Submitted:

05 March 2025

Posted:

07 March 2025

You are already at the latest version

Abstract

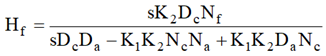

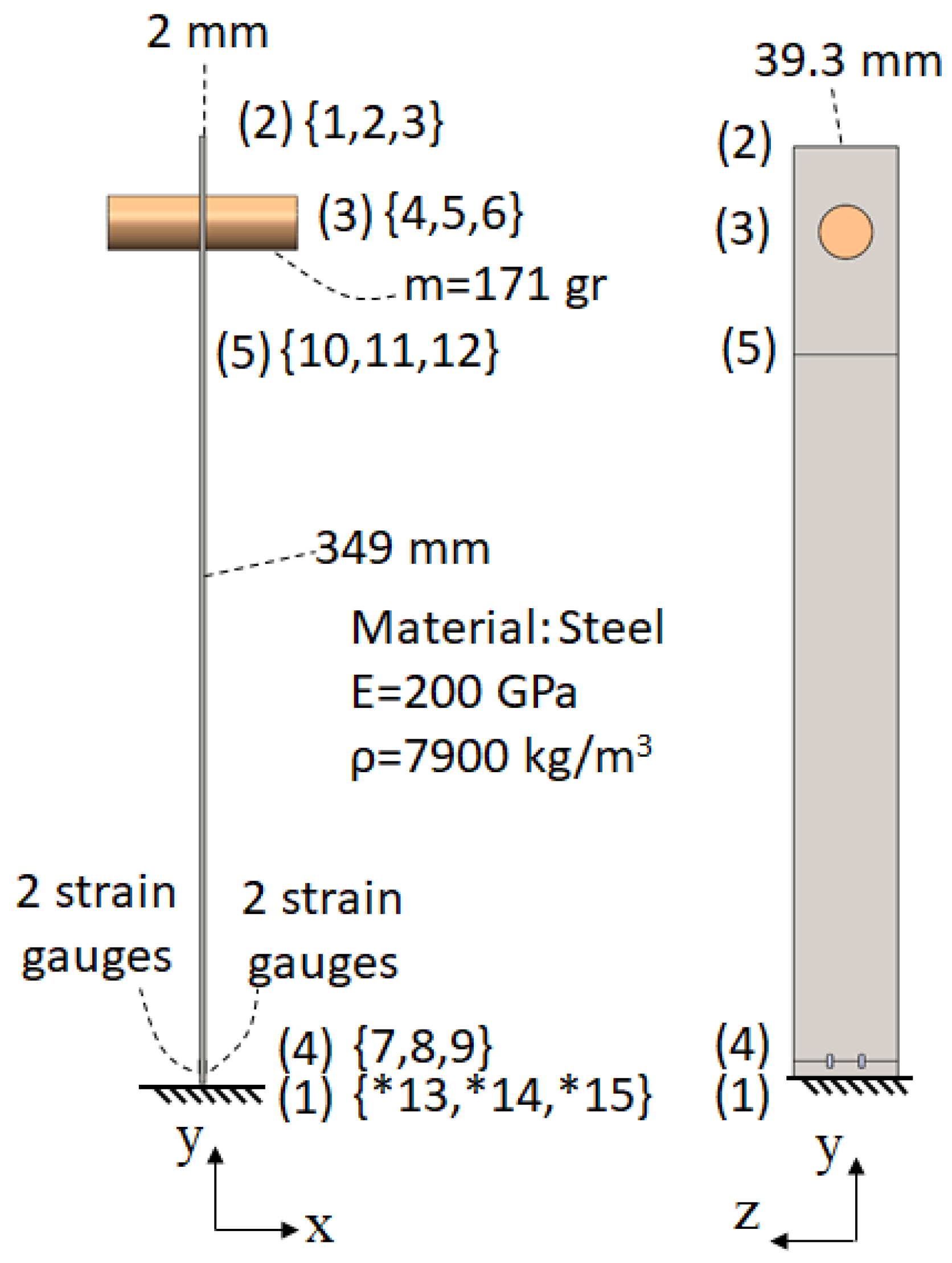

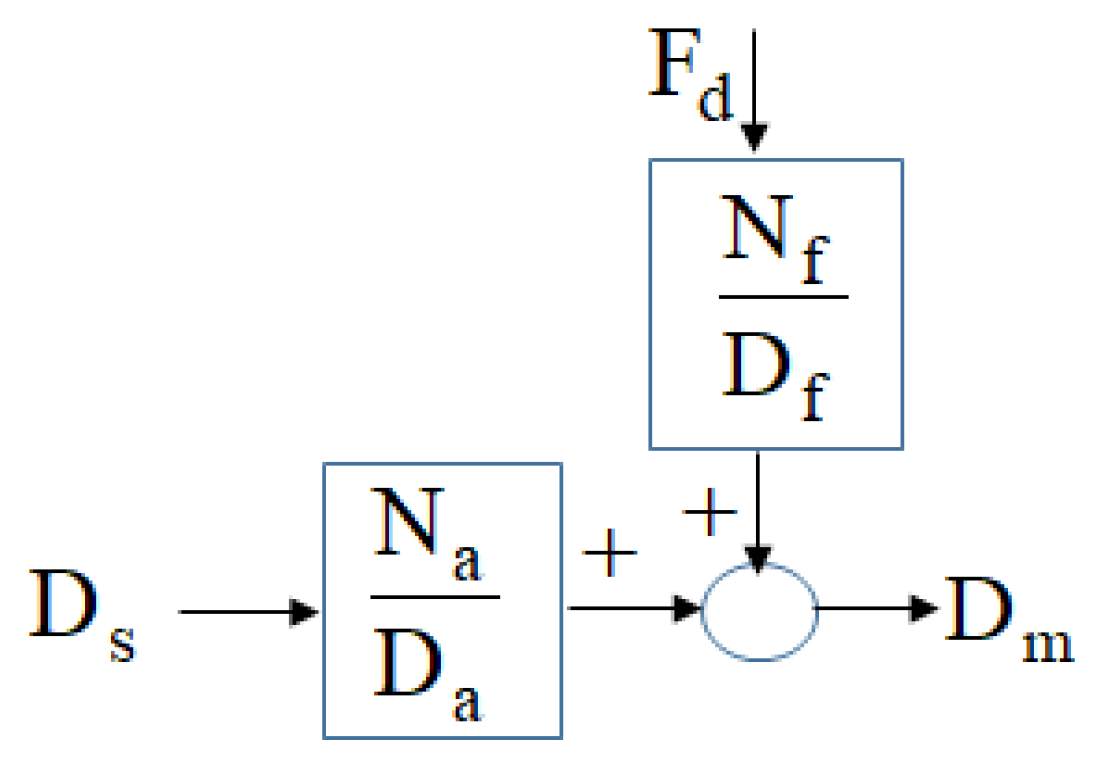

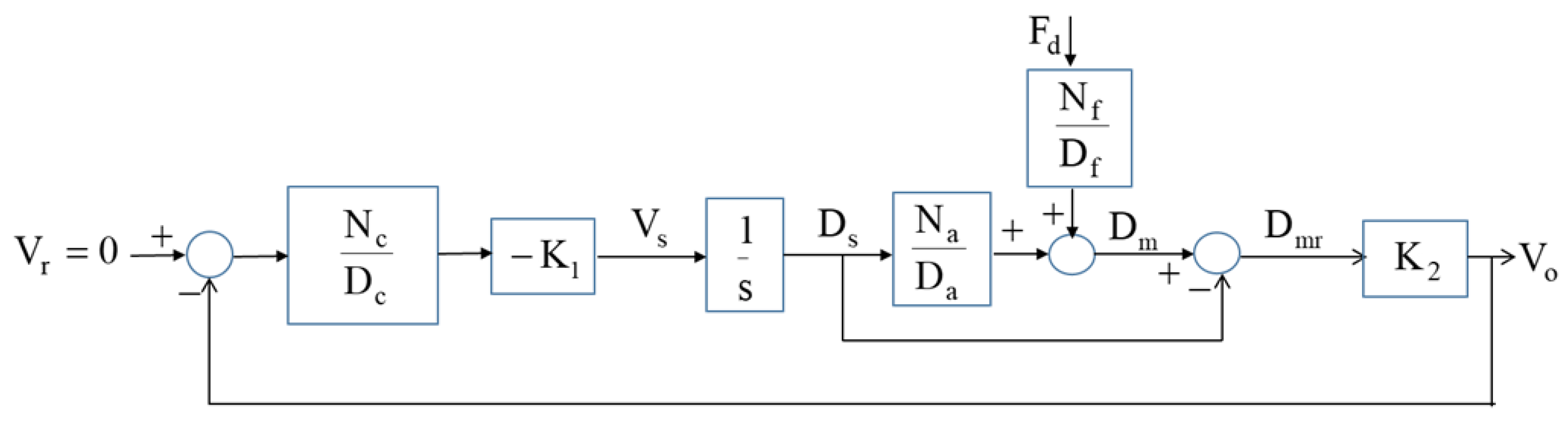

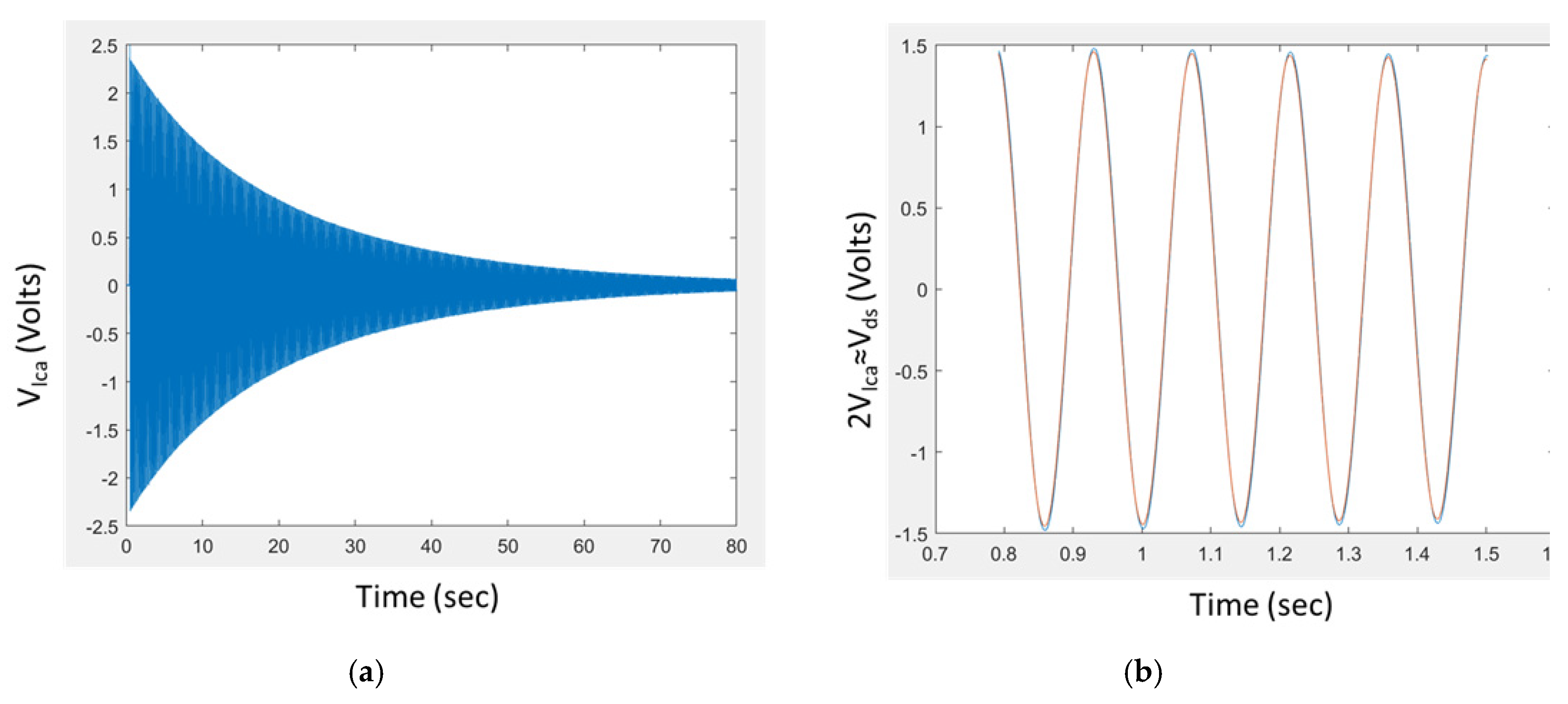

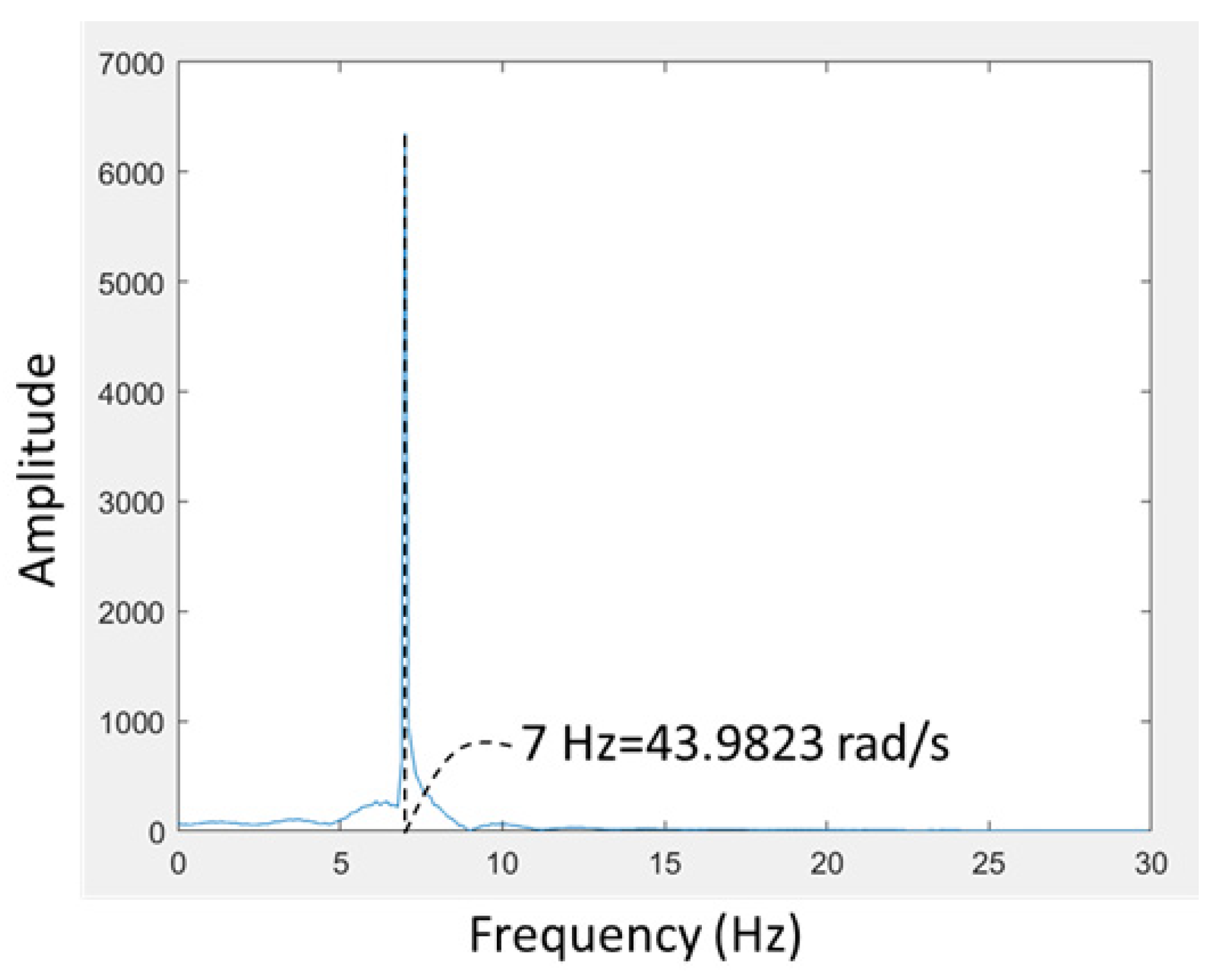

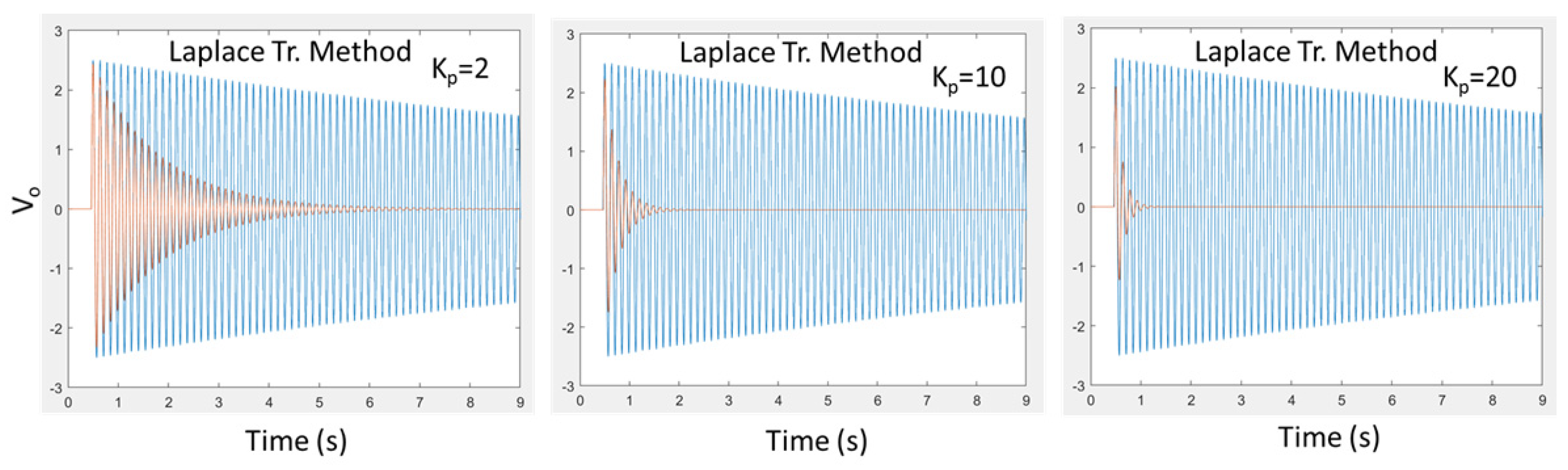

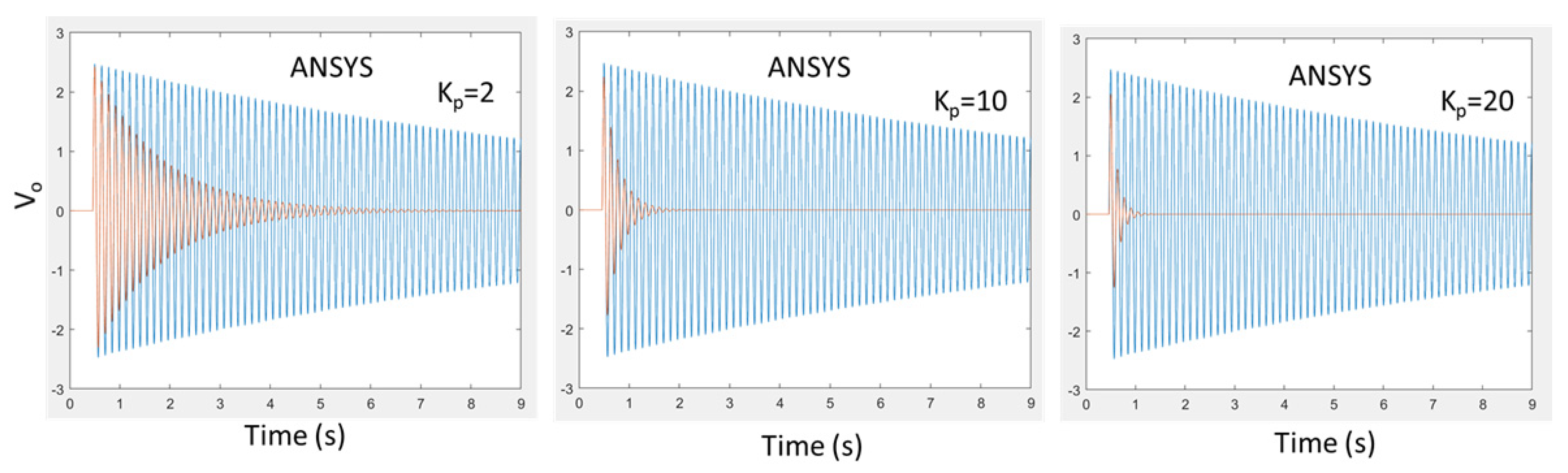

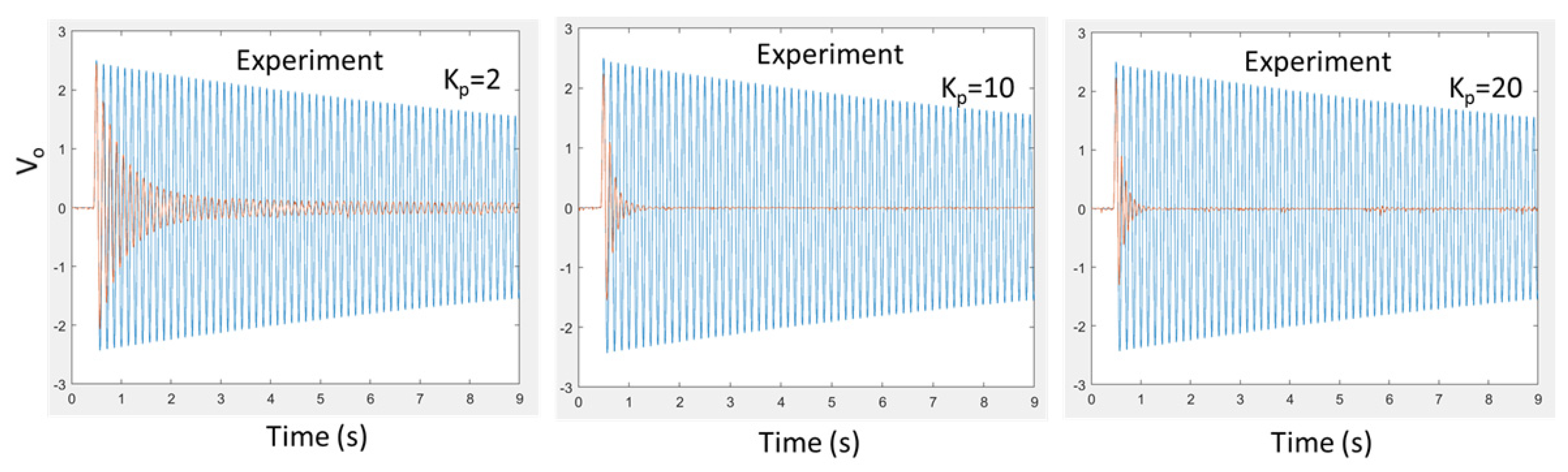

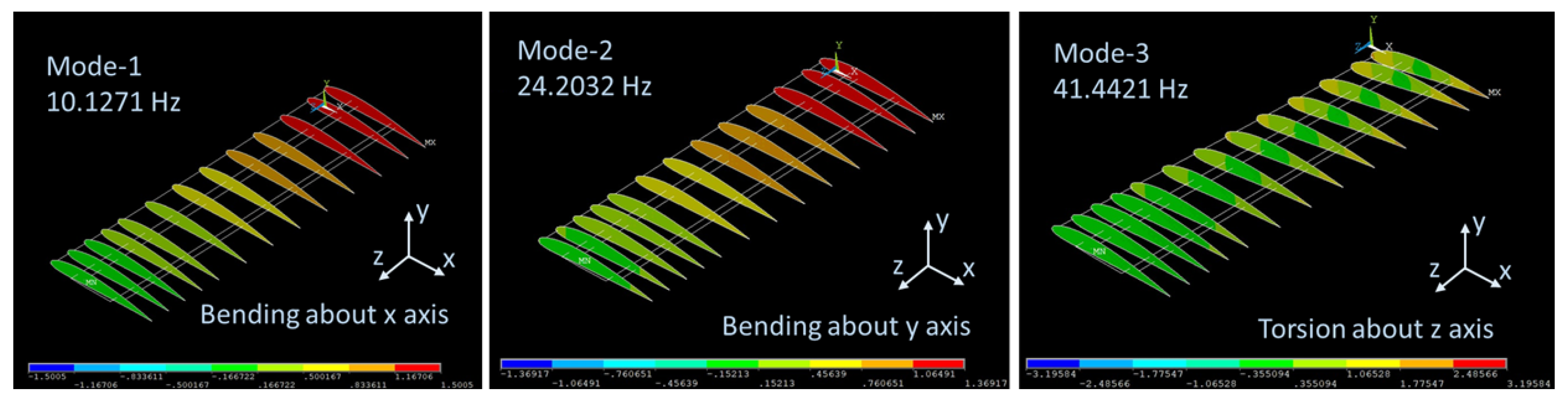

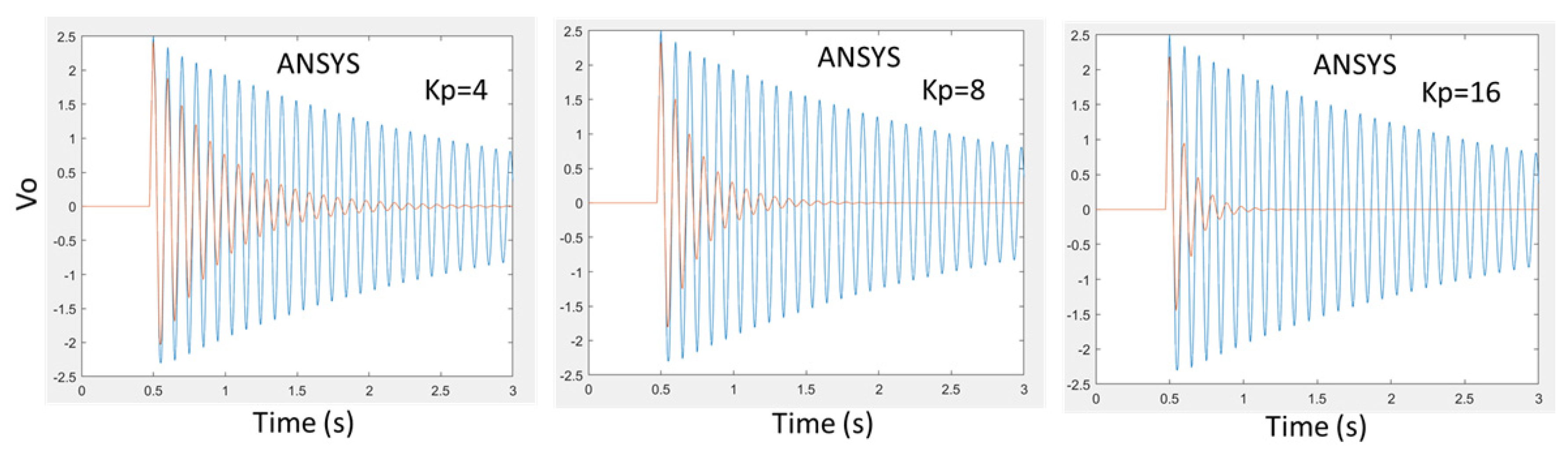

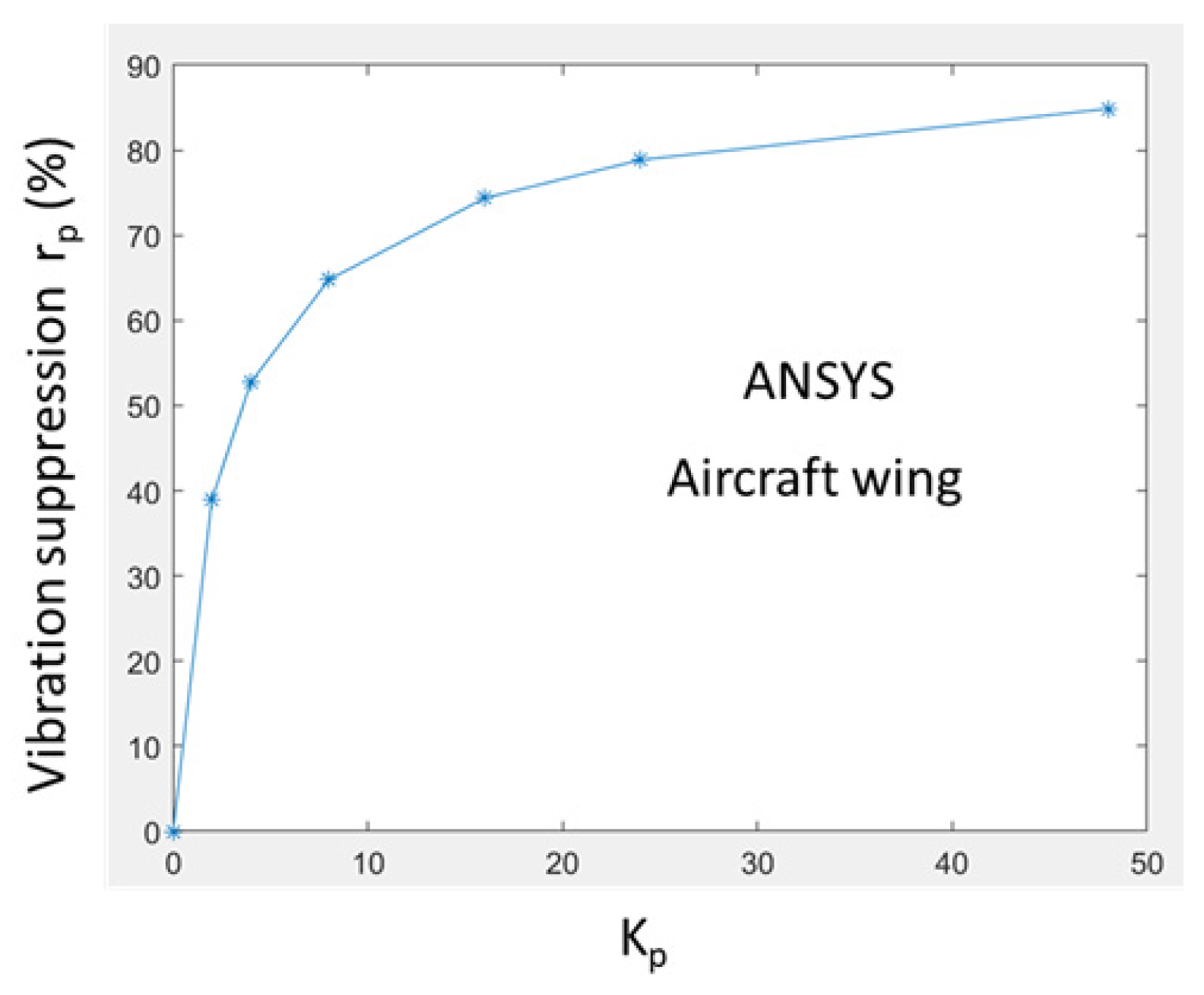

