2.1. Different Types of Crank Mechanisms. Connecting Coupler Curve

In the following sections, by the term crank mechanisms we shall mean only those mechanisms that can be derived from the mechanisms of articulated four-link mechanisms and their special cases [

14]. As the cases considered so far have shown, connecting coupler curves, i.e. trajectories described by a connecting coupler point, are of particular importance to the designer. Therefore, it is necessary to study the properties of these curves in more detail and use the corresponding regularities for the requirements of practice. In the mathematical sense, connecting coupler curves [

15] are curves described by points of a rigid system, two points of which

and

move in circles α and β, and these circles can also degenerate into straight lines.

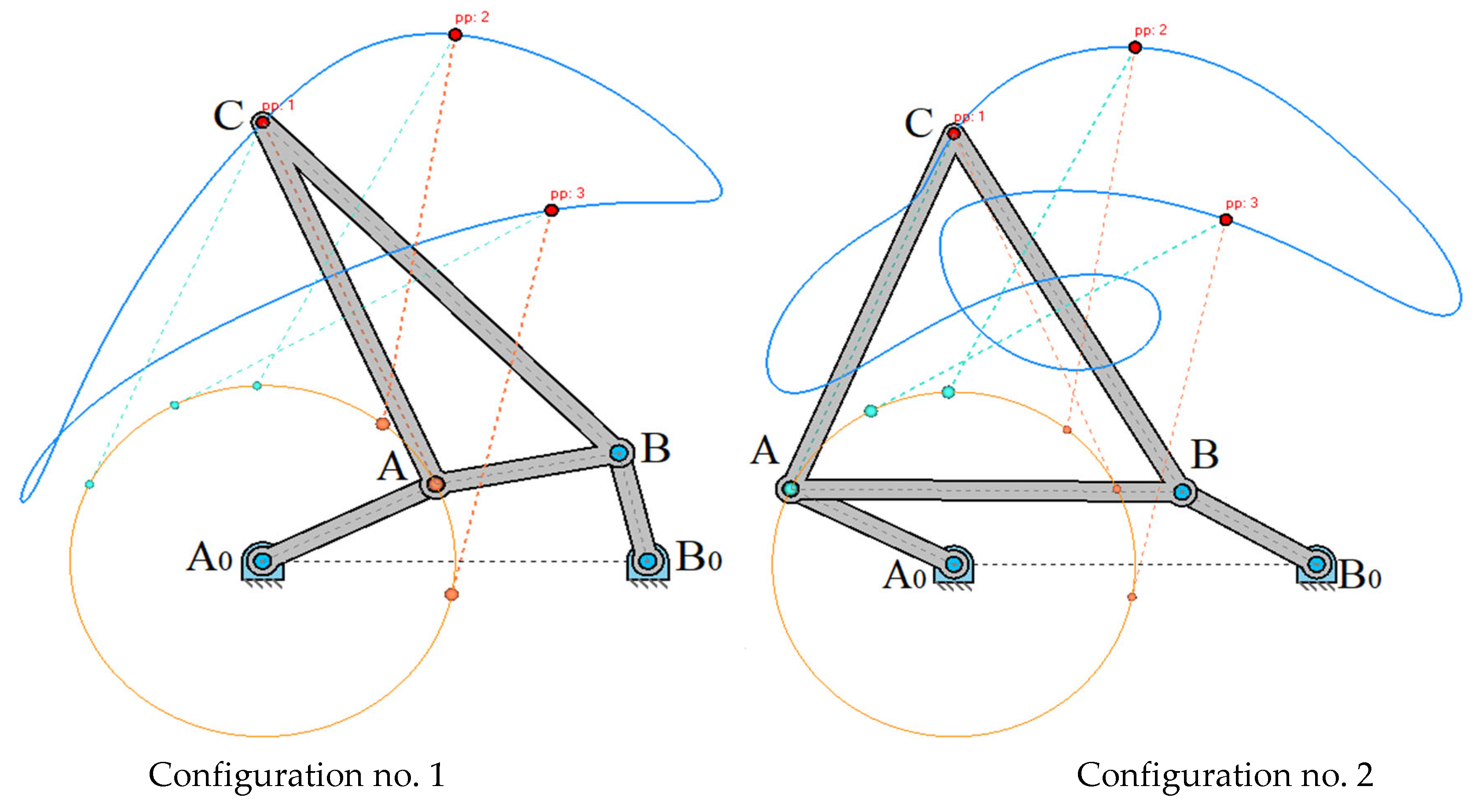

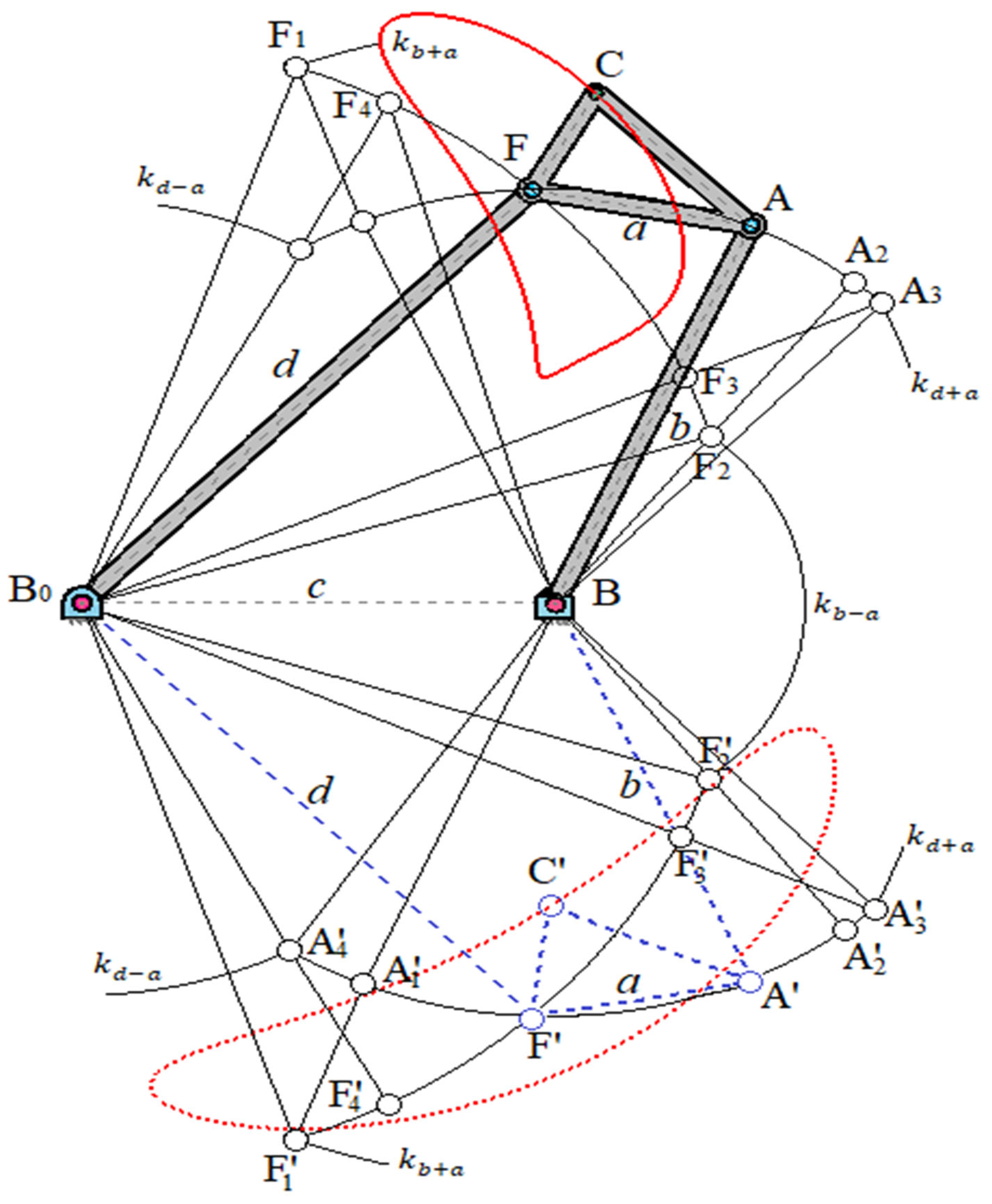

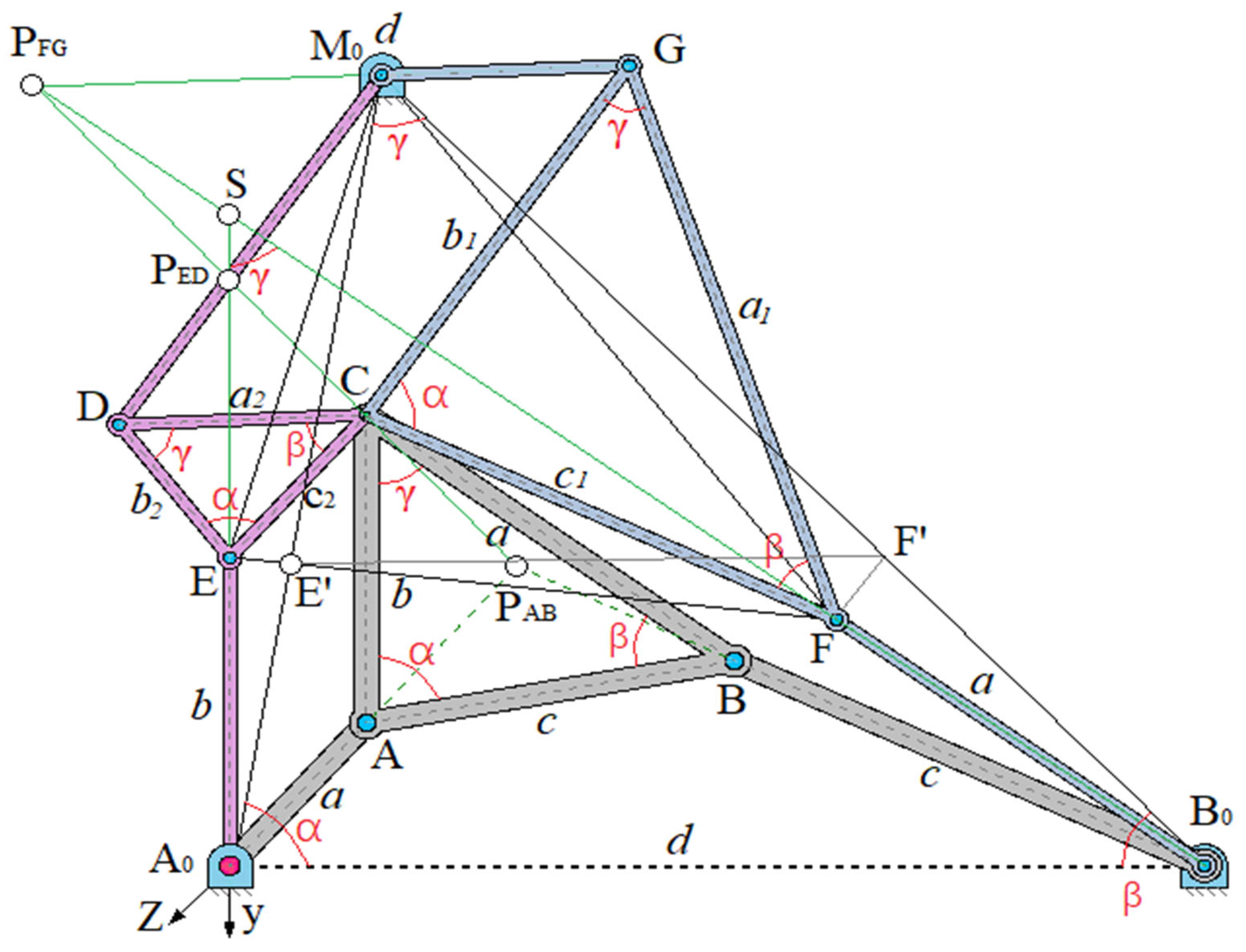

