1. Introduction

Global fishery resources are increasingly nearing saturation, while population growth and rising demand for seafood are driving aquaculture to become a crucial means of bridging the fishery supply-demand gap. According to data from the Food and Agriculture Organization of the United Nations (FAO), aquaculture production has steadily increased over the past few decades and is projected to become one of the primary sources of global aquatic products in the future [

1,

2]. However, traditional aquaculture methods, particularly cage aquaculture, face numerous challenges, including high initial investments, technical barriers, and escalating operational costs, which significantly limit the industry's sustainable development and technological innovation potential [

3].

The introduction of smart technologies, particularly Artificial Intelligence of Things (AIoT) systems, offers an effective solution [

4]. AIoT technology enables real-time monitoring, data analysis, and optimization of resource allocation in aquaculture farms. This capability significantly enhances risk management, increases production efficiency, reduces operational costs, and improves environmental monitoring [

5,

6]. Despite advancements in smart aquaculture technology, most underwater remotely operated vehicle (ROV) systems currently available for marine monitoring still face numerous challenges that require attention. Traditional commercial ROV systems are often expensive, feature closed designs, and lack flexibility, making them ill-suited to adapt to the specific requirements of various aquaculture environments [

7,

8]. This situation places aquaculture operators in a difficult position, as they encounter high costs while being unable to precisely align their monitoring tools with their operational needs. The rapid advancement of mobile communication technology has made the implementation of smart ocean aquaculture monitoring systems increasingly vital [

9]. Real-time data processing and analytical capabilities are particularly essential for aquaculture environments that demand swift responses and continuous monitoring [

10].

With the introduction of Non-Terrestrial Networks (NTN) in 3GPP Release 17 and the maturation of low-orbit satellite communication technology [

11], the challenges of communication stability in remote sea aquaculture areas are gradually being addressed, overcoming the limitations of inadequate coverage provided by traditional terrestrial networks. Related literature indicates that numerous studies have investigated smart aquaculture solutions that integrate AIoT technology with underwater remotely operated vehicle (ROV) systems. These studies demonstrate significant capabilities in water quality monitoring and the potential for automating environmental management [

12,

13]. Such systems illustrate that real-time sensor networks and underwater robots can substantially improve the effectiveness of aquaculture monitoring. However, most existing systems continue to depend on costly commercial ROV hardware, which often features closed functional designs and limited flexibility [

14]. As a result, current solutions struggle to meet the diverse needs of various aquaculture scenarios.

This research has developed a smart underwater remotely operated vehicle (ROV) system based on 4G mobile communication networks and integrated it into an AIoT smart aquaculture management platform. This system provides an efficient, cost-effective, and highly customizable monitoring solution for the aquaculture industry. The primary objective of this research is to design and develop a new monitoring system that incorporates self-developed underwater ROVs, water quality sensors, and related technology platforms. Particular emphasis is placed on the integration of multiple remote control systems and mobile communication technologies. The system not only supports remote operation and real-time data transmission and analysis through various platforms, such as mobile phones, smartwatches, and multi-site central control centers, but it can also operate autonomously for extended periods. This significantly enhances the intelligence and automation levels of aquaculture farm management. The main innovations of this research include:

The integration of 4G mobile communication network architecture, utilizing existing 4G mobile communication networks, includes interfaces within the buoy system that are reserved for future upgrades to BEYOND 5G low-orbit satellite communication networks.

Multiple remote control interfaces enable users to operate the underwater remotely operated vehicle and monitor data through various devices, including computers, smartphones, smartwatches, and multi-site central control centers.

A low-cost, customized underwater remotely operated vehicle design that offers a more economical platform for underwater monitoring, which can be flexibly configured to suit various aquaculture scenarios.

2. Materials and Methods

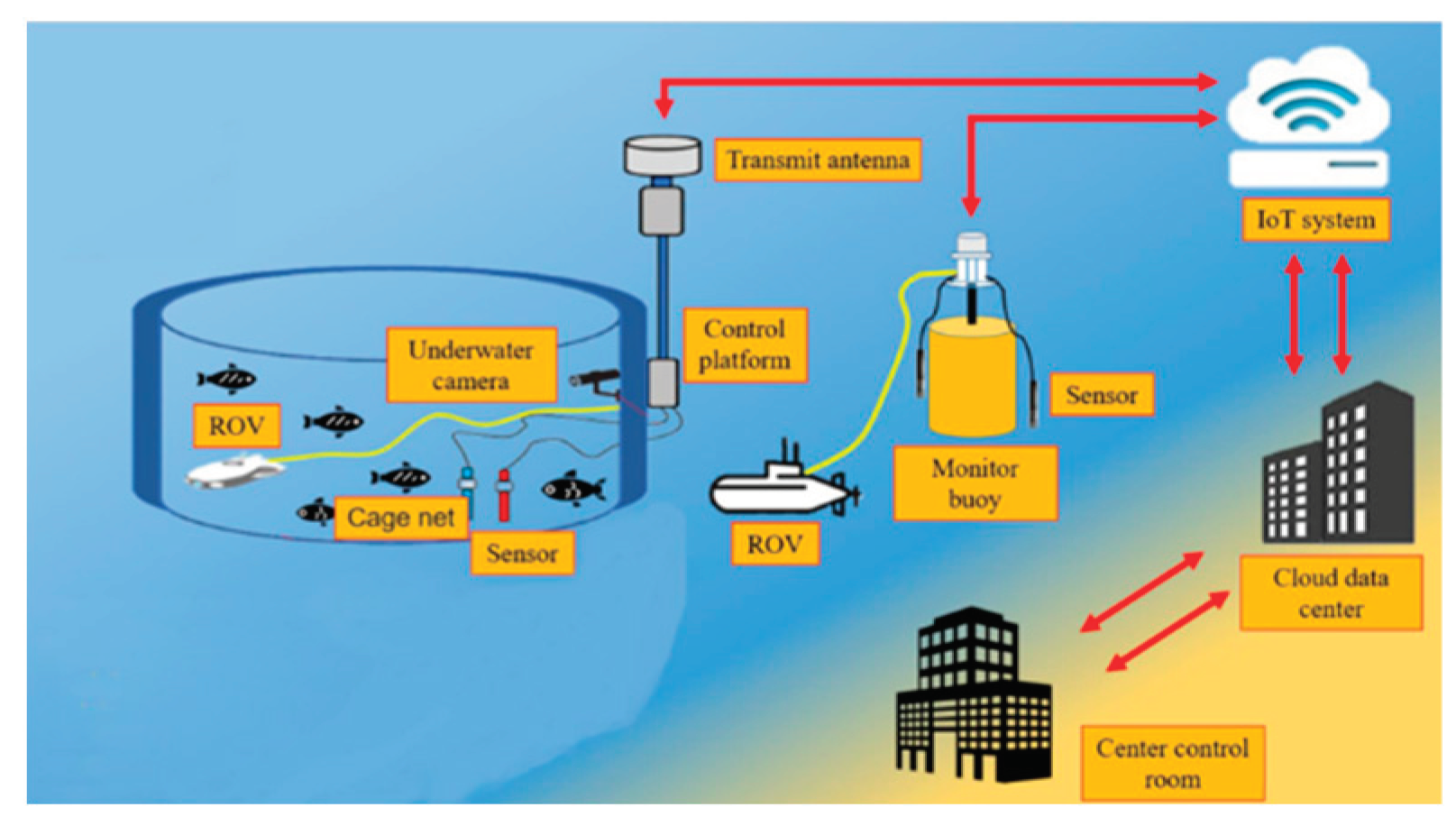

2.1. Overall System Architecture

The smart ocean aquaculture monitoring system proposed in this research is a highly integrated platform that utilizes multiple remote control systems and mobile communication technologies as its core components. This system facilitates refined management and real-time monitoring of aquaculture sites. The overall system architecture, illustrated in

Figure 1, comprises an underwater remotely operated vehicle, a 4G mobile communication network module, and several remote control systems. The design focus of the system is to empower aquaculture operators to perform remote control through various devices while leveraging mobile communication technology to ensure stable and reliable data transmission. This design maintains robust connectivity even in aquaculture environments that are far from land. Each component has clearly defined responsibilities and works collaboratively, ensuring that the system operates efficiently and stably across diverse aquaculture environments.

