Introduction

Pollution is one of the biggest problems the world is currently facing. The pollution crisis has paved the way for more biodegradable solutions to emerge. Yet, some biodegradable solutions have yet to be created for items people deem necessary for everyday life, according to the Global Alliance for Incinerator Activities. (2019), around three million diapers are discarded in the Philippines daily, or 1.1 billion diapers annually. Sommers M.J et al. (2021) state that most diapers are single-use and typically comprise polypropylene, polyethylene, elastics, cellulose, and superabsorbent polymers (SAPs). These materials were estimated to take 400 years to disintegrate in a landfill (Sachidhanandham, A. 2020). Eco-friendly diapers have become more prevalent in recent years to combat diaper waste. While these biodegradable diapers have already been invented and sold, studies such as Czarnecka, E. (2022) have found that these biodegradable diapers still need to meet environmental safety expectations. The materials this study covers are kapok fiber and bamboo cloth. These two materials are what make up the biodegradable solution to solve the big problem of diaper waste.

Rathod (2014) has found that bamboo cloth has a higher breaking point compared to other materials tested, while still having antibacterial and antibacterial properties. Bamboo fiber has also been found to have a natural sterilization effect, moisture vapor transmission, and easy drying properties as stated by (Gowda R.V. 2012). On the other hand (Wolok, E. et al. 2019). Kapok was determined to be the best absorbent, biodegradable material since it Has been found to absorb 285% of its weight in water. In the Philippines, it is known as Buboi or Buboy. Kapok is cultivated for its seed fiber, a cotton-like fluff from its seed pods. This paper has concluded that bamboo cloth and kapok fiber would be the best materials to create a fully biodegradable diaper that is safe for the environment. Bamboo cloth would be able to replace the polyester fabric used in normal disposable diapers, while kapok fiber could be an alternative to SAP or Super Absorbent Polymers.

