Submitted:

24 April 2025

Posted:

24 April 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Experimental Methods

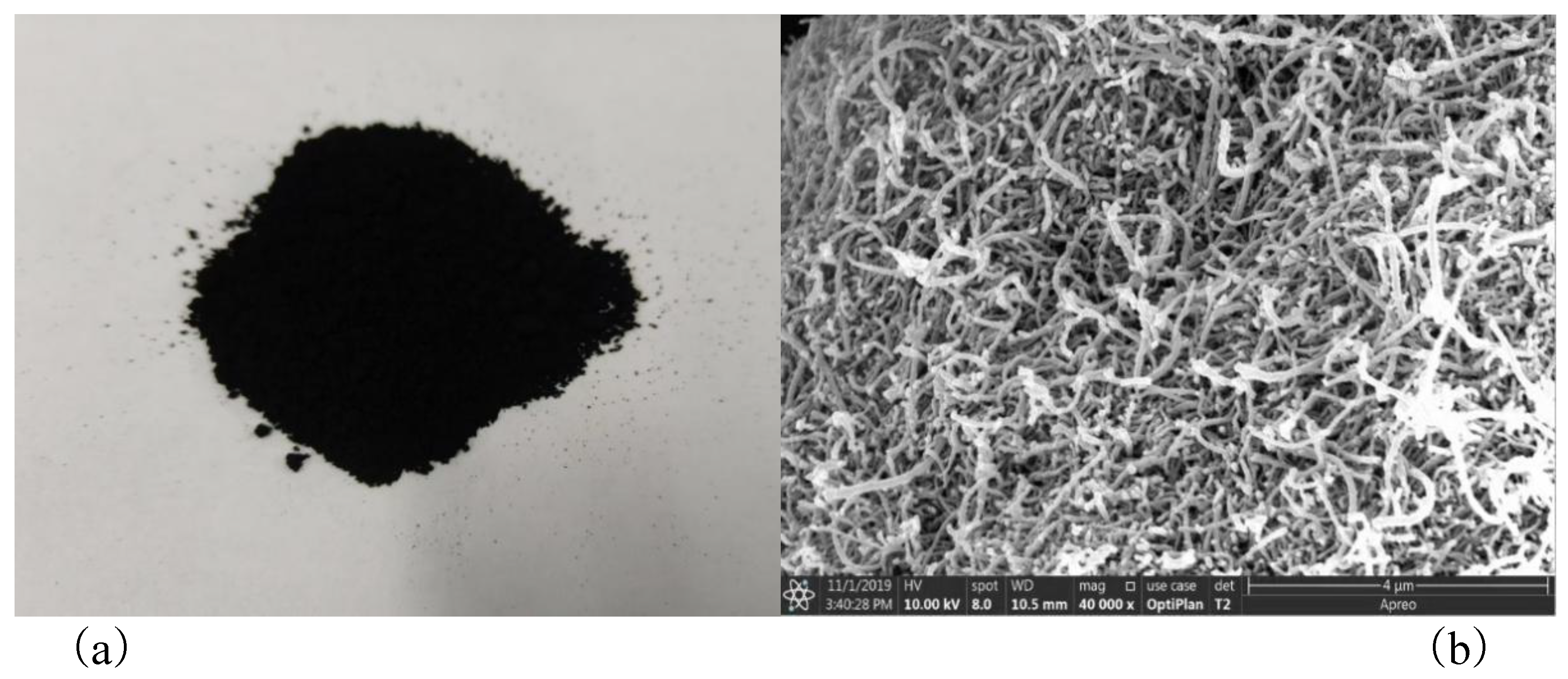

2.1. Materials

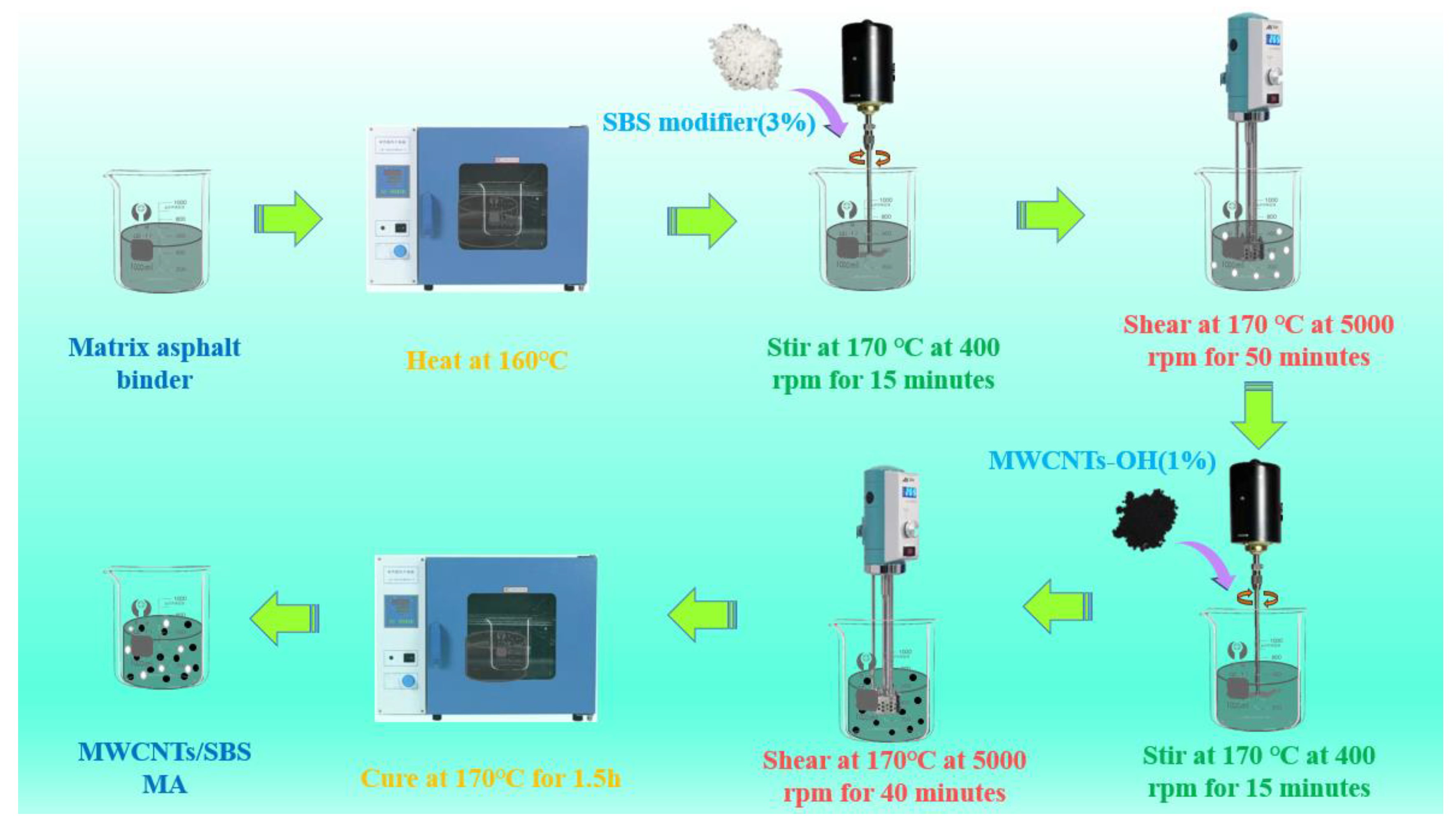

2.2. Preparation of Modified Asphalt

2.3. Experimental Method

3. Results and Analysis

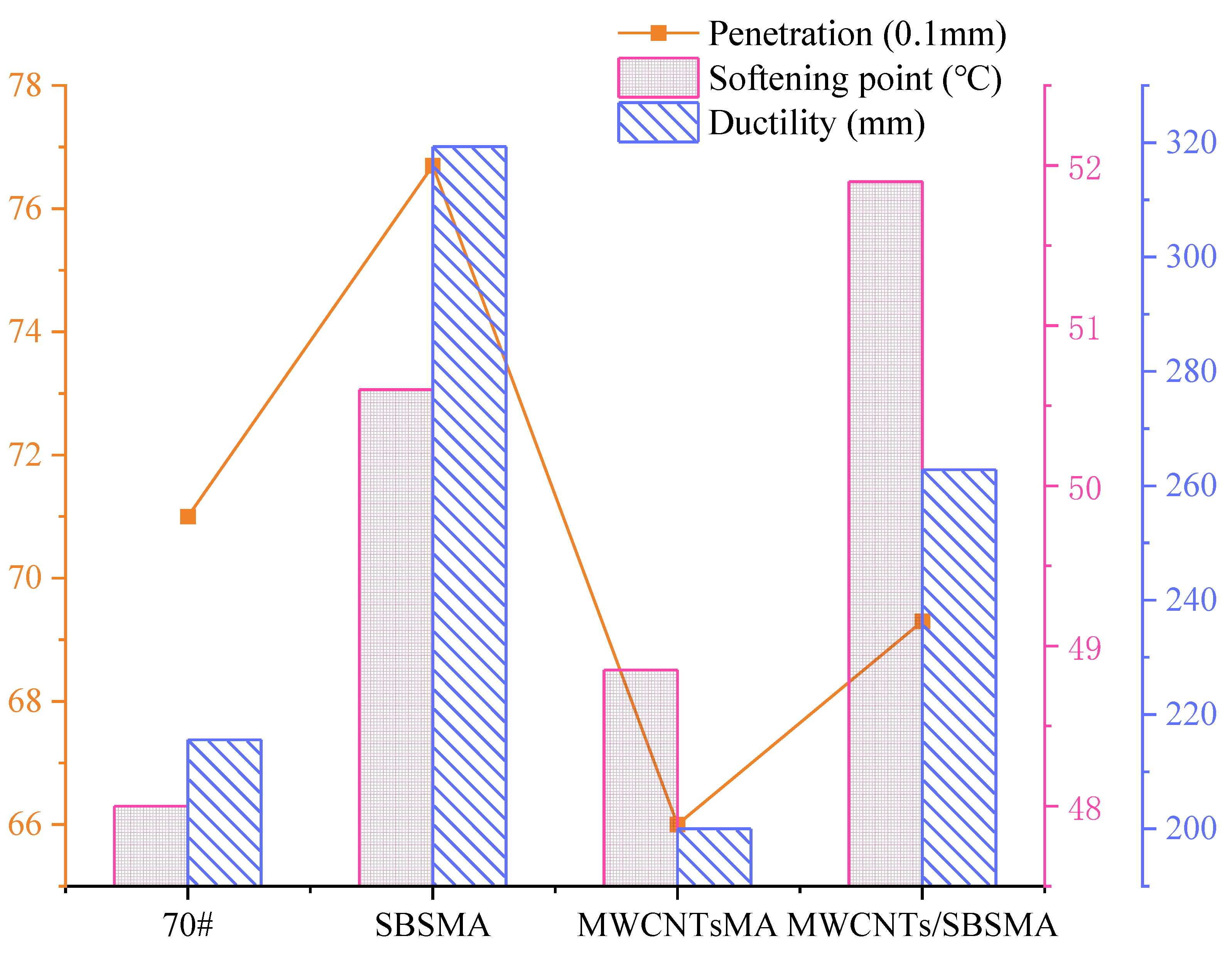

3.1. Basic Physical Properties

3.1.1. Penetration, Softening Point and Ductility

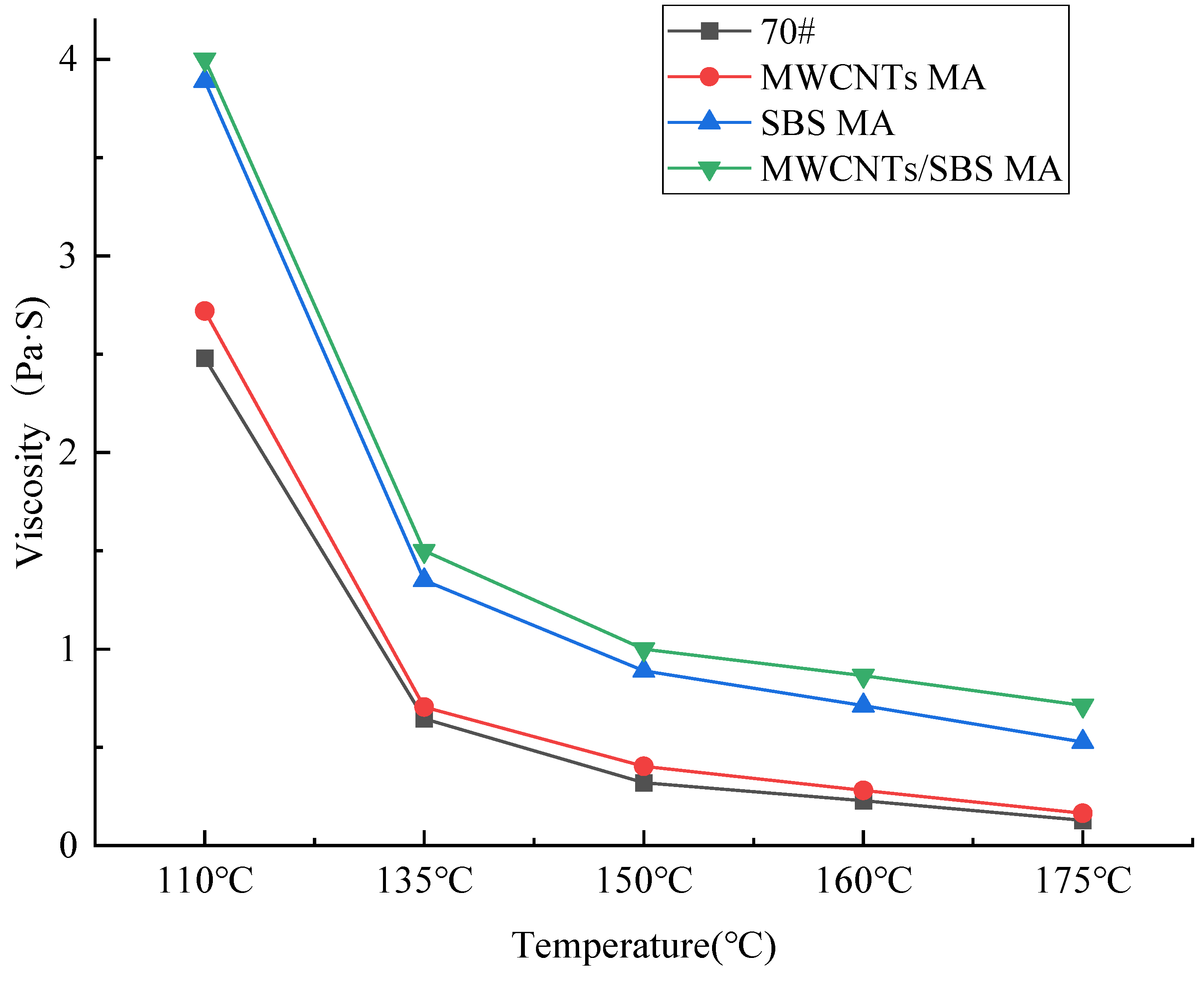

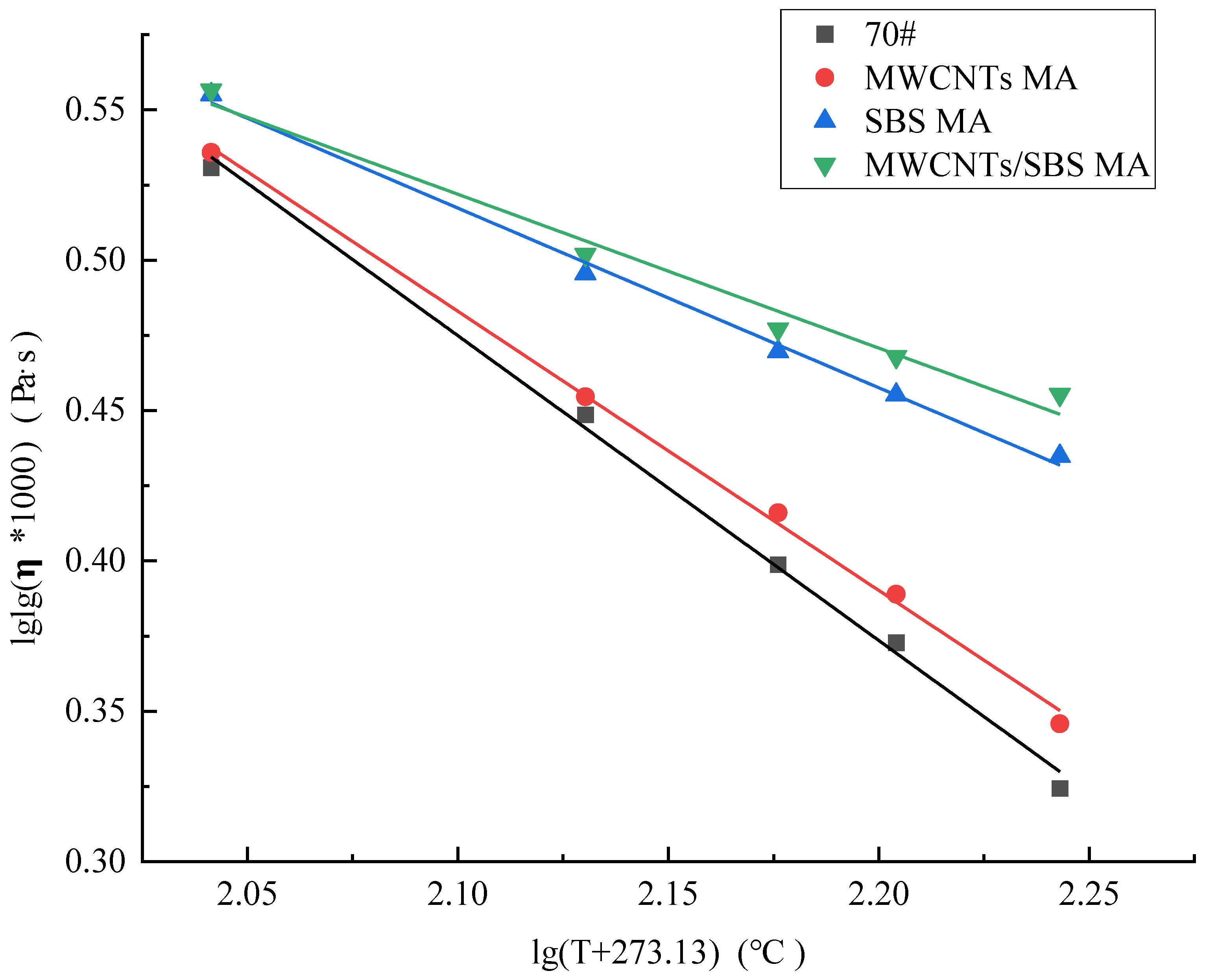

3.1.2. Viscosity-Temperature Relationship

3.2. Dynamic Shear Rheological Test

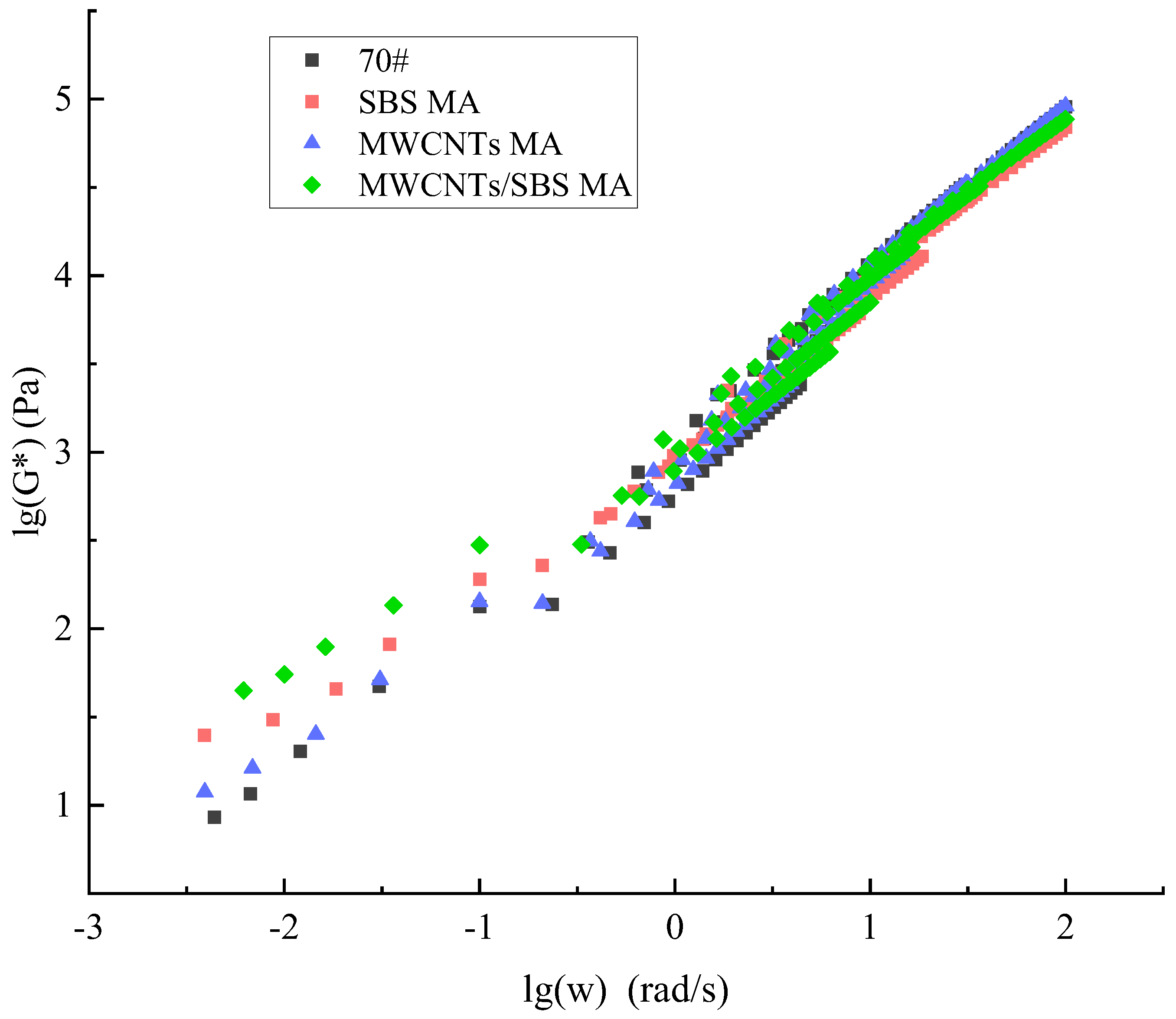

3.2.1. Frequency Sweeping

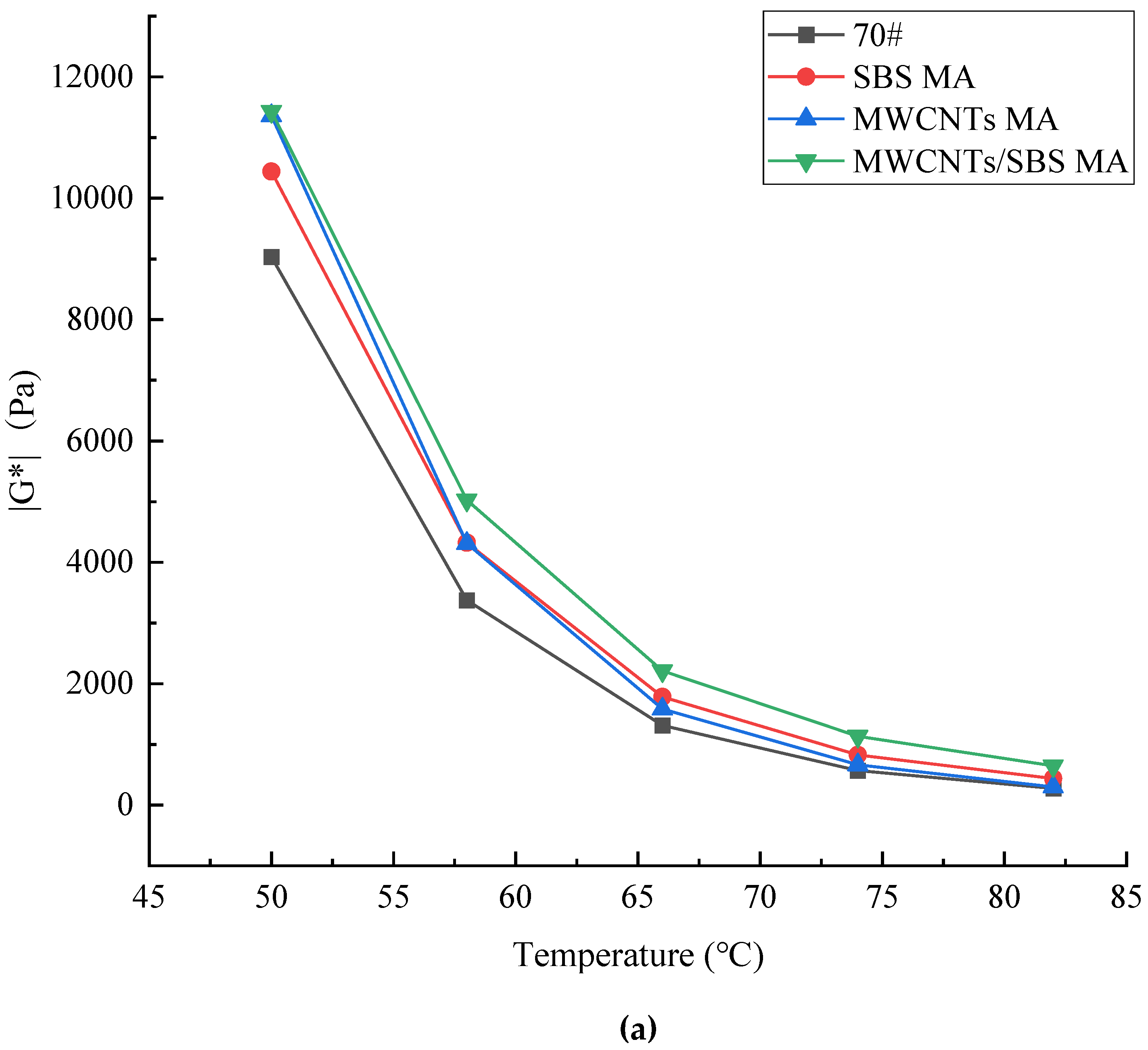

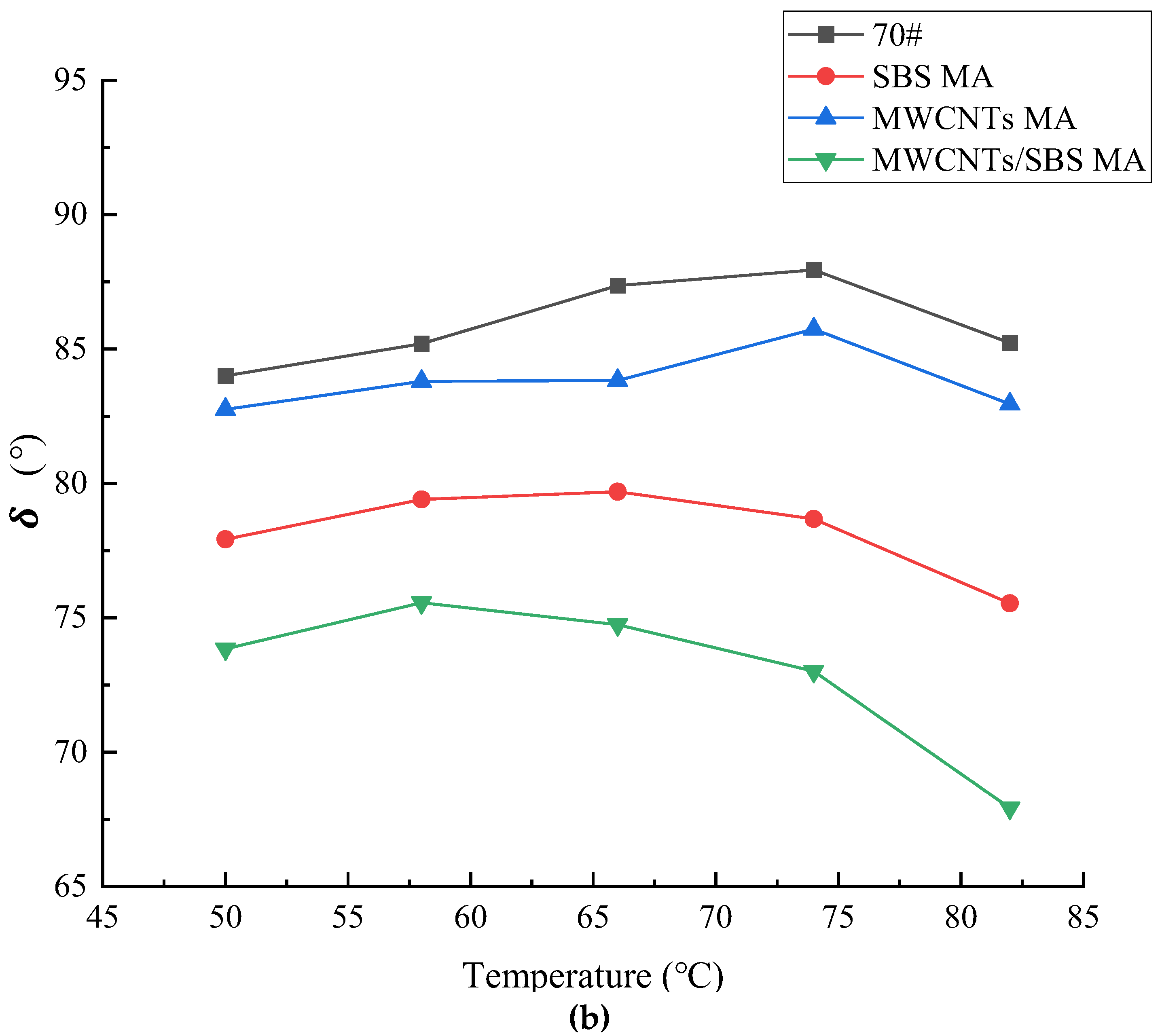

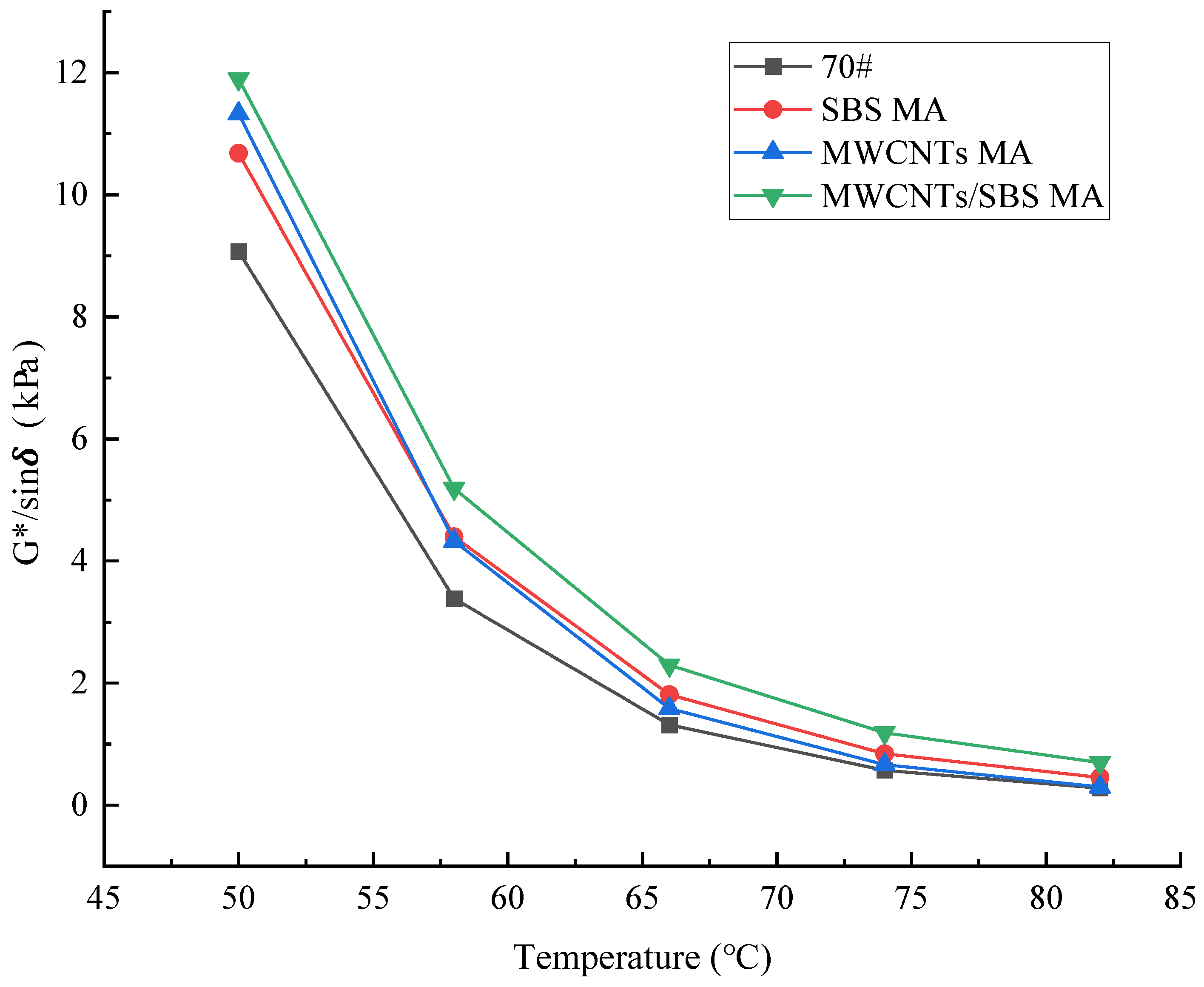

3.2.2. Temperature Sweeping

