1. Introduction

In recent years, power systems, as critical infrastructure supporting socio-economic development, have experienced rapid growth and profound technological innovations [

1,

2]. With the global energy structure transitioning and electricity demand continuously increasing, the scale and complexity of power systems have grown significantly, leading to higher requirements for the performance and reliability of key equipment[

3]. As a critical component of power systems, high-voltage switchgear performs functions such as circuit breaking, circuit making, protection, and control, directly influencing the safe and stable operation of power systems. High-capacity test stations, as essential facilities for evaluating and validating the performance of high-voltage switchgear, play an irreplaceable role in ensuring the reliable operation of power systems[

4,

5].The global energy structure transition has facilitated the large-scale integration of renewable energy sources, such as wind and solar power, which are classified as clean energy [

6].The advent of smart grid technology has imposed stricter requirements on the performance of high-voltage equipment. High-voltage switchgear must now feature faster circuit breaking speeds, higher voltage ratings, stronger arc extinguishing capabilities, and longer service lifespans to meet the demands of smart grids regarding power system reliability and economic efficiency[

7]. Additionally, as power systems continue to expand, the operational environment of high-voltage switchgear becomes increasingly complex, requiring stable performance under harsh conditions such as high voltage, large currents, and strong electromagnetic interference. These factors further underscore the importance of high-capacity test stations [

8].

The ongoing global energy transition, characterized by large-scale integration of renewable energy sources (e.g., wind and solar power), has imposed stricter demands on grid stability and reliability. Concurrently, the emergence of smart grid technologies has increased system complexity and intelligence, further elevating performance requirements for high-voltage equipment and underscoring the significance of high-capacity test stations [

9,

10,

11].High-capacity refers to the ability of medium /high- voltage circuit breakers and other equipment to withstand high-voltage and high-current loads, validated through short-circuit testing.

While the construction and operation of high-capacity test stations have achieved substantial progress globally, challenges persist in high-current testing environments. Current limitations include complex procedures, multi-step operations, and high costs in high-voltage/high-current testing laboratories, which constrain testing efficiency [

12,

13,

14,

15]. To address these issues, developing an integrated monitoring and control system for full-process testing is imperative. Such systems could significantly reduce human and material resource inputs, mitigate potential system risks caused by non-standardized workflows, and enhance the operational efficiency of high-capacity testing infrastructure [

16,

17,

18,

19].

Reference [

20] discusses a high-power test control system. It features intelligent main circuit control, system integration, and user-friendly customer support, which improves test efficiency and service levels. However, efforts are needed to address issues such as security, reliability, and maintainability.Reference [

21] proposes the application of a computer-aided analysis system in high-power laboratories. It includes functions such as test operation ticket management, test circuit diagram management, simulation calculation, and networking. The establishment of this system ensures the standardization and unity of tests and initially realizes the standardization of test circuits.Reference [

22] focuses on high-power laboratories using short-circuit generators as power sources. It analyzes the operating conditions of the generator and test requirements, as well as its system composition, and constructs a control system based on S7-300, covering hardware design and configuration, software design (including main programs, human-machine interfaces, etc.). Practice has proven that this system is flexible, reliable, and highly automated. However, it does not discuss high-power test systems based on power system power sources.Reference [

23] presents a 550 kV/80 kA test circuit based on a short-circuit generator, which can meet the requirements of multiple test standards, and some of the circuits are more economical and safer. However, it does not fully discuss the secondary control, monitoring, data acquisition, and other systems of the test system.Reference [

24] puts forward the types of high-power test stations, some key test circuits, and test equipment, and finally analyzes and discusses the principles and techniques of high-power short-circuit tests. The content in this article provides a reference and basis for implementing, developing, and researching high-power short-circuit breaking test technologies.

To address the challenges of complex testing procedures, insufficient safety, and incomplete secondary control/data acquisition systems in high-capacity test stations, this study proposes standardized methodologies for high-capacity testing, a ring-network monitoring topology, and automated workflows. It presents an integrated solution to enhance testing efficiency and data reliability, effectively resolving issues of low system integration and inadequate automation. The research proposes:

A standardized methodology for test circuit design;

A ring network topology for test monitoring and control;

Systematic solutions for test data acquisition, signal monitoring, and control schemes;

Optimized procedures for high-capacity short-circuit testing.

2. Power Network-Based High-Capacity Test Circuit Design

2.1. Main Test Circuit Architecture

The high-capacity test circuit utilizing the power system network as its test power supply comprises the following key equipments: short-circuit transformer, protective circuit breaker, operating circuit breaker, phase selection switch, disconnector, reactor, resistor, capacitor, and transient recovery voltage (TRV) equipment.

2.1.1. Dual-Voltage Test Circuit Configuration (12kV/40.5kV)

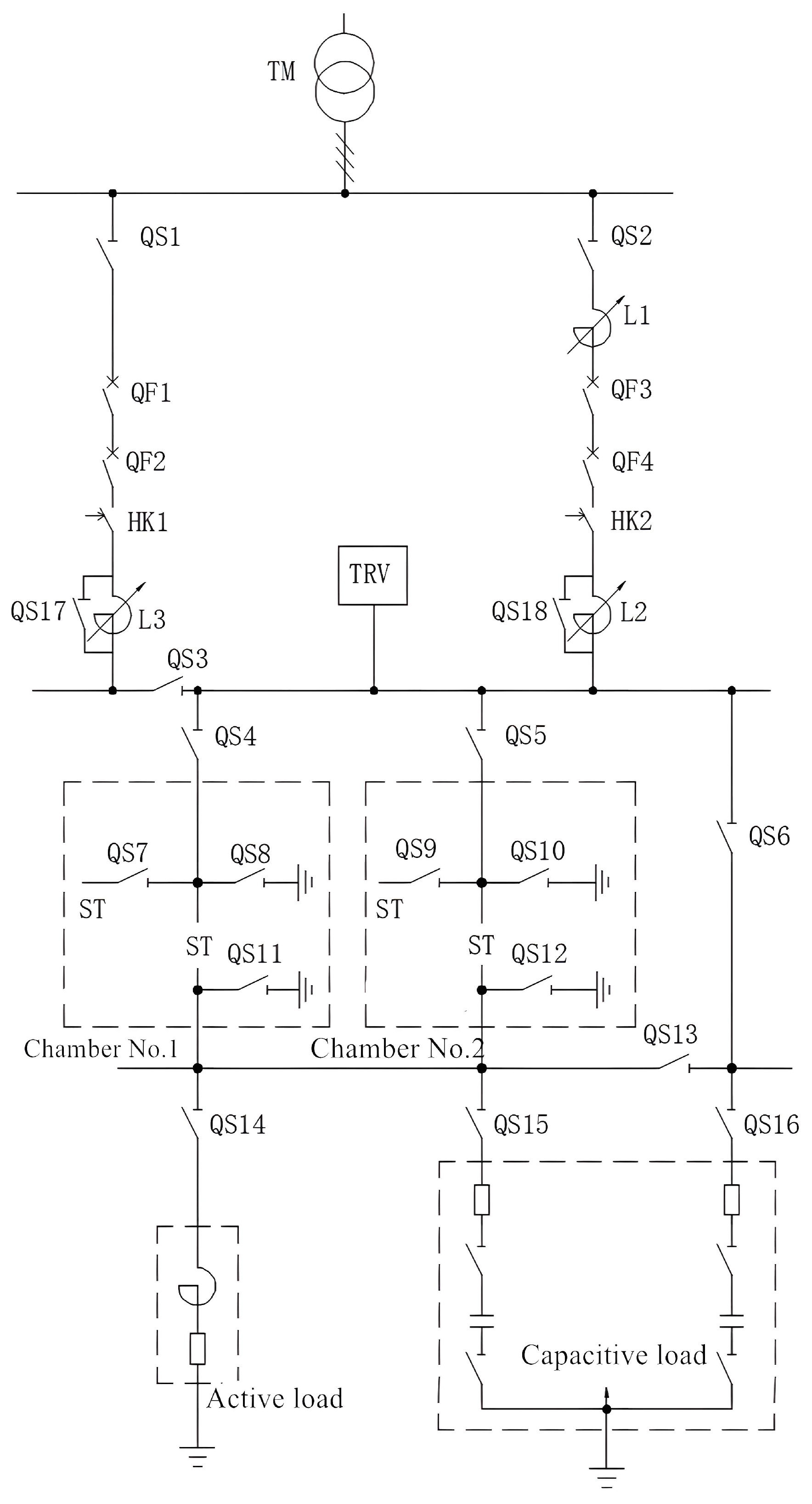

As shown in

Figure 1, the 12 kV test circuit delivers power to test chamber 1 or 2 through the following sequential components:

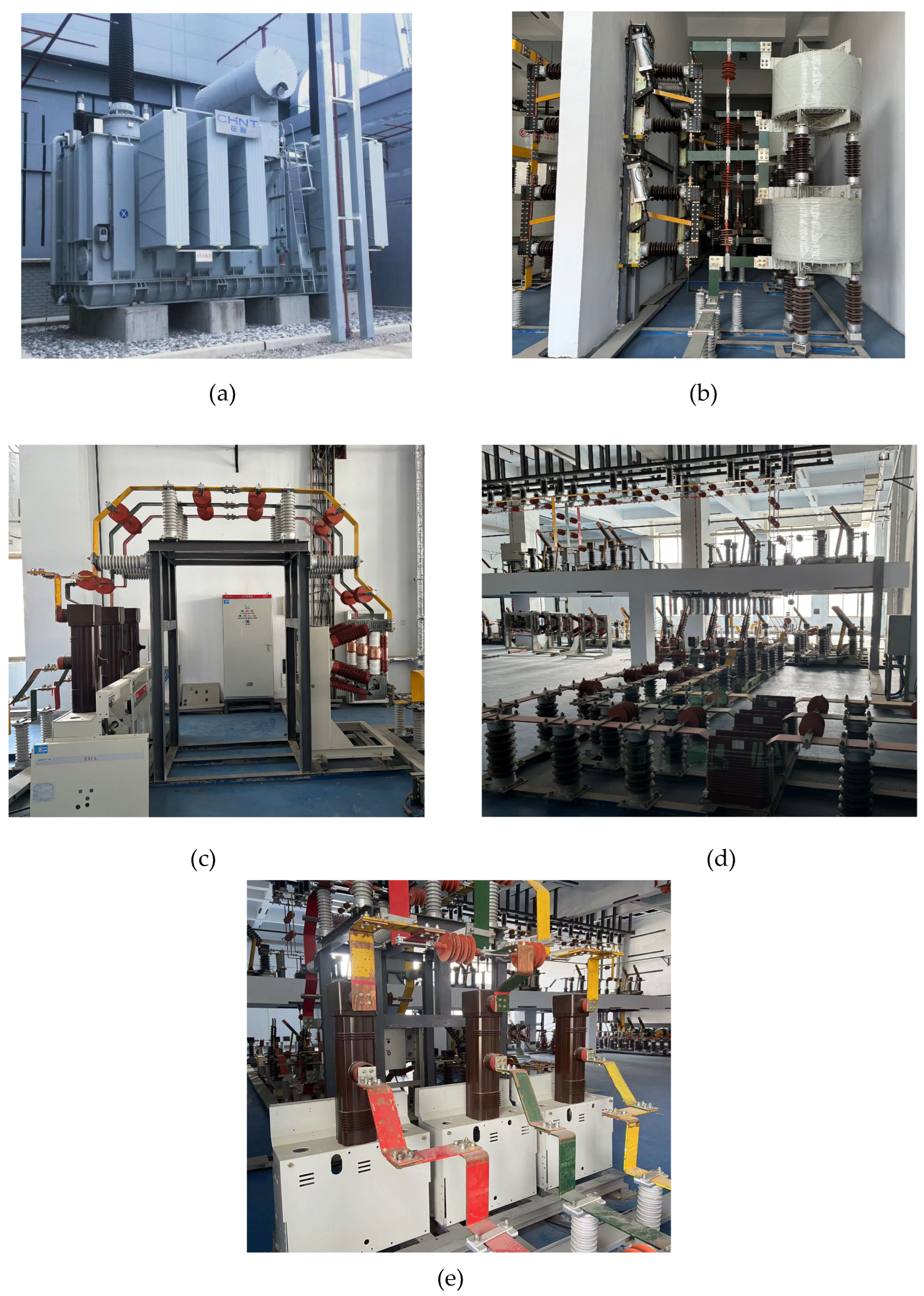

Short-circuit transformer (TM), see

Figure 2(a)

Disconnecting switch (QS1), see

Figure 2(b) and (d)

Protective circuit breaker (QF1), see

Figure 2(c)

Operating circuit breaker (QF2), see

Figure 2(c)

Phase-selection switch (HK1), see

Figure 2(e)

Adjustable reactor (L3), see

Figure 2(b)

For test voltages ≤12 kV, this circuit operates with a current range of 31.5–80 kA, enabling short-circuit making/breaking tests for switchgear (e.g., circuit breakers, switch cabinets) rated ≤12 kV. Key system specifications include:

Similarly, the 40.5 kV test circuit (

Figure 1) feeds test chamber 1 or 2 through an analogous configuration with modified components:

Short-circuit transformer (TM)

Busbar system

Disconnecting switch (QS2)

Current-limiting reactor (L1)

Protective circuit breaker (QF3)

Operating circuit breaker (QF4)

Phase-selection switch (HK2)

Adjustable reactor (L2)

This circuit supports operational currents of 1.6–31.5 kA, designed for short-circuit making/breaking tests on switchgear rated at 40.5 kV and 24 kV.

2.1.2. Active Load and Capacitive Load

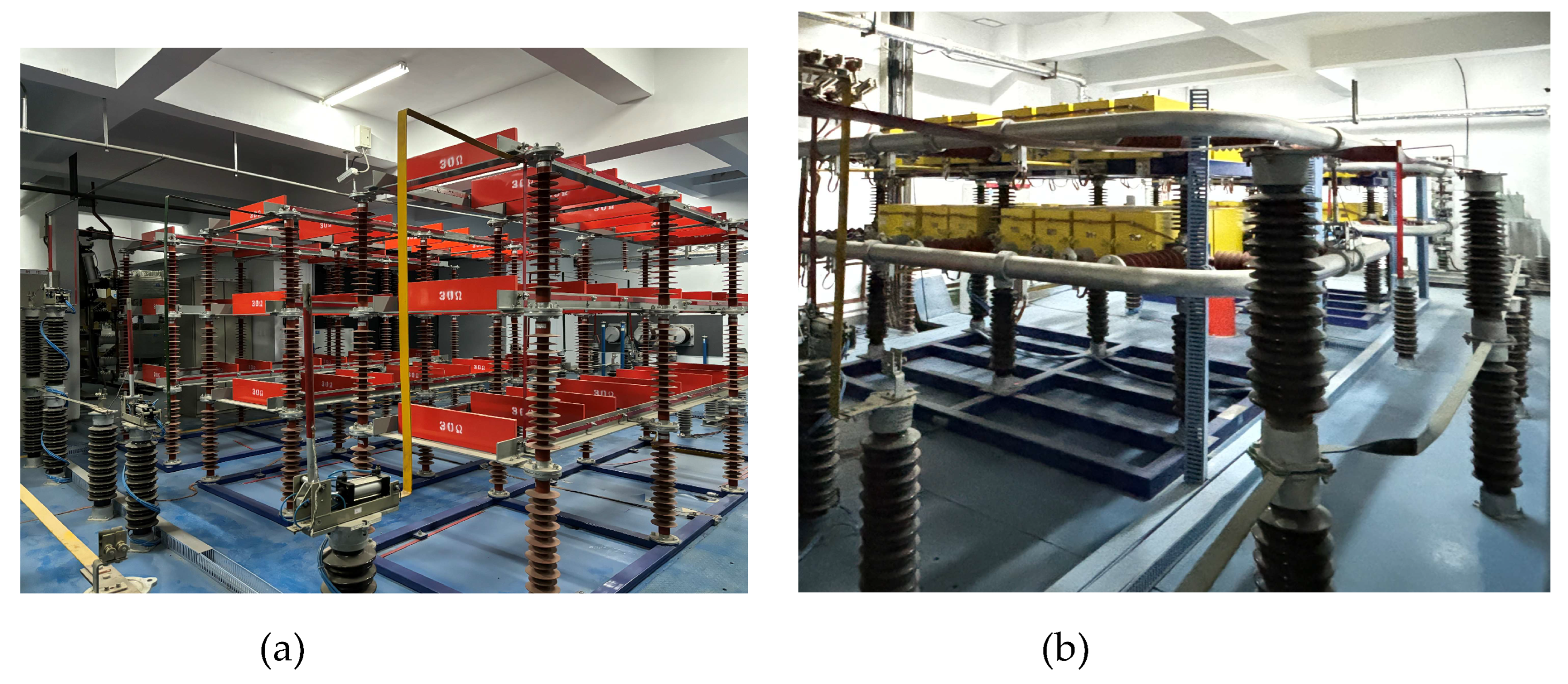

A programmable active load system is configured downstream of Test Chamber 1, comprising:

Load resistor bank (adjustable), see

Figure 3(a)

Load reactor bank (adjustable), see

Figure 3(b)

This system enables precise regulation of test current (range: 31.5–1000 A) and power factor (PF: 0.3–1.0), supporting active load testing for the following devices rated ≤40.5 kV:

Load switches

Fuses

AC contactors

A capacitive current switching test platform is installed downstream of Test Chamber 2, featuring:

This configuration meets IEC 62271-103 requirements for single-phase or three-phase capacitive current switching tests on:

High-voltage AC circuit breakers

High-voltage AC load switches

Applicable test parameters:

Rated voltage range: 3.6–40.5 kV

Capacitive current range: 1–1000 A.

2.1.3. TRV Equipment

Transient recovery voltage (TRV) is a critical parameter significantly influencing the short-circuit breaking capability of circuit breakers. TRV waveform characteristics include amplitude (

Uc), rise rate (

dUc/

dt), and natural oscillation frequency (

f0). According to IEC 62271-100, TRV parameters are essential rated parameters for high-voltage circuit breakers, with strict specifications (two-parameter or four-parameter methods) to ensure performance and reliability. In high-capacity testing, proper TRV equipment operation is crucial to obtain waveforms compliant with standards [

25,

26].

As shown in

Figure 1, the TRV equipment is typically connected in parallel to the busbar at the test chamber outlet. It consists of a frequency-tuning circuit and an injection circuit. The frequency-tuning circuit, comprising capacitors (

C0) and resistors (

R0), adjusts TRV frequency and damping characteristics based on test requirements. High-speed data acquisition systems are employed to record and analyze TRV waveforms, ensuring accurate parameter extraction.Here, several important TRV parameters are explained.

Uc (Peak voltage) is the maximum voltage peak reached by the TRV.

t3 (Peak time) is the time interval from the current zero-crossing point to the moment when the TRV reaches the peak voltage

Uc.

td (Fall time) is the time it takes for the TRV to drop from the peak voltage

Uc to a certain reference value.

2.2. Standardization of Test Circuits

The standardization of high-capacity test circuits is crucial for ensuring the repeatability and consistency of tests. Standardization encompasses parameter unification, process optimization, and compliance with industry standards, providing a scientific basis for verifying the performance of electrical equipment. By unifying parameters and optimizing processes, standardized test circuits address the dual challenges of efficiency and safety. Mainly in the following two aspects:

Traditional tests rely on manual configuration of circuit parameters (such as impedance, TRV waveform, etc.), and operational differences often lead to inconsistent results. Standardization solves these problems through a predefined parameter library (

Figure 4), enabling automated configuration.