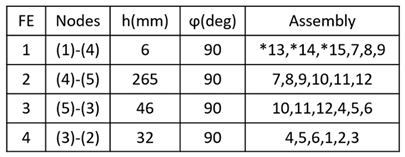

In this work, the active vibration control (AVC) of a cantilever beam with an end mass is considered first, and studied experimentally and through simulation. Laplace transform method, Newmark method, and ANSYS are used for finite element simulations. An impulse force applied to the mass and the velocity actuation applied to the base are assumed to be disturbance and controlling input, respectively. The displacement of the mass taken as the feedback signal in simulations. Four strain-gauges located near the bottom point, connected with Wheatstone bridge, and the output voltage of a load-cell amplifier (LCA) is used as the feedback signal in experiments. Strain feedback is considered in experiments because it is easy to implement, cost effective and applicable in applications. Experimental displacement signals obtained from the top of the beam are compared with the output signals from LCA and it is observed that they are approximately linearly dependent. Velocity input is generated with a servo motor driven linear actuator in experiments. The closed loop control is achieved by a personal computer with Adlink-9222 PCI DAQ card and a C program in the experiments. The integration of the closed loop control action into the transient solution with Newmark method and ANSYS is implemented in simulations. The input reference value is taken as zero for vibration control. The instantaneous value of the feedback signal at a time step is subtracted from zero to find the error signal value and the error value is multiplied by the control gain to calculate the controlling signal. The simulation results obtained with Newmark method and ANSYS are in good agreement with the analytical results obtained with Laplace transform method. Simulation results are also in acceptable agreement with experimental results for explaining the behaviour of the success of AVC depending on the control gain, Kp. After verifying ANSYS solutions, ANSYS procedure is applied to an aircraft wing as a real complex cantilever structure. The wing with a length of 810.8 mm, 13 ribs with a length of 300 mm and NACA 4412 aerofoil is considered in the study. It is observed that AVC of real engineering structures can be simulated by integrating control action into transient solution in ANSYS.

Keywords:

