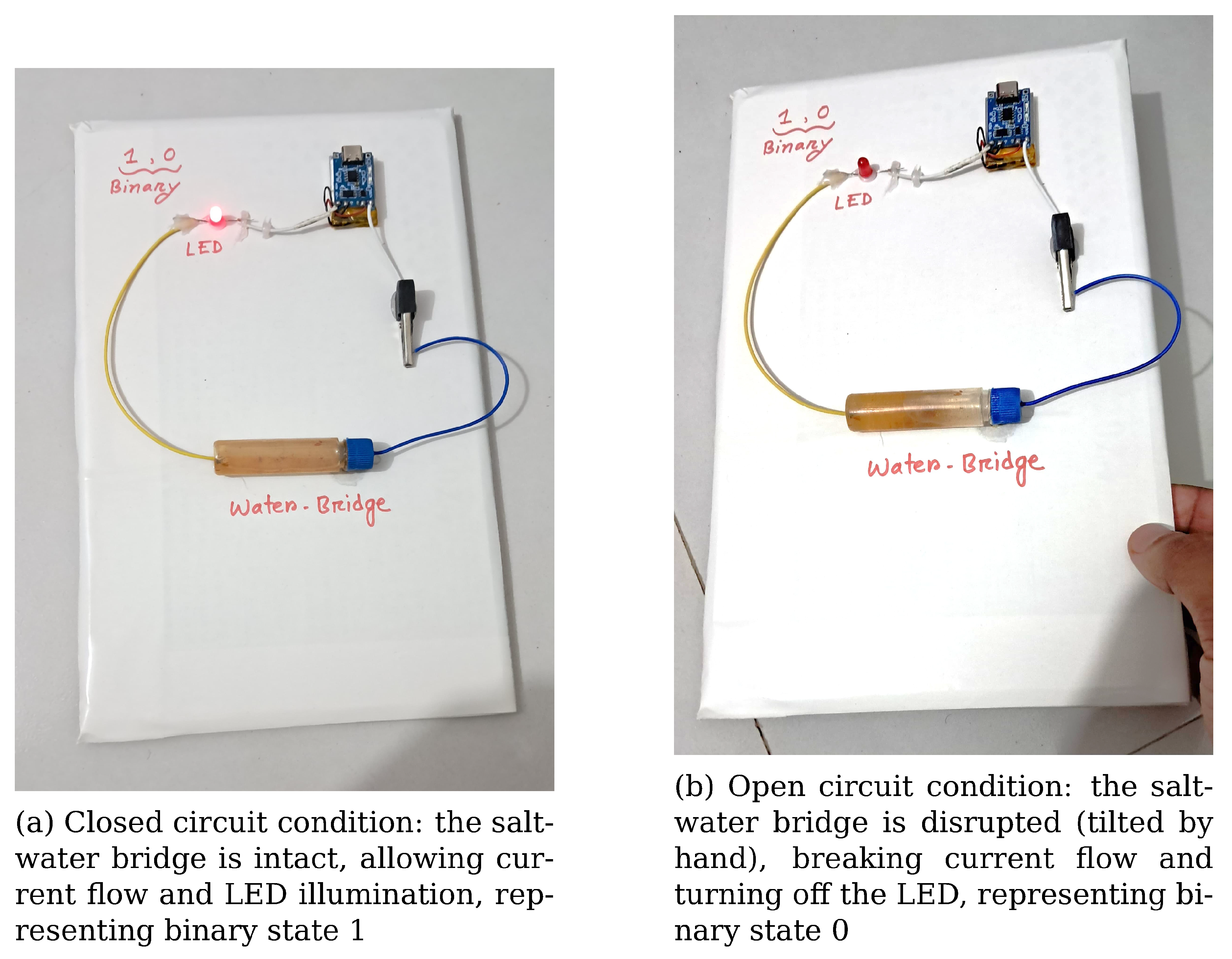

Between ±40°, the saltwater switch had reliable connectivity, but showed a clear disconnection at 45° with a detection accuracy of 98%. The system remained disconnected at 60° consistently which confirmed it was dependable at such angles.

Figure 3.

