Submitted:

05 February 2025

Posted:

05 February 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

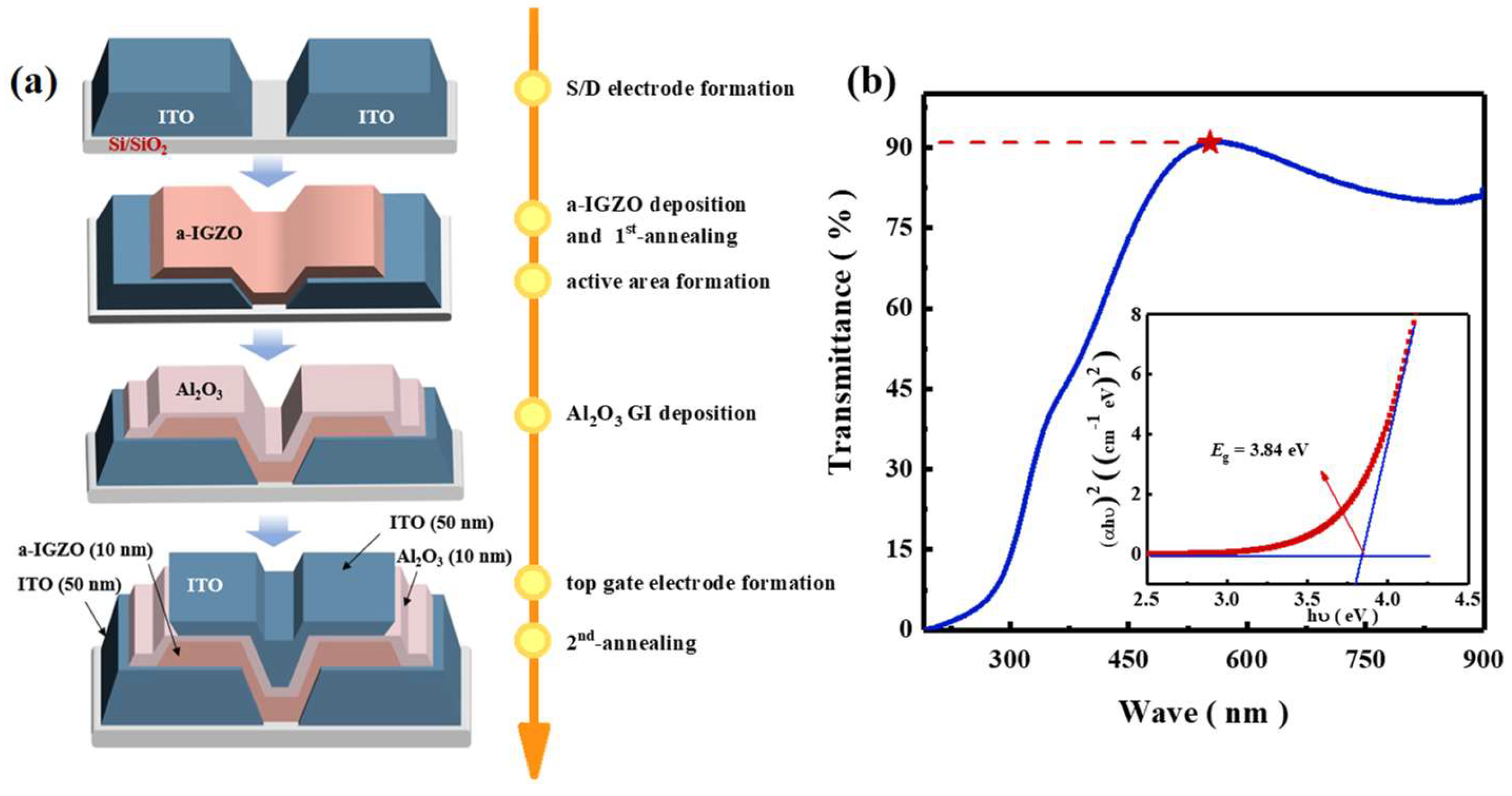

2. Materials and Methods

3. Results

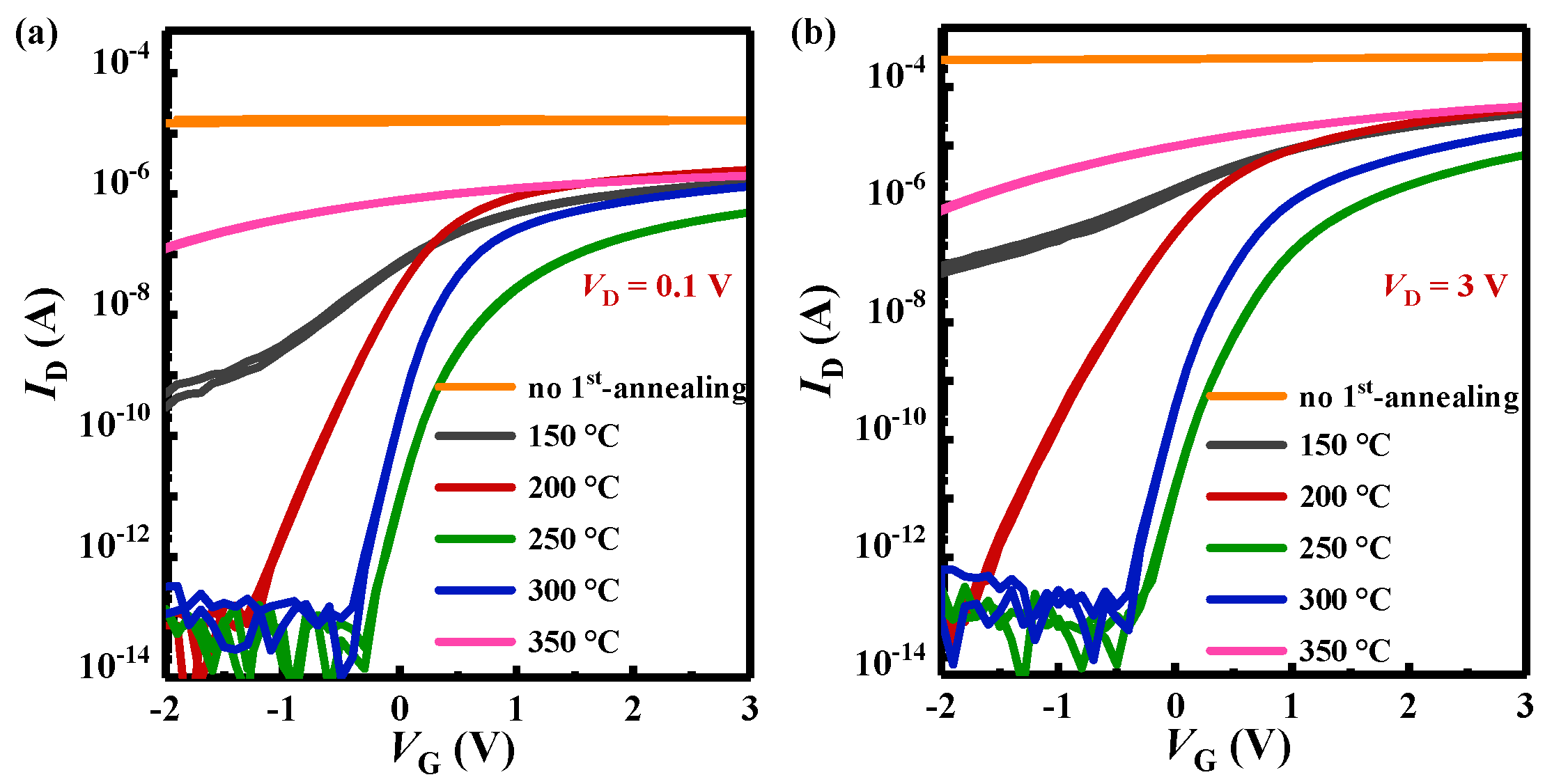

3.1. Optical and Electric characteristics of TG-TFTs

| Parameters T (°C) |

Vth-lin(V) | Vth-sat(V) |

μsat (cm2V-1s-1) |

Ion/Ioff (VD = 3 V) |

SS (mV/dec) |

