1. Introduction

With the rapid depletion of fossil fuels, there has been growing interest in the development of renewable energy sources. New energy resources, such as solar, wind, hydro, geothermal, and bioenergy are garnering significant attention [

1]. Among these luminous energy is a critical component owing to its minimal environmental impact. The energy conversion process produces almost no pollutants and requires no additional resources compared with traditional fossil fuels, making it environmental friendly [

2]. With advancement in photovoltaic (PV) technology, the construction and operation of PV power generation systems have become significant drivers of economic growth. In the late 20th century, scientific researchers discovered the phenomenon of the PV effect, where sunlight illuminating the surface of semiconductor materials generates an induced current [

3]. Technological advancement have led to the successful development of monocrystalline Si solar cells, making a breakthrough in solar-to-energy conversion [

4]. In Europe, United States and Japan, the microgrids basic theoretical analysis is completed. The model tools and simulation tools of distributed energy resources and microgrids are preliminary establishment [

5]. According to the verification of experimental test and on-side demonstration, the basic theory of microgrids operation, protection and economic analysis can be solved. The available microgrid models are mainly built based on microgrids economic operation. However, the microgrid models combined with renewable energy and energy storage are missing, from which the important role of renewable energy on microgrid operation is unable to reflect [

6]. Therefore, in this manuscript, a microgrid model based on renewable energy is proposed. This model is developed in Matlab, from which the output characteristic of PV microgrid can be observed directly.

In traditional energy systems, distribution networks primarily use alternating current (AC) [

7]. Recently, researchers have proposed a direct current (DC) microgrid to reduce energy conversion loss in transmission systems. This approach reduces the power conversion and DC load conversion losses, enhancing economic efficiency. It also avoids synchronization with large AC power grids [

8]. For security, the bus voltage remains stable during power outages or voltage drops owing to the high energy storage capacity of the DC capacitor and converter voltage control [

9]. This study presents a power-plan mathematical model based on a PV microgrid.

Photovoltaic power generation is the most important form to develop and make use of the solar energy. Photovoltaic cell is the important part of photovoltaic power generation [

10]. Due to the effect of parameters, ambient temperature, illuminance and loads, the output characteristic of photovoltaic cell is nonlinear. In order to improve the PV power generation efficiency effectively, at present, the MPPT control device being added into PV power generation system is a common method. In regard to PV power generation system, the typical MPPT control model mainly includes PV array module, MPPT algorithm, PWM module and DC/DC transformation module. Among them, PV array module is formed by multiple PV cell units series and parallel connection and tight packing. The MPPT module mainly includes the control algorithm. At present, there is a wide variety of MPPT algorithms [

11]. Each algorithm owns its advantage and defect. Because of the mature development, simple control and high precision, the perturbation and observation method and incremental conductance(INC) are used commonly. In regard to PWM module output, it is used as drive signal of later DC/DC circuit. In DC/DC conversion, the efficiency of Buck and Boost converter is the highest. From Buck converter, the high voltage can be transformed to low voltage. In general, the output voltage level of PV array is low [

12]. For grid-connected, the grid-side level must be higher. So the Buck converter seldom used in Grid-connected. From Boost converter, the output voltage of PV array increases. The Grid-connected easy to implement. Besides, the Impedance transformation function of Boost converter commonly used for MPPT control. The circuit is easy to driven.

In this manuscript, based on the analysis of MPPT control model in PV power generation, the Simulink models for different modules are built. Among them, the PV cell model is built by engineering mathematics model. The MPPT algorithm used INC method. The boost converter is used for DC/DC conversion. According to the analysis of these modules, the MPPT control system based on Boost circuit is deeply explored. Besides, it can also be applied to the analysis and study of MPPT control in actual PV power generation system.

2. Simulation Construction of Photovoltaic Microgrid

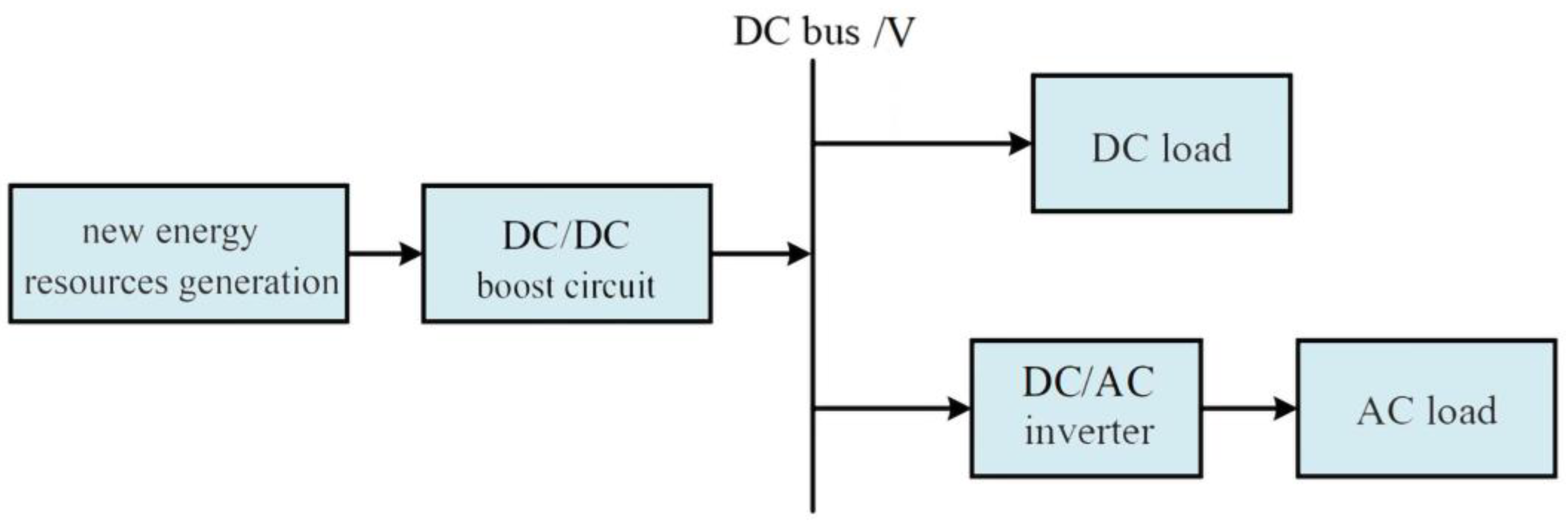

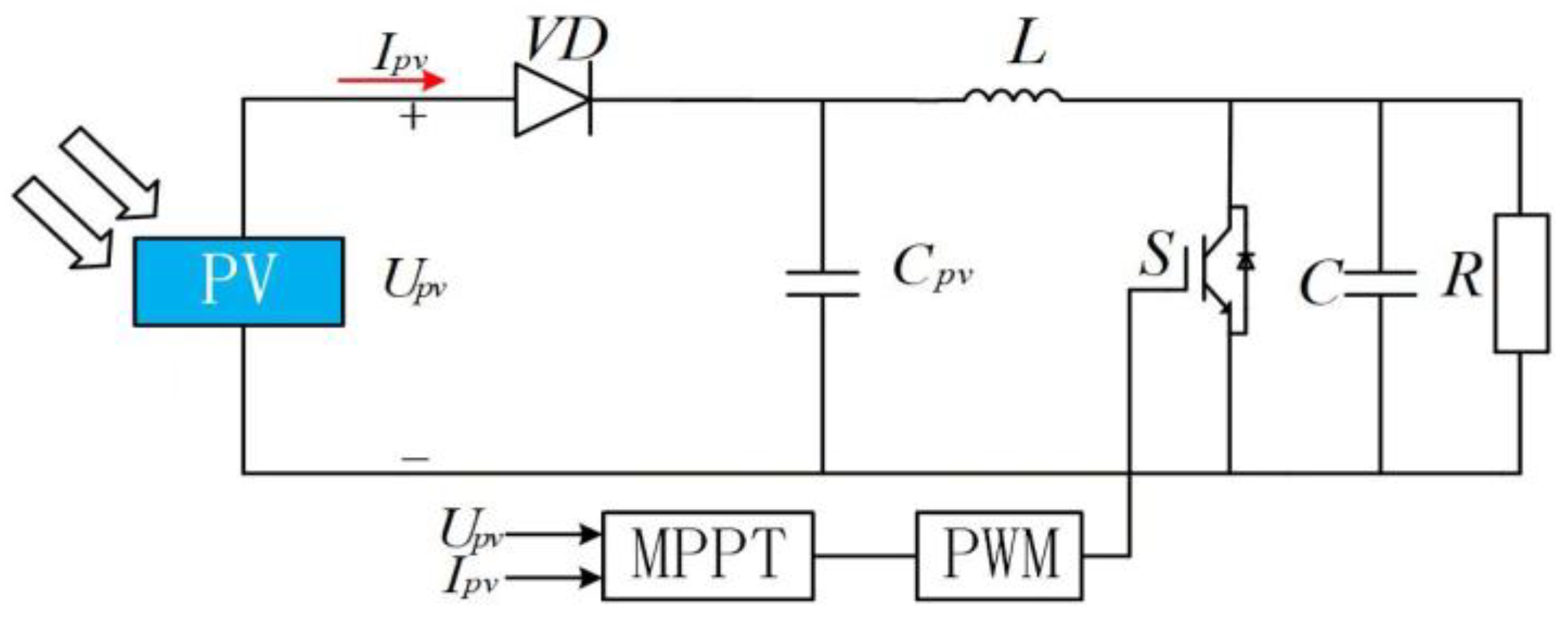

The primary modules of PV microgrid include a PV cell, boost converter, and DC load. This system forms a compact microgrid model, as illustrated in

Figure 1.

2.1. Photovoltaic Cell Modeling

The current in the system is determined by the output power of the PV array. The output current of the solar cell is calculated using Equation 1:

Where

is photocurrent.

is diode saturation current.

is diode quality factor.

is charge constant.

is Blotzman constant.

is photovoltaic cell temperature.

and

are internal resistance of PV cell series connection and parallel connection [

13]. To accurately calculate the output current, relevant parameters can be adjusted to simplify Equation 1, as shown in Equation 2:

For simplicity, Equation 2 can be replaced by Equation 3, where

B represents the battery capacity:

To simplify the calculation at room temperature, the value of

exceeds one, as shown in Equation 4:

To precisely represent the state of the electric circuit, we obtain Equation 5:

When

significantly exceeds one, the battery capacity is given by Equation 6:

Equations 2 to 6 can be incorporated into a simulation model, from which the voltage–current(U-I) characteristic curve of the PV power can be obtained [

14].

After obtaining the U-I characteristics, the values of light intensity and system temperature variation are calculated [

15]. Subsequently, these values are substituted into Eq. 7 and used in the simulation. Firstly, under normal external condition (the solar external condition

, the ambient temperature

), the model is used to simulate. Then the Power-Voltage(P-V) simulation curves before and after MPPT tracking are obtained.

