1. Introduction

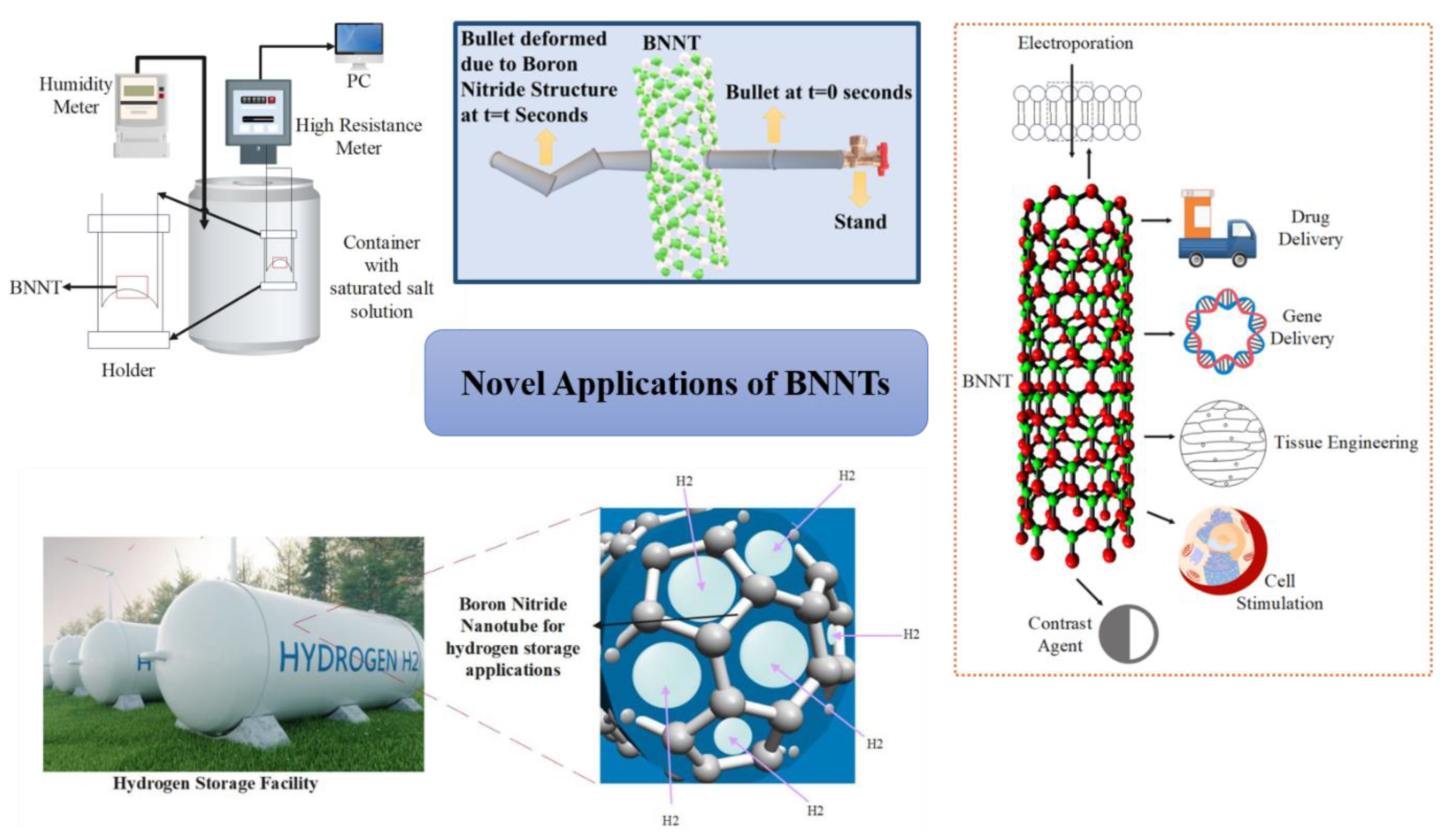

Boron nitride nanotubes are analogous to structural compositions of carbon nanotube portrays with excellent mechanical properties and thermochemical stability. Despite the diameter, chirality, or number of tube walls (single or multi-walled), BNNTs in their pure state are semiconductors (Maestre et al., 2021; Tiano et al., 2014; Wang et al., 2020). When synthesized, the multi-walled F-doped BNNTs are the p-type semiconductors. The band gap difference and increased thermochemical stability are the two main characteristics that set BNNTs apart from CNTs making them more suitable for thermo-insulation applications (Chang et al., 2006; Lee et al., 2020; Merlo et al., 2018; Suryavanshi et al., 2004; Weng et al., 2016). Based on these excellent properties, boron nitride nanotubes showcase multidisciplinary applications such as polymer dielectric composites, polymer composite reinforcements (ceramics and lightweight armours), biomedical applications, sensor applications, and high-pressure energy gas storage tanks as demonstrated in

Figure 1 (Genchi & Ciofani, 2015; Kim et al., 2018).