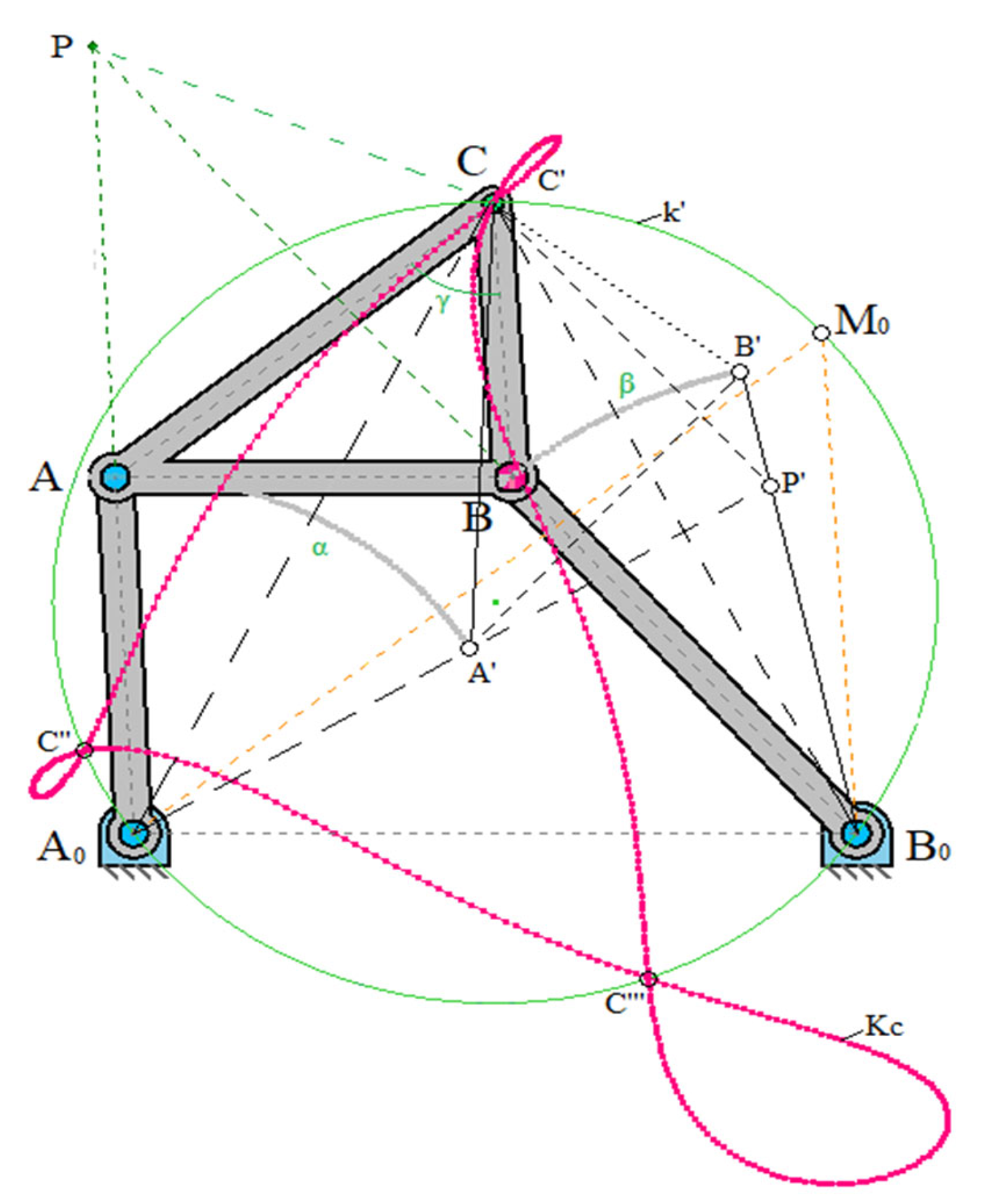

Figure 1 shows an articulated four-link mechanism

,

,

,

, which can also be called a crank-rocker mechanism [

16]. The dimensions of the four-link mechanism under consideration satisfy the Grashof condition (

) [

17]. Circles

and

with centers at

and

and with radii

and

intersect circle β at points

and

and, respectively, at в

and

, which correspond to the centers of crank pins

and

and, respectively,

and

.

The movement of the connecting coupler plane

, rigidly connected

, along the circles α, β can be carried out, thus, with the help of both crank-rocker mechanisms [

18]

and

; in this case we see that the connecting coupler curve consists of two parts

and

(

). If the shortest link

is made a rack, then according to

Figure 1 we will obtain a two-crank mechanism [

19], shown in

Figure 2, the connecting coupler curve of which again consists of two parts

,

.

