Submitted:

08 March 2025

Posted:

11 March 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

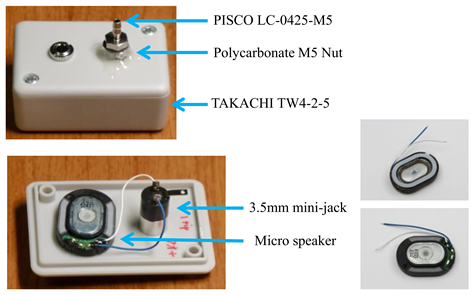

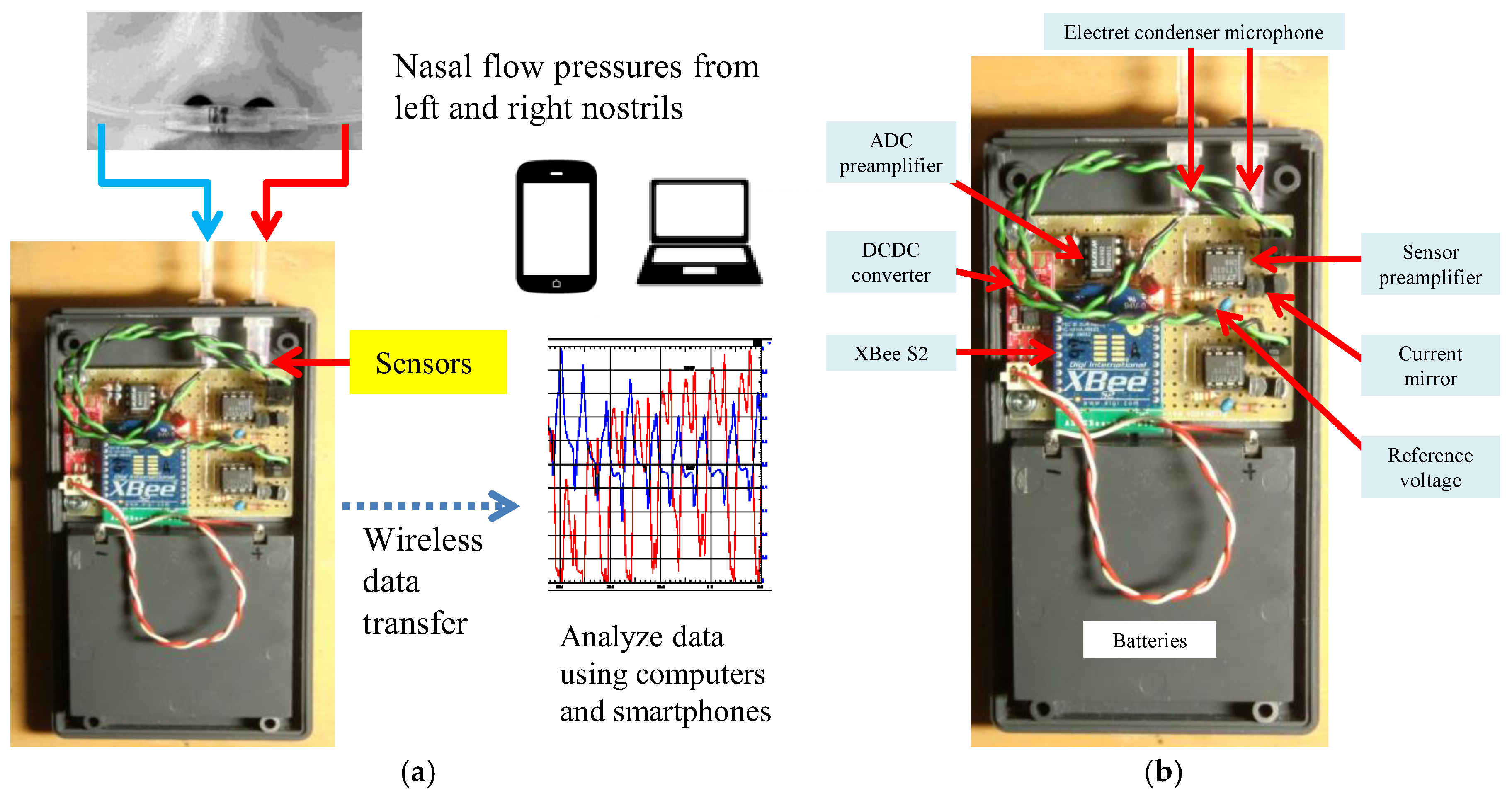

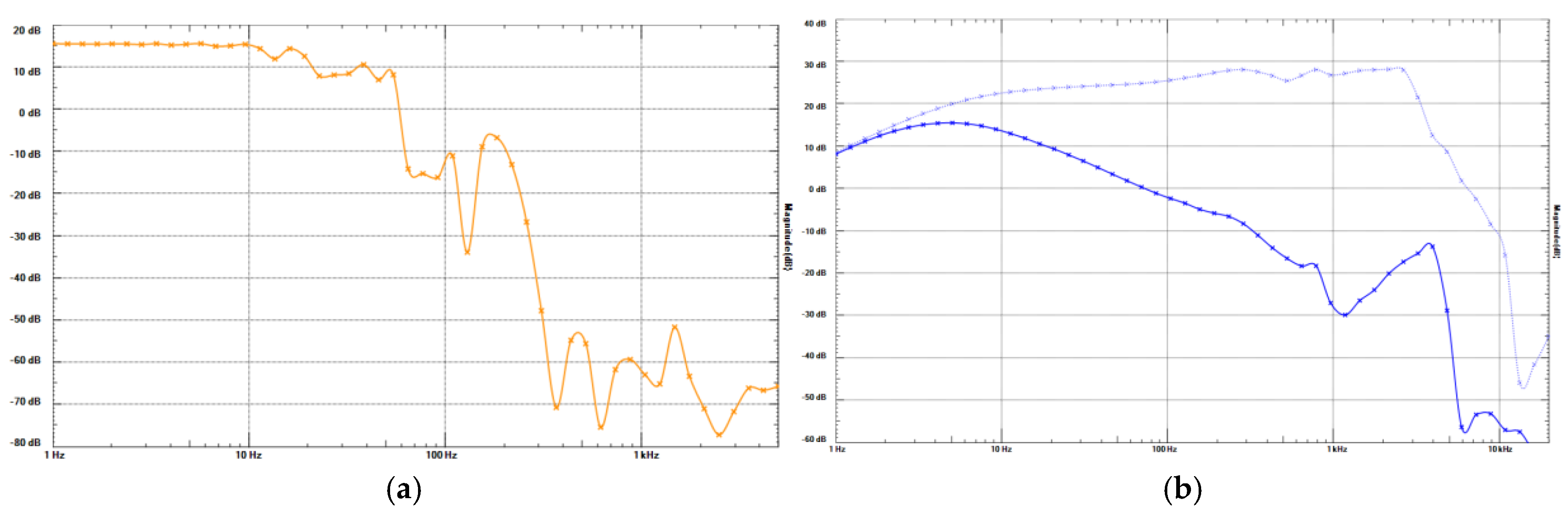

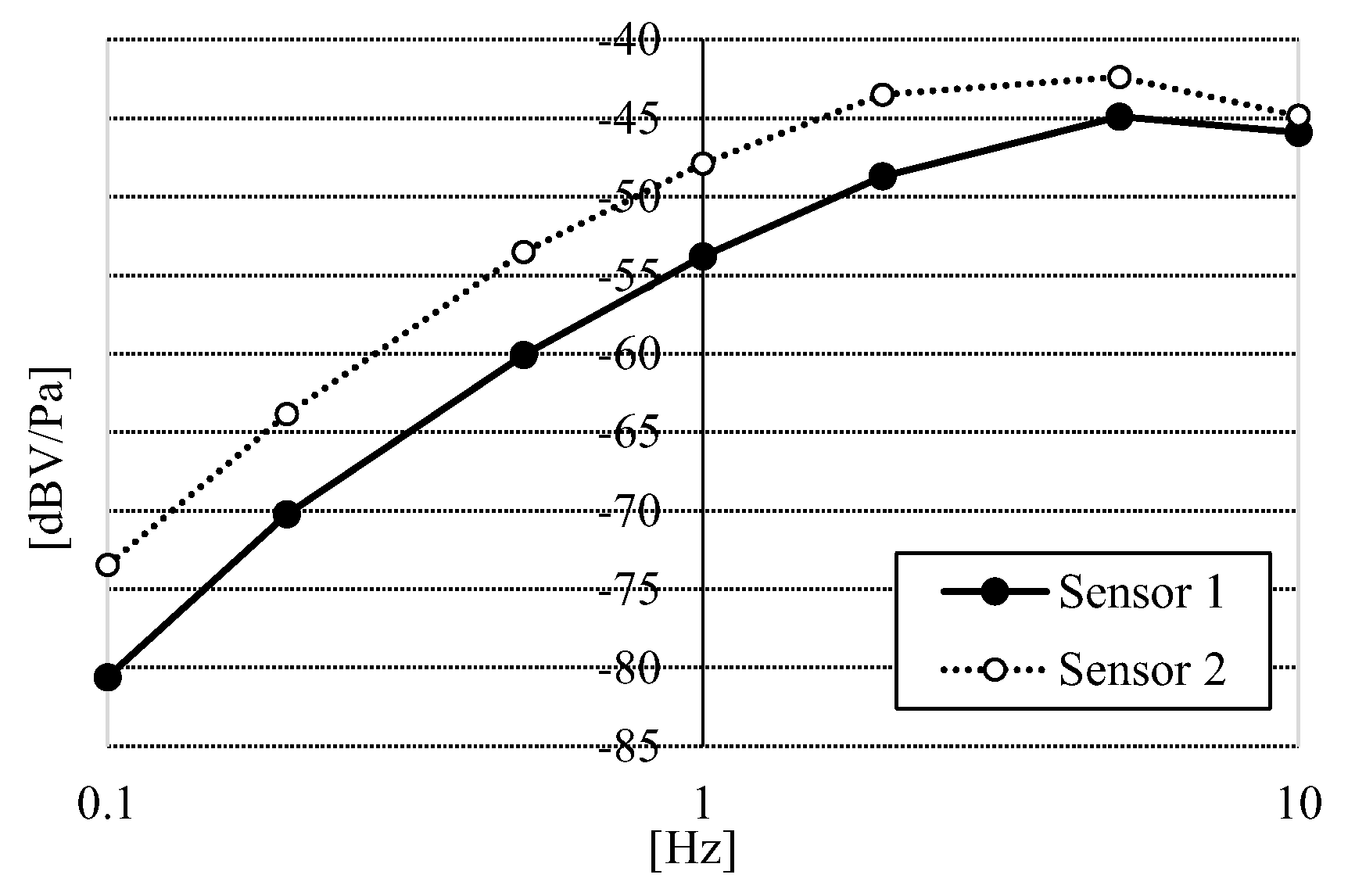

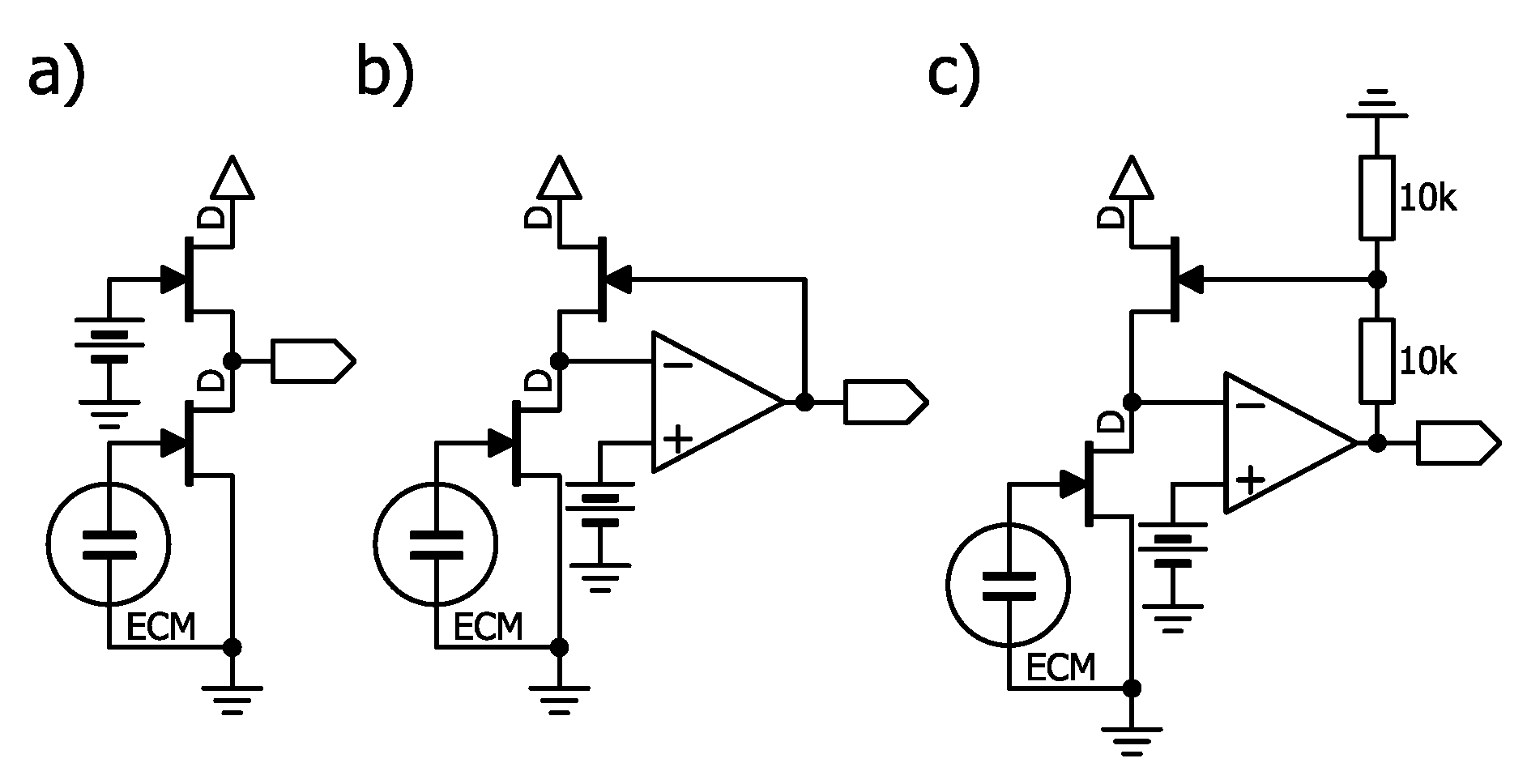

2.1. Sensor and Circuit Overview

2.2. Wireless Data Transmission Module

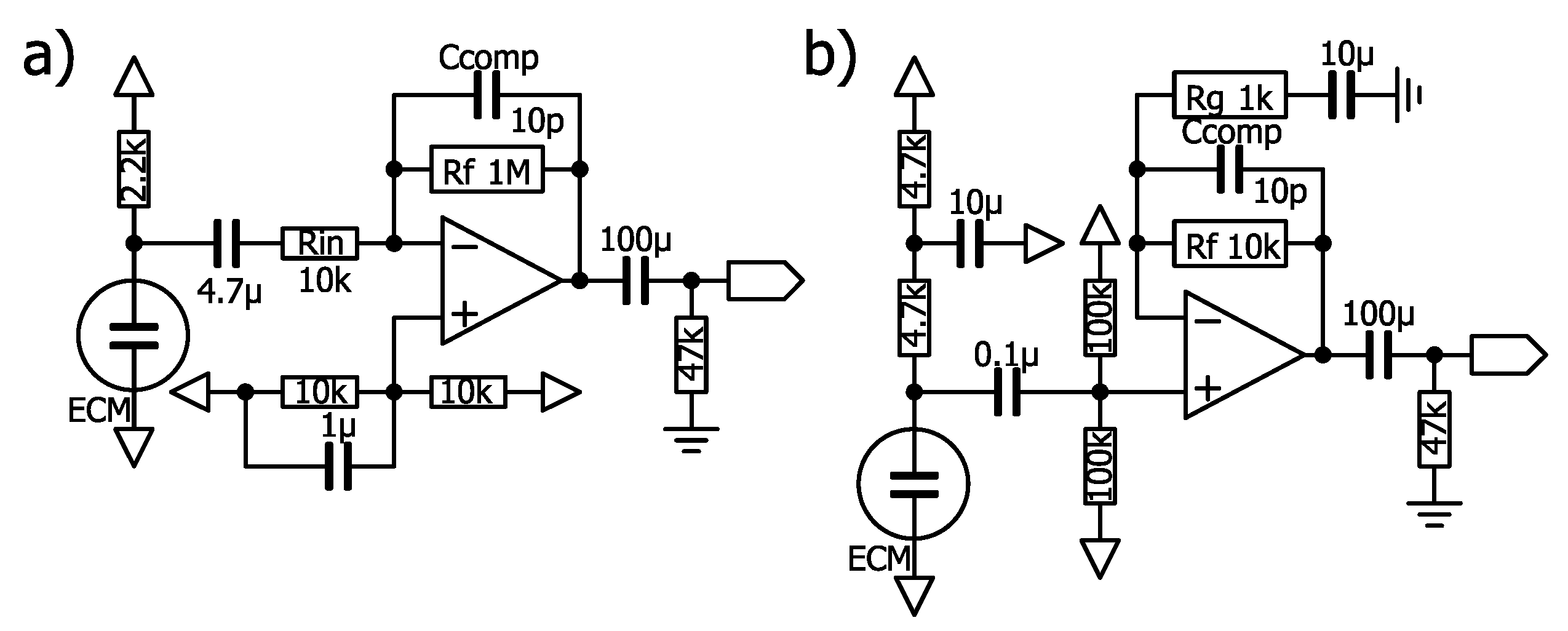

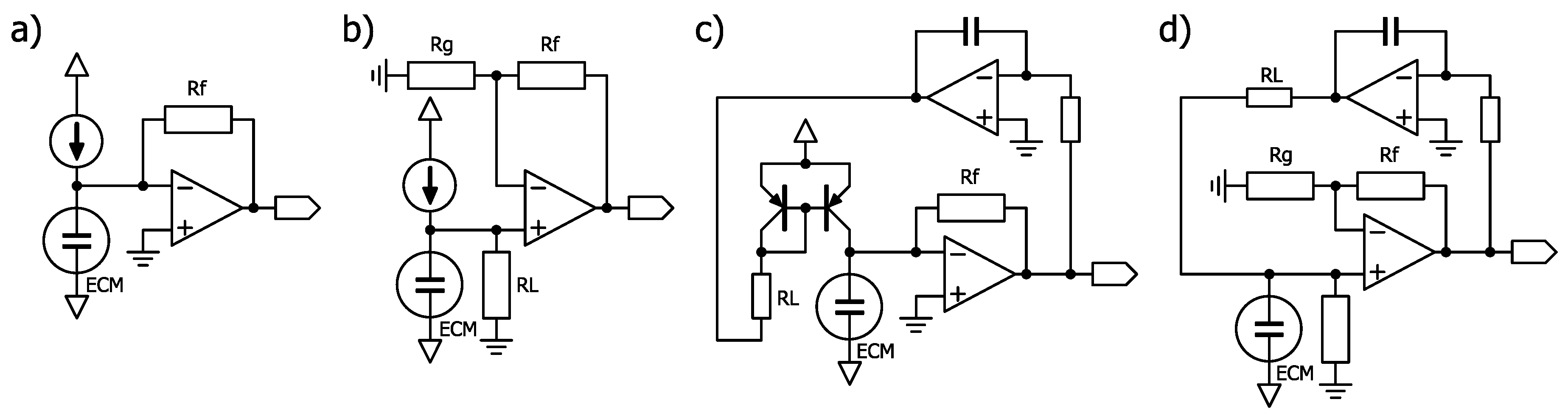

2.3. Consideration of the Sensor Amplifier Circuit

2.4. Possibility of Reducing Crosstalk Using Regulators