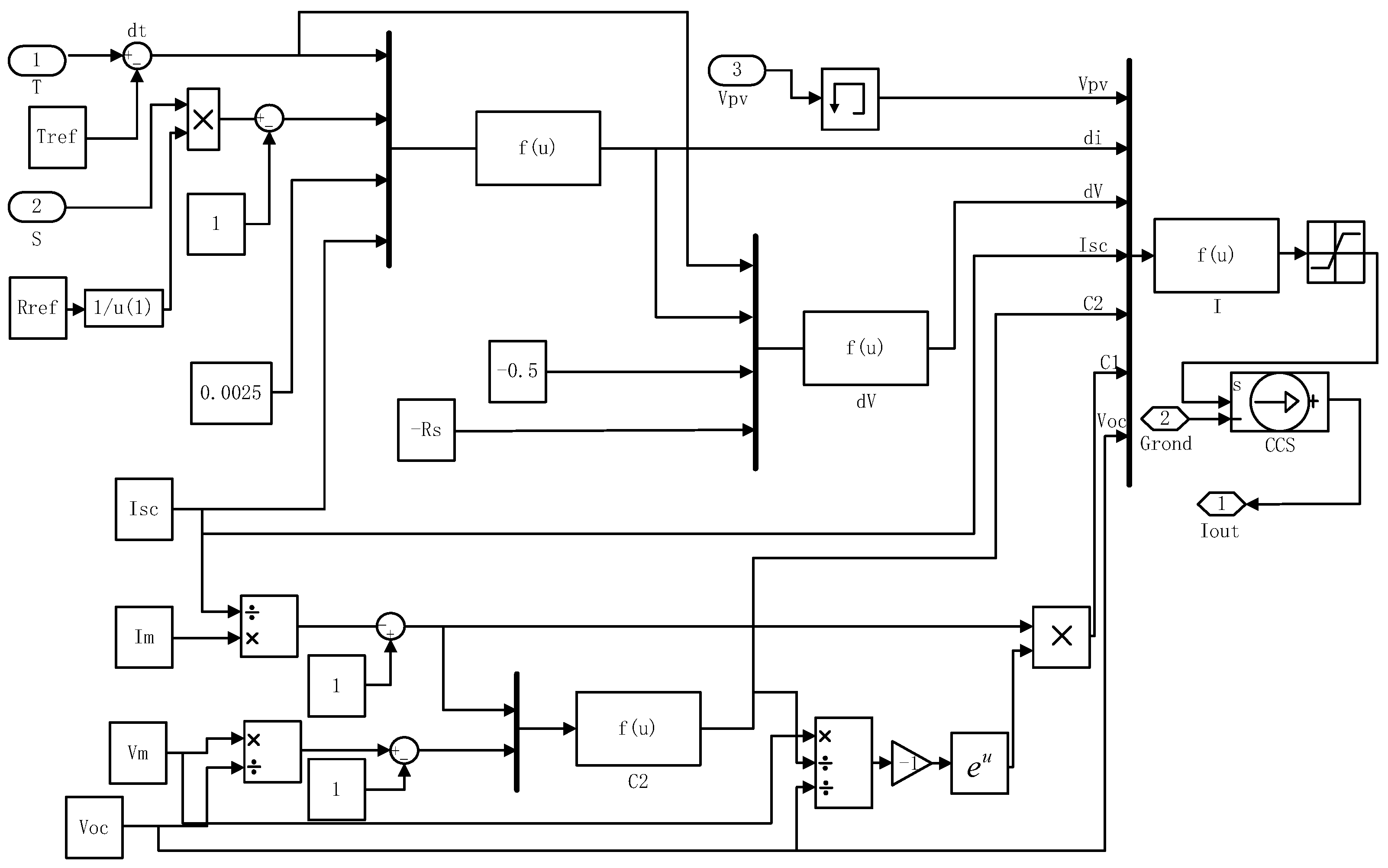

The simulation model of the PV power is developed using the MATLAB/Simulink simulation software, as shown in

Figure 2 [

16]. Where f(u) is S-Function. S-function module is the s-function of MPPT in PV module.

2.2. DC Load Modeling

Compared with PV power, establishing a DC load model is more convenient. The RLC load is selected using the Simscape module.

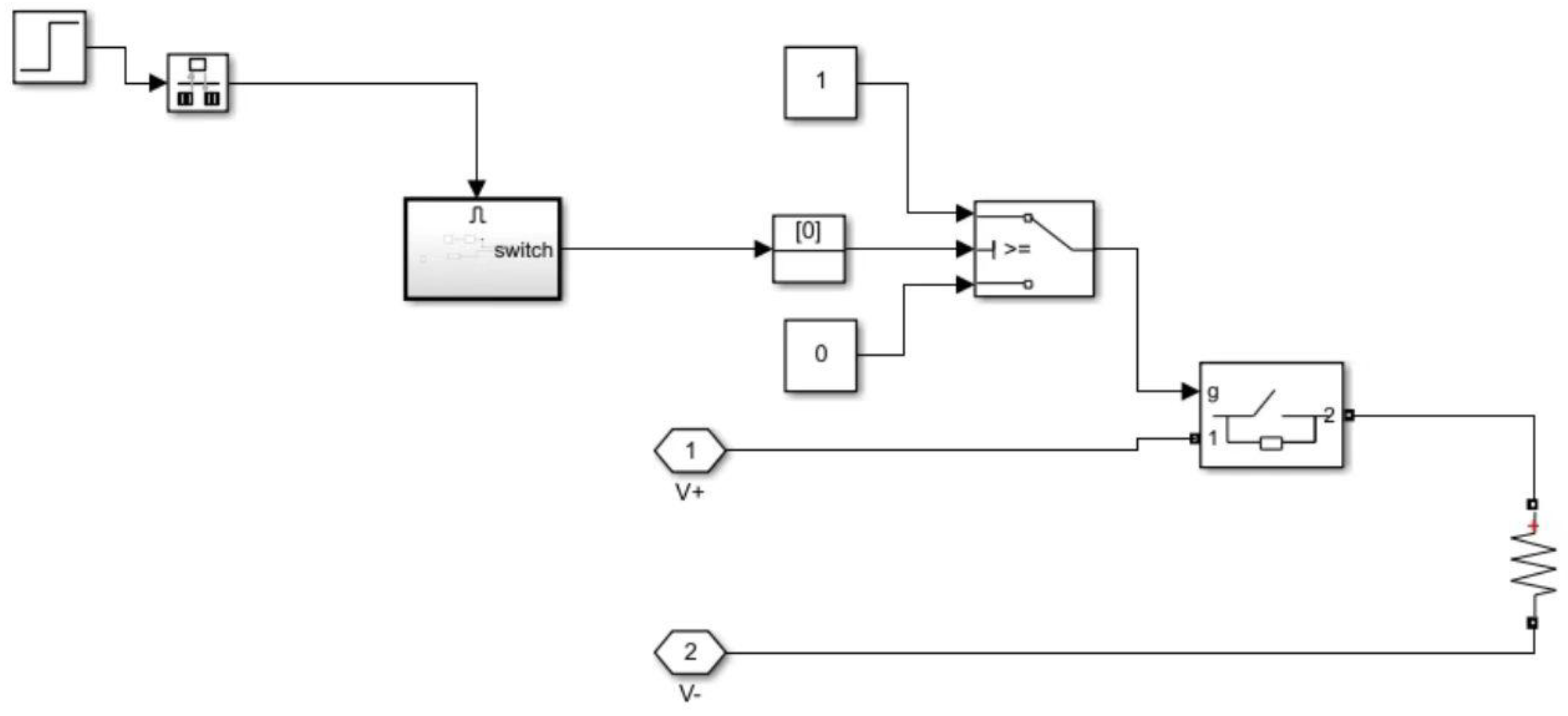

The selected components are loaded into the simulation model. After encapsulation, a DC pulse load is obtained [

17]. These load power variations are processed using module instructions that possess good flexibility and operation. This model is illustrated in

Figure 3.

2.3. DC Microgrid Modeling and Parameters Setting

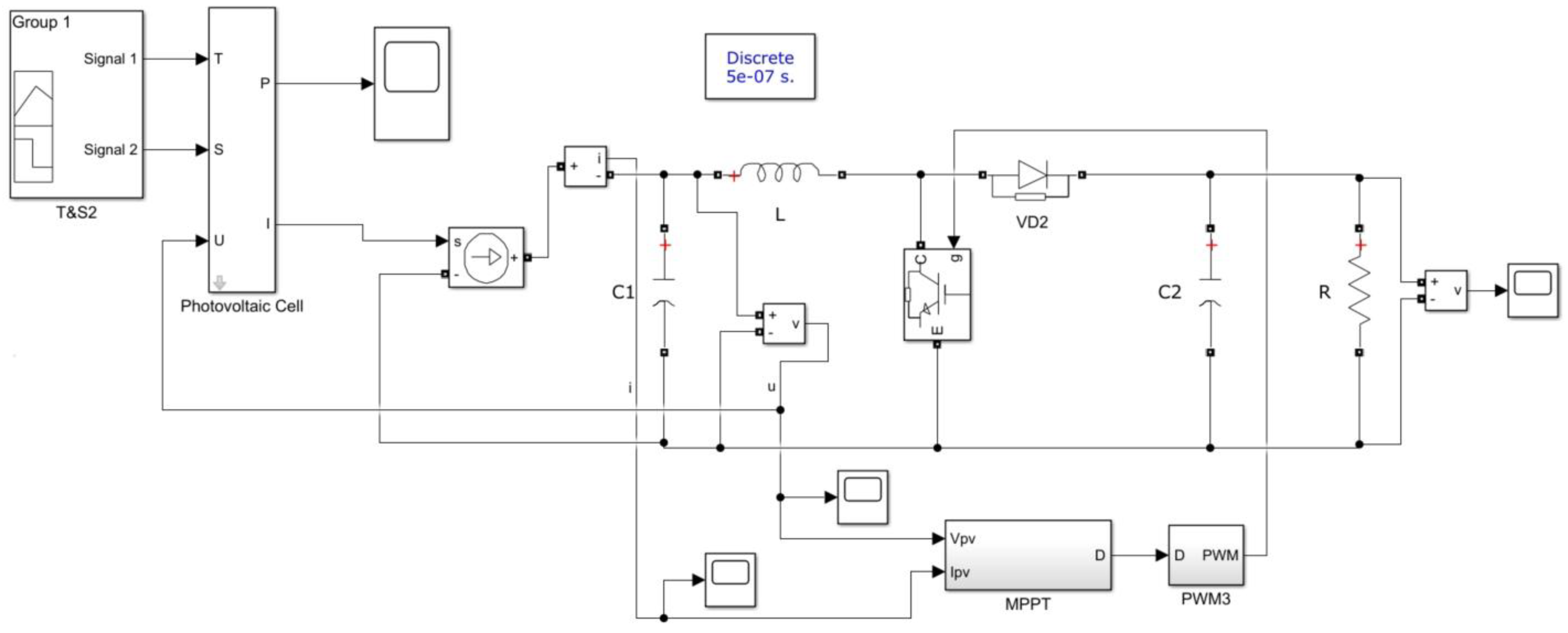

After modeling each module, a DC microgrid simulation model is built using Simulink, as depicted in

Figure 4 [

18]. The elapsed time is set as 3 s, while the discrete step is set at 5×10

-7 s.

The simulation environment is set as a discrete state, and the ode23tb simulation algorithm is used. Other simulation parameter settings, including the maximum and minimum step sizes.

The important parameters of each simulation components are presented in

Table 1.

