Submitted:

26 May 2025

Posted:

30 May 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials & Methodology

2.1. Materials

- o Modern Sustainable and

- o Conventional machine. (open Bath)

2.2. Method

2.2.1. Sustainable Machine with Enzymatic DM8639B Enzyme on Denim Fabric:

- Here, we taken a modern sustainable machine (m/c Brand: Borongo)

- Then we set programmer for our test according to our recipe.

- Garments Are Desized here by Using Desizing Agent (0.6 gm/L).

- Set 60 °C Temperature for Desizing.

- we used 2070 ML water for 90 gm fabric.

- Used 2.16 gm Enzymatic DM8639B enzyme.

- Used acetic Acid 1.24 gm (0.6 gm/L).

- We set temperature at 45° Celsius for Enzyme Wash.

- first 4 min started time, here we followed temp and when it risen up 45° Celsius then 15 min was run time.

- Then 5min was rinse time.

- 5min was done by hydro extraction and

- 20 min was drayed time.

| SI NO | Materials | Quantity |

|---|---|---|

| 01 | L:R | 1:23 |

| 02 | Fabric Weight | 90 gm |

| 03 | Water | 2070 ml |

| 04 | Desizing Agent | 1.24 gm |

| 05 | Detergent | 1.65 gm |

| 06 | Temp | 60 Celsius |

| 07 | Run Time | 10 min |

| SI NO | Materials | Quantity |

|---|---|---|

| 01 | M:L | 1:23 |

| 02 | Enzyme (Enzymatic DM8639B) | 2.16 gm |

| 03 | Fabric Weight | 90 gm |

| 04 | Water | 2070 ml |

| 05 | Acetic Acid | 1.24 gm |

| 06 | Anti-Back Staining Agent | 1.24 gm |

| 07 | Temp | 45 Celsius |

| 08 | Run Time | 20 min |

| 09 | Hydro Extraction | 5 min |

| 10 | Dryer | 20 min |

2.2.2. Sustainable Machine with Enzymatic DM8642 Enzyme on Denim Fabric:

- Here, we taken a modern sustainable machine (m/c Brand: Borongo)

- Then we set programmer for our test according to our recipe.

- Garments Are Desized here by Using Desizing Agent (0.6 gm/L)

- Set 60 °C Temperature for Desizing.

- we used 2070 ML water for 90 gm fabric and

- Used 2.16 gm Enzymatic DM8639B enzyme.

- Used acetic Acid 1.24 gm (0.6 gm/L)

- We set temperature at 45° Celsius for Enzyme Wash

- first 4 min started time, here we followed temp and when it risen up 45° Celsius then 15 min was run time.

- Then 5min was rinse time.

- 5min was done by hydro extraction.

- 20 min was drayed time.

| SI NO | Materials | Quantity |

|---|---|---|

| 01 | L:R | 1:23 |

| 02 | Fabric Weight | 90 gm |

| 03 | Water | 2070 ml |

| 04 | Desizing agent | 1.24 gm |

| Detergent | 1.65 gm | |

| 05 | Temp | 60 Celsius |

| 06 | Run Time | 10 min |

| 07 | Wash with Cold water | 1 Time |

| SI NO | Materials | Quantity |

|---|---|---|

| 01 | M:L | 1:23 |

| 02 | Enzyme (Enzymatic DM8642) | 2.16 gm |

| 03 | Fabric Weight | 90 gm |

| 04 | Water | 2070 ml |

| 05 | Acetic Acid | 1.24 gm |

| 06 | Anti-back Staining Agent | 1.24 gm |

| 07 | Temp | 45 Celsius |

| 08 | Run Time | 20 min |

| 09 | Hydro Extraction | 5 min |

| 10 | Dryer | 20 min |

2.2.3. Conventional Machine (Open Bath) with Enzymatic DM8639B Enzyme on Denim Fabric:

- Here, we taken a bath for washing

- Then we had taken 1610 ml water according to our recipe.

- Garments Are Desized here by Using Desizing Agent (0.6 gm/L)

- Set 60 °c Temperature for Desizing.

- Then we used 1.68 gm Enzymatic DM8639B enzyme for 70 gm fabric.

- Then we waited for raised up temperature 45° Celsius and after 5-6 min it comes.

- But we face difficulties to maintain temperature because it was manually. Every 30 second I checked temperature.

- First 4 min started time, here we followed temp and when it risen up 45° Celsius then 15 min was run time.

- Then 5min was rinse time.

- There was no hydro extraction and dryer machine. It was dry on sun.

| SI NO | Materials | Quantity |

|---|---|---|

| 01 | M:L | 1:23 |

| 02 | Fabric Weight | 70 mg |

| 03 | Water | 1610 ml |

| 04 | Desizing Agent | 0.9 gm |

| 05 | Detergent | 1.29 gm |

| 06 | Temp | 60 c Celsius |

| 07 | Run Time | 10 min |

| 08 | Wash With Cold water | 1 Time |

| SI NO | Materials | Quantity |

|---|---|---|

| 01 | M:L | 1:23 |

| 02 | Enzyme (Enzymatic DM8639B) | 1.68 gm |

| 03 | Fabric Weight | 70 mg |

| 04 | Water | 1610 ml |

| 05 | Acetic Acid | 0.9 gm |

| 06 | Anti-back Staining Agent | 0.9 gm |

| 07 | Temp | 45 Celsius |

| 08 | Run Time | 20 min |

| 09 | Hydro Extraction | By sun |

| 10 | Dryer | Not need |

2.2.4. conventional Machine with Enzymatic DM8642 Enzyme on Denim Fabric:

- Here, we taken a bath for washing

- Then we had taken 1610 ml water according to our recipe.

- Garments Are Desized here by Using Desizing Agent (0.6 gm/L).

- Set 60 °c Temperature for Desizing.

- Then we used 1.68 gm Enzymatic DM8639B enzyme for 70 gm fabric.

- Then we waited for raised up temperature 45° Celsius and after 5-6 min it comes.

- But we face difficulties to maintain temperature because it was manually. Every 30 second I checked temperature.

- First 4 min started time, here we followed temp and when it risen up 45° Celsius then 15 min was run time.

- Then 5min was rinse time.

- There was no hydro extraction and dryer machine. It was dry on sun.

| SI NO | Materials | Quantity |

|---|---|---|

| 01 | M:L | 1:23 |

| 02 | Fabric Weight | 70 mg |

| 03 | Water | 1610 ml |

| 04 | Desizing Agent | 0.9 gm |

| 05 | Detergent | 1.29 gm |

| 06 | Temp | 60°c Celsius |

| 07 | Run Time | 10min |

| 08 | Wash With Cold water | 1 Time |

| SI NO | Materials | Quantity |

|---|---|---|

| 01 | M:L | 1:23 |

| 02 | Enzyme (Enzymatic DM8642) | 1.68 gm |

| 03 | Fabric Weight | 70 mg |

| 04 | Water | 1610 ml |

| 05 | Acetic Acid | 0.9 gm |

| 06 | Anti-back Staining Agent | 0.9 gm |

| 07 | Temp | 45 c |

| 08 | Run Time | 20 min |

| 09 | Hydro Extraction | on sun |

| 10 | Dryer | Not need |

2.3. Preparation for Washing Ingredients:

- Fabric

- Enzyme (according to recipe)

- Machine (sustainable and conventional bath)

- Water (according to recipe)