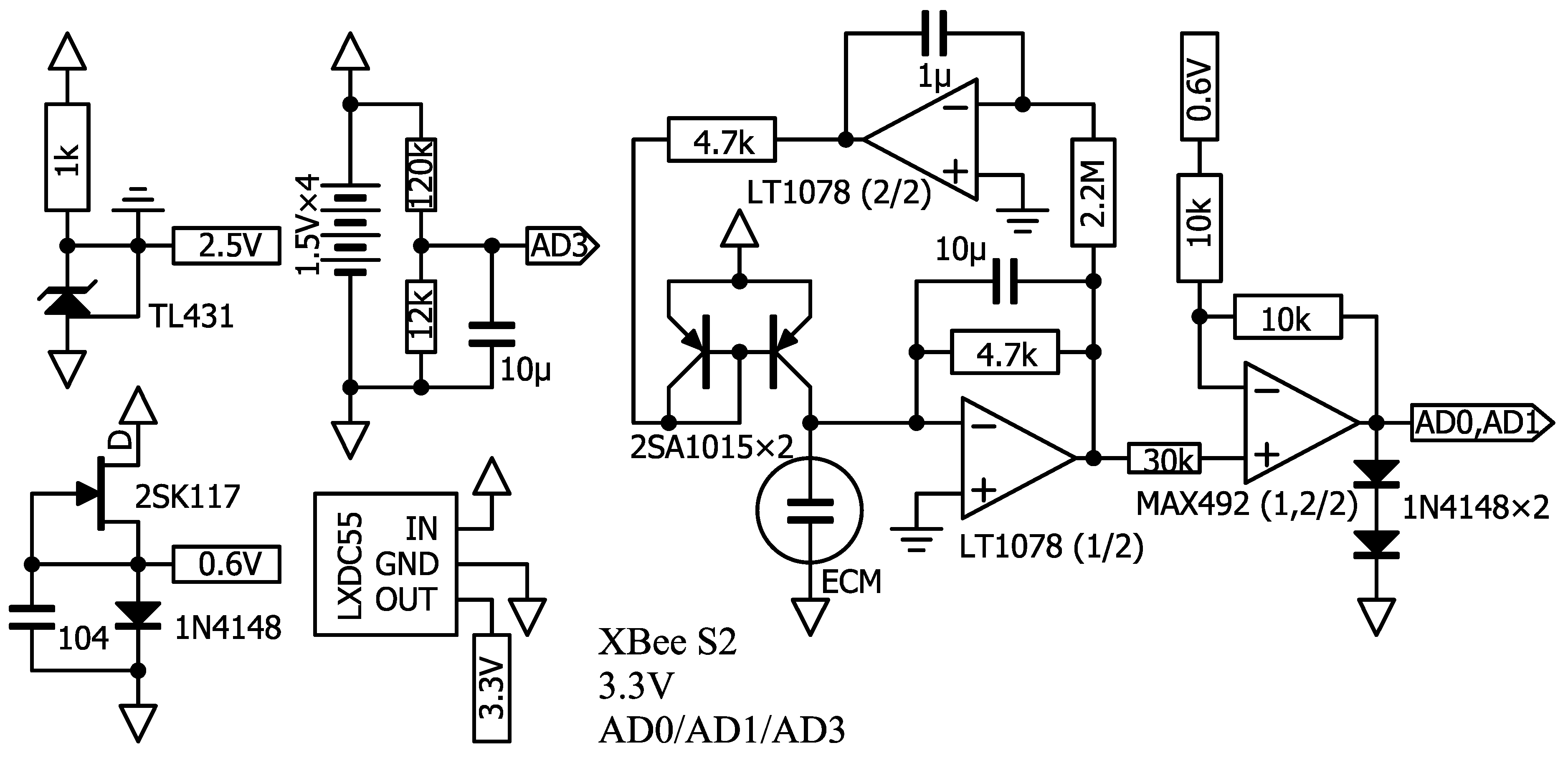

2.5. Biasing an ECM with a Constant Current

2.6. Consideration of Circuit Constants and Components

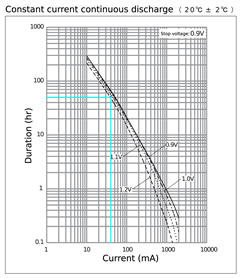

2.6.1. Power Supply Voltage

2.6.2. I/V Resistance

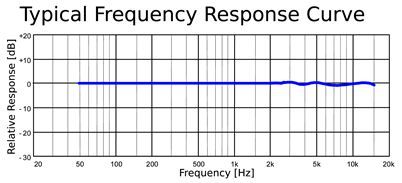

2.6.3. Low Pass Filter (LPF) and High Pass Filter (HPF)

2.6.4. Reference Voltage

2.6.5. XBee ADC Midpoint Voltage

2.6.6. Resistor to Measure Remaining Battery Capacity

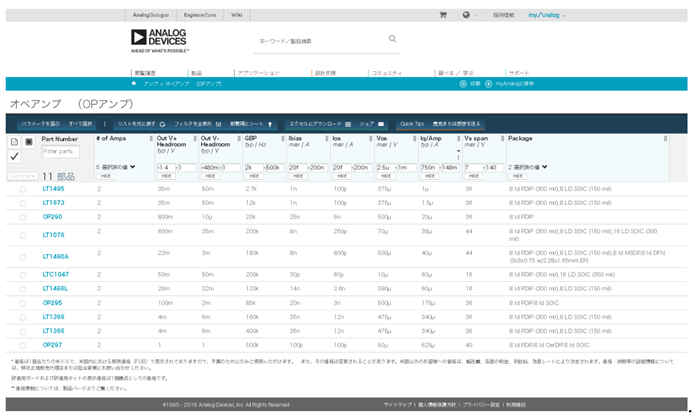

2.6.7. Op-Amps

