Submitted:

28 February 2025

Posted:

03 March 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

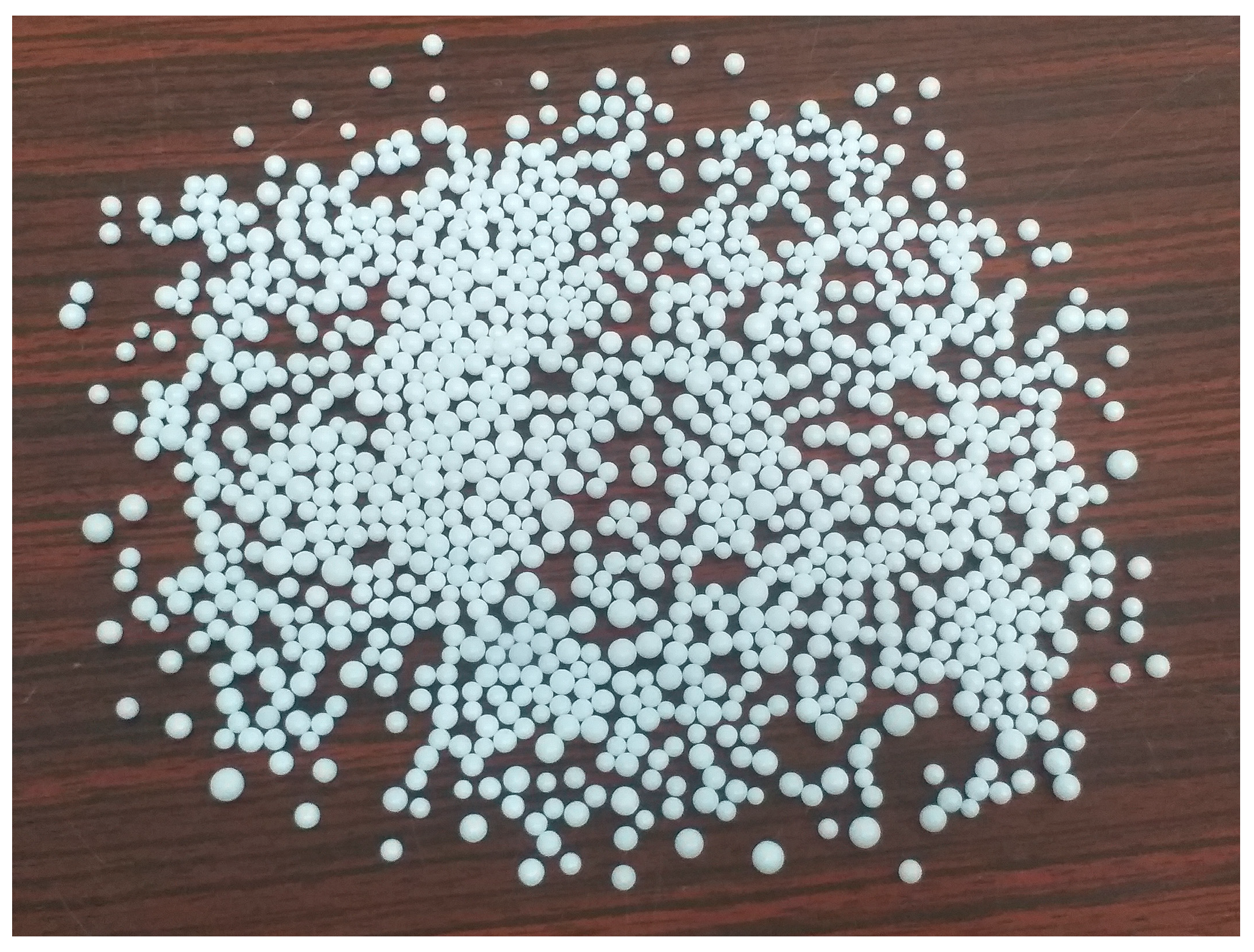

2.1. Specimen Preparation

2.2. Mix Composition

2.3. Mix Production