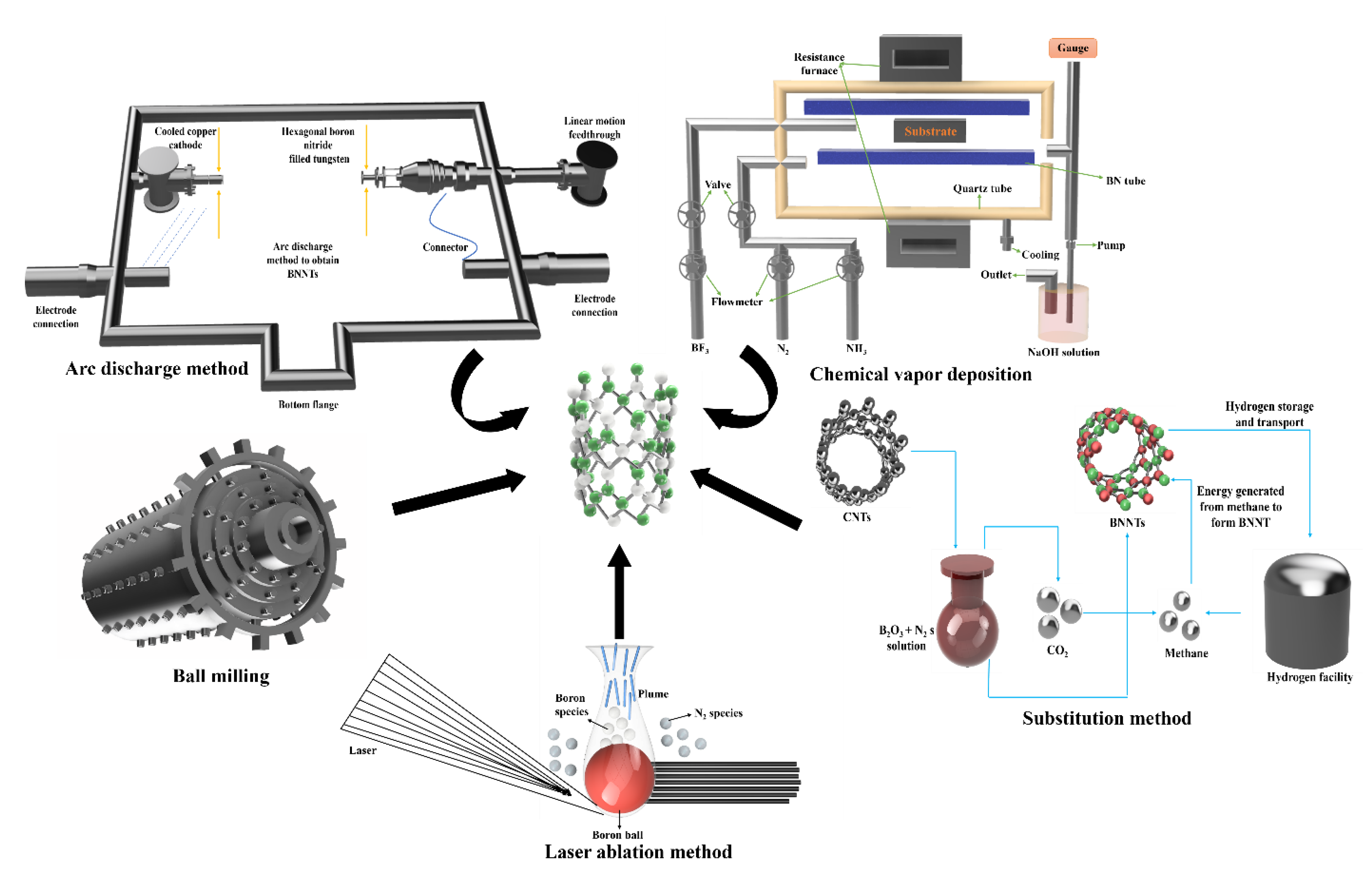

Based on the current computational, practical and theoretical studies, there has not been much advancements in exploring multidisciplinary applications where BNNTs can be substituted. The major challenges due to which BNNTs are not commercialised is because of less yield through conventional synthesis methods and high costs of production. Through process optimization of synthesis methods including laser ablation method, arc discharge method, ball milling, substitution method, and chemical vapor deposition, the yield of synthesis methods can be increased by using the modified synthesis methods as shown in

Figure 2 (Kalay et al., 2015; Li et al., 2009; Ma et al., 2001; Meng et al., 2014). For such process optimization to be used in experimentations and commercialisation, some computational parameters are to be tested, which involve simulink, ansys, visual basics application and aspen.

