Submitted:

07 May 2025

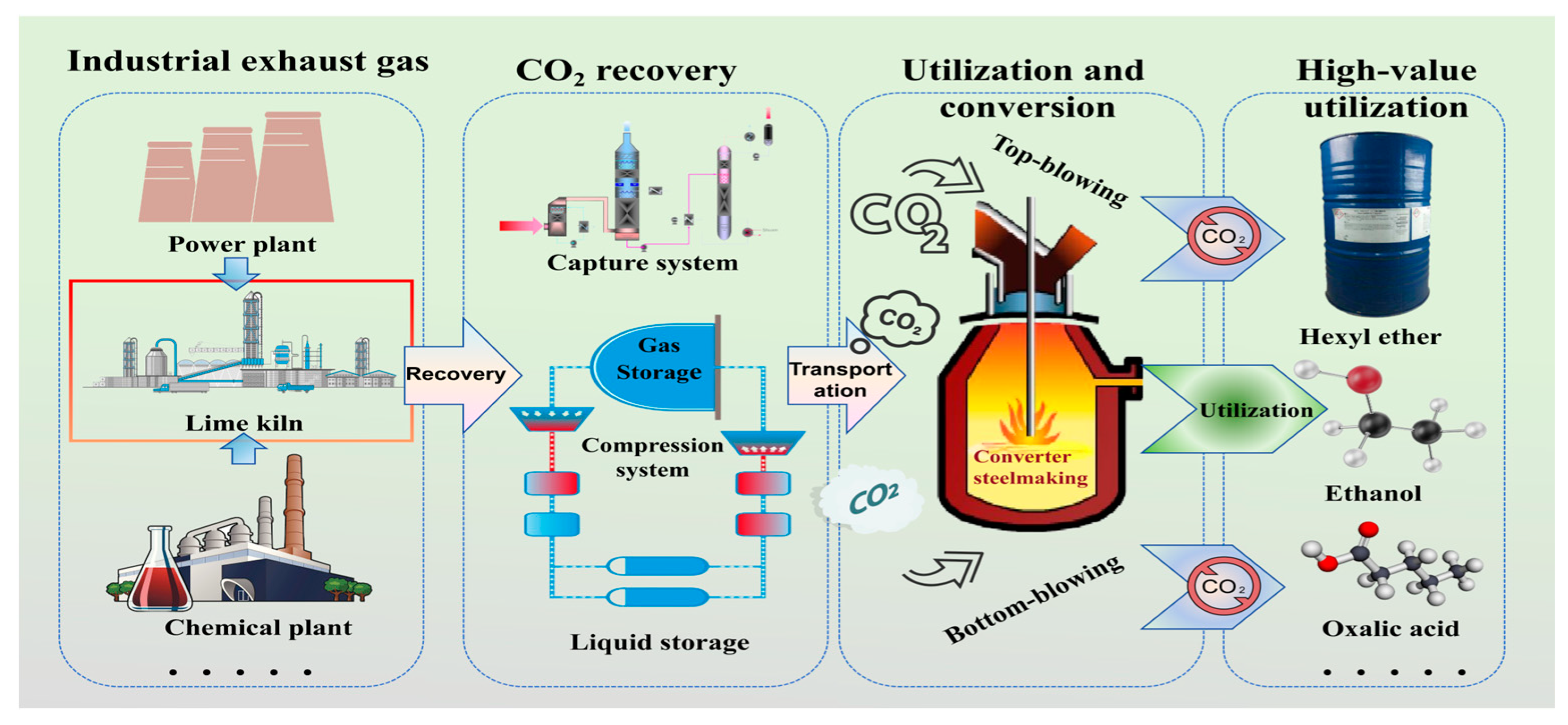

Posted:

08 May 2025

You are already at the latest version

Abstract

Keywords:

