1. Introduction

This introduction sets a stage for a comprehensive investigation into the impact of different capacitor types on the circuit design, and performance into terms of circuit efficiency, as well as the disposal and sustainability challenges associated with different capacitor technologies. By exploring the sustainability and disposal considerations that are associated with different capacitor types, we aim to address the ecological footprint in the capacitor manufacturing and aim to promote practices that are environmentally conscious in the electronics industry. Thus, it is an utmost priority in the field of electronics and electrical engineering to address environmental implications of the production of capacitors and their disposal, as well as to address their impact on the design of the circuit and the efficiency of these electrical circuits in terms of functionality and performance in the modern-day sustainability-focused world. In terms of electronics and electrical engineering field, a capacitor is briefly defined as a passive electronic component that stores energy in the form of an electrostatic field, which consists of two conducting plates separated by an insulating material called the dielectric [

1,

2]. The capacitance (i.e. the maximum amount of electric charge that a capacitor can store, which is usually known as the rated value of the capacitor) is directly proportional to the surface areas of the plates and inversely proportional to the separation between the plates [

3]. The capacitance is commonly measured in farads (F), microfarads (μF), nanofarads (nF) or picofarads (pF) depending on the scale of the capacitor rating [

3,

4]. Capacitors are either connected in series or in parallel to achieve the desired capacitance and voltage rating for specific applications in particular electrical circuitry [

3,

4].

Furthermore, capacitors are utilized in a wide range of applications, from power supplies and energy storage instruments to bypassing and decoupling or coupling in the electrical circuits [

5]. Thus, with different types of capacitors offering unique characteristics for specific applications, the choice of the type of a capacitor significantly affects parameters of an electrical circuit such as the efficiency and performance of the circuit. For illustration, capacitors with low equivalent series resistance (ESR) and equivalent series inductance (ESL) are preferable for bypassing and decoupling, as they provide better power filtering and noise reduction [

5,

6]. However, capacitors with high capacitance and low equivalent series resistance (ESR) are appropriate for energy storage and sudden load change applications where high current is a requisite [

6].

Table 1 evaluates six capacitor types by contrasting technical performance (ESR, ESL, stability) with environmental metrics (recyclability, hazardous materials).

The table elucidates the superior performance of MLCCs (Multilayer Ceramic Capacitors) and Class 1 ceramics in high-frequency applications, attributable to their low equivalent series resistance (ESR) and equivalent series inductance (ESL). In contrast, aluminum electrolytic capacitors excel in power storage capabilities, but present significant toxicity concerns due to the use of liquid electrolytes. Film capacitors emerge as the most environmentally sustainable option, boasting a recyclability rate of 70% and the absence of hazardous materials, which starkly contrasts with the 25% recyclability rate of electrolytic capacitors. Moreover, supercapacitors are associated with the risk of thermal runaway, while MLCCs encounter challenges related to barium titanate. The table underscores the inherent trade-offs between circuit efficiency and ecological impact, emphasizing the necessity for engineers to prioritize lifecycle sustainability in their design processes.

1.1. Research Motivation

This research is motivated by the dual imperative of enhancing electronic device performance through optimal capacitor selection while simultaneously addressing the environmental challenges posed by electronic waste and the sustainability of capacitor materials.

Capacitors play a pivotal role in energy storage, filtering, and signal processing within electronic circuits. Their selection is critical for optimizing circuit performance, highlighting the need for in-depth research into their characteristics and applications.

Analyzing the performance implications of various capacitor types—such as ceramic, electrolytic, and tantalum—can lead to advancements in design efficiency and overall electronic device enhancement. Understanding these differences is vital for engineers and designers aiming to improve circuit functionality.

The presence of materials in many capacitors that pose disposal challenges raises significant environmental concerns, contributing to the growing issue of electronic waste. Addressing these challenges is essential for promoting sustainable practices in the electronics industry.

This research seeks to explore and identify sustainable practices in the production and disposal of capacitors. By focusing on minimizing environmental impact while maintaining performance standards, the literature review aims to contribute to more responsible manufacturing processes.

The importance of balancing technological advancements with ecological responsibility is further explored in this research as to ensure that future innovations in electronics are both efficient and sustainable, thus this research aims to foster a more environmentally conscious approach in the field of electrical engineering.

1.2. Research Novelty

To the best of our knowledge, no comprehensive systematic research exists that examines the effects of different capacitor types on circuit design and performance, alongside their environmental implications. This research introduces a novel dual approach that emphasizes both the functional properties of capacitors and the importance of environmental responsibility, thereby making a significant and unique contribution to the existing literature.

This study uniquely combines electrical engineering principles with environmental science, addressing how the choice of capacitor affects not only circuit efficiency but also long-term sustainability through proper disposal and recycling practices.

By examining advancements in capacitor technology, such as eco-friendly materials and manufacturing processes, this research highlights innovative solutions that align with Global Sustainability Goals, commonly known as Sustainable Development Goals (SDGs).

The findings are intended to guide designers and engineers in understanding the trade-offs between performance and environmental impact, thereby facilitating informed decision-making in the selection of capacitors for various applications.

