1. Introduction

Hydrodynamic cavitation occurs when, in a moving fluid, the pressure drops below the vapor tension (ρᵥ), causing the formation of bubbles that, upon collapse, rapidly release energy in the form of shock waves. The pioneering work of Brennen [

1] and the contributions of Franc and Michel [

2] provided the theoretical foundations for understanding this phenomenon, which is now applied in industrial processes such as the extraction of active ingredients, sanitation, and the optimization of chemical reactions [

3,

4].

Bernoulli’s equation, expressed as:

is fundamental for understanding pressure recovery along the flow; however, Venturi tubes with circular sections show limitations in generating extremely high pressure gradients. The Reuleaux Triangle (VRA from Venturi, Reuleaux, and Albanese), stands out precisely for its high Perimeter/Area ratio, which allows for a more rapid and intense pressure recovery, thereby increasing the pressure difference (Δp). Experimental and numerical studies have shown that an increase in Δp reduces collapse times and increases the implosion speed of bubbles [

5,

6,

7], intensifying the cavitation phenomenon and enhancing its energetic effectiveness [

8,

9]. These results, together with further research on future applications, suggest that the VRA may offer more efficient and sustainable solutions for water treatment and the extraction of bioactive compounds [

10,

11].

This contribution is theoretical and methodological, focusing on a comparative geometrical analysis of the Perimeter-to-Area ratio between the Reuleaux triangle and circular cross-sections, in order to highlight its influence on the key parameters of controlled cavitation.

2. Mathematical Comparison Between Circular Venturi and VRA

In order to quantitatively assess the advantages of the Venturi Reuleaux Triangle (VRA) over the traditional circular Venturi, it is essential to compare their key geometric and physical parameters. This section presents a detailed mathematical analysis, focusing on perimeter-to-area ratios, pressure differences, bubble dynamics, and the resulting effects on cavitation performance.

2.1. Perimeter and Area

As highlighted in (2), the VRA exhibits a higher P/A ratio, meaning that per unit area the fluid interacts with a larger surface, generating more intense pressure gradients.

2.2. Pressure Difference (Δp)

The pressure difference, defined as the difference between the recovery pressure and the vapor pressure, is commonly expressed by Bernoulli’s equation (1). In traditional devices, this Δp is limited by classical geometries, whereas the VRA, thanks to its higher Perimeter/Area configuration, enables a more rapid pressure recovery and consequently a significant increase in Δp. Studies conducted by

Shi et al. [

12] have shown that higher pressure gradients can intensify the cavitation phenomenon, while

Advani and Arefmanesh [

13] demonstrated that a high Δp contributes to greater efficiency in extraction and purification processes. These findings suggest that the VRA, with its increased Δp, offers operational advantages over circular models.

2.3. Collapse Time and Velocity

Several studies, beginning with those of Board and Kimpton [

14], have highlighted the importance of the relationship between Δp and bubble behavior. According to these studies, an increase in Δp results in a reduction in collapse time—making the process faster—and a higher implosion velocity of the bubbles. Naidu et al. [

15] further elaborated on this concept, emphasizing that devices with high Δp, such as the VRA, generate more violent and rapid bubble implosions. This effect is crucial for industrial applications that require a strong energy release, for example, to break down cellular structures during the extraction of bioactive compounds or to enhance water purification processes.

2.4. Shock Pressure

The shock pressure developed during bubble collapse is a key indicator of cavitation effectiveness. For example, Charrière and Goncalvès [

16] conducted experiments demonstrating that an increase in the pressure gradient—i.e., a higher Δp—leads to shock waves of significantly greater intensity. Similarly, Qiu et al. [

17] developed numerical models that confirm that a higher collapse velocity, directly correlated with an elevated Δp, translates into intensified shock pressure. These observations clearly indicate that the VRA, capable of generating a higher Δp, produces much more violent bubble implosions—essential for industrial applications that require a robust energy release to break up aggregates or cellular structures. Such evidence is further supported by studies showing that greater pressure gradients result in more intense shock pressure, significantly enhancing the overall effectiveness of cavitation applications [

18].

