Submitted:

30 June 2024

Posted:

02 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

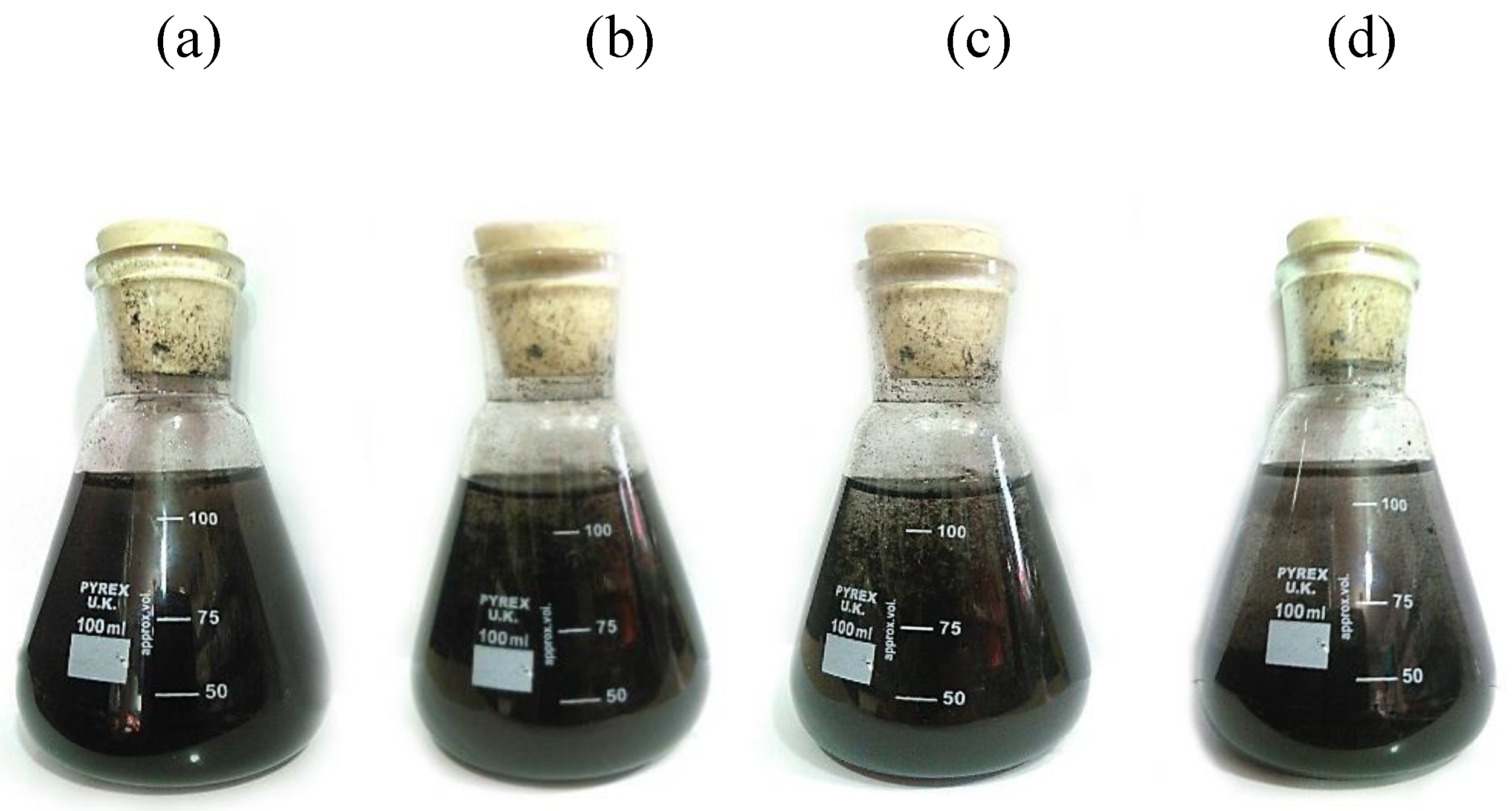

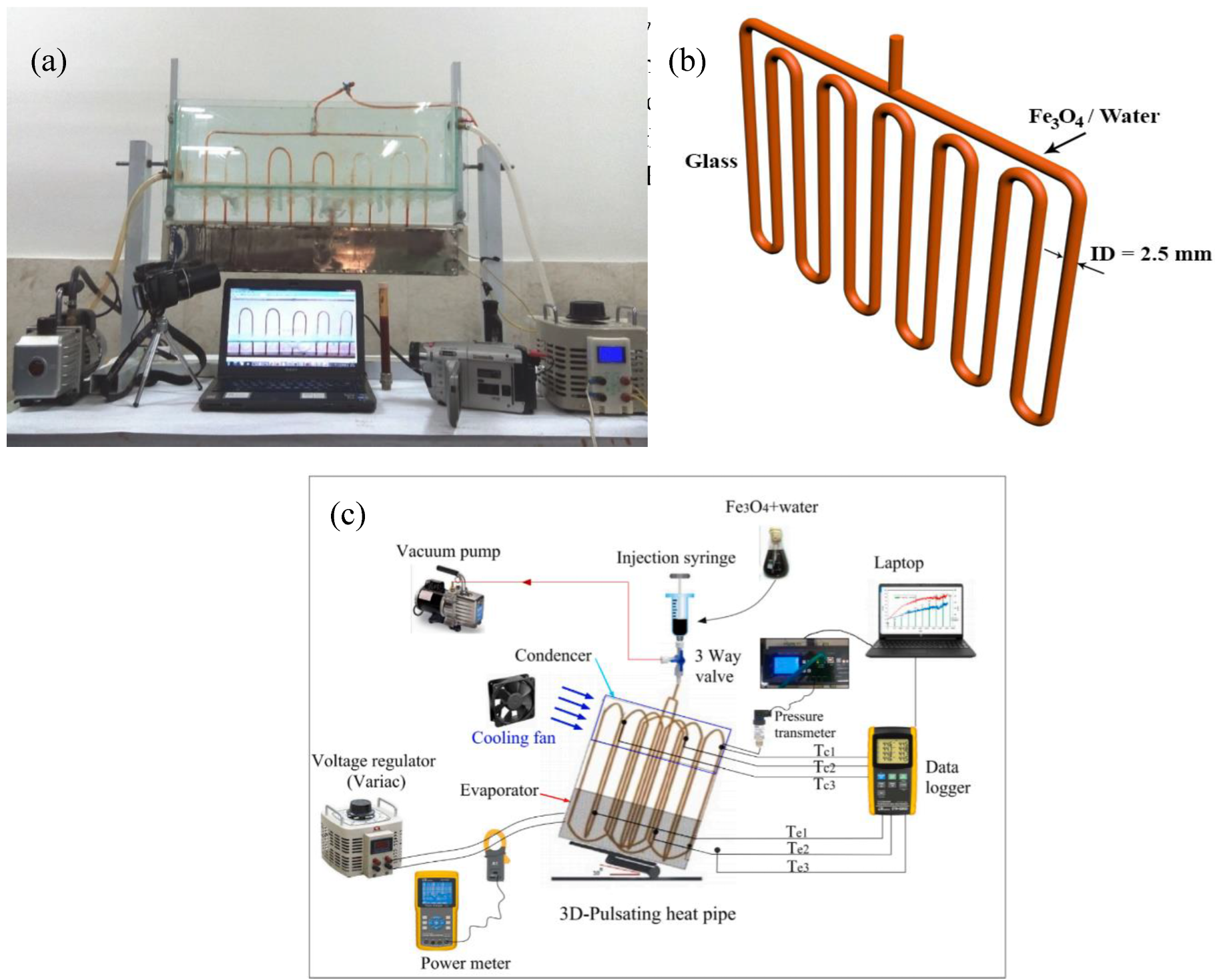

2. Experimental Section

3. Methodology and Reproducibility

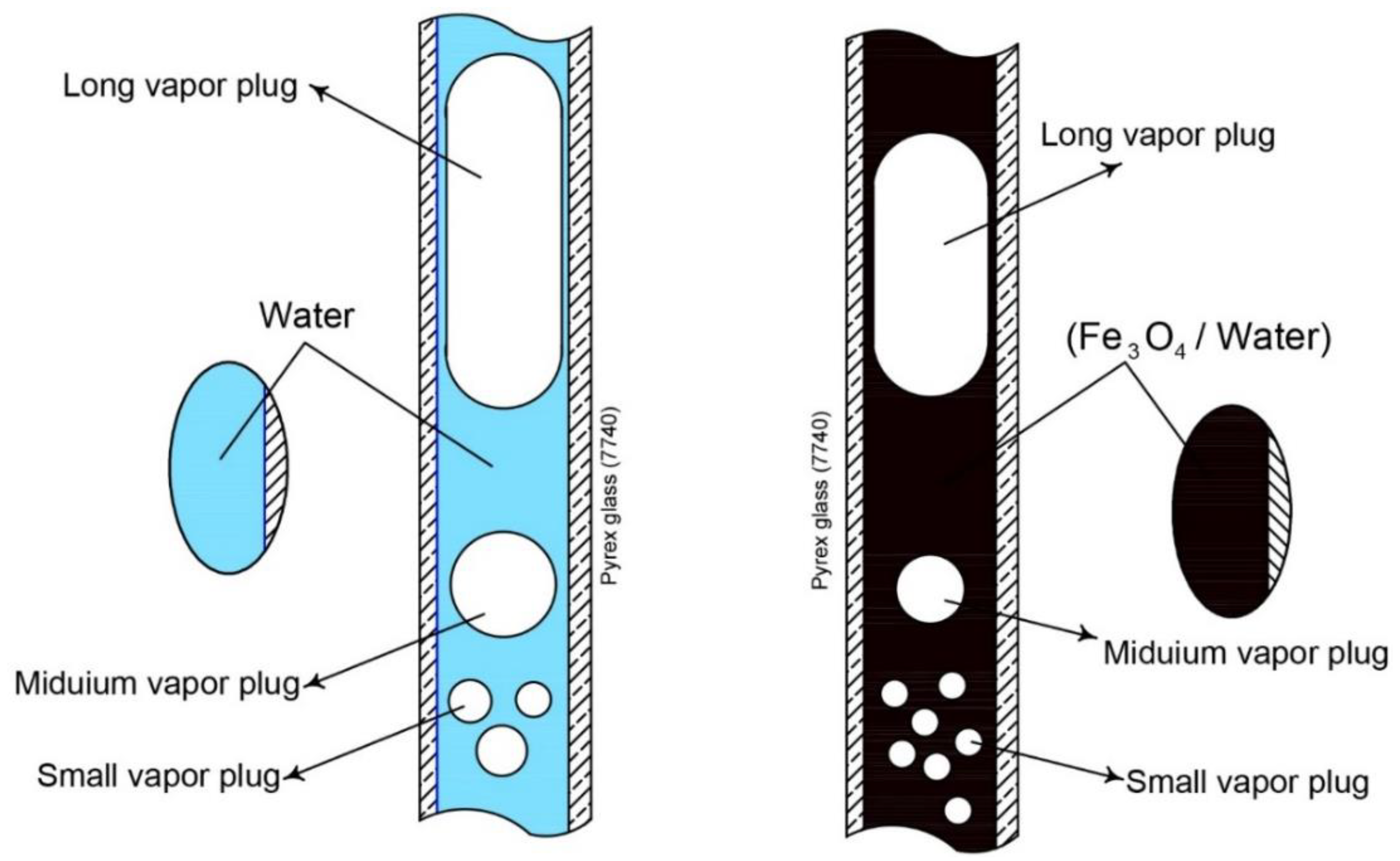

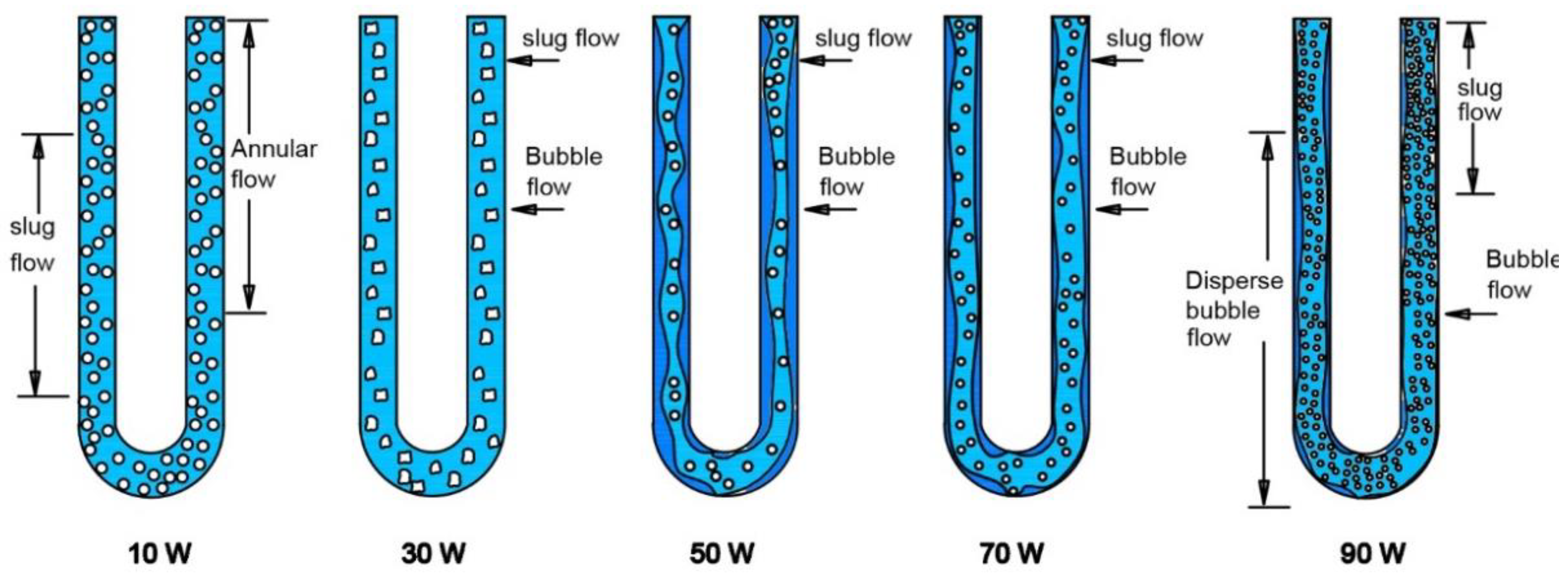

4. Visualization Results

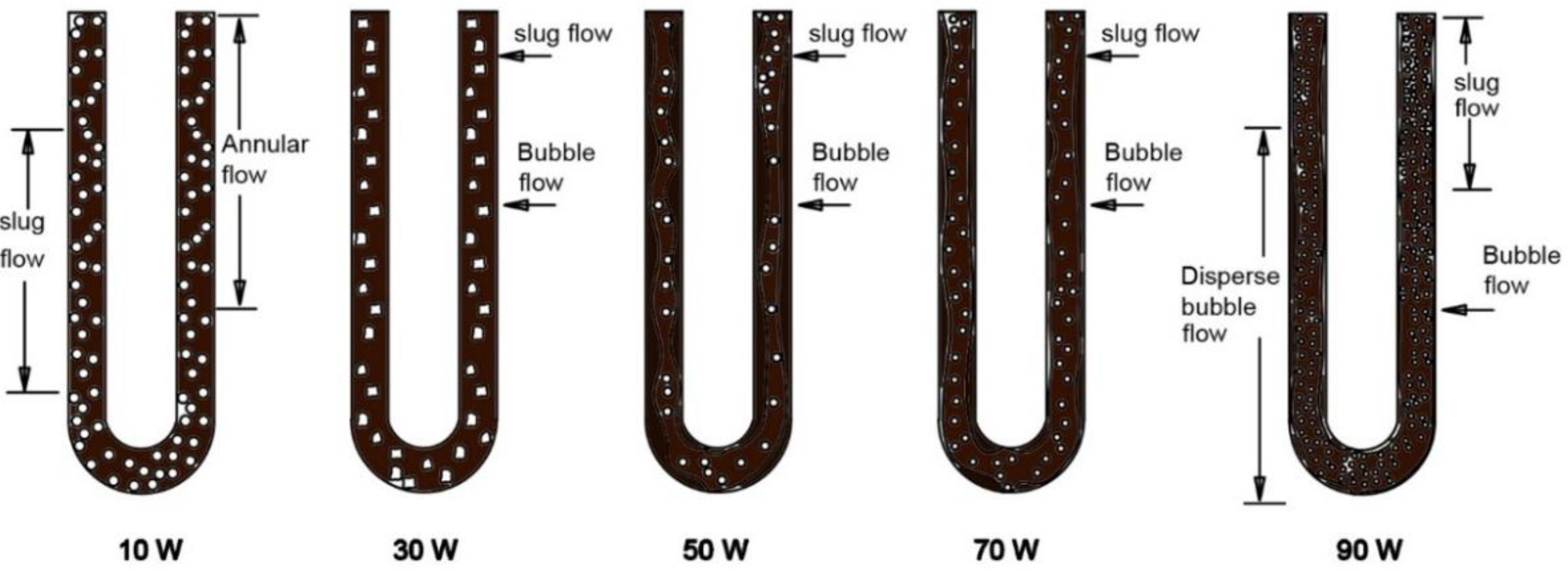

