1. Introduction

The environmental problem is becoming more and more serious and has become a global problem with the rapid development of the global economy. Cleaner production can improve the efficiency of resource utilization, reduce and avoid the generation of pollutants, protect and improve the environment, protect human health, and promote sustainable economic and social development [

1]. The United Nations Environment Programme (UNEP) defines ‘cleaner production’ as the continuous application of integrated preventive environmental strategies to production processes and products in order to reduce risks to humans and the environment [

2]. Therefore, the essence of cleaner production is to emphasize three aspects: clean energy, clean production process and clean products, and to realize the 'greening' of the whole process of production and the whole process of product life cycle. It is a new type of pollution prevention and control strategy proposed by the international community after summarizing the experience and lessons of industrial pollution control. It is of great significance to prevent and control environmental pollution, reduce the burden of end treatment, improve the market competitiveness of enterprises, cope with the new situation of international trade and implement the strategy of sustainable development [

3].

It is necessary to integrate the concept of cleaner production CP into the production of enterprises for realizing the sustainable development of CP and better adapt to the changing environment of social economy.

Yu et al. [

4] integrated the concept of CP into all aspects of the enterprise, including raw materials, waste, process control, process flow, product quality, staff quality, administrative management, etc., and established a cleaner production management model. Lv Lishu et al. [

5] proposed a multi-level and multi-objective optimization model of grinding process scheme for cleaner production for energy saving and emission reduction of grinding process. The experiment confirmed the effectiveness and put forward the corresponding energy saving and emission reduction strategy. Ma et al. [

6] proposed a data-driven cleaner production strategy for energy-intensive manufacturing based on product life cycle management, and explained it through the life cycle of cleaner production data. Wang et al. [

7] revealed the characteristics of changes in consumption structure forced by the transfer of low-carbon costs in enterprises, embedded the concept of low-carbon consumption in the utility function of consumers, established a production decision-making model of enterprises, and discussed the mechanism of the impact of the transfer of emission reduction costs on consumer demand changes. Sharma [

8] studied the use of the best and worst method (BWM), Grey Decision Making Trial and Evaluation Laboratory(Grey DEMATEL)and grid framework to explore the transformation strategy and sub-strategy of the integration of cleaner production and environment, focusing on green, flexible and inclusive development. The results show that strategies such as ' using artificial intelligence and the Internet of Things for optimization (STG B)' and ' combining block chain technology (STG D)(Incorporating Block chain technology)' are crucial. The study also classifies these strategies and their sub-strategies into causal groups, of which ' using artificial intelligence and the Internet of Things for optimization (STG B)(Leveraging AI & IoT for optimization)' has the greatest impact. The adoption of advanced digital twins technology (STG C)(employing advanced digital twins technology)has the least impact. However, the implementation of cleaner production still faces many obstacles. Although the relevant policies of cleaner production have played a guiding and constraining role, they can help enterprises to achieve comprehensive utilization of resources and reduce pollutant emissions to a certain extent. However, cleaner production activities are a dynamic process. Technology is constantly improving. The latest market demand and resource management require enterprises to continuously improve their own management models. The existing industrial enterprise management system still rarely considers the sustainability of cleaner production and the lack of comprehensive consideration of resources, energy, economy and environment [

9].

With the increasingly serious energy and environmental problems, China has put forward the development concept of " innovation, coordination, green, open and sharing. " New energy vehicles and intelligent manufacturing in emerging industries have become the key strategies [

10]. With the rapid development of the global automobile industry, the energy consumption, material consumption and pollutant production of the whole automobile industry chain are also increasing sharply, especially in the coating process [

11]. The coating production line is the production line with the largest investment and the highest process requirements in automobile production. It is also the process production line with the highest energy consumption and three waste emissions. Hydropower consumption accounts for more than 60 % [

12] of the entire automobile production, and the impact of a large number of pollutants on the environment is also increasingly serious. The wastewater discharged from the production process of coating pretreatment only contains a large amount of pollutants such as acid, alkali, oil, heavy metals, nitrates and phosphates. A large amount of electrophoresis wastewater from the electrophoresis primer process, due to its poor biodegradability, is currently widely used. The chemical coagulation treatment method is difficult to meet the relevant pollutant discharge standards, and it will inevitably have serious adverse effects on the surrounding environment [

13]. In the process of coating transportation, modulation and coating, these organic solvents escape into the air and then produce a large amount of volatile organic compounds (VOCs), which not only pollutes the atmospheric environment, but also directly causes great harm to human health [

14]. Restricted by today's environmental protection requirements, automobile coating production-related enterprises may be in trouble due to environmental pollution problems caused by the coating production process, which in turn limits the development of enterprises. In order to adapt to the development of the times, enterprises have carried out a lot of research on cleaner production to improve efficiency and enterprise management level [

15]. At present, there are different requirements for cleaner production audit of automobile spraying production in different regions, and there are no uniform standards and requirements. The pass rate of cleaner production audit is less than 40 % [

12]. Changing the concept, changing the traditional way of thinking, implementing cleaner production, accelerating technological innovation, reducing energy consumption, material consumption and pollutants from the source, strengthening the control of the whole process of product production and the whole life cycle, and coordinating the development of economy and environment are the needs of sustainable development of enterprises. It is also the embodiment of corporate social responsibility and the inevitable trend of developing low-carbon economy.