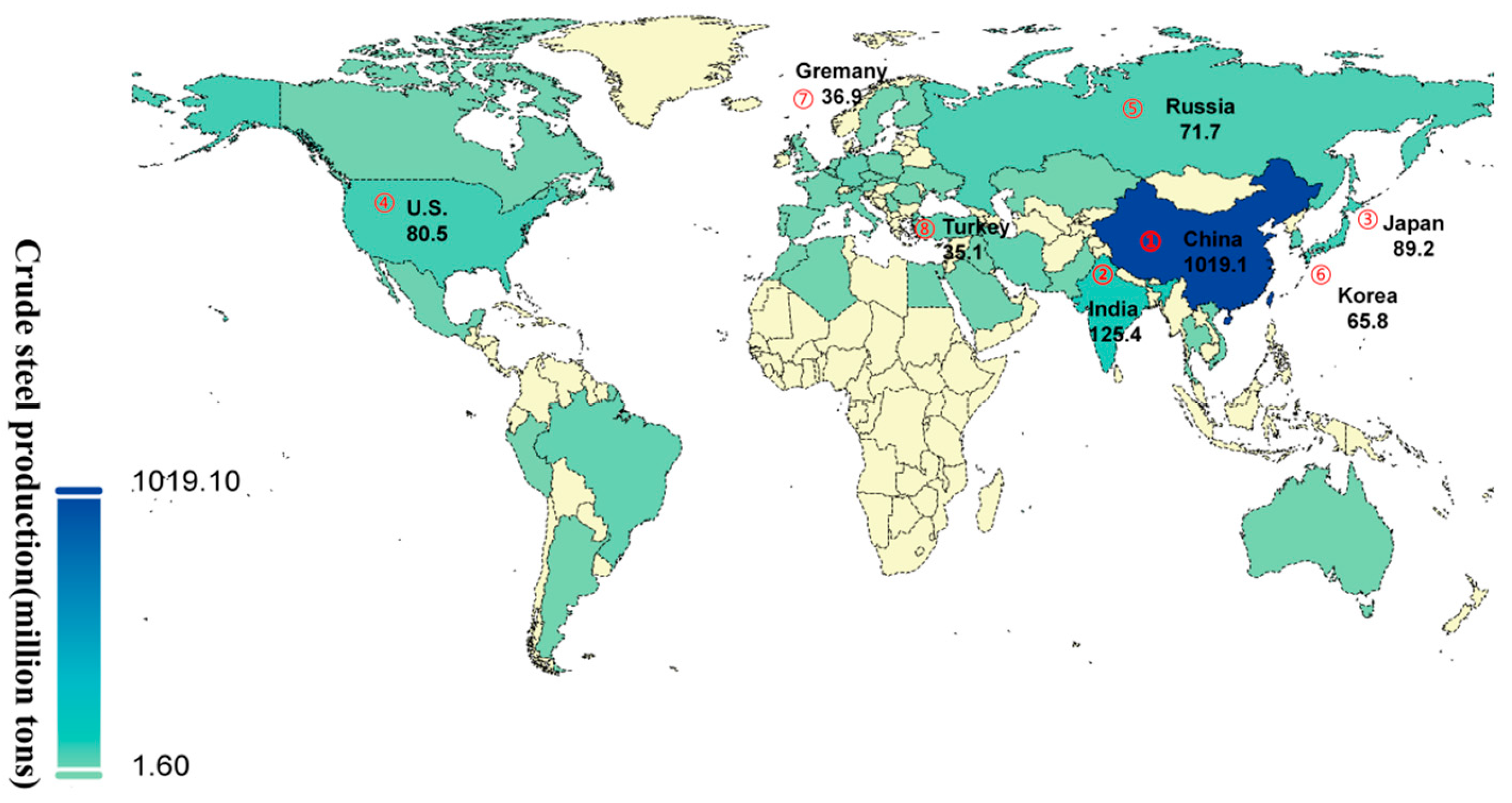

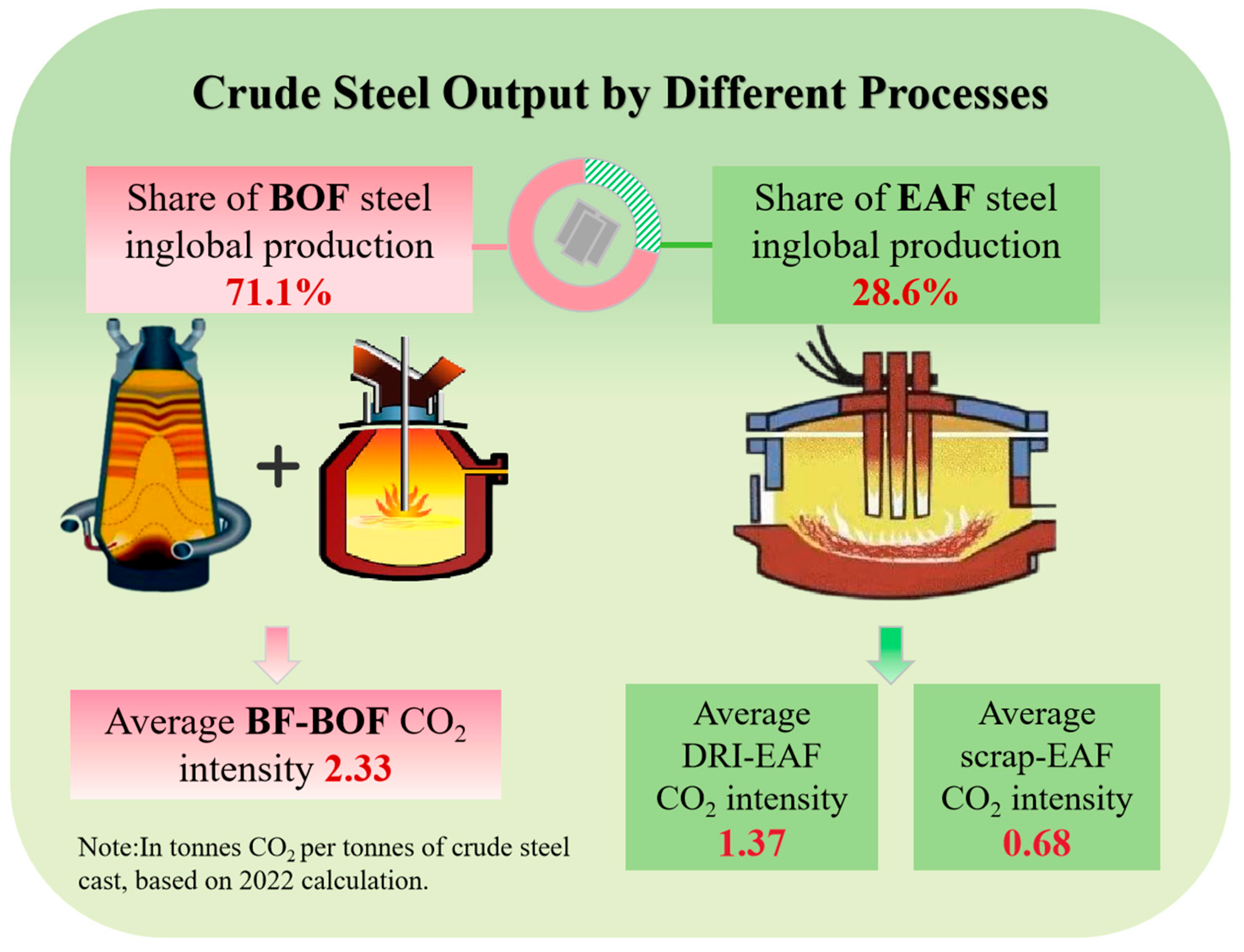

1. Introduction

- Replacing conventional energy sources with clean energy;

- Improving energy utilization efficiency;

- Advancing fundamental research on energy utilization theories;

- Implementing carbon capture and resource utilization [6].

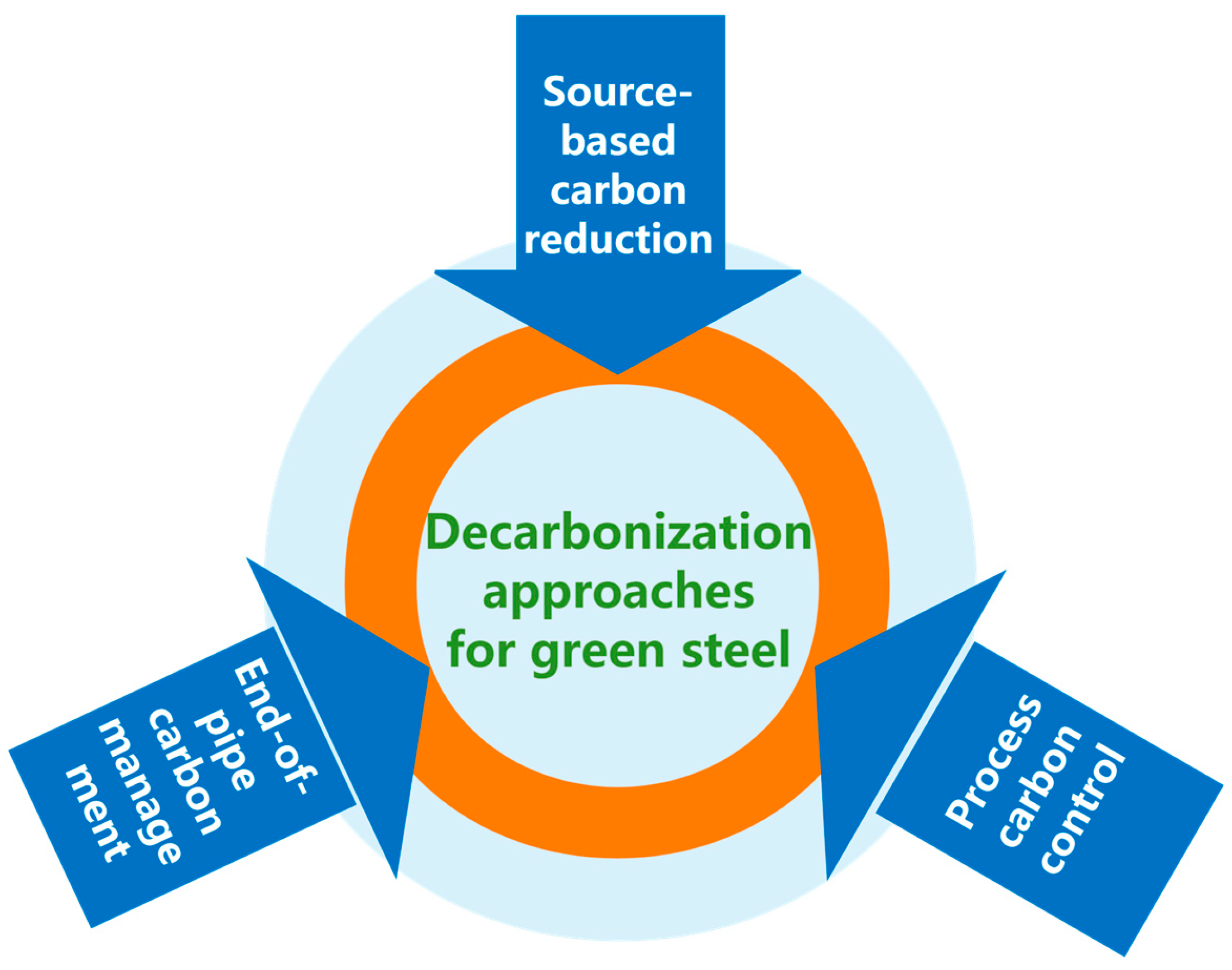

2. Decarbonization Pathways for BF-BOF Long-Process Steelmaking

2.1. Source-Stage Carbon Reduction

2.1.1. Application Case Studies of High-Proportion Pellet Charging in Blast Furnaces

2.1.2. Application Case Studies of High-Scrap-Ratio Steelmaking

2.2. Process Carbon Control

2.3. End-of-Pipe Carbon Mitigation

- Oxygen-enriched and CO2 pre-concentration technologies: Including sinter carbon pre-concentration, lime kiln carbon pre-concentration, BF oxygen enrichment, and BF CO2 enrichment.

- Low-cost carbon capture driven by waste heat: Analyzing steel process energy consumption, coupling medium-low temperature flue gas waste heat with carbon capture.

- CO2 conversion to reducing gases: Catalytic hydrogenation of CO2 (using coke oven gas-derived blue hydrogen) and CO2 electrolysis for syngas production.

- Recycling of conversion products: Steel slag carbonation and direct utilization of CO2 in iron/steelmaking.

2.3.1. CO2 Recycling in Steelmaking Technologies

- 4.09 kg/t reduction in iron consumption,

- 3.73% increase in CO concentration in off-gas,

- 5.57 Nm³/t increase in gas recovery,

- 10.08 kg/t steel CO2 utilization,

- 6.12 kgce/t reduction in energy consumption,

- 26.28 kg/t steel CO2 emission reduction.

2.3.2. Case Analysis of Carbon Capture: Pressure Swing Adsorption (PSA) and Chemical Absorption

- Material Innovation: Develop high-capacity, sulfur- and moisture-resistant adsorbents (e.g., metal-organic frameworks, MOFs) and low-regeneration-energy solvents (e.g., phase-change absorbents like NCCC), targeting chemical absorption energy consumption below 1.5 GJ/t.

- Process Hybridization: Integrate PSA with membrane separation and cryogenic distillation for multi-stage CO2 enrichment. For example, combining PSA (pre-concentrating CO2 to 40%~50%) with chemical absorption (purifying to 99%) could reduce energy use by 15%~25% in blast furnace gas treatment.

- Carbon Valorization: Breakthroughs in catalytic conversion of CO2 to methanol, polycarbonates, and other bulk chemicals, achieving >80% conversion efficiency via electrocatalysis/photocatalysis to establish a “capture-conversion-utilization” value chain.

3. Decarbonization Pathways for EAF Short Process

3.1. Source-Stage Decarbonization

3.1.1. Case Analysis of Green High-Efficiency Electric Arc Furnace Applications

3.1.2. Case Analysis of Advanced Electric Arc Furnace (EAF) Applications

- Hydrogen-Electric Coupling Processes: Integrating technologies like Danieli Q-ONE with green hydrogen to enhance decarbonization.

- Blockchain-Based Carbon Tracking Systems: Ensuring transparency in emission reduction across supply chains.

- Carbon Tax Policy Incentives: Driving adoption through fiscal mechanisms (e.g., >$80/t CO2 pricing).

3.1.3. Case Studies of Low-Carbon Green Power Applications

3.1.4. Case Analysis of Hydrogen-Based Shaft Furnace Applications

3.2. Process Carbon Control

3.3. End-of-Pipe Treatment

3.3.1. Case Studies on Waste Heat Utilization in EAF Steelmaking

3.3.2. Case Studies on Slag Treatment in EAF Steelmaking

4. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Holappa,L. A general vision for reduction of energy consumption and CO2 emissions from the steel industry.Metals 2020 ,10(9).

- Zhang,X.Y. A review on low carbon emissions projects of steel industry in the World.J. Cleaner Prod. 2021 ,306.

- Tang,J.;Chen,M.;Li,F.;Zhou,Y.;Wang,J.;Li,S.;Liu,Z. Development status and future trend of hydrogen metallurgy in China.Hebei Metallurgy 2020 ,(8),1–6+51.

- PEM electrolyser from Siemens for Salzgitter steelmaking hydrogen. Fuel Cells Bulletin 2019, 2019(12), 10. [CrossRef]

- Sustainability indicators of the steel industry.worldsteel News 2024. Available online: https://worldsteel.org/data/ world-steel-in-figures-2024 (accessed on 3 December 2024).

- Hongming,N.Study on energy efficiency and CO2 emission of typical iron and steel manufacturing process.Master’s Thesis,Northeastern University,2022.