2. Type of Capacitors

In modern-day electronics and electrical field, there are various types of capacitors employed in different electrical circuity due to their unique characteristics to yield high performance and good integrity of the circuitry. For illustration, common types of capacitors include the ceramic capacitors which are widely utilized due to their versatility and reliability while offering stable capacitance values suitable for high-frequency applications such as decoupling power supplies because they have low inductance [

7]. Then the electrolytic capacitors which are commonly employed due to their high capacitance and compact size, but they are temperature sensitive, and they have relatively high current leakage, thus, making them ideal for applications such as DC Power Supplies and energy storage instruments [

8]. And the film capacitors which are widely utilized in applications requiring high frequency, high current, high power and high voltage handling capabilities for their excellent reliability and low equivalent series resistance and inductance, as well as they have a long lifespan [

9]. They have various types such as polyester capacitors, metallized film capacitors and polypropylene capacitors (i.e. capacitors made of materials such as polyester, metallized film or polypropylene that use these materials as very thin plastic film for a dielectric insulation) which are often utilized for bypassing and decoupling purposes [

3,

5,

9].

Moreover, the commonly used types of capacitors includes the tantalum capacitors which have higher capacitance per volume and low equivalent series resistance (ESR), and they employ tantalum material to form the anode of the capacitor (i.e. offering polarity), thus they are utilized in applications where maximum capacitance in a small space is essential, where stability over a range of temperatures or voltages is a requisite and where reliable performance is a crucial factor [

10,

11]. Then the variable capacitors are a type of capacitors whose capacitance is deliberately and repeatedly changed either mechanically or electronically, which are often utilized in LC tank circuits to set the resonance frequency such as tuning radios or a variable reactance for impedance matching in antenna tuners (i.e. these capacitors are significantly important in applications requiring high-powered transmitters such as military radio technology, commercial radios and broadcasting in telecommunications due to their high working voltage and current handling capacity in applications including symmetrical antenna tuners and Radio Frequency (RF) power amplifier) [

12]. And the silver mica capacitors are also commonly known as precision capacitors due to their high stability, reliability and performance [

13]. This type of capacitors are non-polarized components which employ mica as their dielectric material with thin silver coatings playing a role of electrodes [

13]. Their construction guarantees high precision in their values of capacitance thus making them very suitable for applications requiring accuracy and stability, such as oscillators, filters and resonant circuits [

14]. Despite their high-cost relative to other dielectrics, they have features which include high stability, low dielectric loss, high quality factor, high insulation resistance and low temperature coefficient, which are desirable in applications demanding high accuracy and performance [

14,

15].

Furthermore, the commonly utilized capacitor types include the poly-carbonate capacitors which are a type of capacitor that employs polycarbonate as its dielectric material, and they are utilized due to their high stability and tolerance, and their ability to operate over a wide temperature range, approximately from 55°C to +125°C without degrading its rating [

15]. They have features which include high insulation resistance, low dissipation factor, self-healing properties that enhance their reliability and longevity, and a reasonable dielectric constant due to their size [

15,

16]. However, this type of capacitors is no longer manufactured or readily available in the electronics and electrical industry as their production was ceased in early 2000 by their major manufacturer called The Bayer Corporation [

16]. Then the polystyrene capacitors are a type of capacitors which have low distortion factor making them popular in audio applications [

16,

17]. They are utilized in applications requiring high tolerance capacitors and in various equipment such as guitar amplifiers, power amplifiers, and Cable Television (CATV) amplifiers because they have features such as low power factor, high quality factor, low dielectric absorption, low distortion, low leakage, high insulation resistance and excellent temperature and capacitance stability [

18]. Not only do they have a wide range of capacitance from approximately 10pF to 2μF but also a small deviation of about ±0.1% in precision [

19].

Furthermore, the paper capacitors are the type of capacitors that employ the paper as a dielectric material such that two metallic plates are separated by a paper sheets and these papers are coated with wax to protect them from environmental hazards [

19,

20]. These capacitors have fixed capacitance ranging from about 500pF to 50nF, and they have significant leakage current [

21,

22]. However, due to their hygroscopic nature which requires sealing, they are most suitable for low frequency applications and DC circuits instead of high frequency applications [

23]. Then the bipolar capacitors are a type of capacitors that can store electrical charge in both polarities, and they have features such as high energy storage capacity and low equivalent series resistance [

24]. Hence, they are designed to have voltage ratings that are higher than the voltage of the power supply or the voltage of the circuit in which they are utilized [

24,

25]. These capacitors are commonly employed in applications such as power supplies (i.e. they smooth out the voltage and provide a stable power supply in the voltage regulators), high frequency circuits (i.e. in radio transmitters and receivers, where they assist to filter out undesirable noise and improve the signal quality) [

26]. This type of capacitors is commonly made of materials such as tantalum, aluminum, or film, and they have various types such as electrolytic, ceramic or film capacitors [

27].

