1. Introduction

A metallography specimen is a carefully prepared section of a metallic or non-metallic material, extracted to analyze its physical properties, such as grain size and type, phase distribution, surface hardness, and other microstructural characteristics [

1]. To perform such analysis, the sample surface must be meticulously conditioned through a series of steps, including grinding, polishing to achieve a highly reflective surface, and etching to reveal its microstructure. A critical step in this process is mounting the sample, which typically involves encapsulating it in a polymeric material. This encapsulation not only facilitates handling and surface conditioning, but also ensures the stability of small or irregularly shaped samples during subsequent analysis.

However, current metallography sample mounting systems often have significant drawbacks. Many designs are too complex, requiring integrated hydraulic presses and heating systems, which complicate maintenance and increase costs [

2,

3,

4,

5,

6,

7]. This high cost poses a barrier, particularly in resources-constrained environments such as public schools in Latin American countries such as Mexico, where the acquisition of such specialized equipment is often unfeasible. The lack of access to affordable mounting systems limits the students’ opportunities to engage with and learn metallography, a field essential to advancements in industry and technology.

To address these challenges, this work proposes the development of a compact, low-cost, and easy-to-manufacture mounting device. The proposed system is designed to produce high-quality polymer encapsulated specimens comparable to those obtained from commercial equipment. It is maintenance-efficient and compatible with any commercially available hydraulic press, making it accessible to a wider range of users. In addition, it incorporates an economical and readily available heating system. By democratizing access to metallography technology, this device aims to foster greater interest and training among students, empowering them to explore and contribute to this critical field.