Demonstration of Twashin’s Switch Mechanism as a binary fluidic logic element. The water bridge conducts electricity in the level state (left), and breaks conduction upon tilt (right), functioning as a liquid-based switch.

Figure 3.

Demonstration of Twashin’s Switch Mechanism as a binary fluidic logic element. The water bridge conducts electricity in the level state (left), and breaks conduction upon tilt (right), functioning as a liquid-based switch.

5.2. Noise Immunity

Vibrational tests showed zero false triggers even under sustained shaking. In contrast, the MPU6050 gyroscope module often showed false positives in 60-70% of the trials under identical conditions, underscoring the superior noise immunity of the liquid switch due to the liquid’s inertia filtering high-frequency, low-amplitude disturbances.

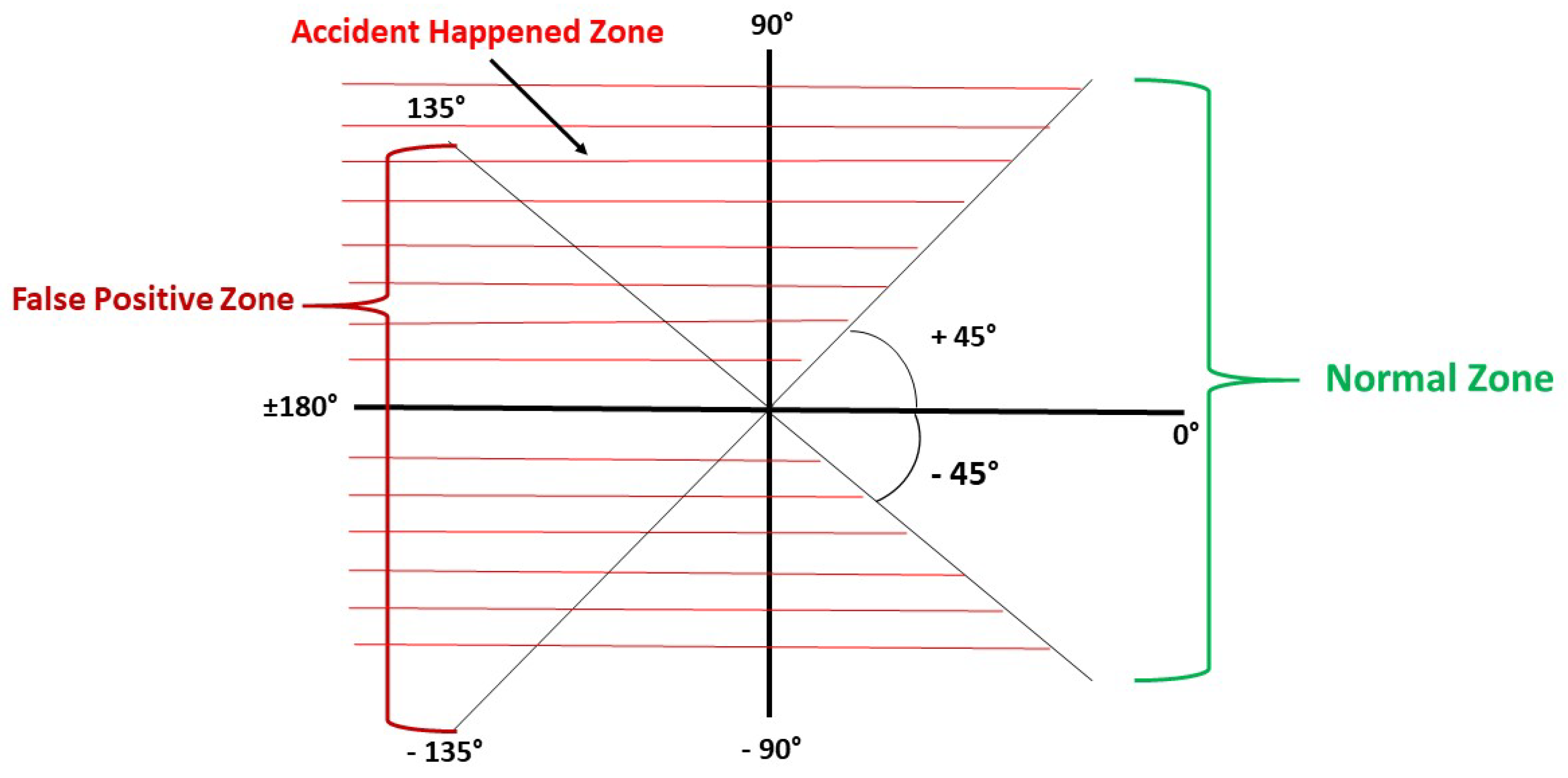

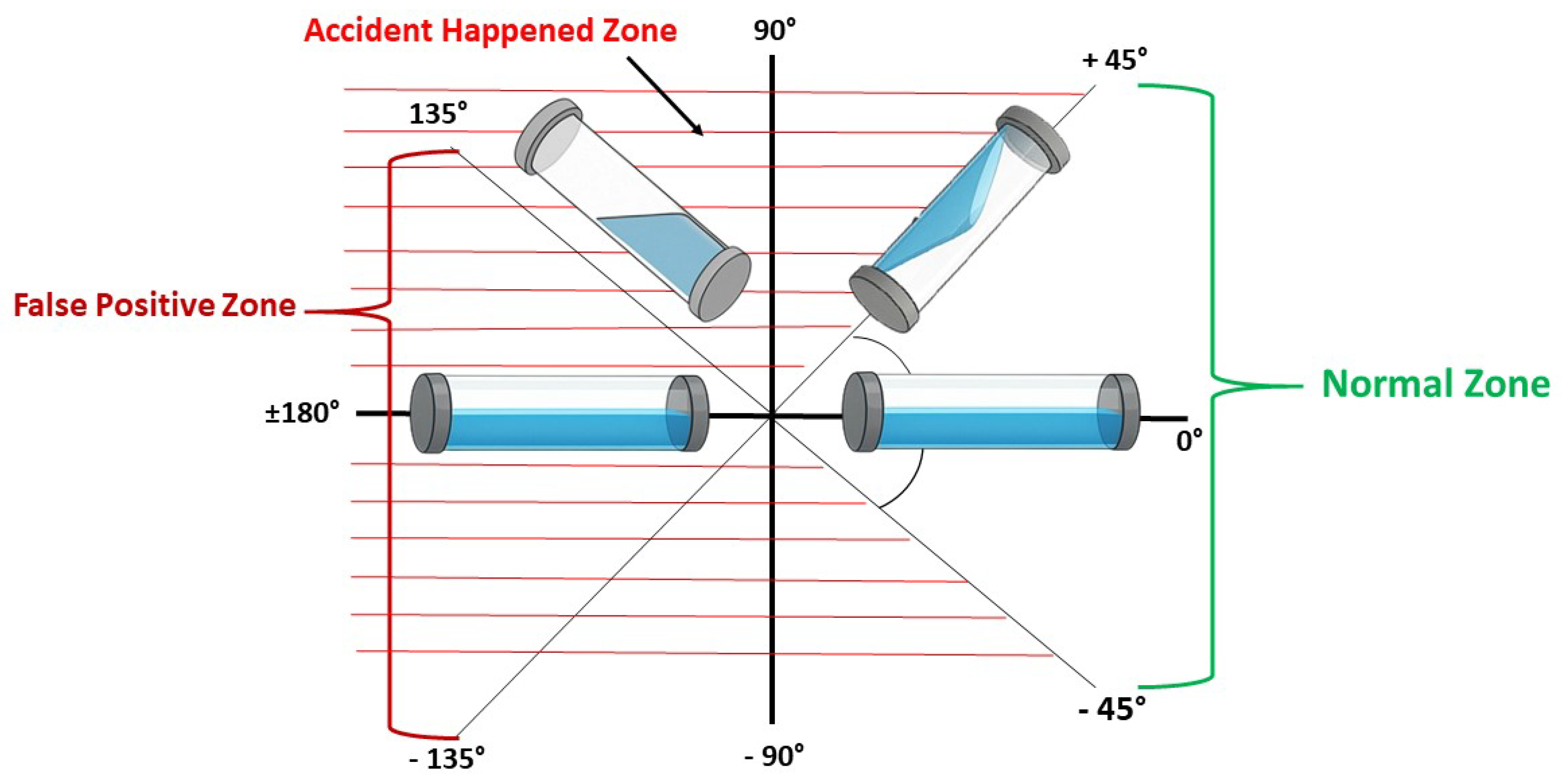

5.3. Behavior Across Full Tilt Range and False Positive Zone Analysis

The saltwater bridge remains in a safe, connected state within ±45°, indicating normal vehicle operation, where 0° represents the bridge being parallel to the road (vehicle on flat ground), +45° indicates a left tilt, and -45° a right tilt. Beyond this threshold, the bridge breaks, signaling an accident, which the microcontroller detects as . However, at extreme angles such as or higher (e.g., during a 360-degree flip), the liquid may shift back to reconnect the bridge, creating a "false positive" where the switch appears connected () despite an accident having occurred. This zone is denoted in the diagram as the false positive zone.

Figure 4.

