Submitted:

24 March 2025

Posted:

24 March 2025

You are already at the latest version

Abstract

Keywords:

Chapter I. Introduction

1.1. Background of Study

1.2. Statement of the Problem

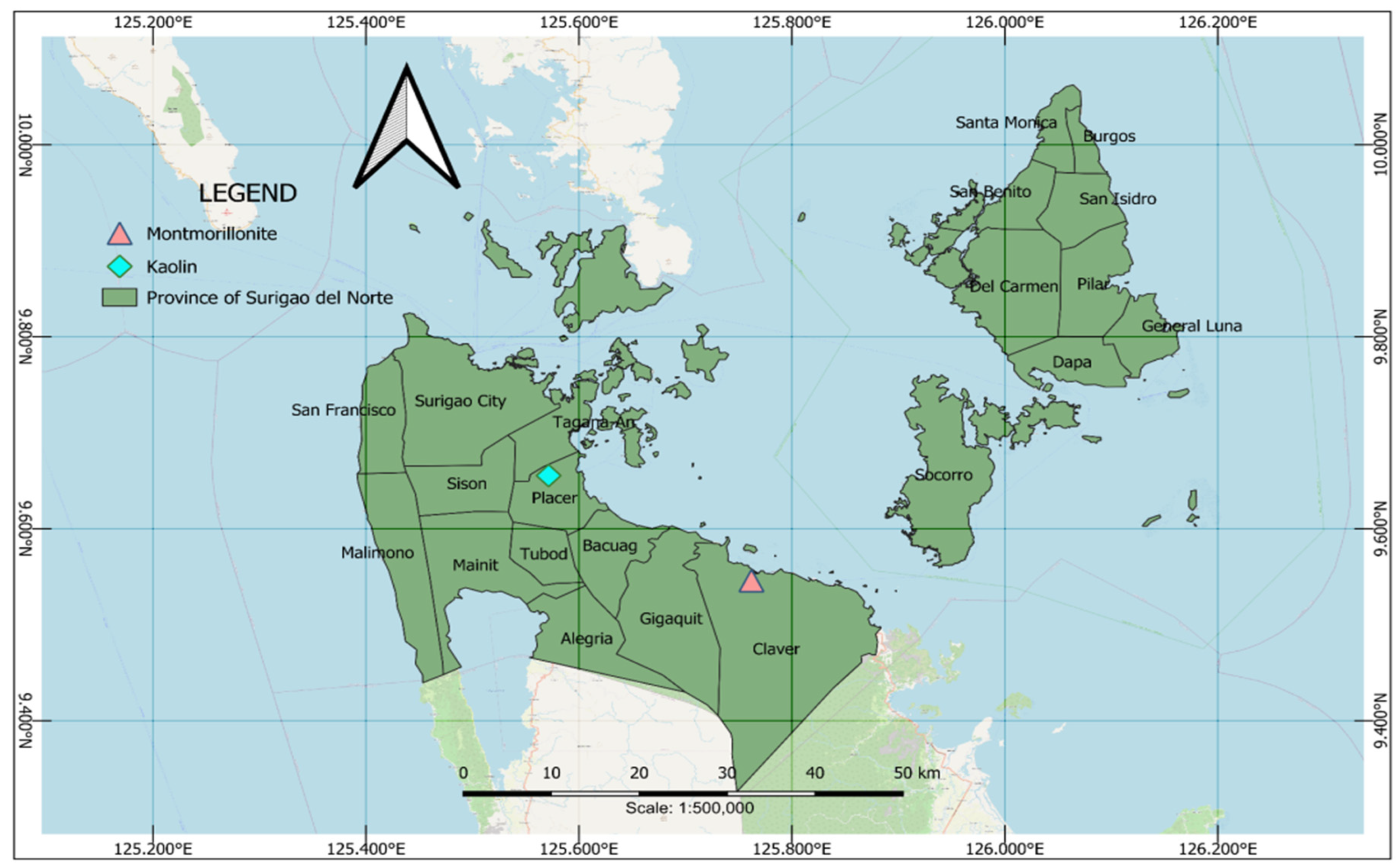

- What are the types of clay minerals that can be found in the spaces of Brgy. Bugas-Bugas, Placer and Brgy.Cabugao, Claver, Surigao del Norte through XRD analysis?

- What are the chemical, physical, and mechanical properties of clay minerals found in Brgy. Bugas-Bugas, Placer and Brgy.Cabugao, Claver, Surigao del Norte?

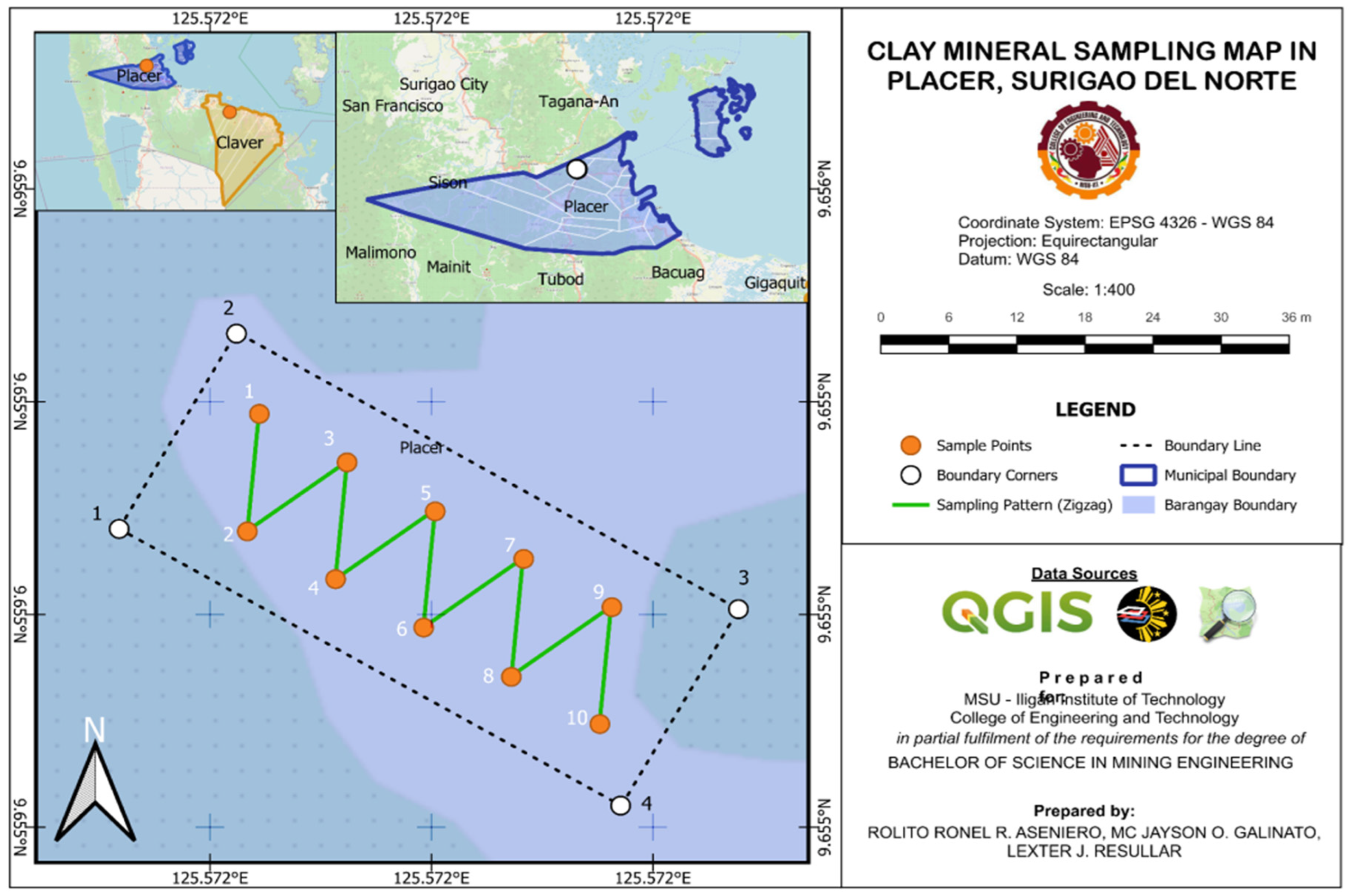

- How can the use of GPS technology and QGIS enhance the accuracy and efficiency of clay mapping processes in Brgy. Bugas-Bugas, Placer and Brgy.Cabugao, Claver, Surigao del Norte?

1.3. Objectives of the Study

- To identify the type of clay minerals at Brgy. Bugas-Bugas and Cabugo, in Placer and Claver Surigao del Norte respectively through XRD analysis.

- To investigate its chemical, physical, and mechanical properties found in Brgy. Bugas-Bugas, Placer, and Brgy. Cabugo, Claver in the province of Surigao del Norte, in terms of XRF analysis, physico-mechanical properties assisted by BS Ceramic Engineering students.

- To generate the map of clay resources with their properties and profile found in Brgy. Bugas-Bugas, Placer, and Brgy. Cabugo, Claver in the province of Surigao del Norte.

1.4. Significance of the Study

1.5. Scope and Limitations

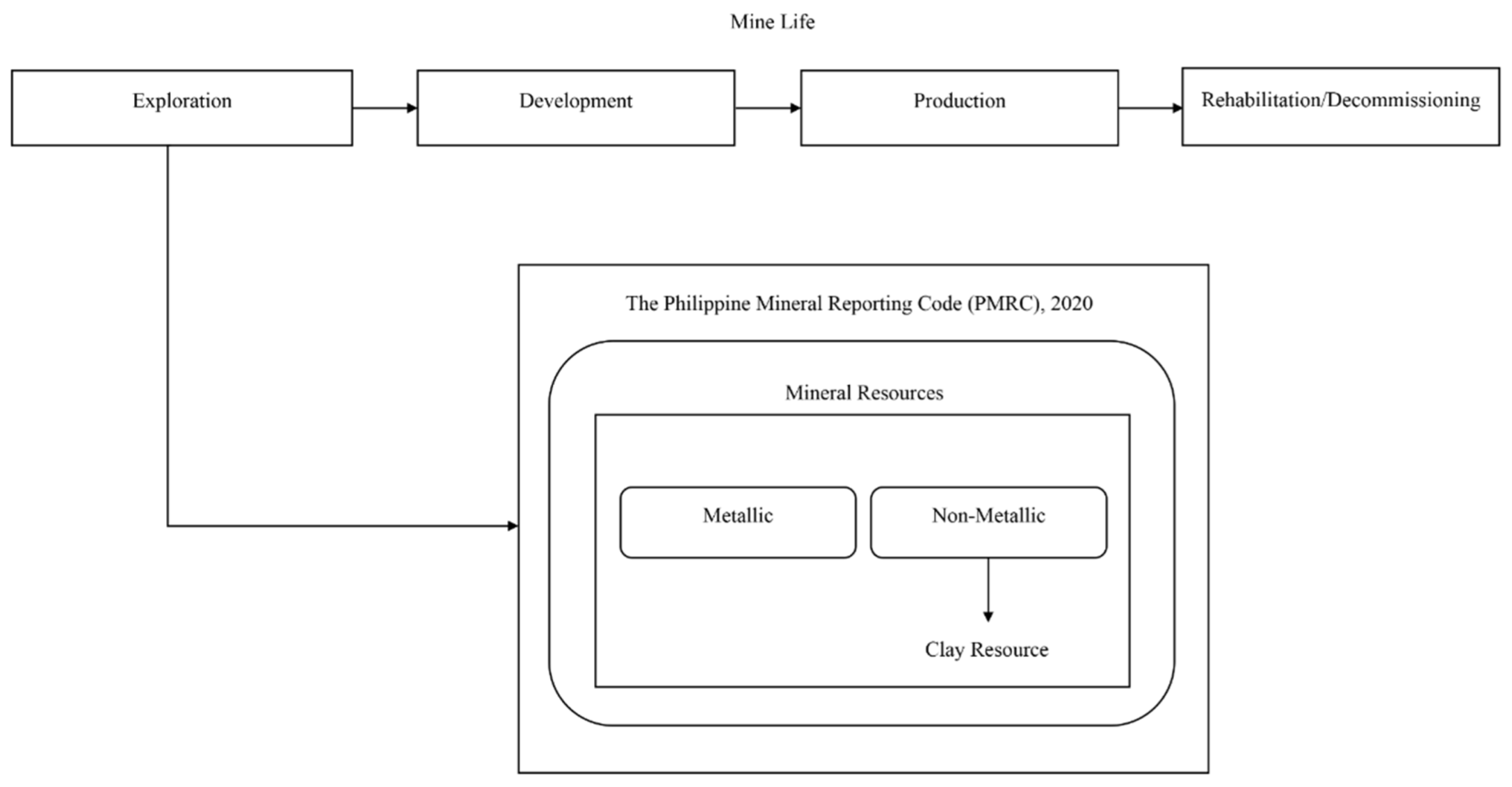

1.6. Conceptual Framework

1.7. Definition of Terms

Chapter II. Review of Related Literature

Clay: Properties and Types

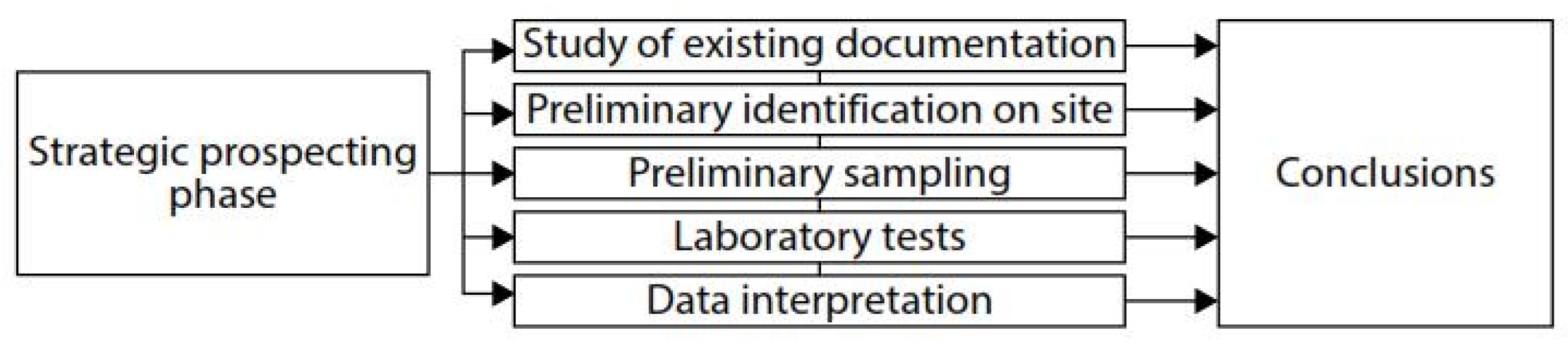

Exploration Stage: Inferred Geological Sampling

| No. | Crop | Soil Sampling Depth (cm) |

|---|---|---|

| 1 | Grasses and grasslands | 5-7 |

| 2 | Annual crops: rice groundnut, beans, vegetables, etc. (shallow-rooted crops) | 15-20 |

| 3 | Cotton, sugarcane, banana, tapioca | 20-25 |

| 4 | Perennial crops, plantations, and orchard crops | Three soil samples at 30, 60, and 90 |

| Degree of Expansion | Plasticity Index, % | Liquid Limit, % |

|---|---|---|

| Low | ||

| Medium | ||

| High | ||

| Very High |

| Degree of Expansion | Shrinkage Limit |

|---|---|

| Low | |

| Medium | |

| High | |

| Very High |

Topography of Surigao del Norte: Mapping Clay Resources

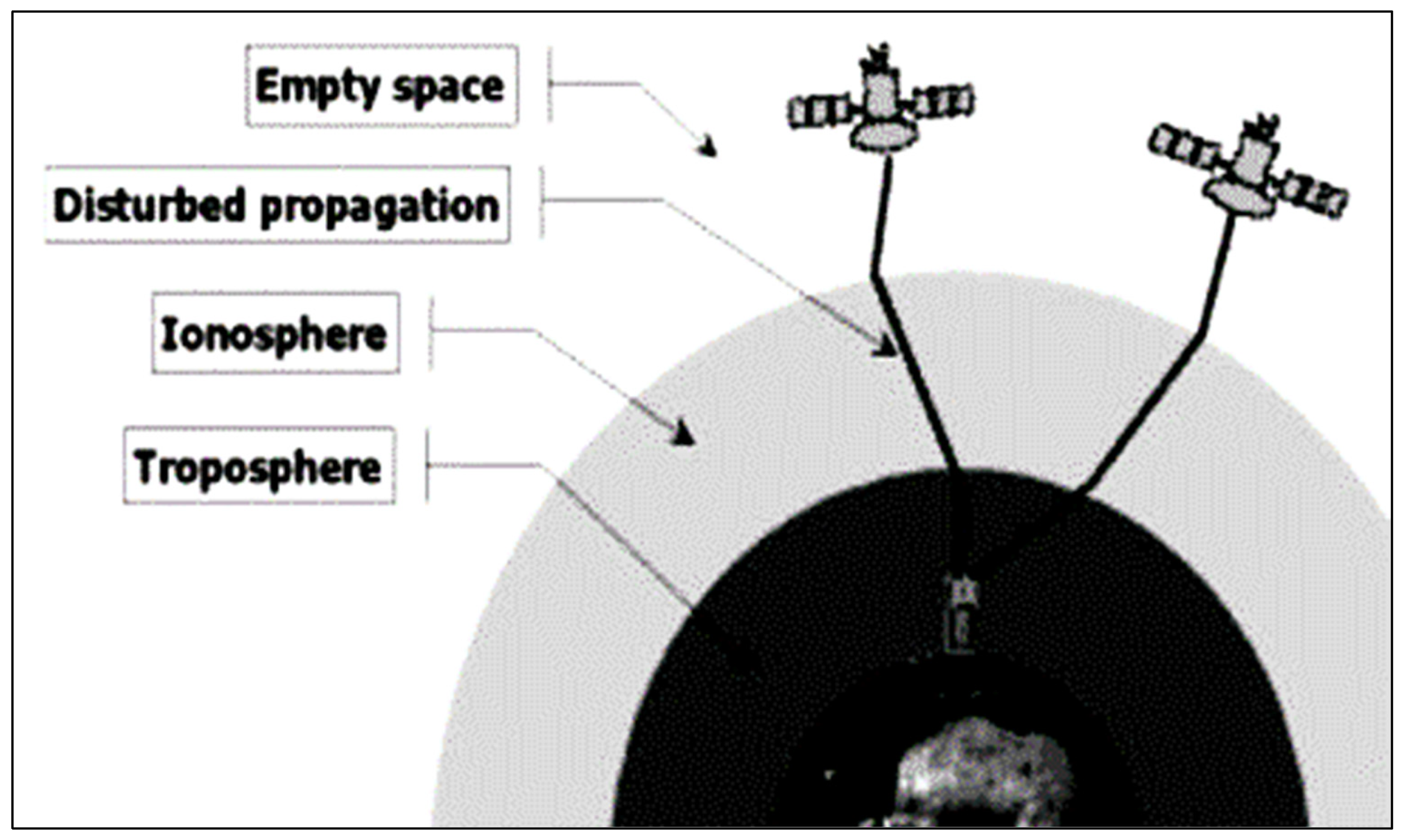

Mapping Identified Clay Resources

| Effect | Error Values |

|---|---|

| Ionospheric effects | |

| Shift in satellite orbits | |

| Clock errors of the satellites’ clock | |

| Multipath effect | |

| Tropospheric effects | |

| Calculation and rounding errors |

| GPS Satellite Signal | GPS Receiver | Usage Environment |

|---|---|---|

| Number of satellites visible | Receiver clock errors | Ionosphere and troposphere delay |

| Satellite geometry/shading | --- | Orbital errors |

| Satellite position | --- | Ephemeris errors |

| Signal delay | --- | Multi-path distortions |

| Satellite clock errors | --- | Numerical errors |

Remote Sensing

Geophysical Surveys

- 1.

- Gravity

- 2.

- Magnetic

- 3.

- Electromagnetic

- 4.

