Submitted:

12 May 2025

Posted:

13 May 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Database and methods

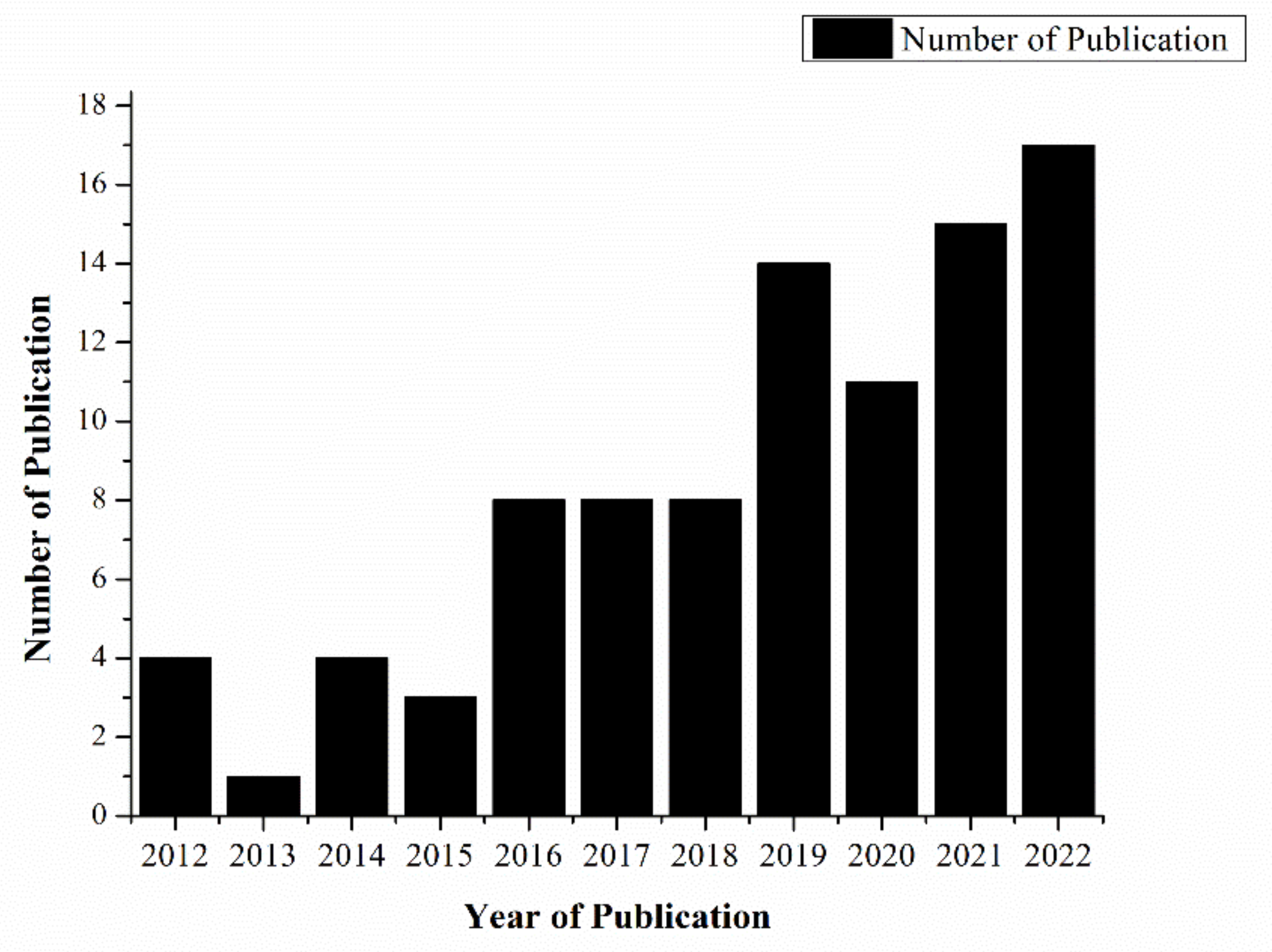

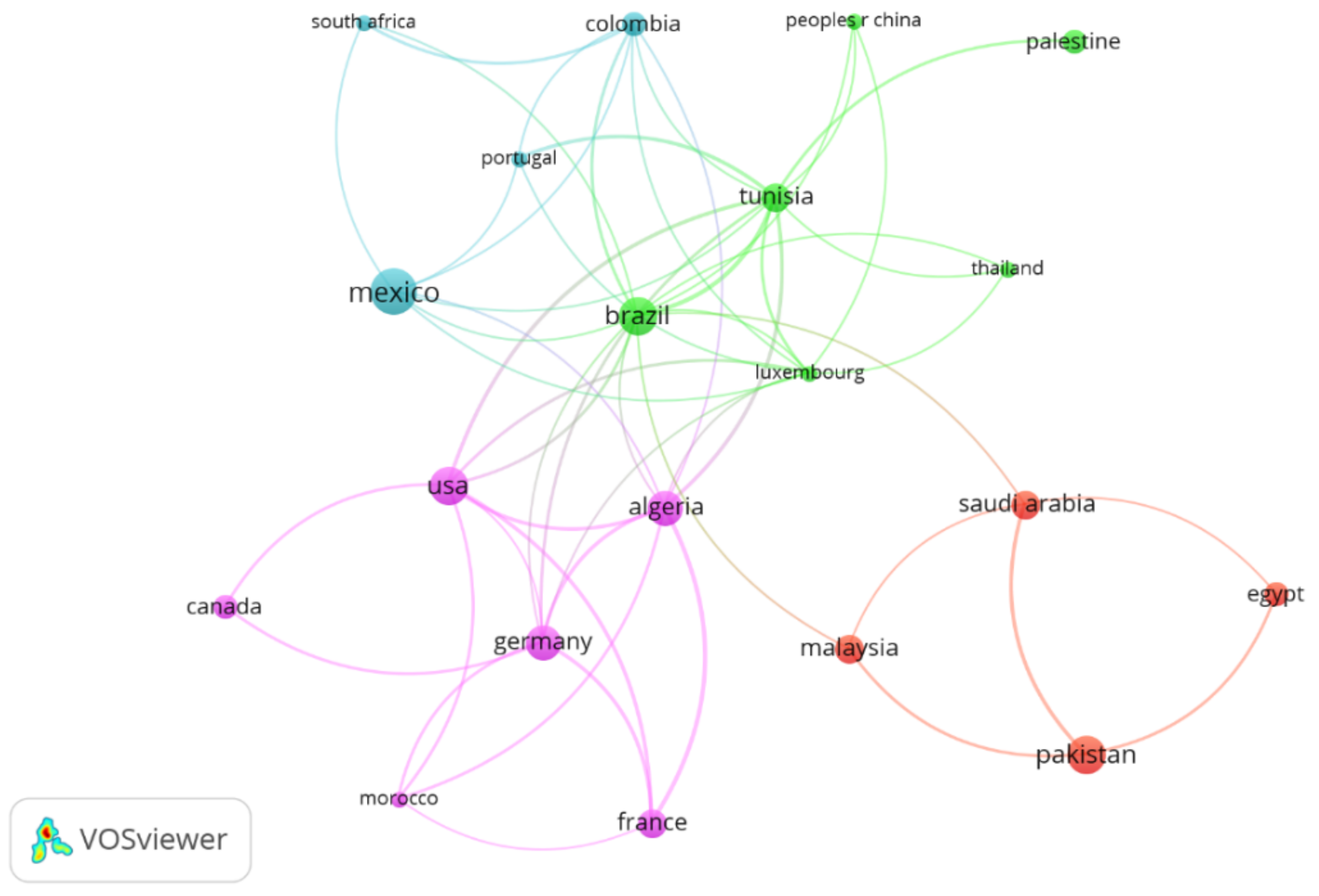

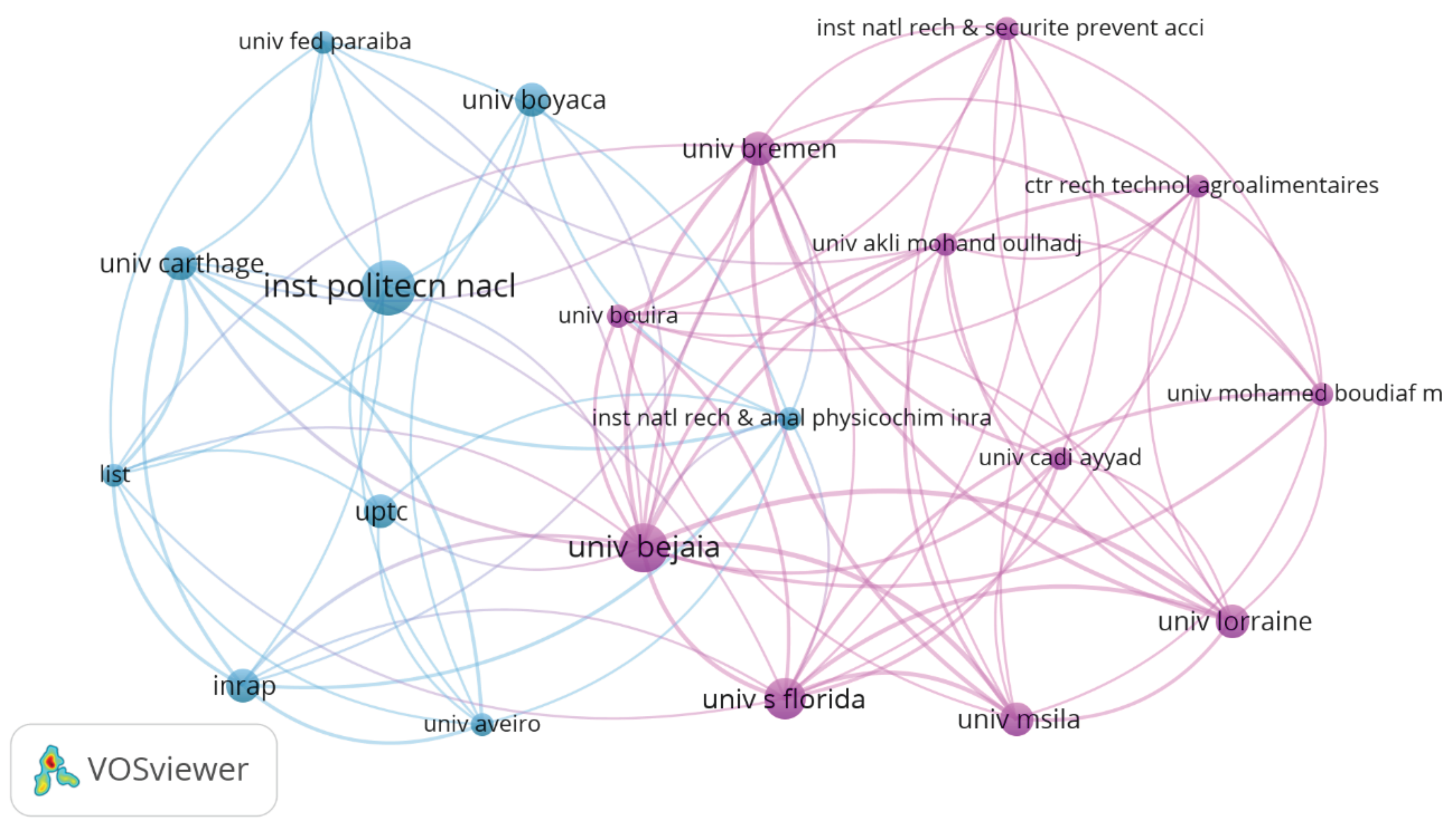

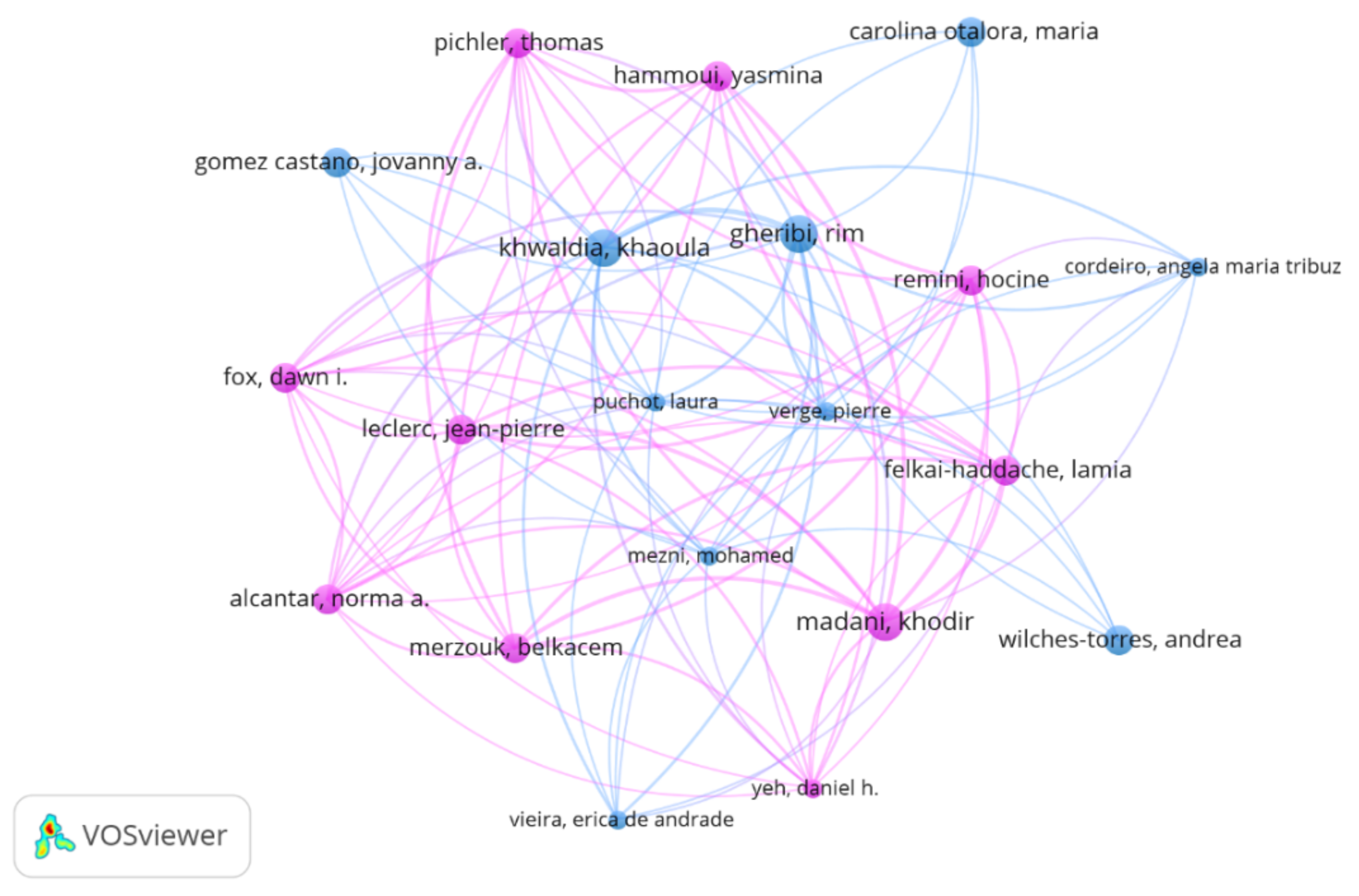