- Hydro extraction machine

- Dryer

- Thermometer

- Electric Balance

- Beaker

- Pipette

2.4. Testing Methodology

2.4.1. Color Fastness to Wash Test

| Type of fabric | Method of washing | Rating |

|---|---|---|

| Cotton | Machine wash at 40°C | 4-5 (Good) |

| Polyester | Hand wash with mild detergent | 3-4 (Fair-Good) |

| Silk | Machine wash at 30°C | 5 (Excellent) |

| Wool | Machine wash at 60°C | 2 (Poor) |

2.4.2. Color Fastness to Rubbing Test

| Dark Shade | Medium shades | Light Shades | |

|---|---|---|---|

| Dry | 3-4 | 4 | 4-5 |

| Wet | 2-2.5 | 3 | 3.5-4 |

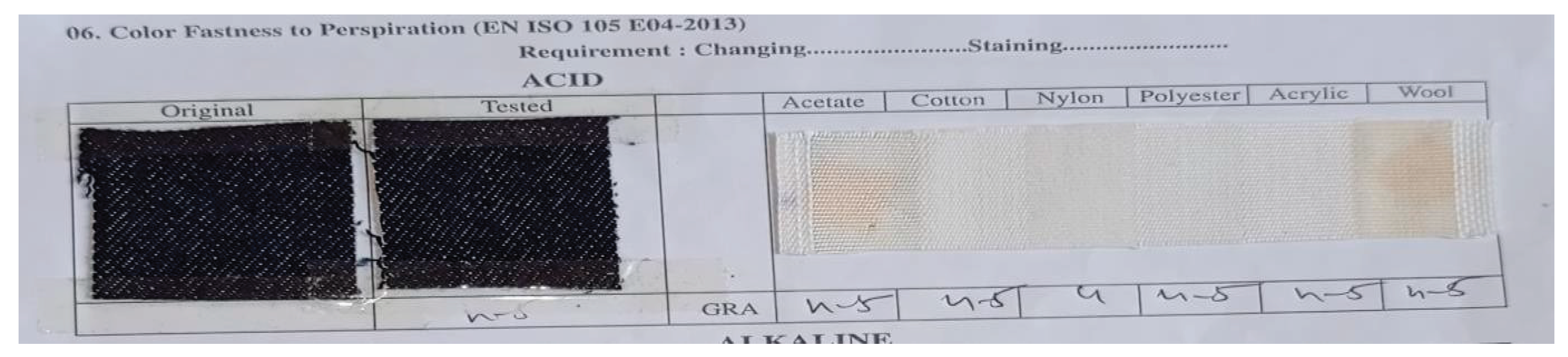

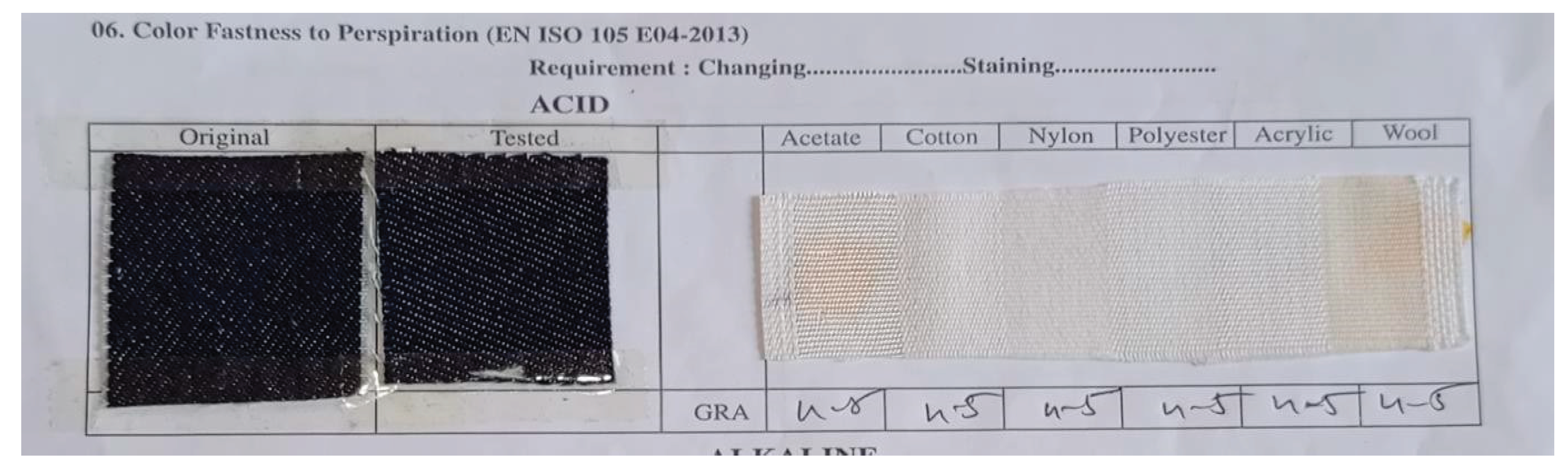

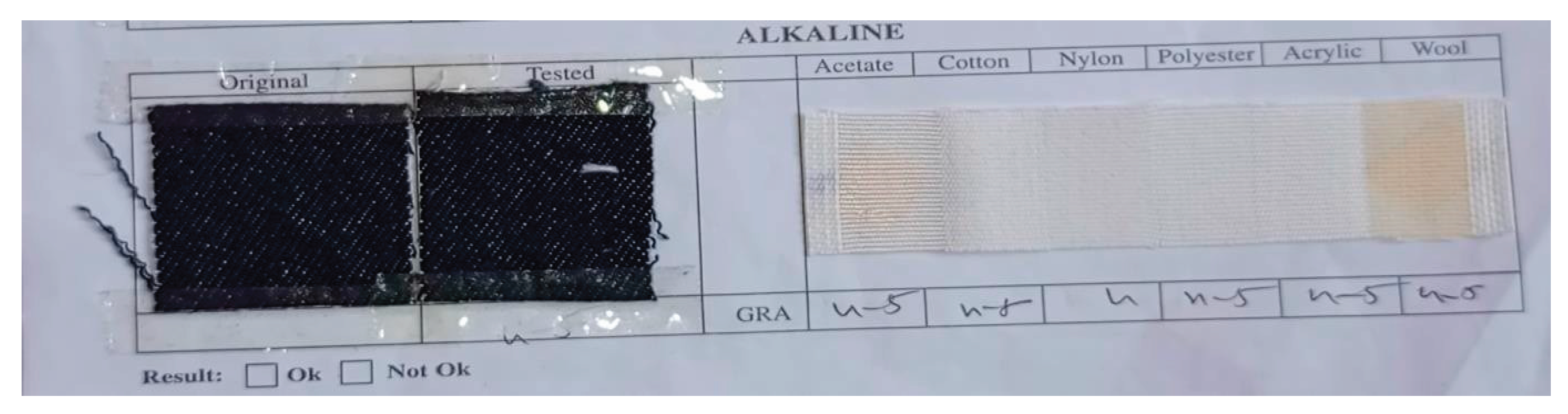

