1. Introduction

Asphalt pavements have been widely used in the construction of highways of different grades due to their good properties [

1,

2]. Asphalt pavement consists of asphalt, aggregate, filler and voids. The asphalt binding material plays an important role in bonding the aggregates and fillers to give the pavement better bearing capacity and driving comfort [

3]. However, asphalt is susceptible to aging under the influence of temperature, light, oxygen, water and other factors during long-term use [

4,

5,

6]. A series of complex physicochemical reactions continuously occur in the aging process of asphalt. The high temperature, low temperature and adhesion properties of asphalt will be significantly affected. Therefore, accurately simulating the real environmental conditions of indoor aging acceleration and aging evaluation methods are current research hotspots.

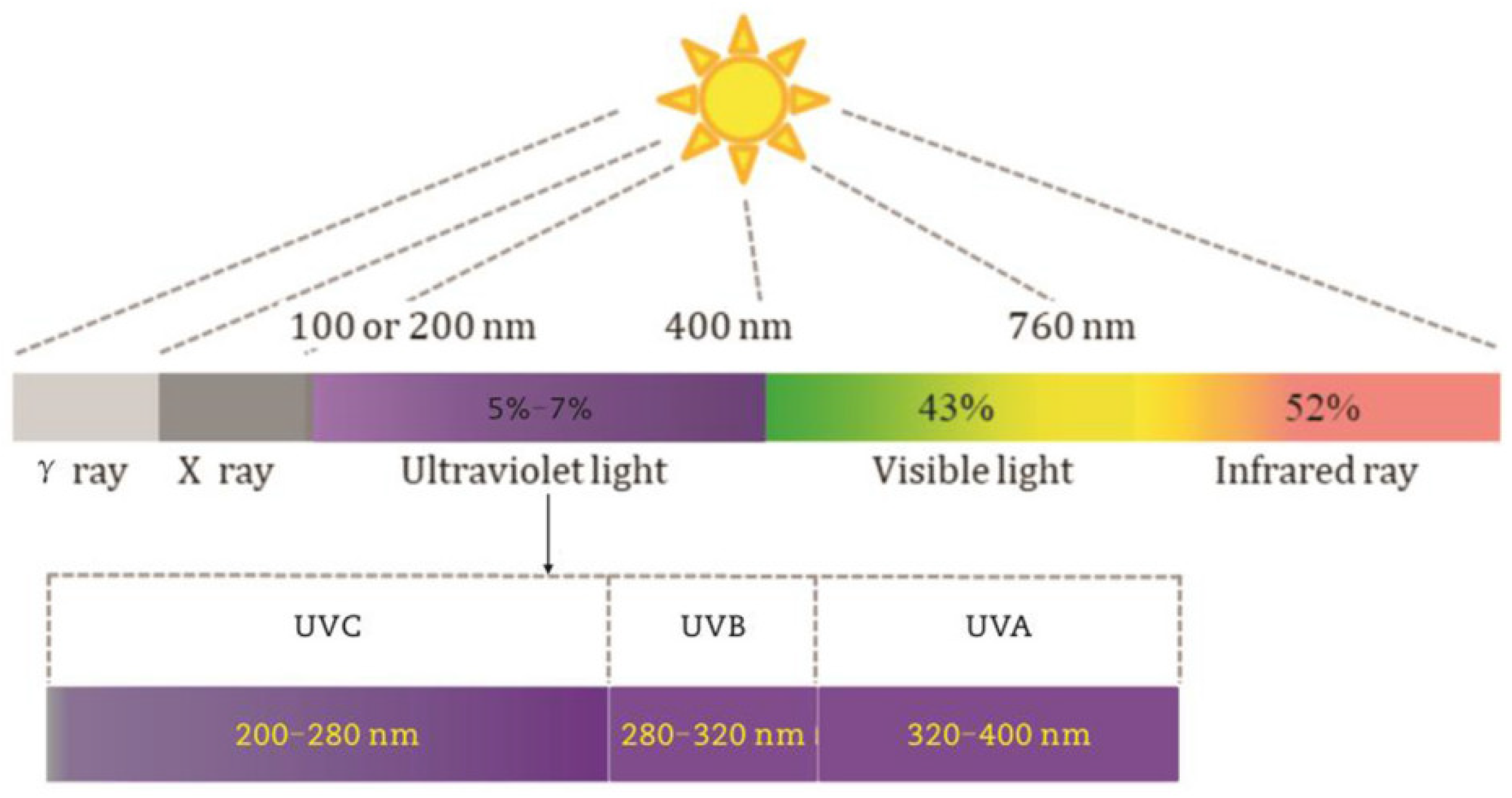

Asphalt aging mainly consists of thermo-oxidative aging and UV aging [

7,

8]. In the past decades, the thermo-oxidative aging process of asphalt has been evaluated mainly by means of the thin film oven test (TFOT), rolling film oven test (RTFOT), and pressurized aging vessel (PAV).TFOT and RTFOT aging simulate the aging process of asphalt from the mixing of asphalt mixtures to the on-site paving of asphalt pavements. PAV aging simulates the aging of asphalt from the on-site paving of asphalt mixtures to the end of the service life of the pavements [

9,

11]. The results of Diouri et al. showed that cracks in asphalt pavements increase with the degree of aging and this change is more significant with increasing temperature [

12]. Li et al. showed that as asphalt binders age, colloidal particles aggregate, which affects changes in their basic physicochemical properties. These changes translate into changes in the engineering properties of asphalt binders [

13]. Liu et al. concluded that volatilization of asphalt binding material components, oxidation reactions and migration of components are key factors in determining the degree of aging [

14]. Wang et al. found that the high temperature performance increased with the degree of aging. After aging, the irrecoverable creep compliance decreased and the creep recovery percentage increased significantly [

15]. Previous studies have found that the current research on thermo-oxidative aging of asphalt is basically mature. The factors affecting thermo-oxidative aging have been basically elucidated and the mechanism of thermo-oxidative aging is basically clear. However, there is a lack of indoor simulation devices and characterization methods for UV aging, one of the key factors affecting asphalt aging.

