1. Introduction

Hydraulic systems are widely used in the modern machinery, aircraft, automobile, and construction industries to provide high pressure and stable velocity with low energy consumption [

1]. Hydraulic cylinders and valves are common actuators components that used in a hydraulic system. The fault that occurs in the hydraulic system is one of the major failure modes that lead to a decrease in the efficiency of the system. The faults in the actuators can occur due to internal leakage, wear, or fracture of the seal or may be caused by pitting of the piston could significantly reduce engineered hydraulic system performance. Owing to the dynamic working condition of hydraulic systems, the non-intrusive online detection of faults is therefore difficult to achieve. Hence, this paper proposes a method for fault detection in a cylinder or valve. Currently, the fault detection techniques can be categorized into three categories that are model based methods , data driven approaches and signal-based methods. The mathematical models of the systems are developed before diagnosis for model-based methods. The mathematical models are based on fluid mechanics which consider variable and uncertain parameters in the hydraulic system that clarifies the principle, structure and mechanism of diagnosed component [

2]. Kumar et al. [

3] improved the fault isolation using computed bond graph model in the model-based fault detection and isolation (FDI) method. The hydro-motor drive system was considered for the FDI analysis, where source flow is supplied through a priority flow divider valve to two hydro-motors. A methodology for fault isolation with minimum measured values has discussed to find the remaining useful life (RUL) of the faulty components of a system. Skormin and Apone [

4] developed a linear model for the aircraft pump leakage. They addressed the causes of the failure of the control valve, the adjustment of the bulk modulus and the fault caused by the excessive friction to the hydraulic system in detail. Shi et al. [

5] combined an adaptive threshold with model-based faults detection method for controlling a nonlinear electro-hydraulic system. Their model was able to diagnose many types of faults, such as failure of parts, failure of actuators and failure of sensors. Garimella and Yao [

6] suggested a nonlinear model that would analyze a hydraulic device failure based on the adaptive robust observer. An and Sepehri [

7] utilizes the Extended Kalman Filter (EKF) to detect hydraulic cylinder fault leakage. An experiment was performed to prove that the internal and external fault leakage could be identified by the EKF based on matrix coefficients.

For data driven methods, May et al. [

8] used cross-correlation of the obtained pressure signals to estimate the double-acting hydraulic cylinder health condition by means of the voting classification algorithm, that could reliably assess by different leakage rates. Paul et al. [

9] studied the open-loop hydrostatic transmission system with fault tolerant control (FTC) and validated by experimentation. Single fault hypothesis was considered, FTC uses single-step PI controller for simulation and comply with single step. A novel internal leakage fault detection method proposed by Yao et al. [

10] based on performance-oriented scheme for single-rod hydraulic actuators. Using quadratic Lyapunov functions the performance-oriented fault detection obtained the performance index for the system. The proposed tolerant controller activated based on the obtained performance index. A novel method of Featured Temporal Segmentation (FTS) and detector based on Adaboost-BP algorithm proposed by Li et al. [

11] to study the online non-intrusive internal leakage for hydraulic cylinder. Proposed leakage method indicates the internal leakage based on internal pressure without using sensors in practical application. A novel model-based methodology proposed by Tan and Sepehri [

12] to fault diagnosis (FD) of a nonlinear hydraulic drive system. The characterization of system has done using the linear-in-parameters second-truncated Volterra model. Using the proposed scheme, the fault features detect and isolate system faults in geometric domain. The result obtained after simulation and experimentation shows, the fault detection problem resolved with high success rate using proposed parametric identification technique. Using a parameter-estimation method a fault diagnosis method developed by Yu [

13] for a linear part of hydraulic experimental set-up. The fault diagnosis method applied on the hydraulic system based on real data and simulation faults; and the change in physical parameters observed. The obtained simulation results show same direction faults in state space of the system model using the developed technique, which can neither obtained by using any parity equation method nor any observer-based method.

Signal-based diagnostic approaches are based on state signals, such as sound, vibrations, sound and pressure. If the machine does have a fault it will reflect on the signal. Thus, the essential fault features can be extracted theoretically from the signal and the recognised pattern is carried out. Signal-based fault method widely used in intelligent fault diagnosis technique. The online fault detection method and condition monitoring method developed by Raduenz et al. [

14] on proportional directional valves. The faults in valves detected experimentally with different sizes using five different proportional valves. And the condition monitoring based on monitoring both the spool position and valve supply current. Observation made after implementation of a fault detection and monitoring system increases safety and decreases maintenance cost. The experimental results validated with the valve operating under healthy conditions and with induced faults were compared. For detecting and specify the internal leakage fault in hydraulic actuators Yao et al. [

15] uses different artificial neural networks. After simulation and experimentation, it shows deep neural network (DNN) with five layers can attain high detection accuracy along with proposed neural network. The proposed method shows various advantage over previous research. And proposed method also detect the internal leakage fault in eleven leakage degrees with fast speed. The application of wavelet transform(WT) used by Goharrizi and Sepehri [

16] to detect the internal leakage fault due to seal damage or wear in hydraulic actuators. Analysing the pressure signal at one side of the actuator and decomposed pressure signal using discrete WT, the internal leakage obtained. Daubechies 8 wavelet used for obtaining the feature signature from experimental pressure signal. The proposed application method can be use for small internal leakage due to wear or seal damage and ease of implementation, since it requires only the one side actuator experimental pressure signal. Wrat et al. [

17] presents a method for detecting internal leakage faults in hydraulic actuator cylinders using signal analysis and a supervised artificial neural network classifier. The approach focuses on extracting features from pressure signals to categorize fault levels into healthy, low fault, and high fault systems. The method improve the reliability and efficiency of hydraulic systems in heavy machinery by reducing downtime and maintenance costs .

A fault-tolerant control (FTC) method designed by Karpenko and Sepehri [

18] for a servo-hydraulic positioning system with faulty, internal leakage between the actuator chambers. A fixed-gain, linear time-invariant fault-tolerant controller via quantitative feedback theory (QFT) developed to maintain the experimental servo hydraulic positioning system tracking performance despite of increasing the effecting damping and decreasing the open-loop gain. After experimentation, it shows the designed FTC can compensate the degrading fault effects as compare to normal controller. A fixed-gain fault tolerant controller designed by Karpenko and Sepehri [

19] for an electrohydraulic actuator with leakage piston seal operating under variable loading in the presence of parametric uncertainty. The designed controller needs only actuator position for feedback and it can compensate internal leakage fault almost 40% of servo-valve flow across the actuator piston. A nonlinear offline feedforward controller with PID controller designed by Mishra et al. [

20] as fault tolerant control measure for a closed loop hydraulic system. The speed characteristics curve significantly influenced by disturbance related to external torque and system parameters like supply pressure and inertia load. After implementation of developed fault tolerant control; real-time speed curve of the system shows better response respect to the demand for various loading condition. A methodology based on cyclo-stationarity theory proposed by Casoli et al. [

21] for acceleration signal analysis obtained from rotodynamic machines. The proposed methodology involves computation of FFT after extraction of periodic components. The proposed methodology applied to a variable displacement axial-piston pump, and considering artificial worn slipper fault. After experimentation worn piston slippers condition and evident detected using proposed methodology.