The hardware implementation employs a modular design approach, comprising two primary modules: the underwater remotely operated vehicle (ROV) and the buoy system. The buoy system functions as a communication relay station, linking the ROV with land-based control systems. To optimize resource management, the system architecture is designed to minimize the weight of the ROV while enhancing its mobility. It transmits information and control signals through composite cables, significantly simplifying connection complexity.

The primary application sites for this system include offshore cage nets, oyster racks, land-based fish ponds, and various other aquaculture environments. By utilizing an integrated solution, it not only enables real-time water quality monitoring but also facilitates periodic inspection and maintenance of underwater equipment, significantly enhancing the management efficiency and productivity of the aquaculture environment.

2.2. Cloud and Software Architecture

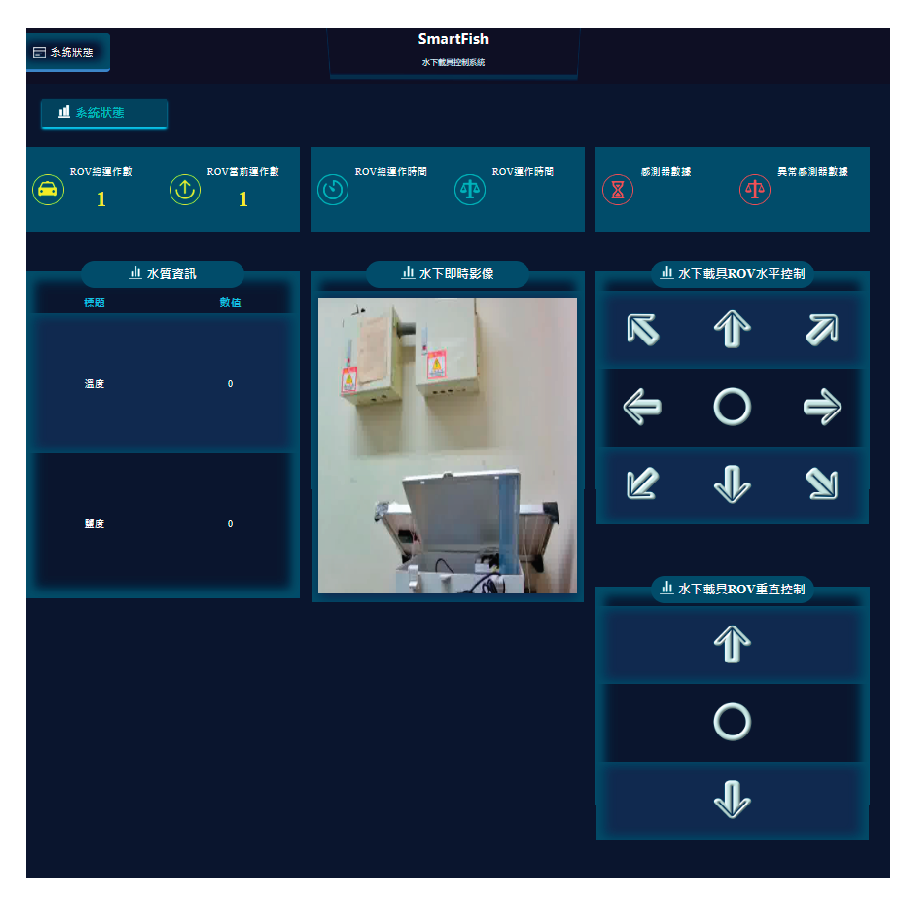

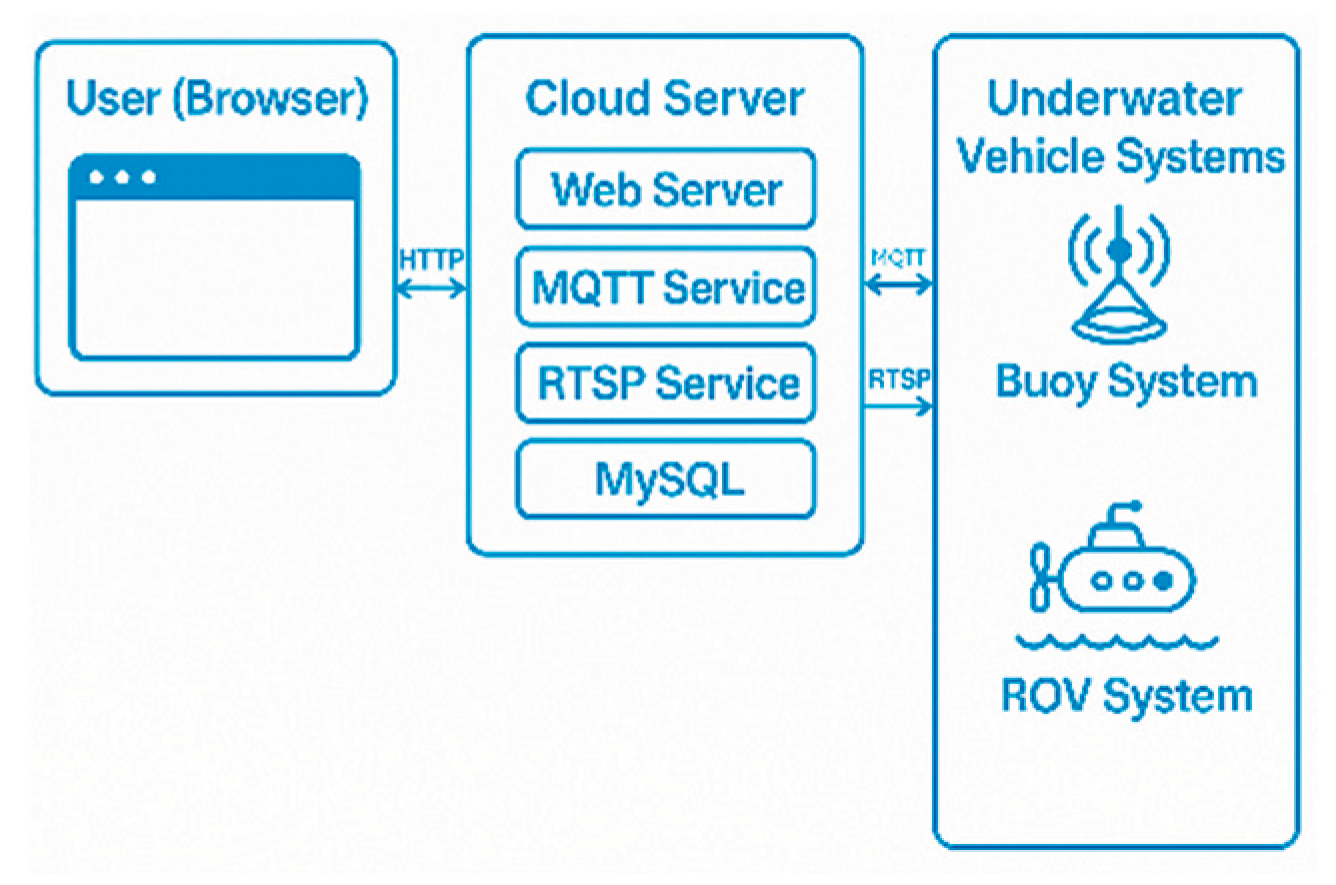

The cloud and software architecture proposed in this research, illustrated in

Figure 2, is primarily divided into three components: the client interface, the cloud server platform, and the underwater remotely operated vehicle system. This architectural design facilitates the seamless integration of various remote control and mobile communication technologies, ensuring smooth communication between different control platforms and the underwater remotely operated vehicle system.

