Submitted:

14 February 2025

Posted:

17 February 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Material and Methods

2.1. Coal and Solvents Used

2.2. Reactor Unit and Dissolution Procedure

2.3. Analytical Techniques

3. Results

3.1. Characterization of Coal and Solvents

3.2. Coal Dissolution

3.2.1. The Composition of the Pitch-Like Products

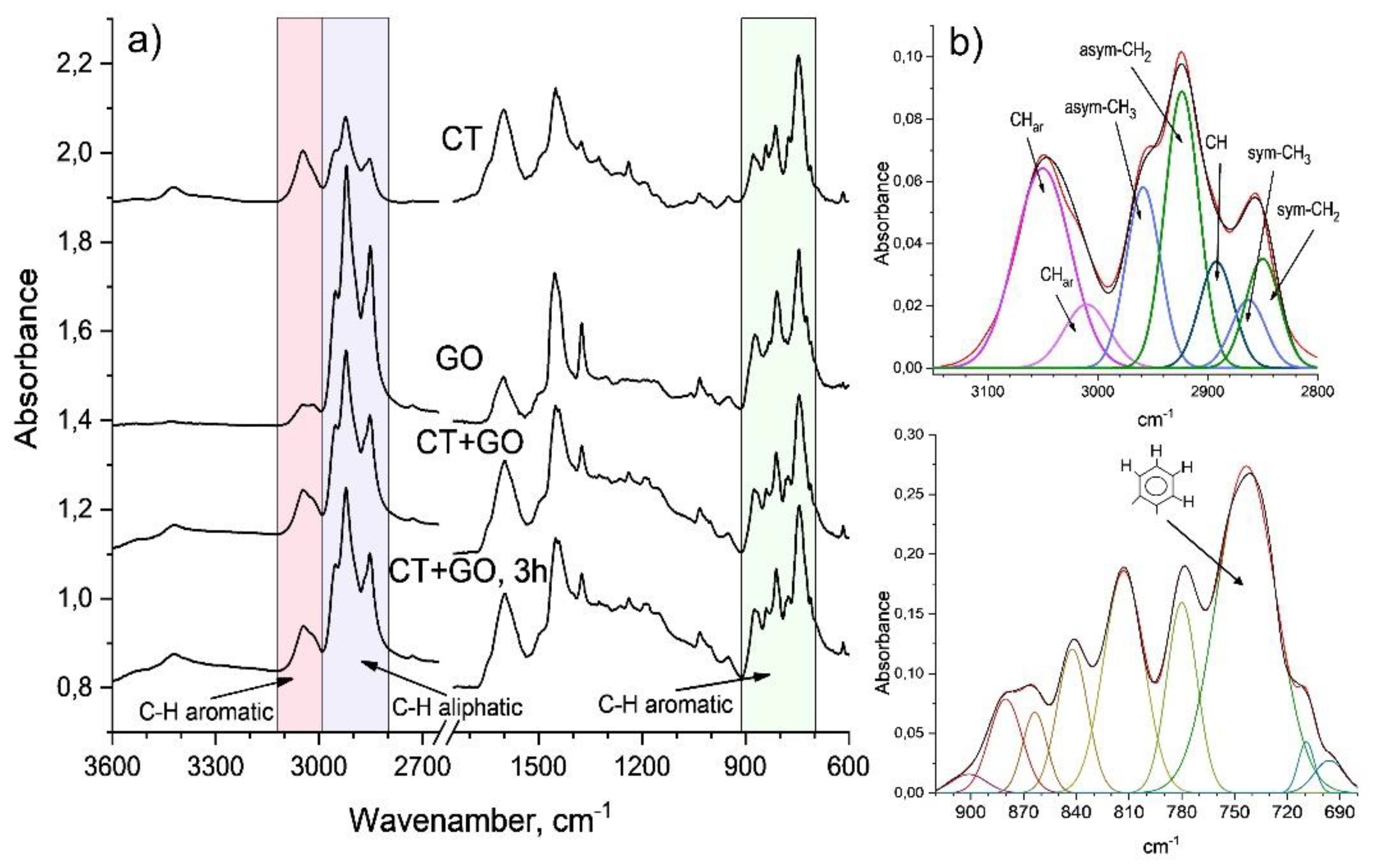

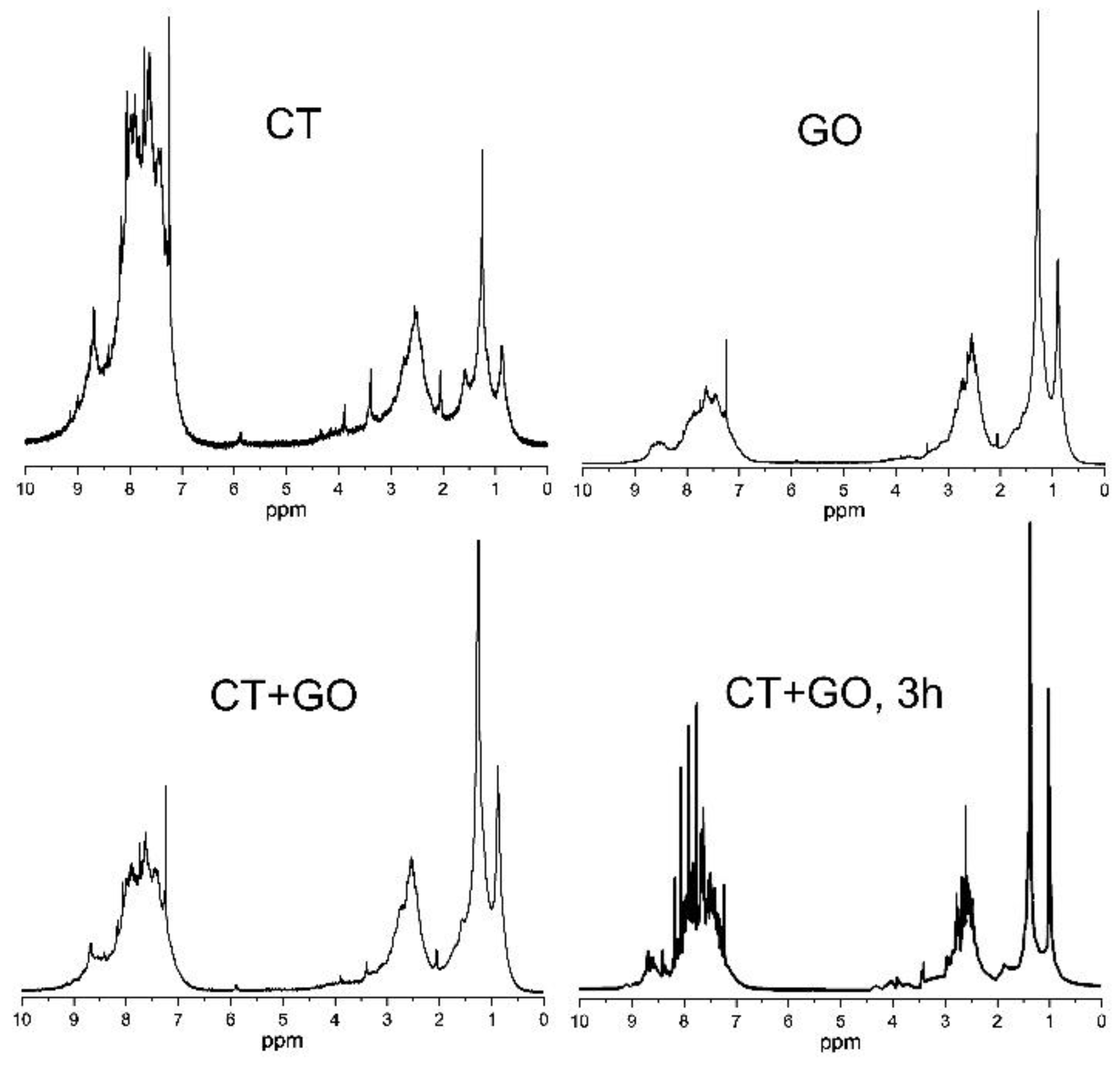

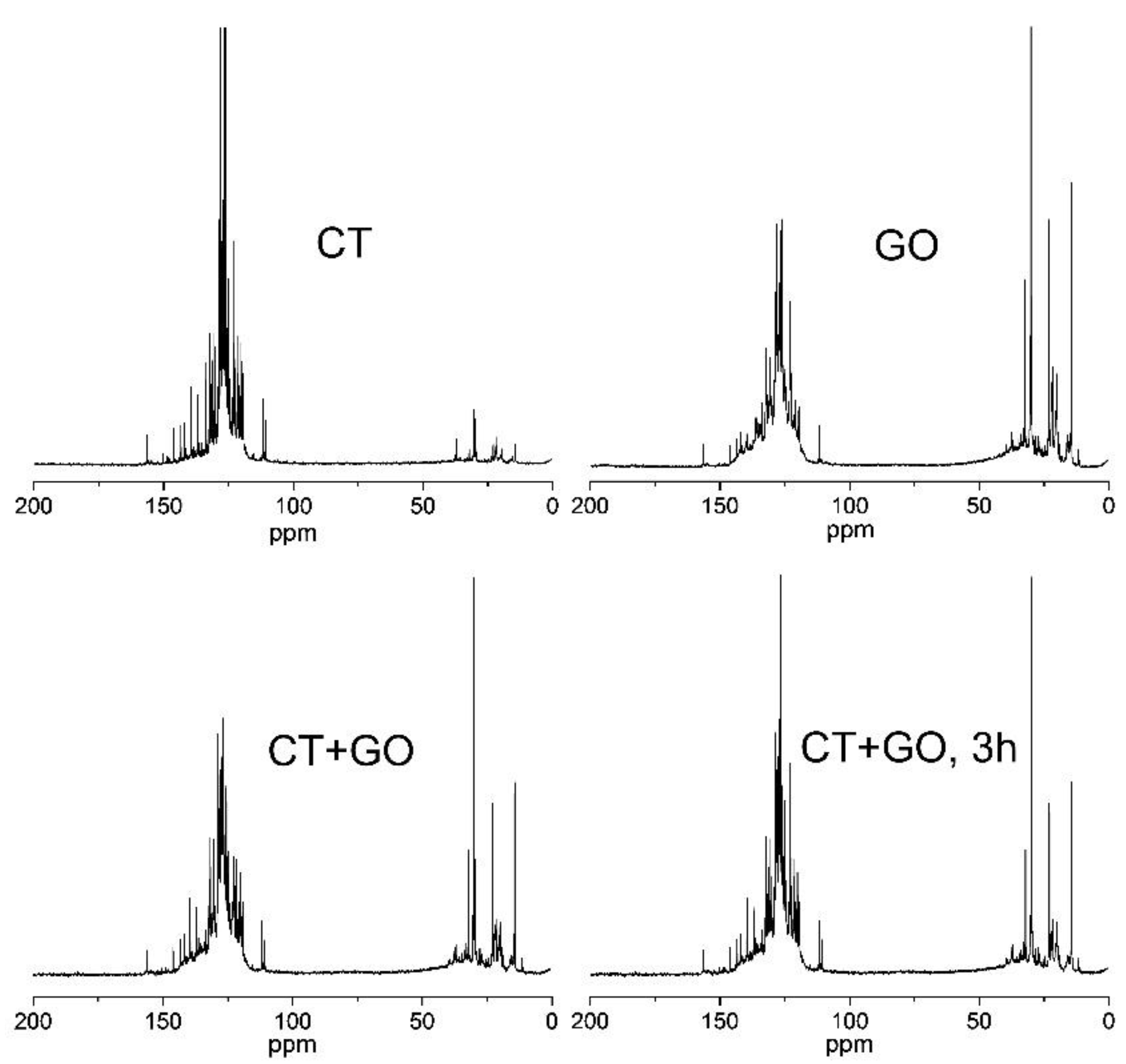

3.2.2. Molecular Structure of the Pitch-Like Products

4. Discussion

4. Conclusions

- The liquid-phase reaction of bituminous coal with commercially available heavy hydrocarbon fractions of coal- and petroleum origin at moderate temperature of 380 °C and autogenous pressure of 2.5 MPa resulted in deep and selective coal dissolution into quinoline-soluble substances (to more than 80%), the yield of gaseous products being no more than 0.5%. The binary blend of highly aromatic coal tar and aliphatic petroleum-derived gasoil fraction exhibited some synergistic effect resulting in improved coal dissolution.

- The resultant products represented typical pitch-like matter with the softening points of 82 to 90 °C. The product obtained using coal tar as solvent was highly aromatic, its aromatic nuclei consisted of predominantly protonated and pericondensed cycles sparsely substituted by CH3 and occasionally CH2 groups. The product obtained using petroleum-derived solvent was less aromatic, its aromatic structure contained protonated and highly alkylated catacondensed chains. The pitch-like product with the intermediate structural parameters was obtained using binary solvent.