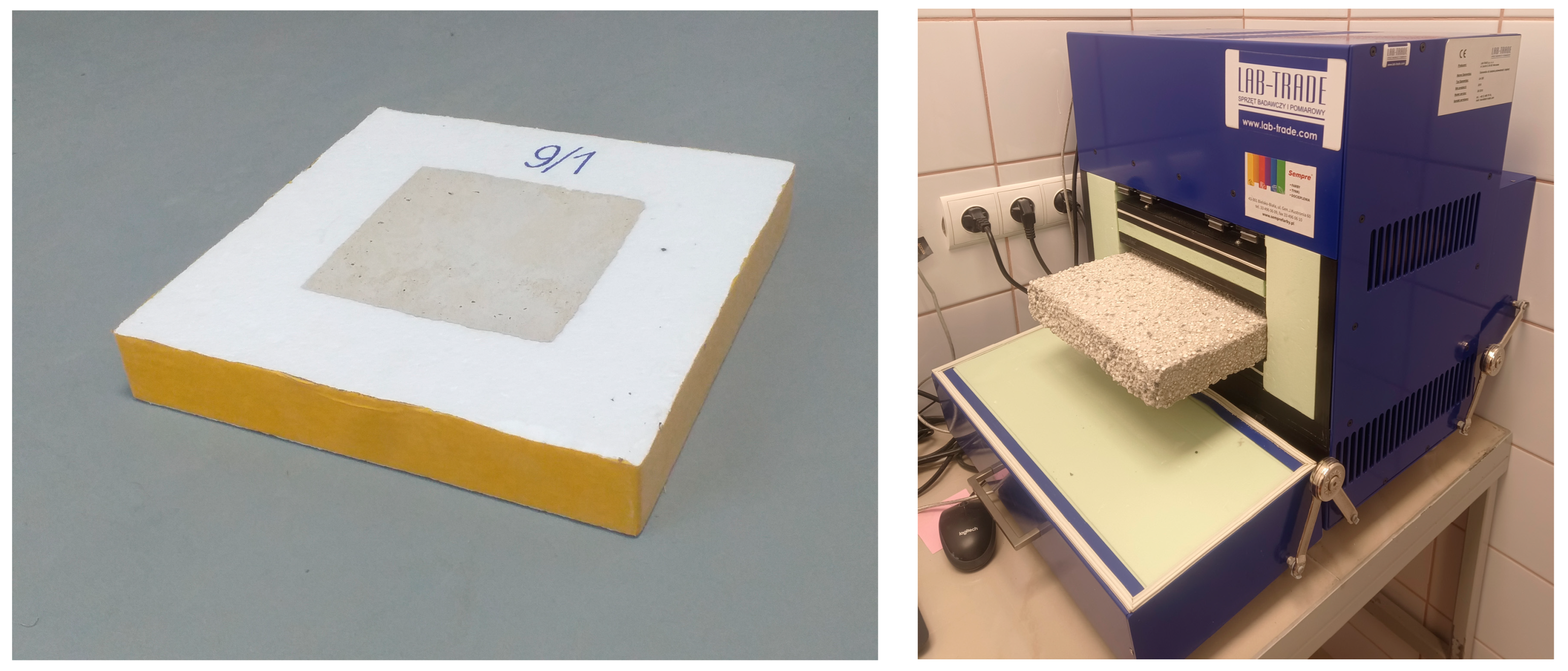

2.4. Methodology

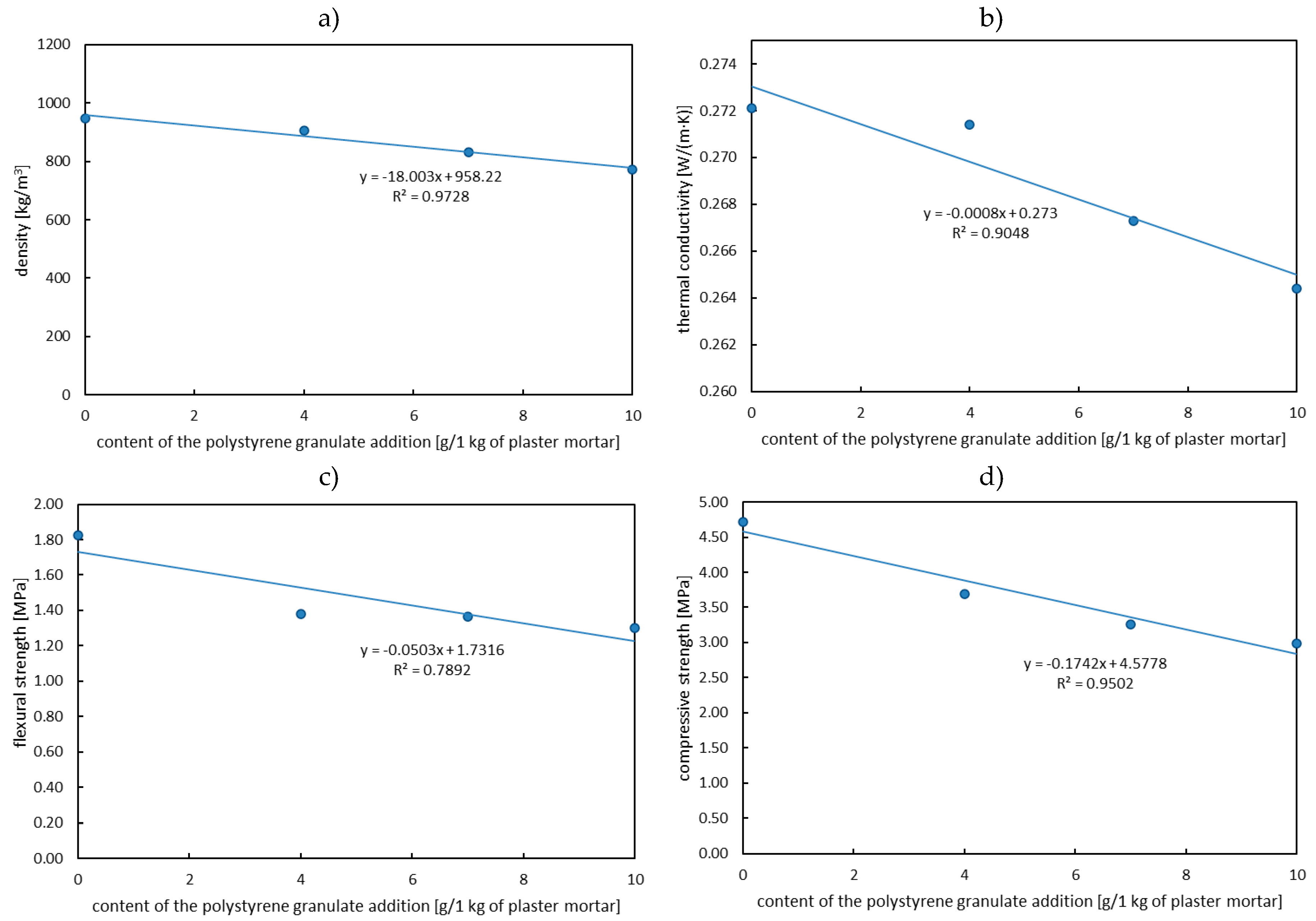

2.4.1. Density

2.4.2. Thermal Conductivity

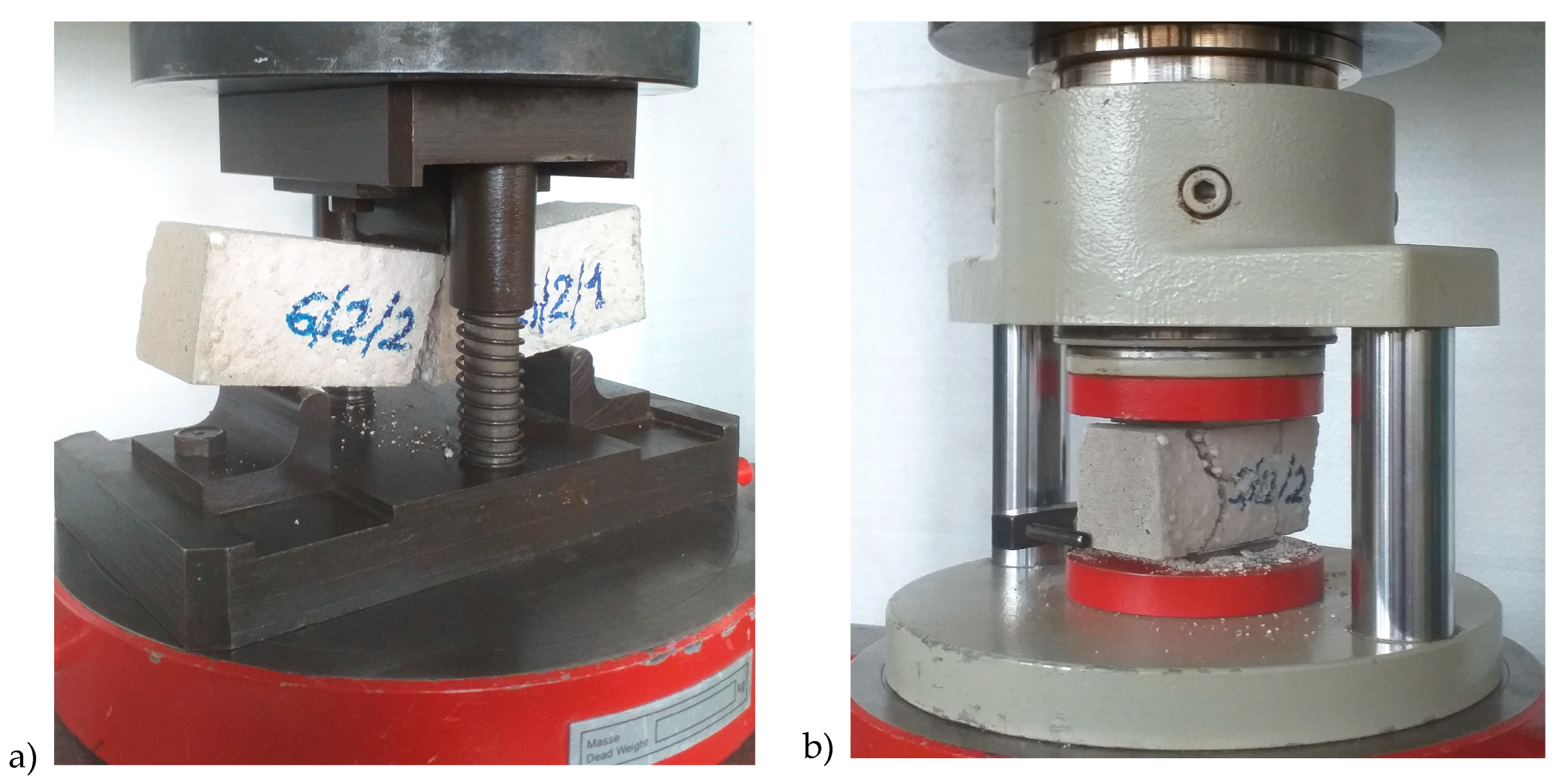

2.4.3. Flexural Strength

2.4.4. Compressive Strength