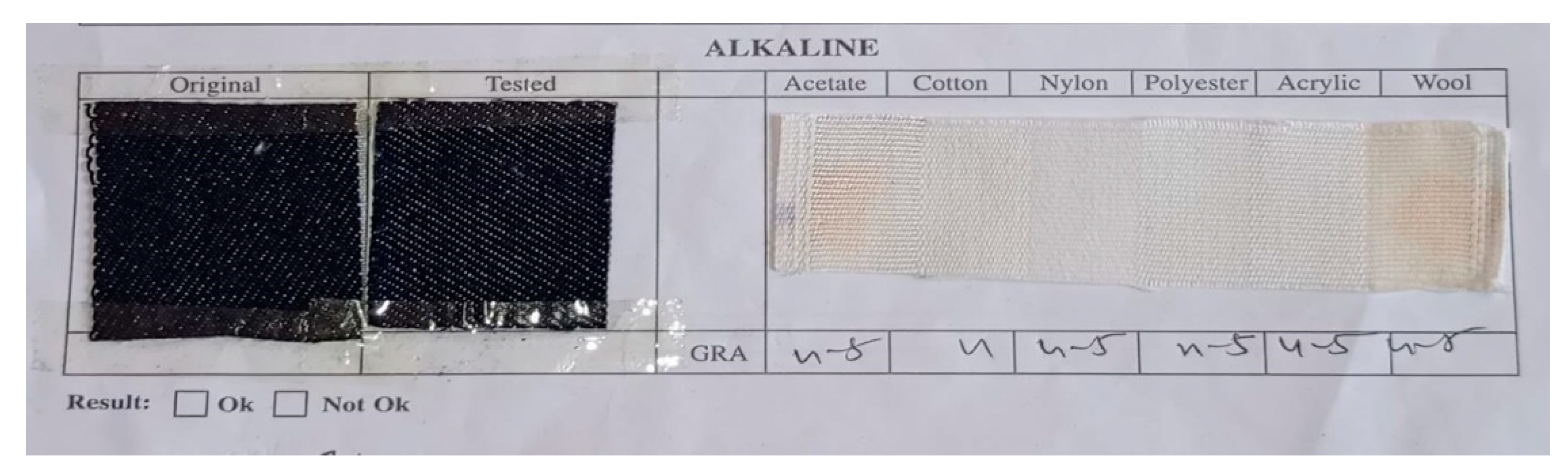

2.4.3. Color Fastness to Perspiration Test

| Grade | Degree of Fading | Light Fastness Type |

|---|---|---|

| 5 | No fading | Excellent |

| 4 | Slight fading | Good |

| 3 | Significant fading | Fair |

| 2 | Extensive fading | Poor |

| 1 | Very extensive fading | Very poor |

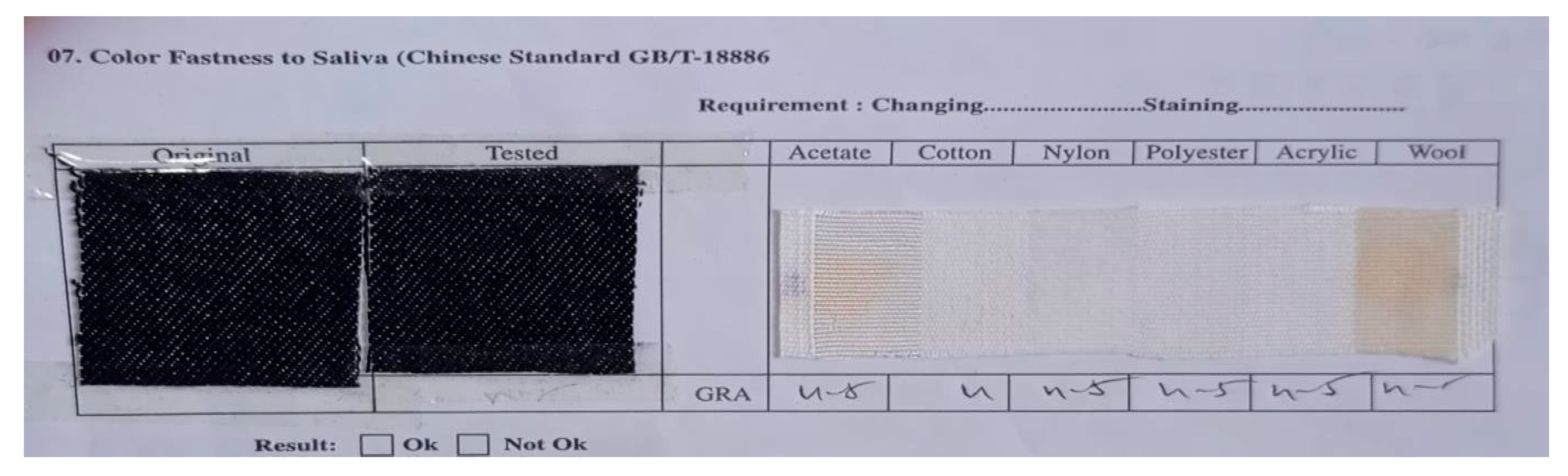

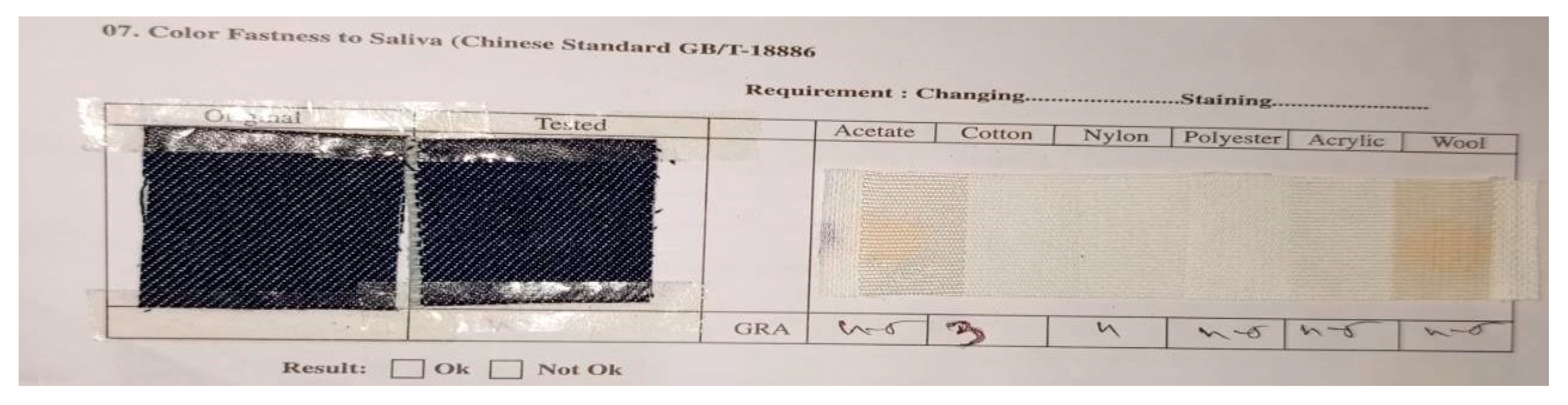

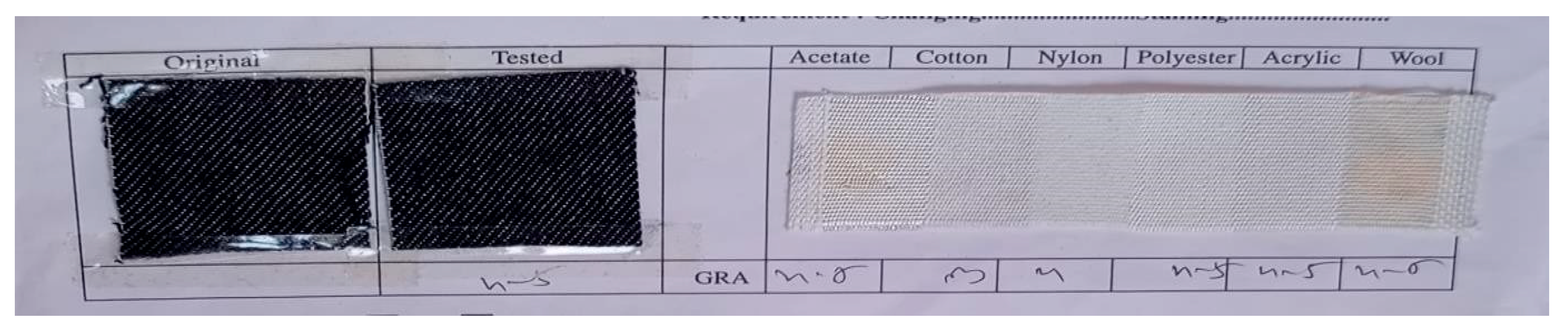

2.4.4. Color Fastness to Saliva Test:

| Grade | Degree of Fading | Saliva performance rate |

|---|---|---|

| 5 | No fading | Excellent |

| 4 | Slight fading | Good |

| 3 | Significant fading | Fair |

| 2 | Extensive fading | Poor |

| 1 | Very extensive fading | Very poor |