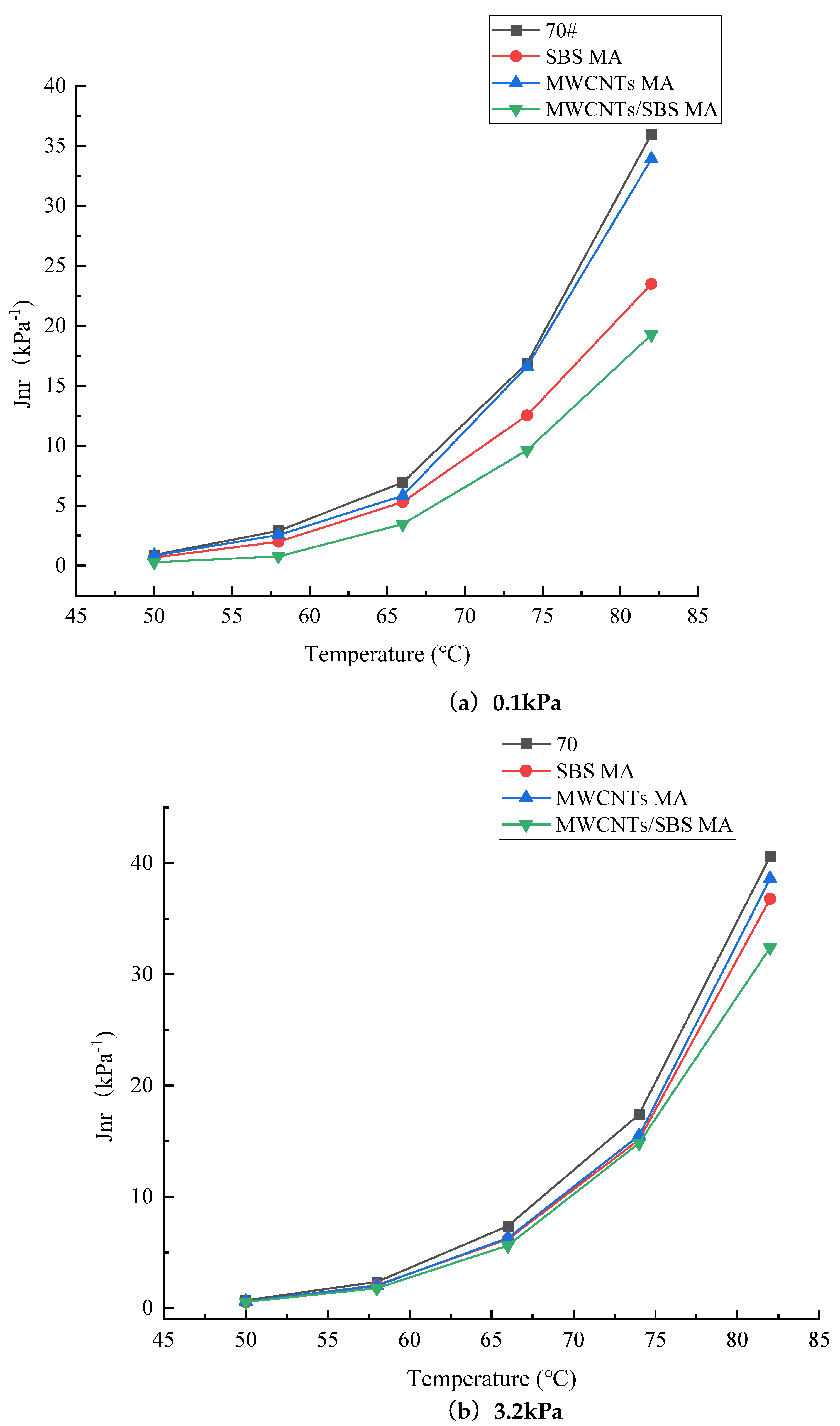

3.3. Multiple Stress Creep Recovery Test (MSCR)

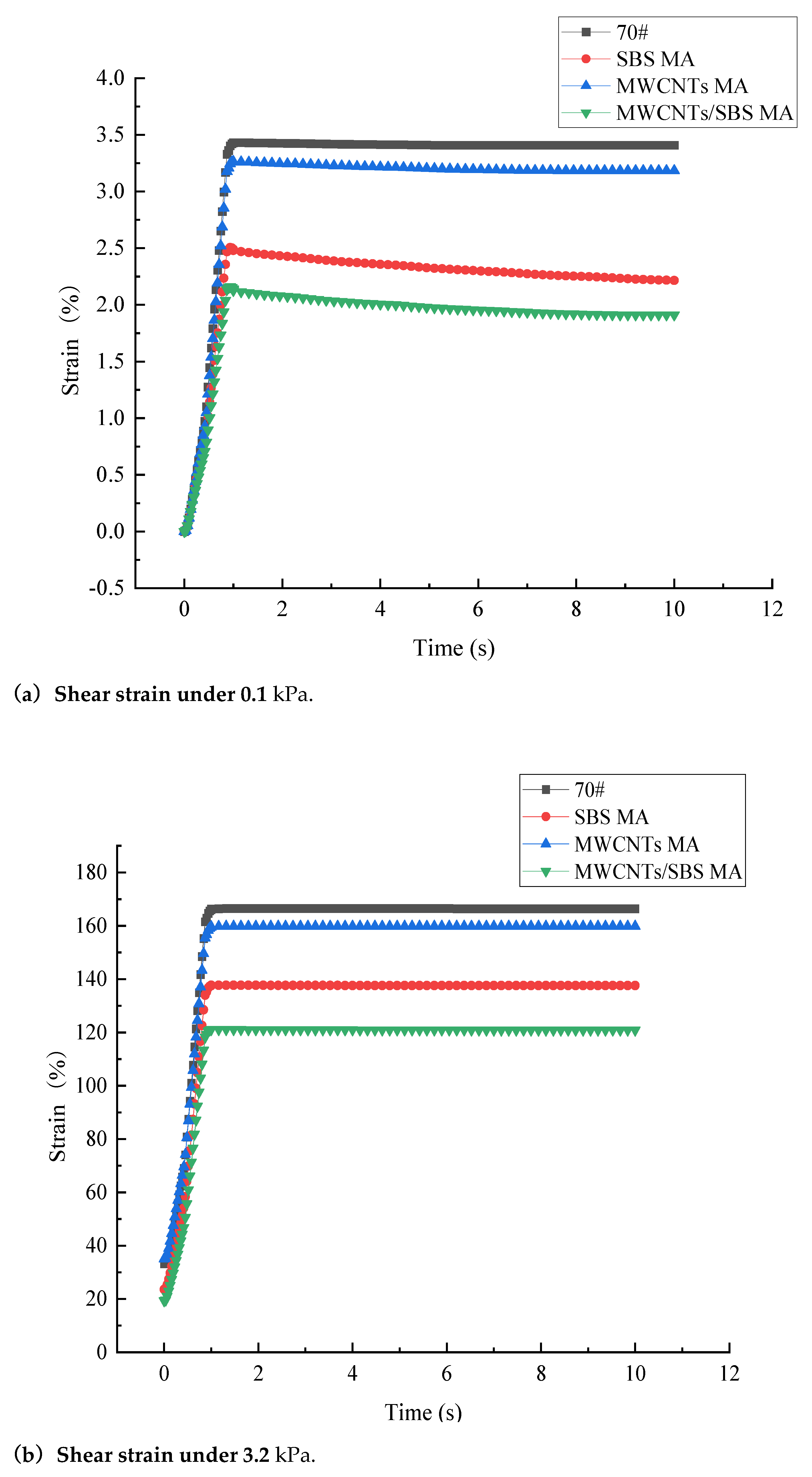

3.3.1. Stress-Strain Characteristic Analysis

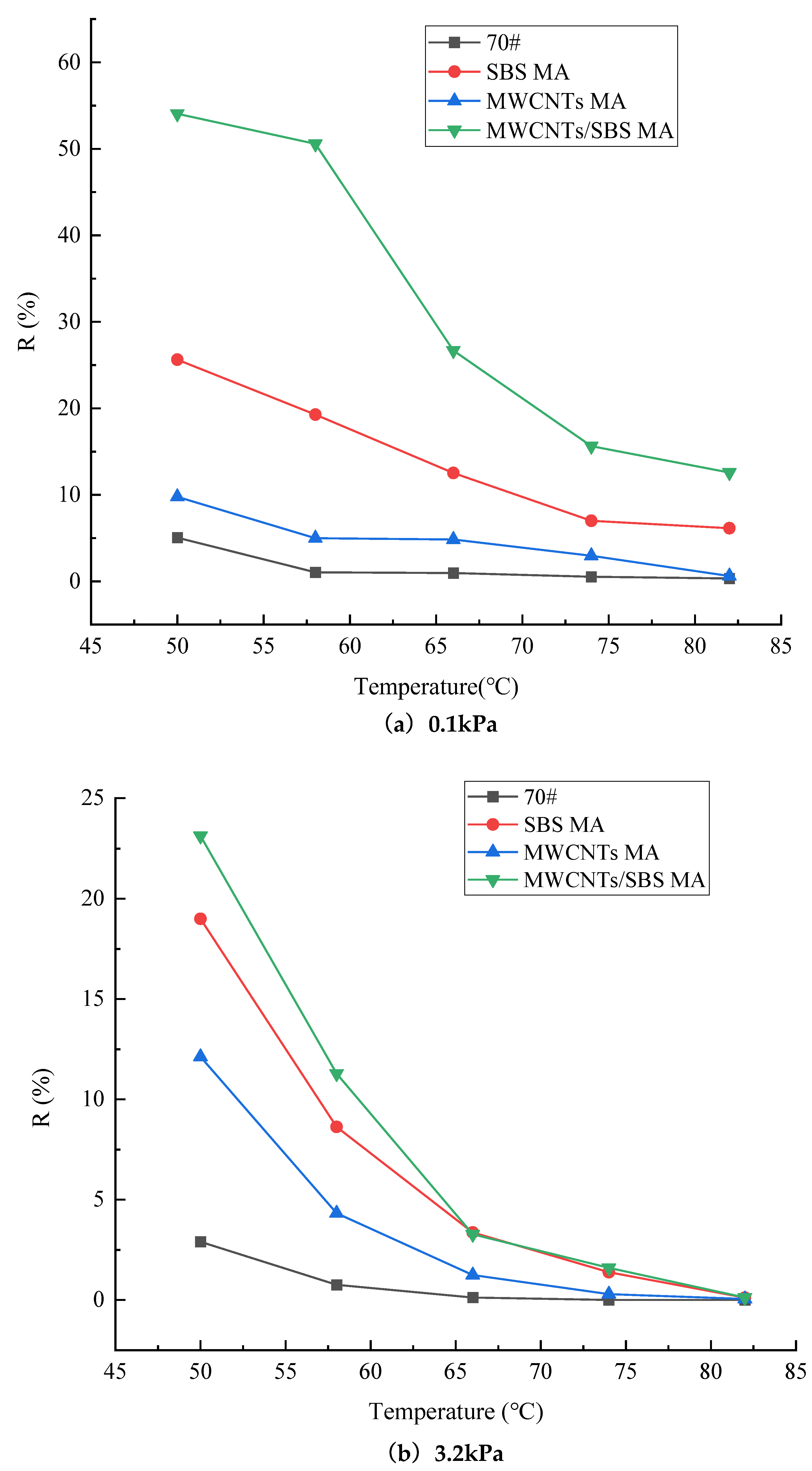

3.3.2. Creep Characteristic Analysis

3.4. Micro-Properties

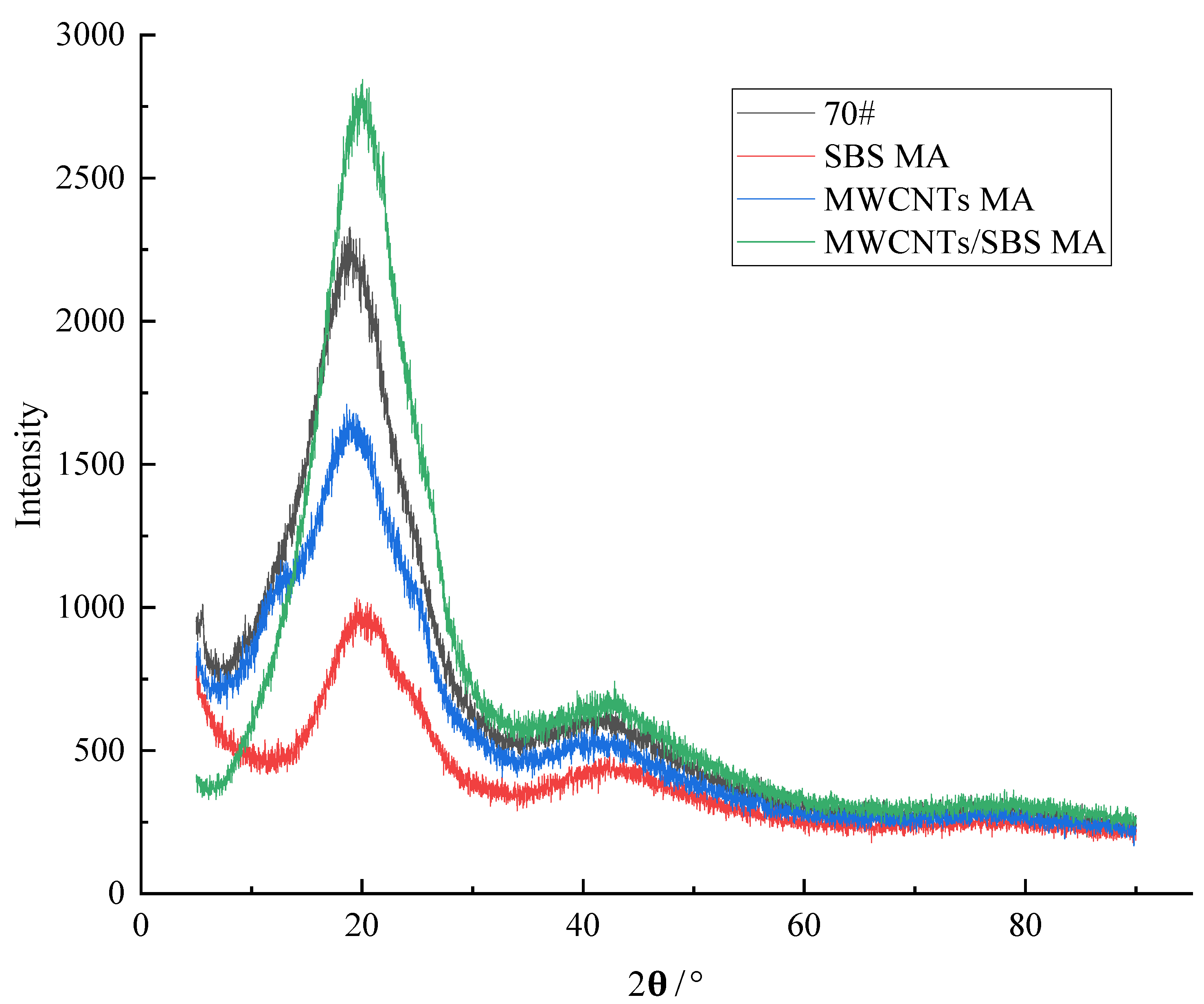

3.4.1. XRD Characterization

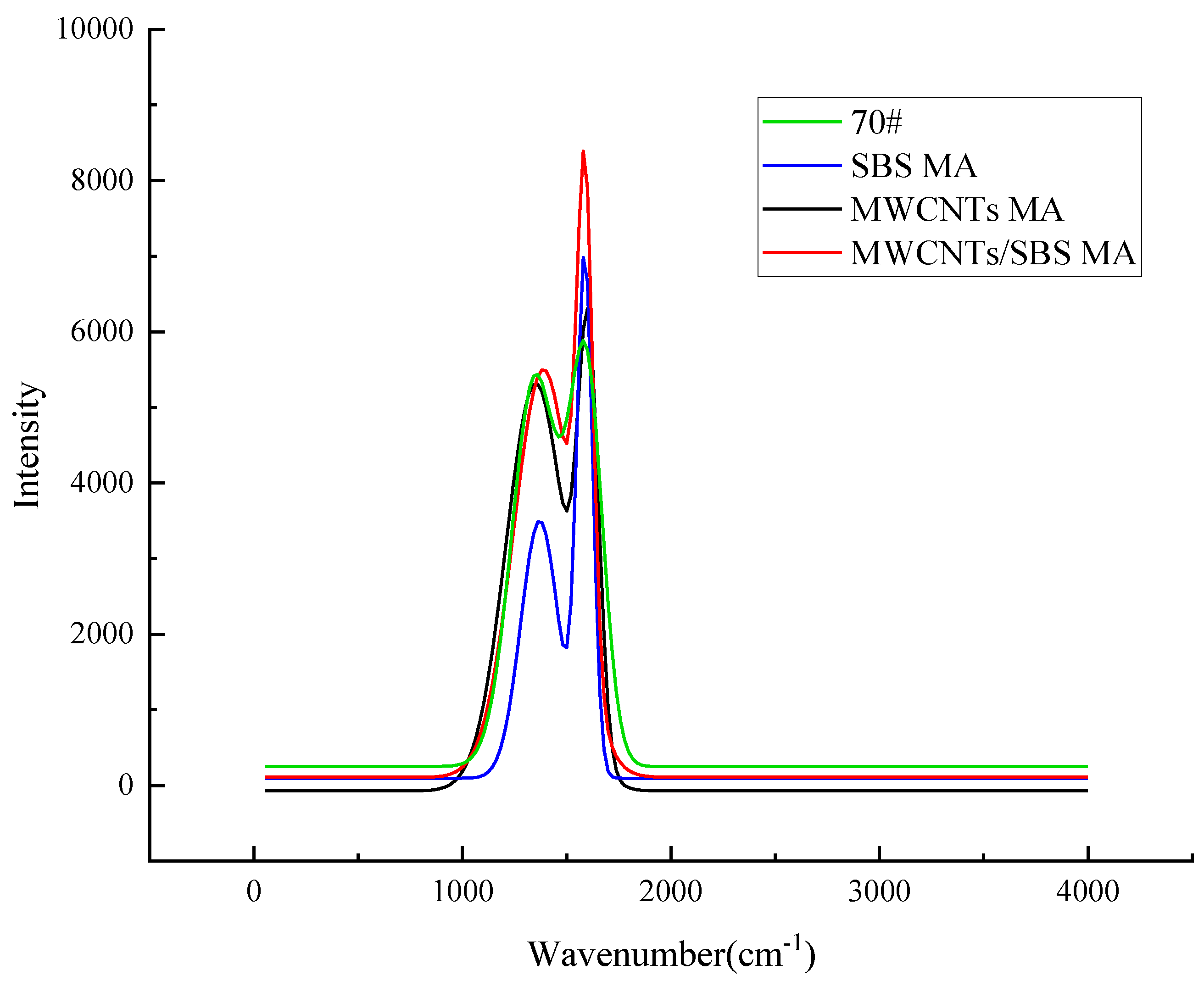

3.4.2. Raman Characterization

4. Conclusions

Acknowledgments

References

- Zhang, Z.; Liu, H.; Ban, X.; Liu, X.; Guo, Y.; Sun, J.; Liu, Y.; Zhang, S.; Lei, J. Thermosetting resin modified asphalt: A comprehensive review. J. Traffic Transp. Eng. (English Ed. 2023, 10, 1001–1036. [Google Scholar] [CrossRef]

- Jin, D.; Xin, K.; Yin, L.; Mohammadi, S.; Cetin, B.; You, Z. Performance of rubber modified asphalt mixture with tire-derived aggregate subgrade. Constr. Build. Mater. 2024, 449. [Google Scholar] [CrossRef]