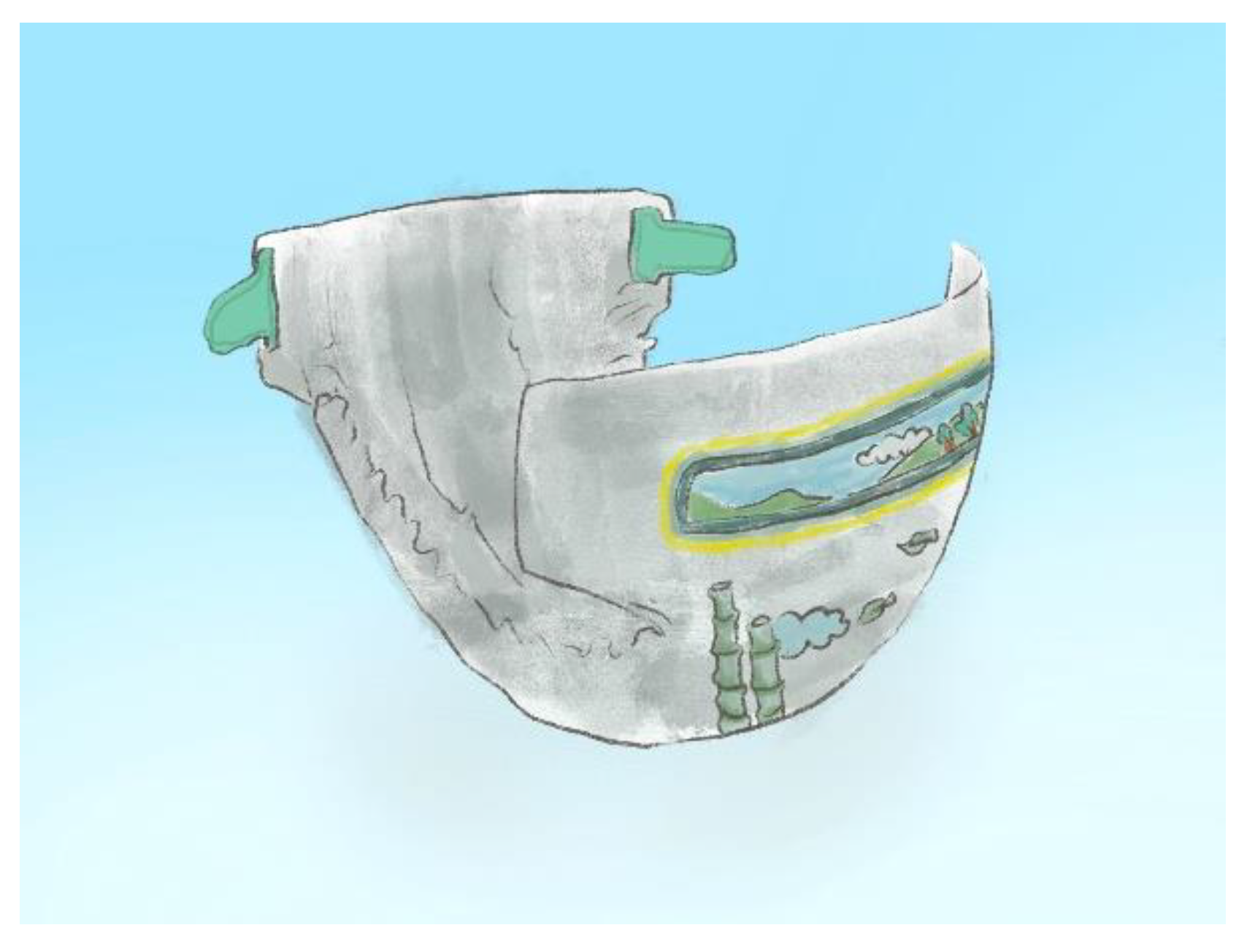

The diaper has the kapok fiber on the inside acting as an alternative to the absorbing gel inside normal diapers. The bamboo cloth is on the outside to wrap around the skin. To acquire these materials, it goes through a treatment process. Harvesting Kapok fibers requires the pods to be cut down. These pods are crushed open with a mallet and the contents are placed in a basket and stirred so the seeds fall to the bottom and separate from the fiber (Philippine Fiber Industry Development Authority. 2016) These fibers are then compressed and made into a pad that can be inserted into the Kaboo diaper. Bamboo fiber comes from bamboo timber which has matured for at least 4 years. The supportability of bamboo texture relies heavily on the way it is produced. The most environmentally friendly process which is mercerization utilizes natural enzymes, rather than harmful chemicals, to create bamboo cloth. The bamboo cloth is made from the pulp of the plant itself. Its stalks are crushed and fibers are separated from the cellulose which is then turned into thread and woven into fabric (Bamboo Textiles Australia. 2017).

Concerns about the true environmental effect of so-called "biodegradable" diapers have been raised by the market's overabundance. The fact that many of these products make eco-friendly claims yet may not degrade as promised creates a substantial obstacle to dealing with diaper trash in an ecologically acceptable way. sustainable diaper alternatives like biodegradable diapers, cloth diapers, or reusable solutions are frequently unaffordable (Hirsh, S. 2022). Adoption of such goods is hampered by their high initial cost and restricted supply, which leads to a persistent dependence on non-biodegradable disposable diapers.

This paper answers the following questions.

1. Is it possible to create an environmentally safe and fully biodegradable diaper made from kapok fiber and bamboo cloth?

2. Will a fully biodegradable diaper be as effective as a normal disposable diaper in absorption and comfortability?

With these problems and questions brought up in this research, we can make the hypothesis That if we can make a diaper with bamboo cloth And kapok fiber, will we be able to make it fully biodegradable?

The scope of this study is focused on the materials and designs needed to create a fully biodegradable diaper that will lessen pollution. This study uses bamboo cloth and kapok fiber as its materials. This study can also be used to make sanitary napkins, pads, and booster pads. This is the first attempt to test this diaper made with kapok and bamboo fiber. This study does not cover using other possible fabrics as diaper material. The main focus of this study is how kapok and bamboo fibers can be used as diaper materials.