Based on this, the team studied the clean production management of automobile body spraying. On the basis of the combination of the value flow chart analysis technology of lean production theory and the ECRS optimization principle of process reengineering, the artificial intelligence algorithm is further integrated to optimize the spraying process. The main innovations are as follows:

(1) An improved Whale Optimization Algorithm (NEDWOA) is proposed, incorporating a nonlinear convergence factor, elite opposition-based learning, and adaptive dynamic parameters. The NEDWOA demonstrates significant improvements in global search capability, convergence speed, and robustness.

(2) The clean production problem in automotive body painting is defined as a multi-objective optimization issue involving material flow, energy flow, and environmental emissions in the painting process. From the perspective of "low-carbon consumption + emission-reducing production," a multi-level, multi-objective decision-making model for automotive painting is established, considering both process and operational layers, with objectives including material cost, painting energy consumption, carbon emissions, and painting time.

(3) The NEDWOA is applied to optimize the automotive painting model, proposing a production method for automotive body painting based on the NEDWOA. Taking the new energy vehicles of TJ Automotive Manufacturing Plant in China as an example, compared to other algorithms, the proposed algorithm achieves superior optimization results, improving painting production efficiency by 42.1%, achieving a waste gas purification rate of over 98%, enhancing average energy-saving effects by more than 18.2%, and reducing manufacturing costs by 17.9%.

The structure of this paper is as follows. The first section is the introduction, outlining the research background, current status, and significance of clean production, and emphasizing the urgency of clean production management in the automotive painting industry. The second section presents the improved Whale Optimization Algorithm (NEDWOA). The third section details the multi-level, multi-objective optimization method for the painting process based on the NEDWOA. The fourth section conducts experimental validation before and after optimization, followed by result analysis. The fifth section summarizes the research conducted in this paper.

2. Improved Whale Optimization Algorithm

The Whale Optimization Algorithm (WOA) is a swarm intelligence optimization method inspired by the bubble-net hunting behavior of humpback whales, first proposed by Mirjalili and Lewis [

16]. This algorithm mimics the "spiral bubble-net feeding strategy" of whales, characterized by structural simplicity, minimal parameter requirements, and ease of implementation. It has been widely applied to function optimization, engineering design, and machine learning. Recent research on WOA has focused on three areas: algorithmic enhancements, multi-objective optimization, and practical industrial applications. To address WOA’s issues of easily falling into local optima and slow convergence speed, researchers have proposed various improvement strategies, such as introducing nonlinear convergence factors [

17], adaptive weights [

18], and chaotic mapping. Hybrid approaches combining WOA with other optimization algorithms (e.g., Particle Swarm Optimization [PSO], Genetic Algorithm [GA]) have also been developed to enhance global search capability and robustness. For multi-objective optimization, extensions like Pareto front-based Multi-Objective WOA (MOWOA) have been explored.

To further improve WOA’s convergence and robustness, this study introduces three enhancement strategies:

(1) Nonlinear Convergence Factor: Replaces the linear-decreasing convergence factor with a nonlinear version to flexibly balance exploration and exploitation.

(2) Elite Opposition-Based Learning: Generates reverse solutions from high-quality elite individuals to increase population diversity.

(3) Dynamic Parameter Self-Adaptation: Adjusts parameters in real time based on search states to enhance adaptability.

The improved algorithm, named NEDWOA (Nonlinear convergence factor + Elite opposition-based learning + Dynamic parameter adaptation), implements these strategies as follows.

2.1. Nonlinear Convergence Factor

In the original WOA, the convergence factor a decreases linearly, resulting in rigid search step size adjustments that cannot adapt to complex optimization processes. The proposed exponential nonlinear convergence factor is defined as,

where hyperparameter controlling the decay rate γ>1 (typically γ=2). Initial convergence factor α

init is 2.

In the early phase (t<<Tmax), rapid decay of α enables larger step sizes which can accelerate global exploration. In the late phase (t→Tmax), gradual decay of α refines local exploitation, stabilizing convergence toward the optimal solution.

This exponential formulation allows dynamic adaptation to problem complexity and scale, significantly enhancing the algorithm’s flexibility compared to the linear counterpart.

2.2. Elite Opposition-Based Learning

To address the premature convergence caused by decaying population diversity, this study employs elite opposition-based learning to expand search space coverage. For each generation, the top k fitness-ranked elite individuals are selected, and their opposition solutions are generated and selectively retained.

For an elite individual X

elite, its opposition solution is computed as,

where UB and LB represent the variable’s upper and lower bounds, respectively. The superior solutions between X

elite and X

oppo are retained.The opposition solutions are integrated into the population while maintaining a constant total population size by removing the worst-performing individuals. This strategy effectively mitigates local optima stagnation and demonstrates enhanced performance in multimodal optimization problems due to its systematic exploration-exploitation balance.