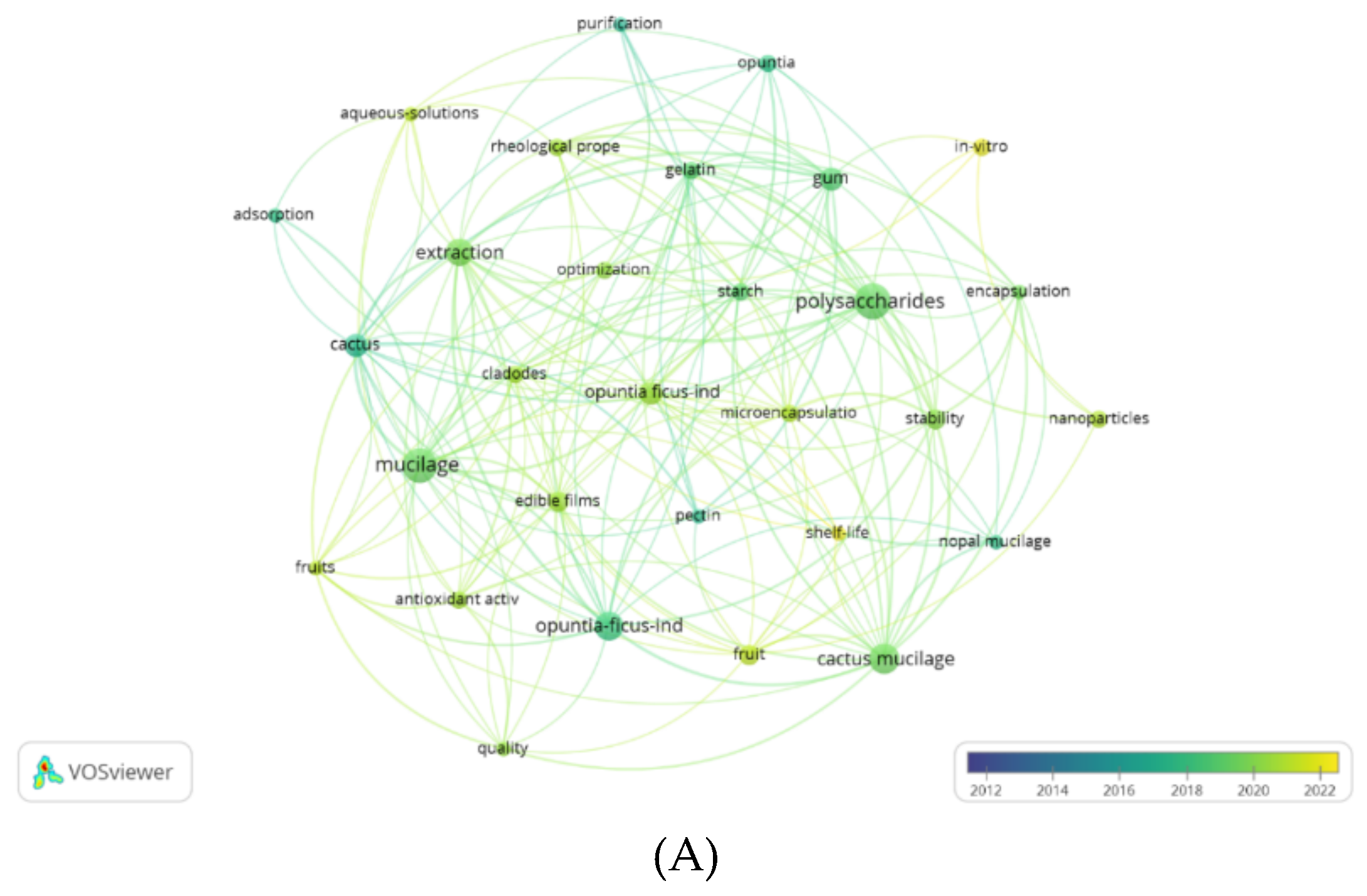

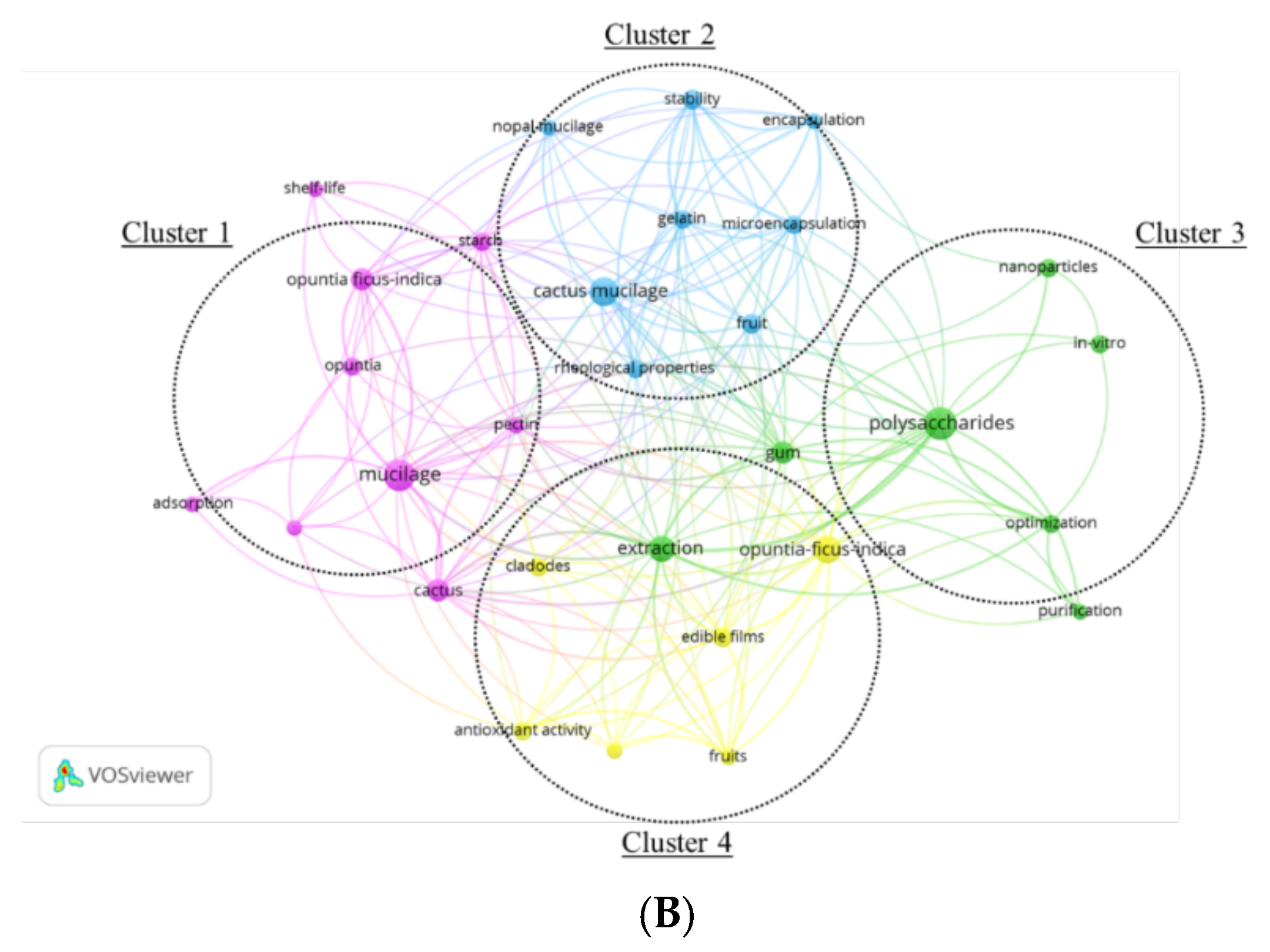

3. Results and Discussions of Bibliometric Analysis

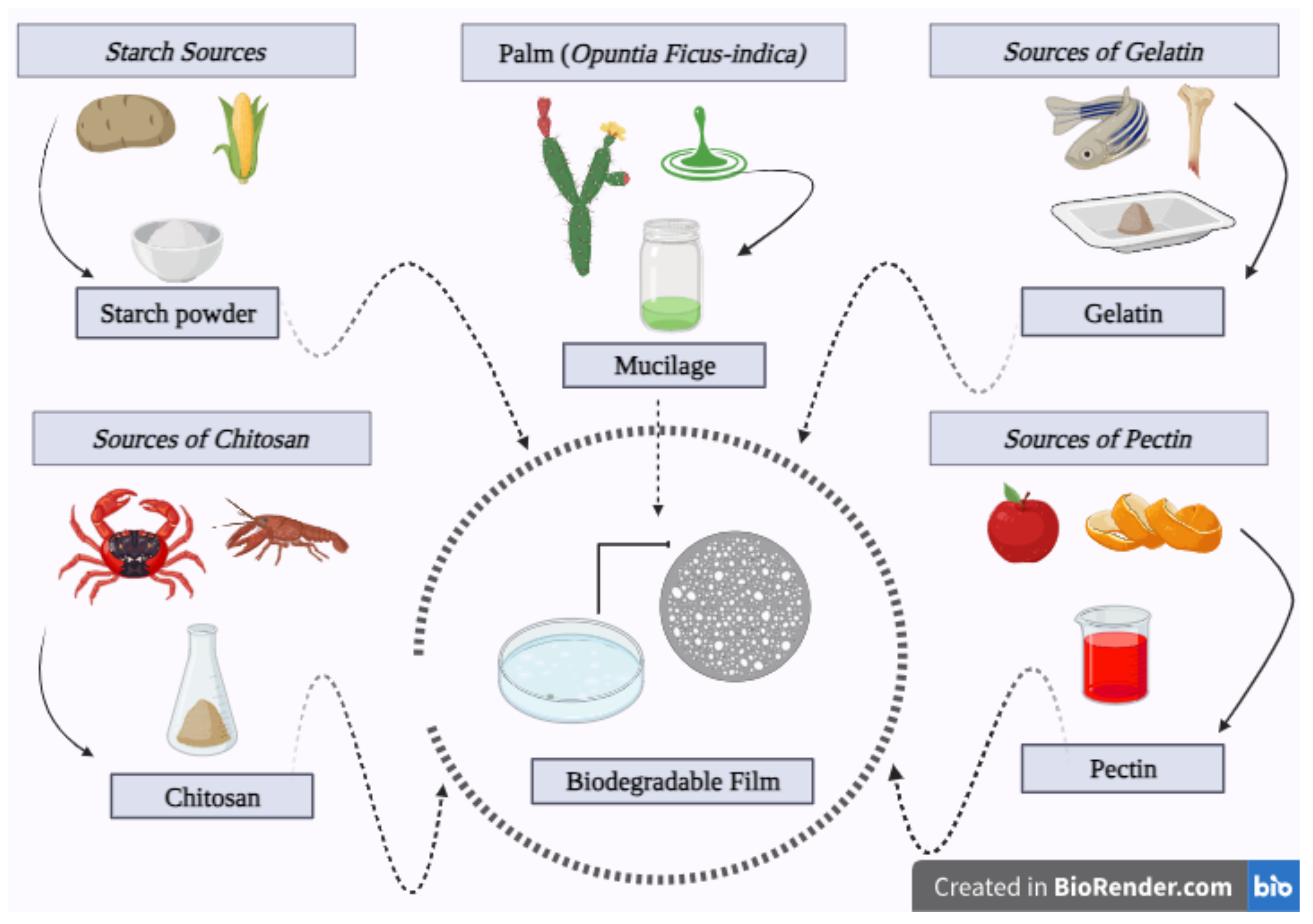

4. Main Natural Polymers Combined with Palm Mucilage to Form Biodegradable Films

5. Trends and Future Perspectives on the Application of Palm Mucilage Films (Opuntia Ficus-Indica) in Foods

6. Conclusion

Funding

Acknowledgments

Declaration of Conflicting Interests

References

- Saratale, R.G.; Cho, S.-K.; Saratale, G.D.; Kadam, A.A.; Ghodake, G.S.; Kumar, M.; Bharagava, R.N.; Kumar, G.; Kim, D.S.; Mulla, S.I.; Shin, H.S. A comprehensive overview and recent advances on polyhydroxyalkanoates (PHA) production using various organic waste streams. Biores Technol. 2021, 325, 1–13. [Google Scholar]

