Submitted:

11 May 2025

Posted:

12 May 2025

You are already at the latest version

Abstract

Keywords:

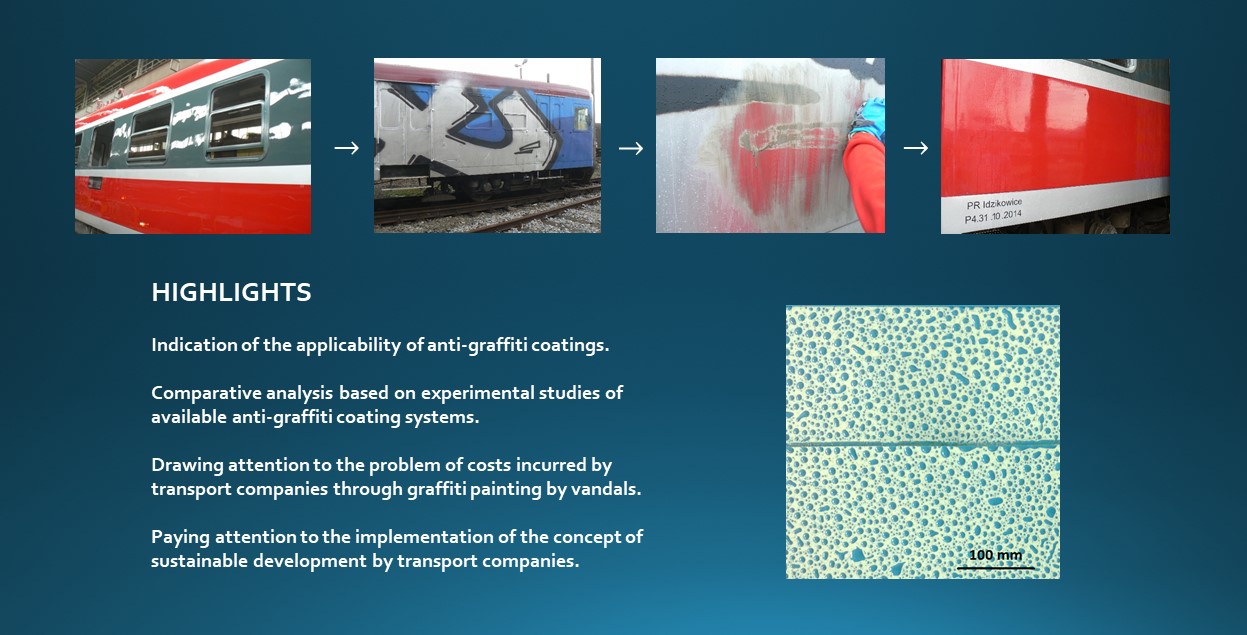

1. Introduction

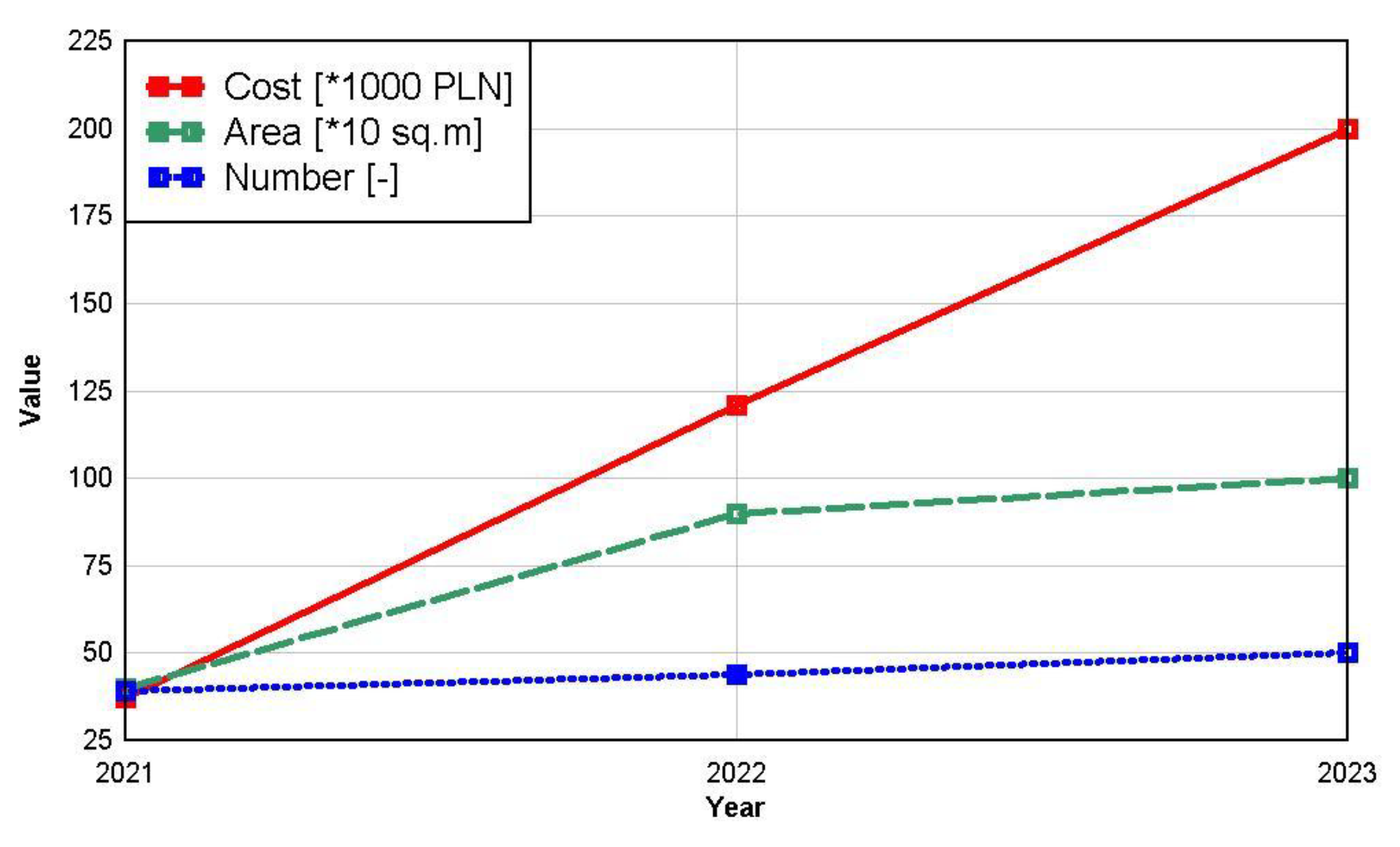

2. Costs of Anti-Graffiti Removal

3. Materials and Methods

3.1. Protective Coatings

3.2. Anti-Graffiti Coatings Laboratory Tests

- application technique: pneumatic spray,

- application: four layers,

- surface temperature: 21-23 oC,

- operating pressure: 0.20-0.22 MPa,

- evaporation time between layers: 20 minutes,

- evaporation before baking: 20 minutes,

- annealing temperature: 50 oC,

- annealing time: 60 minutes,

- thickness of dry film: 40-50 µm.