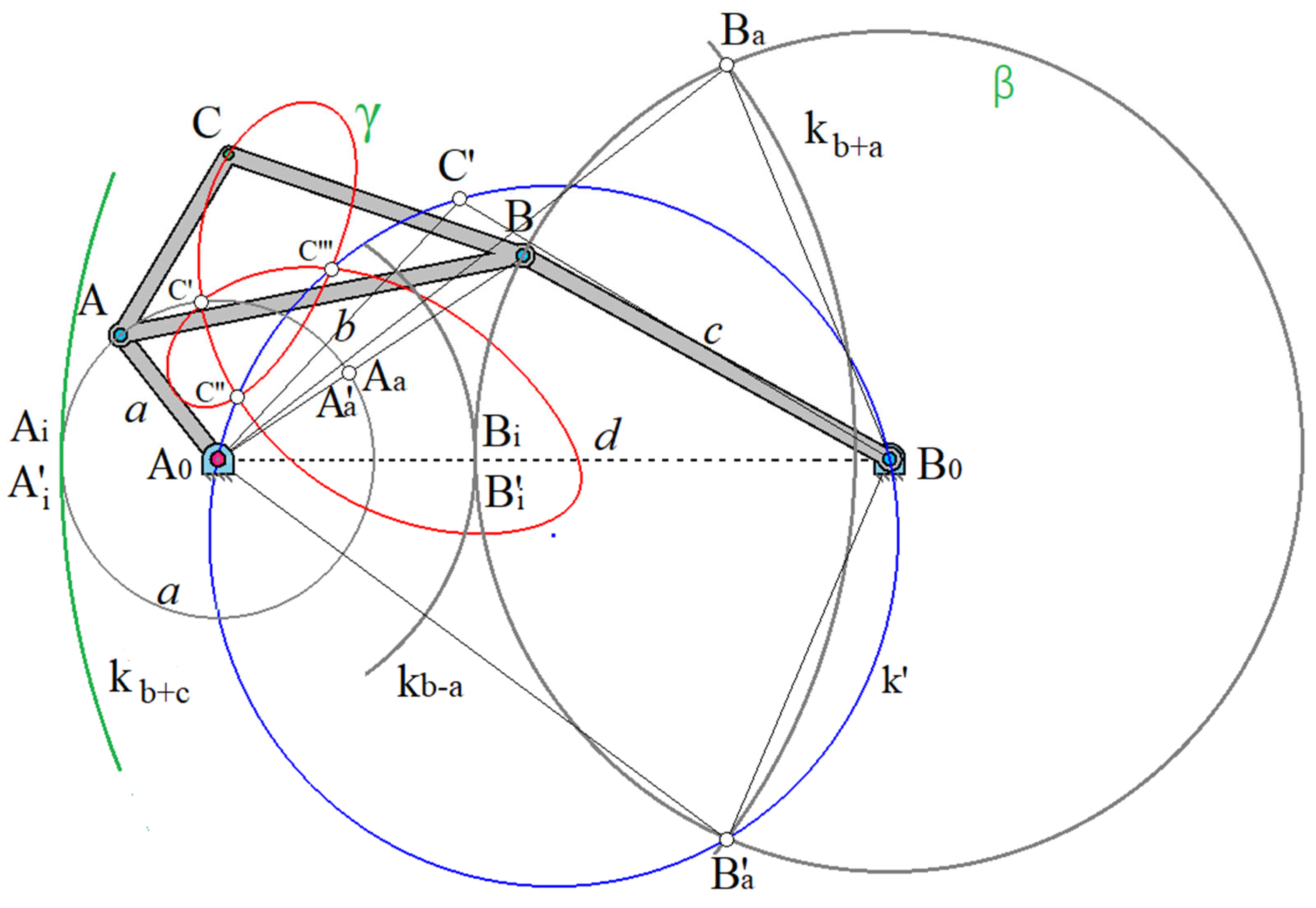

The two-rocker mechanism

Figure 3 with the rack

с, i.e. placed on the link opposite to the smallest, has for each of the mechanisms

and

(under the conditions of the Grashof theorem) [

17]. These 8 dead positions are constructed using the circles

,

,

,

; in this case the connecting coupler curve [

20] also consists of two parts. In

Figure 4 the hinged four-link mechanism

Figure 1 is placed on link

, and while maintaining the dimensions

,

and

it is modified so that

. Circles

and

с with centers

and

and with radii

and

touch the guide circles α and β at points

and

, corresponding to the external dead position.

The motion processes in this limit mechanism [

21] can be of two kinds. If the crank

rotates clockwise from the point

, and passes through

into

, then

passes into

onto

. If the connecting coupler

at the point

is stopped by a stop mounted on the stand, then

will move further, and the rocker arm pin

will return from

through

into

. If there is no such stop at the point

then the rocker arm c can move in an oscillatory motion between

and

(forward and reverse stroke), when the crank

(if

is taken as the starting point) makes two complete revolutions. It follows that in this case the connecting coupler

passes through all its possible positions in a continuous motion. Thus, the connecting coupler curve

for the point С consists of one branch. Since the arc

, described by the rocker journal faces the center of rotation of the crank

with its convex side, this mechanism according to Burmester is called a convex limit crank-rocker mechanism. At

The transition through the indefinite positions of such mechanisms can be realized by installing the corresponding gear engagements, and the centroids in the relative motion of links

and

are used. If, while maintaining the dimensions

,

,

link

becomes smaller than the size shown in

Figure 4, then we obtain a two-rocker mechanism [

22] (

Figure 5), for which

, i.e. the Grashof condition is not satisfied [

17].

This two-rocker mechanism differs significantly from the mechanism in

Figure 3, since it has only four dead positions, and the connecting coupler

passes through all its positions in a continuous motion. In this case, the connecting coupler curve

of point

С consists of one branch. Based on all of the above, the following theorem is true.

Theorem 1. Connecting coupler curves consisting of two branches can be obtained if and only if the sum of the smallest and largest lengths of the links is less than the sum of the lengths of the other two links; in all other cases we obtain connecting coupler curves in the form of a single closed contour.