- Li,H.;Ge,C.;Wang,X.;Zhang,C.;Zheng,A.;Wang,X.Technical path analysis and development suggestion of blast furnace low carbon ironmaking.Iron&Steel 2024 ,59(09),56–70+101.

- Yin,R.;Shen,F. Pay attention to the flow of scrap steel and develop the electric furnace process——Outlook on the total output control of crude steel and the alternating evolution of manufacturing process structure.Resource Recycling 2025 ,(02),20–23.

- Chang,C.Process technology-economic analysis and carbon reduction potential evaluation of hydrogen-enriched blast furnace coupled with coke oven gas hydrogen production enhanced by slag.Ph.D.Thesis,SHANXI University,2024.

- Xu,W.;Fan,L.;Yang,Y.;Tian,Q.;Li,C.;Wang,Y.;Zhu,T.;Hao,R. Research progress in low carbon smelting technology of blast furnace gas cycle coupling carbon capture.Energy Environmental Protection 2023 ,37(03),175–184.

- Wang,Y.;Huang,Q. Analysis of low temperature reduction pulverization of fluxed pellets.Sintering and Pelletizing. 2024, 49(04), 70–76.

- Zhang,C. Basic research on combined injection of natural gas and pulverized coal in blast furnace tuyere.Master’s Thesis,University of Science and Technology Beijing,2024.

- Wan,P.;Xu,Z.;Ding,L.;He,L.;Zhuo,R. Experimental study on the”Magnetic Separation-flotation” combined process for a refractory low-grade iron ore.Journal of Jiamusi University(Natural Science Edition) 2024 ,42(11),139–142.

- Li,Q. Feasibility of new biofuel replacing traditional fuel.China Science and Technology Information 2024, (07), 116–118.

- Sitaraman,H. High-fidelity arc-discharge model for hydrogen-plasma-smelting-reduction of iron ore.Technical Report,National Renewable Energy Laboratory(NREL),Golden,CO,USA,2024.

- Gao,T. Application of plasma in metallurgical field.JOM 2024 ,1–19.

- Liu,Z.;Han,J.;Zhang,J.;Niu,L.;Wang,Y. Development and practice of high-pellet-proportion smelting technology of blast furnace.J. Univ. Sci. Technol. Liaoning 2021 ,44(02),85–91.

- Xin-min,C.;Yang,X.;Yu,X.;Xu,T.;Dong,X. Design and production practice of blast furnace based on high proportion pellet smelting in Tangsteel.Southern Metals. 2024, (03), 38–41.

- Zhu,G. Research progress and prospects of low-carbon technologies in Shougang.In Proceedings of the 12th Youth Academic Annual Conference of the Chinese Society for Metals and the First”Carbon Neutrality”Metallurgical Youth Scientists Salon,Ganzhou,China,2024.

- Ma,C.;Gao,A.;Cao,Y.;Liu,S.;Dong,X. Intensified smelting experience in Shougang Jingtang No.1 BF under high percentage of pellet charge.Ironmaking. 2022, 41(04), 7–11.

- Yuan,X.;Li,X.;Ke,H. Practice of high-proportion pelletizing in No.2 blast furnace of Tangsteel.Gansu Metallurgy 2023 ,45(05),31–33.

- Matsui,Y. All pellets operation in Kobe No.3 blast furnace under intensive coal injection.ISIJ Int. 2003, 43(2), 166–174.

- Zhang,C.;Zhang,T.;Xu,W. Production practice of high scrap ratio in Tangshan Iron and Steel Company.Shanxi Metallurgy. 2022, 45(03), 189–191.

- Wu,B.;Xu,Z.;Song,S. Smelting process of 180 t converter with high scrap ratio under MHCC coupling model.Title(s) J. Mater. Metall. 2024 ,23(06),598–606.

- Keysberg,K.;Müller,M.;Burkhard,O. ThyssenKrupp Steel Annual Report 2020.ThyssenKrupp AG,2020.

- NIPPON STEEL. Technical Overview 2019.Nippon Steel Corporation,Tokyo,Japan,2020.

- Luo,Z. Vigorously promote technological innovation to support EAF steel industry development.China Metallurgy News 2025 ,001.

- Liu,K. Application of three-dimensional temperature online detection system in electrolysis workshop.Metall. Trans. B 2025 ,45(01),83–85.

- Zhou,Z. Fundamental and applied research on deep vanadium extraction and carbon retention in vanadium-bearing hot metal by combined blowing converter.Ph.D.Thesis,Chongqing University,2019.

- Liu,J. ;Li,H. A multi-directional weighted complex network model for flame image texture feature extraction aiming at predicting endpoint carbon content in converter steelmaking. J. Iron Steel Res. Int. 2025, 37(02), 151–163. [Google Scholar]

- Peng,H. Research and practice on intelligent factory construction for steel metallurgical enterprises oriented by digital twins.Ph.D.Thesis,Kunming University of Science and Technology,2023.

- Zhao,X. ;Ma,Z.;Hu,H. The progress of Baosteel RH setup and technology in recent 20 years.Baosteel Technology 2024, (04), 47–51. [Google Scholar]

- Jia,G. ;Zhang,Y.;Gao,F. Effect of pre-slagging on optimization of LF refining process. Shanxi Metallurgy 2024, 47(08), 192–194. [Google Scholar]

- He,D. Practice and analysis of SPHC steel production via CAS-OB process at Shougang Jingtang.Science&Technology Information 2015 ,13(01),92.

- Mo,L. Transforming AOD slag toward a highly reactive mineral admixture with appreciable CO2 sequestration:Hydration behavior,microstructure evolution,and CO2 footprint. Cem. Concr. Compos. 2025, 156, 105863. [Google Scholar] [CrossRef]

- Fang,Y.;Yin,C.;Wang,C.;Liang,G.;Li,Y.;Duan,H. Thermodynamic analysis of decarburization and chromium preservation of stainless steel in oxygen blowing process of VOD.Continuous Casting 2022 ,(01),25–30+38.

- Zhu,R. A review of carbon dioxide disposal technology in the converter steelmaking process. Int. J. Miner., Metall. Mater. 2020, 27, 1421–1429. [Google Scholar] [CrossRef]

- Han,B. Energy saving analysis for CO2–O2 mixed injection technology in converter steelmaking.J. Iron Steel Res. Int. 2024 ,31(5),1095–1103.

- Institute of Bricks. Influence of bottom blowing CO2 in LF on molten steel quality and erosion of ventilated bricks. Chinese Journal of Engineering 2014, 36(S1), 226–229. [Google Scholar]

- Li,Q. ;Wang,H.;Zhu,R.;Shou,D.;Liu,R.;Gu,Y. Experimental research on using CO2 as shielding gas in continuous casting. Continuous Casting 2015, 40(02), 5–9. [Google Scholar]

- Li,C. ;Zhang,Y.;Yao,X.;Sun,H.;Shen,H.;Meng,X. Thermal decomposition mechanism of small particle limestone at steelmaking temperature. China Metallurgy 2023, 33(12), 24–30. [Google Scholar]

- Kang,W. ;Li,H.;Liao,X.;Zhu,X.;Yang,J. Application and development of inclusion control and removal technology in Ansteel. Continuous Casting 2024, (01), 78–84. [Google Scholar]

- HBIS Group. HBIS achieves revolutionary breakthrough in steelmaking technology:World’s first”Converter bottom oxygen blowing+lime powder injection+dry dedusting”process.2024. Available online: http://hebgtgf.com/site/hggf/news/info/2024/ 40526.html (accessed on 21 February 2025).

- ngang Steel Co.,Ltd. A bottom-blowing element structure for converters and its application method.Patent CN220183322U,2023.

- University of Science and Technology Beijing;Jiuquan Iron&Steel. Industrial experimental study on high-intensity bottom blowing CO2 in converter steelmaking.In Proceedings of the China Iron&Steel Annual Conference,Beijing,China,2021.

- Baoshan Iron&Steel Co., Ltd. Baosteel Sustainability Report 2018.Shanghai,China,2018.

- Zhu,R.;Ren,X.;Xue,B. Research progress of ultimate carbon emission in BOF steelmaking process.Iron&Steel 2023 ,58(03),1–10.

- Li,H. Analysis of technological pathways and development suggestions for blast furnace low-carbon ironmaking.Metals 2024 ,14(11),1276.

- Ujisawa,Y. Breakthrough topic:by COURSE50 CO2 Program in Japanese Steel Industry Sector. In Energy Technology Roadmaps of Japan:Future Energy Systems Based on Feasible Technologies Beyond 2030; Springer: Tokyo, Japan, 2016; pp. 431–450. [Google Scholar]

- Yang,Q.;Feng,L.;Yan,L. Oxidation kinetics of elements in hot metal under O2-CO2 mixed injection.Modern Transportation and Metallurgical Materials 2018 ,46(03),7–11.

- Chunqiang,Y. Application of converter bottom blowing carbon dioxide technology.Hebei Metallurgy 2022 ,(10),35–38+44.

- Wang,H. Enhanced carbon dioxide sequestration and Cr detoxification:Direct carbonation of AOD slag with additives under ambient conditions. J. Cleaner Prod. 2024, 443, 141181. [Google Scholar] [CrossRef]

- Li,Q. ;Liu,R.;Zhu,R.;Wang,H.;Wang,X.;Li,Z.;Shen,H. Research on decarburization and chromium conservation by blowing carbon dioxide. Ind. Heat. 2015, 44(04), 24–26. [Google Scholar]

- Li,C.;Liu,X.;Wei,G.;Zhu,R.;Li,T.;Meng,L. Study on the influence of CO2 injection process of 115 t quantum electric arc furnace.Steelmaking 2023 ,39(06),1–7+22.

- Wang,B.;Li,W.;Han,Y.;Li,P. Design of CO2 absorption tower with the method of MEA for blast furnace gas.In Proceedings of the 14th China Iron&Steel Annual Conference,Chongqing,China, 2023.

