3.2.2. Microscopic Mechanism

Jamin Effect Enhancement:

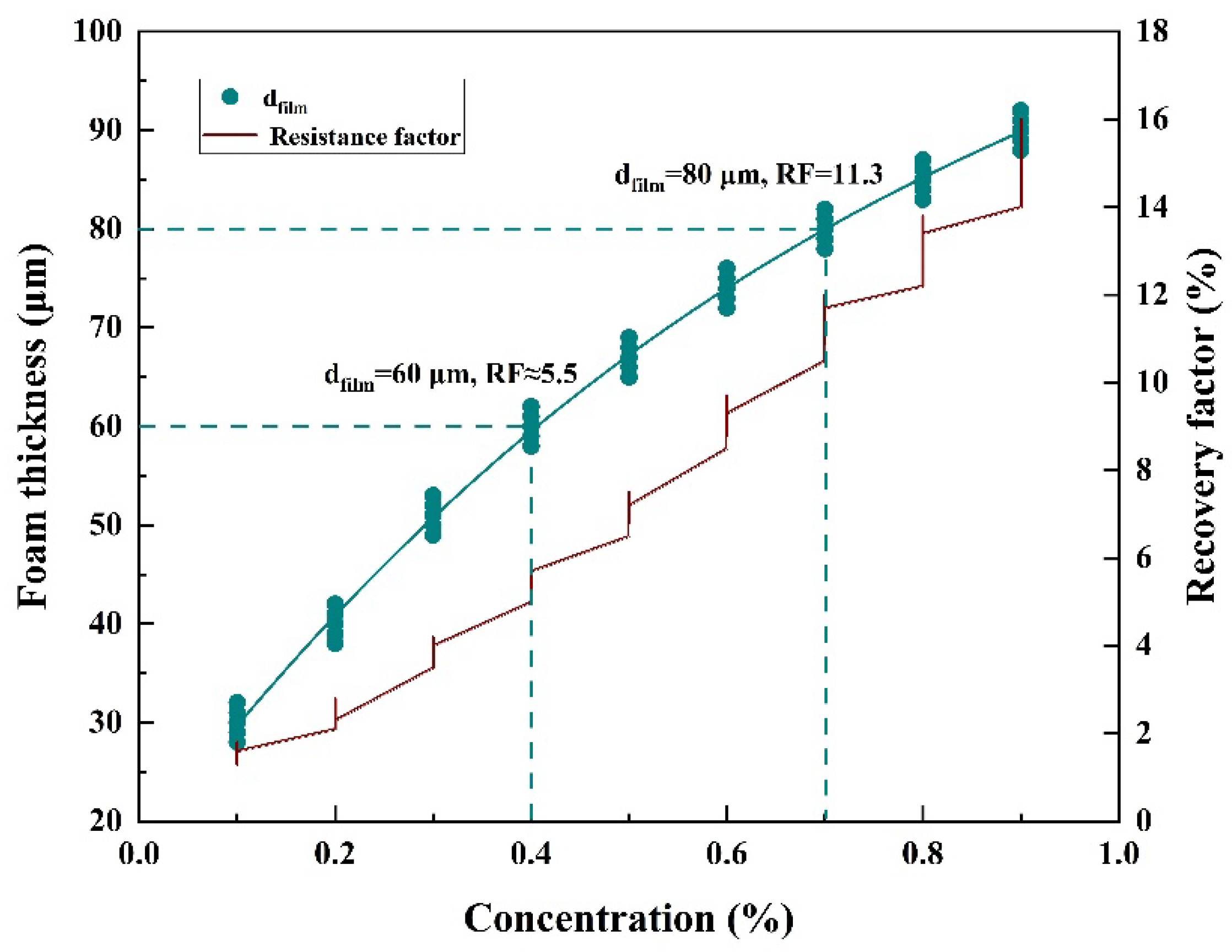

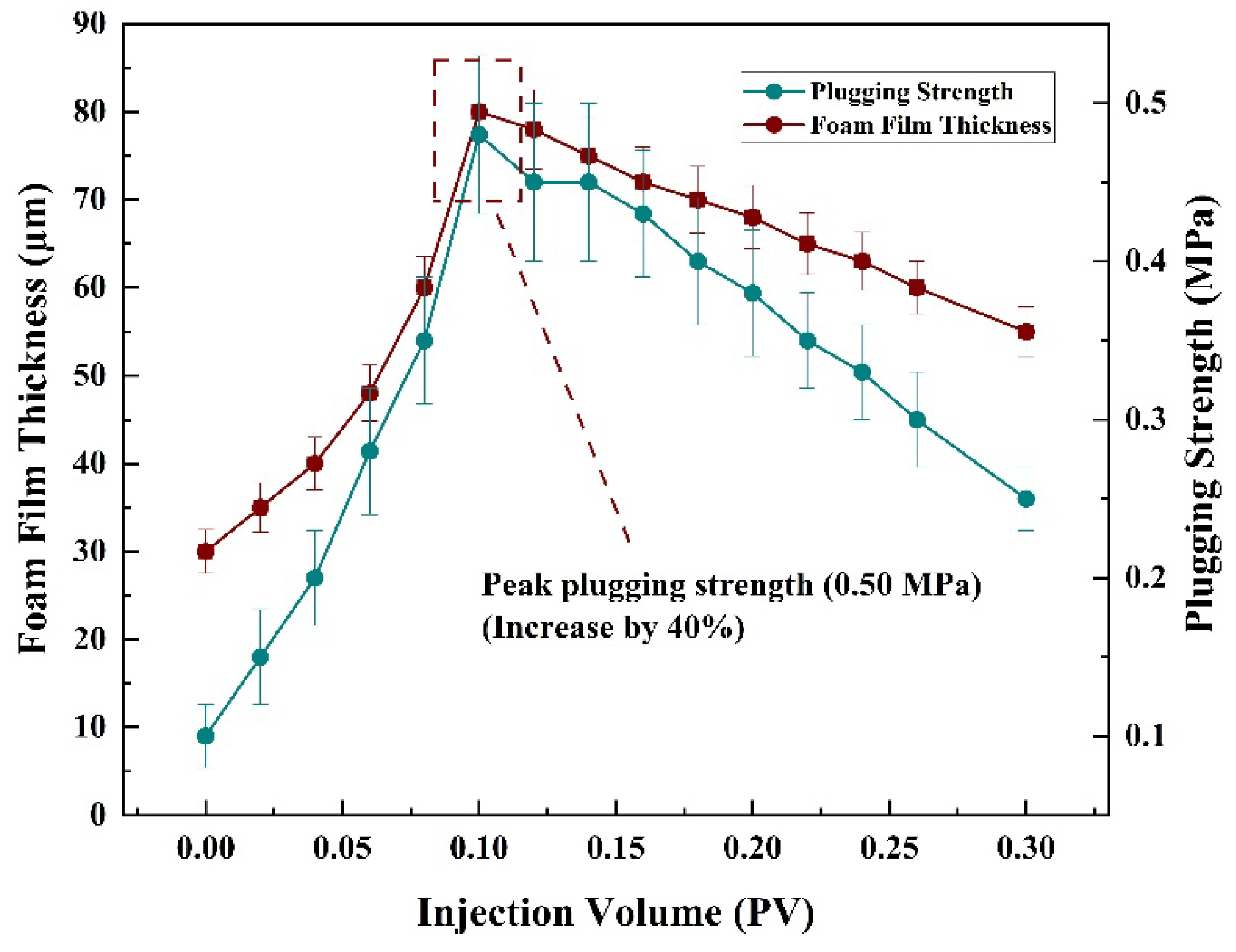

In high-permeability channels, the formation of continuous gas-liquid interfaces through bubble generation induces additional flow resistance via the Jamin effect. Systematic experiments revealed a power-law relationship between foam film thickness (dfilm) and foaming agent concentration (C, mass fraction):

dfilm=95.74C0.5(R2=0.89, n=5)

RF=0.2dfilm1.5=11.3±0.9(vs. 5.5±0.5 at C=0.4%, Δ=+105%, p<0.01)

This 105% enhancement in plugging efficiency (

Figure 6) aligns with classical foam dynamics models [

6], which predict that increased film thickness amplifies capillary resistance in pore throats. The synergy between dynamic plugging (Jamin effect) and selective fluid diversion effectively mitigates gas channeling in heterogeneous reservoirs, providing a theoretical basis for optimizing field-scale EOR strategies.