Hydraulic cylinders are critical components in various industrial applications, including wind turbines, construction machinery, and manufacturing equipment. Leakage faults in hydraulic cylinders can lead to significant operational inefficiencies, increased maintenance costs, and potential safety hazards. Guo et al. [

22] developed a model to simulate small internal leakages in hydraulic cylinders using neural networks. The study demonstrated that convolutional neural networks provided the highest prediction accuracy for leakage faults. Zhao et al. [

23] discussed sustainable maintenance strategies for industrial equipment, emphasizing the need for predictive maintenance to enhance equipment reliability and reduce environmental impact. Saihi et al. [

24] conducted a systematic review of modeling-based literature on sustainable maintenance, identifying key trends and gaps in integrating sustainability into maintenance decision-making.

In this article the novel fault leakage characterization using pressure signal for the hydraulic actuator has been studied. The leakage resistance of cylinder has been considered as fault injecting parameter for cylinder. The simhydraulic model is developed for the simple hydraulic system. In order to simulate the fault, the fault incorporated into the validated mathematical model of actuator, and identified with the extraction of the PID control dynamics signal functions. The relationship between the faulty type and healthy type cylinder was distinguished using the obtained PID signal features as explained in the following sections of the paper.

The rest of this article is structured as follows:

Section 2 and

Section 3 describe the hydraulic system and its governing equations.

Section 4 outlines the modeling methodology used for simulation.

Section 5 presents results from two innovative fault scenarios. Finally,

Section 6 concludes the study with key findings and future research directions.

2. System Description

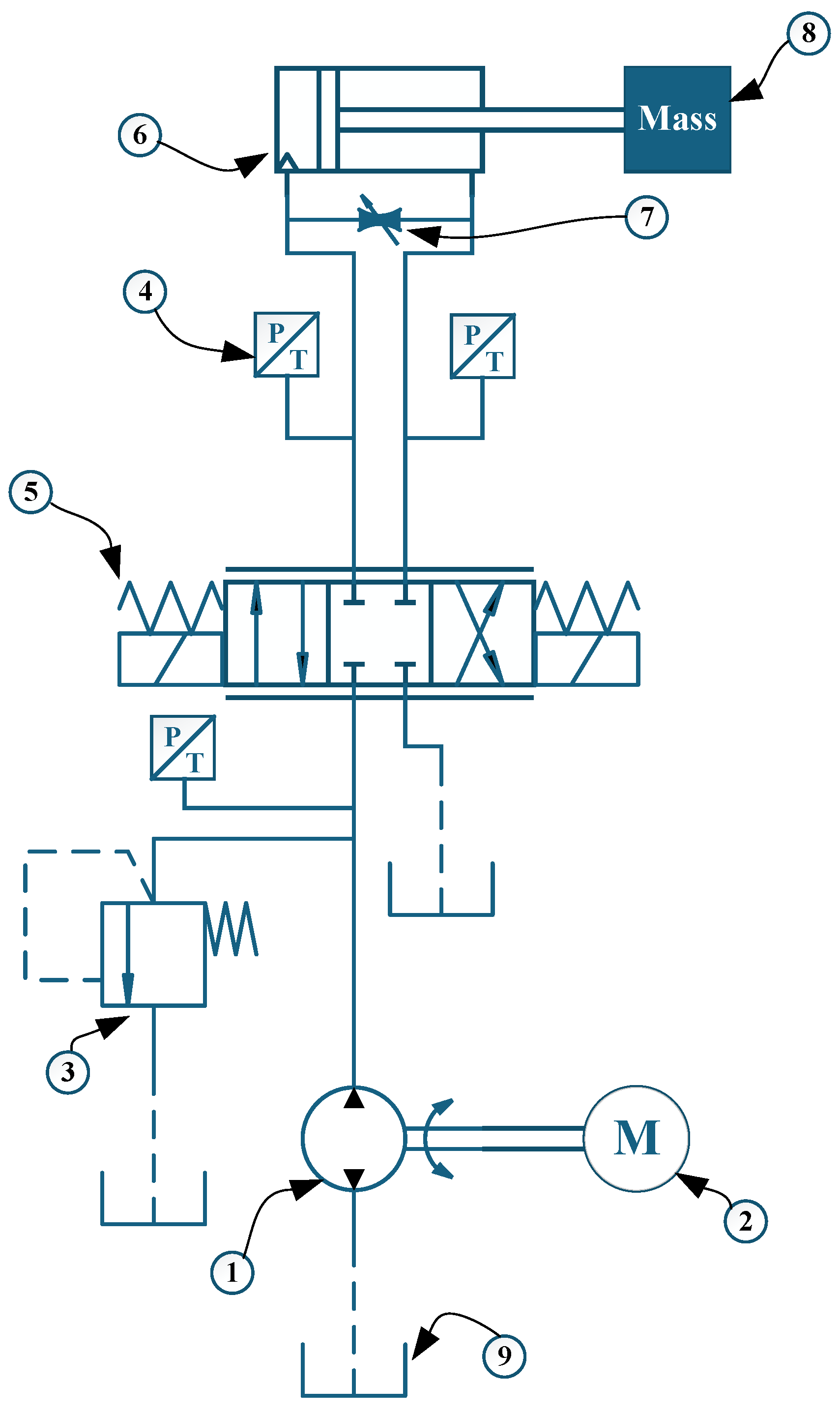

The major components of the hydraulic circuit used for fault detection in the cylinder and valve are illustrated in

Figure 1. The system includes a main pump (2) powered by an electric motor (1), supplying hydraulic fluid to the actuator via a directional control valve (5). A relief valve (3) regulates system pressure, while a pressure transducer (4) records pressure changes during piston rod extension and retraction. The key components are listed in

Table 1, and the symbols and nomenclature used in the modeling are provided in

Table 2.