Nt (eV-1cm-2) |

|---|---|---|---|---|---|---|

| 150 | -1.13 | -1.23 | 9.13 | 4.03×103 | -- | -- |

| 200 | -0.53 | -0.83 | 30.52 | 4.46×108 | 203 | 6.10×1012 |

| 250 | 1.12 | 0.78 | 6.87 | 6.98×107 | 137 | 3.28×1012 |

| 300 | 0.52 | 0.33 | 13.05 | 1.73×108 | 130 | 2.98×1012 |

| 350 | -2.05 | -3.05 | -- | 7.2 | -- | -- |

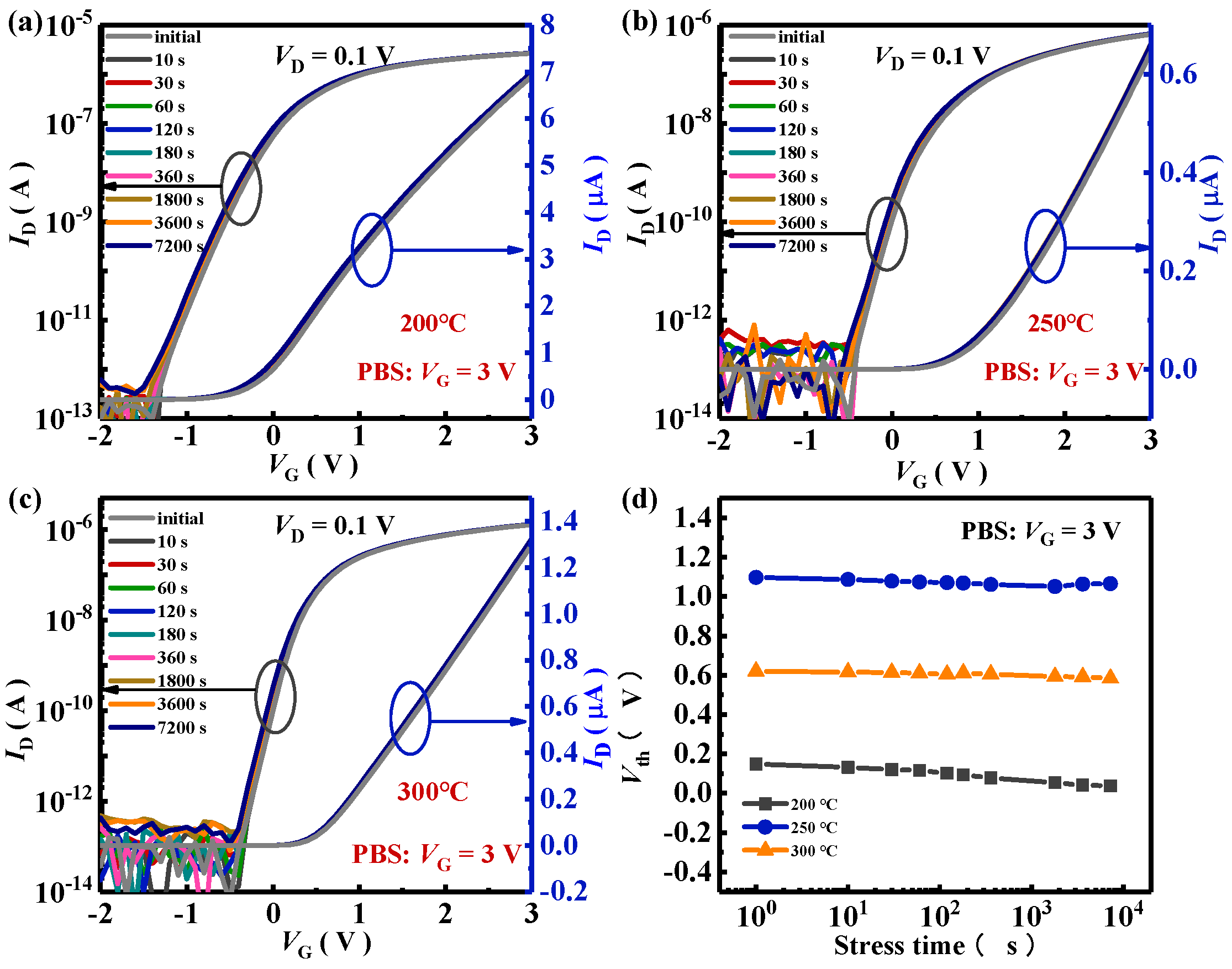

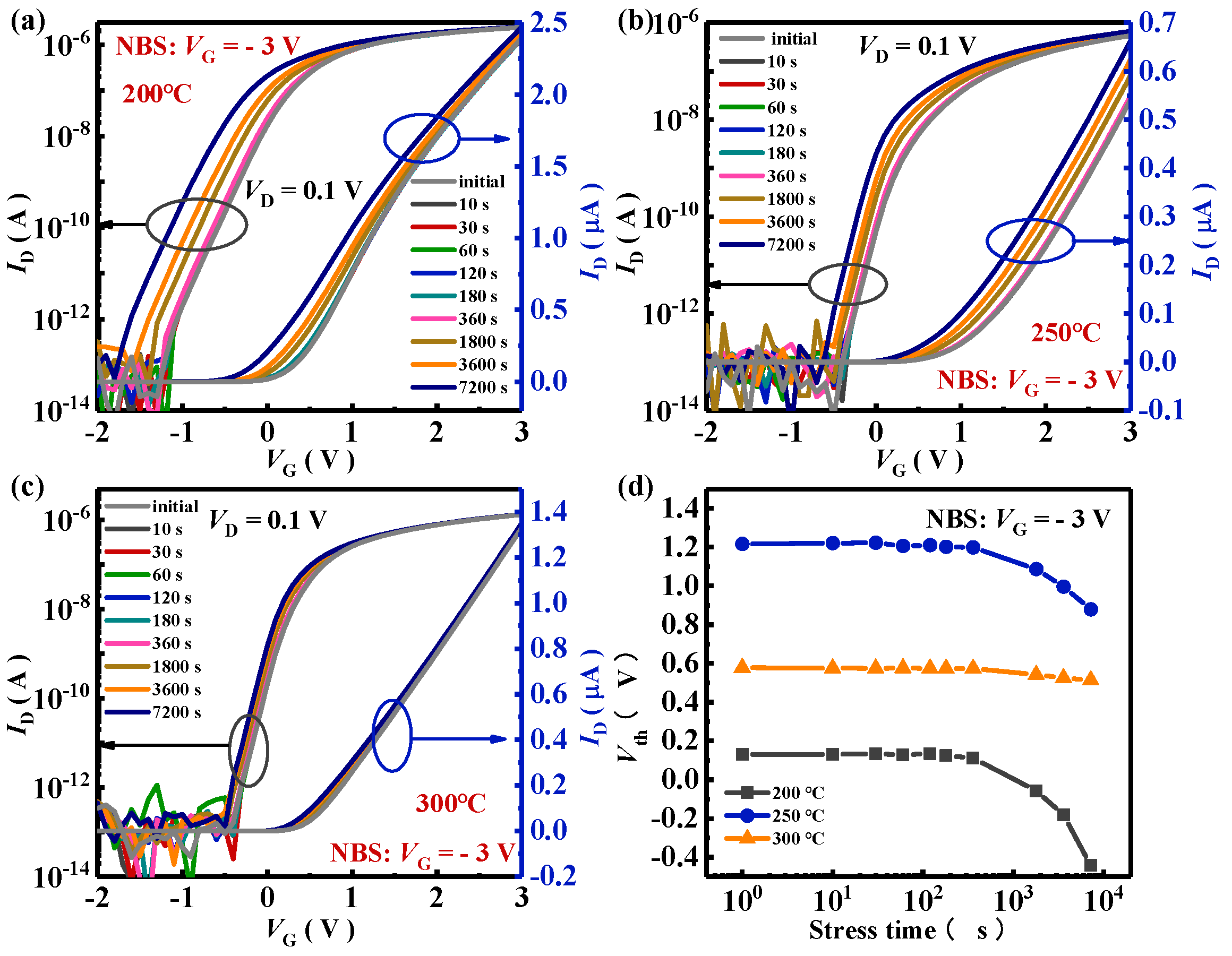

3.2. Electrical stability test on a-IGZO TG-TFTs

3.3. 1st-annealing effect on a-IGZO films

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Y. Kim, G. J. Y. Kim, G. J. Jeon, M. K. Lee, S. H. Lee and S. H. K. Park, "Transparent top gate oxide TFT with ITO/Ag/ITO low resistance electrode for the application to the high speed operation fingerprint sensor array in the touch panel," in 13th Symposium on Thin Film Transistor Technologies (TFT), Ed., pp. 247-251, Honolulu, HI, 2016.

- M. Mativenga, F. M. Mativenga, F. Haque and Ieee, "Highly Stable Thin-Film Transistors for Flexible and Transparent Displays," in IEEE International Conference on Electrical, Computer, and Energy Technologies (ICECET), Ed., pp. 2273-2278, Cape Town, SOUTH AFRICA, 2021.