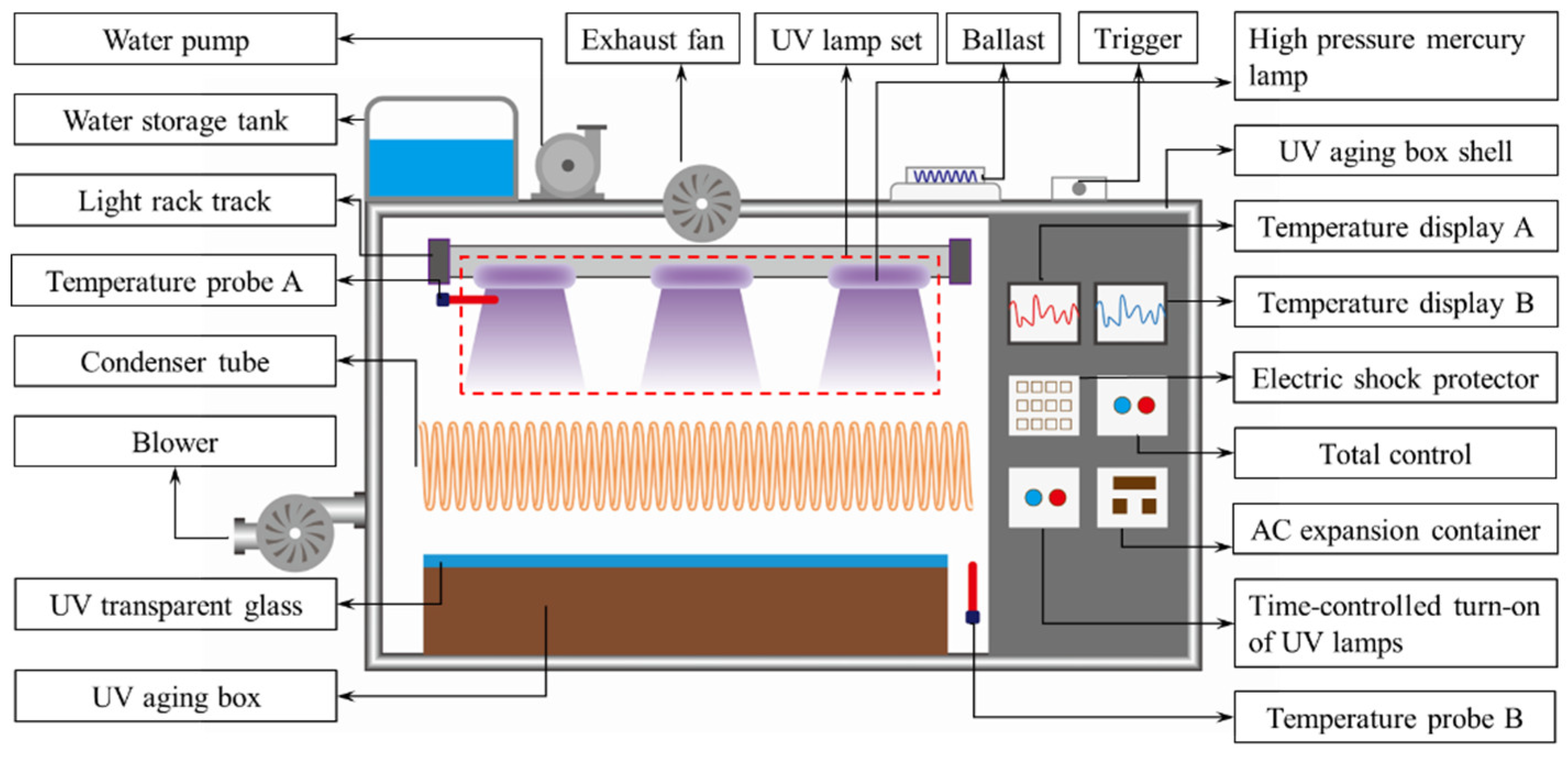

To solve the indoor simulation device problem of asphalt UV aging, researchers simulated the effects of UV, oxygen, and temperature on the performance of asphalt pavement, and developed corresponding UV aging test devices [

16,

17,

18]. Initially, Montepara et al. independently developed a UV aging test chamber. UV aging was conducted using a mercury lamp at a temperature of 140 ° C, with an asphalt sample film thickness of 1.5 mm. Different degrees of aging were simulated for actual asphalt pavement at 1 year, 2 years, 6 years, and 10 years [

19,

20]. However, due to the high experimental temperature, the results were significantly different from the actual situation. Subsequently, Bocci and Cemi designed a simulation method for asphalt UV accelerated aging and found that UV aging is completely different from thermal oxidation aging [

21]. Ye et al. established a simulation system for asphalt UV aging, further proving that light oxidative aging is completely different from thermal oxidative aging [

22]. On this basis, Pang et al. improved the UV aging test method from the perspective of selecting UV aging light sources and temperature control [

23]. Zeng et al. proposed suggestions for selecting the thickness of UV aged asphalt coatings [

24]. Li et al. provided relevant references for wavelength selection of ultraviolet aging [

25].

Meanwhile, scholars have conducted a lot of research on the performance change and aging mechanism of asphalt after UV aging through indoor simulation devices. Xiao et al. used Materials Studio software to simulate the dynamic behavior of asphalt microstructure during UV aging, showing that with the progress of UV aging, the light components of asphalt molecules gradually transformed into heavy components [

26]. Zhang et al. found that the carbonyl index increases with the increase of the UV aging degree of the asphalt binder, and when the asphalt binder tends to the aging limit, the carbonyl index also tends to be stable [

27]. Zeng explored that the asphalt aging index and the deterioration performance of SBS modifier increased significantly at a temperature of 70 °C, and the mass loss of asphalt after UV aging was four times that of thermal aging conditions [

28]. Jamal et al. compared thermal aging and UV aging, and found that thermal aging makes the light components volatilize and the aliphatic index decreases. However, UV aging mainly contains aliphatic hydrocarbon chain components whose volatile bond energy is lower than 413 kJ/mol, such as C-C, C-O and C-H [

29]. Rajib’s research shows that UV aging is more likely to deteriorate the asphalt performance than thermal oxygen aging, and the asphalt binder containing biochar can delay the UV aging process [

30]. Liu et al. found that two processes may exist during the UV aging process of asphalt, namely molecular excitation process and chemical bond breaking process [

31].To sum up, Ithe UV aging process of asphalt is relatively complex, and scholars have focused on considering the evolution law of asphalt road performance under the joint action of UV and oxygen, and initially analyzed the UV aging mechanism of asphalt. However, none of the current studies have considered the single contribution of oxygen and UV radiation in the UV aging process.

In addition, warm mix asphalt (WMA) is used as a green road construction material. Scholars have conducted extensive research on its various road performance warm mix mechanisms and its aging performance evolution during long-term service [

34,

35,

36,

37,

38]. The adhesion performance of WMA asphalt after UV aging, as a key indicator affecting its service life, has not yet been studied for the evolution law of adhesion performance during the UV aging process of WMA. Meanwhile, the contribution rate of oxygen and ultraviolet radiation on the adhesion performance of WMA during UV aging is not yet clear, which restricts its promotion and application in engineering.

