1. Introduction

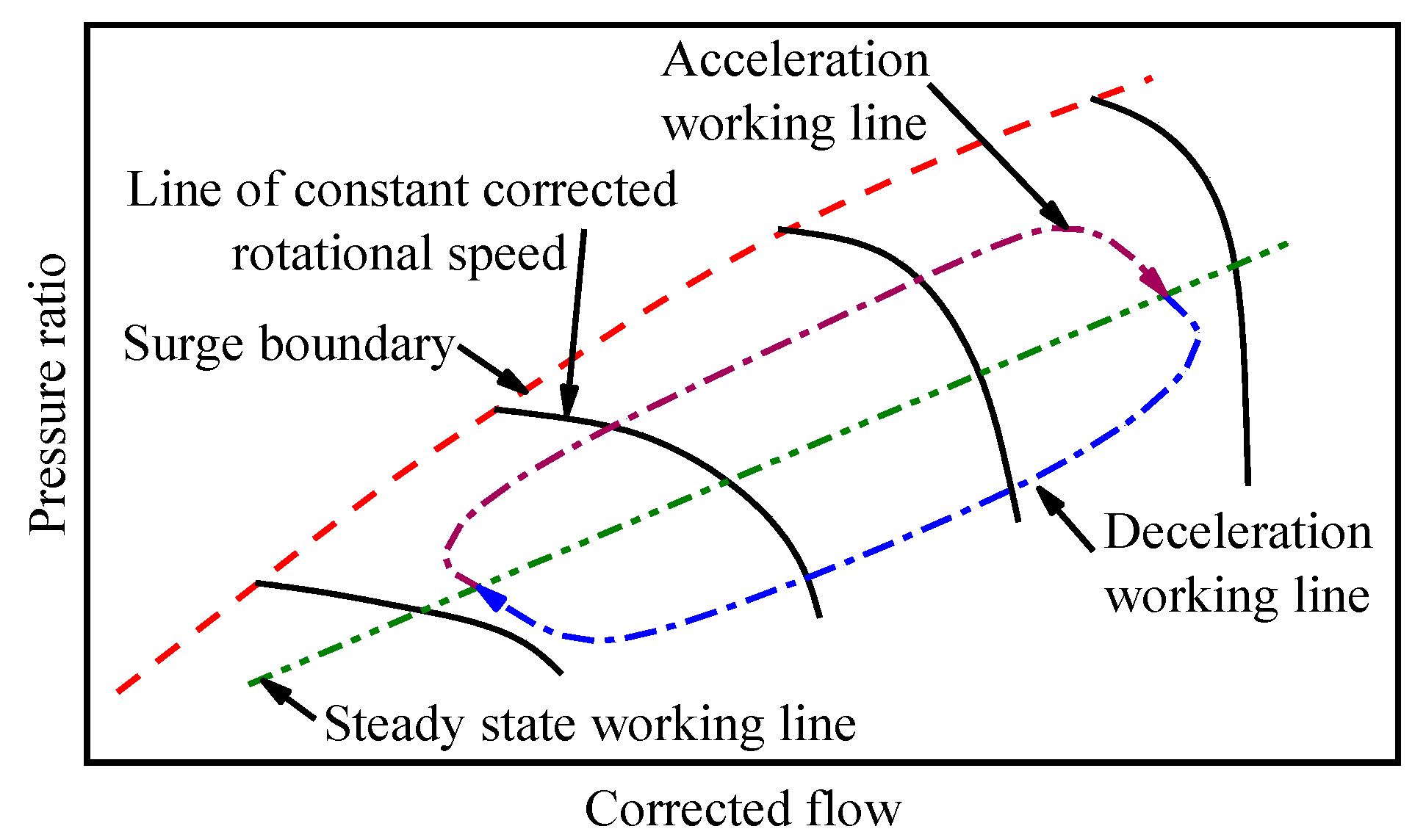

The transition performance of aero-engines plays a crucial role in aircraft maneuverability. However, due to the complexity and strong nonlinearity of aero-engines, it is difficult to quickly design the optimal transition control schedules within the constraints[

1,

2]. At present, there are mainly two types of optimization methods for the transition control schedules of aero-engines, which are the pointwise optimization methods and the global optimization methods.

The pointwise optimization methods discretize the optimization problem of the transition control schedules into sub-optimization problems at each time step or discrete operating point. These methods attempt to adjust the engine’s adjustable parameters within each sub-optimization problem, enabling the engine to complete transition operation rapidly and smoothly. Hao [

3] and Zheng [

4] ignored the engine’s dynamic effects and optimized the adjustable parameters of key working points in the transition process based on the engine’s steady-state model. Although a smooth mode transition of the variable cycle engine was achieved, the neglect of dynamic effects led to low design accuracy of the transition control schedules and inability to guarantee the minimum mode transition time. Chen [

5] and Kurzke [

6] proposed the virtual power extraction method that can use the power extraction for the steady state of the engine to simulate the remaining power in the dynamic process. Thus, the transition control schedules of the engine can be analyzed and optimized at discrete steady-state operating points. Jia [

7,

8] proposed a dynamic state reverse method based on the virtual power extraction method. This method incorporates specific adjustable parameters and performance parameters of the engine into the unknown variables and equilibrium variables of the equations for the engine model respectively. During the process of solving the engine equations, the adjustable parameters corresponding to the specified performance parameters can be automatically solved, thus simplifying the design process of the transition control schedules. However, the virtual power extraction method assumes that the relationship between the rotational speeds of the high-pressure and low-pressure rotors in the transition state is the same as that in the steady state. Moreover, it ignores dynamic factors such as the volume effect, resulting in a low design accuracy of the transition control schedules. Lu et al. [

9] iterated the virtual power extraction method and used the optimized transition control schedules from the previous step to calculate the relationship between the rotational speeds of the high-pressure and low-pressure rotors. Although this has improved the optimization accuracy, it has also multiplied the optimization time. Qi [

10] and Li [

11] proposed a kind of pointwise optimization method that directly optimizes the adjustable parameters of the engine at each time step during the transition state, and obtained the control schedule curves of fuel flow rate and nozzle throat area during the acceleration process. The pointwise optimization methods are widely used for various aero-engines due to their relatively fast optimization speed [

12,

13,

14]. However, since they don’t consider the relationship between working points in the transition state, there are fluctuations in the optimized control schedules [

15]. Zhao et al. [

16] constrained the adjustable parameters at the current time step according to the predicted values of the performance parameters in the next few time steps. Although this suppresses the high-frequency fluctuations of the control schedules, it prolongs the transition time. Hao [

17,

18,

19] and Zhang [

20] added constraints on the change rate of adjustable parameters in pointwise optimization, largely inhibiting the high-frequency fluctuations of control schedules. However, there are still low-frequency fluctuations. To suppress the fluctuation problem that occurs in the pointwise optimization methods, the global optimization methods are proposed.

The global optimization methods parameterize the transition control schedule curves into discrete control points. These methods directly optimize the control points to minimize the transition time. Moreover, it is quite easy to enhance the smoothness of the control curves by various means. Zhang et al. [

21] restricted the control parameters to change monotonically during the global optimization. While this enhanced the smoothness of the control schedules, it significantly limited the flexibility of the control schedules, thus making it impossible to guarantee the shortest transition time. Zheng et al. [

15]. used Bezier curves to construct the control schedules for fuel flow ratio and nozzle throat area, and directly optimized the control points of the Bezier curves to minimize the acceleration time. The smoothness of the Bezier curve effectively suppresses the fluctuation problem of the control schedules. Song et al. [

22] introduced the maximum entropy theory in the global optimization. They suppressed the high-frequency fluctuations by maximizing the entropy value of the control schedules. Additionally, they suppressed the low-frequency fluctuations through the piecewise linearization of the optimized control schedules. Although the global optimization methods demonstrate advantages in suppressing fluctuations of control schedules, they involve numerous control points of the control schedules, which leads to a high-dimensional global optimization problem. Moreover, repeated evaluations of transition times for different control schedules make the optimization time cost unacceptable. To reduce the time for global optimization, Ye et al. [

23,

24,

25] used surrogate models to estimate the engine’s transition time. However, due to the complexity of the aero-engines, it is difficult to guarantee the accuracy of surrogate models, which leads to noticeable differences in the control schedules and transition times obtained from different surrogate models.