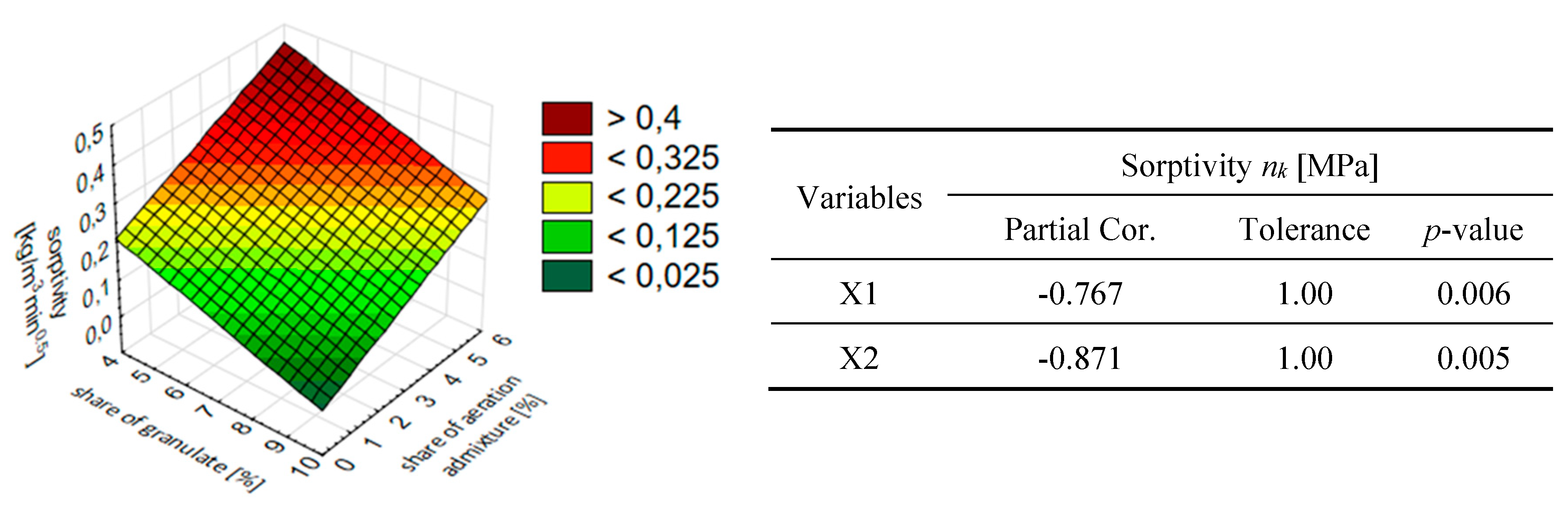

2.4.5. Sorptivity

3. Results and Discussion

- bi – model parameter (regression coefficient) describing the impact of the i-th variable,

- ε – random component (standard error of the estimation Se).