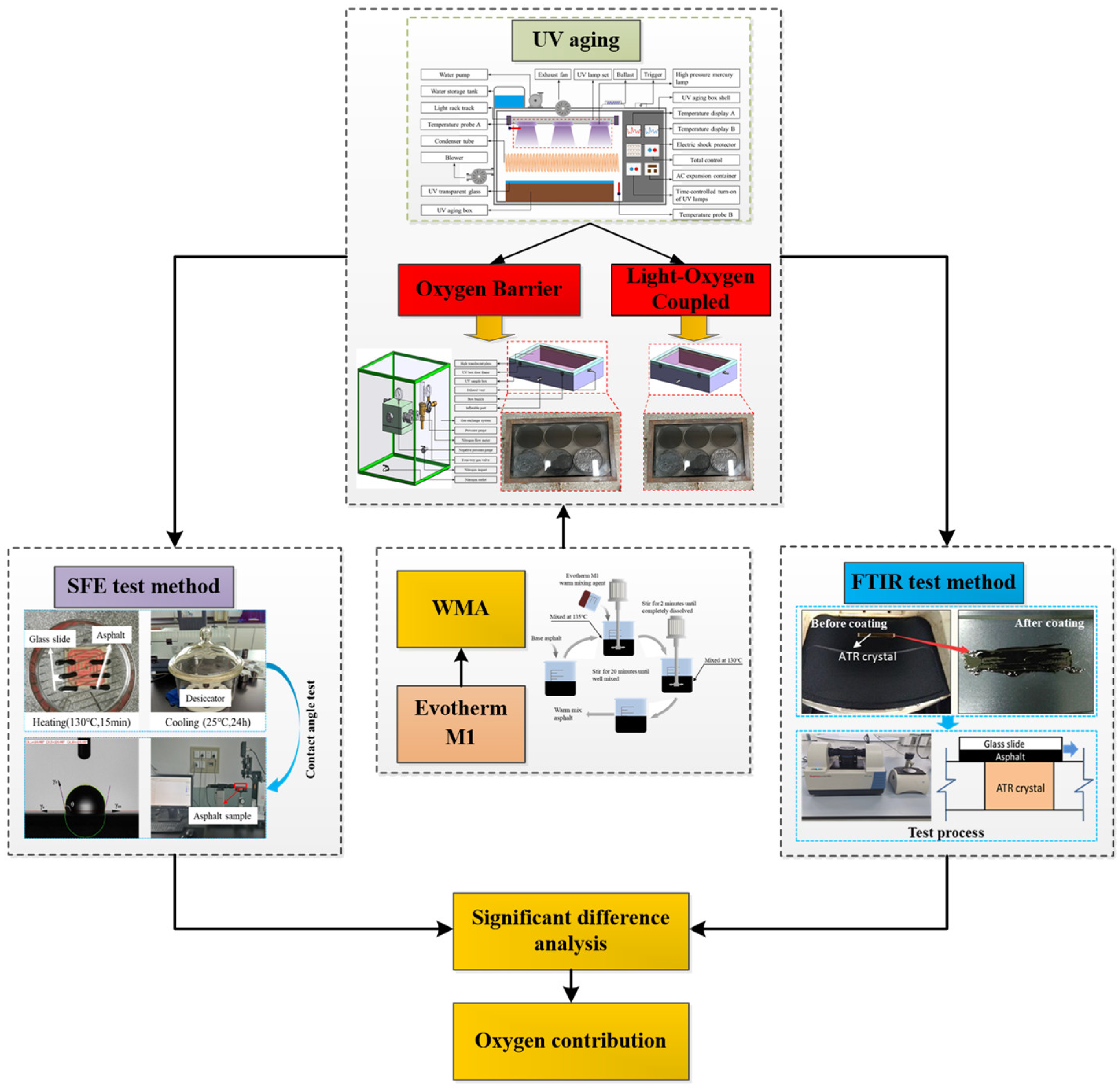

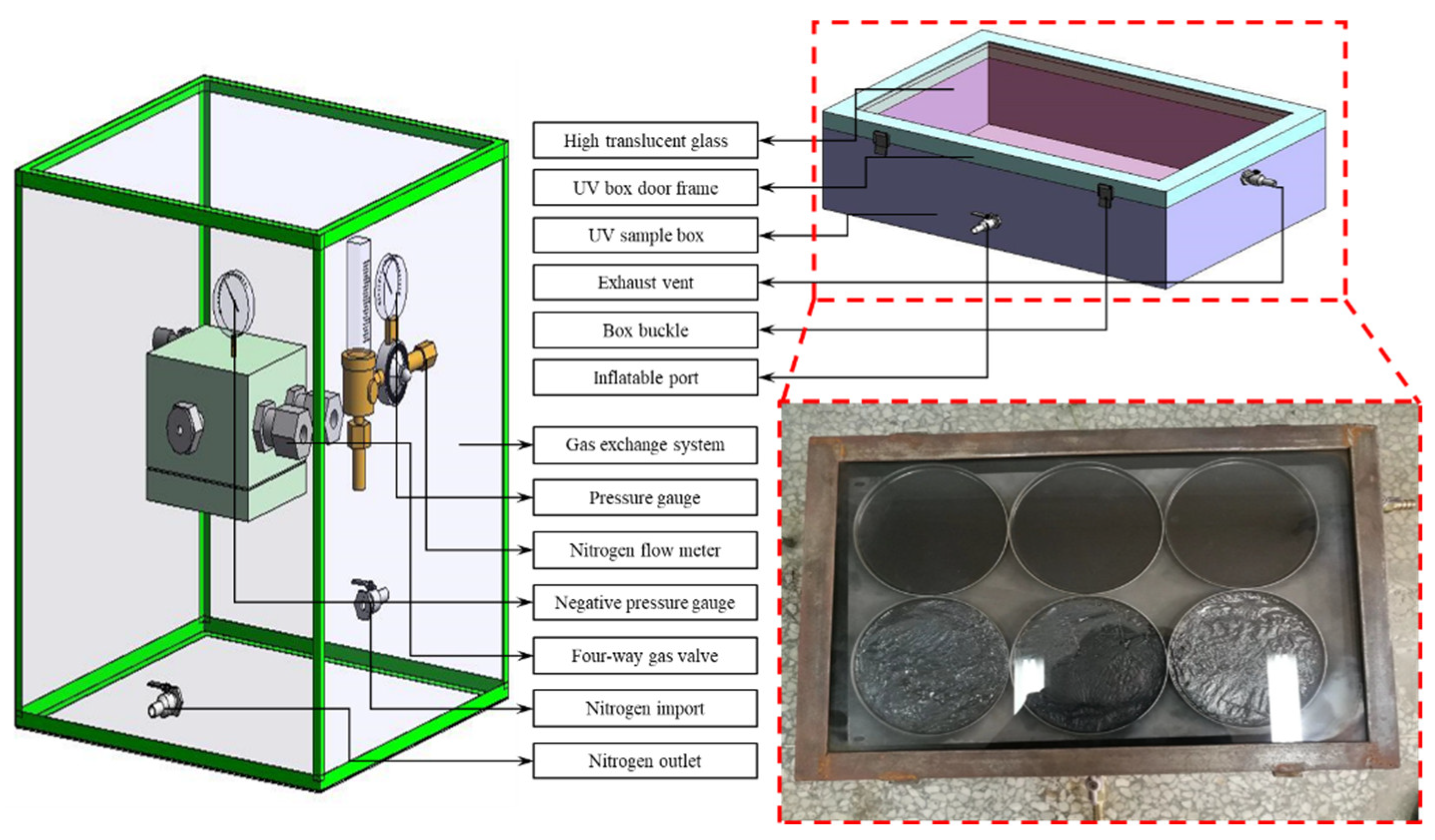

In this paper, two UV aging methods, oxygen isolation and light oxygen coupling, were designed to carry out the UV aging of WMA. WMA samples with different aging methods (RTFOT, PAV and UV) and UV aging time (50h, 100h, 150h and 200h) were prepared. Then, the surface free energy theory was used to calculate the cohesive work and adhesive work of different samples. Based on the carbonyl and sulfoxide functional group index obtained by infrared spectroscopy, the relationship between adhesive performance index and functional group index was established. Then, significant difference analysis was used to compare and analyze the differences between oxygen barrier WMA and light-oxygen coupled UV aging. Finally, a random forest model was used to analyze the contribution rates of oxygen and ultraviolet radiation in the light-oxidative coupling aging process of warm mix asphalt. The research results can provide some reference and reference for the establishment of asphalt ultraviolet aging evaluation methods and standards.

3. Results and Discussion

3.1. Adhesive Performance Analysis Based on SFE

3.1.1. Contact Angle

From

Table 4, it can be seen that as the degree of aging increases, the contact angle between WMA and water gradually increases, indicating that aging improves the hydrophobicity of asphalt. Comparing the coupling of light and oxygen and the isolation of oxygen, it was found that the addition of oxygen increases the contact angle. In addition, the larger the contact angle, the more cos θ, the smaller the value, the weaker the wettability and the better the floatability. The smaller the contact angle, the cos θ, the larger the value, the stronger the wettability and the worse the floatability. It can be seen that the floatability of WMA will increase after UV aging.