2.2.1. Multiple Remote Control System Architecture

The multiple remote control system is compatible with a variety of terminal devices, enabling users to operate computers, smartphones, smartwatches, and multi-site central control centers, as well as any devices with web browsing capabilities. Through these devices, users can access web services on the cloud server, view real-time underwater environmental sensing data, and perform remote operations of the underwater remotely operated vehicle.

To achieve multi-platform remote operation, this research developed a web-based control interface called the "Smart-Fish Control System." This interface serves as the core component of the multi-remote control system, deployed on a cloud server and accessible via web browsers on computers, smartphones, or smartwatches. The control interface displays real-time video from the underwater remotely operated vehicle, along with real-time sensor readings, such as temperature and pH levels. Users can send control commands to the underwater remotely operated vehicle through this interface, allowing them to manipulate its movement direction, among other functions.

Communication between the user interface and the underwater remotely operated vehicle utilizes a publish/subscribe model based on the MQTT (Message Queuing Telemetry Transport) protocol. In this system, the cloud server operates as an MQTT message broker. The Smart-Fish Control System functions as an MQTT client, publishing relevant control messages—targeting various control topics, such as movement commands—to the broker when users interact with the interface. The Raspberry Pi on the buoy also acts as an MQTT client, subscribing to these control topics. When the user interface publishes a control command (such as "forward") to the MQTT broker, the message is promptly transmitted to the Raspberry Pi on the buoy. This publish/subscribe architectural design is both lightweight and reliable, ensuring command delivery even in situations where mobile communication networks may occasionally experience delays. The system supports a variety of control devices, enabling truly diverse remote control options:

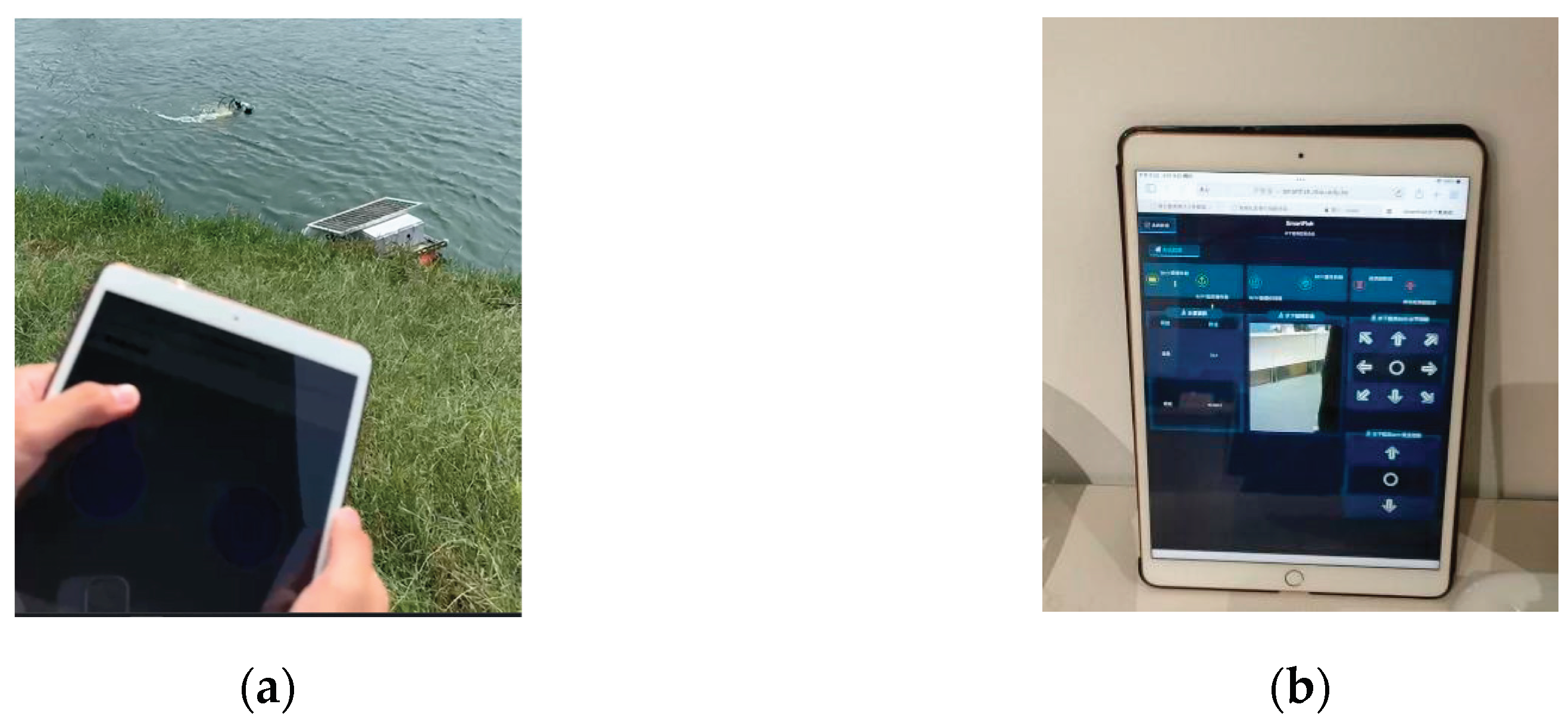

Smartphones and Tablets: Users can access the Smart-Fish Control System via web browsers on smartphones or tablets, allowing for comprehensive control and monitoring of underwater remotely operated vehicles. The touch interface of mobile devices is optimized to ensure intuitive and precise operation, making it particularly suitable for outdoor environments at aquaculture farms.

Smartwatches: A specialized, simplified control interface has been developed for smartwatches, enabling users to send straightforward commands (such as instructing the underwater remotely operated vehicle to surface). This feature offers aquaculture operators an exceptionally convenient emergency control option.