2.3. Dynamic Parameter Self-Adaptation

To resolve the limitations of fixed parameters in the original algorithm, which struggle to adapt to distinct optimization phases, this study introduces a fitness variance-driven dynamic parameter adjustment mechanism. Fitness variance calculation is written as,

where

is average fitness of the current population,

N is population size.

Dynamic adjustment rules are as follows. When σ

2(t) is small, low fitness variance indicates population convergence. Increasing the spiral coefficient

b intensifies local exploitation.

When σ

2(t) is large, high fitness variance indicates population diversity. Increasing the random search probability

p strengthens global exploration.

This strategy enables parameters to self-adapt based on population states, balances exploration and exploitation, and enhances the algorithm’s adaptability to complex optimization problems.

2.4. Implementation Workflow of the NEDWOA

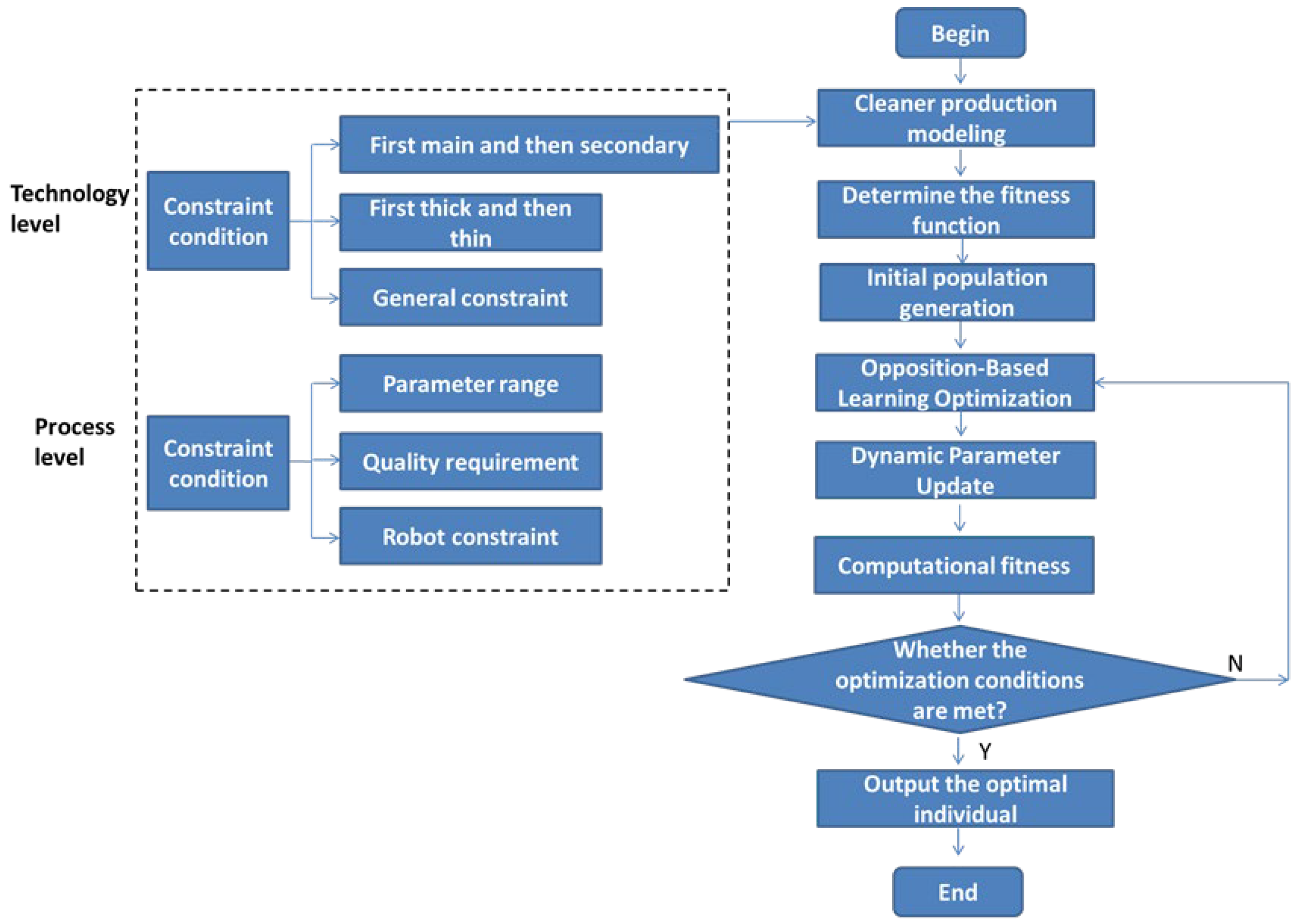

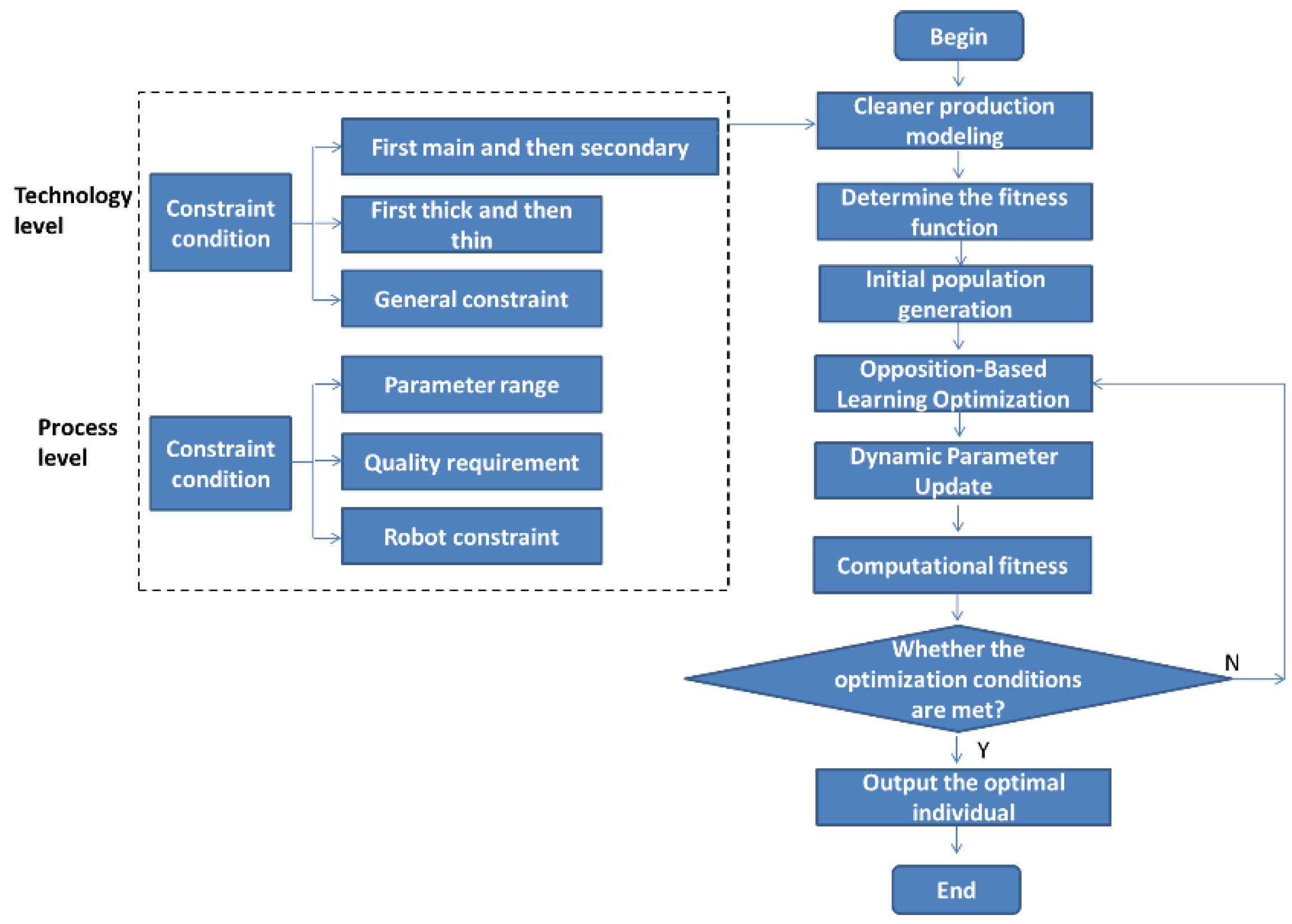

The workflow of the NEDWOA is as shown in the

Figure 1.

Specific steps are as follows.

Step 1: Initialize

Generate initial population {Xi} (which can be combined with chaotic mapping to enhance diversity);

Set parameters: αinit=2,γ=2, k=0.1N, bmin=1,bmax=3.

Step 2: Iterative optimization

For each generation t=1 to Tmax,

(1) Calculate the convergence factor: update a(t) according to the nonlinear formula.

(2) Update parameters, adjust b(t) and p(t) based on 2(t).

(3) Surround prey with spiral updates.

If p<0.5:

if ∣A <1: Surround the prey (towards the current optimal individual);

if ∣A ≥1: random search;

If p≥0.5: spiral update position;

(4) Elite reverse learning: Generate the reverse solution of the first k elite individuals to update the population;

(5) Fitness evaluation: Calculate the fitness of the new population and update the global optimal solution X*.

Step 3: Terminate and output

After the termination condition is satisfied, the global optimal solution X* is output.