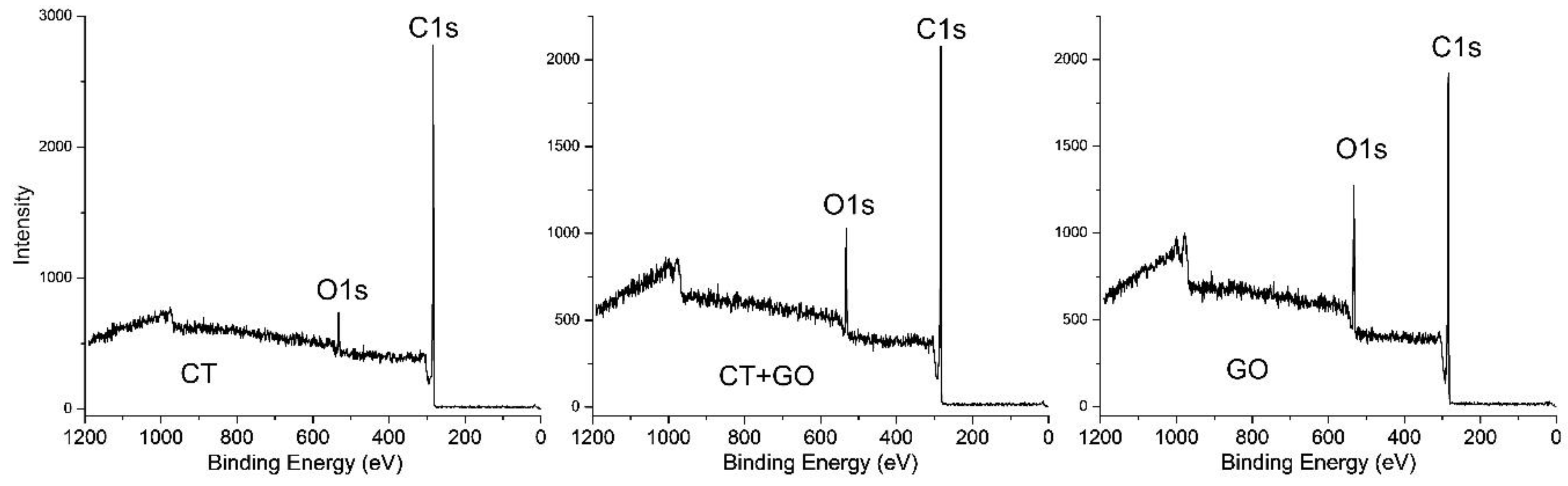

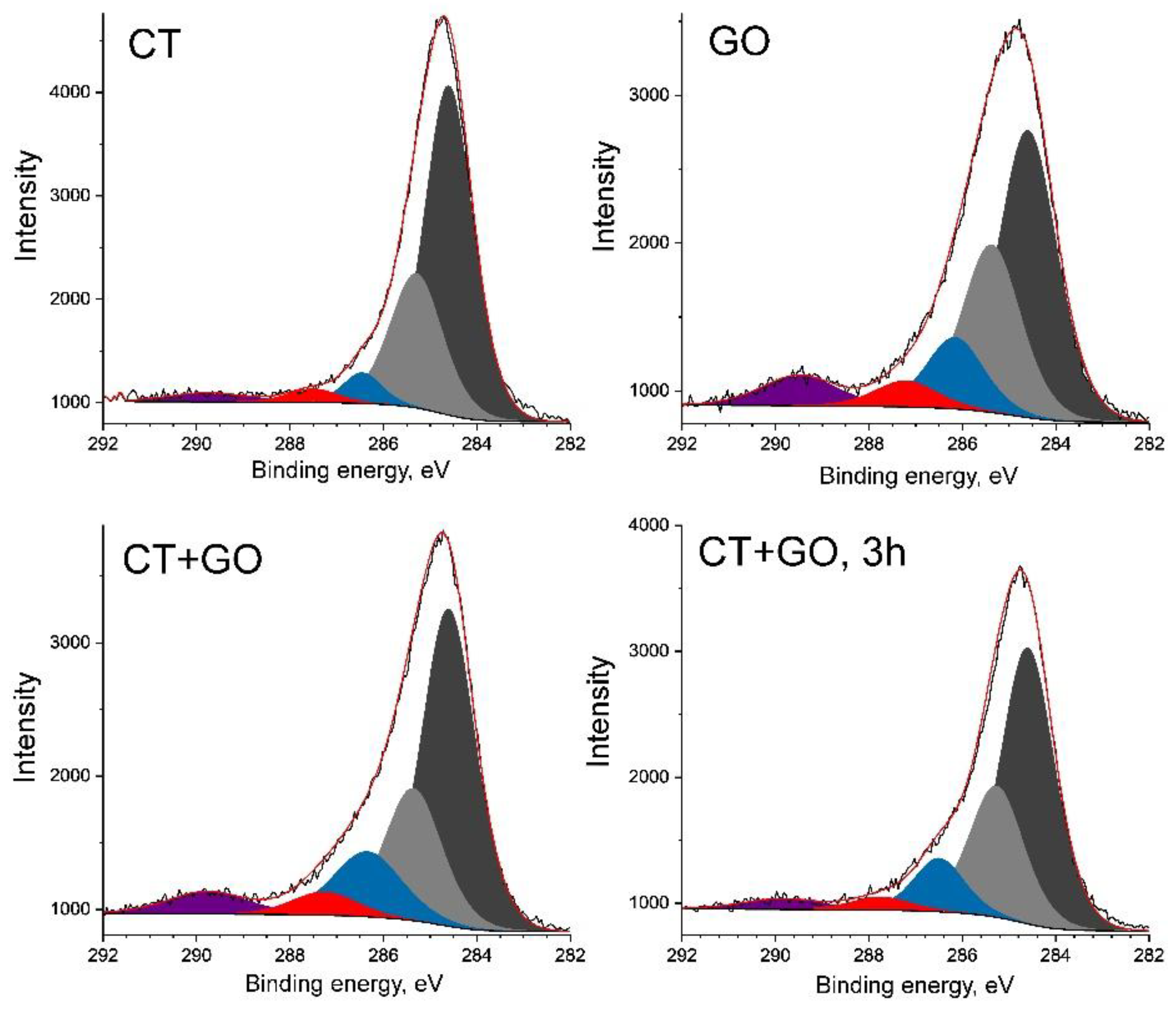

- The pitch-like products underwent autogenous surface oxidation by the atmospheric oxygen at room temperature. The product obtained using petroleum-derived solvent was most susceptible to surface oxidation due to presence of highly alkylated aromatics. The surface of the product obtained using coal tar was much less oxidized, just like a commercial coal-tar pitch sample. The product obtained using a binary solvent showed moderate surface oxidation.