- J. Fan, L. J. Fan, L. Chia-Yu, C. Shu-jhih, G. Liu Ming, J. Zhang Li, Y. Sun, C. Lu Ma, F. Xie Hua, N. Liu, S. Jianqing, S. Chongyu and L. Jay Guoxu, "High transparent Active matrix Mini-LED Full Color Display with IGZO TFT Backplane," SID Symposium Digest of Technical Papers, vol. 50, no. 1, pp. 454-456, 2019.

- Y. B. Li and T. P. Chen, "Enhancement in Performance and Reliability of Transparent IGZO Thin-Film Transistors by ITO/Ti Stacked Source/Drain Contacts," Ecs Journal of Solid State Science and Technology, vol. 12, no. 9, pp. 095003, 2023.

- J. Li, Y. J. Li, Y. Zhang, J. Wang, H. Yang, X. Zhou, M. Chan, X. Wang, L. Lu and S. Zhang, "Near-Ideal Top-Gate Controllability of InGaZnO Thin-Film Transistors by Suppressing Interface Defects with an Ultrathin Atomic Layer Deposited Gate Insulator," ACS applied materials & interfaces, vol. 15, no. 6, pp. 8666-8675, 2023.

- H. Ning, X. H. Ning, X. Zeng, H. Zhang, X. Zhang, R. Yao, X. Liu, D. Luo, Z. Xu, Q. Ye and J. Peng, "Transparent Flexible IGZO Thin Film Transistors Fabricated at Room Temperature," Membranes, vol. 12, no. 1, pp. 1-7, 2022.

- Y.-D. Kim, K.-L. Y.-D. Kim, K.-L. Han, J.-H. Kim, J.-I. Lee, W.-B. Lee, J.-S. Park and B.-D. Choi, "Effects of Tensile Strain on Dynamic and Static Inverters Using Amorphous Indium-Gallium-Zinc-Oxide TFTs," Ieee Electron Device Letters, vol. 42, no. 3, pp. 359-362, 2021.

- R. Velichko, Y. R. Velichko, Y. Magari and M. Furuta, "Defect Passivation and Carrier Reduction Mechanisms in Hydrogen-Doped In-Ga-Zn-O (IGZO:H) Films upon Low-Temperature Annealing for Flexible Device Applications," Materials, vol. 15, no. 1, pp. 334, 2022.

- Y. Hanyu, K. Y. Hanyu, K. Abe, K. Domen, K. Nomura, H. Hiramatsu, H. Kumomi, H. Hosono and T. Kamiya, "Effects of High-Temperature Annealing on Operation Characteristics of a-In-Ga-Zn-O TFTs," Journal of Display Technology, vol. 10, no. 11, pp. 979-983, 2014.

- N. Oka, T. N. Oka, T. Aoi, R. Hayashi, H. Kumomi and Y. Shigesato, "Electronic State of Amorphous Indium Gallium Zinc Oxide Films Deposited by DC Magnetron Sputtering with Water Vapor Introduction," Applied Physics Express, vol. 5, no. 7, pp. 075802, 2012.

- W. Zhang, Z. W. Zhang, Z. Fan, A. Shen and C. Dong, "Atmosphere Effect in Post-Annealing Treatments for Amorphous InGaZnO Thin-Film Transistors with SiOx Passivation Layers," Micromachines, vol. 12, no. 12, pp. 1551, 2021.

- D. H. Kang, I. D. H. Kang, I. Kang, S. H. Ryu, Y. S. Ahn and J. Jang, "Effect of SiO2 and/or SiNx Passivation Layer on Thermal Stability of Self-Aligned Coplanar Amorphous Indium-Gallium-Zinc-Oxide Thin-Film Transistors," Journal of Display Technology, vol. 9, no. 9, pp. 699-703, 2013.

- H.-H. Hsieh, T. H.-H. Hsieh, T. Kamiya, K. Nomura, H. Hosono and C.-C. Wu, "Modeling of amorphous InGaZnO4 thin film transistors and their subgap density of states," Applied Physics Letters, vol. 92, no. 13, pp. 133503, 2008.

- W.-T. Chen, S.-Y. W.-T. Chen, S.-Y. Lo, S.-C. Kao, H.-W. Zan, C.-C. Tsai, J.-H. Lin, C.-H. Fang and C.-C. Lee, "Oxygen-Dependent Instability and Annealing/Passivation Effects in Amorphous In-Ga-ZnO Thin-Film Transistors," Ieee Electron Device Letters, vol. 32, no. 11, pp. 1552-1554, 2011.