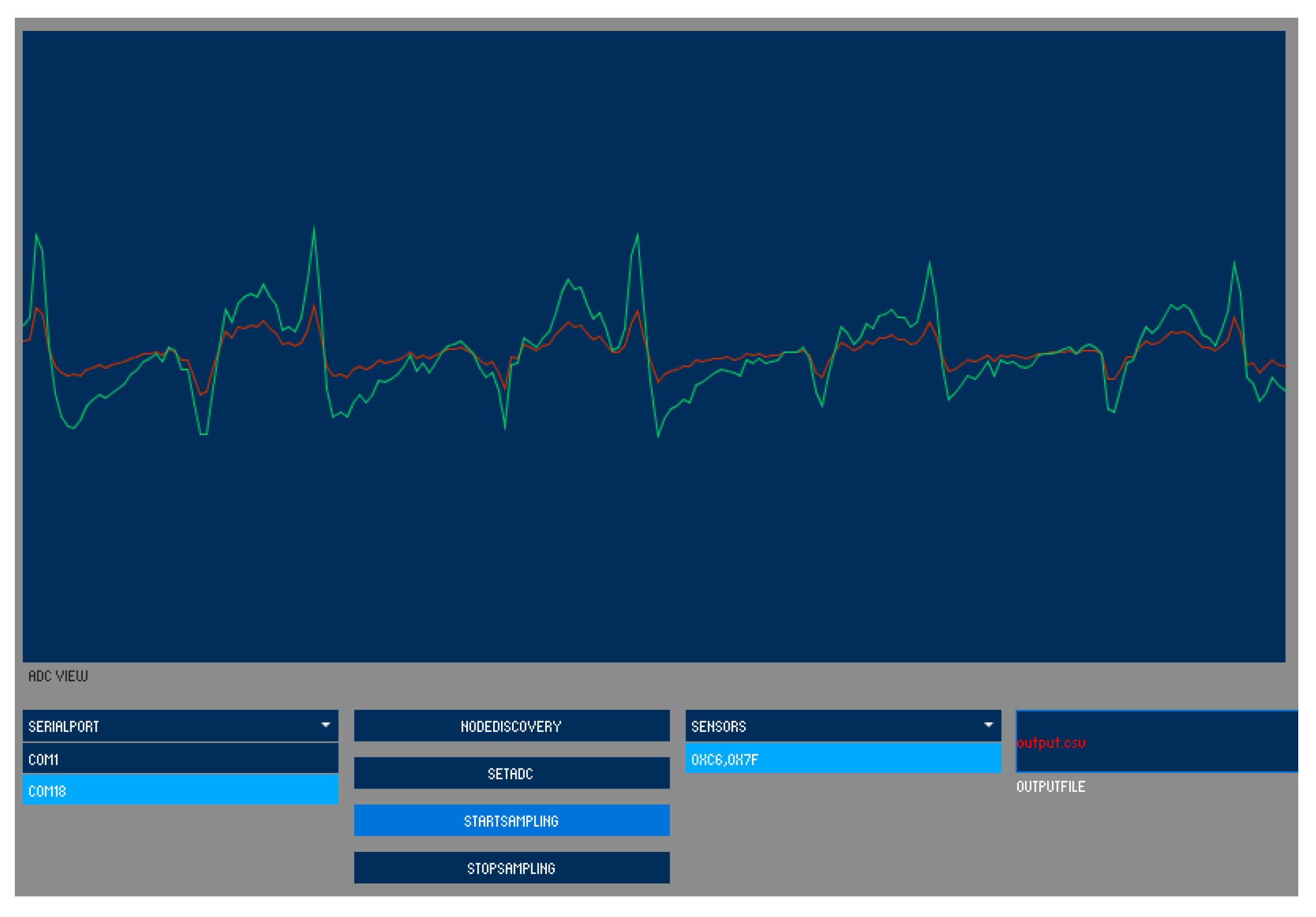

2.7. Production and Recording Program

2.8. Pressure Calibration Using a Micro Pressure Sensor

3. Results

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

Appendix C

Appendix D

Appendix E

Appendix F

References

- Snoeks, S.; Velasco, E.; Talavera, K.; Hellings, P.W. Nasal Obstruction: Overview of Pathophysiology and Presentation of a Clinically Relevant Preoperative Plan for Rhino(Septo)plasty. Facial Plast. Surg. 2024, 40, 275–286. [Google Scholar] [CrossRef] [PubMed]