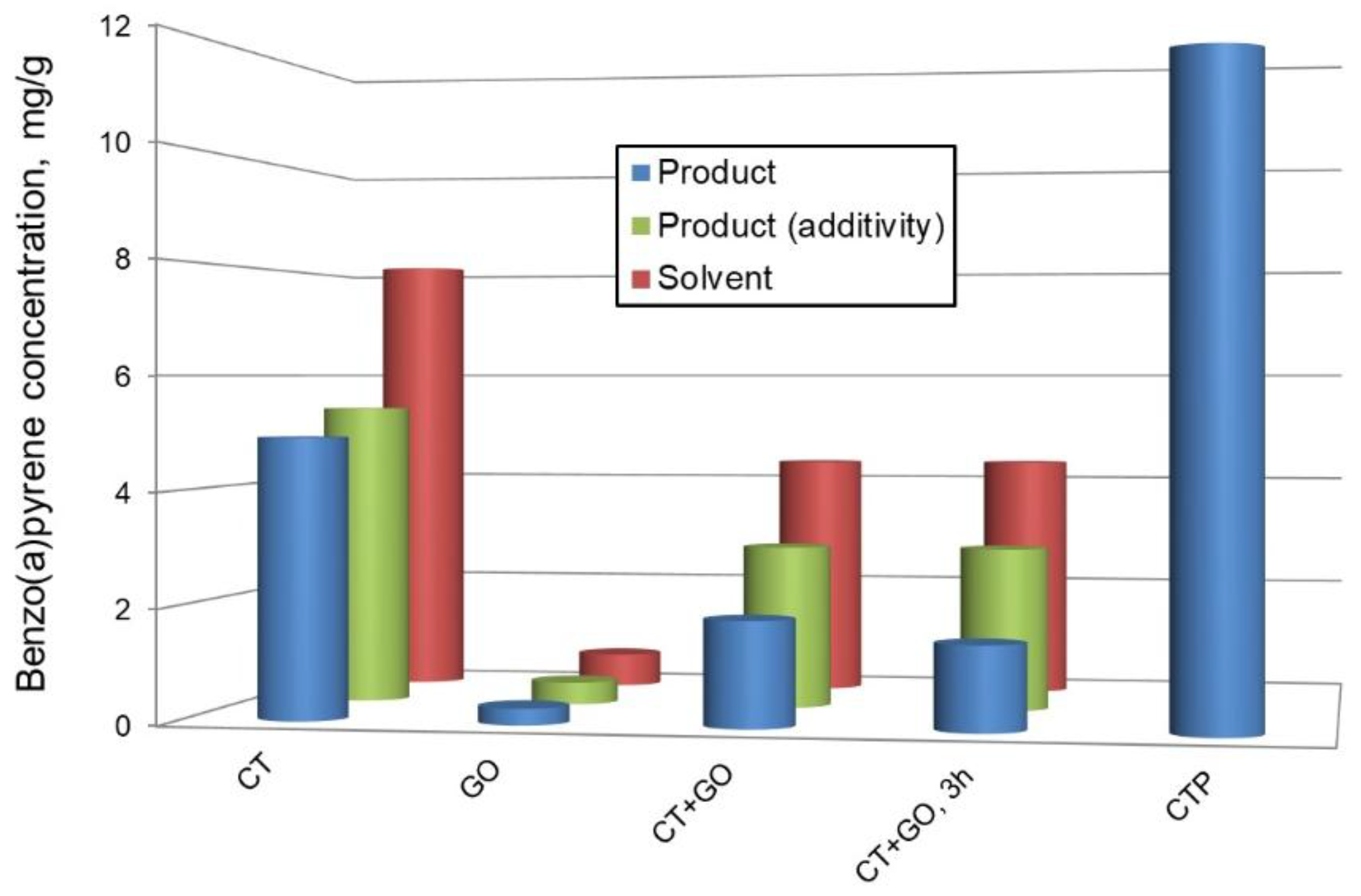

- All the pitch-like products obtained had a reduced concentration of BaP, the smallest concentration showing the product obtained using petroleum-derived solvent (40 times less than in typical coal-tar pitch). An increase in coal dissolution duration led to further decrease in BaP concentration.

- In terms of molecular composition, pitch-like products obtained by low-temperature dissolution of coal can serve as low-carcinogenic polyaromatic raw materials for the production of needle coke and other valuable carbon materials.

- By selecting solvents, it is possible to optimize the molecular-structural characteristics of the dissolved products in order to obtain favorable feedstock. Based on the structure of needle coke, a preferred feedstock for its preparation can be CT products containing large content of polyaromatic molecules with pericondensed rings.

Author Contributions

Declaration of Competing Interest

Funding

Acknowledgments

References

- Predel, H. Petroleum Coke. In Ullmann’s Encycl. Ind. Chem., Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA, 2014; pp. 1–21. [CrossRef]

- Steppich, D. Graphite Electrodes for Electric Arc Furnaces. In Industrial Carbon and Graphite Materials, Volume I; Jäger, H., Frohs, W., Eds.; John Wiley & Sons, Ltd: GmbH, 2021; pp. 281-319. [CrossRef]

- Wachtler, M.; Öttinger, O.; Schweiss, R. Carbon and Graphite for Electrochemical Power Sources. In Industrial Carbon and Graphite Materials, Volume I; Jäger, H., Frohs, W., Eds.; John Wiley & Sons, Ltd: GmbH, 2021; pp. 379-455. [CrossRef]

- Global Needle Coke Industry Trends Analysis Report 2024, Forecast to 2032 (Broken Down by Type, End User, Regional Analysis, and Competitive Landscape). Available online: https://www.marketgrowthreports.com/global-needle-coke-industry-25826630 (accessed on 27 Jan 2025).

- Needle Coke Market Size & Share Analysis - Growth Trends & Forecasts (2025 - 2030). Available online: https://www.mordorintelligence.com/industry-reports/needle-coke-market (accessed on 27 Jan 2025). (accessed on 27 Jan 2025).