- Chen, L.; Qing, T.; Chen, X.; Ren, W.; Zhang, H. Fabrication and evaluation of biodegradable multi-cross-linked mulch film based on waste gelatina. Chem Engineering J. 2021, 419, 1–10. [Google Scholar] [CrossRef]

- Menossi, M.; Mario, C.; Vera, A.; Claudia, C. Current and emerging biodegradable mulch films based on polysaccharide bio-composites. A review. Agron for Sustain Develop. 2021, 41, 41–53. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Q.; Man, L. Bamboo-derived carboxymethyl cellulose for liquid film as renewable and biodegradable agriculture mulching. International J of Biolog Macromol. 2021, 192, 611–617. [Google Scholar] [CrossRef] [PubMed]

- Sid, S.; Mor, R.S.; Kishore, A.; Sharanagat, V.S. Bio-sourced polymers as alternatives to conventional food packaging materials: A review. Trends is Food Scien & Technol 2021, 111, 87–104. [Google Scholar]

- Makhloufi, N.; Chougui, N.; Rezgui, F.; Benramdane, E.; Silvestre, A.J.D.; Freire, C.S.R.; Vilela, C. Polysaccharide-based films of cactus mucilage and agar with antioxidant properties for active food packaging. Polymer Bullet. 2022, 79, 11369–11388. [Google Scholar] [CrossRef]

- Gheribi, R.; Puchot, L.; Verge, P.; Jaoued-Grayaa, N.; Mohamed, M.; Habibi, Y.; Khaoula, K. Development of plasticized edible flms from Opuntia fícus indica mucilage: A comparative study of various. Carbohyd Polymer. 2018, 190, 204–211. [Google Scholar] [CrossRef]

- Contreras-Padilha, M.; Rodríguez-García, M.E.; Gutiérrezcortez, E.; Valderrama-Bravo, M.C.; Rojas-Molina, J.I.; Riveramunoz, E.M. Physicochemical and rheological characterization of Opuntia fícus mucilage at three diferente maturity stages of cladode. Europ Polymer J. 2016, 78, 226–234. [Google Scholar] [CrossRef]

- Taheri, A.; Jafari, S.M. Gum-based nanocarriers for the protection and delivery of food bioactive compounds. Advanc Colloid Interf Scien. 2019, 269, 277–295. [Google Scholar] [CrossRef]

- Gheribi, R.; Gharbi, M.A.; Ouni, M.E.; Khwakdia, K. Enhancement of the physical, mechanical and thermal properties of cactus mucilage films by blending with polyvinyl alcohol. Food Packaging and Shelf Life. 2019, 22, 1–10. [Google Scholar] [CrossRef]

- Kumar, L.; Deshmukh, R.K.; Gaikwad, K.K. Antimicrobial packaging film from cactus (Cylindropuntia fulgida) mucilage and gelatine. Internat J Biolog Macromol. 2022, 251, 596–605. [Google Scholar] [CrossRef] [PubMed]

- Mannai, F.; Mechi, L.; Alimi, F.; Alsukaibi, A.K.D.; Belgacem, M.N.; Moussaoui, Y. Biodegradable composite films based on mucilage from Opuntia ficus-indica (Cactaceae): Microstructural, functional and thermal properties. Internat J Biolog Macromol. 2023, 252, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Zegbe, J.A.; Mena-Covarrubias, J.; Domínguez-Canales, V.S.I. Cactus mucilage as a coating film to enhance shelf life of unprocessed guavas (psidium guajava l.). Acta Horticul. 2015, 1067, 423–427. [Google Scholar] [CrossRef]

- Vieira, E.A.; Cordeiro, A.M.T.M. Bioprospecting and potential of cactus mucilages: A bibliometric review. Food Chemist. 2023, 401, 1–18. [Google Scholar]

- Zhang, X.; Zhang, Y.; Wang, Y.; Brian, D. Research progress and hotspot analysis for reactive nitrogen flows in macroscopic systems based on a CiteSpace analysis. Ecolog Model. 2021, 443, 1–15. [Google Scholar] [CrossRef]

- Liu, L.; Zou, G.; Zou, Q.; Shunjiang, L.; Zhe, B.; Tuo, J.; Dongsheng, L.; Lianfeng, D. It is still too early to promote biodegradable mulch film on a large scale: A bibliometric analysis. Environm Techno Innov. 2022, 27, 1–12. [Google Scholar] [CrossRef]

- Ribeiro, N.G.; Xavier-Santos, D.; Campelo, P.H.; Guimarães, J.T.; Pimentel, T.C.; Duarte, M.C.K.H.; Freitas, M.Q.; Esmerino, E.A.; Silva, M.C.; Cruz, A.G. Dairy foods and novel thermal and non-thermal processing: A bibliometric analysis. Innovative Food Scien Emerg Technol. 2022, 76, 1–11. [Google Scholar] [CrossRef]

- Prabakusuma, A.S.; Wardono, B.; Fahlevi, M.; Zulham, A.; Sunarno, M.T.D.; Syukur, M.; Aljuaid, M.; Saniuk, S.; Apriliani, T.; Pramoda, R. A bibliometric approach to understanding the recent development of self-sufficient fish feed production utilizing agri-food wastes and by-products towards sustainable aquaculture. Heliyon 2023, 9, 1–10. [Google Scholar] [CrossRef]

- Eck, N.J.V.; Waltman, L. Visualizing Bibliometric Networks. Measu Scholar Impact. 2014, 3, 285–320. [Google Scholar]

- Dirpan, A.; Ainani, A.F.; Djalal, M. A bibliometrics visualization analysis of active packaging system for food packaging. Heliyon 2023, 9, 1–17. [Google Scholar] [CrossRef]

- Carpinteyro-Urban, S.; Vaca, M.; Torres, L.G. Can Vegetal Biopolymers Work as Coagulant–Flocculant Aids in the Treatment of High-Load Cosmetic Industrial Wastewaters? Water, Air, Soil Pollut. 2012, 223, 4925–4936. [Google Scholar] [CrossRef]

- Felkai-Haddache, L.; Dahmoune, F.; Remini, H.; Lefsih, K.; Mouni, L.; Madani, K. Microwave optimization of mucilage extraction from Opuntia ficus indica Cladodes. Internat J of Biolog Macromol. 2016, 84, 24–30. [Google Scholar] [CrossRef] [PubMed]

- Dominguez-Martinez, B.M.; Martínez-Flores, H.E.; Berrios, J.D.J.; Otoni, C.G.; Wood, D.F.; Velazquez, G. Physical Characterization of Biodegradable Films Based on Chitosan, Polyvinyl Alcohol and Opuntia Mucilage. J Polym Environm. 2017, 25, 683–691. [Google Scholar] [CrossRef]