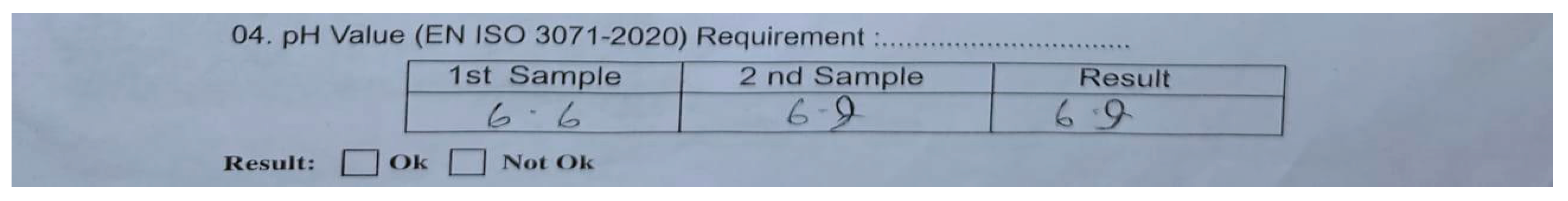

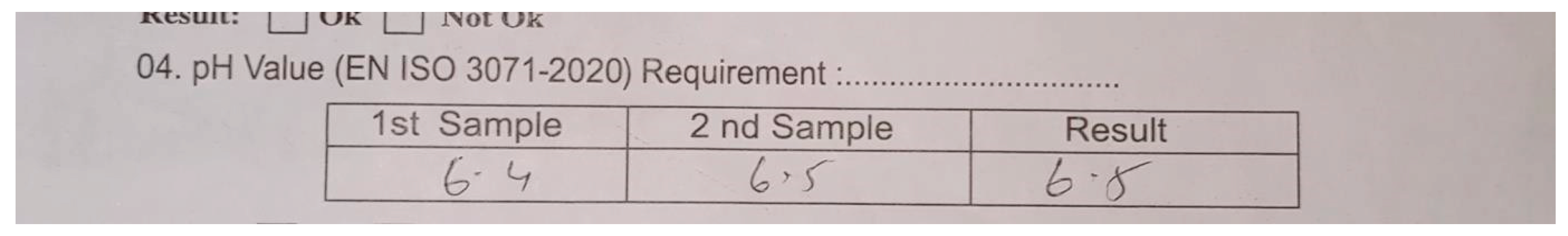

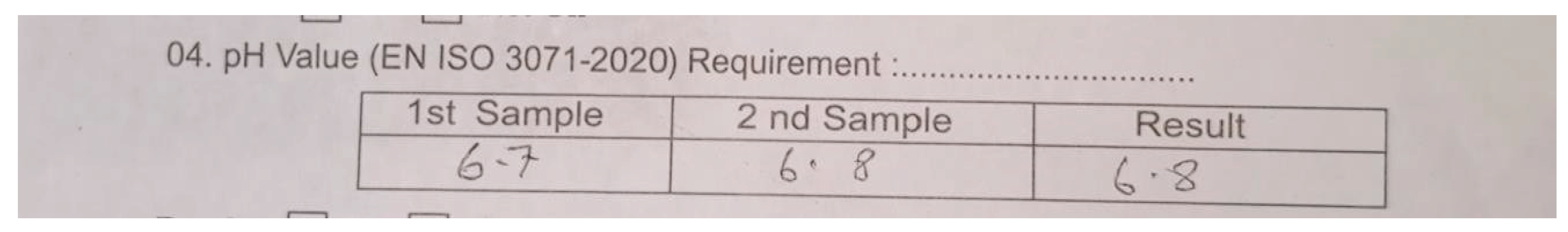

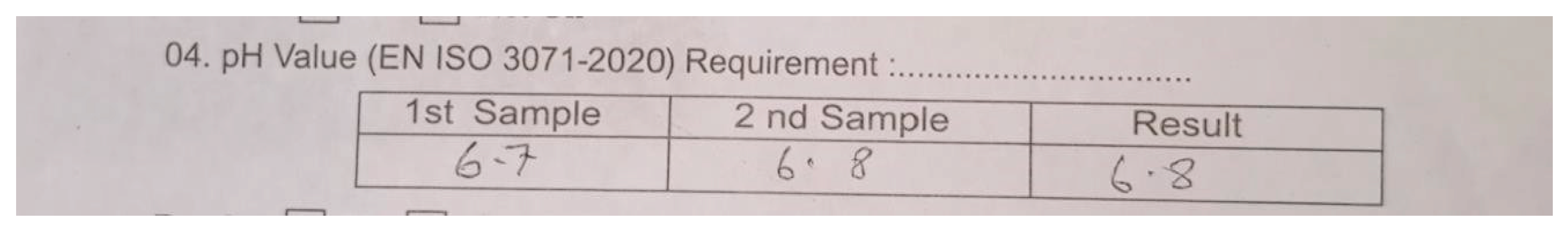

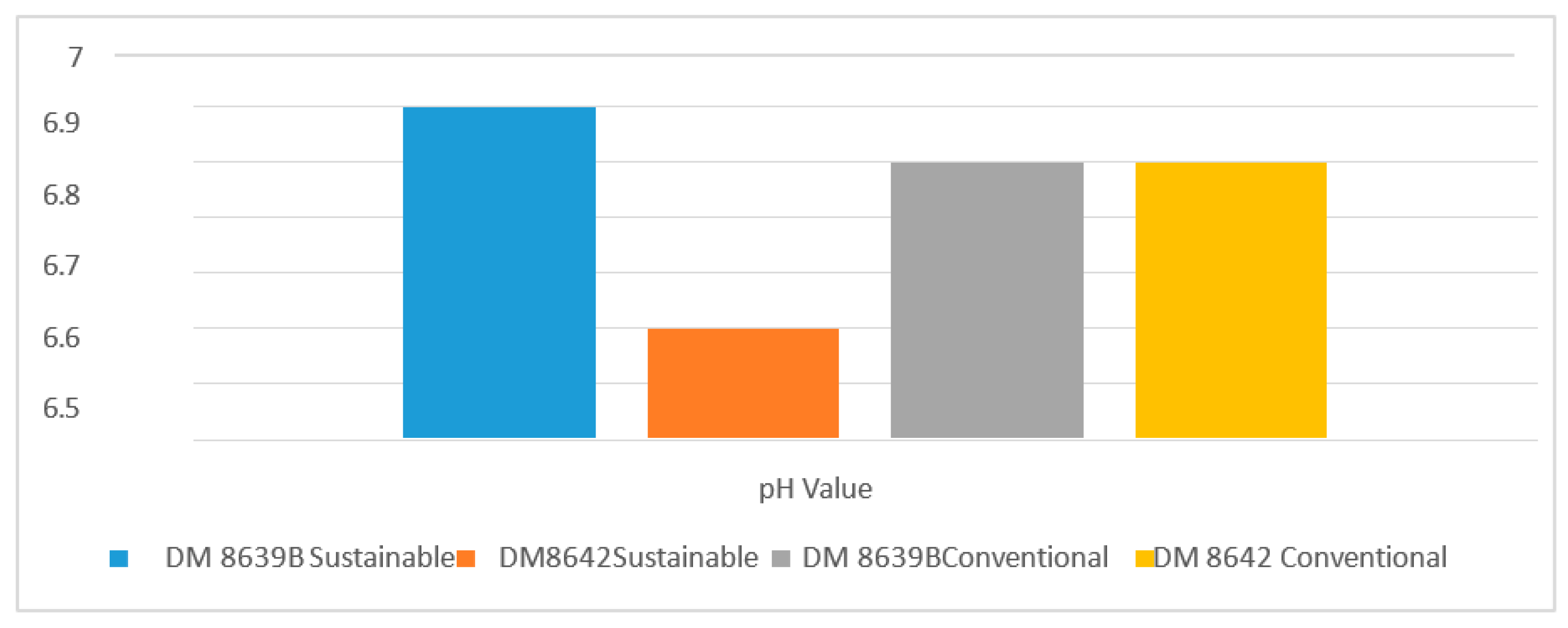

2.4.5. PH Value (EN ISO 3071-2020)

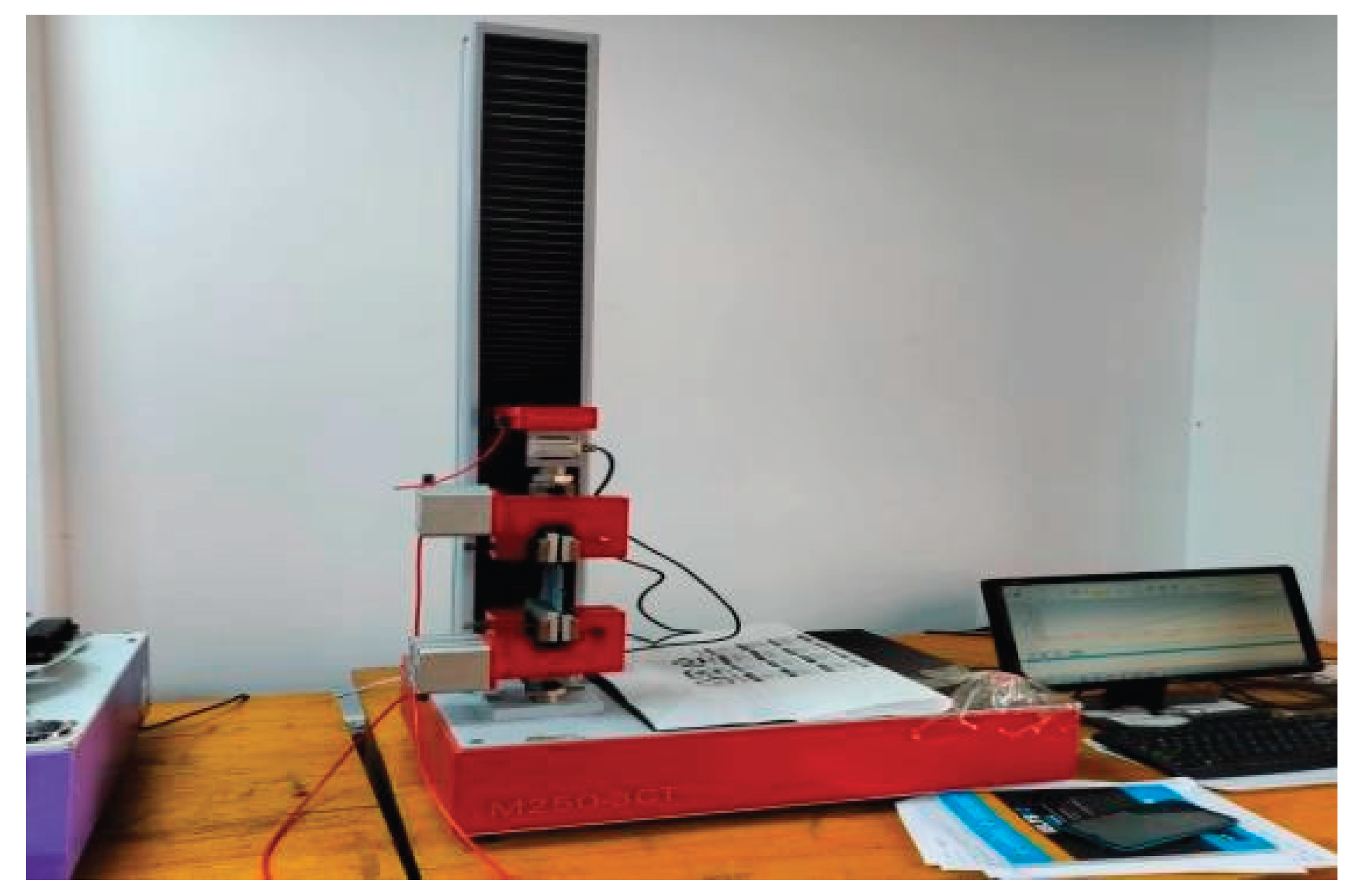

2.4.6. Tensile Strength

3. Result Analysis

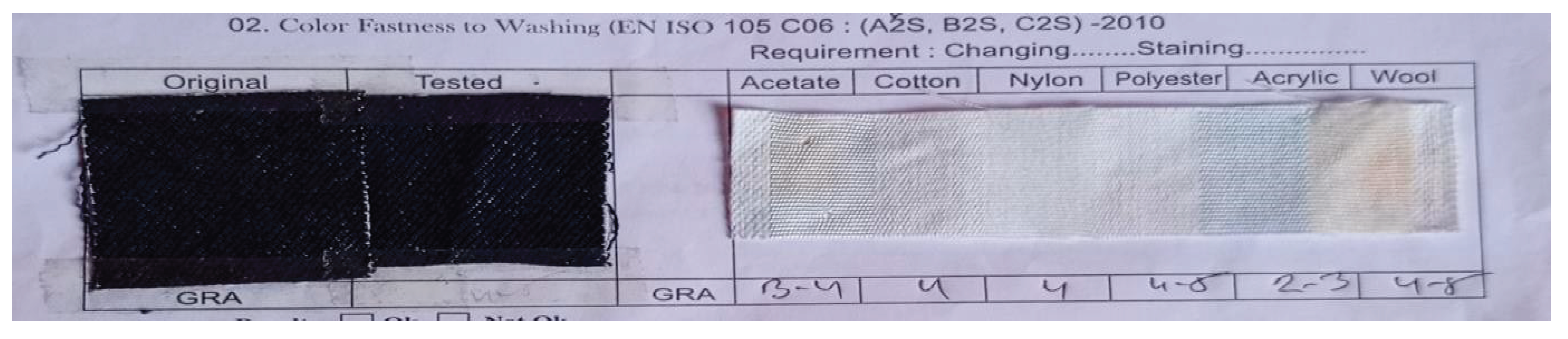

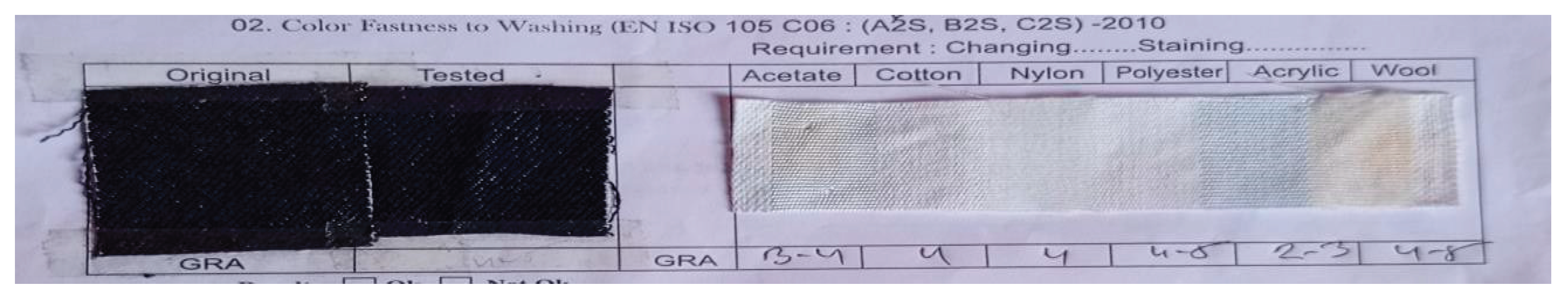

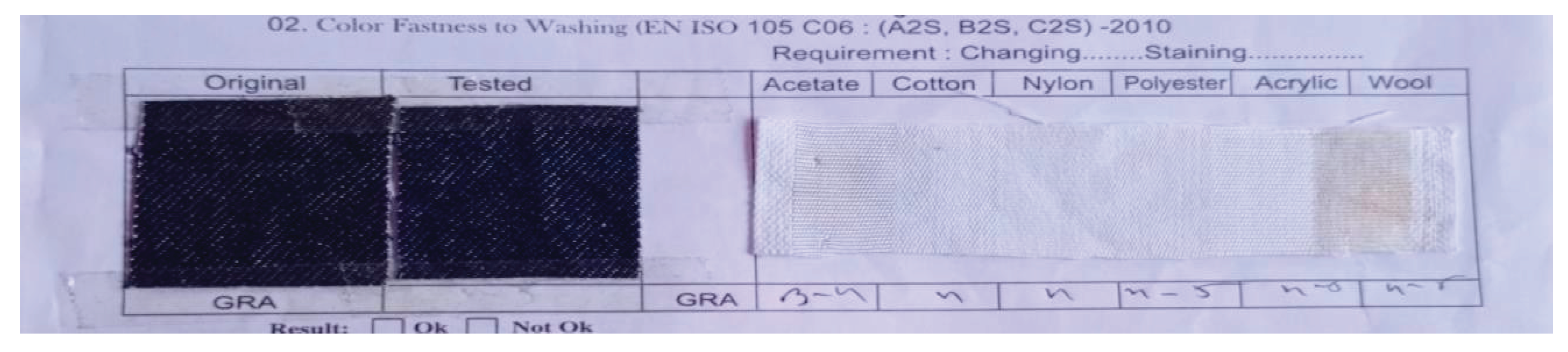

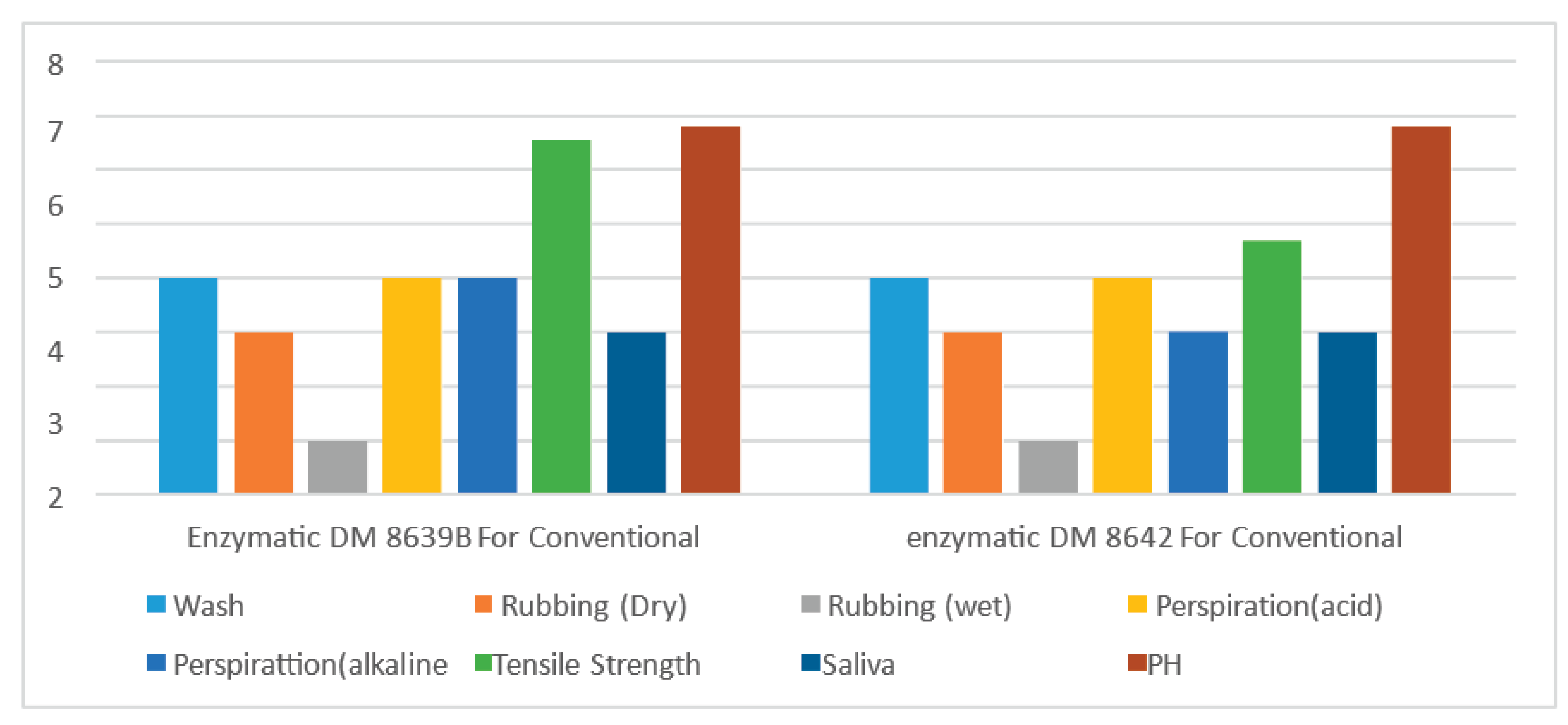

3.1. Color Fastness to Washing Test Report & Result

| S.L. | Washing Type | Fabric type | Test result (according to cotton) |

Performance |

|---|---|---|---|---|

| 1 | Enzymatic DM8639B(Sustainable) | Cotton | 5 | Excellent |