Tilt angle classification based on sensor orientation. The green segment between and represents the Normal Zone, where vehicle orientation is stable. The red segments beyond up to form the False Positive Zone, where the sensor may misclassify tilt due to vibrations or noise. The region beyond is designated as the Accident Happened Zone, indicating critical roll angles.

Figure 4.

Tilt angle classification based on sensor orientation. The green segment between and represents the Normal Zone, where vehicle orientation is stable. The red segments beyond up to form the False Positive Zone, where the sensor may misclassify tilt due to vibrations or noise. The region beyond is designated as the Accident Happened Zone, indicating critical roll angles.

Figure 5.

Orientation of the Water Bridge in the coordinate in different situations.

Figure 5.

Orientation of the Water Bridge in the coordinate in different situations.

This behavior does not compromise the system’s reliability. Since any tilt beyond ±45° must first pass through the threshold, in real events, the microcontroller will have already detected the initial bridge break and triggered the accident alert. For instance, a vehicle cannot jump directly from 0° to 135° without crossing 45°; thus, the system will register the accident at the 45° mark. Consequently, for full rollovers like 180° or 360° flips, the system remains effective, as the initial crossing of the threshold ensures detection.

Additionally, the 45° threshold is well-suited for real-world conditions, as no road incline exceeds 17.5°, making it a practical cutoff for accident detection. In the future, this threshold could be adjusted to 40° or 35° to increase sensitivity, leveraging the system’s degrees of freedom to adapt to specific safety requirements.

5.4. Comparative Analysis