- Zoghlami, N.; Chrita, I.; Bouamama, B.; Gargouri, M.; Zemni, H.; Ghorbel, A.; Mliki, A. Molecular based assessment of genetic diversity within Barbary fig (Opuntia ficus indica (L.) Mill.) in Tunisia. Scien Horticult. 2007, 13, 134–141. [Google Scholar] [CrossRef]

- Amani, E.; Marwa, L.; Hichem, B.S.; Amel, S.-H.; Ghada, B. Morphological variability of prickly pear cultivars (Opuntia spp.) established in ex-situ collection in Tunisia. Scien Horticult. 2019, 248, 163–175. [Google Scholar] [CrossRef]

- Campo, C.; Dick, M.; Santos, P.P.; Costa, T.M.H.; Paese, K.; Guterres, S.S.; Rios, A.O.; Flôres, S.H. Zeaxanthin nanoencapsulation with Opuntia monacantha mucilage as structuring material: characterization and stability evaluation under different temperatures. Colloids Surfaces A: Physico and Engine Aspec. 2018, 558, 410–421. [Google Scholar] [CrossRef]

- Araújo, C.G.S.; Sardinha, A. H-index of cited articles: a contribution to the evaluation of the scientific production of researchers. Brazilian Journal of Sports Medicine. 2011, 17, 358–362. [Google Scholar]

- Barbosa Júnior, L.G.; Almeida, F.L.C.; Luna, L.C.; Castro, M.P.J.; Almeida, E.C. Cotton oil and flour: A bibliometric study. Holos. 2021, 2, 1–17. [Google Scholar]

- Manhivi, V.E.; Venter, S.; Amonsou, E.O.; Kudanga, T. Composition, thermal and rheological properties of polysaccharides from amadumbe (Colocasia esculenta) and cactus (Opuntia spp.). Carbohyd Polym. 2018, 195, 163–169. [Google Scholar] [CrossRef]

- Fox, D.I.; Stebbins, D.M.; Alcantar, N.A. Combining Ferric Salt and Cactus Mucilage for Arsenic Removal from Water. Environm Scien Technol. 2016, 50, 2507–2513. [Google Scholar] [CrossRef]

- Beikzadeh, S.; Khezerlou, A.; Jafari, S.M.; Pilevar, Z.; Mortazavian, A.M. Seed mucilages as the functional ingredients for biodegradable films and edible coatings in the food industry. Advances Colloid Interf Scien. 2020, 280, 1–10. [Google Scholar] [CrossRef]

- Carmona, J.C.; Robert, P.; Vergara, C.; Sáenz, C. Microparticles of yellow-orange cactus pear pulp (Opuntia ficus-indica) with cladode mucilage and maltodextrin as a food coloring in yogurt. LWT 2020, 138, 1–9. [Google Scholar] [CrossRef]

- Otálora, M.C.; Gómez-Castaño, J.A.; Wilches-Torres, A. Preparation, study and characterization of complex coacervates formed between gelatin and cactus mucilage extracted from cladodes of Opuntia ficus-indica. LWT 2019, 112, 1–9. [Google Scholar] [CrossRef]

- Todhanakasem, T.; Boonchuai, P.; Ayutthaya, P.I.; Suwapanich, R.; Hararak, B.; Wu, B.; Young, B.M. Development of Bioactive Opuntia ficus-indica Edible Films Containing Probiotics as a Coating for Fresh-Cut Fruit. Polymers. 2022, 14, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Otálora, M.C.; Carriazo, J.G.; Iturriaga, L.; Nazareno, M.A.; Osorio, C. Microencapsulation of betalains obtained from cactus fruit (Opuntia ficus-indica) by spray drying using cactus cladode mucilage and maltodextrin as encapsulating agents. Food Chemistry. 2015, 187, 174–181. [Google Scholar] [CrossRef] [PubMed]

- Di Lorenzo, F.; Silipo, A.; Molinaro, A.; Parrilli, M.; Schiraldi, C.; D’AGOSTINO, A.; Izzo, E.; Rizza, L.; Bonina, A.; Bonina, F.; Lanzetta, R. The polysaccharide and low molecular weight components of Opuntia ficus indica cladodes: Structure and skin repairing properties. Carbohyd Polym. 2017, 157, 128–136. [Google Scholar] [CrossRef]

- Rodríguez-González, S.; Martínez-Flores, H.E.; Chávez-Moreno, C.K.; Macías-Rodríguez, L.I.; Zavala-Mendoza, E.; Garnica-Romo, M.G.; Chacón-García, L. Extraction and Characterization of Mucilage From Wild Species of Opuntia. J Food Process Engine. 2014, 37, 285–292. [Google Scholar] [CrossRef]

- Delia, S.-C.; Chávez, G.M.; León-Martínez, F.M.; Araceli, S.-G.P.; Irais, A.-L.; Franco, A.-A. Spray drying microencapsulation of betalain rich extracts from Escontria chiotilla and Stenocereus queretaroensis fruits using cactus mucilage. Food Chemistry. 2019, 272, 715–722. [Google Scholar] [CrossRef]

- Gheribi, R.; Khwaldia, K. Cactus Mucilage for Food Packaging Applications. Coatings. 2019, 9, 1–19. [Google Scholar] [CrossRef]

- DICK, M.; DAL MAGRO, L.; RODRIGUES, R.C.; RIOS, A.; DE, O.; FLÔRES, S.H. Valorization of Opuntia monacantha (Willd.) Haw. cladodes to obtain a mucilage with hydrocolloid features: Physicochemical and functional performance. Internat J Biolog Macromol. 2019, 123, 900–909. [Google Scholar] [CrossRef]

- Madera-Santana, T.J.; Vargas-Rodríguez, L.; Núñez-Colín, C.A.; González-García, G.; Peña-CaballerO, V.; Núñez-Gastélum, J.A.; Gallegos-Vázquez, C.; Rodríguez-Núñez, J.R. Mucilage from cladodes of Opuntia spinulifera Salm-Dyck: Chemical, morphological, structural and thermal characterization. CyTA - J Food. 2018, 16, 650–657. [Google Scholar] [CrossRef]

- Messina, C.M.; Arena, R.; Morghese, M.; Santulli, A.; Liguori, G.; Inglese, P. Seasonal characterization of nutritional and antioxidant properties of Opuntia ficus-indica [(L.) Mill.] mucilage. Food Hydrocol. 2021, 111, 1–10. [Google Scholar] [CrossRef]

- Morais, M.A.S.; Fonseca, K.S.; Viégas, E.K.D.; Almeida, S.L.; Maia, R.K.M.; Silva, V.N.S.; Simões, A.N. Mucilage of spineless cactus in the composition of an edible coating for minimally processed yam (Dioscorea spp.). J Food Measurem Characteriz. 2019, 3, 1–9. [Google Scholar] [CrossRef]

- Liguori, G.; Gaglio, R.; Settanni, L.; Inglese, P.; D’anna, F.; Miceli, A. Effect of Opuntia ficus-indica Mucilage Edible Coating in Combination with Ascorbic Acid, on Strawberry Fruit Quality during Cold Storage. J of Food Quality. 2021, 1, 1–8. [Google Scholar] [CrossRef]