3. Comparison of Operational Performance

It is clear that, at equal flow rate, the VRA generates a higher Δp compared to the circular Venturi tube. This increase, achieved through a more rapid pressure recovery, leads to shorter bubble collapse times and a higher implosion velocity [

14,

17]. These effects combine to produce an intensified shock pressure, a fundamental element for improving cavitation effectiveness [

16,

17]. In practical terms, the VRA enables more violent bubble implosions that can break down cellular structures or contaminant aggregates, thus enhancing processes such as the extraction of bioactive compounds and water treatment [

13,

18]. These results, supported by both theoretical models and experimental evidence, demonstrate the operational superiority of the VRA over the circular model.

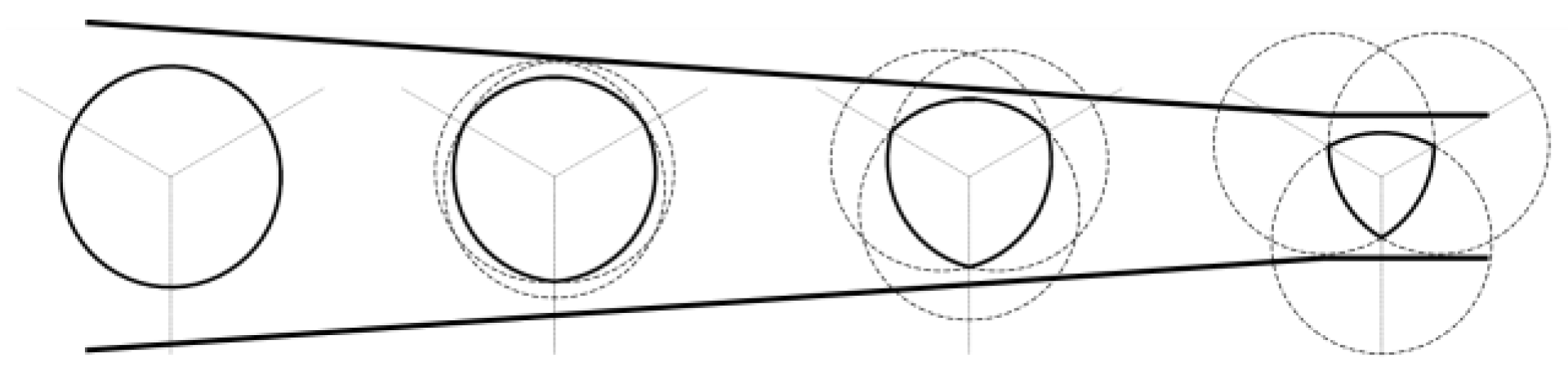

4. Transition from Circular Section to VRA

It is appropriate to describe the geometric transformation process from the classic circular-section Venturi tube to the new VRA.

Figure 1.

Transition from the circular section to the Reuleaux section.

Figure 1.

Transition from the circular section to the Reuleaux section.

The figure shows how a tube with a circular section can be gradually transformed into a VRA section. This transformation can be achieved through electroerosion.