In addition, the feed through capacitors are the type of capacitors that are designed to allow the passage of electrical signals or power through a material such as a metal or ceramic, while providing capacitance [

28]. They have features such as low equivalent series resistance and high-quality factor, which enables them to handle high power levels and maintain high performance over a wide frequency range [

29]. Thus, they are commonly utilized in high frequency applications such as Radio Frequency (RF) circuits including amplifiers, filters and tuning circuits; where they help with high impedance matching and improving the signal quality [

30].

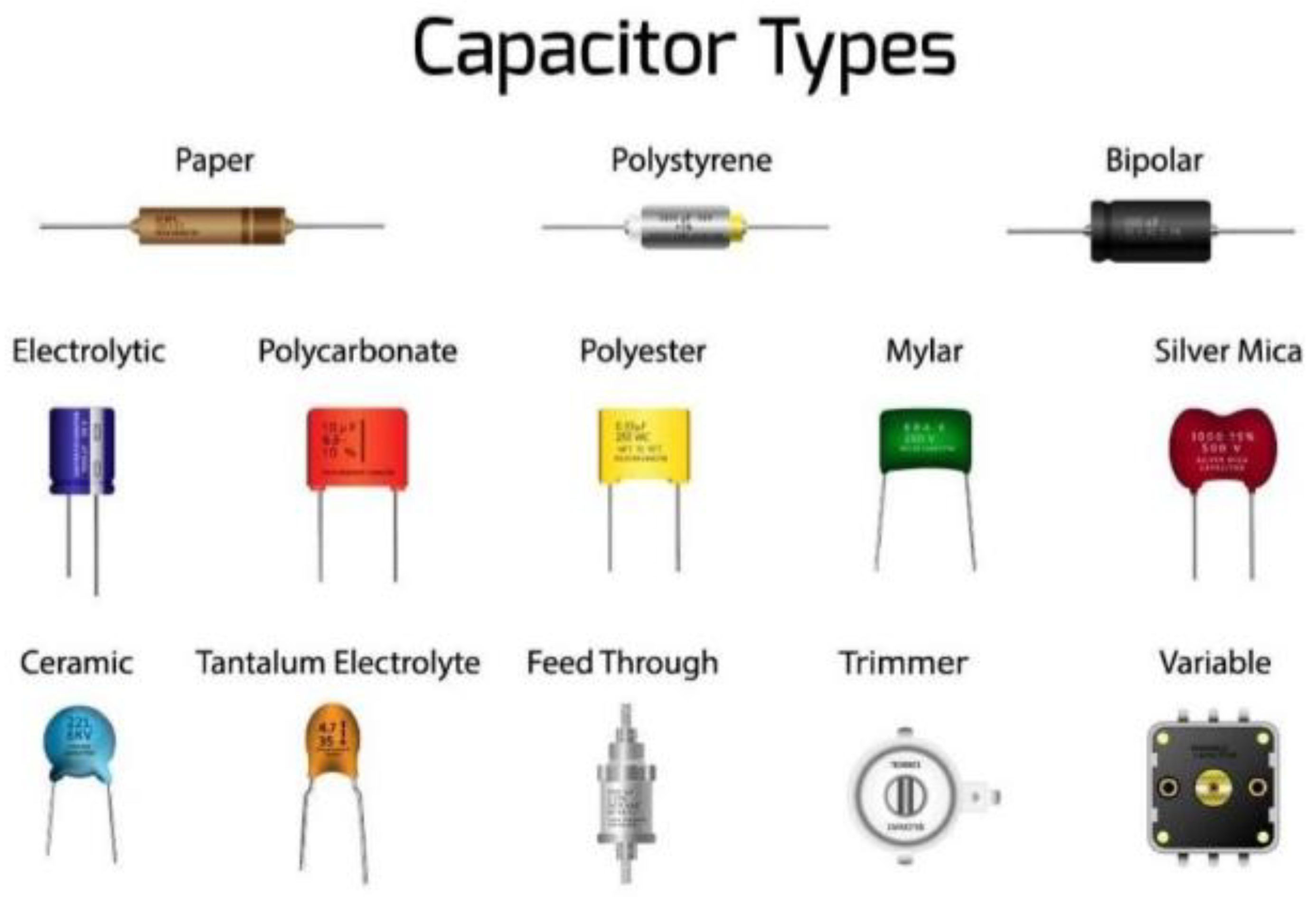

Figure 1.

An image showing different capacitor types (Available online at: Link).

Figure 1.

An image showing different capacitor types (Available online at: Link).

3. Circuit Design and Performance

The choice of capacitor in circuit design significantly impacts the performance of the electronic system. Different types of capacitors have unique properties and characteristics that make them suitable for specific applications. In this literature review, we explore the impact of various capacitor types on circuit design and performance.

Ceramic capacitors are widely used in electronic circuits due to their high stability, low cost, and high voltage handling capabilities. They are commonly used for decoupling power supplies for integrated circuits (ICs) and filtering applications. However, their capacitance value can change with voltage and temperature, which can affect the circuit’s performance in certain applications [

31].

Electrolytic capacitors are known for their high capacitance and low cost. They are commonly used in power supplies and filtering applications. However, they have a limited lifespan, can suffer from self-discharge, and can lose capacitance over time. Additionally, they have a polarized design, which means they must be installed correctly in the circuit to avoid damage [

32].

