1. Introduction

1.1. Overview of Indominco Mandiri Operational Areas

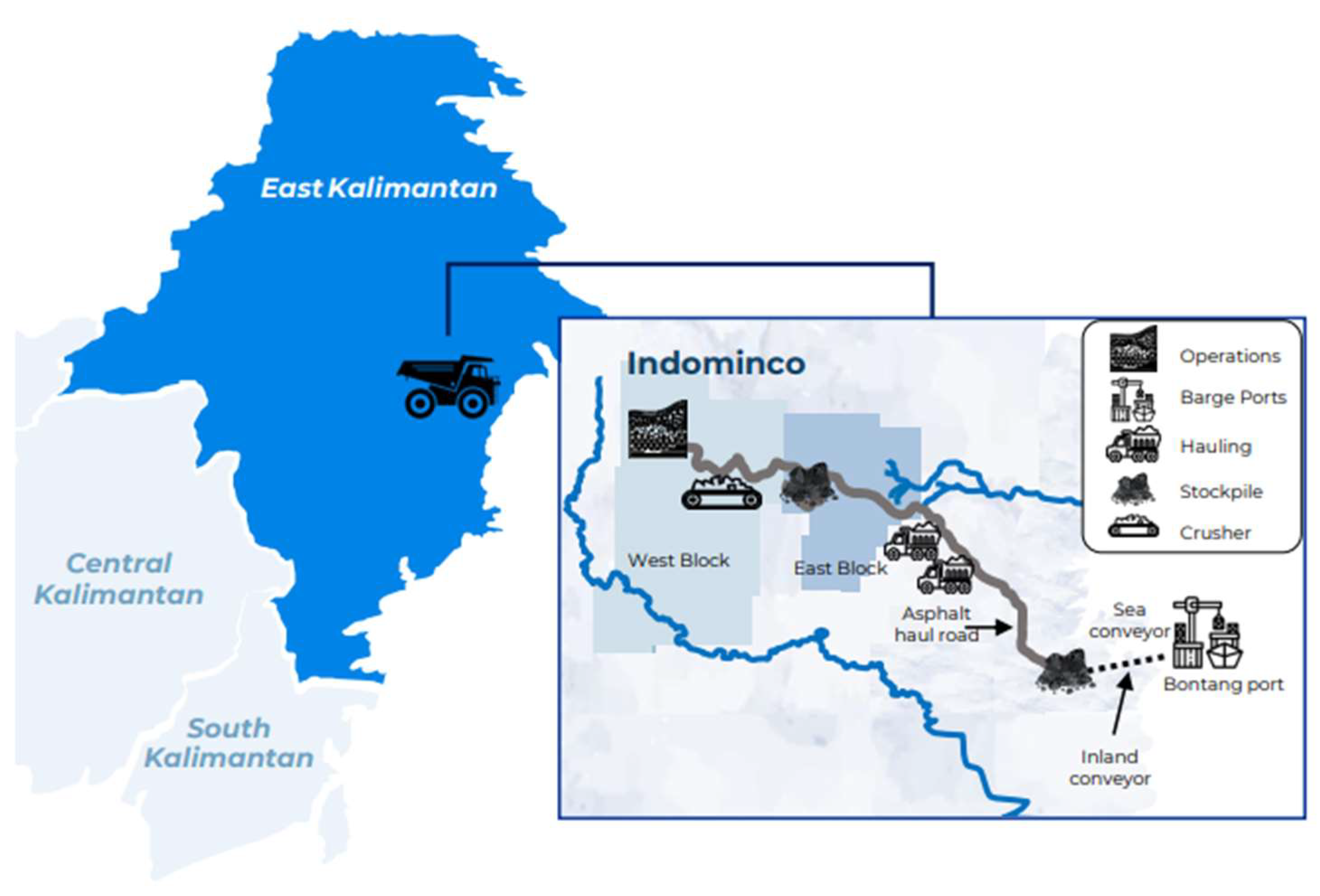

Indominco Mandiri (IMM), is a company engaged in the coal mining industry sector, which is also a subsidiary of Indo Tambangraya Megah Tbk. manages the mining area at Bontang Mine Site, Kalimantan Timur, Indonesia, based on the principles of sustainability. A map of the operational location of IMM is shown in

Figure 1 below:

This paper discusses a series of initiatives by IMM to encourage the sustainability of environmentally friendly mining activities, with emphasis on the continuity between life cycle assessments (Permatasari, et al., 2021; Guinée and Reinout, 2024; Ramakrishna and Ramasubramanian, 2024), as well as efforts to be efficient in natural resources and waste utilization, to biodiversity conservation and community empowerment. The overall initiative aims to support the preservation of the surrounding natural setting, including encouraging community self-reliance so that later when the company is no longer operating, the community can still run a sustainable livelihood.

Previous studies focused on IMM’s contribution to the development and provision of clean water facilities in villages around the mining area, as well as capacity building for internal and external stakeholders based on life cycle assessment principles (Elnaggar, 2024; Pinto, et al., 2023).

1.2. Approach and Methodology

Approach

This paper discusses the issue of best practices in the mining sector, which also take into account various socioeconomic and environmental considerations, using the following approaches:

- -

Technological approach through the implementation of life cycle assessment-based innovation programs in the fields of energy efficiency, emission reduction, and mine water management.

- -

Social approach through the implementation of community empowerment programs.

- -

Socio-environmental approach through the implementation of biodiversity conservation programs, domestic and hazardous waste management.

Each of these research approaches has resulted in a number of qualitative and quantitative results that will be presented next.