In this paper, a combined optimization method for the transition control schedules of aero-engines is proposed. This method divides the optimization of control schedules into two layers. For the inner-layer optimization, the pointwise optimization technique is used to quickly optimize the control schedules that usually do not fluctuate. For the outer-layer optimization, the global optimization technique is employed to suppress the control schedules that are prone to fluctuations. Furthermore, to reduce the time cost of global optimization, a construction method for non-uniformly distributed control points is proposed. Thus, the number of control points that need to be optimized can be reduced.

The rest of this paper is organized as follows.

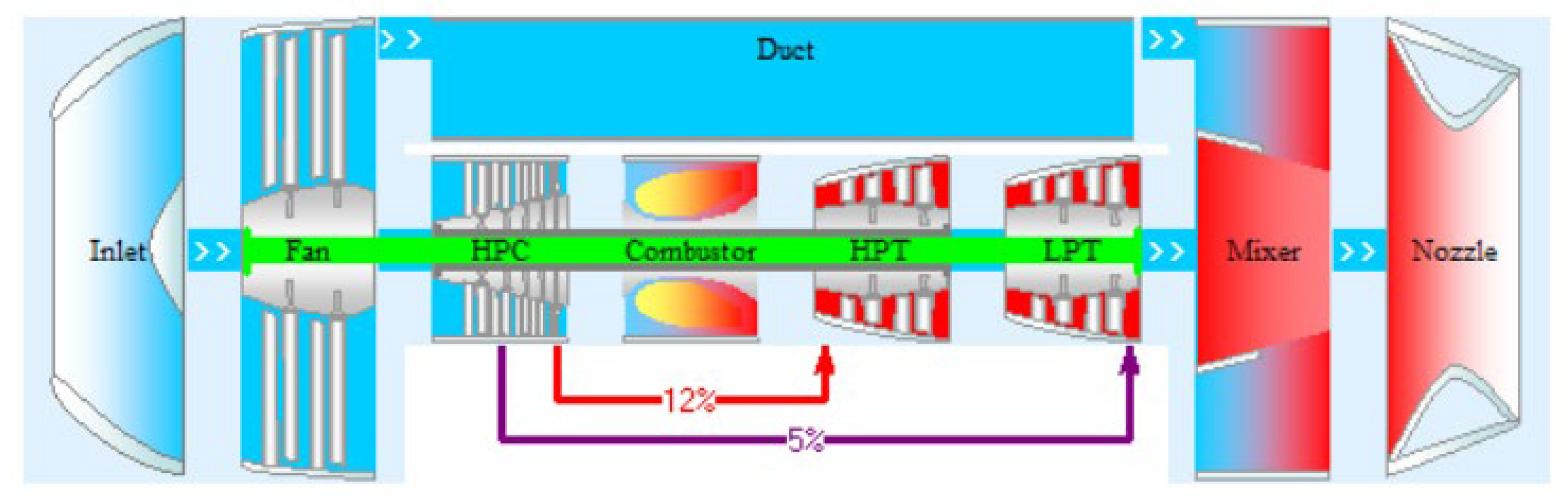

Section 2 introduces the transition optimization problem of engines.

Section 3 elaborates on the principle, process and innovation of the combined optimization method. In

Section 4, the method is applied to the optimization of acceleration and deceleration control schedules for a mixed-flow turbofan engine to verify its effectiveness and advancement.

Section 5 presents a summary of this paper.

3. Combined Optimization Method

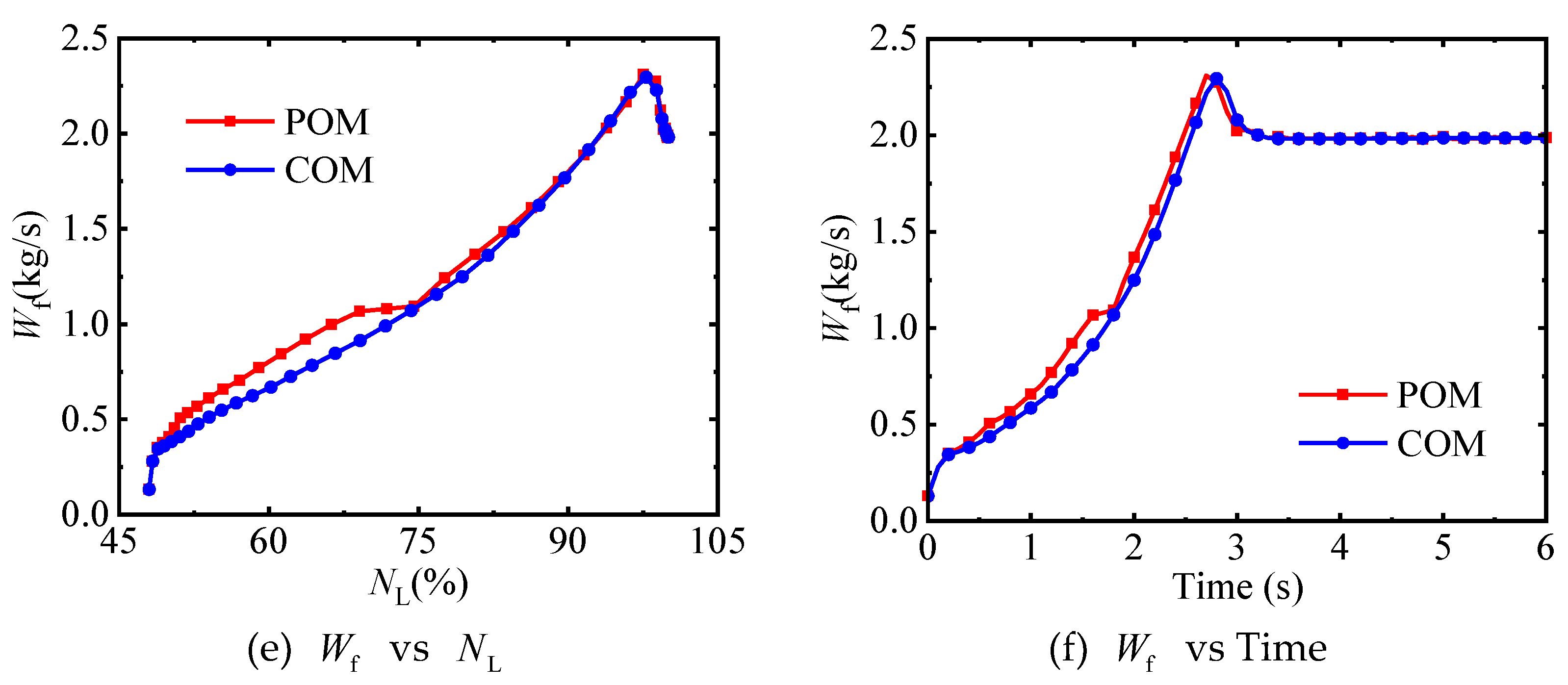

Generally, the fuel flow rate has a strong correlation with the transient performance of the engine. According to the results in references [

9] and [

10], even when the pointwise optimization method is adopted, the optimized control schedule of the fuel flow rate is quite smooth. Compared with the fuel flow rate, the geometrically adjustable parameters have a weaker correlation with the transient performance of the engine. Moreover, there is a strong coupling relationship among the geometrically adjustable parameters. According to the results in references [

22] and [

23], even when the global optimization method is adopted, the geometrically adjustable parameters will still fluctuate. Apparently, traditional optimization methods overlook the disparities among different adjustable parameters. They directly incorporate all adjustable parameters into the optimization variables, which imposes a heavy burden on the optimization algorithm and makes it very difficult to quickly optimize smooth control schedules.