1. Introduction

2. Simulation Of Active Vibration Control of Cantilever Beam with End Mass

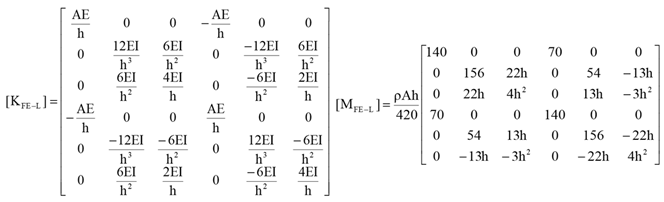

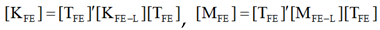

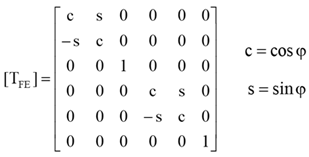

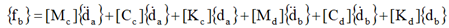

2.1. Finite Element Model for Laplace Transform and Newmark Method Solution

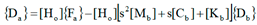

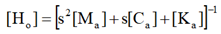

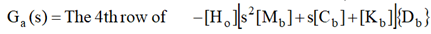

2.2. Simulation by Laplace Transform Method

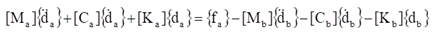

2.3. Simulation by Newmark Method

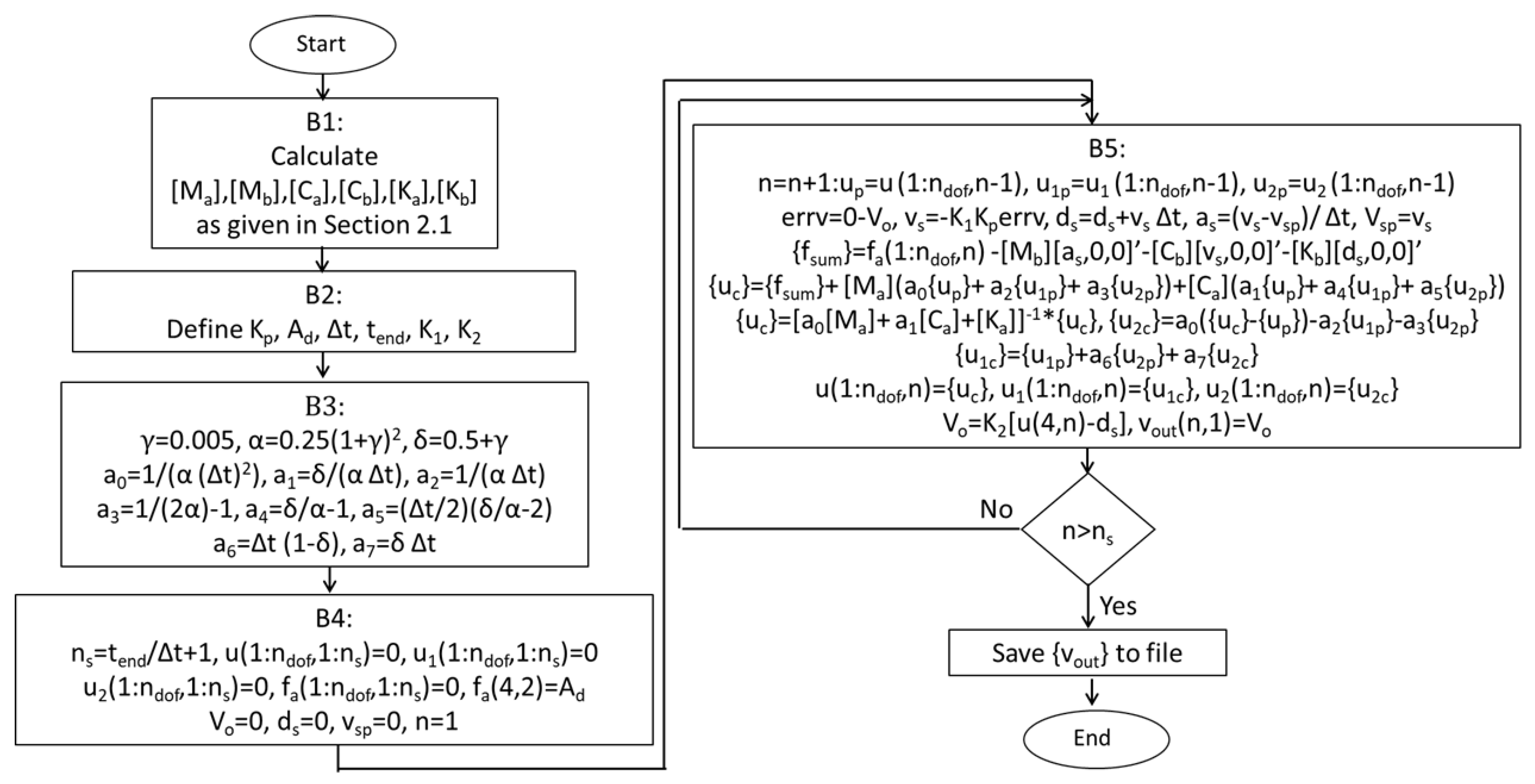

2.4. Simulation by ANSYS APDL

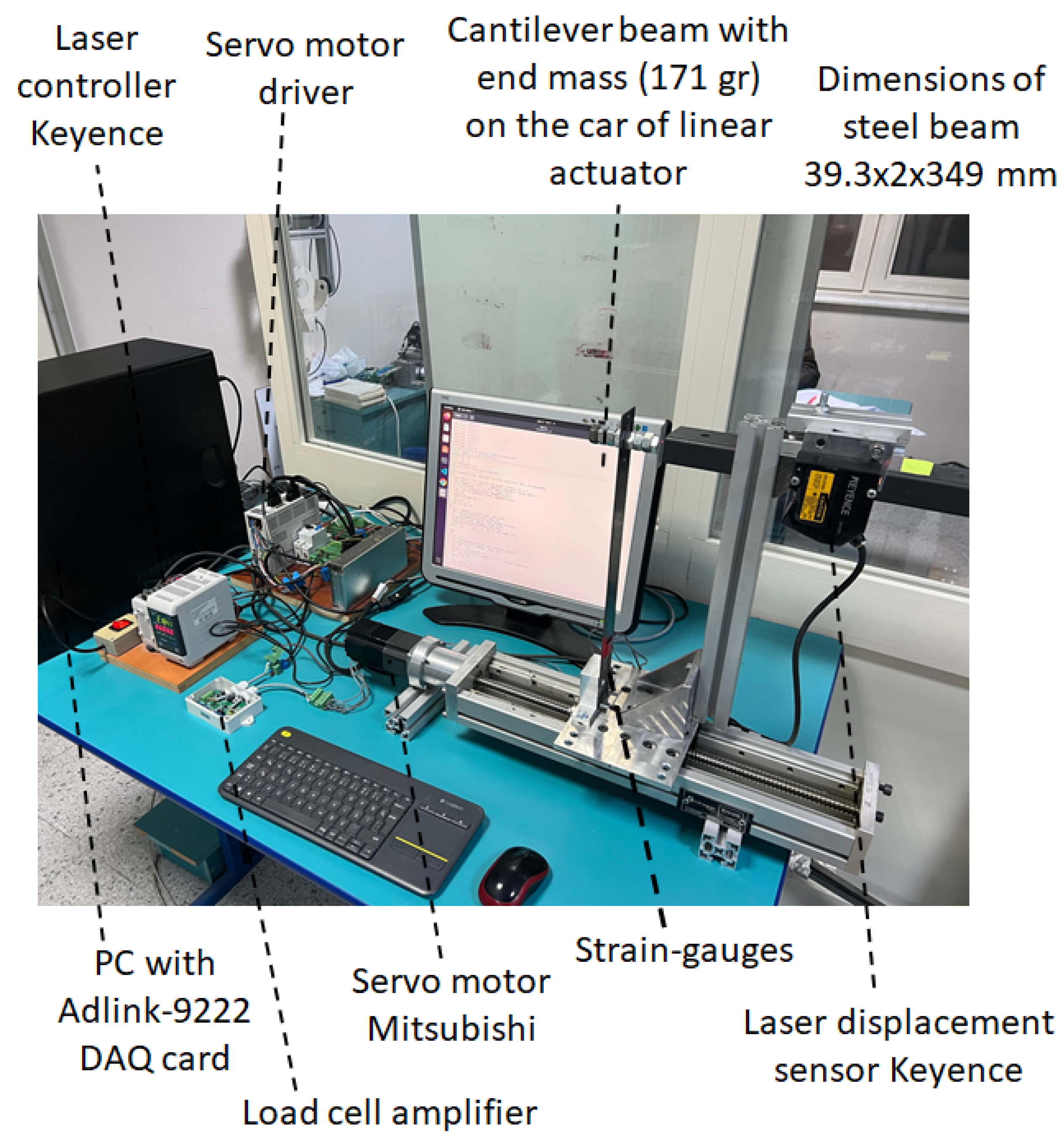

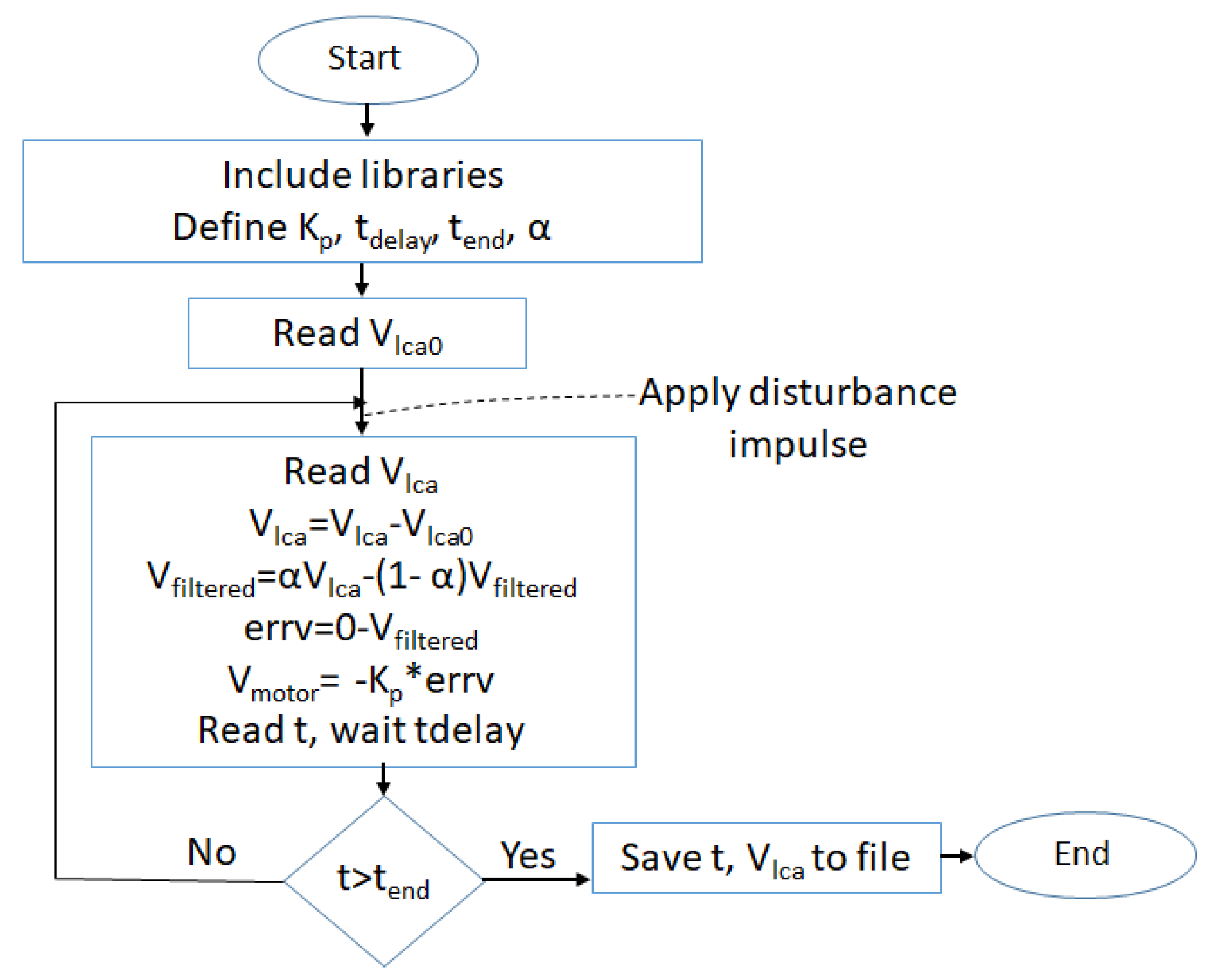

