Submitted:

21 May 2025

Posted:

22 May 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Proposed Simulation and Experimental Methods

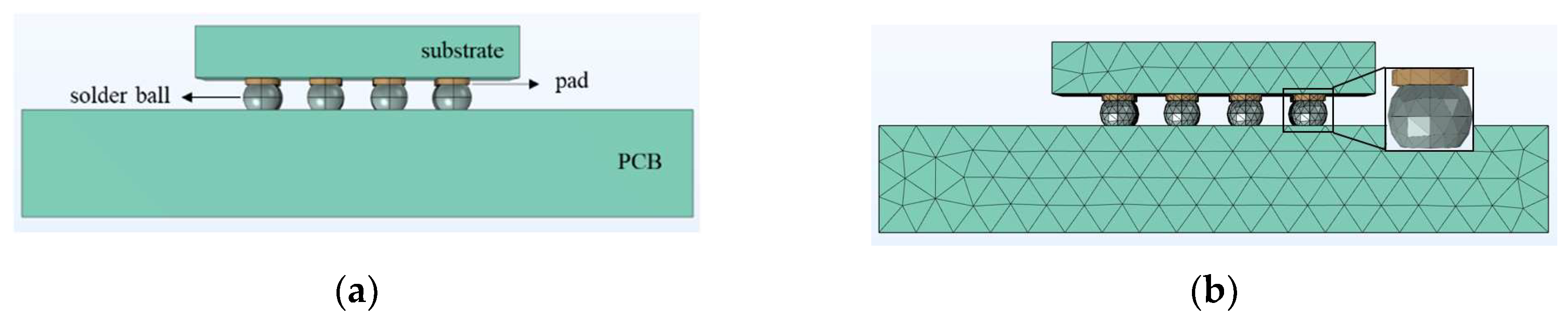

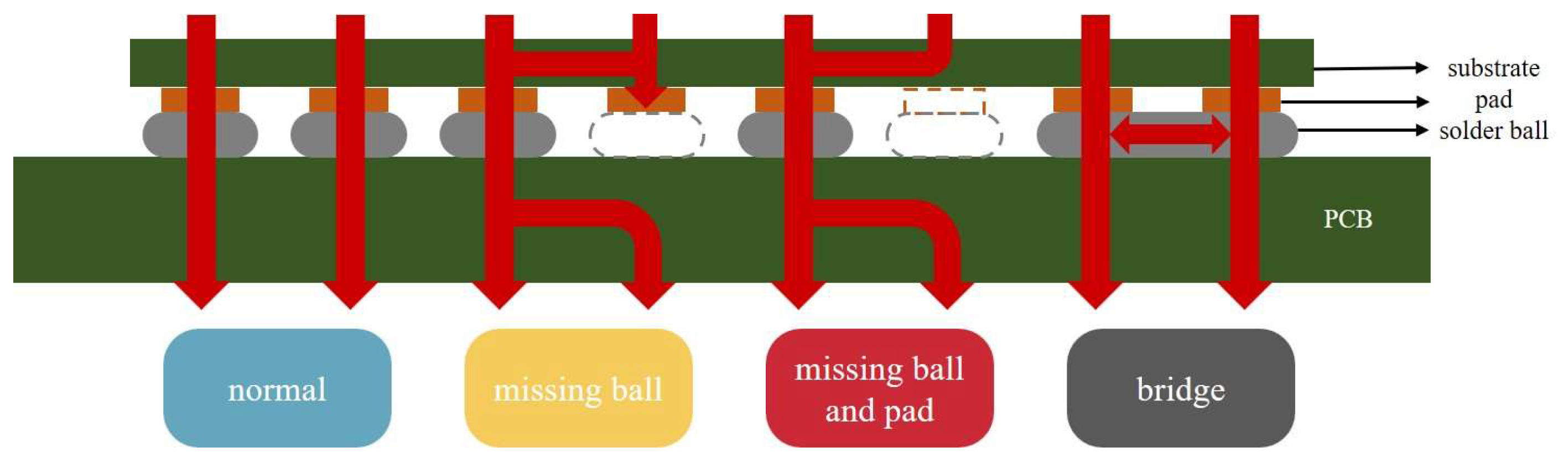

2.1. Finite Element Modeling of Packaging Structure

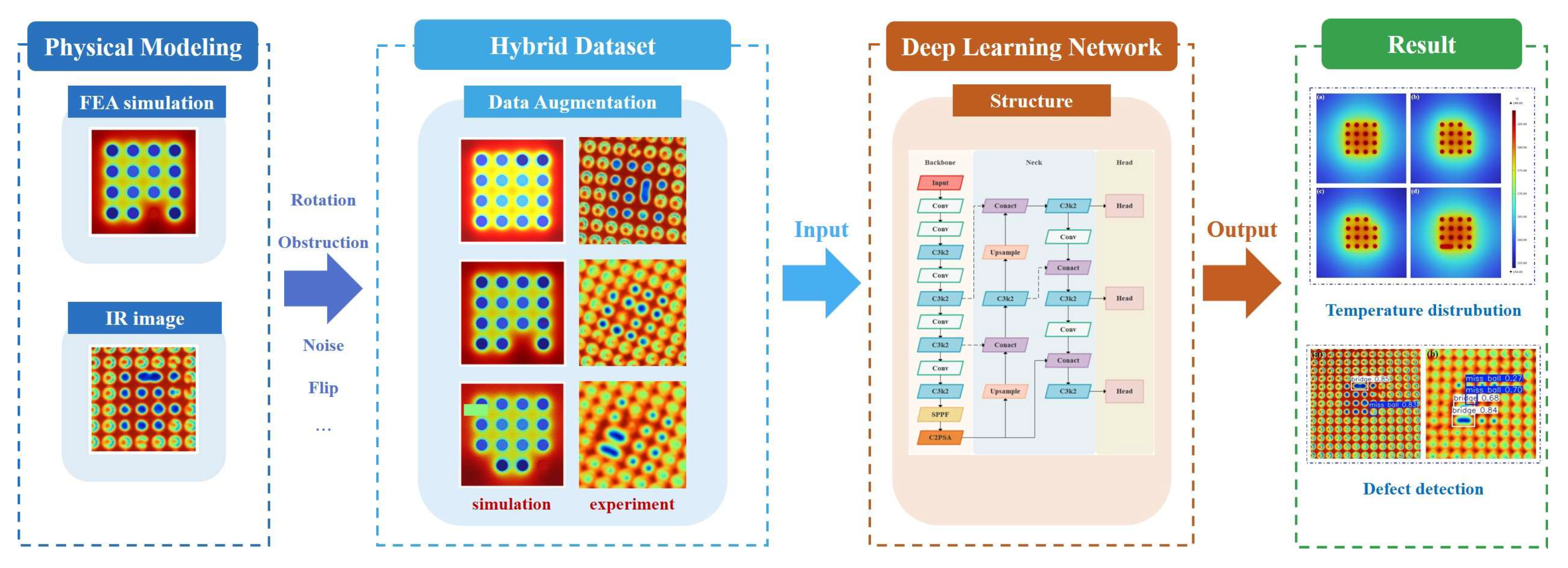

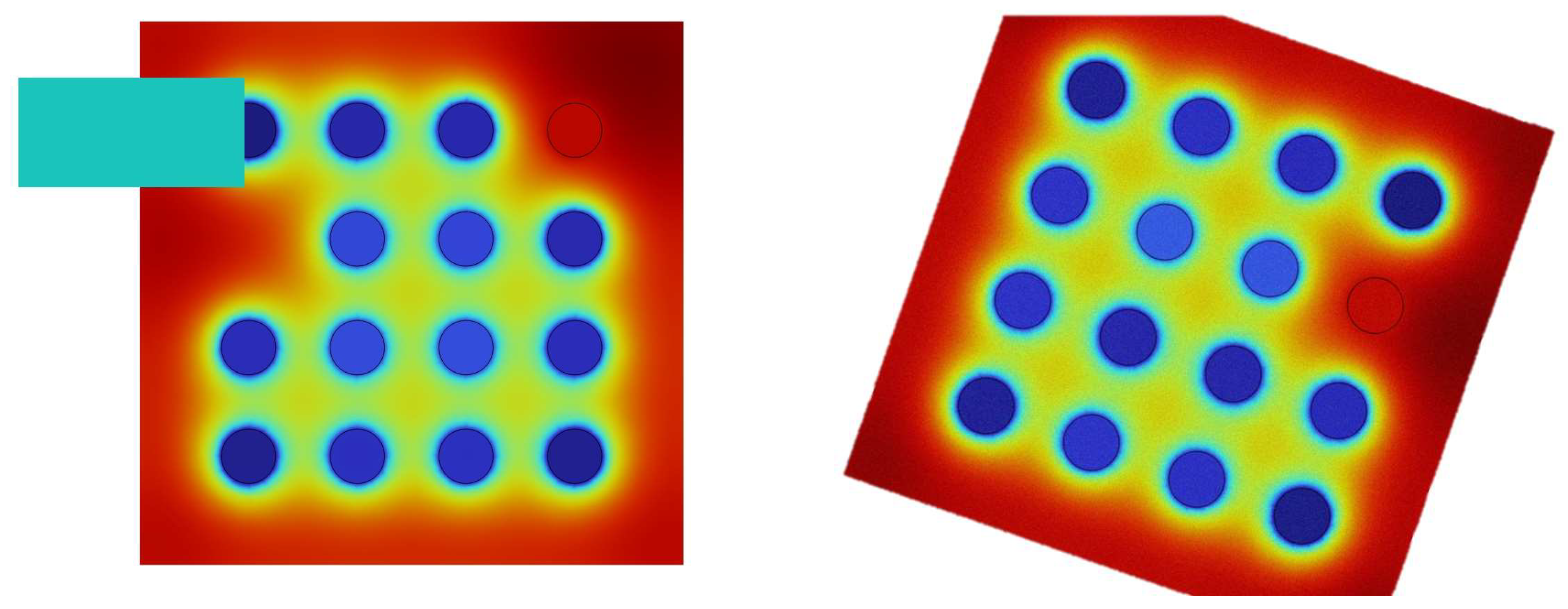

2.2. Dataset Construction and Deep Learning Framework

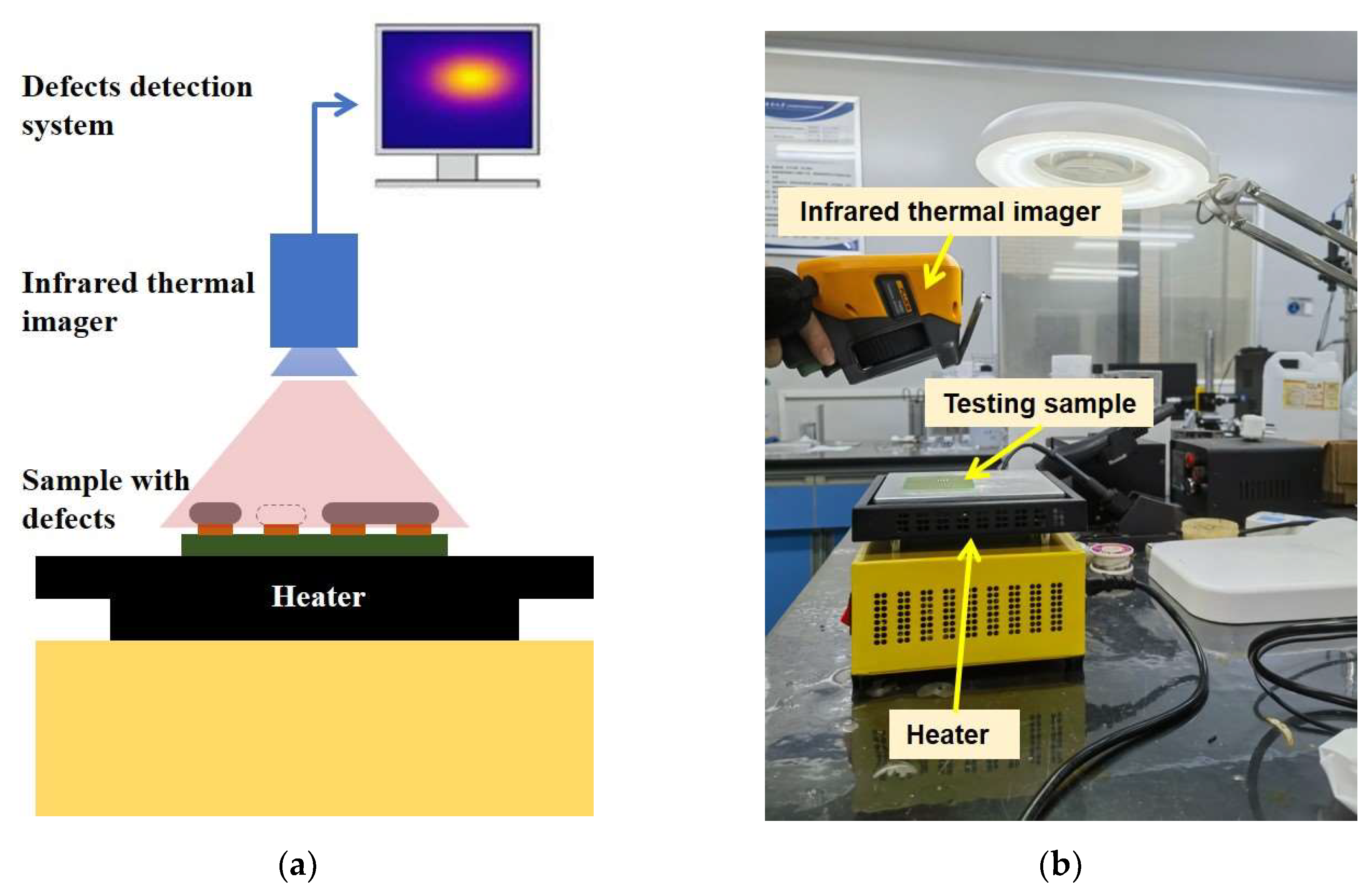

2.3. Experimental Setup for Infrared Thermal Imaging

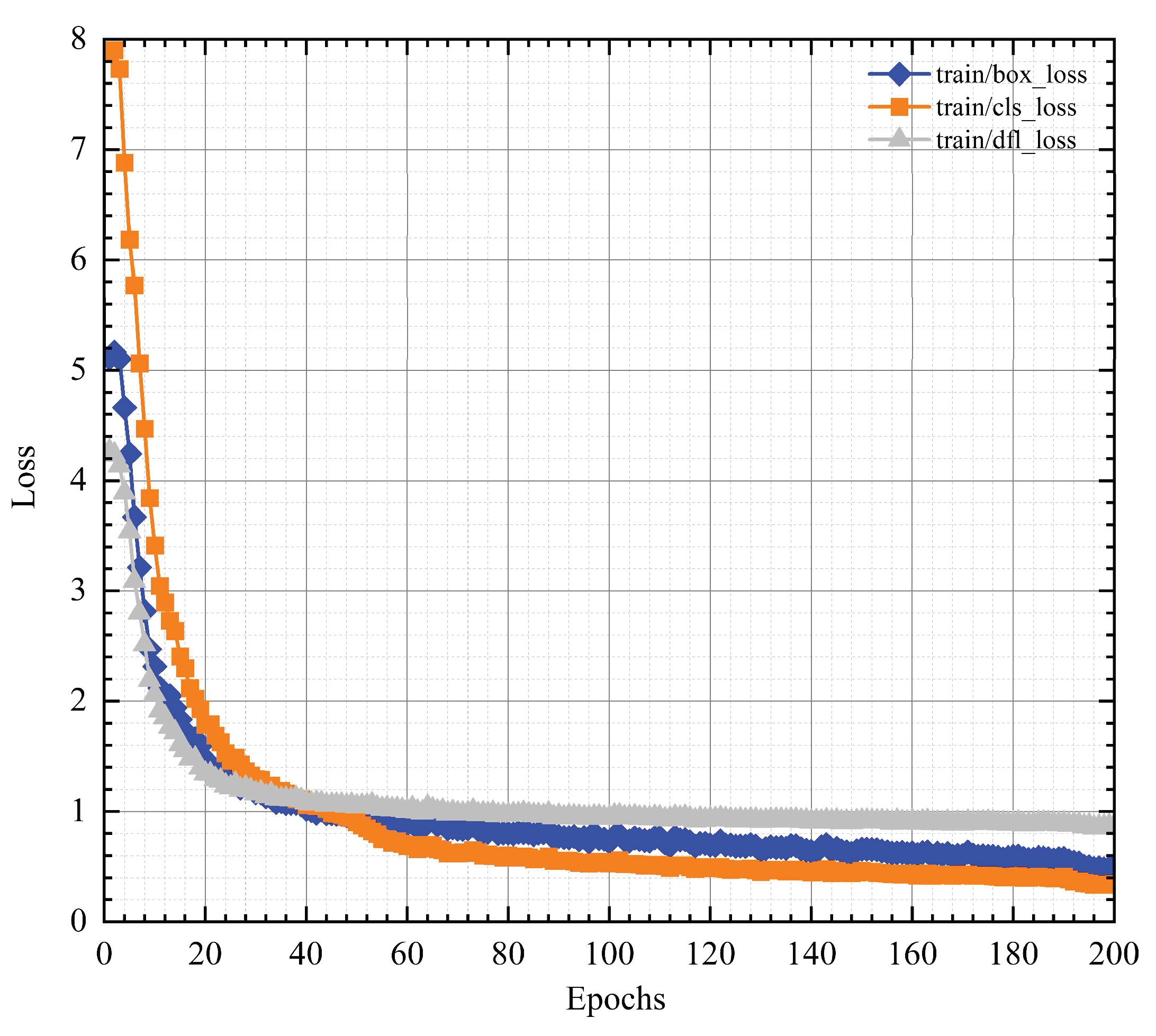