3. System Simulation Results and Analysis

3.1. Output Characteristic Analysis of Photovoltaic Cell

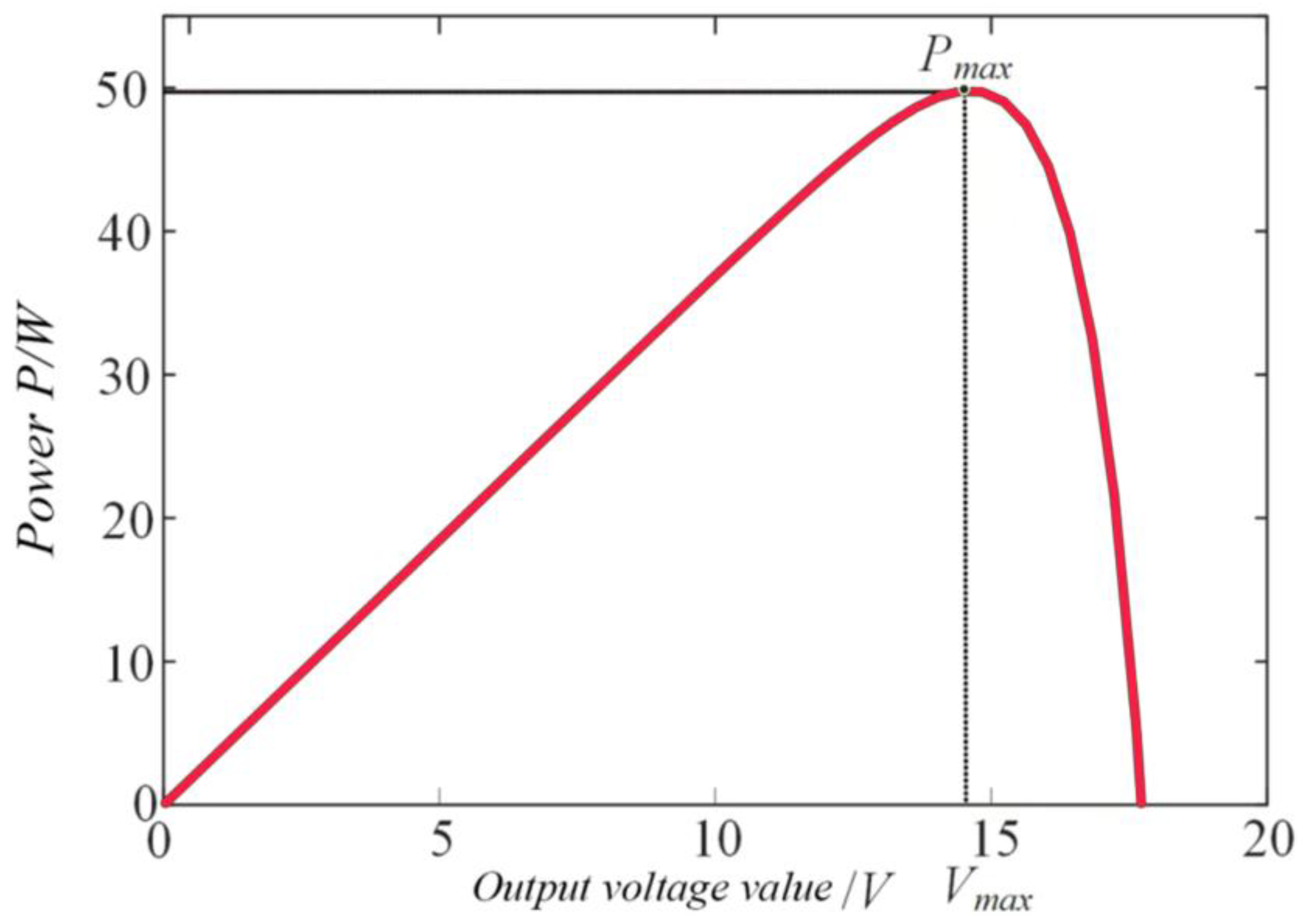

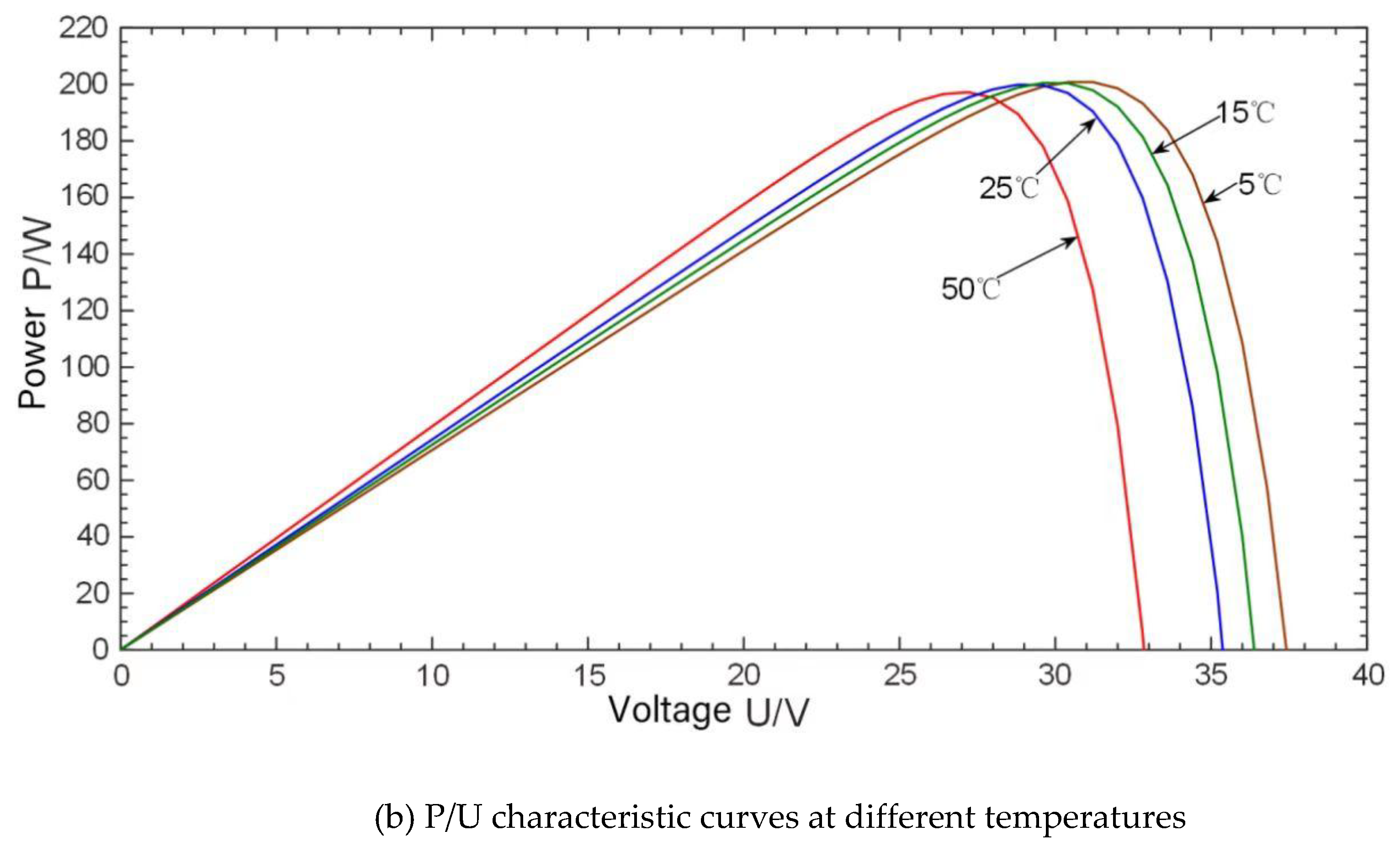

The power–voltage (P-V) characteristics of the PV array are shown in

Figure 5. When the operating voltage of the generator is lower than the maximum voltage

Vmax, the output voltage of the array increases [

19,

20,

21]. However, when the operating voltage exceeds

Vmax, the output voltage gradually decreases, leading to a reduced output power of the array [

22,

23]. From the curve graph, the PV array performance can be optimized automatically using maximum power point tracking (MPPT) technology [

24]. According to the voltage regulation on the console, the output power of the PV array can be adjusted under varying temperatures and lighting conditions, which improves efficiency.

Studies have demonstrated that fluctuations in temperature and light intensity continuously affect the output power, no-load voltage, and short-circuit current of PV arrays. These environmental changes alters the system’s equilibrium points reducing efficiency and impacting the rate of energy conversion [

25,

26]. Therefore, the adaptability of the system to environmental changes must be improved. Power variation under different situations must be constantly monitored to maintain maximum power output (MPO). Therefore, a detailed system-control strategy must be explored. Consequently, the output characteristics of PV cell are analyzed.