4.1. Flow Patterns

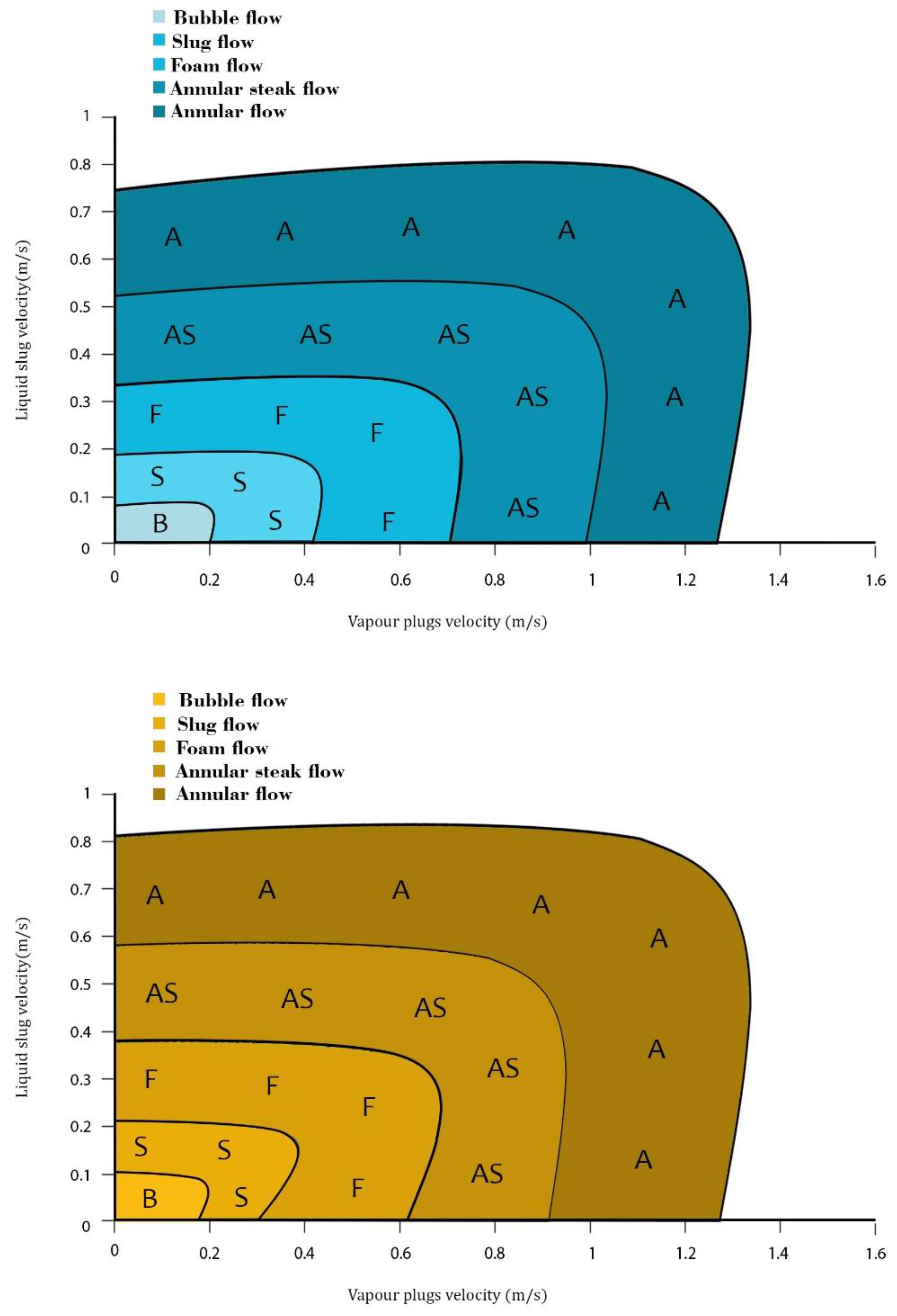

4.2. Mapping of Flow Patterns

5. Conclusions

- The vapor slug length decreased rapidly with increasing slug velocity, facilitating the determination of the main regime for each flow pattern using the proposed map.

- Fe3O4/water mixture exhibited reduced dimensions for liquid and vapor slugs compared to pure water, attributed to higher non-dimensional parameters specific to acetone, indicating more favorable fluid flow within the PHP.

- The internal fluid flow in the PHP was found to be more complex than single bubble-liquid slug flow, with various distinct flow patterns observed, contributing to an enhanced net heat transfer coefficient.

- PHPs displayed self-adjusting characteristics for flow patterns to meet increasing heat input demands, notably demonstrated in 50% filling ratio tests.

- The dynamic circulation of Fe3O4/water in the PHP facilitated efficient heat transfer from the evaporator to the condenser, showcasing diverse phase change phenomena in the heating section.

- Fe3O4/water velocity correlated directly with heat input magnitude, influencing prevailing flow patterns within the PHP significantly.