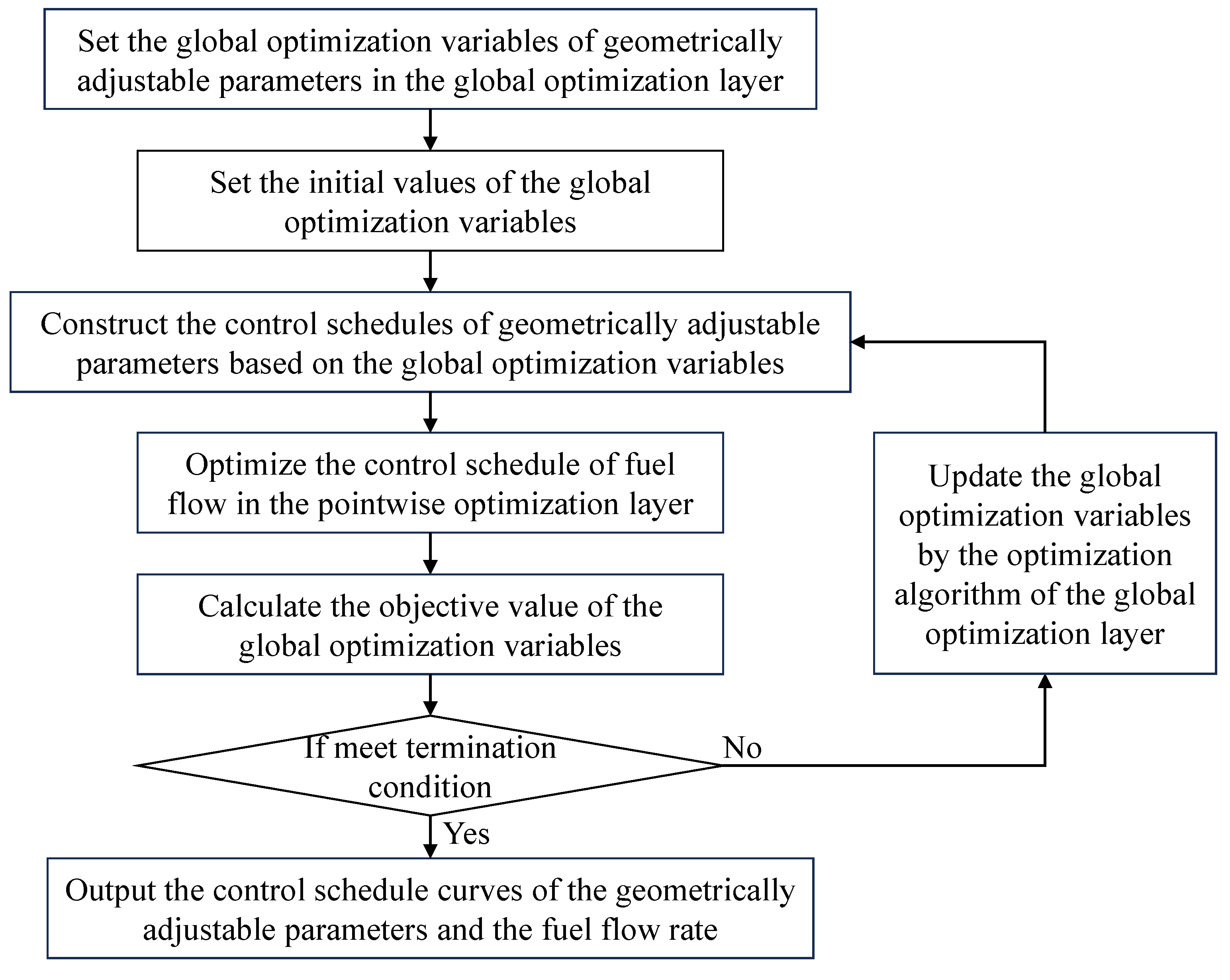

The combined optimization method proposed in this paper divides the optimization of the dynamic control schedules into two layers. In the outer-layer optimization, the global optimization technique is applied to suppress the geometrically adjustable parameters that are prone to fluctuations. In the inner-layer optimization, the pointwise optimization technique is used to quickly obtain the control schedule of the fuel flow rate. Furthermore, the global optimization technology has been improved, which can significantly reduce the time cost of global optimization. The flowchart of the combined optimization method is shown in

Figure 2.

Specifically, the combined optimization method involves the following steps:

1) Set the global optimization variables of geometrically adjustable parameters in the global optimization layer.

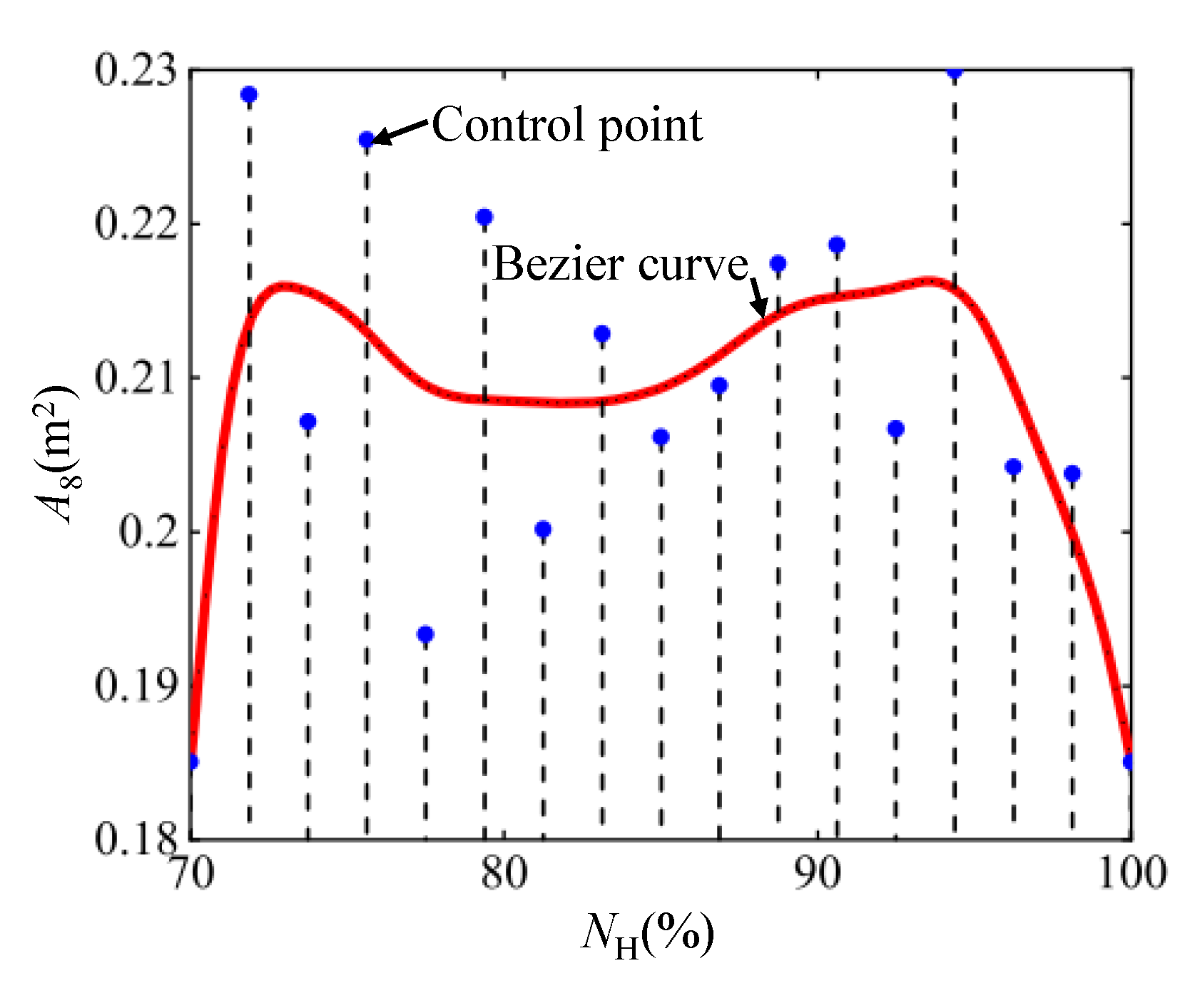

Generally, traditional global optimization methods uniformly divide the adjustable parameters into multiple control points according to time or rotor speed. For example, in Reference [

23], the uniformly-distributed control points for the Bezier curve of the nozzle throat area versus the high-pressure rotor speed are optimized, as shown in

Figure 3. However, an excessive number of control points makes the dimension of global optimization extremely high, which greatly intensifies the difficulty of global optimization. In addition, the control schedules for engineering applications are required to be as simple as possible, so as to reduce the burden of the controller. In the case of uniformly-distributed control points, the number of control points cannot be directly reduced. Otherwise, the degree of freedom of the control schedules will be limited. Therefore, a construction method for non-uniformly distributed control points is proposed.

