1. Introduction

The Architecture, Engineering, and Construction (AEC) industry is undergoing a transformative shift driven by the rapid growth of mega-construction projects and the need for multi-project coordination. Large-scale infrastructure programs, such as urban megacomplexes and transportation hubs, require simultaneous management of hundreds of geographically dispersed sites[

1], each with unique safety, quality, and scheduling demands[

2]. Traditional management approaches, reliant on fragmented data systems and reactive problem-solving, struggle to address these challenges. Many studies have proposed digital solutions in improving the efficiency and safety of construction projects[

3]. Siloed workflows, where BIM (Building Information Model), IoT (Internet of Things) sensors, and document management operate independently. This hinder real-time decision-making and lead to inefficiencies in resource allocation, safety compliance, and quality assurance[

4,

5]. For instance, manual inspections and paper-based reporting delay issue resolution, while isolated AI models trained on single-project data fail to generalize across diverse sites[

6].

Current practices in digital construction management focus on single-project applications, where BIM and IoT systems operate in isolation, limiting cross-project learning and optimization[

7]. AI models trained on single-project datasets struggle with generalization due to variability in site conditions, workflows, and regulatory requirements[

8]. Traditional knowledge management systems, reliant on manual documentation and file-based storage, fail to leverage unstructured data from contracts, reports, and sensor networks[

9,

10]. These gaps hinder the development of an integrated ecosystem capable of supporting federated learning, dynamic resource allocation, and intelligent decision-making across multiple projects.

These gaps are particularly critical for large general contractors, such as the authors’ organization, which oversees hundreds of projects annually. The company’s need for real-time, data-driven decision-making stems from escalating industry demands: clients prioritize faster delivery, stricter safety regulations, and cost-effective scalability[

11]. Existing tools, including standalone BIM platforms and ERP (Enterprise Resource Planning) systems, lack interoperability and computational power to synthesize data from thousands of cameras, sensors, and documents across projects[

12,

13]. Consequently, high-level managers face blind spots in monitoring safety violations, equipment utilization, and progress bottlenecks, risking delays and budget overruns[

14,

14].

This paper addresses these challenges by proposing “Building Smarter”, a unified framework that integrates BIM, 5G, IoT and AI technologies to enable scalable, interoperable, and knowledge-driven construction management for large general contractor companies. The framework emphasizes novel infrastructure design, intelligent site management functions, and multi-project federated learning for AI models. By synthesizing advancements in digital twins, and intelligent optimization, this approach aims to bridge the gap between isolated project workflows and holistic, data-driven construction ecosystems for multiple projects. In

Section 3, this paper proposed a multi-project framework of the Building Smarted ecosystem, and detailed method to build the system. Then, in

Section 4, some application cases were analyzed from the perspective of general contractor companies.

Section 5 and 6 provided discussion and conclusions.

2. Literature Review

In single-project contexts, digital construction using BIM, IoT, and AI has been developed for many years[

15]. BIM has revolutionized design coordination and construction monitoring through 3D modeling and simulation[

16]. Integrated with IoT sensors, BIM enables real-time progress tracking, as demonstrated in airport pavement projects using GPS and GIS for material logistics[

17]. AI applications, such as vision-based object detection and activity recognition, enhance safety and productivity by automating quality checks and equipment monitoring[

18]. For instance, RFID and photogrammetry improve prefabricated component tracking[

19]. Virtual reality (VR) and augmented reality (AR), in construction management is an emerging area to increase efficiency and effectiveness[

20]. Mixed-reality platforms integrate BIM with augmented reality for remote bridge inspections[

13]. However, these innovations predominantly operate within single-project silos, limiting their adaptability to multi-project environments[

5]. BIM models are rarely synchronized with IoT data across phases, leading to the decay of digital twin, that is, as-built conditions diverge from designs[

21].

As for multi-project management, existing tools often lack interoperability with BIM and IoT platforms. Blockchain-based frameworks show promise for cross-project document version control[

21], yet their integration with real-time sensor data remains underdeveloped. Existing digital process platforms aim to unify geofencing, equipment tracking, and scheduling[

12], but scalability is constrained by inconsistent data standards and vendor-specific protocols[

23]. The absence of federated learning mechanisms further exacerbates inefficiencies, as AI models cannot leverage shared datasets without compromising data privacy[

6].

Recently AI is widely used in construction industry, and has gain significant benefit through human-free intelligent functions. AI applications ranging from automated scheduling with ChatGPT[

8] to safety helmet detection using CNNs[

24] rely on single-project datasets, leading to overfitting and poor generalization[

11]. For example, vision-based progress monitoring achieves high accuracy in controlled environments but falters under variable lighting or occlusions[

19]. Federated learning, though nascent in construction, offers a solution by enabling collaborative model training across distributed datasets while preserving data privacy[

25]. This approach aligns with Industry 4.0 principles, where edge computing and digital twins enhance predictive maintenance and resource optimization[

26].

Traditional document management systems struggle with unstructured data, such as contracts and inspection reports, which constitute 80% of project knowledge[

9]. Recent advances in NLP, knowledge graph, and large language models (LLMs) automate keyword extraction and semantic analysis[

27], as seen in risk management frameworks for metro projects[

28]. Blockchain ensures data integrity in document workflows, with smart contracts automating approval processes and version control[

29]. However, knowledge circulation across project lifecycles remains fragmented, lacking systematic frameworks for validation and reuse[

30].

Despite progress in individual technologies, the AEC industry lacks integrated ecosystems that unify BIM, IoT, AI, and blockchain into a scalable, interoperable platform[

31]. Current systems fail to address cross-project variability in data formats, regulatory requirements, and stakeholder workflows. Federated learning and intelligent optimization are underexplored in multi-project contexts, while knowledge management remains reliant on manual interventions[

10]. Bridging these gaps requires a holistic framework that prioritizes data standardization, secure interoperability, and collaborative AI training.