- Caballero, L.R.C.; Wilches-Torres, A.; Cárdenas-Chaparro, A.; Gómez castaño, J.A.; Otálora, M.C. Preparation and Physicochemical Characterization of Softgels Cross-Linked with Cactus Mucilage Extracted from Cladodes of Opuntia ficus-indica. Molecules 2019, 24, 1–13. [Google Scholar] [CrossRef]

- Scognamiglio, F.; Gattia, D.M.; Roselli, G.; Persia, F.; Angelis, U.; Santulli, C. Thermoplastic Starch (TPS) Films Added with Mucilage from Opuntia Ficus Indica: Mechanical, Microstructural and Thermal Characterization. Materials 2020, 13, 1–14. [Google Scholar] [CrossRef]

- Liu, F.; Chen, Q.; Liu, C.; Ao, Q.; Tian, X.; Fan, J.; Tong, H.; Wang, X. Natural polymers for organ 3D bioprinting. Polymers 2018, 10, 1–26. [Google Scholar] [CrossRef]

- Cheng, W.; Sun, Y.; Xia, X.; Yang, L.; Fan, M.; LI, Y.; Wang, LI.; Qian, H. Effects of β-amylase treatment conditions on the gelatinization and retrogradation characteristics of wheat starch. Food Hydrocol. 2022, 124, 1–10. [Google Scholar] [CrossRef]

- Torres, F.G.; De- La- Torre, G.E. Synthesis, characteristics, and applications of modified starch nanoparticles: A review. Internat J of Biolog Macromol. 2022, 194, 289–305. [Google Scholar] [CrossRef]

- Li, X.; Sha, X.-M.; Yang, H.-S.; Ren, Z.-Y.; Tu, Z.-C. Ultrasonic treatment regulates the properties of gelatin emulsion to obtain high-quality gelatin film. Food Chemistry. 2023, 18, 1–10. [Google Scholar] [CrossRef]

- Tavares, W.S.; Barreto, G.A.V.; Pinto, E.P.; Silva, P.G.B.; Sousa, F.O. Influence of gelatin on the functional characteristics and wound healing potential of chitosan/zein films loaded with ellagic acid nanoparticles. J Drug Deliv Scien Technol. 2023, 88, 1–10. [Google Scholar] [CrossRef]

- Hosseini, S.F.; Gómez-Guillén, M.C. A state-of-the-art review on the elaboration of fish gelatin as bioactive packaging: Special emphasis on nanotechnology-based approaches. Trends Food Scien & Technol. 2018, 79, 125–135. [Google Scholar]

- Bakshi, P.S.; Selvakumar, D.; Kadirvelu, K.; Kumar, N.S. Chitosan as an environment friendly biomaterial – a review on recent modifications and applications. Internat J of Biolog Macromol. 2020, 150, 1072–1083. [Google Scholar] [CrossRef]

- Cazón, P.; Várquez, M. Mechanical and barrier properties of chitosan combined with other components as food packaging film. Environm Chemist Letters. 2020, 18, 257–267. [Google Scholar] [CrossRef]

- Flórez, E.; Guerra-Rodríguez, P.; Cazón, M.; Vázquez. Chitosan for food packaging: Recent advances in active and intelligent films. Food Hydrocoll. 2022, 124, 1–11. [Google Scholar] [CrossRef]

- HOSSEINI, S.; PARASTOUEI, K.; KHODAIYAN, F. Simultaneous extraction optimization and characterization of pectin and phenolics from sour cherry pomace. Internat J of Biolog Macromol. 2020, 158, 911–921. [Google Scholar] [CrossRef]

- Rahmani, Z.; Khodaiyan, F.; Kazemi, M.; Sharifan, A. Optimization of microwave-assisted extraction and structural characterization of pectin from sweet lemon peel. Internat J of Biolog Macromol. 2020, 147, 1107–1115. [Google Scholar] [CrossRef]

- Gupta, R.K.; Guha, P.; Srivastav, P.P. Natural polymers in bio-degradable/edible film: A review on environmental concerns, cold plasma technology and nanotechnology application on food packaging- A recent trends. Food Chemist Advanc. 2022, 1, 1–17. [Google Scholar] [CrossRef]

- Mostafavi, F.S.; Zaeim, D. Agar-based edible films for food packaging applications - A review. Internat J of Biolog Macromol. 2020, 59, 1165–1176. [Google Scholar] [CrossRef]

- Xiao, Q.; Weng, H.; Ni, H.; Hong, Q.; Lin, K.; Xiao, A. Physicochemical and gel properties of agar extracted by enzyme and enzyme-assisted methods. Food Hydrocolloids. 2019, 87, 530–540. [Google Scholar] [CrossRef]

- Ranjbar, M.; Tabrizzad, M.H.A.; Asadi, G.; Ahari, H. Investigating the microbial properties of sodium alginate/chitosan edible film containing red beetroot anthocyanin extract for smart packaging in chicken fillet as a pH indicator. Heliyon. 2023, 9, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Gheorghita, R.; Gutt, G.; Amariei, S. The use of edible films based on sodium alginate in meat product packaging: an eco-friendly alternative to conventional plastic materials. Coatings. 2020, 10, 1–12. [Google Scholar]

- Mahcene, Z.; Khelil, A.; Hasni, S.; Akman, P.K.; Bozkurt, F.; Birech, K.; Goudjil, M.B.; Tornuk, F. Development and characterization of sodium alginate based active edible films incorporated with essential oils of some medicinal plants. Internat J of Biolog Macromol. 2020, 15, 124–132. [Google Scholar] [CrossRef]

- Huang, H.-D.; Ren, P.-G.; Zhong, G.-J.; Olah, A.; Li, Z.-M.; Baer, E.; Zhu, L. Promising strategies and new opportunities for high barrier polymer packaging films. Progres Polymer Scien. 2023, 144, 1–10. [Google Scholar] [CrossRef]

- Kamel, S.M. Utilization of Cactus Dear Peels Mucilage as an Edible Coating of Chicken Meat to Prolong its Shelf Life. Food Scien Quality Managem 2014, 18, 1–8. [Google Scholar]

- Lira-Vargas, A.A.; Corrales-Garcia, J.J.E.; Valle-Guadarrama, S.; Pena-Valdivia, C.B.; Trejo-Marquez, M.A. Biopolymeric films based on cactus (Opuntia ficus-indica) mucilage incorporated with gelatin and beeswax. J Profes Associat for Cactus Develop. 2014, 16, 51–70. [Google Scholar]

- Sandoval, D.C.G.; Sosa, B.L.; Martínez-Ávila, G.C.G.; Fuentes, H.R.; Abarca, V.H.A.; Rojas, R. Formulation and Characterization of Edible Films Based on Organic Mucilage from Mexican Opuntia ficus-indica. Coatings 2019, 9, 1–11. [Google Scholar] [CrossRef]