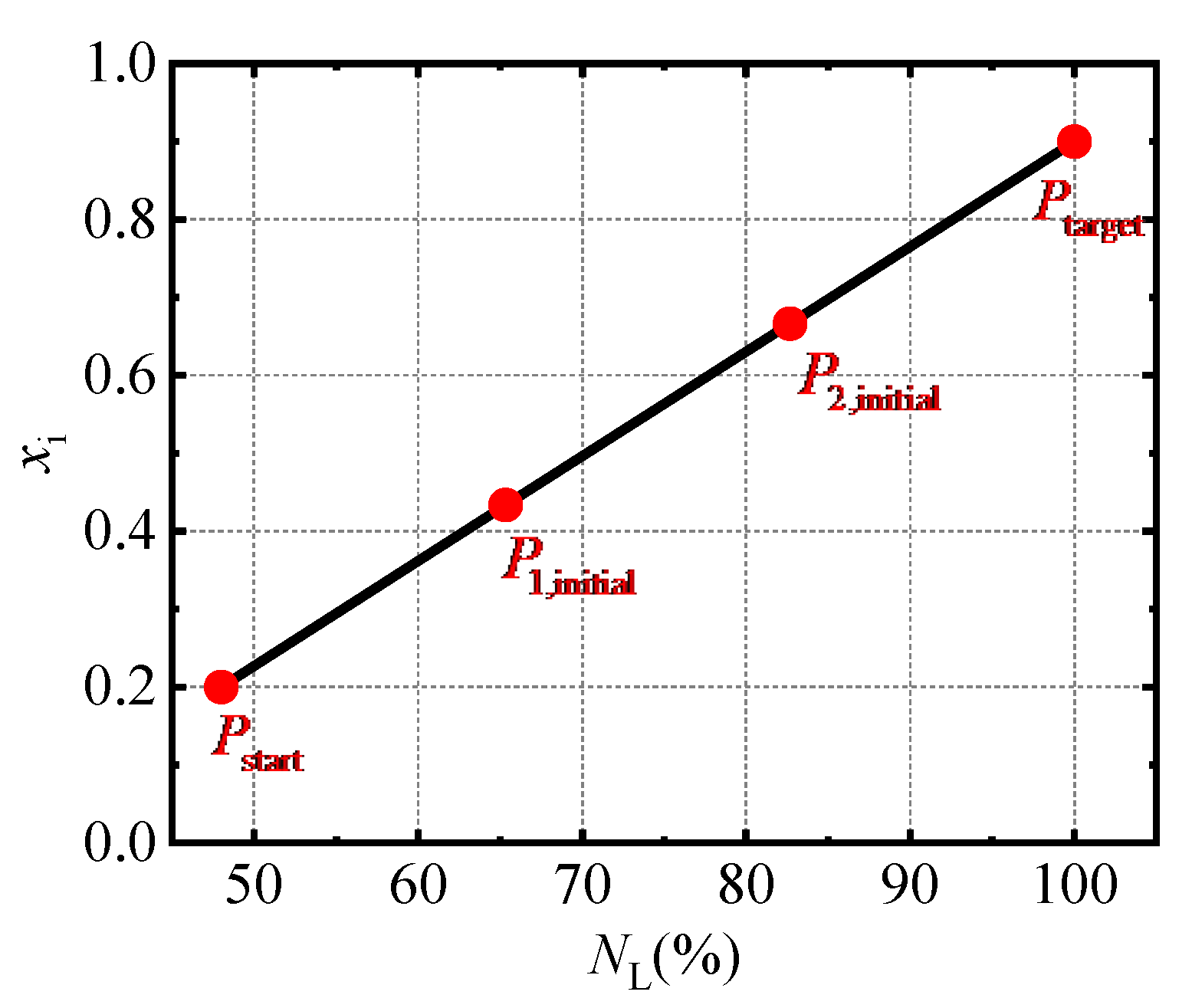

In this paper, the low-pressure rotor speed

is selected as the independent variable of the control schedule. For the

i-th adjustable parameter

, the non-uniform distribution of two control points is shown in

Figure 4. If the coordinate values of the control points are directly taken as the optimization variables, the optimization algorithm cannot guarantee that the rotor speeds of the control points increase monotonically, i.e.,

. Therefore, the dimensionless rotor speed increment is defined as optimization variable:

where,

represents the

m-th dimensionless rotor speed increment which is within the interval (0, 1],

and

respectively represent the target and start value of the

,

represents the number of control points,

represents the scaling factor.

When all the dimensionless rotor speed increments are known, the

can be calculated according to Equation (8). Thus, the rotor speeds of all control points can be calculated in turn:

where, the subscript

denotes the index number of the control point. And it should be noted that

.

Furthermore, to avoid sudden changes of the adjustable parameter, the change rate of the adjustable parameter is constrained. The change rate of the

i-th adjustable parameter with respect to the rotor speed is defined as follows:

In order to complete the transition process rapidly, the adjustable parameter of the last control point will naturally approach its target value. Therefore, it is usually unnecessary to limit the change rate of the adjustable parameters between the last control point and the target point. However, if the coordinate values of the control points are directly taken as the optimization variables, the optimization algorithm cannot ensure that of all control points is less than their limit value .

When the values of

,

, and

are all known, the upper and lower limits of

can be calculated according to

:

In addition,

. Evidently,

. Therefore, the dimensionless value

of the adjustable parameter, which belongs to the interval [0, 1], is defined as the optimization variable. And the actual value of each adjustable parameter can be calculated in turn:

In conclusion, the optimization variables of the

i-th adjustable parameter can be expressed as:

It should be noted that represents the dimensionless rotor speed increment between the last control point and the target point. Since the adjustable parameter of the target point is known, does not need to be an optimization variable.

For each adjustable parameter, the number of control points

can be different. And the global optimization variables of

adjustable parameters in the global optimization layer can be described as:

By optimizing , it can be ensured that the rotor speeds of the control points increase monotonically and the change rate of the adjustable parameters does not exceed the limit.

2) Set the initial values of the global optimization variables.

If gradient optimization algorithms such as the sequential quadratic programming algorithm are used in the global optimization layer, it is assumed that the initial control points are uniformly distributed along the rotational speed, and the straight line connecting the start point and the target point of the transition process is used to determine the initial coordinates of the control points. For instance, regarding the two control points in

Figure 4, their initial positions are shown in

Figure 5. Therefore, the value of

for each initial control point can be set to the same value of

, where

represents the number of control points. Subsequently, the value of

for each control point can be calculated inversely in sequence according to Equation (12).

If population-based algorithms like the differential evolution algorithm are used in the global optimization layer, each individual representing global optimization variables only needs to be randomly initialized within the optimization region. In addition, to give the initial population relatively reasonable initial values, the initialization method used in gradient optimization algorithms can be adopted to initialize a single individual in the population. Generally, the number of individuals in a population is relatively large. Assigning an initial value to a single individual will not affect the diversity of the initial population, and thus will not affect the convergence of the algorithm.

3) Construct the control schedules of geometrically adjustable parameters based on the global optimization variables.

When the global optimization variables are given, the coordinate values of each control point can be calculated according to Equation (9) and Equation (12). The results of Reference [

22] show that the piecewise linearization of the control schedule has little impact on the transition performance. Therefore, in order to reduce the complexity of the control schedule, this paper no longer constructs complex curve such as Bezier curve based on the control points. Instead, the control schedule of each adjustable parameter is directly constructed through linear interpolation of the control points.

4) Optimize the control schedule of fuel flow in the pointwise optimization layer.

In the pointwise optimization layer, the control schedules of geometrically adjustable parameters delivered by the global optimization layer are adopted. During each time step of the transition process, the fuel flow is optimized to meet Equation (4).

It should be noted that at this time, the in Equation (3) only contains one optimization variable, that is, the fuel flow. Therefore, the speed of pointwise optimization can be very fast.

5) Calculate the objective value of the global optimization variables.

The objective function described in Equation (2) needs to be integrated over time. Its discretized form over time steps is shown as follows:

where,

represents the total number of time steps.