Tantalum capacitors are known for their high stability, low leakage current, and high volumetric efficiency. They are commonly used in applications that demand high reliability and volumetric efficiency. However, they have a higher cost than aluminum electrolytic capacitors and can suffer from catastrophic failure if overstressed [

33].

Film capacitors are known for their high stability, low loss, and high voltage handling capabilities. They are commonly used in power supplies, filtering applications, and high-frequency circuits. However, they have a higher cost than ceramic and aluminum electrolytic capacitors and can suffer from microphonic effects, which can cause noise in the circuit [

34].

Supercapacitors are known for their high energy storage capabilities and high-power density. They are commonly used in energy harvesting, renewable energy, and backup power applications. However, they have a lower voltage rating than other capacitor types and can suffer from high self-discharge rates [

35].

The choice of capacitors affects circuit performance. Ceramic capacitors are stable and cost-effective, while electrolytic ones offer high capacitance but have limited lifespans. Tantalum capacitors provide reliability, film capacitors are low-loss, and supercapacitors excel in energy storage but have lower voltage ratings and higher self-discharge rates.

Table 2 provides overview of capacitor types, their properties and applications, and their respective pros and cons.

Table 2 summarizes various capacitor types, highlighting their key characteristics, applications, advantages, and disadvantages. Ceramic capacitors offer high stability at low costs, while electrolytic capacitors provide high capacitance but have limited lifespans. Tantalum capacitors excel in reliability, film capacitors in low losses, and supercapacitors in energy storage, albeit with specific drawbacks.

4. Environmental Implications

The environmental effect of capacitors varies according to the kind of capacitor and manufacturing procedures used. The manufacturing of capacitors involves various materials and processes, each contributing to its environmental impact. The production of capacitors faces several critical challenges that pose environmental and health risks. One prominent issue is the extraction of raw materials, such as aluminum, tantalum, and ceramics, which often results in deforestation and habitat destruction [

36]. These mining activities can release harmful pollutants into air and water sources, adversely affecting ecosystems and human health [

36,

37]. Furthermore, the manufacturing process of capacitors is characterized by high energy consumption, leading to substantial greenhouse gas emissions [

38]. This contributes significantly to global warming and climate change, highlighting the urgent need for more sustainable practices within the industry.

In addition to environmental concerns, the use of hazardous chemicals during capacitor production presents severe risks. Majority of capacitor types require solvents and acids, which, if not managed properly, can contaminate soil and water supplies [

39]. The cumulative impact of these challenges underscores the importance of adopting environmentally friendly practices and technologies in capacitor manufacturing. Addressing these issues not only mitigates ecological damage but also promotes public health and safety, paving the way for a more sustainable future in electronic component production.