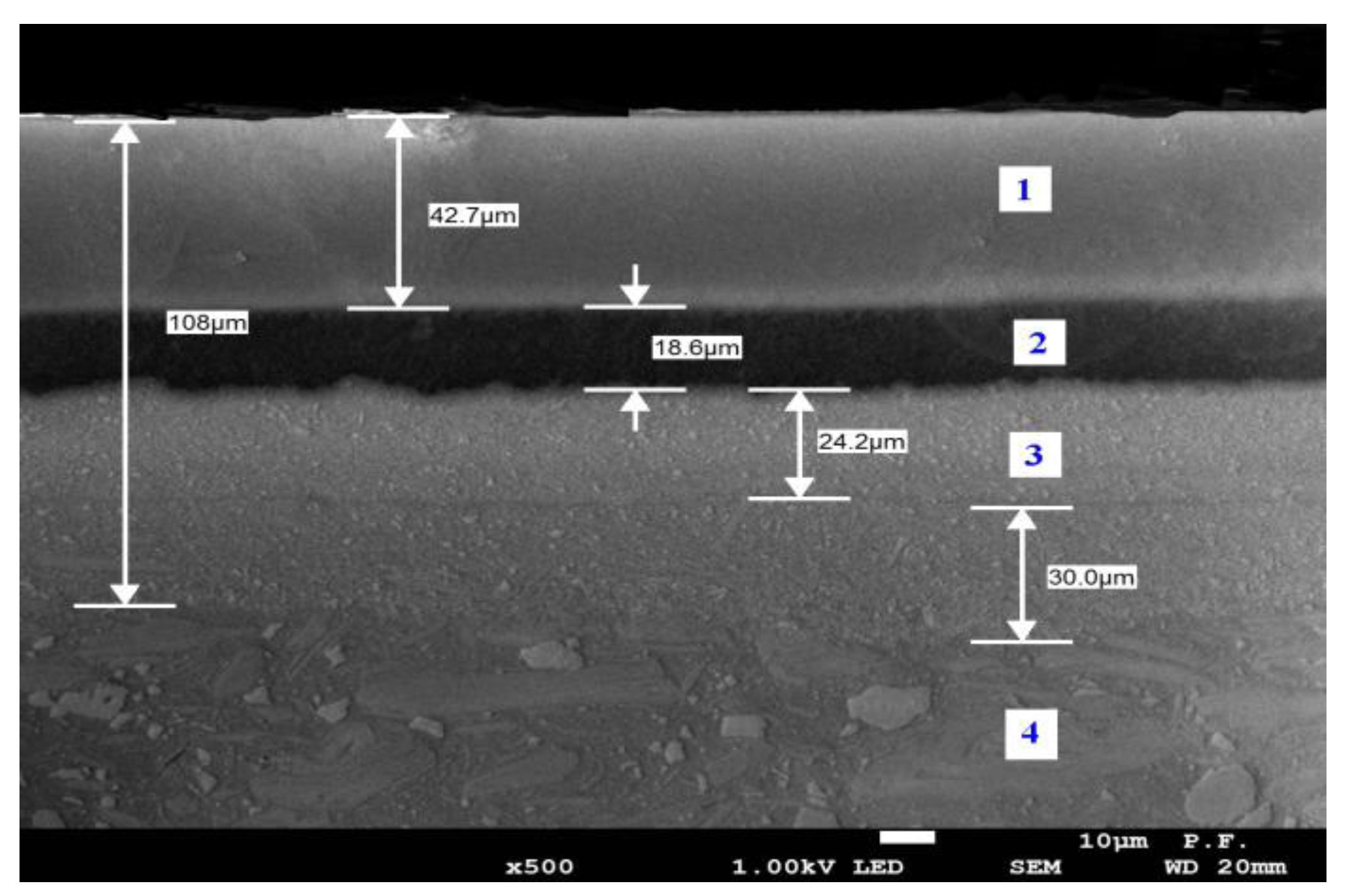

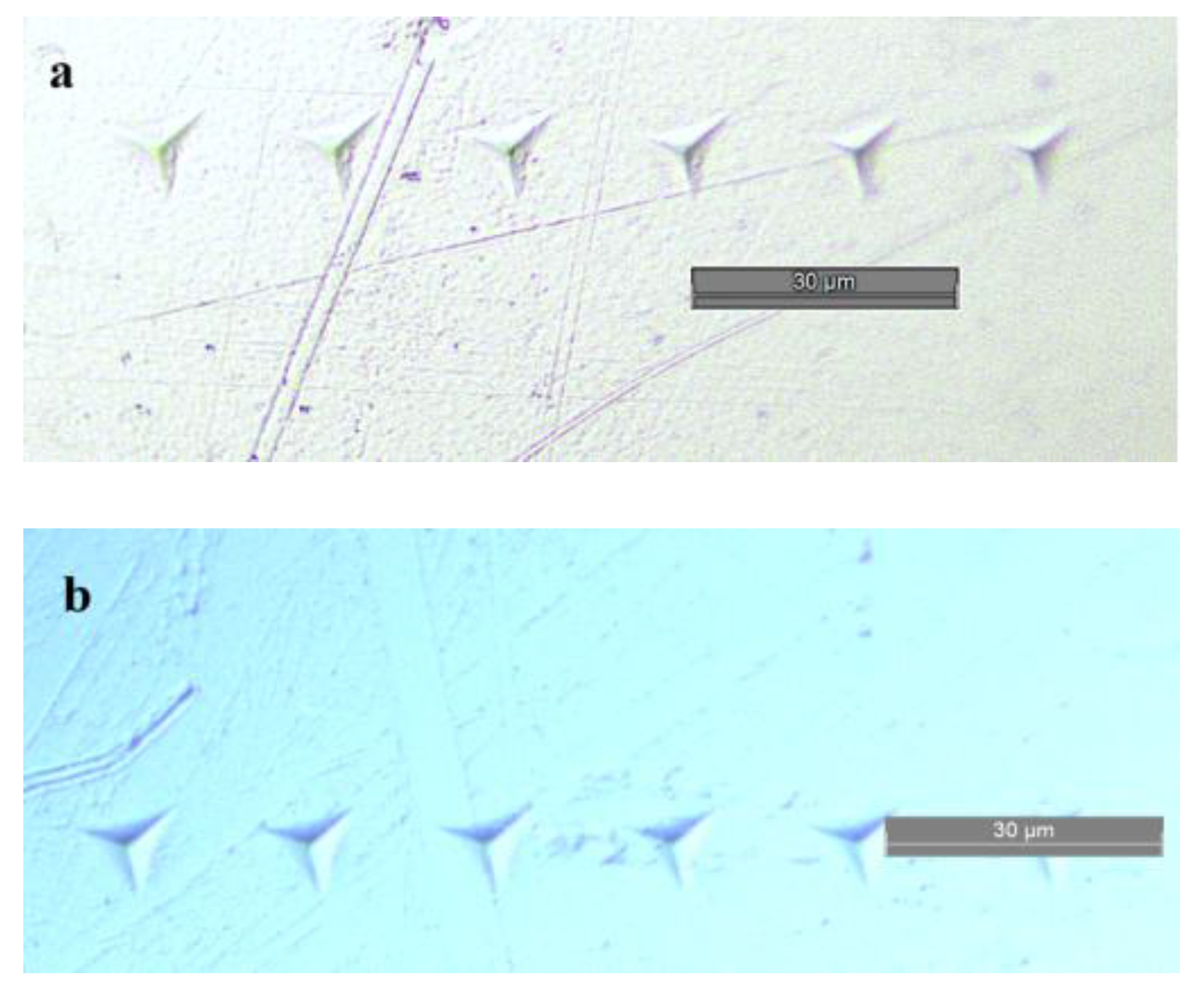

3.2.1. Microstructural Analysis