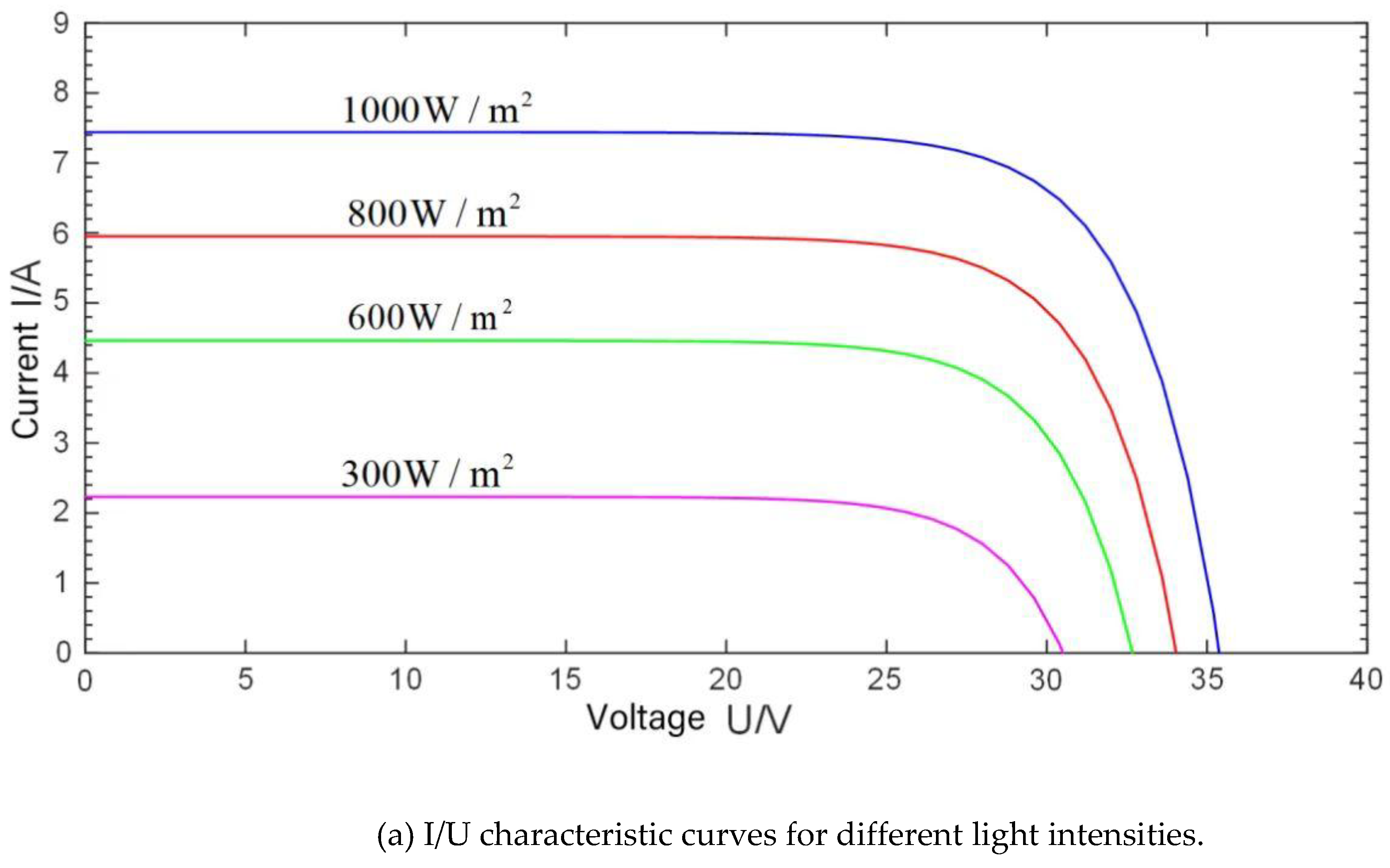

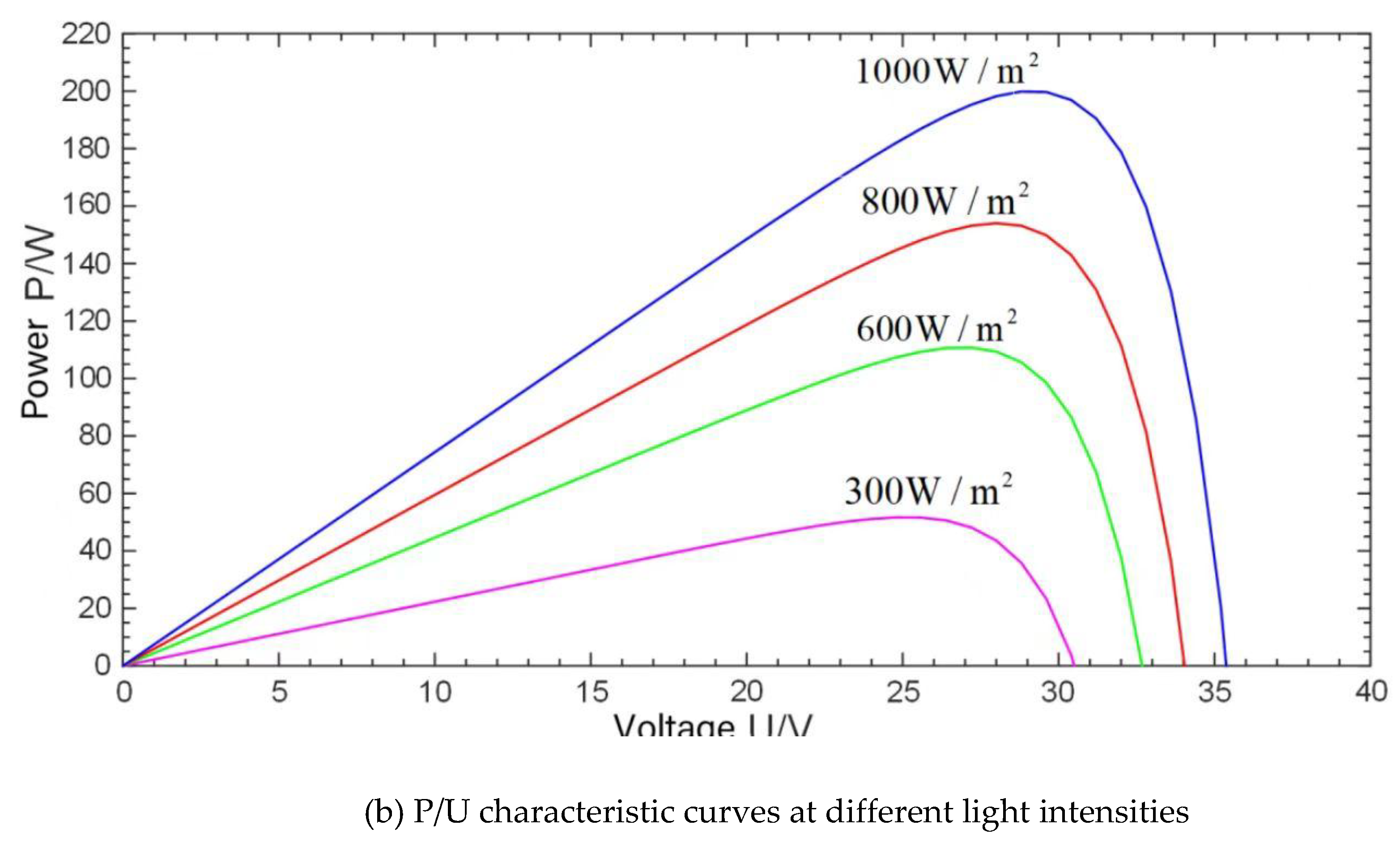

(1) I/U and P/U characteristic curves under constant temperature and light intensity

The operating temperature of PV unit is set at constant 25 ℃, with simulations of the effects of different light intensities on PV array shown in

Figure 6.

From

Figure 6(a), under a constant ambient temperature (25 ℃), battery current increases with increasing light intensity. Additionally, the open-circuit voltage (VOC) slightly increases, but its growth rate is lower than that of the electric current. This indicates that electric voltage is less sensitive to changes in illumination [

27,

28]. A single parabolic peak is observed in the P-U characteristic diagram. At 25 ℃, the battery output power positively correlates with light intensity, but beyond the maximum power point, system power decreases despite an increase in voltage. In

Figure 6(b), the maximum power point is also positively correlated with light intensity. Therefore, under constant ambient temperature, the output power of the PV module positively correlates with light intensity.

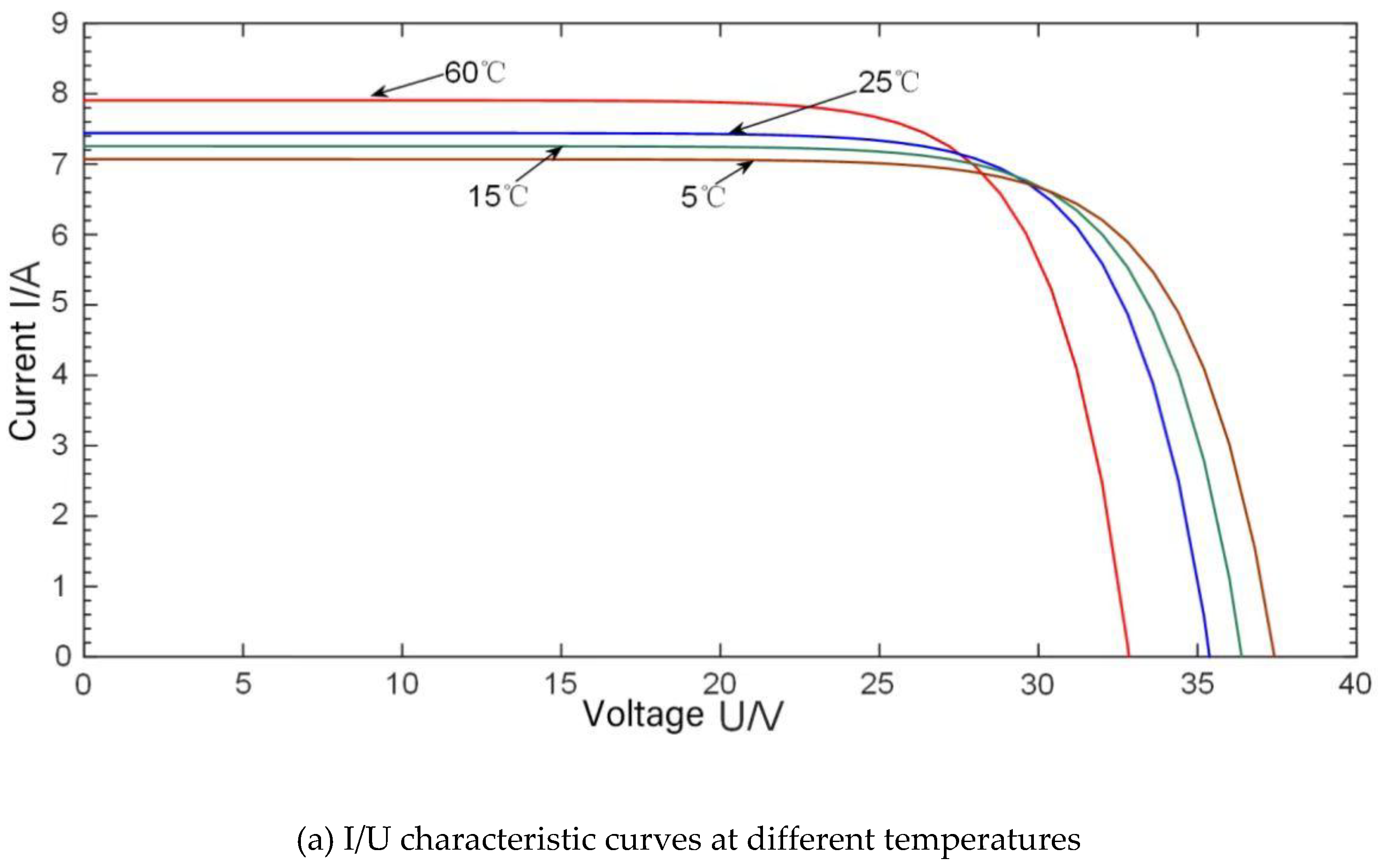

(2)I/U and P/U characteristic curves for the same light intensity and temperature

After the light intensity of the PV unit is set to 1000 W/m

2, the effects of different temperatures on the PV array are simulated, as shown in

Figure 7.

As shown in

Figure 7(a), with increasing temperature, the electric voltage decreases as electric current also increases. This change is more significant at different temperatures.

Figure 7(b) shows that the temperature increases with decreasing output power, which explains the inverse proportionality between maximum power and temperature. Consequently, under constant light conditions, an increase in temperature causes the output photovoltaic (OPV) device voltage to decrease while increasing the current, ultimately reducing output power. By contrast, when the temperature decreases, the property parameters of the PV device exhibit a reverse trend.

According to PV characteristic curve, the relationship between voltage and current of PV cell is totally different with traditional energy storage cell. With the voltage increasing, the current decreases. From the product of voltage and current, the curve of power change caused by voltage is obtained. With the voltage increasing, the power increases first and then decreases. So a Maximum Power Point(MPPT) exists. In order to improve the efficiency of PV cell, it should always works in MPPT. Therefore, the research of MPPT tracking algorithm in PV cell is extremely important [

28].

3.2. Calculation Process of Maximum Power Algorithm

The maximum power algorithm significantly affects output characteristics. Variations in temperature and light intensity can affect the maximum power point of a PV cell, as well as its output voltage and current. In DC/DC conversion, the efficiency of Buck and Boost converters are highest. From Buck converter, the high voltage can be transformed to low voltage. In general, the output voltage level of PV array is low. For grid-connected, the grid-side level must be higher. So the Buck converter seldom used in Grid-connected. From Boost converter, the output voltage of PV array increases. The Grid-connected easy to implement. Besides, the impedance transformation function of Boost converter commonly used for MPPT control. The circuit is easy to driven.

The boosting process of DC boost circuit is energy transfer process of inductance. On charge, the inductance absorbs energy. On discharge, the inductance gives off energy. If the capacitance is large enough, a stable electric current can be kept during discharge process in output terminal. If this on and off process continuously repeating, the voltage in both sides of capacitance is higher than input voltage. This adjustment, which involves changes in the battery power, is an effective control method, as illustrated in

Figure 8. Owing to the maximum power control structure, a PV cell can approach or reach the MPO in different environments.

The Incremental Conductance Method(INC) was used for MPPT control. Instantaneous conductivity changes in PV array can be monitored, and the MPPT can be defined. Photovoltaic cell conductivity changes with MPPT. The MPPT corresponds to the point at which the conductivity changes significantly. In this study, the MPPT realization by incremental conductance followed these steps.

(1) The voltage(U) and power(P) of PV cell were measured.

(2) The rate of change in the conductivity(G) was calculated as dG/dV.

(3) The maximum power point is confirmed when dG/dV=0.

With this method, additional sensors and complicated mathematical models are not required. MPPT can be found only with voltage and current measurements. Additionally, the incremental conductance algorithm is robust to the nonideal characteristics of PV cells and environmental changes.

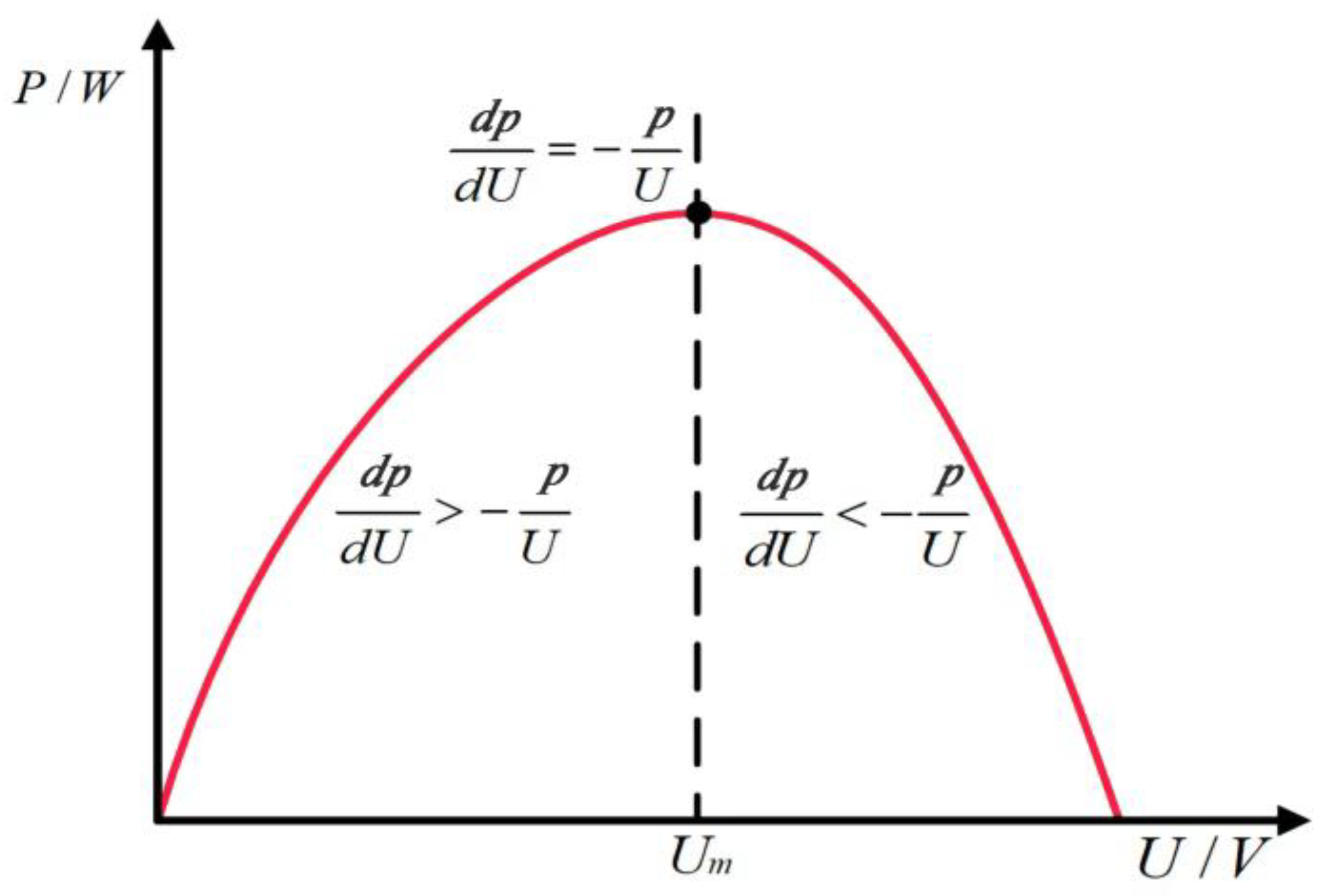

As illustrated in

Figure 9, the operating points are continuously adjusted using the incremental conductance algorithm. The PV cell always operates around the MPPT. This method can significantly improve the energy utilization of PV systems, from which solar energy can be maximally used. Based on accurate control and optimization, MPPT technology plays an important role in the field of PV power generation.