The dimensionless global optimization variables proposed in this paper have considered the change rate constraints of geometrically adjustable parameters, and the pointwise optimization layer has considered engine performance constraints. Thus, there’s no need to account for other constraint conditions in the global optimization layer’s objective function.

Particularly, for the case of interruption in the transition process calculation, it is stipulated that the engine performance parameters at subsequent time steps are equal to their interruption values. At this moment, a relatively large objective function value will cause the optimization algorithm to discard current optimization variables.

6) Check whether the termination condition of the global optimization layer is met.

The termination condition of the global optimization layer is associated with the optimization algorithm used in this layer. When gradient optimization algorithms such as the sequential quadratic programming algorithm are used, the termination condition is usually that the change in the objective function value is less than a predefined threshold. When population-based algorithms like the differential evolution algorithm are employed, the termination condition is usually that the number of optimization generations reaches its predetermined value.

If the termination condition is met, output the control schedule curves of the geometrically adjustable parameters and the fuel flow rate. Otherwise, update the global optimization variables by the optimization algorithm of the global optimization layer and then, return to step 3.

In conclusion, the combined optimization method proposed in this paper can integrate the advantages of the global optimization methods and the pointwise optimization methods. In the pointwise optimization layer, the only optimization variable is the fuel flow rate. The sequential quadratic programming algorithm is adopted to ensure relatively high optimization efficiency [

29]. In the global optimization layer, the non-uniform control points construction method proposed in this paper can significantly reduce the number of control points, thus greatly shortening the time required for global optimization. The differential evolution algorithm [

30], which has good global convergence, is applied to the global optimization layer, thus ensuring that the algorithm is less likely to fall into local optimal solutions.