- S. G. M. Aman, Y. S. G. M. Aman, Y. Magari, K. Shimpo, Y. Hirota, H. Makino, D. Koretomo and M. Furuta, "Low-temperature (150 °C) activation of Ar+O2+H2-sputtered In-Ga-Zn-O for thin-film transistors," Applied Physics Express, vol. 11, no. 8, pp. 081101, 2018.

- S. Zheng, S. S. Zheng, S. Lv, C. Wang, Z. Li, L. Dong, Q. Xin, A. Song, J. Zhang and Y. Li, "Post-annealing effect of low temperature atomic layer deposited Al2O3 on the top gate IGZO TFT," Nanotechnology, vol. 35, no. 15, 2024.

- K. Nomura, T. K. Nomura, T. Kamiya, H. Ohta, M. Hirano and H. Hosono, "Defect passivation and homogenization of amorphous oxide thin-film transistor by wet O2 annealing," Applied Physics Letters, vol. 93, no. 19, pp. 192107, 2008.

- H.-W. Lee and W.-J. Cho, "Effects of vacuum rapid thermal annealing on the electrical characteristics of amorphous indium gallium zinc oxide thin films," Aip Advances, vol. 8, no. 1, pp. 015007, 2018.

- N. Thi Thu Thuy, B. N. Thi Thu Thuy, B. Aventurier, O. Renault, T. Terlier, J. P. Barnes, F. Templier and Ieee, "Impact of hydrogen diffusion on electrical characteristics of IGZO TFTs passivated by SiO2 or Al2O3," in 21st International Workshop on Active-Matrix Flatpanel Displays and Devices - TFT Technologies and FPD Materials (AM-FPD), Ed., pp. 149-152, Ryukoku Univ, Kyoto, JAPAN, 2014.

- C. Wang, C. C. Wang, C. Zeng, H. Ning, F. Li, M. Liu, K. Xu and F. Ma, "Enhanced performances of a-IGZO TFTs with oxide passivation layers fabricated by hollow cathode assisted PLD," Journal of Alloys and Compounds, vol. 961, no. 170972, pp. 1-15, 2023.

- C. Peng, S. C. Peng, S. Yang, C. Pan, X. Li and J. Zhang, "Effect of Two-Step Annealing on High Stability of a-IGZO Thin-Film Transistor," Ieee Transactions on Electron Devices, vol. 67, no. 10, pp. 4262-4268, 2020.

- J. Li, Y. J. Li, Y. Zhang, J. Wang, H. Yang, X. Zhou, M. Chan, X. Wang, L. Lu and S. Zhang, "High-Performance Self-Aligned Top-Gate Amorphous InGaZnO TFTs With 4 nm-Thick Atomic-Layer-Deposited AlOX Insulator," Ieee Electron Device Letters, vol. 43, no. 5, pp. 729-732, 2022.

- M. Yokoyama, Y. M. Yokoyama, Y. Asakura, H. Yokoyama, M. Takenaka, S. Takagi and Ieee, "Impact of Al2O3 ALD temperature on Al2O3/GaSb metal-oxide-semiconductor interface properties," in 2013 International Conference on Indium Phosphide and Related Materials, Ed., pp. 6132, 2013.

- P. Ma, L. P. Ma, L. Du, Y. Wang, R. Jiang, Q. Xin, Y. Li and A. Song, "Low voltage operation of IGZO thin film transistors enabled by ultrathin Al2O3 gate dielectric," Applied Physics Letters, vol. 112, no. 2, pp. 023501, 2018.

- S. W. Tsao, T. C. S. W. Tsao, T. C. Chang, S. Y. Huang, M. C. Chen, S. C. Chen, C. T. Tsai, Y. J. Kuo, Y. C. Chen and W. C. Wu, "Hydrogen-induced improvements in electrical characteristics of a-IGZO thin-film transistors," Solid-State Electronics, vol. 54, no. 12, pp. 1497-1499, 2010.

- Y.-H. Chang, M.-J. Y.-H. Chang, M.-J. Yu, R.-P. Lin, C.-P. Hsu and T.-H. Hou, "Abnormal positive bias stress instability of InGaZnO thin-film transistors with low-temperature Al2O3 gate dielectric," Applied Physics Letters, vol. 108, no. 3, pp. 033502, 2016.