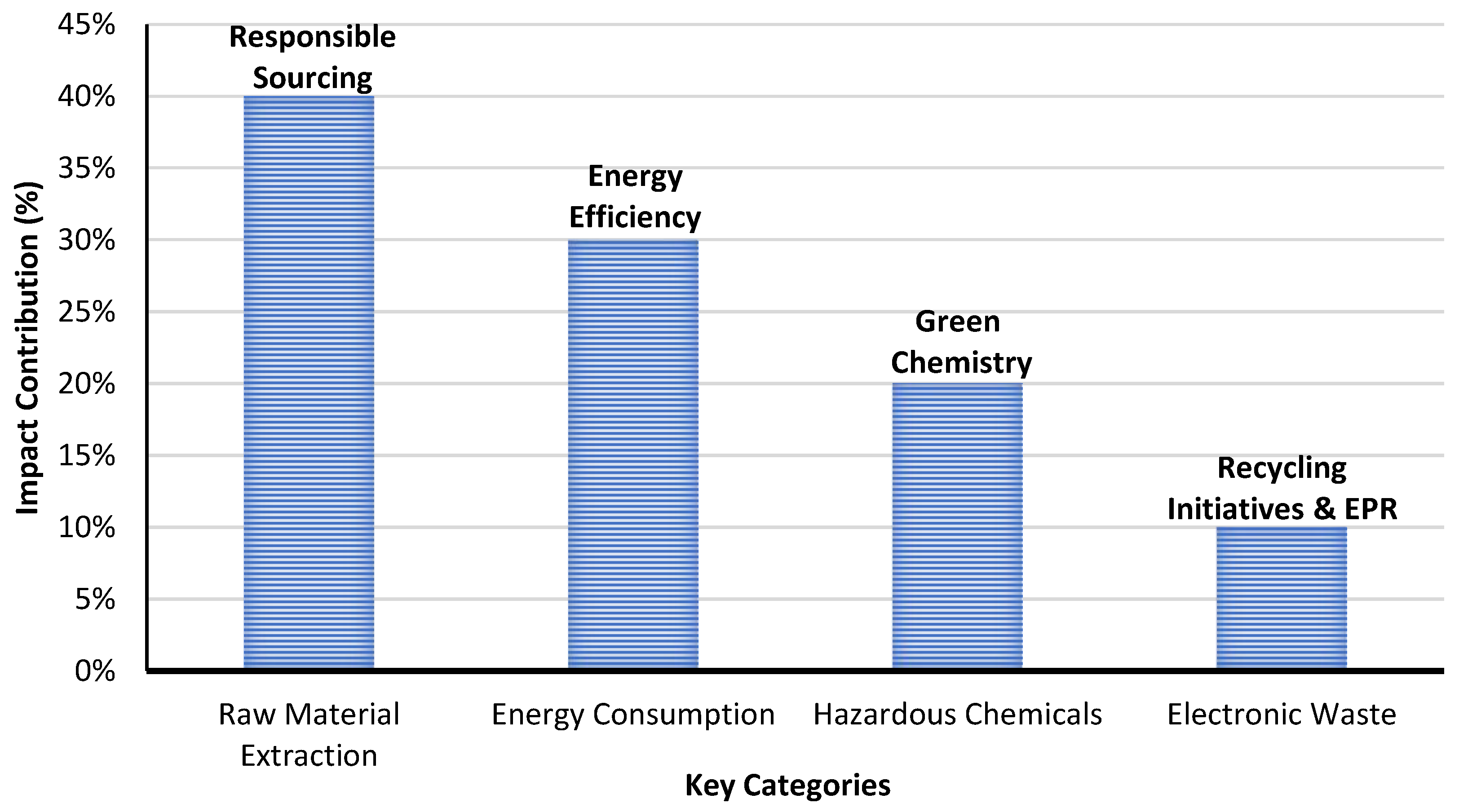

To address these environmental challenges, capacitor manufacturers ought to adopt various sustainable practices, including responsible sourcing of materials, energy efficiency, green chemistry, recycling initiatives, and Extended Producer Responsibility (EPR). These practices can minimize the ecological footprint of capacitor production and contribute to a greener and more sustainable future. The industry initiatives, such as establishing industry-wide standards and certifications for sustainable capacitor manufacturing, can guide companies towards sustainable practices and foster environmental consciousness. Government incentives and regulations, such as offering incentives, tax breaks, or grants to capacitor manufacturers implementing sustainable measures, can also encourage sustainable design, reuse, and proper recycling.

The environmental impact of capacitor manufacturing is a critical aspect of modern technology. By embracing sustainable practices, capacitor manufacturers can significantly reduce their ecological footprint, thereby fostering a greener and more sustainable future. Collaborative initiatives, bolstered by the support of industry associations and governmental bodies, are essential in facilitating a transformative shift towards ecological responsibility within the electronics sector. Such partnerships not only enhance the industry’s commitment to sustainability but also promote innovation and accountability, ultimately leading to a more environmentally conscious manufacturing landscape.

Figure 3 illustrates the primal environmental impacts of capacitor manufacturing across four categories: raw material extraction, energy consumption, hazardous chemicals, and electronic waste.

The bar chart presents the environmental implications associated with various aspects of the electronics industry. It highlights the key categories of impact, including raw material extraction, energy consumption, hazardous chemical usage, and electronic waste management. The data indicates that responsible sourcing, energy efficiency, green chemistry, and recycling initiatives are crucial in minimizing the industry’s ecological footprint. This information underscores the need for collaborative efforts among manufacturers, industry associations, and governments to drive a sustainable transformation within the electronics sector, fostering a greener and more environmentally conscious future.

5. Sustainability and Disposal Concerns

As global environmental awareness rises and the urgency to address climate change intensifies, industries are increasingly pursuing sustainable practices to reduce their ecological impact [

40]. Capacitor manufacturing, a vital part of the electronics industry, is significant in this context. With the growing demand for electronic devices, it is crucial to assess the environmental implications of capacitor production and to implement sustainable practices that reflect ecological responsibility. Different types of capacitors have different environmental challenges as mentioned previously in the environmental implications and they require sustainable practices to minimize their ecological footprint. Capacitors are widely used in electronic circuits for storing and managing energy, with typical applications including filtering, decoupling, energy storage, and tuning. However, practical capacitors are non-ideal and contain parasitic elements that can significantly affect their performance, such as equivalent series resistance (ESR) and equivalent series inductance (ESL) [

40,

41]. Improper disposal and recycling of capacitors can lead to electronic waste, further burdening landfill sites, causing potential environmental harm and posing health risks to humans and wildlife due to the leaching of toxic substances [

42].

In response to these challenges, manufactures can opt for ethically sourced raw materials to minimize the ecological impact of extraction, ensuring sustainable practices are followed throughout the supply chain. Energy efficiency can be achieved by implementing energy-efficient manufacturing processes, utilizing renewable energy sources, and optimizing equipment to reduce the carbon footprint of capacitor production [

42,

43]. Green chemistry involves exploring eco-friendly alternatives to hazardous chemicals, promoting the use of safer substances and adopting green chemistry principles to minimize environmental risks [

44]. Recycling initiatives can promote a circular economy by recovering valuable materials from end-of-life capacitors, reducing the need for new raw materials and minimizing waste [

45]. Extended Producer Responsibility (EPR) encourages sustainable design, reuse, and proper recycling by involving manufacturers in the entire lifecycle of the product, from production to disposal [

46].