Tubular nanostructures of BNNTs are identical to those of CNTs, while the nitrogen and boron atoms are usually arranged in a hexagonal network. The intrinsic features of BNNTs include excellent mechanical strength with electrically insulating behaviour, strong oxidation resistance, neutron shielding capabilities, and piezoelectric qualities. According to cost comparison, BNNTs are 11,000 percent more expensive than the CNTs. The high cost of BNNT synthesis is currently one of the main reasons for the dearth of BNNT research. However, BNNTs use easier-to-use synthetic methods to replace CNTs. According to the entire market size production of BNNTs, the annual compound annual growth rate (CAGR) from 2023 to 2027 will be 6.35% or about 345.00 million USD more than the market size in 2022 (Ko et al., 2023; Lu et al., 2023; Mittal & Kushwaha, 2024b; Zhuang et al., 2014). For high-end applications and cost-cutting needs, BNNTs' high price range and reduced market value make them an ideal example of recycling and a circular economy model.

Based on literature cost and computational analysis, in order to assess the total deformation, equivalent stress, strain energy and equivalent elastic strain of BNNT storage tank applications, finite element analysis is required. A complex subject in materials science and engineering to predict the BN behaviour, simulate the physical phenomena, and determine the quantification of mechanical properties is known as Finite Element Analysis (FEA) of BNNTs in storage tanks (Lamb et al., 2019; Mittal, Kushwaha, et al., 2024; Soorya Prabha et al., 2021). Because of their remarkable mechanical strength, chemical resistance, and thermal stability, BNNTs are a material that shows promise for use in strengthening composite storage tanks.