5. Conclusions

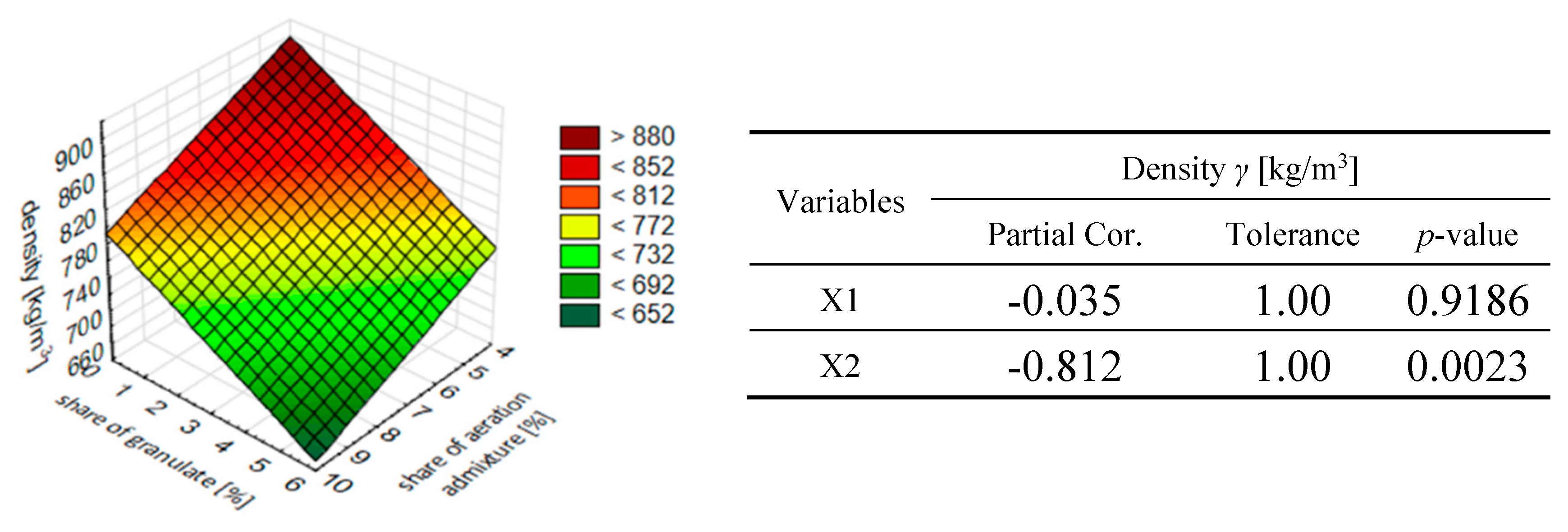

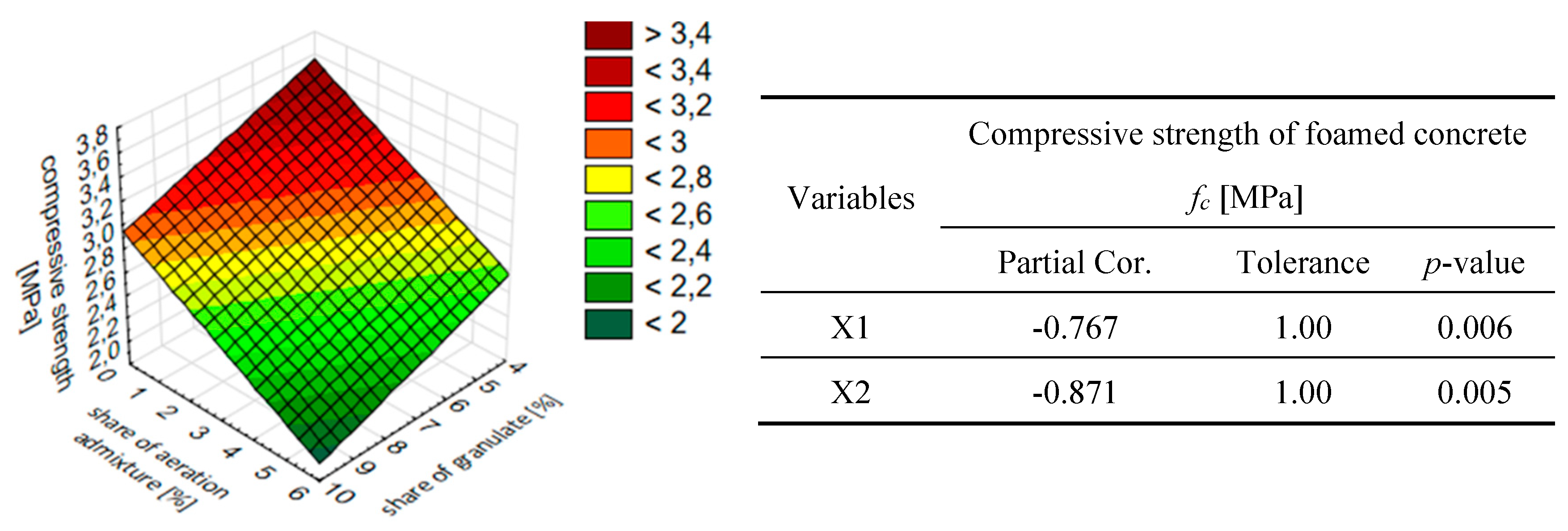

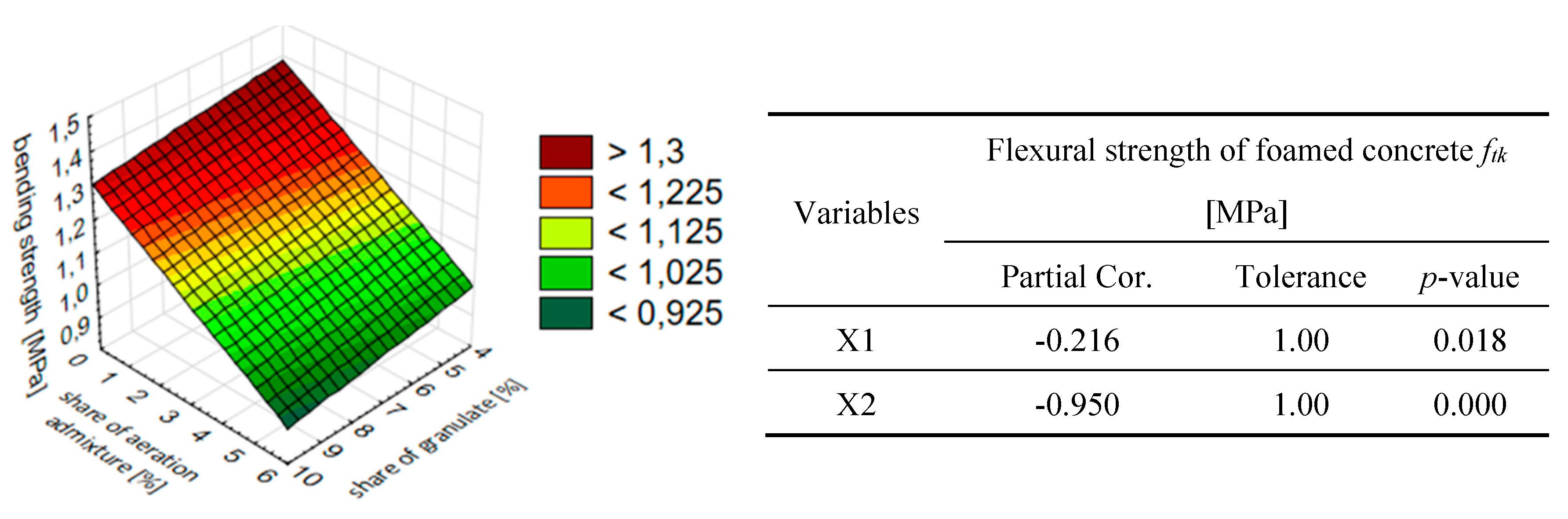

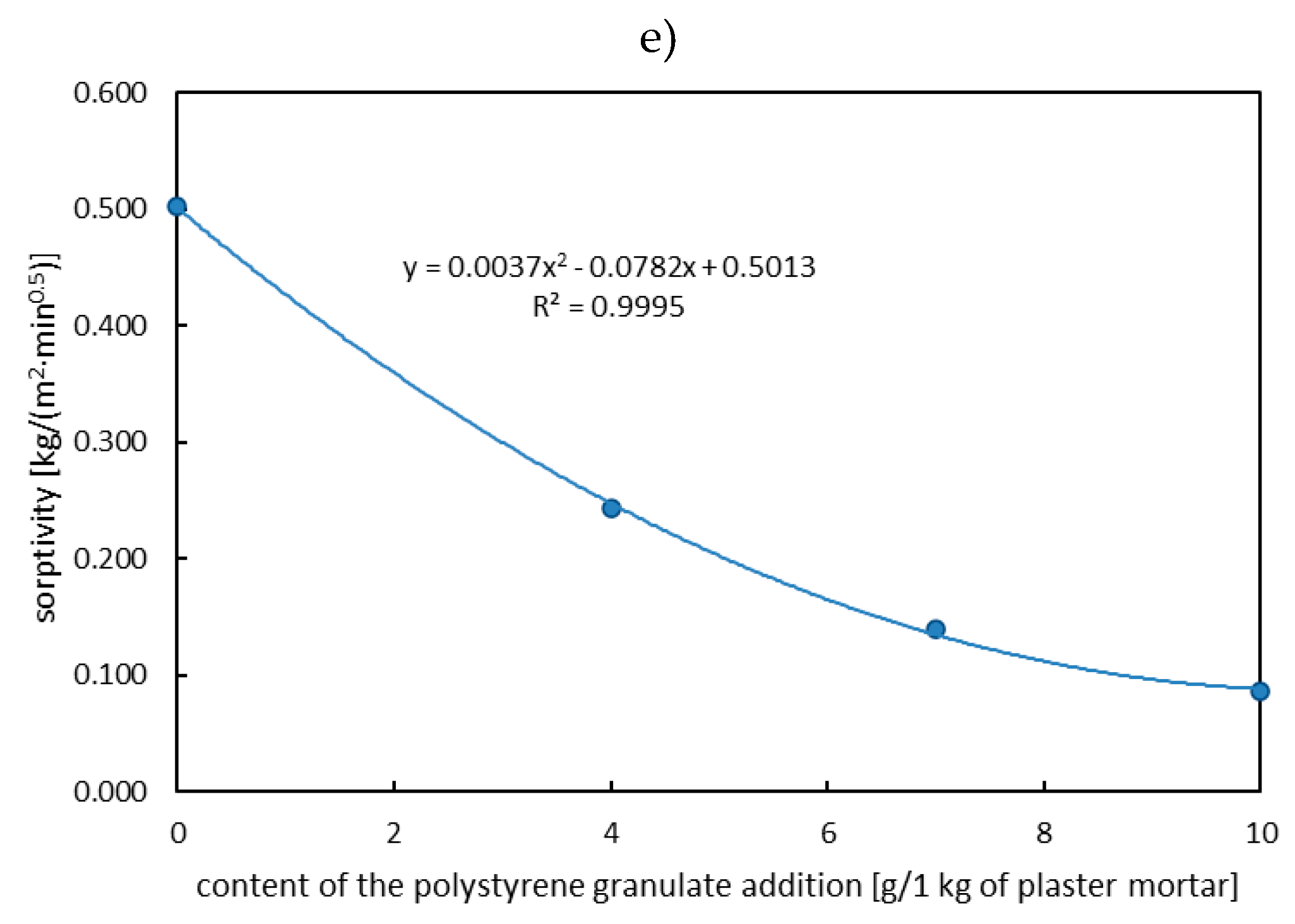

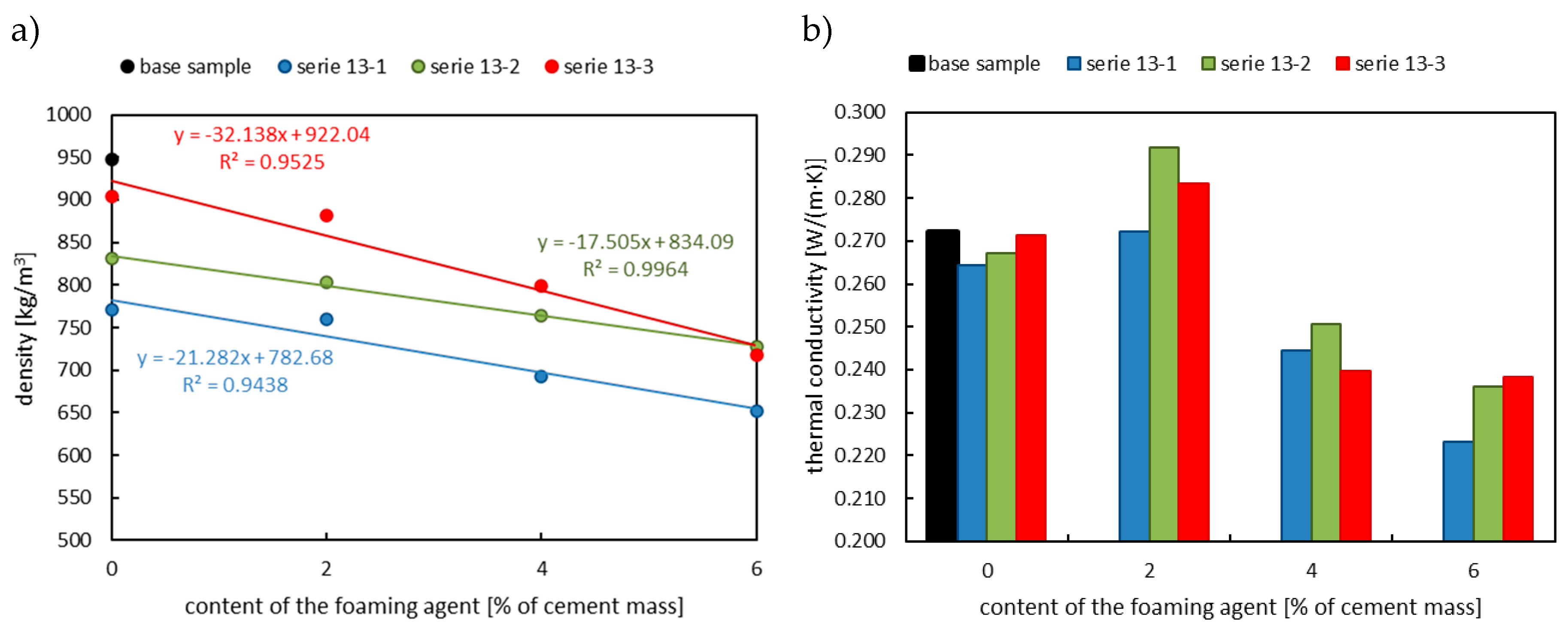

- With the increase in the content of addition of polystyrene granulate, density, thermal conductivity coefficient and sorptivity were decreased, what is a positive phenomenon. However, at the same time, a reduction in mechanical properties was demonstrated.