5. Case Study

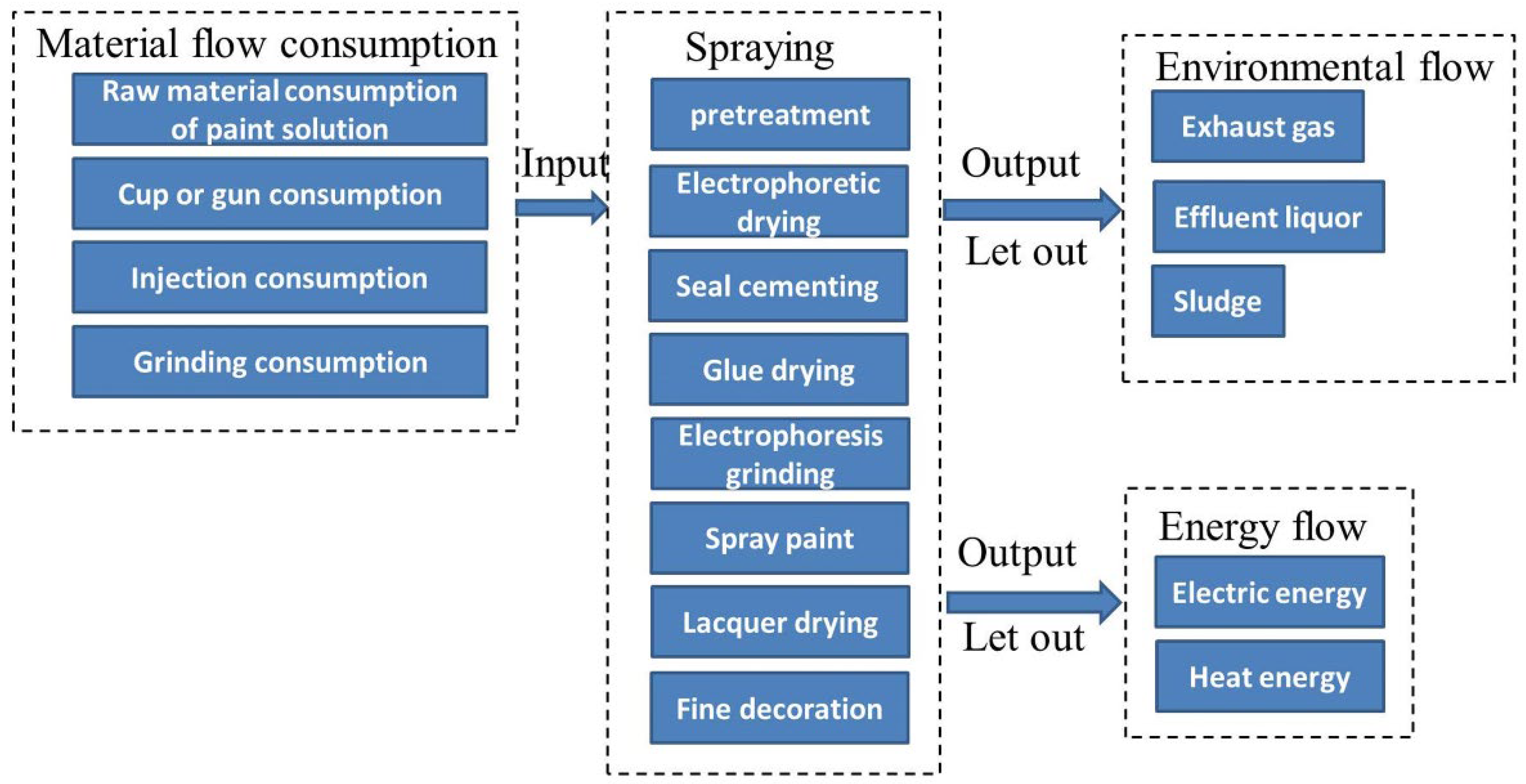

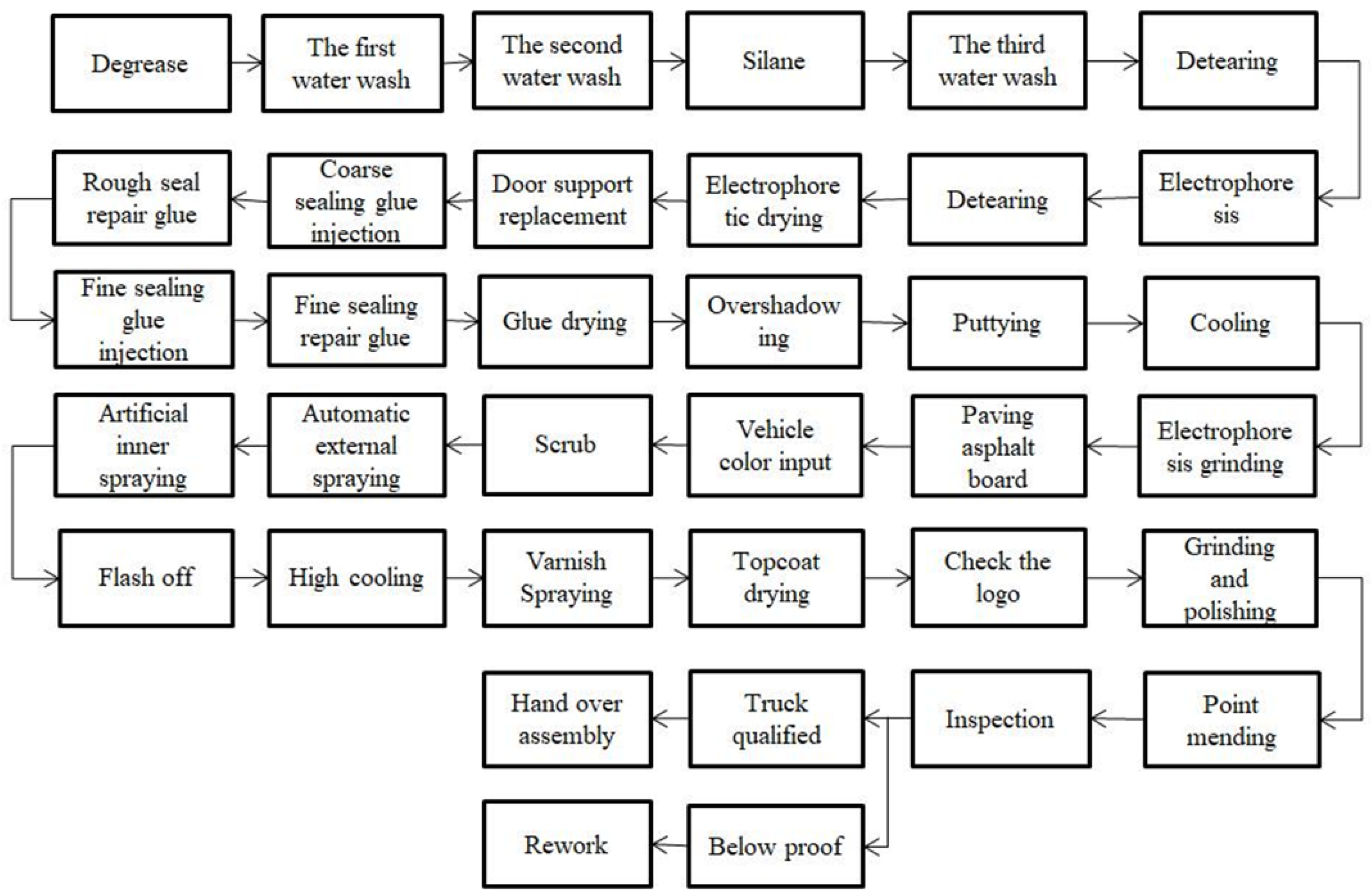

In order to verify the effectiveness of the clean production of spraying process based on the NEDWOA, this paper takes TJ Company's new energy vehicle body painting production system as an example to study. The painting workshop is responsible for the painting tasks of body, frame, cargo box and plastic parts. The painting process is divided into two parts: the surface treatment technology of metal before painting and the construction technology of painting. The process flow diagram is shown in

Figure 5. The main processes include pretreatment, electrophoresis drying, sealing glue injection, glue drying, electrophoresis grinding, spray painting, paint drying and finishing.

5.1. Spraying Process Parameter Setting and Calculation

Among the spraying process parameters, the main parameters of rotary high-voltage electrostatic spraying as an example are spraying distance, spray cup speed, spraying flow, forming air, high-voltage electrostatic, rotary cup profiling speed, etc. The best spraying distance is set to 250 mm. The working speed of the rotating cup is 30000r/min during spraying, and the maximum no-load speed is 60000r/min. The working speed of the rotating cup varies according to the composition of the paint liquid. The rotation speed of the paint and the background paint in the solvent-based paint spraying is 30000r/min to 35000r/min, 32000r/min is selected here, and 35000r/min to 45000r/min can be selected when spraying varnish, 40000r/min is selected here. The thickness of the varnish coating film is 35 to 50 m, the thickness of the middle coating film is 30 to 45 m, and the thickness of the metal paint is 12 to 18 m [