This research hopes to reduce waste in rural communities without formal waste management systems. This research primarily focuses on the parents of newborn children in these rural areas. Similarly, this research also helps the babies and newborns of these people in rural areas. This research also aids similar products that will be developed in the future. The hopeful result of this product would be to create a simple, cheap, and effective product that could one day replace regular disposable diapers that have polluted our earth for decades.

Methodology

The primary focus of this study is to see if it is possible to create a fully biodegradable diaper from kapok fiber and bamboo cloth is environmentally safe. This study utilizes a true experimental pre-test post-test research design based on the guide of (Cambell et al., 1963 as cited by

Choueiry 2022). We used a normal disposable diaper for the control group and different experimental designs. Using this experimental design, we aim to find the design and ratio of kapok fiber to best match the results of the disposable diaper or the control. The first experimental group would be a design with normal bamboo cloth on the inside and bamboo rayon on the inside. The second experimental group had bamboo rayon inside and outside the diaper. The third design uses normal bamboo fiber for the inside and outside of the diaper.

| Groups |

t1 |

Treatment |

t2 |

| E1 |

O |

X |

O |

| E2 |

O |

X |

O |

| E3 |

O |

X |

O |

| C1 |

O |

X |

O |

To create our prototype, we first had to process the Kapok fiber, which was separated from the seeds of the Kapok from the actual fibers. The next step was to felt the fibers by compressing and compacting them together to produce a fabric. After that, we cut the bamboo cloth into 4 panels, putting 2 on top and 2 at the bottom of the felted kapok fibers. Next, we added a quick-drying layer on top of the kapok to help better absorb and dry waste excreted by the infants. After that, we got extra help from professional tailors and stitched the whole thing together to make a diaper. They also helped us print a friendly design on it.

Illustration 1.

Diaper diagram.

Illustration 1.

Diaper diagram.