3. Methodology: The Building Smarter Ecosystem

3.1. Design of the Ecosystem

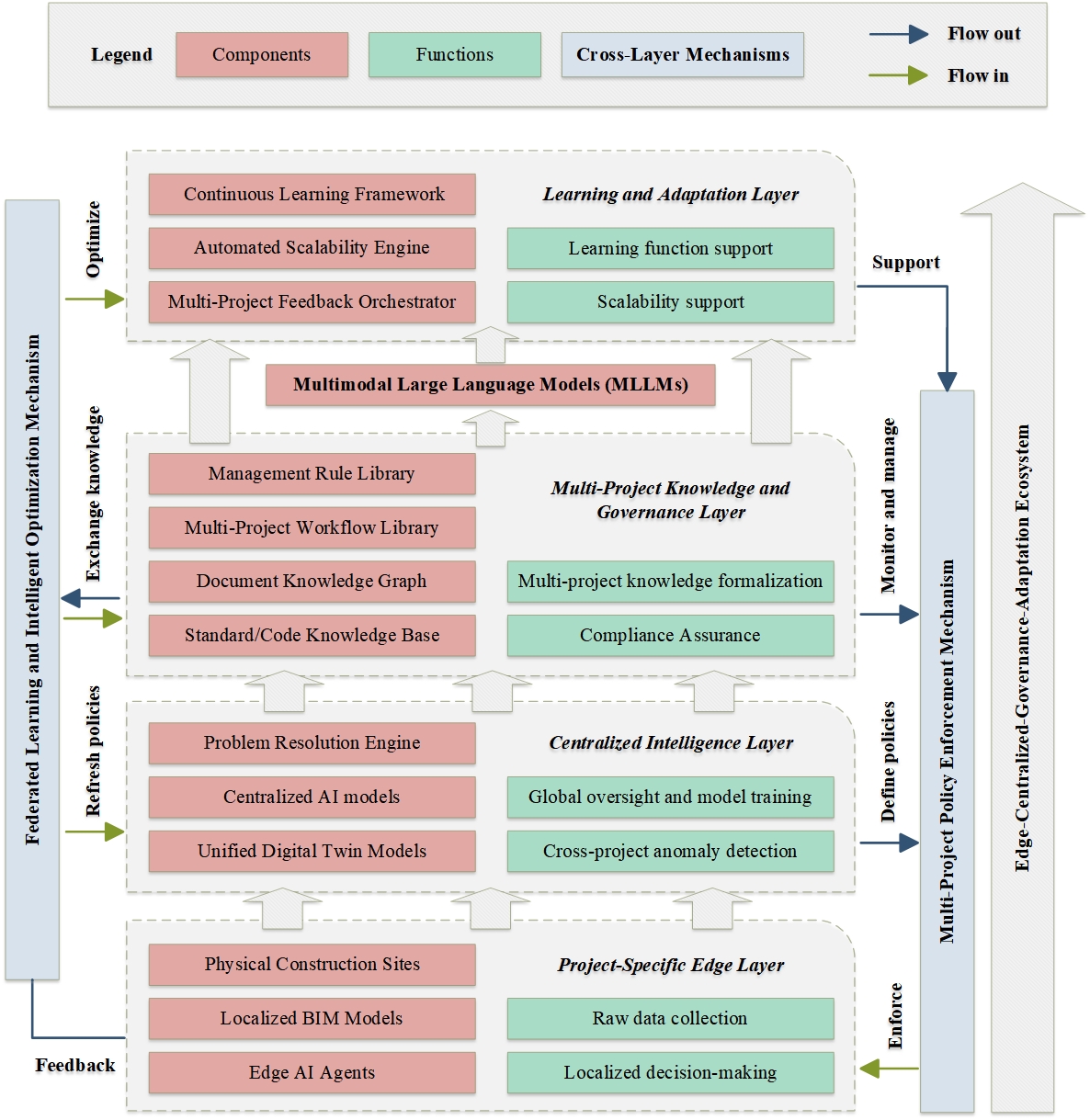

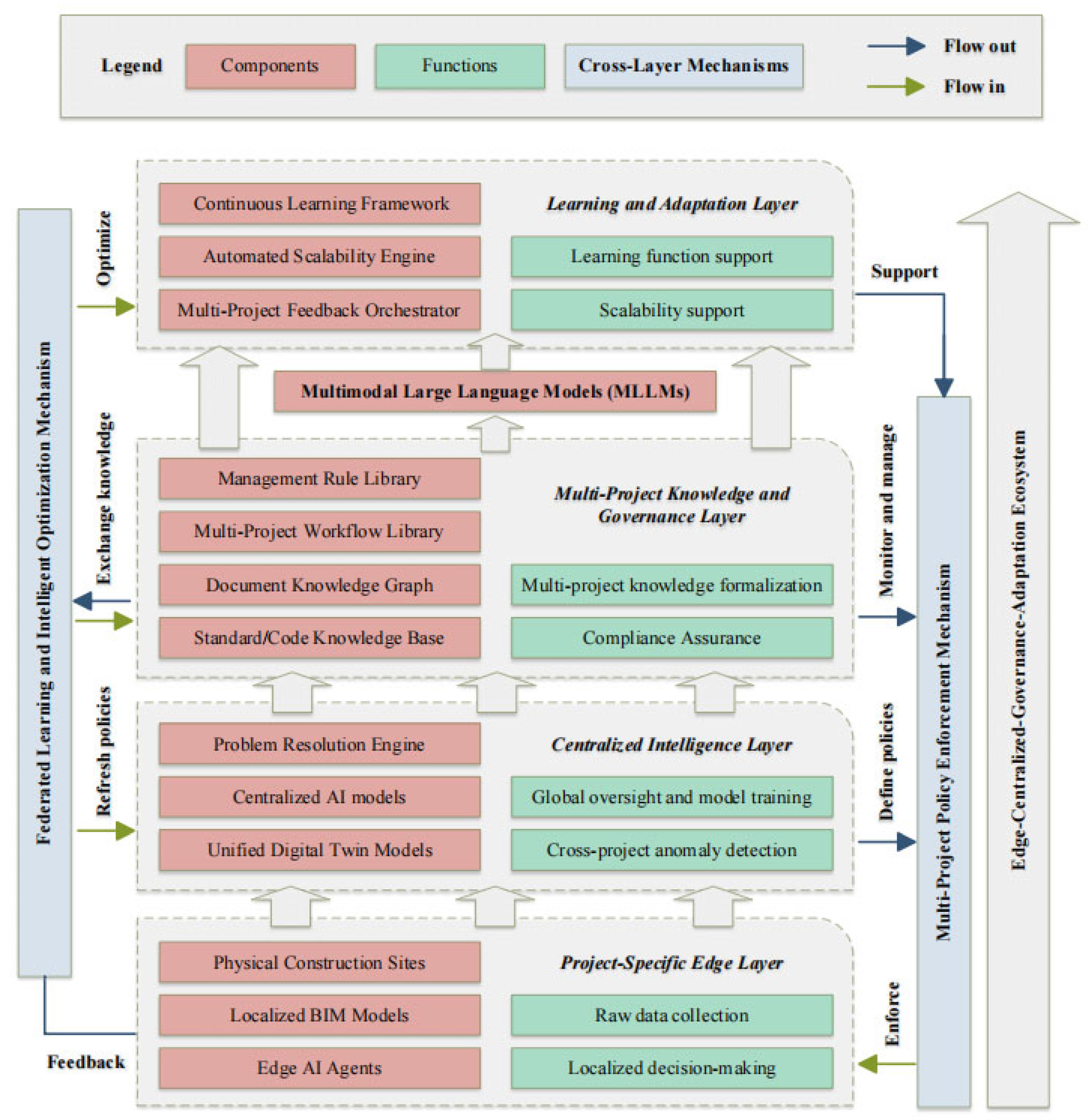

The proposed framework of Building Smarter is called “Multi-Project Intelligent Construction Ecosystem (MP-ICE)”, which adopts a hierarchical, four-layer architecture to unify dispersed construction projects into a scalable, self-optimizing network (see

Figure 1). This architecture connected isolated projects through mechanisms.

At the foundation, Project-Specific Edge Layer equips individual sites with IoT sensors, localized BIM models, and edge AI agents to capture real-time data and execute immediate tasks such as safety monitoring. This data feeds into Centralized Intelligence Layer, where a unified digital twin hub synthesizes multi-project inputs, deploying AI models for anomaly detection, predictive analytics, and task assignment. Above this, Cross-Project Knowledge and Governance Layer institutionalizes ecosystem-wide intelligence through federated datasets, reusable workflows, and a rich knowledge graph based on documents, ensuring standardized policies and rapid access to multiple project insights. At the top, Learning and Adaptation Layer enables autonomous scalability via meta-learning frameworks and automated deployment engines, while feedback orchestrators convert on-site resolutions into systemic improvements. The multimodal LLM (MLLMs, extends traditional LLM by processing multiple data types such as text, images, audio, video to enable cross-modal understanding, generation, and interaction) was properly trained, and then serves as an important intermediate service component between the knowledge layer and the learning layer. Critically, there are two main cross-layer mechanisms: Multi-Project Policy Enforcement Mechanism and Federated Learning and Intelligent Optimization Mechanism, binding four layers into a cohesive ecosystem by information or function flows. The framework ensured that knowledge, AI models, and best practices evolve collectively, reducing marginal costs for new projects.

3.2. Foundational Infrastructure

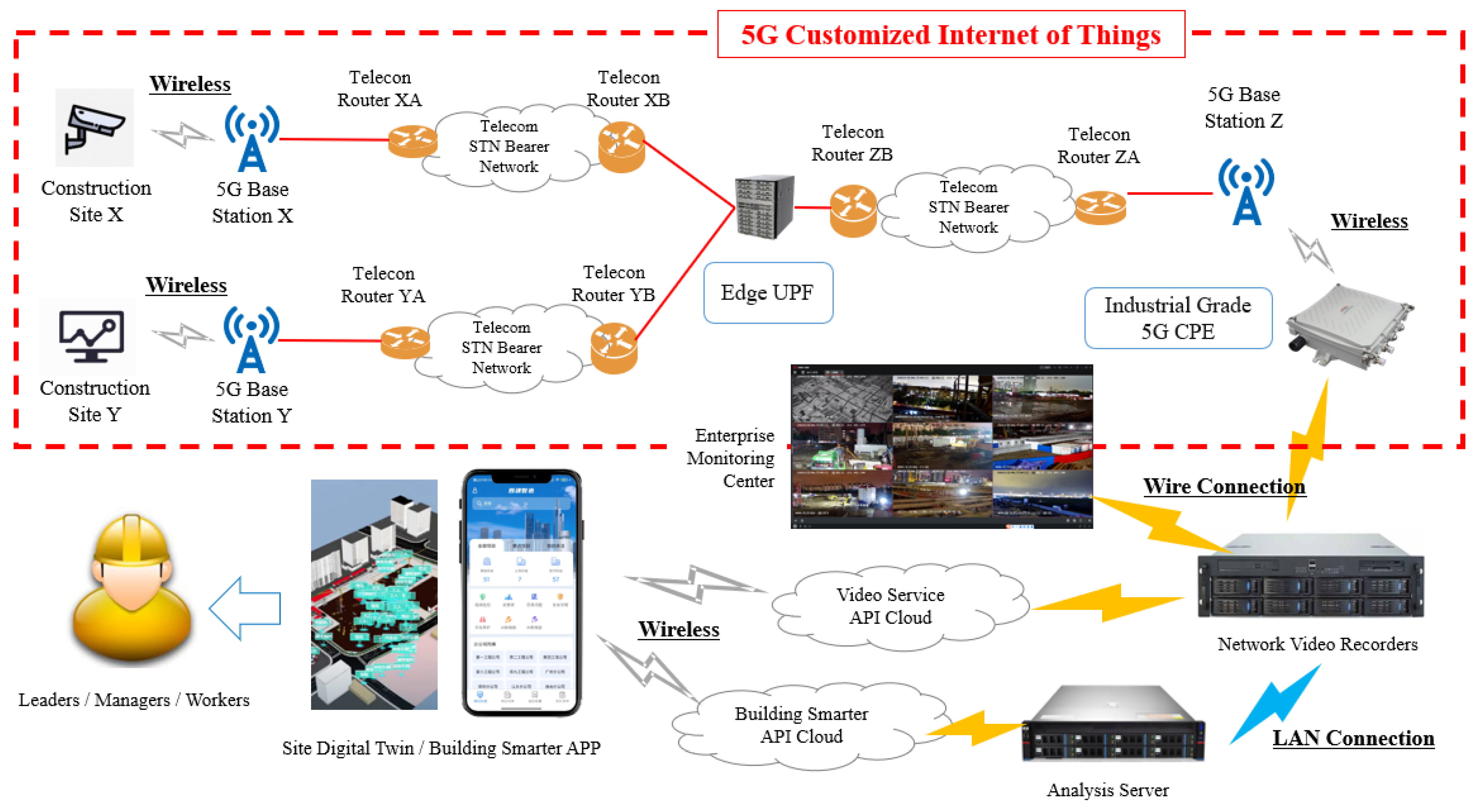

The deployment of intelligent infrastructure across large-scale construction sites faces three interconnected challenges. First, the installation of reliable wired networks is particularly problematic at elevated locations (such as cranes or scaffolds), where long cable distances lead to unstable signals and high maintenance costs. Second, the transmission of high-definition video streams to the cloud imposes immense bandwidth demands that exceed the capacity of traditional site networks, while reliance on commercial 5G would be prohibitively expensive. Third, limited on-site computing resources hinder real-time safety risk detection and long-term video storage. To address these challenges, this study collaborates with Chinese national telecom company to develop a hybrid infrastructure model combining enterprise 5G private networks and a centralized data center, as shown in

Figure 2.

3.2.1. Edge and Cloud-Side Deployment

The foundation of the system was designed for low-latency data processing and cost-efficient transmission. At the edge-side, construction sites are equipped with IoT sensors and 5G-enabled HD cameras strategically positioned to monitor critical areas such as crane operations, material storage zones, and worker entrances. Devices are connect directly to a dedicated 5G private network infrastructure deployed by national telecom company. The network leverages localized 5G base stations and UPF (User Plane Function) gateways to route data streams from dispersed sites to a centralized CPE (Customer Premises Equipment) located within the enterprise data center.