25]. The flash drying time of the coating film was controlled at about 5 min. The wind speed of the circulating air filtration system that maintains the cleanliness of the spray room is generally controlled at 0.2 ~ 0.5m/s. The number of coating overlaps was selected 3 times.

Assuming that the total amount of paint is not lost during the spraying process, and all of it is attached to the vehicle body, the spraying flow Q of each spin cup of the spraying robot is,

where Q is the spraying flow rate (ml/min),

Sp is the area needed to be sprayed (m

2),

δ is the dry film thickness (μm),

TE is the coating efficiency of the coating,

NV is the mass fraction (%) of paint solid under construction viscosity;

N is the number of robots in the station ( the number of rotating cups ).

The formed air is ejected from the annular gap at the rear side of the rotary cup to adjust the amplitude of the paint mist. The setting of forming air parameters is proportional to the paint flow rate and the rotating speed of the rotating cup. Generally, the parameter value of forming air is 100-350NL / min.

The strength of the electrostatic field directly affects the electrostatic coating effect, such as coating efficiency, electrostatic effect, and uniformity of the paint film. The suitable range of the average electric field intensity required for electrostatic coating is 3900-4000 V/cm. Electrostatic spraying stipulates that the safe distance between the electrode and the coated object is 250-300 mm. Different voltage settings should be adopted according to the different types of coatings sprayed. Intermediate coating is generally set as 65-75kV. Varnish is set as 65-80 kV. Metallic paint is set as 50-65 kV. Due to the protruding corner of the body, it is easy to form the corner effect of electrostatic concentration. It is usually necessary to reduce the voltage setting, which can be controlled at 45kV-55kV.