2. Device Design

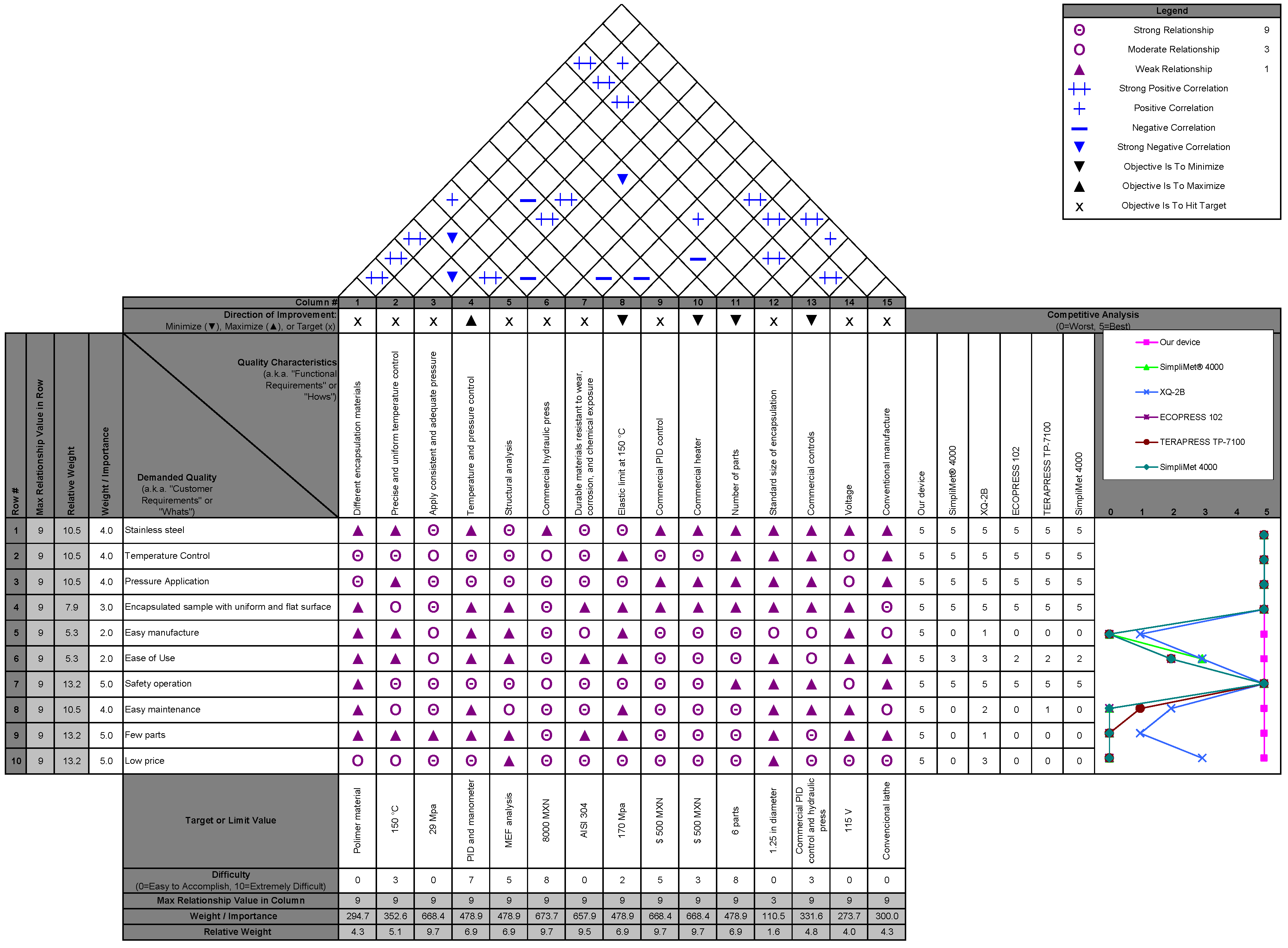

The House of Quality (HoQ), a key tool within the Quality Function Deployment (QFD) methodology [

8,

9], was used in the design of this device to ensure that it met both customer needs and technical requirements effectively. During the process, customer needs were determinate. Then, these needs were translated into specific engineering characteristics using the HoQ matrix, which established clear relationships between customer demands and design parameters. Through this process, they were prioritized, ensuring that the most important aspects were addressed first. The data obtained from the HoQ included a prioritized list of customer requirements, their relative importance, and their correlation with technical specifications, as well as benchmarks comparing the device’s performance against competitors. This structured approach not only streamlined the design process but also ensured that the final product was in line with the expectations of the customer. Ultimately, the use of the HoQ in QFD contributed to a more efficient development process, reduced risks, and a device that successfully met market demands.

To ensure a minimum wall thickness capable of withstand the stresses generated by the pressure applied during the operation, Equation

1 was used because only tangential stresses are presented [

10].

where P is the pressure (Max. 29 Mpa based on the pressure recommendations of the polymer supplier), d is the inner diameter (1.25 in) and e is the minimum wall thickness to use (0.25 in).