| 2 | Enzymatic DM8642(sustainable) | Cotton | 4 | Good |

| 3 | Enzymatic DM8639B(Conventional) | Cotton | 4 | Good |

| 4 | Enzymatic DM8642(Conventional) | Cotton | 4 | Good |

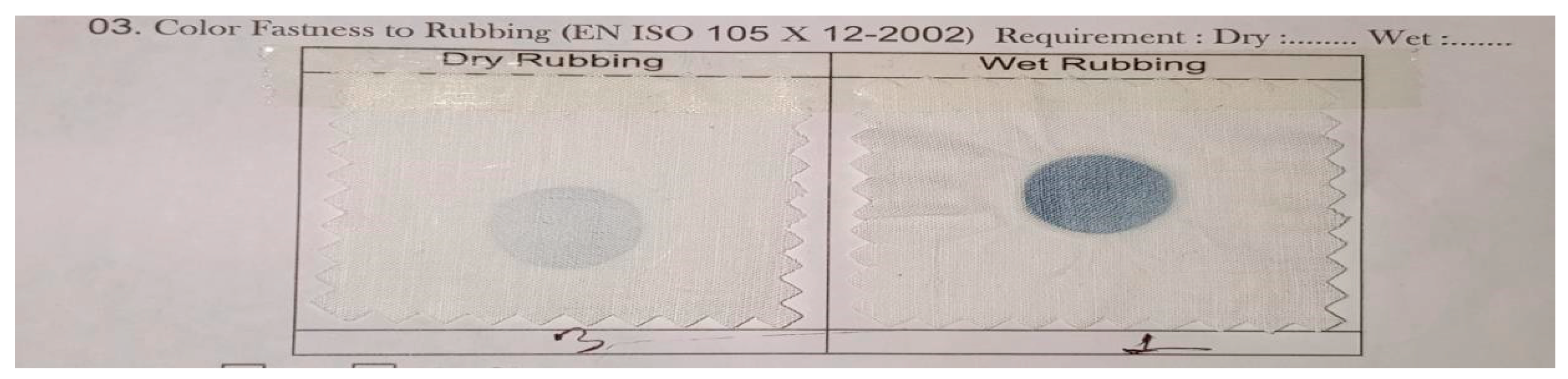

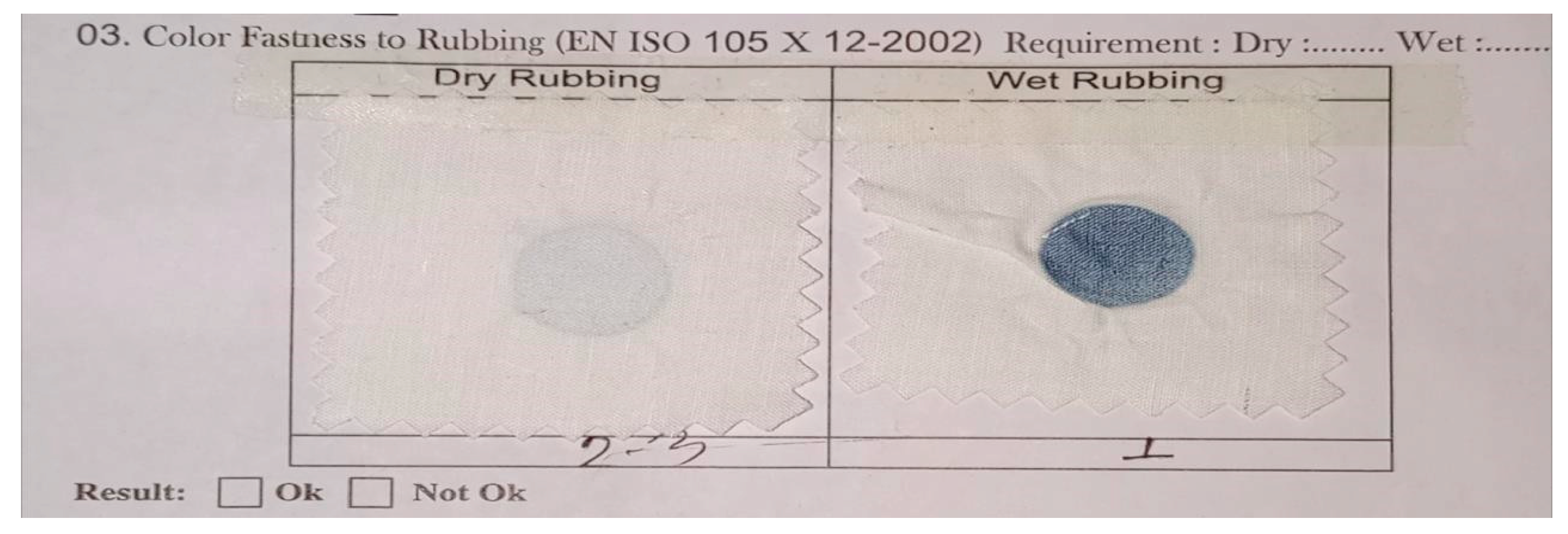

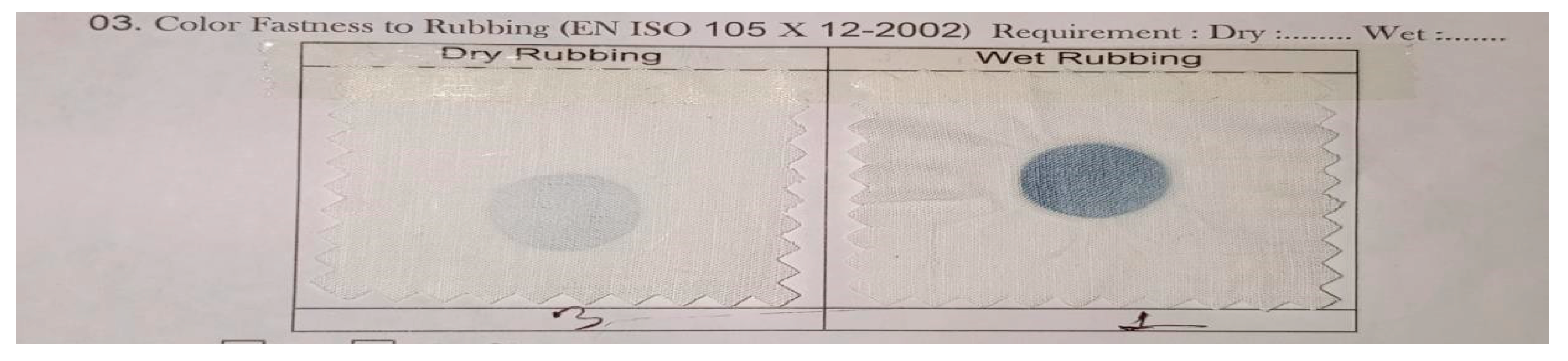

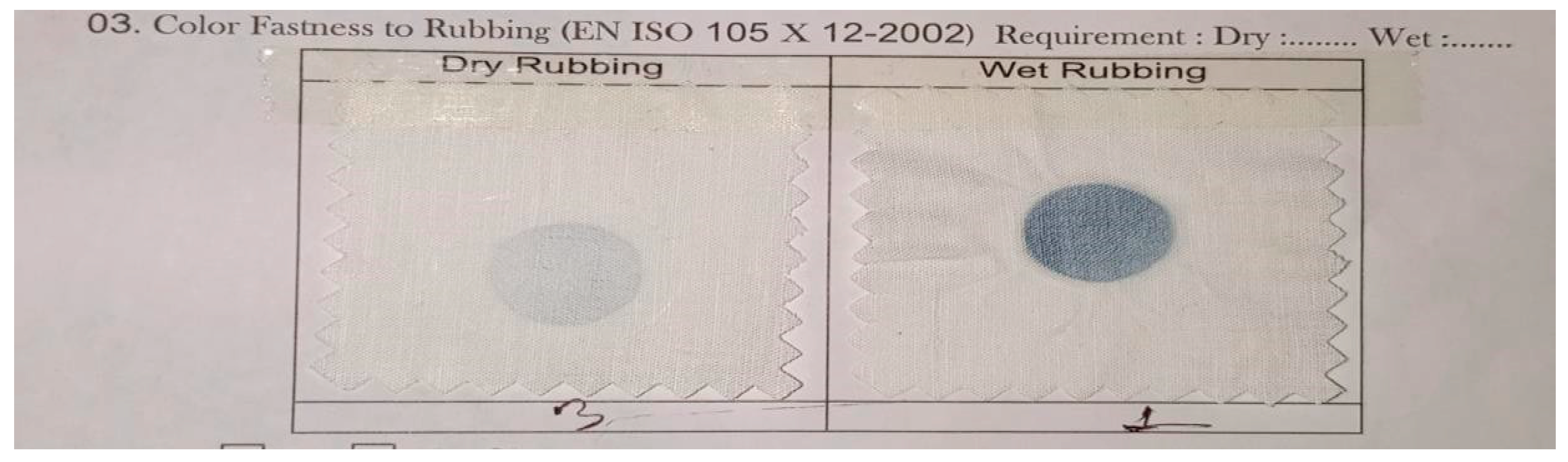

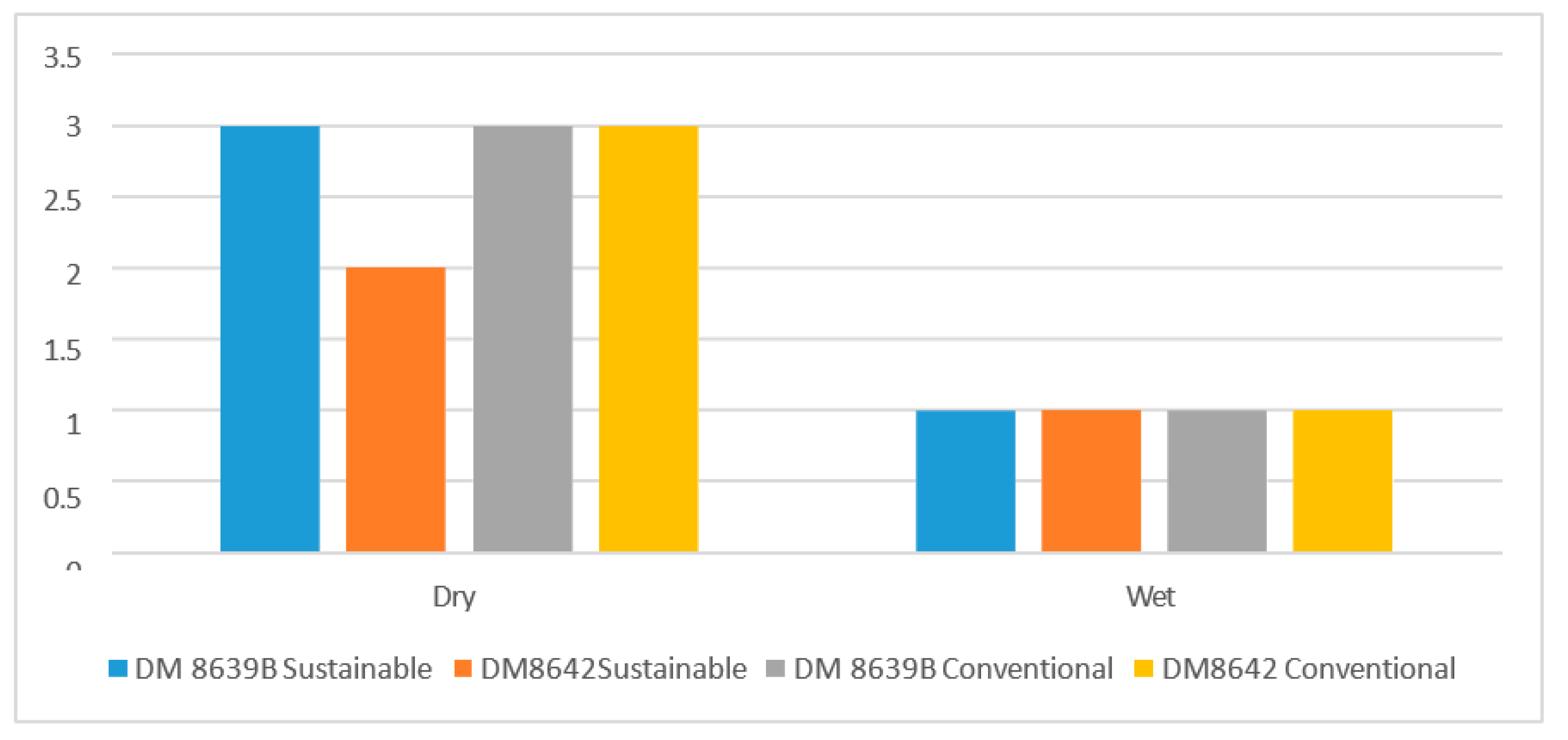

3.3. Color Fastness to Rubbing Test Report & Result

| S.L | Wash Type | Fabric type | Dry | Wet | Performance |

|---|---|---|---|---|---|

| 1 | Enzymatic DM8639B(Sustainable) | Cotton | 3 | 1 |

Fair for dry and very poor for wet fastness |

| 2 | Enzymatic DM8642(sustainable) | Cotton | 2/3 | 1 | Poor or fair for dry and very poor for wet fastness |