Funding

Author contribution

Ethical approval

Data availability

Declaration of competing interest

References

- H. Akachi, Pulsating heat pipes, Proc. 5th International Heat Pipe Symp., 1996, 1996, pp. 208-217.

- H. Xian, W. Xu, Y. Zhang, X. Du, Y. Yang, Thermal characteristics and flow patterns of oscillating heat pipe with pulse heating. , International Journal of Heat and Mass Transfer 2014, 79, 332–341. [CrossRef]

- Z. Kang, D. Shou, J. Fan, Numerical study of single-loop pulsating heat pipe with porous wicking layer, International Journal of Thermal Sciences 2022, 179, 107614. [CrossRef]

- M. Alhuyi Nazari, M.H. Ahmadi, R. Ghasempour, M.B. Shafii, How to improve the thermal performance of pulsating heat pipes: A review on working fluid, Renewable and Sustainable Energy Reviews 2018, 91, 630–638. [CrossRef]

- L. Krambeck, K.G. Domiciano, L.A. Betancur-Arboleda, M.B.H. Mantelli, Novel flat plate pulsating heat pipe with ultra sharp grooves, Applied Thermal Engineering 2022, 211, 118509. [CrossRef]

- X. Liu, Y. Chen, M. Shi, Dynamic performance analysis on start-up of closed-loop pulsating heat pipes (CLPHPs), International Journal of Thermal Sciences 2013, 65, 224–233. [CrossRef]

- V. Ayel, M. Slobodeniuk, R. Bertossi, A. Karmakar, F. Martineau, C. Romestant, Y. Bertin, S. Khandekar, Thermal performances of a flat-plate pulsating heat pipe tested with water, aqueous mixtures and surfactants, International Journal of Thermal Sciences 2022, 178, 107599. [CrossRef]

- J. Qu, Q. Wang, Experimental study on the thermal performance of vertical closed-loop oscillating heat pipes and correlation modeling, Applied Energy 2013, 112, 1154–1160. [CrossRef]

- Y. Xu, Y. Xue, H. Qi, W. Cai, Experimental study on heat transfer performance of pulsating heat pipes with hybrid working fluids, International Journal of Heat and Mass Transfer 2020, 157, 119727. [CrossRef]

- A. A. Sarvari, S.Z. Heris, M. Mohammadpourfard, S.B. Mousavi, P. Estellé, Numerical investigation of TiO2 and MWCNTs turbine meter oil nanofluids: Flow and hydrodynamic properties, Fuel 2022, 320, 123943. [CrossRef]

- S. B. Mousavi, S.Z. Heris, P. Estellé, Viscosity, tribological and physicochemical features of ZnO and MoS2 diesel oil-based nanofluids: An experimental study, Fuel 2021, 293, 120481. [CrossRef]

- H. Ebadiyan, S.Z. Heris, S.B. Mousavi, S.H. Nami, M. Mohammadpourfard, The influence of nano filter elements on pressure drop and pollutant elimination efficiency in town border stations, Scientific Reports 2023, 13, 18793. [CrossRef] [PubMed]

- H. Pourpasha, S.Z. Heris, S.B. Mousavi, Thermal performance of novel ZnFe2O4 and TiO2-doped MWCNT nanocomposites in transformer oil, Journal of Molecular Liquids 2024, 394, 123727. [CrossRef]

- Z. Karimi Shoar, H. Pourpasha, S. Zeinali Heris, S.B. Mousavi, M. Mohammadpourfard, The effect of heat transfer characteristics of macromolecule fouling on heat exchanger surface: A dynamic simulation study, The Canadian Journal of Chemical Engineering 2023, 101, 5802–5817. [CrossRef]

- S. B. Mousavi, H. Pourpasha, S.Z. Heris, High-temperature lubricity and physicochemical behaviors of synthesized Cu/TiO2/MnO2-doped GO nanocomposite in high-viscosity index synthetic biodegradable PAO oil, International Communications in Heat and Mass Transfer 2024, 156, 107642.

- O. Khouri, H.R. Goshayeshi, S.B. Mousavi, S. Hosseini Nami, S. Zeinali Heris, Heat transfer enhancement in industrial heat exchangers using graphene oxide nanofluids, ACS Omega 2024.

- S. Hosseini Nami, S.B. Mousavi, Nitrate removal performance of different granular adsorbents using a novel fe-exchanged nanoporous clinoptilolite, Industrial & Engineering Chemistry Research 2023, 62, 3659–3671.

- S. Z. Heris, M. Etemadi, S.B. Mousavi, M. Mohammadpourfard, B. Ramavandi, Preparation and characterizations of TiO2/ZnO nanohybrid and its application in photocatalytic degradation of tetracycline in wastewater, Journal of Photochemistry and Photobiology A: Chemistry 2023, 443, 114893.

- S. B. Mousavi, M. Heidari, F. Rahmani, R.A. Sene, P.T. Clough, S. Ozmen, Highly robust ZrO2-stabilized CaO nanoadsorbent prepared via a facile one-pot MWCNT-template method for CO2 capture under realistic calcium looping conditions, Journal of Cleaner Production 2023, 384, 135579. [CrossRef]

- A. Jalaie, A. Afshaar, S.B. Mousavi, M. Heidari, Investigation of the Release Rate of Biocide and Corrosion Resistance of Vinyl-, Acrylic-, and Epoxy-Based Antifouling Paints on Steel in Marine Infrastructures, Polymers 2023, 15, 3948.