Raw video feeds and sensor data undergo initial processing at the edge using lightweight AI models. Real-time object detection algorithms identify immediate safety violations, such as unauthorized personnel entering hazardous zones, and trigger on-site alarms within milliseconds. Processed data, including compressed video clips and metadata, is then uploaded to cloud platforms. These platforms support advanced analytics, such as progress tracking and anomaly detection, while enabling mobile app access for on-the-go monitoring by site managers.

3.2.2. Central Computing Hub

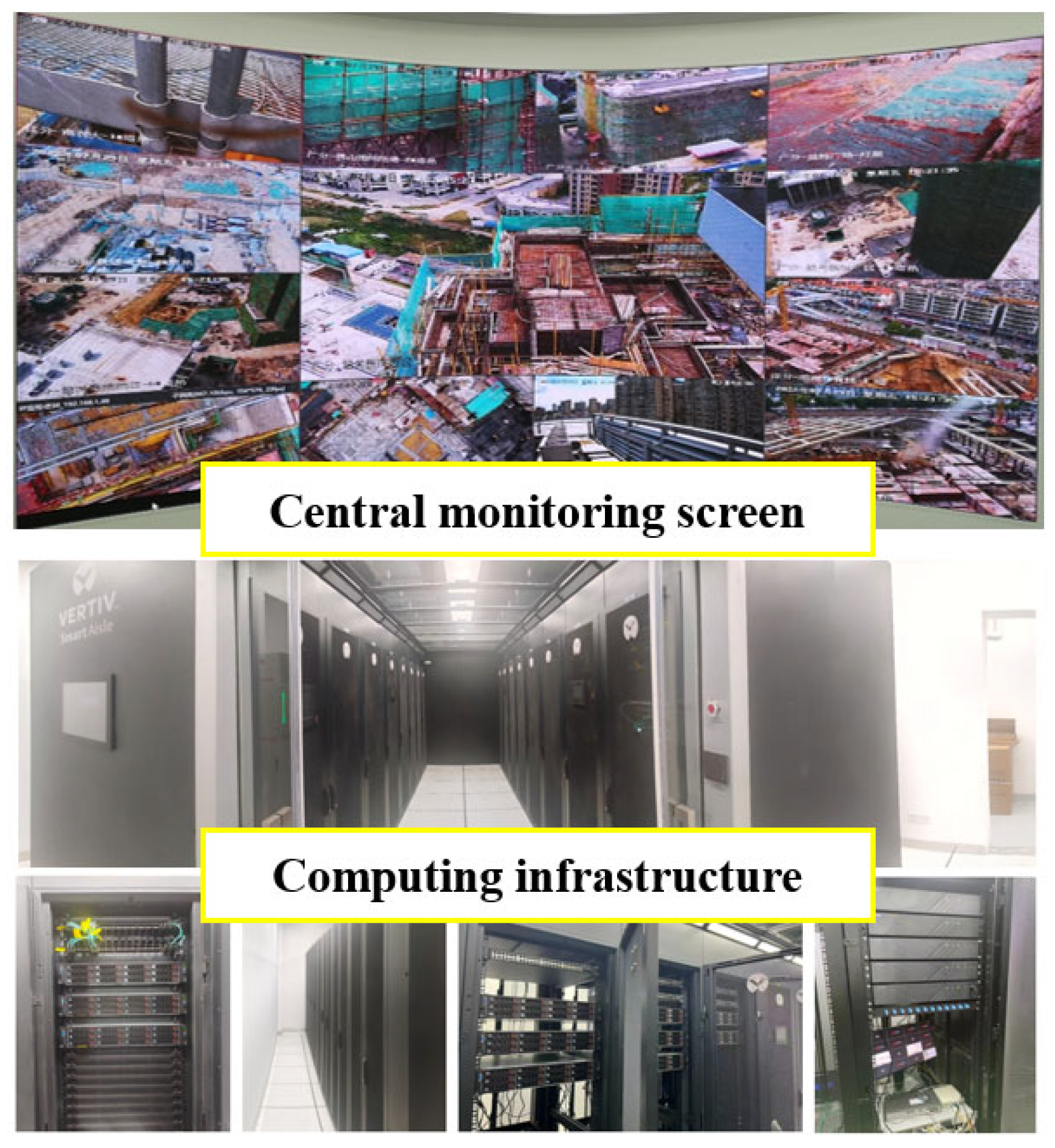

At the core of the infrastructure is the enterprise data center, designed to manage centralized storage and cross-project data integration. The center receives aggregated video streams and sensor data via the 5G CPE, where they are stored in a tiered architecture combining NVRs (Network Video Recorders) for short-term retention and object storage systems for long-term archiving.

A centralized dashboard, displayed on a 3x4 video wall in the enterprise monitoring center, provides real-time visibility into all active projects. This interface overlays safety alerts, progress metrics, and live video feeds onto dynamic BIM models, allowing executives to assess site conditions holistically. Meanwhile, web and mobile interfaces grant field personnel access to real-time data, enabling rapid response to incidents.

3.3. Core Functional Modules

Building Smarter system revolutionizes construction site oversight through a suite of interconnected intelligent functionalities designed to enhance real-time visibility, safety enforcement, and operational efficiency. These functional modules establish a closed-loop intelligence framework where real-time data acquisition, automated decision-making, and human oversight converge to elevate construction management into a predictive, rather than reactive, discipline.

3.3.1. On-Site Management based on videos and MLLMs

(1)

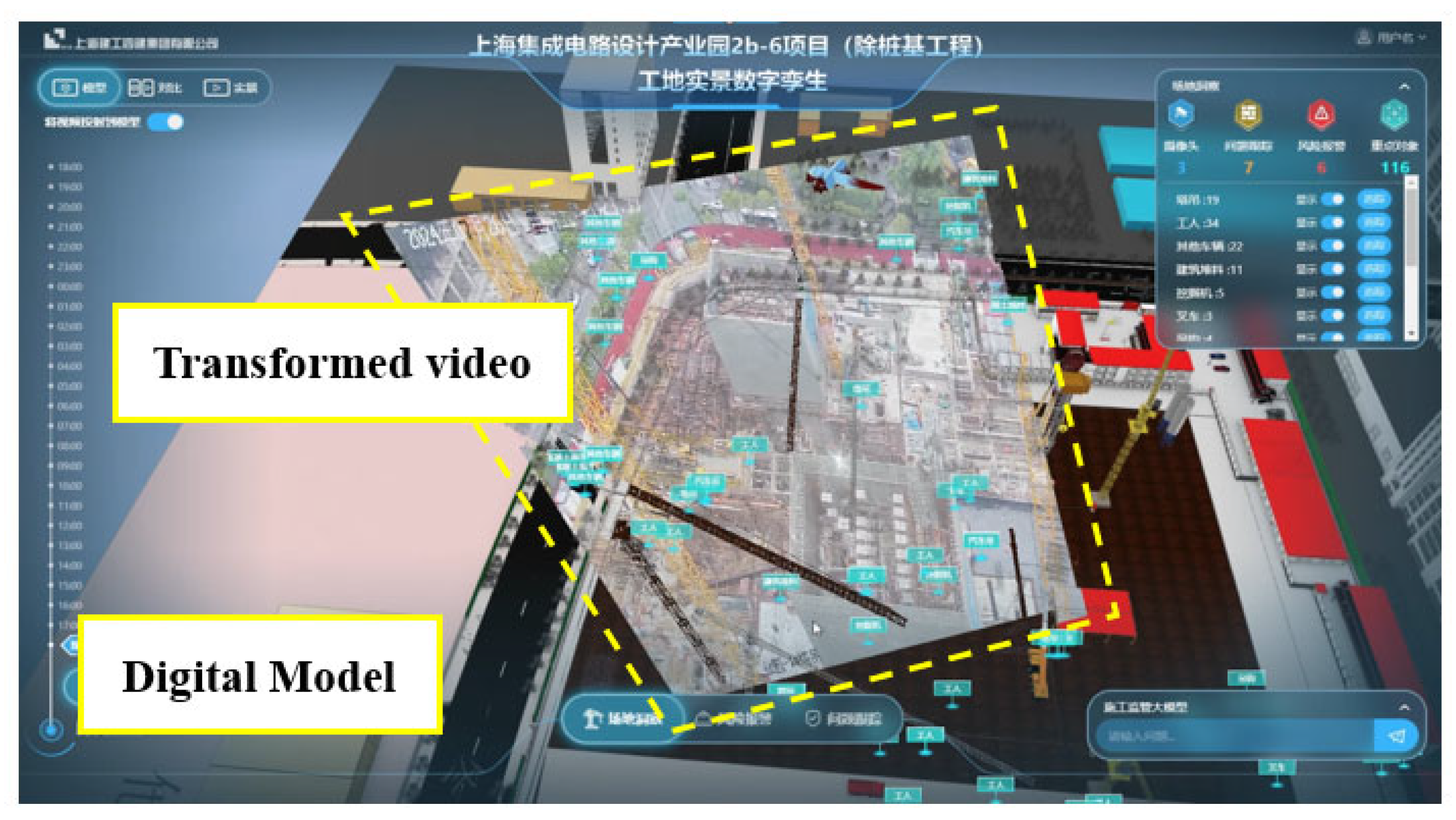

Dynamic integration of multi-camera spatial data with digital twin models enabled a seamless fusion of virtual and physical environments. By performing multi-view camera pose estimation, the platform aligns live video streams with BIM models in real time. When users rotate or zoom the BIM interface, the corresponding video perspectives undergo linear transformations to match the adjusted viewpoint, creating an augmented reality-like overlay of the construction site (