- Trang, H.; Leske, V.; Gaultier, C. Use of nasal cannula for detecting sleep apneas and hypopneas in infants and children. Am. J. Respir. Crit. Care Med. 2002, 166, 464–468. [Google Scholar] [CrossRef]

- Choudhury, N.; Deshmukh, P. Obstructive Sleep Apnea in Adults and Ear, Nose, and Throat (ENT) Health: A Narrative Review. Cureus 2023. [Google Scholar] [CrossRef]

- Yeghiazarians, Y.; Jneid, H.; Tietjens, J.R.; Redline, S.; Brown, D.L.; El-Sherif, N.; Mehra, R.; Bozkurt, B.; Ndumele, C.E.; Somers, V.K. Obstructive Sleep Apnea and Cardiovascular Disease: A Scientific Statement from the American Heart Association. Circulation 2021, 144, E56–E67. [Google Scholar] [CrossRef] [PubMed]

- Kurnool, S.; McCowen, K.C.; Bernstein, N.A.; Malhotra, A. Sleep Apnea, Obesity, and Diabetes — an Intertwined Trio. Curr. Diab. Rep. 2023, 23, 165–171. [Google Scholar] [CrossRef]

- Gills, J.L.; Bubu, O.M. Obstructive Sleep Apnea and Alzheimer’s Disease Pathology: Is Sleep Architecture the Missing Key? J. Alzheimer’s Dis. 2024, 98, 69–73. [Google Scholar] [CrossRef]