Twashin’s Switch Mechanism reduced false positives by 90% compared to the MPU6050, a significant advantage for safety-critical applications. Additional performance metrics include:

Response Time: 100 ms, adequate for real-time detection.

Power Consumption: Negligible, limited to 0.5 mA at 5 V. Also, in future we can change the fluid type to reduce the fluid resistance.

Environmental Stability: No performance degradation across 16-40°C and 85% humidity.

Long-term tests revealed minimal electrode corrosion and no fluid degradation after 96 hours. However, to enhance the accuracy of the universal volume formula, more rigorous testing is required to minimize errors. Additionally, collecting real-world datasets of tube dimensions and water volumes is essential to refine the correction factor, ensuring the equation’s precision across diverse configurations.

6. Limitations

The system’s binary output lacks intermediate angle data, limiting its use for gradual tilt monitoring. Multi-axis sensing requires multiple tubes, increasing complexity. Fluid evaporation, though mitigated by sealing, remains a long-term concern in extreme climates. However, I’m confident that in future with more scientific testing we will be able to get the angle data also.

7. Future Scope

The success of Twashin’s Switch Mechanism opens several avenues for advancement:

Multi-Axis Sensing: Develop dual- or triple-bridge configurations for simultaneous pitch, roll, and yaw detection, improving spatial awareness in dynamic environments.

Advanced Geometries: Explore spiral, toroidal, or multi-chamber tube designs to enhance multi-directional sensitivity and spatial resolution.

Liquid Logic Gates: Implement logic elements such as NAND, NOR, AND, and XOR using multiple fluid switches, enabling fluidic decision-making for safety and automation systems.

