Submitted:

27 March 2025

Posted:

31 March 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

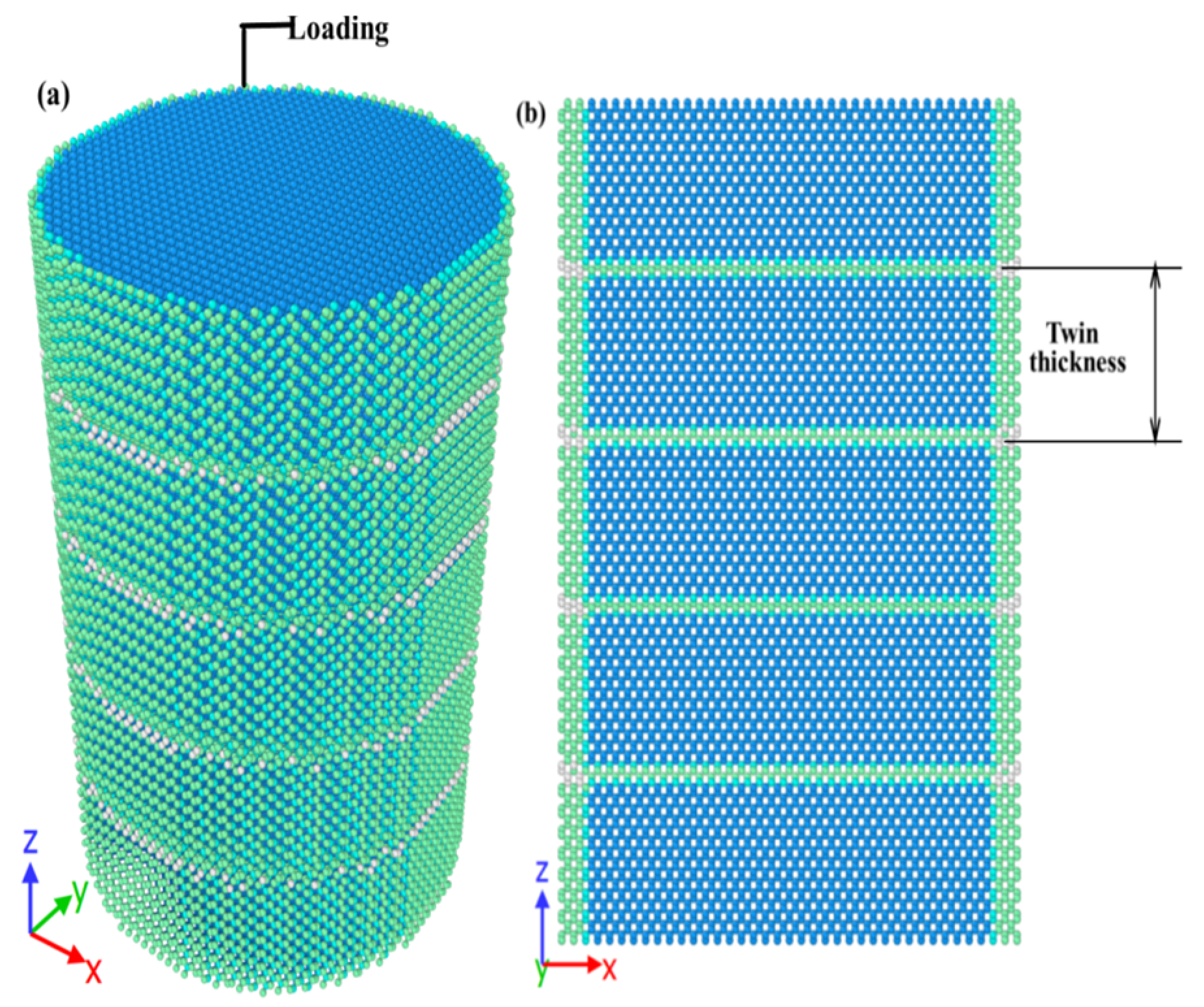

2. Simulation Models and Methods

3. Results and Discussion

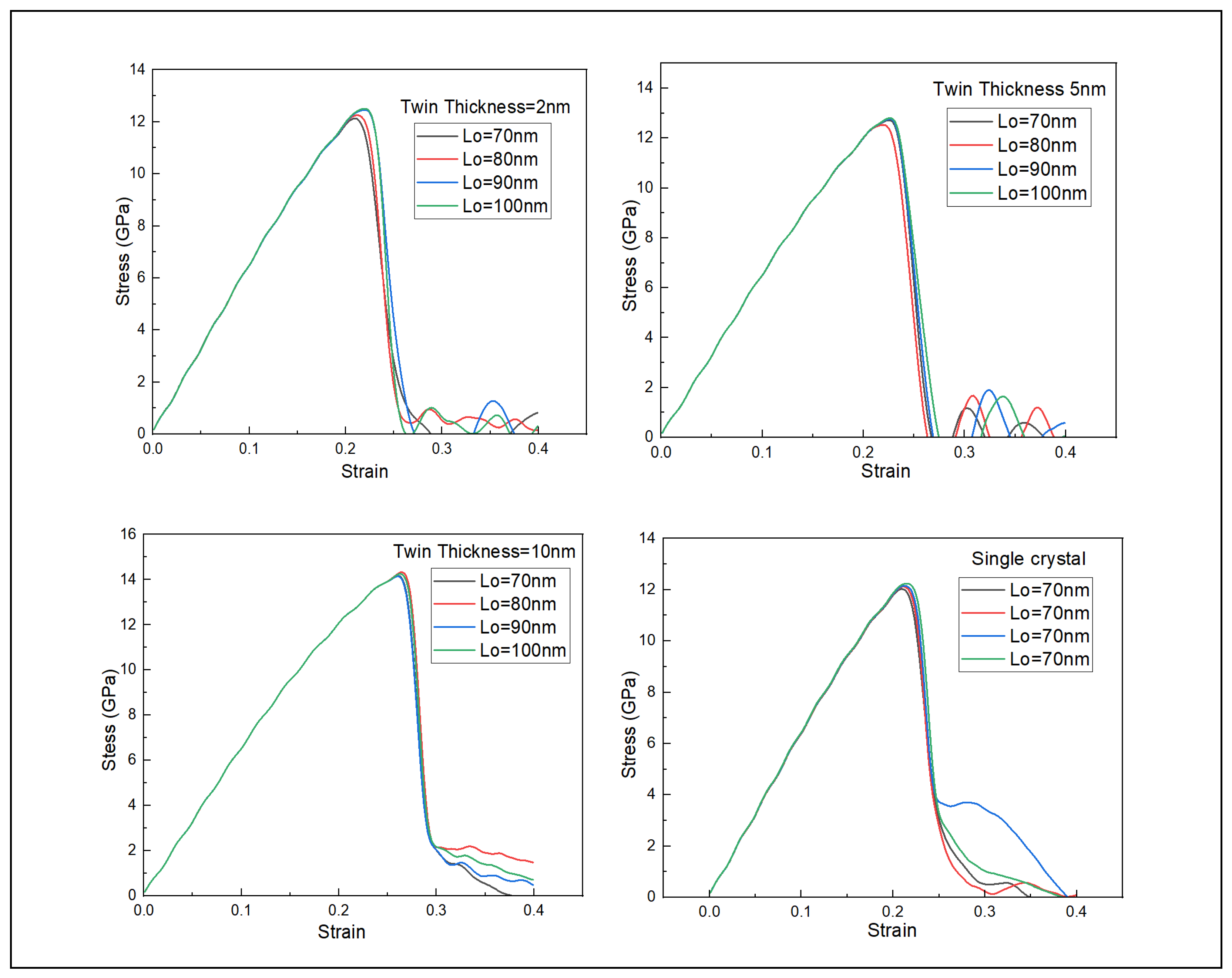