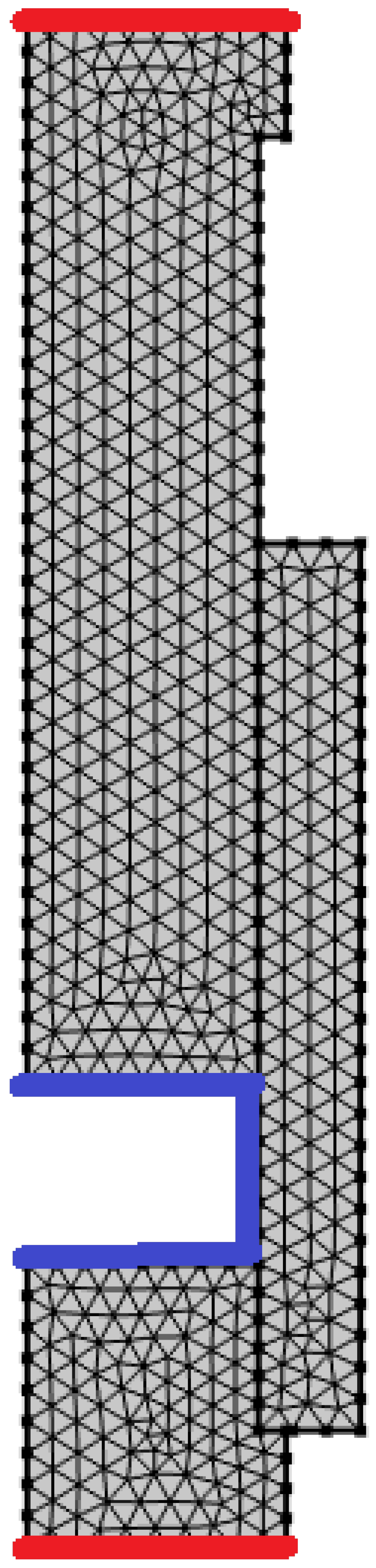

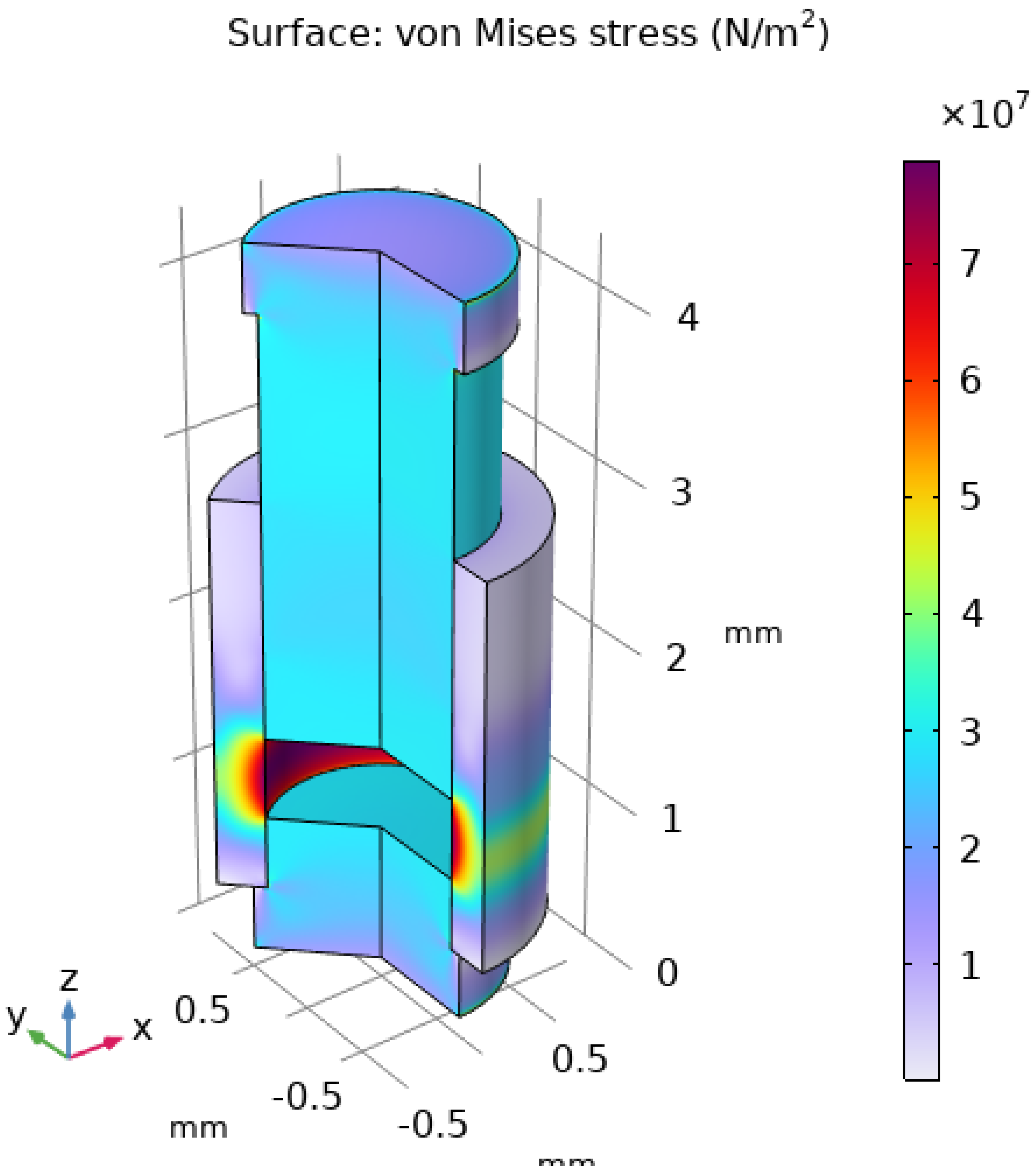

In order to ensure that the device’s operation is safe, it was validated using the finite element method (FEM). The modeling considered the following aspects: the program used for the numerical analysis was COMSOL Multiphysics [

11]. In addition, the main parameters used in the FEM were symmetric 2D geometry [

12]; triangle element type; 2387 elements; 439 nodes; and a linear shape function. Since transient effects were not studied, a static simulation was performed in which a pressure of 29 MPa was applied to the walls housing the encapsulated component (blue lines) and the lower face of the base (E) and the upper face of the piston (A) were fixed constraints as initial boundary condition (red lines) as shown in

Figure 1. Due to being a structural contact model, it was used as a form assembly to create contact pairs [

13].

3. Results and Discussions

Figure 2 shows the House of Quality (HoQ), the core component of Quality Function Deployment (QFD), to design the metallography sample mounting device that bridges the gap between customer needs and technical specifications.

The House of Quality (HoQ) analysis prioritized critical customer requirements (e.g., safety, low cost, ease of manufacturing, compatibility with commercial hydraulic presses, and maintenance efficiency) and mapped them to technical specifications, ensuring alignment between user needs and design parameters. Key outcomes include: material selection (AISI 304 stainless steel) was driven by durability and thermal resistance requirements; dimensional tolerances (for example, sliding H7 / g6 tolerance for the piston-ring interface) were optimized for pressure resistance and manufacturability; heating system design (115 V electric band + thermocouple control) addressed precise temperature management while minimizing costs; benchmarking against competitors highlighted superior cost-effectiveness, adaptability and ease of replication using conventional lathes.