Methodology

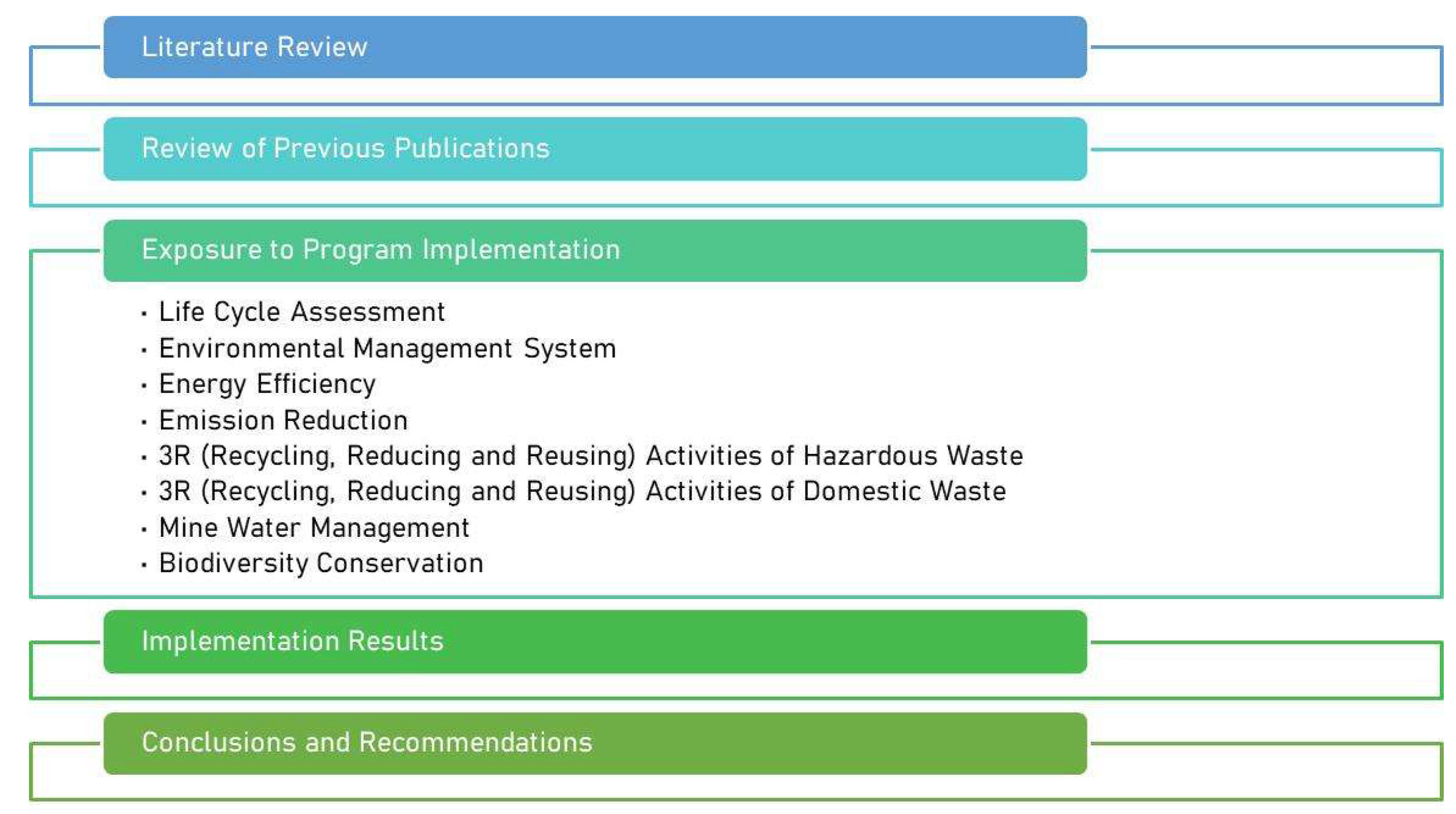

The methods used in the study of previously delivered program initiatives include:

Figure 2.

Methodology of Program Initiatives.

Figure 2.

Methodology of Program Initiatives.

In general, this paper discusses the various activities that have been implemented in IMM in an effort to support sustainability and apply good mining practices.

2. Results

The results of the exposure of a series of programs implemented in IMM in supporting social and environmental sustainability are presented as follows.