2. Materials and Methodology

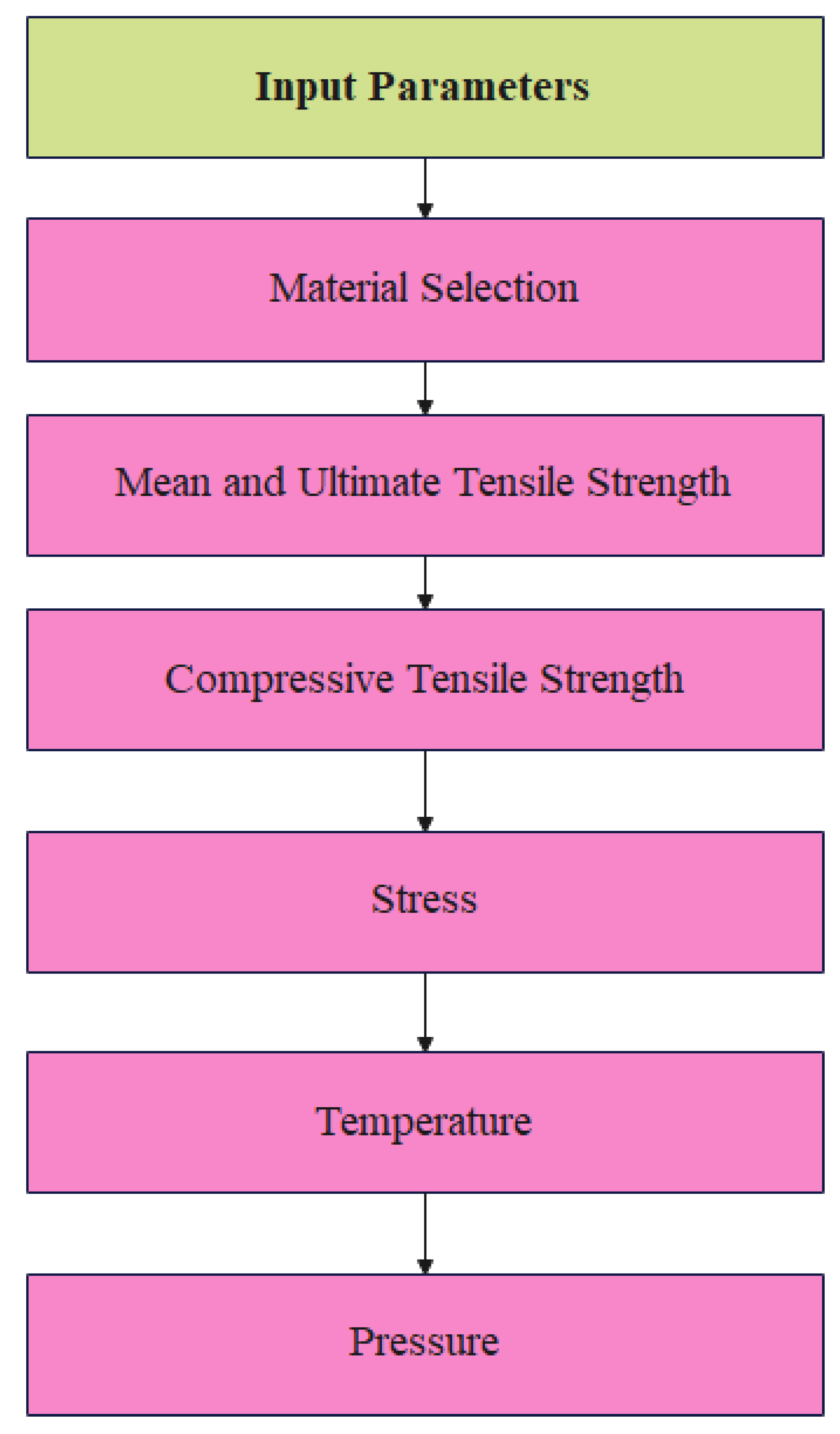

The major objectives of the finite element analysis for incorporation of BNNT into storage tanks involves mechanical structurization under static and dynamic loads, resistance to thermal and chemical environments and fatigue resistance under the operational stresses. The major input values involve high tensile strength (30-60 GPa), high thermal conductivity (2000 W/mK) and chemical stability of boron nitride nanotubes (Ciofani et al., 2013; Hayat et al., 2022). Based on these input values and intermediate equations, several output values are generated involving elastic modulus, Poisson’s ratio, thermal expansion coefficient and yield strength. The input values required for the conduction of finite element analysis for BNNT incorporated storage tanks is shown in

Figure 3 (Mittal & Kushwaha, 2024a; Mpourmpakis & Froudakis, 2007; Sun et al., 2018; Vatanpour et al., 2021).

The schematics include using Ansys Workbench software to calculate 100L (industrial scale) high pressure energy gas storage tanks based on boron nitride nanotubes for one year. The storage tanks' total deformation, strain energy, stress, elastic strain, strain energy, and volume expansion are all carefully examined for Finite Element Analysis (FEA) after one year of computation. The following correlations are utilized, as indicated in Eqs. (1-4), for the essential computations of storage tank variability and materials employed in tanks (Davis, 2012; Mittal, Kushwaha, et al., 2024; Nørskov et al., 2009; Talebi, 2006).

Total deformation:

……………………………………………………………………………………..(1)

where X, Y and Z are the directional deformation

Equivalent stress:

…………………………………………………………..(2)

The primary stresses or stress components represented by three stress tensors can be used to compute von Mises stress. For a given stress condition, each of the following formulae yields the same von Mises stress, σv.

Equivalent elastic strain

………………………………(3)

The equivalent strain can be computed using strain tensor. Although it does not capture all the information about the strain state, equivalent strain is a scalar and can be used to convey strain findings over a body. The Poisson's ratio is v.

Strain energy

U = σ2 / 2ϵ × V…………………………………………………………………………..……(4)

when stress (σ) is proportional to strain (ϵ).