5. Conclusion

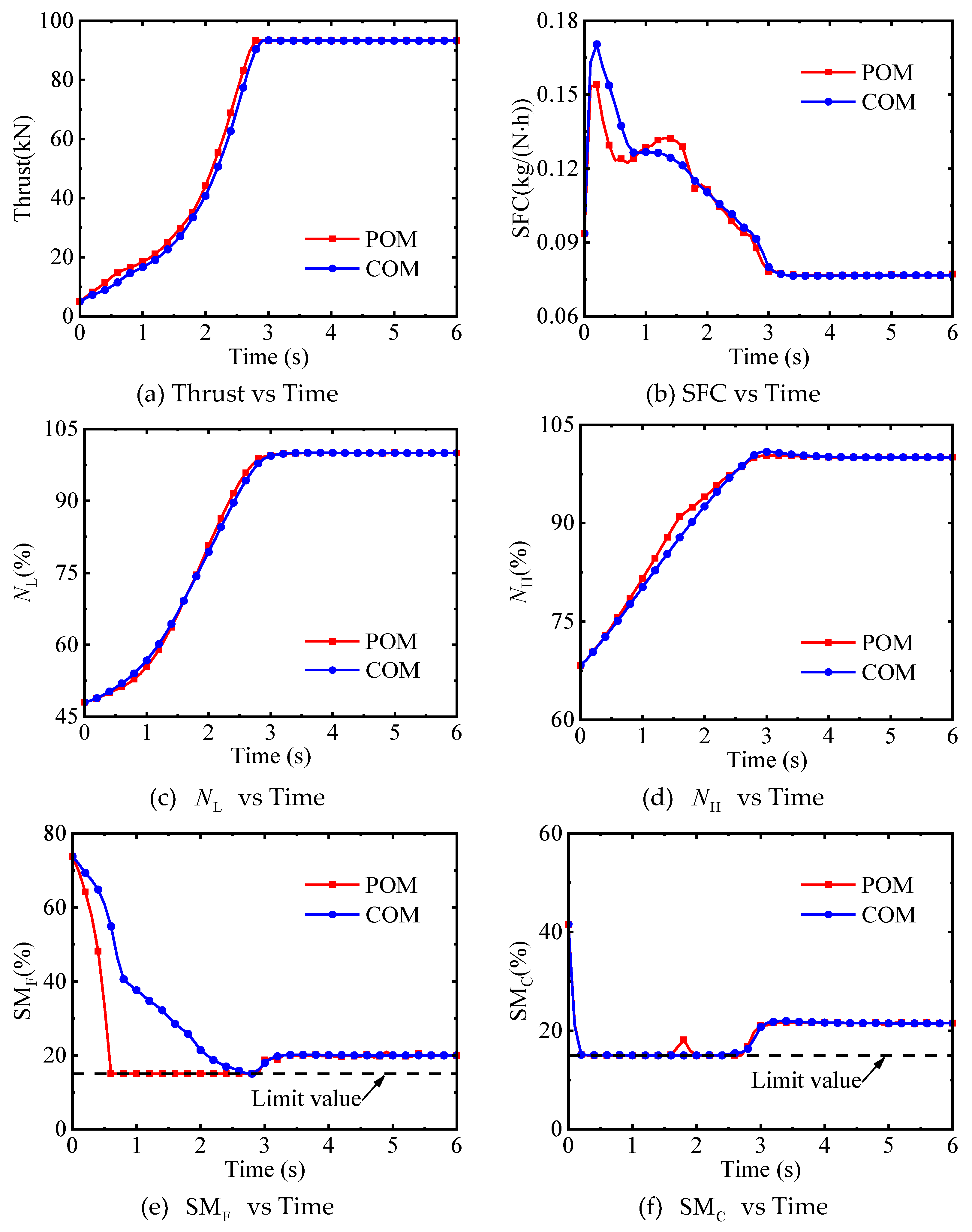

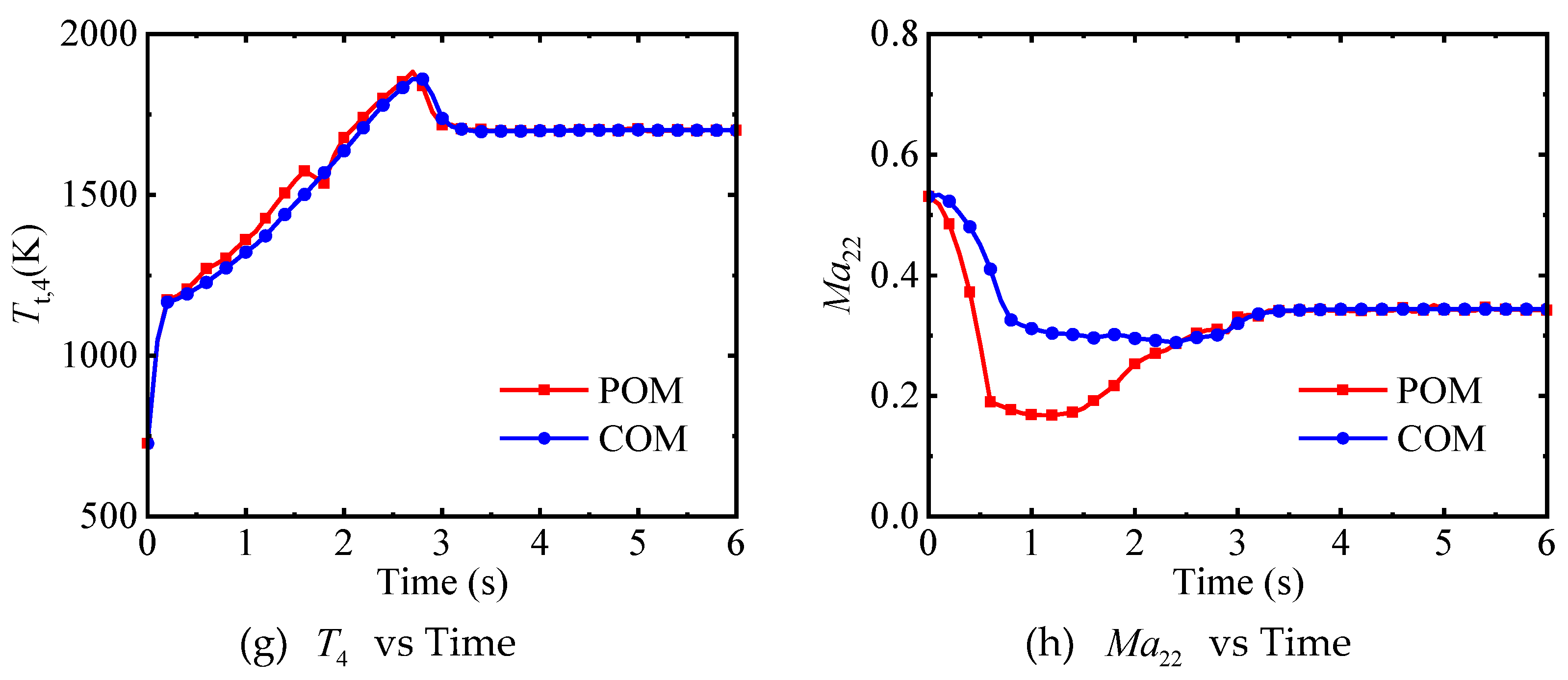

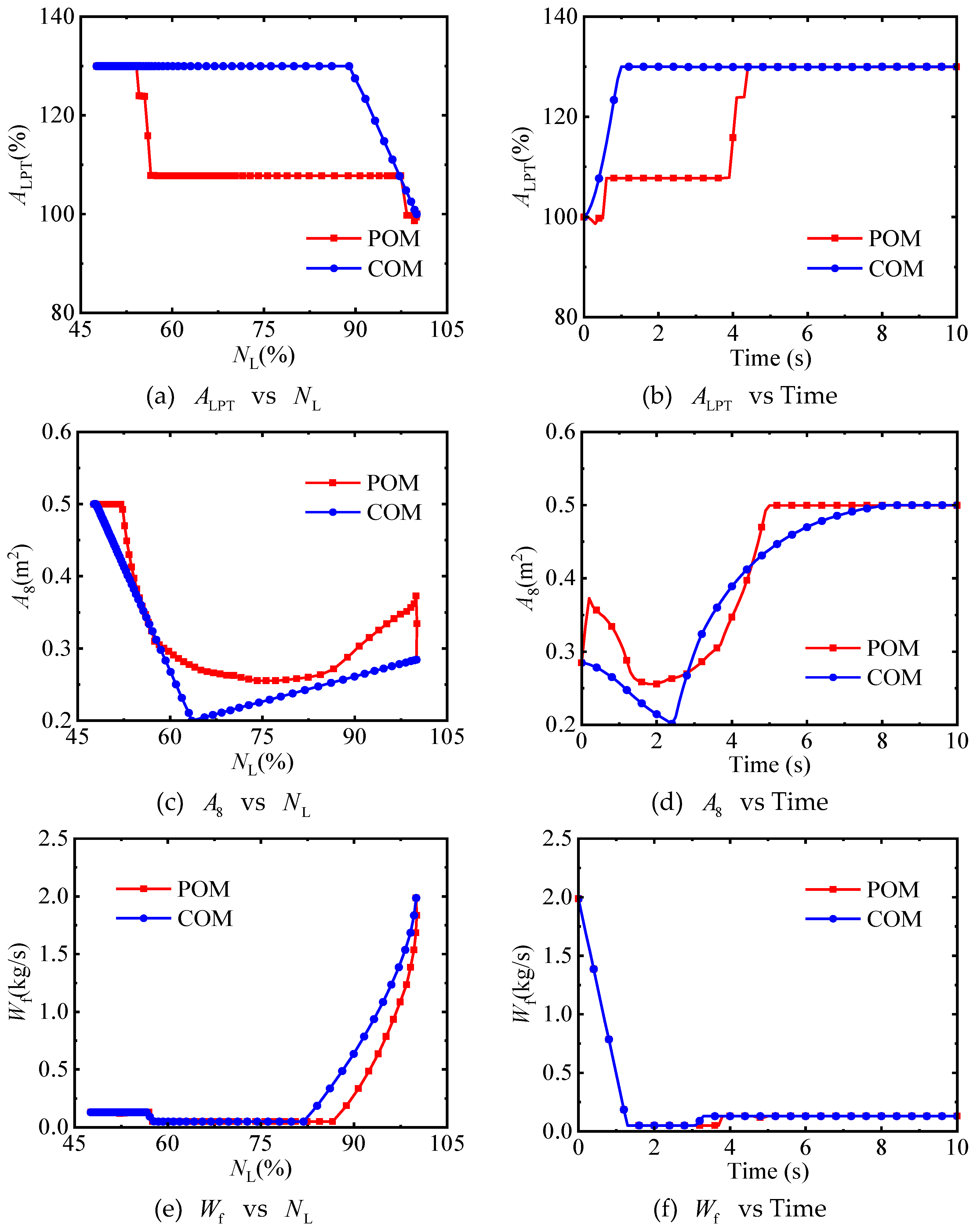

In this paper, a combined optimization method for the transition control schedules of aero-engines was proposed. This method integrates the traditional pointwise optimization method into the global optimization method. In addition, the problem of a large number of control points that needed to be optimized in global optimization methods was solved. The research results showed that:

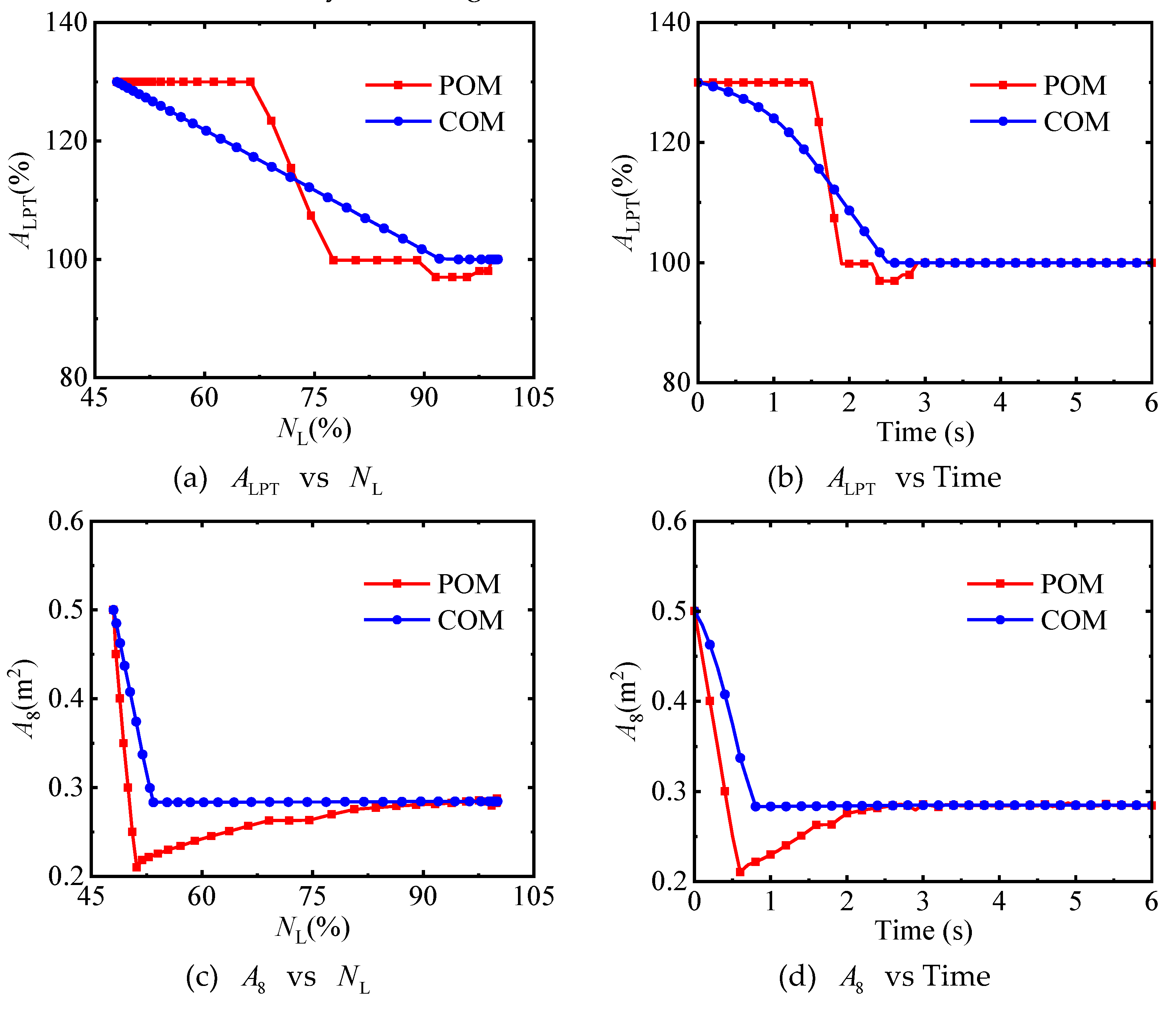

(1) Compared with the fuel flow rate, geometrically adjustable parameters have a relatively minor impact on the transition process. Moreover, there exists a coupling relationship among geometrically adjustable parameters. That is, different combinations of these parameters can achieve the same control effect. This is the main reason why geometrically adjustable parameters obtained by traditional optimization methods tend to fluctuate. This is also the reason why the transition time does not change significantly after the smoothing technologies are applied to the control schedules.