- M. Heidari, M. Tahmasebpoor, S.B. Mousavi, C. Pevida, CO2 capture activity of a novel CaO adsorbent stabilized with (ZrO2+ Al2O3+ CeO2)-based additive under mild and realistic calcium looping conditions, Journal of CO2 Utilization 2021, 53, 101747. [CrossRef]

- M. Heidari, S.B. Mousavi, F. Rahmani, R.A. Sene, Eco-friendly, sustainable and porous eggshell/tea waste-derived CaO nanoparticles as a high-temperature CO2 sorbent: Fabrication and textural/morphological evaluation, Journal of Industrial and Engineering Chemistry 2024, 134, 169–180. [CrossRef]

- M. Heidari, S.B. Mousavi, F. Rahmani, P.T. Clough, S. Ozmen, The novel Carbon Nanotube-assisted development of highly porous CaZrO3-CaO xerogel with boosted sorption activity towards high-temperature cyclic CO2 capture, Energy Conversion and Management 2022, 274, 116461. [CrossRef]

- M. Tahmasebpoor, S. Hosseini Nami, M. Khatamian, L. Sanaei, Arsenate removal from contaminated water using Fe2O3-clinoptilolite powder and granule, Environmental technology 2022, 43, 116–130. [CrossRef] [PubMed]

- M. Khatamian, N. Afshar No, S. Hosseini Nami, S. Fazli-Shokouhi, Synthesis and characterization of zeolite A, Fe3O4/zeolite A, and Fe2O3/zeolite A nanocomposites and investigation of their arsenic removal performance, Journal of the Iranian Chemical Society 2023, 20, 1657–1670. [CrossRef]

- M. Khatamian, S.H. Nami, S.G.H. Mosayeb, B. Divband, Preparation and characterization of nano-Fe (OH) 3, its composites with two natural zeolites, and granulation of them for nitrate removal from polluted water, Physica Scripta 2023, 98, 035024. [CrossRef]

- M. Khatamian, E. Dastar, S. Fazli-Shokouhi, S. Hosseini Nami, Synthesis of pure nano Cr2O3 from chromite ore by a novel method and investigation of its composites with bentonite for their photocatalytic properties, Journal of the Iranian Chemical Society 2023, 20, 2805–2819. [CrossRef]

- M. Khatamian, S.K. Derakhshan, S.H. Nami, S. Fazli-Shokouhi, Nitrate removal study of synthesized nano γ-alumina and magnetite-alumina nanocomposite adsorbents prepared by various methods and precursors, Scientific Reports 2024, 14, 7673. [CrossRef] [PubMed]

- F. Yousefi, S.B. Mousavi, S.Z. Heris, S. Naghash-Hamed, UV-shielding properties of a cost-effective hybrid PMMA-based thin film coatings using TiO2 and ZnO nanoparticles: a comprehensive evaluation, Scientific Reports 2023, 13, 7116. [CrossRef] [PubMed]

- M. Heidari, S.B. Mousavi, F. Rahmani, T.M. Aminabhavi, M. Rezakazemi, Insightful textural/morphological evaluation of cost-effective and highly sustainable Ca-Zr-O nanosorbent modified with the waste date kernel as a biomass pore-former for high-temperature CO2 capture, Sustainable Materials and Technologies 2023, 38, e00778.

- A. Gholami, S.B. Mousavi, S.Z. Heris, M. Mohammadpourfard, Highly efficient treatment of petrochemical spent caustic effluent via electro-Fenton process for COD and TOC removal: optimization and experimental, Biomass Conversion and Biorefinery 2023, 1–17.

- M. Ashrafivala, S.B. Mousavi, S.Z. Heris, M. Heidari, M. Mohammadpourfard, H. Aslani, Investigation of H2O2/UV advanced oxidation process on the removal rate of coliforms from the industrial effluent: A pilot-scale study, International Journal of Hydrogen Energy 2022, 47, 33530–33540. [CrossRef]

- M. Heidari, S.B. Mousavi, F. Rahmani, P.T. Clough, S. Ozmen, The MWCNT-assisted development of highly porous Zr-decorated CaO xerogel with boosted sorption activity towards high-temperature cyclic CO2 capture, Available at SSRN 4119156.

- M. Alhuyi Nazari, R. Ghasempour, M.H. Ahmadi, A review on using nanofluids in heat pipes, Journal of Thermal Analysis and Calorimetry 2019, 137, 1847–1855. [CrossRef]

- R. Javadpour, S.Z. Heris, Y. Mohammadfam, S.B. Mousavi, Optimizing the heat transfer characteristics of MWCNTs and TiO2 water-based nanofluids through a novel designed pilot-scale setup, Scientific Reports 2022, 12, 15154. [CrossRef] [PubMed]

- S. B. Mousavi, S.Z. Heris, M.G. Hosseini, Experimental investigation of MoS2/diesel oil nanofluid thermophysical and rheological properties, International Communications in Heat and Mass Transfer 2019, 108, 104298. [CrossRef]

- H.R. Goshayeshi, S.B. Mousavi, S.Z. Heris, I. Chaer, Insights into Enhanced Thermal Performance: Visualizing Diverse Flow Patterns in Fe3O4/Water Pulsating Heat Pipes, (2024).

- S. Mousavi, S. Heris, P. Estellé, Experimental comparison between ZnO and MoS2 nanoparticles as additives on performance of diesel oil-based nano lubricant. Sci Rep. 2020, 10, 5813.