- Yao, H.; Cao, Y.; Zhou, X.; Wang, J.; Wang, Q. Improvement on the high-temperature performance and fuel resistance of SBS modified asphalt by hybridizing with polyamide resin. Constr. Build. Mater. 2021, 309. [Google Scholar] [CrossRef]

- Kakar M R, Mikhailenko P, Piao Z, et al. Analysis of waste polyethylene (PE) and its by-products in asphalt binder[J]. Construction and Building Materials, 2021, 280: 122492.

- Mojabi, S.A.; Kordani, A.A.; Hajikarimi, P.; Nazari, M. Evaluating fracture performance of stone mastic asphalt with SBS and SEBS modifications. Theor. Appl. Fract. Mech. 2024, 134. [Google Scholar] [CrossRef]

- Ren, S.; Liang, M.; Fan, W.; Zhang, Y.; Qian, C.; He, Y.; Shi, J. Investigating the effects of SBR on the properties of gilsonite modified asphalt. Constr. Build. Mater. 2018, 190, 1103–1116. [Google Scholar] [CrossRef]

- Loise, V.; Vuono, D.; Policicchio, A.; Teltayev, B.; Gnisci, A.; Messina, G.; Rossi, C.O. The effect of multiwalled carbon nanotubes on the rheological behaviour of bitumen. Colloids Surf. A: Phys. 2019, 566, 113–119. [Google Scholar] [CrossRef]

- Monteiro, L.; Moghaddam, T.B.; Freed, K.; Shafiee, M.; Maadani, O.; Hashemian, L. Investigation of self-healing properties of nanoclay-modified asphalt binder using two-piece healing test. Can. J. Civ. Eng. 2023, 50, 126–136. [Google Scholar] [CrossRef]

- Ghabchi R, Castro M P P. Effect of laboratory-produced cellulose nanofiber as an additive on performance of asphalt binders and mixes[J]. Construction and Building Materials, 2021, 286: 122922.