- Gabdulkhakov, R.R.; Rudko, V.A.; Pyagay, I.N. Methods for modifying needle coke raw materials by introducing additives of various origin (review). Fuel 2022, 310, 122265. [CrossRef]

- Mondal, S.; Yadav, A.; Pandey, V.; Sugumaran, V.; Bagai, R.; Kumar, R.; Pradeep, P.R.; Das, S.K.; Christopher, J.; Kapur, G.S.; Ramakumar, S.S.V. Dissecting the cohesiveness among aromatics, saturates and structural features of aromatics towards needle coke generation in DCU from clarified oil by analytical techniques. Fuel 2021, 304, 121459. [CrossRef]

- Zhang, Z.; Du, H.; Guo, S.; Lou, B.; Yu, R.; Gong, X.; Li, Z.; Li, M.; Duan, Y.; Yuan, H.; Liu, D. Probing the effect of molecular structure and compositions in extracted oil on the characteristics of needle coke. Fuel 2021, 301, 120984. [CrossRef]

- Rana, M.S.; Sámano, V.; Ancheyta, J.; Diaz, J.A.I. A review of recent advances on process technologies for upgrading of heavy oils and residua. Fuel 2007, 84, 1216-1231. [CrossRef]

- Speight, J.G. Hydrotreating and Desulfurization. In The Refinery of the Future; William Andrew, 2010; pp. 237-273. [CrossRef]

- Kozlov, A.P.; Cherkasova, T.G.; Frolov, S.V.; Subbotin, S.P.; Solodov, V.S. Innovative Coal-Tar Products at PAO Koks. Coke Chem. 2020, 63, 344–350.

- Stompel, D.Z. Eastern European Coal Tar Market A.D. 2023. International Tar Association. 2023. https://www.itaorg.com/conf-presentations.php?year=2023.

- Tiwari, H.P.; Saxena, V.K. Industrial perspective of the cokemaking technologies. In New Trends in Coal Conversion; Suárez-Ruiz, I.; Diez, M.A.; Rubiera, F., Eds.; Woodhead Publishing, Cambridge, 2019; pp. 203–246. [CrossRef]

- Cheng, X.; Li, G.; Peng, Y.; Song, S.; Shi, X.; Wu, J.; Xie, J.; Zhou, M.; Hu, G. Obtaining needle coke from coal liquefaction residue. Chem Technol Fuels Oils 2012, 48, 349–355. [CrossRef]

- Shui, H.; Zhou, Y.; Li, H.; Wang, Z.; Lei, Z.; Ren, S.; Pan, C.; Wang, W. Thermal dissolution of Shenfu coal in different solvents. Fuel 2013, 108, 385–390.

- Griffith, J.M.; Clifford, C.E.B.; Rudnick, L.R.; Schobert, H.H. Solvent extraction of bituminous coals using light cycle oil: characterization of diaromatic products in liquids. Energy Fuels 2009, 23, 4553–4561. [CrossRef]

- Rahman, M.; Pudasainee, D.; Gupta, R. Review on chemical upgrading of coal: Production processes, potential applications and recent developments. Fuel Process. Technol. 2017, 158, 35–56. [CrossRef]

- Kuznetsov, P.N.; Kuznetsova, L.I.; Buryukin, F.A.; Marakushina, E.N.; Frizorger, V.K. Methods for the Preparation of Coal-Tar Pitch. Solid Fuel Chem. 2015, 49, 213−225. [CrossRef]

- Shimanoe, H.; Mashio, T.; Nakabayashi, K.; Inoue, T.; Hamaguchi, M.; Miyawaki, J.; Mochida, I.; Yoon, S.H. Manufacturing spinnable mesophase pitch using direct coal extracted fraction and its derived mesophase pitch based carbon fiber. Carbon 2019, 158, 922-929. [CrossRef]

- Yang, J.; Nakabayashi, K.; Miyawaki, J.; Yoon, S.H. Preparation of pitch based carbon fibers using hyper-coal as a raw material. Carbon 2016, 106, 28−36. [CrossRef]

- Hamaguchi, M. Prebaked Anode from Coal Extract (3) - Carbonization Properties of Hypercoal and Its Blends with Binder Pitch. In Light Metals; Suarez, C.E., Eds.; Springer, Cham. 2012; pp.1219-1221. [CrossRef]

- Craddock, J.D.; Rantell, T.D.; Hower, J.C.; Whitlow, D.T.; Wiseman, J.; Weisenberger, M.C. Anode coke from coal – A low cost approach. Fuel 2017, 187, 229–241. [CrossRef]

- Andrews, R.J.; Rantell, T.; Jacques, D.; Hower, J.C.; Gardner, J.S.; Amick, M. Mild coal extraction for the production of anode coke from Blue Gem coal. Fuel 2010, 89, 2640–2647. [CrossRef]

- Kuznetsov, P.N.; Kamenskiy, E.S.; Kuznetsova, L.I. Comparative study of the properties of the coal extractive and commercial pitches. Energy Fuels 2017, 31, 5402–5410. [CrossRef]

- Kuznetsov, P.N.; Kamenskiy, E.S.; Kuznetsova, L.I. Solvolysis of bituminous coal in coal- and petroleum-derived commercial solvents. ACS OMEGA 2020, 5, 14384–14393. [CrossRef]

- Kuznetsov, P.; Safin, V.; Avid, B.; Kuznetsova, L.; Purevsuren, B.; Ismagilov, Z. Thermal Dissolution of Coals of the Metamorphism Series in the Anthracene Fraction of Coking Tar: An Analysis of Correlations with the Chemical and Technological Properties of Coals. Solid Fuel Chem. 2021, 55, 69–77. [CrossRef]