- J. T. Jang, D. J. T. Jang, D. Ko, S.-J. Choi, D. M. Kim and D. H. Kim, "Observation of Hydrogen-Related Defect in Subgap Density of States and Its Effects Under Positive Bias Stress in Amorphous InGaZnO TFT," Ieee Electron Device Letters, vol. 42, no. 5, pp. 708-711, 2021.

- Y.-T. Chien, Y.-L. Y.-T. Chien, Y.-L. Tsai, K.-J. Zhou, Y.-Z. Zheng, M.-C. Tai, H.-Y. Tu, C.-W. Kuo, T.-C. Chang and T.-M. Tsai, "Performance Enhancement of InGaZnO Top-Gate Thin Film Transistor With Low-Temperature High-Pressure Fluorine Treatment," Ieee Electron Device Letters, vol. 42, no. 11, pp. 1611-1614, 2021.

- T. Morimoto, Y. T. Morimoto, Y. Yang, Y. Ochiai, N. Fukuda and Y. Ohki, "Effects of metal content on electrical and physical properties in solution-processed IGZO thin films," Applied Physics a-Materials Science & Processing, vol. 126, no. 5, pp. 03579-03572, 2020.

- S. H. Jeong, B. S. S. H. Jeong, B. S. Bae, K. M. Yu, M. K. Ryu, K. I. Cho and E.-J. Yun, "Properties of IGZO thin films irradiated by electron beams with various energies," Journal of the Korean Physical Society, vol. 61, no. 6, pp. 867-872, 2012.

- A. Hino, T. Kishi, S. Morita, K. Hayashi and T. Kugimiya, "Study of electronic structure and composition at back channel surface of amorphous In-Ga-Zn-O thin films," in 11th Symposium on Thin Film Transistor Technologies (TFT), Ed., pp. 197-202, Honolulu, HI, 2012.

- Y. Takamori, T. Morimoto, N. Fukuda and Y. Ohki, "Effects of ultraviolet photon irradiation and subsequent thermal treatments on solution-processed amorphous indium gallium zinc oxide thin films," Aip Advances, vol. 8, no. 11, pp. 115304, 2018.

- E. K.-H. Yu, S. Jun, D. H. Kim and J. Kanicki, "Density of states of amorphous In-Ga-Zn-O from electrical and optical characterization," Journal of Applied Physics, vol. 116, no. 15, pp. 154505, 2014.

- H. Pu, Q. Zhou, L. Yue and Q. Zhang, "Investigation of oxygen plasma treatment on the device performance of solution-processed a-IGZO thin film transistors," Applied Surface Science, vol. 283, pp. 722-726, 2013.

- Y. Y. Zhang, L. X. Qian, W. B. Ge, P. T. Lai and X. Z. Liu, "Tailoring the Band Alignment of GaxZn1-xO/InGaZnO Heterojunction for Modulation-Doped Transistor Applications," Physica Status Solidi a-Applications and Materials Science, vol. 215, no. 18, pp. 180032, 2018.

- H.-K. Noh, K. J. Chang, B. Ryu and W.-J. Lee, "Electronic structure of oxygen-vacancy defects in amorphous In-Ga-Zn-O semiconductors," Physical Review B, vol. 84, no. 11, pp. 115205, 2011.

- C.-K. Kim, E. Kim, M. K. Lee, J.-Y. Park, M.-L. Seol, H. Bae, T. Bang, S.-B. Jeon, S. Jun, S.-h. K. Park, K. C. Choi and Y.-K. Choi, "Electrothermal Annealing (ETA) Method to Enhance the Electrical Performance of Amorphous-Oxide-Semiconductor (AOS) Thin-Film Transistors (TFTs)," Acs Applied Materials & Interfaces,vol. 8, no. 36, pp. 23820-23826, 2016.

- H. Xie, Y. Zhou, Y. Zhang and C. Dong, "Chemical bonds in nitrogen-doped amorphous InGaZnO thin film transistors," Results in Physics, vol. 11, no. 2018, pp. 1080-1086.

- R. Kishore, K. Vishwakarma and A. Datta, "Effect of Non-identical Annealing on the Breakdown Characteristics of Sputtered IGZO Films," 2022 IEEE International Reliability Physics Symposium (IRPS), pp. P24(24pp)-P24(24pp), 2022.