3. Results and Discussions

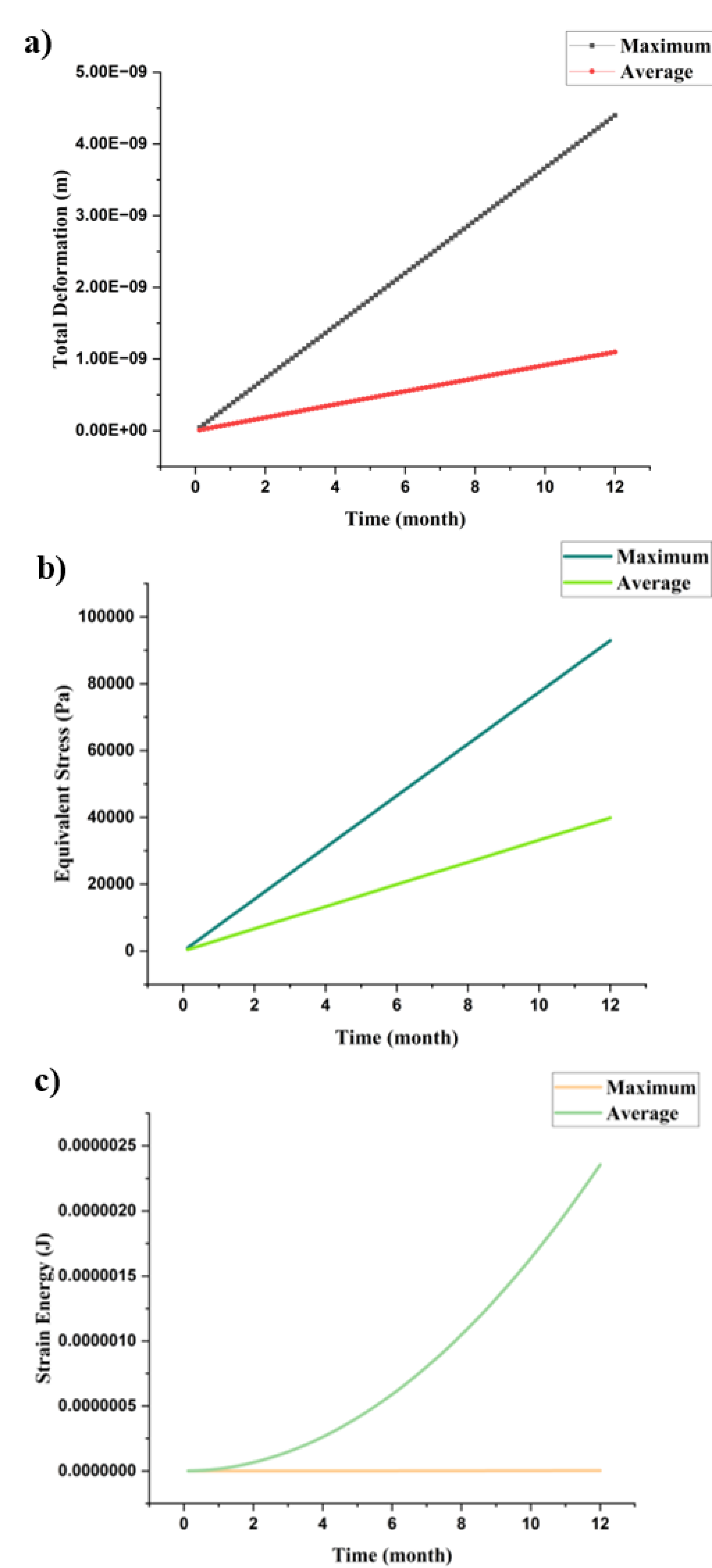

Through the completion of computational experimentations, which ran for 12 months showcased results in minimum, maximum and average (in %) values for various parameters including strain energy, equivalent stress, equivalent elastic strain and total deformation as shown in Figure 4. This increase in energy rather than increasing the strain in the storage tank could be converted into kinetic energy through several centrifugal applications to make BNNT storage tanks not only energy carriers but also energy producers. Similar to the strain energy, the FEA analysis also demonstrates equivalent stress, and equivalent elastic strain making it easier to identify increase in the pressure points on storage tanks, which cause the leaks, resulting in accidents. Through FEA, mechanical strength and thermochemical stability is calculated through identifying the output values, which ran over one year. These results clearly state that by having BNNT material absorbing the total stress and strain caused from high-pressure energy gases. Upon computing, it was examined that by calculating the average from the minimum and maximum range computed, the total deformation, equivalent stress and strain energy is 10-9 m, 3986 Pa and 0.000025J, respectively after 1 year. After comparison with the mechanical distortions of carbon nanotubes, BNNT material showcases less deformation and equivalent stress, making it a better substitute than CNTs (Byrne & Gun’ko, 2010; Mittal, Yadav, et al., 2024; Pan et al., 2022; Praveenkumar et al., 2024; Shanbedi et al., 2015).