- S. S. Seyedi, M.R. Shabgard, S.B. Mousavi, S.Z. Heris, The impact of SiC, Al2O3, and B2O3 abrasive particles and temperature on wear characteristics of 18Ni (300) maraging steel in abrasive flow machining (AFM), International Journal of Hydrogen Energy 2021, 46, 33991–34001. [CrossRef]

- E. Sobhani, S.Z. Heris, S.B. Mousavi, The synergistic effect of intumescent fire-resistive paint containing TiO2 nanoparticles and chlorinated paraffin onto atmospheric-metallic substrates, ChemistrySelect 2022, 7, e202203513. [CrossRef]

- S.B. Mousavi, S.Z. Heris, Experimental investigation of ZnO nanoparticles effects on thermophysical and tribological properties of diesel oil, International Journal of Hydrogen Energy 2020, 45, 23603–23614. [CrossRef]

- S. B. Mousavi, S.Z. Heris, P. Estellé, Experimental comparison between ZnO and MoS2 nanoparticles as additives on performance of diesel oil-based nano lubricant, Scientific reports 2020, 10, 5813. [CrossRef] [PubMed]

- S.Z. Heris, H. Bagheri, S.B. Mousavi, S. Hosseini Nami, Optimizing nanofluid additives for enhanced thermophysical properties in anionic crude oil for EOR applications, The Canadian Journal of Chemical Engineering 2024.

- M. Kaya, A.E. Gürel, Ü. Ağbulut, İ. Ceylan, S. Çelik, A. Ergün, B. Acar, Performance analysis of using CuO-Methanol nanofluid in a hybrid system with concentrated air collector and vacuum tube heat pipe, Energy Conversion and Management 2019, 199, 111936. [CrossRef]

- P. Venkataramana, P. Vijaya Kumar, B. Bala Krishna, Thermal and flow performance in a CLPHP with Al2O3/copper nanofluids: Application in microelectronics and power generation, Materials Today: Proceedings (2023).

- A. R. Alizadeh Jajarm, H.R. Goshayeshi, K. Bashirnezhad, Experimental Study of Thermal Performance of a Newly Designed Pulsating Heat Pipe with Fe3O4 Nanofluid-Exposed Magnetic Field and Corrugated Evaporator, International Journal of Thermophysics 2022, 43, 40. [CrossRef]

- S. Naghash-Hamed, N. Arsalani, S.B. Mousavi, Facile copper ferrite/carbon quantum dot magnetic nanocomposite as an effective nanocatalyst for reduction of para-nitroaniline and ortho-nitroaniline, Nano Futures 6(4) (2022) 045003.

- S. Naghash-Hamed, N. Arsalani, S.B. Mousavi, The catalytic reduction of nitroanilines using synthesized CuFe2O4 nanoparticles in an aqueous medium, ChemistryOpen 11 (2022) e202200156.

- S. Naghash-Hamed, N. Arsalani, S.B. Mousavi, Facile fabrication of CuFe2O4 coated with Carbon Quantum Dots nanocomposite as an efficient heterogeneous catalyst toward the reduction of nitroaniline compounds for management of aquatic resources, Journal of Photochemistry and Photobiology A: Chemistry 2023, 443, 114822.

- S. Naghash-Hamed, N. Arsalani, S.B. Mousavi, The catalytic performance of CuFe2O4@ CQD nanocomposite as a high-perform heterogeneous nanocatalyst in nitroaniline group reduction, Scientific Reports 2023, 13, 3329. [CrossRef] [PubMed]

- R. R. Riehl, S.M.S. Murshed, Performance evaluation of nanofluids in loop heat pipes and oscillating heat pipes, International Journal of Thermofluids 2022, 14, 100147. [CrossRef]

- H. Davari, H.R. Goshayeshi, H.F. Öztop, I. Chaer, Experimental investigation of oscillating heat pipe efficiency for a novel condenser by using Fe3O4 nanofluid, Journal of Thermal Analysis and Calorimetry 2020, 140, 2605–2614. [CrossRef]

- K. Jin, Y. Tai, D. Toghraie, M. Hekmatifar, The effects of nanoparticle percentages and an external variable magnetic field on the atomic and thermal behaviors in an oscillating heat pipe via molecular dynamics simulation, Journal of Molecular Liquids 2022, 360, 119570. [CrossRef]

- R. Naik, V. Varadarajan, G. Pundarika, K.R. Narasimha, Experimental investigation and performance evaluation of a closed loop pulsating heat pipe, (2013).

- M. Shafii, S. Arabnejad, Y. Saboohi, H. Jamshidi, Experimental investigation of pulsating heat pipes and a proposed correlation, Heat Transfer Engineering 2010, 31, 854–861. [CrossRef]

- J. Clement, X. Wang, Experimental investigation of pulsating heat pipe performance with regard to fuel cell cooling application, Applied Thermal Engineering 2013, 50, 268–274. [CrossRef]

- J. Qu, H.-Y. Wu, Q. Wang, Experimental investigation of silicon-based micro-pulsating heat pipe for cooling electronics, Nanoscale and Microscale Thermophysical Engineering 2012, 16, 37–49. [CrossRef]

- M. Mohammadi, M. Taslimifar, S. Haghayegh, S.K. Hannani, M.B. Shafii, M.H. Saidi, H. Afshin, Open-loop pulsating heat pipes charged with magnetic nanofluids: powerful candidates for future electronic coolers, Nanoscale and microscale thermophysical engineering 2014, 18, 18–38. [CrossRef]

- R. Naik, L. Pinto, G. Pundarika, K.R. Narasimha, Effects of working fluid on the performance of a multi turn pulsating heat pipe, Journal of Applied Fluid Mechanics 2013, 6, 267–275.