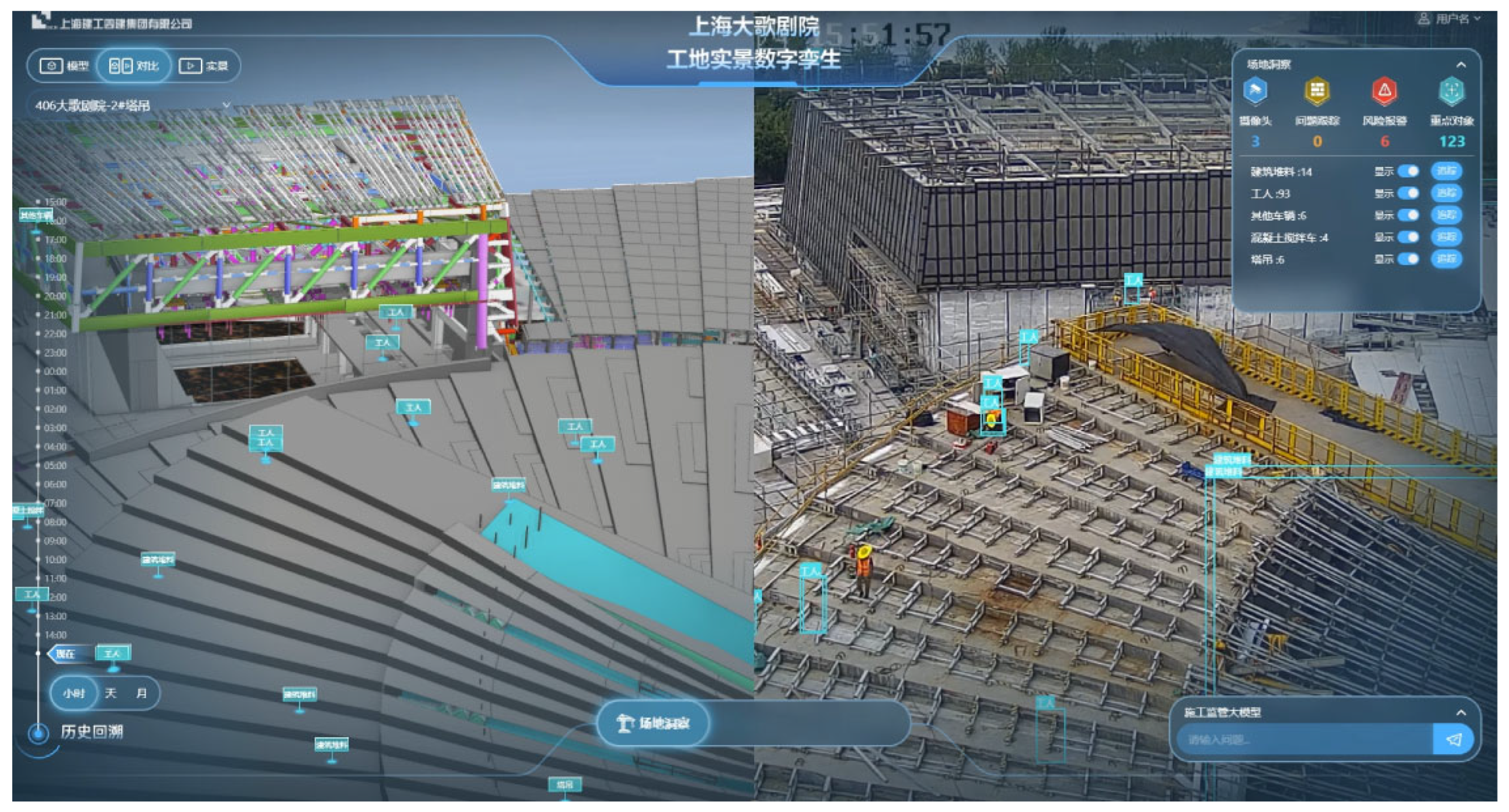

Figure 3). This alignment allows managers to virtually inspect critical areas—such as deep foundation pits or prefabricated component hoisting zones—while viewing actual worker activities through 360° cameras with 23 times optical zoom. For example, during a high-rise steel structure installation, supervisors remotely zoomed into a 150-meter elevation to verify lifting accuracy, eliminating the need for risky manual inspections.

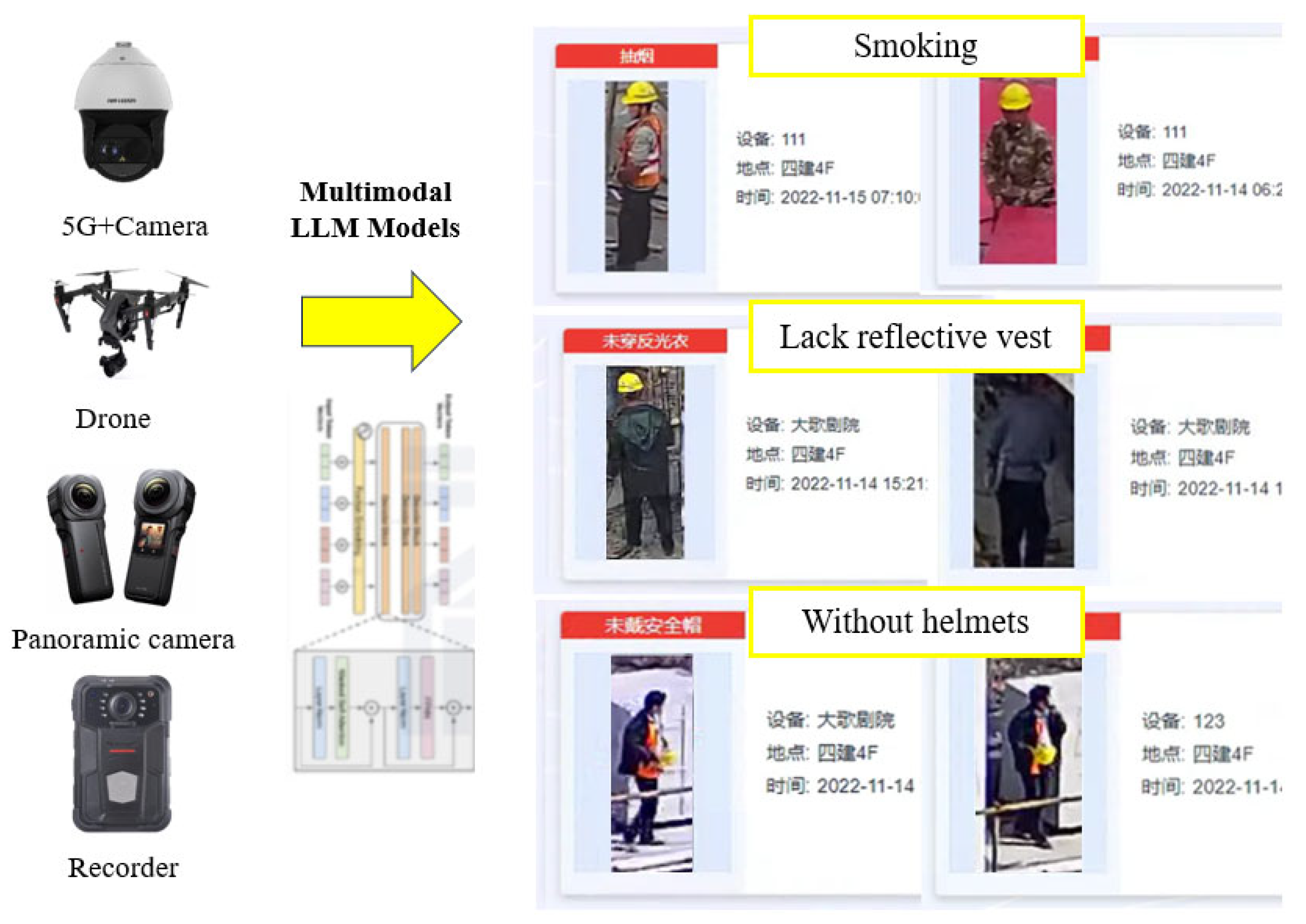

(2) AI-driven object behavior detection function serves as a proactive guardian of on-site safety and compliance. An MLLM model was fine-tuned on a proprietary dataset of 50,000 annotated construction images, and the model can identify 20 categories of objects ranging from workers and machinery to temporary scaffolding. The system cross-references video feeds with IoT sensor data to flag safety violations, such as workers without helmets in crane operation zones, smoking in working areas, lack of reflective vest in night construction, unauthorized personnel entering confined spaces. When anomalies are detected, the platform autonomously generates rectification tickets, attaches timestamped video evidence, and triggers mobile app alerts to designated personnel. This functionality reduced safety incident response times from 40 minutes to under 8 minutes, demonstrating its capacity to transform passive monitoring into actionable interventions.

Figure 4.

AI-driven behavior detection using MLLM.

Figure 4.

AI-driven behavior detection using MLLM.

(3)

Adaptive geofencing function establishes intelligent operational boundaries that evolve with project phases. The digital twin predefines functional zones (restricted areas for crane swings, material storage corridors), and emergency evacuation routes, which are dynamically projected onto live video streams. The system continuously use MLLM to identify objects and track personnel and equipment movements, triggering instant alerts for boundary breaches. A congestion prediction module extends this capability by analyzing vehicle dwell times using recurrent neural networks, forecasting traffic bottlenecks with 85% accuracy. For example, in a high-rise project (

Figure 5), the system detected a concrete mixer truck stuck in a mobile crane geofencing, exceeded the allowed stay time, and causing the concrete tanker truck to pass significantly slowly.