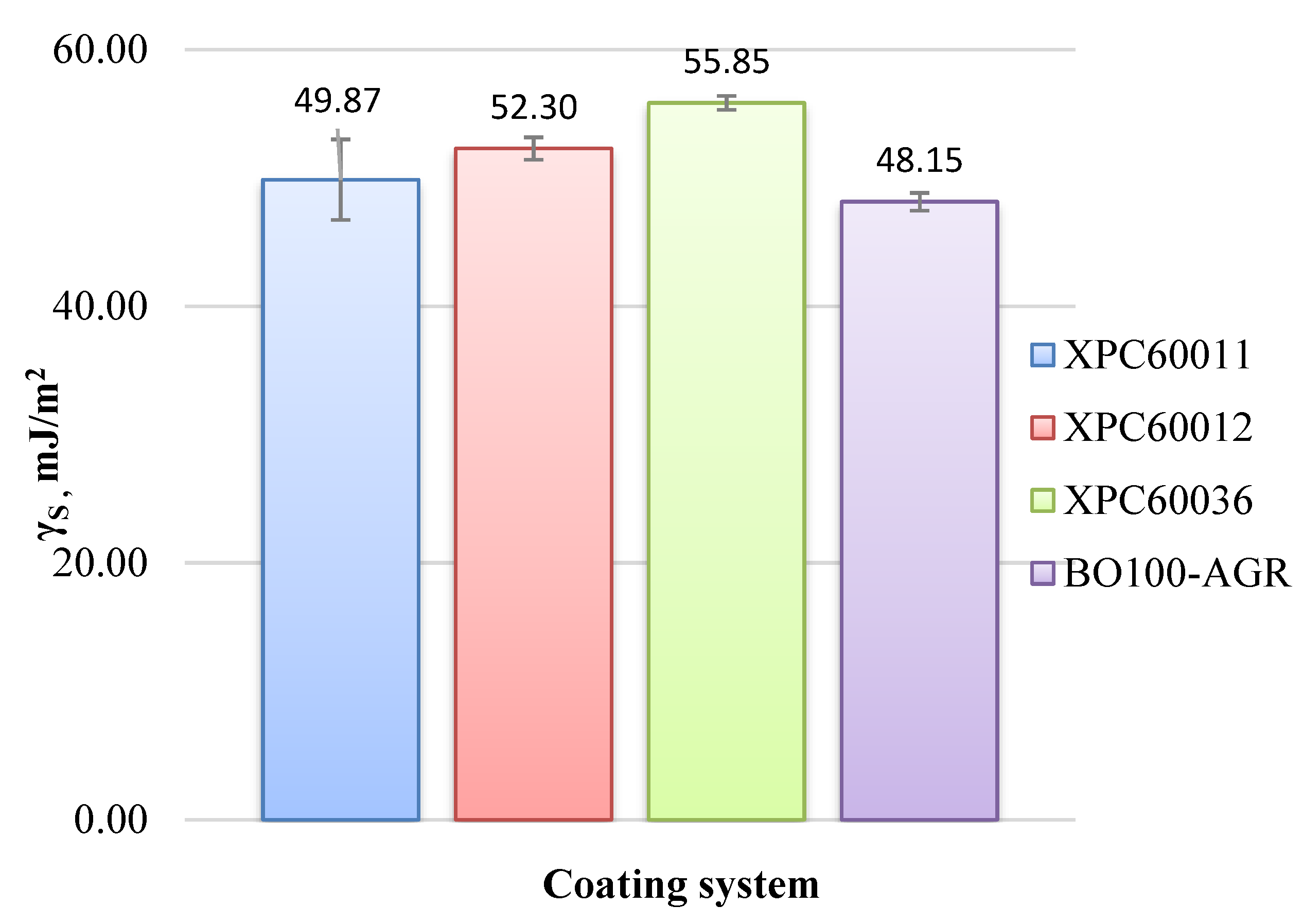

3.2.2. Measurement of Surface Free Energy

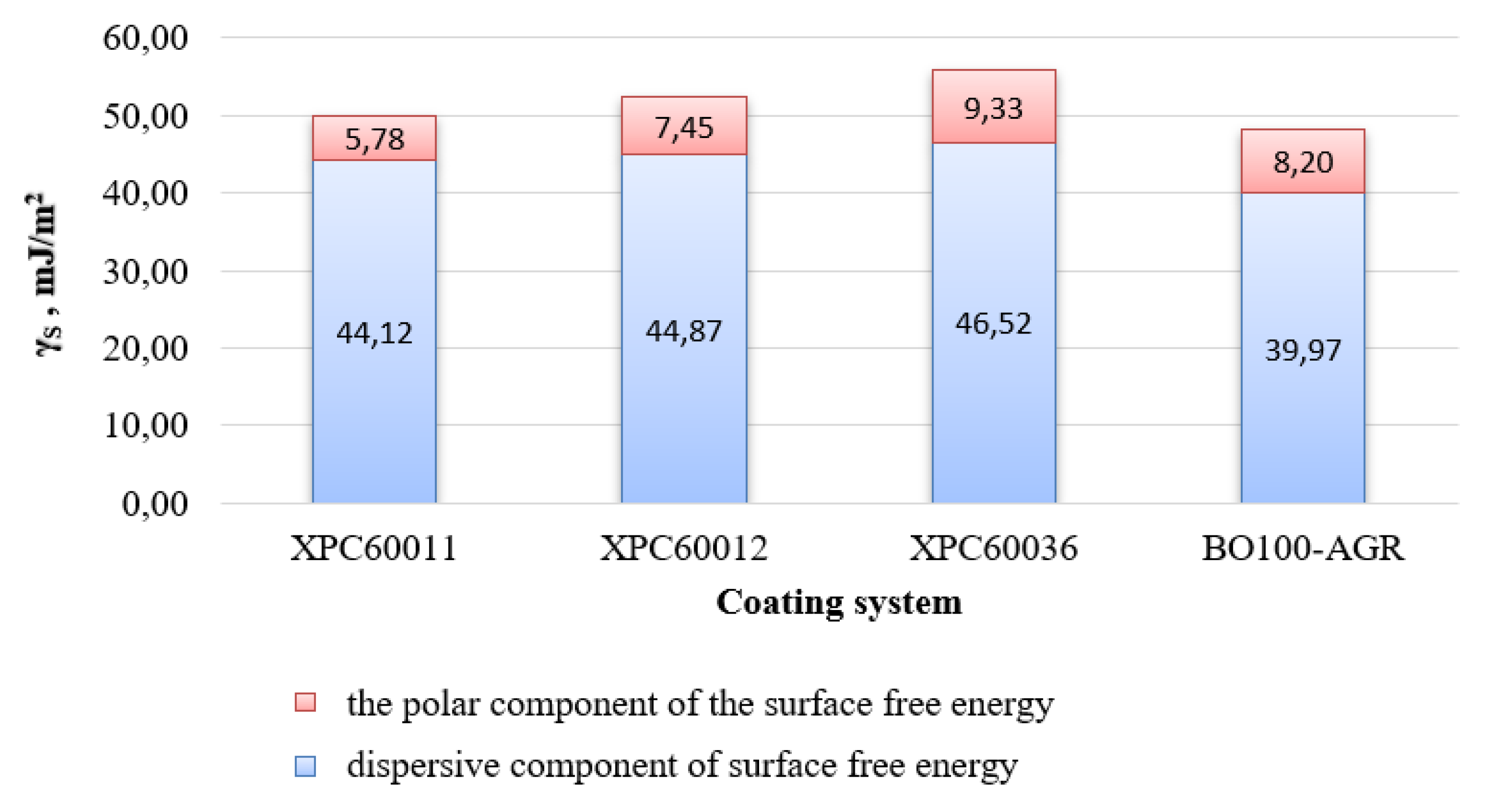

- a)