Moreover, the path towards a sustainable future for the capacitor manufacturing industry requires a multifaceted approach. Collaborative efforts from manufacturers, policymakers, consumers, and industry associations are essential to address the various environmental impact areas. Establishing industry-wide standards, government incentives, and consumer awareness can collectively drive the adoption of responsible sourcing, energy efficiency, green chemistry, and recycling initiatives. By embracing these sustainable practices, capacitor manufacturers can contribute to a greener and more environmentally conscious electronics sector, benefiting both the environment and their long-term business operations.

6. Conclusions

The impact of capacitor types on circuit design and performance is significant, as different capacitor types exhibit unique properties that influence their suitability for specific applications. Capacitor types include ceramic, electrolytic, supercapacitors, and others, each with distinct characteristics such as capacitance, voltage rating, ESR, leakage, and temperature stability. These properties impact the capacitor’s ability to store and discharge electric charge, filter signals, decouple, and withstand voltage spikes and transient events. Environmental implications, particularly disposal and sustainability considerations, are also crucial factors in capacitor selection. Electrolytic capacitors, for instance, have a shorter lifespan and degraded performance over time, leading to a higher replacement rate and increased waste generation. Supercapacitors, on the other hand, offer high-power delivery and high-efficiency charge or discharge cycles but they have a high self-discharge rate when idle, which can impact on their overall energy efficiency.

Sustainability and disposal concerns are critical aspects of capacitor manufacturing and utilization. Responsible sourcing of materials, energy efficiency, green chemistry, recycling initiatives, and extended producer responsibility (EPR) are essential practices for minimizing the ecological footprint of capacitor production and disposal. Industry initiatives, government incentives, and consumer awareness are vital to promoting sustainable capacitor manufacturing and disposal practices. Therefore, the choice of capacitor type significantly impacts circuit design and performance, and environmental implications must be considered in capacitor selection and disposal. Adopting sustainable practices in capacitor manufacturing and disposal is crucial for minimizing environmental impact and promoting a circular economy in the electrical and electronics industry.

Author Contributions

N.L and I.N carried out the data collection, and investigations, wrote, and prepared the article. N.L and I.N were responsible for conceptualization, reviewing, and editing the manuscript. The authors have read and agreed to the published version of the manuscript.

Funding

This literature review received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank all the researchers for their contribution in the database.

Conflicts of Interest

The authors declare no conflict of interest.

References

- TE Connectivity. “Passive Components,” (n.d) [Online]. Available online: https://www.te.com/usa-en/products/passive-components.html (accessed on 2 March 2025).

- Newark.com. “Capacitor types and performance | Newark,” 2018. [Online]. Available online: https://www.newark.com/capacitor-types-and-performance (accessed on 2 March 2025).

- Physics LibreTexts. “Unit 8.2: Capacitors and Capacitance,” Nov. 01, 2016. [Online]. Available online: https://phys.libretexts.org/Bookshelves/University_Physics/University_Physics_%28OpenStax%29/Book%3A_University_Physics_II_-_Thermodynamics_Electricity_and_Magnetism_%28OpenStax%29/08%3A_Capacitance/8.02%3A_Capacitors_and_Capacitance (accessed on 2 March 2025).

- Electronics Tutorials. “Introduction to Capacitors, Capacitance and Charge,” Basic Electronics Tutorials, Sep. 15, 2018. [Online]. Available online: https://www.electronics-tutorials.ws/capacitor/cap_1.html (accessed on 2 March 2025).

- Ravi Teja. “Applications of Capacitors,” ElectronicsHub, Jan. 16, 2017. [Online]. Available online: https://www.electronicshub.org/applications-of-capacitors/ (accessed on 2 March 2025).

- JavaTpoint. “Applications of Capacitors – JavaTpoint,” (n.d) [Online]. Available online: https://www.javatpoint.com/applications-of-capacitors (accessed on 2 March 2025).

- eepower.com. “Ceramic Capacitor | Types | Capacitor Guide,” (n.d) [Online]. Available online: https://eepower.com/capacitor-guide/types/ceramic-capacitor/ (accessed on 2 March 2025).

- eepower.com. “Electrolytic Capacitor | Types | Capacitor Guide,” (n.d) [Online]. Available online: https://eepower.com/capacitor-guide/types/electrolytic-capacitor/ (accessed on 2 March 2025).

- eepower.com. “Film Capacitor | Types | Capacitor Guide,” (n.d) [Online]. Available online: https://eepower.com/capacitor-guide/types/film-capacitor/ (accessed on 2 March 2025).

- eepower.com. “Tantalum Capacitor | Types | Capacitor Guide,” (n.d) [Online]. Available online: https://eepower.com/capacitor-guide/types/tantalum-capacitor/ (accessed on 2 March 2025).

- N. Powers. “The Ups and Downs of Tantalum Capacitors,” Arrow.com, Dec. 07, 2016. [Online]. Available online: https://www.arrow.com/en/research-and-events/articles/the-ups-and-downs-of-tantalum-capacitors (accessed on 2 March 2025).