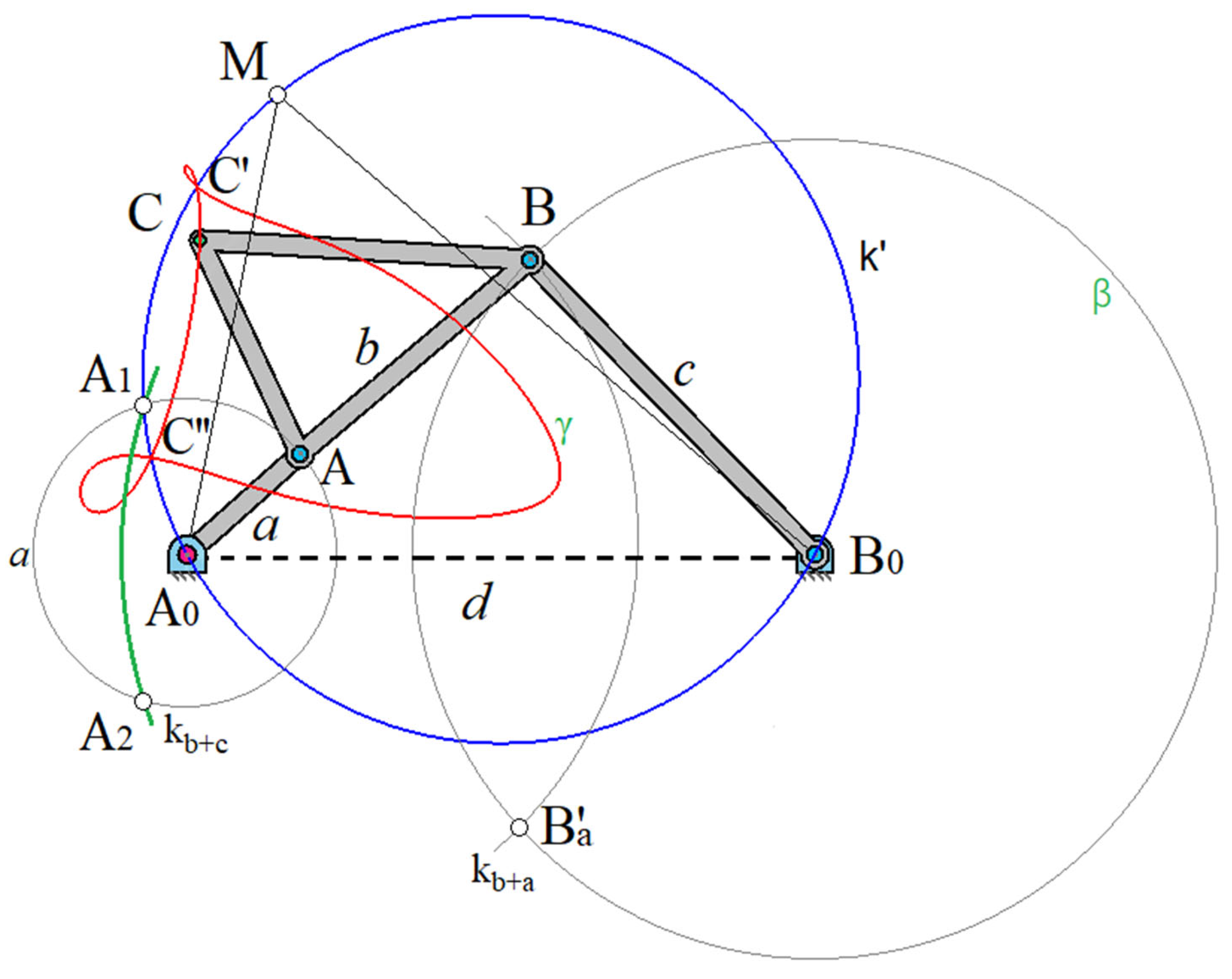

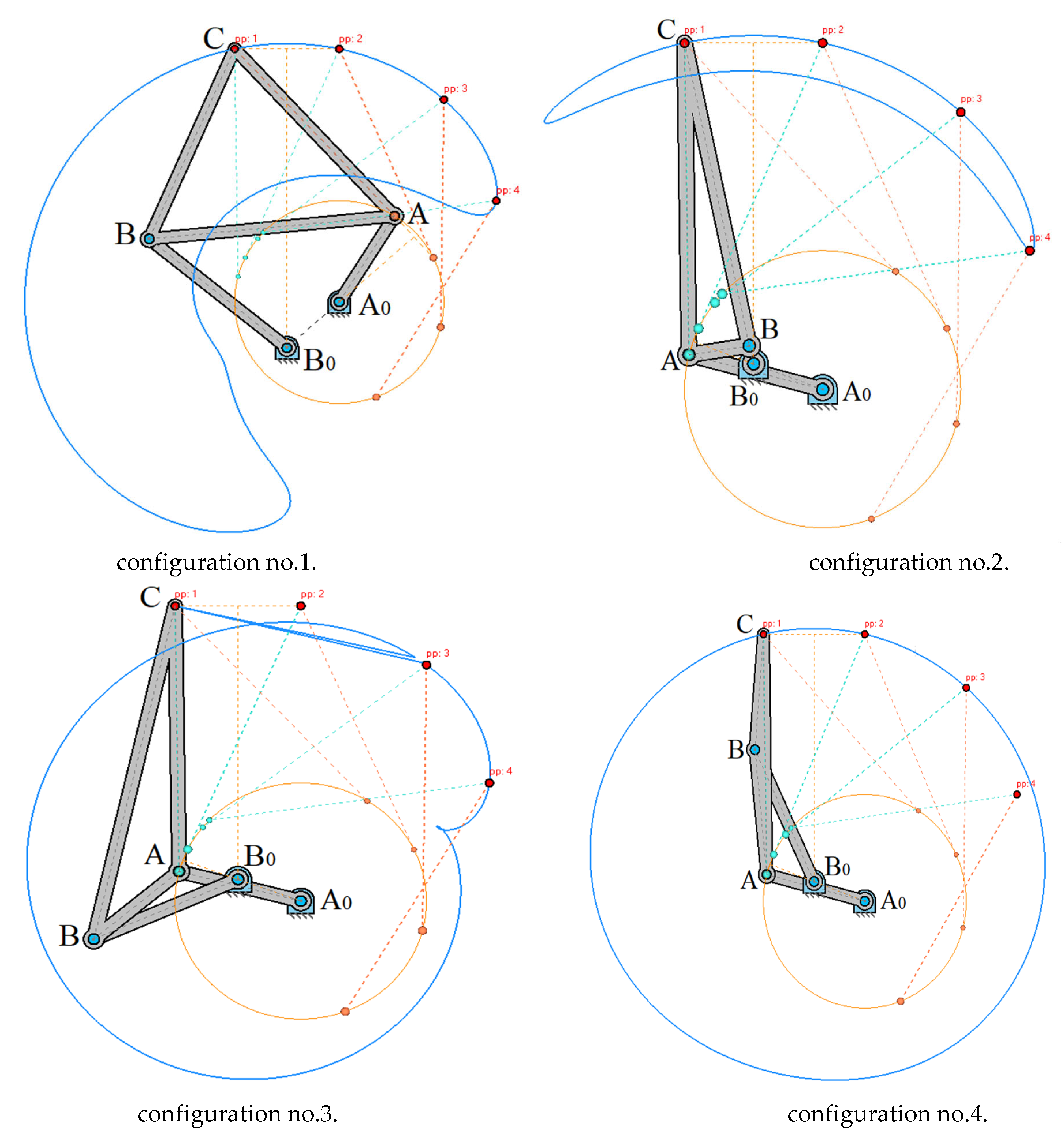

2.2. Formation of a Crank Curve by Three Different Four-Link Joints. Roberts' Theorem

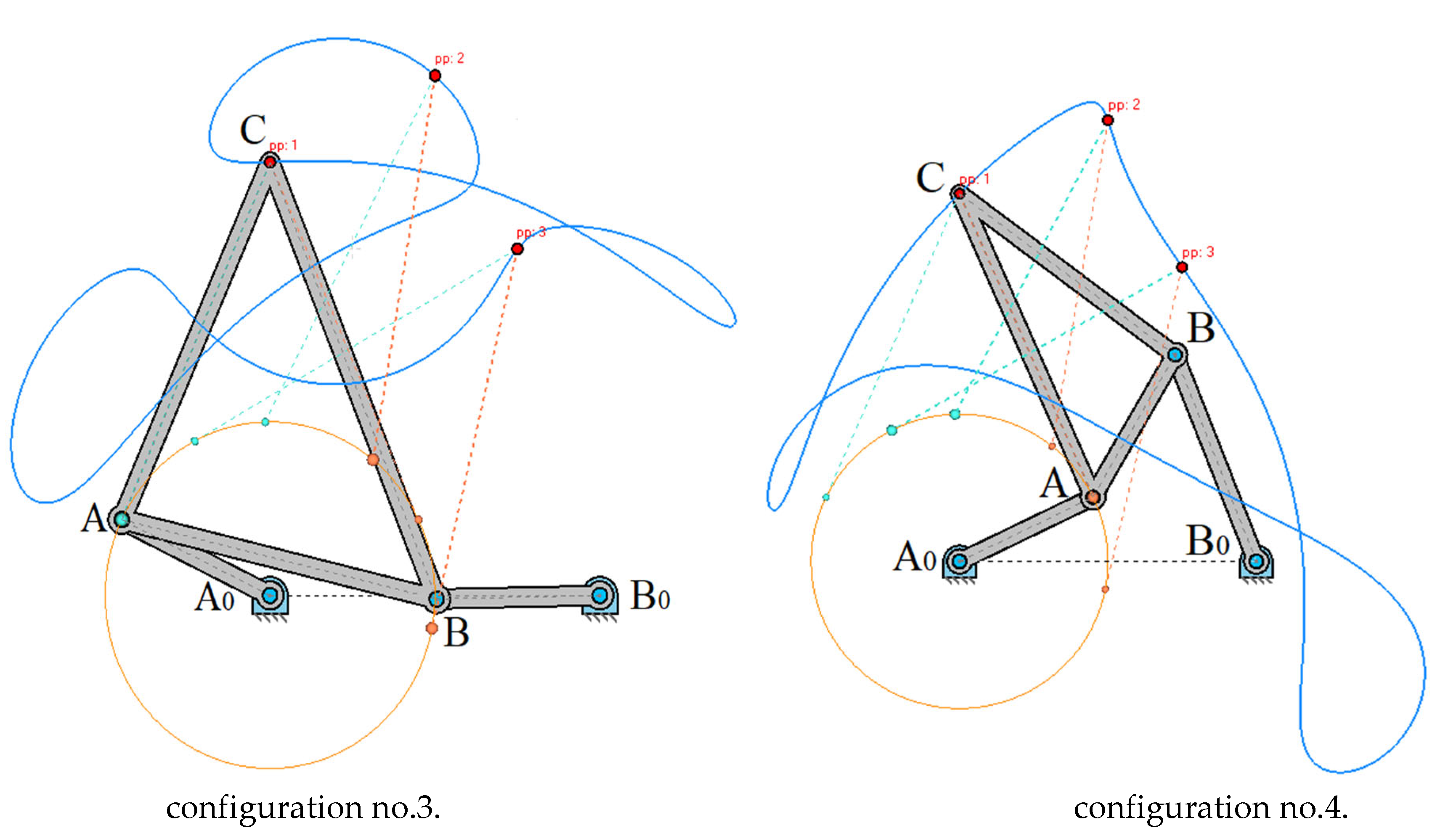

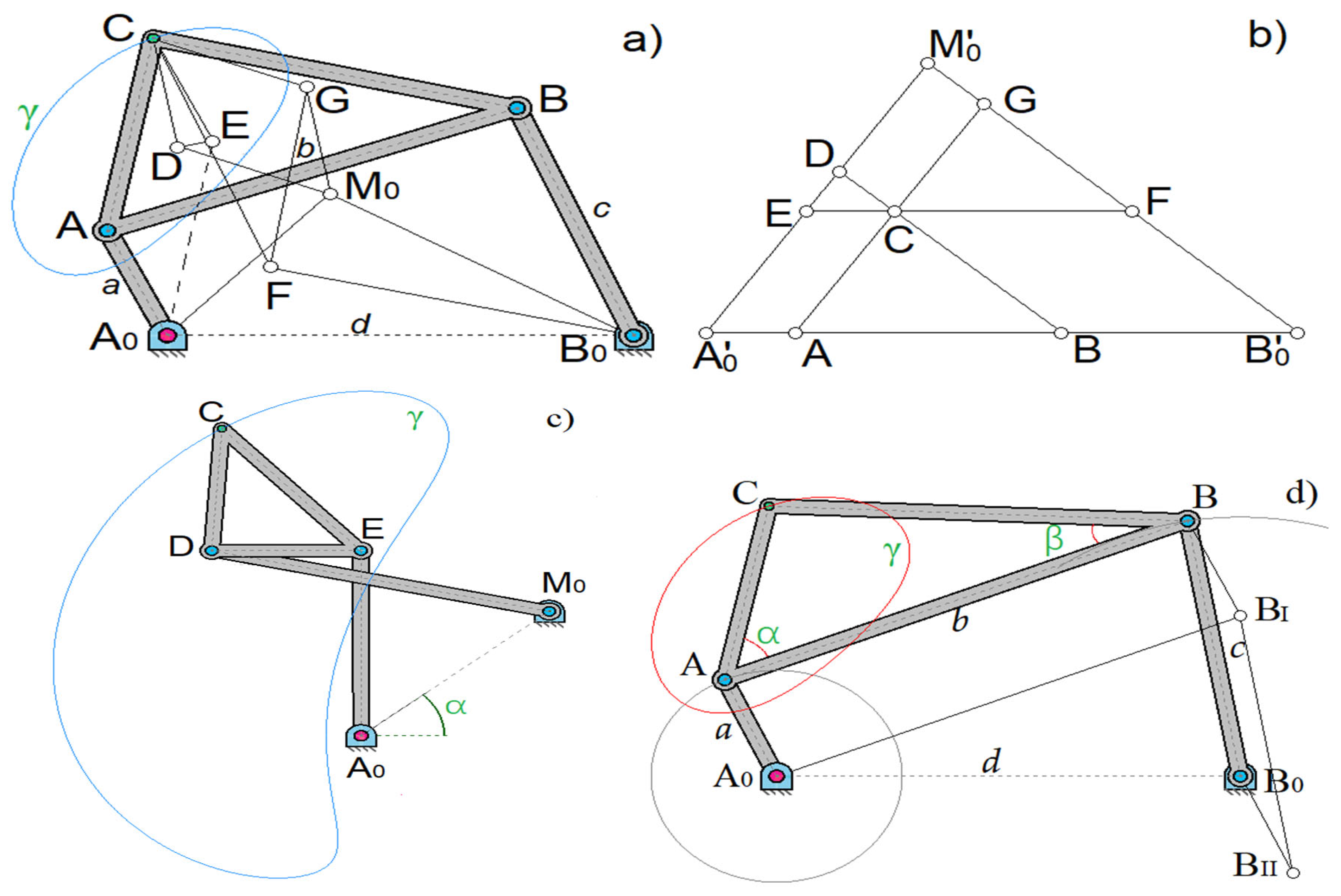

Before proceeding to further studies of the connecting coupler curves [

23] of flat four-link mechanisms, let us dwell on an important theorem obtained by Soni A.H.; and Harrisberger, L.; and having great significance for the synthesis of crank mechanisms. If we draw straight lines parallel to the sides of a triangle

(

Figure 6) through an arbitrary point

С in its plane, we obtain three similar triangles

and three parallelograms

,

,

. The resulting figure can be called a hinge mechanism, which consists of hinge parallelograms and triangles articulated with each other by hinges at

С, where

С is a double hinge. The mechanism obtained in this way has two degrees of freedom, which means that when one link is fixed, it can be set in motion by means of links

and

and thus gives a new mechanism, shown in

Figure 7, which is the basis for Roberts' theorem [

23].