- Seismic Surveys

Geologic Mapping

Petrographic and Mineralogical Analysis

Chapter III

Methodology

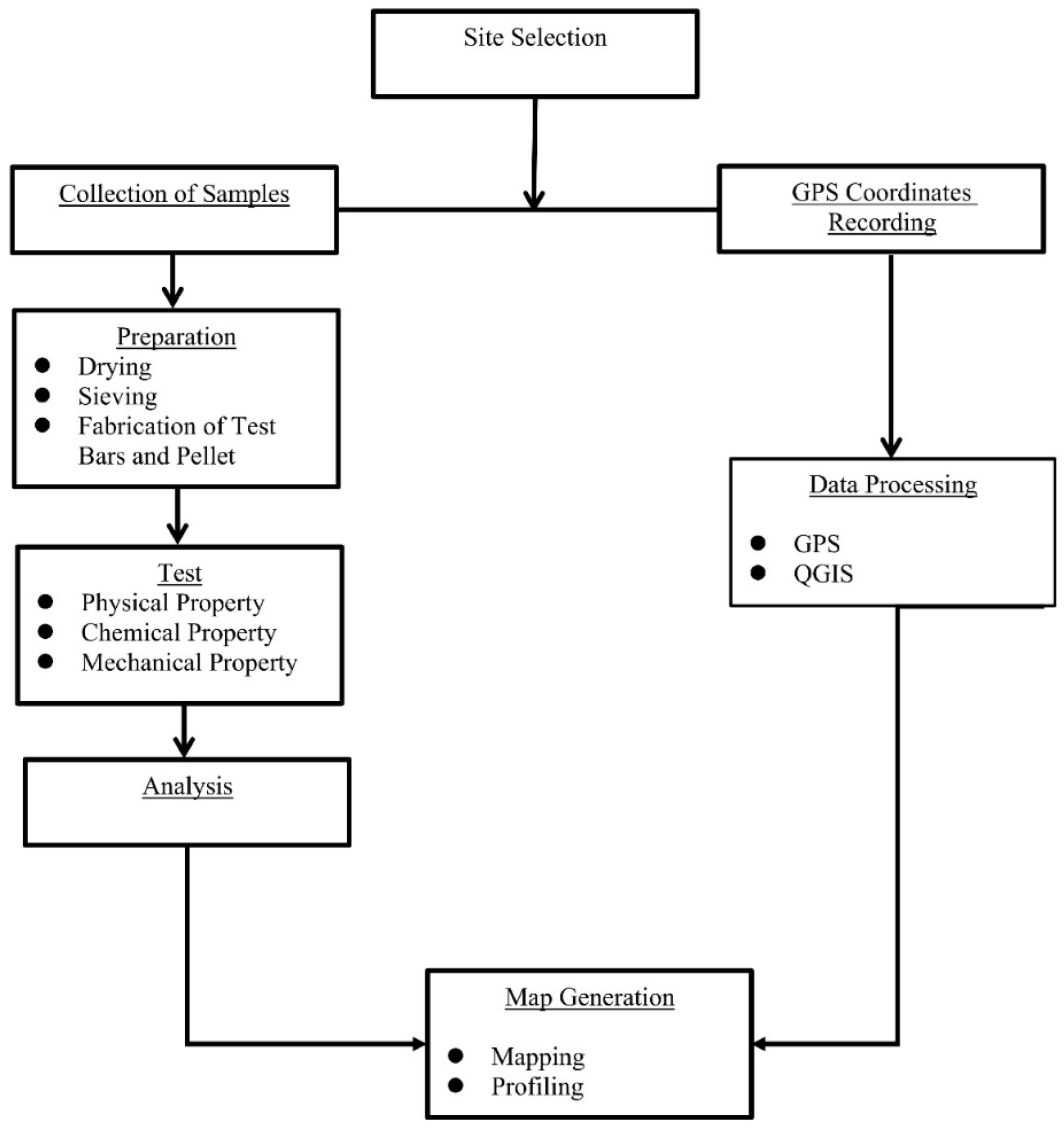

3.1. Process Flow Chart

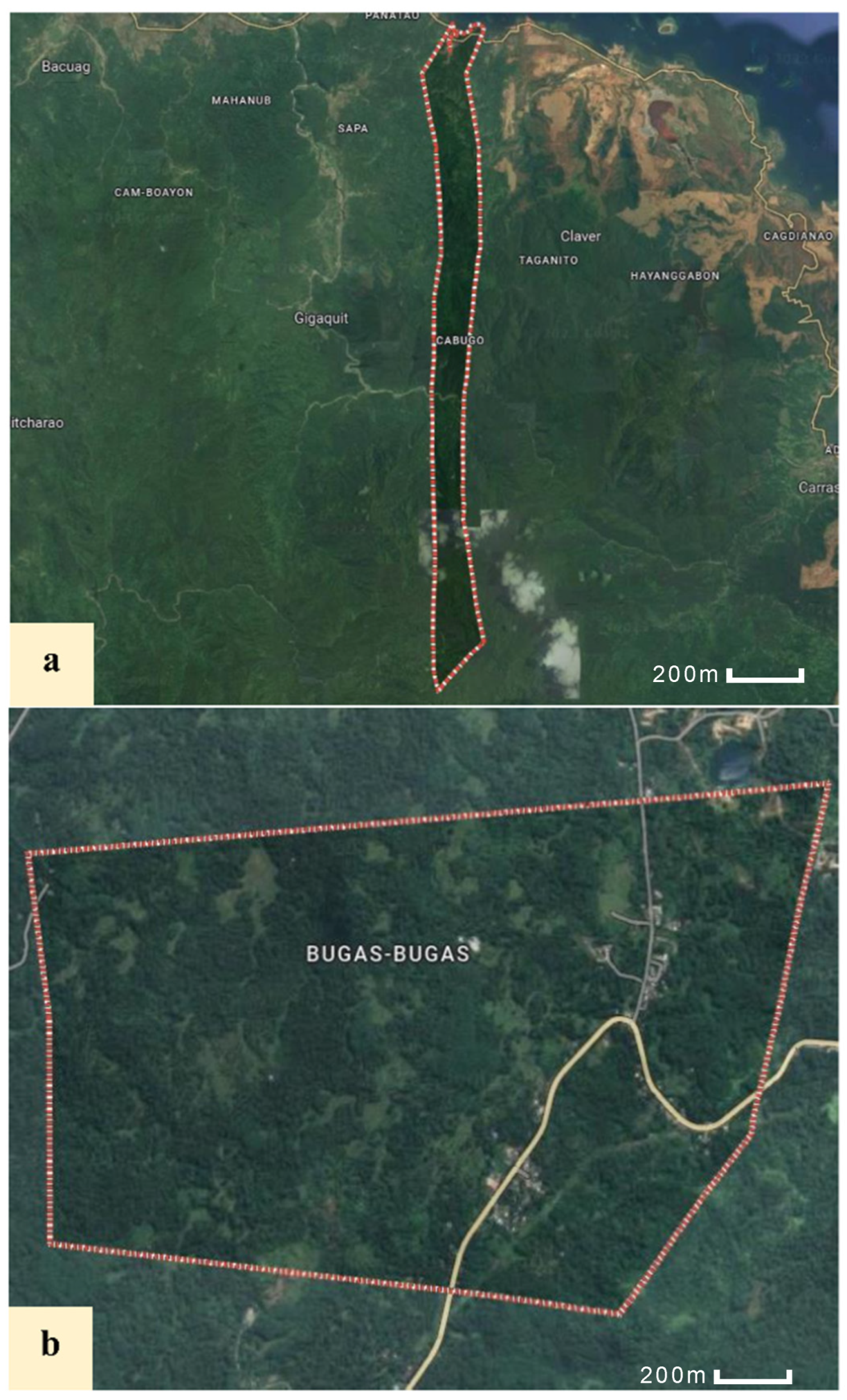

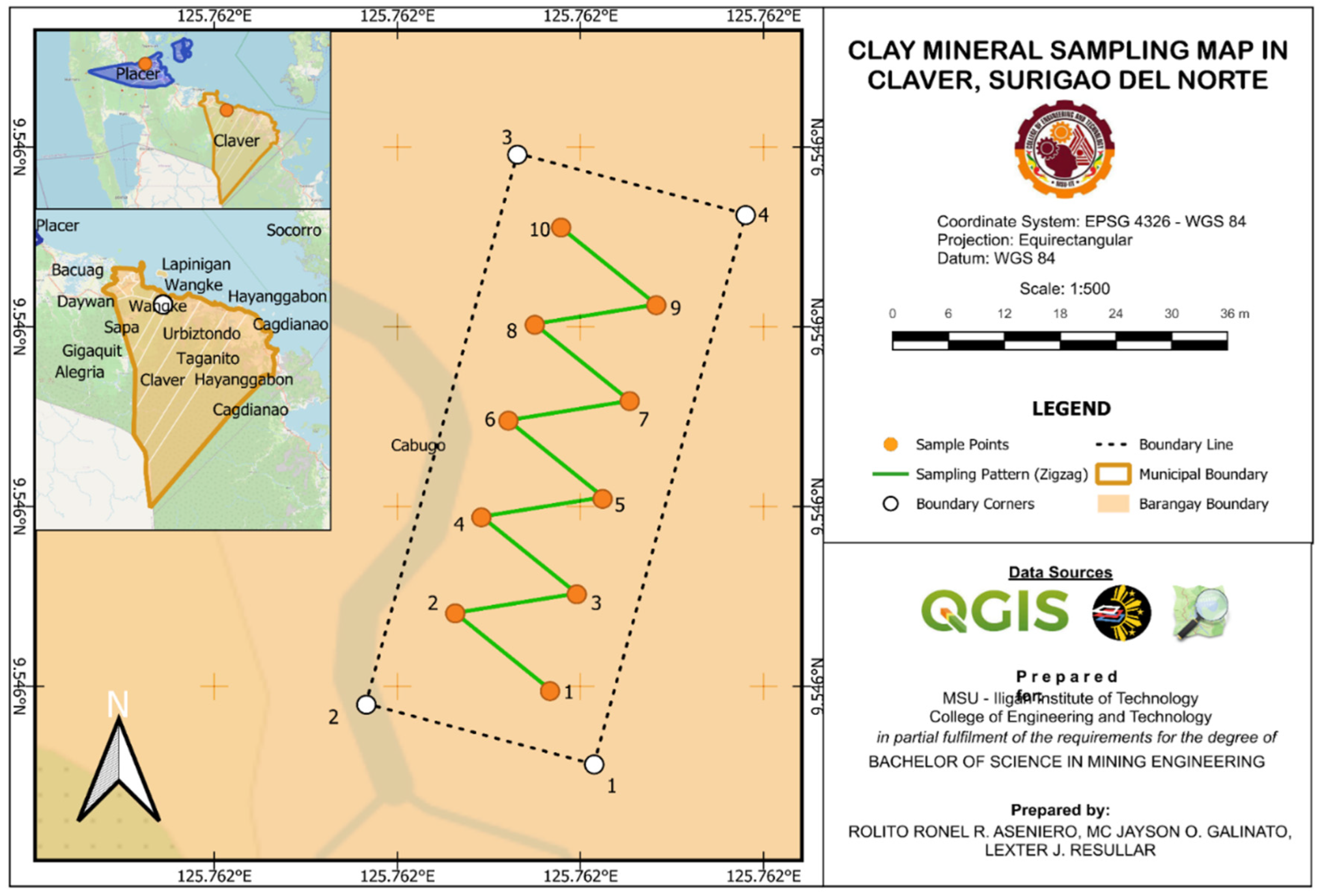

3.2. Site Selection

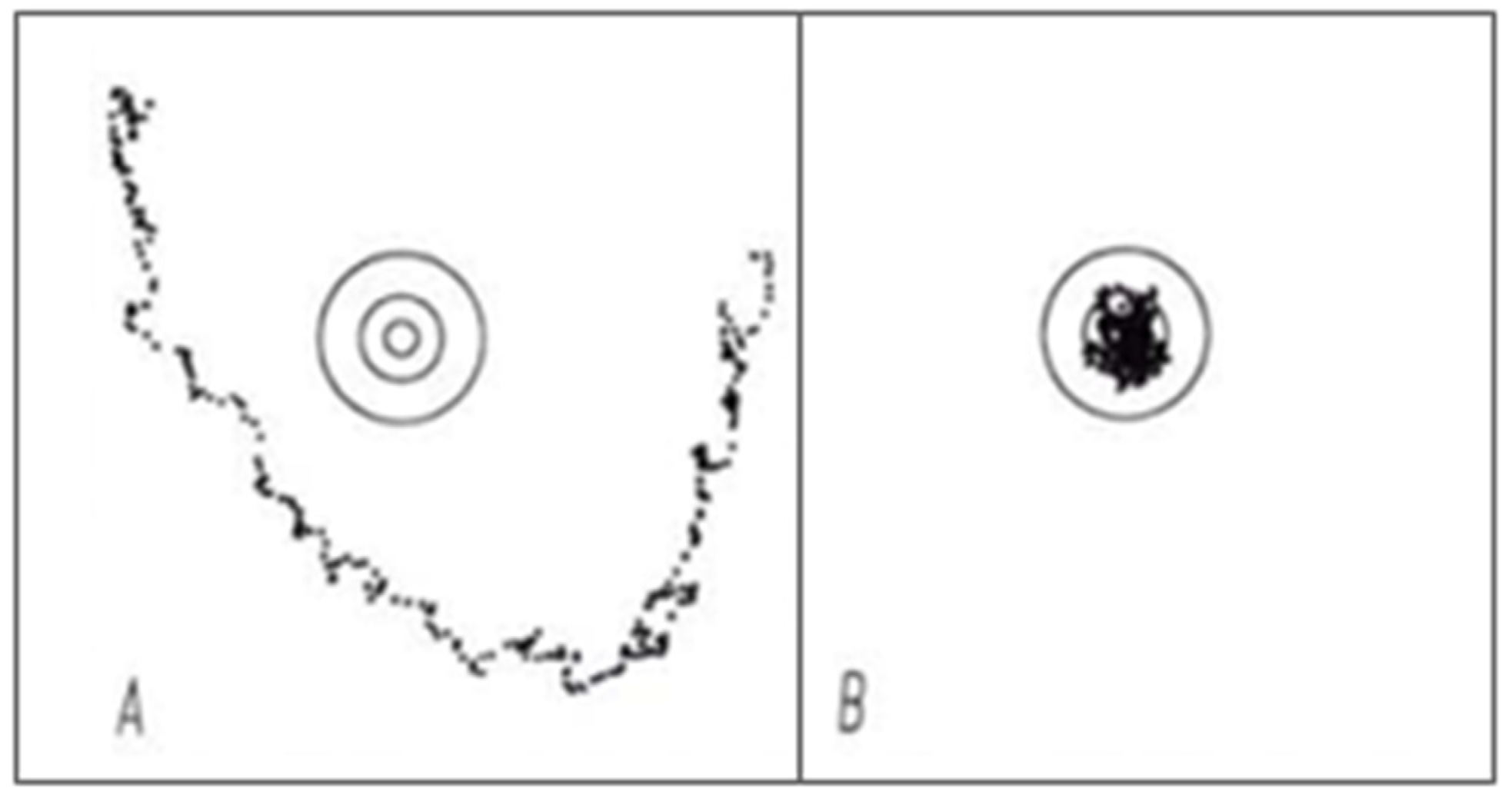

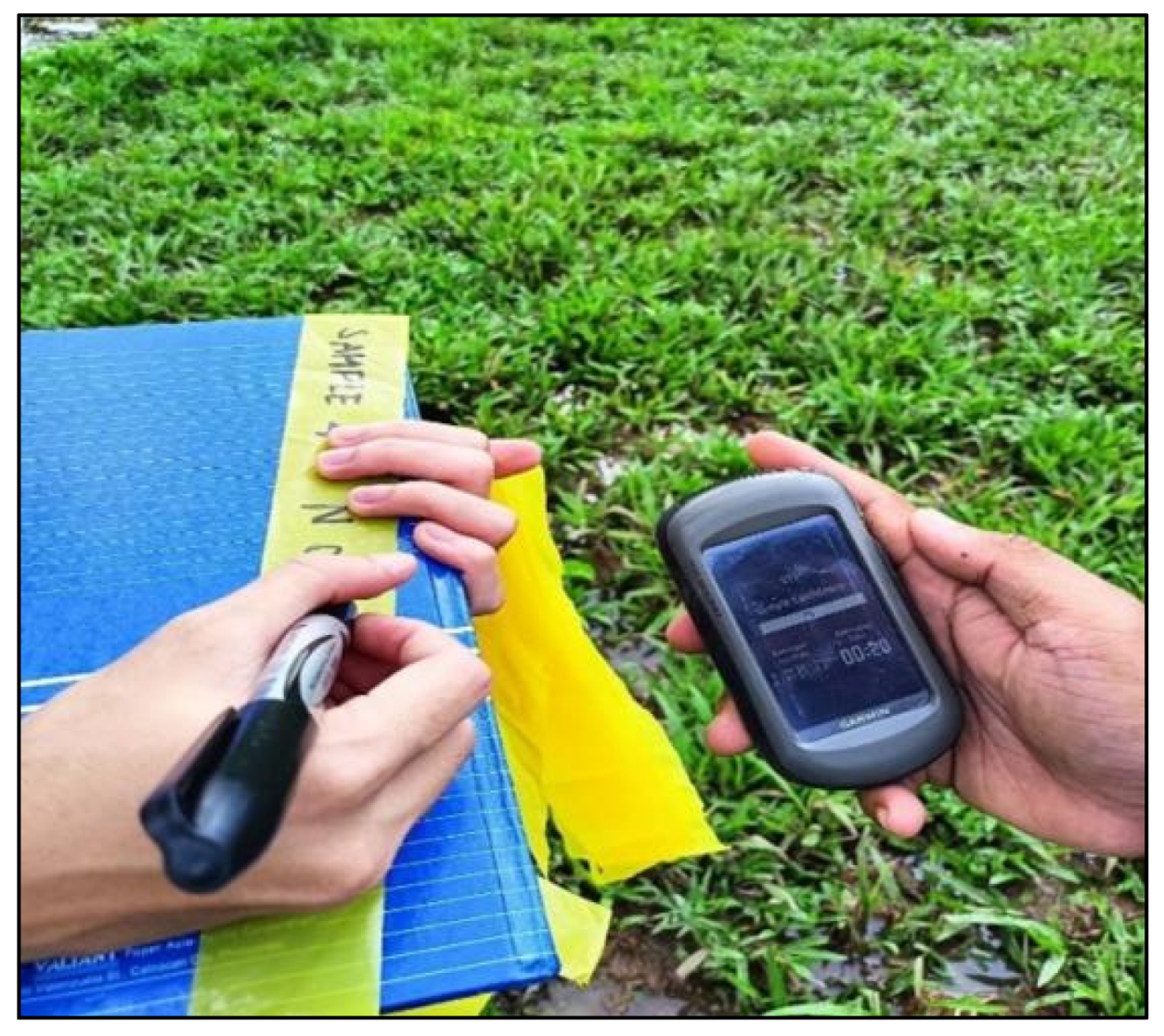

3.3. Sample Collection and Coordinates Recording

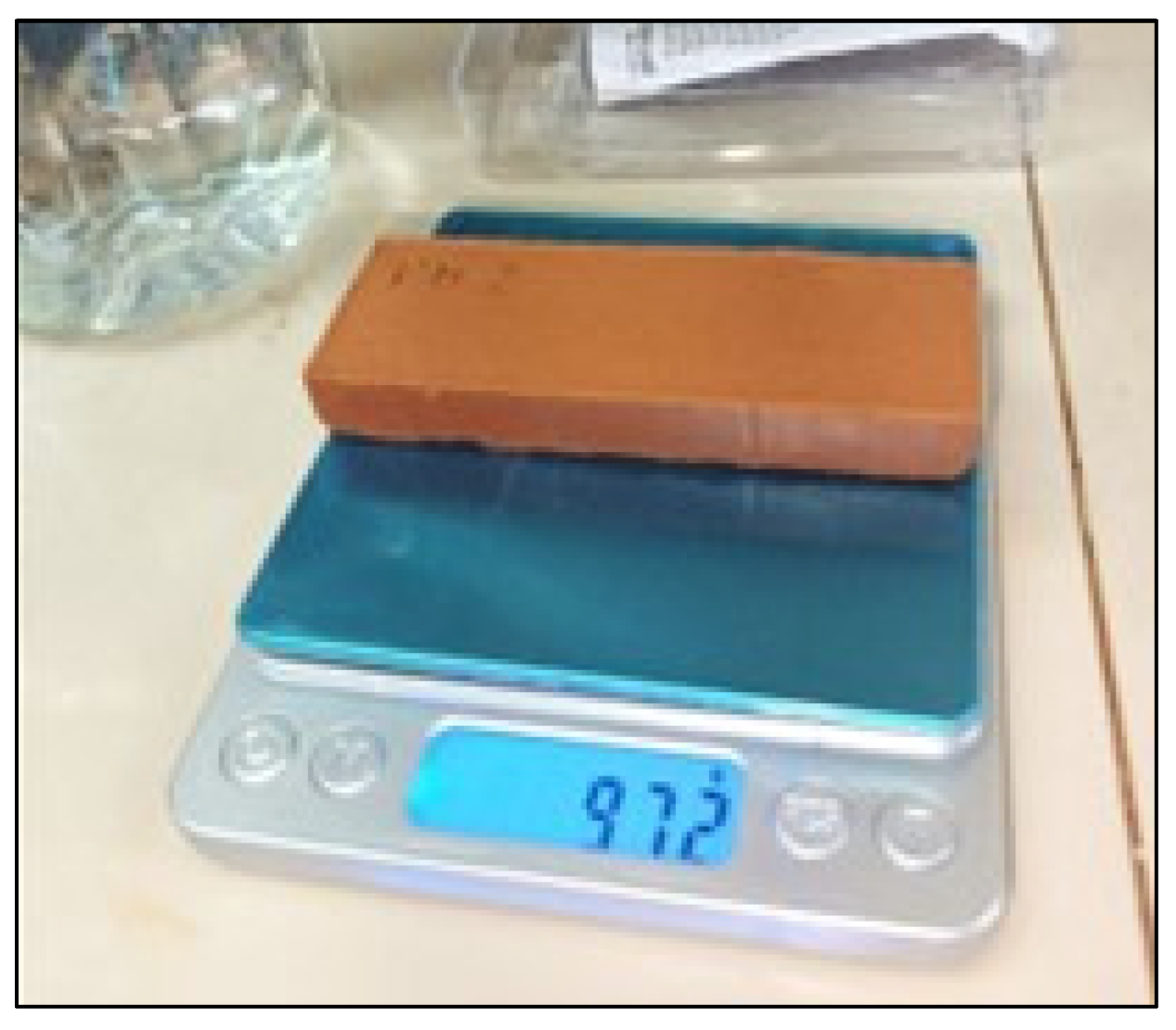

3.4. Sample Preparation

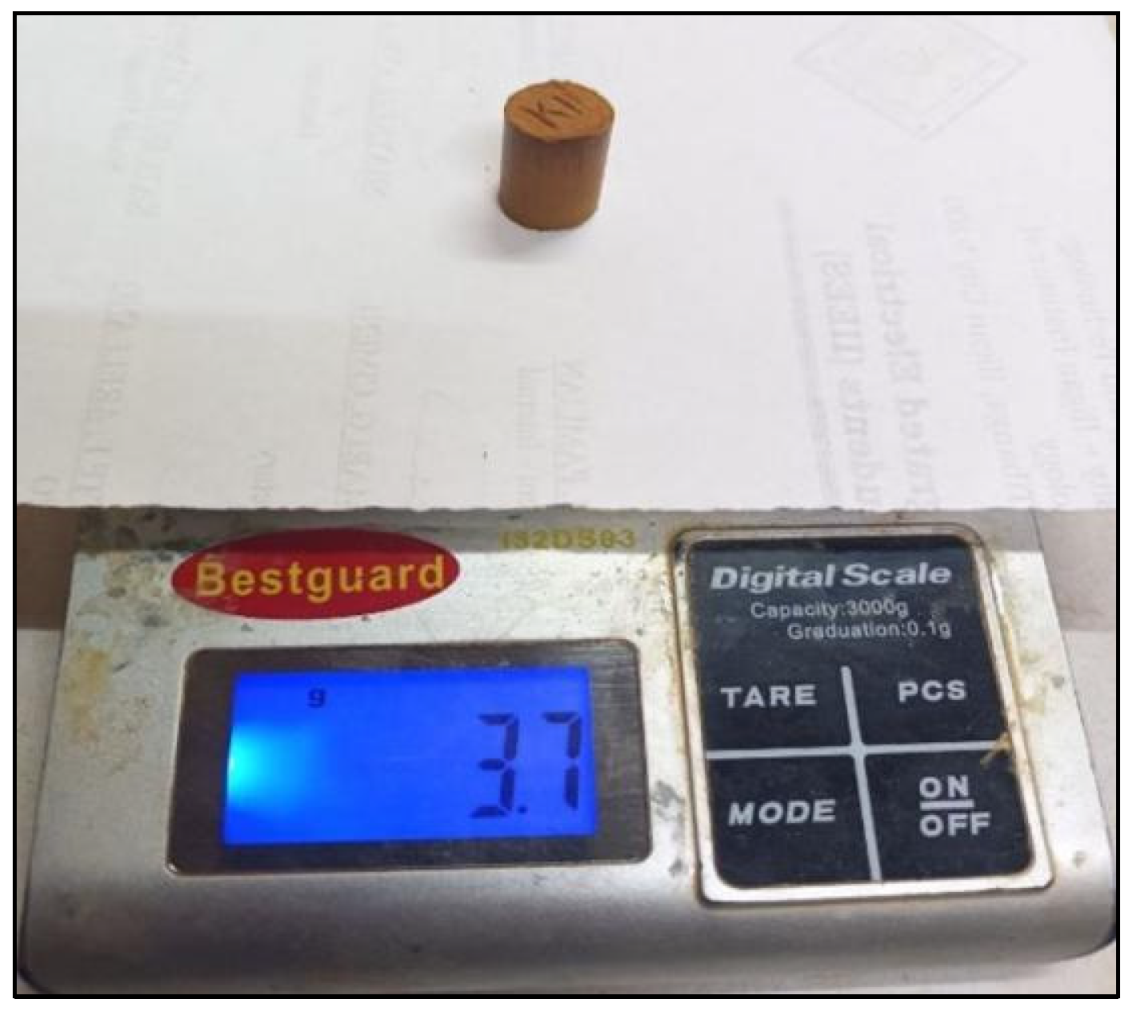

3.5. Fabrication Process

3.5.1. Test Bar Making

3.5.2. Pellet Making

3.5.3. Drying and Firing

3.6. Characterization of Samples

3.6.1. Chemical Analyses

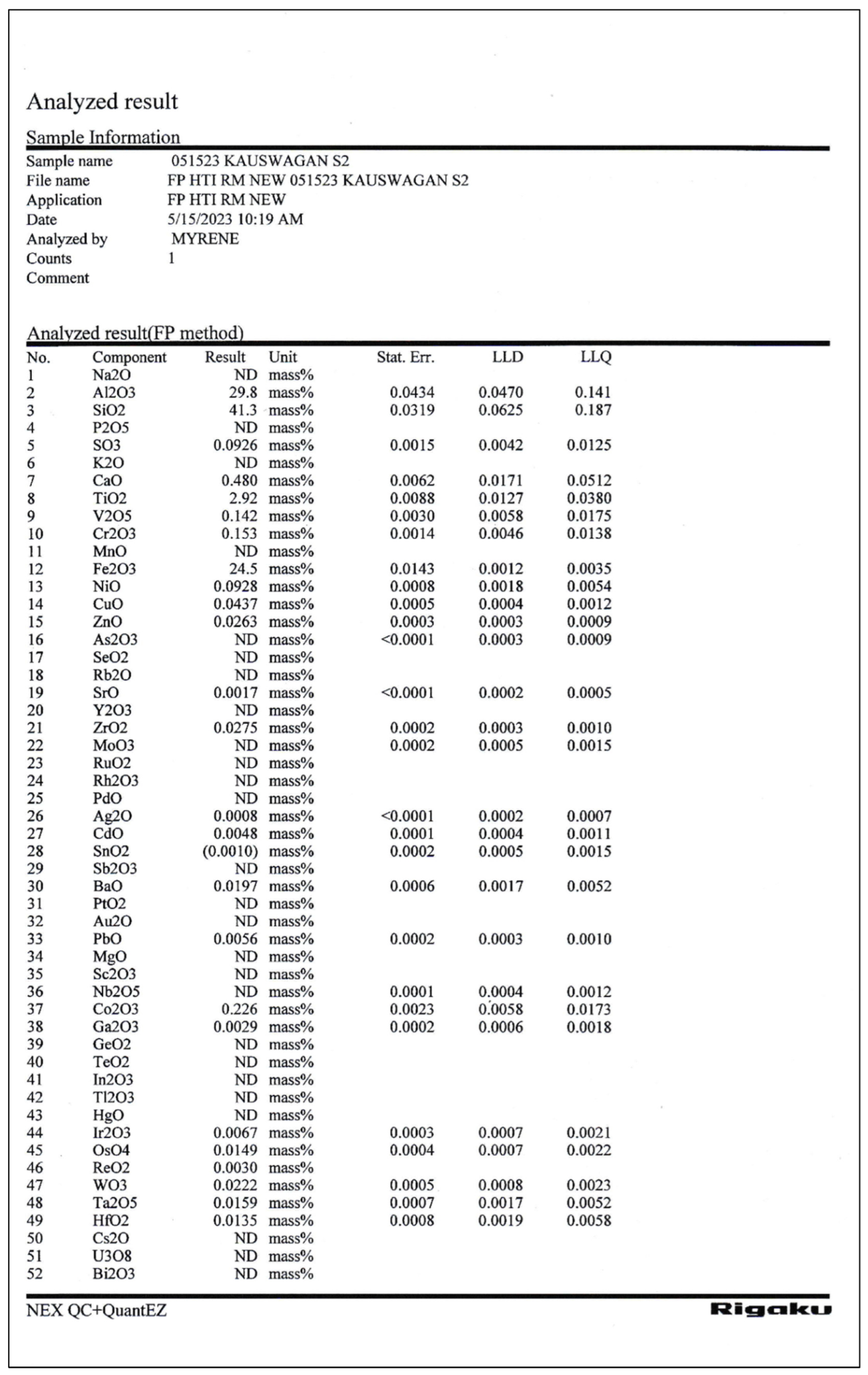

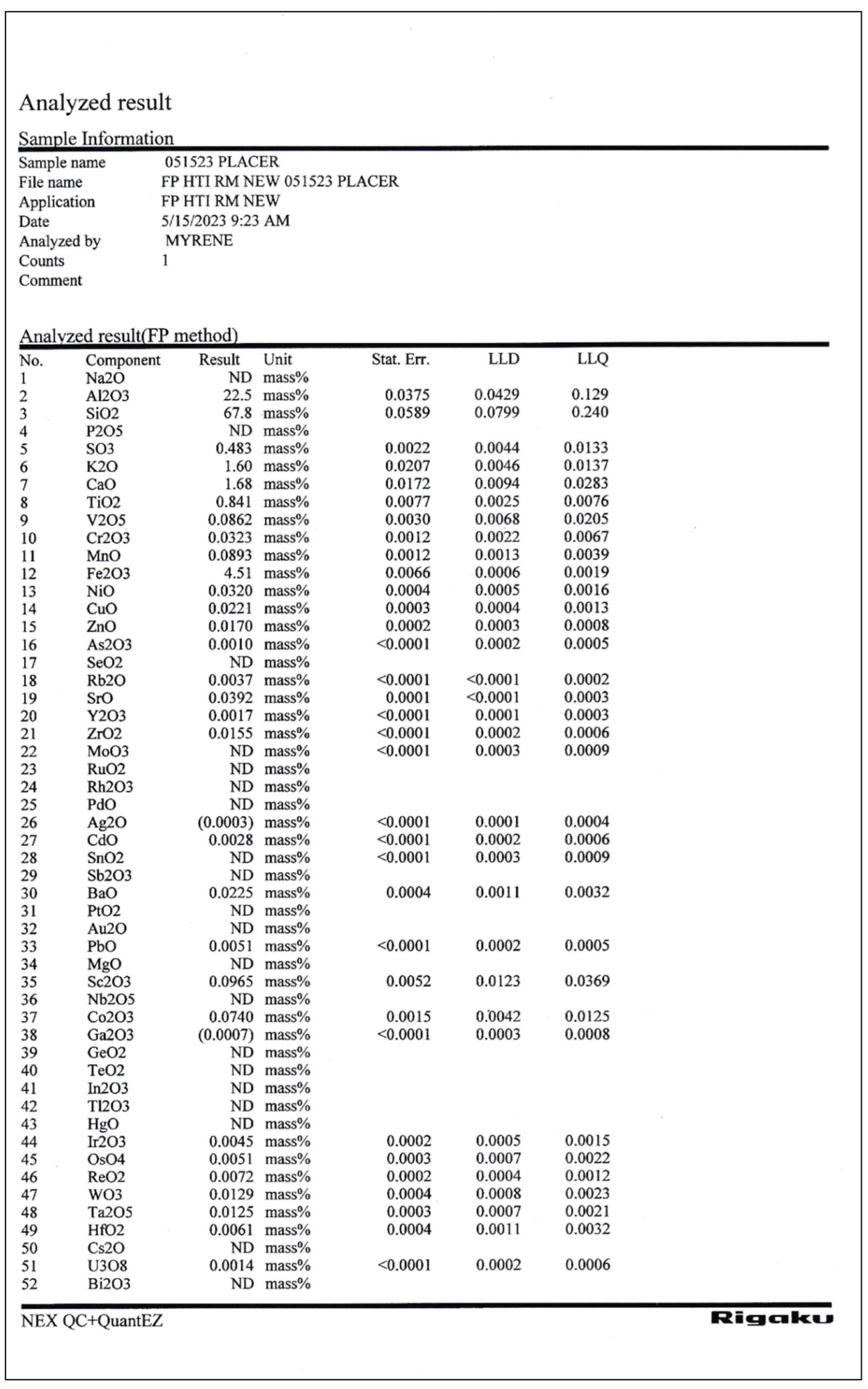

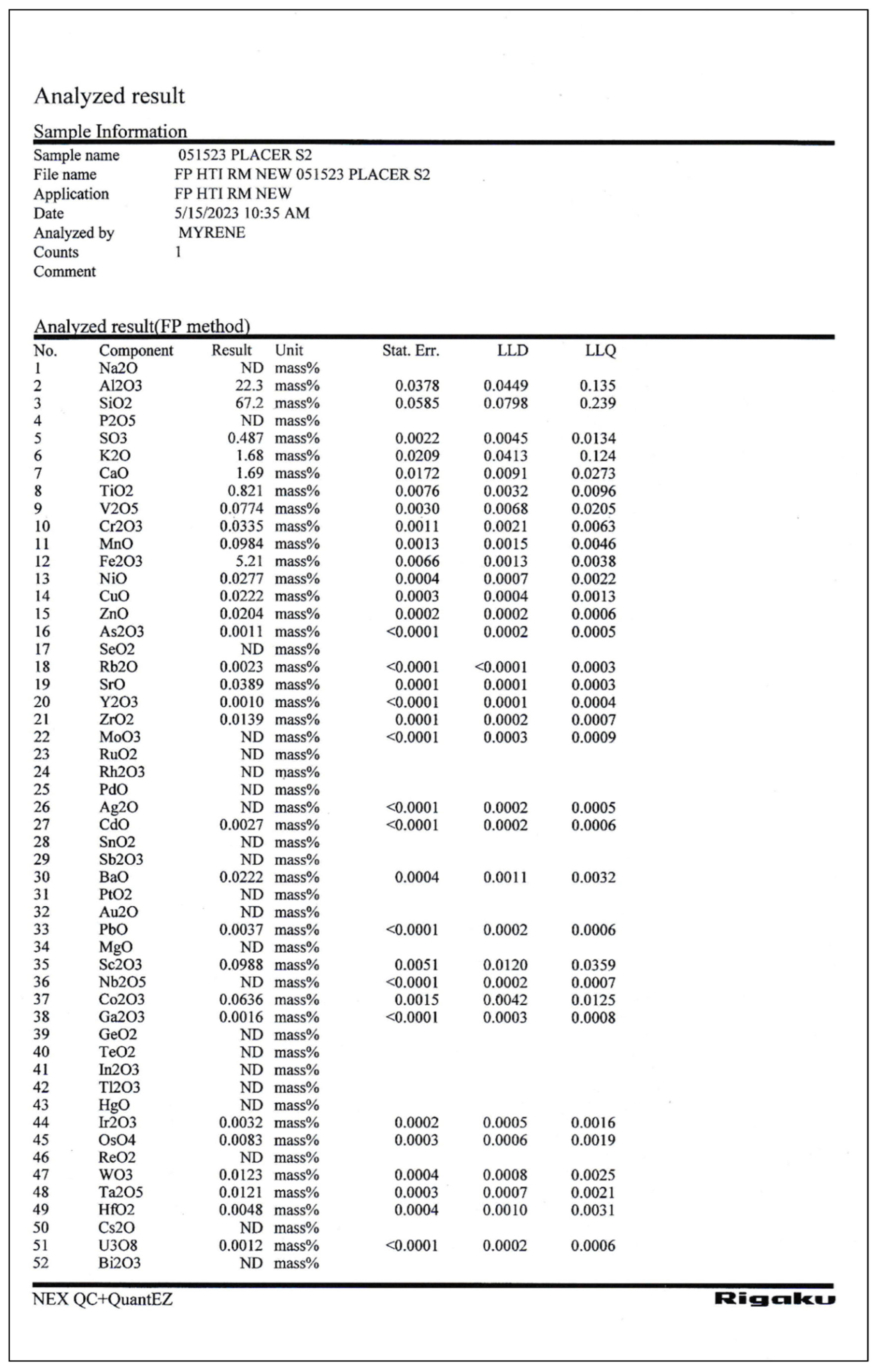

3.6.1.1. X-Ray Fluorescence Analysis

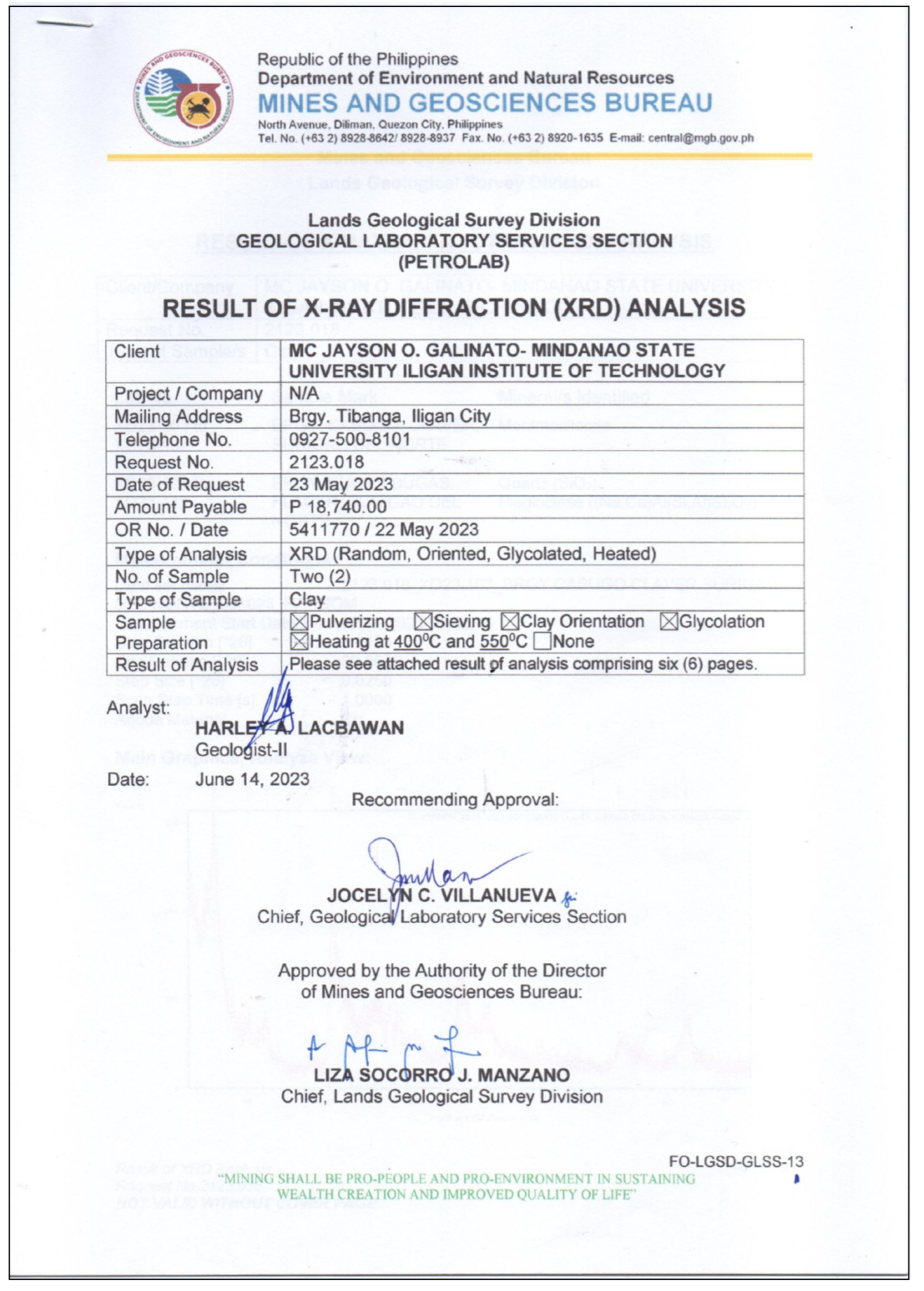

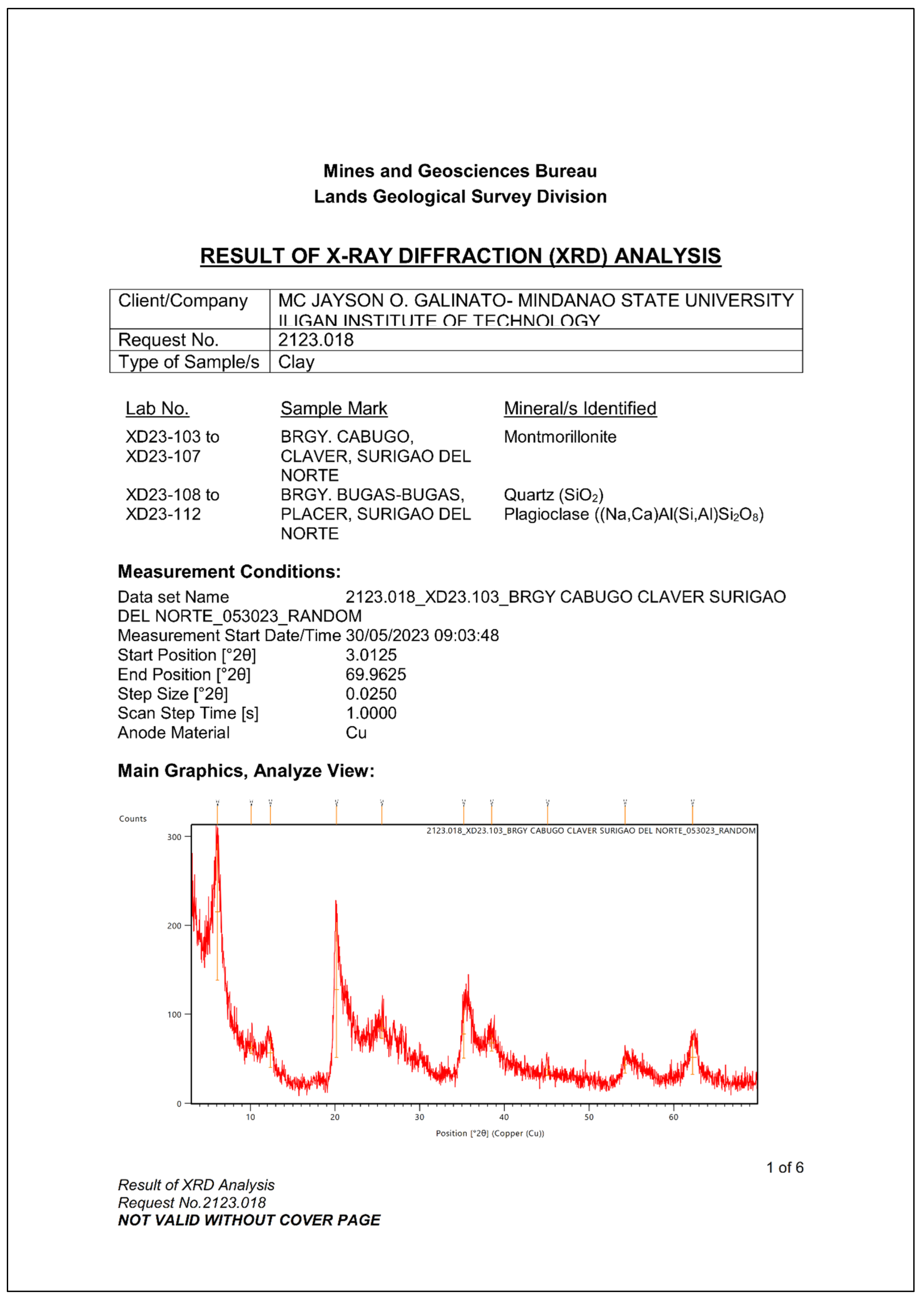

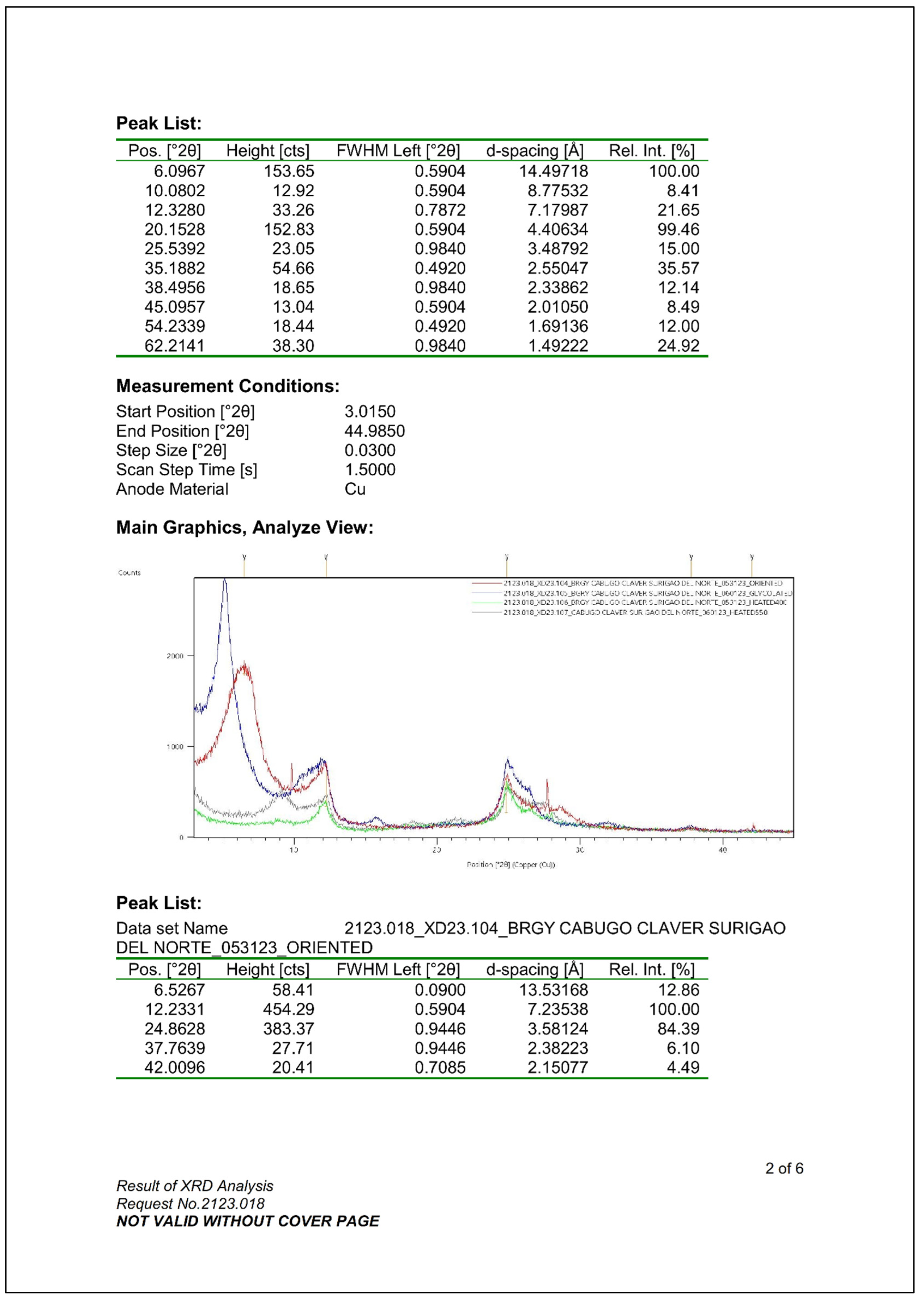

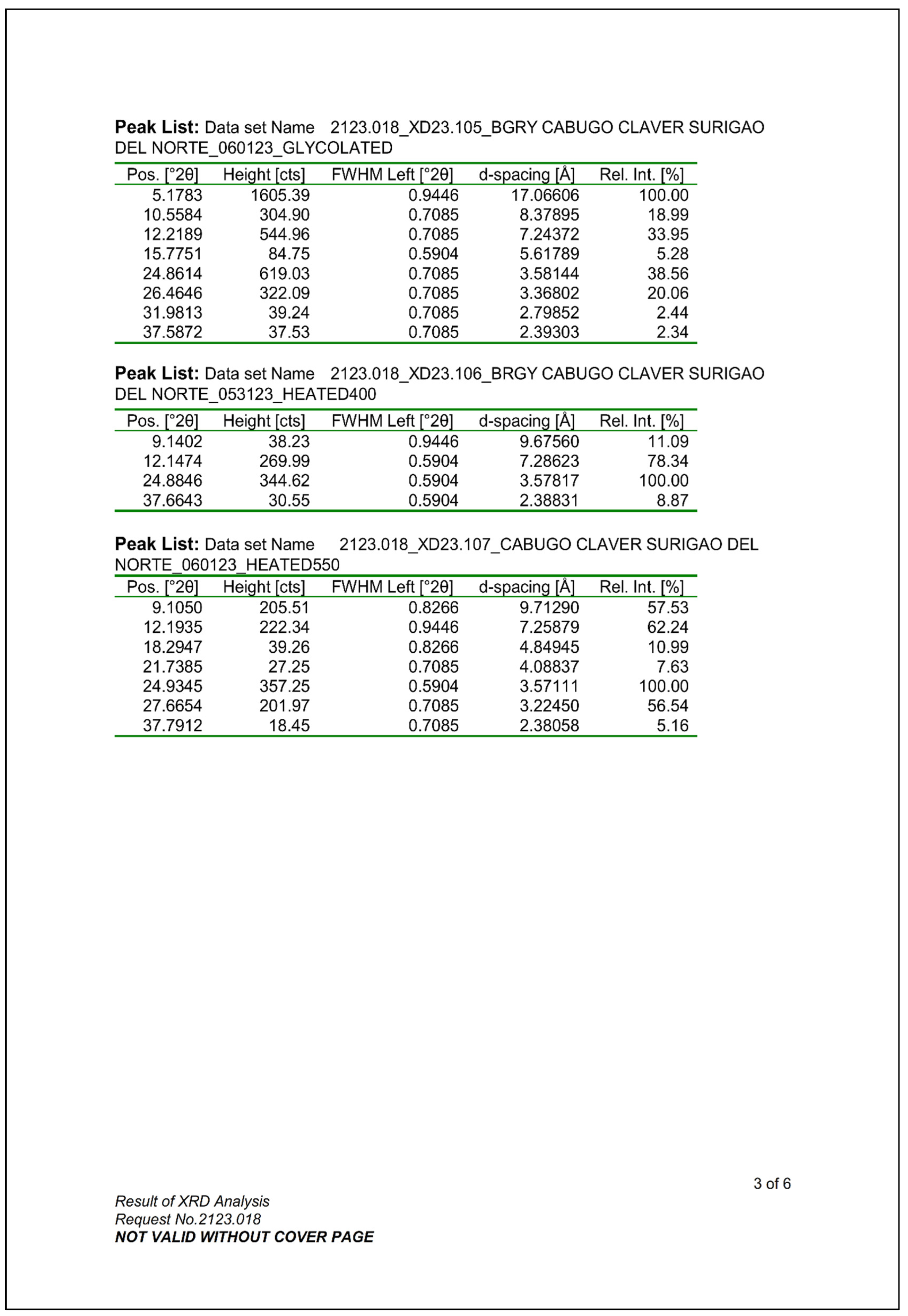

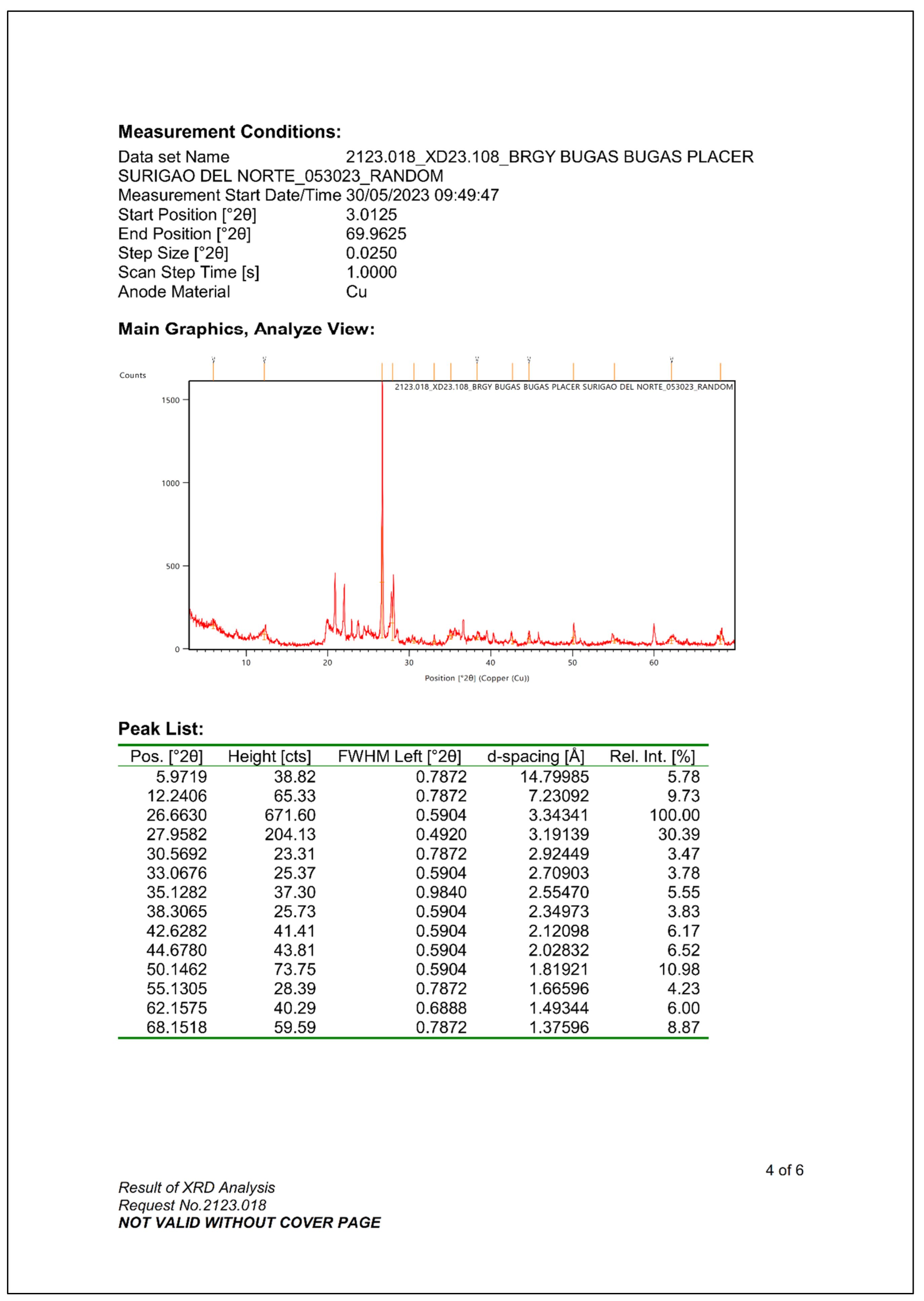

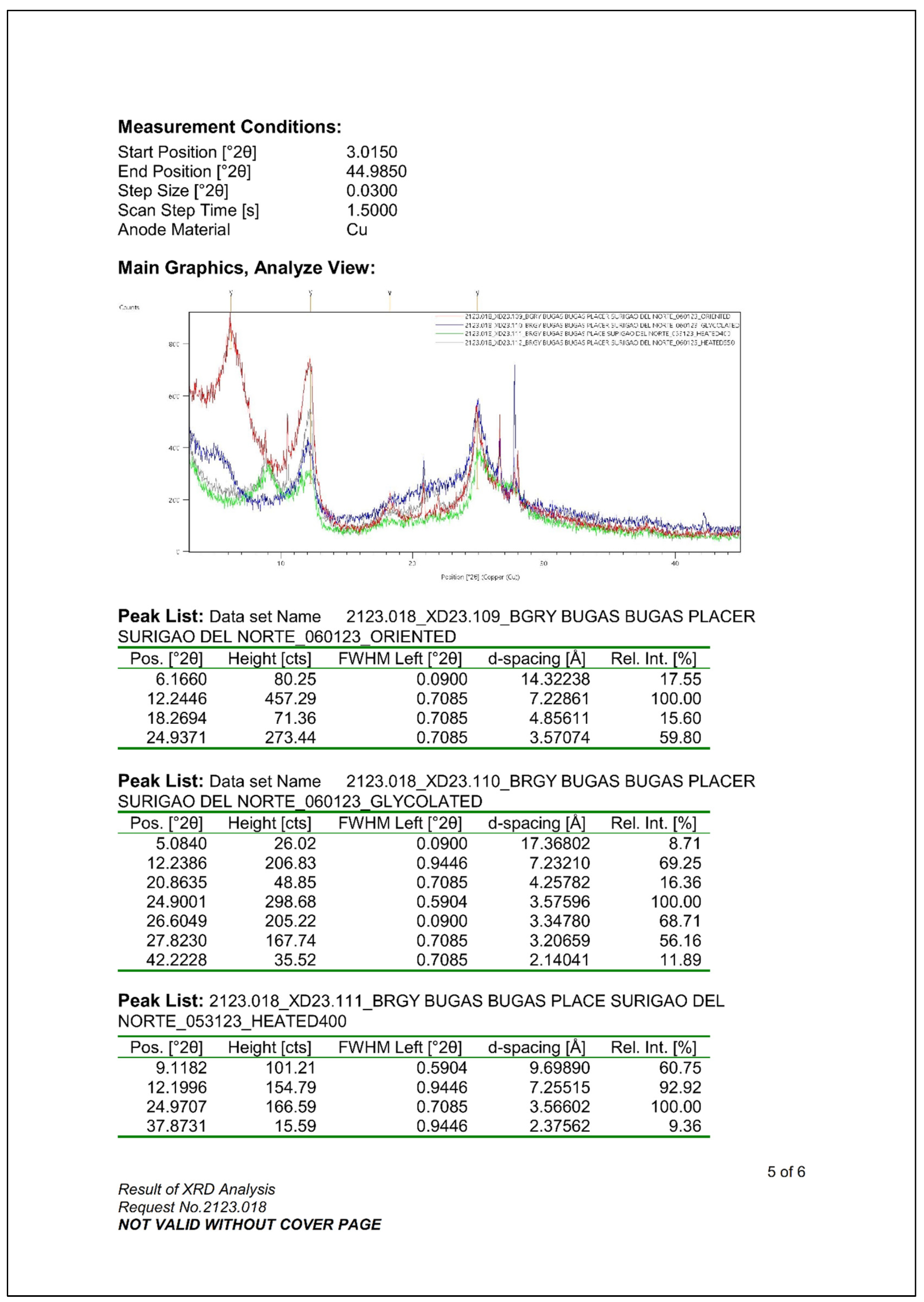

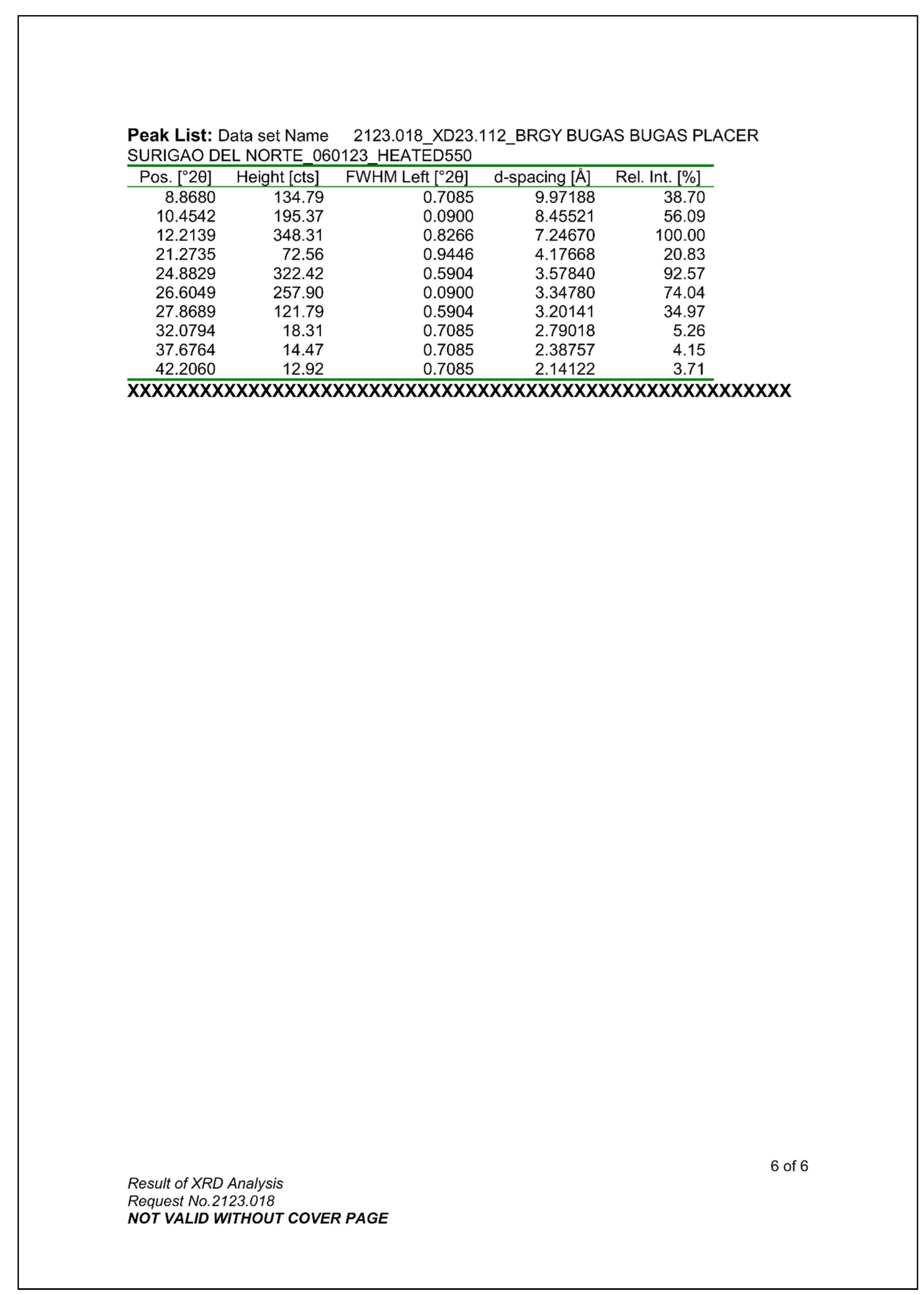

3.6.1.2. X-Ray Diffraction Analysis

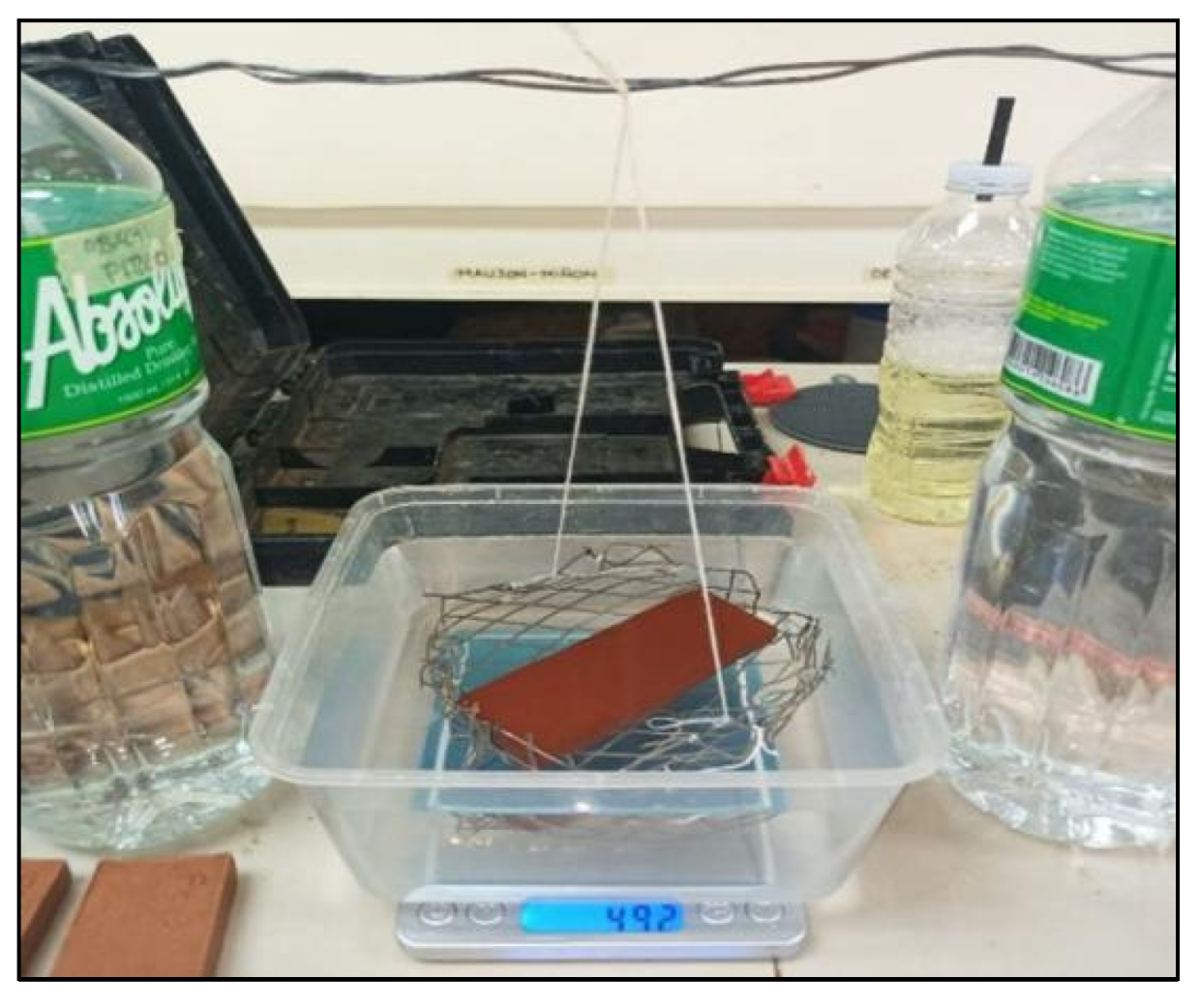

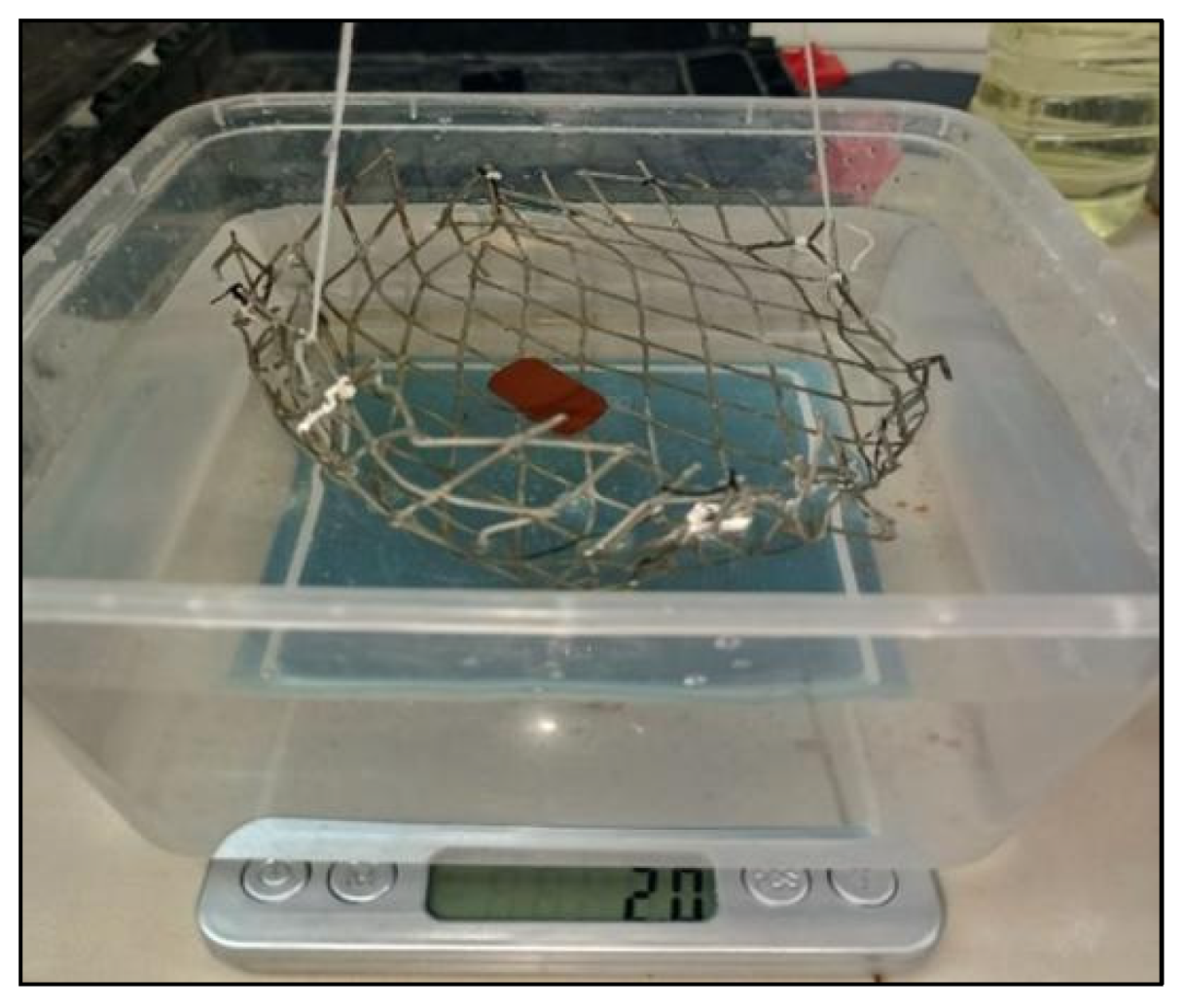

3.6.2. Physical Property Testing

3.6.2.1. Plasticity Test

3.6.2.2. Shrinkage Test

3.6.2.3. Loss on Ignition

3.6.2.4. Water Absorption

3.6.2.5. Apparent Porosity

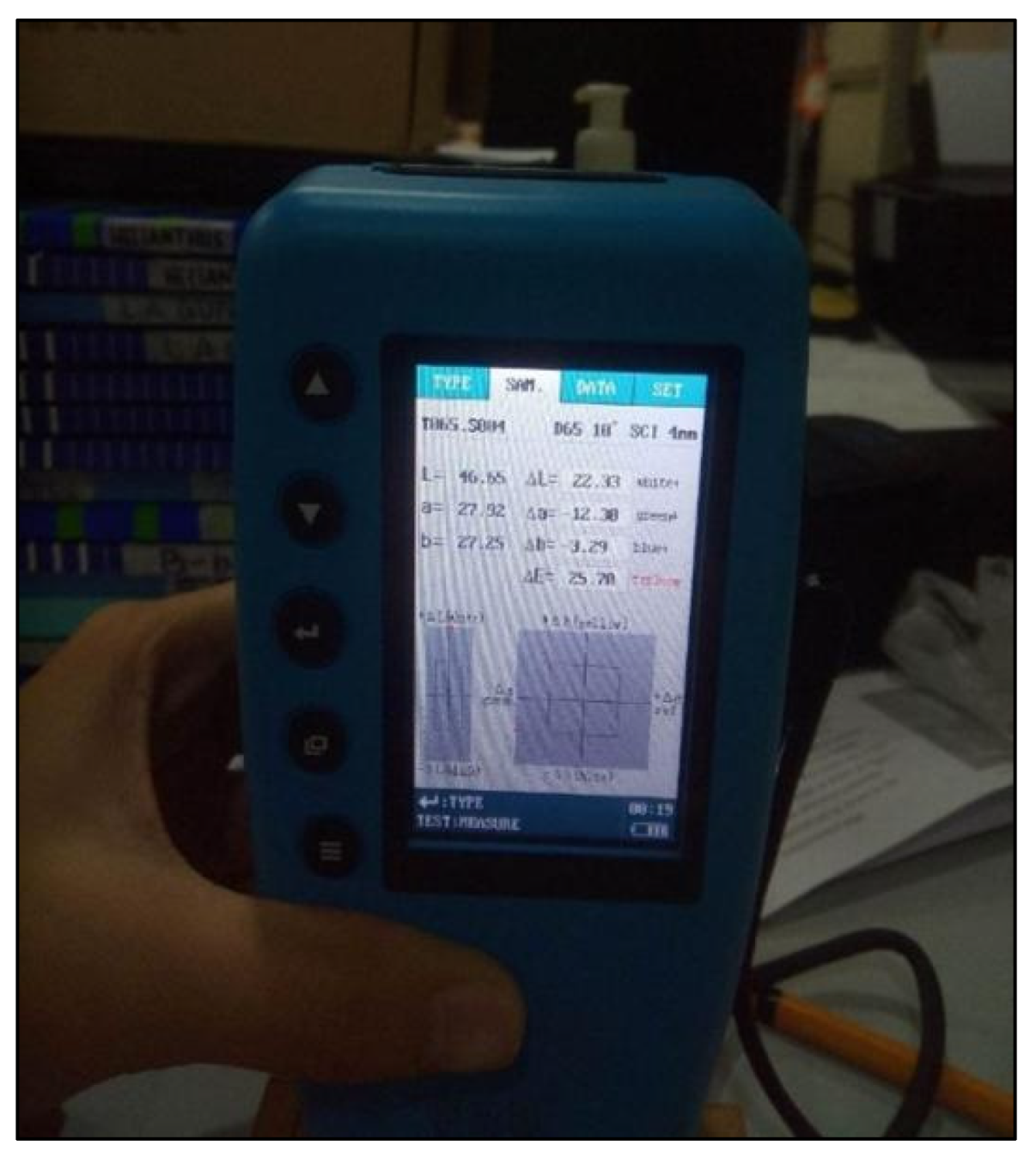

3.6.2.6. Color

3.6.3. Mechanical Property Testing

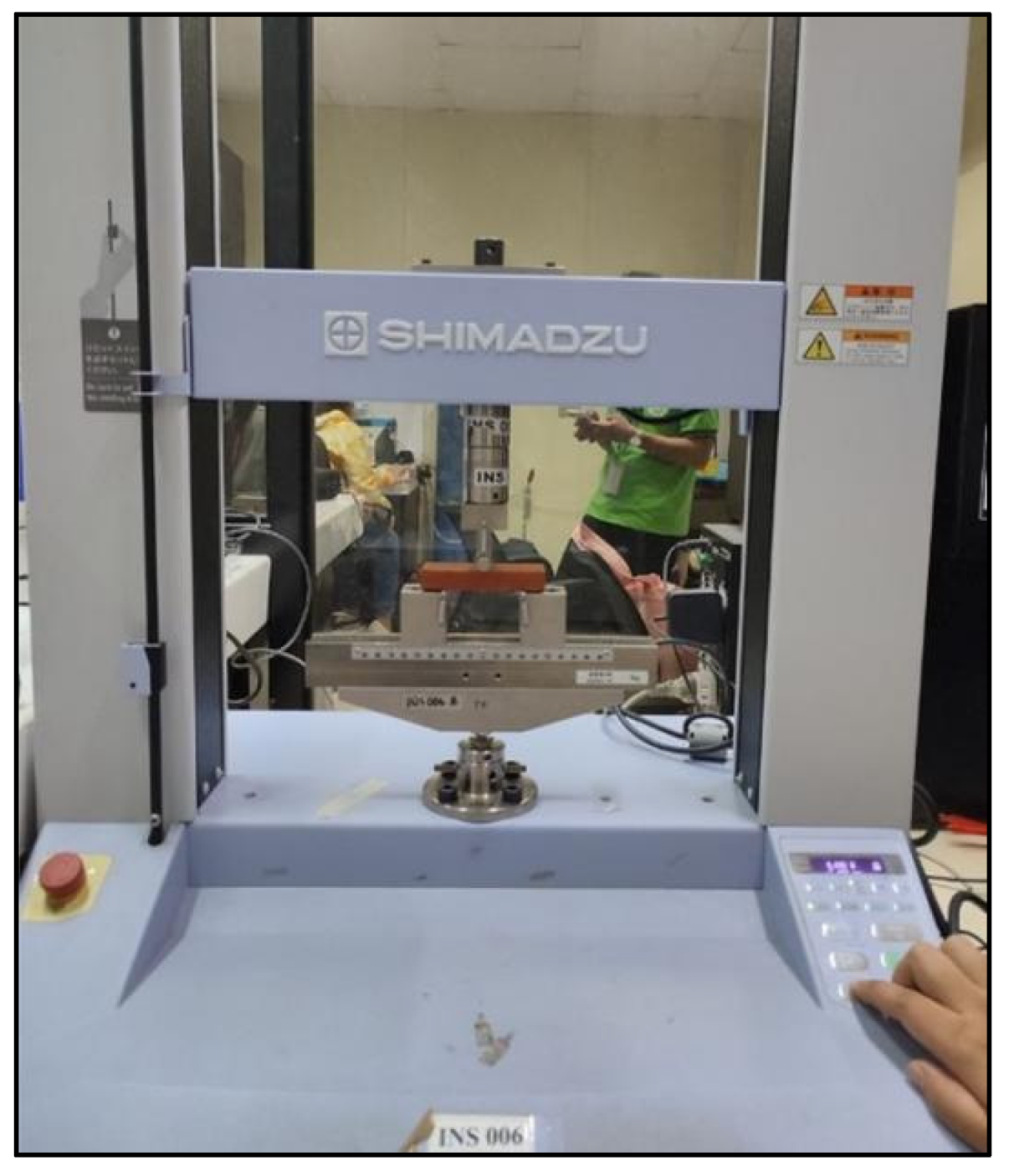

3.6.3.1. Modulus of Rupture

3.7. Map Generation

3.7.1. Mapping and Profiling

Chapter IV. Results and Discussion

4.1. Chemical Analysis

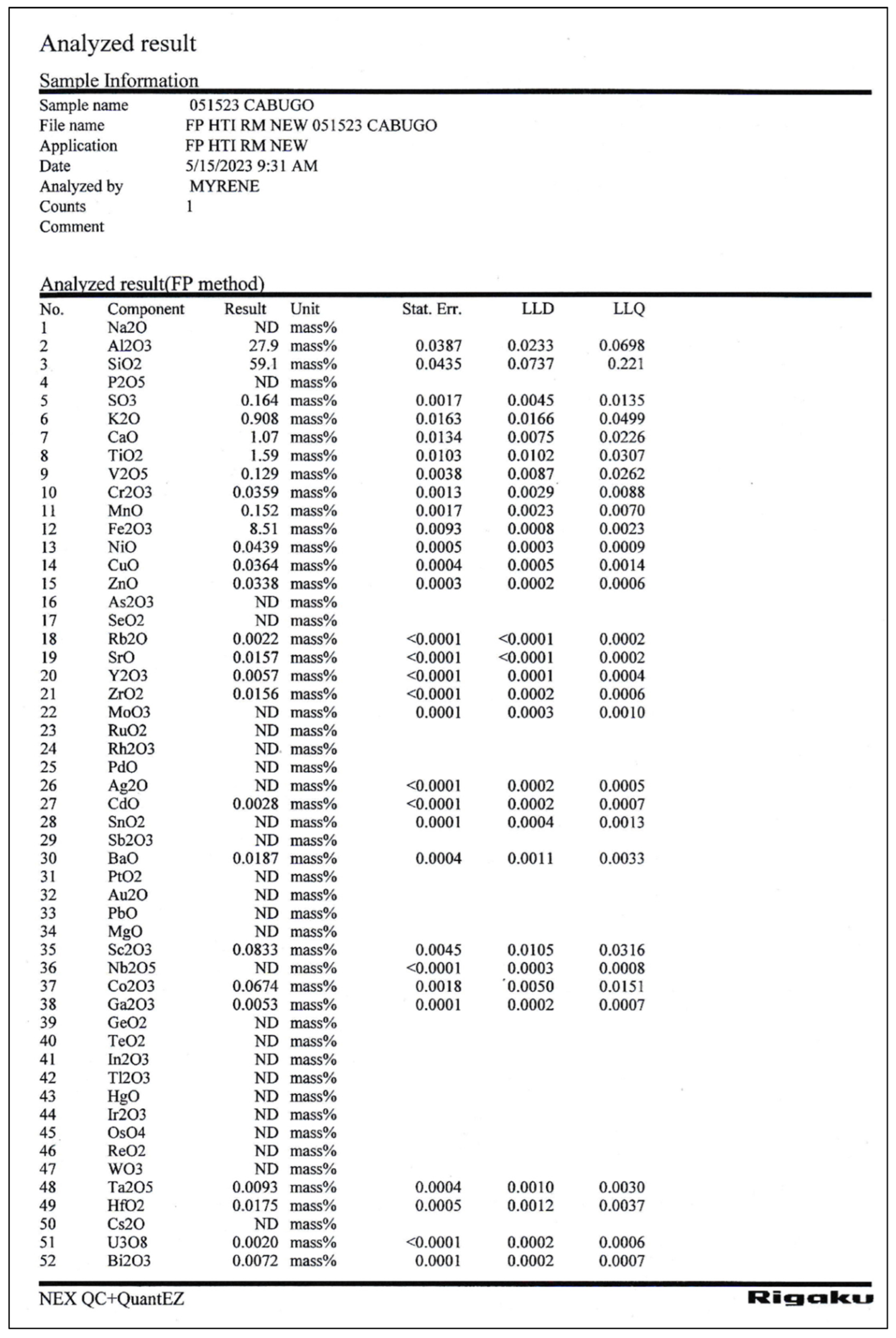

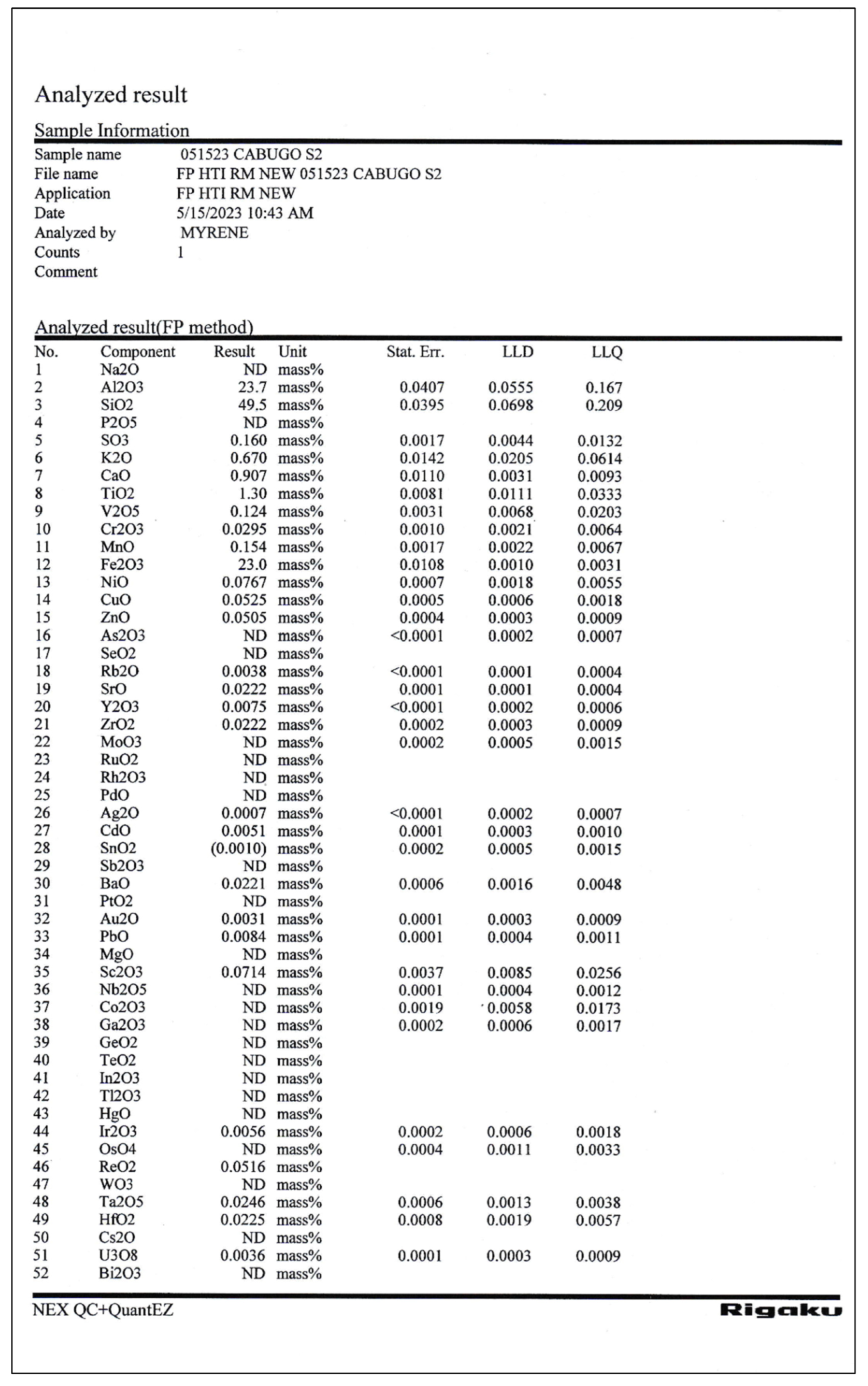

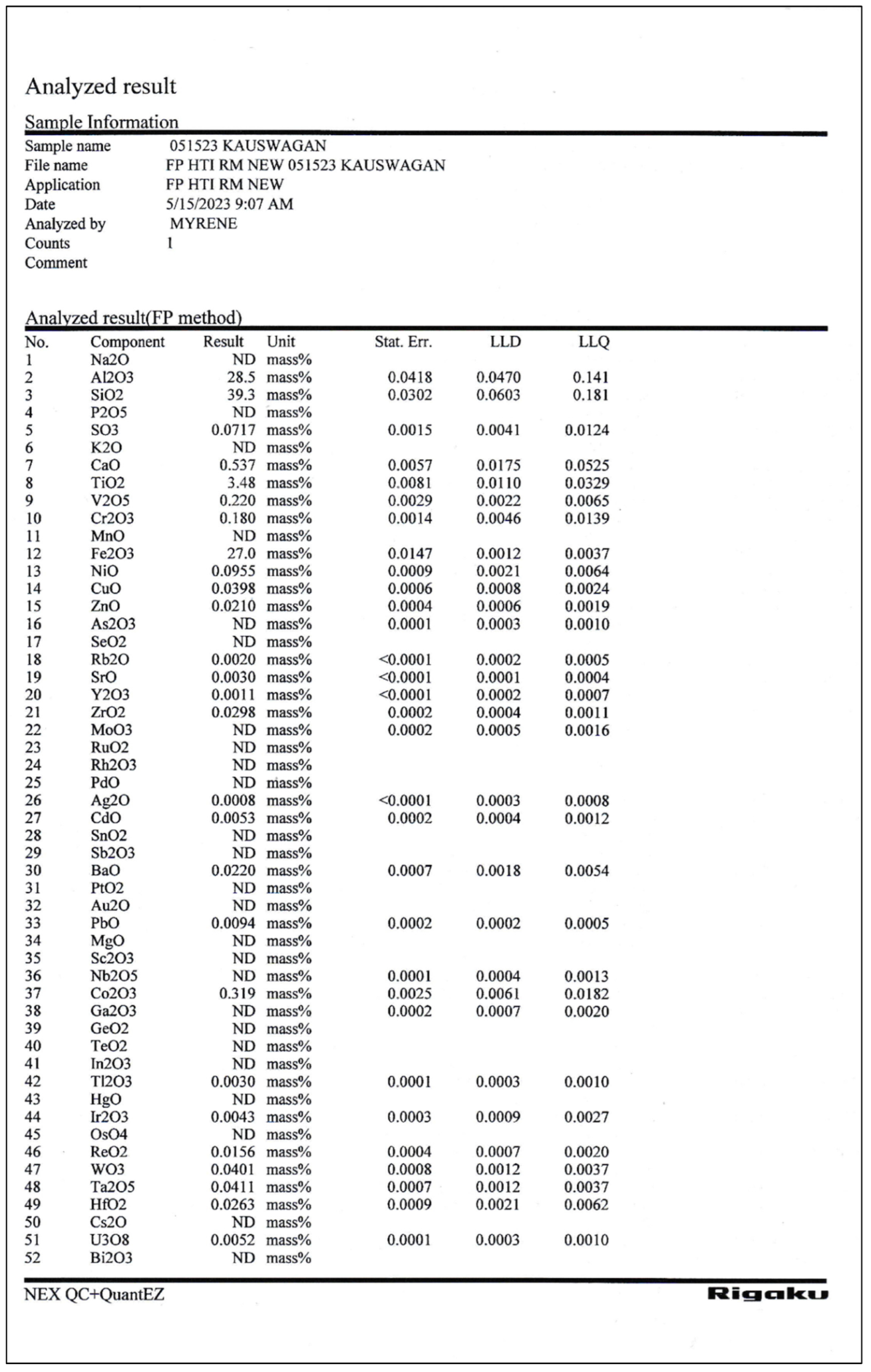

4.1.1. XRF Analysis

| COMPONENT | Oxide Content (weight %) | ||

|---|---|---|---|

| Kauswagan (Control) |

Placer | Claver | |

| SiO2 | 40.300 | 67.500 | 54.300 |

| Al2O3 | 29.150 | 22.400 | 25.800 |

| Fe2O3 | 25.750 | 4.8600 | 15.755 |

| CaO | 0.5085 | 1.6850 | 0.9885 |

| MgO | ND | ND | ND |

| Na2O | ND | ND | ND |

| K2O | ND | 1.6400 | 0.7890 |

| SO3 | 0.08215 | 0.4850 | 0.1620 |

| TiO2 | 3.2000 | 0.8310 | 1.4450 |

| BaO | 0.2085 | 0.0223 | 0.0204 |

| MnO | ND | 0.0938 | 0.1530 |

| P2O5 | ND | ND | ND |

| Cr2O3 | 0.1665 | 0.0329 | 0.0327 |

| V2O5 | 0.1810 | 0.0818 | 0.1265 |

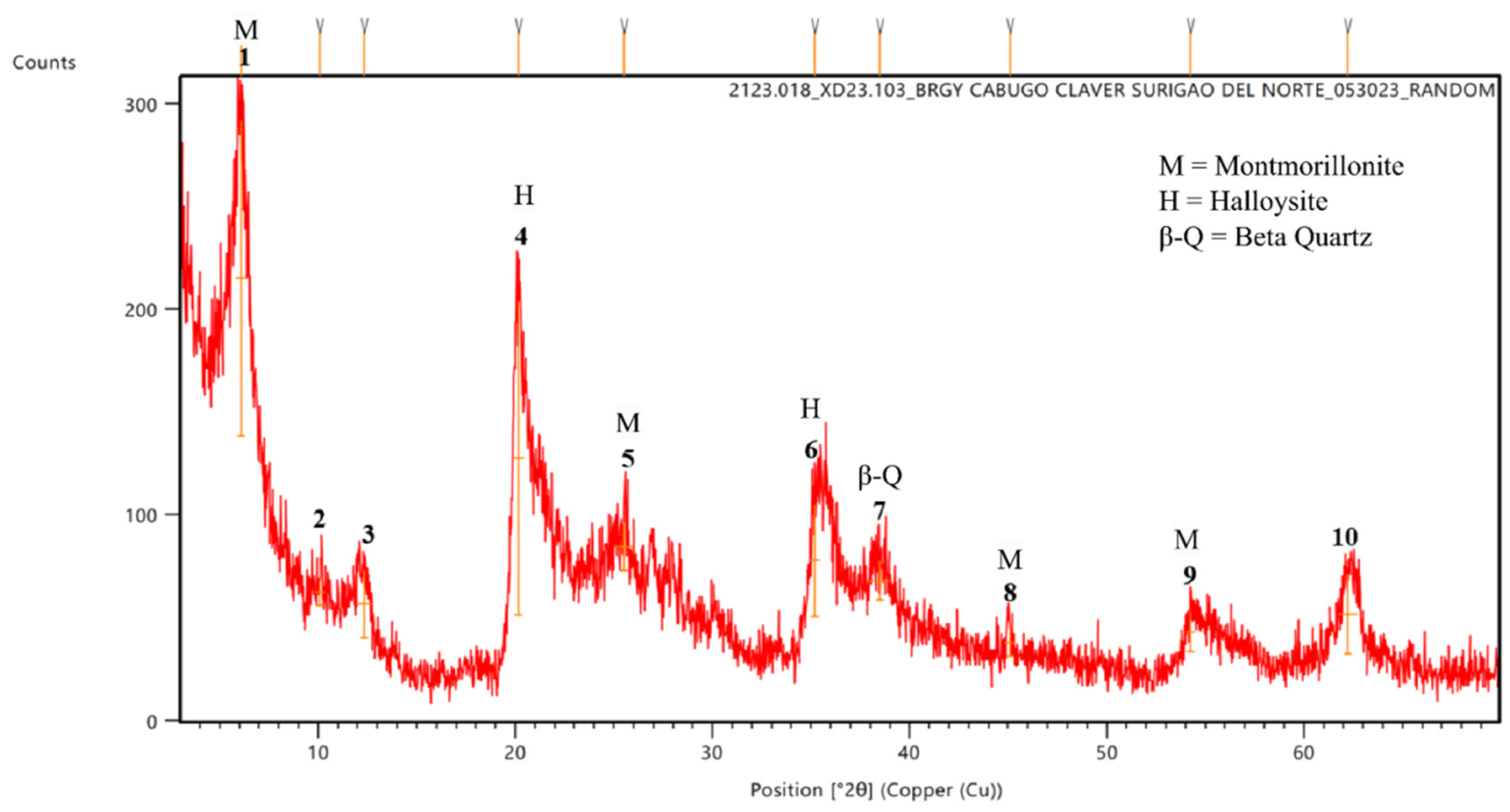

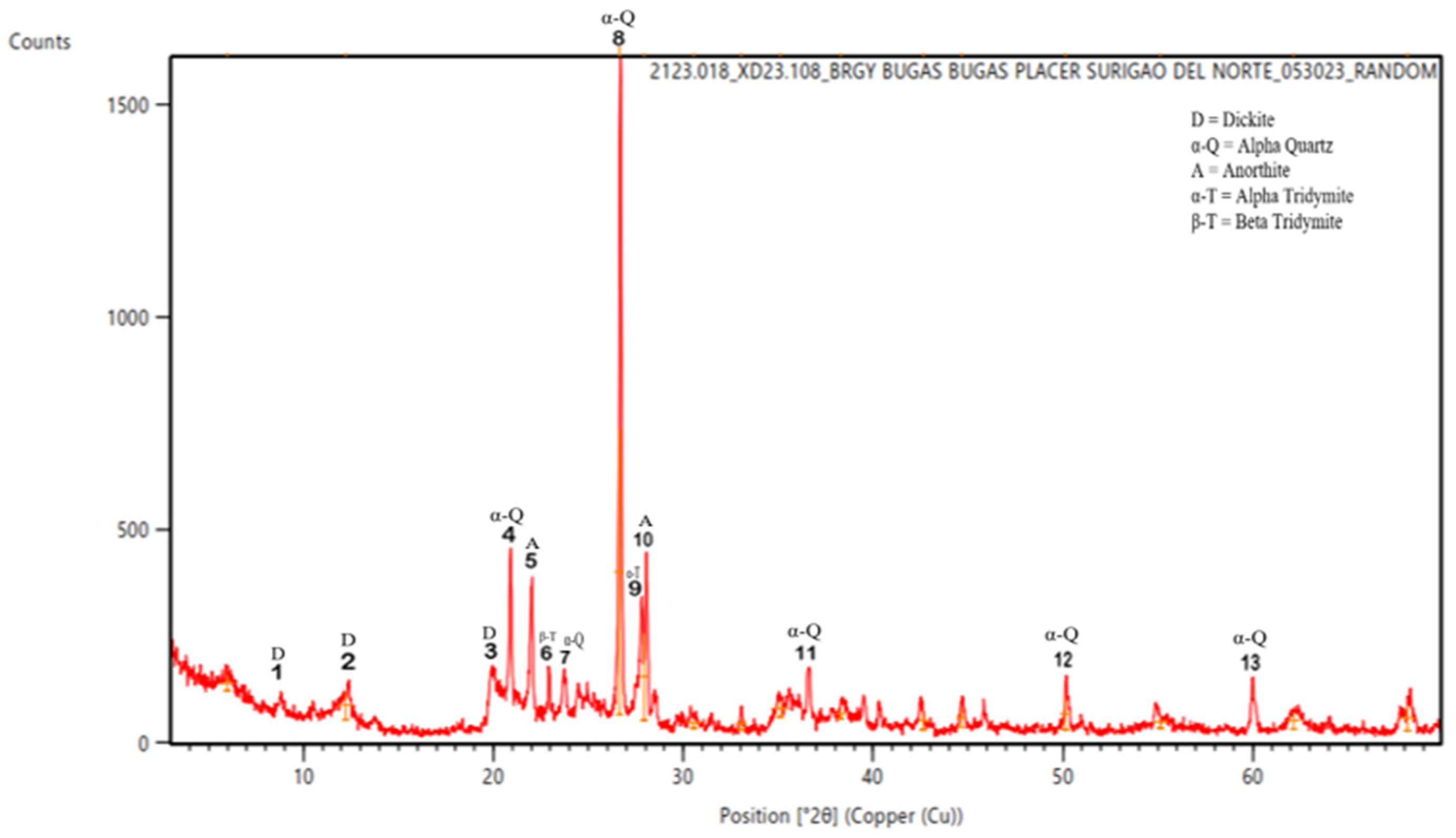

4.1.2. XRD Analysis

| Minerals Identified | Mineral Abundance (%) |

|---|---|

| Montmorillonite | 40 |

| Halloysite | 20 |

| Quartz (β) | 10 |

| Minerals Identified | Mineral Abundance (%) |

|---|---|

| Quartz (α) | 38.46% |

| Dickite | 30.77% |