2.1. Life Cycle Assessment: Cradle to Gate

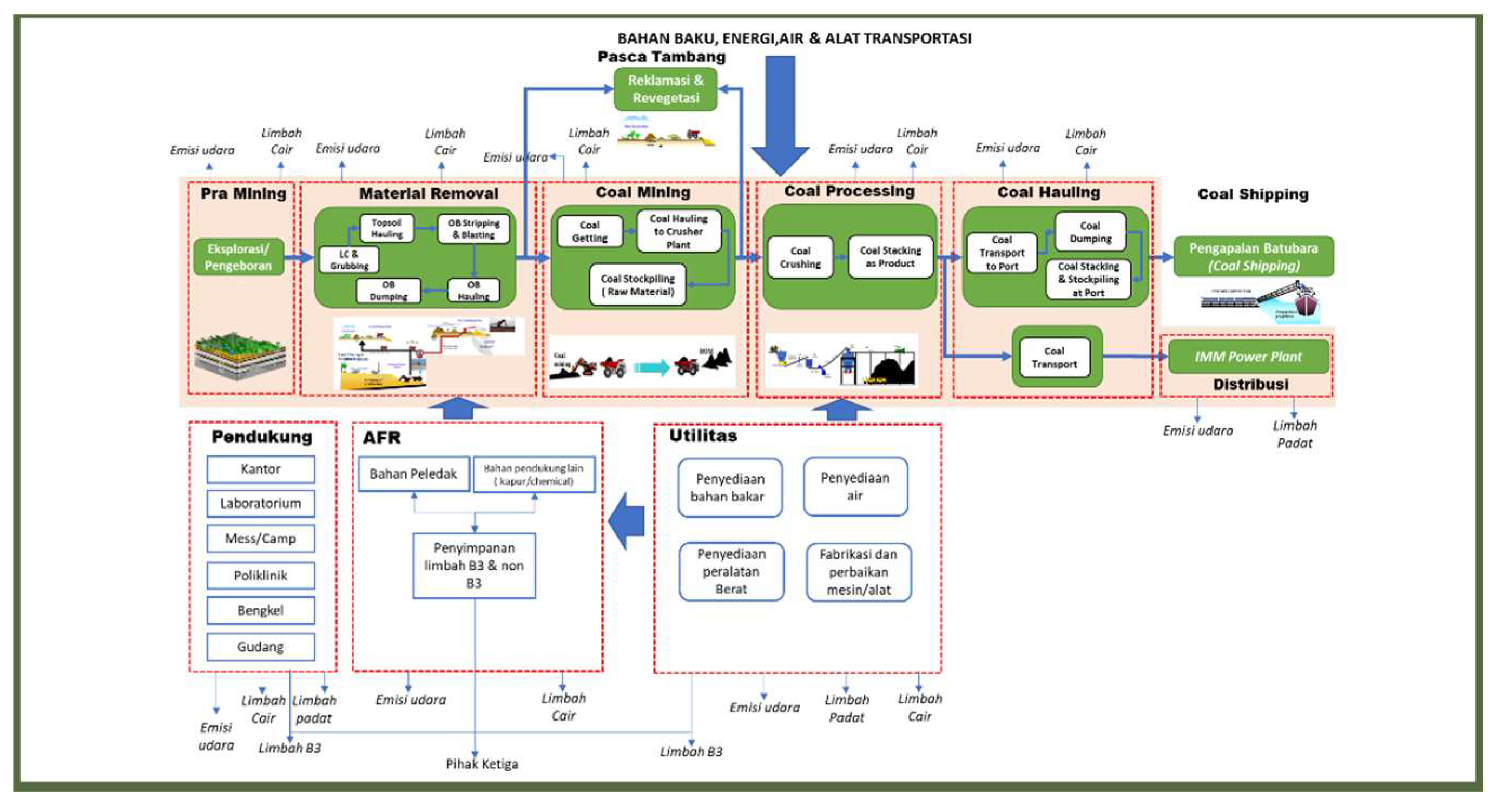

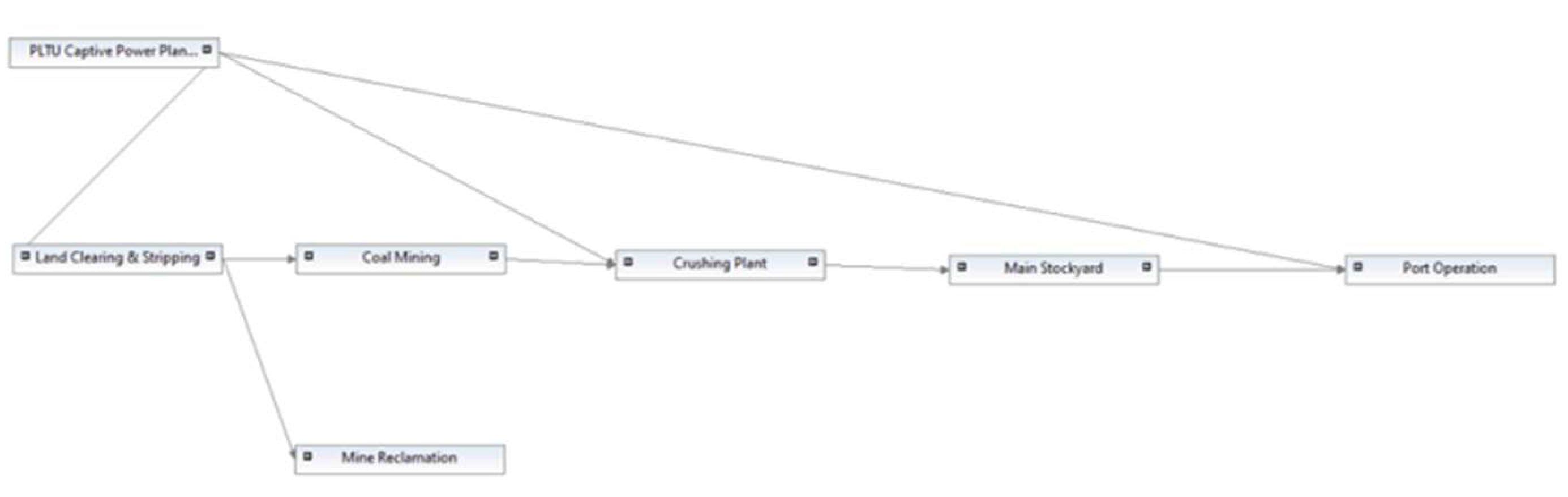

IMM conducted a life cycle assessment study with the scope of Cradle to Gate on the coal mining process until it is ready to be transported through the port unit. The study in general begins with a life cycle inventory, by making a process flow diagram and mass balance in coal production activities as follows.

Figure 3.

Flowchart of Raw Materials, Energy and Waste Generated (Suharyono, et al., 2023).

Figure 3.

Flowchart of Raw Materials, Energy and Waste Generated (Suharyono, et al., 2023).

IMM produces one product type only, namely coal with system boundaries in the LCA study is cradle-to-gate. The function unit used is 1 ton of coal produced. The product system in question is shown in

Figure 4.

Calculation of the impact of life cycle assessment on the previously mentioned scope is carried out using Open-LCA software in assessing the life cycle of coal products produced. Where the life cycle assessment is carried out using 2 methods, namely CML 2 baseline 2000 and Re-Ci-Pe 2016 Midpoint (H), with the following results.