The HoQ framework confirmed that the device successfully balances technical rigor (e.g., FEM-validated stress limits) with accessibility, making it ideal for educational and industrial settings. This structured QFD approach ensured that the final design met priority needs such as safety (through validation of FEM), affordability, and compatibility with existing infrastructure, as reflected in the device’s successful performance in producing high-quality metallography samples.

In this sense, the device was designed considering factors such as user requirements as shown in

Figure 2: sample geometry, heat and pressure control, user-friendly, few parts, cost, etc. The versatility of enabling an encapsulated sample with a uniform and flat surface was a key consideration. A conductive heating method, capable of melting different thermoplastics, was selected. A commercial 115 V electric heating band resistance, known for its high temperature tolerance, was chosen as the heat source. In addition, the device can be easily adapted to any commercial hydraulic press, making it compact, economical, and easy to manufacture, operate, and maintain.

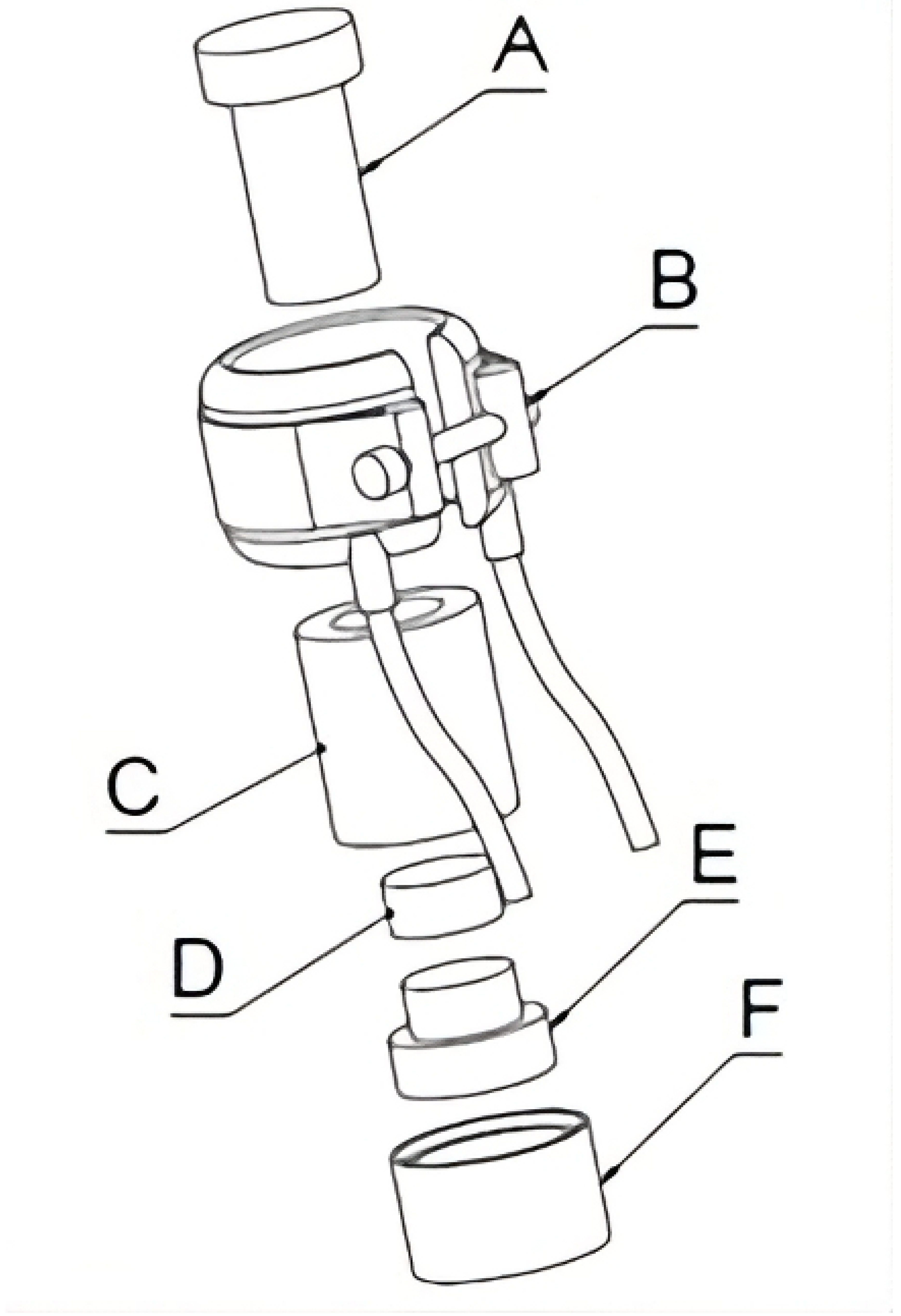

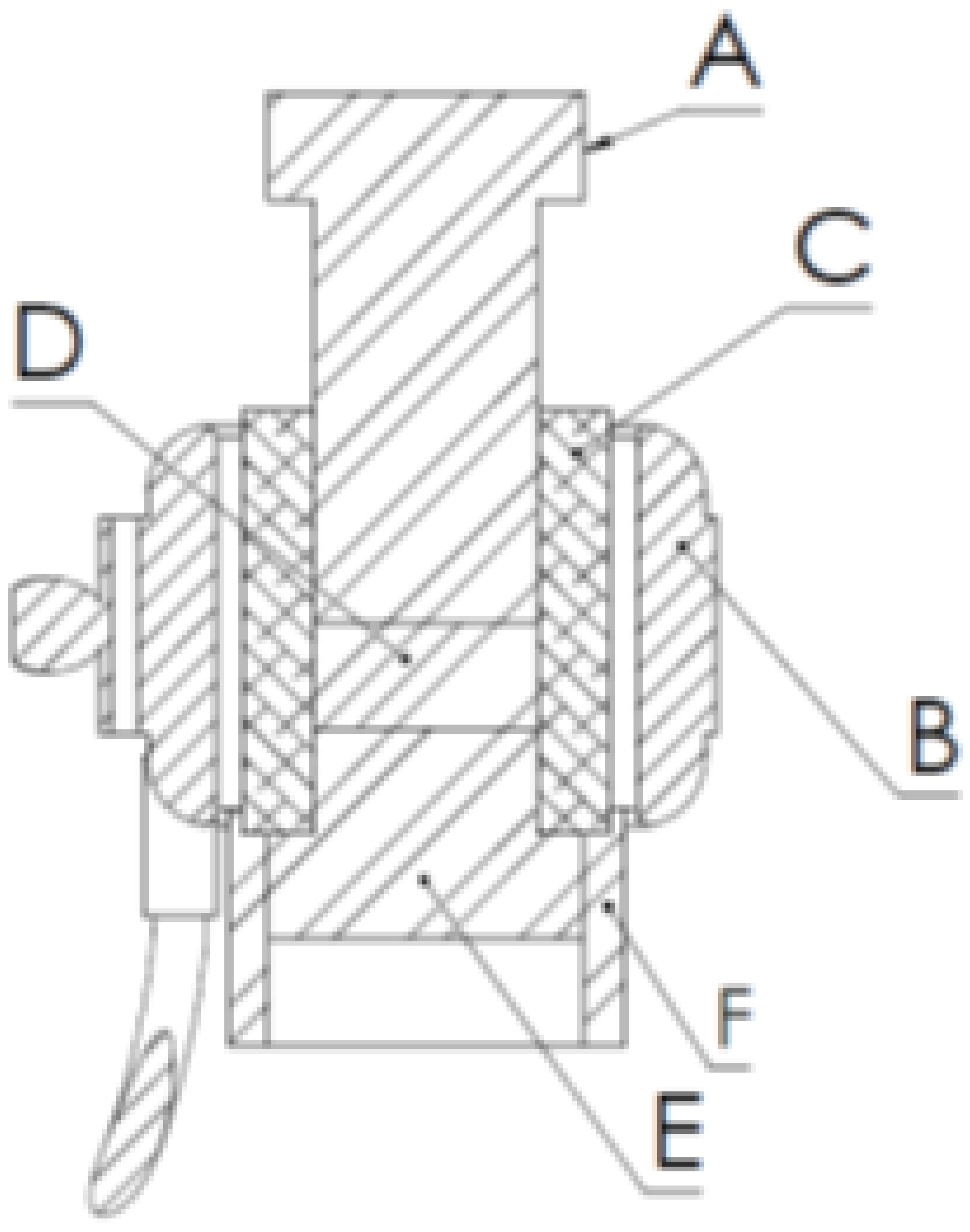

Figure 3 shows the assembly of the mounting device of the metallography specimen.

The metallography sample mounting device features a cylindrical heating ring (C) with an inner hole for sample placement. The ring is mounted on a base (E) and is compressed by a pressure piston (A). An expelling ring (F) facilitates sample removal. The heating band (B) wrapped around the ring provides the necessary heat, while a thermocouple and a temperature controller ensure precise temperature control.

It is important to note that the device can be replicated using any conventional lathe.