| Anorthite | 15.38% |

| Tridymite (α) | 7.69% |

| Tridymite (β) | 7.69% |

4.2. Physical Property Testing

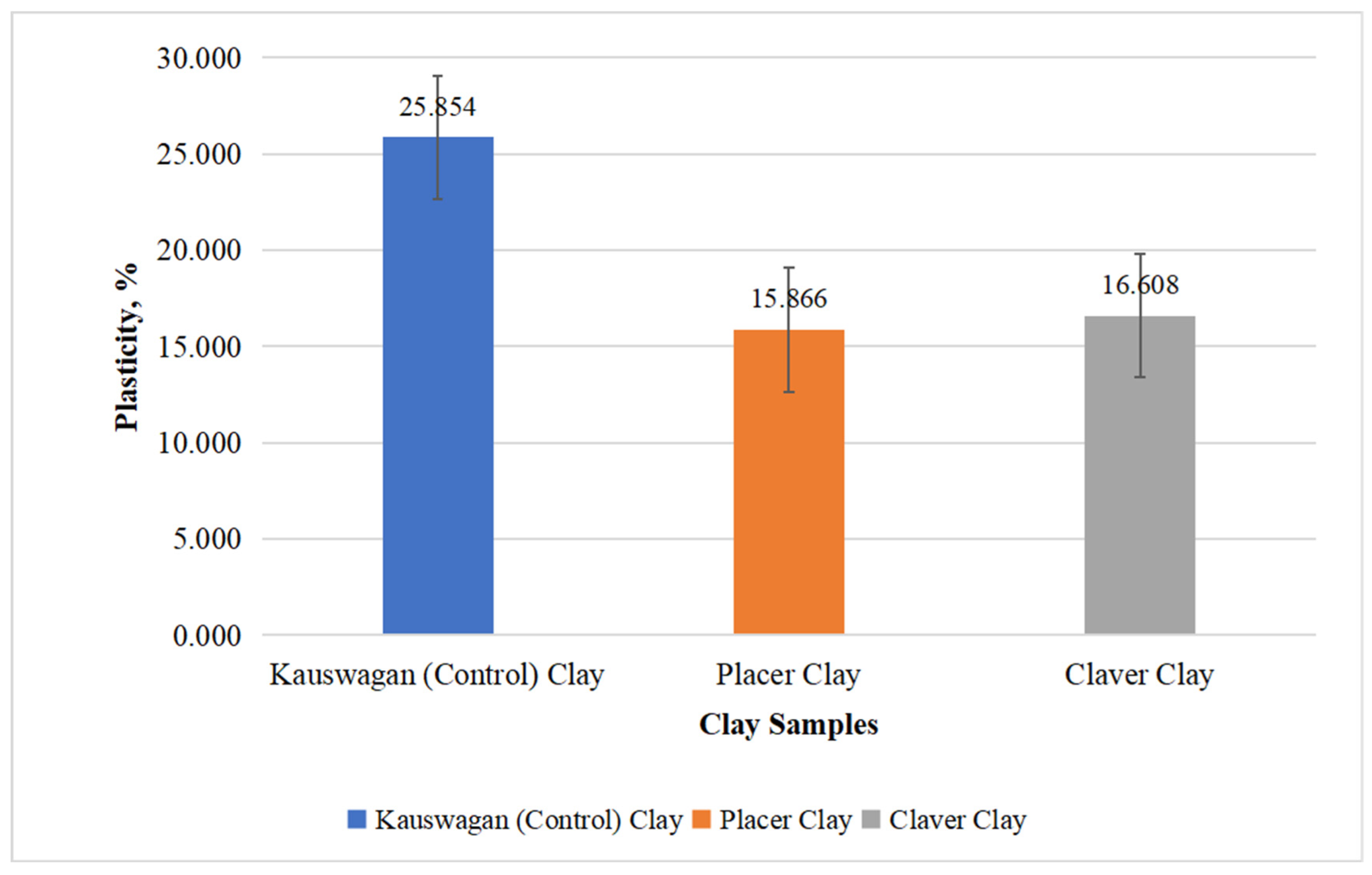

4.2.1. Plasticity Test

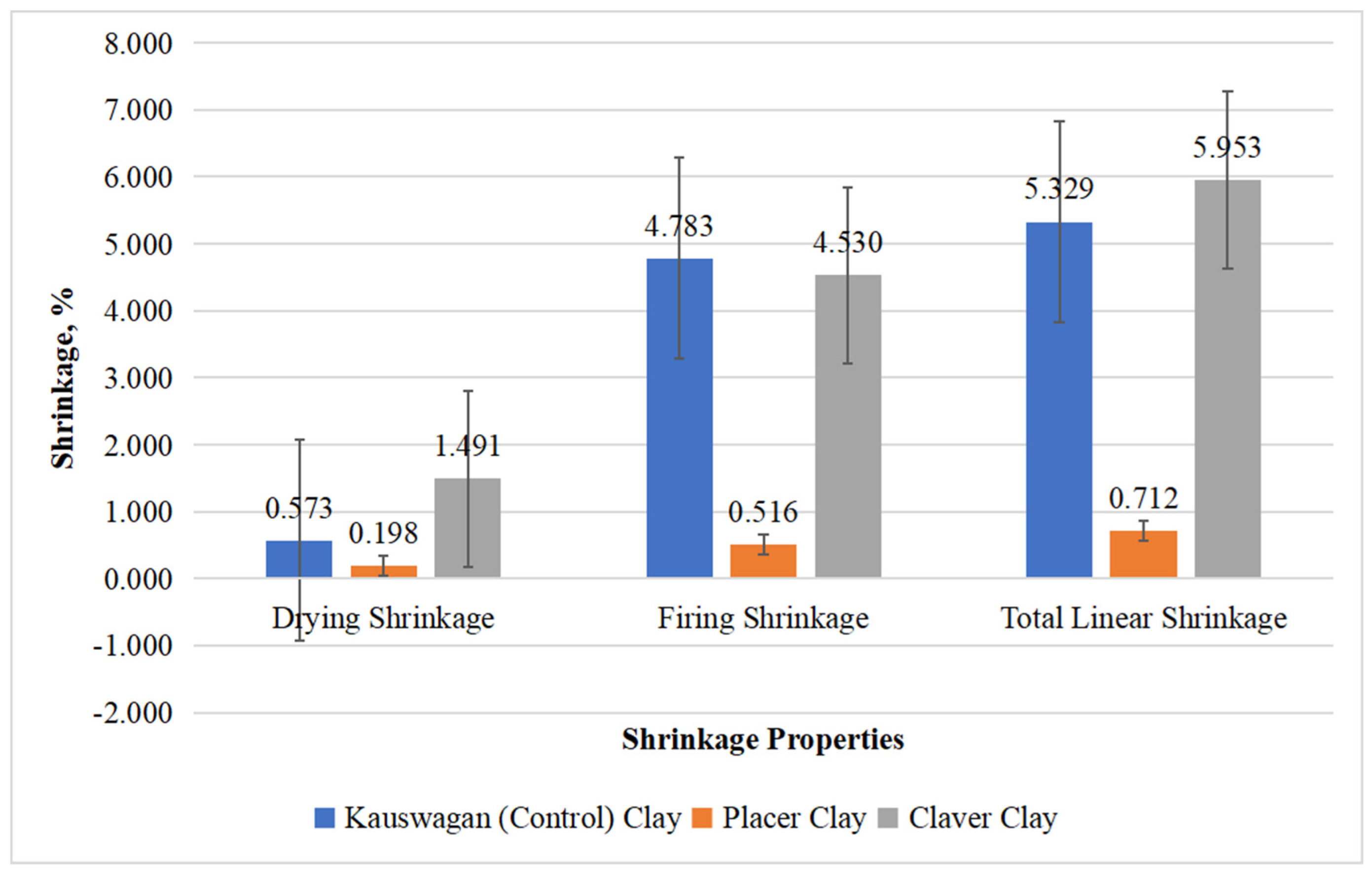

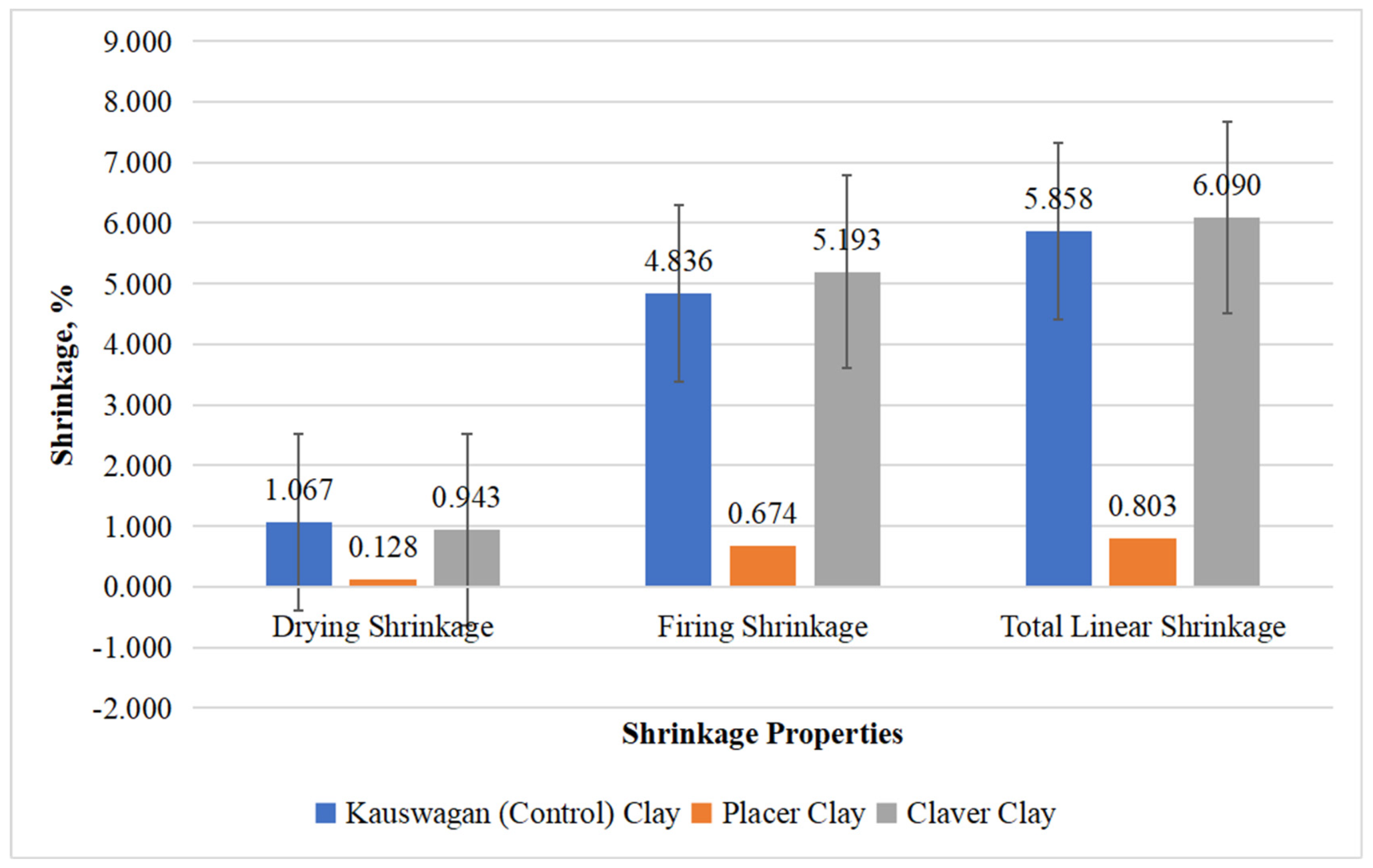

4.2.2. Shrinkage Test

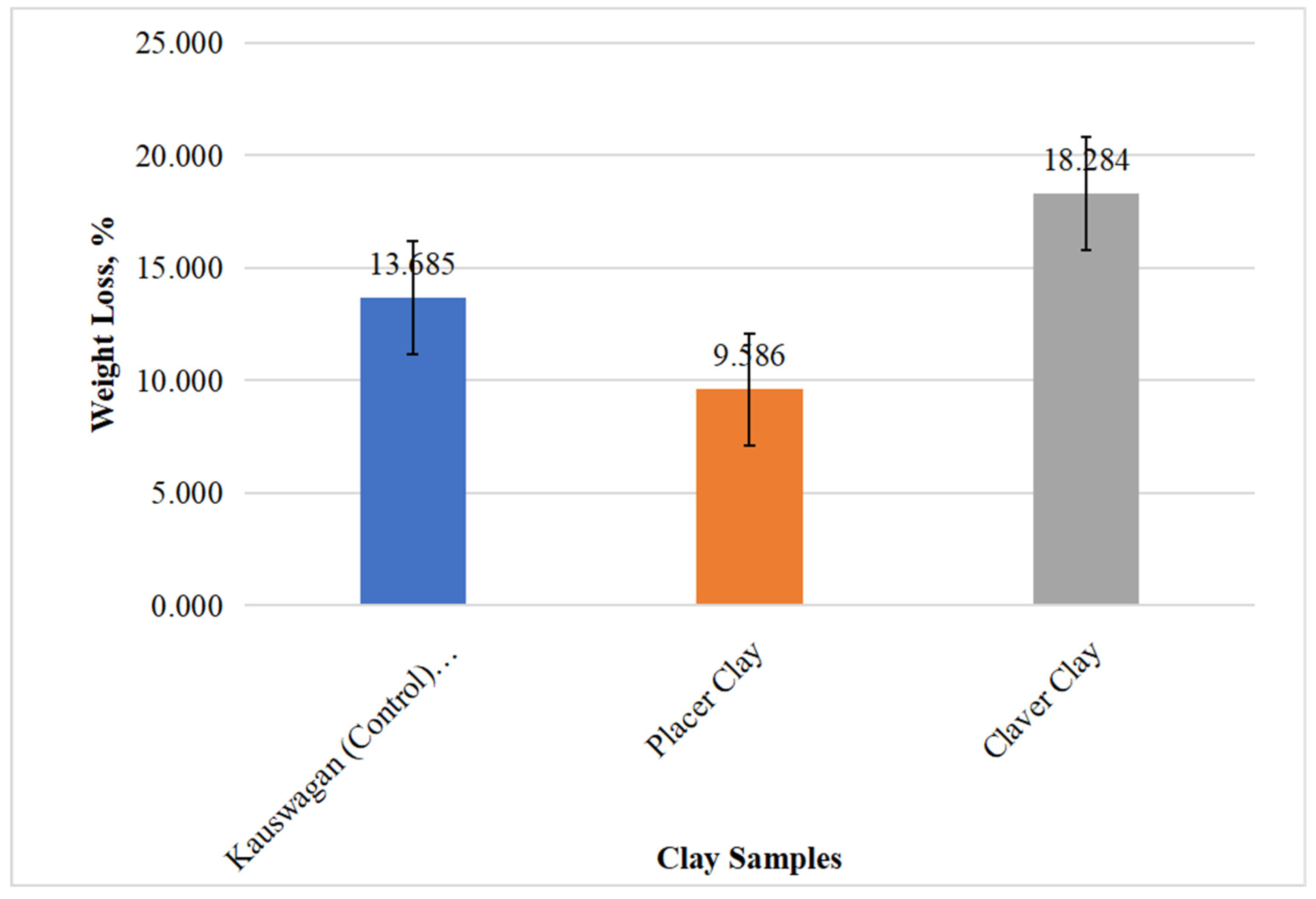

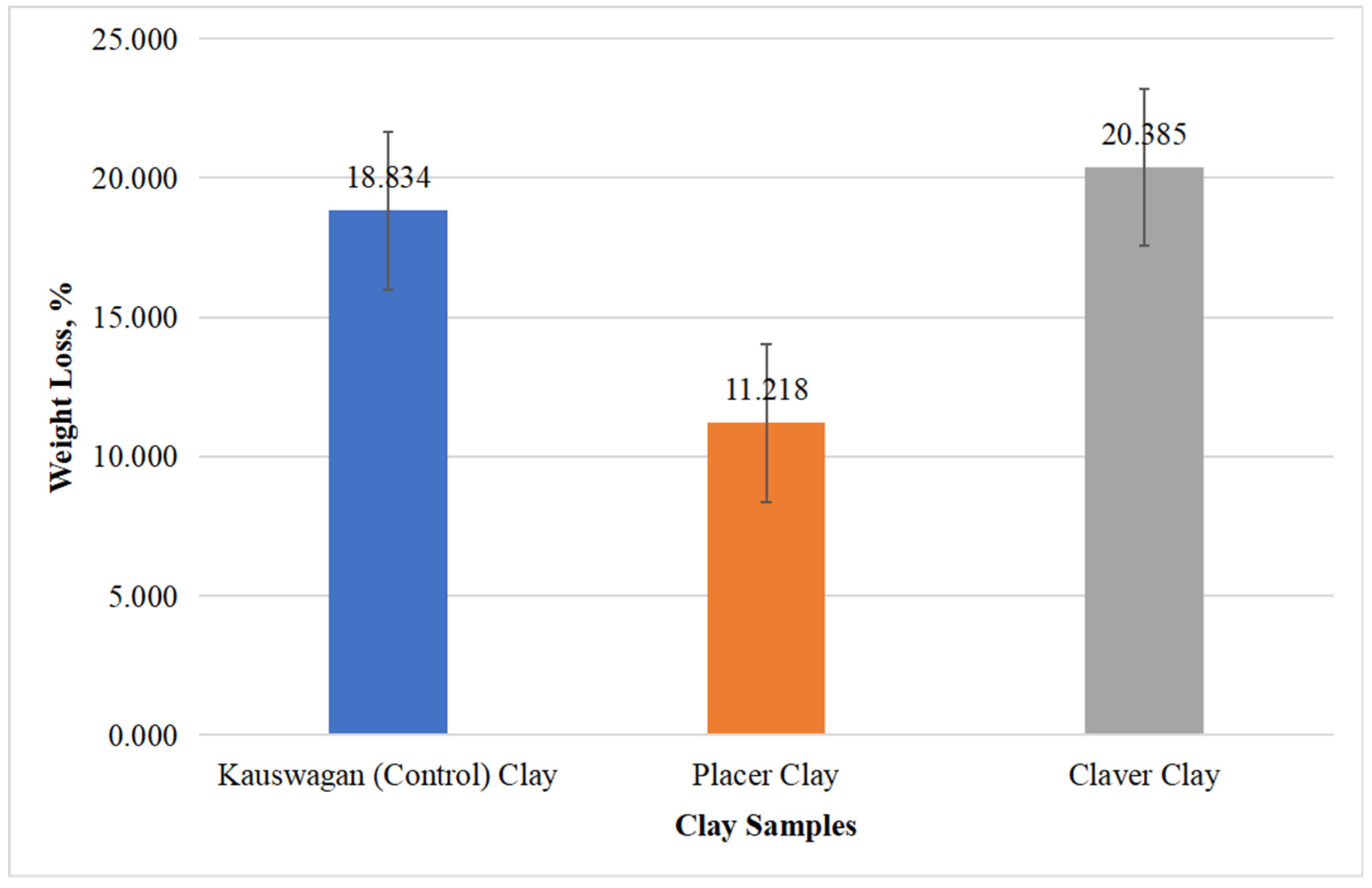

4.2.3. Weight Loss on Ignition

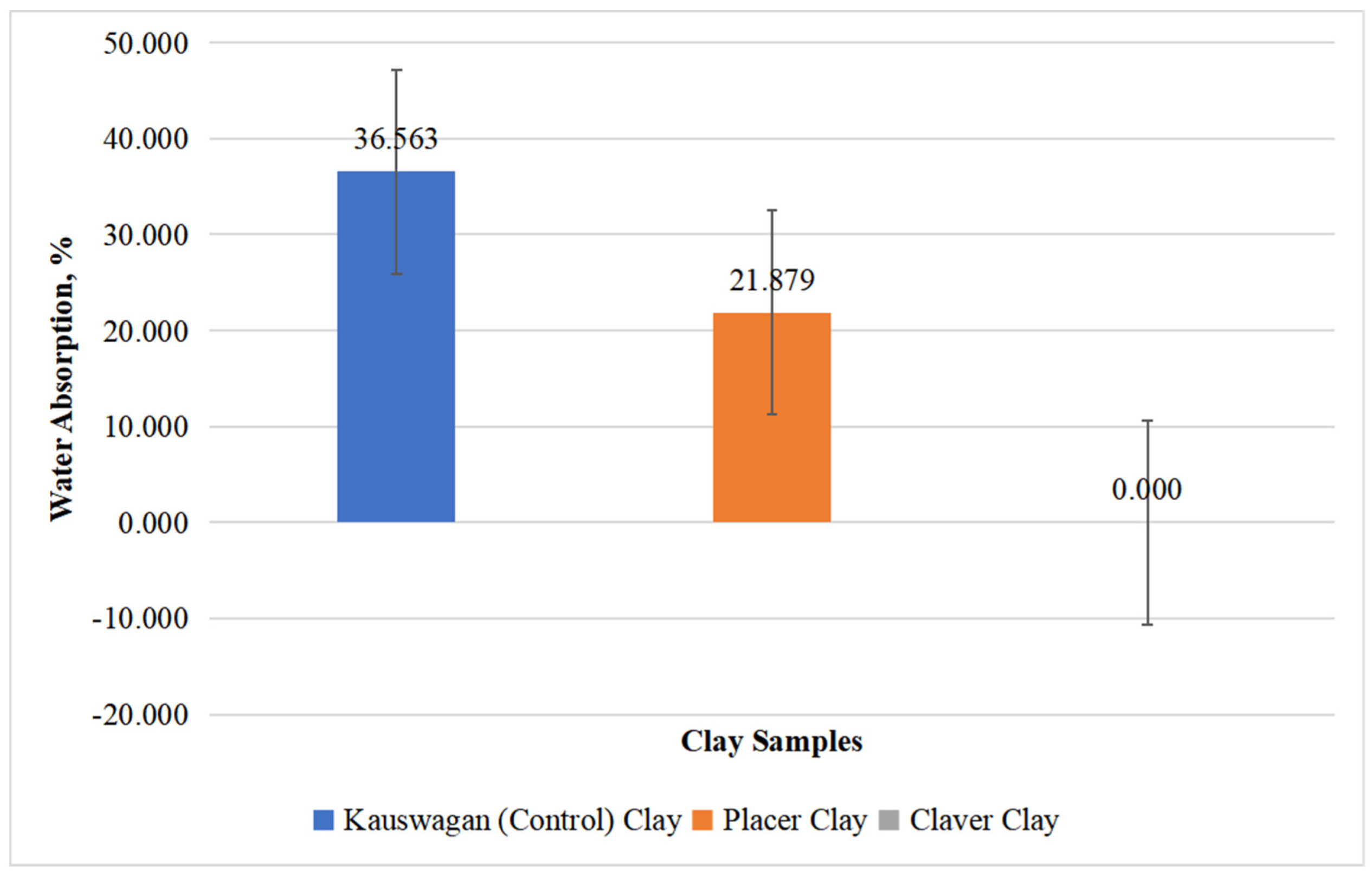

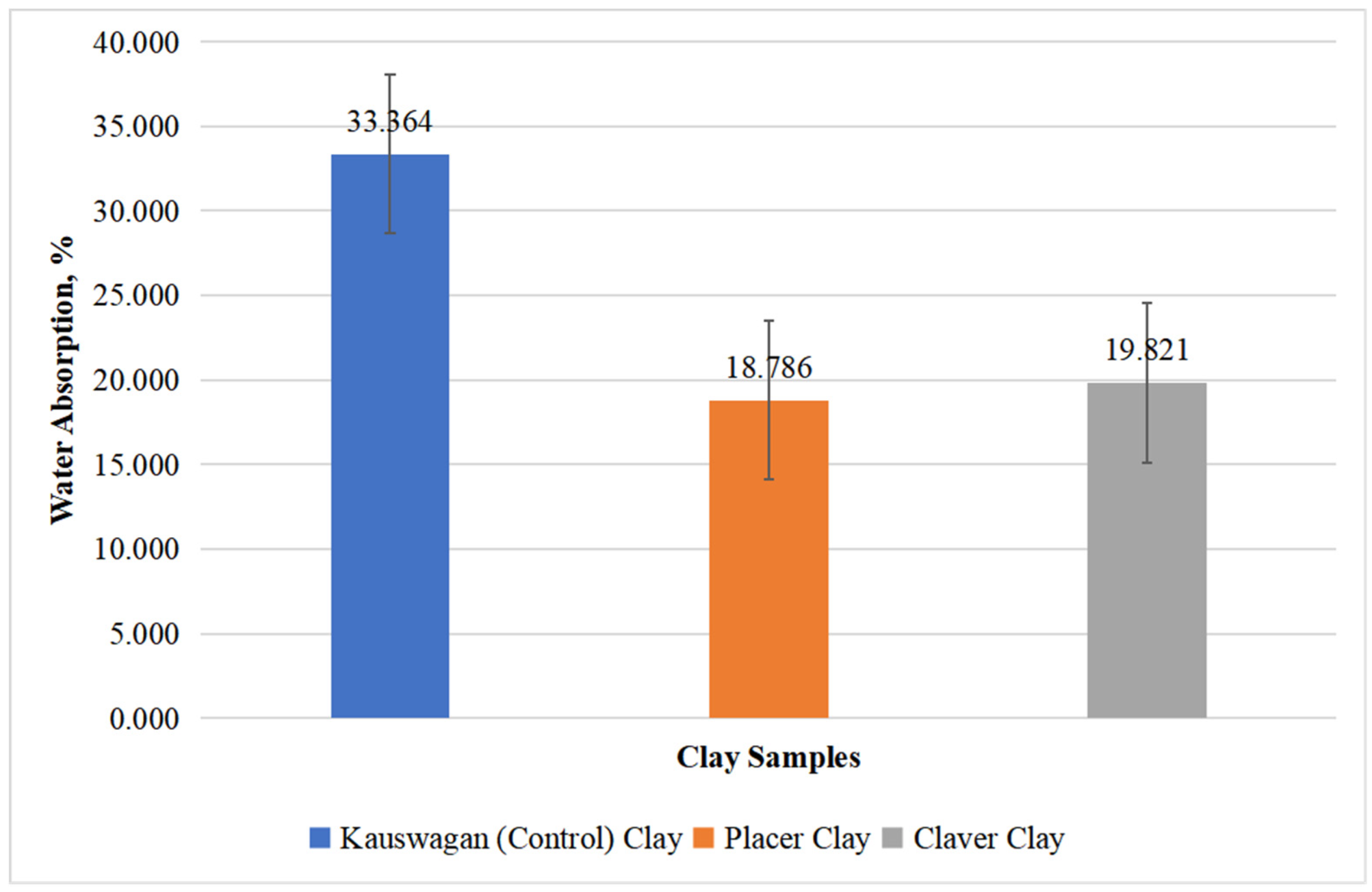

4.2.4. Water Absorption

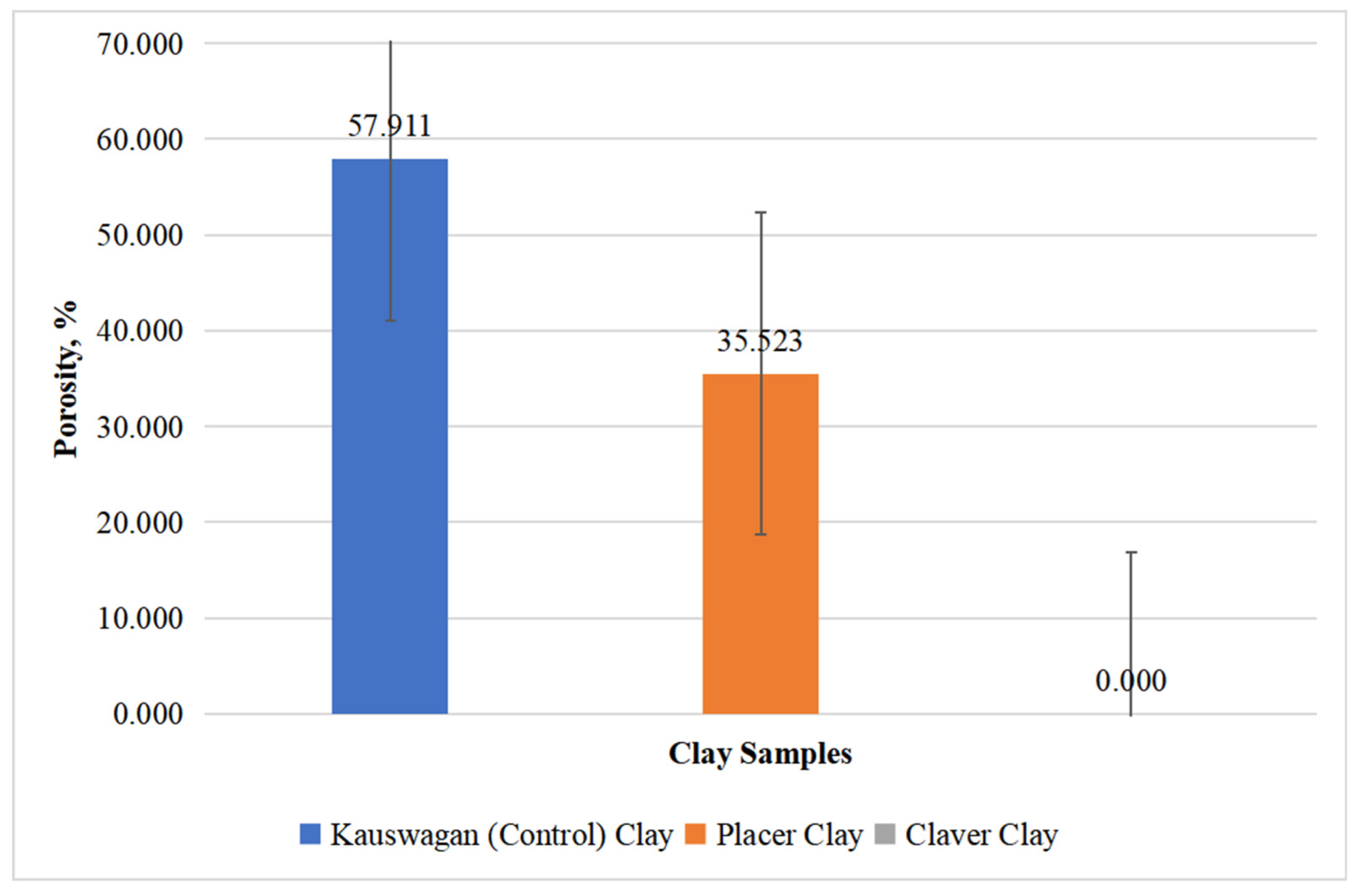

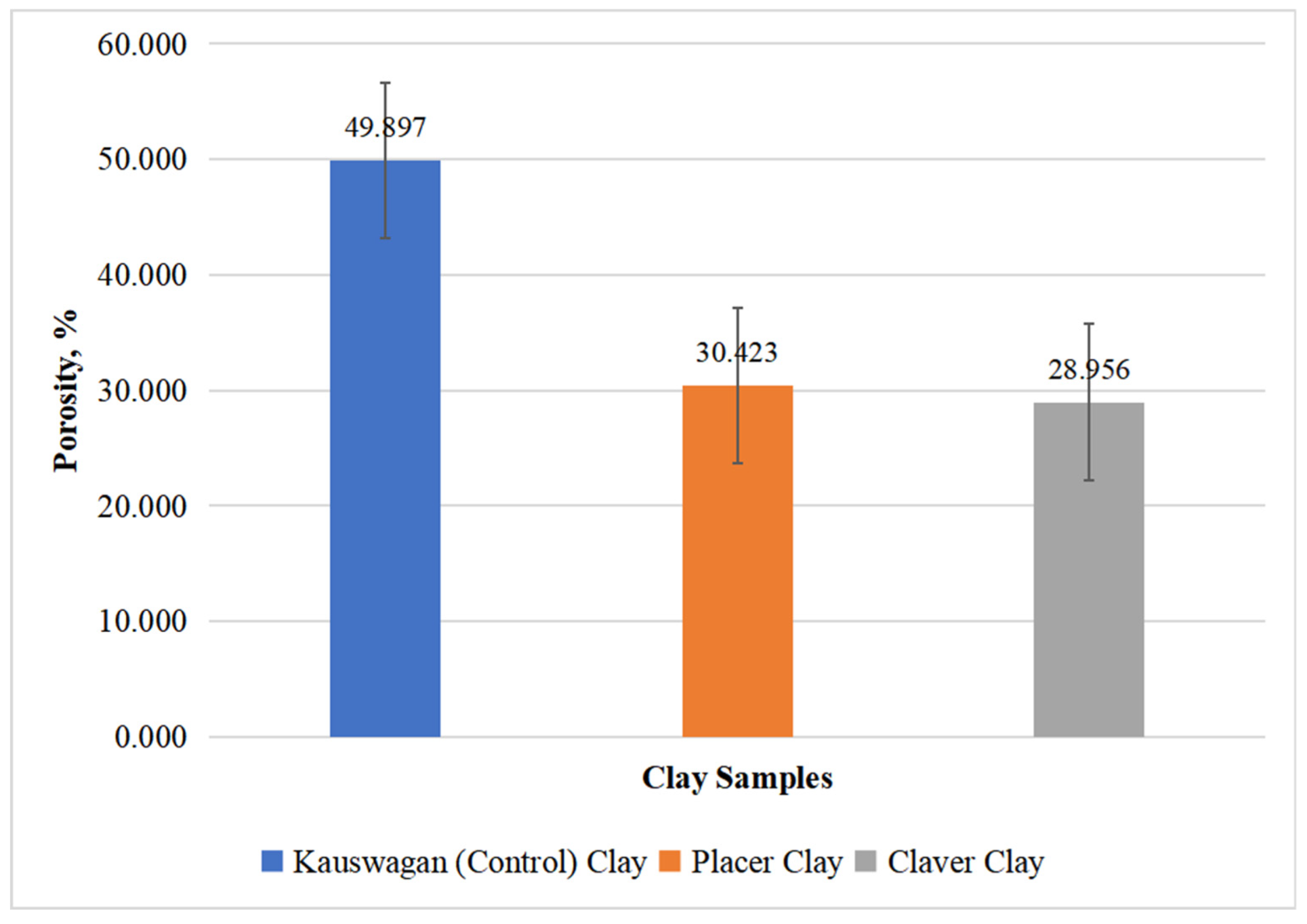

4.2.5. Apparent Porosity

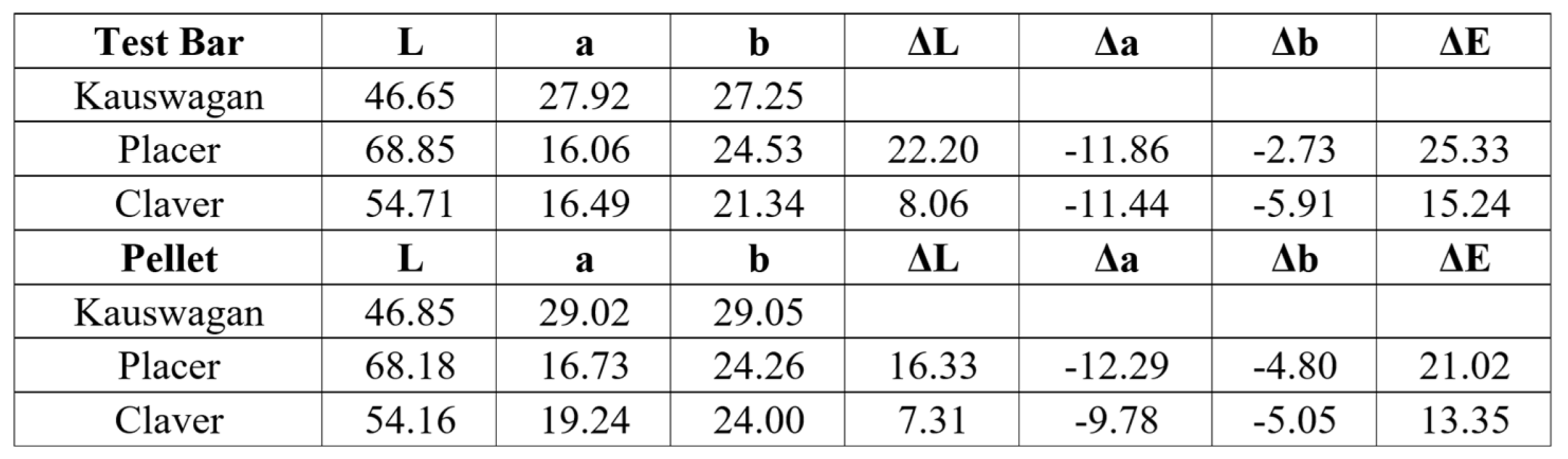

4.2.8. Color Analysis

4.3. Mechanical Property Testing

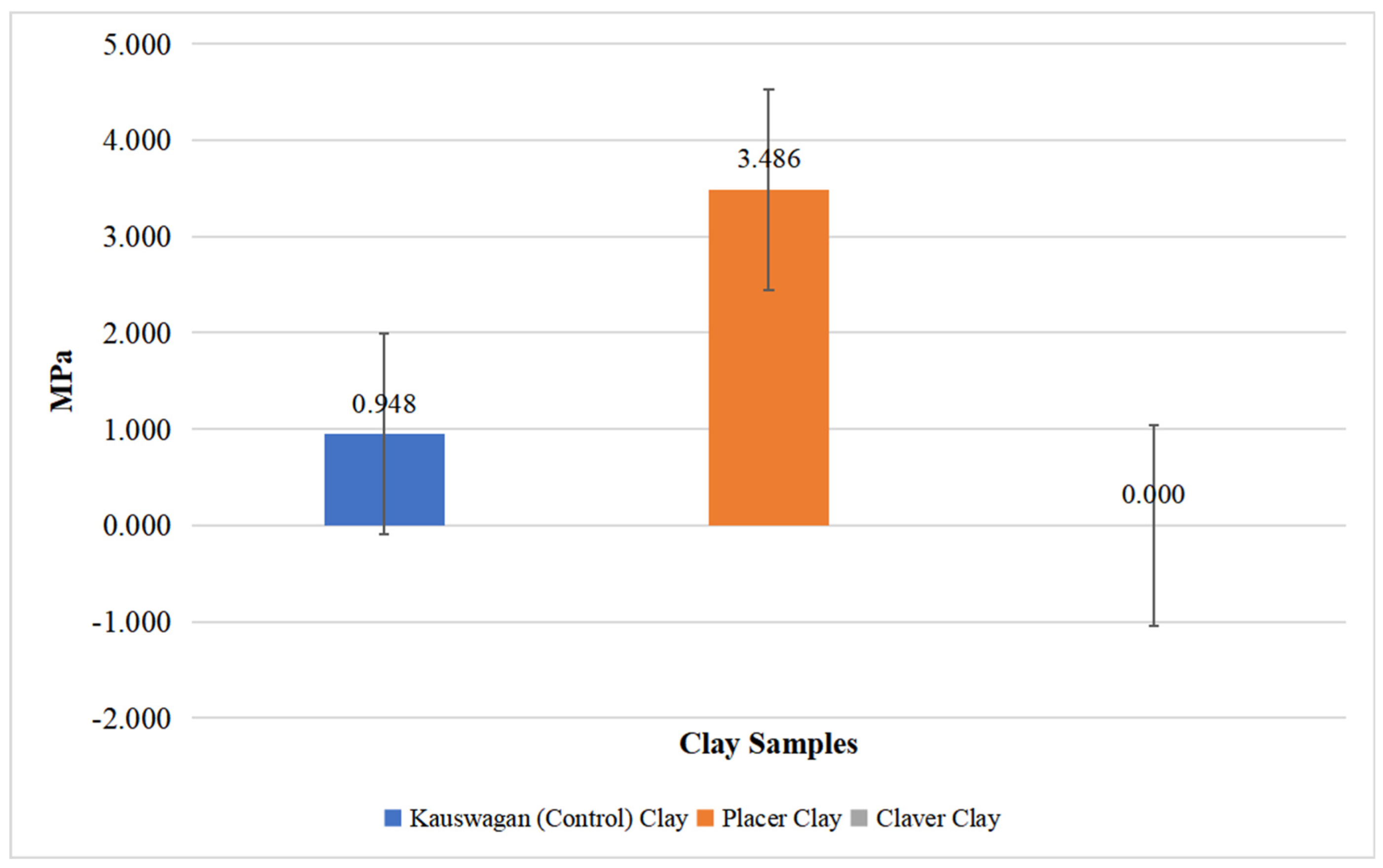

4.3.1. Modulus of Rupture

4.4. Map Generation

4.4.1. Mapping and Profiling

Chapter V. Conclusions and Recommendations

5.1. Conclusion

5.2. Recommendations

- Employing Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC) to gather structured and profound information into the thermal properties and behavior of the clay considering its environment.

- Conduct of additional physical testing such as specific gravity, and particle size to gain in-depth understanding of the clay’s properties on samples taken.

- Employ drilling techniques to conduct thorough exploration of the clay resource and accurately estimate the clay reserve.

- Expand the mapping on areas closely related to Brgy. Bugas-Bugas in Placer and Brgy. Cabugao in Claver Surigao del Norte for further discovery of other types of clay resources with significant physical and mechanical properties.

- Connect with the Local Government Unit to make sure that the mapping of and profiling of the identified clay will be known locally and used for community’s advancement.

- Submerged to Indicated and Measured level of Exploration Stage in mining life cycle to get probable and proven sample and increase geological sampling confidence.

Acknowledgments

- -

- to Engr. Larry M. Heradez, MGB Regional Director of Caraga Region, and staff for their invaluable support and guidance, greatly benefiting the study.

- -

- also extending appreciation to Mayor Georgia Gokiangkeee for lending us the crucial GPS device, instrumental in the successful implementation of our research fieldwork.

- -

- to the House Technology Industries PTE. Ltd, especially to Ma’am Roxanne Climacosa for their valuable assistance in our research sample analysis.

- -

- to our advisers Engr. Seigfreid Kempis and co-adviser, Engr. Lori-ann Cabalo, whose dedication, and commitment shaped the success of our research.

- -

- to our parents for their unconditional love, care, unwavering financial support, and encouragement to move along.