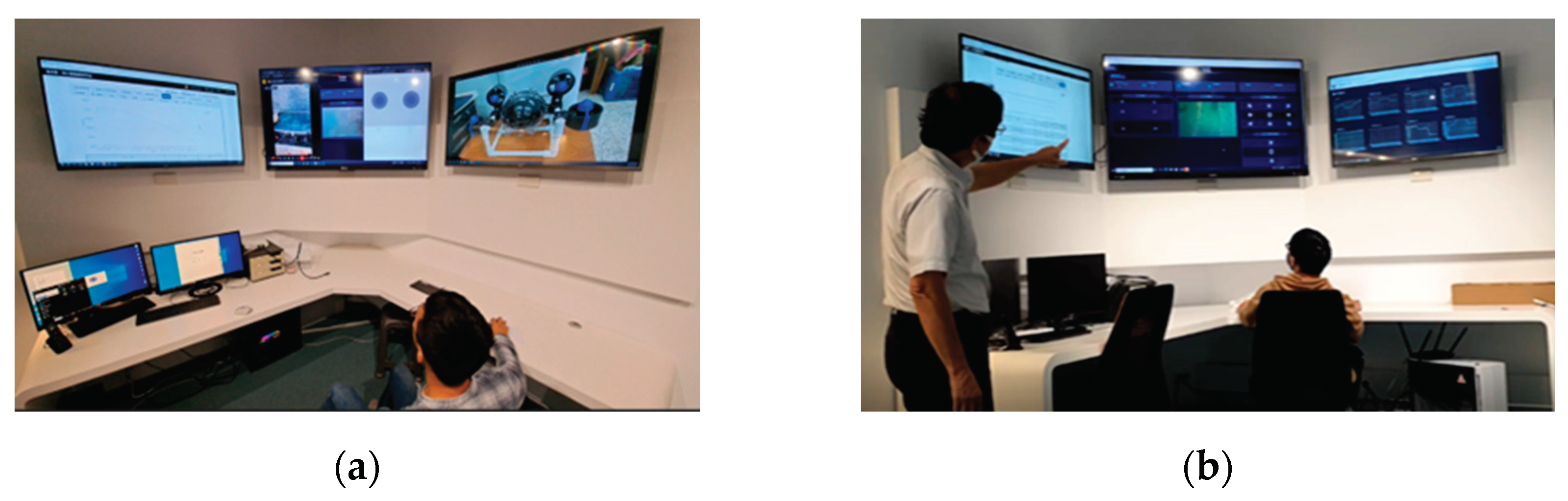

Multi-Site Central Control Center: Professional monitoring stations established at aquaculture headquarters or research institutions, equipped with large display screens, can simultaneously oversee multiple underwater remotely operated vehicle systems and data from aquaculture areas, providing a comprehensive monitoring perspective. The system design enables the simultaneous monitoring and management of multiple aquaculture farms across different regions from the central control center, significantly enhancing management efficiency and response capabilities.

Figure 3. Central Control Room Monitoring Setup: (a) An operator is working at the multi-screen monitoring station, where wall-mounted and desktop displays present various ROV data streams, sensor readings, and control interfaces within the NTOU central control facility; (b) Researchers are analyzing real-time aquaculture data on multiple monitors, with one staff member explaining the data visualizations while another operates the control system, showcasing the collaborative monitoring capabilities.

2.2.2. Cloud Server Architecture

The cloud server features a modular design that integrates four core functions:

Web Server: Responsible for handling HTTP requests from multiple user devices and providing a unified user interface. The system allows users to log in through various platform browsers to view real-time monitoring data, watch underwater video streams, and send remote control commands.

MQTT Service: This service utilizes the lightweight MQTT communication protocol, which is responsible for bidirectional data transmission. It manages the transmission of motor status control commands for the underwater remotely operated vehicle (ROV) while also receiving and distributing water quality sensor data from the ROV system. The MQTT protocol is particularly well-suited for mobile communication environments, as it can maintain reliable connections even under limited bandwidth and unstable network conditions. This ensures the accurate delivery of control commands and timely updates of sensing data. By leveraging MQTT’s publish/subscribe mechanism, the system achieves precise control of the underwater ROV and synchronized monitoring of environmental parameters.

RTSP Service: This service is responsible for real-time underwater video streaming, ensuring the timeliness and stability of image data. The system integrates Ffmpeg technology for video conversion and compression, optimizing transmission efficiency. It is capable of maintaining image transmission in 4G mobile communication network environments.

MySQL Database: Provides long-term storage and management functions for sensor data and the operational status of underwater remotely operated vehicle systems.

Figure 4.

System Control Interface.

Figure 4.

System Control Interface.

2.2.3. Design of the Underwater Monitoring System

The underwater monitoring system is divided into two components: The Buoy System and the Underwater Remotely Operated Vehicle (ROV) System:

Buoy System: Functions as a communication relay node, establishing connections with the cloud server via 4G mobile communication networks. Its primary functions include:

Receiving and processing real-time MQTT control commands from the cloud server and forwarding them to the underwater remotely operated vehicle system.

Integrating RTSP video streams and MQTT sensor data from the underwater remotely operated vehicle system and forwarding them to the cloud server.

Collecting local water quality sensor data and transmitting it to the cloud server using the MQTT protocol.

Figure 5. Communication System Components: (a) Deployed buoy system serving as a relay node between the underwater ROV and the cloud server; (b) Close-up of the ROV communication module with an integrated solar panel, highlighting the waterproof enclosure, power configuration, and connectivity components mounted on flotation elements. Underwater Remotely Operated Vehicle System: Communicates with the buoy system via wired connections, with primary functions including:

Receiving and executing real-time control commands transmitted from the buoy system.

Real-time transmission of underwater camera images to the buoy system using the RTSP protocol.

Collecting underwater water quality sensing data and transmitting it to the cloud server via the buoy system using the MQTT protocol.

2.3. 4G Mobile Communication Network Module

Stable data communication is essential for the real-time transmission of data collected by underwater remotely operated vehicles and other sensing equipment to the central system. In this architecture, the mobile communication module serves as the communication backbone of the multiple remote control system, ensuring that data can be transmitted quickly and reliably.

The system employs 4G mobile communication networks for data transmission, leveraging the extensive coverage provided by 4G mobile communication network base stations to facilitate remote operations. The underwater remotely operated vehicle (ROV), along with its connected buoy or shore-based station, is equipped with a 4G mobile communication network data terminal that includes a SIM card for connectivity to land-based 4G base stations. This communication setup enables real-time uploading of data collected underwater by the ROV, including sensor readings and camera images, to a cloud server or control center. Additionally, it allows for the transmission of control commands from the multiple remote control system to the ROV. The seamless integration of the mobile communication module with the remote control system empowers aquaculture operators to conduct remote monitoring and operations using various devices.

This research focuses on Chunghwa Telecom’s 4G mobile communication network, primarily due to its extensive base station coverage in Taiwan’s coastal regions. Field surveys indicate that Chunghwa Telecom boasts the densest distribution of base stations in Taiwan, with coverage in near-sea areas significantly surpassing that of other telecommunications operators. This characteristic is essential for maintaining stable communication connections in maritime aquaculture farms.

The technical architecture of the communication system includes:

4G Mobile Communication Network Module: This module supports multi-frequency band operation, ensuring stable connections across various regions. It provides the essential communication foundation required for multiple remote control applications. Actual measurements in maritime environments indicate that the communication system maintains average download speeds of 5-10 Mbps and upload speeds of 3-8 Mbps, fully meeting the demands of underwater remotely operated vehicle control and data transmission.

High-Gain Antenna: This external high-gain antenna is optimized for long-distance environments, significantly enhancing communication capabilities. It effectively addresses maritime signal attenuation issues, ensuring that commands from multiple control devices can be reliably transmitted to deep-sea areas. Actual deployment tests demonstrate that with high-gain antennas, the system can maintain stable connections in offshore environments up to 2 kilometers from shore.