- Safin, V.A.; Kuznetsov, P.N.; Avid, B.; Kuznetsova, L.I.; Fan, X.; Ismagilov, Z.R. The relationship between the molecular composition of coal and the conversion of its organic matter during thermal dissolution. Carbon Letters 2022, 32, 1101-1109. [CrossRef]

- Sobkowiak, M.; Painter, P. Determination of the aliphatic and aromatic CH contents of coals by FT-i.r.: studies of coal extracts. Fuel 1992, 71, 1105–1125. [CrossRef]

- Solomon, P.R.; Carangelo, R.M. FT-i.r. analysis of coal: 2. Aliphatic and aromatic hydrogen concentration. Fuel 1988, 67, 949–959. [CrossRef]

- Dick, C.; Ediger, V.; Fabbri, D.; Gaines, A.F.; Love, G.D.; McGinn, A.; McRae, C.; Murray, I.P.; Nicol, B.J.; Snape, C.E. Eastern Mediterranean Sapropels: chemical structure, deposition and relation to oil-shales. Fuel 2002, 81, 431–448. [CrossRef]

- Supaluknari, S.; Larkins, F.P.; Redlich, P.; Jackson, W.R. Determination of aromaticities and other structural features of Australian coals using solid state 13C NMR and FTIR spectroscopies. Fuel Process. Technol. 1989, 23, 47–61. [CrossRef]

- Diaz, C.; Blanco, C.G. NMR: A powerful tool in the characterization of coal tar pitch, Energy Fuels 2003, 17, 907–913. [CrossRef]

- Twigg, A.N.; Taylor, R.; Marsh, K.M.; Marr, G. The characterization of coal tar pitches used in electrode binder manufacture by n.m.r. spectroscopy. Fuel 1987, 66, 28–33. [CrossRef]

- Yang, H.; Xiong, Y.; Xie, Z.; Jin, L.; Li, Y.; Yang, J.; Hu, H. Quantitative characterization of coal structure by high-resolution CP/MAS 13C solid-state NMR spectroscopy. Proceedings of the Combustion Institute 2021, 38, 4161–4170. [CrossRef]

- Yoshida, T.; Nakata, Y.; Yoshida, R.; Ueda, S.; Kanda, N.; Maekawa, Y. Elucidation of structural and hydroliquefaction characteristics of Yallourn brown coal by 13C CP/MAS NMR spectrometry. Fuel 1982, 61, 824–830. [CrossRef]

- Solum. M.S.; Sarofim, A.F.; Pugmire, R.J.; Fletcher, T.H.; Zhang, H. 13C NMR Analysis of Soot Produced from Model Compounds and a Coal. Energy Fuels 2001, 15, 961–971. [CrossRef]

- Dı´az, J.; Paolicelli, G.; Ferrer, S.; Comin, F. Separation of the sp3 and sp2 components in the C1s photoemission spectra of amorphous carbon films. Physical Review B 1996, 54, 8864–8869. [CrossRef]

- Mateos, J.M.J.; Fierro, J.L.G. X-ray photoelectron spectroscopic study of petroleum fuel cokes. Surface and Interface Analysis 1996, 24, 223–236.

- Niu, H.; Zuo, P.; Shen, W.; Qu, S. Evaluating multistep oxidative stabilization behavior of coal tar pitch-based fiber. Journal of Applied Polymer Science 2020, 138, e50002. [CrossRef]

- Guan, T.; Zhang, G.; Zhao, J.; Wang, J.; Li, K. Insight into the oxidative reactivity of pitch fractions for predicting and optimizing the oxidation stabilization of pitch. Fuel 2019, 242, 184–194. [CrossRef]

- Machnikowski, J.; Kaczmarska, H.; Gerus-Piasecka, I.; Dez, M.A.; Alvarez, R.; Garca, R. Structural modification of coal-tar pitch fractions during mild oxidation-relevance to carbonization behavior. Carbon 2002, 40, 11, 1937-1947. [CrossRef]

- Russo, C.; Ciajolo, A.; Stanzione, F.; Tregrossi, A.; Oliano, M.M.; Carpentieri, A.; Apicella, B. Investigation on chemical and structural properties of coal- and petroleum-derived pitches and implications on physico-chemical properties (solubility, softening and coking). Fuel 2019, 245, 478–487. [CrossRef]