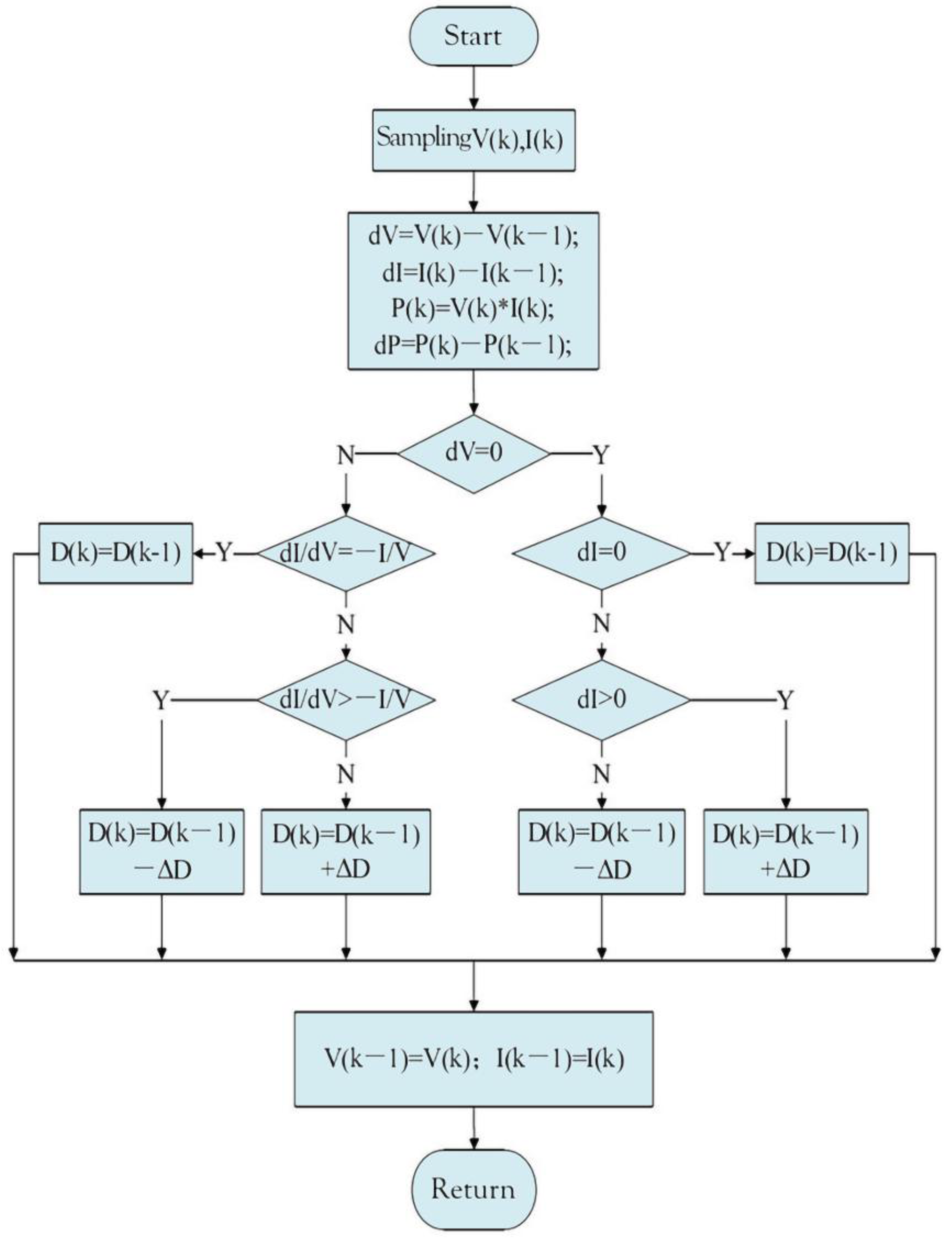

The control process of incremental conductance algorithm is shown in

Figure 10.

In

Figure 10, the duty cycle variation isΔD. MPPT is defined as the change in dG/dV. In MPPT, the value of dG/dV changed from positive to negative. The duty cycle was adjusted to search for MPPT. This is a function of tracking control. In

Figure 10, V(k) and I(k) represent the latest detected voltages and currents, respectively. V(k-1)、I(k-1) are previous detected voltage and current. the D-values of the latest and previously detected values were calculated. K is a variable coefficient with a value is 5-10.

4. Simulation of Different Influence Factors on Output Power Situation

Based on the output characteristics of PV cell, the maximum output power of PV array was affected by the MPPT algorithm, light intensity, and temperature. Therefore, a wide-range and fast-response incremental conductance algorithm was used as the MPPT control algorithm.

4.1. MPPT Controller

The MPPT controller is the core component of PV power generation system realizing MPPT. The main function of this module is using the relevant MPPT algorithm to adjust the duty cycle of Boost circuit, from which the Boost circuit can be driven by PWM output signal. Therefore, this module should include MPPT algorithm and implementation of PWM.

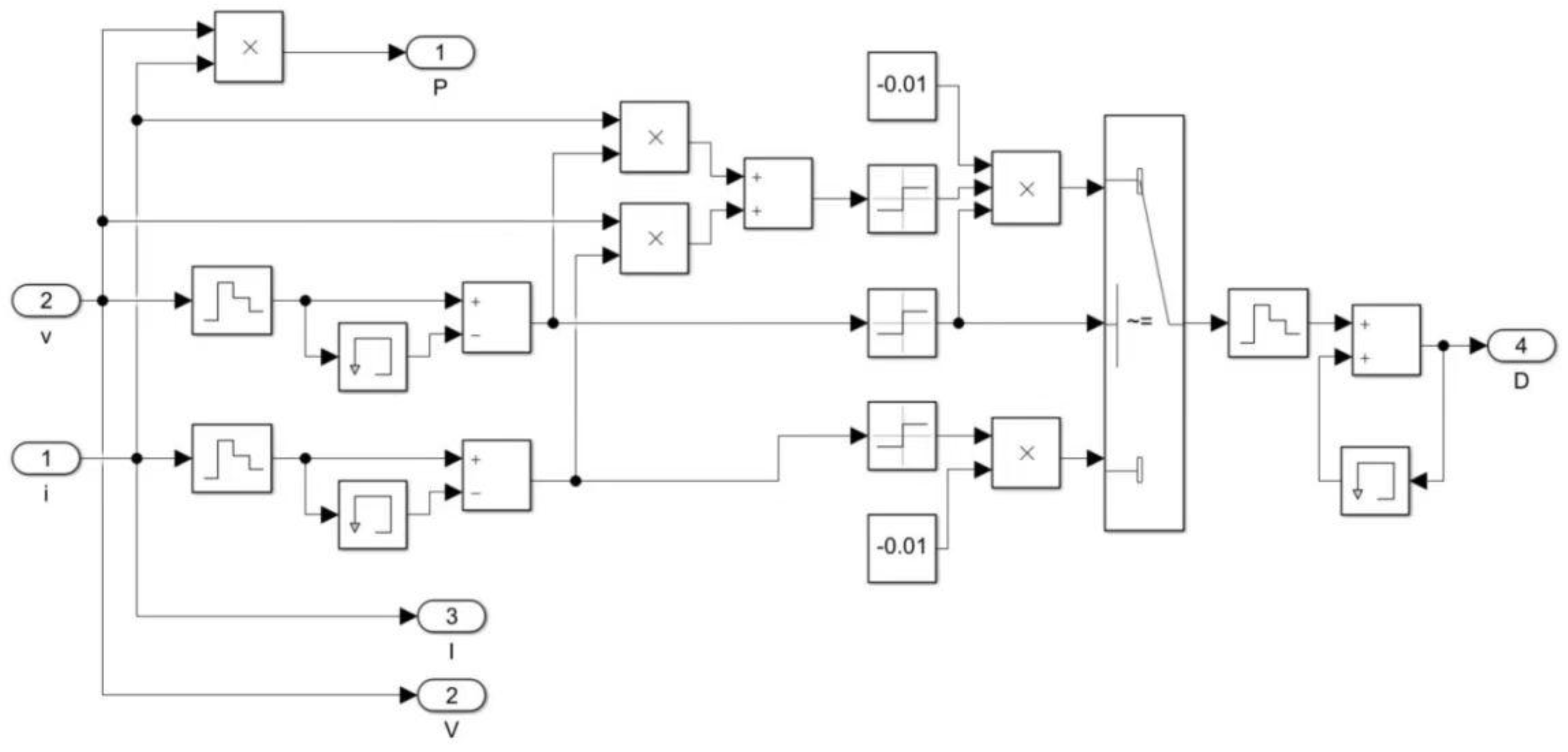

The simulation module is illustrated in

Figure 11. It uses INC method to realize the PWM control. As the MPPT control algorithm, INC method is high precision and easy to implement. The principles is as follow: From V-P curve of photovoltaic cell in

Figure 8, it shows

in MPP. According to mathematical derivation, in MPP,

is valid. In other words, when the output conductivity variation of photovoltaic cell(

) is equal to negative value of output conductance(

), the solar battery works in Maximum Power Point(MPPT). It is the implementation principle of INC method. Therefore, according to the symbols cases of equation

, whether the PV power generation system working in MPP can be identified. If

, this system works in the right side of MPP. At this point, the output voltage should be reduced. If

, this system works in the left side of MPP. At this point, the output voltage should be increased. Only if

, this system works in MPP.

In

Figure 11, U and I are the first inputs. Subsequently, the rate of signal change is calculated. MPPT is obtained using dV=0. The step length is set at -0.01.

