Submitted:

09 January 2025

Posted:

10 January 2025

You are already at the latest version

Abstract

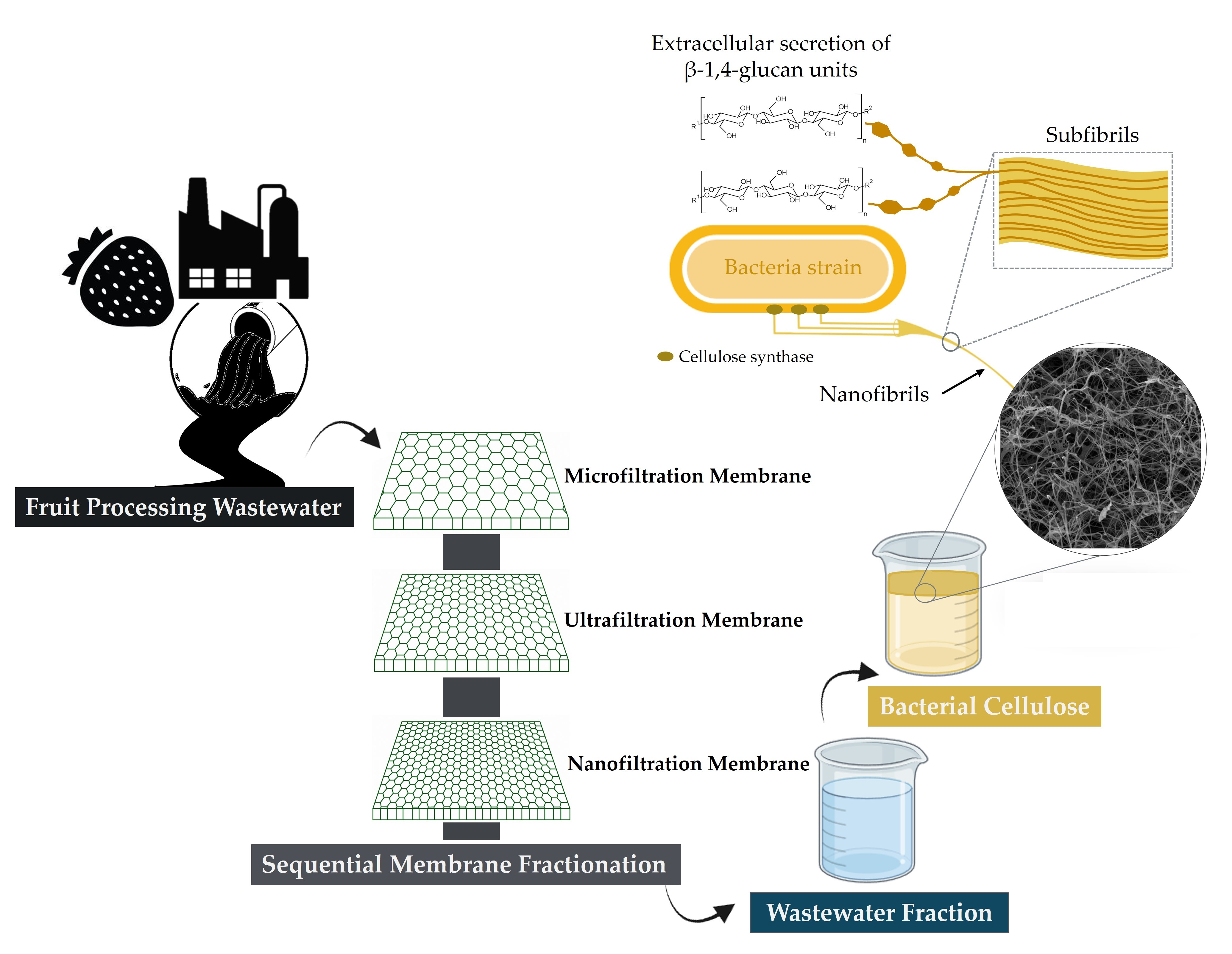

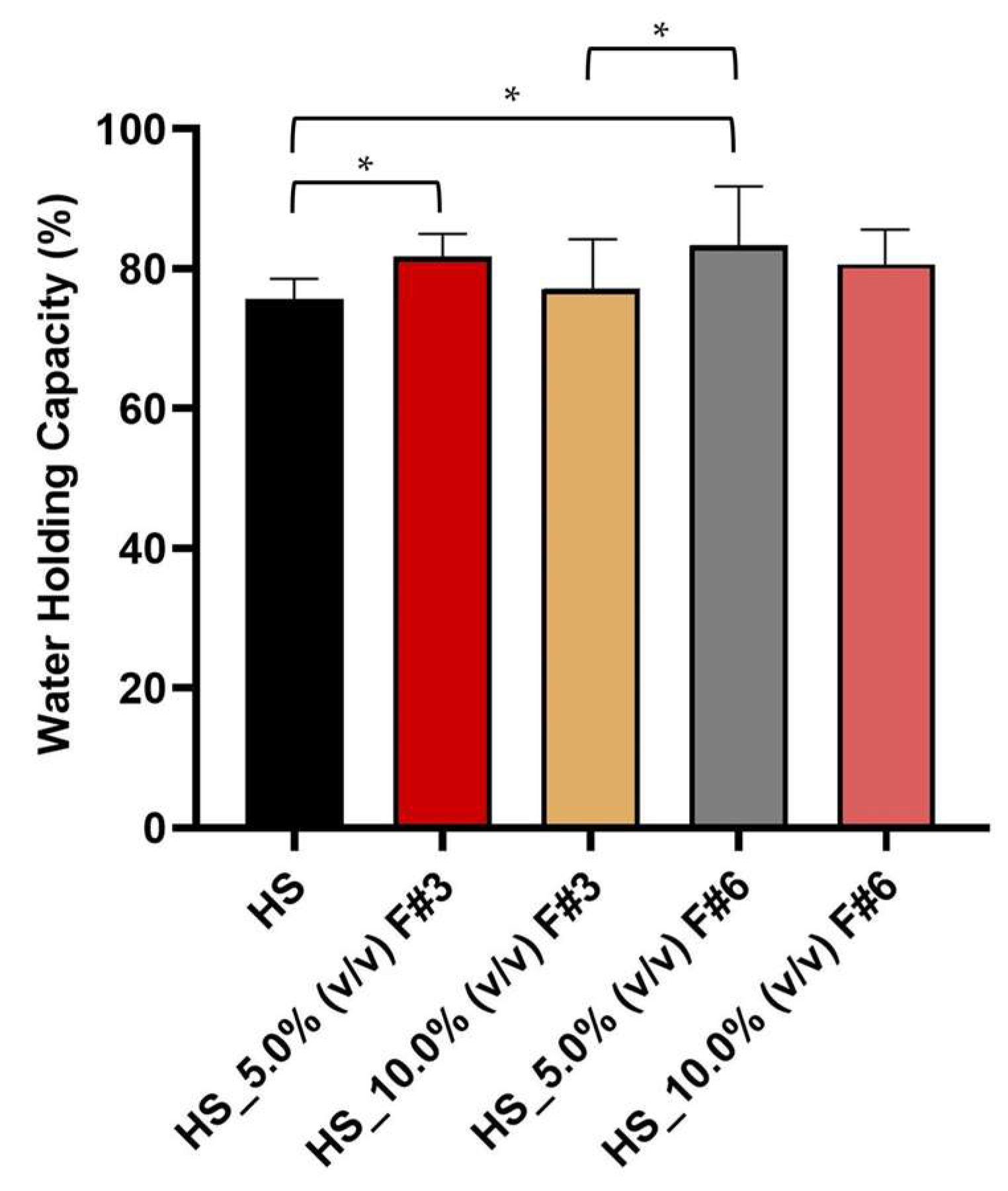

Bacterial cellulose (BC) is a versatile biopolymer prized for its remarkable water absorption, nanoscale fiber architecture, mechanical robustness, and biocompatibility, making it suitable for diverse applications. Despite its potential, the high cost of conventional fermentation media limits BC’s scalability and wider commercial use. This study investigates an economical solution by utilizing fractions from fruit processing wastewater, refined through sequential membrane fractionation, as a supplement to commercial HS medium for BC production. BC films were thoroughly characterized using Fourier transform infrared spectroscopy (FTIR), scanning and transmission electron microscopy (SEM and TEM), X-ray diffraction (XRD), differential scanning calorimetry (DSC), and assessments of mechanical properties and water holding capacity (WHC). FTIR confirmed the BC structure, while SEM and TEM validated its nanofibrillar 3D network. XRD showed increased crystallinity with the wastewater fractions, and DSC revealed a slight increase in thermal stability for F#6. Adding these fractions notably improved the BC films' tensile strength, Young's modulus, and WHC. Overall, the results underscore that fruit processing wastewater fractions can serve as a cost-efficient, eco-friendly alternative to traditional fermentation media. This approach supports circular economy principles by lowering reliance on intensive wastewater treatments, promoting waste valorization, and advancing sustainable production methods for high-value biopolymers.