The highest impact is abiotic depletion of 13.17323 kg Sb-eq/year/ton of coal from coal mining activities. The next highest impact which is a potential area of improvement is in the category of global warming impact of 39.9518 kg CO2-eq/year/ton of coal which is a direct impact of the use of diesel fuel derived from coal mining activities. The largest potential area of improvement is in the use of fuel oil which plays a major role in the global warming impact category.

2.2. Environmental Management System: ISO 14001

In addition to the implementation of the life cycle assessment initiated by IMM, the company has also been certified with ISO 14001: 2015 Environmental Management System (EMS) which covers all operational areas ranging from mining to the management of special ports for coal transportation terminals. One of the activities to implement the EMS is conducting socialization to stakeholders regarding the implementation of good mining procedures and rules. IMM also manages a tour showing participants good mining practices as part of the EMS program implementation, which is shown in

Figure 5.

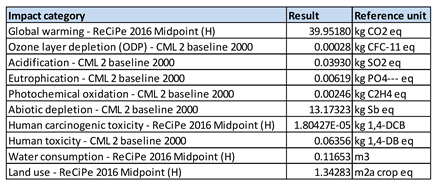

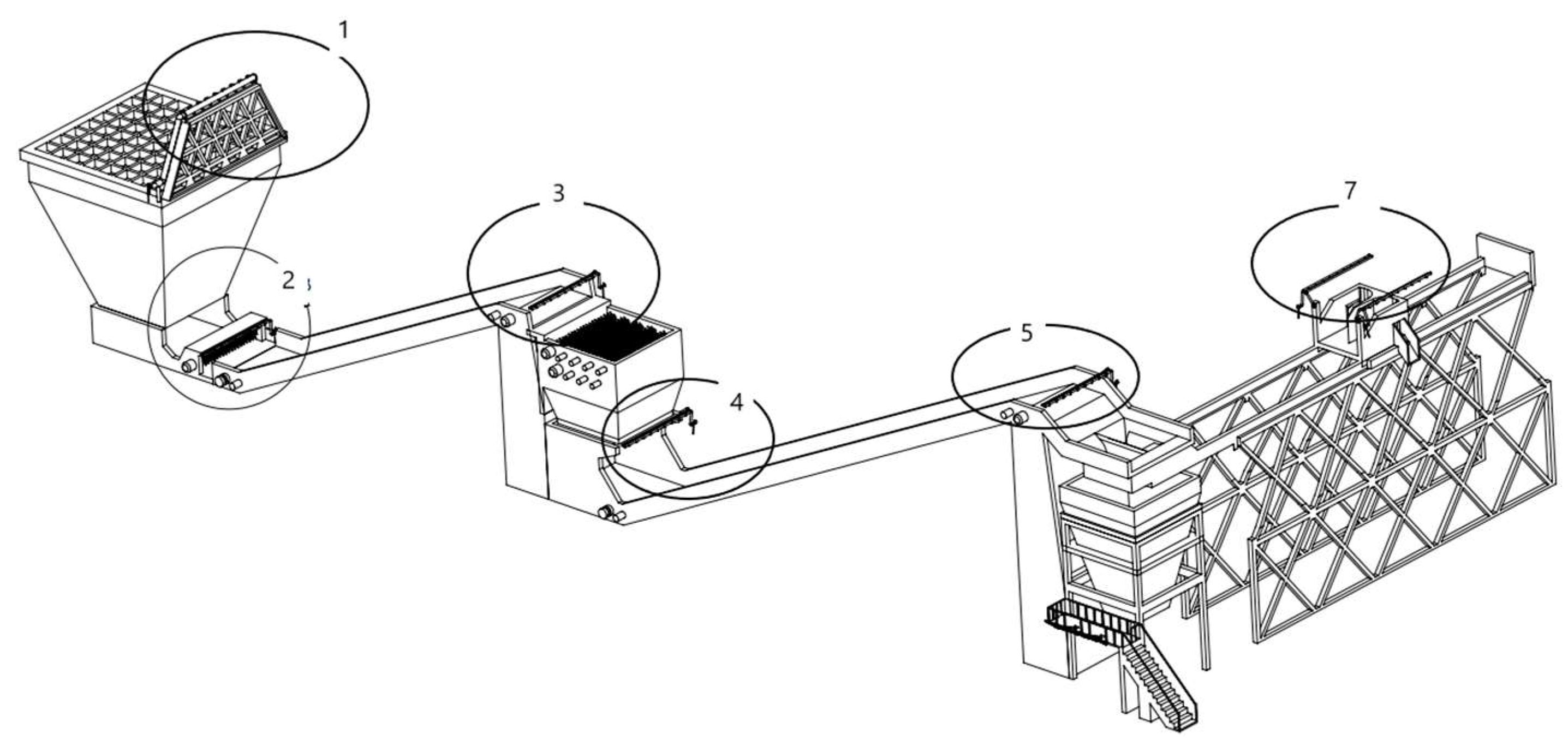

2.3. Energy Efficiency: Coal Conveyor Edge Cleaning System Modification

Rubber skirt systems are used to concentrate most of the material and minimize coal spillage. There is often damage to the section between the skirting and the conveyor belt. For this reason, the idea of modifying the rubber skirt and installing a high-pressure air blower to protect the conveyor belt from damage emerged. Through this modification idea, a design is also made in determining the best position of the conveyor edge cleaning equipment. This Conveyor Edge Cleaning System (SASS) is able to extend the life of the conveyor belt from 26 months to 55 months.

Figure 6.

Illustration of the Conveyor Edge Cleaning Program (Estiarko, et al., 2022).

Figure 6.

Illustration of the Conveyor Edge Cleaning Program (Estiarko, et al., 2022).