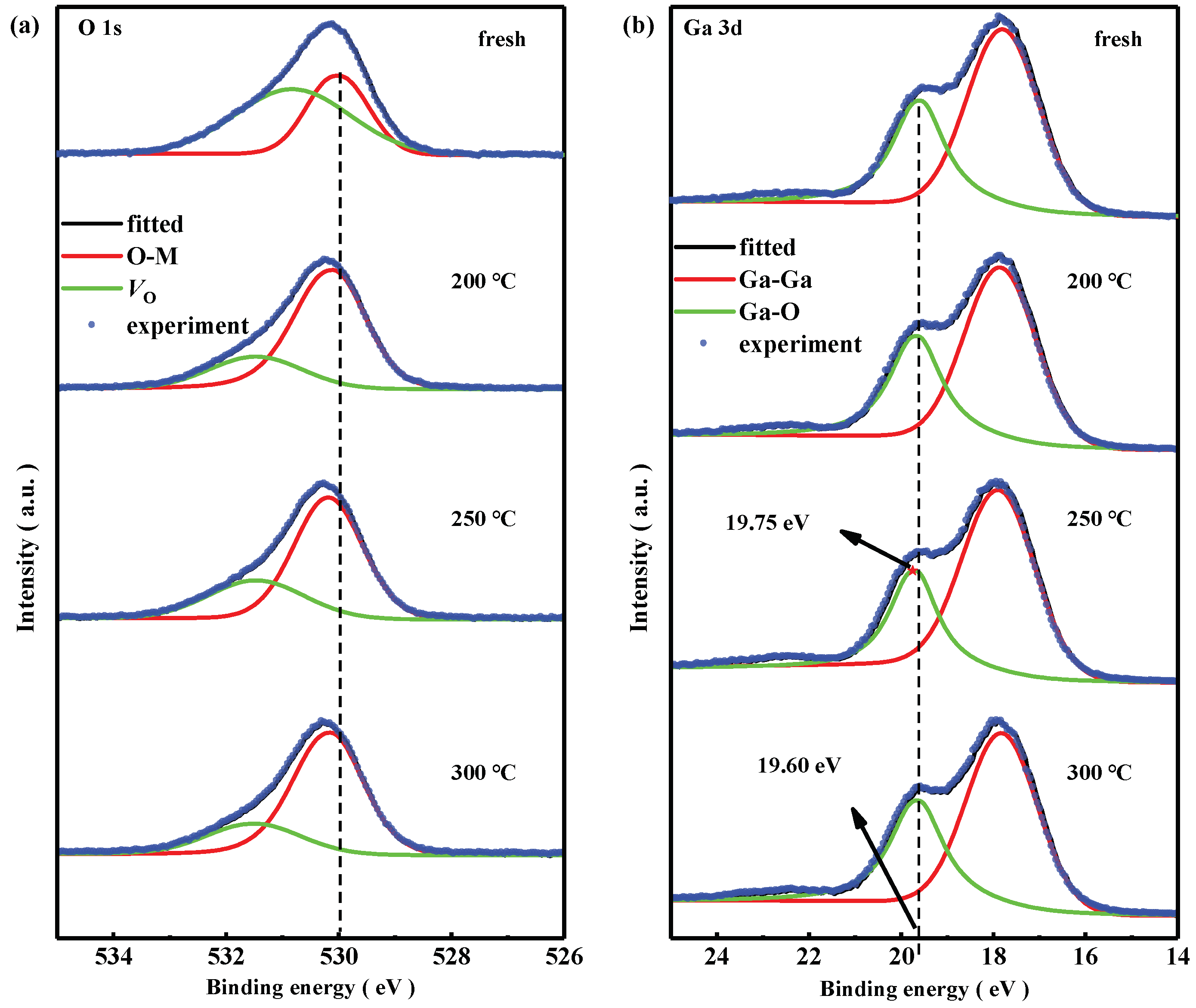

| Annealing condition (°C) | Content (%) | |||

| VO | O-M | Ga-Ga | Ga-O | |

| fresh | 26.60 | 17.27 | 23.74 | 12.82 |

| 200 | 11.17 | 32.57 | 23.81 | 12.92 |

| 250 | 12.84 | 30.45 | 25.85 | 11.18 |

| 300 | 11.01 | 32.44 | 23.6 | 13.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).