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

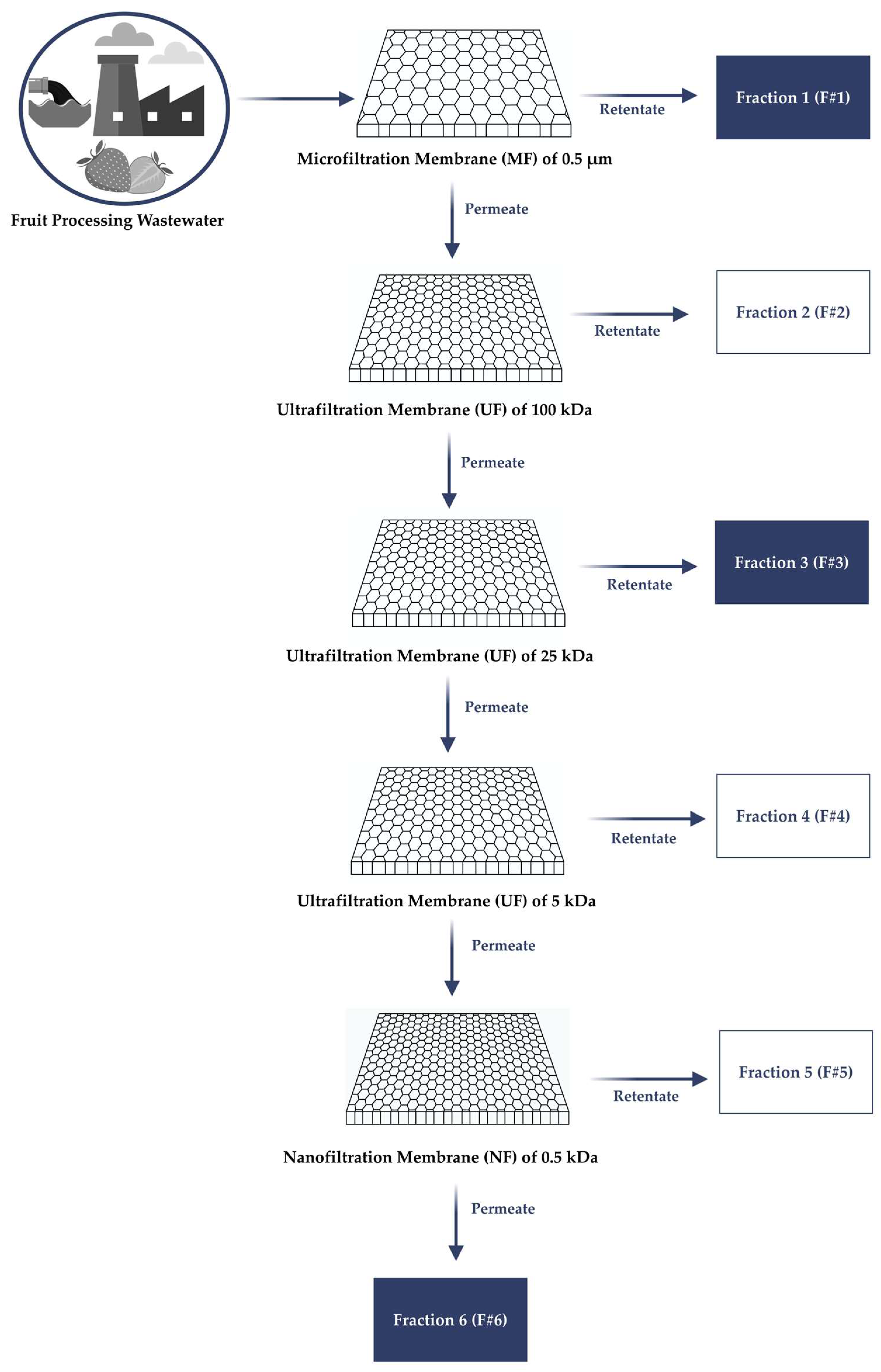

2.2. Membrane Fractionation Technique from Fruit Processing Wastewater

2.3. Determination of the Carbon (C) and Nitrogen (N) Content in the Fruit Processing Wastewater

2.4. Inoculum Preparation for BC Production