2.4. Model Training and Evaluation Metrics

3. Results and Discussion

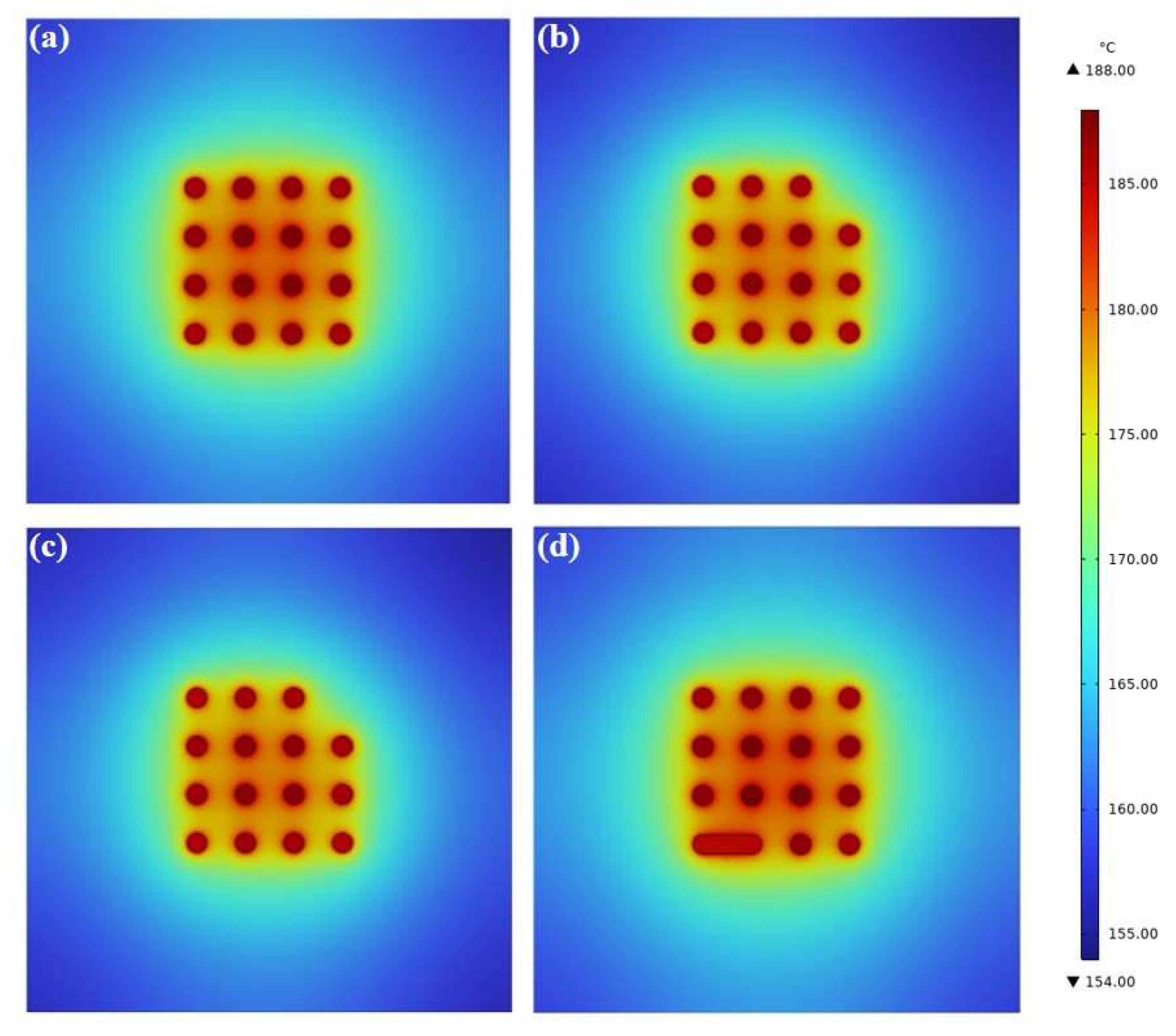

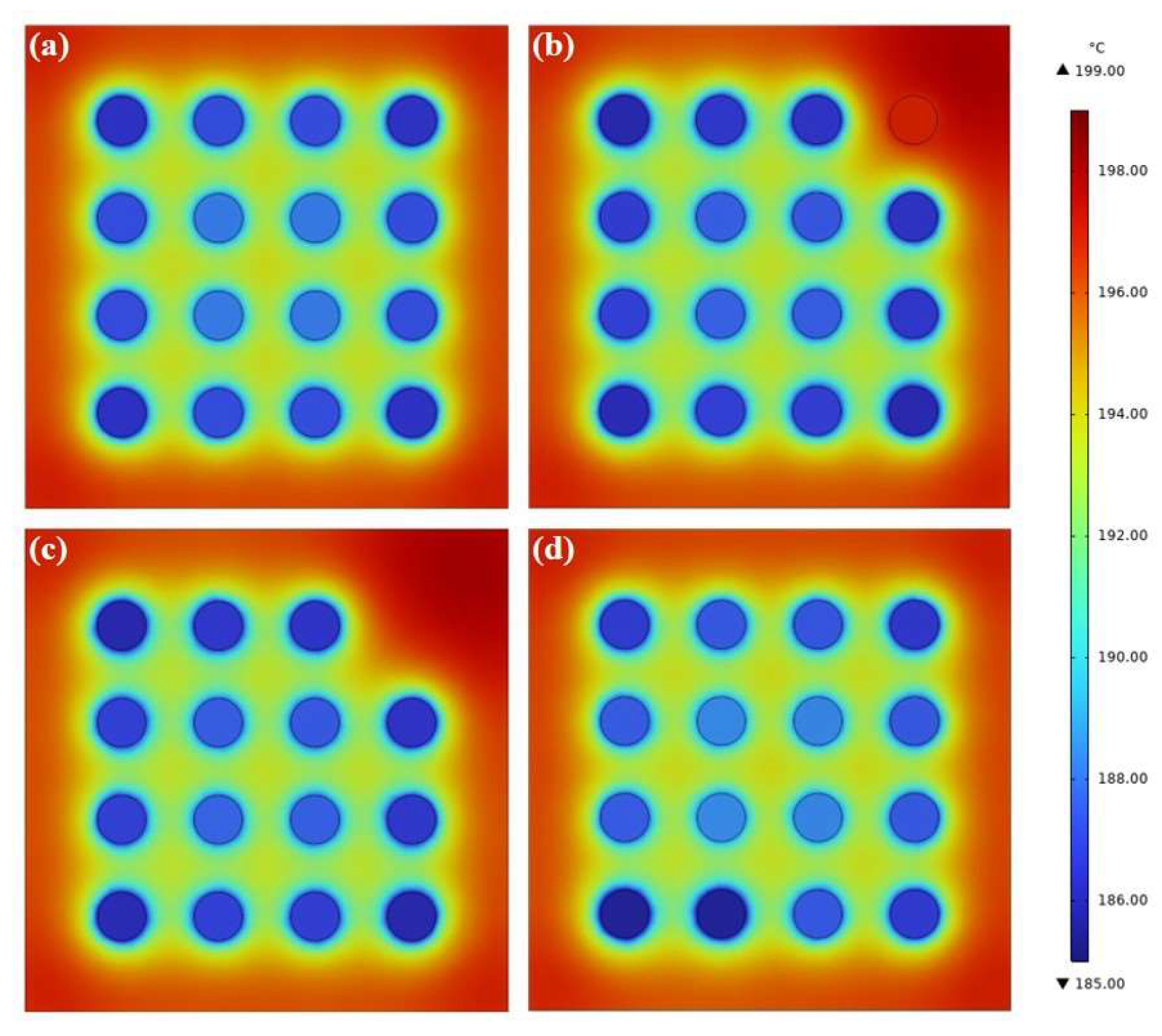

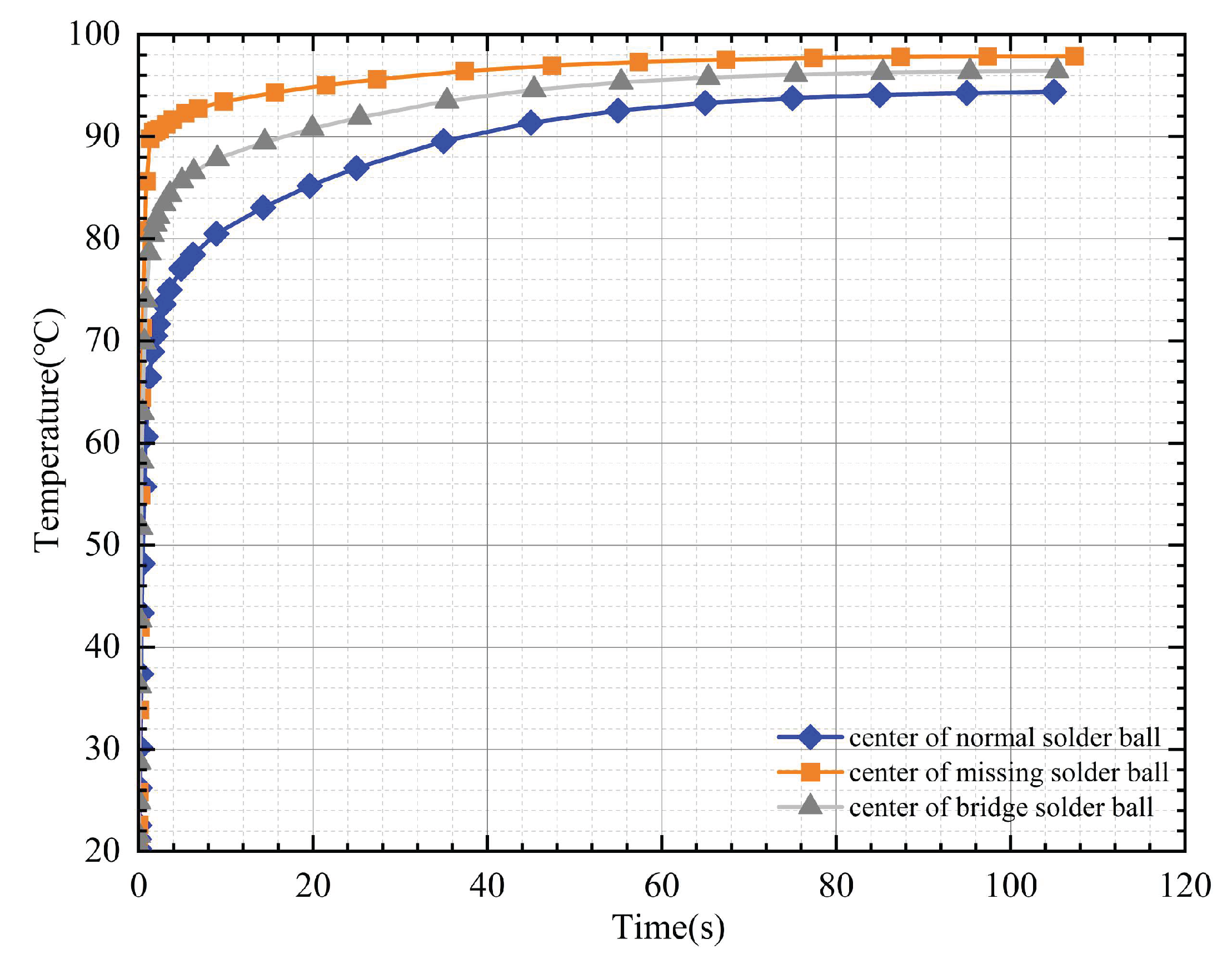

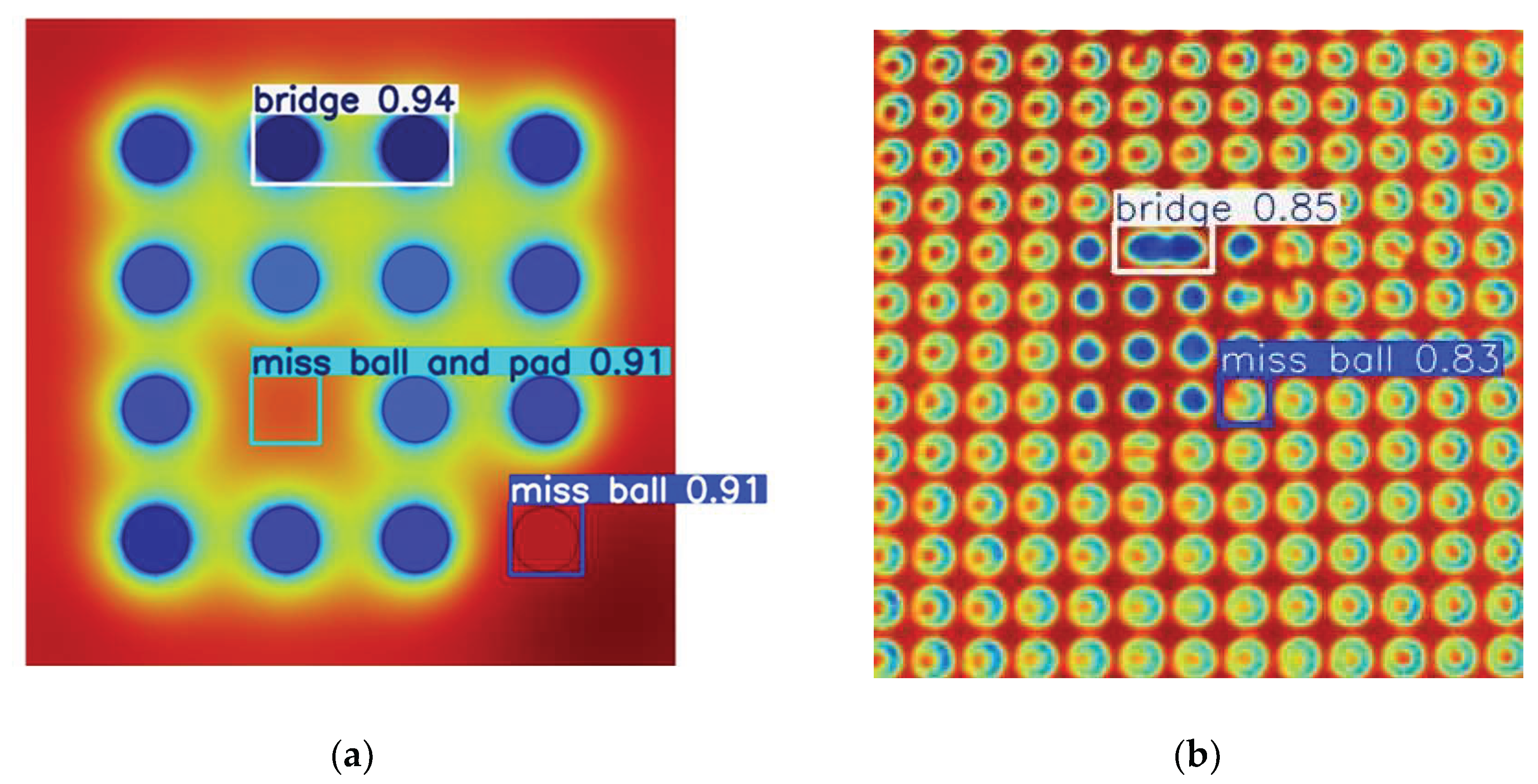

3.1. Thermal Simulation Analysis of Packaging Defects

3.2. Performance Evaluation of Defect Detection

4. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cramer, K.E. Research developments in nondestructive evaluation and structural health monitoring for the sustainment of composite aerospace