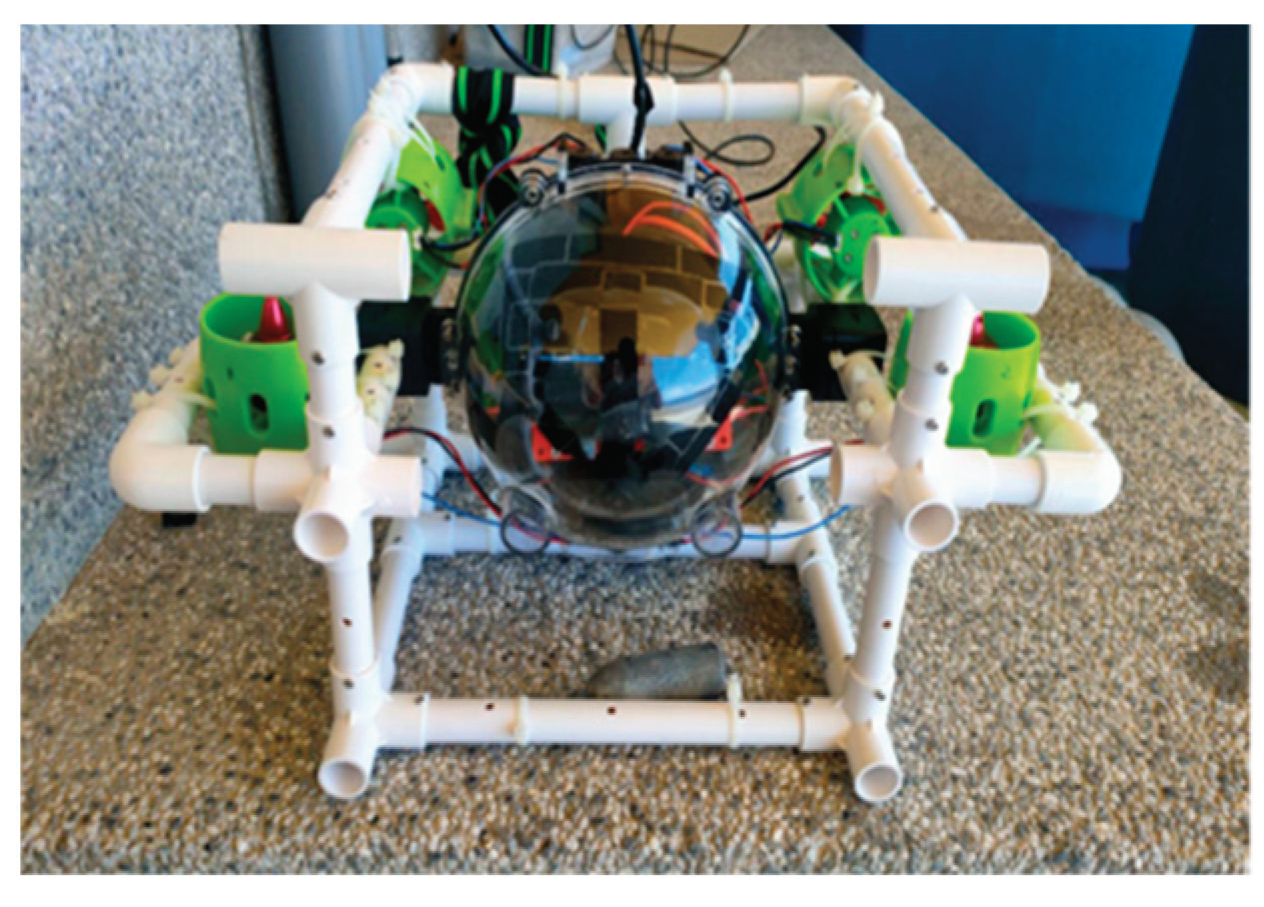

2.4. Underwater Remotely Operated Vehicles

The underwater remotely operated vehicle developed in this research serves as a system component specifically designed for the integration of various remote control and mobile communication technologies. This self-developed underwater vehicle system incorporates multiple water quality sensors and underwater camera equipment, enabling precise measurement of environmental parameters such as water temperature, pH level, dissolved oxygen concentration, and other key indicators. Additionally, it provides real-time underwater image transmission capabilities.

The hardware architecture features”a wa’erproof housing design that protects internal electronic components from water pressure and corrosion. The main structure is constructed using PVC pipes and adapter fittings, effectively balancing lightweight design with structural strength. The waterproof performance has been verified through vacuum testing. The propulsion system incorporates RM-168 brushless motor thrusters paired with 20A electronic speed controllers (ESC), with a maximum operating current of approximately 5A. This system is configured with both horizontal and vertical forward and reverse motors, ensuring full three-dimensional spatial mobility.

The system employs a modular design that facilitates the rapid replacement or expansion of sensing modules based on monitoring requirements, thereby enhancing environmental adaptability. The precise weight distribution design enables the vehicle to achieve stable underwater hovering, effectively reducing energy consumption and improving control flexibility. The processing and computing architecture utilizes a Raspberry Pi 3 B+ as the central computing unit, in conjunction with an Arduino Uno to create a dual-processor collaborative framework. The Arduino is dedicated to motor control and the collection of raw sensor data, while the Raspberry Pi manages high-level computing and network communication tasks, including image processing, data acquisition, and remote transmission. This dual-controller design significantly enhances multitasking capabilities, ensuring that the underwater remotely operated vehicle can efficiently execute multiple remote control commands and maintain stable bidirectional data transmission through the mobile communication module.

Figure 6.

Prototype of the Self-Developed Underwater Remotely Operated Vehicle.

Figure 6.

Prototype of the Self-Developed Underwater Remotely Operated Vehicle.

3. Results

This research developed and validated a smart ocean aquaculture monitoring system that integrates multiple remote control and mobile communication technologies. This system significantly enhances the efficiency of aquaculture monitoring and the precision of management through a self-developed underwater remotely operated vehicle. To verify the effectiveness and stability of the system integration architecture, the research team conducted on-site deployment tests in various aquaculture environments, including controlled laboratory settings and open water scenarios. The experiments focused on assessing the collaborative operational performance of multiple remote control systems and 4G mobile communication networks under different environmental conditions. The test sites were approached sequentially, starting from controlled environments and progressing to open waters: initial system validation was conducted in laboratory tanks, followed by integration testing at the Gongliao Aquatic Center’s cage aquaculture, communication stability was assessed during offshore cage testing at Keelung Harbor, long-distance operational capabilities were verified at large-scale cage nets in Pingtung offshore waters, and finally, the system’s adaptability was evaluated in shallow water environments at traditional fish ponds in Xuejia, Tainan.

3.1. Initial Laboratory Tank Testing

Geographic Location: National Taiwan Ocean University biological cultivation building, indoor controlled environment.

Experiment Purpose: To verify fundamental system functions and calibrate motor control parameters prior to field deployment.

Experiment Content: The ROV was placed in a large aquaculture tank with a volume of approximately 1 cubic meter, filled with freshwater and live fish to simulate real aquaculture conditions. The ROV was equipped with sensors to measure temperature, pH, and dissolved oxygen levels, with cross-verification against handheld instruments to ensure accuracy. The communication system transmitted video via 4G mobile networks, allowing the research team to remotely control the ROV from a computer using the Smart-Fish control system to evaluate data collection capabilities.

The test results indicated that, in the initial testing environment, the underwater remotely operated vehicle was able to accurately execute a variety of actions, including motor speed tests, forward and backward movement, left and right turns, as well as descent and ascent.

In the initial testing phase, the system demonstrated the effectiveness of multiple remote control functions. Researchers successfully operated the ROV using various control terminals, including smartphones, tablets, smartwatches, and multi-site central control centers, with seamless and smooth transitions between platforms. Through the web interface of the Smart-Fish control system, all control commands were accurately transmitted to the ROV, enabling it to execute actions according to preset motion modes, with control delay times maintained at an average of 1 to 2 seconds. Notably, this network-based remote control method allowed personnel at the National Taiwan Ocean University control center to obtain and analyze water quality data and fish activity in the aquaculture tank in real-time, significantly enhancing monitoring efficiency.

Figure 7. Smart Device-Controlled ROV Monitoring System: (a) A researcher uses a smartphone to control and monitor a remotely operated vehicle (ROV) during laboratory tank testing at National Taiwan Ocean University, demonstrating the system’s functionality in controlled freshwater conditions; (b) A smartwatch interface displays the ROV control system and live video feed during field testing operations near Keelung Harbor, showcasing the versatility of wearable device integration.

3.2. Deployment Site – Gongliao Aquatic Center Cage Aquaculture

Geographic Location: Gongliao District, northeastern Taiwan.

Experiment Purpose: To assess the feasibility of cage aquaculture in this region and evaluate the potential application of underwater remotely operated vehicles for smart monitoring.

Experiment Content: The self-constructed underwater remotely operated vehicle (ROV), equipped with cameras and sensors, conducted underwater monitoring by recording water quality parameters, such as dissolved oxygen and pH levels, as well as the growth status of cultured organisms. The integration of various remote control technologies enabled users to operate the ROV in real-time and acquire data through multiple platforms, including computers and mobile devices.