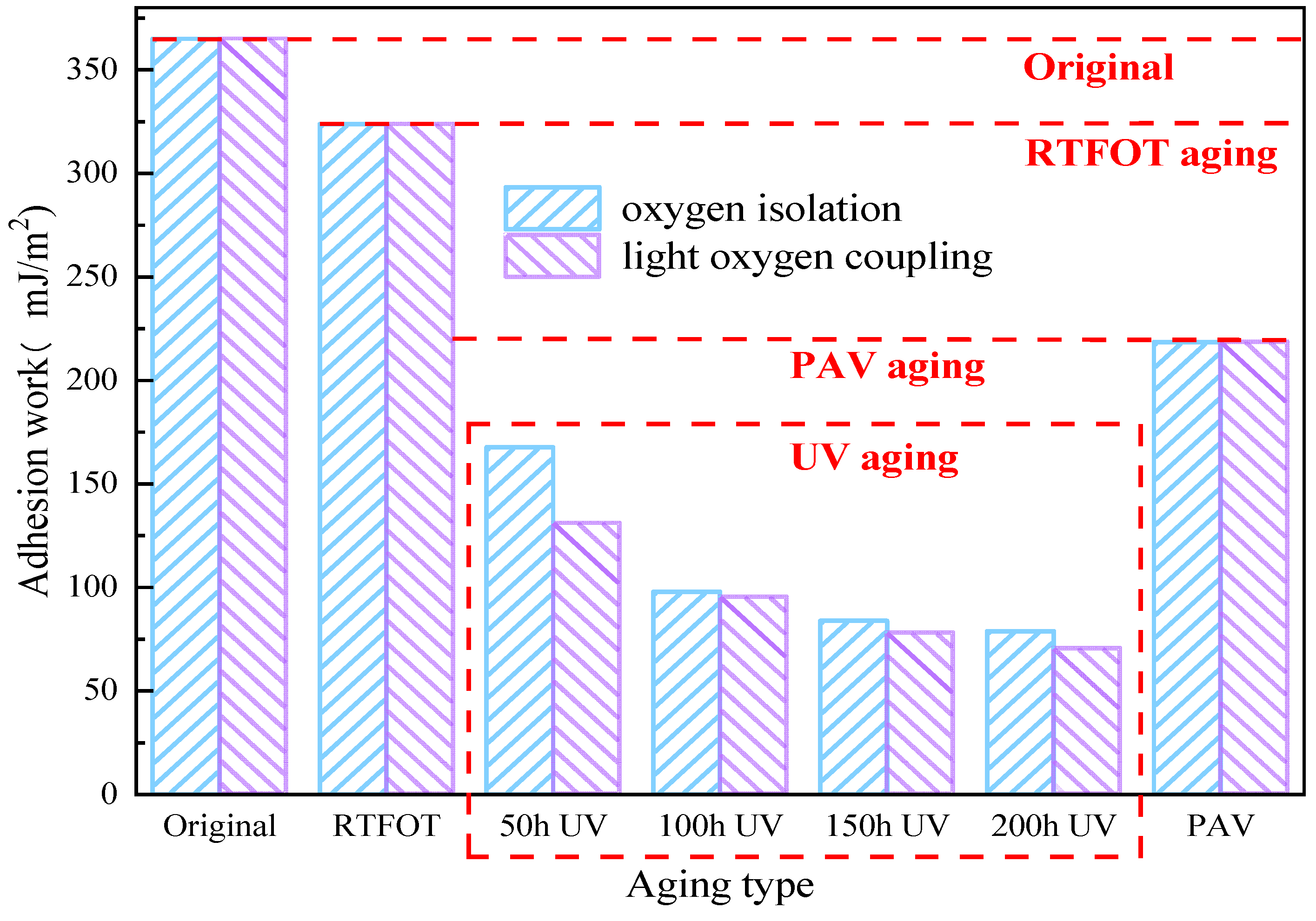

3.1.2. Adhesive Work

The adhesive work reflects the bonding quality between aggregates and asphalt. A large adhesive strength indicates good adhesive performance and strong resistance to water damage. Studied the adhesion between WMA and limestone aggregate system before and after UV aging. The experimental results are shown in

Figure 5.

The results in

Figure 5 shown that the cohesive work of warm mix asphalt without aging is 365.03 mJ/m

2. After RTFOT aging, it was 323.73mJ/m

2, decreased by 11.3%. After aging, PAV was 218.51 mJ/m

2, decreased by 40.1%. After aging, it was 167.69mJ/m

2, 97.90mJ/m

2, 83.89mJ/m

2 and78.86mJ/m

2, which decreased by 54.1%, 73.2%, 77.0% and 78.4% respectively. After light oxygen coupling aging, it was 130.96mJ/m

2, 95.25mJ/m

2, 77.86mJ/m

2 and 70.36mJ/m

2, which decreased by 64.1%, 73.9%, 78.1% and 80.7%. Compared with light oxygen coupling aging and oxygen isolation aging, it decreased by21.9%, 2.7%, 7.2% and 10.8%.

It can be seen from

Figure 5 that in RTFOT aging, PAV aging and UV aging, The work of adhesive of WMA showed a decreasing trend. Compared with RTFOT and PAV aging, UV aging makes the WMA decline more obvious. It shows that UV aging and thermo-oxidative aging have different effects on WMA, and UV aging has a greater impact on WMA adhesive work. UV aging reduces the WMA adhesive work, and when the UV aging time exceeds 150h, the decreasing trend gradually becomes stable. Under the light-oxygen coupling condition, the WMA adhesive work is smaller. It shows that the presence of oxygen aggravates the reduction of WMA adhesive work, which reduces the water damage resistance of WMA. It may be due to the presence of oxygen that the light components in WMA are more likely to react with oxygen. As a result, the hard components in WMA increase, and WMA becomes hard, which further reduces the bonding performance of WMA.

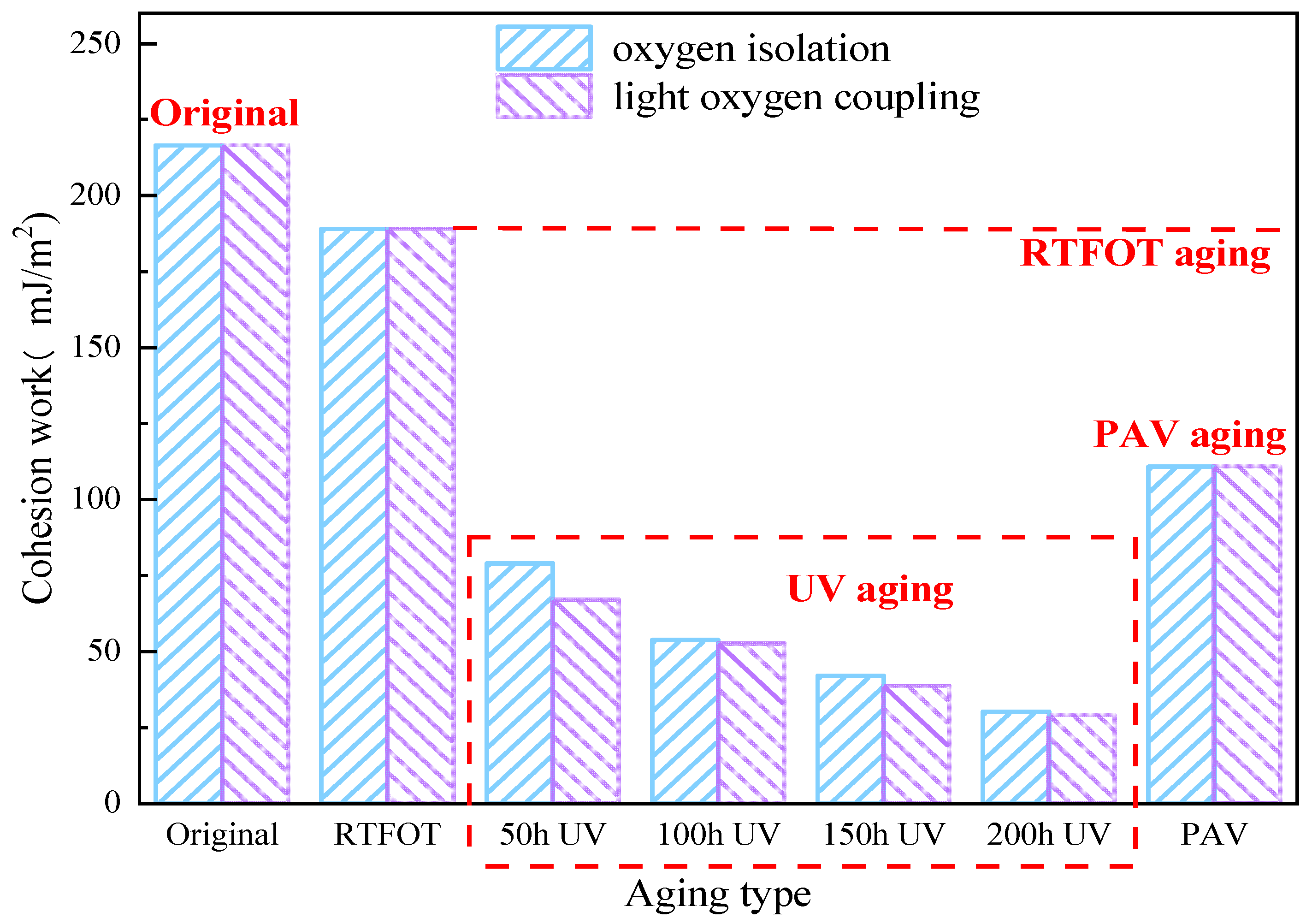

3.1.3. Cohesive Work

Cohesive work refers to the energy consumed to overcome the interaction between asphalt molecules. The greater the cohesive work is, the better the cohesive property of asphalt is, and the stronger the cracking resistance is. The cohesive work of WMA before and after aging in different ways and times is shown in

Figure 6.