The construction of the standardized circuit library adopts a dual approach combining simulation modeling and experimental verification (

Figure 2). Key parameters (such as voltage, current, source/load impedance, TRV parameters, etc.) are obtained through MATLAB/Simulink simulation. Then, these results are verified through a physical test circuit, and the parameters are fine-tuned according to the measurement data. Finally, standardized circuit templates are established and stored. This library supports multiple test types (such as T60, T100a) and voltage levels (from 12kV to 40.5kV).

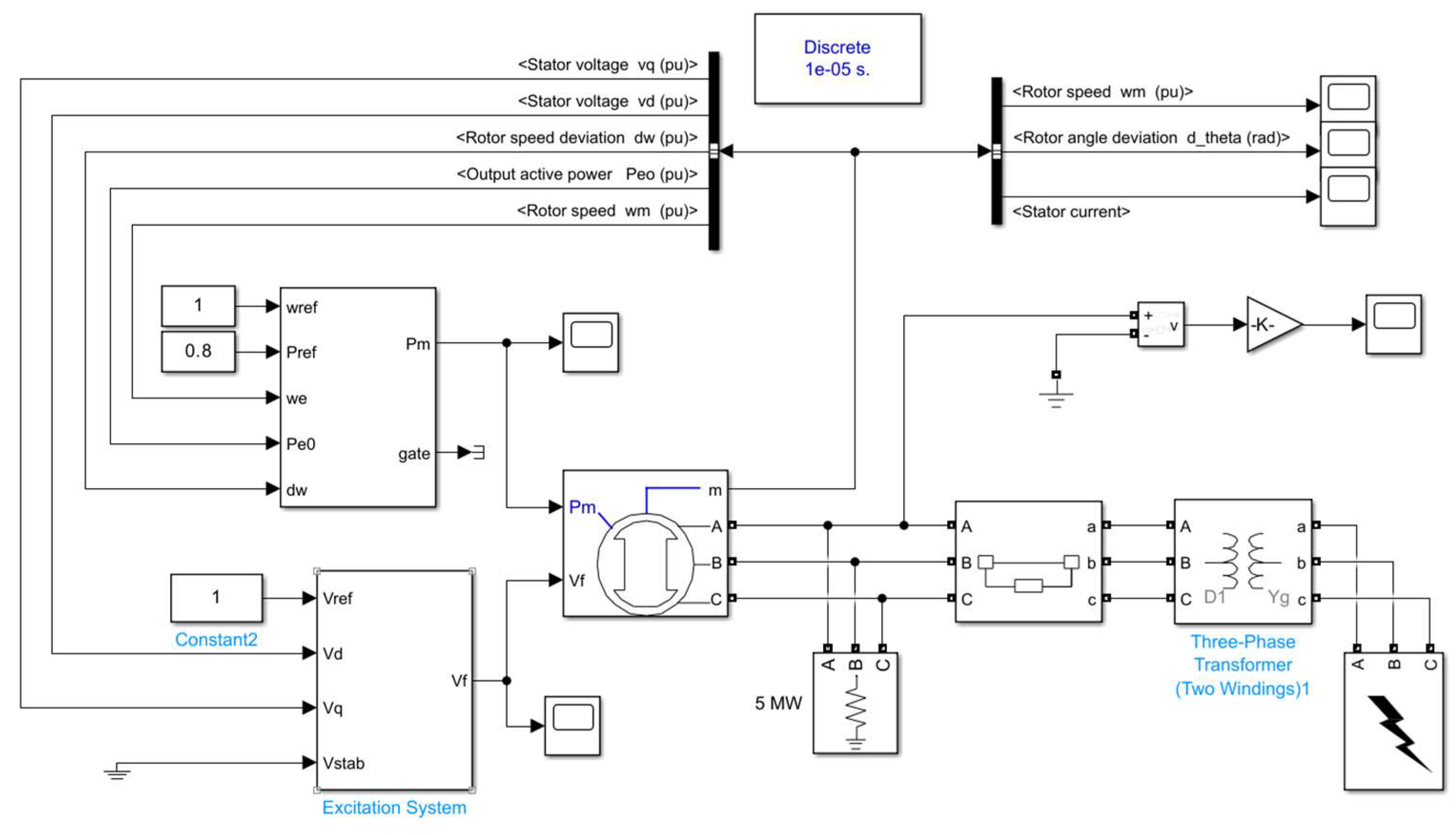

2.2.1. Simulation

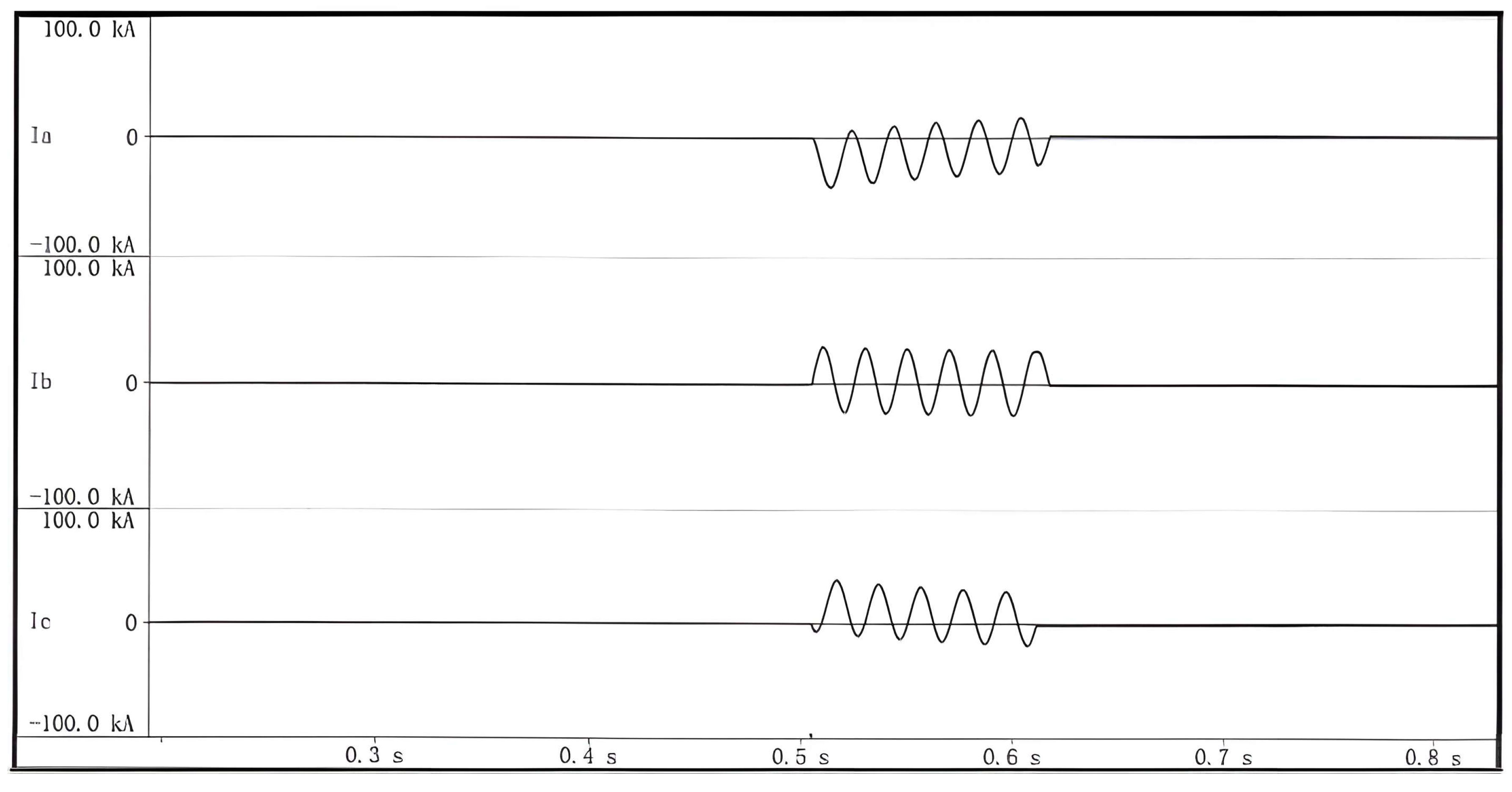

(1) High-capacity test circuit and short-circuit current simulation

In order to obtain the parameters of the test circuit and standardize the test circuit, a simulation model of the main test circuit in

Figure 1 is now established using MATLAB/Simulink. To simplify the model, a single-machine infinite-bus system is used to replace the power grid power source of the power system, and a three-phase fault module is used to simulate the short-circuit closing and short-circuit breaking of the circuit breaker. By analyzing the simulation waveform diagrams, parameters such as the power supply voltage, contact voltage, short-circuit current, DC component of the current, and TRV (Transient Recovery Voltage) parameters before and after the high-capacity test can be obtained. The simulation model is shown in

Figure 5.