- Stoksted, P. Rhinometric measurements for determination of the nasal cycle. Acta Otolaryngol. 1953, 43, 159–175. [Google Scholar] [CrossRef]

- Kahana-Zweig, R.; Geva-Sagiv, M.; Weissbrod, A.; Secundo, L.; Soroker, N.; Sobel, N. Measuring and characterizing the human nasal cycle. PLoS One 2016, 11, e0162918. [Google Scholar] [CrossRef]

- Shannahoff-Khalsa, D. Lateralized rhythms of the central and autonomic nervous systems. Int. J. Psychophysiol. 1991, 11, 225–251. [Google Scholar] [CrossRef]

- Ishii, J.; Ishii, T.; Ito, M. The nasal cycle in patients with autonomic nervous disturbance. Acta Otolaryngol. 1993, 113, 51–56. [Google Scholar] [CrossRef]

- Norman, R.G.; Ahmed, M.M.; Walsleben, J.A.; Rapoport, D.M. Detection of respiratory events during NPSG: Nasal cannula/pressure sensor versus thermistor. Sleep 1997, 20, 1175–1184. [Google Scholar] [CrossRef] [PubMed]

- Roopa Manjunatha, G.; Roy Mahapatra, D.; Prakash, S.; Rajanna, K. Validation of polyvinylidene fluoride nasal sensor to assess nasal obstruction in comparison with subjective technique. Am. J. Otolaryngol. - Head Neck Med. Surg. 2015, 36, 122–129. [Google Scholar] [CrossRef]