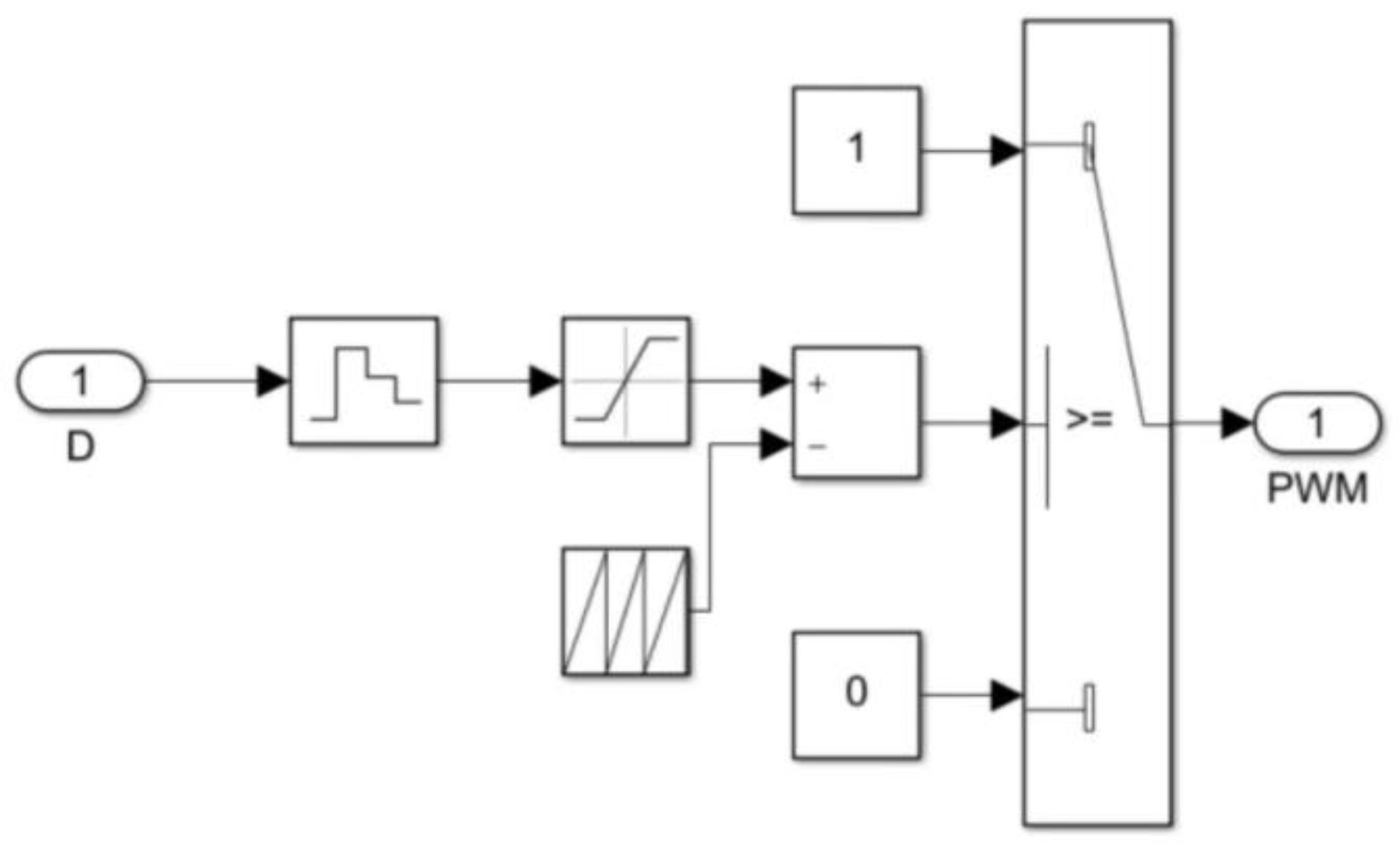

The control structure of duty cycle is shown in

Figure 12.

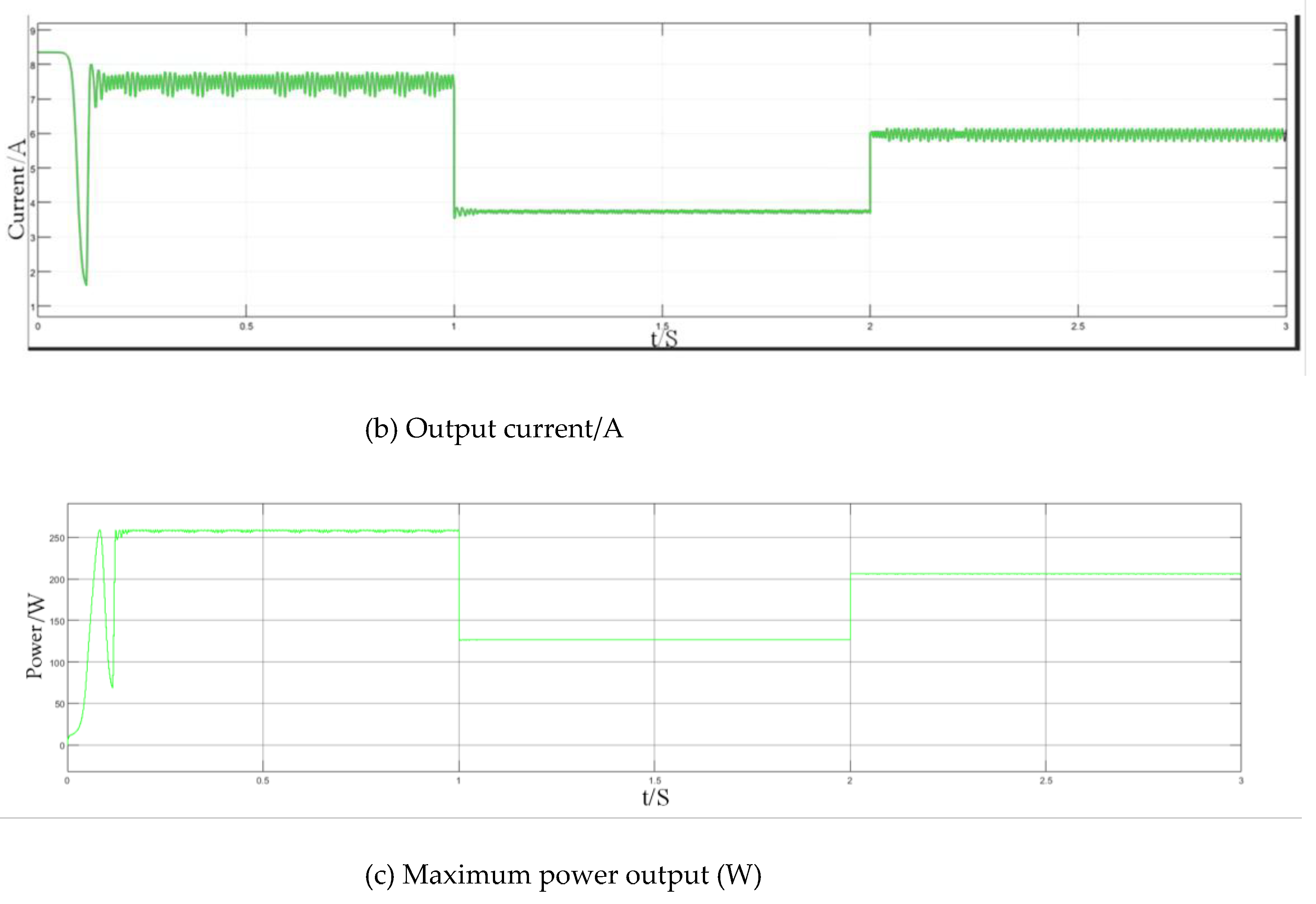

4.1. Effect of Different Light Intensity on Output Power Situation

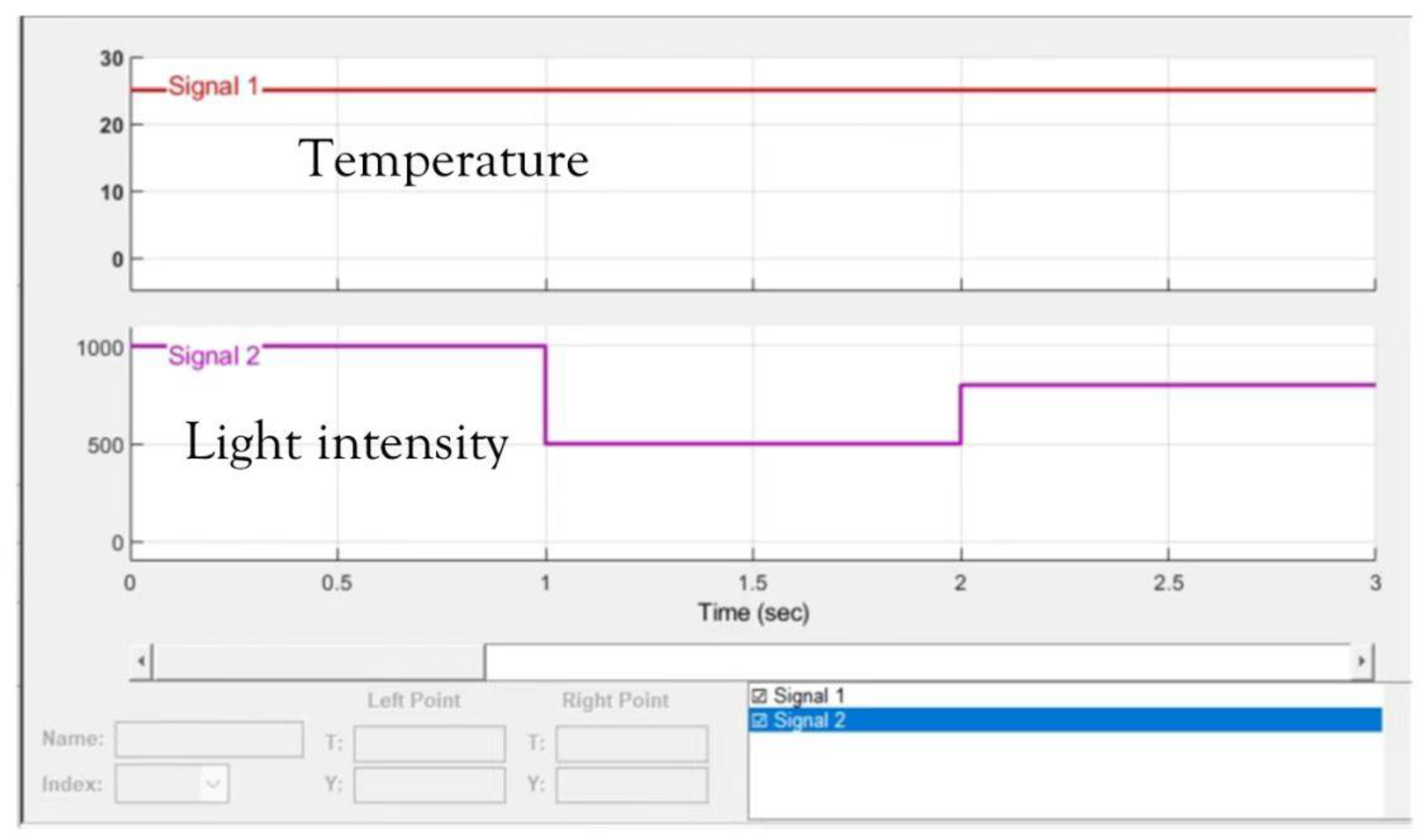

The constant temperature and initial light intensity are set at 25 ℃ and 1000 W/m2, respectively. The light intensity at 1 s fluctuates at 500 W/m2 and increases to 800 W/m2 after 2 s. The PV panel parameters and light intensity change curves are listed in

Table 2.

The light intensity variation curve is shown in

Figure 13.