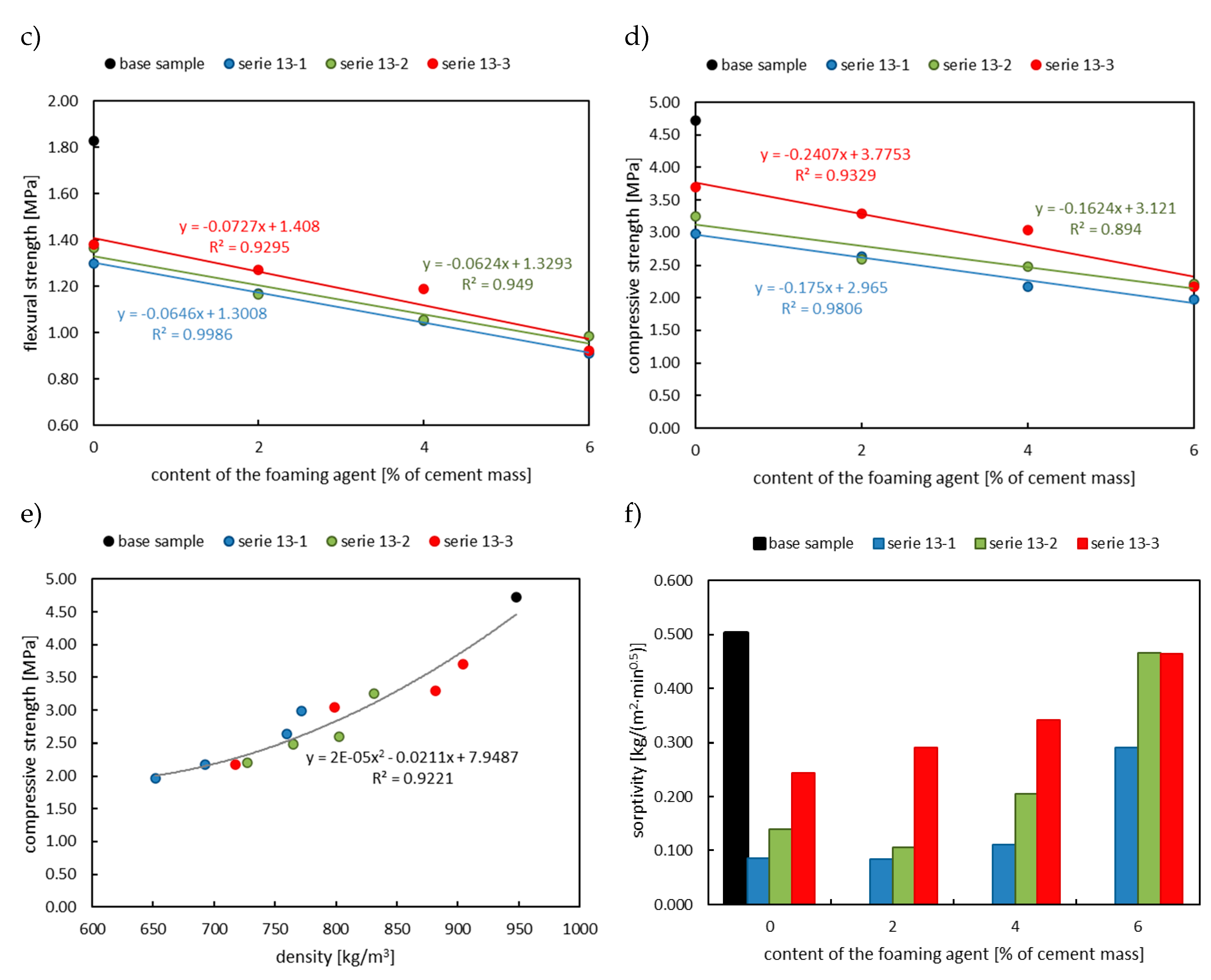

- Sorptivity of all samples is lower than the base sample of light plaster mortar, but sorptivity increases with the addition of a foaming agent for samples with the addition of polystyrene granulate.

- The addition of polystyrene granulate affects the density of foamed mortar in a similar way to a foaming agent. Both components can be used to regulate the density of this product.

- The addition of polystyrene granulate reduces the flexural strength to a lesser extent than the foaming agent. Also in the case of compressive strength, a greater decrease was noted for samples with an increased amount of foaming agent.

- The addition of polystyrene granulate reduces the sorption of foamed mortar, while the addition of a foaming agent increases it.