- Hakimi, A.A.; Sharma, G.K.; Ngo, T.; Heidari, A.E.; Badger, C.D.; Tripathi, P.B.; Hong, E.M.; Chen, Z.; Wong, B.J.F. Coupling Pressure Sensing with Optical Coherence Tomography to Evaluate the Internal Nasal Valve. Ann. Otol. Rhinol. Laryngol. 2021, 130, 167–172. [Google Scholar] [CrossRef]

- Silvestri, S.; Schena, E. Micromachined flow sensors in biomedical applications. Micromachines 2012, 3, 225–243. [Google Scholar] [CrossRef]

- Kottapalli, A.G.P.; Tan, C.W.; Olfatnia, M.; Miao, J.M.; Barbastathis, G.; Triantafyllou, M. A liquid crystal polymer membrane MEMS sensor for flow rate and flow direction sensing applications. J. Micromechanics Microengineering 2011, 21, 085006. [Google Scholar] [CrossRef]

- Jiang, P.; Zhao, S.; Zhu, R. Smart sensing strip using monolithically integrated flexible flow sensor for noninvasively monitoring respiratory flow. Sensors (Switzerland) 2015, 15, 31738–31750. [Google Scholar] [CrossRef]

- Sabil, A.; Glos, M.; GüNther, A.; Schöbel, C.; Veauthier, C.; Fietze, I.; Penzel, T. Comparison of apnea detection using oronasal thermal air?ow sensor, nasal pressure transducer, respiratory inductance plethysmography and tracheal sound sensor. J. Clin. Sleep Med. 2019, 15, 285–292. [Google Scholar] [CrossRef]

- Teichtahl, H.; Cunnington, D.; Cherry, G.; Wang, D. Scoring polysomnography respiratory events: The utility of nasal pressure and oro-nasal thermal sensor recordings. Sleep Med. 2003, 4, 419–425. [Google Scholar] [CrossRef]

- Berry, R.B.; Koch, G.L.; Trautz, S.; Wagner, M.H. Comparison of respiratory event detection by a polyvinylidene fluoride film airflow sensor and a pneumotachograph in sleep apnea patients. Chest 2005, 128, 1331–1338. [Google Scholar] [CrossRef]

- Arnin, J.; Anopas, D.; Horapong, M.; Triponyuwasi, P.; Yamsa-Ard, T.; Iampetch, S.; Wongsawat, Y. Wireless-based portable EEG-EOG monitoring for real time drowsiness detection. In Proceedings of the Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society, EMBS; IEEE, 2013; pp. 4977–4980. [Google Scholar] [CrossRef]

- Fraile, L.P.; Tsampas, S.; Mylonas, G.; Amaxilatis, D. A Comparative Study of LoRa and IEEE 802.15.4-Based IoT Deployments Inside School Buildings. IEEE Access 2020, 8, 160957–160981. [Google Scholar] [CrossRef]

- Haque, K.F.; Abdelgawad, A.; Yelamarthi, K. Comprehensive Performance Analysis of Zigbee Communication: An Experimental Approach with XBee S2C Module. Sensors 2022, 22, 3245. [Google Scholar] [CrossRef] [PubMed]

- Shikida, M.; Naito, J.; Yokota, T.; Kawabe, T.; Hayashi, Y.; Sato, K. A catheter-type flow sensor for measurement of aspirated- and inspired-air characteristics in the bronchial region. J. Micromechanics Microengineering 2009, 19, 105027. [Google Scholar] [CrossRef]

| Power supply | Four AA batteries (1.5V) |

| Uptime | About 2 days (50 hours) |

| Sensing pressure | ±50 Pa |

| Sensor response frequency | Around 3Hz |

| Sampling Rate | 20Hz |

| Data output | Wireless / Real-time |

| Module | Standard | Current consumption | Remarks |

|---|---|---|---|

| XBee S2 | ZigBee | Transmit: 33 mA Receive: 28 mA |

Java SDK is available. |

| TWE-Lite (TWE-001L) | IEEE802.15.4 | Transmit: 17 mA Receive: 15 mA |

Java SDK is not available. |

| XBee S6 (Wi-Fi) | Wi-Fi | Transmit: 309 mA Receive: 100 mA |

|

| ESP8266 (ESP-WROOM-02) |

Wi-Fi | Average 80 mA | |

| ESP32 (ESP-WROOM-32) |

Wi-Fi + Bluetooth LE |

Wi-Fi transmission 160-260 mA |

|

| nRF51822 | Bluetooth LE | Transmit: 16 mA | Requires Windows 8.1 or later |

| RN4020 | Bluetooth LE | Transmit: 16 mA | Requires Windows 8.1 or later |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).