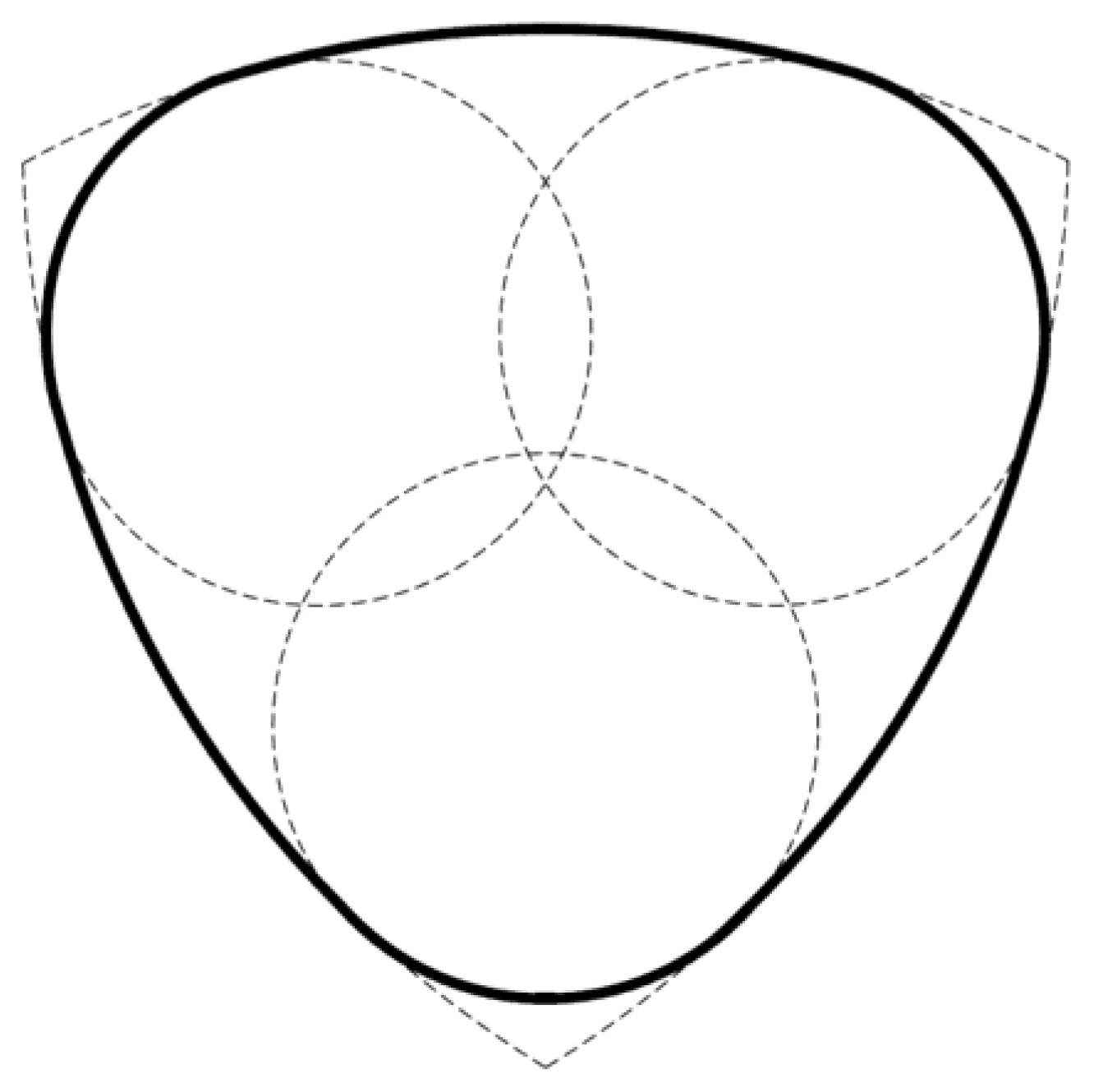

5. Internal Section

A possible internal configuration is illustrated, characterized by curvatures designed to evenly distribute energy during bubble collapse and to reduce the risk of friction, erosion, and the accumulation of solid particles.

Figure 2.

internal geometry of the VRA with curvatures designed to reduce friction, erosion, and solid deposits.

Figure 2.

internal geometry of the VRA with curvatures designed to reduce friction, erosion, and solid deposits.

This solution was designed because sharp angles can create zones of stress concentration Yang et al. [

19]. Shad’s work highlights the importance of developing configurations that minimize the effects of friction and erosion, while Jiang et al. [

20] show that an accurate internal design increases durability and operational reliability. Thus, the VRA not only intensifies the cavitation phenomenon due to the higher Δp, but also ensures high performance under extreme operating conditions.

6. Future Applications

The potential applications of the VRA extend to numerous industrial sectors. In the food industry, for instance, the VRA could revolutionize the extraction of bioactive compounds from plant raw materials, improving both yield and extract quality through its ability to facilitate the breakdown of cellular structures [

3,

4,

21]. Similarly, in the beverage sector, the VRA can optimize both sterilization and mixing processes, reducing processing times and ensuring higher-quality final products [

8,

10,

22,

23,

24]. In the pharmaceutical field, the adoption of the VRA for the extraction of active ingredients and the formulation of emulsions and suspensions promises to enhance product efficacy and bioavailability [

4,

25,

26]. Furthermore, the VRA’s ability to generate intense shock waves makes it particularly suitable for water treatment and purification, facilitating the removal of both organic and inorganic contaminants [

9,

18,

27,

28].