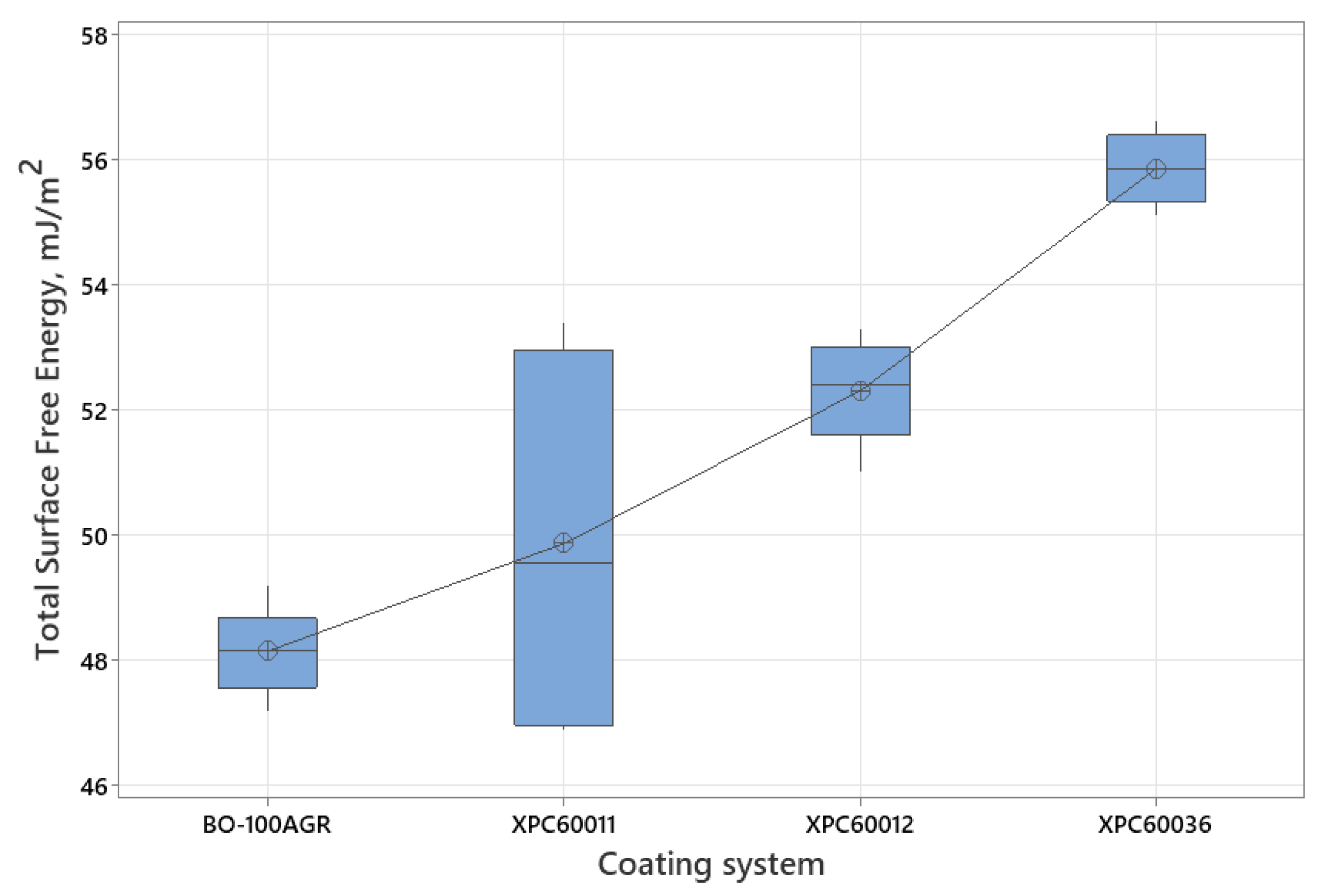

- Total surface free energy (TSFE).

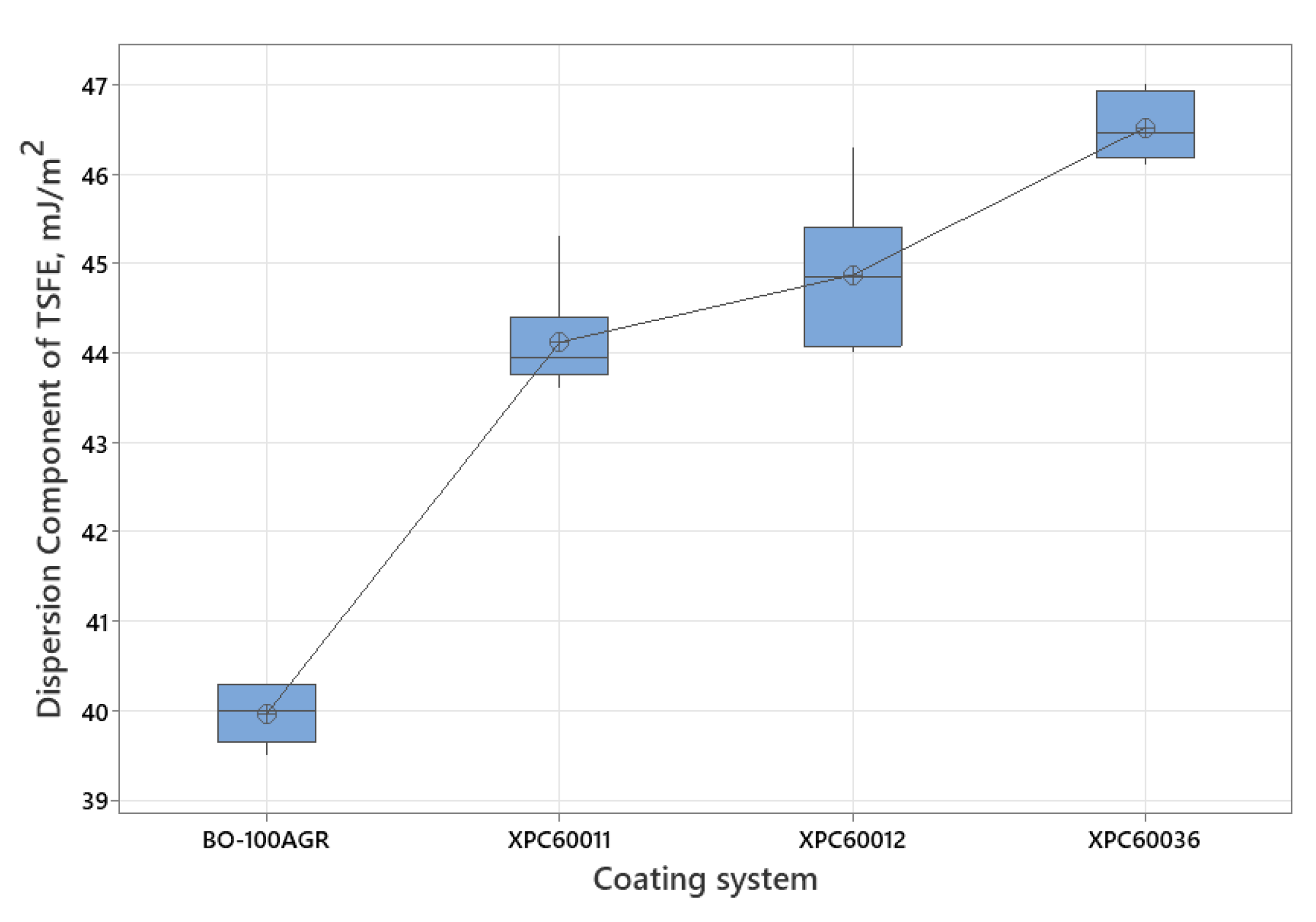

- b) Dispersive component of total surface free energy (DC-TSFE).