This program was initiated and has been running since 2021 with an estimated energy efficiency calculation of 1,624.00 GJ per year.

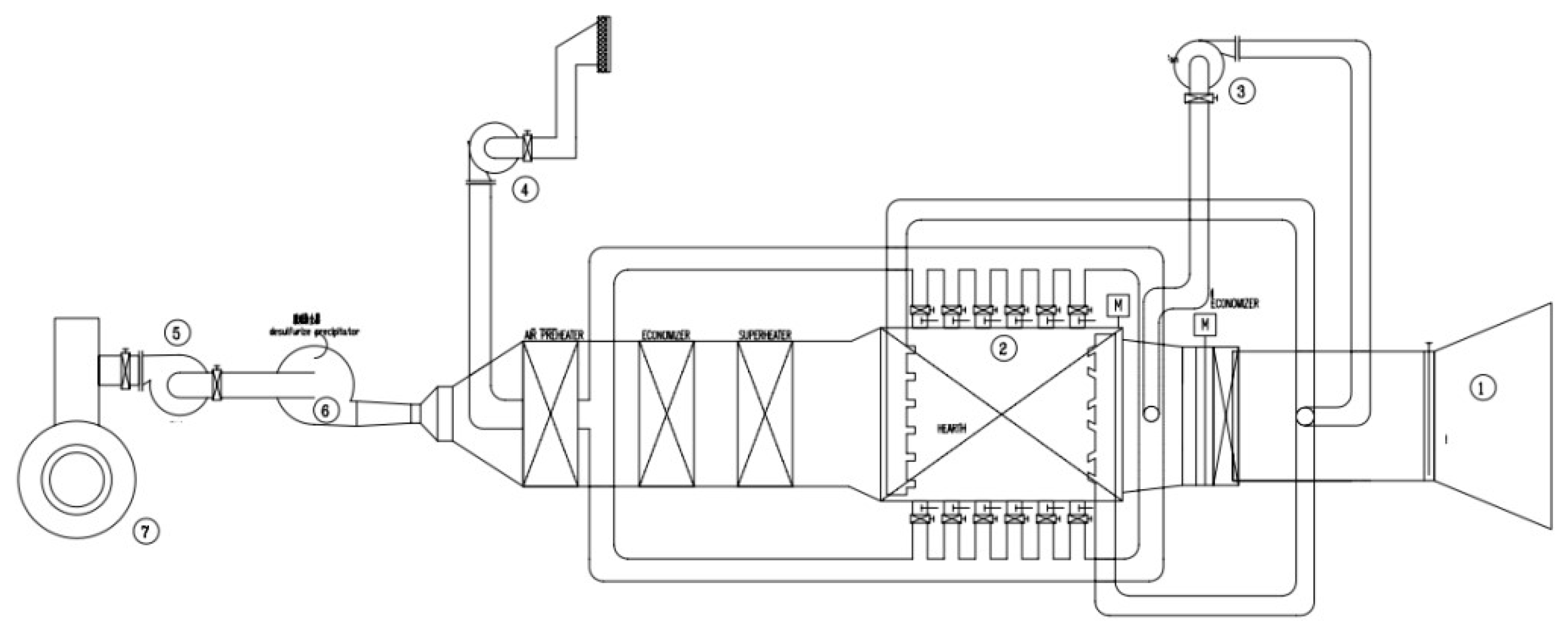

2.4. Emission Reduction: Coal Combustion System Optimization with Secondary Air Fan

IMM has 2 PLTU boiler units each with ID-Fan, PA-Fan, and SA-Fan to control combustion. The initial problem occurred due to overheating in the boiler caused by fluctuations in load (swing load) so that slagging and bar grate melting formed which is an indication if the furnace reaches a temperature of > 1300 deg-C. While the maximum design capacity is 1200 deg-C and this condition is associated with the formation of NOx emissions at temperatures > 1250 deg-C. The idea of innovation is done by controlling the combustion ratio so that the temperature in the boiler furnace returns to normal, so that NOx is automatically normalized and below the threshold value. The illustration of the innovation is shown in

Figure 7.

This SAF innovation does not financially provide savings from the operational side to the company, but is able to increase competitive products from optimizing electricity generation operations, and is able to have a positive environmental impact on energy efficiency with an absolute result of 1,034.9 ton-NO2 per year. This innovation is also able to reduce conveyor belt waste through the extension of equipment life.