The results in

Figure 6 shown that the cohesive work of warm mix asphalt without aging is 216.52 mJ/m

2. After RTFOT aging, it was 189.07 mJ/m

2, decreased by 12.6%. After aging, PAV was 110.79 mJ/m

2, decreased by 48.8%. After aging, it was 78.98 mJ/m

2, 53.8 mJ/m

2, 42 mJ/m

2 and 30.2 mJ/m

2, which decreased by 63.5%, 75.2%, 80.6% and 86.1%. After light oxygen coupling aging, it was 69.1 mJ/m

2, 52.5 mJ/m

2, 38.56 mJ/m

2 and 28.98 mJ/m

2, which decreased by 68.1%, 75.8%, 82.2% and 86.7%. Compared with light oxygen coupling aging and oxygen isolation aging, it decreased by 12.5%, 2.4%, 8.2% and 4.0%.

It can be seen that the cohesive work of warm mix asphalt shows a downward trend after aging. Compared with RTFOT, PAV and UV aging, the reduction of cohesive work of warm mix asphalt after UV aging is the largest, and the reduction of RTFOT is the smallest. With the extension of UV aging time, the cohesive work decreased gradually. When UV aging for 50 h, oxygen has the greatest influence on the cohesive work of warm mix asphalt, and then gradually becomes stable. In general, when there is oxygen, the ability of anti adhesive damage of warm mix asphalt after UV aging is the weakest. When the lightoxidation coupled ultraviolet aging exceeds 150h, the possibility of cohesive failure of warm mix asphalt is the largest, indicating that the water damage resistance is the worst at this time.

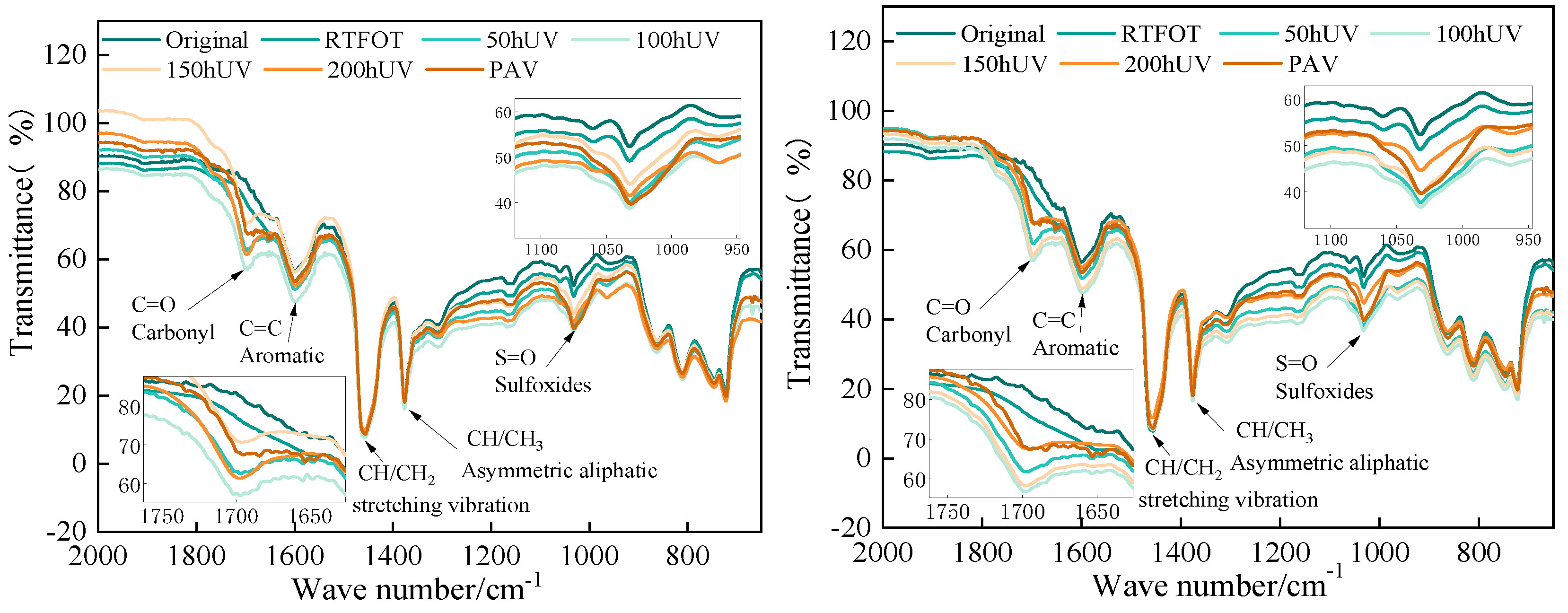

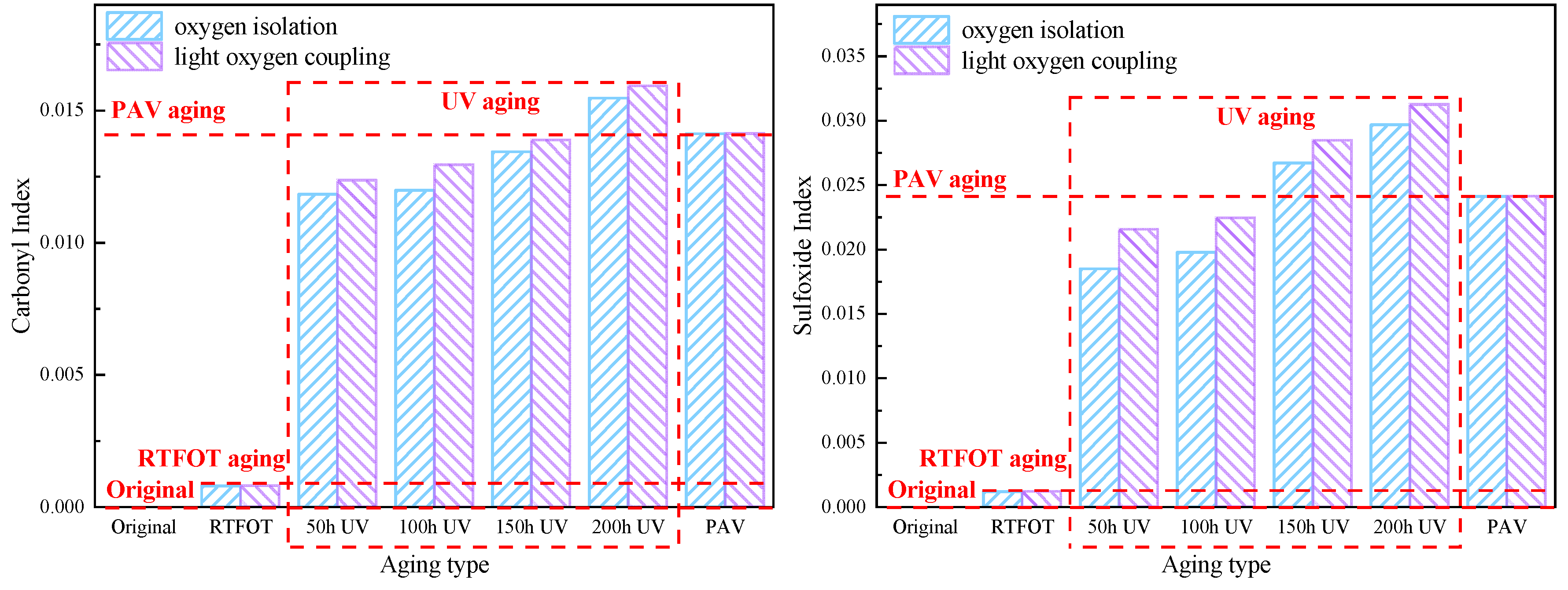

3.2. Functional Groups Analysis Based on FTIR

The carbonyl (C=O) absorption peak at 1700 cm-1 and the sulfoxide (S=O) stretching vibration peak at 1030 cm-1 of WMA increased significantly during oxygen barrier aging and light-oxygen coupled UV aging. Comparing the oxygen barrier aging and light-oxygen-coupled UV aging, it is found that the light-oxygen-coupled UV aging condition has a greater effect on these two absorption peaks than the oxygen barrier aging condition. The peak and area of the sulfoxide (S=O) functional group located at 1030 cm-1 increased slightly after short-term aging. However, after PAV aging and light-oxygen-coupled UV aging, the sulfoxide functional group changed significantly, indicating that a severe oxidation reaction occurred in the warm mix asphalt. The analysis of the causes showed that the sulfoxide group is a characteristic peak that characterizes the oxygen absorption aging of asphalt, and the increase of this peak indicates that the asphalt has undergone oxygen absorption aging. As a result, its properties will change significantly with the participation of oxygen. In addition, the change of functional groups after aging of PAV is comparable to the result of 50 h UV aging, while the carbonyl peak of WMA stabilizes after 150 h UV aging.