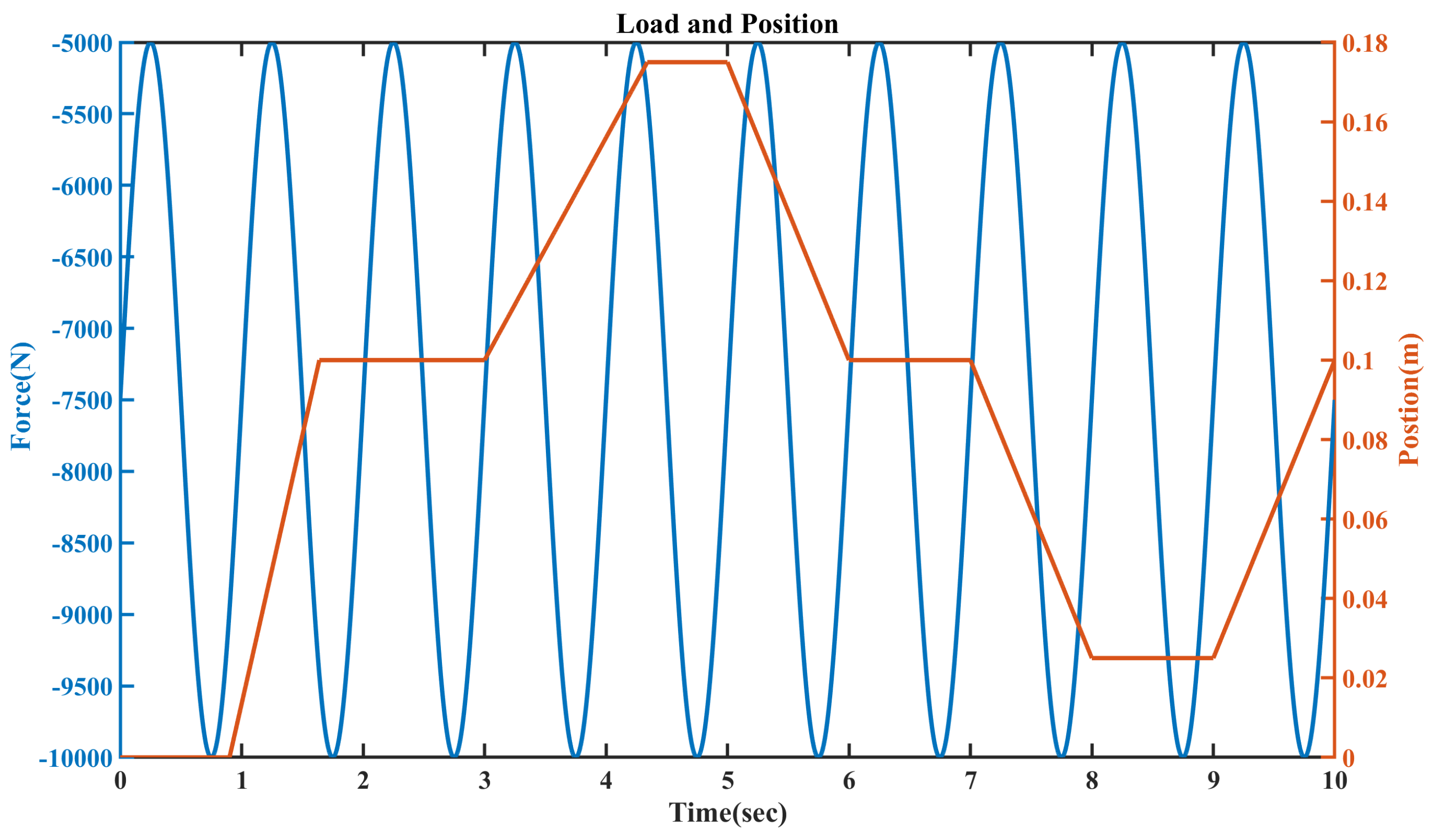

The

Figure 2 illustrates the dynamic load and position demand profile imposed on a hydraulic cylinder system. Anomalies or mismatches between expected and actual responses under such cyclic loading conditions can help in the characterization of internal or external leakage faults, which is critical for developing predictive and sustainable maintenance strategies for hydraulic equipment.

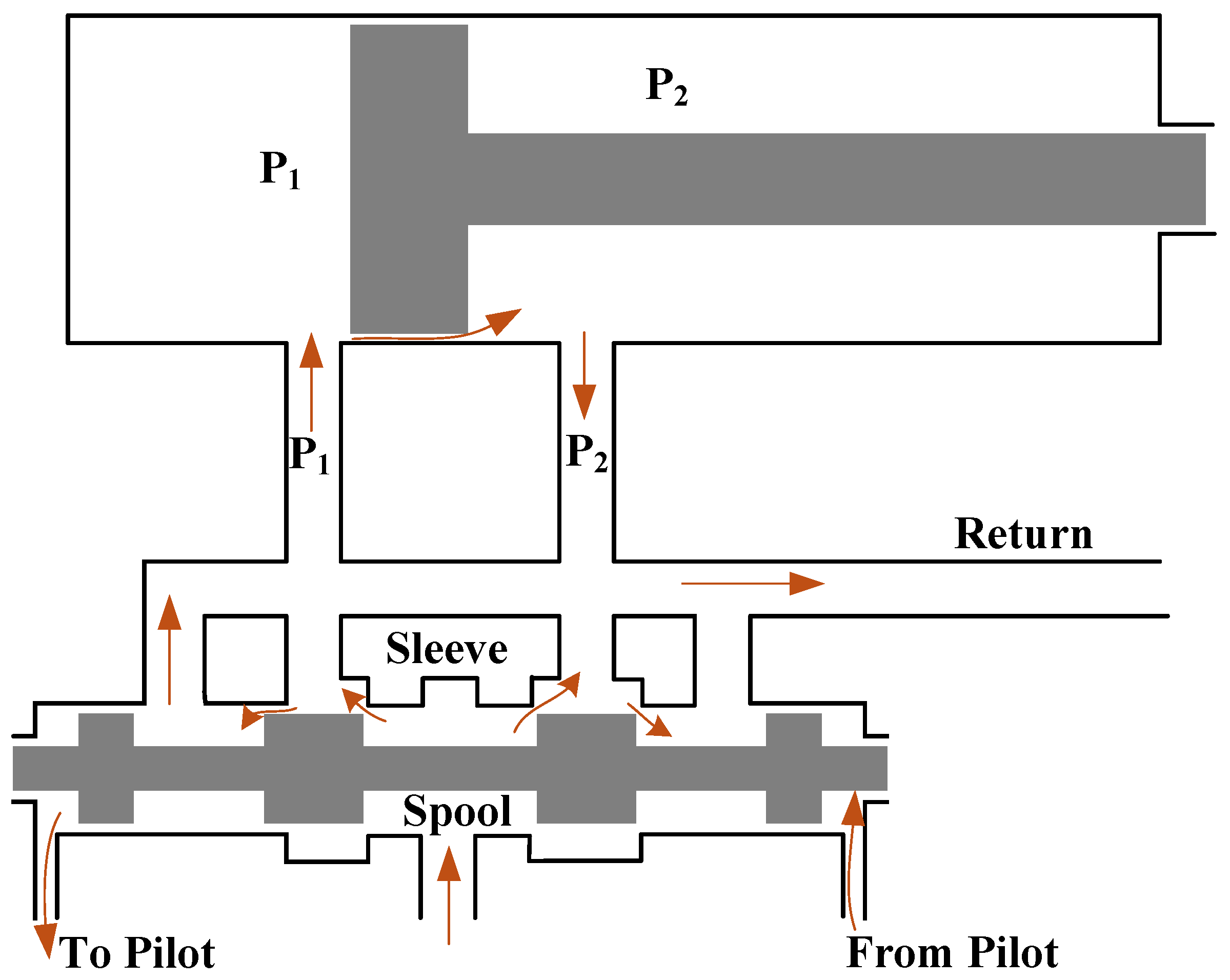

3. Mathematical Modeling

The mathematical models of the two hydraulic systems are described below, from Equation (

1) to Equation (

5). The system equations are derived from MATLAB/Simulink models, reflecting the hydraulic circuits under consideration.