- Rong,W. ;Gu,S.;Han,B.;Zhang,C. Metallurgical reaction behavior of CO2 as RH lifting gas. Chinese Journal of Engineering 2020, 42(02), 203–208. [Google Scholar]

- Yunling,G. Exploratory research on bottom blowing CO2 during the LF refining process.Iron&Steel 2013 ,48(08),34–39.

- Liu,Y. A review of physical and numerical approaches for the study of gas stirring in ladle metallurgy. Metallurgical and Materials Transactions B 2019, 50, 555–577. [Google Scholar] [CrossRef]

- Yan,S. Research progress on carbon capture and utilization technology in steel industry. Power Generation Technology 2025, 1–10. [Google Scholar]

- McQueen,N. CCS in the Iron and Steel Industry.Technical Report,Global CCS Institute,2019.

- Nygård,H.S. Techno-economic study of the CCMS Technology for CO2 capture from ferro-silicon production.In Proceedings of the 10th Trondheim Conference on CO2 Capture,Transport and Storage,Trondheim,Norway,2019.SINTEF Academic Press.

- Ravary,B. Towards a climate-friendly ferroalloy industry in Norway.In Proceedings of the 16th International Ferro-Alloys Congress(INFACON XVI),Trondheim,Norway,2021.

- Kennedy,G. WA Parish Post-Combustion CO2 Capture and Sequestration Demonstration Project.Final Technical Report,Petra Nova Power Holdings LLC,2020.

- Jenkins,J. A case study of the Petra Nova carbon capture project.The Paulson Institute 2015.

- Li,Y. ;Zhang,G.;Zhao,M.;Jia,C. Research on the domestic and foreign steel production process structure. Metallurgical Economy and Management 2023, (03), 24–27. [Google Scholar]

- Chaobin,L. Development status of high-efficiency energy-saving technology for electric arc furnace steelmaking.Ind. Heat. 2024,53(01),1–5.

- Zhiwei,D.;Yang,Z.;Ma,G. Status and technical challenges of hydrogen-based ironmaking technology.Jiangxi Metallurgy 2025 ,45(01),32–38.

- Yongpeng,L. Gas treatment technology of quantum electric furnace. Hebei Metallurgy 2022, (10), 63–66. [Google Scholar]

- Wang,C. ;Xu,P.;Zhu,L.;Zhu,R. Intelligent acceptance model for steel scrap based on dense small object detection. China Metallurgy 2024, 1–14. [Google Scholar]

- Shengtao,H. Research on classification and measurement system and data collection method for steel scrap. Shanxi Metallurgy 2023, 46(07), 192–194. [Google Scholar]

- Yao,C. ;Zhang,H.;Fan,X.;Wang,Y.;Yang,L.;Cao,J. Research on heat transfer behavior and efficiency improvement method of scrap in Consteel EAF. Ind. Heat. 2024, 53(11), 6–12. [Google Scholar]

- Jagtap,H. P. RAM analysis and availability optimization of thermal power plant water circulation system using PSO.Energy Reports 2021, 7, 1133–1153.

- Li,J. ;Yang,S.;Li,Y.;Wang,Z.;Wang,G. Development and application of low temperature uniform heating technology of tempering furnace for medium and heavy plate. Steel Rolling 2024, 41(01), 75–78. [Google Scholar]

- Su,W. ;Zhang,D. Opportunities and challenges of green electricity direct supply. China Power Enterprise Management 2024, (19), 8–9. [Google Scholar]

- Wang,X. Research on high-efficiency and low-carbon development of iron and steel enterprises. Popular Standardization 2024 ,(13),99–101.

- ArcelorMittal publishes 2019 integrated annual review.2020. Available online: https://corporate.arcelormittal.com/media/ news-articles/arcelormittal-publishes-2019-integrated-annual-review-1# (accessed on 3 January 2025).

- Nucor Corporation. Nucor 2020 Sustainability Report.Charlotte,NC,USA,2020.

- Xiaodi,W. 2018 Annual Report of Baosteel.Baosteel Group,Shanghai,China,2019.

- Nippon Steel Corporation. Annual report Japan, 2019.

- Wen,W. Practice and prospect of CISDI green electric arc furnace.Iron&Steel 2024 ,59(09),184–195.

- World Steel Association. Steel Statistical Yearbook 2023.Brussels,Belgium,2023;p.45.

- Primetals Technologies Limited. EAF Quantum Electric Arc Furnace Technology White Paper.2021;pp.4,32.

- CISDI. Technical report on EAF grid impact control technology.CISDI Electric Technology Co.,Ltd.,Chongqing,China,2021; p.11.

- TENOVA. Technical manual for EAF waste heat recovery system.Tenova Group,Milan,Italy,2020;p.15.

- Danieli Group. Q-MELT intelligent steelmaking system technical description.Buttrio,Italy,2023;p.23.

- Jiangyin Xingcheng Special Steel. Data analysis report of DC electric arc furnace industrial test.Jiangyin,China,2020.

- Yan,X. Current status and economic analysis of green hydrogen energy industry chain.Processes 2024 ,12(2).

- Suer,J.;Traverso,M.;Jäger,N. Carbon footprint assessment of hydrogen and steel.Energies 2022 ,15(24).

- Wang,C. Green steel:Synergies between the Australian iron ore industry and the production of green hydrogen.Int. J. Hydrogen Energy 2023 ,48(83),32277–32293.

- Chen,Z.;Tian,B.;Jiang,X.;Wu,W.;Wei,G.;Zhu,R. Progress and prospects of low-carbon high-efficiency and intelligent steelmaking technologies for electric arc furnaces.Iron&Steel 2024 ,59(09),167–183.

- Zhu,R.;Wang,G.;Zhang,H. Research and prospect of EAF steelmaking with near-zero carbon emissions.Iron&Steel 2022 ,57(10),1–9.

- Walsh,S. D.C. Evaluating the economic fairways for hydrogen production in Australia. Int. J. Hydrogen Energy 2021, 46(73), 35985–35996. [Google Scholar]

- Boldrini,A. The impact of decarbonising the iron and steel industry on European power and hydrogen systems. Appl. Energy 2024, 361. [Google Scholar]

- Kurecki,M. Recycling perspectives of electric arc furnace slag in the United States:A review.Steel Res. Int. 2024 ,2300854.

- Pareliussen, J. ;Purwin,A. Climate policies and Sweden’s green industrial revolution. Documents de travail du Département des Affaires économiques de l’OCDE, 2023.

- JI Y, CHI Z, YUAN S. Development and Application of Hydrogen-Based Direct Reduction Iron Process. Processes, 2024, 12(9): 1829.

- Pei,M. Toward a fossil free future with HYBRIT:Development of iron and steelmaking technology in Sweden and Finland.Metals 2020 ,10(7),972.

- Duarte,P. Trends in H2-based steelmaking.Steel Times Int. 2019 ,43(1),27–32.

- Lechtenböhmer,S. Climate innovations in the steel industry.REINVENT Deliverable 2018 ,2.

- Baowu Steel. Million-ton hydrogen-based shaft furnace ignition and commissioning.Baowu Group,Shanghai,China,2023.

- China Iron&Steel Research Institute Group. New progress:Development and application of pure hydrogen metallurgy technology.Beijing,China,2024.

- Li,F.;Chen,M.;Tang,J.;Liu,Z.Environmental impact analysis of hydrogen shaft furnace-electric furnace process.China Metallurgy 2021 ,31(09),104–109.

- Li,F.;Chen,M.;Tang,J.;Liu,Z.;Zhou,Y.Environmental performance analysis of coal gasification-shaft furnace-electric furnace process and BF-BOF process based on life cycle assessment.J. Iron Steel Res. Int. 2020 ,32(07),577–583.

- User,S.Short-process revolution:Global direct reduction iron production technology status and prospects.2014. Available online: http://www.ral.neu.edu.cn/2014/1223/c4423a89076/page.htm (accessed on 24 January 2025).

- Xie,Q. ;Wu,J.;Zhu,J.Design of unmanned scrap charging system in intelligent steelmaking workshop. Metallurgical Industry Automation 2022, 46(S1), 427–432. [Google Scholar]

- Hu,Y. ;Yang,J.;Zhou,X.;Peng,S. Similarity comparison of scrap based on Siamese neural network. Metallurgical Industry Automation 2024, 48(05), 67–72. [Google Scholar]

- Ding,C. ;Xu,S.;Chang,R.;Jiang,F.;Long,H.;Yu,Z. Application of plasma reduction technology in metallurgical processes. J. Iron Steel Res. Int. 2024, 36(05), 568–579. [Google Scholar]

- Rao,W. ;Wang,W.;Cai,F.;Yang,J.;Li,W. Zero carbon metallurgy process energy supply and energy use technology and equipment development. Shanghai Energy Conservation 2022, (11), 1436–1446. [Google Scholar]

- Liu,Y. ;Yang,J.;Liu,J. Dynamic scheduling method of optical storage power generation resources based on intelligent algorithm. Computer Simulation 2020, 37(12), 53–57. [Google Scholar]

- Gong,M.;Zhang,S.;Zhao,G. Application and practice of digital system in modern steelmaking workshop.China Foundry Machinery&Technology 2019 ,54(01),68–71.

- Deng,Y.;Liu,R.;Liu,X.;Li,A.;Li,T. Erosion process of carbon brick in hearth and control of interface reaction based on AHP.Iron&Steel 2020 ,55(08),175–180+186.

- HBIS Xuanhua Technology successfully develops green high-end materials using short-process route. Jiangxi Building Materials 2023, (06), 328.

- Scipolo,V.;Zuliani,D. Industry 4.0 leading to the evolution of intelligent EAF steelmaking.In AISTech 2018 Conference Proceedings,Philadelphia,PA,USA,2018.