In the cage tests conducted at the Gongliao Aquatic Center, various remote control technologies demonstrated excellent adaptability. The research team utilized different control platforms—computers, tablets, and smartphones—to operate the underwater remotely operated vehicle, transmitting control commands to the site through 4G mobile communication networks. Test results indicated that in near-shore environments, the signal coverage of the 4G mobile communication network was robust, enabling smooth real-time image transmission. Additionally, sensor data—including temperature, dissolved oxygen, and pH levels—transmitted via the MQTT protocol could be reliably returned to the database, allowing the remote monitoring system to display and analyze changes in the cage environment in real-time.

Water quality monitoring data indicated that the ROV camera could effectively display the condition of the cage structure. It was particularly adept at detecting sediment accumulation at the bottom of the cage and identifying potential damage areas on the net surface. This technology offers comprehensive monitoring capabilities that are not attainable through traditional manual inspections.

Figure 8.

Smartphone-Based Operations in Cage Net Aquaculture at the Gongliao Aquatic Center.

Figure 8.

Smartphone-Based Operations in Cage Net Aquaculture at the Gongliao Aquatic Center.

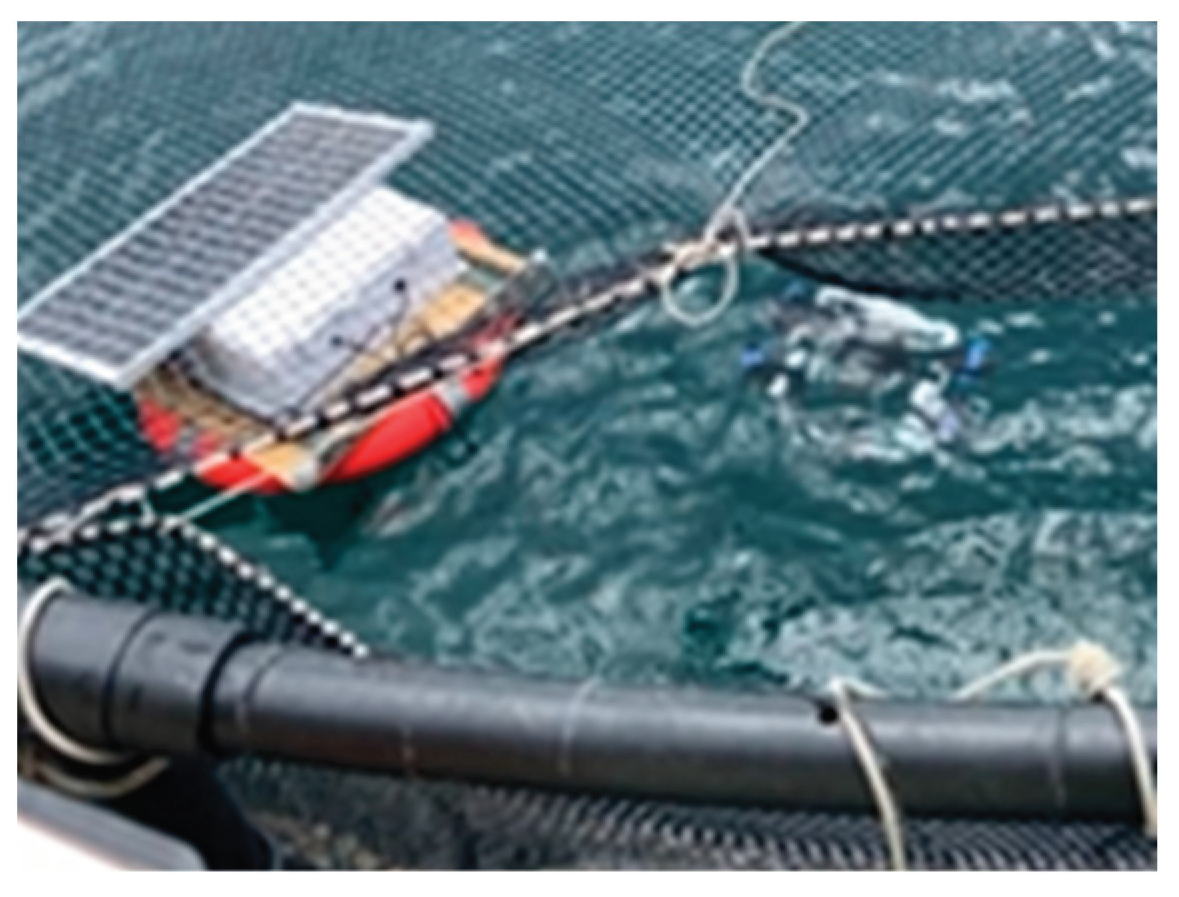

3.3. Deployment Site – Keelung Harbor Offshore Cage

Geographic Location: Offshore of Keelung Harbor, Northern Taiwan

Experiment Purpose: To investigate the effects of cage aquaculture technology in marine environments and to analyze the associated environmental challenges.

Experiment Content: The ROV monitored environmental parameters, such as temperature and salinity, while assessing the stability of the cage structure. The integration of multiple remote control technologies enabled operators to adjust the ROV's path in real-time, allowing for adaptation to dynamic changes in the marine environment.

The Keelung offshore test showcased the system's performance in more challenging environments. Operators were able to select the most suitable control interface based on the prevailing communication conditions. The system successfully transmitted critical environmental parameters, such as temperature and salinity, in real-time, enabling operators to adjust monitoring strategies immediately based on this data. These results demonstrated the system's reliability and flexibility in offshore environments.

Figure 9.

Installation of Cage Nets in the Open Sea off Keelung Harbor.

Figure 9.

Installation of Cage Nets in the Open Sea off Keelung Harbor.

3.4. Deployment Site - Large-Scale Cage Net in Pingtung Offshore Waters

Geographic Location: Offshore environment in southern Taiwan.

Experiment Purpose: To assess the feasibility of large-scale cage aquaculture.

Experiment Content: The ROV monitored the density, distribution, and health status of cultured organisms while also assessing the stability of cage structures. The integration of multiple remote control technologies offered operational flexibility across various platforms, enabling users to remotely control the ROV and analyze data in real-time.

The deployment of large-scale cage nets in the offshore waters of Pingtung presented a significant challenge to the system. In areas distant from the shore, the signals of the 4G mobile communication network became unstable. Tests demonstrated that even in these challenging environments, the system could still maintain basic monitoring functions by switching between different control platforms and communication modes.

Figure 10.

Aquaculture Pen Monitoring Setup at a Large-scale Cage Net in Jiaque Bay, Pingtung.

Figure 10.

Aquaculture Pen Monitoring Setup at a Large-scale Cage Net in Jiaque Bay, Pingtung.

Figure 11.

Underwater and Control Views from Monitoring Equipment at a Large-scale Cage Net in Jiaque Bay, Pingtung.

Figure 11.

Underwater and Control Views from Monitoring Equipment at a Large-scale Cage Net in Jiaque Bay, Pingtung.

3.5. Deployment Site – Xuejia Fish Pond

Geographic Location: Xuejia District, southwestern Taiwan, characterized by a freshwater or brackish water environment.

Experiment Purpose: To investigate the effectiveness and stability of aquaculture technology in freshwater and brackish water environments.

Experiment Content: The underwater remotely operated vehicle monitored fish pond water quality parameters in fish ponds, including conductivity and dissolved oxygen, as well as the growth conditions of cultured organisms. The integration of multiple remote control technologies facilitated remote operation and real-time data transmission.

In the tests conducted at the Xuejia fish ponds, the system exhibited excellent adaptability, comparable to that of cage environments. Thanks to improved network coverage in terrestrial settings, all control platforms functioned seamlessly. Notably, the tablet control mode proved particularly valuable in this context, as its large screen enabled operators to simultaneously monitor multiple water quality parameters and underwater images, thereby facilitating precise operations. Researchers successfully operated the underwater remotely operated vehicle (ROV) from the central control center to perform water quality monitoring and biological observations, obtaining and analyzing critical data such as dissolved oxygen levels, pH, and conductivity in real-time. This data was compared with traditional manual sampling methods, resulting in a significant reduction in labor input and sampling time.