Equation (

1) represents the flow in the main pump. The first term denotes the pressure of the main pump flow, the second term corresponds to the supply flow actuating the actuator, the third term represents the flow through the valve, and the last term accounts for the flow to the pressure relief valve (PRV).

Equation (

2) describes the cylinder inlet flow. The first term represents the cylinder inlet pressure, the second and last terms account for external leakage of the cylinder, the third term represents the flow in the cylinder, and the fourth term represents the internal leakage in the cylinder.

Equation (

3) represents the cylinder outlet flow. The first term denotes the cylinder outlet pressure, the second term represents the force of the load on the rod side, the third and last terms account for the external leakage of the cylinder, and the fourth term represents the internal leakage in the cylinder.

Equation (

4) describes the inlet flow of the directional control valve (DCV). The first term represents the inlet pressure of the valve, the second term accounts for the cylinder leakage, the third term represents the valve leakage, and the last term corresponds to the valve flow.

Equation (

5) represents the expression for piston velocity. The first term denotes the load mass, the second term represents the pressure force on the cylinder bore side, the third term represents the pressure force on the cylinder rod side, the fourth term accounts for the spring force, and the fifth term represents the frictional force.

4. System Modeling

The system modeling is performed using the MATLAB/SimHydraulic library, where the main hydraulic components are selected from the library and leakage is introduced through the fixed orifice component, where the leakage area is manually varied first to find the maximum leakage (0.6 lpm) for which the controller is able to control the actuator position.

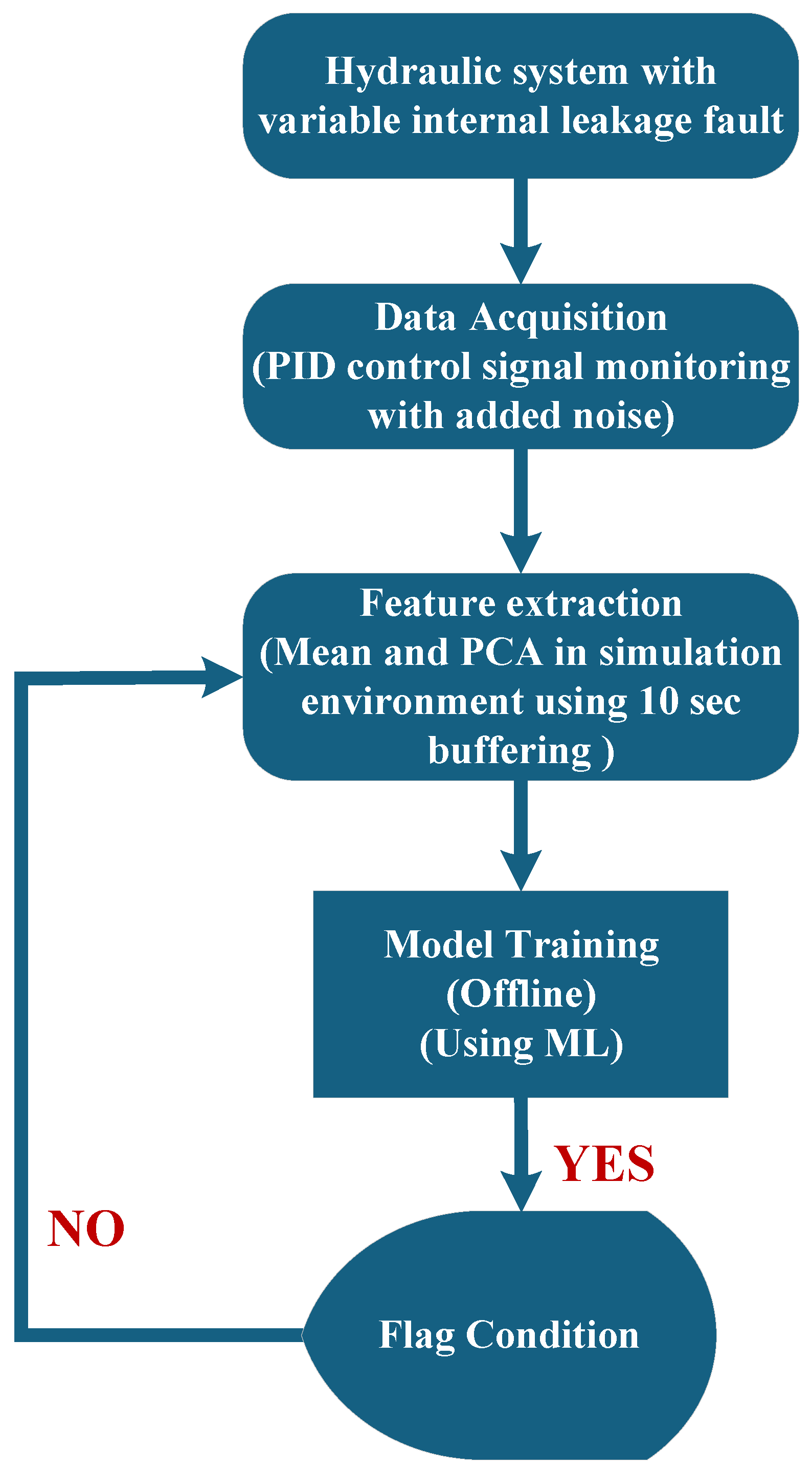

The Flowchart shown in

Figure 4 represents a systematic approach to detecting internal leakage faults in a hydraulic actuator system using machine learning techniques. The process begins with a hydraulic system configured to exhibit variable internal leakage faults, mimicking real-world degradation scenarios in mobile machinery. These faults impact the system’s behavior and are critical for monitoring and diagnostics.

The next step is data acquisition, where signals from the system are captured, particularly focusing on the PID controller’s output. The signal includes added noise to realistically simulate field conditions, reflecting the disturbances and inaccuracies typically encountered in operational environments. The data serves as the foundation for fault analysis.

Once features are extracted, they are used for offline model training. This step employs machine learning (ML) algorithms to build a classification model that can distinguish between different fault conditions, particularly varying levels of internal leakage. Offline training ensures that the model is developed using historical or simulated data, avoiding real-time computation delays and allowing for extensive tuning and validation.