- utmel.com. “What is a variable capacitor? - Utmel,” Feb. 24, 2020. [Online]. Available online: https://www.utmel.com/blog/categories/capacitors/what-is-a-variable-capacitor (accessed on 2 March 2025).

- eepower.com. “Mica Capacitor | Types | Capacitor Guide,” (n.d) [Online]. Available online: https://eepower.com/capacitor-guide/types/mica-capacitor/ (accessed on 2 March 2025).

- Nagaraj, K. “High-precision switched-capacitor integrator using low-gain opamp,” Electronics Letters, vol. 47, no. 5, pp. 309-310, Mar. 2011. [Online]. Available online: https://digital-library.theiet.org/doi/abs/10.1049/el.2010.3342 (accessed on 2 March 2025).

- www.electronics-notes.com. “Polycarbonate Capacitor & Replacement Alternatives» Electronics Notes,” (n.d) [Online]. Available online: https://www.electronics-notes.com/articles/electronic_components/capacitors/polycarbonate.php (accessed on 2 March 2025).

- www.electronics-notes.com. “Polystyrene Capacitor: Polystyrene Film» Electronics Notes,” (n.d) [Online]. Available online: https://www.electronics-notes.com/articles/electronic_components/capacitors/polystyrene.php (accessed on 2 March 2025).

- Electrocube. “Polycarbonate Capacitors Replacements - What Are The Options?,” Nov. 2007. [Online]. Available online: https://www.electrocube.com/pages/polycarbonate-capacitors-no-longer-available-data-sheet (accessed on 2 March 2025).

- Y. K. Mc. EngineerinG, “Paper Capacitor,” Instructables. (n.d) [Online]. Available online: https://www.instructables.com/Paper-Capacitor/ (accessed on 2 March 2025).

- ElProCus. “Paper Capacitor: Construction, Types, Working & Its Advantages,” Electronic Projects for Engineering Students, Feb. 04, 2020. [Online]. Available online: https://www.elprocus.com/what-is-a-paper-capacitor-construction-working-applications/ (accessed on 2 March 2025).

- Hamiter, L. “Capacitor Technologies, Applications and Reliability,” NASA Conference Publication 2136, presented at the Symposium on Capacitor Technologies, Applications and Reliability, Huntsville, AL, Feb.1981. [Online]. Available online: https://ntrs.nasa.gov/api/citations/19810017835/downloads/19810017835.pdf (accessed on 2 March 2025).

- enrgtech. “Paper Capacitors: Their Construction, Working Principle, and Applications,” May 30, 2022. [Online]. Available online: https://www.enrgtech.co.uk/blog/paper-capacitors-their-construction-working-principle-and-applications/ (accessed on 2 March 2025).

- Blooming, T.M.; Carnovale, D.J. “Capacitor Application Issues,” Eaton Corporation Technical Datasheet, Smyrna, GA, USA, 2025. [Online]. Available online: https://www.eaton.com/content/dam/eaton/markets/experience-centers/technical-datasheets/Capacitor-Application-Issues.pdf (accessed on 31 March 2025).

- Wang, H.; Blaabjerg, F. “Reliability of Capacitors for DC-Link Applications – An Overview,” in Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE 2013), Denver, CO, USA, Sep. 14–19, 2013, pp. 1866–1873. [Online]. Available online: https://vbn.aau.dk/ws/portalfiles/portal/152271344/reliability_of_capacitors_for_dc_link_applications_an_overview.pdf (accessed on 2 March 2025).

- Electrical Engineering Stack Exchange. “What is a bipolar capacitor and when is it used?,” (n.d) [Online]. Available online: https://electronics.stackexchange.com/questions/304445/what-is-a-bipolar-capacitor-and-when-is-it-used (accessed on 2 March 2025).

- Emadi, A.; Williamson, S.S.; Khaligh, A. “Enhanced Bipolar Stacked Switched Capacitor Energy Buffers,” in Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE 2012), Raleigh, NC, USA, Sep. 15–20, 2012, pp. 4209–4216. [Online]. Available online: https://collaborate.princeton.edu/en/publications/enhanced-bipolar-stacked-switched-capacitor-energy-buffers (accessed on 2 March 2025).

- Wang, H. “Capacitors in Power Electronics Applications – Reliability and Circuit Design,” in IECON 2016 Tutorial, Florence, Italy, Oct. 24, 2016. [Online]. Available online: https://vbn.aau.dk/ws/portalfiles/portal/243654015/IECON_2016_Cap_HW.pdf (accessed on 2 March 2025).

- Cadence PCB Design. “A Brief Overview of Capacitor Types,” Cadence Resources Blog, 2022. [Online]. Available online: https://resources.pcb.cadence.com/blog/2022-a-brief-overview-of-capacitor-types (accessed on 31 March 2025).

- Utmel Electronics. "What is Feedthrough Capacitor?" Utmel Blog, Nov. 20, 2021. [Online]. Available online: https://www.utmel.com/blog/categories/capacitors/what-is-feedthrough-capacitor (accessed on 31 March 2025).