| 3 | Enzymatic DM8639B(Conventional) | Cotton | 3 | 1 |

Fair for dry and very poor for wet fastness |

| 4 | Enzymatic DM8642(Conventional) | Cotton | 3 | 1 |

Fair for dry and very poor for wet fastness |

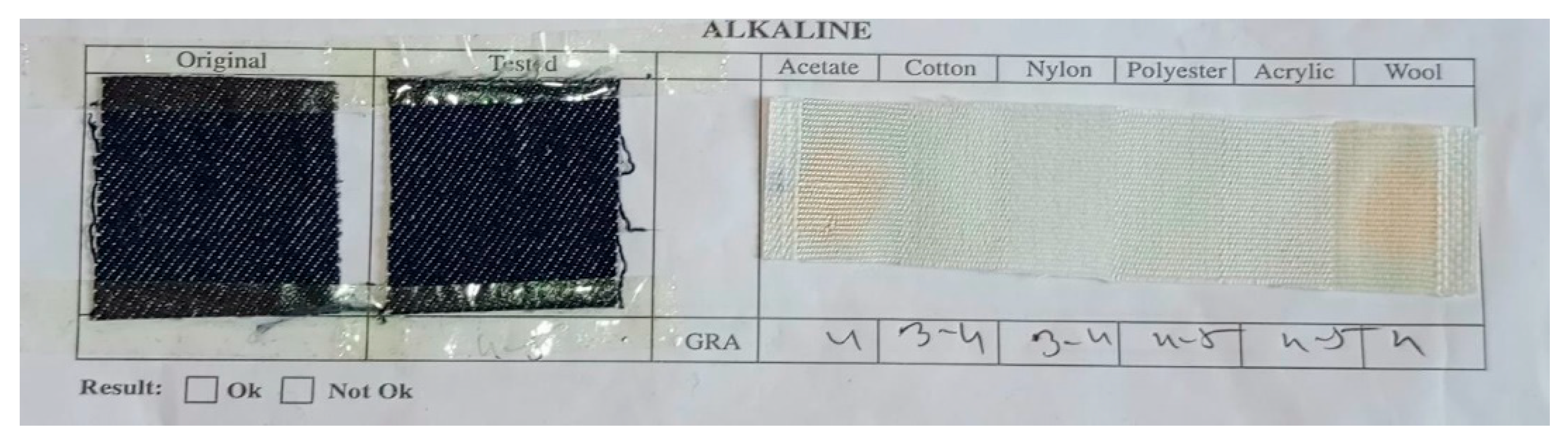

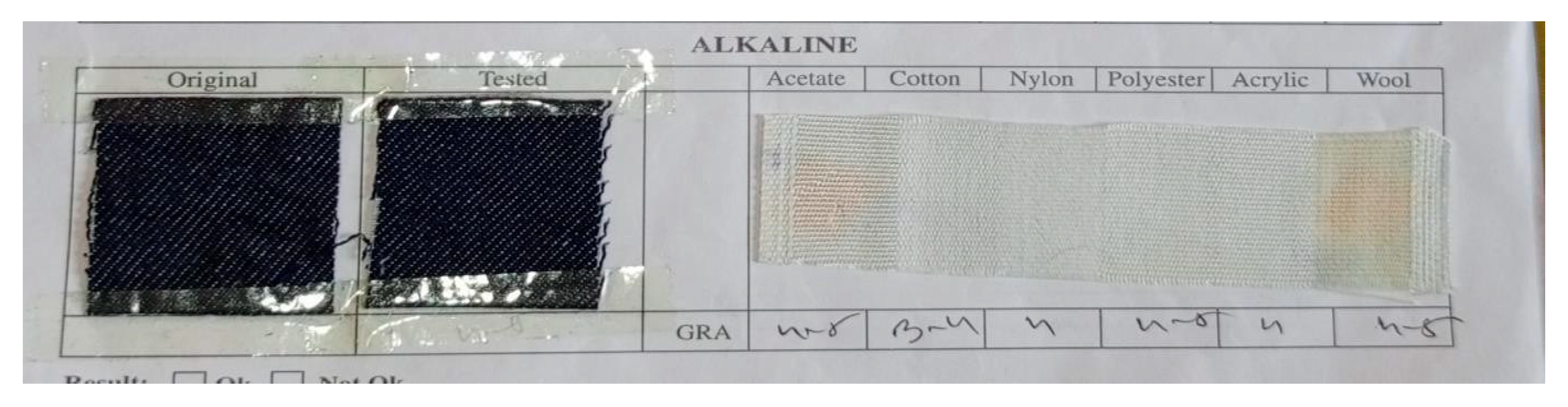

3.5. Color Fastness to Perspiration:

| S.L | Washing Type | Fabric type |

Test result (according to cotton) |

Performance |

|---|---|---|---|---|

| 1 | Enzymatic DM8639B(Sustainable) |

Cotton | 5 | Excellent |

| 2 | Enzymatic DM8642(sustainable) |

Cotton | 4 | Good |

| 3 | Enzymatic DM8639B(Conventiona l) |

Cotton | 4 | Good |

| 4 | Enzymatic DM8642(Conventional) |

Cotton | 4 | Good |

| S.L | Washing Type | Fabric type | Test result (according to cotton) |

Performance |

|---|---|---|---|---|

| 1 | Enzymatic DM8639B (Sustainable) |

Cotton | 5 | Excellent |

| 2 | Enzymatic DM8642 (sustainable) |

Cotton | 4/5 | Good |

| 3 | Enzymatic DM8639B (Conventional) | Cotton | 3/4 | Fair |

| 4 | Enzymatic DM8642 (Conventional) |

Cotton | 3/4 | Fair |

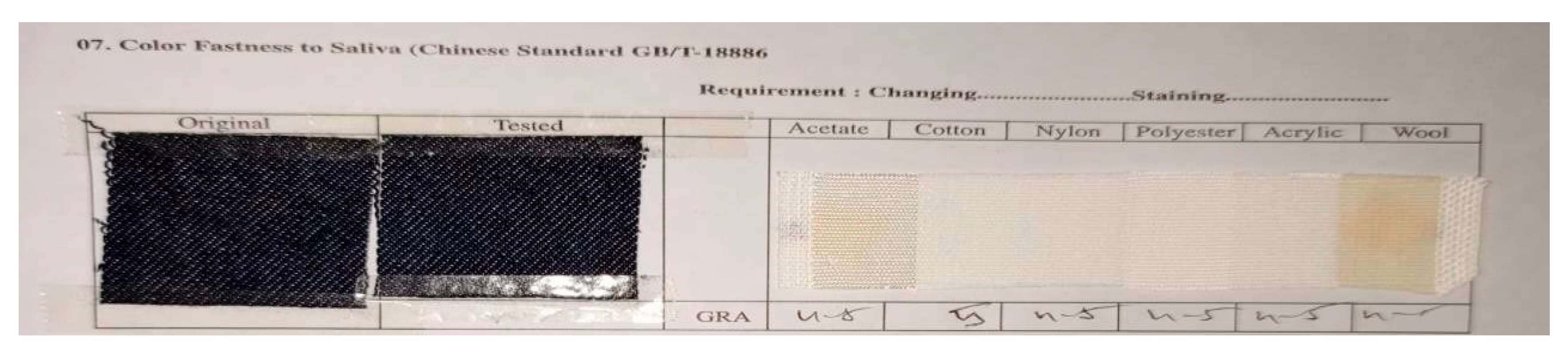

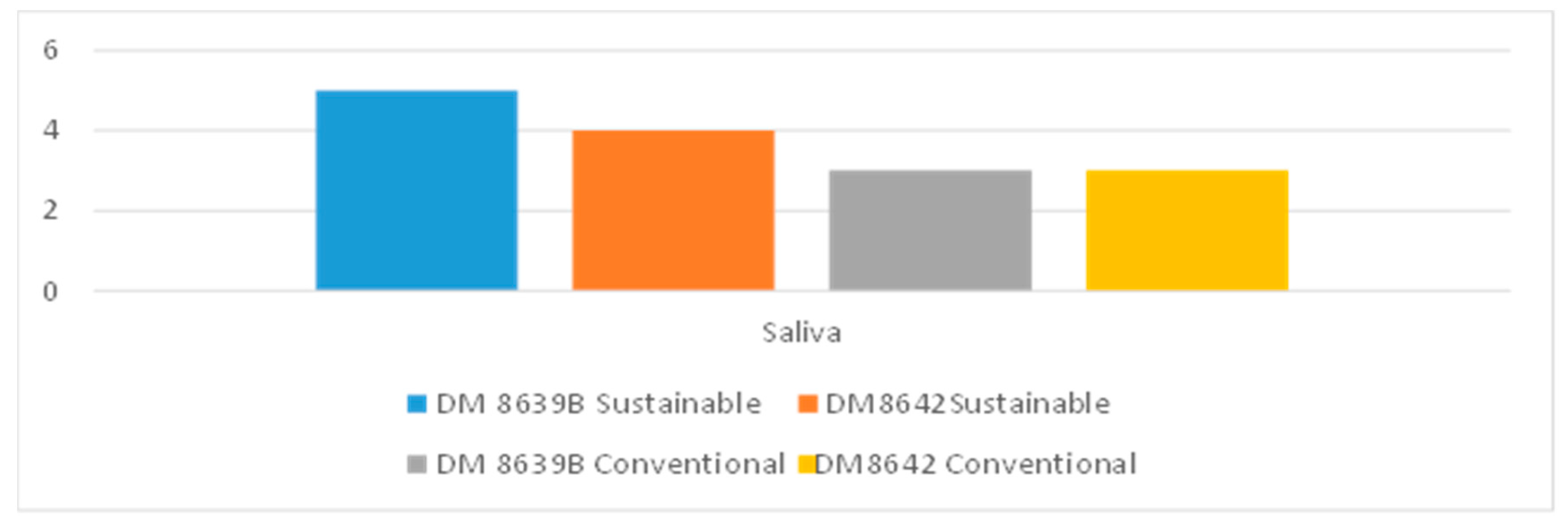

3.6. Saliva Test Report & Result

| S.L | Washing Type | Fabric type | Test result (according to cotton) |

Performance |

|---|---|---|---|---|

| 1 | Enzymatic DM8639B(Sustainable) |

Cotton | 5 | Excellent |

| 2 | Enzymatic DM8642(sustainable) |

Cotton | 4 | Good |

| 3 | Enzymatic DM8639B(Conventional) |

Cotton | 3 | Fair |

| 4 | Enzymatic DM8642(Conventional) |

Cotton | 3 | Fair |

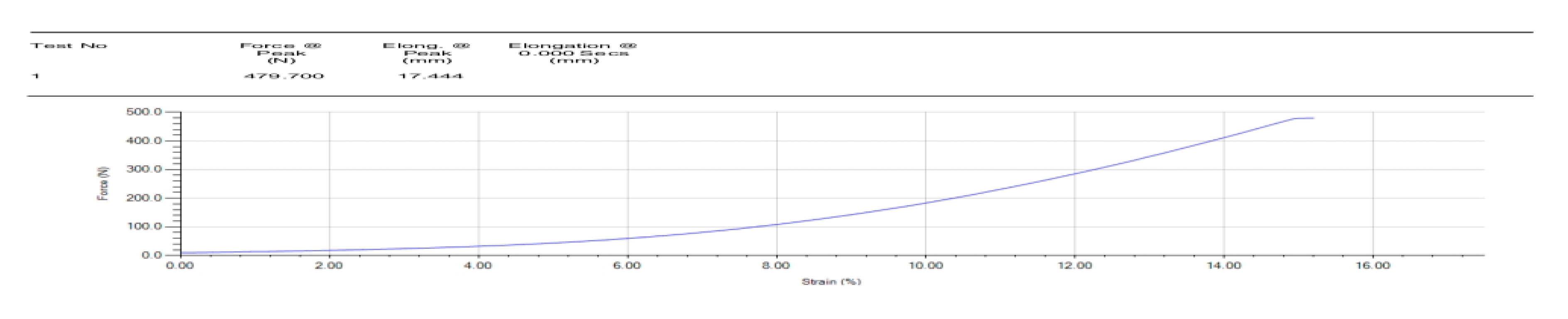

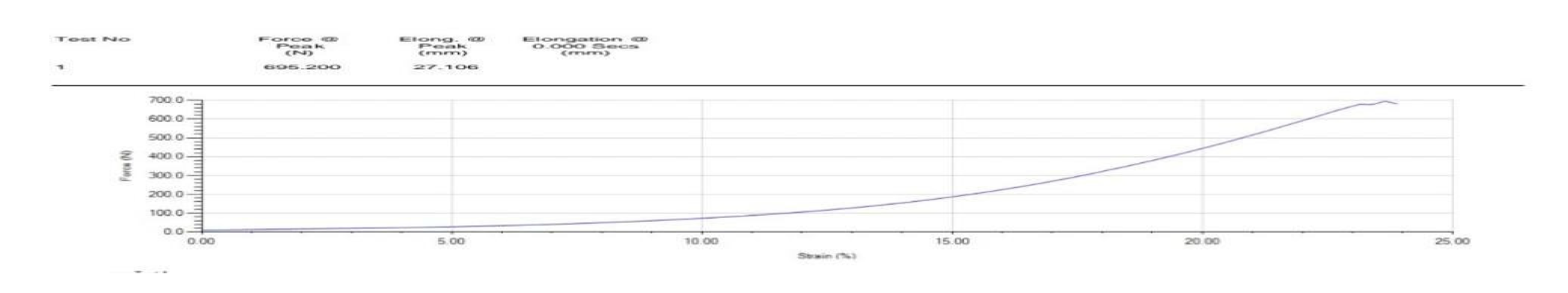

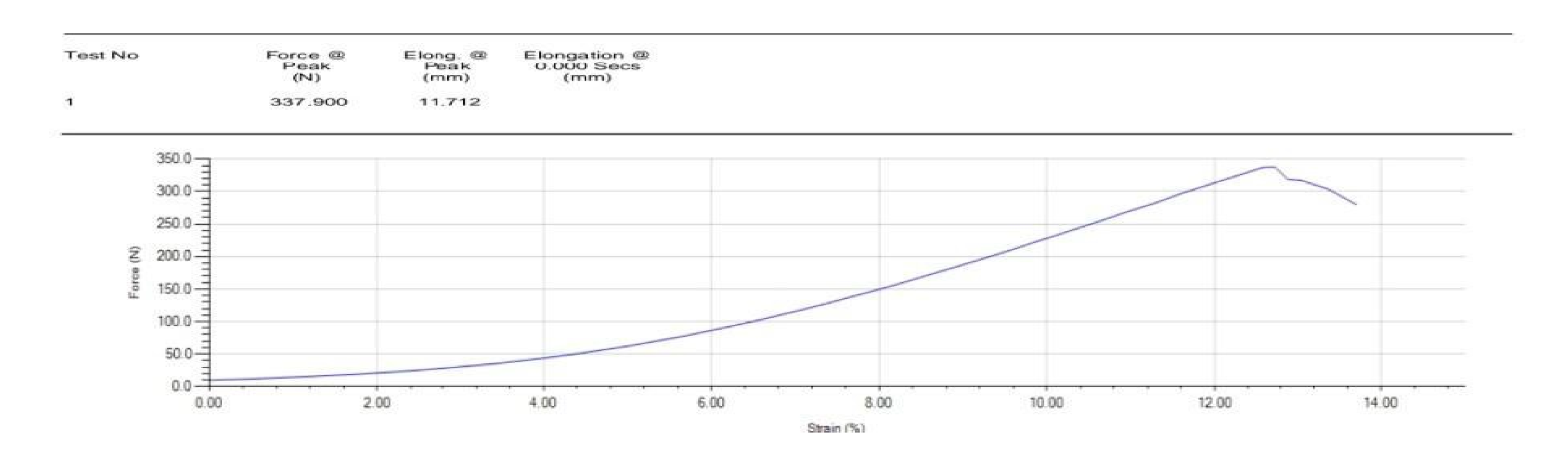

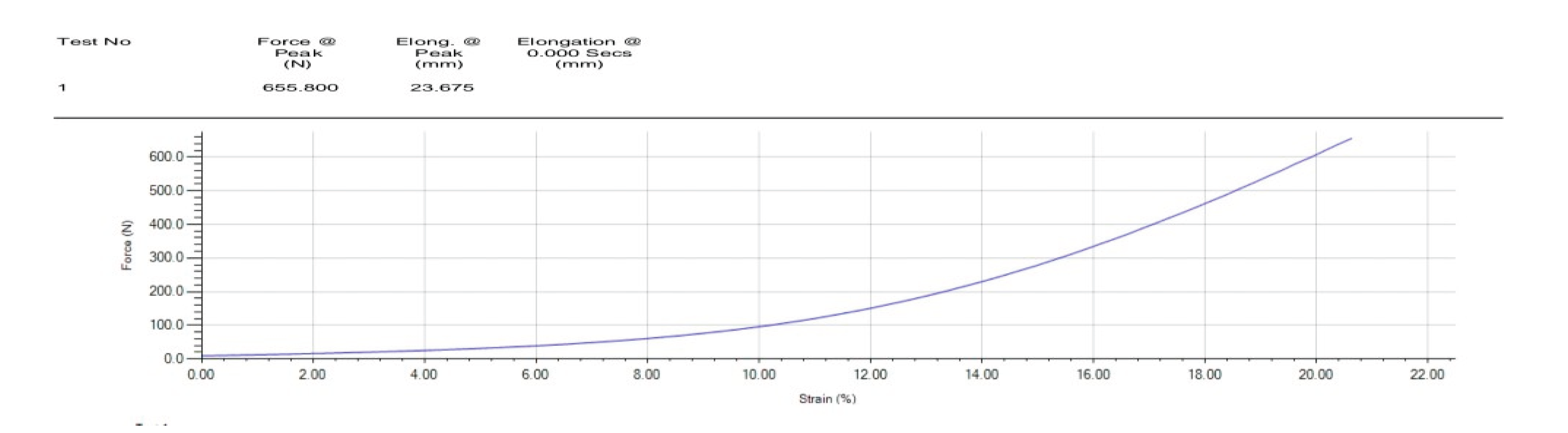

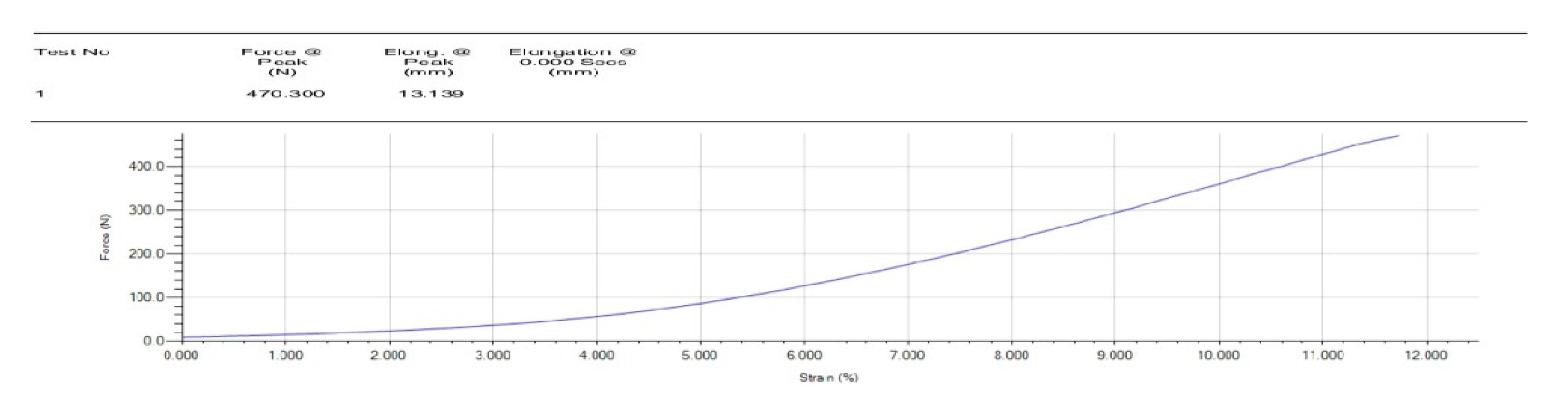

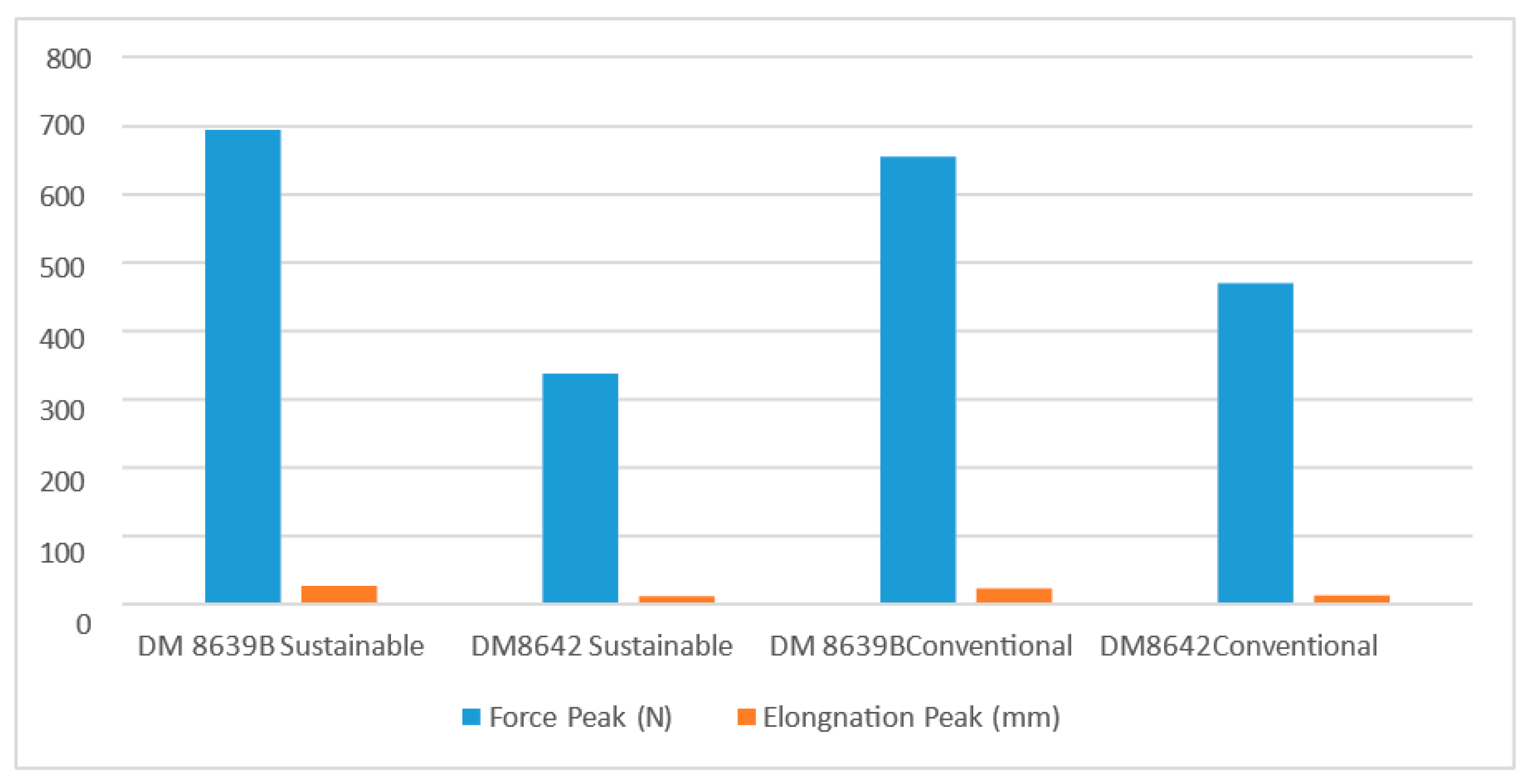

3.7. Tensile Strength Test Report and Result:

| S.L | Washing Type | Fabric type | Force Peak(N) | Elongation Peak(mm) |

|---|---|---|---|---|

| 1 | Enzymatic DM8639B(Sustainable) |

Cotton | 695.200 | 27.106 |

| 2 | Enzymatic DM8642(sustainable) |

Cotton | 337.900 | 11.712 |

| 3 | Enzymatic DM8639B(Conventional) |

Cotton | 655.800 | 23.675 |

| 4 | Enzymatic DM8642(Conventional) |

Cotton | 470.300 | 13.139 |

| 5 | Unwash (Raw fabric) | Cotton | 479.700 | 17.444 |

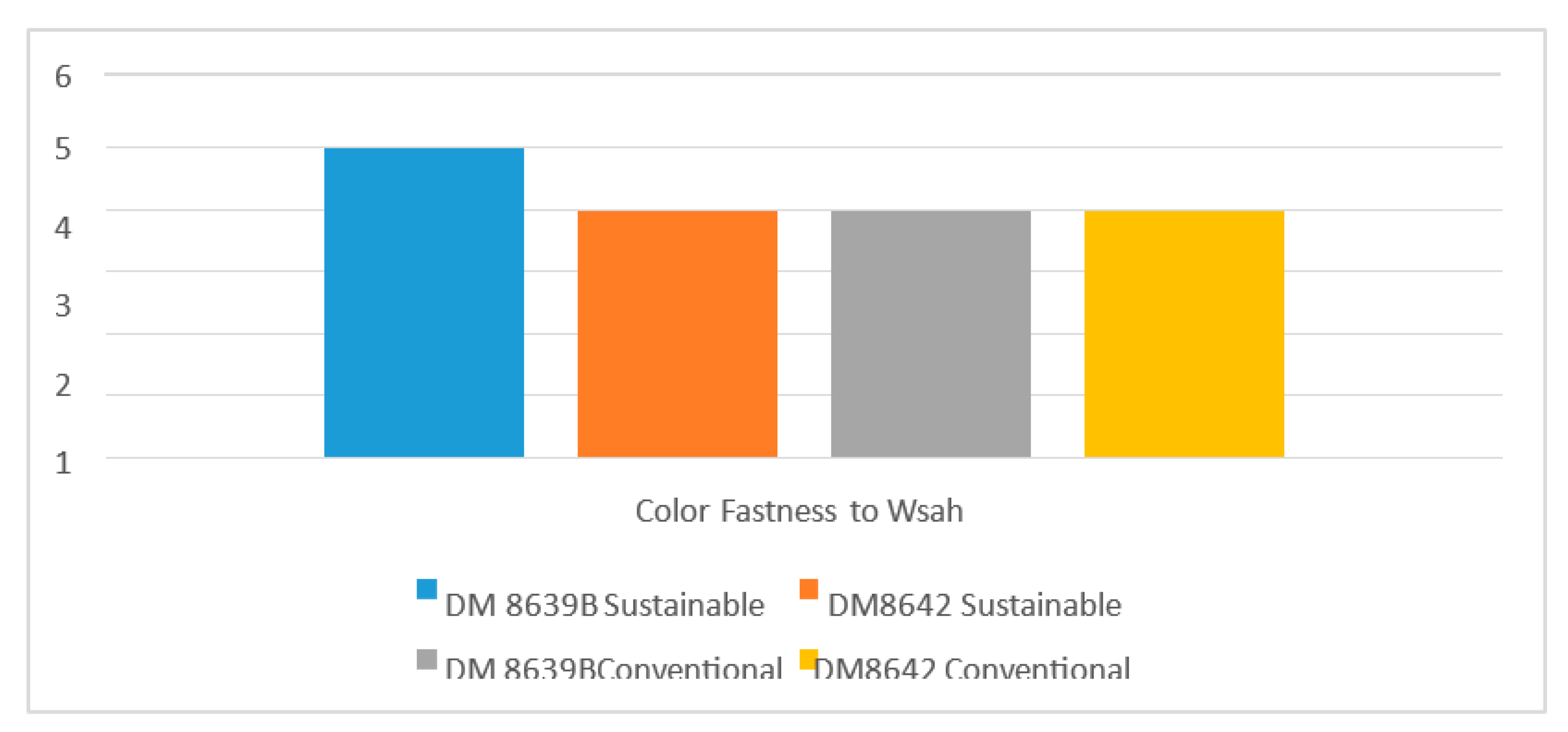

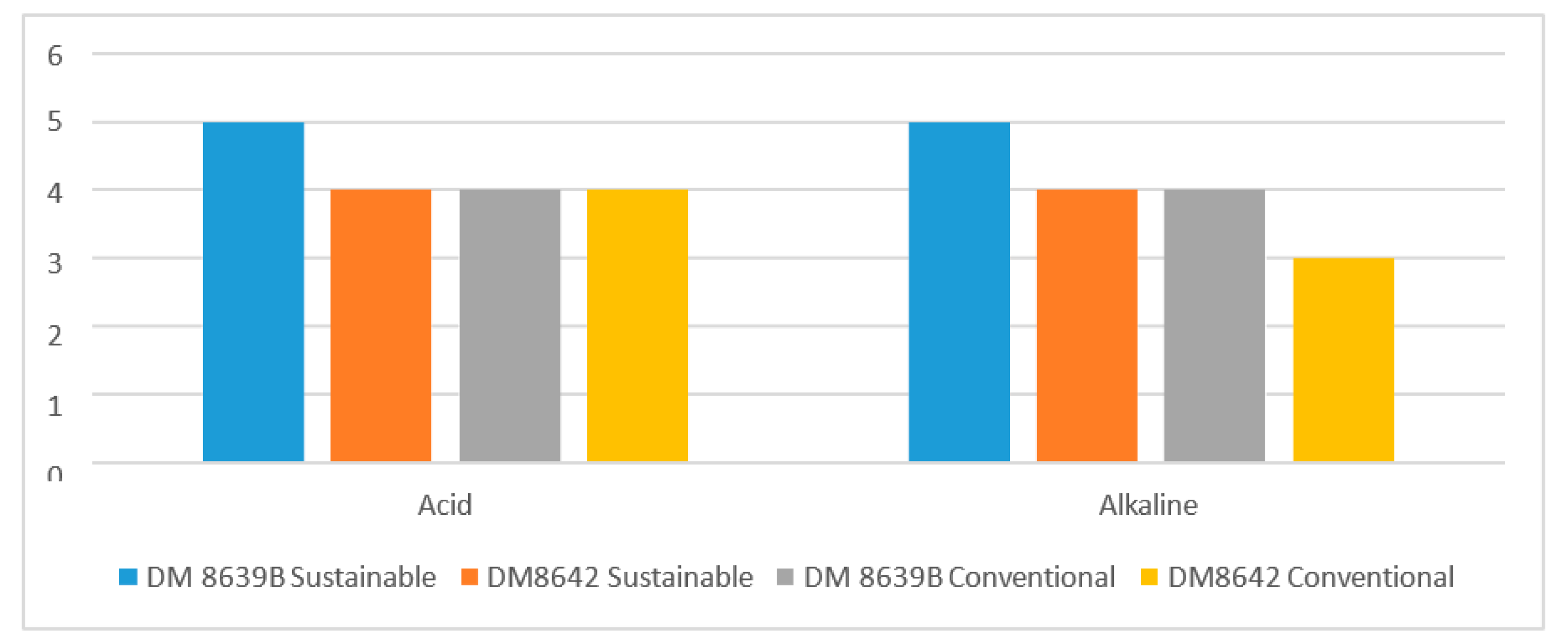

3.8. Differentiate Between Enzymatic DM8639B and DM 8642 Performance Graph in Sustainable Machine:

3.9. Differentiate Between Enzymatic DM8639B and DM 8642 Performance in Conventional Machine