In the future, pilot tests will be necessary to verify the VRA’s performance in the field. Yang et al. [

19] underscore the importance of developing configurations that reduce friction and erosion effects, ensuring consistent performance, while Jiang et al. [

20] suggest that refined geometric modifications can intensify chemical reactions in industrial processes. These findings, together with numerous experimental and theoretical studies, open new prospects for the industrial application of the VRA.

7. Conclusions

The Venturi Reuleaux Triangle (VRA) represents a significant evolution compared to the traditional circular Venturi tube, thanks to its high Perimeter/Area ratio that enables the generation of more intense pressure gradients and more violent bubble collapses. By adopting this configuration, the VRA achieves a higher Perimeter/Area ratio, which accounts for the increase in pressure difference (Δp) observed in the studies of Shi et al. [

12] and Advani and Arefmanesh [

13].

The analyses by Board and Kimpton [

14] indicate that a higher Δp leads to shorter collapse times and a greater collapse velocity, thereby generating shock waves of higher intensity. This aspect is further confirmed by the experimental work of Charrière and Goncalvès [

16] and the numerical models developed by Qiu et al. [

17], which demonstrate that higher pressure gradients translate into intensified shock pressure—significantly improving the effectiveness of cavitation processes. Similarly, studies by Yang et al. [

19] emphasize the importance of developing configurations that reduce friction and erosion effects, ensuring performance stability over time. These results suggest that, thanks to its innovative configuration, the VRA may prove to be superior and more efficient compared to traditional circular models.

Author Statements

Ethical approval: The conducted research is not related to either human or animal use. Conflict of interest: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Acknowledgement: The authors declare that they have nobody or no-company to acknowledge. Author contributions: The authors declare that they have equal right on this paper. Funding information: The authors declare that there is no funding to be acknowledged. Data availability statement: The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.

References

- Brennen, C.E. (1995). Cavitation and Bubble Dynamics. Oxford University Press: Oxford, UK.

- Franc, J.P.; Michel, J.M. (2004). Fundamentals of Cavitation. Kluwer Academic Publishers: Dordrecht, The Netherlands.

- Soyama, H.; Hiromori, K.; Shibasaki-Kitakawa, N. (2024). Simultaneous extraction of caffeic acid and production of cellulose microfibrils from coffee grounds using hydrodynamic cavitation in a Venturi tube. Ultrason. Sonochem., 108, 106964. [CrossRef]

- Manoharan, D.; Zhao, J.; Ranade, V.V. (2024). Cavitation technologies for extraction of high value ingredients from renewable biomass. TrAC Trends Anal. Chem., 174, 117682. [CrossRef]

- Galloni, M.G.; Zhao, J.; Karri, S.; Ranade, V.V. (2025). Applications and applicability of the cavitation technology. Curr. Opin. Chem. Eng., 48, 101129. [CrossRef]

- Li, M.; Bussonnière, A.; Bronson, M.; Xu, Z.; Liu, Q. (2019). Study of Venturi tube geometry on the hydrodynamic cavitation for the generation of microbubbles. Miner. Eng., 132, 268–274. [CrossRef]

- Ding, W.; Tan, Z.; Yang, T.; et al. (2024). A comprehensive study on the effects of annular protrusion for cavitation intensification in Venturi tubes. Chem. Eng. J., 498, 155306. [CrossRef]

- Garcia Bustos, K.A.; Rossetti, C.; Frascarelli, D.; Brunori, G. (2024). Hydrodynamic cavitation as a promising technology for fresh produce-based beverages processing. Innov. Food Sci. Emerg. Technol., 96, 103784. [CrossRef]

- Islam, M.S.; Ranade, V.V. (2024). Enhancing BMP and digestibility of DAF sludge via hydrodynamic cavitation. Chem. Eng. Process., 198, 109733. [CrossRef]

- Meneguzzo, F.; Albanese, L.; Zabini, F. (2021). Hydrodynamic Cavitation in Beer and Other Beverage Processing. In Innovative Food Processing Technologies; Elsevier: pp. 369–394. [CrossRef]

- Zhu, J.; et al. (2017). Unsteady cavitation characteristics of liquid nitrogen flows through venturi tube. Int. J. Heat Mass Transf., 112, 544–552. [CrossRef]