- -

- to our classmates for their invaluable assistance and support by stimulating discussion where some ideas are solicited for the fulfillment of the research.

- -

- above all, to God for providing unwavering guidance, sustenance, and bestowed protection in the entire duration of our research.

Appendix A. (Sample Collection and GPS Coordinates Recording)

A.1 Sampling and GPS Coordinates Recording

Appendix B. (Fabrication Process)

B.1 Sample Preparation

B.2 Fabrication Process

B.2.1 Test Bar Making

B.2.3 Drying and Firing

Appendix C. (Characterization of Samples)

C.1 Physical Property Testing

C.1.1 Shrinkage Test

C.1.2 Water Absorption

C.1.3 Apparent Porosity

C.1.4 Color Test

C.2 Mechanical Property Test

C.2.1 Modulus of Rupture Test

Appendix D. (XRF Analysis Results)

Appendix E. (XRD Analysis Results)

Appendix F. (GPS Spatial Data)

| Claver | Elevation (m) | Coordinates |

| A | 16 | N09° 32.749’, E125° 45.729’ |

| B | 14 | N09° 32.754’, E125° 45.726’ |

| C | 14 | N09° 32.755’, E125° 45.733’ |

| D | 14 | N09° 32.758’, E125° 45.725’ |

| E | 14 | N09° 32.759’, E125° 45.732’ |

| F | 14 | N09° 32.764’, E125° 45.729’ |

| G | 14 | N09° 32.767’, E125° 45.737’ |

| H | 14 | N09° 32.771’, E125° 45.728’ |

| I | 14 | N09° 32.771’, E125° 45.738’ |

| J | 14 | N09° 32.778’, E125° 45.728’ |

| Placer | Elevation (m) | Coordinates |

| 1 | 74 | N09° 39.321’, E125° 34.300’ |

| 2 | 74 | N09° 39.325’, E125° 34.307’ |

| 3 | 74 | N09° 39.322, E125° 34.307’ |

| 4 | 74 | N09° 39.321’, E125° 34.311’ |

| 5 | 74 | N09° 39.319’, E125° 34.311’ |

| 6 | 74 | N09° 39.317’, E125° 34.313’ |

| 7 | 74 | N09° 39.314’, E125° 34.314’ |

| 8 | 74 | N09° 39.317’, E125° 34.322’ |

| 9 | 72 | N09° 39.311’, E125° 34.320’ |

| 10 | 68 | N09° 39.312’, E125° 34.324’ |

Appendix G. (Sample Classification According to Flexural Strength and Water Absorption)

| Ceramic Peace | Flexural strength (kgf/cm2) | Water Absorption (%) |

| Indicated Values | Indicated Values | |

| Not Classified | ||

| Massive Bricks | ||

| Ceramic Bricks | ||

| Roof Tiles |

References

- Singh, N. B. (2022). Clays and clay minerals in the construction industry. MDPI. Available online: https://www.mdpi.com.

- Shahrokh, V., Khademi, H., Zeraatpisheh, M.(2023). Mapping clay mineral types using easily accessible data and machine learning techniques in a scarce data region: A case study in a semi-arid area in Iran. CATENA.

- Surveying & mapping. (n.d.). Available online: https://www.gps.gov.

- Philippine Mineral Reporting Code 2020. PMRCC. (2021, November 21). Available online: https://www.pmrcc.org.ph/resources/cc91813e-79d7-4d8c-8d88-e9909cec6353.