3.1. Length-Dependent Mechanical Properties of Si NWs

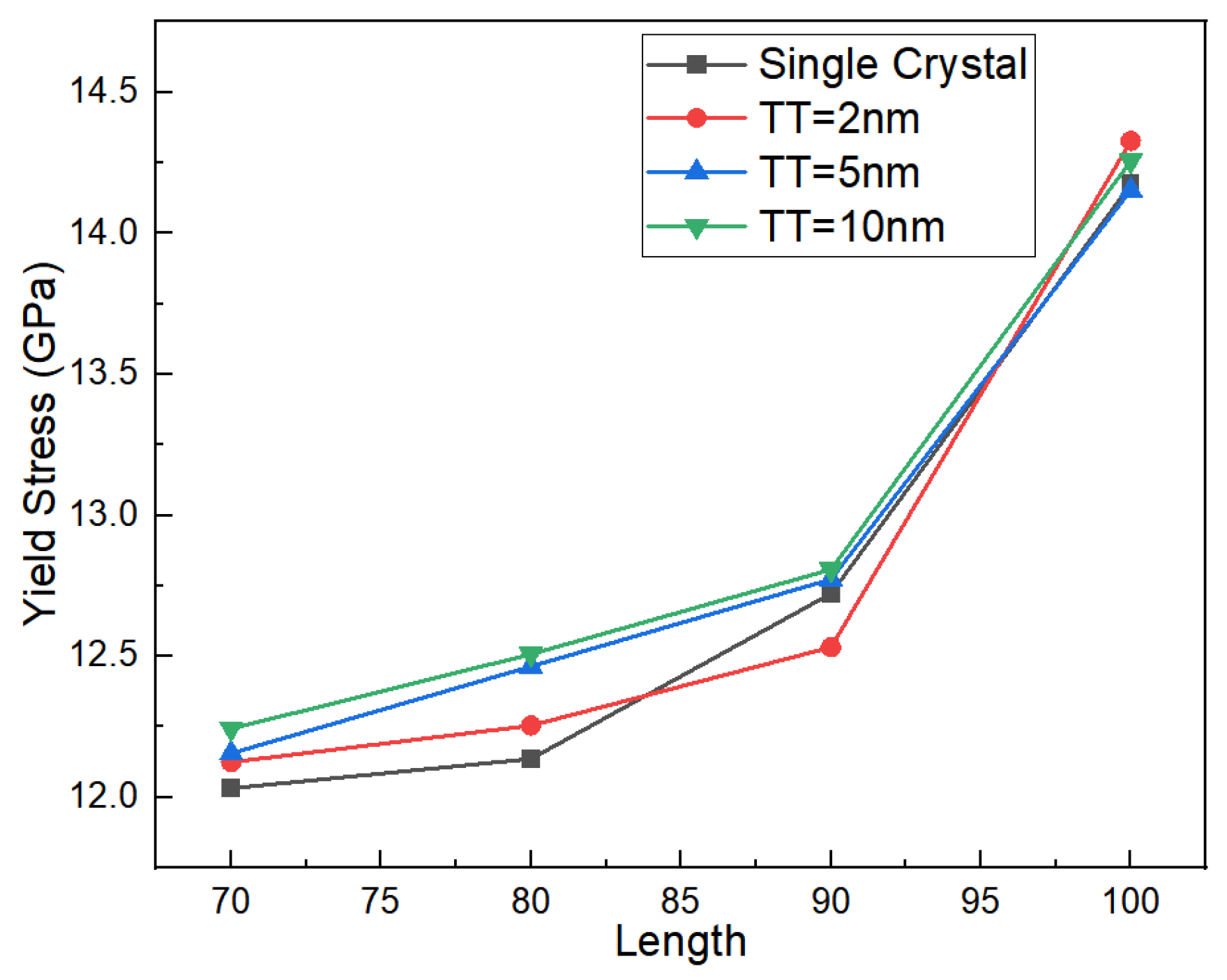

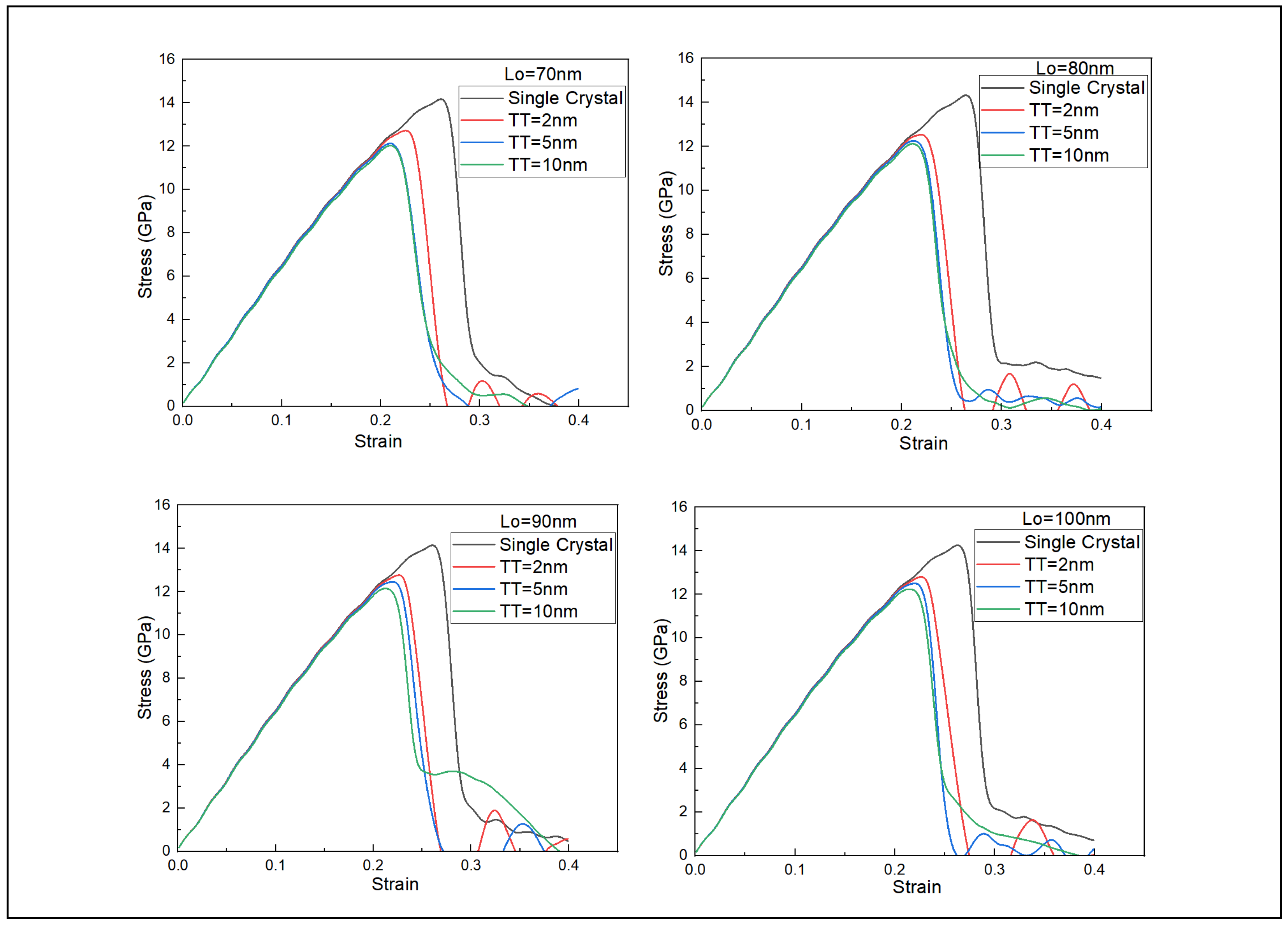

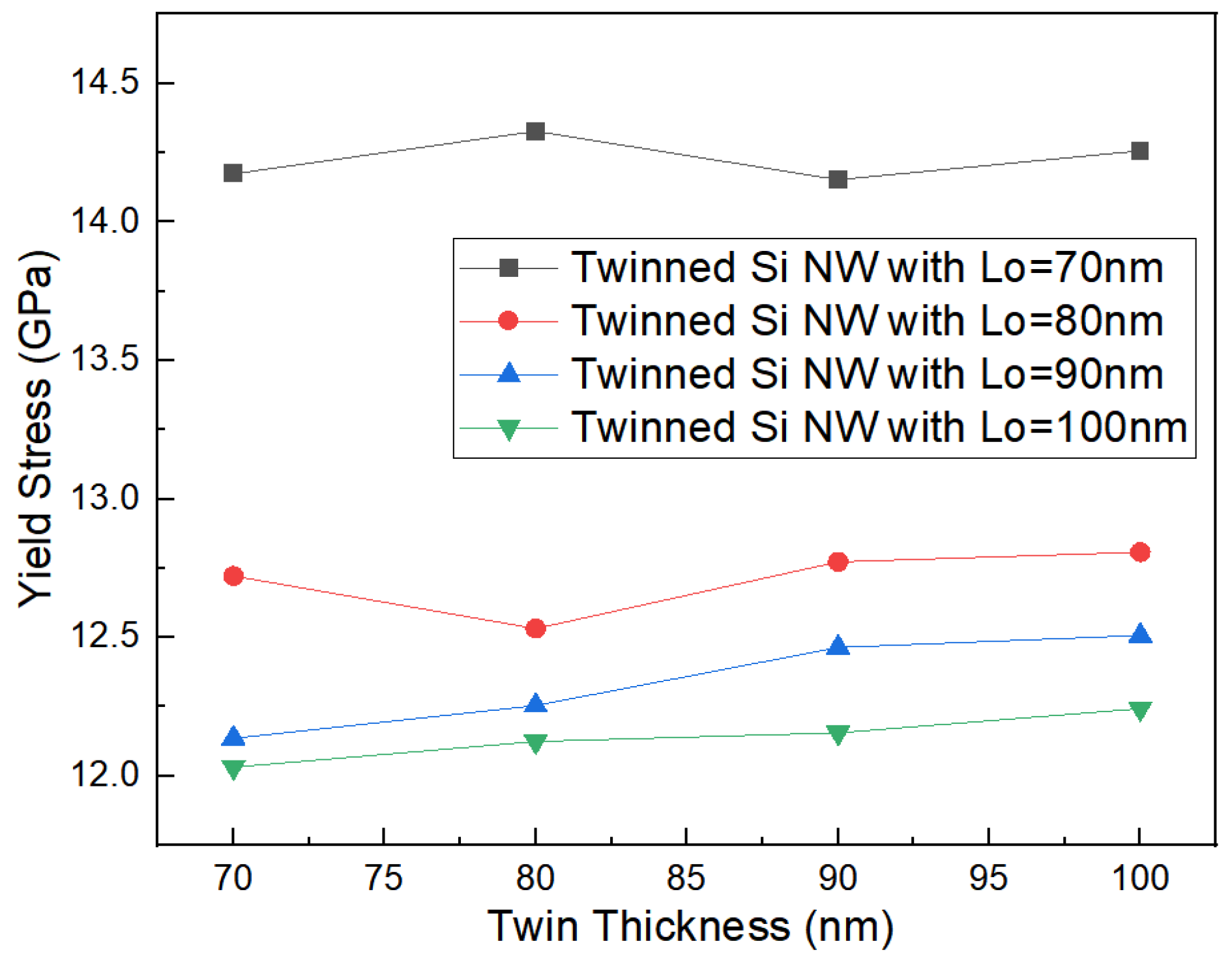

3.2. Twin Thickness-Dependent Mechanical Properties of Si NWs

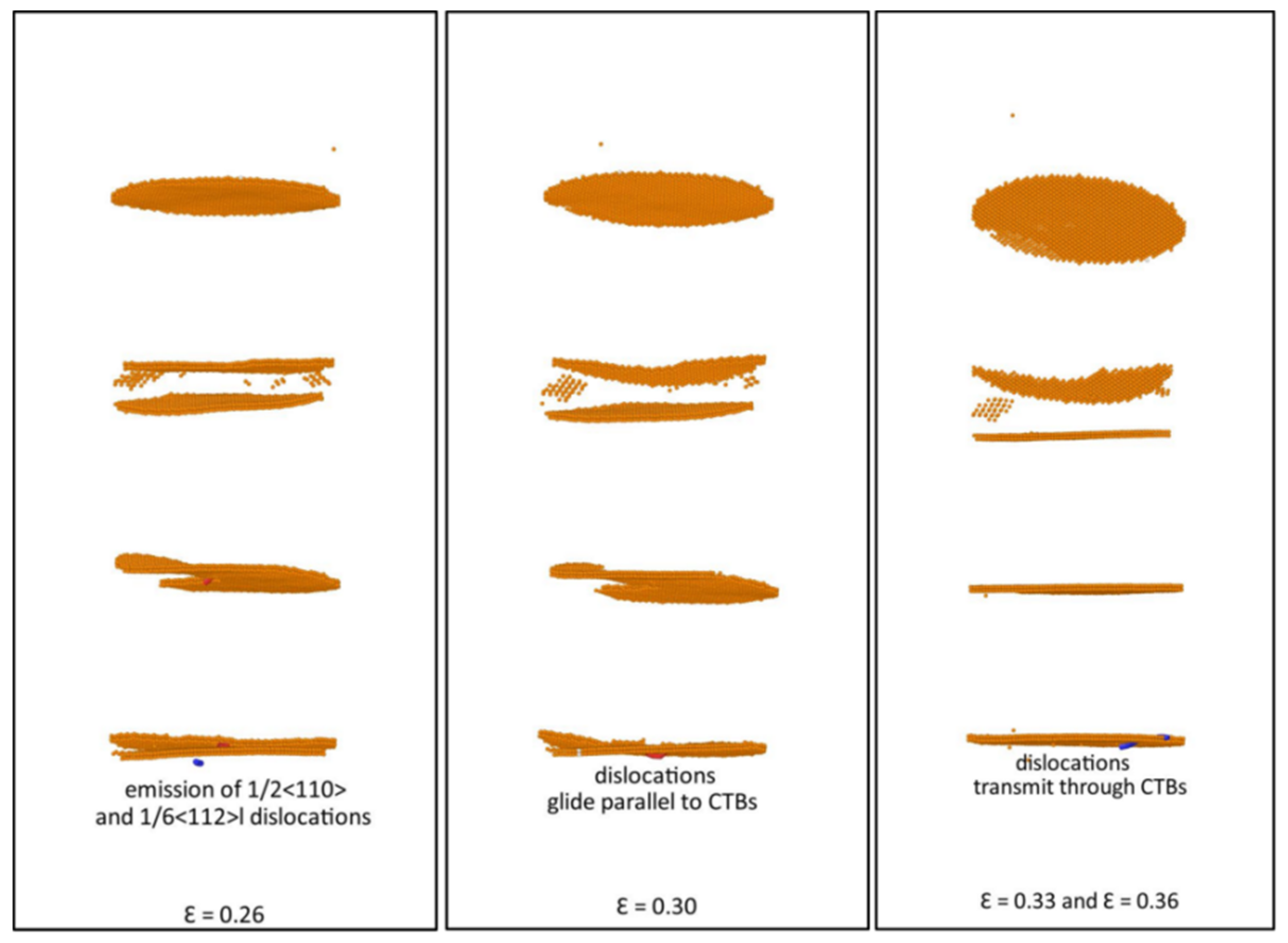

3.3. Observation of Mechanical and Deformation Behaviors of Si NWs

4. Conclusions

- ▪

- Our simulation findings indicate that the mechanical properties of the twinned silicon nanowires are significantly affected by the length of the nanowires, which is regarded as an extrinsic size effect, and the thickness of the twins, which is considered an intrinsic size effect. This demonstrates a pronounced impact of both nanowire length and twin thickness on yield strength and deformation mechanisms. Depending on the effects of the nanowire length and twin thickness, the twinned Si nanowires undergo ductile as well as brittle failure modes (fracture) and ductile-to-brittle transition. When the twin thickness is increased, the twinned Si nanowires undergo a ductile-to-brittle transition as the critical length increases from 70 nm to 100 nm. When compared to single-crystal nanowires, twinned Si nanowires exhibit a strong NW length effect (longer is stronger) and a strong twin thickness effect (thinner is stronger).