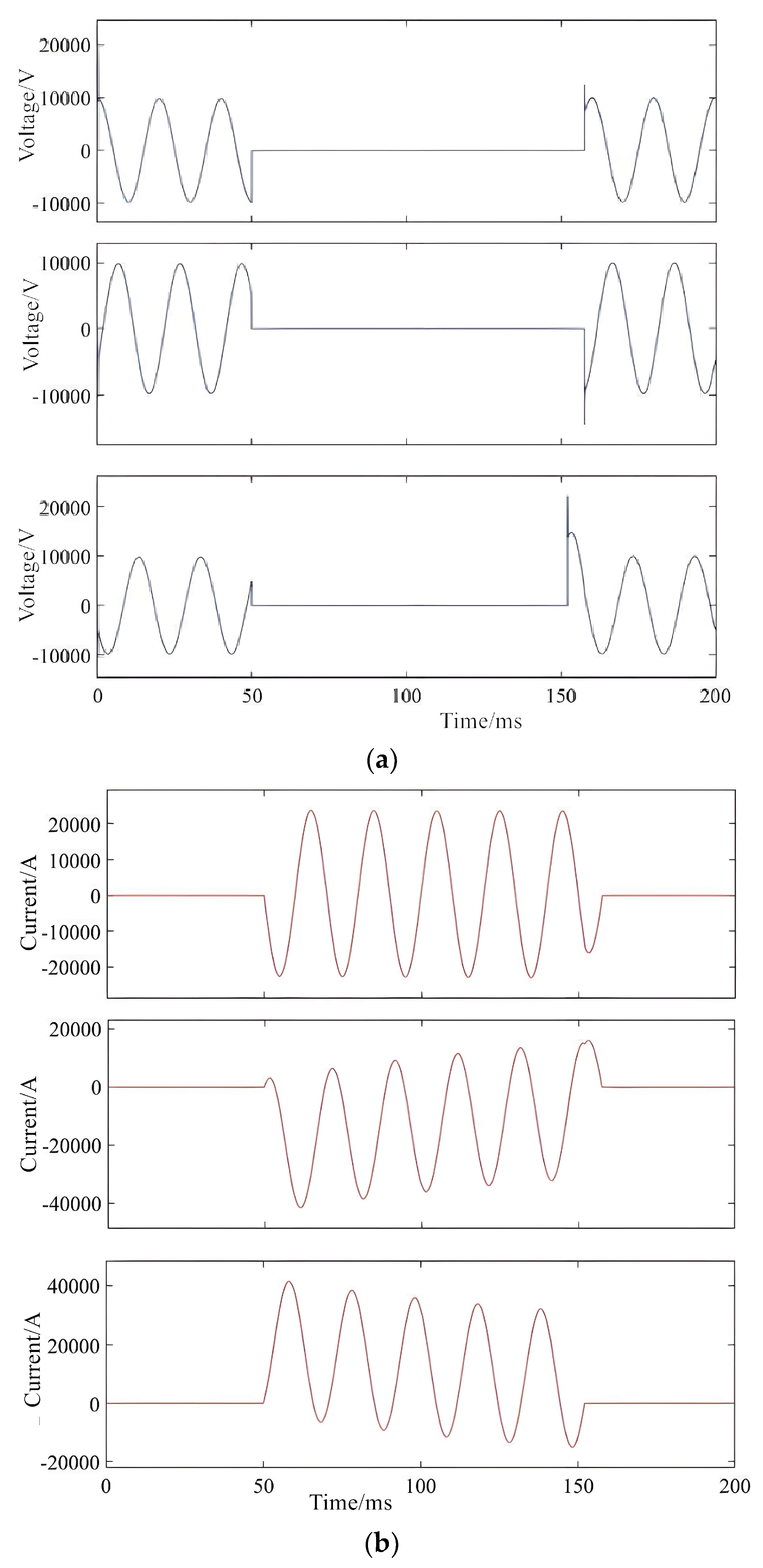

Take the T60 test method of the basic short-circuit test for a 12kV indoor high-voltage vacuum circuit breaker as an example. A simulation model is established based on the 12kV test circuit in 2.1. The short-circuit time is set to 0.1s. The resistance of the power supply side circuit is 0.6Ω and the inductance is 0.0375H. The TRV parameters are set as a resistance of 81Ω and a capacitance of 26nF. The power supply voltage and the voltage across the breaker contacts are shown in

Figure 6 (a), and the short-circuit current waveform is shown in

Figure 6 (b). The measured interrupting currents are 19.0kA, 18.9kA, and 19.1kA respectively, and the DC components of the short-circuit current are 3.1%, 8.3%, and 5.2% respectively.

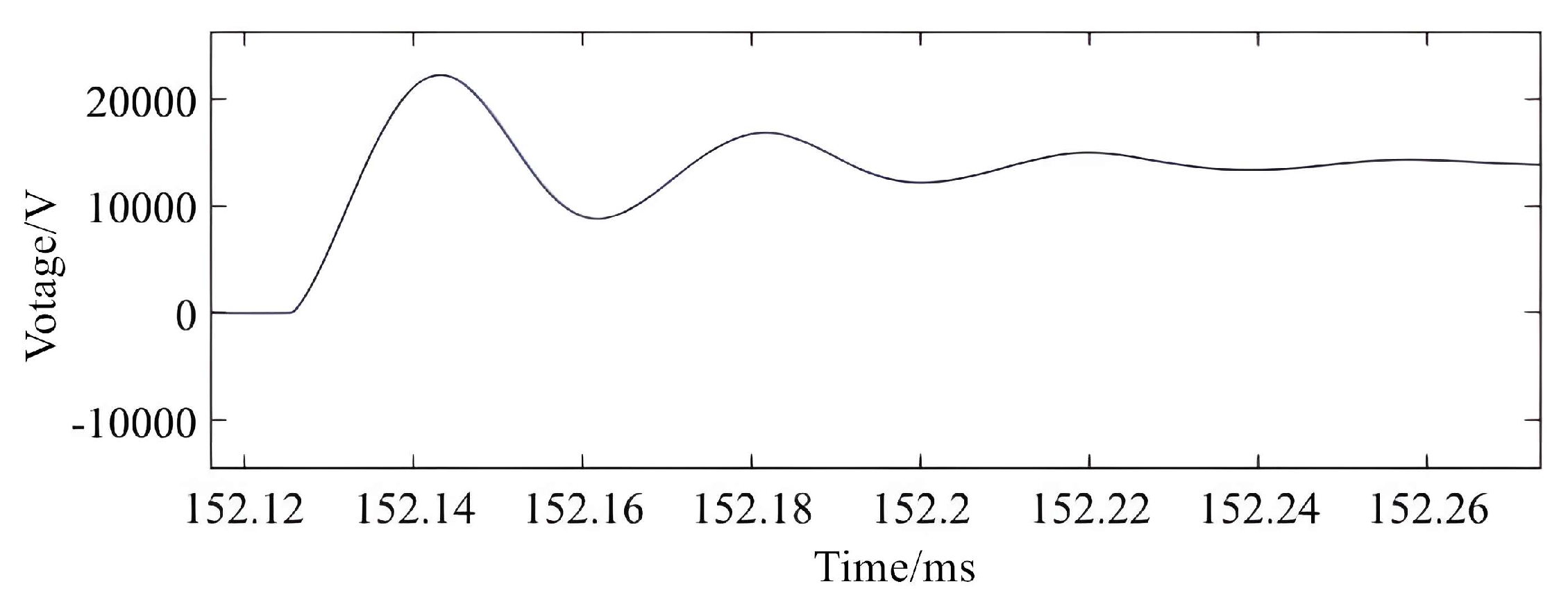

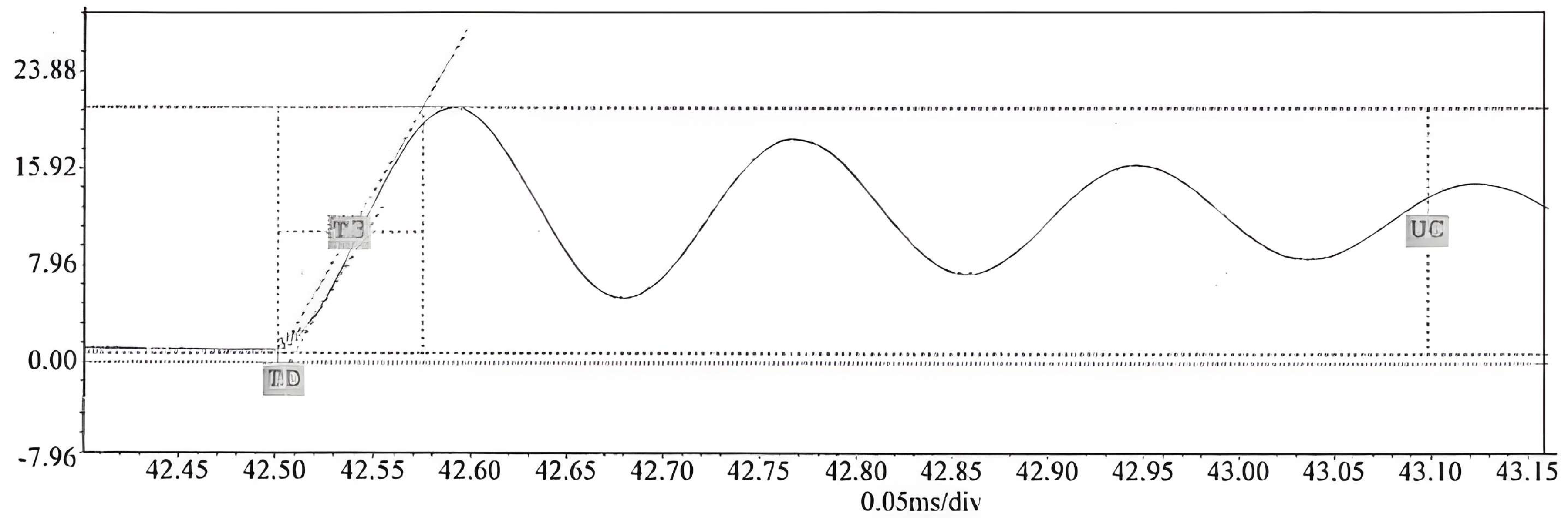

(2) TRV characteristic simulation

The rise time in the TRV (Transient Recovery Voltage) waveform is usually very short, generally ranging from a few microseconds to dozens of microseconds. The TRV waveform is typically complex and may contain multiple oscillation and attenuation processes, which makes the analysis and prediction of TRV difficult. Here, the simulation waveform of TRV can be obtained through this method: magnify the C-phase in

Figure 6 (a), and the TRV waveform as shown in

Figure 7 can be obtained. Using the methods in references [

25,

26], the TRV parameters are measured as

Uc: 20.2kV,

t3: 23

μs, and

td: 3

μs.