- Olicón-Hernández, D.R.; Acosta-Sánchez, A.; Monterrubio-López, R.; Guerra-Sánchez, G. Chitosan and Opuntia ficus-indica mucilage as the base of a polymeric edible film for the protection of tomatoes against Rhizopus stolonifera. Special Journal on Ciên Quím-Bióg. 2019, 22, 1–9. [Google Scholar]

- Dhall, R.K. Advances in Edible Coatings for Fresh Fruits and Vegetables: A Review. Critic Reviews Food Scien Nutrit. 2013, 53, 435–450. [Google Scholar] [CrossRef]

- Cakmak, H.; Ilyasoglu-Buyukkestelli, H.; Sogut, E.; Ozyurt, V.H.; Gumus-Bonacina, C.E.; Simsek, S. A review on recent advances of plant mucilages and their applications in food industry: Extraction, functional properties and health benefits. Food Hydrocol Health. 2023, 3, 1–10. [Google Scholar] [CrossRef]

| Journal | Country | Citations | Publications | Impact factor* | CiteScore |

|---|---|---|---|---|---|

| Carbohydrate Polymers | United Kingdom | 148 | 2 | 11,20 | 18,90 |

| Environmental Science & Technology | United States | 93 | 2 | 11,40 | 16,70 |

| LWT- Food Science and Technology | Switzerland | 73 | 3 | 6,00 | 6,70 |

| Separation and Purification Technology | Netherlands | 70 | 2 | 8,60 | 12,70 |

| Food Chemistry | United Kingdom | 58 | 3 | 8,80 | 14,90 |

| Coatings | Switzerland | 40 | 1 | 3,40 | 4,70 |

| Journal of Electroanalytical Chemistry | Netherlands | 31 | 1 | 4,50 | 7,50 |

| Colloids and Surfaces B: Biointerfaces | Netherlands | 31 | 1 | 5,80 | 11,00 |

| Water Science and Technology | United Kingdom | 31 | 1 | 2,70 | 3,40 |

| Saudi Pharmaceutical Journal | Saudi Arabia | 31 | 1 | 4,56 | 5,70 |

| International Journal of Biological Macromolecules | Netherlands | 28 | 2 | 8,20 | 14,50 |

| Journal of the Taiwan Institute of Chemical Engineers | Taiwan | 24 | 1 | 5,70 | 9,60 |

| Food Packaging and Shelf Life | Netherlands | 17 | 1 | 8,00 | 12,90 |

| Journal of Food Measurement and Characterization | United States | 13 | 2 | 3,06 | 3,00 |

| Molecules | Switzerland | 11 | 1 | 4,60 | 6,70 |

| International J. of Environmental Analytical Chemistry | United Kingdom | 8 | 1 | 2,73 | 5,45 |

| Saudi Journal of Biological Sciences | Saudi Arabia | 5 | 1 | 4,05 | 5,30 |

| Polymers | Switzerland | 4 | 1 | 5,00 | 6,60 |

| Publication | Year | NC | Journal | Reference |

|---|---|---|---|---|

| Microencapsulation of betalains obtained from cactus fruit (Opuntia ficus-indica) by spray drying using cactus cladode mucilage and maltodextrin as encapsulating agents | 2015 | 133 | Food Chemistry | Otalora et al. [35] |

| Development of plasticized edible films from Opuntia ficus-indica mucilage: A comparative study of various polyol plasticizers | 2018 | 108 | Carbohydrate Polymers | Gheribi et al. [7] |

| The polysaccharide and low molecular weight components of Opuntia ficus indica cladodes: Structure and skin repairing properties | 2017 | 54 | Carbohydrate Polymers | Di Lorenzo et al. [36] |

| Extraction and characterization of mucilage from wild species of Opuntia | 2014 | 51 | Journal of Food Process Engineering | Rodríguez-González et al. [37] |

| Spray drying microencapsulation of betalain rich extracts from Escontria chiotilla and Stenocereus queretaroensis fruits using cactus mucilage | 2019 | 43 | Food Chemistry | Delia et al. [38] |

| Cactus Mucilage for Food Packaging Applications | 2019 | 41 | Coatings | Gheribi; Khwaldia, [39] |

| Valorization of Opuntia monacantha (Willd.) Haw. cladodes to obtain a mucilage with hydrocolloid features: Physicochemical and functional performance | 2019 | 37 | International Journal of Biological Macromolecules | Dick et al. [40] |

| Zeaxanthin nanoencapsulation with Opuntia monacantha mucilage as structuring material: Characterization and stability evaluation under different temperatures | 2018 | 32 | Colloids and Surfaces A-Physicochemical and Engineering Aspects | Campo et al. [26] |

| Physical Characterization of Biodegradable Films Based on Chitosan, Polyvinyl Alcohol and Opuntia Mucilage | 2017 | 29 | Journal of Polymers and the Environment | Dominguez-Martinez et al. [23] |

| Mucilage from cladodes of Opuntia spinulifera Salm-Dyck: chemical, morphological, structural and thermal characterization | 2018 | 22 | Cyta-Journal of Food | Madera-Santana et al. [41] |

| Microwave optimization of mucilage extraction from Opuntia ficus indica Cladodes | 2016 | 20 | International Journal of Biological Macromolecules | Felkai-Haddache et al. [22] |

| Enhancement of the physical, mechanical and thermal properties of cactus mucilage films by blending with polyvinyl alcohol | 2019 | 17 | Food Packaging and Shelf Life | Gheribi et al. [10] |

| Preparation, study and characterization of complex coacervates formed between gelatin and cactus mucilage extracted from cladodes of Opuntia ficus-indica | 2019 | 17 | LWT- Food Science and Technology | Otalora et al. [33] |

| Seasonal characterization of nutritional and antioxidant properties of Opuntia ficus-indica [(L.) Mill.] mucilage | 2021 | 14 | Food Hydrocolloids | Messina et al. [42] |

| Mucilage of spineless cactus in the composition of an edible coating for minimally processed yam (Dioscorea spp.) | 2019 | 13 | Journal of Food Measurement and Characterization | Morais et al. [43] |

| Effect of Opuntia ficus-indica Mucilage Edible Coating in Combination with Ascorbic Acid, on Strawberry Fruit Quality during Cold Storage | 2021 | 11 | Journal of Food Quality | Liguori et al. [44] |

| Preparation and physicochemical characterization of softgels Cross-Linked with cactus mucilage extracted from cladodes of Opuntia ficus-indica | 2019 | 11 | Molecules | Caballero et al. [45] |

| Cactus Mucilage as a Coating Film to Enhance Shelf Life of Unprocessed Guavas (Psidium guajava L.) | 2015 | 10 | Acta Horticulturae | Zegbe et al. [13] |

| Development of Bioactive Opuntia ficus-indica Edible Films Containing Probiotics as a Coating for Fresh-Cut Fruit | 2022 | 4 | Polymers | Todhanakasem et al. [34] |

| Thermoplastic Starch (TPS) Films Added with Mucilage from Opuntia Ficus Indica: Mechanical, Microstructural and Thermal Characterization | 2020 | 4 | Materials | Scognamiglio et al. [46] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).