- ▪

- The mechanical behaviors for twinned Si NWs were demonstrated to be considerably improved by Σ3 coherent twin boundaries (CTBs). It was observed that longer nanowires exhibit a more pronounced strengthening effect whereas shorter nanowires experience a diminished strengthening response.

- ▪

- It was found that 1/2<110> {111} full dislocations and 1/6<112> {111} partial dislocations were produced from the free surface near the coherent twin boundaries (CTBs) by analyzing atomic configurations during the early stages of plastic deformation. On the other hand, dislocations were shown to accumulate at these TBs as they glided parallel to the CTBs under specific strain levels. As a result, the dislocations’ buildup and migration accross the CTBs affect the twinned silicon nanowires’ yield strength.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- A. Husain, J. Hone, H.W.Ch. Postma, X.M.H. Huang, T. Drake, M. Barbic, A. Scherer, M.L. Roukes, Nanowire-based very-high-frequency electromechanical resonator, Applied Physics Letters 83 (2003) 1240–1242. [CrossRef]

- M. Liao, S. Hishita, E. Watanabe, S. Koizumi, Y. Koide, Suspended Single-Crystal Diamond Nanowires for High-Performance Nanoelectromechanical Switches, Advanced Materials 22 (2010) 5393–5397. [CrossRef]

- Zheng Fan, Miao Yu, Xinyong Tao, R. Shanmugam, Xudong Fan, Wei Lai, Lixin Dong, In situ investigation of nanoelectrochemical systems, in: 14th IEEE International Conference on Nanotechnology, IEEE, Toronto, ON, 2014: pp. 882–883. [CrossRef]

- Y.T. Zhu, X.Z. Liao, X.L. Wu, Deformation twinning in nanocrystalline materials, Progress in Materials Science 57 (2012) 1–62. [CrossRef]

- K. Lu, L. Lu, S. Suresh, Strengthening Materials by Engineering Coherent Internal Boundaries at the Nanoscale, Science 324 (2009) 349–352. [CrossRef]

- Y.F. Shen, L. Lu, Q.H. Lu, Z.H. Jin, K. Lu, Tensile properties of copper with nano-scale twins, Scripta Materialia 52 (2005) 989–994. [CrossRef]

- M. Dao, L. Lu, Y.F. Shen, S. Suresh, Strength, strain-rate sensitivity and ductility of copper with nanoscale twins, Acta Materialia 54 (2006) 5421–5432. [CrossRef]

- A.M. Hodge, Y.M. Wang, T.W. Barbee, Mechanical deformation of high-purity sputter-deposited nano-twinned copper, Scripta Materialia 59 (2008) 163–166. [CrossRef]

- N. Li, J. Wang, S. Mao, H. Wang, In situ nanomechanical testing of twinned metals in a transmission electron microscope, MRS Bull. 41 (2016) 305–313. [CrossRef]

- X. Li, Y. Wei, L. Lu, K. Lu, H. Gao, Dislocation nucleation governed softening and maximum strength in nano-twinned metals, Nature 464 (2010) 877–880. [CrossRef]

- L. Zhu, H. Ruan, X. Li, M. Dao, H. Gao, J. Lu, Modeling grain size dependent optimal twin spacing for achieving ultimate high strength and related high ductility in nanotwinned metals, Acta Materialia 59 (2011) 5544–5557. [CrossRef]

- J. Sun, L. Fang, K. Sun, J. Han, Direct observation of dislocations originating from perfect twin boundaries, Scripta Materialia 65 (2011) 501–504. [CrossRef]

- J. Sun, L. Fang, A. Ma, J. Jiang, Y. Han, H. Chen, J. Han, The fracture behavior of twinned Cu nanowires: A molecular dynamics simulation, Materials Science and Engineering: A 634 (2015) 86–90. [CrossRef]