2.2.2. Simulation Result Verification

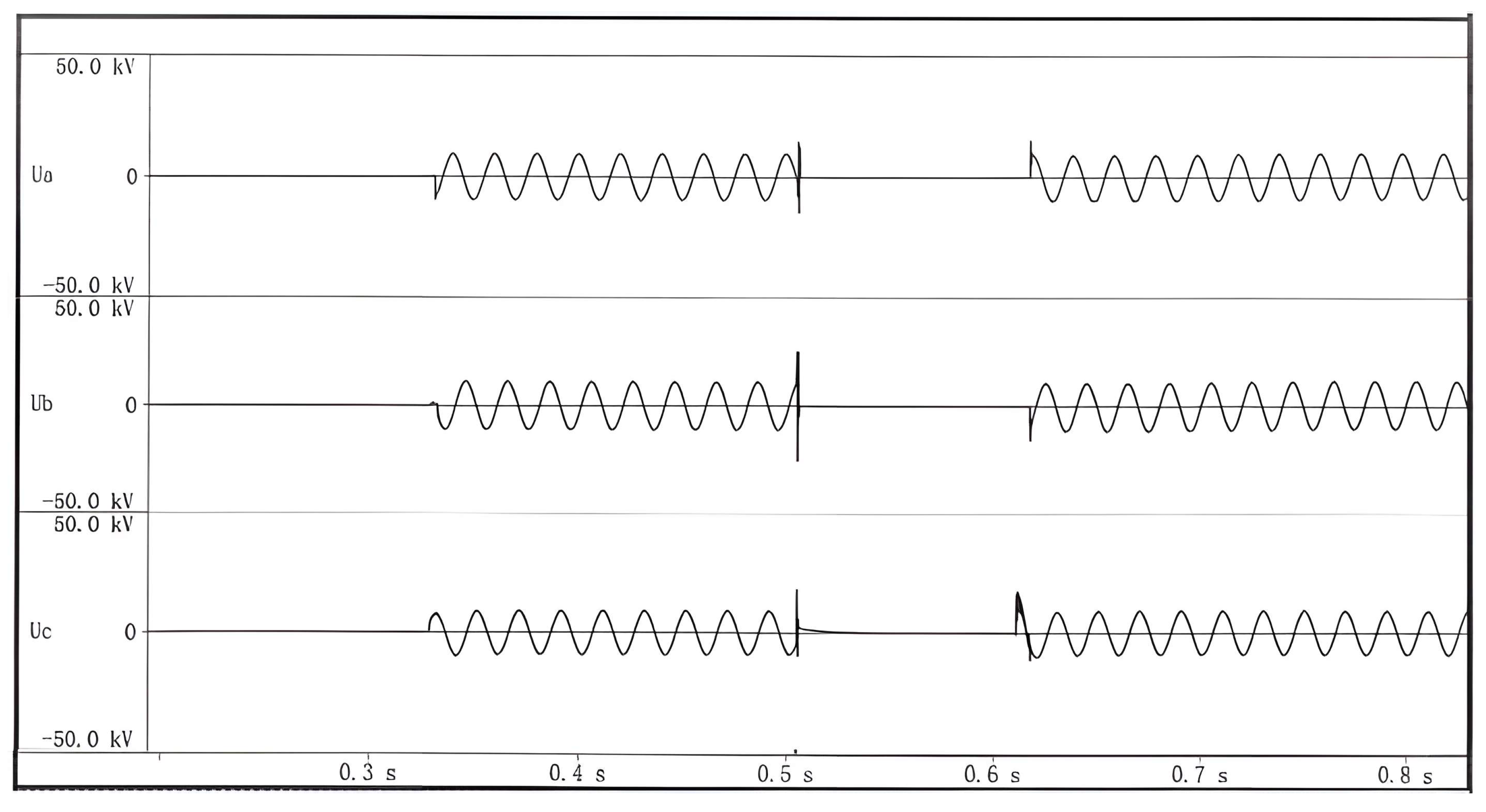

(1) Verification of short-circuit current simulation

In the high-capacity test laboratory, a high-capacity test circuit is built according to the simulation parameters. The parameters are set as follows: the resistance of the power-supply-side circuit is 0.6Ω, the inductance is 0.0375H, and for TRV, the resistance is 81Ω and the capacitance is 26nF. Based on the above-mentioned parameter circuit, the basic short-circuit test of the T60 test method is carried out for the 12kV indoor vacuum circuit breaker. The power supply voltage and the voltage across the breaker contacts are shown in

Figure 8, and the short-circuit current is shown in

Figure 9. The interrupting currents obtained are 19.0kA, 18.9kA, and 19.1kA respectively, and the DC components of the short-circuit current are 7.3%, 2.6%, and 6.9% respectively. By comparing the current and DC-component parameters, it can be seen that they are less than the error specified by the standard.

(3) Verification of TRV characteristics

When conducting the basic short-circuit test of the T60 test method for the 12kV indoor vacuum circuit breaker in the high-capacity test circuit built, the TRV parameters of the oscillogram in

Figure 10 can be obtained, where

Uc: 20.6kV,

t3: 26

μs, and

td: 4

μs.

2.2.3. Comparison and Discussion

The simulation and test results for both short-circuit testing and TRV characteristics were systematically compared. As shown in

Table 2, the TRV parameters obtained from simulations (

Uc: 20.2kV,

t3:23

μs,

td:3

μs) closely align with the test values (

Uc:20.6kV,

t3:26

μs,

td:4

μs). The minor discrepancies in amplitude and timing (e.g., t3 increased by 13% and td by 33%) fall within the acceptable tolerance range specified by IEC 62271-100, confirming the validity of the simulation model. These deviations may arise from factors such as transient electromagnetic interference, component aging, or slight variations in parameter settings during physical testing.

For short-circuit current analysis (

Table 3), the interrupting currents in both simulation and tests were nearly identical (19.0-19.1 kA), demonstrating high consistency. However, the DC component proportions exhibited phase-specific variations. For example, in Phase B, the simulated DC component was 8.3%, while the test value dropped to 2.6%, likely due to differences in arc quenching dynamics or asymmetrical current distribution in the actual test circuit. These results highlight the necessity of incorporating real-world operational variability into simulation models to enhance their predictive accuracy.

3. Test Data Acquisition and Monitoring Control System

In high-capacity laboratories with complex electromagnetic environments, PLC control systems directly control the opening and closing of isolation switches, circuit breakers, etc., without achieving effective electrical isolation between the primary main circuit and the secondary system, posing certain safety hazards and electromagnetic interference [

15,

22].

3.1. Secondary Monitoring and Control Scheme

3.1.1. Test Circuit Connection Control

To achieve effective electrical isolation between the secondary system and the primary circuit during high-capacity testing and to eliminate switch malfunctions and refusal to act due to electromagnetic interference, the test circuit connection is realized through valve islands controlling pneumatic isolation switches. When the isolation switches are connecting the test circuit, all isolation switches are controlled to open and close via valve islands, which can also feedback the open/closed position status signals of the isolation switches.

The valve island boxes, PLCs (Programmable Logic Controller), industrial switches, switching quantity devices, host computer, and HMI (Human Machine Interface) touchscreen collectively form a ring-shaped PROFINET network to enable the interaction of experimental data flows. The PROFINET network effectively facilitates communication between PLCs, as well as between PLCs and HMI, and host computers. It boasts high network real-time performance and strong anti-interference capabilities. To enhance the anti-interference ability and communication distance of network communication, the ring network is laid with multimode optical fibers.

3.1.2. Secondary Signal Monitoring and Control

The signal monitoring and control of secondary circuit equipment are implemented using PLCs and HMI. Both PLCs and HMI utilize the PROFINET network for data transmission. The PLC's primary role is to receive digital signals, such as door switch status, various monitoring measurements of short-circuit transformers, circuit breaker opening and closing status, and switch closing status, perform logical calculations on the input digital signals, or output corresponding digital control signals after logical calculations based on instructions from the PC host computer, including alarm signals, electric bells, indicator lights, and switching commands. For more complex visualization tasks, the use of HMI facilitates intuitive and dynamic displays of analog or digital states such as the oil top layer temperature of short-circuit transformers, making it convenient for field test personnel to view and record.