- Pei,Z. The high efficiency and intelligence of modern EAF steelmaking. Hebei Metallurgy 2022, (06), 1–6. [Google Scholar]

- Emi,T. Steelmaking technology for the last 100 years:Toward highly efficient mass production systems for high quality steels.ISIJ Int. 2015 ,55(1),36–66.

- Zheng,C. ;Li,Q.;Zhang,H. R&D and application of intelligent one-key unmanned steelmaking system. Industrial Metrology 2024, 34(04), 66–71. [Google Scholar]

- Song,B.;Wang,J.;Shi,S. Industrial practice of smart steelmaking model.Henan Metallurgy 2021 ,29(04),40–43+56.

- Feng,J. ;Wang,J.;Liu,J.;Guo,N.;Wang,Y. Review of converter flue gas waste energy recycling technology. Science Technology and Engineering 2023, 23(17), 7183–7193. [Google Scholar]

- Hu,Y.;Zhang,H.;Qi,P.;Ding,L.;Qian,L.;Long,H. Effect of adding steel plant sludge into sintering process on flue gas and production quality.Iron&Steel 2024 ,59(12),152–161.

- Yang,J. Analysis on utilization of converter gas under dual-carbon target.Metallurgy and Materials 2024 ,44(05),46–48.

- Yu,A. ;Li,Z.;Xie,X.;Liu,Y. Research status and future prospect of carbon capture technology using steel slag in the context of carbon neutrality. Chinese Journal of Engineering 2025, 47(03), 562–571. [Google Scholar]

- Xing,W. Collaborative treatment and comprehensive utilization technology of copper-containing sludge combined with heating solid waste.World Nonferrous Metals 2024 ,(08),14–16.

- Du,J.;Wang,X.;Wang,J.;Zhao,A.;Mao,Z.;Kang,Z.;Cai,H. Study on product distribution regulation of non-thermal plasma CH4-CO2 reforming.Low-Carbon Chemistry and Chemical Engineering 2024 ,1–7.

- Han,R.;He,Q.;Zhang,Z.;Sun,Y.;Qiao,Z. Coupling machine learning with high-throughput computing study the structure-performance correlation of hydrophobic MOFs for membrane-based CO2/C2H2 separation.Membr. Sci. Technol. 2025 ,1–10.

- Yu,G. Research progress of polymer membrane separation materials in the field of natural gas desulfurization and decarbonization.Chemical Engineering of Oil&Gas 2025 ,1–14.

- Wang,X. ;Ma,Q.;Song,Z. Equipment selection and application of heat recovery system of a 90t EAF. Ind. Heat. 2019, 48(04), 48–52. [Google Scholar]

- Guo,J. ;Deng,W. Design and application of dust removal and waste heat recovery system for 70 t electric arc furnace. Ind. Heat. 2016, 45(01), 55–57. [Google Scholar]

- Chunyan,L. Current situation and optimal and improvable direction of waste heat heating in Laiwu Steel. Metallurgical Power 2022, (01), 78–83. [Google Scholar]

- Shen,Z. Waste heat recovery technology of electric furnace steelmaking. Hebei Metallurgy 2020, (S1), 87–89. [Google Scholar]

- Kohle,S. Improvements in EAF operating practices over the last decade.In Proceedings of the 57th Electric Furnace Conference,Pittsburgh,PA,USA,1999.

- Biryukov,A.B. Сoвременныетехнoлoгиипредварительнoгoпoдoгревалoмапередпoдачейвдугoвуюсталеплавильнуюпечь[Modern technologies for preheating scrap before feeding into electric arc furnaces].Ferrous Metallurgy.Bulletin of Scientific,Technical and Economic Information 2021 ,77(7),782–790.

- Conejo,A.N. Electric Arc Furnace:Methods to Decrease Energy Consumption. Springer:Cham, Switzerland,2024.

- Southern African Institute of Mining and Metallurgy. Journal of the Southern African Institute of Mining and Metallurgy 2006.

- Kobe Steel. Danieli completes spooler line modernization.Press Release,Kobe,Japan,2020.

- Kurecki,M. Recycling perspectives of electric arc furnace slag in the United States:A review.Steel Res. Int. 2024 ,2300854.

- Arribas,I. Electric arc furnace slag and its use in hydraulic concrete. Constr. Build. Mater. 2015, 90, 68–79. [Google Scholar] [CrossRef]

- Yang,L. ;Xu,B.;Song,J.;Wei,G.;Guo,Y.;Xie,X.;Liu,Q. Real-time prediction model of slag composition in electric arc furnace steelmaking. Chinese Journal of Engineering 2020, 42(S), 39–46. [Google Scholar]

- Yi,H. An overview of utilization of steel slag. Procedia Environ. Sci. 2012, 16, 791–801. [Google Scholar] [CrossRef]

- Yokoyama,S. Influence of amount of oxidizing slag discharged from stainless steelmaking process of electric arc furnace on elution behavior into fresh water. In Journal of Physics:Conference Series; IOP Publishing: Bristol, UK, 2012. [Google Scholar]

- Liu,M.K. Preparation of black ceramic tiles using waste copper slag and stainless steel slag of electric arc furnace.Materials 2020,13(3).

| Technology Name | Description | Industrial Maturity |

|---|---|---|

| 3R Carbon-Hydrogen BF Technology [9] | Recirculates reducing gases from furnace gas and enhances reduction via carbon-hydrogen coupling, reducing coke consumption | Pilot stage (partial demonstration) |

| Top Gas Recycling & Full-Oxygen Smelting [10] | Injects hydrogen-enriched gas after CO2 separation and reduces coke ratio through full-oxygen blast | Demonstration stage (under validation) |

| Fluxed Pellets & Composite Iron Coke [11] | Replaces traditional sinter with low-carbon burden to reduce flux demand | Small-scale application |

| Hydrogen-Blended Injection [12] | Co-injects hydrogen with natural gas/pulverized coal to progressively replace fossil fuels | Pilot stage (exploratory development) |

| High-Grade Ore & Pellets [13] |

Reduces sintering energy consumption by adopting high-grade ore and pellets | Gradual adoption (partial industrial use) |

| Biomass Fuel Substitution [14] |

Substitutes coke breeze/anthracite with charcoal/biomass to reduce fossil carbon reliance | Limited pilot trials |

| Plasma Blast Heating [15,16] |

Enhances blast temperature using green electricity-driven plasma to lower coke demand | Demonstration stage |

| Project Name | BF Volume (m³) | Pellet Ratio | Fuel Ratio (kg/t HM) |

Coke Rate (kg/t HM) |

Productivity (t/(m³·d)) | Carbon Reduction (Baseline) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Shougang Jingtang No.1 |

5,500 | >50% | 510 | 264 | 2.15 | 18% (CN: 1.8 tCO2/t HM) [19] |

||||

| Tangsteel No.2 | 2,922 | 40% | 510 | 313 | 3.066 | 12% (CN baseline) | ||||

| SSAB Sweden | 1,800 | ~100% | 457 (H2-DRI) | — | 3.5 | 35% (EU: 1.6 tCO2/t HM) | ||||

| U.S. Great Lakes | 1,645 | 92% | 430 (coke+coal) | 270 | 2.31 | 22% (NA: 1.7 tCO2/t HM) | ||||

| Kobe Steel No.3 | 4,850 | 100% | 497 | 275 | 2.91 | 25% (JP: 1.5 tCO2/t HM) | ||||

| Project Name | Technical Highlights | Advantages | Limitations | Distinctive Features | ||||||

| Shougang Jingtang No.1 | High O2 (7.3%), top pressure 277 kPa, blast 8,300 m³/min [20] |

Gas utilization 49%~50%, stable Si <0.3% |

Pellet strength >3,200 N, cost +10% | Blast energy 140 kJ/s, Zn <160 g/t | ||||||

| Tangsteel No.2 | Tuyere area 0.4051 m², blast temp. 1,220°C, slag Al2O3 <16.5% |

Slag/HM 210 kg/t, HM temp. >1,500°C [18] | RDI fluctuation ±5% [21] |

Fluxed pellet RDI+6.3 >90%, MgO/Al2O3 0.5~0.55 | ||||||

| SSAB Sweden | Full-pellet, TFe >66.8%, slag 146 kg/t |

Flue gas -28%, HM cost -€15/t |

Pellet energy +20% | Slag FeO <0.5%, S <0.02% [17] |

||||||

| U.S. Great Lakes | Fluxed pellets (52%), slag <200 kg/t |

Flux -40%, HM cost -$8/t |

Heat load ±10°C adjustments | Basicity (CaO/SiO2) 1.2~1.5 |

||||||

| Kobe Steel No.3 | Coke interlayer, O2 >8%, flame 2,250~2,400°C | ΔP -15%, Temp. error ±20°C |

Basicity ±0.1 (limestone needed) | Coke layer 80~100 mm, permeability +12% [17,22] | ||||||

| Company | Process Type | Scrap Ratio | Key Technical Support | Carbon Reduction Effect | Cost Change | Applicable Scenarios |

|---|---|---|---|---|---|---|

| Tangsteel | BF-BOF Synergy | 10% [23] | Direct scrap charging + hot metal ladle preheating | 6% reduction in CO2/t steel |

5.8% lower hot metal cost | Abundant hot metal, retrofit constraints |

| JFE Steel | BOF-SMP Process | 35% [24] | Scrap pre-melting + secondary combustion oxygen lance |

15% reduction in CO2/t steel |

12% lower fuel cost | Scrap availability, upgrade-capable equipment |

| ThyssenKrupp | BOF-Jet Process | 40% | Natural gas injection preheating + dynamic thermal model [25] | 18% reduction in CO2/t steel |

5%~9% higher profit/t steel | Carbon tax >$50/t |

| NuCOr | EAF-BOF Hybrid | 86% | EAF scrap melting + DRI blending [26] | 78% reduction in CO2/t steel |