If we consider the points

,

and

as fixed hinges, we obtain a mechanism with

links and

hinges, and the hinges

,

,

and С must be considered double, i.e. we obtain a mechanism with the number of degrees of freedom

. The kinematic chain should therefore be a rigid body; but it is not such due to the existing geometric relationships, and belongs to mechanisms with passive connections [

24].

Proof of Theorem 1. The proof of Roberts' theorem is based mainly on the following: the mechanism under consideration consists of a movable hinged parallelogram

, articulated by a hinge

with a stand and supplemented by similar triangles

and

; then, if, for example, a point

moves along an arbitrary curve

relative to the stand, then the point

describes a similar curve

. Further, in the transition from

Figure 6 to

Figure 7 we have similarity of triangles

. If we disconnect the joint at point С, we will see that the mechanism in

Figure 7 breaks down into the following mechanisms: crank mechanism

with connecting rod triangle

; crank mechanism

with connecting coupler triangle

; crank mechanism

with connecting coupler triangle

, and the connecting coupler point С of each of these mechanisms describes the same connecting coupler curve

. Thus, the following important theorem on the formation of the connecting coupler curve by three different four-link joints is true.

Theorem 2. The trajectory of point С can be obtained as the connecting coupler curve of three articulated four-link chains , , with posts , , , and their connecting coupler triangles , , and are similar to each other and similar to triangle .

Proof of Theorem 2. There are a number of proofs of Roberts' theorem [

23], for example by Soni A.H.; and Harrisberger, L. If the mechanism

, shown in

Figure 7, is a limiting crank mechanism [

25], then the other two mechanisms will be the same. The importance of Roberts' theorem for the synthesis of mechanisms can be explained by the following example: if for some problem, for example, for constructing a connecting coupler mechanism with stops, a hinged four-link mechanism

, is found, then, using Roberts' theorem [

23], two other four-link mechanisms can be found with the help of which the same connecting coupler curve can be constructed [

26]. This circumstance is especially important in those cases when in the found hinged four-link mechanism we have, for example, unfavorable values of the transmission angles or if any difficulties arise in its drive and the possibility of changing the position of the hinges

and

, should be taken into account, and this change may prove expedient.

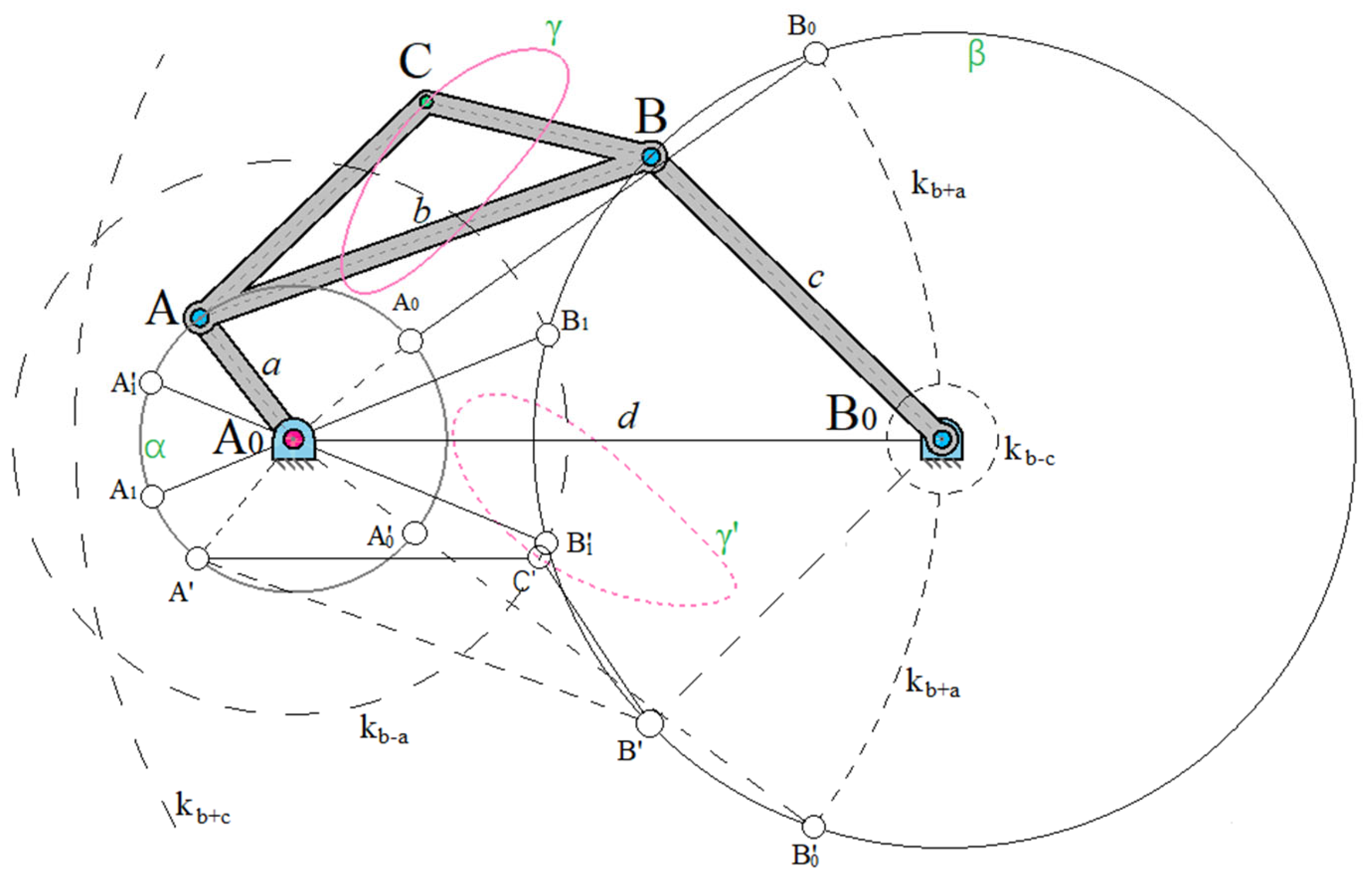

Example. The working machine includes a crank-rocker mechanism

, and the connecting coupler curve of point С of the connecting coupler triangle

is used for some specific purpose, for example, to obtain a dwell. When reconstructing the machine, it is desirable to change the drive without changing the shape of the connecting coupler curve

(

Figure 8).

Solution. Let's consider a four-link articulated link

with a connecting rod triangle

and bring the links

,

,

to the positions

,

,

, going along the same straight line with the rack (

Figure 8, b). The lines passing through

and

parallel to

and

, intersect at

and intersect the lines

and

at points

and

. The line passing through point

parallel to

, intersects

at

, and

at

. Next, on

Figure 8, a we construct

and thus find the point

.

The lines passing through

and

parallel to

and

, yield a point

. at their intersection. Constructing triangle

(

Figure 8, b), on side

(

Figure 8, a) we obtain point

; from here we find the crank

and thus obtain the desired crank mechanism, which is shown again in (

Figure 8, c). Similarly, the lines drawn through

and

parallel to

and

, intersect at point

; constructing triangle

on side

we obtain

, from here we find the crank

; thus, we find the crank mechanism this mechanism is also shown in (

Figure 8, e). In other words, it follows from all of the above that it is necessary to articulate the three-link chains

,

,

and

,

,

(

Figure 8, b) with points

and

and, accordingly, with

and

Figure 8, a. It is necessary to take into account that these chains must be installed on the proper side of the rack (the connecting coupler curves must consist of two branches). (

Figure 8, c), d, e together with the congruent connecting coupler curves

plotted on them clearly illustrate Roberts' theorem [

23], according to which one can find (

Figure 8, e) another crank-rocker mechanism; the two-rocker mechanism in (

Figure 8, c) is unsuitable for our purposes due to the difficulties arising in implementing its drive.