- Shi, H.; Li, M.; Nikrityuk, P.; Liu, Q. (2019). Experimental and numerical study of cavitation flows in Venturi tubes: From CFD to an empirical model. Chemical Engineering Science, 207, 672–687. [CrossRef]

- Advani, S.G.; Arefmanesh, A. (1993). Bubble growth and collapse in viscoelastic liquids. Advances in Transport Processes. 445–499. [CrossRef]

- Board, S.J.; Kimpton, A.D. (1974). Spherical vapour bubble collapse. Chemical Engineering Science. 29(3), 859–862. [CrossRef]

- Naidu, D.V.P.; Rajan, R.; Kumar, R.; Gandhi, K.S.; Arakeri, V.H.; Chandrasekaran, S. (1994). Modelling of a batch sonochemical reactor. Chemical Engineering Science. 49(6), 877–888. [CrossRef]

- Charrière, B.; Goncalvès, E. (2017). Numerical investigation of periodic cavitation shedding in a Venturi. International Journal of Heat and Fluid Flow. 64, 41–54. [CrossRef]

- Qiu, N.; Xu, P.; Zhu, H.; et al. (2023). Effect of micro vortex generators on cavitation collapse and pressure pulsation: An experimental investigation. Ocean Engineering. 288(Pt 1), 116060. [CrossRef]

- Yuan, G.; Ni, B.; Wu, Q.; et al. (2024). Experimental study on ice breaking by a cavitating water jet in a Venturi structure. Applied Thermal Engineering. 239, 122095. [CrossRef]

- Qing Yang; Mingming Chen; Chengqian Pei; Bo Liu; Meng Zhao; Xuanjun Wang; Zhe Lin; Linmin Li. (2025). Experimental and Eulerian-Lagrangian numerical investigation on cavitation erosion characteristics in Venturi pipes with different divergent angles. Ultrasonics Sonochemistry. 114, 107278. [CrossRef]

- Jiang, Y.; Li, M.; Duan, Y.; Liu, Q. (2022). Investigation of cavitation-induced erosion in a Venturi channel with micro-jets: Experimental and numerical approach. Wear. 494–495, 204255. [CrossRef]

- Albanese, L.; Ciriminna, R.; Meneguzzo, F.; Pagliaro, M. (2017). Beer-brewing powered by controlled hydrodynamic cavitation: Theory and real-scale experiments. Journal of Cleaner Production. 142, 1457–1470. [CrossRef]

- Wu, Z.; Ferreira, D.F.; Crudo, D.; Bosco, V.; Stevanato, L.; Costale, A.; Cravotto, G. (2019). Plant and Biomass Extraction and Valorisation under Hydrodynamic Cavitation. Processes. 7(12), 965. [CrossRef]

- Arya, S.S.; More, P.R.; Ladole, M.R.; Pegu, K.; Pandit, A.B. (2023). Non-thermal, energy efficient hydrodynamic cavitation for food processing, process intensification and extraction of natural bioactives: A review. Ultrasonics Sonochemistry. 98, 106504. [CrossRef]

- Meneguzzo, F.; Albanese, L.; Zabini, F. (2021). Hydrodynamic Cavitation in Beer and Other Beverage Processing. In Innovative Food Processing Technologies; Elsevier: pp. 369–394. [CrossRef]

- Alex Sebastian Raj. (2023). Advancing phytonutrient extraction via cavitation-based methodology: Exploring catechin recovery from Camellia sinensis leaves. Biocatalysis and Agricultural Biotechnology. 54,102895. [CrossRef]

- Boček, Ž.; Procházka, J.; Málek, J.; Szymański, P.; Veverka, P. (2024). Kelvin–Helmholtz instability as one of the key features for fast and efficient emulsification by hydrodynamic cavitation. Ultrasonics Sonochemistry. 108, 106970. [CrossRef]

- Kosel, J.; Šuštaršič, M.; Petkovšek, M.; Gregorc, A.; Hočevar, M.; Dular, M. (2020). Application of (super)cavitation for the recycling of process waters in paper producing industry. Ultrasonics Sonochemistry. 64, 105002. [CrossRef]

- Taşdemir, A.; Cengiz, İ.; Yildiz, E.; Bayhan, Y.K. (2020). Investigation of ammonia stripping with a hydrodynamic cavitation reactor. Ultrasonics Sonochemistry. 60, 104741. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).