10%~15% lower cost/t steel | Green power access, stable DRI supply |

| Danieli Q-One | 100% Scrap EAF | 100% | Oxy-fuel burners + carbon powder injection | Near-zero carbon (green power) | >500 kWh/t power consumption | Zero-carbon steel certification required |

| Technology Name | Core Function | Application Maturity |

|---|---|---|

| Sub-lance/Online Detection [28] | Real-time monitoring of molten steel composition and temperature to optimize smelting rhythm | Widely adopted |

| Coolant Control [29] | Precise regulation of furnace temperature and molten steel composition stability | Mature application |

| Endpoint Prediction Model (AI) [30] | Machine learning-based prediction of smelting endpoint parameters | Promotion and validation phase |

| Digital Twin & Simulation [31] | Virtual production line modeling for process optimization | Promotion and validation phase |

| RH Vacuum Degassing [32] |

Efficient removal of gases and inclusions in steel | Mature application (high-grade steel) |

| LF Refining [33] | Fine-tuning of temperature/composition and inclusion control | Widely adopted |

| CAS-OB [34] | Rapid alloy adjustment and temperature boosting | Mature application (small-medium mills) |

| CO2 as Oxidizer [35,36] |

Replaces O2 for decarbonization, desiliconization, and demanganization, reducing oxygen content | Industrial trial stage |

| CO2 as Stirring Gas [37,38] |

Enhances bath stirring, improves composition homogeneity, lowers nitrogen content | Industrial adoption phase |

| CO2 as Protective Gas [39,40] |

Continuous casting protection and ladle covering to suppress reoxidation and nitrogen pickup | Industrial trial stage |

| CO2 Temperature Control & Dust Suppression [41,42] | Reduces localized temperature, minimizes metal evaporation, and suppresses dust generation | Laboratory research stage |

| Country | Company/Project | Technical Features & Outcomes | Key Data & Emission Reduction |

| China | HBIS Handan 120t BOF Project | Optimized bottom tuyere layout enhances stirring; external trunnion design simplifies structure, enabling high gas flow rates | Carbon-oxygen product: 0.0026 [43]; Bottom-blowing lifespan matches furnace campaign; Energy consumption reduced by 10% |

| China | Ansteel | Patented bottom-blowing components (eccentric gas ducts + bent nozzles) widen injection angles, improving bath dynamics | Enhanced process visibility; Smelting efficiency +15%; Oxygen consumption -10% [44] |

| China | JISCO Group | High-intensity CO2 bottom-blowing (0.21 m³/(t·min)) with N2/Ar switching optimizes final steel composition | Final nitrogen content <20 ppm; De-phosphorization rate +8%; CO2 emissions -15% [45] |

| China | Baosteel | Annular-gap swirling bottom-blowing device with multi-layer sleeve design enhances gas flow, reducing inclusions [46] | Steel cleanliness +20%; Slag volume -30%; Dust emissions -25% [47] |

| Germany | ThyssenKrupp | O2-CO2 hybrid bottom-blowing with off-gas recycling optimizes slag oxidation | Annual CO2 reduction: 2 million tonnes [48]; Gas consumption -20%. |

| Japan | Nippon Steel | O2-CO2 bottom-blowing + CaO optimization reduces final oxygen content and boosts de-phosphorization | De-sulfurization rate +10%; Final nitrogen content -20% [49] |

| Europe | ThyssenKrupp Decarb Project | Produces low-carbon steel via EAF technology, reducing emissions by 70% and driving green supply chains | CO2 emissions -70%; Applied in Volkswagen’s supply chain [48] |

| Technology Name | Core Function | Application Maturity |

|---|---|---|

| CO2-O2 Mixed Injection Dephosphorization [50,51] | Optimizes thermodynamic conditions for dephosphorization, improving efficiency | Industrial trial stage |

| CO2 in AOD Furnace Decarburization [52,53] | Utilizes CO2’s weak oxidation to selectively decarburize stainless steel, reducing Cr loss | Industrial adoption phase |

| CO2-Enhanced EAF Smelting [54] | Suppresses metal evaporation in arc zones via CO2 injection, lowering electrode consumption | Industrial trial stage |

| CO2-CCUS Integration [55] | Captures and reuses steel plant off-gas CO2 in steelmaking, forming a carbon loop | Demonstration project stage |

| Dynamic CO2 Injection Control Model [51] |

Adjusts CO2 flow in real-time based on bath sensor feedback to optimize decarburization rate | Laboratory research stage |

| CO2 for RH Refining Oxygen Control [56] |

Replaces partial Ar with CO2 in vacuum degassing to reduce molten steel oxygen content | Industrial trial stage |

| CO2-Powder Injection Synergy [57] | Uses CO2 as carrier gas for desulfurizers (CaO/Mg), enhancing interfacial mass transfer | Laboratory research stage |

| CO2 Inclusion Removal [58] | Generates dispersed CO bubbles via CO2 reactions to adsorb micro-inclusions | Theoretical validation stage |

| Company/ Project |

Technical Pathway & Process Features | Emission Reduction & Efficiency Data | Economic Benefits & Costs |

|---|---|---|---|

| Shougang Jingtang Lime Kiln CCUS Project (China) | Physical adsorption (PSA) + waste heat cascade utilization | Annual capture: 50,000 t; CO2 concentration: 15%~20% → 99%; steelmaking energy consumption reduced by 3%~5%, argon use reduced by 30% [59] |

Total investment: 120 million CNY; annual benefits: 8 million CNY; carbon reduction cost: ~240 CNY/t |

| Japan COURSE50 Project (Nippon Steel) |

BFG PSA (zeolite/activated carbon adsorption) + hydrogen reduction |

Capture rate: 80%; full-process emission reduction: 30% (lab); pilot plant captures 100,000 t/year [59] | Hydrogen reduction cuts coke reliance by 15%; carbon reduction cost: ~55 USD/t steel [60] |

| TISCO BFG CCUS Project (China) |

Chemical absorption (MEA solvent) + water washing desulfurization | Annual capture: 100,000 t; energy consumption: 2.8 GJ/t; purity: 99.9%; dry ice production: 30 million CNY/year |

Total investment: 250 million CNY; carbon reduction cost: ~40 USD/t |

| Elkem Ferrosilicon CCUS Project (Norway) | Chemical absorption (high-concentration CO2 capture) + geological storage |

Annual capacity: 1.5 Mt; capture rate: 95%; ferrosilicon carbon intensity reduced by 60% [61] | Norwegian government funding: 16 million NOK; storage cost: ~50 EUR/t; reuse revenue: 12 million EUR/year [62] |

| Petra Nova Coal Plant CCUS (USA) |

Amine-based absorption (KM-CDR process) | Annual capture: 1.4 Mt CO2; EOR boosts oil production by 15,000 barrels/day [63] |

Total investment: 1billion; EOR revenue: 30/t CO2; payback period: 8 years [64] |

| Technology Name | Core Function | Key Technologies/Methods | Application Maturity |

| Scrap Pretreatment & Sorting [68] | Enhances scrap utilization and reduces impurity impacts | AI visual recognition, magnetic/eddy current separation, high-temperature degreasing, shredding/compaction | Mature application |

| Real-Time Scrap Data Adjustment [69,70] | Dynamically optimizes charging mix and process parameters | Sensor monitoring, IoT, machine learning prediction models | Demonstration & promotion phase |

| Side-Draft Full Preheating [71] |

Recovers waste heat, reduces energy use and pollution | Multi-stage heat exchangers, exhaust gas recirculation (EGR), high-temperature preheating (>1200 °C) | Mature application |

| Dynamic Sealing & Heat Recovery [72] |

Minimizes heat loss and enhances waste heat utilization | Water-cooled flexible seals, regenerative combustion, waste heat power generation | Demonstration & promotion phase |

| Uniform Heating & Intelligent Control [73] | Ensures molten steel quality and reduces energy waste | Multi-electrode layout optimization, electromagnetic stirring, digital twin & AI control | Demonstration & promotion phase |

| Continuous Charging Optimization [71] | Enables continuous production and shortens smelting cycles | Twin-shell design, Consteel continuous charging, scrap preheating synchronization | Demonstration & promotion phase |

| Green Power Direct Supply & Storage [74,75] | Reduces carbon emissions and stabilizes power fluctuations | Wind/solar PPA, molten salt/battery storage, microgrids | Pilot application phase |

| Project | Country/Region | Technical Highlights | Investment Scale | Key Performance Indicators (Energy Saving/Emission Reduction) |

| ArcelorMittal Belgium Plant | Belgium | Scrap preheating system + waste gas recovery | €100 million | Energy consumption reduced by 12% (electricity)CO2 emissions reduced by 15% (1 million tonnes/year)Scrap ratio increased to 75% (from 60%) [76] |

| Nucor Arkansas Retrofit | USA | High-efficiency EAF design + renewable energy supply (solar/wind) | $200 million | Energy consumption reduced by 11% (400 kWh/t steel)CO2 emissions reduced by 20% (2 million tonnes/year)Scrap ratio increased to 85% (from 65%) [77] |

| Baosteel Changxing Retrofit | China | EAF + secondary refining technology + increased scrap ratio | ¥1 billion | Energy consumption reduced by 10% (450 kWh/t steel)CO2 emissions reduced by 18% (150,000 tonnes/year)Scrap ratio increased to 70% (from 55%) [78] |

| Nippon Steel Kobe Gas Recovery | Japan | Waste gas recovery for scrap preheating + oxygen-enriched combustion | $600 million | Energy consumption reduced by 12% (electricity)CO2 emissions reduced by 15% (1.3 million tonnes/year)Scrap ratio maintained at 80% [79] |

| Project | Advantages | Challenges | Distinctive Features |

| ArcelorMittal (Belgium) | Mature heat recovery technology; high scrap utilization rate (75%) | Difficulty in scrap impurity control; reliance on imported scrap | Representative of Europe’s circular economy model; policy-driven retrofitting |

| Nucor (USA) |

High green power integration (solar/wind); world-leading scrap ratio (85%) | Geographically constrained green power supply (limited replicability in low-resource areas) | Deep market-driven integration of renewables and steel production |

| Baosteel (China) | Advanced secondary refining technology; suitability for large-scale production | Underdeveloped scrap recycling system (low domestic scrap quality/poor sorting) | Indigenous technology development path; policy -backed under China’s “Dual Carbon” goals |

| Nippon Steel (Japan) | High waste gas recycling rate (scrap preheating + oxygen enrichment); precision processes | High upgrade costs ($600 million); unaffordable for SMEs | Exemplar of resource efficiency; embodies lean manufacturing culture |

| Company | Year | Technology/ Application |

Key Metrics/Performance | Application Case |

|---|---|---|---|---|

| MCC-CISDI | 2021 | World’s first IGBT DC EAF |

30%~40% CO2 reduction per tonne of steel |

Panzhihua Special Steel Project |

| MCC-CISDI | 2022 | Domestic stepwise continuous charging EAF |

35-minute smelting cycle | Sichuan Dujiangyan Steel Project |

| MCC-CISDI | 2023 | First industrial-scale “Super EAF” | Target smelting energy consumption: 300 kWh/t | Yunnan Yuxi Xianfu Project |

| SMS Group | 2021 | Twin-shaft DC EAF (China’s first) | 45% reduction in smelting energy consumption |