- T. Zhu, H. Gao, Plastic deformation mechanism in nanotwinned metals: An insight from molecular dynamics and mechanistic modeling, Scripta Materialia 66 (2012) 843–848. [CrossRef]

- K.A. Afanasyev, F. Sansoz, Strengthening in Gold Nanopillars with Nanoscale Twins, Nano Lett. 7 (2007) 2056–2062. [CrossRef]

- A.J. Cao, Y.G. Wei, S.X. Mao, Deformation mechanisms of face-centered-cubic metal nanowires with twin boundaries, Applied Physics Letters 90 (2007) 151909. [CrossRef]

- Y. Zhang, H. Huang, Do Twin Boundaries Always Strengthen Metal Nanowires?, Nanoscale Res Lett 4 (2009) 34. [CrossRef]

- C. Deng, F. Sansoz, Enabling Ultrahigh Plastic Flow and Work Hardening in Twinned Gold Nanowires. Nano Lett 2009, 9, 1517–1522. [CrossRef] [PubMed]

- C. Deng, F. Sansoz, Size-dependent yield stress in twinned gold nanowires mediated by site-specific surface dislocation emission, Applied Physics Letters 95 (2009) 091914. [CrossRef]

- C. Deng, F. Sansoz, Fundamental differences in the plasticity of periodically twinned nanowires in Au, Ag, Al, Cu, Pb and Ni, Acta Materialia 57 (2009) 6090–6101. [CrossRef]

- D. Jang, X. Li, H. Gao, J.R. Greer, Deformation mechanisms in nanotwinned metal nanopillars, Nature Nanotech 7 (2012) 594–601. [CrossRef]

- J. Wang, F. Sansoz, J. Huang, Y. Liu, S. Sun, Z. Zhang, S.X. Mao, Near-ideal theoretical strength in gold nanowires containing angstrom scale twins, Nat Commun 4 (2013) 1742. [CrossRef]

- C. Deng, F. Sansoz, Near-Ideal Strength in Gold Nanowires Achieved through Microstructural Design, ACS Nano 3 (2009) 3001–3008. [CrossRef]

- Z.X. Wu, Y.W. Zhang, M.H. Jhon, J.R. Greer, D.J. Srolovitz, Nanostructure and surface effects on yield in Cu nanowires, Acta Materialia 61 (2013) 1831–1842. [CrossRef]

- T. Zhu, J. Li, S. Ogata, S. Yip, Mechanics of Ultra- Strength Materials, (n.d.).

- H.Y. Song, Y. Sun, Effect of coherent twin boundary and stacking fault on deformation behaviors of copper nanowires, Computational Materials Science 104 (2015) 46–51. [CrossRef]

- J. Wang, F. Sansoz, C. Deng, G. Xu, G. Han, S.X. Mao, Strong Hall–Petch Type Behavior in the Elastic Strain Limit of Nanotwinned Gold Nanowires, Nano Lett. 15 (2015) 3865–3870. [CrossRef]

- S. Plimpton, Fast Parallel Algorithms for Short- Range Molecular Dynamics, (n.d.).

- P. Erhart, K. Albe, Analytical potential for atomistic simulations of silicon, carbon, and silicon carbide, Phys. Rev. B 71 (2005) 035211. [CrossRef]

- E. Maras, O. Trushin, A. Stukowski, T. Ala-Nissila, H. Jónsson, Global transition path search for dislocation formation in Ge on Si(001), Computer Physics Communications 205 (2016) 13–21. [CrossRef]

- J. Han, L. Fang, J. Sun, Y. Han, K. Sun, Length-dependent mechanical properties of gold nanowires, Journal of Applied Physics 112 (2012) 114314. [CrossRef]

- J. Sun, C. Li, J. Han, X. Shao, X. Yang, H. Liu, D. Song, A. Ma, Size Effect and Deformation Mechanism in Twinned Copper Nanowires, Metals 7 (2017) 438. [CrossRef]

- G.-W. Zhang, Z.-L. Yang, G. Luo, Investigation of mechanical properties of twin gold crystal nanowires under uniaxial load by molecular dynamics method, Chinese Phys. B 25 (2016) 086203. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).