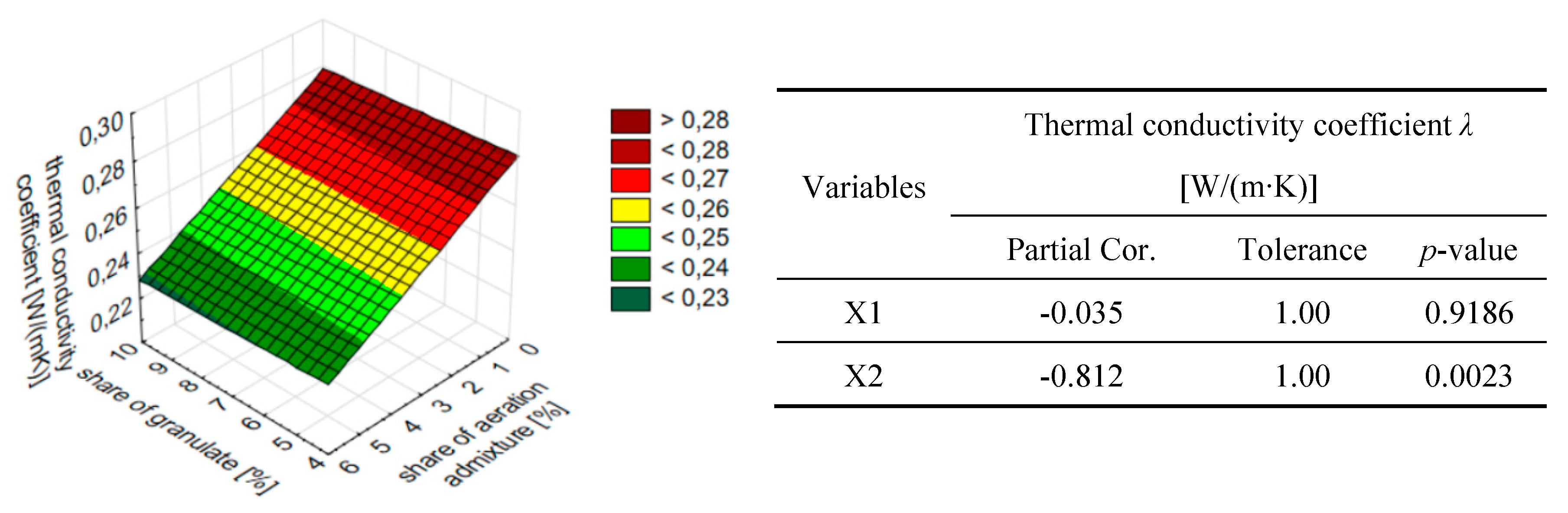

- The effect of polystyrene granulate on the thermal conductivity coefficient is insignificant. Hence, the addition of granulate is not an equivalent of a foaming agent, but can be an interesting addition to the composition of foamed concrete mix, foamed slurry or foamed mortar.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

| 1 | according to PN-EN 197-1:2011 |

References

- Heim, D. Isothermal storage of solar energy in building construction. Renew. En. 2010, 35(4), 788–796. [Google Scholar] [CrossRef]

- Jędrzejuk, H., Wojciech, M. Optimization of shape and functional structure of buildings as well as heat source utilization. Ex., Build. Environm.2002, 37(12), 1249-1253. [CrossRef]

- Nambiar, E.K.; Ramamurthy, K. Air-void characterization of foam concrete. Cem. Concr. Res. 2007, 37, 221–230. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and functional characteristics of foam concrete: A review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, X.; Wang, L.; Li, Y. Foam concrete: A state-of-the-art and state-of-the-practice review. Adv. Mater. Sci. Eng. 2020, 2020, 6153602. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Nambiar, E.K.; Ranjani, G.I.S. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Dhir R.K., Newlands M.D., McCarthy A. (eds.): Use of foamed concrete in construction. Proceedings of International Conference on the Use of Foamed Concrete in Construction. University of Dundee, Scotland, 5 July 2005, London: Thomas Telford Ltd., 2005.

- Park, S.B. , Yoon, E.S., Lee, B.I. Effects of processing and materials variations on mechanical properties of lightweight cement composites. Cem. Concr. Res. 1999, 29(2), 193–200. [Google Scholar] [CrossRef]

- Giannakou, A., Jones M.R. Potential of foamed concrete to enhance the thermal performance of low-rise dwellings [in:] Innovations and Developments in Concrete Materials and Construction: Proceedings of the International Conference Held at the University of Dundee, Scotland, UK on 9–11 September 2002. London: Thomas Telford Publishing, 2002.

- Bindiganavile V., Hoseini M. Foamed concrete, [in:] Mindess S. (ed.): Developments in the formulation and reinforcement of concrete. 1st ed., Sawston: Woodhead Publishing Limited, 2008, pp. 231-255.

- Chen, B. , Liu, N. A novel lightweight concrete-fabrication and its thermal and mechanical properties. Constr. Build. Mater. 2013, 44, 691–698. [Google Scholar] [CrossRef]

- Amran, M.Y.H, et al. Design Efficiency, Characteristics, and Utilization of Reinforced Foamed Concrete: A Review. Crystals2020, vol. 10, 948. [CrossRef]

- Priyatham, B.P.R.V.S., Lakshmayya, M.T.S., Chaitanya, D.V.S.R.K. Review on performance and sustainability of foam concrete, Mater. Tod.: Proc.2023. [CrossRef]

- Jones, M.R., McCarthy, A. (2005), Behaviour and assessment of foamed concrete for construction applications, [in:] Dhir R.K., Newlands M.D., McCarthy A. (eds.): Use of foamed concrete in construction. Proceedings of International Conference on the Use of Foamed Concrete in Construction. University of Dundee, Scotland, 5 July 2005, London: Thomas Telford Ltd., 2005, pp. 61–88.

- Jones, M.R., McCarthy, A. (2006), Heat of hydration in foamed concrete: Effect of mix constituents and plastic density, Cem. Concr. Res.2006, 36(6), 1032-1041. [CrossRef]

- Mohd Zahari, N., et al. Foamed concrete: potential application in thermal insulation, [in:] Proceedings of Malaysian Technical Universities Conference on Engineering and Technology (MUCEET), MS Garden, Kuantan, Pahang, Malaysia, 2009.

- She, W. , Zhang, Y., Jones, M.R. Three-dimensional numerical modeling and simulation of the thermal properties of foamed concrete. Constr. Build. Mater. 2014, 50, 421–431. [Google Scholar] [CrossRef]

- Vinith Kumar, N., Arunkumar, C., Srinivasa Senthil, S. Experimental Study on Mechanical and Thermal Behavior of Foamed. Mater. Tod.: Proc.2018, 5(2), Part 3, 8753-8760. [CrossRef]

- Shang, X. , Qu, N., Li, J. Development and Functional Characteristics of Novel Foam Concrete. Constr. Build. Mater. 2022, 324, 126666. [Google Scholar] [CrossRef]

- Silva N., et al. Foam concrete-aerogel composite for thermal insulation in lightweight sandwich facade elements, [in:] Concrete 2015: Proceedings of the 27th Biennial National Conference of the Concrete Institute of Australia in conjunction with the 69th RILEM Week "Construction Innovations, Research into Practice", Institute of Australia, 30.08–02.09.2015, Melbourne, Australia, p. 1355-1362.

- Gołaszewski, J. i in. (2022a). Effect of Foaming Agent, Binder and Density on the Compressive Strength and Thermal Conductivity of Ultra-Light Foam Concrete. Buildings 2022, 12, 1176. [Google Scholar] [CrossRef]

- Proshin A.P., et al. (2005b), Unautoclaved foam concrete and its construction adapted to regional conditions, [in:] Use of foamed concrete in construction. Proceedings of International Conference on the Use of Foamed Concrete in Construction. Dundee: University of Dundee, Scotland, 5 July 2005, London: Thomas Telford, 2005, pp. 113–120.