HBIS Shisteel New District |

| SMS Group | 2024 | World’s largest AC EAF (185t, 300 MVA) | Supports 80% DRI hybrid smelting; annual output: 1.9 Mt molten steel | Saarstahl AG, Germany |

| Danieli | 2023 | Q-ONE Lossless EAF Power System |

Reduced power loss, improved energy efficiency | Commercial Metals Company, USA |

| SPCO (Japan) | — | ECOARC Ecological EAF |

Fully enclosed scrap preheating; dioxin emissions <0.1 ng TEQ/m³ | Benxi Steel Application |

| Primetals | — | Ultimate EAF (120t) | 40 heats/day; 10% energy reduction | NSMMZ Steel Plant, Russia |

| Thyssen & SMS | 2026 | Midrex H2-DRI + EAF Hybrid Plant (Planned) | Annual DRI output: 2.5 Mt | Duisburg, Germany (Planned) |

| Voestalpine | 2026 | Hyfor-EAF (Hy4Smelt Pilot) |

Pilot scale: 3 t/h; commercialization plan: 2.5 Mt/a | Based on Primetals Technologies |

| POSCO | 2028 | HyRex Fluidized Bed DRI + EAF Process | Fluidized bed DRI technology under pilot validation | Developed from FINEX Process |

| Tenova | — | iBlue (Enerqiron DRI + OSBF EAF) | BF alternative with cost advantages over DRI-EAF routes | Technical feasibility study phase |

| BHP & Hatch | 2023 | EAF Pilot Plant | Annual capacity: 10,000 t; informs decision-making for Australian facilities | Australia (Joint Design) |

| BHP, Rio Tinto & BlueScope | 2024 | ESF Process Development | Joint development of EAF-based smelting technology | Collaborative Framework Agreement |

| Rio Tinto & China Baowu | 2023 | Pilot-Scale EAF | Produces DRI from mid/low-grade iron ore fines for low-carbon steel | Baowu Demonstration Project (Planned) |

| Company | Type | Technical Features | Advantages | |||

|---|---|---|---|---|---|---|

| CISDI | Super EAF (IGBT Flexible DC) | Dual-electrode DC power supply, continuous scrap preheating, dioxin control via flue gas diversion, intelligent electrode adjustment |

30-minute smelting cycle; 40% lower electrode consumption; 160 kg/t steam recovery from waste heat | |||

| Primetals Quantum EAF | Shaft Preheating EAF | Fully automatic charging, finger scrap retention system, bottom-blown stirring | Flexible feedstock (0%~100% scrap/DRI); 15 dB noise reduction | |||

| Tenova Consteel | Continuous Charging EAF | Horizontal scrap conveyor + flue gas preheating, dynamic sealing, smart slag foaming |

Adapts to low-density scrap; 50% reduction in grid impact [83] | |||

| Danieli Q-ONE | Quantum EAF | Electromagnetic stirring + ultrasonic detection, AI dynamic model, scrap-DRI co-preheating |

Endpoint carbon control precision ±0.02% [85]; 2% higher metal yield | |||

| SMS Group | Intelligent EAF | Multi-sensor fusion (infrared + laser), digital twin system, CO2 injection denitrification |

Nitrogen content <60 ppm; dioxin emissions <0.1 ng TEQ/m³ | |||

| Japan NKK DC EAF | Dual-Electrode DC EAF | Water-cooled bottom anode, stepwise charging, bottom argon blowing | Suitable for high-alloy steel; 70% harmonic pollution reduction |

|||

| Company | Emission Reduction | Energy Savings | Cost-Saving Case | |||

| CISDI | 30%~40% reduction vs. conventional EAF |

300 kWh/t steel (industry-leading) | Panzhihua Special Steel Project saves ¥20 million/year in electricity costs [80] | |||

| Primetals Quantum EAF | <500 kg CO2/t steel [81] | 350 kWh/t steel | Tyasa Mexico achieves 25% higher smelting efficiency [82] |

|||

| Tenova Consteel | 20%~30% reduction vs. conventional |

>70% waste heat utilization [84] |

Nucor USA reduces 35% electrode consumption |

|||

| Danieli Q-ONE | Up to 80% reduction with H2-DRI |

25% lower oxygen consumption | Erdemir Turkey reduces $8.5/t steel cost |

|||

| SMS Group | Optimal green power adaptation |

40% lower natural gas use | Salzgitter Germany cuts 18% maintenance costs | |||

| Japan NKK DC EAF | 60% reduction vs. BF-BOF | Electrode consumption <1.2 kg/t [86] |

Nippon Steel improves 30% production rhythm | |||

| Country | Project/Enterprise | Technology Applied | Implementation Method | Energy Saving & Emission Reduction Effects |

|---|---|---|---|---|

| Sweden | HYBRIT Project (SSAB) | Green Hydrogen- EAF Steelmaking |

Hydrogen production via water electrolysis | >90% CO2 reduction; targets 1 Mt/year green steel; requires ~70,000 m³/h electricity [87] |

| Germany | Thyssenkrupp | Hydrogen-based DRI-EAF | Green power and hydrogen for steel production |

4.9 kWh/t steel; 0.75 kg CO2/kg steel by 2040 [88,89] |

| Australia | Green Steel Project | Green Hydrogen DRI-EAF | Optimized wind-solar hybrid hydrogen production | 1.2~2.7 GW renewables + 200~400 MW electrolyzer per Mt steel; cost: AUD 900/t (2030), AUD 750/t (2050) [89] |

| China | Baowu Zhanjiang Demo Line | Solar/Wind- Powered EAF |

Green electricity for EAF operations | 20%~90% CO2 reduction per tonne steel [90,91] |

| Australia | Economic Fairways | Wind/Solar-to- Hydrogen for EAF |

Renewable hydrogen integration | Replacing 1% global steel output requires 35 GW renewables, 11 GW electrolyzers; >85% indirect emission reduction [92] |

| EU | Low-Carbon Transition Project | EAF with Green Hydrogen DRI | Hydrogen-centric decarbonization | 25% direct CO2 reduction by 2030; additional 20 TWh power and 40 TWhHHV hydrogen demand [93] |

| USA | Nucor Arkansas Plant | 100% Scrap-EAF + Green Power | Solar farm + storage (1.8 TWh/year) | 300-tonne EAF; 3 Mt/year output; 85% green power share (2025 target) [94] |

| Project | Technology | Scale/Case | Advantages | |||

|---|---|---|---|---|---|---|

| MIDREX H2 | Natural gas reforming (H2>90%); metallization >94% [95] | Boden Plant, Sweden (2.1 Mt/year) |

Fully replaces blast furnaces; 0.04 t CO2/t steel | |||

| HYBRIT | Wind-powered H2 + EAF; targets 25 kg CO2/t steel | Pilot in Sweden (industrial by 2035) | Fossil-free lifecycle; 95% emission reduction potential | |||

| SALCOS | Waste heat-to-H2 (GrInHy 2.0); targets 95% reduction [98] | Germany test (40 Nm³/h H2) |

>80% waste heat utilization; 3.5 kWh/Nm³ H2 production [99] |

|||

| Baowu Zhanjiang | Hybrid gas (57% NG +13% H2); Inconel 625 alloy tubes | China (1 Mt/year) | 58%~89% CO2 reduction; 30,000-hour tube lifespan | |||

| China Iron & Steel Research | Pure H2 (>95%); 85% waste heat recovery |

Shandong demo plant | 40% lower energy use (8.5 GJ/t iron); 0.138 t CO2/t |

|||

| NEU Pilot Base |

High-grade pellets (TFe>70%, >2500 N/pellet) + H2-EAF short process | Global first 10 kt/year demo line |

<300 kWh/t steel; multi-field coupling theory |

|||

| HYL-ZR | Methane self-reforming (950~1050°C); no external reformer | JSPL Plant, India | 2.8 GJ/t DRI (vs. 3.2 GJ industry avg.); 0.4 t CO2/t | |||

| Project | Challenges | Suitable Regions | Distinctive Features | |||

| MIDREX H2 | Relies on natural gas; green H2 cost (~USD 4~6/kg) |

Gas-rich areas (e.g., North America) |

First 100% H2-DRI plant; highest maturity |

|||

| HYBRIT | High green power demand (4~5 MWh/t steel); 10~15 year industrialization |

Renewable-rich (e.g., Scandinavia) |

Full lifecycle decarbonization; integrates wind-H2-EAF | |||

| SALCOS | H2 storage/transport costs (35% share); immature liquid H2 tech | Industrial clusters (e.g., Ruhr, Germany) |