| Name Of Tests | Sustainable | Conventional | Comments | ||

|---|---|---|---|---|---|

| - | DM 8639B | DM 8642 | DM 8639B | DM 8642 | |

| Color Fastness to Wash | 5 | 4 | 4 | 4 | The performance of 8639B is better than others |

| Color Fastness to Rubbing (Dry) |

3 | 2 | 3 | 3 | Both performances were very close |

| Color Fastness to Rubbing (Wet) |

1 | 1 | 1 | 1 | Both are Poor in Wet Condition |

| pH | 6.9 | 6.5 | 6.8 | 6.8 | Both Are well within this optimal range. |

| Color Fastness to Perspiration (acid) |

5 | 4 | 4 | 4 | The performance of 8639B is better than others |

| Color Fastness to Perspiration (Alkaline) |

5 | 4 | 4 | 3 | |

| Color Fastness to Saliva | 5 | 4 | 3 | 3 | The performance of 8639B is better than others |

| Tensile Strength | 6.95 | 3.37 | 6.55 | 4.7 | The performance of 8639B is better than others |

4. Conclusion

References

- K. Irmak, S. Yılmaz, and M. Gideroğlu, “Development Of Sustainable Denim Products with Foam Application Technique in Denim Washing Processes,” Orclever Proceedings of Research and Development, vol. 5, no. 1, pp. 459–469, Dec. 2024. [CrossRef]

- Ben Fraj and B. Jaouachi, “Effects of ozone treatment on denim garment properties,” Coloration Technology, vol. 137, no. 6, pp. 678–688, Jun. 2021. [CrossRef]

- N. Sünter Eroglu, “SUSTAINABILITY APPROACHES IN DENIM PRODUCTS AND PRODUCTION PROCESSES,” Tekstil ve Mühendis, vol. 30, no. 132, pp. 335–350, Dec. 2023. [CrossRef]

- Telli and O. Babaarslan, “The effect of recycled fibers on the washing performance of denim fabrics,” The Journal of The Textile Institute, vol. 108, no. 5, pp. 812–820, Jun. 2016. [CrossRef]

- P. Periyasamy and S. Periyasami, “Critical Review on Sustainability in Denim: A Step toward Sustainable Production and Consumption of Denim.,” ACS Omega, vol. 8, no. 5, pp. 4472–4490, Jan. 2023. [CrossRef]

- S. B. A. Hamid, M. M. Islam, and R. Das, “Cellulase biocatalysis: key influencing factors and mode of action,” Cellulose, vol. 22, no. 4, pp. 2157–2182, Jun. 2015. [CrossRef]

- H. Aykaç Özen, B. Vayiç, and S. Çoruh, “Assessment of organizational carbon footprints in a denim-washing company: a systematic approach to indirect non-energy emissions,” Environmental Science and Pollution Research, vol. 31, no. 24, pp. 35897–35907, May 2024. [CrossRef]

- P. Julapong, P. Srichonphaisarn, O. Juntarasakul, C. B. Tabelin, T. Phengsaart, and T. Meekoch, “The Influence of Textile Type, Textile Weight, and Detergent Dosage on Microfiber Emissions from Top-Loading Washing Machines.,” Toxics, vol. 12, no. 3, p. 210, Mar. 2024. [CrossRef]