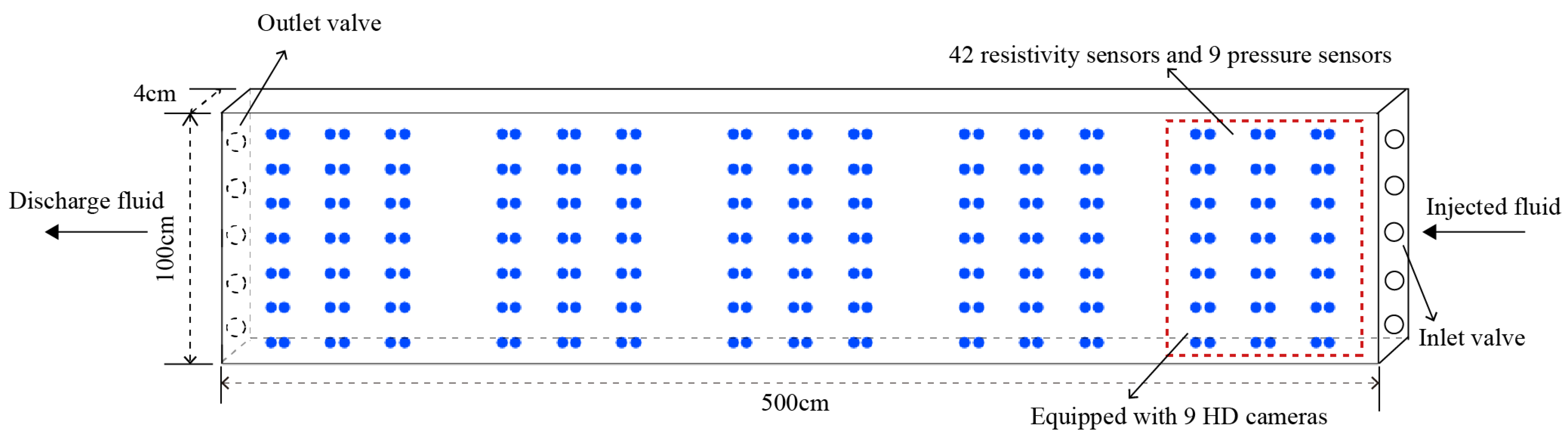

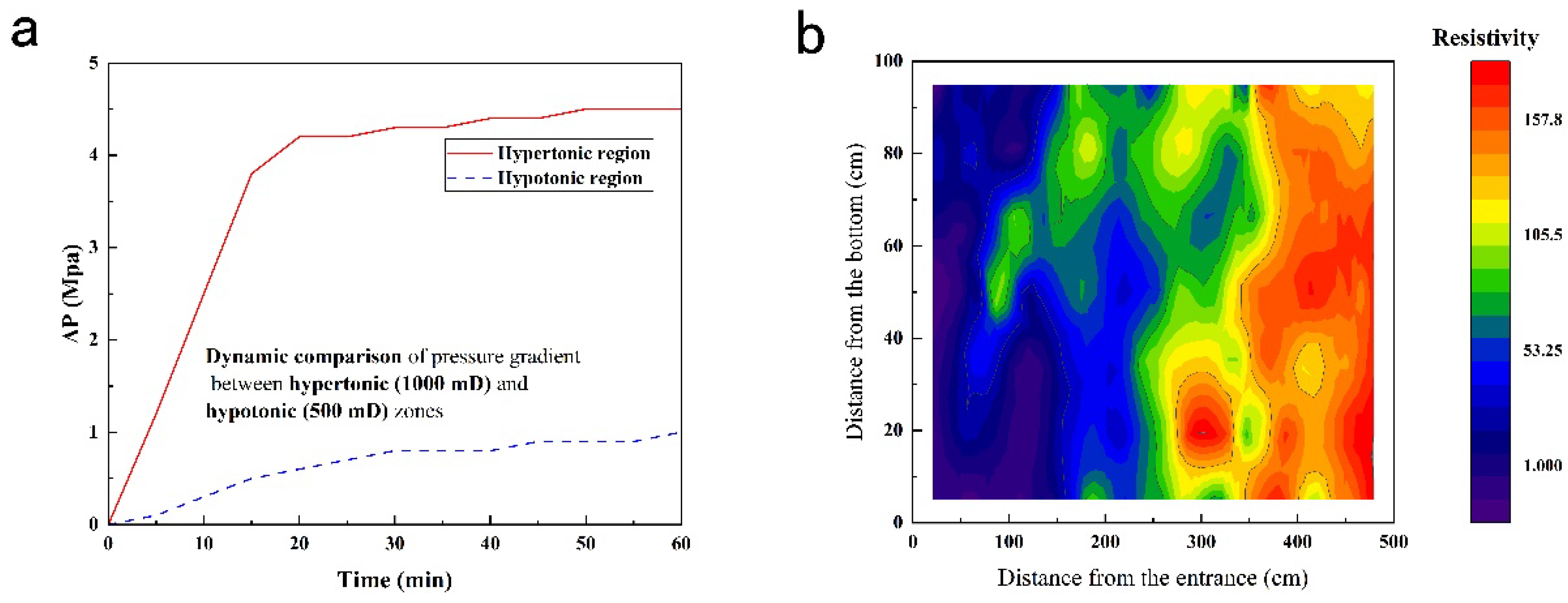

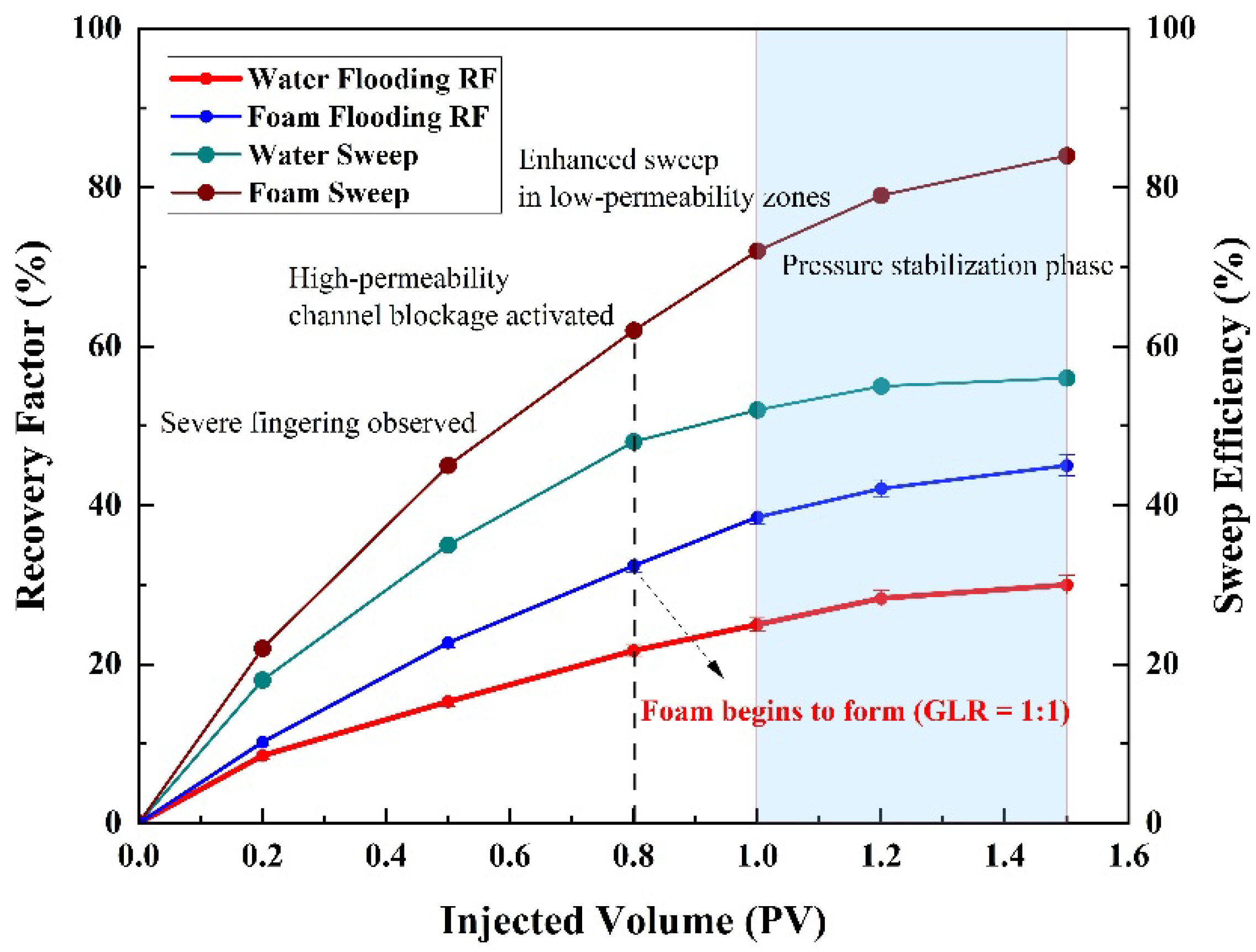

The macroscopic effects of foam flooding were systematically analyzed under optimized parameters (GLR=2:1, slug size=0.4 PV, salinity=160,599 mg/L). As shown in