Waste heat-H2 coupling benchmark | |||

| Baowu Zhanjiang | Low H2 share (13%); fossil fuel dependency |

Coastal renewable hubs (e.g., Guangdong) |

Multi-gas synergy + anti-hydrogen embrittlement materials | |||

| China Iron & Steel Research | DRI reoxidation risk (+USD 20~30/t carburization) |

Stable H2 supply zones (e.g., NW China) |

Pure H2 metallurgy breakthrough; energy efficiency | |||

| NEU Pilot Base | Small scale (10 kt/year); lacks industrial validation |

Specialty steel producers | Short-process integration + pellet innovation |

|||

| HYL-ZR | Carbon deposition (30% higher corrosion); +15%~20% maintenance costs |

Coke-rich regions (e.g., India) |

Simplified process; ideal for coke oven gas reuse |

|||

| Technology | Main Function | Core Technologies |

|---|---|---|

| Fully Automated Scrap Intelligent Batching System [105] | Optimizes raw material ratio to enhance molten steel quality | Machine learning algorithms, multi-source sensor fusion technology |

| Scrap Classification & Impurity Control [106] |

Improves feedstock quality by reducing harmful elements | Machine vision recognition, spectral analysis sorting technology |

| Low-Carbon Metallurgical Process Coupling [107,108] | Achieves energy-process synergy for carbon reduction | Multi-energy coupling modeling, system integration optimization technology |

| Intelligent Power Supply & Energy Management [109] | Optimizes power allocation for energy efficiency | Dynamic scheduling algorithms, energy storage system integration technology |

| Smart & Digital Control Technology [110] | Enhances production automation and real-time optimization |

Industrial IoT platforms, AI-driven process decision systems |

| Short-Process Integration [111,112] |

Shortens production flow to reduce overall energy consumption |

Interface reaction control technology, process reengineering technology |

| Company (Country) | Technical Solution | Key Parameters & Data | Carbon Control & Economic Benefits |

| Nucor (USA) | SHARC DC EAF (150 t/160 MW) Twinshaft scrap preheating (800°C) Supersonic coherent jet oxygen lance (3,500 m³/h) |

Power consumption: 270 kWh/t (decrease18%) Taptotap time: 40 min Electrode consumption: 1.0 kg/t Scrap preheating efficiency: 45% [113] |

35% reduction in CO2 intensity per tonne Annual CO2 reduction: 500,000 t FeO generation decrease30% [114] |

| ECOARC (Japan) | Flat bath AC EAF Ar/N2 bottom stirring (0.5~1.5 Nm³/(min·t)) Offgas scrap preheating (400~800°C) |

Energy consumption decrease22% Dust emissions decrease30% Taptotap time: 45 min Furnace lifespan: 1,000 heats |

Annual coal savings: 120,000 tce FeO in slag decrease15% Arc thermal efficiency increase18% [113,114] |

| Danieli (Italy) | AI stockyard system Machine vision scrap sorting (98% accuracy) IR slag detection (slag thickness ≤35 mm) |

Scrap utilization: 98% Lime consumption decrease15% (baseline: 50 kg/t) Auxiliary materials decrease20% |

28% reduction in CO2/t steel Annual cost savings: $12M Steel purity increase25% [115] |

| HBIS Shisteel (China) | SHARC twinshaft DC EAF (150 t) Ar/N2 bottom blowing (0.8~1.2 Nm³/min) Onetap intelligent smelting system |

Power consumption: 250 kWh/t (decrease25%) Tapping time: 38 min Electrode consumption: 0.95 kg/t Endpoint C deviation: ±0.02% |

Annual CO2 reduction: 300,000 t Total energy consumption decrease25% Manual intervention decrease80% [116] |

| SMS Group (Germany) | Conductive bottom electrode DC EAF Highimpedance circuit design (4~8 mΩ) Arc harmonic suppression technology |

Electrode lifespan: 3,500 heats (increase40%) Electrical efficiency increase12% Harmonic incidence decrease50% |

Electrode consumption decrease40%/t steel Annual power savings: 120 GWh Grid stability: voltage fluctuation ≤5% [114] |

| Sha Steel Group (China) | Static control model Material/heat balance algorithm for slag optimization Endpoint C prediction (±0.02%) |

Lime consumption: 487 kg/t (baseline: 1,200 kg/t) Dolomite decrease683 kg/t Splashing rate decrease90% |

18% reduction in CO2/t steel Iron loss decrease5.63 kg/t Annual savings: ¥8M (auxiliary costs decrease25%) [117] |

| Technology | Primary Function | Core Technology/Method |

|---|---|---|

| Flue Gas Waste Heat Deep Recovery & Utilization [118] | Recovers waste heat from flue gas and converts it into electricity/thermal energy | ORC power generation, absorption heat pump, cascade heat utilization |

| Cooperative Treatment of Flue Gas Pollutants [119] |

Integrated removal of multiple pollutants (SO2, NOx, etc.) | Activated coke adsorption, non-thermal plasma, catalytic oxidation |

| Gas Resource Recovery & Recycling [120] | Purifies and recycles valuable components (H2, CO, etc.) from furnace gas |

Membrane separation, PSA hydrogen purification, syngas conversion |

| Steel Slag Carbonation for CO2 Sequestration [121] | Utilizes steel slag to fix CO2 while improving slag recycling properties | Mineral carbonation (CaO/MgO-CO2 reaction) |

| Co-processing of Solid Wastes [122] |

Synergistic treatment and high-value utilization of multi-source solid wastes | Co-processing in cement kilns, gasification for syngas, building material production |

| Plasma-Assisted Emission Reduction [123] |

Degrades refractory pollutants (dioxins, VOCs, etc.) |

Non-thermal plasma (corona discharge, dielectric barrier discharge) |

| Ultra-Low Energy Membrane Separation [124,125] | High-efficiency separation of target components in gas/liquid streams | MOFs membranes, graphene membranes, mixed-matrix membranes |

| Country | Company/Project | Technical Solution | Key Data & Performance |

|---|---|---|---|

| China | Tianjin Pipe Group (90t EAF Project) | Evaporative cooling system Flue gas heat storage |

Steam output: 242 kg/t steel Annual power generation: 46,000 kWh 5% reduction in power consumption/t steel Annual CO2 reduction: 16,000 t Equipment lifespan extended to >2 years [126,127] |

| China | Laiwu Steel Group Waste Heat Heating System | BF slag flushing water + sintering waste heat recovery | Heating coverage: 5.3 million m² Annual energy cost savings: ¥1.1 million Replaced coal boilers, reducing 3.7 t SO2/year [128] |

| Germany | SMS Group CONSTEEL EAF Project | Continuous scrap preheating Postcombustion technology |

Scrap preheating temp.: 300°C 14% shorter taptotap time [129] Postcombustion rate (PC): 60% 22% lower energy consumption/t steel [130] |

| Japan | Nippon Steel DC EAF System | DC EAF + waste heat boiler power generation | Steam pressure: 2.0 MPa Annual power generation: 8.4 GWh Electrode consumption: 1.1 kg/t 30% reduction in refractory consumption [131] |

| USA | Nucor Crawfordsville Plant | Oxygenfuel burners Hot metal charging (30%) |

Power consumption: 300 kWh/t steel Oxygen supply: 45 m³/t Taptotap time: 50 min [132] |

| South Africa | ISCOR EAF Bottom Blowing Project |

Inert gas bottom stirring Waste heat heating |

Gas flow rate: 0.25~0.3 m³/t 5% lower power consumption Heating coverage: 2 million m² 20% improvement in molten steel homogeneity [133] |

| Italy | Danieli QOne EAF Project |

Fully enclosed design Multistage scrap preheating |

Scrap preheating temp.: 600°C Power consumption: 360 kWh/t steel Dust emissions: <30 mg/m³ EAF lifespan: 2,500 heats [134] |

| Company/Project | Technology Application | Energy-Saving & Emission Reduction Data | Cost Savings Data |

| NucorSteel Brandenburg (USA) | Metal recovery from EAF slag (Cr, V, Mo) |

Annual slag processing: 5~6 Mt; Metal recovery rate: >95%; Reduced iron ore consumption: 1.2 Mt/year |

Value added per tonne slag: 50~80; Annual revenue increase: 300~480M [135] |

| TECNALIA Concrete Substitute Project (Spain) | EAF oxidized slag as concrete aggregate | Aggregate substitution rate: 50%; CO2 reduction: 18%; Energy consumption decrease22% |

Material cost decrease12%; Road construction cost savings: 8% [136] |

| Hengyang Valin Steel Pipe Slag Prediction System (China) | Real-time slag composition prediction model |

Auxiliary material consumption decrease10%~15%; Smelting energy decrease8% |

Annual limestone savings: 12,000 t; Cost reduction: CN¥6M [137] |

| Jinchuan Group DC EAF Project (China) | Selective reduction smelting of Kaldo slag |

Ni/Cu recovery rate: >98.5%; Residual metals in slag: <0.3%; Reduced tailings landfill: 120,000 t/year |

Slag treatment cost decrease35%; Annual high-grade alloy output: 20,000 t; Revenue: CN¥480M [82] |

| ThyssenKrupp Steel Europe AG (Germany) | Magnetic separation & road construction utilization | Slag recycling rate: 94% (70% for road base); Compressive strength: 50 MPa [138] |

Natural aggregate substitution cost decrease25%; Annual raw material savings: €120M |

| Topy Industries Ltd. (Japan) | Slag-based soil amendment | Soil pH increase: 1.5~2.0; Fe utilization efficiency increase40% |

Fertilizer cost decrease30%; Annual lime application reduction: 50,000 t [139] |

| Ceramica S.p.A (Italy) |

Slag-fired ceramic tiles |

Tile water absorption: <2% (40% slag content); Flexural strength: 35 MPa; Heavy metal leaching compliant with EU standards | Production cost decrease20%; Annual eco-tile output: 500,000 m² [140] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).