(4)

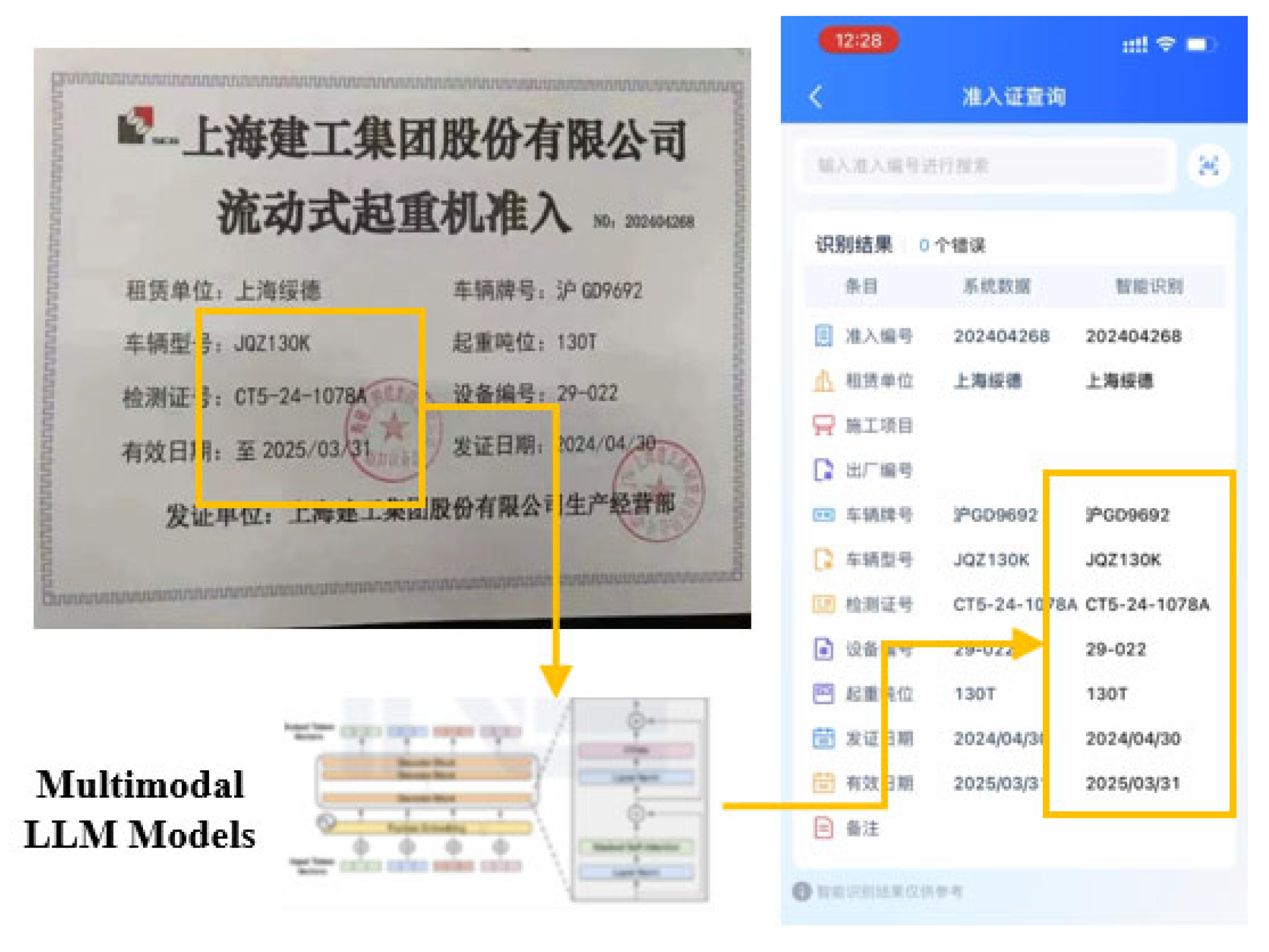

MLLM-powered crane permit verification digitizes the traditionally manual process of validating mobile crane access credentials. Traditionally, security personnel manually cross-checked permit details against spreadsheets. This process was a time-consuming method susceptible to human error. The mobile app of Building Smarter has changed this workflow: field operators photograph permits via smartphones, while multi-modal LLMs extract key-value pairs (for example, equipment ID: JQZ130K, certificate number: CT5-1078A, expiration date: 2025-3-31) and validate compliance against centralized databases in real time (

Figure 6). This system has detected over 100 invalid or non-compliant permits across projects, preventing unauthorized or outdated equipment from entering construction zones.

3.3.2. Automated Progress and Quality Assurance

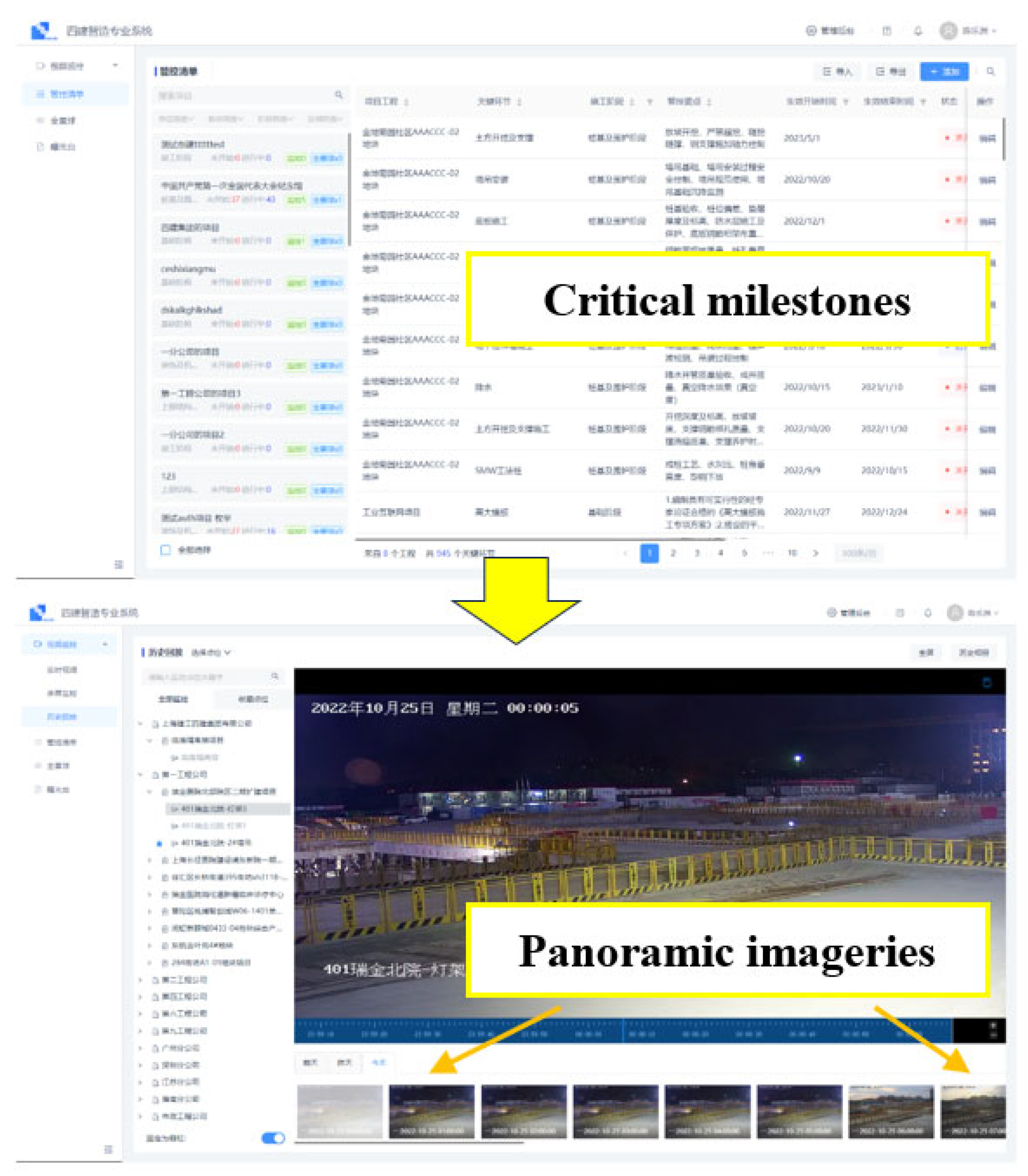

(1) 4D-BIM and panoramic imagery based progress assurance work by synchronizing the 4D BIM model (embeds time as a critical fourth dimension into traditional 3D building models) with periodically captured 360° panoramic ball, the platform leverages feature-point matching algorithms to autonomously monitor real-time construction progress. Each predefined milestone is dynamically linked to granular metadata, including phase-specific timelines, quality benchmarks, and designated responsible personnel. As shown in

Figure 7, when approaching critical deadlines, the system automatically triggers fixed-site cameras to capture timestamped panoramic snapshots. These images are then algorithmically overlaid onto the digital twin model, enabling managers to visually compare as-built conditions against planned milestones through an augmented reality interface. By this remote progress assurance, the platform accelerates progress transparency and also establishes an irrefutable “ground truth” for construction timelines, effectively deterring false reporting across decentralized project teams.