Figure 7.

FTIR spectrum of WMA: (a)oxygen barrier; (b) light oxygen coupling.

Figure 7.

FTIR spectrum of WMA: (a)oxygen barrier; (b) light oxygen coupling.

According to the changing law of each functional group index during the aging process of asphalt, it can reflect the changes in the chemical structure of asphalt before and after aging [

31]. Usually, the carbonyl index and the sulfoxide index are chosen as the indicators to quantitatively characterize the changes in the chemical structure of warm mix asphalt during UV-oxygen coupling and oxygen barrier aging. The carbonyl index and sulfoxide index are calculated from the area ratio of the characteristic peaks in the infrared spectra to the peak region between 600 cm

-1 and 2000 cm

-1, which is calculated as follows.

As can be seen in

Figure 8, the carbonyl index gradually increases with aging time under oxygen barrier and light-oxygen conditions, indicating that warm mix asphalt undergoes a significant oxidation reaction under UV irradiation, and the degree of aging increases with UV aging time. Gradual deepening. The trend of carbonyl index of warm mix asphalt under light-oxygen coupled UV aging is consistent with that under oxygen-isolating conditions, but the carbonyl index of warm mix asphalt under light-oxygen coupled UV aging is significantly higher than that of warm mix asphalt under oxygen-isolating UV aging, indicating that there is the participation of oxygen, and the degree of aging of warm mix asphalt is more serious.

In addition, under oxygen-isolating UV aging conditions, the sulfenyl index of WMA increased rapidly with the extension of UV aging time, indicating that warm mix asphalt under UV irradiation undergoes a significant oxidation reaction, and the degree of aging increases with the increase in UV aging time. The aging time is gradually prolonged and deepened; the change trend of the sulfenyl group index of warm mix asphalt under light-oxygen coupled UV aging is consistent with that under oxygen isolating conditions, but the sulfenyl group index of warm mix asphalt under light-oxygen coupled UV aging is significantly higher than that under oxygen-isolating conditions. Sulfoxide group index of warm mix asphalt under oxygen UV aging conditions. The results show that oxygen exacerbates the UV aging of warm mix asphalt. In addition, under different UV aging conditions, the carbonyl and sulfoxide group contents of warm mix asphalt increased gradually with the extension of UV aging time, but the growth rate of the carbonyl index was significantly higher than that of the sulfoxide group, suggesting that UV aging makes C=C oxidation more serious.

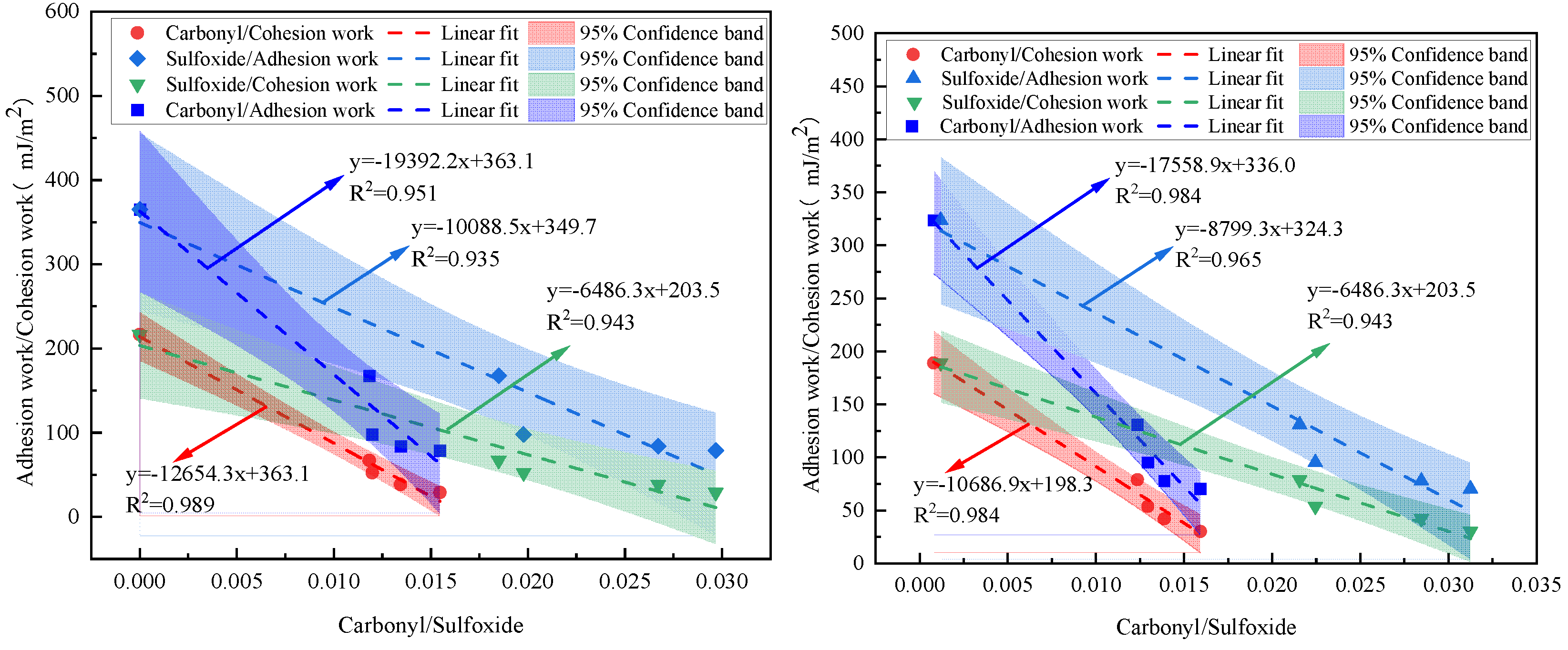

3.3. Correlation Analysis

The correlation regression analysis of surface roughness and adhesive work of WMA under UV aging condition was carried out by using Origin software, and the results are shown in

Figure 9.

The figure shows the linear fitting relationship between the adhesive work and the roughness in the two environments. The correlation coefficients between surface roughness and adhesive work under light-oxygen coupling and single UV aging conditions are 0.9114 and 0.9067, respectively. All points fall within the 95% confidence band, indicating that the WMA roughness and adhesive work have an excellent fitting effect. In addition, under the action of light oxygen, the fitting points of adhesive work and roughness are relatively uniformly dispersed and closer to the fitting line. While the fitting points are relatively aggregated under the action of oxygen barrier and deviate from the fitting line. The pearson index of the fitting curve under the action of light oxygen is larger, indicating a better fit.

3.4. Significant Difference Analysis

A significant difference is an evaluation of the difference in data. SPSS software was used to compare the difference between oxygen barrier and light-oxygen coupled UV aging. The results are shown in

Table 5. If “F > F crit”, there is a significant difference, if “F < F crit”, there is no significant difference. Combined with P-value, if “0.01<P-value<0.05”, it means that the difference is significant, and if “P-value<0.01”, it means that the difference is extremely significant.

Comparing the different sources of difference, F was significantly greater than F specific volume under the four sources of difference. This indicates that there are significant differences in the performance parameters of WMA due to the coupling of oxygen barrier and light-oxidative aging. The P-value results show that the P-values of adhesion and cohesion functions are 0.0191 and 0.006786, respectively, which are significantly different from each other. However, the P-values for carbonyl and sulfoxide indices were 0.000763 and 0.000613, respectively. both results were significantly less than 0.01, indicating that the differences between oxygen barrier and light-oxygen coupling UV were highly significant. In addition, the P-values for the adhesion and cohesion functions of WMA after oxygen barrier and light-oxygen-coupled UV aging were 0.0191 and 0.006786, respectively. Combined with the P-value results for the carbonyl group and the sulfoxide group, it is concluded that the significant differences between the oxygen barrier and light-oxygen-coupled adhesives may be due to the changes in the cohesion of WMA. The main reason for the change in the cohesion of WMA after UV aging is the presence of oxygen. It can be seen that there is a significant difference between the effects of oxygen barrier and light-oxygen coupled UV aging on WMA, and it is necessary to conduct an in-depth study on the mechanism of oxygen barrier UV aging of WMA at a later stage.