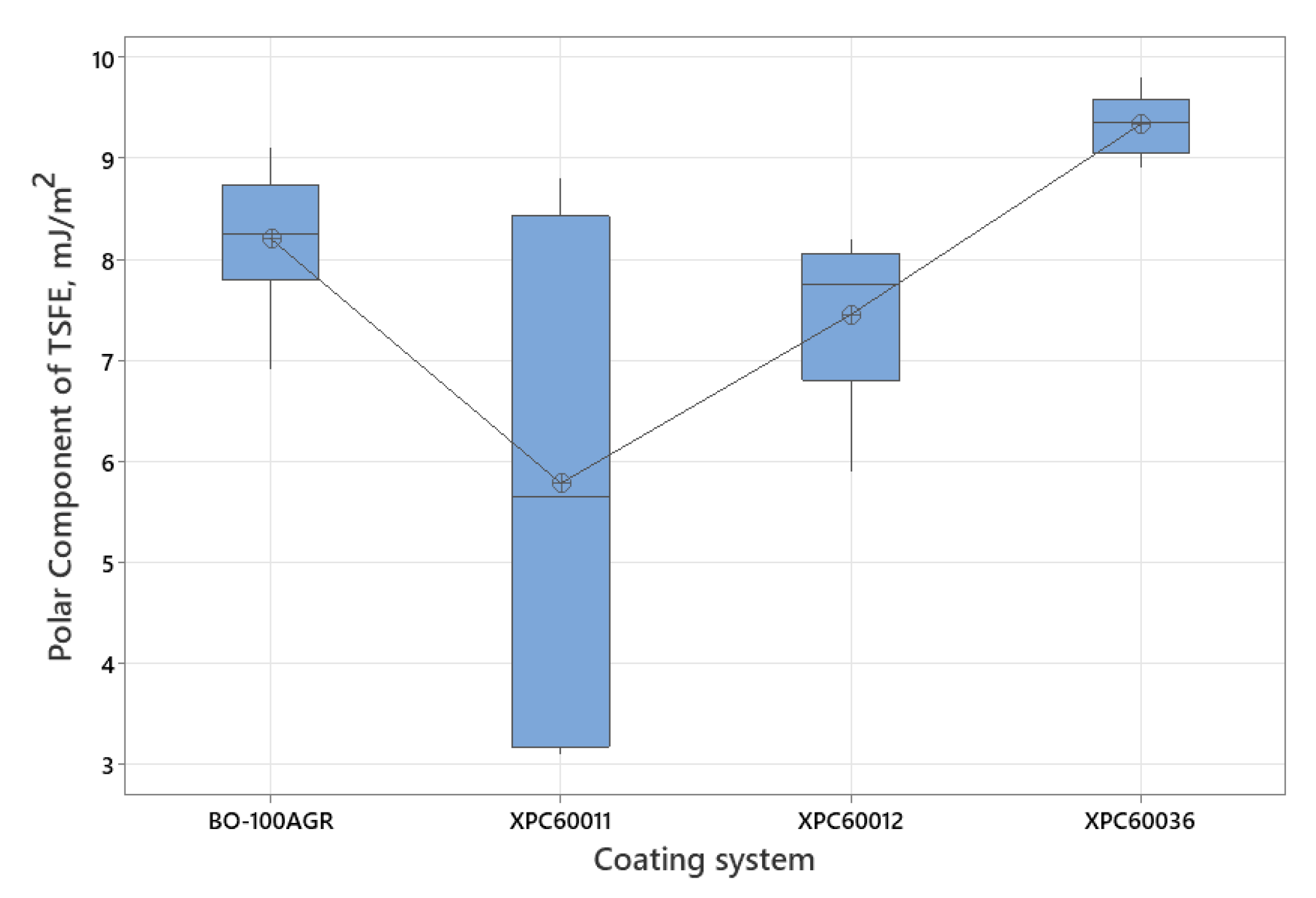

- c) Polar component of total surface free energy (PC-TSFE)