- Moreno-Maroto, J. M., & Alonso-Azcárate, J. (2018, April 24). What is Clay? A new definition of “clay” based on plasticity and its impact on the most widespread Soil Classification Systems. Applied Clay Science. Available online: https://www.sciencedirect.com.

- Kumari, N., & Mohan, C. (2021). Basics of clay minerals and their characteristic properties. IntechOpen. Available online: https://www.intechopen.com.

- Dondi, M. & Bertolotti, G.P. (2021). Basic Guidelines for Prospecting and Technological Assessment of Clays for the Ceramic Industry, Part 1. Interceram - International Ceramic Review. 70. 36-46. 10.1007/s42411-021-0472-x. [CrossRef]

- Sharma, R.P., Singh, S.S., Singh, S.K. (2019). Significance of clay minerals in development of alluvial soils of Aravalli range. Indian Journal of Geo Marine Sciences Vol. 48 (11), pp. 1783-1795. Available online: https://www.researchgate.net.

- Ouahabi, M.E., Ferrari, A.H., Fagel, N.(2017). Lacustrine clay mineral assemblages as a proxy for land-use and climate changes over the last 4 kyr: The Amik Lake case study, Southern Turkey. Quaternary International. [CrossRef]

- Ai Mi, N.V., Thongchart, & S., Mairaing, W.(2023). GEOLOGICAL AND GEOTECHNICAL PROPERTIES OF MEKONG DELTA CLAY AS COMPARISON WITH BANGKOK CLAY. International Journal of GEOMATE, Vol.24, Issue 101, pp.22-32.

- International Reporting Template. Crirsco. (2024). Available online: https://crirsco.com/the-international-reporting-template/.

- Harraz, H.Z.(2010). The Mining Cycle. Tanta University.

- IM Standing Committee on Reserve Definitions. (2014). CIM Definition Standards for Mineral Resources & Mineral Reserves: Inferred Mineral Resource. Canadian Institute of Mining, Metallurgy and Petroleum. Available online: https://mrmr.cim.org.

- Dondi, M. & Bertolotti, G.P. (2022). Basic guidelines for prospecting and technological assessment of clays for the ceramic industry. Part 2. Interceram-International Ceramic Review, 71(1), 28-37. [CrossRef]

- Chon, N. Q. (n.d.). Soil sampling guidelines - eurofins scientific. SOIL SAMPLING GUIDELINES. Available online: https://cdnmedia.eurofins.com.

- Yunta Mezquita, F., Van Liedekerke, M., Fernandez Ugalde, O., Németh, T., Balázs, R.B., Keresztes, M.A., Weiszburg, T., Rábl, E., Királyné Tóth, J., Gazsi, Z., Kovács, I., Ruiz Garcia, A.I., Cuevas, J., Van Eynde, E., Wojda, P., Panagos, P. and Jones, A.(2024). Clay mineral inventory in soils of Europe based on LUCAS survey soil samples. Publications Office of the European Union, Luxembourg. JRC136950. [CrossRef]

- Gillott, J. E. (2018). Some clay-related problems in engineering geology in North America: Clay minerals. Cambridge Core. Available online: https://www.cambridge.org.

- Chen, F. H. (2012). Foundations on expansive soils. Google Books. Available online: https://www.google.com.ph.