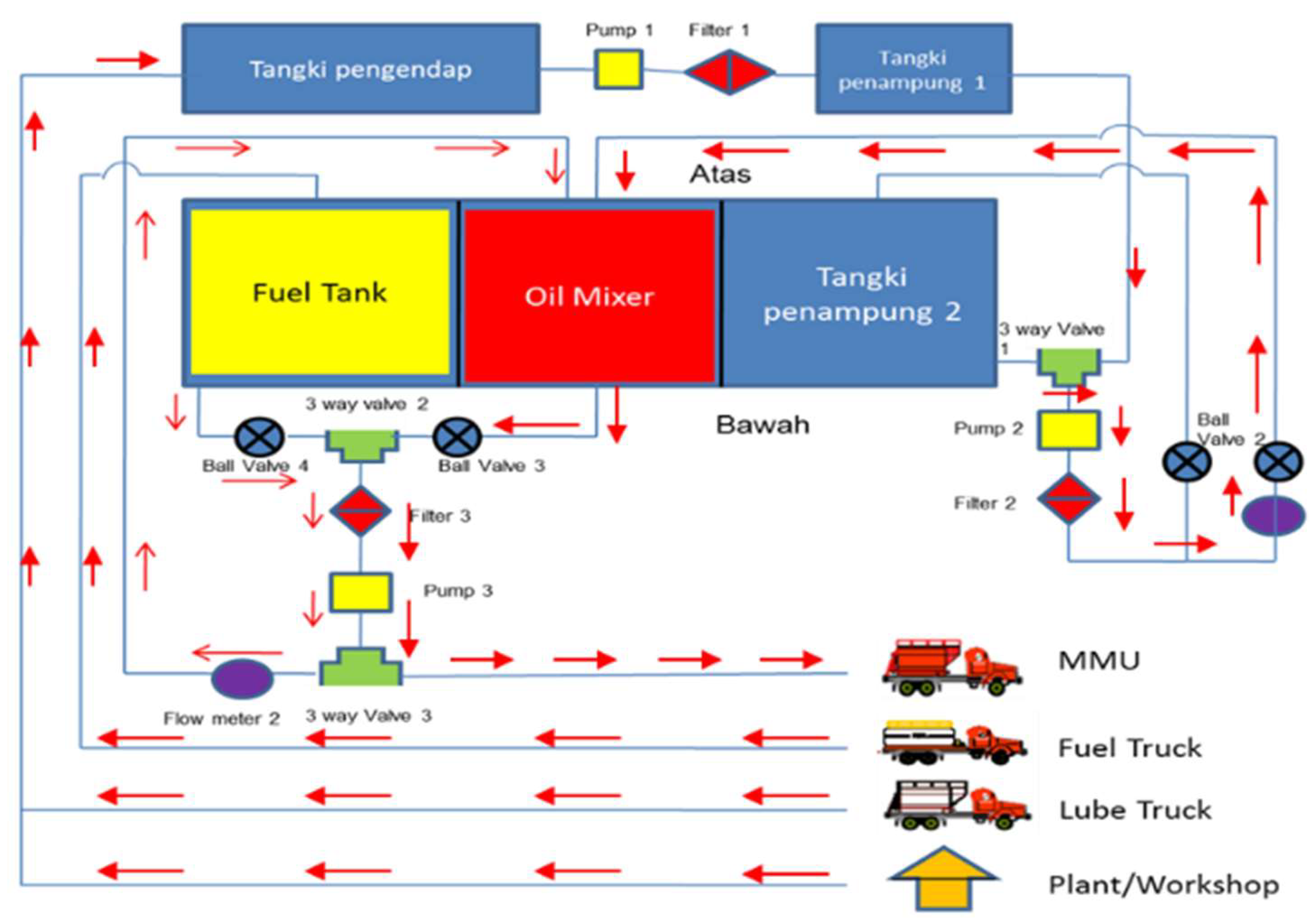

2.5. Hazardous Waste Management: Utilization of Used Oil for Fuel Substitution in Blasting Activities

Coal mining activities are dominated by the use of heavy vehicles for hauling activities. This has an impact on the generation of used oil generated from vehicle maintenance activities. For this reason, an innovation was made to utilize used lubricating oil to be mixed with diesel fuel into fuel oil as a substitute for ANFO in blasting activities. This innovation changes the scheme of using explosives that were previously imported from outside and stored in the explosives warehouse, currently substituted by utilizing hazardous waste. The implementation of the program is shown in

Figure 8.

This innovation is also able to provide a positive environmental impact on reducing the use of commercial explosives and is able to utilize used oil B3 waste of 569.38 tons per year, thereby reducing the generation of B3 waste while reducing the transportation factor of explosives and transportation of B3 waste.

2.6. Solid Waste Management: Introducing the Use of Eco-Tumblers Among Company Contractors and Staf

The use of single-use plastic mineral water bottles causes high plastic waste generation from operational activities at IMM. Not to mention that the total number of employees and contractors who are active in IMM is amounting to more than 2,000 personnel, which certainly has increased the consumption of single-use plastic mineral water bottles that produce lots of plastic waste. The lack of access to plastic waste management causes an imbalance in the total waste generated and managed, so a replacement is made using what is called an “Eco-Tumbler”. This replacement helped reduce plastic waste generated from operational activities both at the mine and in the office area. The documentation of the activity is shown in

Figure 9.

This innovation also succeeded in quantifying environmental improvements from the reduction of plastic waste with a total of 4.8 tons, the absence of reuse of plastic waste for seaweed buoys that have the potential to contaminate aquatic biota, and was able to provide a derivative impact in the form of reduced plastic waste scattering caused by the local macaques.

2.7. Promoting Water Efficiency in the CPP3 Area by Using Automated Sensor on Watering

The Crushing Plant Production (CPP) area’s main activity is reducing the size of coal to match the quality standards of products carried using hauling trucks. The process of transporting coal from the CPP to the Port with a double vessel truck, which when dumped into the port area has the potential to produce coal dust, which is later sprayed with water to minimize the pollution. Initially this process is done manually using valves and labor, but currently a simple PLC sensor is used to do that. This sensor operates automatically according to vehicle activity so as to reduce excess water usage. The appearance of this innovation is shown in

Figure 10.

This innovation also succeeded in providing added value to environmental improvement through effective water usage of 544,137.00 m3 per year from the previous 616,494.00 m3 per year, reducing the potential for coal dust, and reducing the potential for coal dust exposure to workers.

2.8. Mine Water Management: Design of Acid Mine Drainage Treatment System with Artificial Wetland

Artificial Wetland, which people also often refer to as constructed wetland, can function as a Wastewater Treatment facility by utilizing a combination process between plants, organic media, microbes, and soil in waterlogged conditions. There are two types of Artificial Wetlands, namely surface flow system or Free Water System (FWS) and sub-surface flow system (SSF), but the embodiment of this invention uses Artificial Wetlands with surface flow system (FWS).

The prototype design of the Acid Mine Drainage treatment unit with Artificial Wetland is shown in

Figure 11.