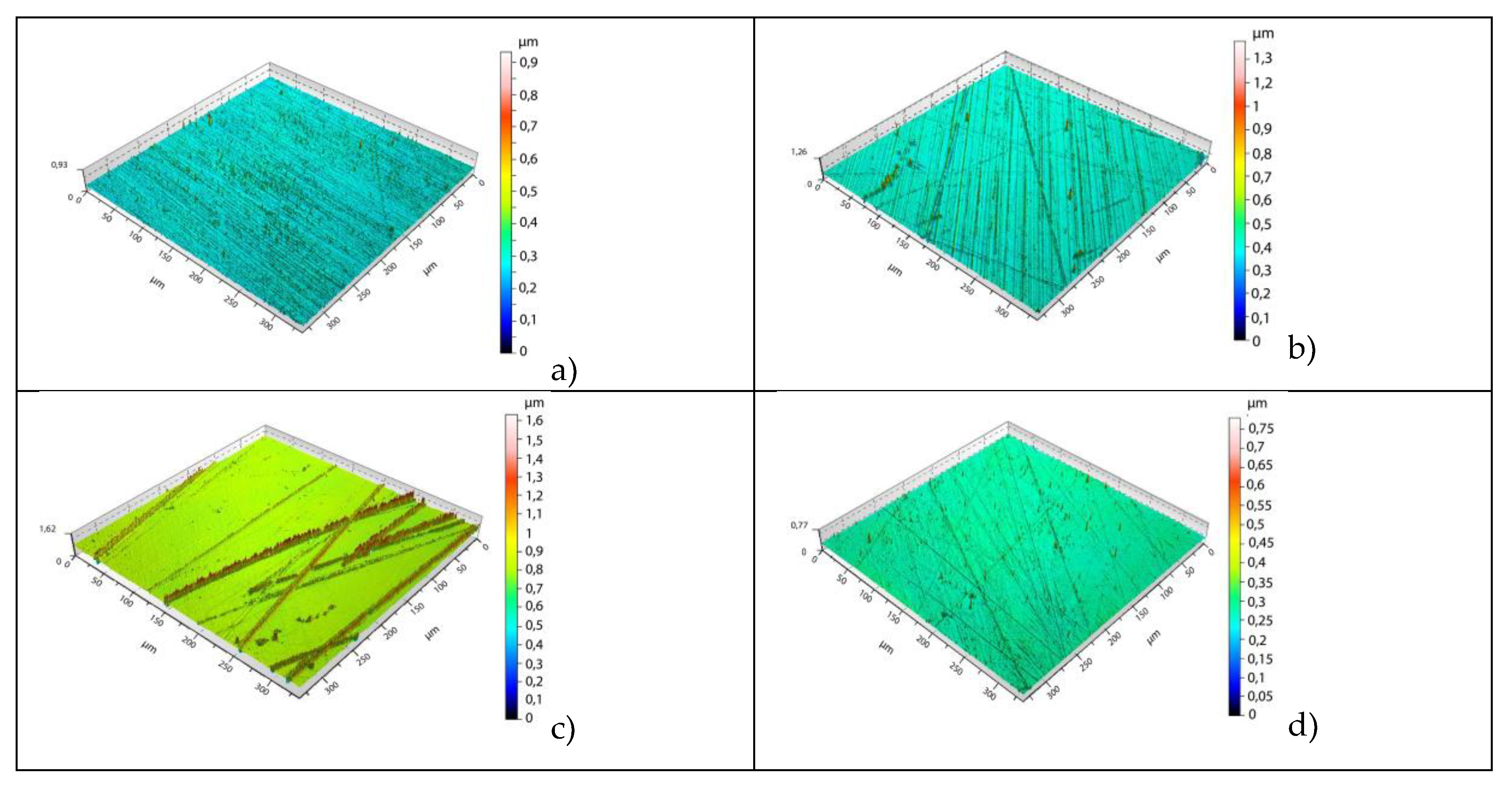

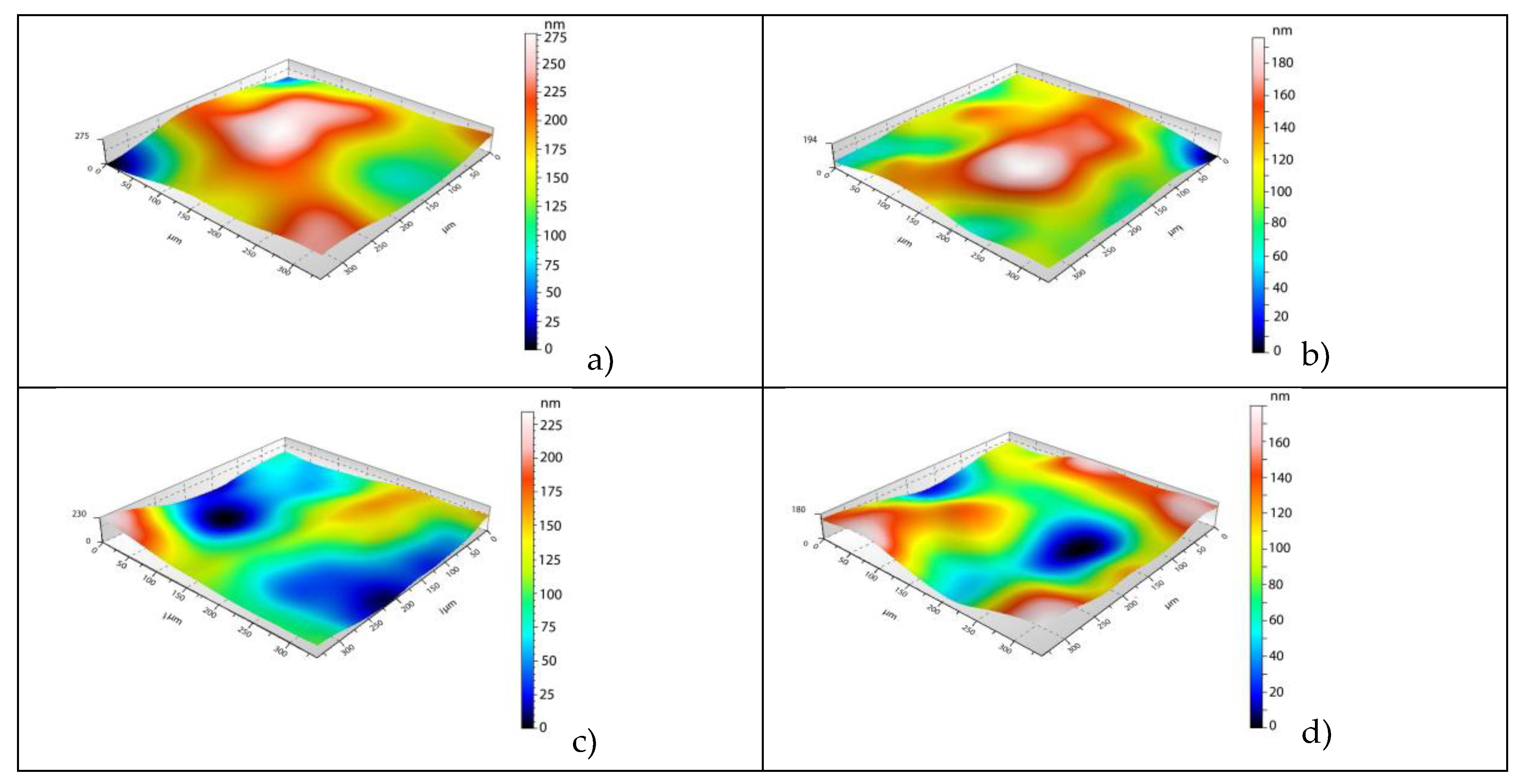

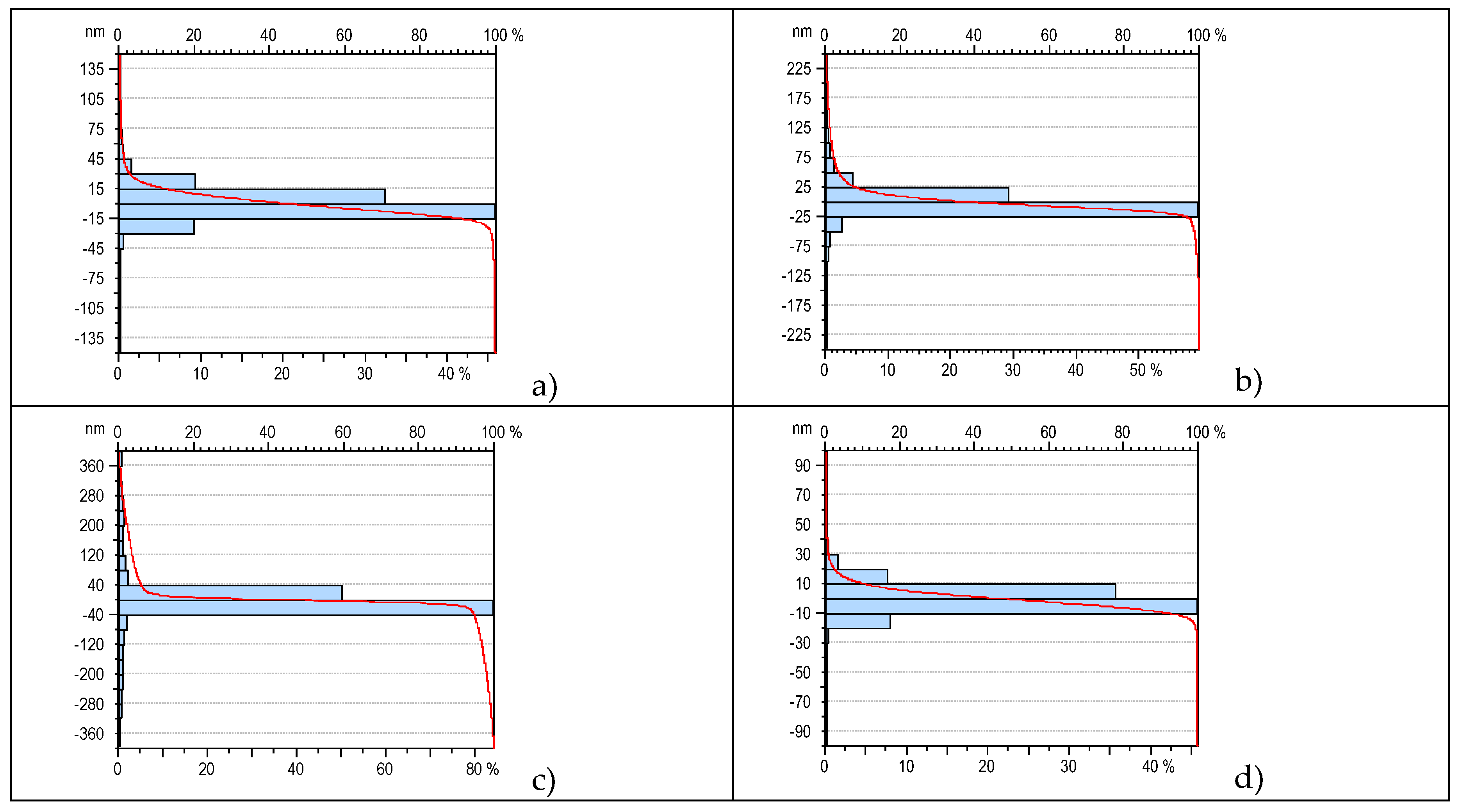

3.2.3. Measurements of the Geometric Structure of the Surface

3.2.4. Adhesion

3.2.5. Nanohardness

3.2.6. Hardness

3.3. Method of Material Selection

- very good - di∈[0.8-1.0]; di=1 - excellent;

- good - di∈[0.6-0.8);

- sufficient - di∈[0.4-0.6);

- bad - di∈[0.2-0.4);

- very bad - di∈[0-0.2); di=0 – unacceptable.

4. Discussion

- Investment in equipping the rail base with a system of monitoring and protection of railroads using modern technologies;

- Organization of preventive measures in the form of patrols specializing in chasing graffiti artists during the day;

- Organization of security services including night patrols with the use of advanced technologies. including surprise actions involving the organization of so-called “ambushes”. in places where railway depots spend the night;

- Widespread implementation of the procedure for identifying and removing graffiti from railroad cars. especially in the context of removing the graffiti coating as soon as possible.

5. Conclusions

- Railway companies need protection systems for their vehicles and wagons.

- The BO100-AGR anti-graffiti coating system was characterized by similar mechani-cal properties to the anti-graffiti coating systems of a foreign manufacturer (PPG).

- The analysis of the microstructure showed that the thickness of the anti-graffiti coat-ing systems was in the range of 2300-2400 µm. Moreover, the paint systems were free of pores and micro-cracks.

- The BO100-AGR anti-graffiti coating system had the lowest free surface energy. Compared to the other three anti-graffiti coating systems, the BO100-AGR paint sys-tem had the best anti-adhesive properties. The anti-adhesive properties of the BO100-AGR system may be of great importance in a potential application on rail ve-hicles.

- Economic considerations make it necessary to introduce new solutions that ensure the reduction of unit manufacturing costs while ensuring the quality of the produced paint systems. The physical properties of the surface layer are important due to the stability of the technological process using the phenomenon of adhesion.

- It is necessary to strictly maintain quality requirements both in the preparation of an-ti-graffiti coatings and in their removal.

- The use of anti-graffiti coatings reduces the negative impact on the environment with a view to reducing the negative impact on the ecosystem.