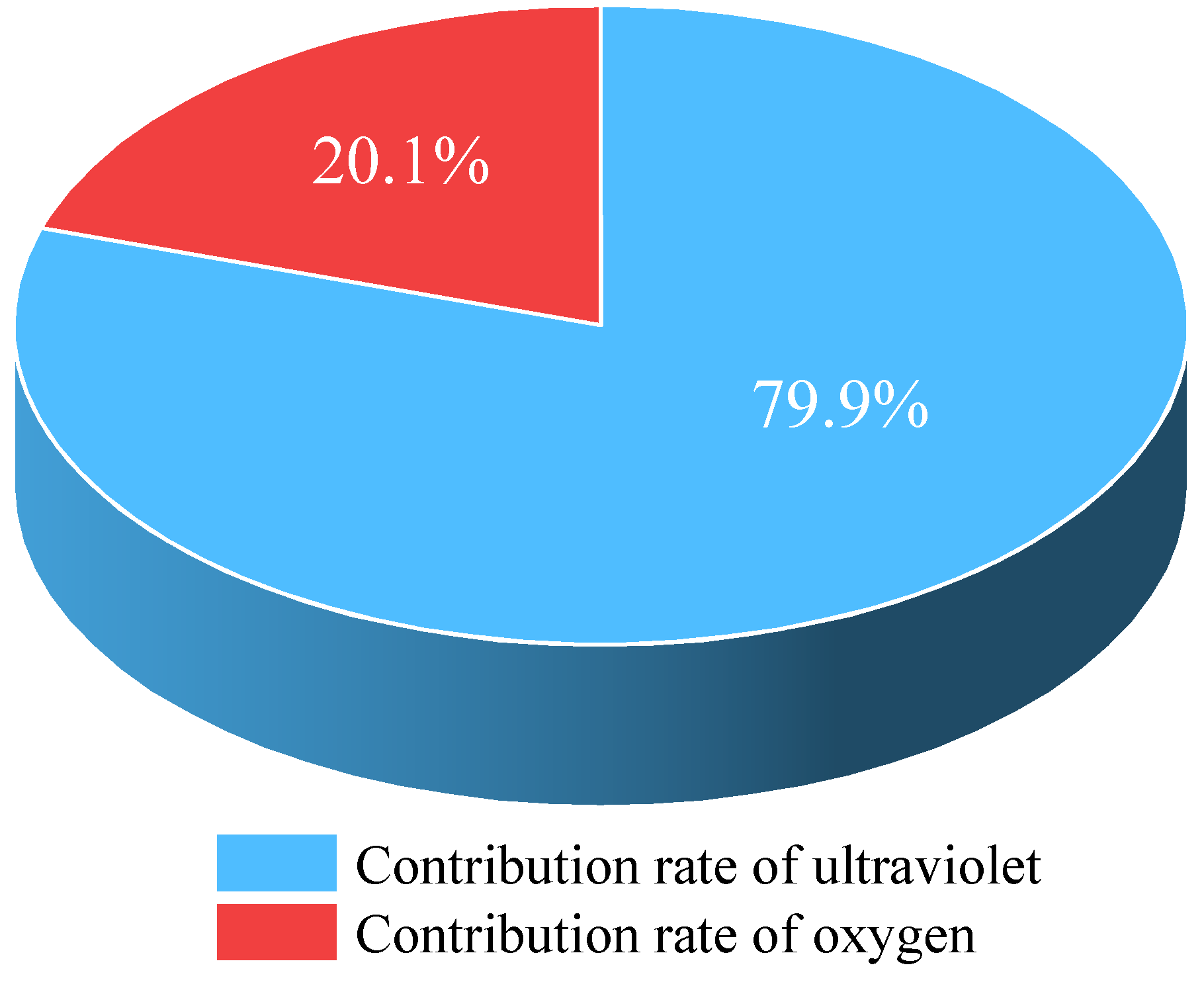

3.5. Contribution Rate of Ultraviolet and Oxygen

To investigate the contribution of oxygen and ultraviolet radiation to the adhesive index of WMA under light oxygen coupled aging conditions. According to equations (5) to (10), calculate the contribution rates of ultraviolet and oxygen to the adhesive index of WMA, as shown in

Table 6.

The results in

Table 6 show that the contribution rates of ultraviolet radiation to the carbonyl index, sulfoxide index, adhesive work, and adhesive work of WMA are 78.6%, 79.0%, 79.2%, and 82.8%, respectively. The contribution rates of oxygen to the carbonyl index, sulfoxide index, adhesive work, and adhesive work of WMA are 21.4%, 21.0%, 20.8%, and 18.2%, respectively. From this, it can be seen that the contribution rate of ultraviolet radiation in the UV aging process of WMA is about 80%, and the contribution rate of oxygen is about 20%.