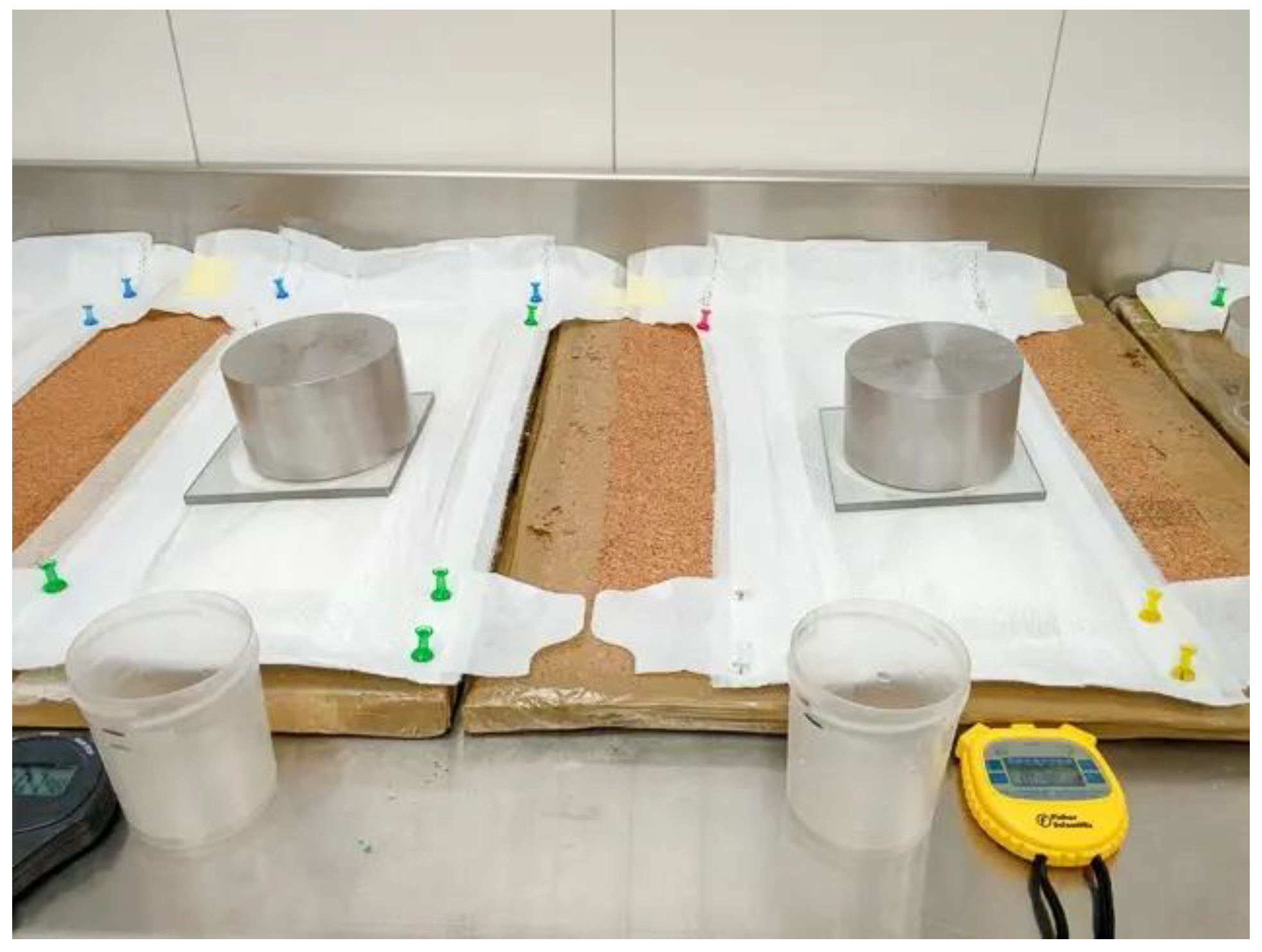

The first test performed was the rewet test using the NWSP 70.9 method, as mentioned by SGS-IPS Testing (2019). The rewet test, or the rate of acquisition test, uses a specified quantity of simulated urine discharged at a certain rate onto the fully biodegradable diaper. The time taken for the entire liquid dose to be absorbed by the diaper is measured. A pre-weighed filter paper is then placed on the specimen, and a known weight is applied carefully on top of the filter paper and specimen. The mass of liquid absorbed by the filter paper is measured, which relates to wearing comfort. The second test is the Absorbancy test, which evaluates how much simulated urine the product can absorb before leaking. The test starts by weighing the fully biodegradable diaper and slowly adding 10ml of water until there is leakage. The final recorded weight before leakage is the absorption capacity of the fully biodegradable diaper.

The instruments used for our testing of the diaper

Figure 1.

Rewet Test with Filter paper, Weight, and timer .

Figure 1.

Rewet Test with Filter paper, Weight, and timer .

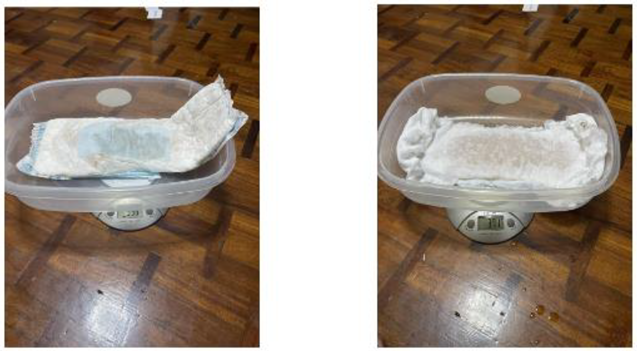

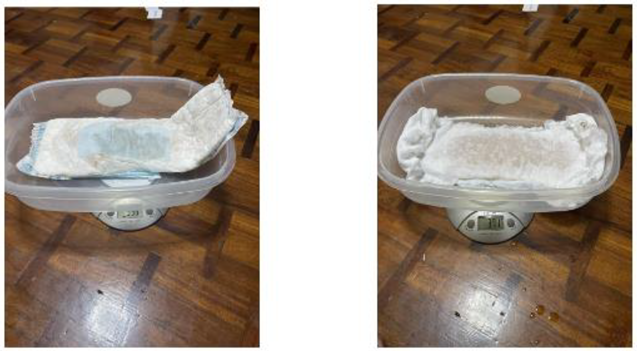

Figure 2.