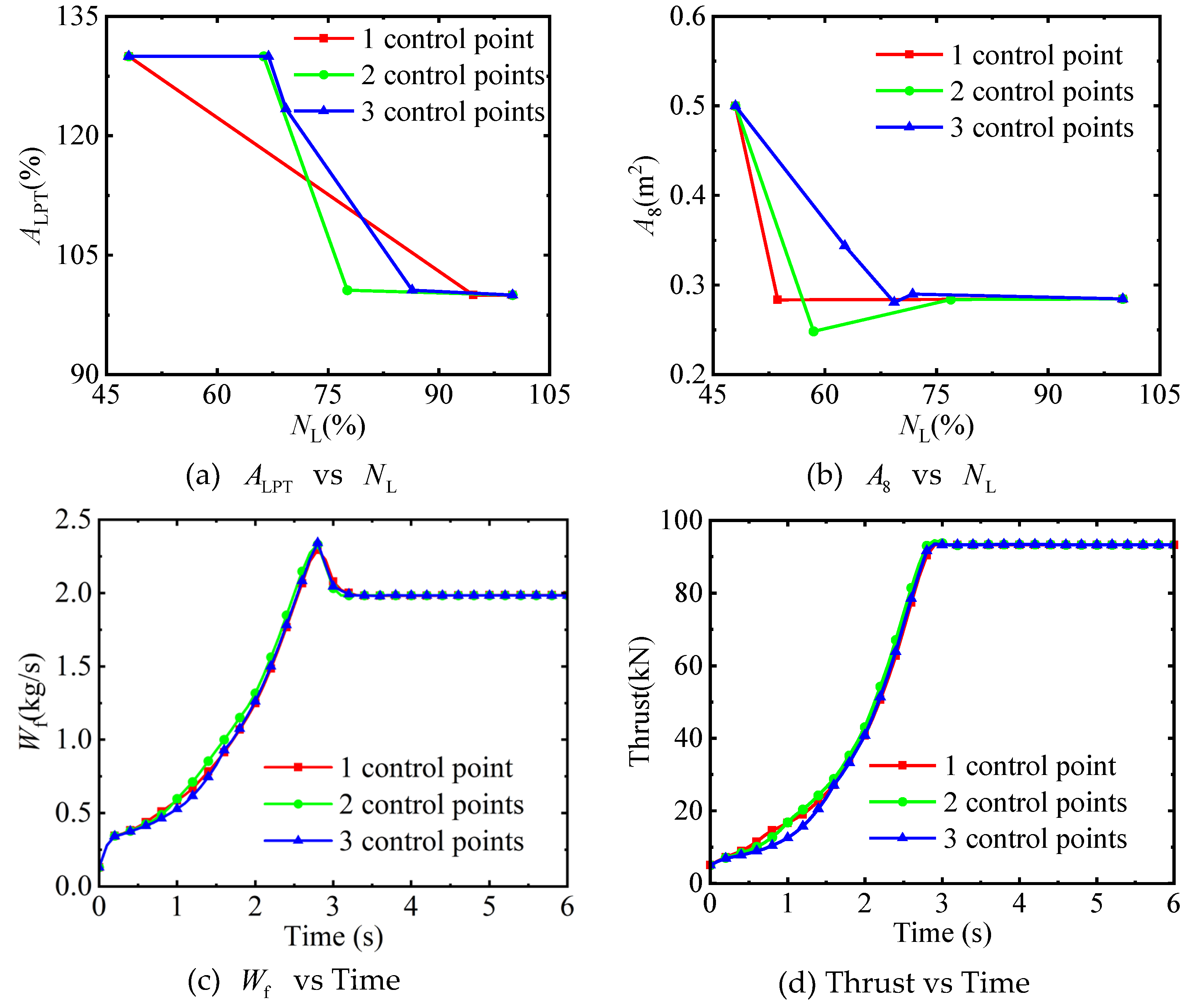

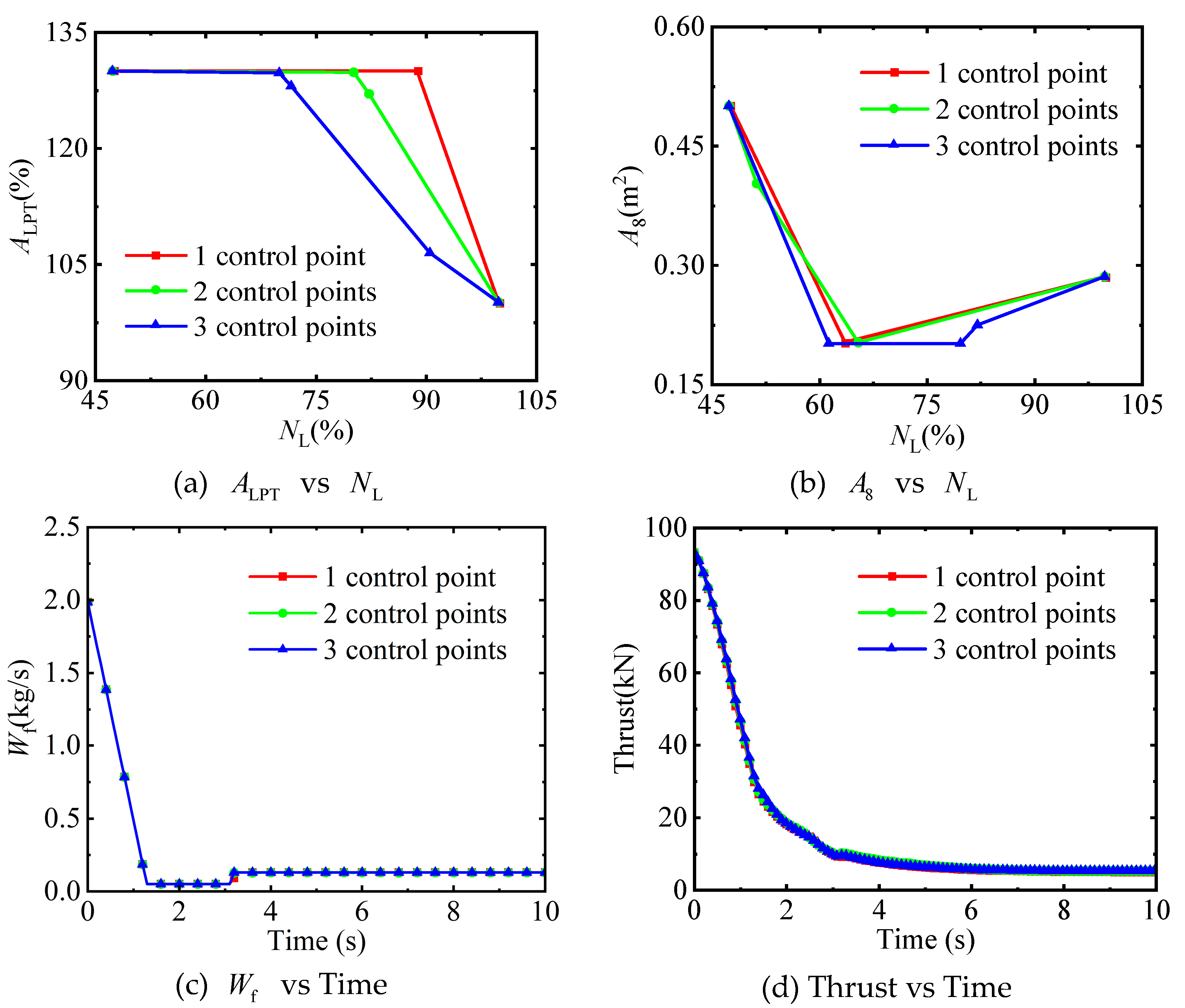

(2) In the global optimization layer of the combined optimization method, the number of control points has no obvious impact on the transition time. The fewer the number of control points, the more beneficial it is not only for reducing the optimization time but also for avoiding fluctuations in the control schedules.