- Official Website: Surigao del Norte Province.(2024). Geography. Republic of the Philippines: Province of Surigao del Norte. Available online: https://surigaodelnorte.gov.ph.

- Panamaldeniya, L. (2021). Timely importance of GIS, GPS and RS. ResearchGate. Available online: https://www.researchgate.net.

- Land Surveying and GPS. E-education. (n.d.). Available online: https://www.e-education.psu.edu.

- Gao, J. (2002). Integration of GPS with Remote Sensing and GIs: Reality and Prospect. Photogrammetric Engineering & Remote Sensing, 68(5), 447–453.

- Jiang, S. Jiang, S. and Zhao, Bao.(2023). Application Analysis of GPS Surveying and Mapping Technology in Engineering Surveying and Mapping. Journal of Theory and Practice of Engineering Science 3(11):7-13.

- Canbaz, O. Canbaz, O., Gürsoy, Ö., & Gökce, A. (2018). Detecting Clay Minerals in Hydrothermal Alteration Areas with Integration of ASTER Image and Spectral Data in Kösedag-Zara (Sivas), Turkey. Journal of the Geological Society of India, 91(4), 483–488.

- Thin, L. N., Ting, L. Y., Husna, N. A., & Husin, M. H. (2016). GPS systems literature: inaccuracy factors and effective solutions. Int. J. Comput. Netw. Commun, 8(2), 123-131.

- Idris, A. N., Suldi, A. M., Hamid, J. R. A., & Sathyamoorthy, D. (2013). Effect of radio frequency interference (RFI) on the Global Positioning System (GPS) signals. IEEE 9th International Colloquium on Signal Processing and Its Applications.

- August, P., Michaud, J., Labash, C., & Smith, C. (n.d.). GPS for environmental applications: Accuracy and precision of locational data ... - ASPRS. Available online: https://www.asprs.org.

- What is remote sensing and what is it used for? USGS Science for a Changing World. (n.d.). Available online: https://www.usgs.gov.

- Babakan, S. & Oskouei, M. (2014). Integrated use of multispectral remote sensing and GIS for primary gold favorability mapping in Lahroud Region (NW Iran). Journal of Tethys. 2. 228-241.

- Shendi, El-Arabi. (2020). Vertical electrical sounding in the investigation of subsurface gravel deposits in arid environments—a case study, El-Salhayia plain, West Ismailia area, Egypt. Arabian Journal of Geosciences. 13. 10.1007/s12517-020-05877-8.

- Omer, I. K. (2021). Gravity Method. ResearchGate. Available online: https://www.researchgate.net.

- Mariita, N.O. (2007). The Magnetic Method. Available online: https://orkustofnun.is.

- Electromagnetic Induction (EM) Surveys. Forest Environmental Services, Inc. (n.d.). Available online: http://www.fesinc.net.

- Mutter, J., & Lerner-Lam, A. (2020). Seismology. AccessScience.

- Soller, D. R. (2004). Introduction to Geologic Mapping. U.S. Geological Survey. Available online: https://www.usgs.gov.