Figure 12. Tablet-Controlled ROV Deployment in Xuejia Fish Pond: (a) Field deployment showing a tablet being operated near the shoreline while the ROV is actively functioning in the water, demonstrating the remote monitoring capabilities in natural aquatic environments; (b) Close-up of the control tablet interface displaying the ROV control system, which includes navigation buttons, a camera feed, and a water quality monitoring dashboard, illustrating the integrated monitoring and control capabilities of the system.

4. Discussion

4.1. The Innovative Value of Integrating Multiple Remote Control and Mobile Communication Technologies

The innovation of this research lies in the successful integration of multiple remote control systems and mobile communication technologies, which provide new solutions for smart ocean aquaculture monitoring. This integration allows aquaculture monitoring systems to transcend the limitations of traditional single control platforms and restricted communication ranges, realizing the concept of "anytime, anywhere, multi-platform" monitoring. Unlike traditional aquaculture monitoring systems that typically offer only a single monitoring interface at a fixed location, this system enables aquaculture operators to conduct remote operations through various devices, such as mobile phones, smartwatches, tablets, or multi-site central control centers. Additionally, the buoy system incorporates 4G mobile communication network technology to ensure stable transmission of data and control commands, even in waters far from shore.

This integration is not merely a collection of technologies; it generates synergistic effects. For instance, when an aquaculture operator receives a water quality anomaly alert on their smartwatch, they can promptly conduct a preliminary check using their mobile phone, evaluate the severity of the situation, and then determine whether to proceed to the multi-site central control center for more comprehensive analysis and processing. The entire process depends on the stable connection provided by mobile communication technology, which ensures data consistency and command reliability across different control platforms.

Compared to existing research [

15,

16], the integration of multiple remote control and mobile communication technologies in this system demonstrates greater completeness and practicality. Most previous studies focused solely on one or two control interfaces and typically relied on local WiFi or directional WiFi for communication, which limited their applicability in real-world aquaculture environments. This research not only successfully integrated four different control devices but also combined them with widely available 4G mobile communication networks, creating opportunities for truly remote aquaculture monitoring.

This research particularly emphasizes the web-based SmartFish control platform, which integrates control of underwater remotely operated vehicles, real-time imaging, and sensor data into a single interface. This integration significantly enhances the system's user-friendliness and practical value.

4.2. Application Performance of Various Remote Control and Mobile Communication Technologies in Diverse Aquaculture Environments

In diverse aquaculture environment tests, the system that integrates multiple remote control and mobile communication technologies demonstrated excellent adaptability and practical value; however, it also encountered various challenges. In near-shore aquaculture farms, such as the Gongliao Aquatic Center and Xuejia fish ponds, the coverage of the 4G mobile communication network was excellent, allowing various control platforms to operate smoothly. Users particularly favored using smartphones for daily monitoring, while they switched to tablets or multi-site central control centers for detailed inspections. The stability of mobile communication technology ensured that switching between multiple platforms was seamless and reliable.

In the large-scale cage net experiment conducted in the offshore waters of Pingtung, the system encountered moderate challenges. Although 4G mobile communication network signals were still available, fluctuations became more pronounced. When the 4G mobile communication network signals became unstable in areas farther from shore, the benefits of integrating mobile communications with multiple control systems remained evident. Throughout the testing process, various control platforms showcased their optimal application scenarios: smartphones emerged as the preferred choice for daily monitoring due to their portability; tablets offered superior visual experiences for detailed inspections because of their larger screens; and multi-site central control centers were essential for long-term monitoring and data analysis. This diversity allows the system to adapt flexibly to the evolving needs of different aquaculture scenarios.

Combining the test results from the three sites, the integration of various remote control and mobile communication technologies allows the system to adapt to diverse aquaculture environments, ranging from freshwater to seawater and from near-shore to deep-sea. This significantly broadens the application range of smart aquaculture monitoring.

4.3. Application Prospects and Future Development of Integrating Multiple Remote Control and Mobile Communication Technologies

The smart aquaculture monitoring system, which integrates multiple remote control and mobile communication technologies, demonstrates significant application potential. First, this integration enables true "remote aquaculture management," allowing operators to overcome location constraints. This advancement greatly reduces the need for manual inspections while maintaining comprehensive perception and control over the aquaculture environment. In the current context of labor shortages and an aging workforce in the aquaculture industry, this distance-independent smart monitoring method is particularly crucial.

The integration of various remote control and mobile communication technologies has established a new model for aquaculture monitoring. For instance, aqua-culturists can receive alerts on their smartwatches around the clock, eliminating the need to constantly monitor the control center. When abnormal situations arise, they can quickly access details via their mobile phones and, if necessary, remotely operate an underwater vehicle to investigate specific issues or take immediate action, such as activating aerators. This seamlessly integrated workflow significantly enhances the efficiency and responsiveness of aquaculture management.

The multiple remote control system described in this research is not only functionally diverse but also possesses fault redundancy capabilities. For instance, when smartphone control becomes unavailable due to network issues or battery depletion, users can seamlessly switch to alternative devices for control. This ensures the continuous operation of the monitoring system and enhances overall system reliability.

From the perspective of technological development trends, future directions for advancement include:

Smarter Multi-Platform Collaboration: Developing intelligent control processes that are informed by user behavior and environmental awareness. For instance, the system can automatically select the most suitable notification method and control interface based on the importance of the event, the user's location, and the device currently in use.

Augmented Reality and Virtual Reality Control Interfaces: Developing AR/VR control interfaces to offer more intuitive remote operation experiences. This technology enables aquaculture operators to control remotely operated vehicles underwater and monitor aquaculture environments as if they were physically present on-site.

Cross-Aquaculture Farm Collaborative Monitoring: Developing cloud-based platforms for collaborative monitoring across multiple aquaculture farms, allowing individual operators to oversee various dispersed aquaculture sites through multiple control interfaces. This approach facilitates scalability and intensive management of aquaculture operations.

The greatest significance of integrating various remote control and mobile communication technologies is that it allows the traditional aquaculture industry to fully benefit from the conveniences of modern technology, facilitating a precise, automated, and intelligent transformation. The system developed in this research offers a viable technological pathway for this transformation, particularly well-suited for application in Taiwan and other resource-limited regions. It is anticipated that this system will promote the development of the aquaculture industry in more sustainable and efficient directions.

5. Conclusions

This research developed an innovative smart ocean and aquaculture monitoring system, integrating multiple remote control systems and mobile communication technologies as its core design concept. The system supports operation through various platforms, including computers, smartphones, smartwatches, and multi-site central control centers, significantly enhancing user operational flexibility and monitoring efficiency. It effectively utilizes existing 4G mobile communication networks while maintaining a flexible architecture for future upgrades to beyond 5G low-orbit satellite communications, ensuring stable communication in deep-sea environments.

The overall system architecture comprises three major components: the underwater remotely operated vehicle, the buoy system, and the cloud server, which together create a comprehensive data collection and command transmission chain. The cloud server incorporates four functional modules: Web Server, MQTT Service, RTSP Service, and MySQL, facilitating seamless connections between multiple control interfaces and mobile communications. Regarding the design of the underwater remotely operated vehicle, the system integrates microcontroller units (MCUs) and a Raspberry Pi 3 B+ as core controllers. It is equipped with underwater cameras and multifunctional water quality sensors, establishing a dual-controller collaborative computing architecture that provides a robust hardware foundation for extensive remote control capabilities.