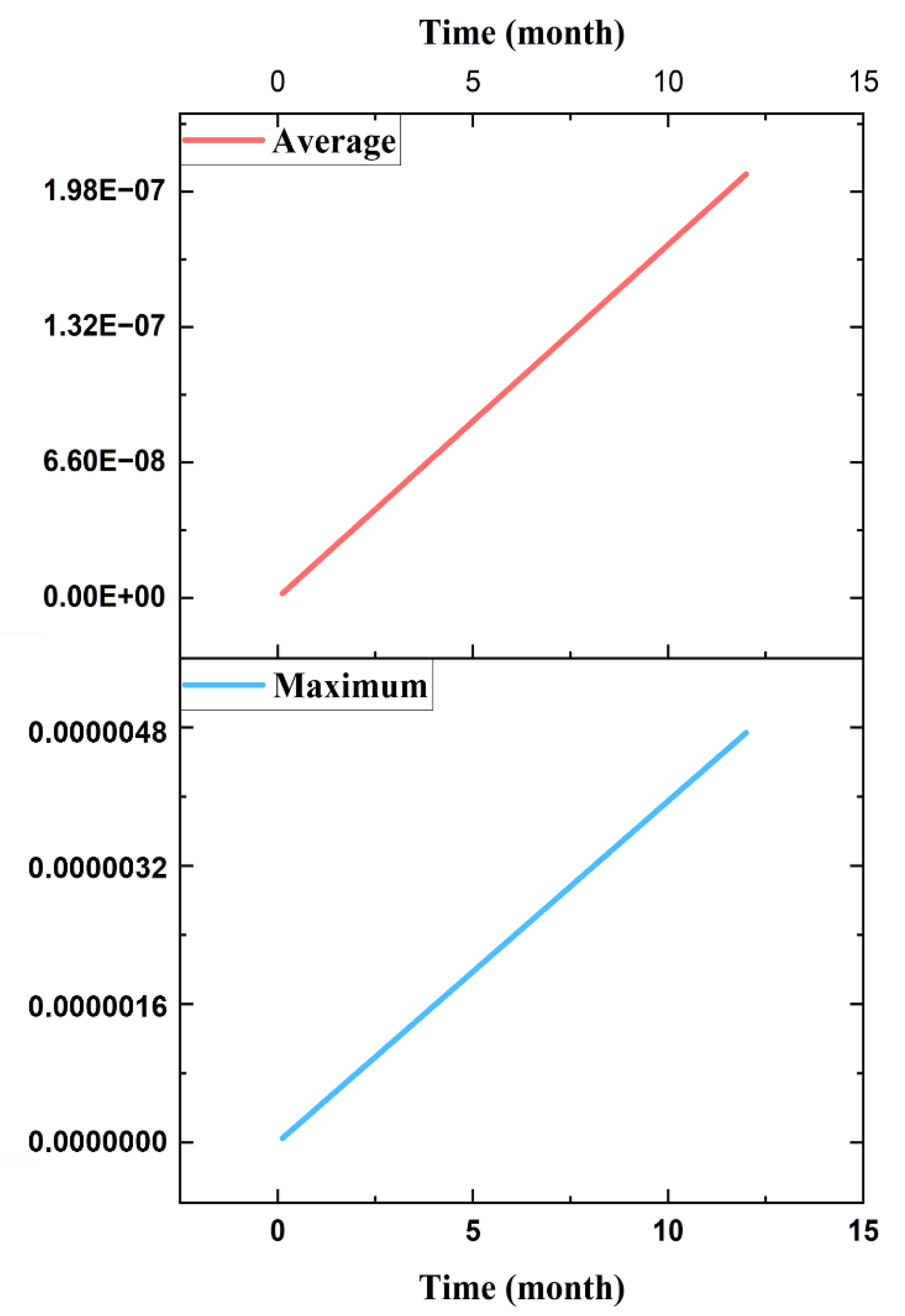

Similar to deformation, equivalent stress and strain energy quantification of BNNTs, the equivalent elastic strain of BNNT can be calculated as shown in

Figure 5. The average and maximum values of equivalent elastic strain is quantified as 1.98 x 10

-7 m/m and 4.8 x 10

-7 m/m respectively after 12 months of finite element analysis. Upon comparison with carbon nanotubes, the overall equivalent elastic strain shown in storage tanks is much less than boron nitride nanotube based 100 L storage tank (Gómez-Gualdrón et al., 2011; Obradović et al., 2015). On the basis of the finite element analysis, the color-coding schemes for the various characterizations done in the storage tank assessment portraying the deformation, stress, strain energy and elastic strain values is also demonstrated in

Figure 6 where blue colour schemes signify minimum values and red colour schemes signify maximum values.

4. Conclusions

Even though conventional synthesis methods of boron nitride nanotubes showcase lesser yield and high cost of manufacturing, it is examined that through substitution method, not only the yield and cost could be optimised, but also these nanotubes could be used as a viable multidisciplinary application material. Realising the current gaps in research of BNNT based applications, there is the dire need of conducting various computational parameters before reaching high technical readiness level through laboratory experimentations and industrial testing. Upon analysing FEA of BNNT based storage tanks, there was 14%, 12.67% and 21% decrease in total deformation, equivalent stress and strain energy values as compared to CNT based storage systems for 100 L setup. This analysis helped to assess the overall high thermo-insulation and thermo-mechanical strengths of BNNTs. Based on this study, one can draw bright scenario for employing BNNT in advanced design of storage tank through materials that portray superior mechanical features along with stability at very long duration. This work may provide immense knowledge towards determining the high-performance applications involving BNNTs as material, giving scope to deeper research across the global industries by its environment suitability concerning great strength resistance and very limited deformation properties at longer run of usage.