Finally, the trained model is deployed to flag fault conditions. When the input data matches patterns learned during training, the system identifies the presence of a leakage fault (indicated as "YES") and raises a flag. This enables timely maintenance actions and prevents further equipment degradation. The loop arrow back to feature extraction suggests iterative refinement or continuous monitoring.

5. Result and Discussion

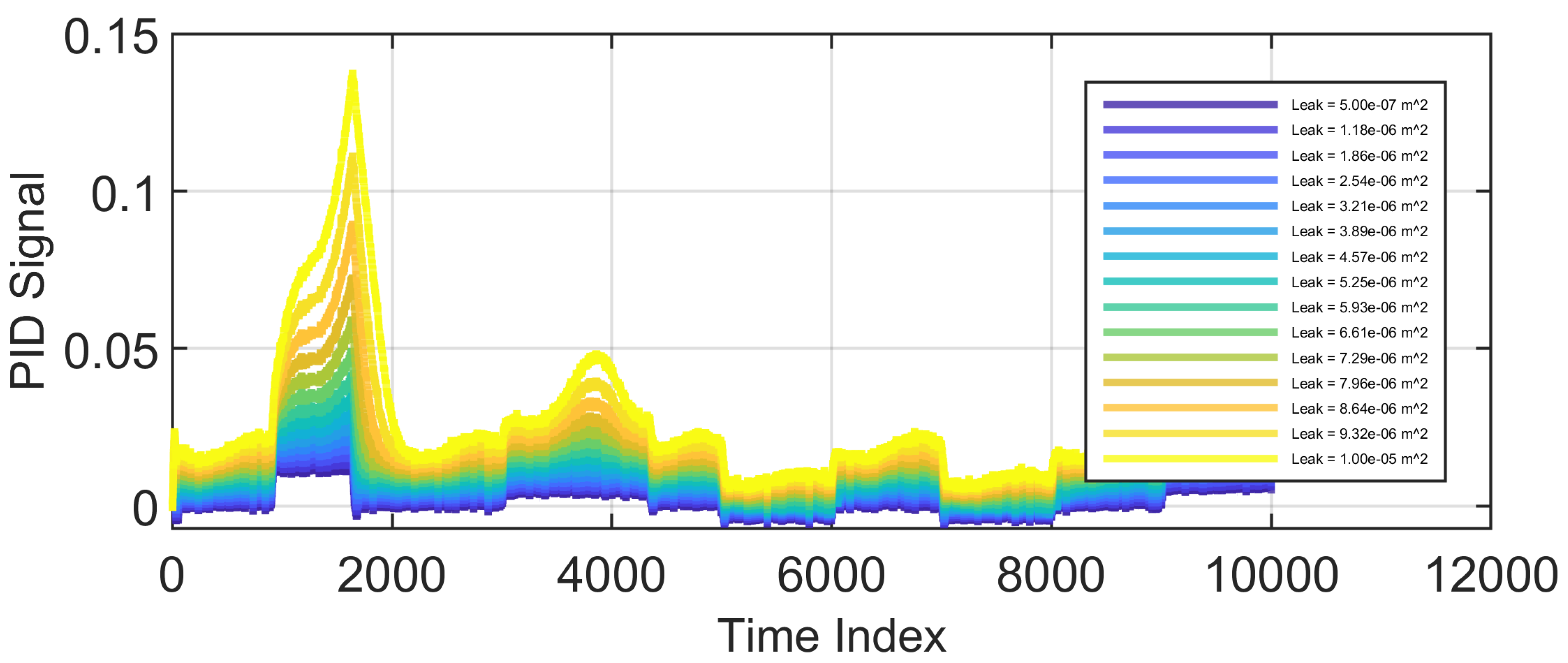

The data from the PID proportional valve control signal been collected by varying the leakage area, and various features have been selected to be trained on the machine learning algorithm. The actual variation of the control signal to the proportional valve, are shown in

Figure 5. The signal shown here shows a variation in the control signal with a change in leakage area across the cylinder. The leak has been found to have a significant impact on the control signal to follow the demand of position. The leakage behavior is shown in

Figure 6 with a variable leakage area. As the throttle valve area increases, it shows an increase in the level of leakage.