The spraying moving speed of the sprayer is related to the factors such as the spraying area completed on this station, the number of overlapping times during spraying, the production beat, the characteristics of the sprayer, and the use efficiency of the robot. The TCP speed

v of the spraying robot can be calculated by the following Equation (35).

where S

p is the spraying area of the automobile body (m

2),

Of is the overlapping coefficient of spraying. When overlapping area is 50 %,

Of = 2. When overlapping area is 66%,

Of = 3; When overlapping area is 50 %,

Of = 4.

W is the spray width, t is the spraying time,

η is the use efficiency of the spraying robot, generally 90% -95%, K is the correction coefficient, generally 0. 6 - 0. 9.

According to the experimental conditions and the commonly recommended values of each factor, the values of each parameter are set in the experiment as shown in

Table 1.

5.2. Spraying Optimization Based on EDOWOA

Based on the AHP method, the subjective weight is determined and the judgment matrix is constructed. In this optimization process, considering the importance of the three (energy consumption, carbon emissions, grinding time), the subjective weight value is (0. 3333, 0. 3333, 0. 3333). The process, robot feed speed, rotary cup speed, paint flow and other parameters were changed to construct the data set. The original data was constructed and normalized, and the objective weight value was calculated by CRITIC method. Among them, the calculated contrast strength was (0. 1306, 0. 0537, 0. 1124), the conflict was (0. 0463, 0. 0621, 0. 0856), so the comprehensive objective weight was (0. 3183, 0. 1752, 0. 5064); therefore, the weight of each optimization objective of the whole spraying is (0. 3258, 0. 2543, 0. 4199).

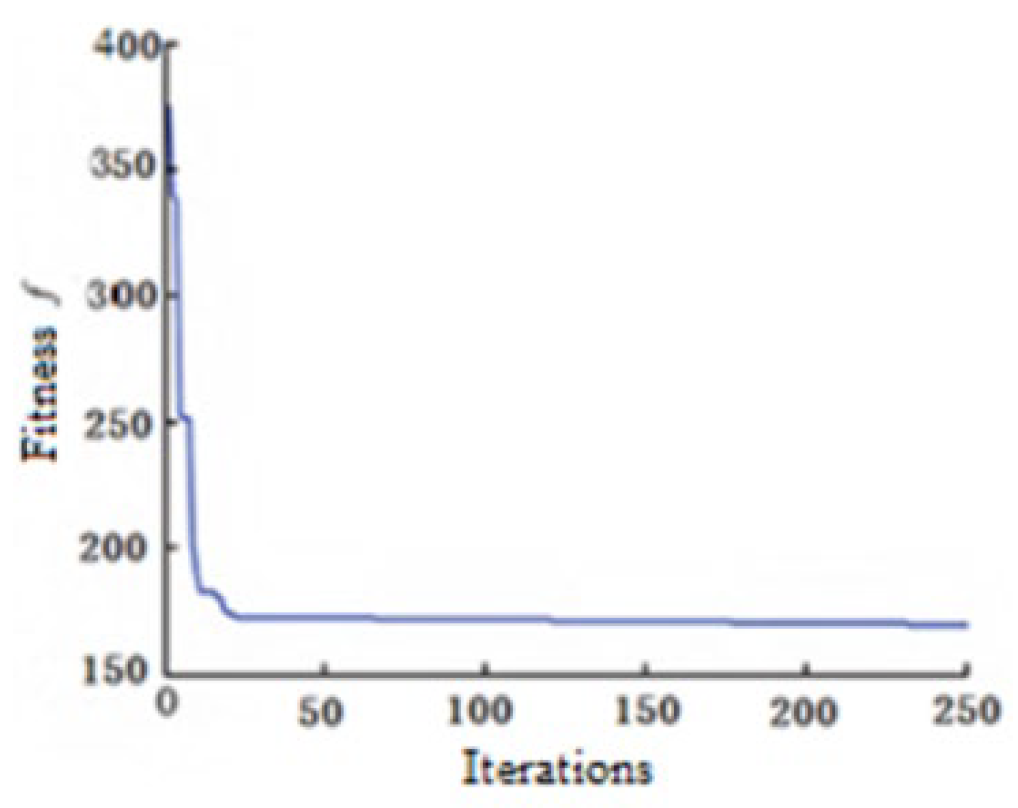

The software platform used in this experiment is MATLAB R2021a, and the computer processor is Intel (R) Xeon (R) W-2255. The algorithm program is written by software to randomly generate the population. The initial population size is 500, the genetic algebra is 250, the crossover probability is 0.9, and the mutation probability is 0.1. After setting the parameters of NED-WOA, the fitness function is defined according to the objective function. Then new individuals are generated by genetic operators. The optimization results that meet the requirements are output after crossover, selection and mutation. The algorithm convergence diagram of the spraying optimization process route is shown in

Figure 6.