- Z. Zareshahrabadi, N. Amirzadeh, K. Pakshir, R. Nasr, R. Mohammadi, and K. Zomorodian, “Evaluation of building washing machines as an extreme environment for potentially pathogenic fungi,” Scientific Reports, vol. 13, no. 1, Dec. 2023. [CrossRef]

- S. Jacksch et al., “Influence of Sampling Site and other Environmental Factors on the Bacterial Community Composition of Domestic Washing Machines.,” Microorganisms, vol. 8, no. 1, p. 30, Dec. 2019. [CrossRef]

- P. Kakkar and N. Wadhwa, “Extremozymes used in textile industry,” The Journal of The Textile Institute, vol. 113, no. 9, pp. 2007–2015, Jun. 2021. [CrossRef]

- M. Mohsin and S. Sardar, “Development of sustainable and cost efficient textile foam-finishing and its comparison with conventional padding,” Cellulose, vol. 27, no. 7, pp. 4091–4107, Feb. 2020. [CrossRef]

- G. Korsa, R. Konwarh, S. Haile, C. Masi, and A. Ayele, “Microbial cellulase production and its potential application for textile industries,” Annals of Microbiology, vol. 73, no. 1, Apr. 2023. [CrossRef]

- N. I. Khalid, N. Ab Aziz, M. H. Abd Rahim, and T. U. Noh, “Alkaline electrolyzed water AS a potential green degreaser for meat processing stainless steel surface,” Journal of Food Process Engineering, vol. 46, no. 12, Sep. 2023. [CrossRef]

- H. Aykaç Özen, B. Vayiç, and S. Çoruh, “Assessment of organizational carbon footprints in a denim-washing company: a systematic approach to indirect non-energy emissions,” Environmental Science and Pollution Research, vol. 31, no. 24, pp. 35897–35907, May 2024. [CrossRef]

- P. Periyasamy and S. Periyasami, “Critical Review on Sustainability in Denim: A Step toward Sustainable Production and Consumption of Denim.,” ACS Omega, vol. 8, no. 5, pp. 4472–4490, Jan. 2023. [CrossRef]

- K. Irmak, S. Yılmaz, and M. Gideroğlu, “Development Of Sustainable Denim Products with Foam Application Technique in Denim Washing Processes,” Orclever Proceedings of Research and Development, vol. 5, no. 1, pp. 459–469, Dec. 2024. [CrossRef]

- N. Sünter Eroglu, “SUSTAINABILITY APPROACHES IN DENIM PRODUCTS AND PRODUCTION PROCESSES,” Tekstil ve Mühendis, vol. 30, no. 132, pp. 335–350, Dec. 2023. [CrossRef]

- S. B. A. Hamid, M. M. Islam, and R. Das, “Cellulase biocatalysis: key influencing factors and mode of action,” Cellulose, vol. 22, no. 4, pp. 2157–2182, Jun. 2015. [CrossRef]

- Ben Fraj and B. Jaouachi, “Effects of ozone treatment on denim garment properties,” Coloration Technology, vol. 137, no. 6, pp. 678–688, Jun. 2021. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).