structures at nasa. In Proceedings of the Congress of the International Council of the Aeronautical Sciences (ICAS 2016) 2016.

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent advances in active infrared thermography for non-destructive testing of aerospace components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef]

- Jaeger, B.E.; Schmid, S.; Grosse, C.U.; Gögelein, A.; Elischberger, F. Infrared thermal imaging-based turbine blade crack classification using deep learning. Journal of Nondestructive Evaluation 2022, 41, 74. [Google Scholar] [CrossRef]

- Bounenni, L.; Arbane, M.; Ibarra-Castanedo, C.; Yaddaden, Y.; Unnikrishnakurup, S.; Yong, A.N.C.; Maldague, X. Advanced Defect Detection on Curved Aeronautical Surfaces Through Infrared Imaging and Deep Learning. NDT 2024, 2, 519–531. [Google Scholar] [CrossRef]

- Guo, S.; Wang, D.; Feng, Z.; Guo, W. UIR-Net: Object detection in infrared imaging of thermomechanical processes in automotive manufacturing. IEEE Transactions on Automation Science and Engineering 2021, 19, 3276–3287. [Google Scholar] [CrossRef]

- Fox, M.; Goodhew, S.; De Wilde, P. Building defect detection: External versus internal thermography. Building and Environment 2016, 105, 317–331. [Google Scholar] [CrossRef]

- Kim, C.; Park, G.; Jang, H.; Kim, E.-J. Automated classification of thermal defects in the building envelope using thermal and visible images. Quantitative InfraRed Thermography Journal 2023, 20, 106–122. [Google Scholar] [CrossRef]

- Di Tommaso, A.; Betti, A.; Fontanelli, G.; Michelozzi, B. A multi-stage model based on YOLOv3 for defect detection in PV panels based on IR and visible imaging by unmanned aerial vehicle. Renewable energy 2022, 193, 941–962. [Google Scholar] [CrossRef]

- Kuo, C.-F.J.; Chen, S.-H.; Huang, C.-Y. Automatic detection, classification and localization of defects in large photovoltaic plants using unmanned aerial vehicles (UAV) based infrared (IR) and RGB imaging. Energy Conversion and Management 2023, 276, 116495. [Google Scholar]

- Hussain, B.; Jalil, B.; Antonietta Pascali, M.; Imran, M.; Serafino, G.; Moroni, D.; Ghelfi, P. Thermal vulnerability detection in integrated electronic and photonic circuits using infrared thermography. Applied optics 2020, 59, E97–E106. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, Z.; Liao, G.; Ma, B. A Novel Chip-on-Board Defect Detection Approach Combining Infrared Thermal Evolution and Self-Supervised Transformer. IEEE Transactions on Industrial Informatics 2024, 20, 8044–8054. [Google Scholar] [CrossRef]

- Xu, Z.; Shi, T.; Lu, X.; Liao, G. Using active thermography for defects inspection of flip chip. Microelectron. Reliab. 2014, 54, 808–815. [Google Scholar] [CrossRef]