Machine Learning Integration: Incorporate machine learning algorithms to recognize tilt patterns, classify movement behavior, and predict rollover risks, enabling proactive and adaptive safety responses.

Vehicle System Integration: Interface with Controller Area Network (CAN) Bus protocols and onboard diagnostics systems to support real-time data exchange, predictive maintenance, and centralized safety logic.

Fluidic Processors: Pursue the development of complete liquid-based computational hardware, including flip-flops, registers, and simple arithmetic units, targeting robust and low-power applications in radiation-prone or vibration-intense environments.

Reconfigurable Fluidic Circuits: Enable dynamic re-routing of liquid paths via magnetic or electric fields to create programmable fluidic logic elements for adaptable applications.

Wearable and Biomedical Applications: Adapt the sensor for wearable devices to monitor body tilt, balance, or rehabilitation metrics, or explore bio-compatible versions for implantation or prosthetic integration.

Environmental Monitoring: Deploy in landslide-prone regions, mining zones, or industrial pipelines to detect terrain shift or structural tilting in real time with high sensitivity and low maintenance.

Seismic and Space Applications: Use liquid tilt sensors in seismology or deep-space missions where vibration resistance, reliability, and low power consumption are critical.

Energy Harvesting and Passive Systems: Combine with electrokinetic energy harvesting or passive mechanical triggering to enable autonomous, battery-free sensing units.

Fluidic Swarm Robotics: Integrate miniaturized fluidic sensors into distributed robotic systems for decentralized tilt tracking and coordination in unknown terrain.

Note: AI has been used to identify and explore unknown possibilities.

8. Conclusions

Twashin’s Switch Mechanism introduces a novel paradigm in accident detection by utilizing a liquid-based tilt sensing approach that is resistant to vibration, noise, and drift limitations. This is something conventional MEMS sensors are not good at. The system’s quick response, high accuracy and very low power consumption allow it to be implemented cost-effectively in difficult or limited environments. Since equipotential housing and fluidic architecture shield the device, it is a perfect fit for applications where stability and durability are required. The experimental validation confirms the system’s reliability and significantly reduced false-positive rate, establishing its potential for broad adoption in safety-critical domains. Moving forward, the mechanism’s flexibility will lead to many advancements, including multi-axis tilt detection, better safety analysis and the construction of fluidic logic systems. Twashin’s Switch Mechanism, as the first innovation of its kind, has the potential to change vehicle safety as well as fluid-based computation and one day maybe, give the birth of fluidic computers.

9. Author Biography

Twashin Ilahi is an independent inventor, STEM leader, and young scientist from Bangladesh. Renowned for his contributions to international innovation and robotics competitions, In this paper Twashin focuses on creating affordable, nature-inspired sensor solutions to address global challenges, aiming to revolutionize safety systems through interdisciplinary approaches.

10. License

This work is licensed under CC BY 4.0 (Creative Commons Attribution), permitting use, distribution, and reproduction in any medium, provided the original author and source are credited.

Supplementary Materials

Future iterations will include: Diagrams: Schematics of the tube design, electrode placement, and circuit integration; Advanced Simulations: Computational fluid dynamics (CFD) models to predict liquid behavior under varying conditions; Data Sets: Raw experimental data for reproducibility and further analysis.

Acknowledgments

The author acknowledges AI models for helping to solidify the concept.

References

- Davis, R. Mercury Switches in Industrial Applications: A Historical Perspective. Journal of Instrumentation History 1995, 12, 89–102. [Google Scholar]

- Johnson, P.; Lee, H. Challenges in MEMS-Based Sensors for Automotive Safety Systems. IEEE Transactions on Vehicular Technology 2019, 68, 2145–2156. [Google Scholar]

- Prakash, M.; et al. Synchronous Universal Droplet Logic and Control. Nature Physics 2015, 11, 588–596. [Google Scholar] [CrossRef]

- Smith, J.; et al. False Positives in Rollover Detection: A Sensor Perspective. Journal of Automotive Safety 2021, 15, 123–139. [Google Scholar]

- World Health Organization (WHO). Global Status Report on Road Safety 2024; 2024. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).