- Petrology & Mineralogy. Geological Sciences. (2018). Available online: https://www.colorado.edu.

- A Brief Introduction on Thin Section Preparation. National Petrographic Service. (n.d.). Available online: http://www.nationalpetrographic.com.

- Gatiboni, L. 2022. Soils and Plant Nutrients, Chapter 1. In: K.A. Moore, and. L.K. Bradley (eds). North Carolina Extension Gardener Handbook, 2nd ed. NC State Extension, Raleigh, NC. Available online: https://content.ces.ncsu.edu.

- Harbitz, A.(2019). A zigzag survey design for continuous transect sampling with guaranteed equal coverage probability. Fisheries and Research.

- Pham. T.N., Acharya, P., Bachina, S., Osterloh, K., Nguyen, K.D.(2023). Deep-Learning Framework for Optimal Selection of Soil Sampling Sites. Available online: https://www.researchgate.net/.

- Food and agriculture organization of the united nations.(2015). World reference base for soil resources: International soil classification system for naming soils and creating legends for soil maps. WORLD SOIL RESOURCES REPORTS. Available online: https://www.fao.org.

- ASTM C326. (2018). Standard test method for drying and firing shrinkages of ceramic Whiteware clays. ASTM International - Standards Worldwide. Available online: https://www.astm.org.

- Tiongson, JM., Adajar, M.A.Q. (2020). Compaction Characteristics of a Fine-Grained Soil Potential for Landfill Liner Application. International Journal of GEOMATE, Vol.19, Issue 71, pp. 211 - 218.

- Bouh, H.A.(2020). X-Ray fluorescence Technique Analysis (Principles and instrumentations). Muruz. Available online: https://www.researchgate.net.

- Bunaciu, A.A., Udriştioiu, E.G., & Aboul-Enein, H.Y (2015). X-Ray Diffraction: Instrumentation and Applications. Critical Reviews in Analytical Chemistry, 45:4, 289-299.

- Rajapakse, R.(2016). Soil Laboratory Testing. Geotechnical Engineering Calculations and Rules of Thumb (Second Edition), Pages 47-60.

- ASTM D4318.(2018). Standard test methods for liquid limit, plastic limit, and plasticity index of Soils. ASTM International - Standards Worldwide. Available online: https://www.astm.org.

- Hobbs, P.R.N. Hobbs, P.R.N., Jones, L.D., Kirkham, M.P., Gunn, & D.A., Entwisle, D.C.(2018). Shrinkage limit test results and interpretation for clay soils. Quarterly Journal of Engineering Geology and Hydrogeology, Volume 52, Pages 220 - 229.

- Hoogsteen, M.J.J., Lantinga, E.A., Bakker, & E.J., Tittonell, P.A.(2018). An Evaluation of the Loss-on-Ignition Method for Determining the Soil Organic Matter Content of Calcareous Soils. Communications In Soil Science and Plant Analysis.

- ASTM C373.(2014). Standard test method for water absorption, bulk density, apparent porosity, and apparent specific gravity of fired Whiteware products. ASTM International - Standards Worldwide. Available online: https://www.astm.org.