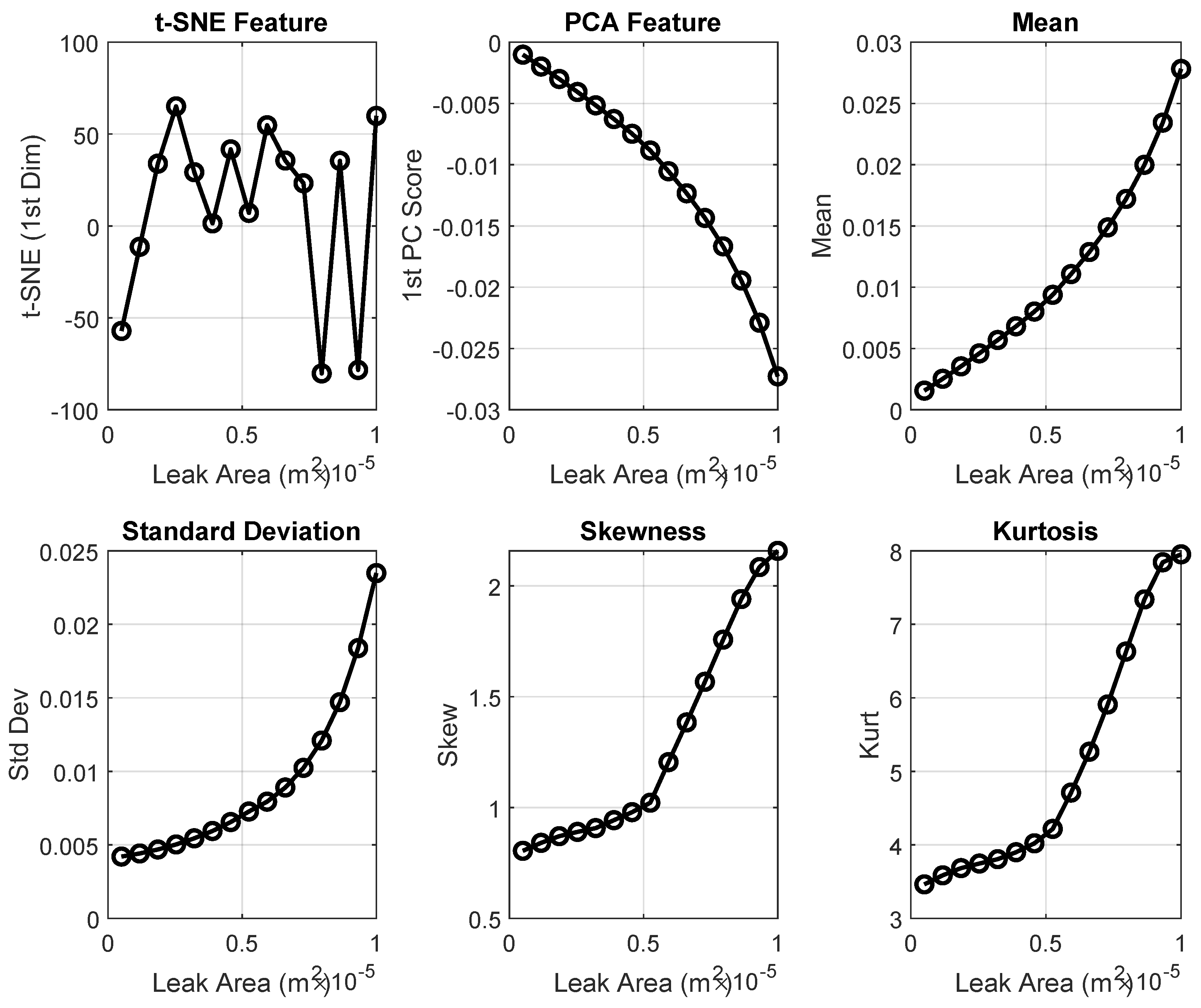

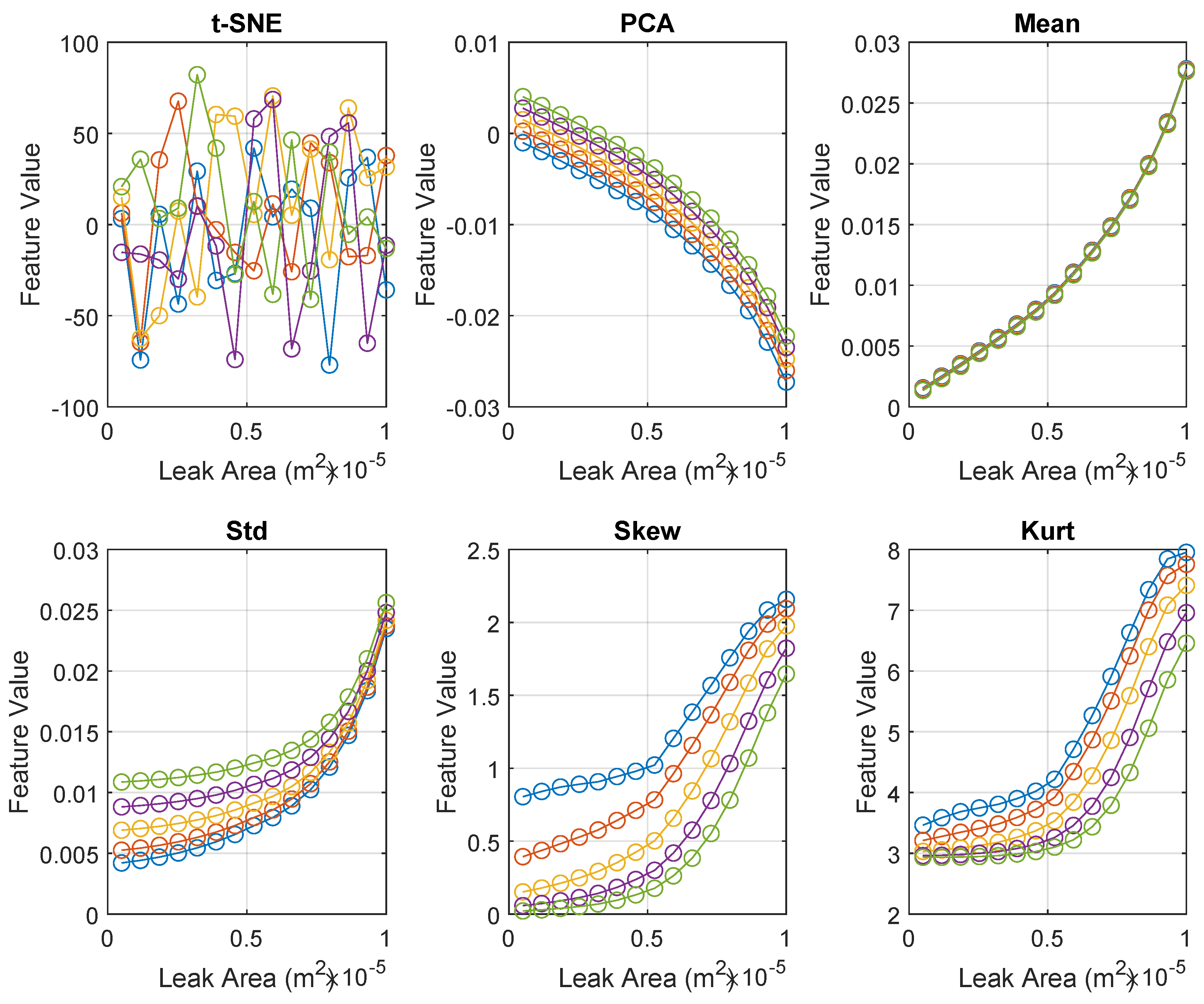

The explored features include the first dimension of t-distributed Stochastic Neighbor Embedding (t-SNE) and Principal Component Analysis (PCA) score, mean, standard deviation, skewness, and kurtosis in time series for 10 seconds of simulation with a sampling frequency of 1000 Hz. Firstly, the features have been calculated in an offline environment to see which features are best combined to train the machine learning regression algorithm so that the features have a meaningful change with a change in leakage area. A bagged ensemble regression model was developed using MATLAB’s fitrensemble function, utilizing decision trees as base learners. The model training was performed on 1,200 observations with a variation in the leakage area from 0.5e-7 m2 to 1e-5 m2, and reproducibility was ensured through a predefined tree template. Automatic hyperparameter optimization was conducted using Bayesian optimization with the expected-improvement-plus acquisition function. The optimization process terminated normally after completing 27 training cycles. The final ensemble, configured with bagging (bootstrap aggregation), showed enhanced generalization by averaging over multiple decision trees. The model does not apply any transformation to the response variable and confirmed consistent learner usage across all observations. These characteristics collectively contribute to the model’s robustness and predictive reliability. The resulting ensemble demonstrated improved predictive accuracy and generalization by leveraging the strengths of multiple weak learners. The noise in the control signal has been added in the simulation environment using the randn function with zero mean and a standard deviation of 0.001.