3. Experimental System of Active Vibration Control of Cantilever Beam

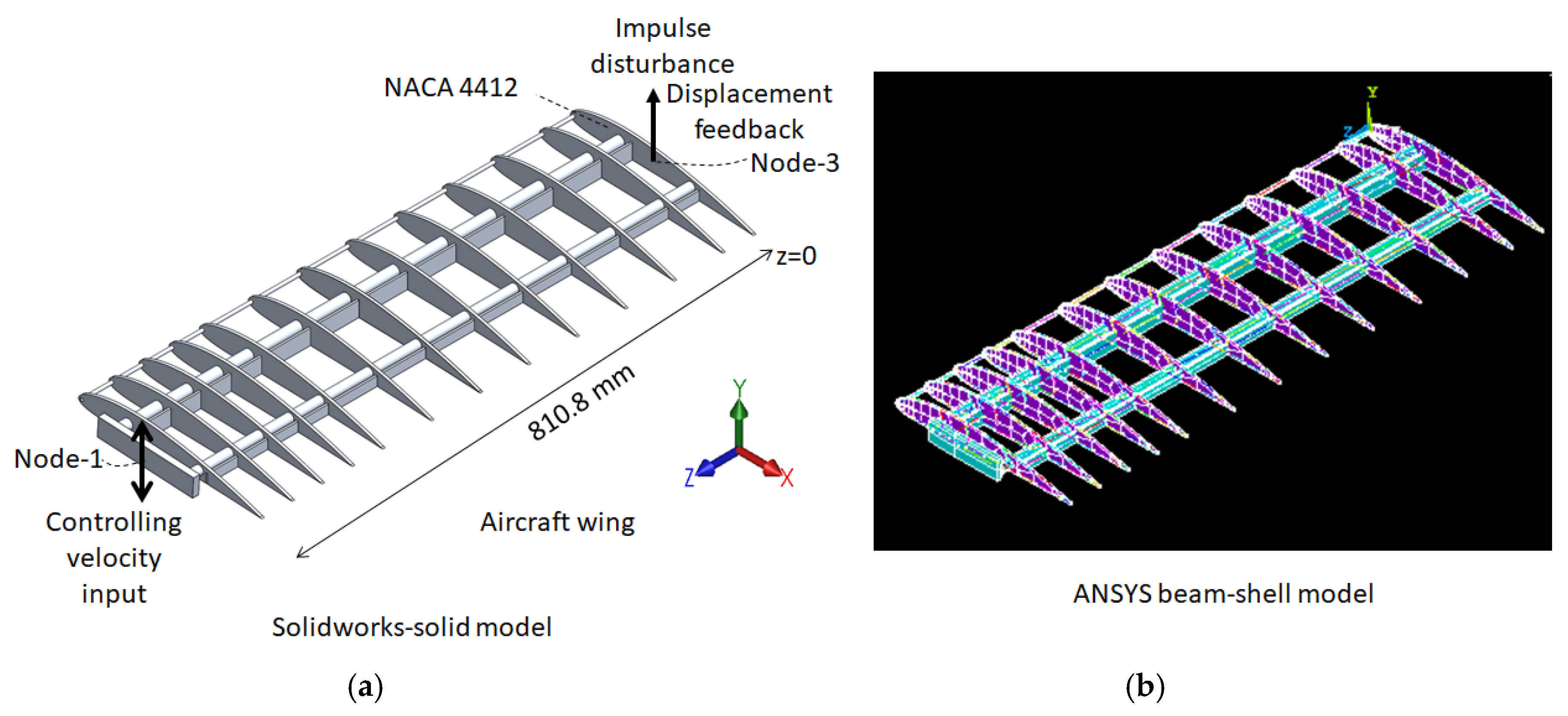

4. Simulation of Active Vibration Control of Aircraft Wing by ANSYS APDL

5. Results and Discussions

5.1. Comparison of Experimental Strain and Displacement Sensor Output Signals

5.2. Determining Damping Constant Experimentally

5.3. AVC of Cantilever Beam Results Obtained by Laplace Transform Method, Newmark Method, ANSYS and Experiments

5.4. AVC of Aircraft Wing by ANSYS APDL

6. Conclusions

Appendix A. C Program for Experimental System

References

- Wang, Y.; Wu, W.; Lou, X.; Görges, D. Adaptive vibration control for stabilisation of the Euler–Bernoulli beam with an unknown payload. International Journal of Control 2024, 1–12. [Google Scholar] [CrossRef]