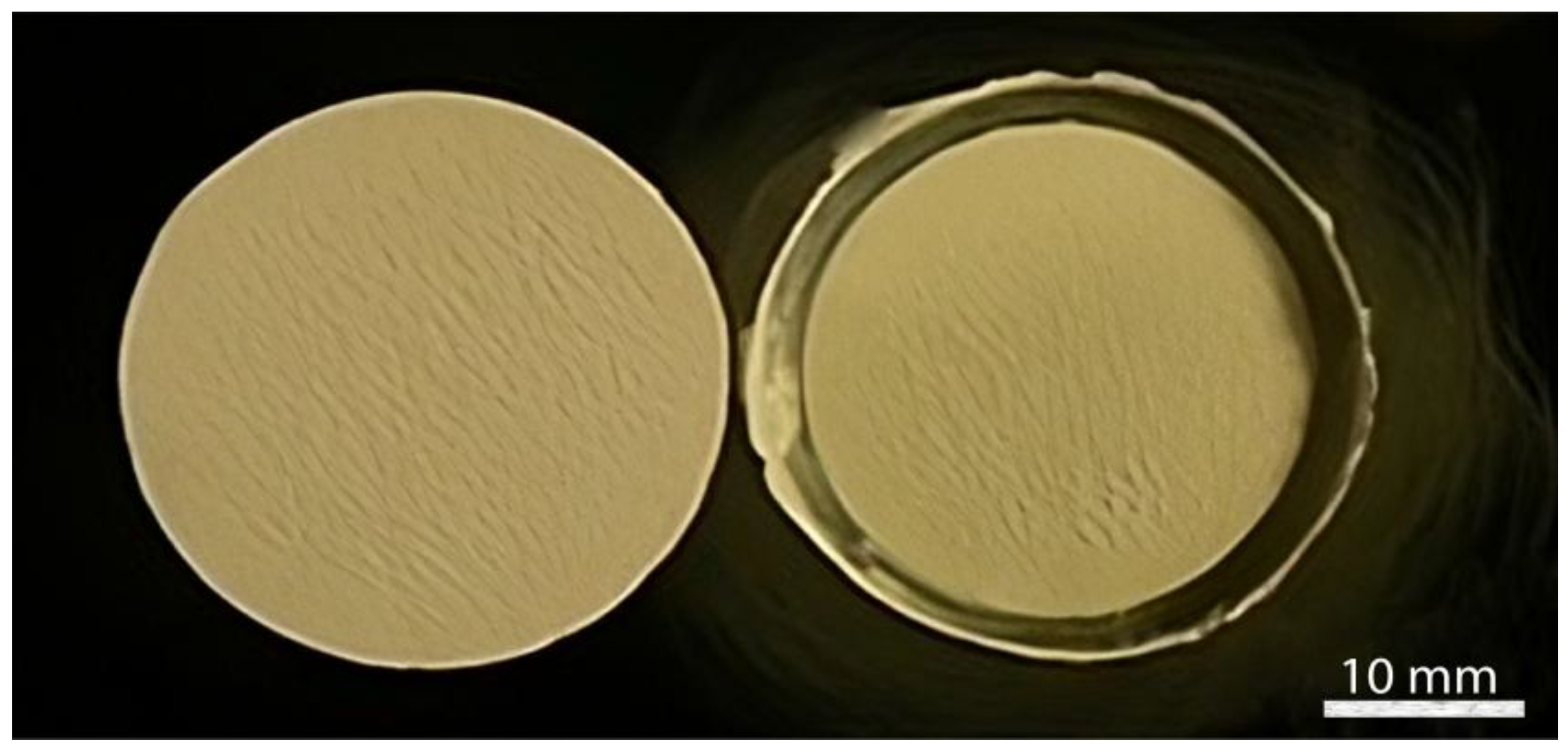

- An alternative method of vehicle skin protection that is currently possible is to cover vehicles with a special film. which significantly increases anti-graffiti protection. According to the manufacturer's declaration. the special film guarantees a seven-year warranty on the material. as well as no limit on the number of graffiti removals when using dedicated agents for this process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vega-Bosh, A.; Santamarina-Campos, V.; Bosh-Roig, P. Assessing the Feasibility of Removing Graffiti from Railway Vehicles Using Ultra-Freezing Air Projection. Appl. Sci. 2024. 14(10). 4165. [CrossRef]

- Pietrzak, A.; Ulewicz, M.; Kozień, E.; Pietraszek, J. Application of a Mixture of Fly Ash and Solid Waste from Gas Treatment from Municipal Solid Waste Incineration in Cement Mortar. Materials 2025. 18, 481. [CrossRef]

- Można poradzić sobie z graffiti. choć to walka nie tylko z spreyowcami. ale także silna konkurencja pomiędzy producentami farb i powłok antygraffiti. Available online: https://www.skm.warszawa.pl/mozna-poradzic-sobie-z-graffiti-choc-to-walka-nie-tylko-ze-spreyowcami-ale-takze-silna-konkurencja-pomiedzy-producentami-farb-i-powlok-antygraffiti-od-lat-tocza-miedzy-soba-wojne-o-zwyciestwo-a-za-2/ (accessed on 15.04.2024).

- Salamon, P. Małopolska zamawia nowe pociągi: z powłoką antygraffiti. Available online: https://lovekrakow.pl/aktualnosci/malopolska-zamawia-nowe-pociagi-z-powloka-antygraffiti_33921.html (accessed on 15.04.2024).

- Pasieczyński, Ł. Performance properties of anti-graffiti coating systems for railway rolling stock. PhD Dissertation, Kielce University of Technology, Kielce, Poland, 2019.

- Radek, N. Properties of WC-Co coatings with Al2O3 addition. Production Engineering Archives 2023. 29(1). 94-100. [CrossRef]

- Burakowski, T.; Wierzchoń, T. Inżynieria powierzchni metali; WNT: Warszawa. Poland. 1995.

- Batchelor, A.W.; Stachowiak, G.W. Predicting synergism between corrosion and abrasive wear. Wear 1988. 123. 281-291. [CrossRef]

- Radek, N.; Michalski, M.; Mazurczuk, R.; Szczodrowska, B.; Plebankiewicz, I.; Szczepaniak, M. Operational tests of coating systems in military technology applications. Eksploatacja i Niezawodnosc - Maintenance and Reliability 2023. 25(1). 12. [CrossRef]

- Decker, C.; Balandier, M. Degradation of poli(vinyl chloride) by U.V. radiation – I. Kinetics and quantum yields. European Polymer Journal 1982. 18. 1085-1091. [CrossRef]

- Decker, C.; Biry, S. Light stabilization of polymers by radiation-cured acrylic coatings. Progress in Organic Coatings 1996. 29(1-4). 81-87. [CrossRef]

- Kotnarowska, D. Influence of Ultraviolet Radiation on Erosive Resistance of Modified Epoxy Coatings. Solid State Phenomena 2006. 113. 585-588. [CrossRef]

- Kotnarowska, D. Analysis of polyurethane top-coat destruction influence on erosion kinetics of polyurethane-epoxy coating system. Eksploatacja i Niezawodność - Maintenance and Reliability 2019. 21(1). 103-114. [CrossRef]

- Kotnarowska, D. Influence of ultraviolet radiation and aggressive media on epoxy coating degradation. Progress in Organic Coatings 1999. 37(3-4). 149-159. [CrossRef]

- Kazicyna, L.A.; Kupletska, N.B. Metody spektroskopowe wyznaczania struktury związków organicznych; PWN: Warszawa. Poland. 1976.

- Dobrzański, L. Podstawy nauki o materiałach i metaloznawstwo; Wydawnictwo Naukowo Techniczne: Warszawa. Poland. 2002.

- Nguyen, T.; Bentz, D.; Byrd, E. Method for measuring water diffusion in a coating applied to a substrate. Journal of Coatings Technology 1995. 67(844). 37-46.

- Nguyen, T.; Hubbard, J.B.; Pommersheim, J.M. Unified model for the degradation of organic coatings on steel in a neutral electro-lyte. Journal of Coatings Technology 1996. 68(855). 45-56.

- Sokólski, W. Światowa Organizacja Korozji – geneza powstania. misja i cele. program działania. Ochrona przed korozją 2009. 9. Polskie Stowarzyszenie Korozyjne. Gdańsk.

- Kotnarowska, D. Destruction of Epoxy Coatings under the Influence of Sodium Chloride Water Solutions. Solid State Phenomena 2015. 220-221. 609-614. [CrossRef]

- Kohl, M.; Kalendova, A. Anticorrosion properties of organic coatings containing polyphenylenediamine phosphate. Advances in Sciences and Technology Research Journal 2015. 9(29). 47-50. [CrossRef]

- Mróz, A.; Szymański, M.; Koch, P.; Pawlicki, M.; Meller, A.; Przekop, R.E. The Influence of Surface Texture of Elements Made of PA6-Based Composites on Anti-Graffiti Effect of Paint Coating. Materials 2024. 17(9). 1951. [CrossRef]

- Bartman, M.; Balicki, S.; Wilk, K.A. Formulation of Environmentally Safe Graffiti Remover Containing Esterified Plant Oils and Sugar Surfactant. Molecules 2021. 26. 4706. [CrossRef]

- Graffiti – kosztowny wandalizm. Available online: https://wiadomosci.wp.pl/graffiti-kosztowny-wandalizm-6109012257666177a (accessed on 15.04.2024).