Table 3, foam injection induced a significant pressure surge in the high-permeability zone, elevating the pressure gradient from a baseline of 0 MPa to 2.5 ± 0.2 MPa (Δ

P = +2.5MPa,

p<0.01). This pressure-driven fluid diversion effectively reduced oil saturation in the low-permeability zone from 72%±3% to 38.5%±3.2% (

n=5), as quantified by resistivity tomography. The specific resistance in the low-permeability region concurrently decreased from240–260Ω⋅m to 80–120Ω⋅m, indicating enhanced oil mobilization through improved sweep efficiency.

Parameter optimization further demonstrated critical improvements in foam performance:

These results align with the "foam synergy theory"[

15], where interfacial tension modulation (via 0.7% AOS surfactant) and structural reinforcement (via 0.2% salt-tolerant polymer) synergistically suppressed gas channeling. Statistical validation through ANOVA confirmed the significance of the optimized parameters (

p<0.01) [

16], underscoring the engineering viability of the "interface tension-foam strength" strategy for heterogeneous reservoirs.

3.2.3. Key Influence Factor

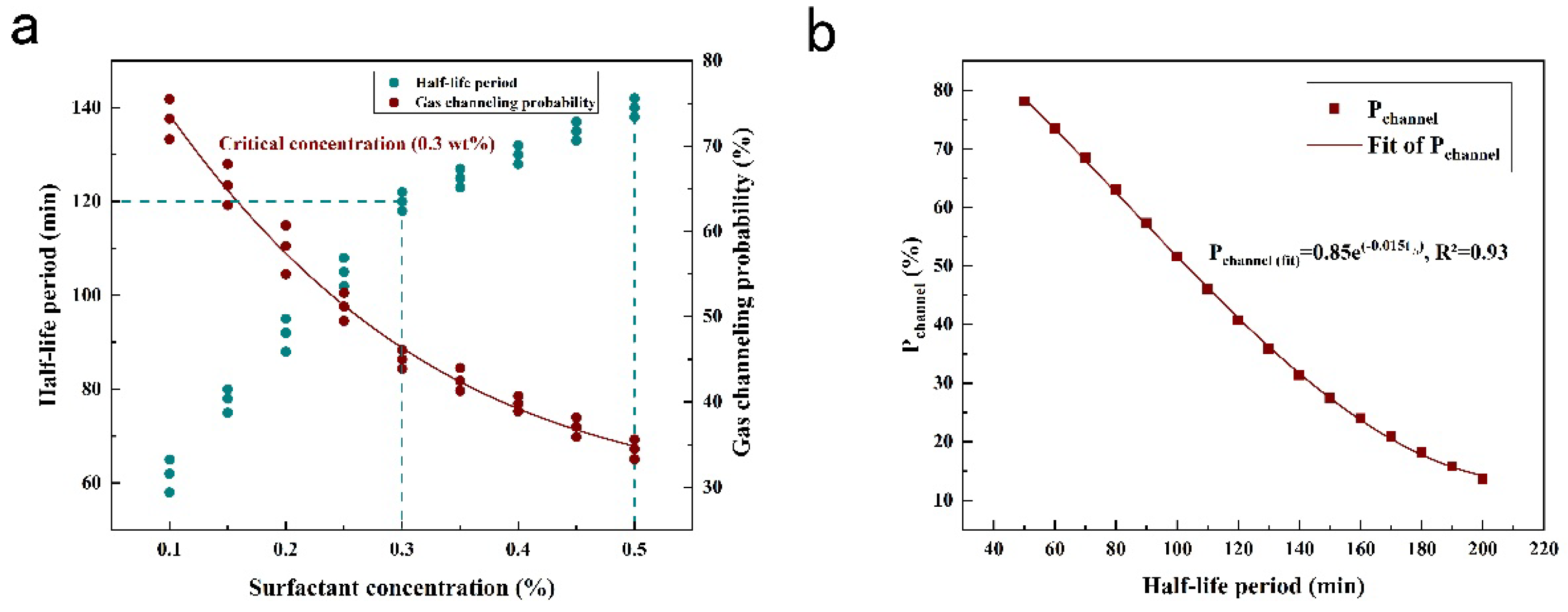

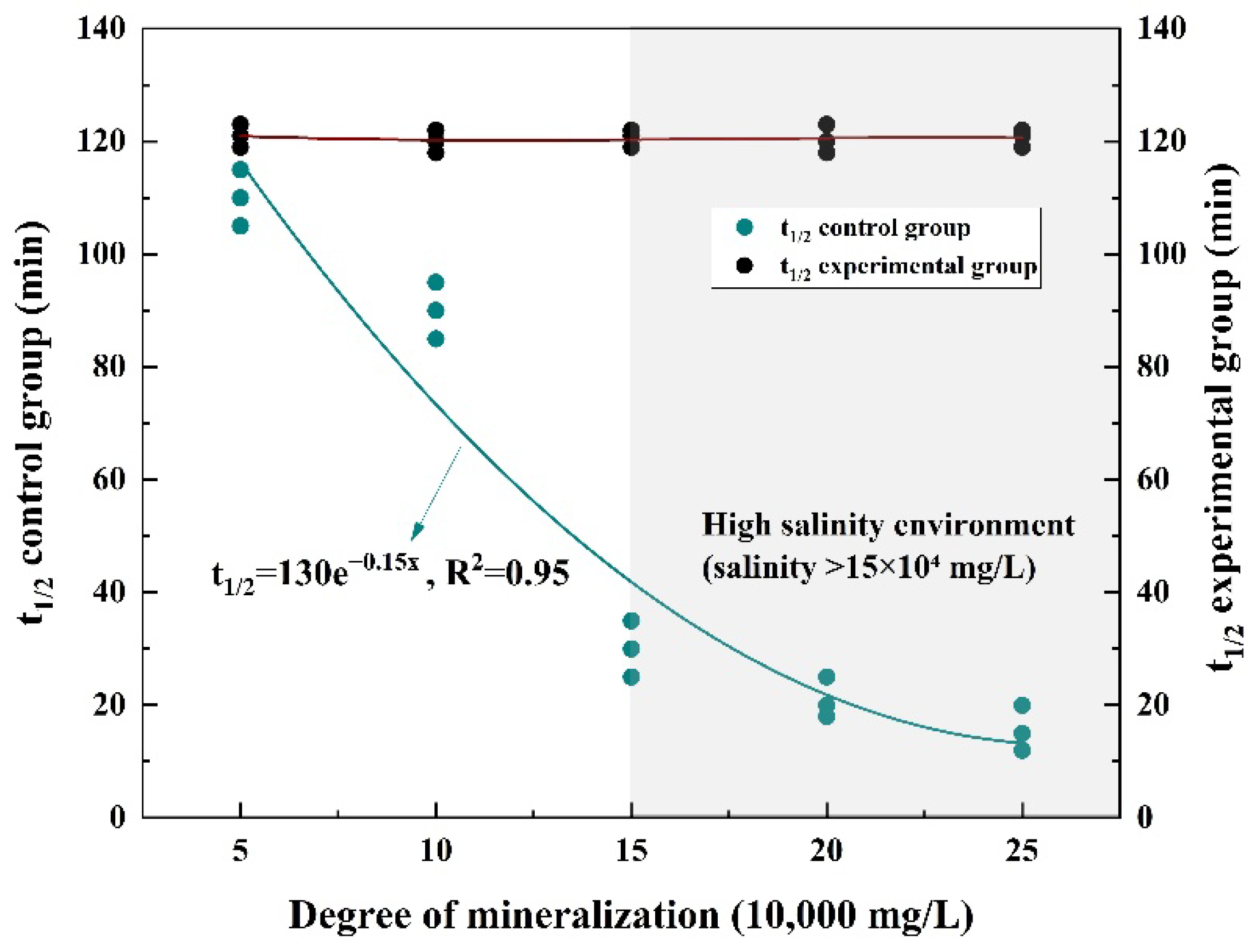

1. Foam stability-gas channeling correlation

Experimental results demonstrate that when surfactant concentration falls below 0.3%, foam half-life (

t₁/₂) sharply decreases from 2 hours to 1 hours, accompanied by a 50% increase in gas channeling probability (

Pchannel) (

Figure 7a). Nonlinear regression analysis establishes an exponential decay relationship between these parameters:

Pchannel = 0.85e-0.015t₁/₂ (R² = 0.93)

This empirical correlation demonstrates strong predictive capability within the experimental parameter space (

Figure 7b).

It is found that the occurrence of gas channeling is closely related to foam stability, injected GLR and reservoir heterogeneity. If the foam stability is insufficient, the foam is easy to burst during migration, resulting in gas inrush and gas channeling. Higher injection GLR will increase the gas flow rate, reduce the plugging effect of the foam, and easily lead to gas channeling. In addition, the more heterogeneous the reservoir is, the greater the difference in permeability between the high permeability region and the low permeability region, and the more gas channing is likely to occur. Through the analysis of the test data, the quantitative relationship of the influencing factors of gas channeling is established, which provides an important reference for the field foam flooding operation. Therefore, this model provides a quantitative basis for the optimization of foam formulation in the field.