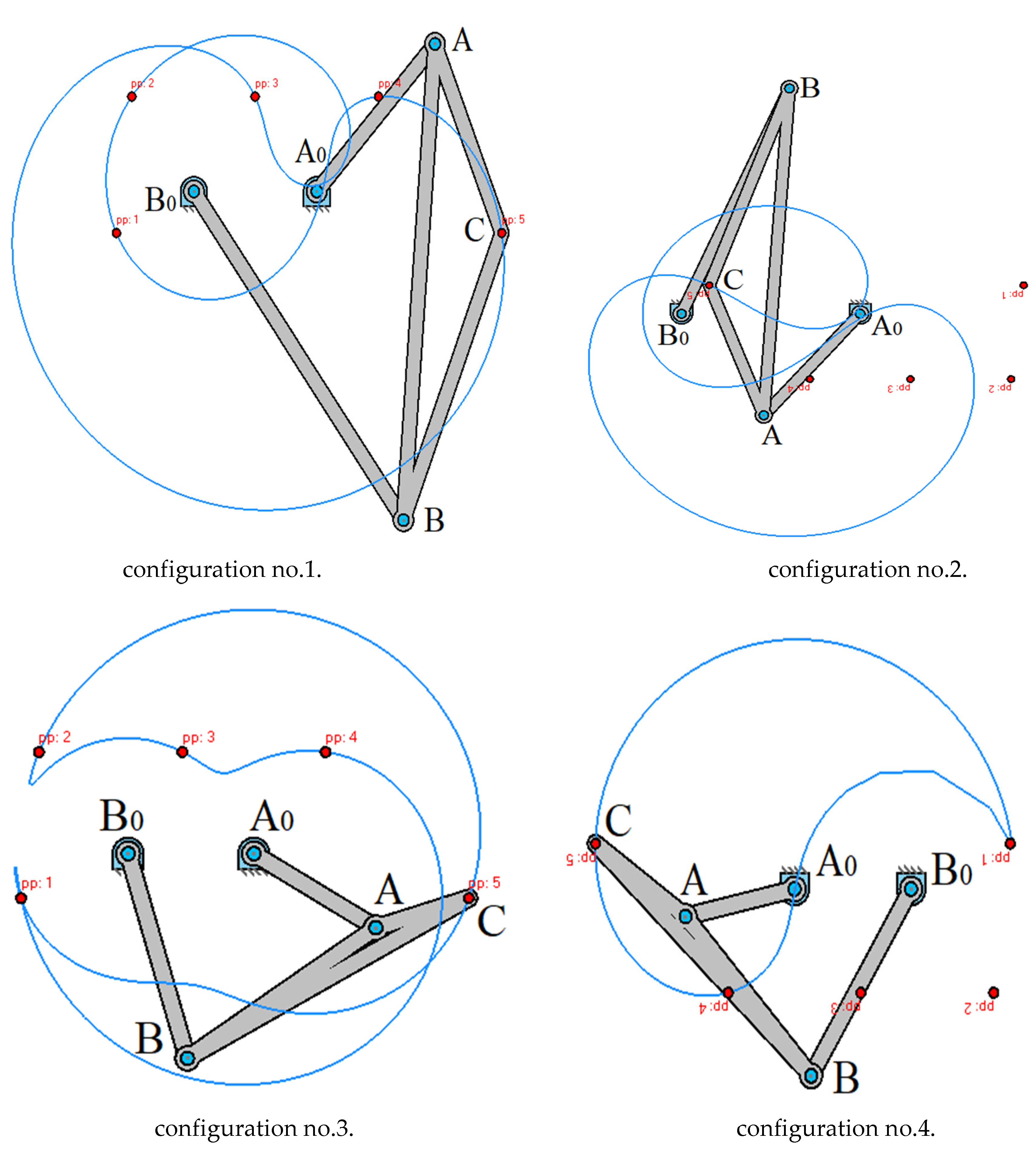

2.3. Transformed Crank Mechanisms

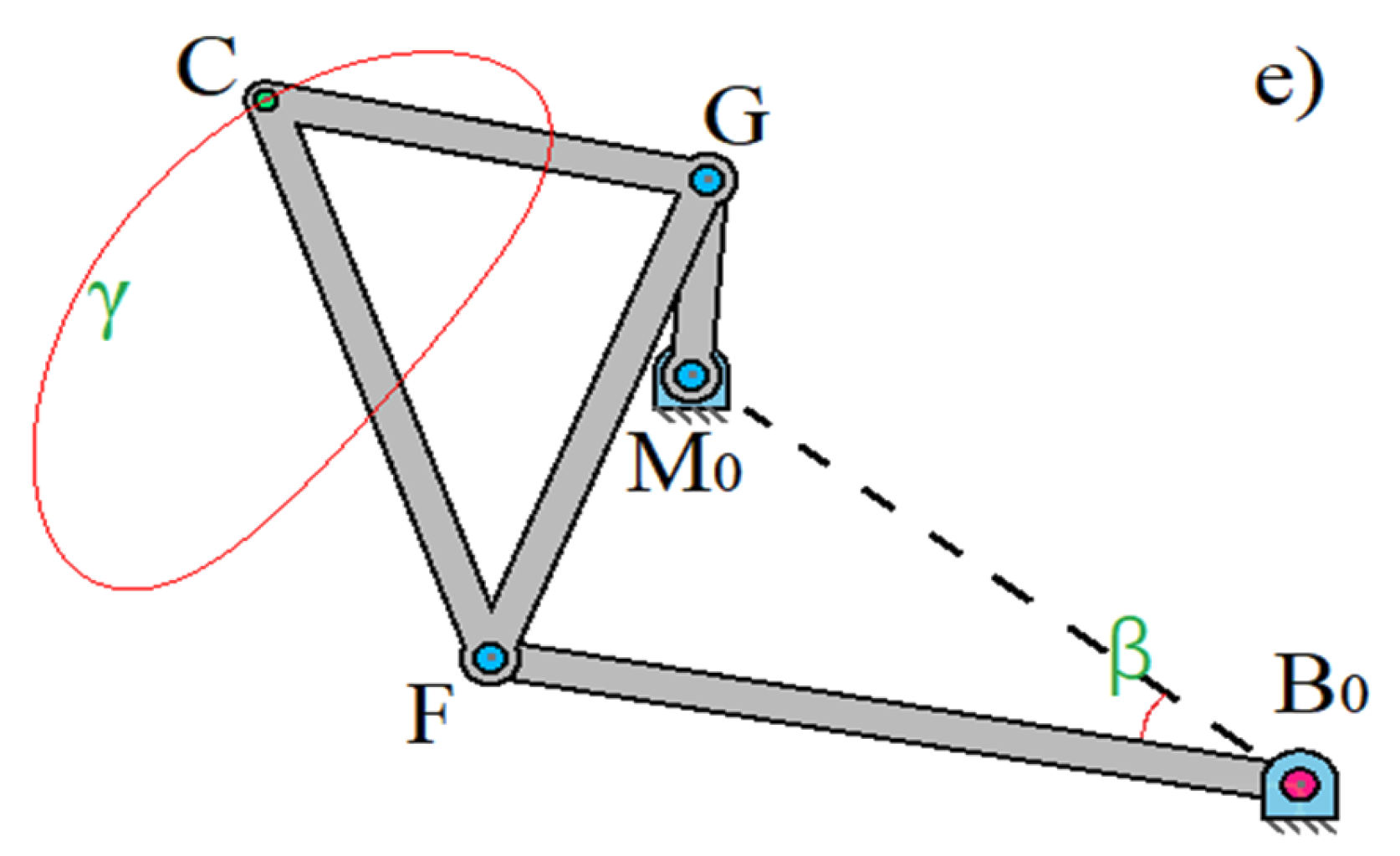

Let us consider a crank-rocker mechanism

(

Figure 9) with a connecting coupler triangle

and with dimensions

,

,

,

,

,

,

,

,

, let the vectors

,

,

,

,

, correspond to complex numbers

,

,

,

of the complex plane

, where

,

,

. Choosing

as the real axis, we obtain the following equations:

Each of these equations, which is derived using the displacement law from the equation Eq. (1), corresponds to a certain crank mechanism [

27]. From the crank mechanisms thus transformed, as shown by A. H. Soni, it is possible to obtain the mechanisms

,

,

in close connection with the Roberts theorem [

23]. Using the indicated notation method and introducing the complex number

, corresponding to the vector

, we obtain the equation of the connecting coupler curve

in complex form:

Moreover, corresponds to the vector and , , . Consequently, after rotation around by the angle becomes parallel to . Further, the complex number corresponds to the unit vector in the complex plane , which is parallel to ; it can be represented as follows: .

If we further set:

then the equation of the connecting coupler curve

in complex form is:

where

is a constant complex value for the entire process of motion (with modulus

and with argument

).

Application of the equation to the crank mechanisms

and

gives an elegant proof of Roberts' theorem [

23]. Without dwelling on this in detail, we note that this is easily seen from (

Figure 8, d) which, in addition to the articulated four-link mechanism

, also shows the transformed four-link mechanisms

(bacd) and

(bcad) in accordance with Eq. (3) and Eq. (2). If we reduce the first four-link mechanism (bacd) in the ratio

, and the second (bcad) in the ratio

, then we obtain as a result, after the corresponding rotations, the articulated four-link mechanisms

(

Figure 8, c) and

(

Figure 8, e). From this it becomes clear that both crank mechanisms constructed according to Roberts' theorem are similar to articulated four-link mechanisms transformed from the original one; in addition, the connecting coupler curves of the transformed crank mechanisms

and

are similar to the connecting coupler curves of the original mechanism [

28]. In order to obtain similar connecting coupler curves in a crank mechanism, the crank and the slider can be interchanged (

Figure 5); in this regard, we refer to the recently published work of Schmid.