(2)

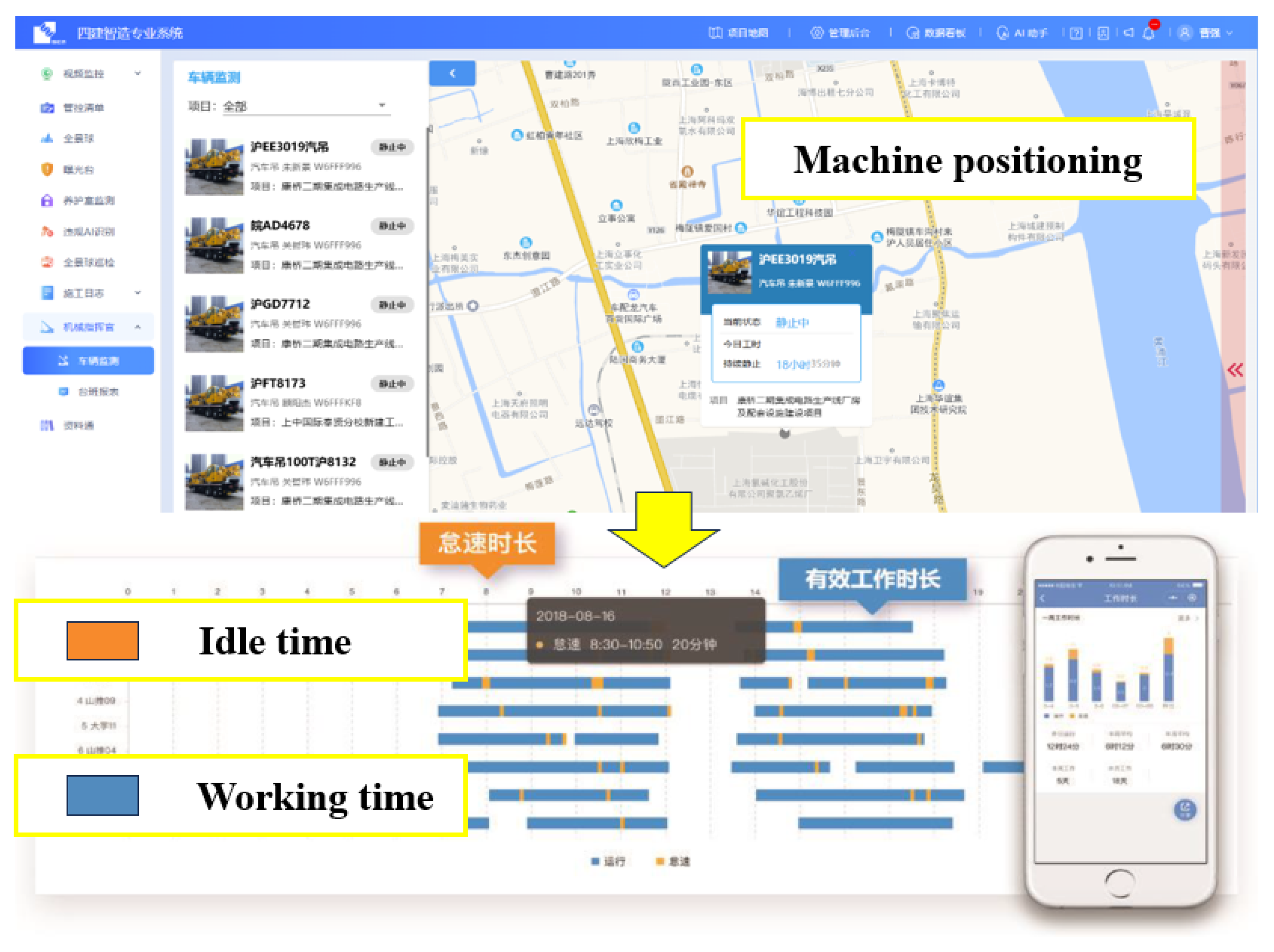

IoT-powered resource optimization by vehicle/excavator analytics redefines equipment management through fine analysis. Embedded sensors on excavators, bulldozers, and trucks monitor parameters like fuel consumption rates, engine idle times, and hydraulic system efficiency (

Figure 8). Machine learning models correlate these metrics with GPS trajectories and work schedules to distinguish productive operations from wasteful practices. By retraining operators based on these insights, fuel costs were significantly reduced monthly while maintaining output levels.

(3)

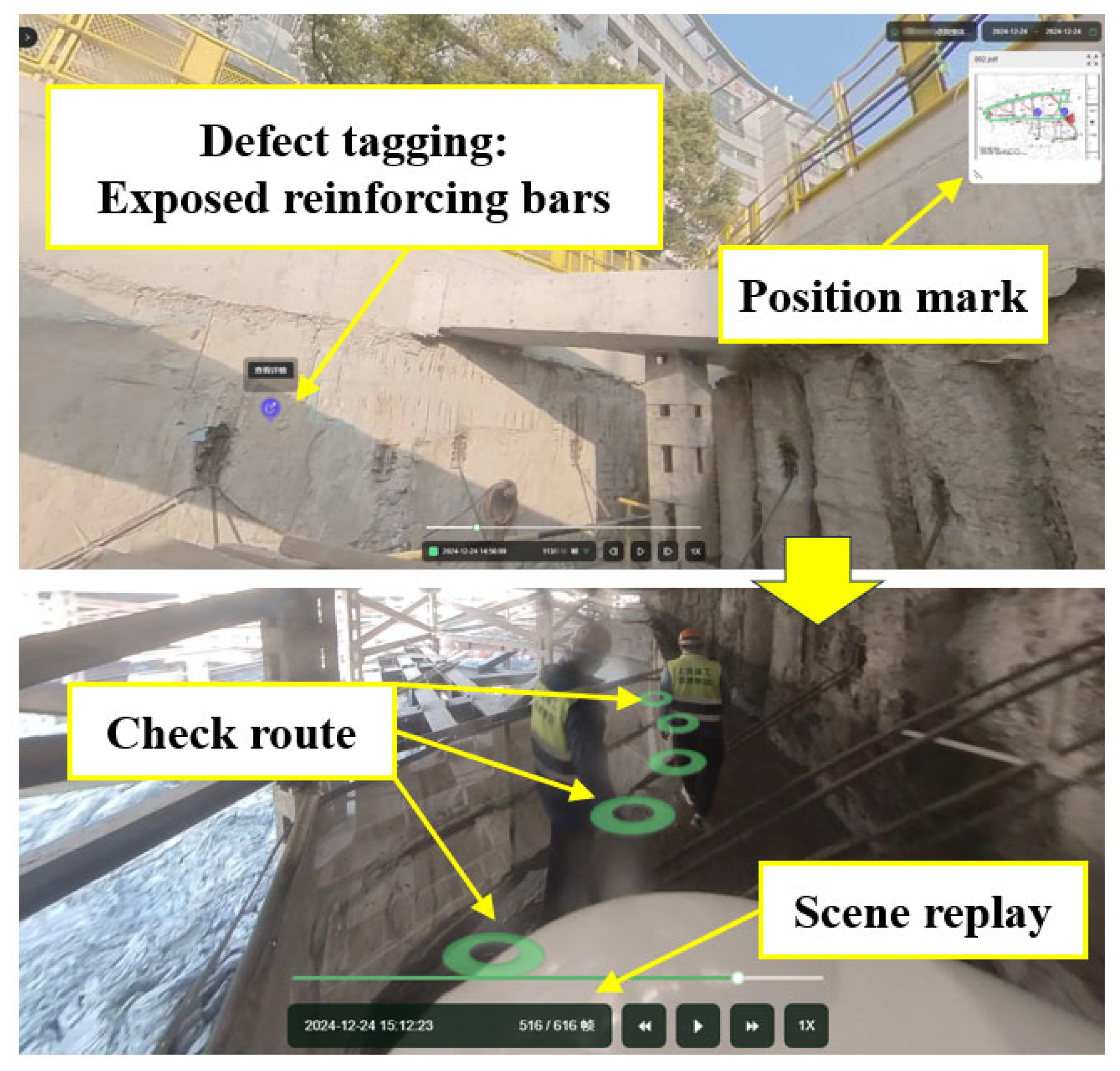

Construction quality control ensures defects are identified, documented, and resolved with precision. Field inspectors equipped with intelligent helmets follow prescribed check routes, automatically optimized to cover high-risk areas like concrete curing zones or temporary scaffolding. As inspectors move through the site, their head-mounted cameras capture wide-range scenes, and identifies micro-cracks in concrete slabs, misaligned rebar spacing, and corrosion in temporary structures (

Figure 9). Identified defects are instantly geo-referenced and mapped onto the project’s digital twin through BIM-integrated defect tagging. Each flaw is annotated in the BIM model with metadata including severity levels, photographic evidence, and recommended remediation steps. Remote engineering teams can then virtually walk through all defect in 3D scenes, validate its urgency via augmented reality overlays, and assign repair tasks to on-site crews.