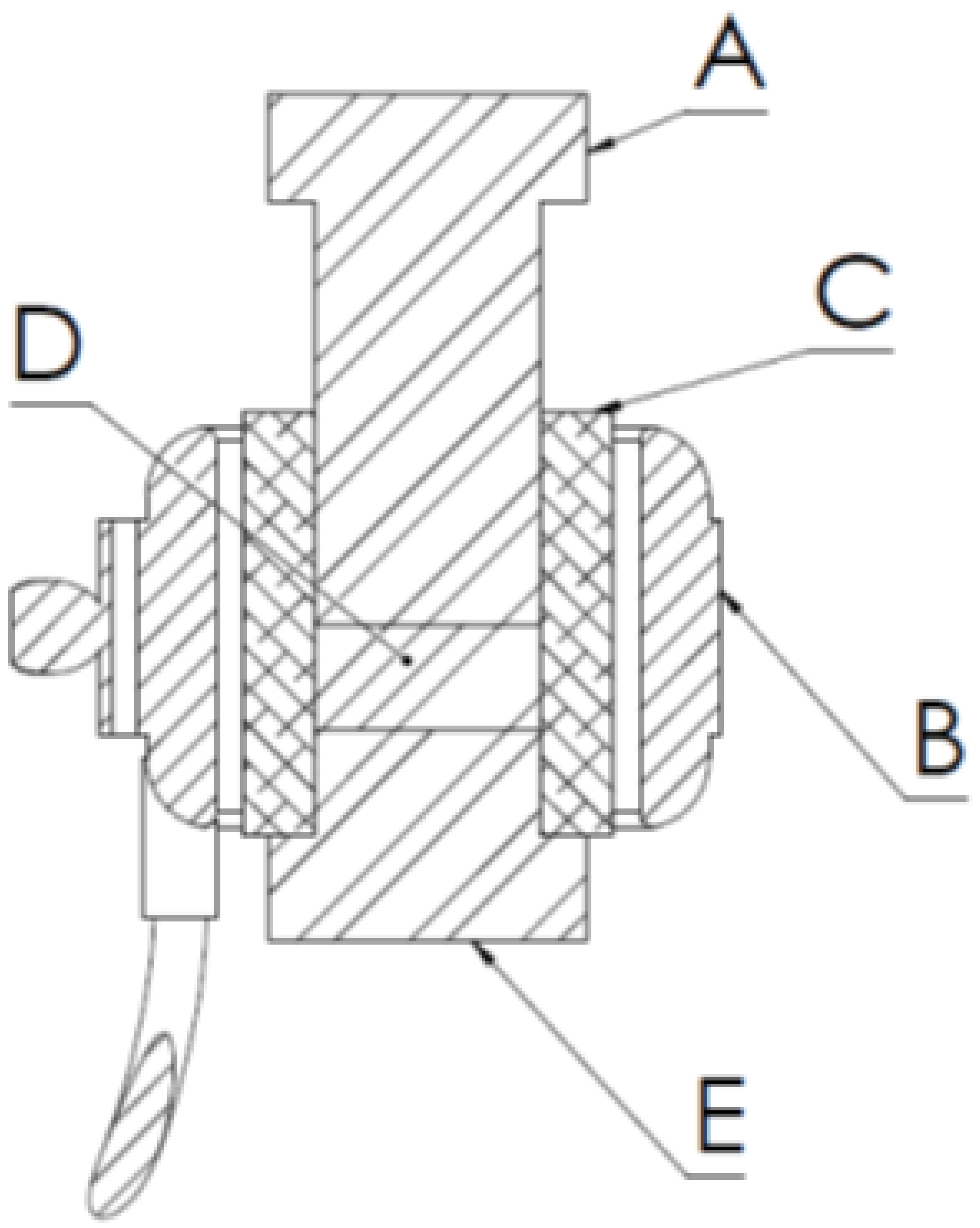

Figure 4 shows the cross-sectional view of the device where the most critical dimensions are the internal diameter of the ring, which can be customized to meet specific requirements, and the wall thickness designed to withstand the pressures recommended by the polymer supplier to be used. In this case, the ring (C) has an inner diameter of 1.25", a wall thickness of 0.25", and 2" long; the piston (A) must have the same inner diameter of the ring with a sliding fit tolerance of H7/g6. The thickness of the sample encapsulation (D) depends on the amount of polymer used. All dimensions can be derived from

Figure 4, based on the internal diameter of the ring of 1.25 in. All parts of the device were manufactured of AISI 304 stainless steel.

The most critical dimensions are the internal diameter of the ring, which can be customized to meet specific requirements (usually 1" or 1.250" diameter) and the wall thickness designed to withstand the pressures recommended by the supplier of the polymer to be used.