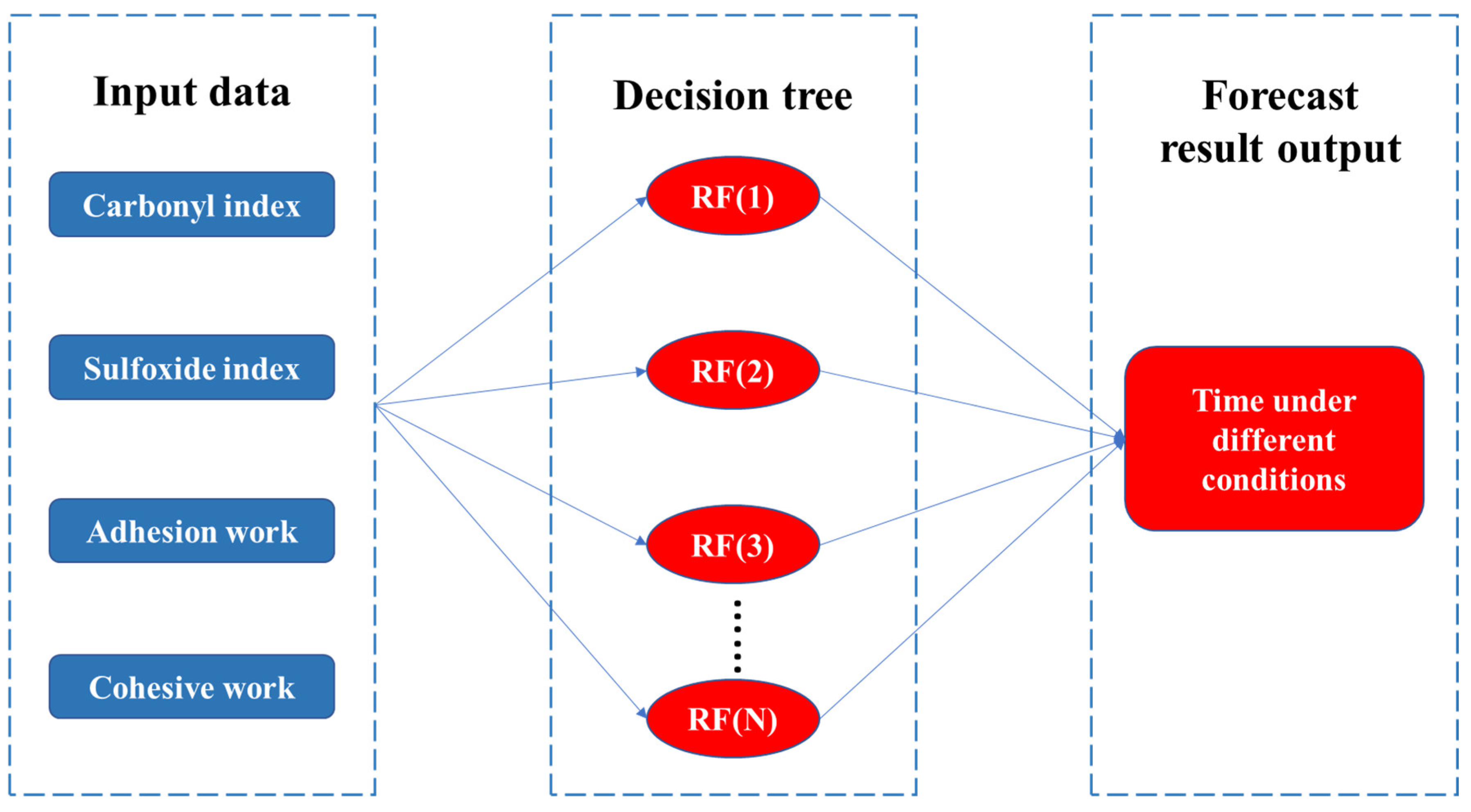

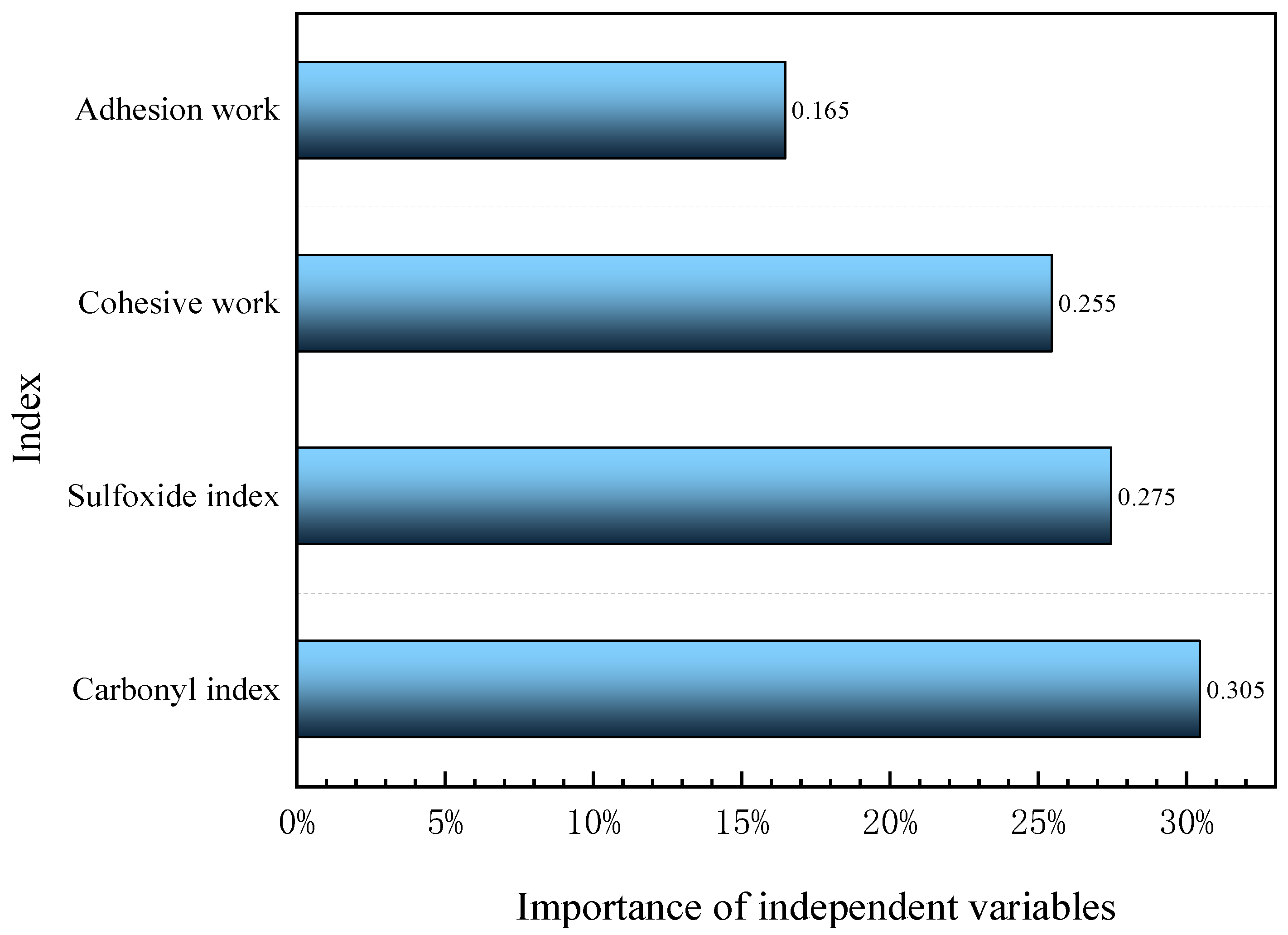

3.6. Importance of Independent Variables

To further analyze the accurate contribution rate of UV and oxygen in the UV aging process of WMA. The adhesive performance evaluation parameters of WMA were optimized using the WMA adhesive performance index as the output layer of the RBF neural network model. Firstly, an RBF neural network model was established using SPSS software. Then set the WMA adhesive performance index as the dependent variable in the output layer. Use the Softmax Activation function to put the normalized data into the hidden layer, as shown in

Figure 10. The importance analysis of independent variables is shown in

Figure 11.

The adhesive performance evaluation parameters of WMA were optimized through RBF neural network model analysis. The results in

Figure 11 indicate that the importance of adhesive work, Cohesive work, sulfoxide index, and carbonyl index are 0.165, 0.255, 0.275, and 0.305, respectively. The carbonyl index has the greatest impact on the adhesive performance of WMA during UV aging, followed by the sulfoxide index and adhesive work, with the lowest importance of adhesive work. In addition, based on the contribution rate in

Table 6 and the importance index in

Figure 11, this article calculates the contribution rate of ultraviolet and oxygen to the aging degree of WMA during the UV aging process according to formulas (14) and (15), as shown in

Figure 12.

In the equation, is the contribution rate of UV to ultraviolet radiation, is the contribution rate of ultraviolet radiation to the carbonyl index, is the importance coefficient of ultraviolet radiation on the carbonyl index, is the contribution rate of ultraviolet radiation to the sulfoxide index, is the importance coefficient of ultraviolet radiation on the sulfoxide index, is the contribution rate of ultraviolet radiation to adhesive work, is the importance coefficient of ultraviolet radiation on adhesive work, is the contribution rate of ultraviolet radiation to the cohesive work, is the importance coefficient of ultraviolet radiation on adhesive work.

4. Conclusions

In the research, a monolithic UV aging and light-oxygen coupling device was developed and a UV aging test method was established. The adhesive properties and functional group changes of WMA under oxygen barrier and photo-oxygen coupling conditions were analyzed using surface free energy and infrared spectroscopy. The relationship between different indexes was established and the differences between oxygen barrier and light-oxygen coupling UV aging were comparatively analyzed. Based on the results discussed above, the following conclusions can be summarized:

(1) RTFOT, PAV and UV aging all reduce the bonding performance and functional group index of warm mix asphalt. UV aging had the greatest effect, followed by PAV aging, and RTFOT aging had the least effect.

(2) The bonding and cohesion functions of WMA decreased with increasing UV aging time. The carbonyl and sulfoxide indices increased with increasing UV aging time. After 150 hours of UV aging, the bonding performance index and functional group index gradually stabilized.

(3) Compared with oxygen isolation and light-oxygen coupled UV aging, light-oxygen coupled UV aging resulted in a wider range of changes in the adhesive property index and functional group index of WMA. The presence of oxygen caused the UV aging properties of WMA to decay more rapidly.

(4) The correlation coefficients for photo-oxidative coupled UV aging were higher than those for oxygen-blocked UV aging. Photo-oxidative coupling and oxygen-free UV aging have significant effects on the adhesive and cohesive work of WMA. The carbonyl index and sulfoxide index have extremely significant effects.

(5) There is a significant difference between the cohesive work of WMA after UV aging. The main reason for this significant difference may be the change in cohesion caused by the internal molecular reaction of WMA due to the presence of oxygen.

(6) The random forest random model shows that during the light-oxygen coupling UV aging process of warm mix asphalt, the contribution rate of UV is 79.9%, and the contribution rate of oxygen is 20.1%.