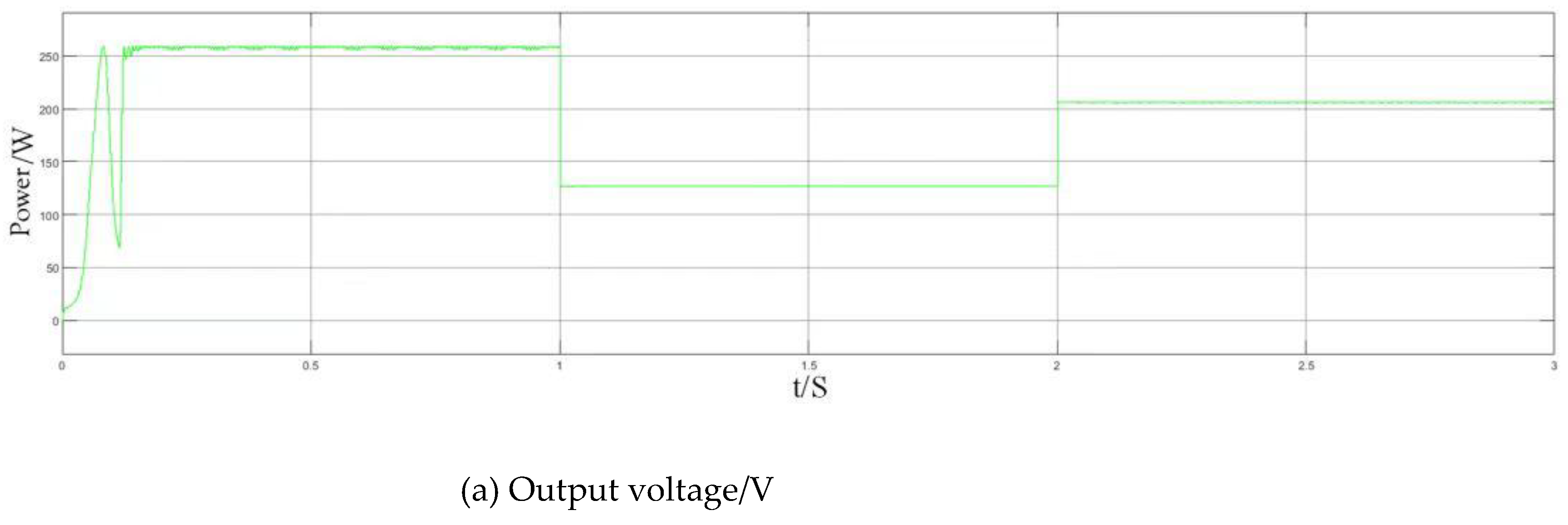

The effects of different lighting conditions on PV array output results are shown in

Figure 14, which shows the actual output voltage and current of PV array.

As shown in

Figure 14(a), the PV output voltage fluctuates at approximately 34.5V within 0.12 s,. Although the light intensity changed, the voltage fluctuation remains small. As shown in

Figure 14(b), during the initial stage of the simulation, the output current rapidly reaches 7.5A, which aligns with the initial PV panel setup parameters. The current waveform can be clearly observed according to the partial enlargement of the oscilloscope. However, with changes in light intensity, the fluctuation becomes more pronounced. According to the PV output curve shown in

Figure 14(c), the incremental conductance is flexibly adjusted. Within 0.12 s, the MPPT is rapidly tracked, which outputs power. With changes in light intensity, the control algorithm continues to adjust, identifying the maximum output point.

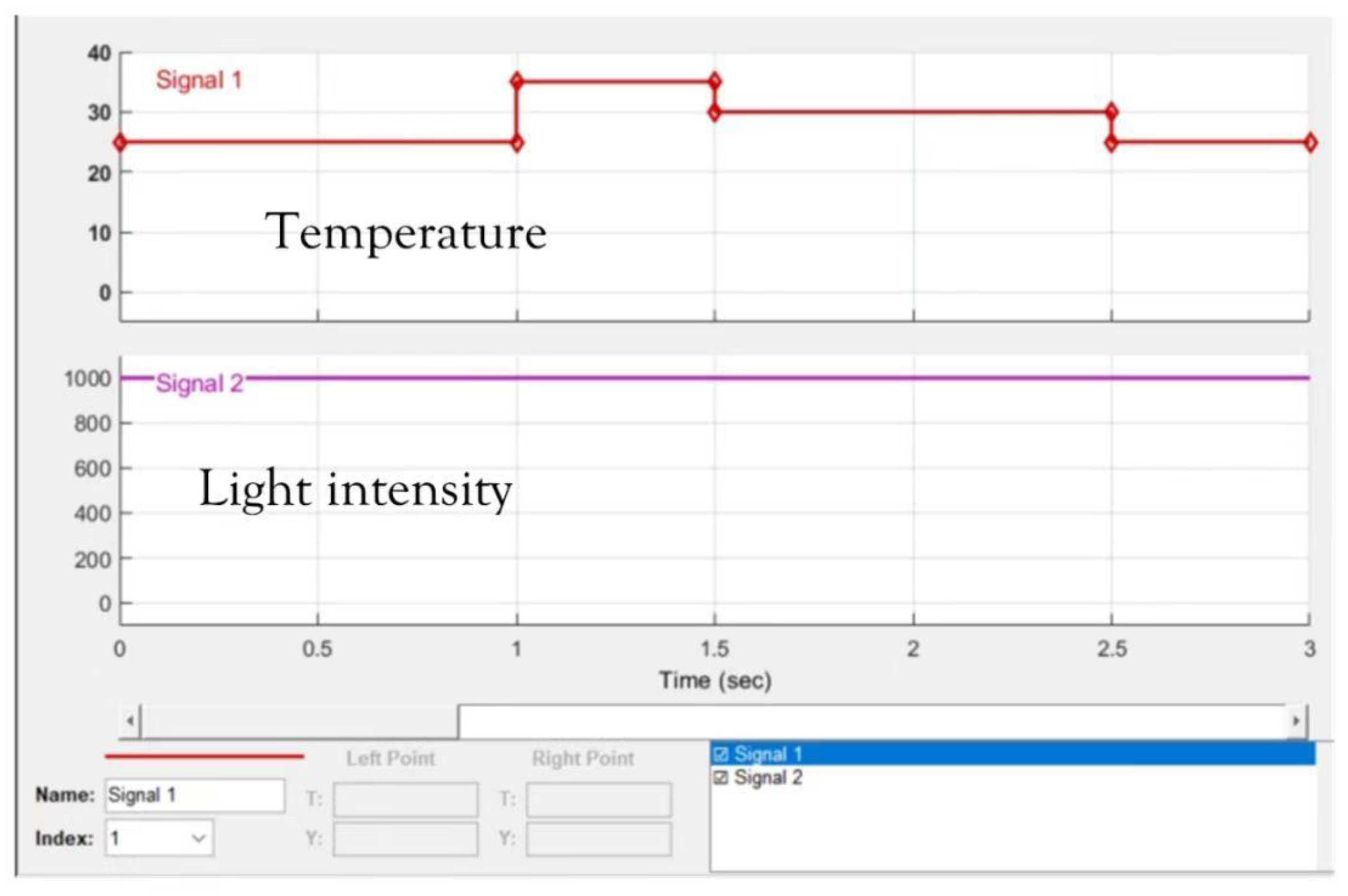

4.2. Effect of Different Temperatures on Power Output

The light intensity is set to 1000 W/m

2, and the initial temperature to 25 ℃. The temperature rises to 35 ℃ in 1 s and decline to 30 ℃ in 1.5 s thereafter. In 2.5 s, the temperature declines again to 25 ℃. The PV panel parameters are listed in

Table 2, and the temperature curves are shown in

Figure 15.

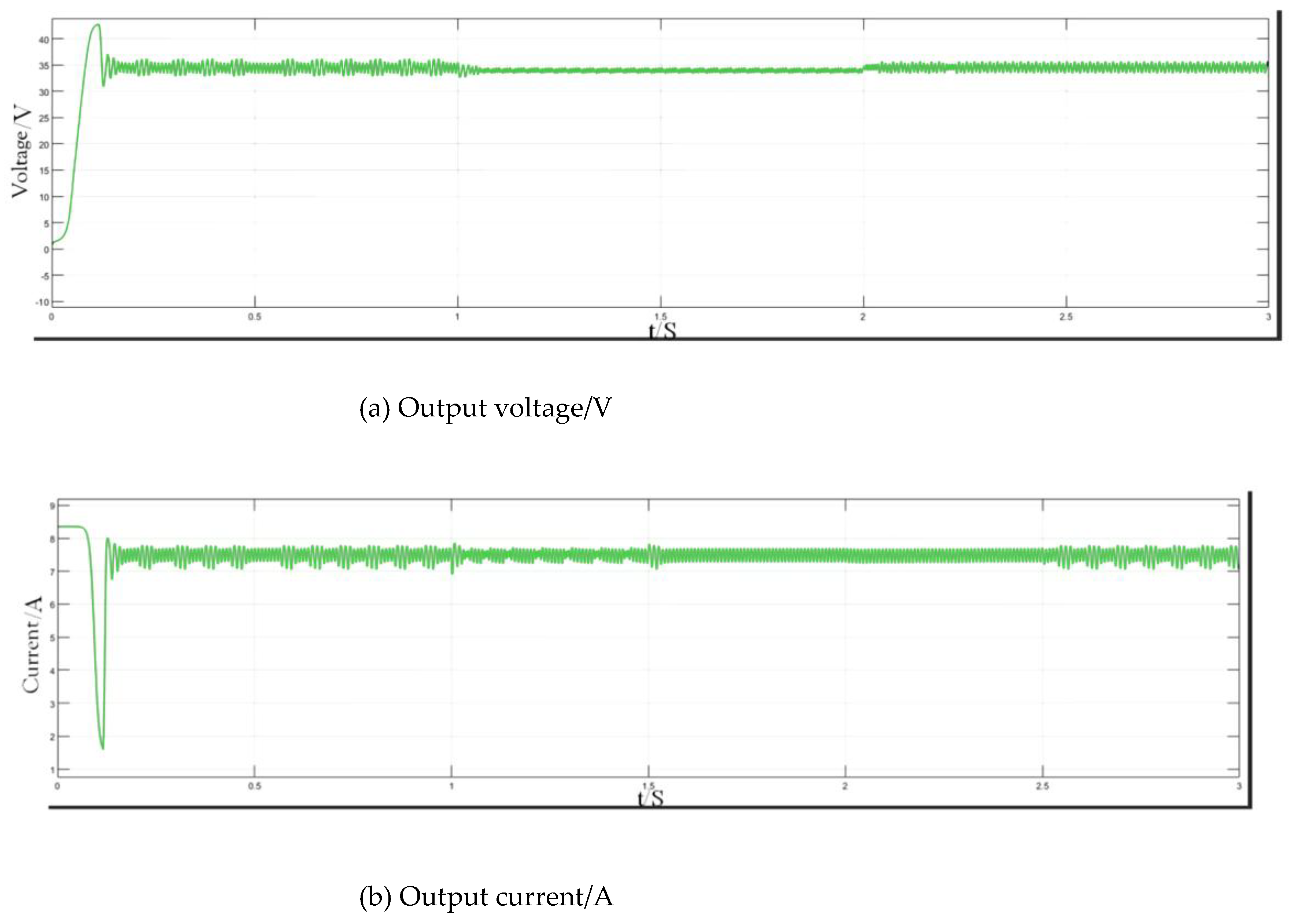

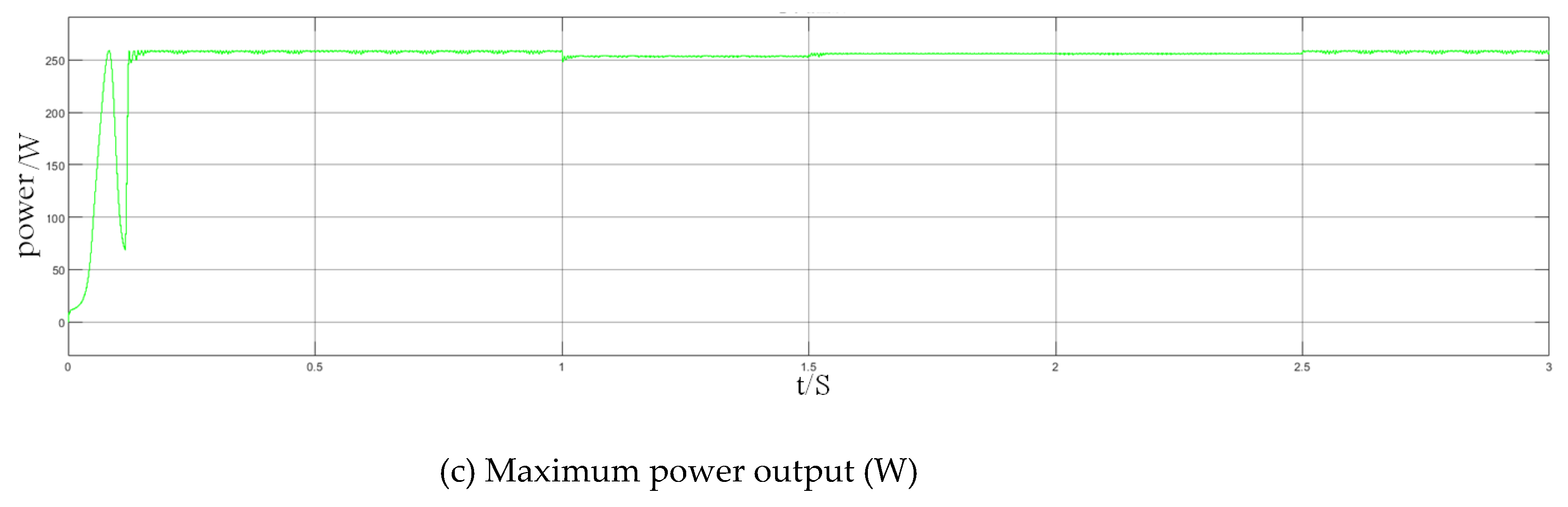

The effects of different temperatures on the power output of the PV array are shown in

Figure 16, along with the actual output voltages and currents.