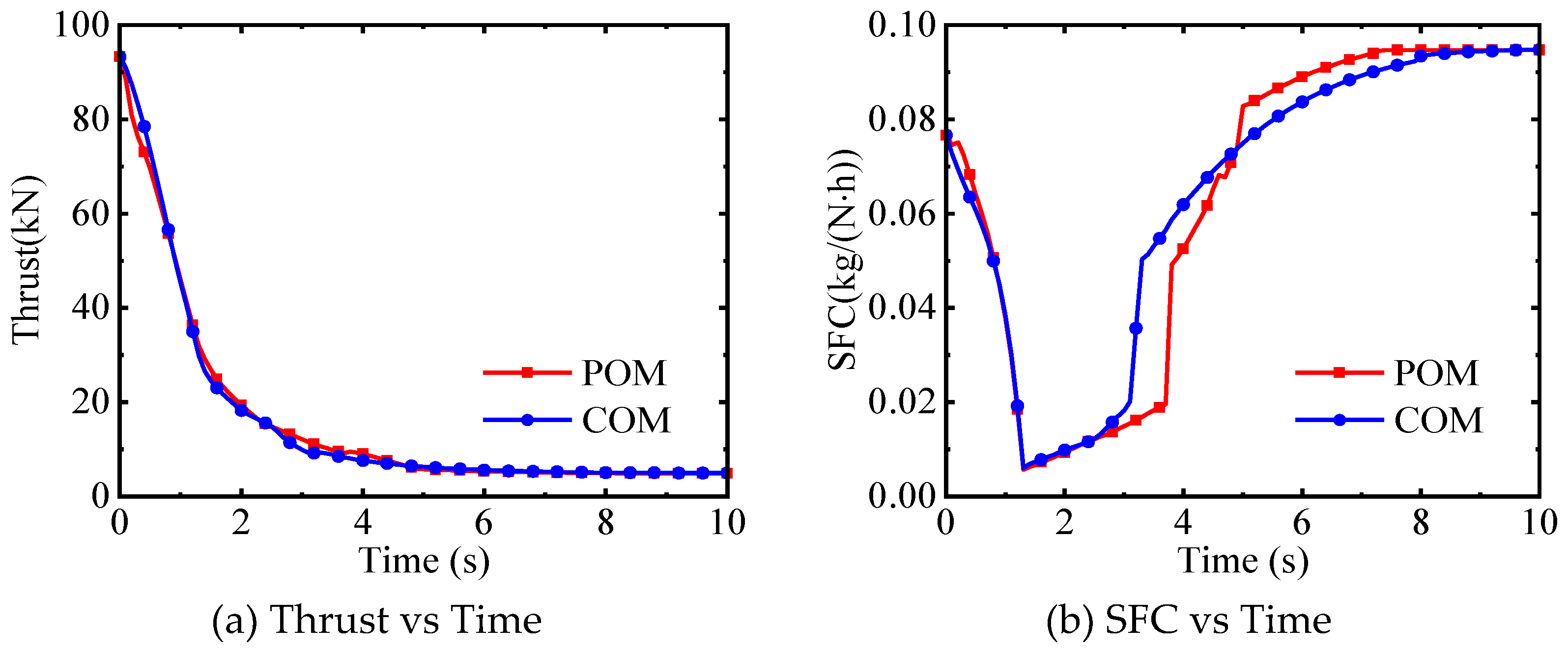

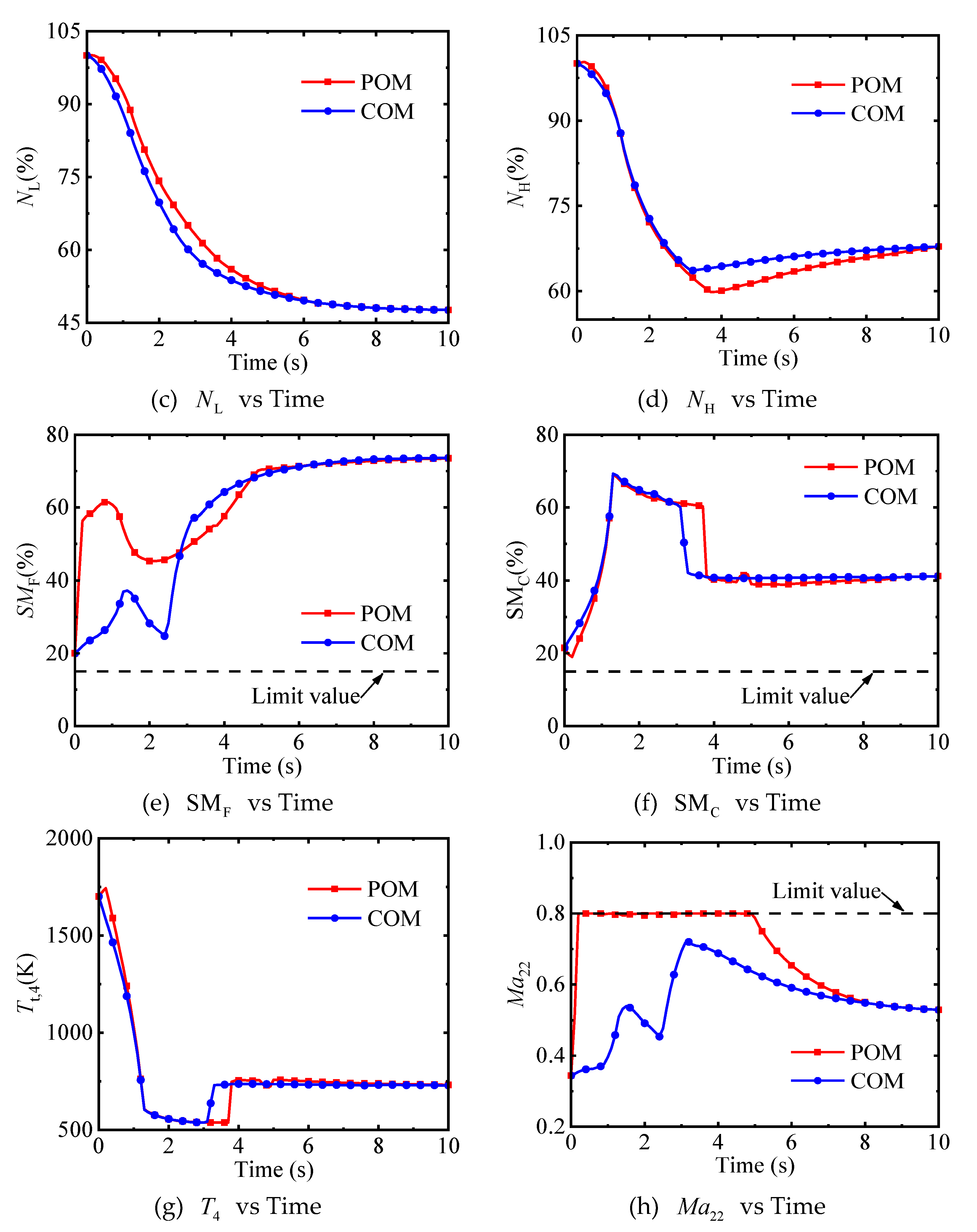

(3) There is no significant difference in the transition time optimized by the combined optimization method and the pointwise optimization method. However, the control schedules obtained by the combined optimization method are not only free from fluctuations but also simple, making them highly applicable in engineering.

(4) Constrained by change rate constraints of the control points of geometrically adjustable parameters, the combined optimization method cannot adjust the geometrically adjustable parameters arbitrarily. This enables the optimized control schedules to prevent some components from getting too close to their working boundaries, thus enhancing the safety of the engine during the transition process.

In future research, the combined optimization method can be applied to new-concept engines with more adjustable parameters, thus further verifying the effectiveness of this method.