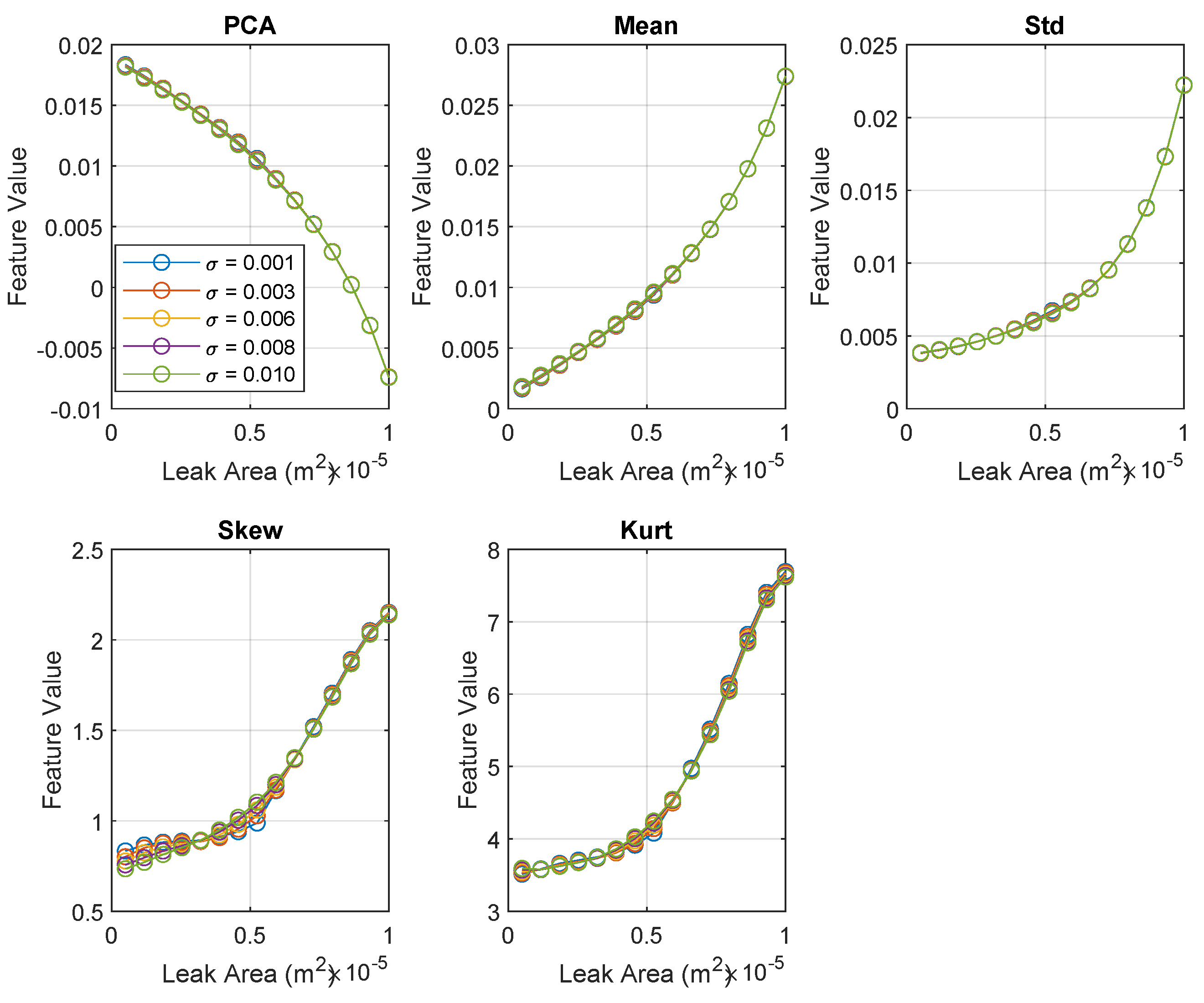

Figure 7 presents the various features extracted from the time series signal. Among these, mean, PCA, standard deviation, skewness, and kurtosis demonstrate a strong correlation with the leakage area of the orifice. In contrast, the t-SNE feature shows weak correlation and has therefore been excluded from further analysis. The other five features have been selected for model training and implemented to predict failure in the simulation; more the features in the training it gives more accurate output tested under this conditions. To see the effect of noise levels on features, these five features have been recalculated at five levels of noise with standard deviation from 0.001 to 0.01. The effect of noise on features has been shown in

Figure 8.

This shows that the features are sensitive to noise expect mean, as it is because the noise has been added with the zero mean. However, if other features can deviate with noise the final results can deviate from the predicted model if there is a more noise in the PID signal. To overcome this issue 1D Kalman filter with Q = 0.001 and R = 5 has been used to feed it into feature calculation so that the noise will dont have any effect on the features output and it has been also be shown in

Figure 9.

This shows that the same ML model has been used for the more noisy signals without effect on the feature calculation for predicting the failure into the cylinder.

6. Conclusion

This study has explored the feasibility of detecting internal leakage faults in hydraulic cylinders using low-cost, real-time signal features derived from existing control signals. A key objective was to eliminate the need for additional sensors or expensive instrumentation by relying solely on data already available from the system’s proportional valve control—specifically the PID control signal. This approach is particularly attractive for practical implementations where hardware modifications are costly, space-limited, or undesirable due to system complexity or environmental conditions.

The main contribution lies in identifying low-computational-cost features from the valve input signal that are sensitive to changes in internal leakage. These features are designed to be efficiently extracted in real time using embedded or edge computing platforms. The underlying idea is that internal leakage in a cylinder alters the system dynamics, which in turn affects how the controller modulates the valve input. By analyzing trends, oscillations, and energy content in the control signal, one can infer the presence and progression of leakage faults.

To ensure that the features are computationally inexpensive, the methodology has deliberately avoided complex signal transformations or deep learning models. Instead, it uses basic time-domain features and statistical measures, such as signal amplitude variation, rise/fall times, and signal energy during steady-state and transient operations. These features are suitable for implementation on low-cost microcontrollers, enabling practical field deployment without requiring significant changes to the existing system.

However, one significant limitation of this approach is that it is most applicable in systems with known and repeatable load conditions. For instance, machines such as hydraulic presses, which operate under consistent duty cycles and predefined loading patterns, are ideal candidates. In these systems, any deviation in control signals due to leakage can be reliably detected because other system variables remain stable and predictable.

On the other hand, systems subjected to stochastic or variable loading, such as mobile hydraulic machinery (e.g., excavators, loaders, or agricultural equipment), introduce significant challenges. In such applications, the control signal may vary not just due to internal leakage but also due to unpredictable changes in external load. This variability can mask the effects of leakage or introduce false positives, thereby reducing the robustness and accuracy of the fault detection strategy.

Despite this limitation, there are promising avenues for extending the applicability of this method. In machines with known geometries and programmed motion cycles—like certain types of industrial robots or semi-automated earthmoving equipment—the loading profile can be estimated or learned over time. In such cases, the expected load pattern can be incorporated into the learning process during training. This would allow the fault detection algorithm to distinguish between normal variations in control signals due to expected load changes and those caused by internal faults like leakage.