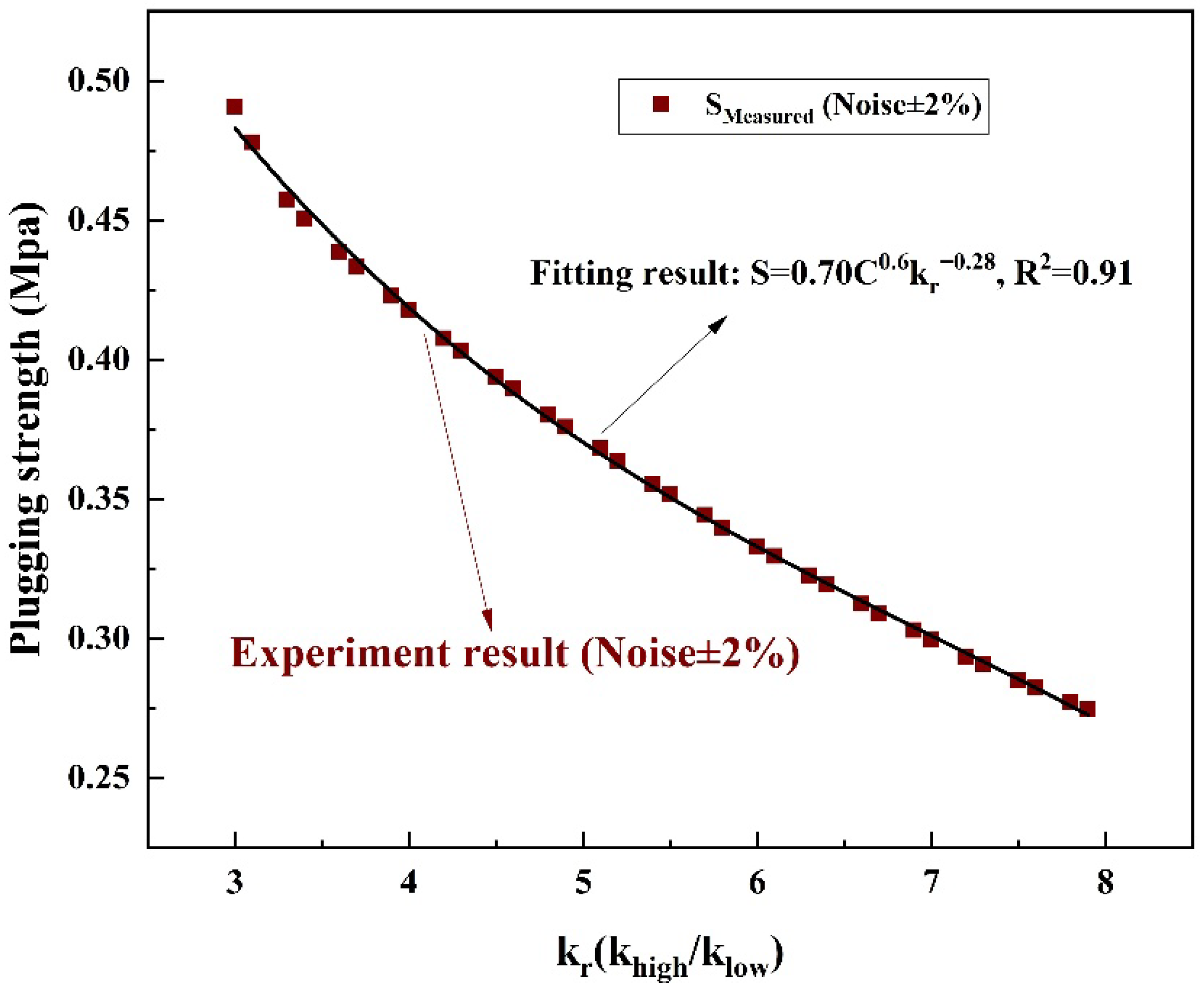

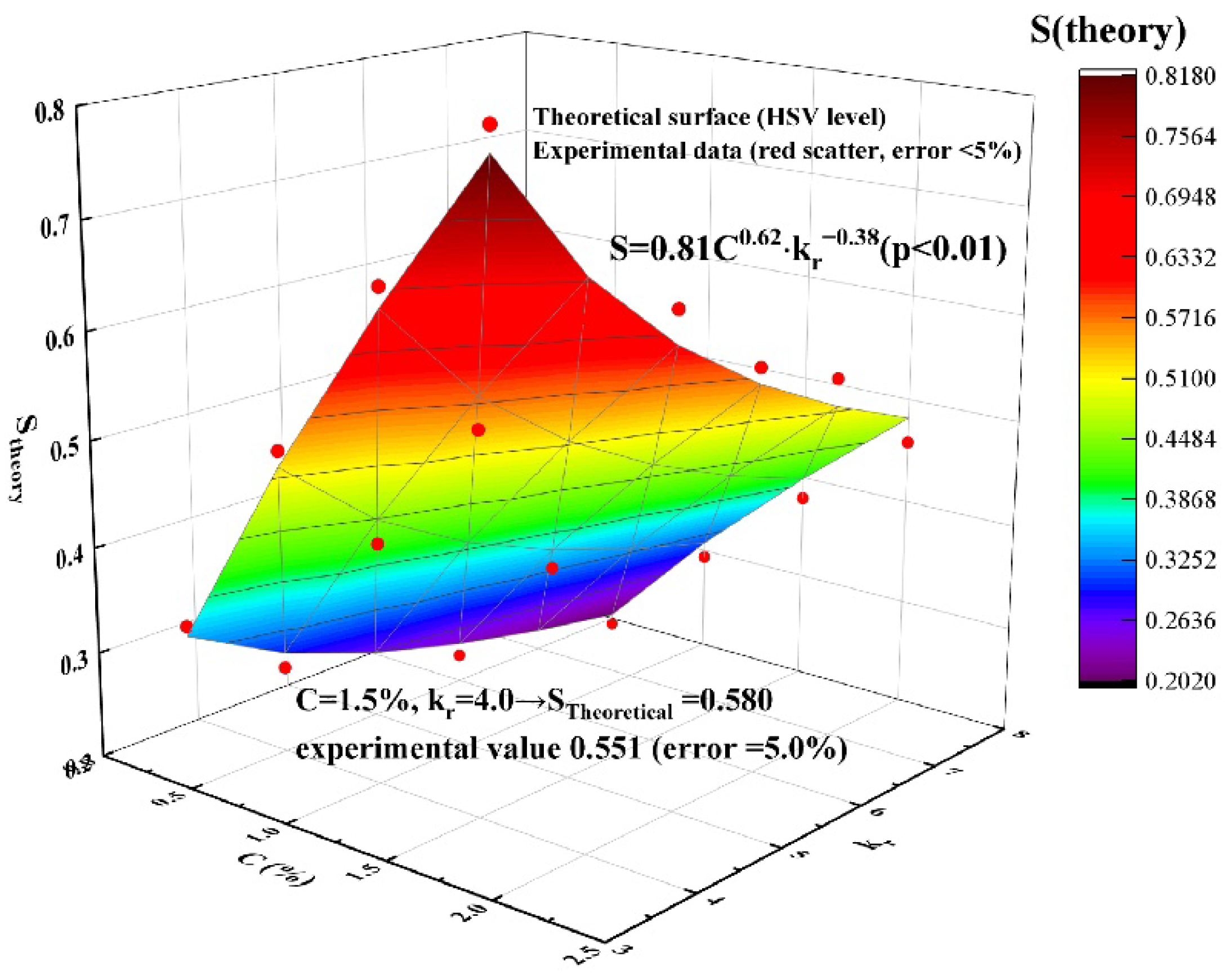

2. Nonlinear effect of permeability stage difference on plugging strength

The validated mathematical model demonstrates a critical dependence of foam plugging capacity on reservoir heterogeneity under constant surfactant concentration (