- Kramarenko, V.V., Nikitenkov, A.N., Matveenko, I.A., Molokov, V.Y., & Vasilenko, Y.S.(2016). Determination of water content in clay and organic soil using microwave oven. IOP Conference Series: Earth and Environmental Science, Volume 43, XX International Scientific Symposium of Students, Postgraduates and Young Scientists on “Problems of Geology and Subsurface Development”. [CrossRef]

- XRite Inc.(2025). A Guide to Understanding Color Communication: Part 3. X-Rite Inc. h. Available online: https://www.pac.gr.

- ASTM C1161. (2023). Standard test method for flexural strength of advanced ceramics at ambient temperature. ASTM International - Standards Worldwide. Available online: https://www.astm.org.

- Mylan, R., Maharaj, C., Maharaj, R.(2017). Creating the Optimal Product Formula for use by A Heavy Clay BlockManufacturer. Clay Research, Vol. 35, No. 2, pp. 71-83. Available online: https://www.researchgate.net.

- Kohut, W. (1986). Process for preparing a clay slurry. Available online: https://patents.google.com.

- Cáceres, J. R., Pineda-Rodríguez, J. R., & Rojas-Suárez, J. P. (2021). Analysis of the ratio between the plasticity of clay and the expansion capacity by changes in humidity and temperature. Journal of Physics: Conference Series, 2139(1), 012010.

- Alam, T. (n.d.). Composition of Bricks - Function of Ingredients. Civil Engineering. Available online: https://civiltoday.com.

- Torres, A., Basto, R., Chaparro, A., & Sánchez, Jorge. (2019). Physicochemical and mineralogical properties of clays used in ceramic industry at North East Colombia. Available online: https://www.researchgate.net.

- Teixeira, Silvio & Souza, S. & Nobre, M.. (2004). Physical and Mechanical Properties of ceramics from Clays of the West Region of São Paulo State-Brazil. Cerâmica. 50. 10.1590/S0366-69132004000300015.

- Yami, A. & Umaru, S. (2007). Characterization of Some Nigerian Clays as Refractory Materials for Furnace Lining. Continental Journal of Engineering Sciences. Vol. 2.. Pp. 30-35. Available online: https://www.researchgate.net.

- Bin, X., Li. X., Lu, J.(2022). Effect of Clay Mineralogy and Soil Organic Carbon in Aggregates under Straw Incorporation. Agronomy.

- Ndjigui, P.-D., Mbey, J. A., Fadil-Djenabou, S., Onana, V. L., Bayiga, E. C., Enock Embom, C., & Ekosse, G.-I. (2021). Characteristics of kaolinitic raw materials from the Lokoundje River (Kribi, Cameroon) for ceramic applications. Applied Sciences, 11(13), 6118.

- Dong, Z., Sun, & Q., Zhang, W.(2021). Physical and Mechanical Properties of Clay After Heating in Different Oxygen Levels and Cooling With Different Methods. Research Square.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).