- Mansourkhaki A, Aghasi A. Low-temperature fracture resistance of asphalt mixtures modified with carbon nanotubes[C]//Proceedings of the Institution of Civil Engineers-Transport. Thomas Telford Ltd, 2021, 174(2): 78-86.

- Xue, Z. H. , & Fan, X. H. “Study on the Performance and Modification Mechanism of Carbon Nanotube - Modified Asphalt”. New Building Materials, 2021, 48(6): 5. [CrossRef]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Dalmazzo, D. Rheological Characterization of Bituminous Binders Modified with Carbon Nanotubes. Procedia - Soc. Behav. Sci. 2012, 53, 546–555. [Google Scholar] [CrossRef]

- Amin, I.; El-Badawy, S.M.; Breakah, T.; Ibrahim, M.H.Z. Laboratory evaluation of asphalt binder modified with carbon nanotubes for Egyptian climate. Constr. Build. Mater. 2016, 121, 361–372. [Google Scholar] [CrossRef]

- Gong, M.; Yang, J.; Yao, H.; Wang, M.; Niu, X.; Haddock, J.E. Investigating the performance, chemical, and microstructure properties of carbon nanotube-modified asphalt binder. Road Mater. Pavement Des. 2017, 19, 1499–1522. [Google Scholar] [CrossRef]

- Goli, A.; Ziari, H.; Amini, A. Influence of Carbon Nanotubes on Performance Properties and Storage Stability of SBS Modified Asphalt Binders. J. Mater. Civ. Eng. 2017, 29. [Google Scholar] [CrossRef]

- Shah P M, Mir M S. Investigating the influence of carbon nanotube on the performance of asphalt binder[J]. Progress in Rubber, Plastics and Recycling Technology, 2021, 37(4): 422-440.

- Latifi, H.; Hayati, P. Evaluating the effects of the wet and simple processes for including carbon Nanotube modifier in hot mix asphalt. Constr. Build. Mater. 2018, 164, 326–336. [Google Scholar] [CrossRef]

- Mamun A A,Arifuzzaman, M. Nano-scale moisture damage evaluation of carbon nanotube-modified asphalt[J].Construction and Building Materials,2018,193:268-275.

- Zhu, Y. Q. , & Shu, B. A. “Influence of Carbon Nanotubes on the High and Low Temperature Performance of SBS - Modified Asphalt”. Journal of Wuhan University of Technology (Transportation Science & Engineering), 2018, 42(1): 103 - 107.

- Fu, Z. , Tang, Y. J., Sun, Q. Y., et al. “Study on the Pavement Performance and Compatibility of Carbon Nanotube/SBS Composite - Modified Asphalt”. Applied Chemical Industry, 2021, 50(8): 2031 - 2036.

- Sun, Q. Y. “Study on the Rheological Properties of Carbon Nanotube/SBS Composite - Modified Asphalt”. Dissertation, Chang’an University, 2020.