- Zhao, L.; He, Z.; Wang, Z.; Su, L.; Lu, X. Simulation and Experimental Investigation on Active Thermography Test of the Solder Balls. IEEE Transactions on Industrial Informatics 2020, 16, 1617–1624. [Google Scholar] [CrossRef]

- Tay, M.Y.; Tan, M.C.; Qiu, W.; Zhao, X.L. Lock-in thermography application in flip-chip packaging for short defect localization. 2011 IEEE 13th Electronics Packaging Technology Conference 2011, 642–646. [Google Scholar]

- Kong, L.C.; Tian, Y.H.; Wang, C.Q.; An, R.; Liu, B.L. Double-thermal imager flip-chip soldering joint defect infrared temperature measurement detection method. 2013.

- Cheng, H.-C.; Tai, L.-C.; Liu, Y.-C. Theoretical and Experimental Investigation of Warpage Evolution of Flip Chip Package on Packaging during Fabrication. Materials 2021, 14, 4816. [Google Scholar] [CrossRef]

- Lu, X.; Shi, T.; Xia, Q.; Liao, G. Thermal conduction analysis and characterization of solder bumps in flip chip package. Applied Thermal Engineering 2012, 36, 181–187. [Google Scholar] [CrossRef]

- Terven, J.; Córdova-Esparza, D.-M.; Romero-González, J.-A. A comprehensive review of yolo architectures in computer vision: From yolov1 to yolov8 and yolo-nas. Machine Learning and Knowledge Extraction 2023, 5, 1680–1716. [Google Scholar] [CrossRef]

- Wang, S.; Wang, H.; Yang, F.; Liu, F.; Zeng, L. Attention-based deep learning for chip-surface-defect detection. The International Journal of Advanced Manufacturing Technology 2022, 121, 1957–1971. [Google Scholar] [CrossRef]

- Huang, H.; Tang, X.; Wen, F.; Jin, X. Small object detection method with shallow feature fusion network for chip surface defect detection. Scientific reports 2022, 12, 3914. [Google Scholar] [CrossRef]

- Wang, J.; Lin, B.; Li, G.; Zhou, Y.; Zhong, L.; Li, X.; Zhang, X. YOLO-Xray: A Bubble Defect Detection Algorithm for Chip X-ray Images Based on Improved YOLOv5. Electronics (2079-9292) 2023, 12, 3060. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, Y.; Zhou, Y.; Li, H.; Huang, Z.; Yao, E. An Auto Chip Package Surface Defect Detection Based on Deep Learning. IEEE Transactions on Instrumentation and Measurement 2023, 73, 3507115. [Google Scholar] [CrossRef]

- Liu, F.; Wang, H.; Feng, P.; Zeng, L. Integrated Circuit Packaging Defect Analysis and Deep Learning Detection Method. IEEE Transactions on Components, Packaging and Manufacturing Technology 2024, 14, 1707–1719. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, S.; Su, J.; Liu, F.; Zeng, L. High-speed and accurate cascade detection method for chip surface defects. IEEE Transactions on Instrumentation and Measurement 2024, 73, 2506612. [Google Scholar] [CrossRef]

- Khanam, R.; Hussain, M. Yolov11: An overview of the key architectural enhancements. arXiv preprint arXiv:2410.17725, arXiv:2410.17725 2024.

- Sohan, M.; Sai Ram, T.; Rami Reddy, C.V. A review on yolov8 and its advancements. In Proceedings of the International Conference on Data Intelligence and Cognitive Informatics; 2024; pp. 529–545. [Google Scholar]

- Wang, C.-Y.; Yeh, I.-H.; Mark Liao, H.-Y. Yolov9: Learning what you want to learn using programmable gradient information. In Proceedings of the European conference on computer vision; 2024; pp. 1–21. [Google Scholar]

- Wang, A.; Chen, H.; Liu, L.; Chen, K.; Lin, Z.; Han, J. Yolov10: Real-time end-to-end object detection. Advances in Neural Information Processing Systems 2024, 37, 107984–108011. [Google Scholar]

| Component | Material | Density (kg/m3 ) | Thermal conductivity (W/(m·K)) | Heat capacity (J/(kg · K)) |

| substrate | FR-4 | 1850 | 0.3 | 1200 |

| pad | Cu | 8960 | kpad1 | 385 |

| solder ball | SAC305 | 7350 | ksolder ball2 | 210 |

| PCB | FR-4 | 1850 | 0.3 | 1200 |

| Model | mAP50 | mAP50-95 | FPS | Params (M) | FLOPs (G) |

| YOLOv8[26] | 99.5% | 94.5% | 667 | 3.01 | 8.2 |

| YOLOv9t[27] | 99.5% | 93.5% | 387 | 2.01 | 7.9 |

| YOLOv10n[28] | 99.3% | 92.9% | 667 | 2.71 | 8.4 |

| YOLO11n[25] | 99.5% | 93.0% | 556 | 2.59 | 6.4 |

| Model Dataset | Number of test images | Recognized Defects | Unrecognized Defects | Recognition Rate |

| Simulation Dataset | 12 | 5 | 7 | 41.7% |

| Hybrid Datasets | 12 | 11 | 1 | 91.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).