A comparative analysis was conducted between the proposed NEDWOA algorithm and existing methods (MHWOA [

26], WOA-RBF [

27], WOA-VMD [

28]) under 250 iterations, with statistical evaluation of energy consumption, carbon emissions, and processing time per painted vehicle body as shown in

Table 2. The NEDWOA-optimized clean production framework demonstrated superior performance. This empirical validation confirms NEDWOA's enhanced capability in balancing ecological and operational objectives, establishing it as a state-of-the-art solution for sustainable automotive painting systems.

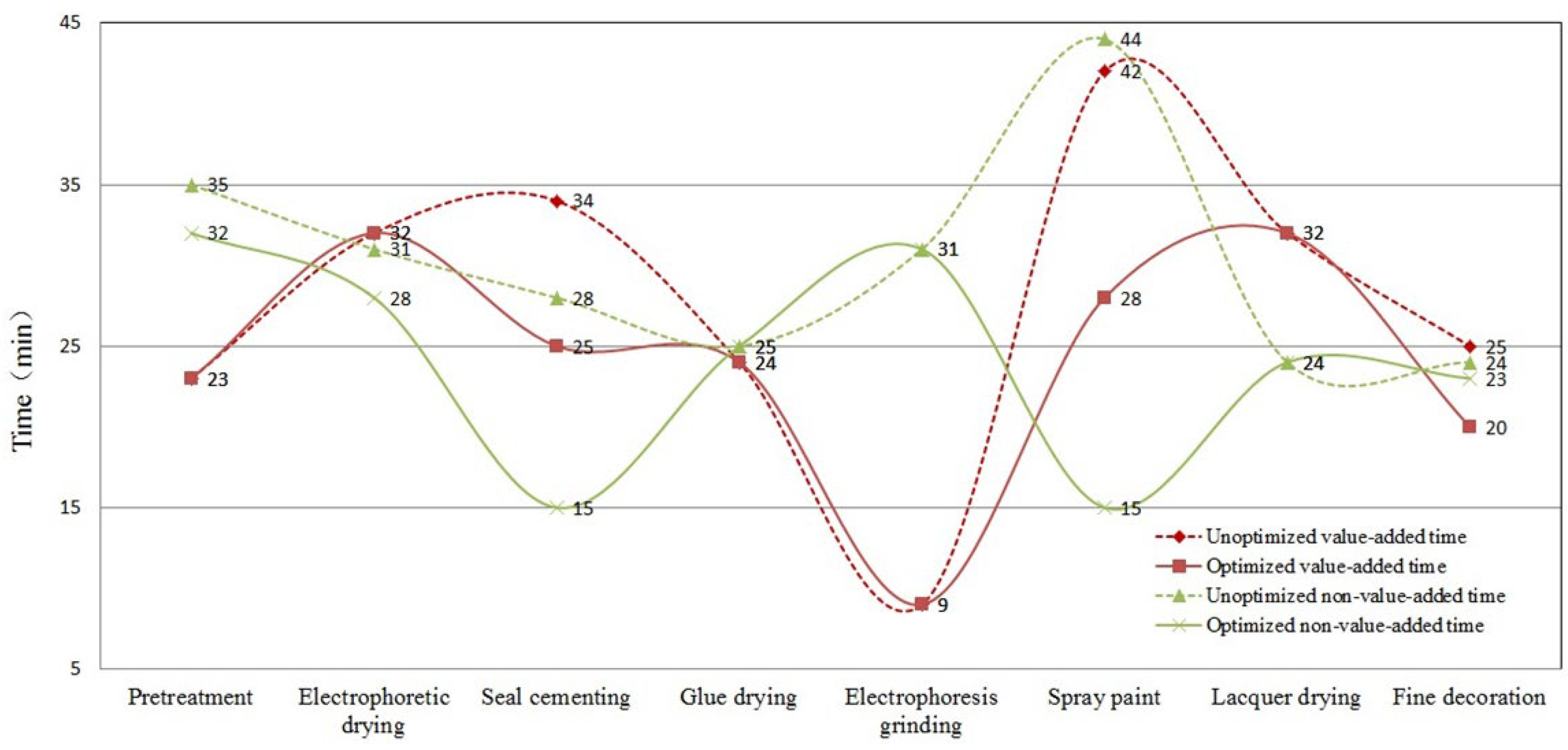

The body painting workshop of TJ Automobile Manufacturing Co., Ltd. has a working time of six days/week. According to the order process and the basic data of body painting production control, the value flow of the body painting process before and after optimization is shown in

Figure 7. It can be seen that good improvement results have been achieved.

According to the value stream map analysis, the value-added ratio

before optimization and the value-added ratio

after optimization are:

where

PT is the value-added operation time of the body painting production process,

PT=

,

is the

ith value-added operation time;

NPT is the non-value-added operation time of the body painting production process,

NPT=

,

is the i th non-value-added operating time.

In addition, the optimized spraying clean production route has greatly improved the company's production efficiency and product quality, as shown in

Table 3.