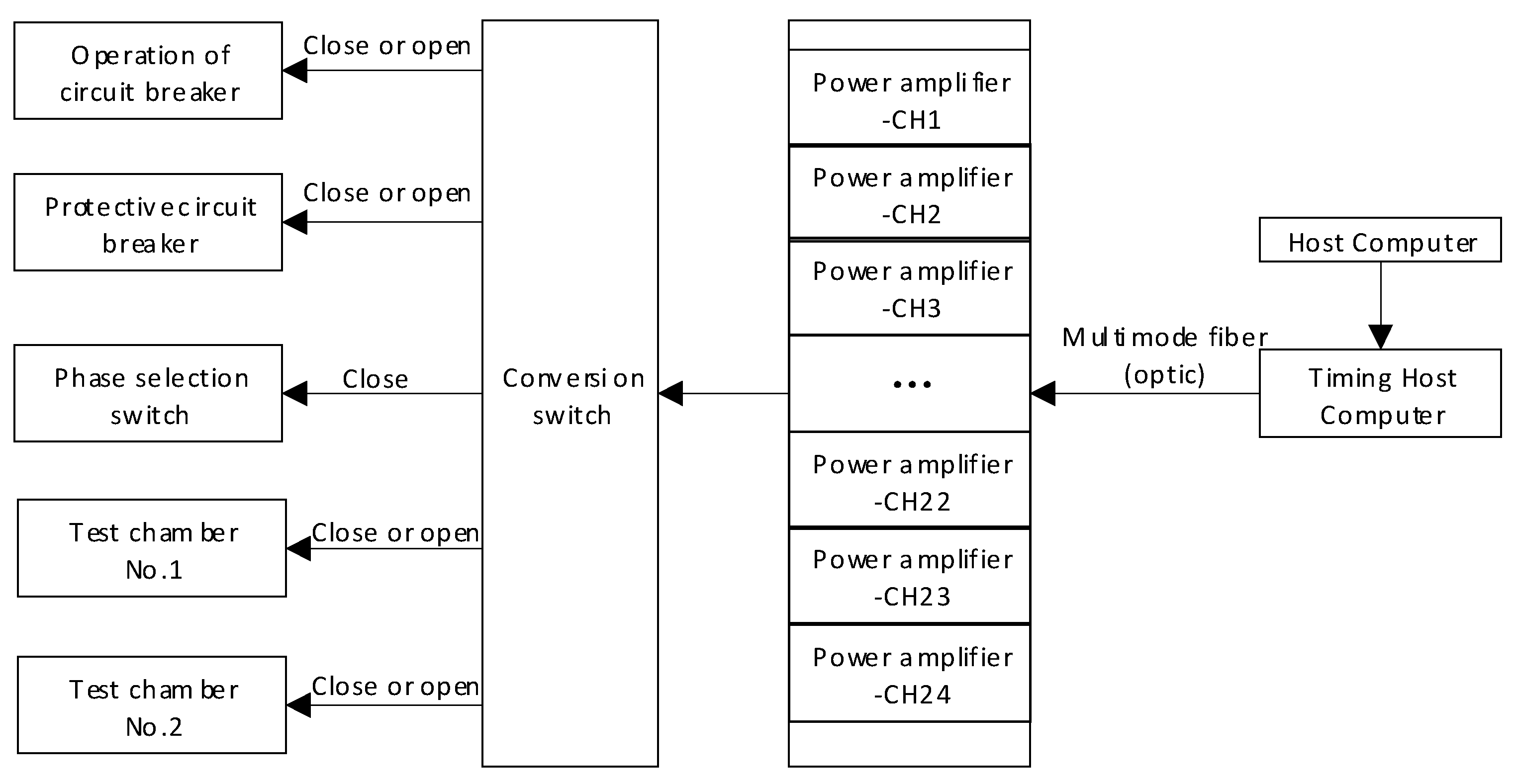

3.1.3. Sequential Control

Sequential control is a crucial technology to ensure that each step in high-capacity testing proceeds correctly and orderly. It controls the sequential actions of circuit breakers and other devices in the test circuit and accurately selects the closing phase angle, enabling automated operation of circuit breakers, switches, test samples, and data acquisition, thereby reducing human intervention and improving the repeatability and consistency of tests. Through rigorous sequential control, tests conducted at different times or by different operators can be highly repeatable. As shown in

Figure 11, during testing, the upper computer sets the control sequence and time interval length for circuit breakers, switches, and test samples on the timing host. The power amplifier amplifies the control signal power. When the sequential control system is activated, it sends control signals in chronological order to control the actions of circuit breakers, switches, and test samples, completing the high-capacity test.

3.1.4. TRV Device Monitoring and Control

The TRV device contains multiple sets of capacitors and resistors. The capacitors in the TRV device serve to store and release electrical energy, while the resistors limit current and dissipate energy, stabilizing voltage and current during the TRV process. Depending on the actual test requirements, parameters such as Uc of the TRV must meet the specified standards. To achieve this, the values of capacitors and resistors in the TRV need to be adjusted to achieve precise control of the transient voltage process at the ports during high-capacity testing. The adjustment of capacitor and resistor values in the TRV is realized through the opening and closing of small isolating switches, which have feedback signals for their open and closed states and are pneumatically controlled via valve island boxes.

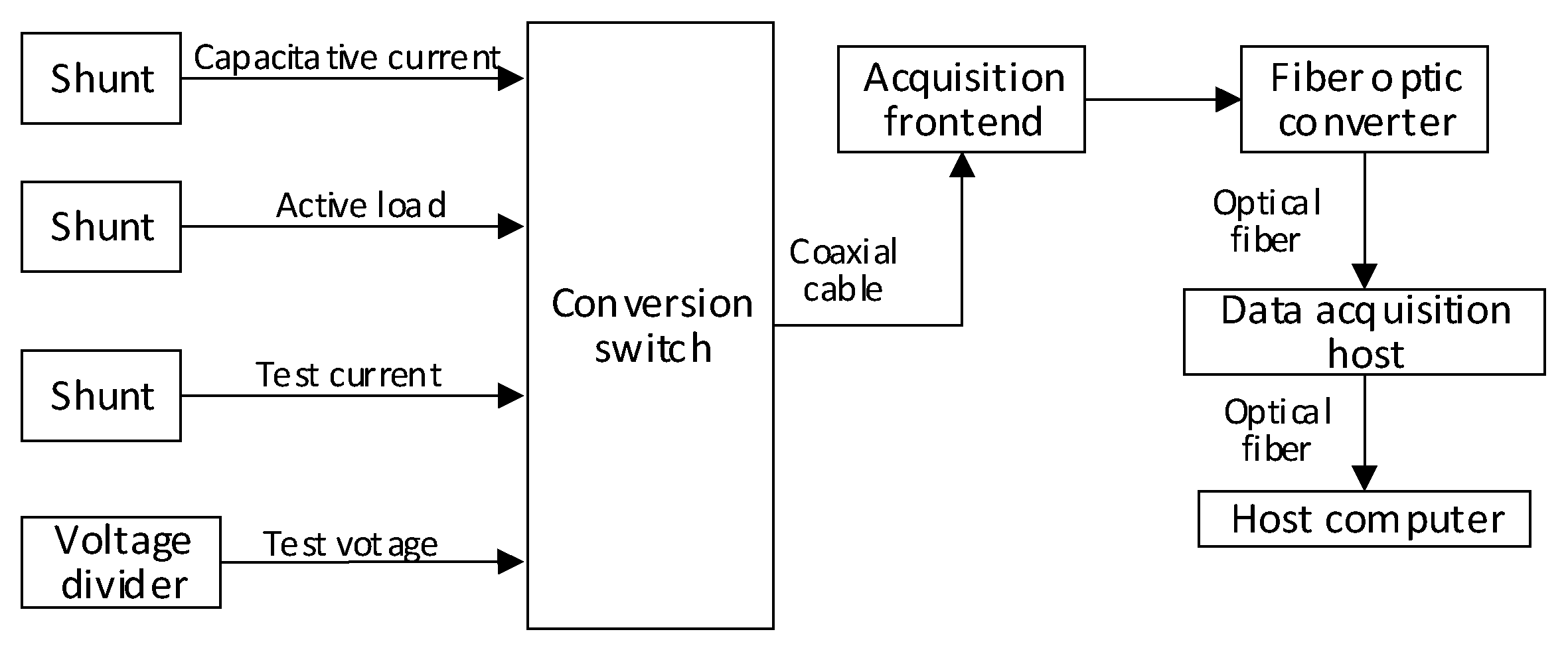

3.2. Test Data Acquisition System

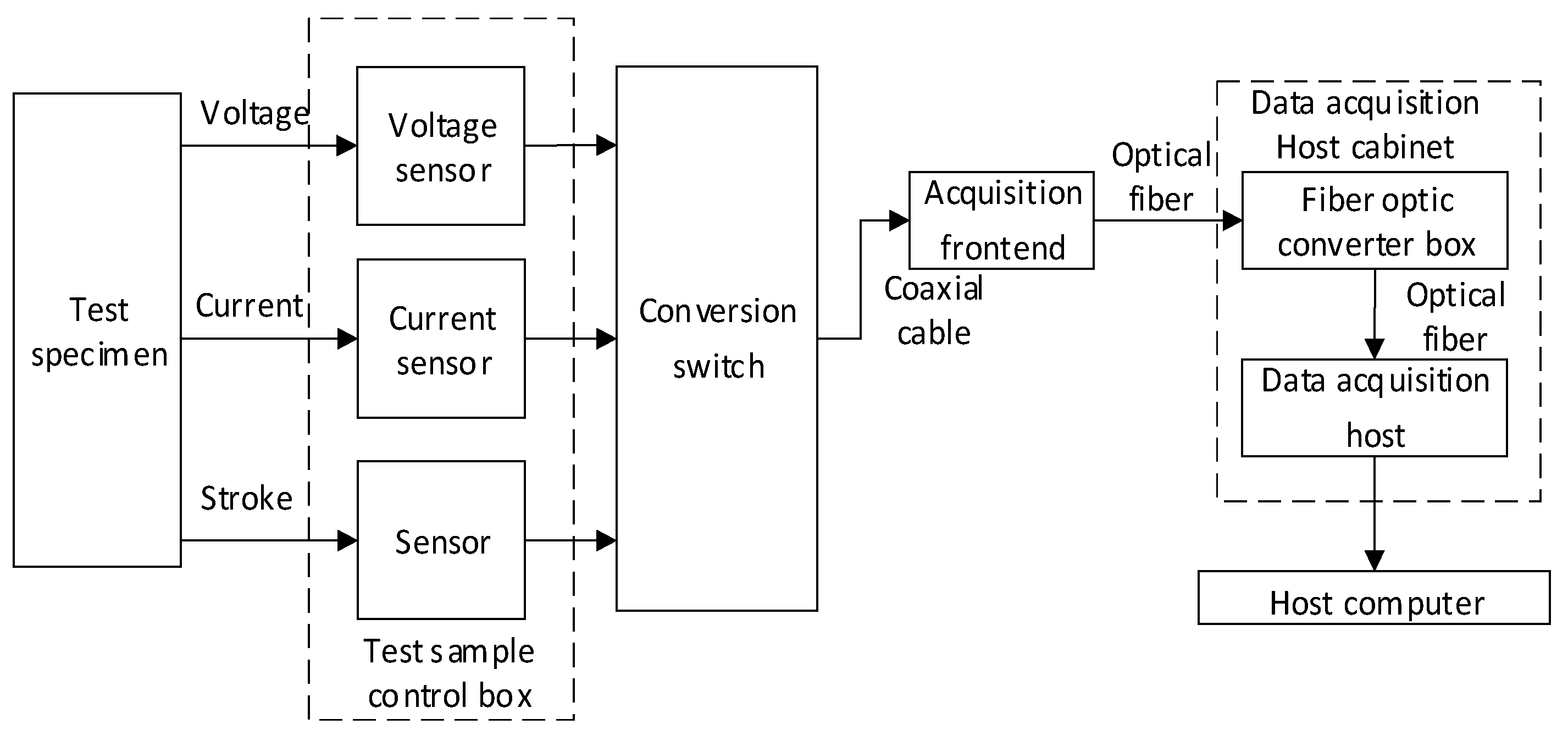

The test data acquisition system is designed to collect and analyze data such as voltage, current, and switch travel during high-capacity testing. It features high sampling rates, high precision, multi-channel input capabilities, data storage, and data analysis and processing functions. The system comprises sensors for voltage, current, and switch travel, a data acquisition front-end, a data acquisition host, control software, and other components. It enables the collection, storage, transmission, and analysis of test parameters such as supply voltage, break voltage, TRV voltage, short-circuit current, and switch travel in the primary circuit.