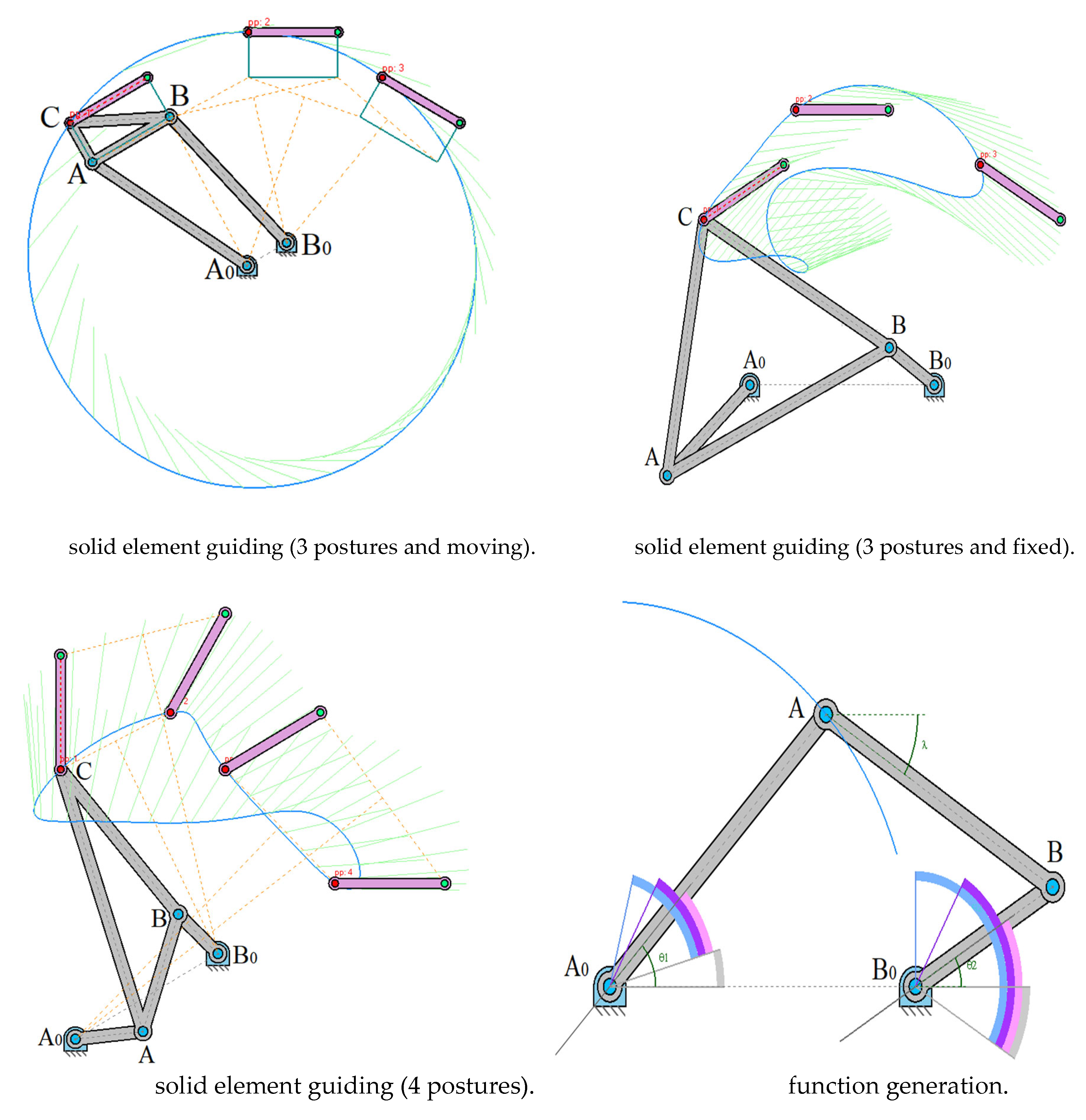

2.4. Analytical Study of the Connecting Coupler Curve

For a four-link articulated link

(

Figure 1) with dimensions

,

,

,

it is necessary to derive the equation of the connecting coupler curve

of point

С in rectangular coordinates

x,

y. Using the auxiliary angle

, we find the following expressions for the coordinates of points

and

:

next we have:

excluding the coordinates of points

А and

В, we obtain:

From here, excluding

, we find the equation of the connecting coupler curve

in the following form:

where we put:

The equation of the connecting coupler curve can also be written in this expanded form:

Since the coupler curve is a sixth-order curve, it has six intersection points when intersected by a straight line. If we assume the line:

then substituting into the coupler curve equation results in a sixth-degree equation in

x:

which confirms that the coupler curve can have up to six intersections with a given line.

Then for the coordinate

x we obtain an equation of the 6th degree, i.e. we will have six intersection points. If, in particular,

when

, then according to the equation Eq. (24) we obtain:

where

, we obtain another form of the sixth-degree equation. This implies that the connecting coupler curve is a highly nonlinear trajectory that can exhibit loops, inflection points, and multiple branches [

29]. Then in the equation Eq. (23) the terms from the 6th to the 4th degree vanish; of the six roots of the equation, three become infinitely large. The imaginary cyclic points at infinity

I and

of the crank curve are triple points. In other words, it is a tricircular curve of the sixth order. The line at infinity has only two imaginary cyclic points in common with the crank curve [

30].

The connecting coupler curve

has at each imaginary cyclic point three asymptotes which intersect the asymptotes corresponding to another cyclic point at three real points, at three focal centers (or foci)

,

and

. Thus, for example, for the lines connecting the origin

with

I and

. (due to the fact that

), the equations have the form

, т.е.

. For the intersection points of the lines

and

in equation Eq. (23) the third-degree term with respect to x; vanishes; the lines

and

are thus tangent to the curve at the points

I and

, which proves that

is a focal center of the connecting coupler curve [

31]. The same is true for the points

and

, and

according to Roberts' theorem [

23] is similar to

and has the same direction of traverse. There is an extensive literature devoted to the study of connecting coupler curves. If a connecting coupler point

С lies on the line

АВ between

А and

В, then we must set

, and

. We should pay attention to the special case when

С is the midpoint of the segment

АВ and at the same time

. We then obtain a lemniscate, i.e. a curve similar to a lemniscate; this curve is often used in practice and is also called the Watt curve. If point

С lies on the line

АВ, but outside the segment

АВ, then we must set

and

. The equation of the connecting coupler curve in this case will have the following form:

moreover:

For the case when С lies between А and В, it is necessary to change the sign in front of а in the equation Eq. (28) and Eq. (29).