Absorbency test with Precision Scale.

Figure 2.

Absorbency test with Precision Scale.

An important tool used in the study is filter paper, particularly for evaluating the absorbency of the diapers. It is used to imitate liquid absorption and, together with weights, aids in determining how successfully a diaper can hold moisture. The performance features of the diapers are assessed with the use of filter paper to make sure they adhere to safety and performance requirements. In the study's testing phase, weights are essential, especially for determining characteristics like absorbency and tensile strength characteristics. Researchers may assess the diapers' resistance to ripping or breaking by gradually adding weights, giving them important information about their performance and durability.

We statistically treated the data gathered from the experiments using a one-sample t-test. As stated by Kent State University (2023), The t-test is a parametric test that examines whether the mean of a population is statistically different from a known or hypothesized value. We are using this to compare two variables with the control group. These variables are the rate of absorption, the mass of the liquid absorbed by the diaper, and the full capacity of absorption before it leaks. These variables would be compared to the regular diapers sold in stores to find out whether or not the prototype would hold the same, if not more than the normal diapers.

Results and Discussion

Table 1 shows the measures of the total absorption capacity of the diaper, utilizing the ABL test from SGS-IPS testing as the basis. We add a 0.9% saline solution and carefully observe the back and sides of the pad for any signs of fluid flow. When then there is flow no more saline solution is added and it is recorded as the full capacity of the diaper.

This study is based on the Rewet test on the NWSP 70.9 method as mentioned by SGS-IPS Testing (2019). The test used a specified quantity of simulated urine discharged at a certain rate onto the fully biodegradable diaper. A pre-weighed filter paper is then placed on the specimen and a 0.25kg weight is applied carefully on top of the filter paper and specimen. The mass of liquid absorbed by the filter paper is measured and this relates to wearing comfort.

From the results in

Table 1, we can see that the regular diaper was able to absorb 304g of simulated urine while the Kaboo diaper was able to absorb 323g of simulated urine. The starting weight of the normal diaper was 34g and its final weight was 338g. On the other hand, the bamboo and kapok fiber diaper’s starting weight was 48g and its final weight was 323 grams. The Kaboo diaper was able to absorb 19g more than a conventional diaper. According to INSPQ (2024) each time a baby pees it produces 30 to 60 grams of urine which means both diapers are more than capable of handling the amount of urine a child can produce.

From the results in

Table 2, we can see that the regular diaper rewet was 4g of simulated urine while the Kaboo diaper rewet was 24g of simulated urine. The starting weight of the normal diaper was 34g and its final weight was 338g. In

Table 2 we can see that the conventional diaper only absorbed 4g of simulated while the Kaboo diaper absorbed 6 times that amount. The acceptable rewet amount that some studies such as Tamar I. (2017) use is around 7g and the diaper did not pass that.

Summary of Findings

After the experiments, it was found that the diapers can absorb more waste compared to conventional diapers. The biodegradable diaper absorbed 19 more grams of water. The researchers also found that the diaper takes longer to dry compared to conventional diapers. After the rewet test, It was found that the diaper was still very wet compared to the conventional diaper. This means that babies may be prone to rashes.

Conclusions

This research looks into the problem of diaper pollution by exploring biodegradable options for diaper materials. The study focuses on developing a prototype using Bamboo Cloth and Kapok Fiber showcasing the possibility of producing a diaper that could potentially outperform regular disposable diapers. The prototype created displayed features similar to or even better than disposable diapers.