Voltage sensors for the primary test circuit utilize voltage dividers or potential transformers, while current sensors employ current shunts, current transformers, or Rogowski coils. The selection of voltage and current sensors is based on voltage levels, current magnitudes, and signal acquisition frequencies. Transformers are connected to the acquisition front-end using coaxial cables, and both the acquisition host and timing host are connected via multimode optical fibers through transfer switches to minimize the impact of strong electromagnetic interference generated during high-capacity testing and to ensure voltage isolation. Additionally, anti-interference algorithms are incorporated into the software design of the acquisition host and timing host to enhance the system's suppression capabilities against noise and interference.

As shown in

Figure 12, the transfer switches, acquisition front-end, and front-end transfer cabinet are locally arranged, while the acquisition host and PC host computer are centrally located in a remote control room. Communications are established through multimode optical fibers for data transmission. As illustrated in

Figure 12, the power amplifier module and timing host are also located in the control room, with data transmission between the timing power amplifier and timing host occurring via multimode optical fibers. This layout minimizes the impact of electromagnetic interference on data acquisition and sequential control while ensuring effective voltage isolation (up to 40.5kV) of the measurement and control system from the primary test circuit. It also prevents high voltage from the primary circuit from entering the control room and causing harm to personnel.

Signals such as closing voltage, closing current, and switch travel of the test sample also need to be acquired. As shown in

Figure 13, the transfer switches, acquisition front-end, and front-end transfer cabinet are arranged locally in the test sample room, while the acquisition host and PC host computer are centrally located in a remote control room. Data transmission from the acquisition front-end to the acquisition host occurs via multimode optical fibers.

3.3. Summary of the System's Advantages

(1) Secondary monitoring and control scheme

Pneumatic isolation switches are controlled by valve islands to achieve electrical isolation between the primary and secondary systems, eliminating switch failures caused by electromagnetic interference. The ring-shaped PROFINET network, combined with multimode optical fibers, enables efficient communication and strong anti-interference capabilities, ensuring stable data transmission.

The sequential control technology precisely controls the test process, operates equipment in an orderly manner, and selects the closing phase angle, reducing human intervention and enhancing the repeatability and consistency of tests.

(2)Test data acquisition system

It has high sampling rates, high precision, and multi-channel input capabilities, meeting the requirements for accurate measurement of multiple parameters in high-capacity tests.Equipment is arranged according to functions. Multimode optical fibers are used for data transmission to reduce electromagnetic interference, prevent high-voltage hazards, and ensure the stability of data acquisition and sequential control.

Sensors are selected reasonably and connections are optimized. Anti-interference algorithms are integrated into the software to reduce electromagnetic interference, achieve voltage isolation, and ensure the safety of personnel.

(3)Sequential Control System

Testing: It accurately controls the action sequence of equipment, ensuring that the high-capacity test process is carried out in an orderly manner and guaranteeing the accuracy and reliability of tests. It optimizes test conditions, reduces the impact of differences in the closing phase angle on test results, and improves the accuracy and consistency of test results.

It realizes automated operation, reduces human errors, and makes tests more standardized and normalized. It ensures that test conditions and procedures are consistent during operations at different times and by different personnel, providing reliable data for equipment performance evaluation.