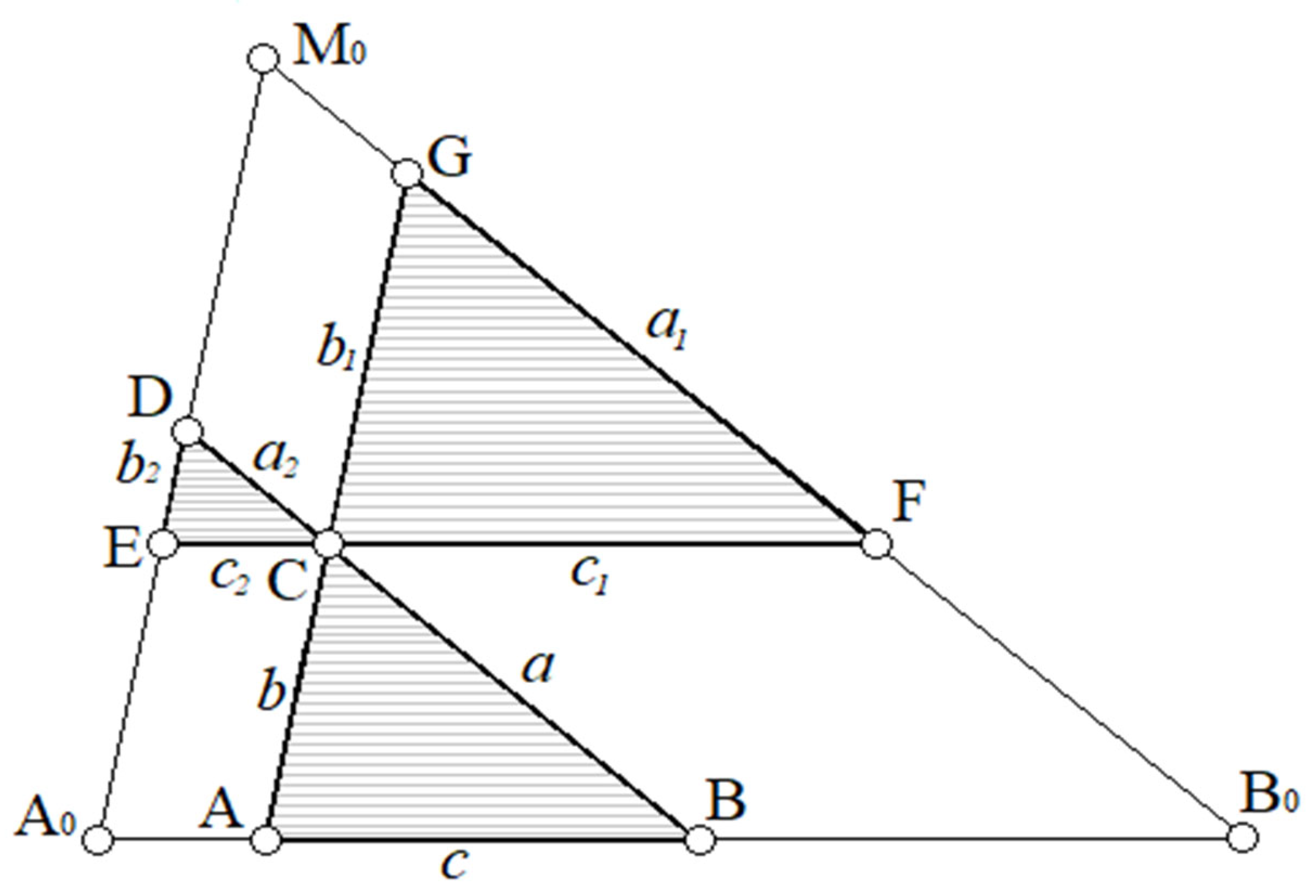

2.5. Double Points of the Crank Curve

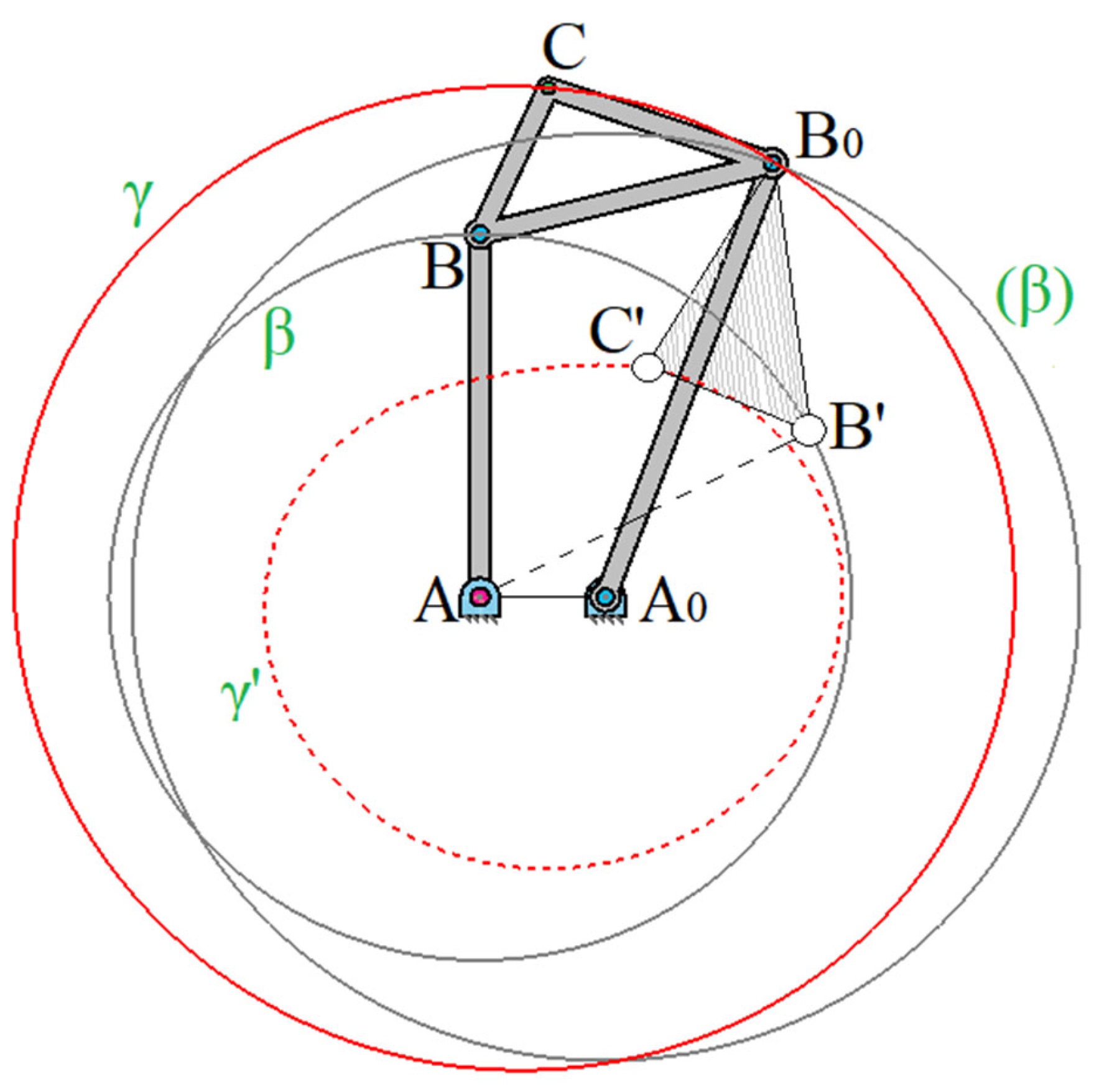

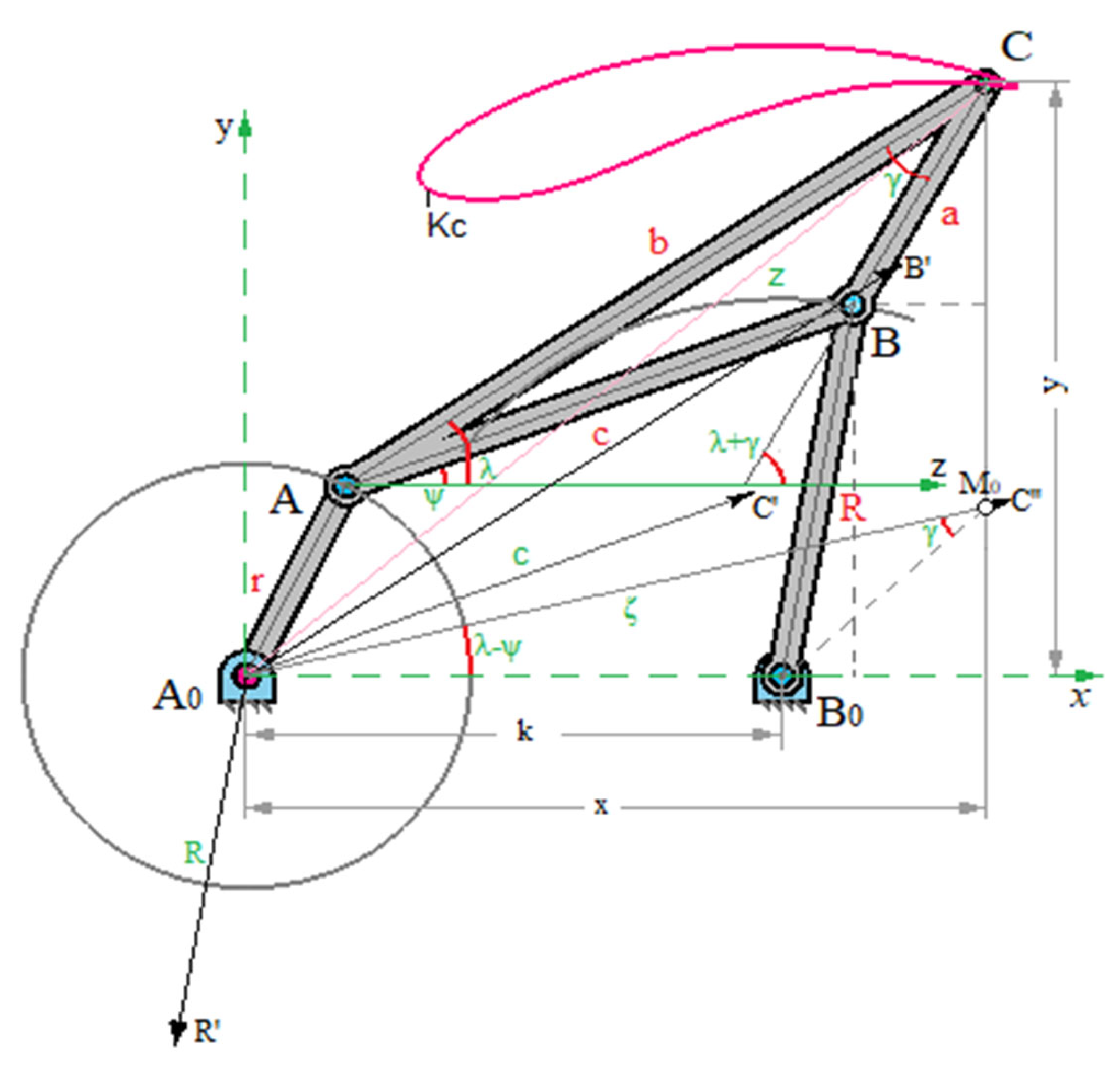

If the crank curve

at a given position of the mechanism

(

Figure 10) with the crank triangle

has a double point in С, then the moving point passes through this position С twice; thus, the point С must correspond to two positions of the crank (

and A’B’), Then

, where

,

lie on the crank circle α, and

,

on the crank circle β. In this case, the crank point С is the pole corresponding to two adjacent positions of the crank

and A’B’. From the equality

it follows

. If we connect С with

and

, we find that the lines

and

are the bisectors of the angles

and

; then follows

.

Thus, the double point С lies on the circle

, and the segment

is a chord, and the angle

is an inscribed angle based on this chord. The circle

also passes through a third point

, considered as the support hinge of two other crank mechanisms, which, according to Roberts' theorem, describe the same connecting coupler curve [

32]. Thus, the theorem is valid.

Theorem 3. Double points of the crank curve lie on the circle, described around the triangle formed by the three focal centers. Conversely, each point of intersection of the crank curve with the circleis a double point of the crank curve.

Since the connecting coupler curve is a curve of the 6th order and has imaginary cyclic points I and as triple points, it can have six more intersection points with each circle in its plane, in addition to the points I and . Thus, each intersection points of the curve with the circle is a double point, which should be considered as two intersection points. The theorem follows from this.

Theorem 4. The connecting coupler curve has three double points on the circle, passing through the three focal centers,,. Of the three double points, two may be complex conjugate; they may also coincide at the point of self-contact of the connecting coupler curve.

Each real double point is either a double point in the proper sense of the word, i.e. a nodal point, such as the points

,

,

(

Figure 10), or a cusp point in those cases where it coincides with the instantaneous pole, or an isolated point to which no real positions of the crank can correspond. For points С, lying on the crank line

, the crank curve

is symmetrical about the midline of the column

. In this case, the third focal center

and the three double points lie on the lines passing through

and

. On double points in limit mechanisms, see Müller. The equation of the circle

, passing through the three focal centers

, , , has the following form:

Assuming that

,

,

, and taking into account the equation Eq. (22), we obtain:

Thus, an analytical study of the crank curve shows that the equations , , , each of which, in accordance with the equation Eq. (19), is a consequence of the other two, give double points of the crank curve.