- J. Li, L. Yan, Experimental research on heat transfer of pulsating heat pipe, Journal of thermal Science 2008, 17, 181–185. [CrossRef]

- Y. Zhang, A. Faghri, Advances and unsolved issues in pulsating heat pipes, Heat transfer engineering 2008, 29, 20–44. [CrossRef]

- R. Senjaya, T. Inoue, Bubble generation in oscillating heat pipe, Applied thermal engineering 2013, 60, 251–255. [CrossRef]

- R.-j. Zhu, J.-m. Chen, Y.-p. Long, X.-f. Hu, Oscillation heat transfer dynamic model for new type oscillation looped heat pipe with double liquid slugs, Journal of Central South University 2012, 19, 3194–3201. [CrossRef]

- R. Senjaya, T. Inoue, Oscillating heat pipe simulation considering bubble generation Part I: Presentation of the model and effects of a bubble generation, International Journal of Heat and Mass Transfer 2013, 60, 816–824. [CrossRef]

- Z. Lin, S. Wang, R. Shirakashi, L. Winston Zhang, Simulation of a miniature oscillating heat pipe in bottom heating mode using CFD with unsteady modeling, International Journal of Heat and Mass Transfer 2013, 57, 642–656. [CrossRef]

- W. Jiansheng, W. Zhenchuan, L. Meijun, Thermal performance of pulsating heat pipes with different heating patterns, Applied Thermal Engineering 2014, 64, 209–212. [CrossRef]

- H. R. Goshayeshi, M.R. Safaei, M. Goodarzi, M. Dahari, Particle size and type effects on heat transfer enhancement of Ferro-nanofluids in a pulsating heat pipe, Powder Technology 2016, 301, 1218–1226. [CrossRef]

- A.R.A. Jajarm, H.R. Goshayeshi, K. Bashirnezhad, I. Chaer, D. Toghraie, S. Salahshour, Combined effect of the magnetic field, orientation, and filling ratio on cylindrical pulsating heat pipe using distilled water and distilled water/Fe3O4 nanofluid, Journal of Magnetism and Magnetic Materials 2024, 590, 171712. [CrossRef]

- T. Wong, B. Tong, S. Lim, K. Ooi, Theoretical modeling of pulsating heat pipe, Proceedings of the 11th International Heat Pipe Conference, McGraw-Hill, 1999, pp. 159-163.

- H. Yang, S. Khandekar, M. Groll, Operational limit of closed loop pulsating heat pipes, Applied Thermal Engineering 2008, 28, 49–59. [CrossRef]

- H.R. Goshayeshi, M. Goodarzi, M. Dahari, Effect of magnetic field on the heat transfer rate of kerosene/Fe2O3 nanofluid in a copper oscillating heat pipe, Experimental Thermal and Fluid Science 2015, 68, 663–668. [CrossRef]

- H. Jamshidi, S. Arabnejad, M.B. Shafii, Y. Saboohi, THERMAL CHARACTERISTICS OF CLOSED LOOP PULSATING HEAT PIPE WITH NANOFLUIDS, 2011, 18, 221–237.

- M. Mohammadi, M. Taslimifar, M.H. Saidi, M.B. Shafii, H. Afshin, S. Kazemzadeh Hannani, Experimental Investigation of an Open Loop Pulsating Heat Pipe Using Ferrofluid, ASME 2012 Third International Conference on Micro/Nanoscale Heat and Mass Transfer, 2012, pp. 175-184.

- L. Lu, L.-C. Lv, Z.-H. Liu, Application of Cu-water and Cu-ethanol nanofluids in a small flat capillary pumped loop, Thermochimica Acta 2011, 512, 98–104. [CrossRef]

- J.L. Xu, Y.X. Li, T.N. Wong, High speed flow visualization of a closed loop pulsating heat pipe, International Journal of Heat and Mass Transfer 2005, 48, 3338–3351. [CrossRef]

- S. Khandekar, P. Charoensawan, M. Groll, P. Terdtoon, Closed loop pulsating heat pipes Part B: visualization and semi-empirical modeling, Applied Thermal Engineering 2003, 23, 2021–2033. [CrossRef]

- S. Liu, J. Li, X. Dong, H. Chen, Experimental study of flow patterns and improved configurations for pulsating heat pipes, Journal of Thermal Science 2007, 16, 56–62. [CrossRef]

- S. Khandekar, N. Dollinger, M. Groll, Understanding operational regimes of closed loop pulsating heat pipes: an experimental study, Applied Thermal Engineering 2003, 23, 707–719. [CrossRef]

| Working Fluid | Used material | Fill Ratio (%) | Conclusions | Ref. |

| Acetone, Methanol, Ethanol | Copper |

60–80 |

Acetone serves as a better working fluid in terms of high heat transfer rates at a 60% fill ratio. | [54] |

| Water, Ethanol |

Copper |

30,40,50,70,80 | The CLPHP has a better thermal performance for water and ethanol at fill ratios of 40% and 50%. | [55] |

| Acetone, Methanol, Deionized Water |

Copper | 40–70 |

Methanol serves as a better working fluid at a fill ratio of 45% and heat input of 120 W respectively. | [56] |

| FC-72 and R113 |

Silicon |

41 and 58 |

The study demonstrated that evaporator, adiabatic, and condenser sections were largely occupied by annular slug-plug bubbly flows. | [57] |

| Water, Ferrofluid |

Copper |

N/A | Ferrofluid improves the efficiency of thermal performance; further, this study helps to improve electronic cooling devices more efficiently. | [58] |

| Acetone, Methanol, Ethanol, Heptane, Distilled Water | Copper |

N/A |

Heptane and Acetone exhibit better heat transfer characteristics among other working fluids | [59] |

| PHP container | Copper & Glass |

| PHP length | 380mm |

| Condenser length | 100mm |

| Adiabatic length | 100mm |

| Evaporator length | 100mm |

| Outer diameter | 3mm |

| Wall thickness | 1.25mm |

| Inner diameter | 1.75mm |

| Liquid filled ratio | 50% |

| Total length of PHP | m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).