2.5. Preparation of Fermentation Medium and BC Production using the Fruit Processing Wastewater Fractions

2.6. Harvesting and Purification of BC Films

2.7. Determination of BC Dry Weights

2.8. Productivity Parameters of BC Films using Fruit Processing Wastewater Fractions

2.9. Analysis of the BC Properties

2.9.1. Thickness and Opacity Measurements of the BC Films

2.9.2. Visual Appearance of BC Films

2.9.3. Fourier Transform Infrared Spectroscopy (FTIR)

2.9.4. Scanning Electron Microscopy (SEM)

2.9.5. Transmission Electron Microscopy (TEM)

2.9.6. X-ray Diffractometry (XRD)

2.9.7. Differential Scanning Calorimetry (DSC) Measurements

2.9.8. Mechanical Properties

2.9.9. Water Holding Capacity (WHC)

2.10. Statistical Analysis

3. Results and Discussion

3.1. Determination of the Carbon (C) and Nitrogen (N) Content in the Fruit Processing Wastewater

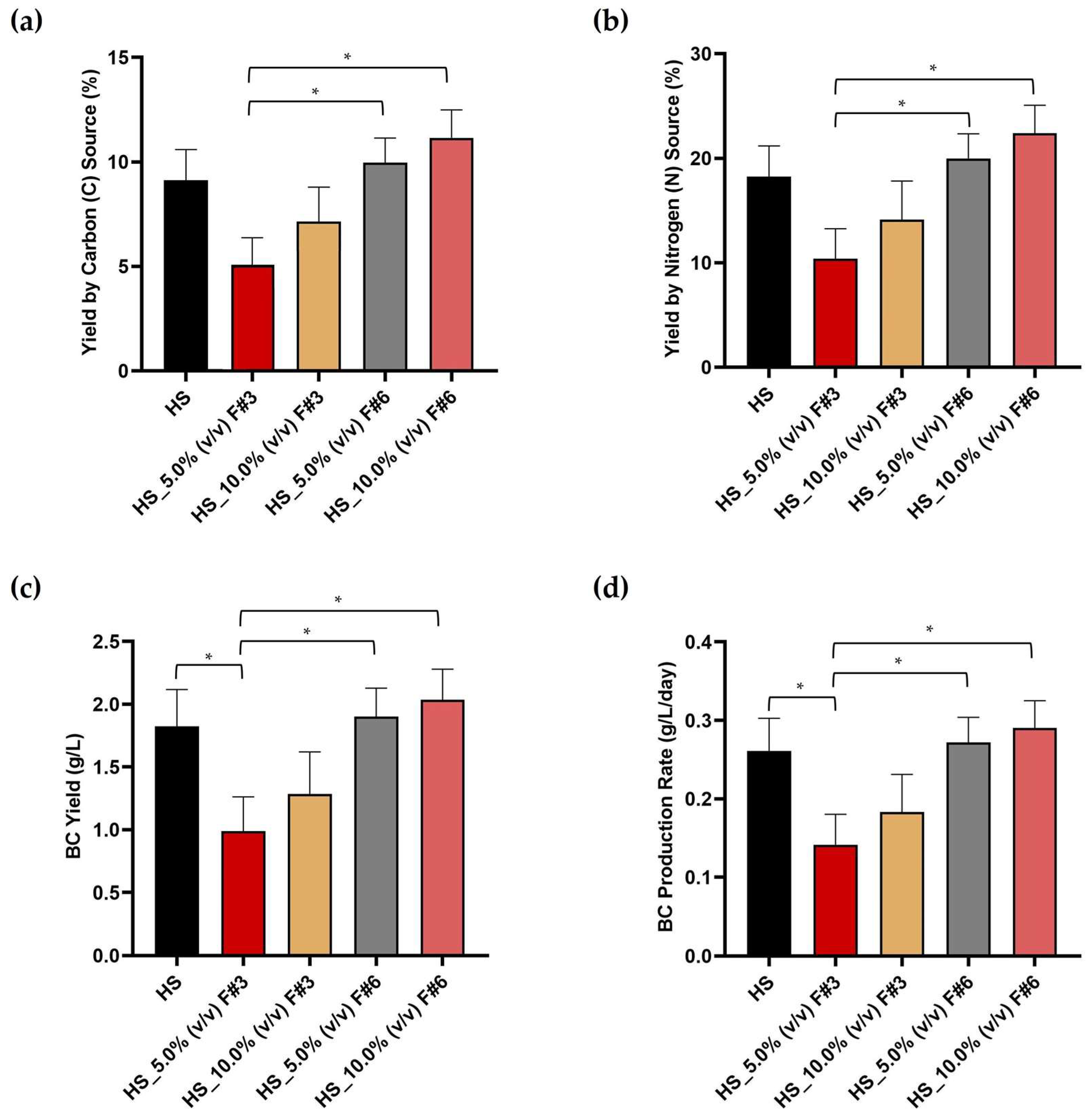

3.2. Bacterial Cellulose (BC) Productivity Parameters Using Fruit Processing Wastewater Fractions

3.3. Analysis of the BC Properties

3.3.1. Visual Appearance of BC Films Produced from Fruit Processing Wastewater Fractions

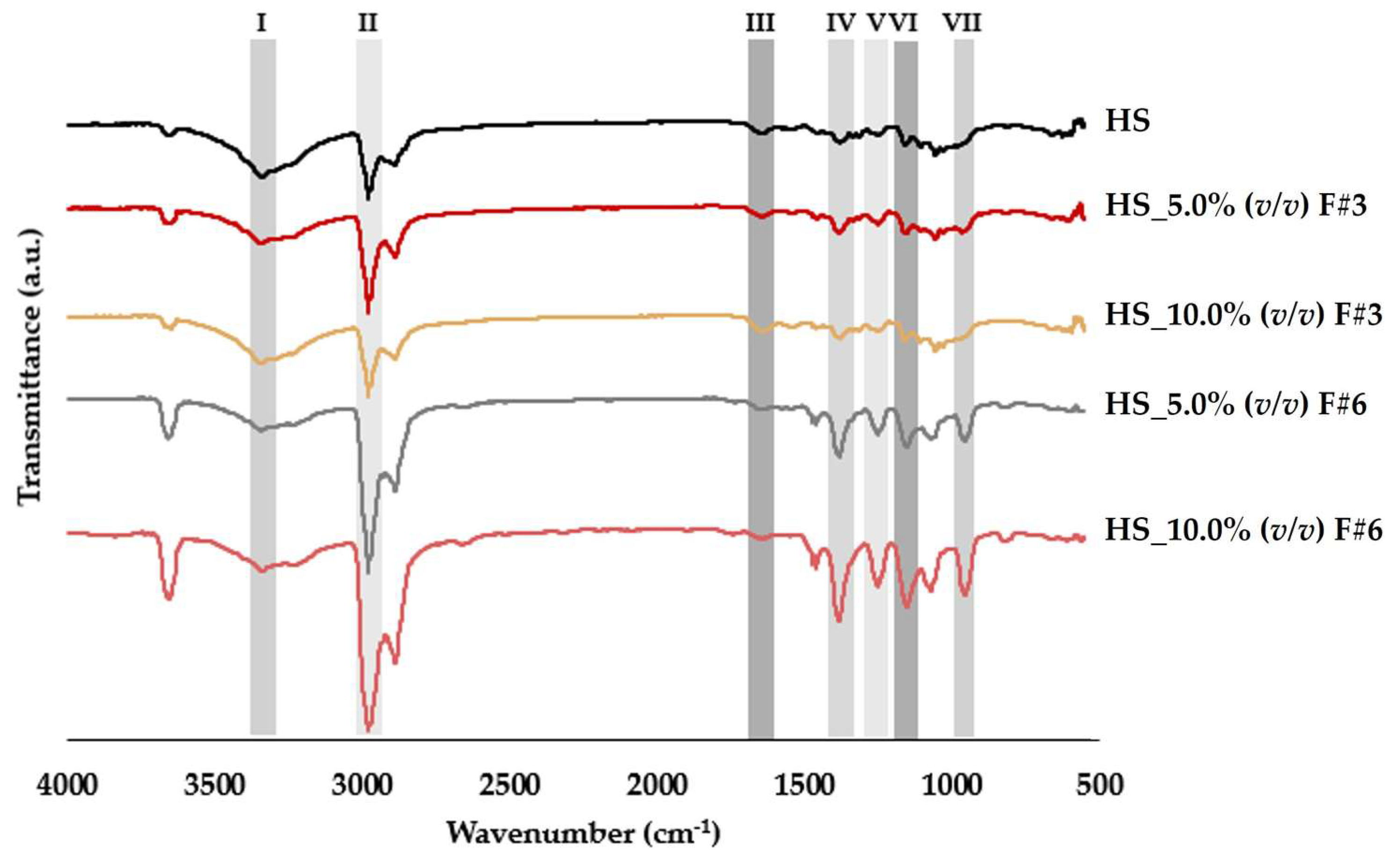