- Kozłowski, M.; Kadela, M.; Kukiełka, A. Fracture energy of foamed concrete based on three-point bending test on notched beams. Proc. Eng. 2015, 108, 349–354. [Google Scholar] [CrossRef]

- Kadela M., Kukiełka A., Małek M. (2020), Characteristics of lightweight concrete based on a synthetic polymer foaming agent, Materials, vol. 13, no. 21, 4979. [CrossRef]

- Amran, Y.H.M. , Farzadnia, N., Ali, A.A.A. Properties and applications of foamed concrete: a review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Kearsley, E.P. Just foamed concrete – an overview. Specialist techniques and materials for construction [in:] Proceedings of the International Conference “Creating with Concrete”, Dundee: University of Dundee, 1999, pp. 8–10.

- Nambiar, E.K.K. , Ramamurthy, K. Sorption characteristics of foam concrete. Cem. Concr. Res. 2007, 37(9), 1341–1347. [Google Scholar] [CrossRef]

- https://semprefarby.pl/component/djcatalog2/?format=raw&task=download&fid=426 (accessed on 8 January 2025).

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Experimental investigation on the compressive strength of foamed concrete: Effect of curing conditions, cement type, foaming agent and dry density. Constr. Build. Mater. 2018, 165, 735–749. [Google Scholar] [CrossRef]

- PN-EN 1015-10:2001+A1:2007 Methods of test for mortar for masonry - Part 10: Determination of dry bulk density of hardened mortar. PKN: Warsaw, Poland, 2007.

- PN-EN 1015-11:2020-04 Methods of test for mortar for masonry - Part 11: Determination of flexural and compressive strength of hardened mortar. PKN: Warsaw, Poland, 2020.

- PN-EN 1015-18:2003 Methods of test for mortar for masonry - Part 18: Determination of water absorption coefficient due to capillary action of hardened mortar. PKN: Warsaw, Poland, 2003.

- Kozłowski, M.; Kadela, M. Mechanical Characterization of Lightweight Foamed Concrete. Adv. Mater. Sci. Eng. 2018, 2018, 6801258. [Google Scholar] [CrossRef]

- Castillo-Lara, J.F. , et al. Mechanical Properties of Natural Fiber Reinforced Foamed Concrete. Materials 2020, 13, 3060. [Google Scholar] [CrossRef]

- Sun, Ch., et al. Effects of foaming agent type on the workability, drying shrinkage, frost resistance and pore distribution of foamed concrete, Constr. Build. Mater.2018, 186, 833-839. [CrossRef]

- Zhu, H. , et al. Experimental study on performance improvement of anionic surfactant foaming agent by xanthan gum. Constr. Build. Mater. 2020, 230, 116993. [Google Scholar] [CrossRef]

- She, W., et al. Application of organic- and nanoparticle-modified foams in foamed concrete: Reinforcement and stabilization mechanisms. Cem. Concr. Res.2018, 106, 12-22. [CrossRef]

| Composite | Quartz sand 0.0-0.5 mm | Cement CEM I 42.5 R1 | Filling aggregate (limestone flour) | Lime | Expanded perlite | Redispersible polymer powder (polyvinyl acetate modified with ethylene) | Thickener (hydroxyethyl methyl cellulose with a viscosity of approx. 15,000 mPa∙s) | Foaming agent based on alpha-olefin sulphate and sodium salt |

|

Unit (vol. %) |

63.02 | 20.00 | 10.00 | 5.00 | 1.20 | 0.50 | 0.25 | 0.03 |

| Mix symbol |

Light plaster mortar [kg] |

Polystyrene granulate addition [g] |

Water [kg] |

Foaming agent [% of cement mass] |

| Serie 13-1 | 12 | 120 | 3.120 | 0.0 |

| 12 | 120 | 3.072 | 2.0 | |

| 12 | 120 | 3.024 | 4.0 | |

| 12 | 120 | 2.976 | 6.0 | |

| Serie 13-2 | 12 | 84 | 3.120 | 0.0 |

| 12 | 84 | 3.072 | 2.0 | |

| 12 | 84 | 3.024 | 4.0 | |

| 12 | 84 | 2.976 | 6.0 | |

| Serie 13-3 | 12 | 48 | 3.120 | 0.0 |

| 12 | 48 | 3.072 | 2.0 | |

| 12 | 48 | 3.024 | 4.0 | |

| 12 | 48 | 2.976 | 6.0 |

| No. | Decrease in [%] | ||||

| density | λ | ftk | fc | sorptivity | |

| [kg/m3] | [W/(m∙K)] | [MPa] | [MPa] | [kg/(m2·min0,5)] | |

| Serie 13-1 | 18.6 | 2.8 | 28.8 | 36.8 | 82.8 |

| Serie 13-2 | 12.2 | 1.8 | 25.4 | 31.1 | 72.2 |

| Serie 13-3 | 4.5 | 0.3 | 24.5 | 21.7 | 51.6 |

| Depemdent variable | F (2,9) | p | Se | R | R2 |

| Thermal conductivity coefficient [W/(m∙K)] | 8.8252 | <0.0076 | 0.01544 | 0.81381 | 0.58248 |

| Density [kg/m3] | 60.383 | <0.0001 | 21.565 | 0,96469 | 0.91523 |

| Flexural strength [MPa] | 85.29 | <0.0000 | 0.04034 | 0.97461 | 0.93874 |

| Compressive strength [MPa] | 20.601 | <0.0004 | 0.24348 | 0.90593 | 0.78088 |

| Sorptivity [kg/(m2∙min0.5)] | 0.9052 | <0.0004 | 0.06505 | 0.90521 | 0.77924 |

| Depemdent variable | b0 | p-value | b1 | p-value | b2 | p-value |

| Thermal conductivity coefficient [W/(m∙K)] | 0.2829 | 0.000 | -0,00041 | 0,818 | -0.0084 | 0,002 |

| Density [kg/m3] | 970.875 | 0.000 | -17.7917 | 0.005 | -23.583 | 0.000 |

| Flexural strength [MPa] | 1.44192 | 0.000 | -0.01375 | 0.017 | -0.0663 | 0.000 |

| Compressive strength [MPa] | 3.97241 | 0.000 | -0.10291 | 0.005 | -0.1673 | 0.000 |

| Sorptivity [kg/(m2∙min0.5)] | 0.33815 | 0.000 | -0.03204 | 0.002 | 0.0406 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).