- Lyu, Z.; Li, C.; Jia, T. Combined vibration control of flexible cantilever beam driven by MFC actuators and rotary motor. Acta Mechanica 2024, 1–16. [Google Scholar] [CrossRef]

- Li, W.; Yang, Z.; Li, K.; Wang, W. Hybrid feedback PID-FxLMS algorithm for active vibration control of cantilever beam with piezoelectric stack actuator. Journal of Sound and Vibration 2021, 509, 116243. [Google Scholar] [CrossRef]

- Amer, Y.A.; EL-Sayed, A.T.; Abd EL-Salam, M.N. A suitable active control for suppression the vibrations of a cantilever beam. Sound Vib 2022, 56, 89–104. [Google Scholar] [CrossRef]

- Saif, A.W.A.; Mohammed, A.A.; AlSunni, F.; El Ferik, S. Active Vibration Control of a Cantilever Beam Structure Using Pure Deep Learning and PID with Deep Learning-Based Tuning. Applied Sciences 2024, 14, 11520. [Google Scholar] [CrossRef]

- Huang, Z.; Huang, F.; Wang, X.; Chu, F. Active vibration control of composite cantilever beams. Materials 2022, 16, 95. [Google Scholar] [CrossRef]

- Djokoto, S.S.; Dragašius, E.; Jūrėnas, V.; Agelin-Chaab, M. Controlling of vibrations in micro-cantilever beam using a layer of active electrorheological fluid support. IEEE Sensors Journal 2019, 20, 4072–4079. [Google Scholar] [CrossRef]

- Cui, M.; Liu, H.; Jiang, H.; Zheng, Y.; Wang, X.; Liu, W. Active vibration optimal control of piezoelectric cantilever beam with uncertainties. Measurement and Control 2022, 55, 359–369. [Google Scholar] [CrossRef]

- Umar, H.M.; Zhang, L.; Yu, R.; Gao, Z. Improved active vibration control of a cantilever beam using MFC actuators with Hammerstein model-based hysteresis modeling and VSS-FxLMS control algorithm. Journal of Low Frequency Noise, Vibration and Active Control 2024, 14613484241295460. [Google Scholar] [CrossRef]

- Teoh, J.Q.; Tehrani, M.G.; Ferguson, N.S.; Elliott, S.J. Eigenvalue sensitivity minimisation for robust pole placement by the receptance method. Mechanical Systems and Signal Processing 2022, 173, 108974. [Google Scholar] [CrossRef]

- Karagülle, H.; Malgaca, L.; Öktem, H.F. Analysis of active vibration control in smart structures by ANSYS. Smart materials and Structures 2004, 13, 661. [Google Scholar]

- Ito, T.; Tagami, M.; Tagawa, Y. Active vibration control for high-rise buildings using displacement measurements by image processing. Structural Control and Health Monitoring 2022, 29, e3136. [Google Scholar]

- Ramírez-Neria, M.; Morales-Valdez, J.; Yu, W. Active vibration control of building structure using active disturbance rejection control. Journal of Vibration and Control 2022, 28, 2171–2186. [Google Scholar]

- Gheni, E.Z.; Al-Khafaji, H.M.; Alwan, H.M. A deep reinforcement learning framework to modify LQR for an active vibration control applied to 2D building models. Open Engineering 2024, 14, 20220496. [Google Scholar]

- Zhang, Q.; Han, S.; El-Meligy, M.A.; Tlija, M. Active control vibrations of aircraft wings under dynamic loading: Introducing PSO-GWO algorithm to predict dynamical information. Aerospace Science and Technology 2024, 153, 109430. [Google Scholar]

- He, T.; Zhu, G.G.; Swei, S.S.M.; Su, W. Smooth-switching LPV control for vibration suppression of a flexible airplane wing. Aerospace Science and Technology 2019, 84, 895–903. [Google Scholar]

- Li, W.; Yang, Z.; Liu, K.; Wang, W. MIMO multi-frequency active vibration control for aircraft panel structure using piezoelectric actuators. International Journal of Structural Stability and Dynamics 2023, 23, 2350157. [Google Scholar]

- Dong, L.; Chen, Z.; Sun, M.; Sun, Q. Phase compensation active disturbance rejection control for shimmy vibration with magnetorheological damper of aircraft. Expert Systems with Applications 2023, 213, 119126. [Google Scholar]

- Sahin, M.; Karadal, F.M.; Yaman, Y.; Kircali, O.F.; Nalbantoglu, V.; Ulker, F.D.; Caliskan, T. Smart structures and their applications on active vibration control: Studies in the Department of Aerospace Engineering, METU. Journal of Electroceramics 2008, 20, 167–174. [Google Scholar]

- Prakash, S.; Kumar, T.R.; Raja, S.; Dwarakanathan, D.; Subramani, H.; Karthikeyan, C. Active vibration control of a full scale aircraft wing using a reconfigurable controller. Journal of Sound and Vibration 2016, 361, 32–49. [Google Scholar]

- Bathe, K.J. Finite Element Procedures, 2nd ed.; Prentice-Hall: New Jersey, 2014. [Google Scholar]

- Rao, S.S. Mechanical Vibrations in SI Units, 6th ed.; Pearson Education Limited, 2018; 1147p. [Google Scholar]

- Yavuz, Ş.; Akdağ, M.; Karagülle, H. A fast processing method to perform transient analysis for vibration control. Simulation Modelling Practice and Theory 2020, 104, 102152. [Google Scholar]

- Figliola, R.S.; Beasley, D.E. Theory and Design for Mechanical Measurements, Fifth ed.; John Wiley & Sons, 2011. [Google Scholar]

- Tan, L. Digital Signal Processing; Elsevier, 2008. [Google Scholar]

- http://airfoiltools.com/airfoil/details?airfoil=naca4412-il.

|

| Kp=0 | Kp=1 | Kp=2 | Kp=4 | Kp=5 | Kp=8 | Kp=10 | Kp=20 | |

| Experiment | 1.3190 | 0.5930 | 0.3307 | 0.2380 | 0.2146 | 0.1934 | 0.1900 | 0.1565 |

| Laplace Tr. | 1.3969 | 0.6627 | 0.4859 | 0.3501 | 0.3143 | 0.2499 | 0.2240 | 0.1590 |

| Newmark | 1.2667 | 0.6385 | 0.4746 | 0.3447 | 0.3101 | 0.2472 | 0.2217 | 0.1577 |

| ANSYS | 1.2484 | 0.6417 | 0.4787 | 0.3484 | 0.3125 | 0.2501 | 0.2244 | 0.1597 |

| Kp=0 | Kp=2 | Kp=4 | Kp=8 | Kp=16 | Kp=24 | Kp=48 | |

| ANSYS | 1.0047 | 0.6127 | 0.4747 | 0.3538 | 0.2575 | 0.2124 | 0.1520 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).