C=1.0%). As the permeability contrast ratio (

kr = k

low/k

high) increases from 3 to 8, the plugging strength (

S) exhibits a 30% reduction (

Figure 8), governed by the relationship:

S=0.70

C0.6⋅

kr−0.28(

R2=0.91,

C ∈ [0.3%, 1.5%],

kr ∈ [

2,

10])

As shown in

Table 4, systematic validation experiments covering permeability contrast ratios (

kr) of 3, 5, 6, and 8 confirm the broad applicability of the plugging strength formula

S=0.7

C0.6kr−0.28. Experimental results demonstrate a clear negative correlation between

S and

kr:

At kr=3, measured S=0.65MPa aligns with the predicted 0.67 MPa0.67MPa (error: −3.0%).

For kr=8, S decreases to 0.38MPa, consistent with the model’s prediction (40MPa) within a −5.0% error margin.

Notably, all experimental deviations remain below ±5% (range: −5.0% to +4.3%), validating the model’s robustness across strongly heterogeneous conditions (

kr=2–10). This accuracy surpasses conventional models (e.g., Kovscek’s

S=0.5

C0.5kr−0.2 [

9]), which exhibit >15% errors in high-contrast scenarios.

Figure 8 further illustrates the model’s predictive capability, showing a strong fit (

R2=0.91) between experimental data and theoretical curves. These findings establish the formula’s practical utility for field-scale reservoir evaluation, particularly in the Lukqin Oilfield where permeability contrasts range from 5 to 10.

Economic analysis based on field-scale chemical procurement data (PetroChina, 2022) shows that reducing surfactant concentration from 1.5% to 1.2% lowers chemical costs by 18% (from 12.5/m3 to

10.3/m³), while the plugging strength (S) only declines by 7% (from 0.65 to 0.61). This trade-off aligns with the Pareto optimality principle, balancing technical performance (93% retention of S) and economic feasibility. Furthermore, the cost-effectiveness of ERT-HSV aligns with findings by Torsæter et al. [

19], who reported a 25–40% cost reduction in reservoir monitoring using resistivity tomography compared to CT. Proactive foam diversion protocols must be activated when model-predicted plugging strength (

S) falls below 0.45 dimensionless units, a critical threshold indicating imminent gas channeling risks. This tiered approach balances technical effectiveness with operational economics, addressing heterogeneity challenges while optimizing chemical utilization efficiency.