References

- Byrne, M. T. , & Gun’ko, Y. K. (2010). Recent Advances in Research on Carbon Nanotube-Polymer Composites. Advanced Materials, 1688. [Google Scholar] [CrossRef]

- Chang, C. W. , Fennimore, A. M., Afanasiev, A., Okawa, D., Ikuno, T., Garcia, H., Li, D., Majumdar, A., & Zettl, A. (2006). Isotope Effect on the Thermal Conductivity of Boron Nitride Nanotubes. ( 97(8), 085901. [CrossRef] [PubMed]

- Ciofani, G. , Danti, S., Genchi, G. G., Mazzolai, B., & Mattoli, V. (2013). Boron Nitride Nanotubes: Biocompatibility and Potential Spill-Over in Nanomedicine. Small, 1672. [Google Scholar] [CrossRef]

- Davis, D. M. (2012). Finite Element Modeling of Ballistic Impact on a Glass Fiber Composite Armor. [CrossRef]

- Genchi, G. G. , & Ciofani, G. (2015). Bioapplications of boron nitride nanotubes. ( 10(22), 3315–3319. [CrossRef] [PubMed]

- Gómez-Gualdrón, D. A. , Gómez-Gualdrón, D. A., Burgos, J. C., Burgos, J. C., Yu, J., Yu, J., Balbuena, P. B., & Balbuena, P. B. (2011). Carbon Nanotubes: Engineering Biomedical Applications. Progress in Molecular Biology and Translational Science. [CrossRef]

- Hayat, A. , Sohail, M., Hamdy, M. S., Taha, T. A., AlSalem, H. S., Alenad, A. M., Amin, M. A., Shah, R., Palamanit, A., Khan, J., Nawawi, W. I., & Mane, S. K. B. (2022). Fabrication, characteristics, and applications of boron nitride and their composite nanomaterials. K. B. ( 29, 101725. [CrossRef]

- Kalay, S. , Yilmaz, Z., Sen, O., Emanet, M., Kazanc, E., & Çulha, M. (2015). Synthesis of boron nitride nanotubes and their applications. ( 6, 84–102. [CrossRef] [PubMed]

- Kim, J. H. , Pham, T. V., Hwang, J. H., Kim, C. S., & Kim, M. J. (2018). Boron nitride nanotubes: synthesis and applications. Nano Convergence. [CrossRef]

- Ko, J. , Kim, D., Sim, G., Moon, S. Y., Lee, S. S., Jang, S. G., Ahn, S., Im, S. G., & Joo, Y. (2023). Scalable, Highly Pure, and Diameter-Sorted Boron Nitride Nanotube by Aqueous Polymer Two-Phase Extraction. Small Methods. [CrossRef]

- Lamb, K. E. , Lamb, K., Dolan, M. D., & Kennedy, D. F. (2019). Ammonia for hydrogen storage; A review of catalytic ammonia decomposition and hydrogen separation and purification. International Journal of Hydrogen Energy. [CrossRef]

- Lee, S. H. , Kim, M. J., Ahn, S., & Koh, B. (2020). Purification of boron nitride nanotubes enhances biological application properties. International Journal of Molecular Sciences. [CrossRef]

- Li, Y. , Zhou, J., Zhao, K., Tung, S., & Schneider, E. (2009). Synthesis of boron nitride nanotubes from boron oxide by ball milling and annealing process. ( 63(20), 1733–1736. [CrossRef]

- Lu, Y. , Zhao, R., Wang, L., & E, S. (2023). Boron nitride nanotubes and nanosheets: Their basic properties, synthesis, and some of applications. Diamond and Related Materials. [CrossRef]

- Ma, R. , Bando, Y., & Sato, T. (2001). CVD synthesis of boron nitride nanotubes without metal catalysts. Chemical Physics Letters. [CrossRef]

- Maestre, C. , Toury, B., Steyer, P., Garnier, V., & Journet, C. (2021). Hexagonal boron nitride: a review on selfstanding crystals synthesis towards 2D nanosheets. Journal of Physics: Materials. [CrossRef]

- Meng, W. , Huang, Y., Fu, Y., Wang, Z., & Zhi, C. (2014). Polymer composites of boron nitride nanotubes and nanosheets. ( 2(47), 10049–10061. [CrossRef]

- Merlo, A. , Mokkapati, V. R. S. S., Pandit, S., & Mijakovic, I. (2018). Boron nitride nanomaterials: biocompatibility and bio-applications. Biomaterials Science, 2311. [Google Scholar] [CrossRef]

- Mittal, H. , & Kushwaha, O. S. (2024a). Emerging Nanofiber Technology for the Purification of Wastewater Treatment Facilities for Elimination of Ions. In Innovative and Hybrid Technologies for Wastewater Treatment and Recycling (pp. 306–325). CRC Press. [CrossRef]