3.3.3. Closed-Loop Problem Resolution

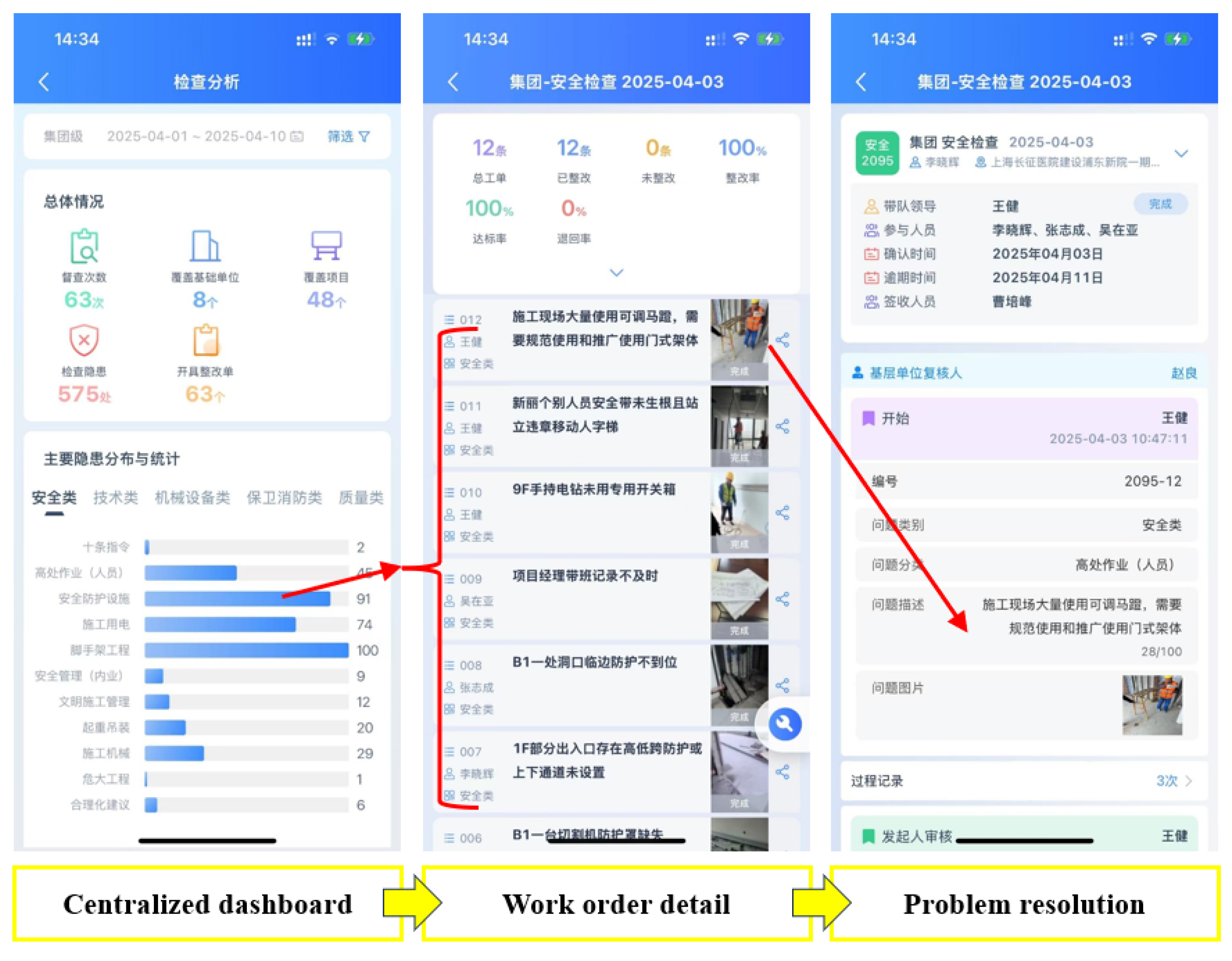

The system establishes a rigorous, traceable workflow for issue management, ensuring every detected problem progresses through a standardized lifecycle from identification, ordering, processing, to systemic improvement. Once a safety hazard, quality defect, or operational discrepancy is identified, a work order is immediately triggered. Task assignment follows predefined escalation protocols: critical issues trigger instant notifications to on-site supervisors via mobile apps, while routine defects are routed to maintenance teams with automated deadlines. Each work order is tracked through a centralized dashboard in Building Smarter.

The feedback phase aggregates work order data across projects to generate actionable insights. As shown in

Figure 10, statistical dashboards analyze trends such as recurring defect types, resolving rate timelines, and spatial hotspots. These metrics empower root-cause analysis. Continuous improvement is driven by closed-loop data integration. Historical work records from hundreds of projects feed into templated best practices. By institutionalizing lessons learned into updated BIM standards and operational checklists, the system ensures every resolved issue contributes to long-term process refinement, transforming isolated fixes into enterprise-wide operational excellence.

3.4. Multi-Project Ecosystem Features

Traditional construction management platforms often operate in silos, limiting cross-project collaboration and hindering the scalability of institutional knowledge. To transcend this limitation, Building Smarter introduces a federated ecosystem architecture that integrates data, workflows, and expertise across multiple projects. By establishing unified mechanisms for cross-project information flow, knowledge sharing, and scalable resource allocation, the platform transforms isolated project management into a cohesive enterprise-wide operations network, significantly enhancing adaptability for diverse construction scenarios.

3.4.1. Shared Knowledge Repository and LLM Integration

At the core of multi-project ecosystem features, a centralized knowledge repository aggregates multi-modal engineering data—including design documents, inspection images, panoramic videos, defect records, and safety reports—from all active and completed projects (

Figure 11). This repository empowers field personnel with query capabilities using MLLMs, enabling instant access to technical guidance (e.g., asking the MLLM to search documents and pictures about cement mixing piles from several similar projects) while synthesizing heterogeneous data into a structured corpus. By training domain-specific models on this corpus, the system unifies defect pattern recognition and risk mitigation strategies, such as identifying recurring crane overload incidents across offshore and urban projects, which are then embedded into preconstruction templates.

3.4.2. Scalability Mechanisms

To ensure rapid, cost-effective scalability across a construction group’s portfolio, the platform adopts a modular microservices architecture supported by standardized hardware and software strategies. Hardware resources including IoT sensors and edge computing devices are centrally planned and deployed by specialized technical teams, eliminating on-site installation burdens. On the software front, Docker containerization enables one-click deployment of core functionalities, while reusable templates for workflows, AI models, and BIM components reduce marginal costs by 40–60%. This adaptability extends to project heterogeneity: infrastructure projects activate heavy machinery tracking modules, whereas commercial buildings prioritize MEP clash detection, all under a unified cloud-based framework that dynamically scales computing resources based on complexity.

4. Applications and Results

Building Smarter system has been deployed across 273 construction projects under our enterprise across cities of China, including Shanghai, Jiangsu, Shenzhen, Guangzhou, and Hainan, achieving 78% coverage and installing 1310 industrial-grade monitoring nodes (detailed in

Table 1).

4.1. System Deployment

The smart construction site sensors used are industrial grade and installed on critical machinery. Central to the system deployment are cameras—equipped with 2-megapixel resolution, 23x optical zoom, 150m visibility, 100m infrared night vision, and heated anti-fog lenses—strategically mounted to withstand harsh on-site conditions. For standard construction sites under 300m×600m, two cameras ensure comprehensive coverage, while larger or linear sites (e.g., concert halls or highways) adaptively scale node density based on spatial complexity. During the initial three-month rollout, video data from these devices trained 12 shared AI vision models, which were integrated into the multi-project knowledge repository. The centralized computing infrastructure (

Figure 12) includes two GPU servers for real-time AI analysis, five high-capacity 64-channel NVR servers, and 40×6TB storage nodes. This architecture supports 60-day full-data retention for all active projects and long-term archival of critical historical datasets, enabling continuous cross-project model refinement. By unifying heterogeneous data, the deployment framework exemplifies the system’s capacity to harmonize distributed intelligence into a cohesive, enterprise-wide operational asset.

4.2. Governance Under Multi-Project Ecosystem

To institutionalize cross-project collaboration and ensure effective adoption of the system, the company headquarters established a hierarchical governance framework that aligns organizational roles, accountability mechanisms, and incentive structures with the platform’s technical capabilities. The framework mandates clear responsibilities for group-level executives, regional units, and project teams, emphasizing proactive risk management through policies such as compulsory camera installation before earthwork phases, automated OA system alerts for devices offline exceeding seven days, and reduced on-site inspection quotas of 50% reduction for leaders who engage in daily remote monitoring. These rules are embedded directly into the platform’s workflows (for example, projects tended to fake report progress until cameras are installed, and real-time dashboards highlight offline devices that was intentionally disabled and trigger accountability reviews). To encourage adoption, the system integrates performance metrics: regional managers who consistently monitor projects via the platform receive prioritized AI-driven risk summaries, enabling faster decision-making, whereas underperforming units are flagged for targeted audits by the corporate safety department. By harmonizing policy enforcement with technical features, the framework transforms fragmented project-level practices into a standardized, enterprise-wide operational discipline, ensuring cross-project data continuity and institutionalizing the ecosystem’s collaborative ethos.

4.3. Application Performance Analysis

The system has demonstrated transformative outcomes across safety, quality, and operational efficiency by leveraging the multi-project ecosystem framework and shared AI model knowledge base.

Figure 13 shows one of the most distinctive major on-site applications of Shanghai Grand Opera House.

Over two years’ operation, senior leaders and functional departments, including safety, quality, and progress departments, frequently utilized the platform to monitor critical workflows such as diaphragm wall construction, foundation slab pouring, and prefab component hoisting, with over 40% of project managers accessing the system weekly. This reduced on-site inspections by 20%, eliminated more than 200 business trips, and saved over 1 million in travel costs and 400 person-days annually. Cross-project AI model sharing enabled the system to detect 3,000+ weekly safety risks), including 2,000+ instances of missing reflective vests, 500+ unhelmeted workers, and structural hazards like compromised safety nets or incomplete foundation barriers, driving a 30% reduction in safety violations. The integration of multi-project data streams—from safety protocols in Jiangsu’s high-rises to pandemic compliance workflows in Shenzhen—highlighted the ecosystem’s adaptability. For example, AI models trained on cross-project video data seamlessly identified region-specific risks, such as typhoon-related scaffolding vulnerabilities in Hainan, while federated learning ensured continuous model refinement without compromising data privacy. Quality control cycles accelerated by 50% through centralized defect resolution workflows, where AI-identified quality issues were matched with historical solutions from similar projects in the knowledge repository.

During the COVID-19 pandemic, the 5G-enabled remote monitoring function proved indispensable. Construction sites in Shanghai identified 100 epidemic risks, such as unsecured quarantine zones or unmasked workers, while system bandwidth sustained 50Mbps throughput and 50+ concurrent users during 80% of operational hours, which significantly outperformed traditional wired networks.

5. Discussion

The multi-project ecosystem framework fundamentally redefines how large general contractor companies manage geographically dispersed projects by integrating centralized data governance, adaptive AI, and proactive digital twin technologies into a unified operational backbone. Unlike traditional reactive approaches that rely on isolated project data, this framework leverages a cross-project knowledge repository, which hosted in enterprise-grade data centers, to train robust AI models for safety and quality control. By centralizing high-bandwidth, low-latency 5G-enabled video streams, the system eliminates the cost and complexity of cloud-based or on-site decentralized storage, offering a scalable way to adapt various scales of projects. Mobile-first remote monitoring further amplifies efficiency: executives oversee safety compliance and pandemic protocols in real-time. Governance policies, such as mandatory camera installation before earthwork phases and OA system penalties for device downtime, institutionalize these digital workflows, transforming sporadic compliance into enterprise-wide discipline. This synergy of adaptive AI based on federated learning on multi-project data, proactive risk mitigation, and cost-effective infrastructure have made this system a replicable blueprint for industry-wide digitization, particularly for contractors managing diverse assets across cities.

While the proposed framework offers transformative potential, its implementation reveals critical technical and operational constraints. The system’s reliance on high-resolution panoramic cameras for microscopic risk detection, but cases such as identifying unhelmeted workers at 150m imposes significant computational burdens on centralized GPU servers, limiting real-time processing scalability. Furthermore, the framework’s dependency on stable wireless connectivity restricts its applicability to some construction phases (e.g., earthwork, structural framing, equipment installation, decoration), leaving indoor workflows unsupervised due to signal attenuation in enclosed spaces such as basements or high-rise cores. Power supply instability, particularly at elevated monitoring points like crane tops, further undermines data continuity. Solar-battery hybrid energy solutions to ensure uninterrupted operation might be needed.