| Coal, solvent | Element composition, wt.% | BaP content, (mg/g) |

Distillation temperature range, °C |

Toluene-insolubles, wt.% | Quinoline-insolubles,wt.% | |||

| C | H | N+S+O | H/C at. | |||||

| Coal | 84.7* | 5.5* | 9.8* | 0.78 | - | – | – | – |

| CT | 91.5 | 5.3 | 3.2 | 0.69 | 8.1 | 180–550 | 11.6 | 1.8 |

| GO | 89.9 | 8.3 | 1.8 | 1.11 | 0.59 | 221–508 | 0.1 | <0.1 |

| Solvent used | Content, wt.% based on daf | H/C | Softening | ||||

| C | H | N | S | O | atom. | point, °C | |

| CT | 89.7 | 5.4 | 1.3 | 1.0 | 2.6 | 0.72 | 86 |

| GO | 90.3 | 7.4 | 0.6 | 0.9 | 0.8 | 0.98 | - |

| CT+GO | 88.7 | 6.6 | 1.1 | 1.3 | 2.3 | 0.89 | 82 |

| CT+GO, 3 h* | 89.7 | 5.9 | 1.2 | 1.4 | 1.8 | 0.79 | 90 |

| Commercial coal tar pitch | 92.5 | 4.6 | 1.1 | 0.6 | 1.2 | 0.60 | 88 |

| Solvent used | Group composition, wt.% based on daf product | |||

| TS | QS |

QIS (α1-fraction) |

QS-TIS (α2-fraction) |

|

| CT | 64.4 | 91.8 | 8.2 | 27.4 |

| GO | 77.6 | 92.1 | 7.9 | 14.5 |

| CT+GO | 73.0 | 92.9 | 7.1 | 19.9 |

| CT+GO, 3h | 71.0 | 90.8 | 9.2 | 19.8 |

| Commercial coal tar pitch |

64.9 | 89.5 | 10.5 | 24.6 |

| Solvent used | Aromaticity index | Ortho-substitution, Ios | CH3/CH2 | |

| Car | Har | |||

| CT | 0.87 | 0.67 | 0.44 | 0.42 |

| GO | 0.64 | 0.31 | 0.20 | 0.33 |

| CT+GO | 0.76 | 0.46 | 0.35 | 0,34 |

| CT+GO, 3 h | 0.78 | 0.50 | 0.37 | 0.41 |

| Solvent used | Proton distribution | Brown-Ladner structural parameters* | ||||||||

| Har | Ho | Hα | Hβ | Hγ | fa | Haru/Car | σ | n | ||

| CT | 0.65 | 0.02 | 0.18 | 0.12 | 0.03 | 0.88 | 0.63 | 0.16 | 1.8 | |

| GO | 0.30 | 0.01 | 0.28 | 0.34 | 0.07 | 0.64 | 0.68 | 0.37 | 2.6 | |

| CT+GO | 0.38 | 0.01 | 0.23 | 0.28 | 0.10 | 0.73 | 0.64 | 0.26 | 2.5 | |

| CT+GO, 3h | 0.44 | 0.002 | 0.22 | 0.27 | 0.07 | 0.78 | 0.58 | 0.23 | 2.5 | |

| Commercialcoal tar pitch | 0.67 | 0.02 | 0.15 | 0.13 | 0.03 | 0.91 | 0.50 | 0.12 | 2.0 | |

| Solvent used | CH3 |

CH2+ CH |

OCH3 | COC | CarO | C=O+ COOH |

Car3+ CarH |

including |

Car2+ CarC |

fa | |

| Car3 | CarH* | ||||||||||

| CT | 0.04 | 0.06 | 0.01 | 0.02 | 0.01 | 0 | 0.71 | 0.24 | 0.48 | 0.15 | 0.87 |

| GO | 0.13 | 0.15 | 0.02 | 0.04 | 0.04 | 0.02 | 0.42 | 0.12 | 0.30 | 0.18 | 0.64 |

| CT+GO | 0.09 | 0.10 | 0.01 | 0.02 | 0.01 | 0.01 | 0.59 | 0.18 | 0.41 | 0.17 | 0.77 |

| CT+GO, 3h | 0.08 | 0.11 | 0.003 | 0.01 | 0.01 | 0.01 | 0.61 | 0.21 | 0.40 | 0.17 | 0.79 |

| Solvent used | Surface concentration, % at | O/C atomic | N/C atomic | ||||||||

| C | O | N | Si | Ca | surface | bulk | surface | bulk | |||

| CT | 89.9 | 7.2 | 2.0 | 0.4 | 0.5 | 0.06 | 0.022 | 0.019 | 0.012 | ||

| GO | 85.6 | 13.5 | 0,6 | 0.2 | 0.1 | 0.12 | 0.007 | 0.006 | 0.006 | ||

| CT+GO | 87.2 | 9.9 | 1,4 | 0.3 | 0.2 | 0.08 | 0.019 | 0.014 | 0.011 | ||

| Commercial coal-tar pitch | 92.3 | 5.5 | 2.2 | - | - | 0.04 | 0.010 | 0.20 | 0.010 | ||

|

Solvent used |

Non-oxidized carbon | Oxidized carbon |

FWHM for CI, eV |

||||||

| CI | CII | total | C-O | C=O | COOH | total | |||

| CT | 0.60 | 0.28 | 0.88 | 0.06 | 0.03 | 0.03 | 0.12 | 1.25 | |

| GO | 0.44 | 0.28 | 0.72 | 0.14 | 0.08 | 0.06 | 0.28 | 1.54 | |

| CT+GO | 0.53 | 0.27 | 0.80 | 0.11 | 0.04 | 0.05 | 0.20 | 1.37 | |

| CT+GO, 3h | 0.55 | 0.28 | 0.83 | 0.11 | 0.03 | 0.03 | 0.17 | 1.35 | |

| Commercial coal tar pitch |

0.74 | 0.16 | 0.90 | 0.07 | 0.01 | 0.02 | 0.10 | 1.23 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).