Although

Figure 5 shows that the Von Mises stress values obtained by the finite element method (FEM) present a stress concentration of ∼80 Mpa, the device perfectly supports these stresses as the tensions do not exceed the elastic limit of the material at 140 °C (170 MPa) [

14].

In this sense, the FEM analysis faced with analytical calculation (Equation

2) matches the FEM result (Von Mises stress = 80 MPa) including a safety margin equal to 2.1 as shown in Equation

3.

The assembly procedure for the metallography sample mounting device can be divided into 2 steps, described below.

Step 1: Sample molding assembly

As shown in

Figure 4, the heating ring (C) is mounted on the base (E) and is externally surrounded by the heating band (B), which provides heat. The sample is placed on top of the base (E) and the polymer pellets are poured in. The pressure piston (A) is inserted into the top of the heating ring. Finally, the desired pressure and temperature are applied to obtain the encapsulated specimen (D).

Step 2: Sample demount assembly

To eject the sample, the expulsion ring (F) is attached to the bottom of the assembly from Step 1, as shown in

Figure 6. Then, a pressure is applied again. Always, the device must be firmly placed on the press and cooled below 60 °C before sample retrieval.

Figure 7 shows the mounting device for the metallography sample mounted on a commercial hydraulic press and heating system.

On the other hand,

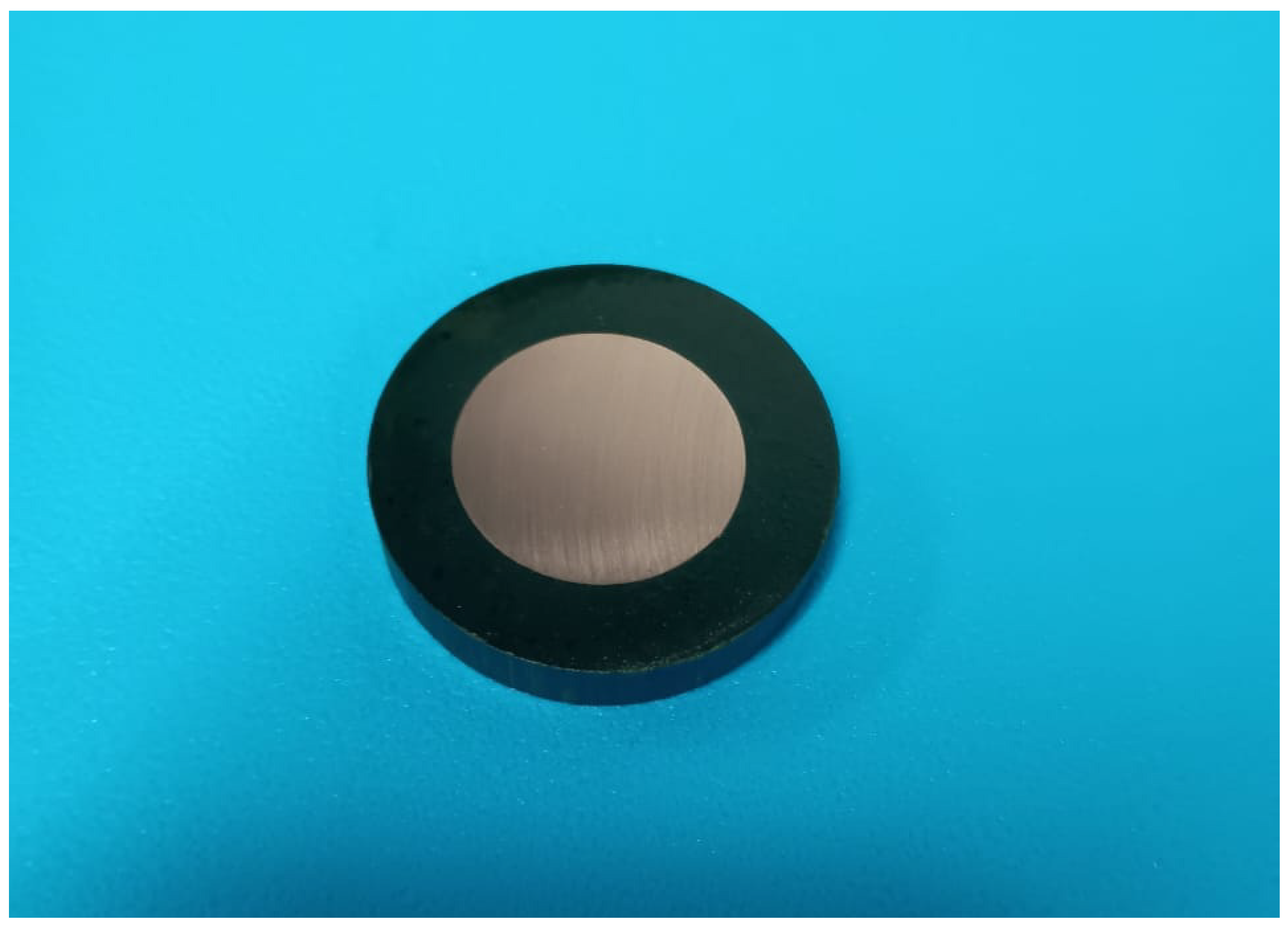

Figure 8 shows the encapsulated sample obtained from the device by applying a pressure of 29 MPa, at 140 °C and a dwell time of 5 minutes in its stable state, which shows that the sample was obtained with quality. The design of the device allows for mounting a metallography sample, allowing for easy handling and conditioning of the surface of interest.

4. Conclusions

This work presents a compact, cost-effective and easily manufactured device capable of producing high-quality encapsulated specimens that rival those obtained from commercial equipment. Its flexibility and compatibility with any commercially available hydraulic press make it a versatile and accessible solution. By democratizing access to metallography technology, this device represents a valuable initiative with the potential to significantly impact education, research, and technological development, particularly in resource-constrained settings. Its implementation could foster greater innovation and learning opportunities, contributing to the advancement of science and industry.

Acknowledgments

We express our gratitude for the support provided by technician Fabian Perez-Cornejo.

Conflicts of Interest

The author declares no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| HoQ |