From

Figure 16(a), in 0.16 s, the PV output voltage fluctuates by approximately 34.5 V. Although the temperature changes, the voltage fluctuation is minimal.

As shown in

Figure 16(b), in the initial stage of the simulation, the output current quickly reaches 7.5 A, which aligns with the initial PV panel setup parameters. The current waveform can be clearly observed according to the partial enlargement of the oscilloscope. However, with changes in temperature, the current change is insignificant. According to the PV output curve shown in

Figure 16(c), the incremental conductance is flexibly adjusted. In 0.16 s, the MPPT is quickly tracked, which outputs power. The maximum power output did not change with changes in temperature.

Overall, the primary factors affecting the maximum power output are light intensity changes and the MPPT algorithm, with the effect of light intensity being the most significant. According to the controlled experiment, the power prediction trend conformed to the output characteristics of the PV cell. The simulation data is consistent with manufacturers’ datasheets [

29].

5. Conclusions

With rapid socioeconomic development, traditional energy-supplying modes cannot meet the demand for overall growth. PV energy, a renewable and clean energy source, holds wide application prospects. Based on the references, the environmental factors make great effect on output characteristics of photovoltaic system. The solar irradiance and temperature are mainly influence factors. According to the meteorological data under different weather condition, the photovoltaic system output can be calculated by Matlab simulation model. It makes positive effect on power grid dispatch. In this manuscript, from the changes of PV system output characteristic curve with meteorological data changing, the meteorological parameters in simulation model is adjusted to acquire higher output power. It is consistent with real experimental result. Based on the output characteristics of photovoltaic system under different typical day, the temperature range of solar panels can be roughly found. It can prevent the thermal damage. The working status of photovoltaic system can be real-time tested. According to the regular cleaning, maintenance and overhaul for solar panels, the service life of solar panels will be extended. Besides, the output power of photovoltaic system can be stabilized, which improves the working efficiency of photovoltaic system. According to the deployment analysis of the PV power generation theory, the following conclusions can be drawn:

(1) The working characteristics and principles of the PV supply were analyzed, exploring the characteristics and advantages of the PV supply. According to an analysis of PV microgrid construction object, the incremental conductance was used for power planning.

(2) PV cells in the microgrid were modeled using the PV cell module in Simulink, and the DC load module was modeled using the RLC load in an electrical storehouse. Subsequently, the simulation parameters were defined.

(3) The output characteristics of the PV power supply and output were simulated. Test results showed that with increasing temperature, system output power and voltage declined, and vice vera. Thus, temperature changes are inversely proportional to the output characteristics of PV power generation, although, the effect was minimal.

(4) The effect of light intensity on the PV power generation output characteristics was significant. When light intensity significantly changed (from 1000 w/m2 to 600 w/m2), the output power of the PV system became unstable. This observation suggested that the performance of the PV system was poor under weak light intensities. Thus, a DC boost circuit can improve output stability.

The proposed work in future work is as follows:

From the experimental result, the MPPT control system in this manuscript can be used for simulation research of MPPT in PV power generation system. It is very significant for the research of external environment effect on PV power generation control. Meanwhile, the pure inductive loads are selected in Boost simulation circuit. Regarding to the effect of capacitive reactance loads on MPPT control system, it is still needed for further research.

Author Contributions

Conceptualization, Y.C. and G.Y.; methodology, G.Y.; software, Y.C.; validation, G.Y.; formal analysis, G.Y.; investigation, Y.C.; resources, Y.C.; data curation, G.Y.; writing—original draft preparation, G.Y.; writing—review and editing, G.Y.; visualization, Y.C.; supervision, Y.C.; project administration, Y.C.; funding acquisition, Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was aided by the key area campaign of regular universities in Guangdong province, No. 2021ZDZX1058. The Feature Innovation project of regular universities in Guangdong province, No. 2022KTSCX194. Guangdong Basic and Applied Basic Research Foundation, No. 2023A1515240063. The key area campaign of regular universities in Guangdong province, No. 2024ZDZX4074.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

There are no conflicts of interest.

References

- Dias, JB.; Batori, S.; Poggi, P.; Ferrari, B. Hybrid microgrid simulation. Journal of solar energy engineering-transactions of the ASME. 2016, 138,4:044501.

- Jacob, E.; Farzaneh, H. Dynamic modeling and experimental validation of a stadalone hybrid microgrid system in Fukuoka, Japan. Energy conversion and management. 2022, 274:116462.

- Gupta, N.; Prusty, BR. Probabilistic load flow of an islanded microgrid with WTGS and PV uncertainties containing electric vehicle charging loads. International transactions on electrical energy systems. 2022, 2022: 9569224. [CrossRef]

- Simonazzi, M.; Delmonte, N.; Cova, P.; Menozzi, R. Models for Matlab simulation of a university campus micro-grid. Energies. 2023, 16,16: 5884. [CrossRef]

- Dunna, VK.; Chandra, KPB.; Rout, PK.; Sahu, BK. Design and real-time validation of higher order sliding mode observer-based integral sliding mode MPPT control for a DC microgrid. IEEE canadian journal of electrical and computer engineering. 2022,45:4: 418-425. [CrossRef]

- Tang, YZ.; Xun, Q.; Liserre, M.; Yang, HZ. Energy management of electric-hydrogen hybrid energy storage systems in photovoltaic microgrids. International journal of hydrogen energy. 2024, 80: 1-10. [CrossRef]

- Gu, JP.; Xie, LY.; Yang, XD.; Zhang, YB.; Wang, LC.; Wang,QR.; Zhang, WJ.; Wang, BJ. Fuzzy piecewise coordinated control and stability analysis of the photovoltaic-storage direct current microgrid. IET renewable power generation. 2022,16, 15:3311-3324. [CrossRef]

- Garcia, YV.; Garzon, O.; Andrade, F.; Irizarry, A.; Rodriguez-Martinez, OF. Methodology to implement a microgrid in a university campus. Applied sciences-basel. 2022, 12, 9: 4563. [CrossRef]

- Meng, XY.; Liu, ZG.; Liu, YM.; Zhou, H.; Tasiu, IA.; Lu, B.; Gou, J.; Liu, JW. Conversion and SISO Equivalence of Impedance Model of Single-Phase Converter in Electric Multiple Units. IEEE Trnsactions on Transportation Electrification. 2023, 9,1:1363-1378. [CrossRef]

- Wang, XS.; Jiang, CQ.; Zhou, JY.; Mo, LP.; Wang, YB. Enhanced Modeling of Wireless Power Transfer System with Battery Load. IEEE Transactions on Power Electronics. 2024, 39, 6: 6574-6579. [CrossRef]

- Shaban, M.; Ben Dhaou, I.; Alsharekh, MF.; Abdel-Akher, M. Design of a partially grid-connected photovoltaic microgrid using lot technology. Applied sciences-basel. 2021, 11, 24: 11651.

- Tang, J.; Liu, JF.; Wu, JH.; Jin, GF.; Kang, HR.; Zhang, Z.; Huang, NT. RAC-GAN-Based Scenario Generation for Newly Built Wind Farm. Energies. 2023, 16, 5:2447. [CrossRef]

- Liu, ZB.; Liu, XJ. Improved Multi-Hysteresis Control Strategy of Hybrid Storage System in a Stand-Alone DC Microgrid. Transactions of China Electrotechnical Society. 2018, 33, 3:490-497.

- Ozturk, E.; Ogliari, E.; Sakwa, M.; Dolara, A.; Blasuttigh, N.; Pavan, AM. Photovoltaic modules fault detection, power output, and parameter estimation: A deep learning approachbased on electroluminescence images. Energy conversion and management. 2024, 319: 118866.

- Alvarez-Arroyo, C.; Vergine, S.; de la Nieta, AS.; Alvarado-Barrios, L.; D’Amico, G. Optimising microgrid energy management: Leveraging flexible storage systems and full integration of renewable energy sources. Renewable Energy. 2024, 229: 120701. [CrossRef]

- Naamane, D.; Benbouhenni, H.; Chebabhi, A.; Laid, Z.; Zellouma, D.; Colak, I. A new nonlinear control to improve the efficiency of the PV-SAPF system. Energy Reports. 2024, 11: 3096-3116. [CrossRef]

- Wang, SM.; Yuan, XH.; Huang, Q.; Chen, AQ.; Ma, HB.; Xu, X. Daily consumption monitoring method of photovoltaic microgrid based on genetic wavelet neural network. International Journal of Low-Carbon Technologies. 2023, 18:167–174. [CrossRef]

- Wenham, SR.; Green, MA.; Watt, ME.; Corkish, R.; Sproul, A. Applied Photovoltaics [M]. London: Routledge. 2011.

- Wang, WJ.; Li, C.; He, Y.; Bai, HN.; Jia, KQ.; Kong, Z. Enhancement of household photovoltaic consumption potential in village microgrid considering electric vehicles scheduling and energy storage system configuration. Energy. 2024, 311: 133330. [CrossRef]

- Lou, JW.; Cao, H.; Meng, X.; Wang, YX.; Wang, JF.; Chen, LQ.; Sun, L.; Wang, MX. Power load analysis and configuration optimization of solar thermal-PV hybrid microgrid based on building. Energy. 2024, 289: 129963. [CrossRef]

- Green, MA. Silicon Solar Cells Advanced Principles & Practice [M]. Sydney: Bridge Printery. 1995.

- Sene, MB.; Samoura, A.; Diouf, S.; Diao, A.; Mbow, C. Electrical modeling of a silicon photovoltaic solar cell: comparative study of models characterizing the photovoltaic solar cell. Open journal of applied science. 2023, 13: 1787-1795. [CrossRef]

- Wang, HP.; Wu, XW.; Sun, K.; Du, XD.; He, YL.; Li, KW. Economic Dispatch Optimization of a Microgrid with Wind-Photovoltaic-Load-Storage in Multiple Scenarios. Energies. 2023, 16, 9:3955. [CrossRef]

- Lou, JW.; Wang, YX.; Wang, HY.; Wang, JF.; Chen, LQ.; Zhang, JY.; Istam, MR.; Chua, KJ. Operation characteristics analysis and optimal dispatch of solar thermal-photovoltaic hybrid microgrid for building. Energy and Buildings. 2024, 315:114340. [CrossRef]

- Weng, ZP.; Zhou, JH.; Zhan, ZD. Reliability evaluation of standalone microgrid based on sequential monte carlo simulation method. Energies. 2022, 15, 18:6706. [CrossRef]

- Pei, XG.; Zhao, XH.; Jia, HY.; Wang, H.; Liu, JP. Fuzzy sliding mode control with adaptive exponential reaching law for inverters in the photovoltaic microgrid Frontiers in Energy Research. 2024, 12: 1416863.

- Szilagyi, E.; Petreus, D.; Paulescu, M.; Patarau, T.; Hategan, SM.; Sarbu, NA. Cost-effective energy management of an islanded microgrid. Energu Reports. 2023, 10:4516–4537. [CrossRef]

- Nan, CH.; Hao, YP.; Huang, X.; Wang, H.; Yang, H. Investigation on temperature dependence of recent high-efficiency silicon solar modules. Solar energy materials and solar cells. 2023, 266:112649. [CrossRef]

- Almuhanni, M.; Yahaya, A.; Alahmed, A. Distributed generation and load modeling in microgrids. Sustainability. 2023, 15:4831. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).