- Obukhova, S.; Korolev, E.; Gladkikh, V. The Influence of Single-Walled Carbon Nanotubes on the Aging Performance of Polymer-Modified Binders. Materials 2023, 16, 7534. [Google Scholar] [CrossRef]

- Tang, Y.; Fu, Z.; Ma, F.; Liu, J.; Sun, Q.; Li, C. Carbon nanotubes for improving rheological and chemical properties of styrene–butadiene–styrene modified asphalt binder. Int. J. Pavement Eng. 2023, 24. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Z.; Wang, H.; Yang, Z.; Zhang, T. Investigating the Rheological Properties of Styrene-Butadiene-Styrene-Based High-Viscosity Modified Asphalt Using Carbon Nanotubes. Sustainability 2022, 15, 71. [Google Scholar] [CrossRef]

- Wang, R.; Yue, M.; Xiong, Y.; Yue, J. Experimental study on mechanism, aging, rheology and fatigue performance of carbon nanomaterial/SBS-modified asphalt binders. Constr. Build. Mater. 2021, 268. [Google Scholar] [CrossRef]

- Yu, C.-H.; Hu, K.; Chen, G.-X.; Chang, R.; Wang, Y. Molecular dynamics simulation and microscopic observation of compatibility and interphase of composited polymer modified asphalt with carbon nanotubes. J. Zhejiang Univ. A 2021, 22, 528–546. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, X.; Ji, W.; Zhang, F.; Otto, F. Characterizing the mechanical properties of Multi-Layered CNTs reinforced SBS modified Asphalt-Binder. Constr. Build. Mater. 2021, 296. [Google Scholar] [CrossRef]

- Wang, P.; Zhai, F.; Dong, Z.-J.; Wang, L.-Z.; Liao, J.-P.; Li, G.-R. Micromorphology of Asphalt Modified by Polymer and Carbon Nanotubes through Molecular Dynamics Simulation and Experiments: Role of Strengthened Interfacial Interactions. Energy Fuels 2018, 32, 1179–1187. [Google Scholar] [CrossRef]

- Shu, B.; Wu, S.; Pang, L.; Javilla, B. The Utilization of Multiple-Walled Carbon Nanotubes in Polymer Modified Bitumen. Materials 2017, 10, 416. [Google Scholar] [CrossRef]

- Nie, G.; Huang, W.; Wu, K.; Cai, X.; Huang, J.; Xie, J.; Zheng, Y. Modification Mechanism of MWCNTs and SBS Composite-Modified Asphalt Binder: Laboratory Investigation and Molecular Dynamic Simulation. J. Mater. Civ. Eng. 2024, 36. [Google Scholar] [CrossRef]

- Xie Shuangrui. Experimental Study on the Influence of Carbon Nanotubes on the Performance of SBS Modified Asphalt and Mixtures[D]. Heilongjiang: Northeast Forestry University, 2020.

- Yang Zhaohui. Research on Rheological Properties and Modifier Dosage of SBS Modified Asphalt[D]. Changan University, 2011. [CrossRef]

- Zhu Haoran, Wei Jianming, Gong Minghui, et al. Research Progress of Carbon Nanotube Modified Asphalt[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2017, 33(2): 386 - 394.

- Ministry of Transport of the People’s Republic of China. Test Specifications for Asphalt and Asphalt Mixtures in Highway Engineering (JTG E20 - 2011)[M]. China Communications Press, 2011.

- Li Fujin, Shen Jinan. Implementation Manual of Technical Specifications for Construction of Highway Asphalt Pavement[M]. Beijing: China Communications Press, 2005.

- ASTM. Standard viscosity-temperature chart for asphalt: ASTM D2493/2493M[S].USA:US-ASTM,2009.

- Shen Jin’an. Road Performance of Asphalt and Asphalt Mixtures[M]. Beijing: China Communications Press, 2001.

- Huang Wei, Guo Rongxin, Zhou Bin, et al. Research on Viscoelastic Behavior of SBS/PPA Modified Asphalt Based on Frequency Sweep[J]. Journal of Highway and Transportation Research and Development (Applied Technology Edition), 2016, 12(06): 134 - 136.

- Williams, M.L.; Landel, R.F.; Ferry, J.D. The Temperature Dependence of Relaxation Mechanisms in Amorphous Polymers and Other Glass-forming Liquids. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar] [CrossRef]

- Rusbintardjo, G.; Hainin, M.R.; Yusoff, N.I.M. Fundamental and rheological properties of oil palm fruit ash modified bitumen. Constr. Build. Mater. 2013, 49, 702–711. [Google Scholar] [CrossRef]

- Konstantinos, S, Andrikopoulos, et al. Evaluation of multi-walled carbon nanotube concentrations in polymer nanocomposites by Raman spectroscopy[J].Carbon: An International Journal Sponsored by the American Carbon Society, 2014, 76:301-309.

| Properties | values | Test Standard |

| Penetration (25℃, 100g, 5s, 0.1mm) | 72 | Specification of China (JTG E20-2011) |

| Softening point (5℃, ℃) | 46.6 | |

| 60℃ dynamic viscosity (Pa·s) | Cm220 | |

| Ductility (10℃, 5 cm/min, cm) | 56 | |

| Flash point (℃) | >300 | |

| Density (15℃, g/cm3) | 1.037 |

| Properties | Values |

| S/B | 31/69 |

| Tensile strength (MPa) | 32 |

| Breaking elongation (%) | 880 |

| Hardness (10s) | 72 |

| Specific gravity | 0.94 |

| Parameters | Values |

| Purity (%) | >98 |

| Diameter (nm) | 40-60 |

| Length (μm) | <10 |

| Specific surface area (m2/g) | 60-100 |

| Production method | Chemical vapor deposition (CVD) |

| Equation | lgη=n-m×T | |||

| Sample | Basic asphalt | CNTs MA | SBS MA | CNTs/SBS MA |

| Fitting equation | lgη=2.8511-0.0223×T | lgη=2.8068-0.0216×T | lgη=2.3405-0.0160×T | lgη=2.1751-0.0144×T |

| Reduced Chi-Sqr | 0.00163 | 0.00451 | 0.02543 | 0.04427 |

| R2 | 0.9983 | 0.996 | 0.98674 | 0.97625 |

| Equation | lglg(η×103)=n-mlg(T+273.13) | ||||

| Sample | Basic asphalt | CNTs MA | SBS MA | CNTs/SBS MA | |

| Fitting equation | lglg(η×103)=2.6034-1.0136×lg(T+273.13) | lglg(η×103)=2.4323-0.9282×lg(T+273.13) | lglg(η×103)=1.7721-0.5975×lg(T+273.13) | lglg(η×103)=1.5962-0.5112×lg(T+273.13) | |

| Reduced Chi-Sqr | 2.54982E-5 | 1.38724E-5 | 1.14701E-5 | 4.0051E-5 | |

| R2 | 0.99691 | 0.998 | 0.99601 | 0.98126 | |

| Equation | η=Aθb | |||

| Sample | Basic asphalt | CNTs MA | SBS MA | CNTs/SBS MA |

| Fitting equation |

η=5.18126E13× T-6.52504 |

η=2.05832E13× T-6.30928 |

η=1.86322E10× T-4.74324 |

η=2.29149E9× T-4.29213 |

| Reduced Chi-Sqr | 1.27112E-4 | 0.00105 | 0.00892 | 0.01989 |

| R2 | 0.9999 | 0.9993 | 0.99651 | 0.992 |

| Sample | Shifting factor | ||||

| 50℃ | 58℃ | 66℃ | 74℃ | 82℃ | |

| Basic asphalt | 0 | -0.5094 | -0.8384 | -1.1629 | -1.4070 |

| SBS MA | 0 | -0.4414 | -0.7891 | -1.0005 | -1.2087 |

| MWCNTs MA | 0 | -0.5155 | -0.9187 | -1.1740 | -1.3586 |

| MWCNTs/SBS MA | 0 | -0.4609 | -0.7362 | -1.4089 | -1.5084 |

| Sample | peaks | 2θ (°) | Peak height | FWHM | d (Å) | Area (mV·min) | |

| Basic asphalt | γ-peak | 18.90562 | 1571.23573 | 10.49541 | 5.84 | 17149.46669 | |

| 002-peak | 25.53529 | 36.17641 | 1.62658 | 3.46 | 64.36886 | ||

| SBS MA | γ-peak | 20.18885 | 564.53763 | 8.67772 | 5.49 | 5199.52202 | |

| 002-peak | 25.67987 | 50.56143 | 2.73259 | 3.44 | 147.07065 | ||

| MWCNTs MA | γ-peak | 18.64421 | 1094.23457 | 12.75621 | 5.91 | 14013.30848 | |

| 002-peak | 25.12883 | 38.22032 | 1.17434 | 3.54 | 44.02699 | ||

| MWCNTs/SBS MA | γ-peak | 19.96733 | 2089.34551 | 8.47616 | 5.56 | 18797.32277 | |

| 002-peak | 26.41321 | 270.0296 | 3.96452 | 3.36 | 1139.55181 | ||

| Sample | WD(cm-1) | ID | WG(cm-1) | IG | ID/IG |

| Basic asphalt | 1361.70 | 5433.2756 | 1579.80 | 5882.2022 | 0.9237 |

| SBS MA | 1361.70 | 3486.2060 | 1579.80 | 6982.6528 | 0.4992 |

| MWCNTs MA | 1361.70 | 5308.6607 | 1599.63 | 6307.8409 | 0.8416 |

| MWCNTs/SBS MA | 1381.53 | 5495.0786 | 1579.80 | 8954.3102 | 0.6137 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).