The dissolved organic matter treatment unit has the function of a dissolved organic matter treatment unit. It is a unit consisting of several compartments that takes into consideration the Biochemical Oxygen Demand (BOD) load generated from the organic matter used. This unit is also facilitated with an inspection road. Inspection roads are ideally built between compartments. The minimum width of the inspection road between embankments is 3 (three) - 5 (five) meters for vehicles to pass with a maximum slope of 12% (twelve percent). The road surface is anticipated to withstand vehicle loads and prevent erosion and damage.

2.9. Biodiversity Conservation: Digital Database System to Monitor the Success of Biodiversity Conservation

Biodiversity protection monitoring is a mandatory activity in the mineral and coal mining sector. In practice, the data collection system for conservation monitoring results is quite difficult to recapitulate due to individual data storage. For this reason, an integrated database system was innovated to monitor the success of conservation, including those based on community empowerment. This innovation is based on ArcGIS technology and a single analytic dashboard scheme that facilitates user access. One of the other functions of this innovation is the monitoring of Mangrove Conservation and Integrated Farming System (IFS) programs which are the icon of Reclamation and Mine Closure carried out by IMM.

Figure 12 depicts this innovation:

This innovation is able to quantify environmental improvements from reclamation and re-vegetation activities in the form of the success of the employee initiative seed bank of 29,952 seeds per year, the conservation of 5 ha of mangroves, and the conservation of natural shreds in 28,070.00 types of local species and fast growing species.

2.10. Community Development: Promoting Sanitation and Clean Water to Address Community Water Scarcity

Prior to 2013, most people in Desa Santan Tengah faced the issue of clean water scarcity, so they used water from the ditch in front of their house that was blackish in color, collected rainwater, or for residents who lived close to the Santan River would take river water to settle for some time before being used for toilet needs, while for drinking water most people bought clean water sold around by water traders. Not to mention the cost of water that needs to be paid every month tends to reduce the quality of community welfare. For this reason, IMM with the collaboration of the Village Government attempted to obtain a clean water source by making an earthen pond for rainwater storage or swamp infiltration water for the first time in the RT 09 community unit, where the Handil Hamlet is located (IMM, 2021). The program did not go well due to the dry season that caused drought. Since then, IMM has continued to strive for social innovation in overcoming this water scarcity, until finally in 2014 it initiated infrastructure support for clean water pipelines so that it was able to reach water distribution to residents' homes, initially as many as 40 home units made possible through a collaboration with the village-owned enterprises. The appearance of this program is shown in

Figure 13:

Value Creation from this innovation is a change in the value chain of water as a source of life for the community, which was previously a major difficulty, and is now able to become a driver of the wheels of life so as to improve living standards both economically, socially, environmentally, and public health. This innovation also supports the Social Life Cycle through reduced CO2 emissions from clean water transportation, reduced potential for clean water spills from transportation with an estimate of 1 m3 per year. In addition, the SDGs support in this program is tiered from (1) No Poverty, (2) No Hunger, (3) Good Health, (6) Clean Water & Sanitation, (8) Decent Work and Economic Growth, (10) Reduced Inequalities, (12) Responsible Consumption, to (17) Partnership to Attain the Goals.

3. Discussion

From the presentation of the results of the implementation of sustainability-based programs that IMM carried out, it is known that there are at least 10 program initiatives, 2 of which are the implementation of a management system based on ISO 14001 and based on life cycle assessment through LCA inventory and simple simulations that show the results of the impact assessment of coal mining activities for the scope of the Cradle to Gate system boundaries, namely starting from land clearing activities, mining processes, to delivery of coal materials to port units.

it is known that there are at least 10 program initiatives, 2 of which are the implementation of a management system based on ISO 14001 and based on life cycle assessment through LCA inventory and simple simulations that show the results of the impact assessment of coal mining activities for the scope of the Cradle to Gate system boundaries, namely starting from land clearing activities, mining processes, to delivery of coal materials to port units.

4. Conclusions

From the results of the discussion above, the following conclusions are obtained.

Environmental management initiatives that have been implemented are based on the principle of continuous improvement through the implementation of ISO 14001 Environmental Management System.

The technological approach applied in IMM is based on energy management initiatives with measurable results of 1,624.00 GJ, emission reduction of 1,034.9 ton-NO2 per year, hazardous waste management of 569.38 tons, water resources management of 544,137.00 m3 and initiation of acid mine drainage management design, to monitoring the success of reclamation and re-vegetation based on information technology and mapping.

The social and environmental approach applied in the discussion of this paper is in the plastic packaging waste control program through the Eco-Tumbler program which is a culture-based activity to bring their own tumblers in the mining environment, this program has reduced plastic packaging waste by 4.8 tons of plastic waste. In addition, there is also a social impact management approach through support for the provision of clean water sources to improve health and basic needs of the community in Santan Tengah villages around the mining area with a total of 40 local home residents.

5. Recommendations

From the above explanation, there are the following recommendations.

The implementation of the implemented program needs to be monitored periodically to measure the level of achievement and usefulness of the program with sustainable development goals.

The development of programs that support environmental sustainability and efforts to address climate change is an important part that needs to be considered in future publications.

by 1,624.00 GJ, reducing conventional emissions by 1,034.9 ton-NO2 per year, reducing domestic waste by of 4.8 tons of plastic waste, utilizing hazardous waste such as used oil as a substitute for explosives by 569.38 tons, reducing water usage by 544,137.00 m3, reducing wastewater pollution loads by artificial wetland, conserving Mangroves covering 5 ha and the conservation of natural shreds in 28,070.00 types of local species and fast growing species, and empowering communities to use desalinated water in salt pond activities for 40 local home residents.

Acknowledgement

We would like to thank the leadership of xxx for their continuous support in the implementation of environmental management improvement programs, supported by company personnel who have been equipped with competencies in their fields. We would also like to thank the company's stakeholders, who have become an integral part of the successful implementation of the program to provide benefits to the surrounding environment, including the community in supporting sustainable living.