House of Quality |

| QFD |

Quality Function Deployment |

| FEM |

Finite Element Method |

| FoS |

Factor of Security |

References

- Saha, S.; Wiese, G. Grain size characterization of nickel alloy 718 with optimized metallographic sample preparation route followed by a novel etching technique. Practical Metallography 2025, 62, 97–120. [Google Scholar] [CrossRef]

- Ravikumar, S.; Surekha, R.; Thavarajah, R. Mounting media: An overview. Journal of Dr. YSR University of Health Sciences 2014, 3, S1–S8. [Google Scholar] [CrossRef]

- Azmi, M.N.B.N.; Suhaimi, K.B. Design and fabrication of JIG to hold metallographic specimen. International Journal of Research and Innovation Management 2022, 8, 21–34. [Google Scholar]

- Warren, D.F.; Tate, R.S.; Cox, M.D. Sample mounting press, 2008. US Patent 7,404,707.

- Akinlabi, O.; Adeiza, B.; Emmanuel, O. Development of laboratory hot compression mounting press machine. Journal of Scientific Research and Reports 2018, 18, 1–12. [Google Scholar] [CrossRef]

- Florin-Timotei, A.; Flaviu-Ionuţ, B. Automation of a Metallographic Sample Preparation Station. Journal of Electrical and Electronics Engineering 2019, 12, 23–26. [Google Scholar]

- Keith Jr, M.W. Mounting press, 1978. US Patent 4,131,403.

- Rimantho, D.; Pratomo, V.A.; Pane, E.A.; Noywuli, N. Quality Function Deployment Method for Cooking Stove Design Using Hermetia Illucens Oil. Mathematical Modelling of Engineering Problems 2025, 12. [Google Scholar] [CrossRef]

- Akao, Y. Quality function deployment: integrating customer requirements into product design; CRC Press, 2024. [Google Scholar]

- Daza, J.I.M.; Sánchez, J.P. Análisis y Estudio De Esfuerzos y Deformaciones En Recipientes Metálicos Cilíndricos De Pared Delgada Sometidos a Presión Utilizando Una Herramienta Computacional (Ansys 5.5). Universidad Tecnológica de Bolívar 2004. [Google Scholar]

- Xiong, L.; Lan, S.; Wang, J.; Ding, X.; Yuan, Y. Numerical simulation analysis of discharge in water under different pressures. IEEE Transactions on Dielectrics and Electrical Insulation 2024. [Google Scholar] [CrossRef]

- Goyal, R.K. Simulation and design of hybrid hydrogen storage tanks: Aluminium liner with glass fiber overwrap. International Journal of Hydrogen Energy 2025, 106, 969–972. [Google Scholar] [CrossRef]

- Vignesh, R.V.; Gunasekaran, S.; Padmanaban, R.; Thirumalini, S. Numerical Simulation of Wear in Wind Turbine Brake Pads. In Advances in Solid-State Welding and Processing of Metallic Materials; CRC Press, 2025; pp. 233–256. [Google Scholar]

- Guthrie, R.; Jonas, J.; ASM, M.H.V. 1: Properties and Selection: Irons Steels and High Performance Alloys. ASM international 1990, 2, 329. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).