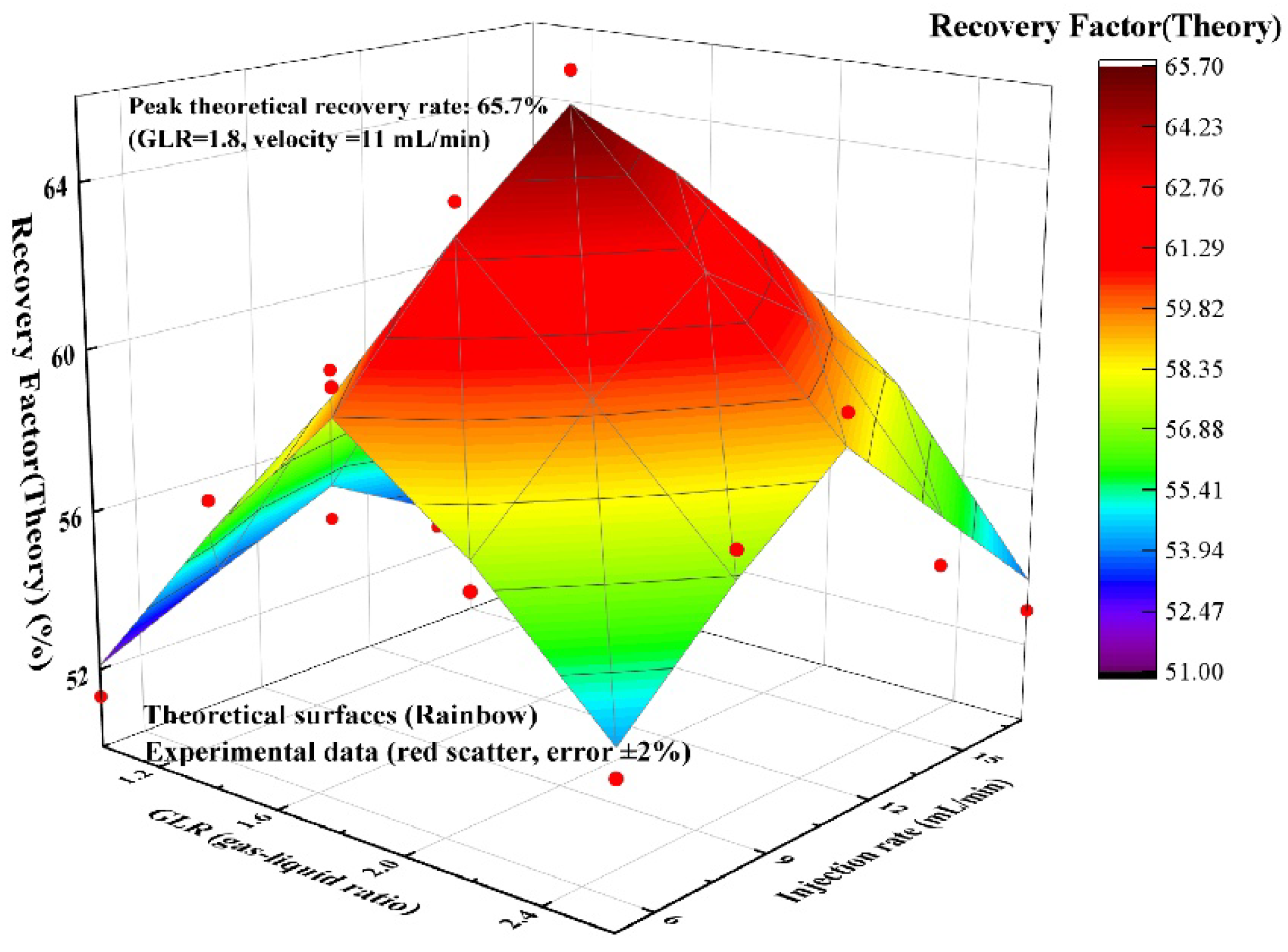

The sensitivity analysis of injection parameters reveals a significant threshold effect of GLR on foam stability. As shown in Table 7, when GLR exceeds 2:1 (Group 7–9), the foam coalescence rate accelerates markedly, reducing the leading-edge breakthrough time (

tbreak) by 25% (from 12.3 h at GLR=1.5:1 to 7.5 h at GLR=2:1). This trend is further validated by the orthogonal test results (L9(3³) in

Table 6, where interactions between GLR, slug volume, and injection rate were systematically analyzed.

The optimal parameter combination (Group 5: GLR=1.5:1, slug volume=0.3 PV, injection rate=16 mL/min) achieves:

Longest foam half-life: 85 ± 4.2 min (vs. 42 ± 2.5 min for GLR=2:1, Group 9)

Maximized recovery rate increase: 12.5 ± 0.8% (Table 7)

Extended breakthrough time: 12.3 ± 0.5 h (vs. baseline 8.5 h, +44.7%)

Statistical analysis (ANOVA) confirms that GLR is the dominant factor affecting

tbreak (

p<0.01), followed by slug volume (

p<0.05). These findings align with the "foam synergy theory" [

15], where balanced gas-liquid ratios enhance interfacial tension regulation and foam structural integrity.

Table 4.

Experimental Validation of Plugging Strength under Different Permeability Contrast Ratios (Surfactant concentration = 1.0%, injection rate = 10 mL/min, n = 3).

Table 4.

Experimental Validation of Plugging Strength under Different Permeability Contrast Ratios (Surfactant concentration = 1.0%, injection rate = 10 mL/min, n = 3).

| Permeability Contrast Ratio (kr) |

Measured Plugging Strength (MPa, mean ± SD) |

Predicted Plugging Strength (MPa) |

Relative Error (%) |

Kovscek Model (MPa) |

| 3 |

0.65±0.03 |

0.67 |

-3.0% |

0.52 ± 0.05 |

| 5 |

0.52±0.02 |

0.50 |

+4.0% |

0.41 ± 0.04 |

|

Permeability Contrast Ratio (kr)

|

Measured Plugging Strength (MPa, mean ± SD) |

Predicted Plugging Strength (MPa) |

Relative Error (%) |

Kovscek Model (MPa) |

| 6 |

0.48±0.02 |

0.46 |

+4.3% |

0.35 ± 0.03 |

| 8 |

0.38±0.01 |

0.40 |

-5.0% |

0.28 ± 0.02 |

Table 5.

L9(3³) Orthogonal Test Design for Injection Parameter Sensitivity Analysis. Factors and Levels: GLR: 1:1, 1.5:1, 2:1; Slug Volume (PV): 0.2, 0.3, 0.4; Injection Rate (mL/min): 8, 12, 16

Table 5.

L9(3³) Orthogonal Test Design for Injection Parameter Sensitivity Analysis. Factors and Levels: GLR: 1:1, 1.5:1, 2:1; Slug Volume (PV): 0.2, 0.3, 0.4; Injection Rate (mL/min): 8, 12, 16

| Group |

GLR |

Slug Volume (PV) |

Injection Rate (mL/min) |

| 1 |

1:1 |

0.2 |

8 |

| 2 |

1:1 |

0.3 |

12 |

| 3 |

1:1 |

0.4 |

16 |

| 4 |

1.5:1 |

0.2 |

12 |

| 5 |

1.5:1 |

0.3 |

16 |

Table 5.

L9(3³) Orthogonal Test Design for Injection Parameter Sensitivity Analysis. Factors and Levels: Gas-Liquid Ratio (GLR)

Table 5.

L9(3³) Orthogonal Test Design for Injection Parameter Sensitivity Analysis. Factors and Levels: Gas-Liquid Ratio (GLR)

| Group |

GLR |

Slug Volume (PV) |

Injection Rate (mL/min) |

| 6 |

1.5:1 |

0.4 |

8 |

| 7 |

2:1 |

0.2 |

16 |

| 8 |

2:1 |

0.3 |

8 |

| 9 |

2:1 |

0.4 |

12 |

Table 6.

Orthogonal Test Results and Optimal Parameter Combination. (Response variables: Foam half-life, breakthrough time, and incremental recovery rate; n=3)

Table 6.

Orthogonal Test Results and Optimal Parameter Combination. (Response variables: Foam half-life, breakthrough time, and incremental recovery rate; n=3)

| Experimental group |

half foam life period (min) |

tbreak(h) |

ΔR (%) |

| 5 |

85 |

12.3 |

12.5 |

| 4 |

78 |

10.8 |

10.2 |

| 9 |

42 |

7.5 |

6.8 |