The innovation of this research lies in the integration of multiple remote control platforms and mobile communication technologies, overcoming the limitations of traditional aquaculture monitoring systems that rely on single control interfaces and have restricted communication ranges. Users can access and operate the system through various devices, including computers, smartphones, smartwatches, and multi-site central control centers, thereby realizing the concept of "anytime, anywhere, multi-platform" monitoring. Field test results indicate that the system's integrated architecture for multiple remote control and mobile communication exhibits outstanding operational performance and communication stability across various real-world locations, including the Gongliao Aquatic Center, the boat dock at National Taiwan Ocean University, large-scale cage nets in the offshore waters of Pingtung, and the Xuejia fish ponds. By facilitating real-time image transmission and sensor data collection, the system enhances both the accuracy and efficiency of water quality monitoring, demonstrating its applicability and practical value in diverse aquaculture environments.

With the maturation of BEYOND 5G low-orbit satellite communication technology, this system is anticipated to significantly enhance its application capabilities in remote ocean waters. This research demonstrates that a smart aquaculture monitoring system, which integrates multiple remote control and mobile communication technologies, can effectively facilitate the transformation of traditional aquaculture into a more precise, automated, and intelligent practice. This approach is particularly beneficial for small-scale aquaculture operators in Taiwan and other resource-limited regions, offering innovative technical support and solutions for the sustainable development of aquaculture.

Author Contributions

Y.-S.L. contributed to the conception and supervision of the work (conceptualization, resources, methodology, writing—original draft, software), collected and analyzed the data, and interpreted the results. C.-F.S. contributed to the conception of the work (project administration, software). Y.-X.W. contributed to the writing and supervision of the work (writing—review and editing, software, project administration). C.-H.Y. contributed to the writing, design and validation of the work. C.-C.C. contributed to the conception of the work, validation, data visualization, writing—review and editing, and funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

The corresponding author would like to thank the National Science and Technology Council of Taiwan for their financial support (grant number MOST 111-2221-E-019-030 and NSTC 110-2221-E-019-041).

Data Availability Statement

No new data were generated for this study. All data supporting the reported results are contained within the article.

Acknowledgments

The authors thank the National Science and Technology Council for financial support under grants MOST 111-2221-E-019-030 and NSTC 110-2221-E-019-041.

Conflicts of Interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Abbreviations

| AIoT |

Artificial Intelligence of Things |

| IoT |

Internet of Things |

| MQTT |

Message Queuing Telemetry Transport |

| NTN |

Non-Terrestrial Networks |

| ROV |

Remotely Operated Vehicle |

| RTSP |

Real-Time Streaming Protocol |

| SIM |

Subscriber Identity Module |

| 3GPP |

3rd Generation Partnership Project |

| FAO |

Food and Agriculture Organization |

| BEYOND 5G |

Post-5G/Next-generation 5G |

| MCU |

Microcontroller Unit |

| ESC |

Electronic Speed Controller |

References

- FAO. The State of World Fisheries and Aquaculture 2022. Food and Agriculture Organization of the United Nations: Rome, Italy, 2022.

- Troell, M.; Naylor, R.L.; Metian, M.; Beveridge, M.; Tyedmers, P.H.; Folke, C.; Arrow, K.J.; Barrett, S.; Crépin, A.S.; Ehrlich, P.R.; et al. Does aquaculture add resilience to the global food system? Proc. Natl. Acad. Sci. USA 2014, 111, 13257–13263. [Google Scholar] [CrossRef] [PubMed]

- Lester, S.E.; Gentry, R.R.; Kappel, C.V.; White, C.; Gaines, S.D. Offshore aquaculture in the United States: Opportunities and challenges. Mar. Policy 2018, 87, 191–198. [Google Scholar]

- O'Donncha, F.; Grant, J. Precision aquaculture. IEEE Internet Things Mag. 2019, 2, 26–30. [Google Scholar] [CrossRef]

- Føre, M.; Frank, K.; Norton, T.; Svendsen, E.; Alfredsen, J.A.; Dempster, T.; Eguiraun, H.; Watson, W.; Stahl, A.; Sunde, L.M.; et al. Precision fish farming: A new framework to improve production in aquaculture. Biosyst. Eng. 2018, 173, 176–193. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y.; Chen, Y.; Li, T. Current situation and future prospect of underwater robotics in aquaculture. Inf. Process. Agric. 2021, 8, 282–293. [Google Scholar]

- Livne, L.; Koschitzky, H.; Klein, I.; Berger, D.; Peretz, S.M.; Schwartzbach, L.; Frischbutter, C. A review on underwater robotic vehicles for aquaculture: System functionalities, challenges, and potential solutions. J. Field Robot. 2022, 39, 965–988. [Google Scholar]

- Shi, W.; Cao, J.; Zhang, Q.; Li, Y.; Xu, L. Edge computing: Vision and challenges. IEEE Internet Things J. 2016, 3, 637–646. [Google Scholar] [CrossRef]

- 3GPP. Study on scenarios and requirements for next generation access technologies. 3GPP TR 38.913 V16.0.0, 2020.

- Lee, C.W.; Kim, T.I.; Lee, G.H.; Kim, S.Y.; Kim, Y.J.; Lee, J.H. Development of the AquaX, a remotely operated underwater vehicle for monitoring in fish farming. Aquac. Eng. 2021, 92, 102142. [Google Scholar]

- Antonucci, F.; Costa, C. Precision aquaculture: A short review on engineering innovations. Aquac. Int. 2020, 28, 41–57. [Google Scholar] [CrossRef]

- Zhou, C.; Xu, D.; Lin, K.; Sun, C.; Yang, X. Intelligent feeding control methods in aquaculture with an emphasis on fish: A review. Rev. Aquac. 2018, 10, 975–993. [Google Scholar] [CrossRef]

- García-Magariño, I.; Lacuesta, R.; Lloret, J. ABS-FishCount: An agent-based simulator of underwater sensors for measuring the amount of fish. Sensors 2017, 17, 2606. [Google Scholar] [CrossRef] [PubMed]

- Parra, L.; Sendra, S.; García, L.; Lloret, J. Design and deployment of low-cost sensors for monitoring the water quality and fish behavior in aquaculture tanks during the feeding process. Sensors 2018, 18, 750. [Google Scholar] [CrossRef] [PubMed]

- Kodheli, O.; Lagunas, E.; Maturo, N.; Sharma, S.K.; Shankar, B.; Montoya, J.F.M.; Duncan, J.C.M.; Spano, D.; Chatzinotas, S.; Kisseleff, S.; et al. Satellite communications in the new space era: A survey and future challenges. IEEE Commun. Surv. Tutor. 2021, 23, 70–109. [Google Scholar] [CrossRef]

- Pham, T.M.; Nguyen, T.T.; Truong, H.L. Low-cost solution for microplastic identification in aquaculture environment using edge computing. Comput. Electron. Agric. 2022, 193, 106636. [Google Scholar]

- García-Soto, C.; Seys, J.J.; Zielinski, O.; Busch, J.A.; Luna, S.I.; Baez, J.C.; Domegan, C.; Dubsky, K.; Kotynska-Zielinska, I.; Loubat, P. Marine citizen science: Current state in Europe and new technological developments. Front. Mar. Sci. 2021, 8, 621472. [Google Scholar] [CrossRef]

- Antonucci, F.; Boglione, C.; Cerasari, V.; Caccia, E.; Costa, C. Technological solutions to support precision aquaculture for enhanced production efficiency. Aquac. Int. 2021, 29, 1075–1096. [Google Scholar]

- Føre, M.; Svendsen, E.; Alfredsen, J.A.; Uglem, I.; Bloecher, N.; Sveier, H.; Sunde, L.M.; Frank, K. Using acoustic telemetry to monitor the effects of crowding and delousing procedures on farmed Atlantic salmon (Salmo salar). Aquaculture 2018, 495, 757–765. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).