Future research can focus on integrating machine learning models that adapt to minor variations in load while still being computationally efficient. For example, lightweight classifiers or anomaly detection methods could be trained on the extracted features under different known load conditions, enabling adaptive fault detection without needing high-end computing resources.

In conclusion, the proposed approach offers a low-cost, scalable, and sensor-less method with on board electronics valve for internal leakage detection in hydraulic systems. While currently most suitable for systems with consistent operating conditions, its applicability can be extended with intelligent learning and load estimation strategies. This opens up the possibility for predictive maintenance and fault diagnosis in a wide range of industrial and mobile hydraulic applications, especially where cost and hardware constraints prevent the use of traditional sensor-based fault detection methods.

Author Contributions

Conceptualization, G.W.and M.B.; Methodology, G.W.and M.B.; Investigation, M.B.and G.W ; Visualization, M.B. and G.W.; Writing—review and editing, G.W. and M.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable

Informed Consent Statement

Not applicable

Data Availability Statement

The dataset is available on request from the authors.

Acknowledgments

This work was carried out during the course of my Doctoral studies. ChatGpt has been used for the refinement and reprhasing of the text.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Totten, G.E. Handbook of Hydraulic Fluid Technology; 2011. [CrossRef]

- Junbin, S.; Huanxi, C.; Xianming, J. Research on Framework of Fault Prognostics and Health Management System for Complex System. In Proceedings of the Journal of Physics: Conference Series, Vol. 1605. 2020. [Google Scholar] [CrossRef]

- Kumar, S.; Dasgupta, K.; Ghoshal, S.K. Fault diagnosis and prognosis of a hydro-motor drive system using priority valve. Journal of the Brazilian Society of Mechanical Sciences and Engineering 2019, 41. [Google Scholar] [CrossRef]

- Skormin, V.A.; Apone, J. On-line diagnostics of a variable displacement pump of a flight actuation system. In Proceedings of the IEEE Proceedings of the National Aerospace and Electronics Conference, 1995, Vol. [CrossRef]

- Shi, Z.; Gu, F.; Lennox, B.; Ball, A.D. The development of an adaptive threshold for model-based fault detection of a nonlinear electro-hydraulic system. Control Engineering Practice 2005, 13. [Google Scholar] [CrossRef]

- Garimella, P.; Yao, B. Model based fault detection of an electro-hydraulic cylinder. In Proceedings of the Proceedings of the American Control Conference, 2005, Vol. [CrossRef]

- An, L.; Sepehri, N. Hydraulic actuator leakage fault detection using extended kalman filter. International Journal of Fluid Power 2005, 6. [Google Scholar] [CrossRef]

- May, M.; Sepehri, N.; Kinsner, W. Hydraulic actuator internal leakage detection using cross-correlation time series analysis. In Proceedings of the ASME/BATH 2014 Symposium on Fluid Power and Motion Control, 2014., FPMC 2014. [Google Scholar] [CrossRef]

- Paul, S.; Ghoshal, S.K.; Samanta, S.; Das, J. Model-based single fault disambiguation and fault tolerant control for a hydraulic drive using receding horizon. Journal of the Brazilian Society of Mechanical Sciences and Engineering 2017, 39. [Google Scholar] [CrossRef]

- Yao, J.; Yang, G.; Ma, D. Internal leakage fault detection and tolerant control of single-rod hydraulic actuators. Mathematical Problems in Engineering 2014, 2014. [Google Scholar] [CrossRef]

- Li, L.; Huang, Y.; Tao, J.; Liu, C.; Li, K. Featured temporal segmentation method and AdaBoost-BP detector for internal leakage evaluation of a hydraulic cylinder. Measurement: Journal of the International Measurement Confederation 2018, 130. [Google Scholar] [CrossRef]

- Tan, H.Z.; Sepehri, N. Parametric fault diagnosis for electrohydraulic cylinder drive units. IEEE Transactions on Industrial Electronics 2002, 49, 96–106. [Google Scholar] [CrossRef]

- Yu, D. Fault diagnosis for a hydraulic drive system using a parameter-estimation method. Control Engineering Practice 1997, 5. [Google Scholar] [CrossRef]

- Raduenz, H.; Mendoza, Y.E.A.; Ferronatto, D.; Souza, F.J.; da Cunha Bastos, P.P.; Soares, J.M.C.; Negri, V.J.D. Online fault detection system for proportional hydraulic valves. Journal of the Brazilian Society of Mechanical Sciences and Engineering 2018, 40. [Google Scholar] [CrossRef]

- Yao, Z.; Yu, Y.; Yao, J. Artificial neural network–based internal leakage fault detection for hydraulic actuators: An experimental investigation. Proceedings of the Institution of Mechanical Engineers. Part I: Journal of Systems and Control Engineering 2018, 232. [Google Scholar] [CrossRef]

- Goharrizi, A.Y.; Sepehri, N. A wavelet-based approach to internal seal damage diagnosis in hydraulic actuators. IEEE Transactions on Industrial Electronics 2010, 57. [Google Scholar] [CrossRef]

- Wrat, G.; Ranjan, P.; Mishra, S.K.; Jose, J.T.; Das, J. Neural network-enhanced internal leakage analysis for efficient fault detection in heavy machinery hydraulic actuator cylinders. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science 2025, 239, 1021–1031. [Google Scholar] [CrossRef]

- Karpenko, M.; Sepehri, N. Fault-tolerant control of a servohydraulic positioning system with crossport leakage. IEEE Transactions on Control Systems Technology 2005, 13. [Google Scholar] [CrossRef]

- Karpenko, M.; Sepehri, N. Quantitative fault tolerant control design for a leaking hydraulic actuator. Journal of Dynamic Systems, Measurement and Control, Transactions of the ASME 2010, 132. [Google Scholar] [CrossRef]

- Mishra, S.K.; Wrat, G.; Ranjan, P.; Das, J. PID controller with feed forward estimation used for fault tolerant control of hydraulic system. Journal of Mechanical Science and Technology 2018, 32. [Google Scholar] [CrossRef]

- Casoli, P.; Bedotti, A.; Campanini, F.; Pastori, M. A methodology based on cyclostationary analysis for fault detection of hydraulic axial piston pumps. Energies 2018, 11. [Google Scholar] [CrossRef]

- Guo, Y.; Xiong, G.; Zeng, L.; Li, Q. Modeling and Predictive Analysis of Small Internal Leakage of Hydraulic Cylinder Based on Neural Network. Energies 2021, 14. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, C.; Tang, T. A review of sustainable maintenance strategies for single component and multicomponent equipment. Sustainability 2022, 14, 2992. [Google Scholar] [CrossRef]

- Saihi, A.; Ben-Daya, M.; As’ ad, R.A. Maintenance and sustainability: a systematic review of modeling-based literature. Journal of Quality in Maintenance Engineering 2022, 29, 155–187. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).