- doEEEt Media Group. “Feedthrough Capacitors Technology and Applications,” EEE Parts Database, Oct. 3, 2020. [Online]. Available online: https://www.doeeet.com/content/eee-components/actives/feedthrough-capacitors-technology-and-applications/ (accessed on 31 March 2025).

- Engineering.com. “The engineer’s guide to feedthrough capacitors,” (n.d) [Online]. Available online: https://www.engineering.com/story/the-engineers-guide-to-feedthrough-capacitors (accessed on 2 March 2025).

- Pan, M.-J.; Randall, C.A. A brief introduction to ceramic capacitors. IEEE Electrical Insulation Magazine. 2010, 26, pp. 44–49. Available online: https://pure.psu.edu/en/publications/a-brief-introduction-to-ceramic-capacitors (accessed on 2 March 2025).

- Cadence PCB Design. “Electrolytic Capacitor Use and Design,” Cadence Resources Blog, 2023. [Online]. Available online: https://resources.pcb.cadence.com/blog/2023-electrolytic-capacitor-use-and-design (accessed on 31 March 2025).

- Wang, R. “Tantalum Capacitors: Characteristics and Component Selection,” KYOCERA AVX Corporation, Fountain Inn, SC, USA. [Online]. Available online: https://www.kyocera-avx.com/docs/techinfo/Tantalum-NiobiumCapacitors/Tantalum-Capacitors-Characteristics-and-Component.pdf (accessed on 31 March 2025).

- Krueger, D. “Contributions to the Performance of Thin Film Capacitors for High Reliability Applications,” Doctoral Dissertation, Missouri University of Science and Technology, 2021. [Online]. Available online: https://scholarsmine.mst.edu/doctoral_dissertations/3008 (accessed on 31 March 2025).

- eepower.com. “Chapter 2 - Capacitor Types – Supercapacitor,” (n.d) [Online]. Available online: https://eepower.com/capacitor-guide/types/supercapacitor/ (accessed on 2 March 2025).

- Evolute. “Sustainability and Environmental Considerations in Capacitor Manufacturing,” Evolute Blog, 2023. [Online]. Available online: https://www.evolute.in/blog/sustainability-and-environmental-considerations-in-capacitor-manufacturing/ (accessed on 2 March 2025).

- R. S. C. Publishing. “Comparative environmental impact assessment of activated carbon electrodes for supercapacitors,” Green Chemistry, vol. 26, no. 3, pp. 700–715, 2024. [Online]. 2024. Available online: https://pubs.rsc.org/en/Content/ArticleLanding/2024/GC/D4GC02700K (accessed on 2 March 2025).

- Greenpeace East Asia. “Semiconductor industry electricity consumption to more than double by 2030: study,” Apr. 20, 2023. [Online]. Available online: https://www.greenpeace.org/eastasia/press/7930/semiconductor-industry-electricity-consumption-to-more-than-double-by-2030-study/ (accessed on 2 March 2025).

- Jones, R.L. Important considerations for capacitor applications in the petroleum and chemical process industries. IEEE Transactions on Industry Applications 1995, IA-18, 1–5. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. “Sustainable Manufacturing,” EPA Sustainability Resources, Mar. 2025. [Online]. Available online: https://www.epa.gov/sustainability/sustainable-manufacturing (accessed on 31 March 2025).

- Sharma, S.; Kumar, S.; Patel, A. Electronic waste pollution and the COVID-19 pandemic: Implication on environment and circular economy. Environ. Chem. Lett. 2021, 19, 1–10. Available online: https://pmc.ncbi.nlm.nih.gov/articles/PMC8314023/ (accessed on 31 March 2025).

- Zhao, W.; Xu, J.; Fei, W.; Liu, Z.; He, W.; Li, G. The reuse of electronic components from waste printed circuit boards: a critical review. Environmental Science: Advances 2023, 2, 266–283. Available online: https://pubs.rsc.org/en/content/articlehtml/2023/va/d2va00266c (accessed on 31 March 2025).

- Zhao, J.; Zhang, X.; Wang, Y. Sustainable practices in electronics manufacturing: A focus on capacitor production. IEEE Transactions on Sustainable Energy 2025, 16, 45–55, (accessed on 31 March 2025). [Google Scholar]

- Anastas, P.T.; Warner, J.C. “Green Chemistry: Theory and Practice,” Oxford University Press, 2nd ed., 2024. [Online]. Available online: https://global.oup.com/academic/product/green-chemistry-9780198506980 (accessed on 31 March 2025).

- Eaton. “First-of-its-kind capacitor recycling program announced by Eaton to drive circular economy,” Renewable Energy World, Dec. 2, 2020. [Online]. Available online: https://www.renewableenergyworld.com/hydro-power/dams-civil-structures/first-of-its-kind-capacitor-recycling-program-announced-by-eaton-to-drive-circular-economy/ (accessed on 31 March 2025).

- Pruess, J.T. Unraveling the complexity of extended producer responsibility policy mix design, implementation, and transfer dynamics in the European Union. Journal of Industrial Ecology 2023, 27, 1234–1248. Available online: https://onlinelibrary.wiley.com/doi/full/10.1111/jiec.13429 (accessed on 31 March 2025).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).