The successful development of the fully biodegradable diaper highlights the potential for environmentally friendly alternatives in various industries. Despite the success of the prototype this research encourages others to enhance its design, manufacturing processes, and scalability

The paper has successfully made a working prototype that is on par and in some aspects better than normal disposable diapers therefore concludes that it is possible to create a fully biodegradable diaper from Bamboo Cloth and Kapok Fiber. In summary, this research represents a step in the right direction for a sustainable future by showcasing how biodegradable materials can help combat diaper pollution.

Recommendations

This study would like to recommend these points to future studies

Look into different chemical treatments for the kapok fibers

Find uses for Kapok in other fields.

Look for ways to sustainably package our product.

Have actual testing on newborn babies.

Appendix A. Creation of a Diaper Prototype

Appendix B. Testing of Diaper Prototype

I. Absorption Test

II. Rewet Test

References

- Philippine Fiber Industry Development Authority. (2016). Kapok Technoguide https://philfida.da.gov.ph/images/Publications/Technoguides/KAPOK.

- Global Alliance for Incinerator Activities. (2019). Plastics exposed://www.no-burn.org/wp-content/uploads/Plastics-Exposed-2nd-Edition-Online-Version.

- Hirsh, S. (2022) Are Diapers Biodegradable? Here Are the Most Sustainable Diaper Options https://www.greenmatters.com/p/are-diapers-biodegradable-compostable#:~:text=Most%20diapers%20marketed%20as%20either,home%20or%20backyard%20compost%20bins.

- Czarnecka, E. , Walczak, M., Kumar, G., Piechota, G., Nowaczyk, J. (2022) Degradation of biodegradable diapers as an element circular economy in waste containing various plastics https://www.sciencedirect. 0959. [Google Scholar]

- Wolok, E. , Lahay, I.H., Machmoed, B.R., Pakaya, F. 2019. [Google Scholar]

- CEIBA PENTANDRA (L.) GAERTN. (KAPOK) FIBER: PHYSICAL PROPERTIES https://www.researchgate. 3406.

- Zheng, Y. , Wang, J., Zhu, Y., Wang, A., (2015) Research and application of kapok fiber as an absorbing material: A mini-review https://www.sciencedirect. 1001. [Google Scholar]

- Rathod, A. , Kolhatkar, A., (2014).

- https://www.researchgate. 2733.

- How is Bamboo Textile Fibre Made? (n.d.). bambootextiles.com.au. Retrieved , 2023, from https://www.bambootextiles.com. 4 September.

- The Editors of Encyclopaedia Britannica. (1998, ). KAPOK | Sustainable, Natural & Lightweight. Encyclopedia Britannica. https://www.britannica. 20 July.

- Nayak, L.; Mishra, S.P. Prospect of bamboo as a renewable textile fiber, historical overview, labeling, controversies and regulation. Fash. Text. 2016, 3, 1–23. [Google Scholar] [CrossRef]

- Lu, W.; Chen, X.; Ho, D.C.W.; Wang, H. Analysis of the construction waste management performance in Hong Kong: The public and private sectors compared using big data. J. Clean Prod. 2016, 112, 521–531. [Google Scholar] [CrossRef]

- Sachidhanandham, A.; M, P. A review on convenience and pollution caused by baby diapers. Sci. Technol. Dev. J. 2020, 23, 694–707. [Google Scholar] [CrossRef]

- Mack, E. (2021, ). An ingenious new biodegradable velcro has some surprising uses. Forbes.https://www.forbes.com/sites/ericmack/2021/11/18/an-ingenious-new-biodegradable-velcro-has-some-surprising-uses/? 18 November.

Table 1.

Absorption test.

Table 1.

Absorption test.

| |

Brand X |

Kaboo diaper |

| Weight of diaper dry (g) |

34g |

48g |

| Weight of diaper wet (g) |

338g |

371g |

| Total liquid absorbed (g) |

304g |

323g |

Table 2.

Rewet test.

| |

Brand X |

Kaboo diaper |

| Weight of filter papers dry (g) |

13g |

13g |

| Weight of filter papers wet (g) |

17g |

37g |

| Total liquid absorbed or Rewet (g) |

4g |

24g |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).