- Mittal, H. , & Kushwaha, O. S. (2024b). Policy Implementation Roadmap, Diverse Perspectives, Challenges, Solutions Towards Low-Carbon Hydrogen Economy. Green and Low-Carbon Economy. [CrossRef]

- Mittal, H. , Kushwaha, O. S., Nadagouda, M., Hegde, G., Allen, S., & M. Aminabhavi, T. (2024). Adsorption and storage of hydrogen- A computational model approach. Environmental Research. [CrossRef]

- Mittal, H. , Yadav, V., & Kushwaha, O. (2024). Carbon Capture Advancements in Metal-Organic Frameworks. [CrossRef]

- Mpourmpakis, G. , & Froudakis, G. E. (2007). Why boron nitride nanotubes are preferable to carbon nanotubes for hydrogen storage?An ab initio theoretical study. Catalysis Today. [CrossRef]

- Nørskov, J. K. , Bligaard, T., Rossmeisl, J., Christensen, C. H., Christensen, C. H., & Christensen, C. H. (2009). Towards the computational design of solid catalysts. Nature Chemistry. [CrossRef]

- Obradović, V. , Stojanović, D. B., Živković, I., Radojević, V., Uskoković, P. S., & Aleksić, R. (2015). Dynamic mechanical and impact properties of composites reinforced with carbon nanotubes. ( 16(1), 138–145. [CrossRef]

- Pan, S. , Feng, J., Safaei, B., Qin, Z., Chu, F., & Hui, D. (2022). A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets. ( 11(1), 1658–1669. [CrossRef]

- Praveenkumar, V. , Mittal, H. N., & Kushwaha, O. S. (2024). Analysing Industrial Scale-Up of Carbon Dioxide Capture in Aqueous Amino Acids for Sustainable Technologies. [CrossRef]

- Shanbedi, M. , Heris, S. Z., & Maskooki, A. (2015). Experimental investigation of stability and thermophysical properties of carbon nanotubes suspension in the presence of different surfactants. Journal of Thermal Analysis and Calorimetry. [CrossRef]

- Soorya Prabha, P. , Ragavi, I. G., Rajesh, R., & Pradeep Kumar, M. (2021). FEA analysis of ballistic impact on carbon nanotube bulletproof vest. Materials Today: Proceedings, 3940. [Google Scholar] [CrossRef]

- Sun, J. , Lu, C., Song, Y., Ji, Q., Song, X., Li, Q., Zhang, Y., Zhang, L., Kong, J., & Liu, Z. (2018). Recent progress in the tailored growth of two-dimensional hexagonal boron nitride via chemical vapour deposition. Chemical Society Reviews, 4257. [Google Scholar] [CrossRef]

- Suryavanshi, A. P. , Yu, M.-F., Wen, J., Tang, C., & Bando, Y. (2004). Elastic modulus and resonance behavior of boron nitride nanotubes. ( 84(14), 2527–2529. [CrossRef]

- Talebi, H. (2006). Finite element modeling of ballistic penetration into fabric armor. Doctoral Dissertation, Universiti Putra Malaysia.

- Tiano, A. L. , Park, C., Lee, J. W., Luong, H. H., Gibbons, L. J., Chu, S.-H., Applin, S., Gnoffo, P., Lowther, S., Kim, H. J., Danehy, P. M., Inman, J. A., Jones, S. B., Kang, J. H., Sauti, G., Thibeault, S. A., Yamakov, V., Wise, K. E., Su, J., & Fay, C. C. (2014). Boron nitride nanotube: synthesis and applications, 9060. [Google Scholar] [CrossRef]

- Vatanpour, V. , Naziri Mehrabani, S. A., Keskin, B., Arabi, N., Zeytuncu, B., & Koyuncu, I. (2021). A Comprehensive Review on the Applications of Boron Nitride Nanomaterials in Membrane Fabrication and Modification. Industrial & Engineering Chemistry Research, 1342. [Google Scholar] [CrossRef]

- Wang, M. , Wang, H., An, L., Zhang, B., Huang, X., Wen, G., Zhong, B., & Yu, Y. (2020). Facile fabrication of Hildewintera-colademonis-like hexagonal boron nitride/carbon nanotube composite having light weight and enhanced microwave absorption. Journal of Colloid and Interface Science. [CrossRef]

- Weng, Q. , Wang, X., Bando, Y., & Golberg, D. (2016). Functionalized hexagonal boron nitride nanomaterials: emerging properties and applications. Chemical Society Reviews, 4012. [Google Scholar] [CrossRef]

- Zhuang, K. , & Herrgård, M. J. (2014). Multi-scale Exploration of the Technical, Economic, and Environmental Dimensions of Bio-based Chemical Production.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).