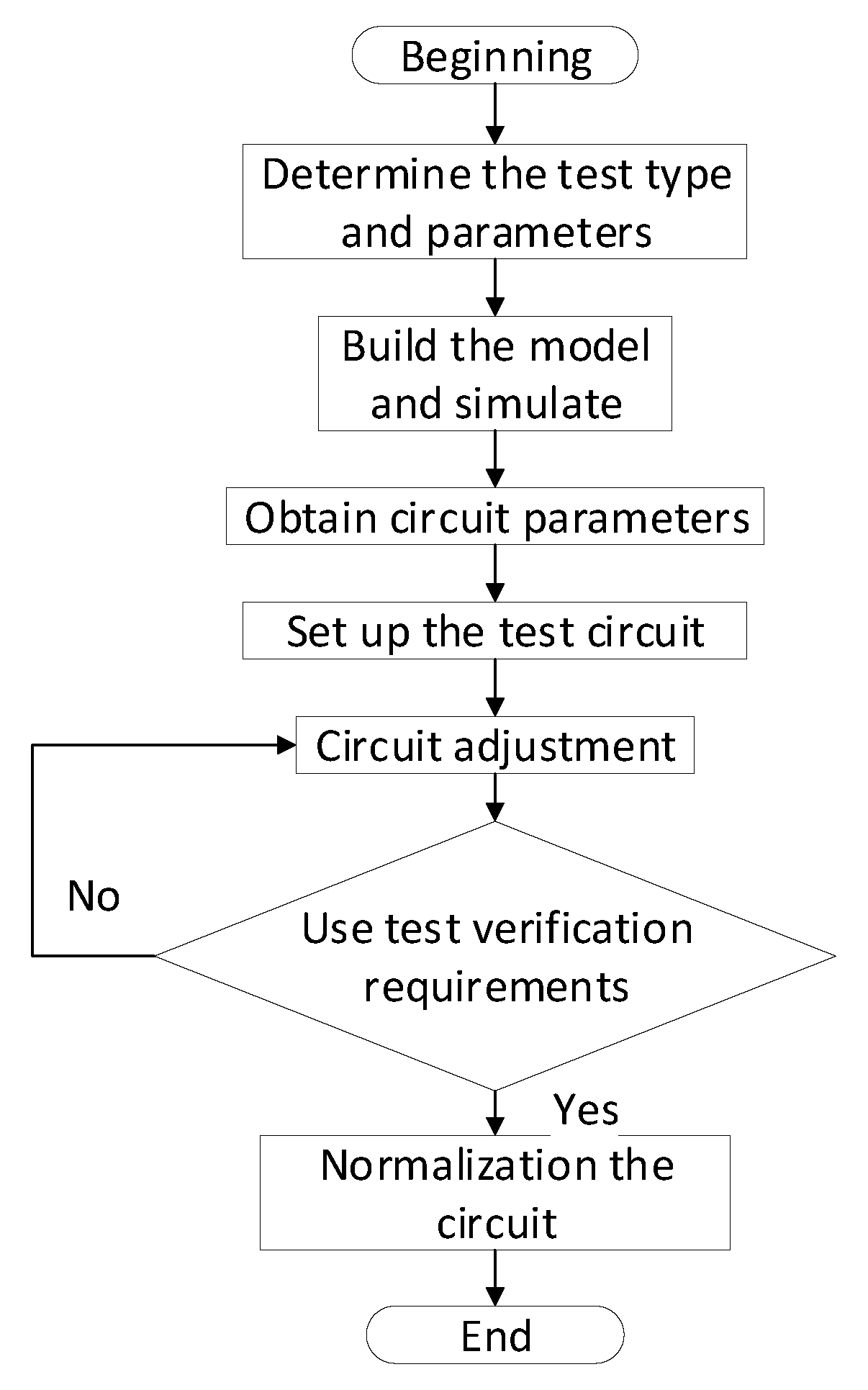

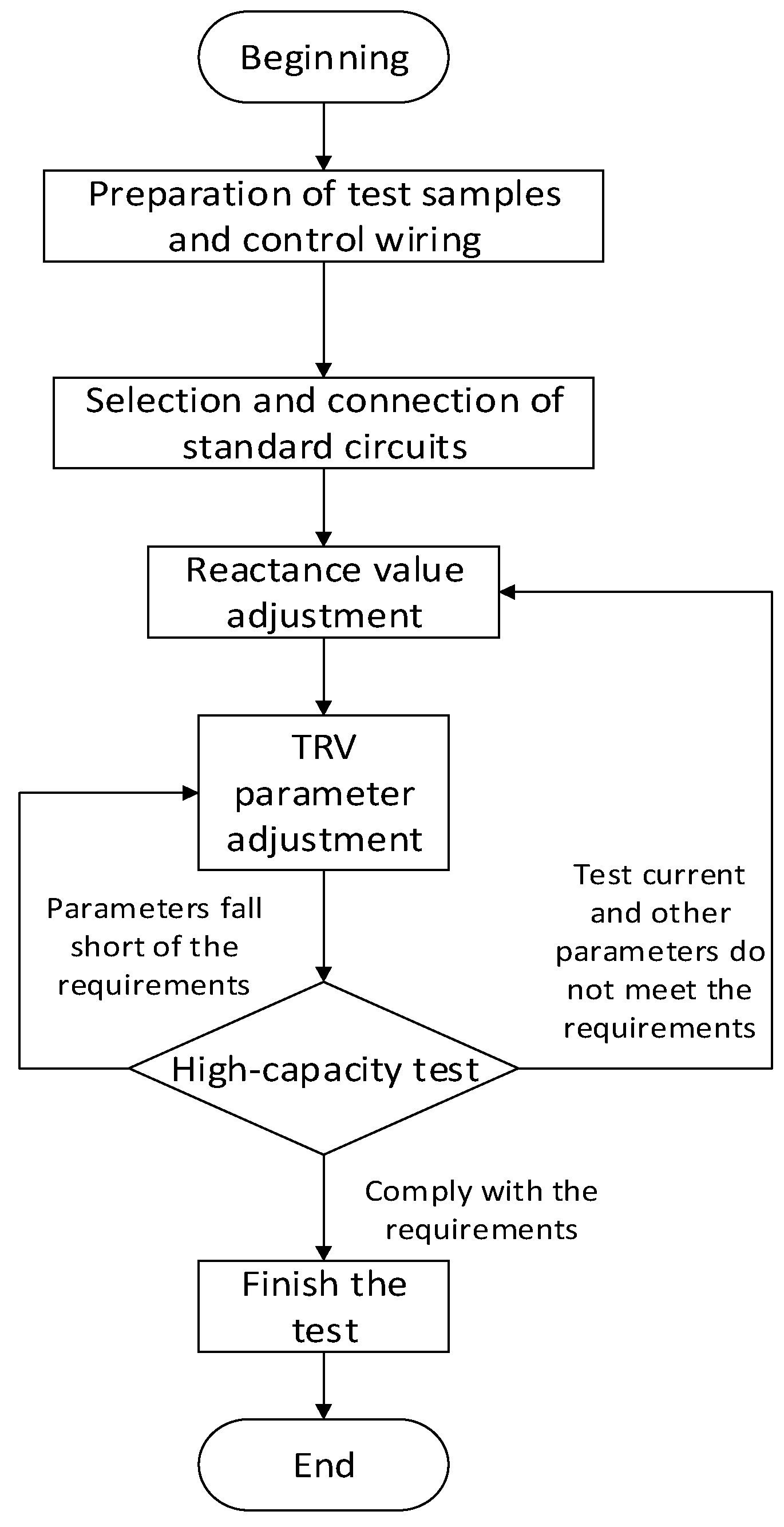

4. High-Capacity Test Process Control

The process control of high-capacity testing is a complex and critical procedure, involving multiple stages and steps to ensure the smooth execution of the test and the accuracy of the results.The workflow of high-capacity testing is illustrated in

Figure 14.

The workflow of high-capacity testing is as follows:

Sample Preparation: based on the test plan, select the test sample and secure it in the test station. Connect the necessary data acquisition lines, sequential control lines, and other required connections.

Parameter Input: input the test parameters into the control computer. The system automatically selects the standard circuit based on the parameters.

Circuit Configuration: the program automatically closes the isolating switches to configure the circuit and selects the reactor value, adjusting the reactor's impedance accordingly.

TRV Parameter adjustment: adjust the transient recovery voltage (TRV) parameters according to the test requirements and the expected TRV waveform.

Parameter Fine-tuning: fine-tune the TRV and reactor parameters based on the preliminary test results.

Test Completion: complete the test in accordance with the specified requirements.

5. Conclusions

This paper systematically investigates the primary test circuit and its measurement and control system scheme for a high-capacity test system based on network power, and draws the following conclusions:

- 1).

Standardization of test circuits

Through the analysis of the constructed test circuit, a Standardization method for test circuits is proposed. The feasibility and accuracy of this method are validated using MATLAB simulation technology. The circuit configurations for different types of tests are standardized, and key circuit parameters are determined through simulation. This provides a reference for the Standardization of test procedures.

- 2).

Automation of test monitoring and control systems

The automated design of the test monitoring and control system, including test data acquisition, signal monitoring, and control schemes, achieves full-process automated control for high-capacity tests. By integrating PLCs, valve islands, coaxial cables, and optical fibers, the system effectively mitigates interference from complex electromagnetic environments on the monitoring and control systems. It also isolates high-voltage intrusion into the test monitoring and control systems during test failures, significantly enhancing the efficiency, reliability, and safety of the tests..

Author Contributions

Conceptualization, Guoping Chen; Formal analysis, Jian Wang; Funding acquisition, Guoping Chen; Methodology, Guoping Chen; Project administration, Guoping Chen; Resources, Yong Li and Yuan Luo; Software, Huixin Chen; Supervision, Yuan Luo; Writing – review & editing, Guoping Chen.All authors will be updated at each stage of manuscript processing, including submission, revision, and revision reminder, via emails from our system or the assigned Assistant Editor.

Funding

Gansu province tianshui city science and technology support plan project: research and application of sequential control technology for high and low voltage switch short-circuit testing system, project number: ts-stk-2024a-282.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of the data; in the writing of the manuscript; or in the decision to publish the results.

References

- Jiang, B. Building a new power system for 30·60 goals: thoughts on china's power 4.0. Global energy interconnection 2021, 4, 534–541. [Google Scholar]

- Voropai, N.; Podkovalnikov, S.; Chudinova, L. The evolution of interstate power grid formation. Global energy interconnection 2021, 4, 335–353. [Google Scholar] [CrossRef]

- Sheng, G.H.; Qian, Y.; Luo, L.G.; et al. Key technologies and application prospects for operation and maintenance of power equipment in new power systems. High Voltage Engineering 2021, 47, 3072–3084. [Google Scholar]

- Chen, J.; Wang, Y.; Huang, H.; et al. Application research on live detection of partial discharge in 10kV switchgear based on multi-dimensional diagnosis technology. Distribution & Utilization 2016, 33, 64–68. [Google Scholar]

- Li, L. Application of intelligent monitoring and automation technology in power systems. Electronic technology 2024, 53, 328–329. [Google Scholar]

- Chen, Shuyong, Song, Shufang, Li, Lanxin; et al. Key technologies and prospects for the transformation of power systems towards carbon neutrality. proceedings of the CSEE (Proceedings of the Chinese Society for Electrical Engineering) 2021, 41, 3989–4003. [Google Scholar]

- Zhang, Q.; Wei, L.; Su, W.; et al. Commissioning of intelligent switchgear based on IEC61850 message simulation and analysis technology. High Voltage Apparatus 2014, 50, 91–95, 101. [Google Scholar]

- Li, G.; Yao, S.; Du, W.; et al. Research on the capacity test circuit of uhv circuit breakers. High Voltage Apparatus 2013, 49, 6–11. [Google Scholar]

- Zhang, Q.; Sun, H.; Tian, M.; et al. Current status and development trends of on-line insulation monitoring technology for high-voltage switchgear. High Voltage Apparatus 2023, 59, 1–11. [Google Scholar]

- Jiang, Z.; Yan, D.; Wang, P.; et al. Research on high-capacity test circuit for 550 kV/80 kA circuit breakers. High Voltage Apparatus 2023, 59, 200–206. [Google Scholar]

- Kang, Z. Design of control system for high-voltage high-capacity laboratory. Electrical Engineering & Electronics 2017, 11, 74–76. [Google Scholar]

- Dai, J.; Zhang, S.; Shen, J.; et al. Research on modeling method and one-click sequential control scheme for high-capacity test system. Global energy interconnection 2023, 6, 660–669. [Google Scholar]

- Chen, H.; Lin, J.; Luo, Y. Research on synchronous control system for synthetic testing. electric drive automation 2017, 39, 56–58. [Google Scholar]

- Synthetic testing of high-voltage alternating current circuit breakers: IEC 60427-2000. International electrotechnical commission, 2000.

- Wang, Y.; Zhang, J.; Pan, C.; et al. Review of research on multi-dimensional performance evaluation indexes for integrated smart energy. Global energy interconnection 2021, 4, 207–225. [Google Scholar]

- Chen, G.; Guo, W. Application of valve island technology in high-voltage high-capacity laboratory. automation instrumentation 2015, 36, 33–36. [Google Scholar]

- Li, G.; Gao, X.; Liu, H.; et al. High-capacity short-circuit breaking and making test technology for high-voltage ac circuit breakers. High voltage apparatus 2018, 54, 68–75. [Google Scholar]

- Gao, X.; Ji, X.; Ma, J.; et al. Analysis and discussion on short-circuit test procedures for high-capacity generator circuit breakers. High voltage apparatus 2017, 53, 172–177. [Google Scholar]

- Bai, Y.; Li, P.; Guan, Y.; Fang, C.; Guo, J.; Wang, Z.; Quan, H. Research on TRV breaking characteristics and suppression measures of high-capacity generator circuit breakers. High voltage apparatus 2024, 60, 92–100. [Google Scholar]

- Liu, Z.; Zhao, Q.; Huang, S.; et al. Brief overview of the control system in high power laboratories. High Voltage Apparatus 2018, 54, 237–241. [Google Scholar]

- Cao, L.; Zhu, X.; Wang, S. Research of computer aided analysis system in high power Lab. High Voltage Apparatus 2002, (02), 32–34. [Google Scholar]

- Chen, G.; Guo, W. Development of control system for impulse generator set based on s7-300. Electric automation 2015, 37, 87–89. [Google Scholar]

- Jiang, Z.; Yan, D.; Wang, P.; et al. Research on High power test circuit for 550 kV/80 kA circuit-breaker. High Voltage Apparatus 2023, 59, 200–206. [Google Scholar]

- Li, G.; Gao, X.; Liu, H.; et al. High-power short-circuit making and breaking test technology for high-voltage AC circuit breakers. High Voltage Apparatus 2018, 54, 68–75. [Google Scholar]

- Huang, S.; Gao, X.; Liu, H.; et al. Calculation of current zero di/dt and trv peak uc for asymmetric current interruption test t100a. High voltage apparatus 2015, 51, 163–167. [Google Scholar]

- Zhou, X.; Lin, Z.; Liu, C.; et al. Calculation of the envelope of transient recovery voltage waveform using the successive approximation method. High voltage apparatus 2018, 54, 159–163. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).