References

- Permatasari D., N S., S R., Estiarko L., M T., Saputra E., & Styawan B. (2022) Life Cycle Thinking & Social Sustainability based on Capacity Building: An Insight from Indominco Mandiri, East Borneo – Indonesia ISSN: 2186-2311 The Asian Conference on Sustainability, Energy and the Environment 2021: Official Conference Proceedings (pp. 63-73) . [CrossRef]

- Guinée, J., Heijungs, R. (2024). Introduction to Life Cycle Assessment. In: Bouchery, Y., Corbett, C.J., Fransoo, J.C., Tan, T. (eds) Sustainable Supply Chains. Springer Series in Supply Chain Management, vol 23. Springer, Cham. [CrossRef]

- Ramakrishna, S., Ramasubramanian, B. (2024). Life Cycle Assessment and Tools. In: Handbook of Materials Circular Economy. Springer, Singapore. [CrossRef]

- Elnaggar, A. Nine principles of green heritage science: life cycle assessment as a tool enabling green transformation. Herit Sci 12, 7 (2024). [CrossRef]

- Pinto, A.S.S., McDonald, L.J., Galvan, J.L.H. et al. Improving life cycle assessment for carbon capture and circular product systems. Int J Life Cycle Assess 29, 394–415 (2024). [CrossRef]

- Indominco Mandiri. Company Profile and Portfolio (2024). Internal Report, Unpublished.

- Suharyono., Randy, A., Sulistiana., et al. Life Cycle Assessment – Inventory Report of Indominco Mandiri (2023). Internal Report, Unpublished.

- Suharyono., Randy, A., Yuliana, D., Sulistiana., et al. Life Cycle Assessment – Inventory Report of Indominco Mandiri (2022). Internal Report, Unpublished.

- Indominco Mandiri. Report of Good Mining Practice Tour based ISO 14001 (2024). Internal Report, Unpublished.

- Estiarko, LK., Muslim, BA., Rudianto, W., et al. Coal Conveyor Edge Cleaning System Modification (2022). Internal Report, Unpublished.

- Rudianto, W., Estiarko, LK., et al. Modification of Secondary Air Fan (SAF) System (2022). Internal Report, Unpublished.

- Pawiloi, ED., Estiarko, LK., Rudianto, W., et al. Hazardous waste as an alternative raw material for explosives (2022). Internal Report, Unpublished.

- Raspati, D., Hatta, W., Randy, A., et al. The use of tumblers to reduce plastic waste generated from single-use plastic mineral water bottles (2024). Internal Report, Unpublished.

- Hernowo, H., Purwoko, DN., Sutikno, et al. An Automated Watering Sensor to Promote Water Efficiency in Managing Coal Dust. (2022). Internal Report, Unpublished.

- Saputra, ET., Soebekti, AB., Suharyono, et al. The prototype design of the Acid Mine Drainage treatment unit using artificial wetland. (2023). Internal Report, Unpublished.

- Styawan, B., Herianto, F., Emilia, E., et al. Digital Database System to Monitor the Success of Biodiversity Conservation. (2024). Internal Report, Unpublished.

- Indominco Mandiri. Social and Stakeholder Mapping for Surrounding Mining Operational Area (2021). Internal Report, Unpublished.

- Permatasari, D., Taryono, Napitupulu, TVW., et al., The Preliminary Study of Social Impact Consideration with Emphasis on Water Infrastructure Program to Overcome Clean Water Scarcity among Local Communities in East Kalimantan. (2023). International Conference of Life Cycle Management.

Figure 1.

Operational Location of IMM (IMM, 2024).

Figure 1.

Operational Location of IMM (IMM, 2024).

Figure 4.

Coal Mining Product System (Suharyono, et al., 2022).

Figure 4.

Coal Mining Product System (Suharyono, et al., 2022).

Figure 5.

A Tour Showing Participants Good Mining Practices (IMM, 2024).

Figure 5.

A Tour Showing Participants Good Mining Practices (IMM, 2024).

Figure 7.

Modification of Secondary Air Fan (SAF) System (Rudianto, et al., 2022).

Figure 7.

Modification of Secondary Air Fan (SAF) System (Rudianto, et al., 2022).

Figure 8.

Hazardous waste as an alternative raw material for explosives. (Pawiloi, ED., et al., 2022).

Figure 8.

Hazardous waste as an alternative raw material for explosives. (Pawiloi, ED., et al., 2022).

Figure 9.

The use of tumblers to reduce plastic waste generated from single-use plastic mineral water bottles. (Raspati, D., et al., 2024).

Figure 9.

The use of tumblers to reduce plastic waste generated from single-use plastic mineral water bottles. (Raspati, D., et al., 2024).

Figure 10.

An Automated Watering Sensor to Promote Water Efficiency in Managing Coal Dust. (Hernowo, H., et al., 2022).

Figure 10.

An Automated Watering Sensor to Promote Water Efficiency in Managing Coal Dust. (Hernowo, H., et al., 2022).

Figure 11.

The prototype design of the Acid Mine Drainage treatment unit using artificial wetland. (Saputra, ET., et al., 2023).

Figure 11.

The prototype design of the Acid Mine Drainage treatment unit using artificial wetland. (Saputra, ET., et al., 2023).

Figure 12.

Digital Database System to Monitor the Success of Biodiversity Conservation (Styawan, B., et al., 2024).

Figure 12.

Digital Database System to Monitor the Success of Biodiversity Conservation (Styawan, B., et al., 2024).

Figure 13.

Clean Water Program (Permatasari, D., et al., 2023).

Figure 13.

Clean Water Program (Permatasari, D., et al., 2023).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).