Data governance presents another challenge. While centralized repositories enable cross-project AI training, they also raise privacy concerns when sharing sensitive project-specific details, such as original BIM designs from commercial complexes or safety incident logs from government’s megaprojects. Balancing data standardization with project-tailored needs requires dynamic policy frameworks yet to be fully realized. These limitations underscore the ecosystem’s current phase as a powerful but still evolving tool. To achieve broader industry applicability, computational scalability, energy resilience, and human-technology synergies should be addressed properly.

Future research should extend the proposed architectural system into broader urban and industrial contexts while addressing emergent challenges in scalability and sustainability. One of the critical frontiers lies in developing industry-wide digital twins that integrate construction data streams with smart city infrastructures This requires advancing interoperability standards to unify heterogeneous data from drones, IoT sensors, and BIM models across contractors. Further, interdisciplinary studies could explore human-AI collaboration frameworks, using generative AI to translate safety alerts into multilingual AR instructions for migrant workers or adaptive interfaces that reduce managerial resistance to remote monitoring.

6. Conclusions

The construction industry, particularly for large general contractor companies, faces mounting challenges in managing multiple construction projects due to fragmented data systems, isolated AI applications, and inefficient cross-project coordination. The proposed Multi-Project Intelligent Construction Ecosystem (MP-ICE) introduces a hierarchical four-layer architecture to unify dispersed construction projects into a scalable, self-optimizing network. By integrating edge computing, centralized AI analytics, cross-project knowledge governance, and federated learning, the framework bridges isolated workflows through bidirectional data sharing and policy enforcement, addressing the fragmentation plaguing traditional multi-project management.

At its core, the MP-ICE is realized by a robust infrastructure, enabling real-time data capture, low-latency processing, and scalable storage, ensuring seamless interoperability across hundreds of sites. Three key functional modules were supported by the infrastructure: AI-powered on-site management via multimodal LLMs for safety and compliance monitoring, automated progress tracking through 4D BIM and IoT synchronization, and closed-loop problem resolution that institutionalizes lessons learned into reusable workflows. The ecosystem’s scalability included a shared knowledge repository and federated learning mechanisms. Cross-project data were aggregated into structured insights, enabling MLLMs to guide decision-making and optimize resource allocation. Preconfigured deployment templates and containerized AI models reduce marginal costs and supported rapid adaptation to diverse projects.

Deployed across 273 projects in China, the proposed system achieved in reduction of safety violations, faster quality control cycles, and fewer on-site inspections. During crises like the COVID-19 pandemic, its 5G-enabled remote monitoring identified critical risks while maintaining operational continuity. By harmonizing infrastructure, intelligence, and cross-project knowledge, this paper realized multiple large-scale construction management, proving that interconnected ecosystems could hold the key to safer, smarter, and more sustainable industry practices.

Acknowledgements

The authors would like to thank the support of the Shanghai Oriental Talent Program Youth Project (Grant No.QNKJ2024047), the Shanghai Science and Technology Innovation Action Plan project (Grant No.22dz1207102), and the Innovation Project of Shanghai State-owned Assets Supervision and Administration Commission (Grant No.2022008).

Declaration of competing interest

The authors have no competing interests to declare that are relevant to the content of this article.

References

- A.E. Oke, V.A. Arowoiya, An analysis of the application areas of augmented reality technology in the construction industry, SMART SUSTAIN BUILT, 11 (2022) 1081-1098. [CrossRef]

- R. Edirisinghe, Digital skin of the construction site: Smart sensor technologies towards the future smart construction site, Engineering, Construction and Architectural Management, 26 (2019) 184-223. [CrossRef]

- A.S. Rao, M. Radanovic, Y. Liu, S. Hu, Y. Fang, K. Khoshelham, M. Palaniswami, T. Ngo, Real-time monitoring of construction sites: Sensors, methods, and applications, AUTOMAT CONSTR, 136 (2022) 104099. [CrossRef]

- C.J. Turner, J. Oyekan, L. Stergioulas, D. Griffin, Utilizing industry 4.0 on the construction site: Challenges and opportunities, IEEE T IND INFORM, 17 (2020) 746-756. [CrossRef]

- M. Ivanova, Digital Document Circulation Management In Construction Companies, HR and Technologies, (2021) 110-123.

- K.U. Ahn, D. Kim, H.M. Cho, C. Chae, Alternative Approaches to HVAC Control of Chat Generative Pre-Trained Transformer (ChatGPT) for Autonomous Building System Operations, BUILDINGS-BASEL, 13 (2023) 2680. [CrossRef]

- Z. Yang, X. Li, C. Yuan, W. Rao, K. Li, S. Zhang, Digital Management Platform of Power Grid Infrastructure Based on Intelligent Construction Site, 2020 International Conference on Artificial Intelligence and Electromechanical Automation (AIEA), IEEE, 2020, pp. 268-271.

- S.A. Prieto, E.T. Mengiste, B. García De Soto, Investigating the use of ChatGPT for the scheduling of construction projects, BUILDINGS-BASEL, 13 (2023) 857. [CrossRef]

- P. Jafari, A Framework for Enhancing Contract-Related Documentation in Construction, University of Alberta, 2021.

- D. Tian, M. Li, J. Shi, Y. Shen, S. Han, On-site text classification and knowledge mining for large-scale projects construction by integrated intelligent approach, ADV ENG INFORM, 49 (2021) 101355. [CrossRef]

- C. Chen, Z. Zhu, A. Hammad, Automated excavators activity recognition and productivity analysis from construction site surveillance videos, AUTOMAT CONSTR, 110 (2020) 103045. [CrossRef]

- H.A. Zhou, A. Gannouni, T. Otte, J. Odenthal, A. Abdelrazeq, F. Hees, Towards a digital process platform for future construction sites, 2020 ITU kaleidoscope: Industry-driven digital transformation (ITU K), (2020) 1-7.

- D. Nguyen, R. Jin, C. Jeon, C. Shim, BIM-based mixed-reality application for bridge inspection and maintenance, Construction Innovation, 22 (2021) 487-503. [CrossRef]

- J. Brozovsky, N. Labonnote, O. Vigren, Digital technologies in architecture, engineering, and construction, AUTOMAT CONSTR, 158 (2024) 105212. [CrossRef]

- Y. Peng, F. Yu, M. Zhang, J. Xu, S. Gao, Solutions on Establishing and Utilizing BIM for General Contractors in Key Scenarios of Digital Construction, ADV CIV ENG, 2023 (2023) 3951336. [CrossRef]

- R. Deng, C. Li, Digital intelligent management platform for high-rise building construction based on bim technology, INT J ADV COMPUT SC, 13 (2022). [CrossRef]

- F. Kong, K. Liu, C. Cao, X. Du, H. Jiao, Application of digital construction whole process monitoring and management technology for airport asphalt pavement, IOP Publishing, 2021, pp. 012190.

- D. Roberts, W. Torres Calderon, S. Tang, M. Golparvar-Fard, Vision-based construction worker activity analysis informed by body posture, J COMPUT CIVIL ENG, 34 (2020) 04020017. [CrossRef]

- M. Wang, C.C. Wang, S. Sepasgozar, S. Zlatanova, A systematic review of digital technology adoption in off-site construction: Current status and future direction towards industry 4.0, BUILDINGS-BASEL, 10 (2020) 204. [CrossRef]

- T. Seyman Guray, B. Kismet, VR and AR in construction management research: bibliometric and descriptive analyses, SMART SUSTAIN BUILT, 12 (2023) 635-659. [CrossRef]

- J.M.D. Delgado, L. Oyedele, P. Demian, T. Beach, A research agenda for augmented and virtual reality in architecture, engineering and construction, ADV ENG INFORM, 45 (2020) 101122. [CrossRef]

- D.J. Scott, T. Broyd, L. Ma, Exploratory literature review of blockchain in the construction industry, AUTOMAT CONSTR, 132 (2021) 103914. [CrossRef]

- S.M. Sepasgozar, S. Davis, Digital construction technology and job-site equipment demonstration: Modelling relationship strategies for technology adoption, BUILDINGS-BASEL, 9 (2019) 158. [CrossRef]

- J. Shen, X. Xiong, Y. Li, W. He, P. Li, X. Zheng, Detecting safety helmet wearing on construction sites with bounding-box regression and deep transfer learning, Computer-Aided Civil and Infrastructure Engineering, 36 (2021) 180-196. [CrossRef]

- B. Xiao, S. Kang, Development of an image data set of construction machines for deep learning object detection, J COMPUT CIVIL ENG, 35 (2021) 05020005. [CrossRef]

- Y. Jiang, Intelligent building construction management based on BIM digital twin, COMPUT INTEL NEUROSC, 2021 (2021) 4979249. [CrossRef]

- M. Boscariol, S. Meschini, L.C. Tagliabue, A Methodological Approach to Asset Information Management via Knowledge Graphs and Large Language Models, European Council on Computing in Construction, 2024, pp. 0-0.

- N. Xu, H. Chang, B. Xiao, B. Zhang, J. Li, T. Gu, Relation extraction of domain knowledge entities for safety risk management in metro construction projects, BUILDINGS-BASEL, 12 (2022) 1633. [CrossRef]

- M. Das, X. Tao, Y. Liu, J.C. Cheng, A blockchain-based integrated document management framework for construction applications, AUTOMAT CONSTR, 133 (2022) 104001. [CrossRef]

- S. Zhu, D. Li, J. Zhu, H. Feng, Towards a data-rich Era: A bibliometric analysis of construction management from 2000 to 2020, BUILDINGS-BASEL, 12 (2022) 2242. [CrossRef]

- L. Chenya, E. Aminudin, S. Mohd, L.S. Yap, Intelligent risk management in construction projects: Systematic literature review, IEEE ACCESS, 10 (2022) 72936-72954. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).