- Włuka, E. Jak przewoźnicy radzą sobie z wandalizmem? Available online: https://zbiorowy.info/2018/11/jak-przewoznicy-radza-sobie-z-wandalizmem/ (accessed on 15.04.2024).

- Wandalizm graffiti na pociągach Renfe wygenerował koszty w wysokości ponad 25 milionów euro. Available online: https://kurier-kolejowy.pl/aktualnosci/41870/wandalizm-graffiti-na-pociagach-renfe-wygenerowal-koszty-w-wysokosci-ponad-25-milionow-euro.html (accessed on 15.04.2024).

- Akt wandalizmu sparaliżował metro. Available online: https://haloursynow.pl/pl/11_wiadomosci/784_stolica/21767_akt-wandalizmu-sparalizowal-metro-zaciagneli-hamulec.html (accessed on 15.04.2024).

- Wierzbicki, P. Szok w warszawskim metrze. Available online: https://www.fakt.pl/wydarzenia/polska/warszawa/groza-w-warszawskim-metrze-zatrzymali-pociag-pasazerowie-byli-przerazeni/x1pr6hl (accessed on 15.04.2024).

- Szokujące sceny z warszawskiego metra. Available online: https://www.fakt.pl/wydarzenia/polska/warszawa/szokujace-sceny-z-warszawskiego-metra-nikt-nie-przeszkodzil-wandalom/qqcve5k (accessed on 15.04.2024).

- Radek, N.; Pasieczyński, Ł.; Pietraszek, J.; Broncek, J. Analysis of the surface geometric structure of the anti-graffiti coating systems intended for rolling stock. Mechanik 2019. 2. 124-127. [CrossRef]

- Adamczak, S.; Makieła, W. Analyzing variations in roundness profile parameters during the wavelet decomposition process using the matlab environment. Metrology and Measurement Systems 2011. XVIII(1). 25-34.

- Miller, T.; Adamczak, S.; Świderski, J.; Wieczorowski, M.; Łętocha, A.; Gapiński, B. Influence of temperature gradient on surface texture measurements with the use of profilometry. Bulletin of the Polish Academy of Sciences 2017. 65(1). 53-61.

- Oczoś, K.; Lubimov, V. Struktura geometryczna powierzchni; Wydawnictwo Politechniki Rzeszowskiej: Rzeszów. Poland. 2003.

- PN-EN ISO 1522:2008: Farby i lakiery - Badanie metodą tłumienia wahadła.

| Year | Company | Activity | Cost (kPLN) | Source |

|---|---|---|---|---|

| 2001 2017 |

PKP Railways Mazovia Railways |

Removal of graffiti Removal of graffiti |

227 1 700 |

[24] [25] |

| 2018 | Silesian Railways | Removal of graffiti | 60 | [25] |

| 2022 | RENFE Railways | Total graffiti costs | 100 000 | [26] |

| 2021 | Malopolska Railways | Removal of graffiti | 37 | own |

| 2022 | Malopolska Railways | Removal of graffiti | 121 | own |

| 2023 | Malopolska Railways | Removal of graffiti | 200 | own |

| Year | Company | Area (km2) | Source |

| 2017 2018 |

Mazovia Railways Mazovia Railways |

11 8 |

[25] [25] |

| 2018 | RENFE Railways | 80 | [26] |

| 2021 | Malopolska Railways | 0.4 | own |

| 2022 | Malopolska Railways | 0.9 | own |

| 2023 | Malopolska Railways | 1 | own |

| Year | Company | Number | Source |

| 2018 2022 |

Silesian Railways RENFE Railways |

40 3559 |

[25] [26] |

| 2021 | Malopolska Railways | 39 | own |

| 2022 | Malopolska Railways | 44 | own |

| 2023 | Malopolska Railways | 50 | own |

| Material | Mass density [kg/m3] | Weight proportion |

| XPC60011 | 990 | 1:1 |

| XPC60012 | 980 | 3:1 |

| XPC60036 | 1010 | 2:1 |

| BO100-AGR | 1020 | 2:1 |

| Coating system | Mean | SE Mean | StDev | Min. | Median | Max. |

| BO-100AGR | 48.15 | 0.28 | 0.69 | 47.2 | 48.15 | 49.2 |

| XPC60011 | 49.87 | 1.28 | 3.14 | 46.9 | 49.55 | 53.4 |

| XPC60012 | 52.30 | 0.36 | 0.87 | 51.0 | 52.40 | 53.3 |

| XPC60036 | 55.85 | 0.23 | 0.55 | 55.1 | 55.85 | 56.6 |

| Coating system | N | Mean | Grouping | ||

| XPC60036 | 6 | 55.9 | A | ||

| XPC60012 | 6 | 52.3 | B | ||

| XPC60011 | 6 | 49.9 | B | C | |

| BO-100AGR | 6 | 48.2 | C | ||

| Coating system | Mean | SE Mean | StDev | Min. | Median | Max. |

| BO-100AGR | 39.97 | 0.13 | 0.33 | 39.5 | 40.00 | 40.3 |

| XPC60011 | 44.12 | 0.25 | 0.61 | 43.6 | 43.95 | 45.3 |

| XPC60012 | 44.87 | 0.34 | 0.84 | 44.0 | 44.85 | 46.3 |

| XPC60036 | 46.52 | 0.15 | 0.37 | 46.1 | 46.45 | 47.0 |

| Coating system | N | Mean | Grouping | ||

| XPC60036 | 6 | 46.5 | A | ||

| XPC60012 | 6 | 44.9 | B | ||

| XPC60011 | 6 | 44.1 | B | ||

| BO-100AGR | 6 | 40.0 | C | ||

| Coating system | Mean | SE Mean | StDev | Min. | Median | Max. |

| BO-100AGR | 8.20 | 0.30 | 0.73 | 6.9 | 8.25 | 9.1 |

| XPC60011 | 5.78 | 1.17 | 2.88 | 3.1 | 5.65 | 8.8 |

| XPC60012 | 7.45 | 0.35 | 0.85 | 5.9 | 7.75 | 8.2 |

| XPC60036 | 9.33 | 0.13 | 0.31 | 8.9 | 9.35 | 9.8 |

| Coating system | N | Mean | Grouping | |

| XPC60036 | 6 | 9.33 | A | |

| XPC60012 | 6 | 8.20 | B | |

| XPC60011 | 6 | 7.45 | B | |

| BO-100AGR | 6 | 5.78 | B | |

| Coating system | Average value | Standard deviation | Range |

| XPC 60011 | 2.28 | 0.14 | 0.38 |

| XPC 60012 | 2.18 | 0.08 | 0.25 |

| XPC 60036 | 2.24 | 0.07 | 0.19 |

| BO100-AGR | 2.22 | 0.07 | 0.18 |

| Materials | Nanohardness (GPa) | Young's modulus (GPa) |

| XPC 60012 | 0.23 ± 0.01 | 2.70 ± 0.05 |

| BO100-AGR | 0.26 ± 0.01 | 2.90 ± 0.02 |

| XPC 60011 | 0.27 ± 0.01 | 2.84 ± 0.04 |

| XPC 60036 | 0.26 ± 0.01 | 2.84 ± 0.03 |

| Steel S355 | 10.60 ± 0.70 | 124.00 ± 5.30 |

| Coating system | Damping time (s) |

Relative hardness (-) |

Damping time – salt (s) |

Damping time – humidity (s) |

| XPC 60011 | 95.2 | 0.4 | 140.0 | 146.7 |

| XPC 60012 | 83.7 | 0.3 | 135.0 | 150.9 |

| XPC 60036 | 109.8 | 0.4 | 132.2 | 145.9 |

| BO100-AGR | 120.8 | 0.5 | 134.4 | 147.8 |

| Quality function | XPC60011 | XPC60012 | XPC60036 | BO100-AGR |

| d1 | 0.73 | 0.69 | 0.72 | 0.71 |

| d2 | 0.81 | 0.68 | 0.42 | 0.87 |

| d3 | 0.81 | 0.81 | 0.80 | 0.81 |

| d4 | 0.53 | 0.55 | 0.55 | 0.62 |

| d5 | 0.25 | 0.21 | 0.56 | 0.42 |

| d6 | 0.66 | 0.88 | 0.81 | 0.75 |

| D | 0.59 | 0.43 | 0.63 | 0.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).