3.3.2. Fourier Transform Infrared Spectroscopy (FTIR)

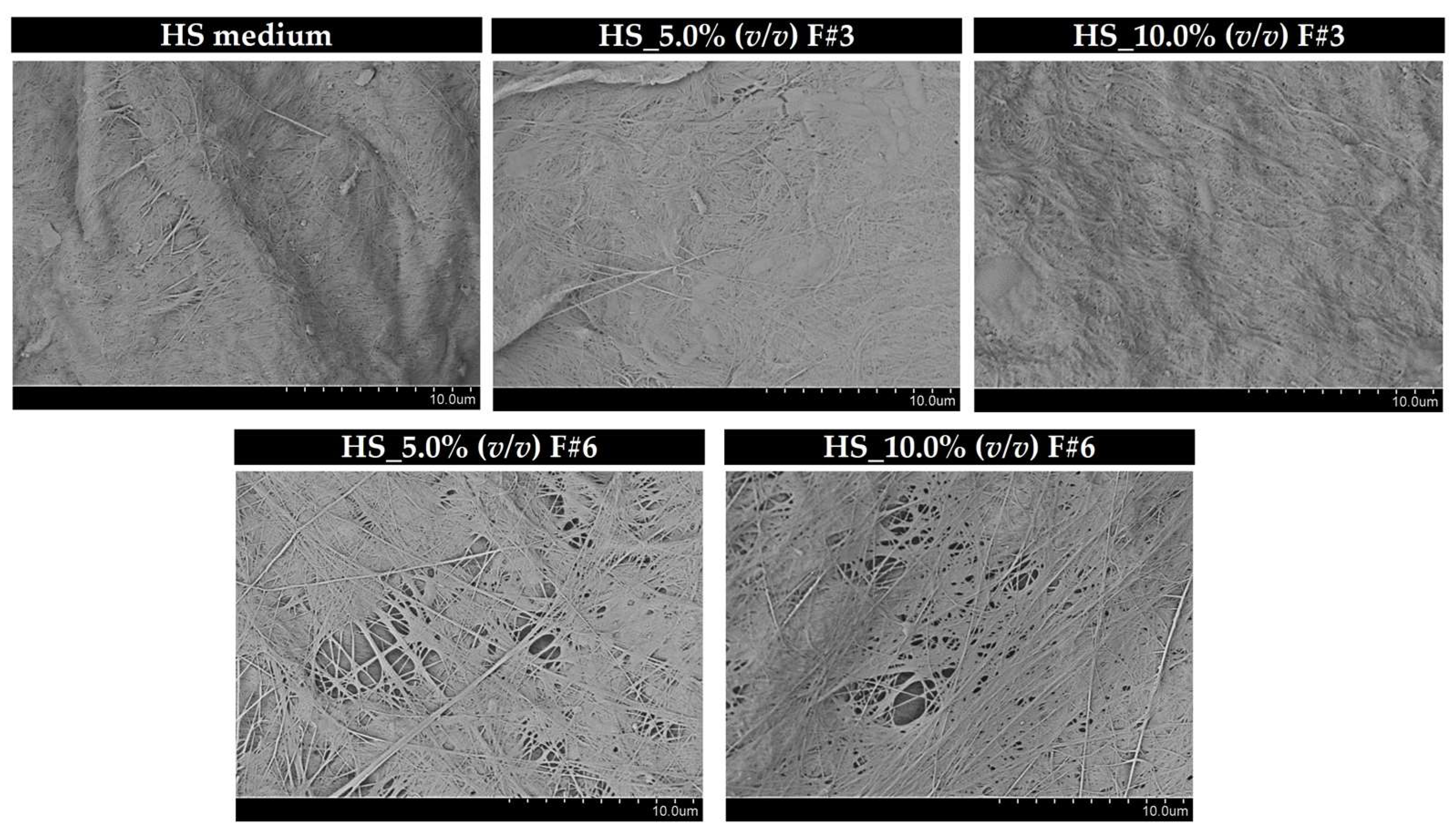

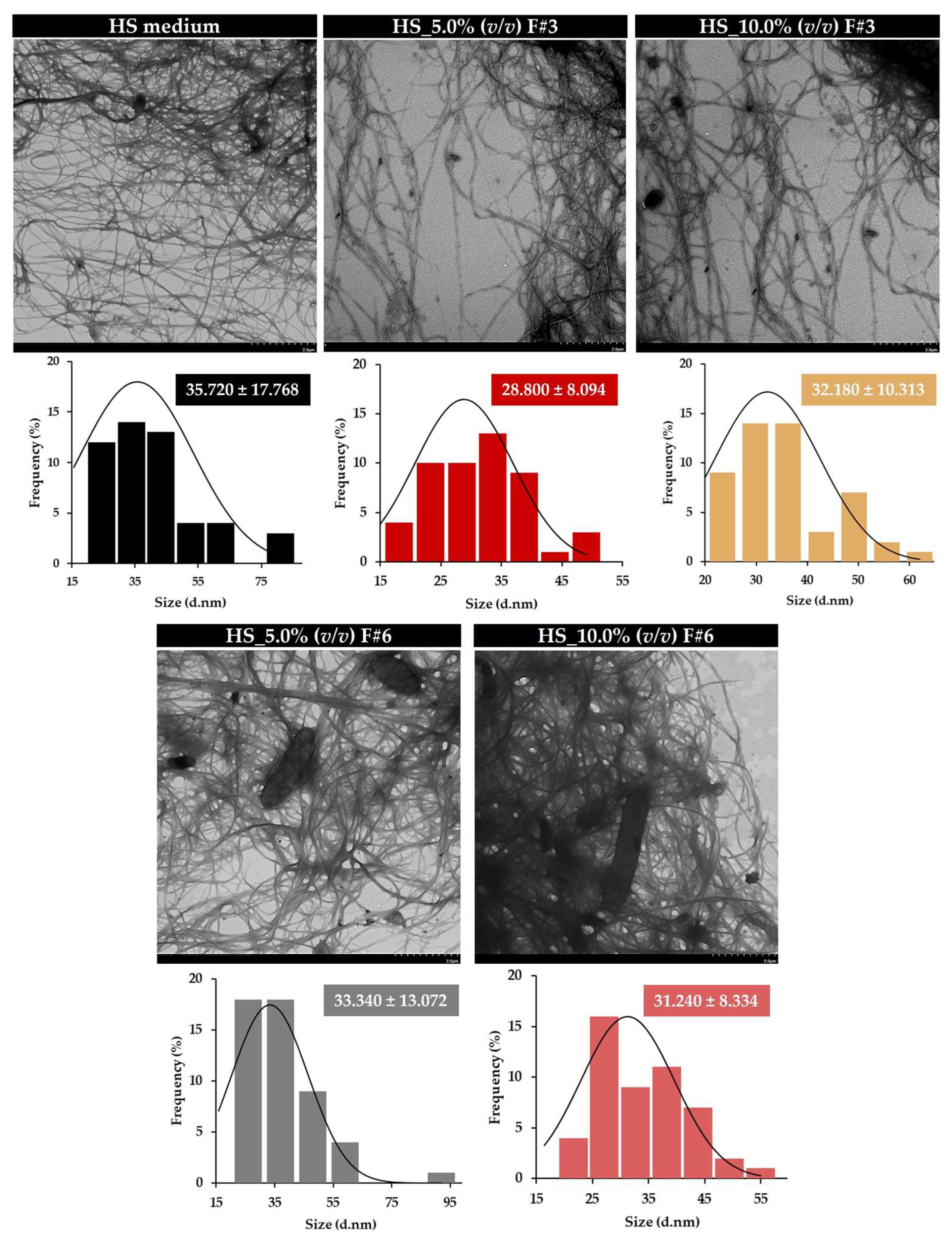

3.3.3. Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM)

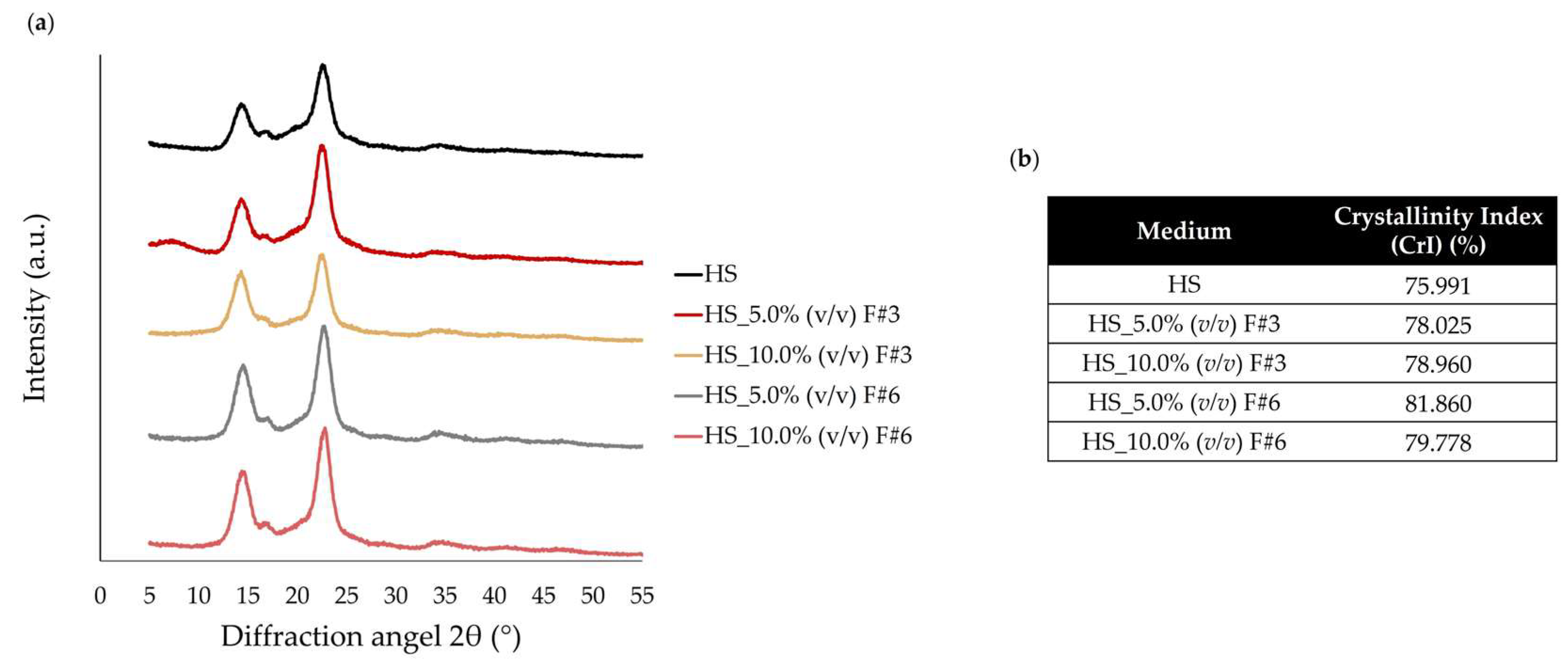

3.3.4. X-ray Diffractometry (XRD)

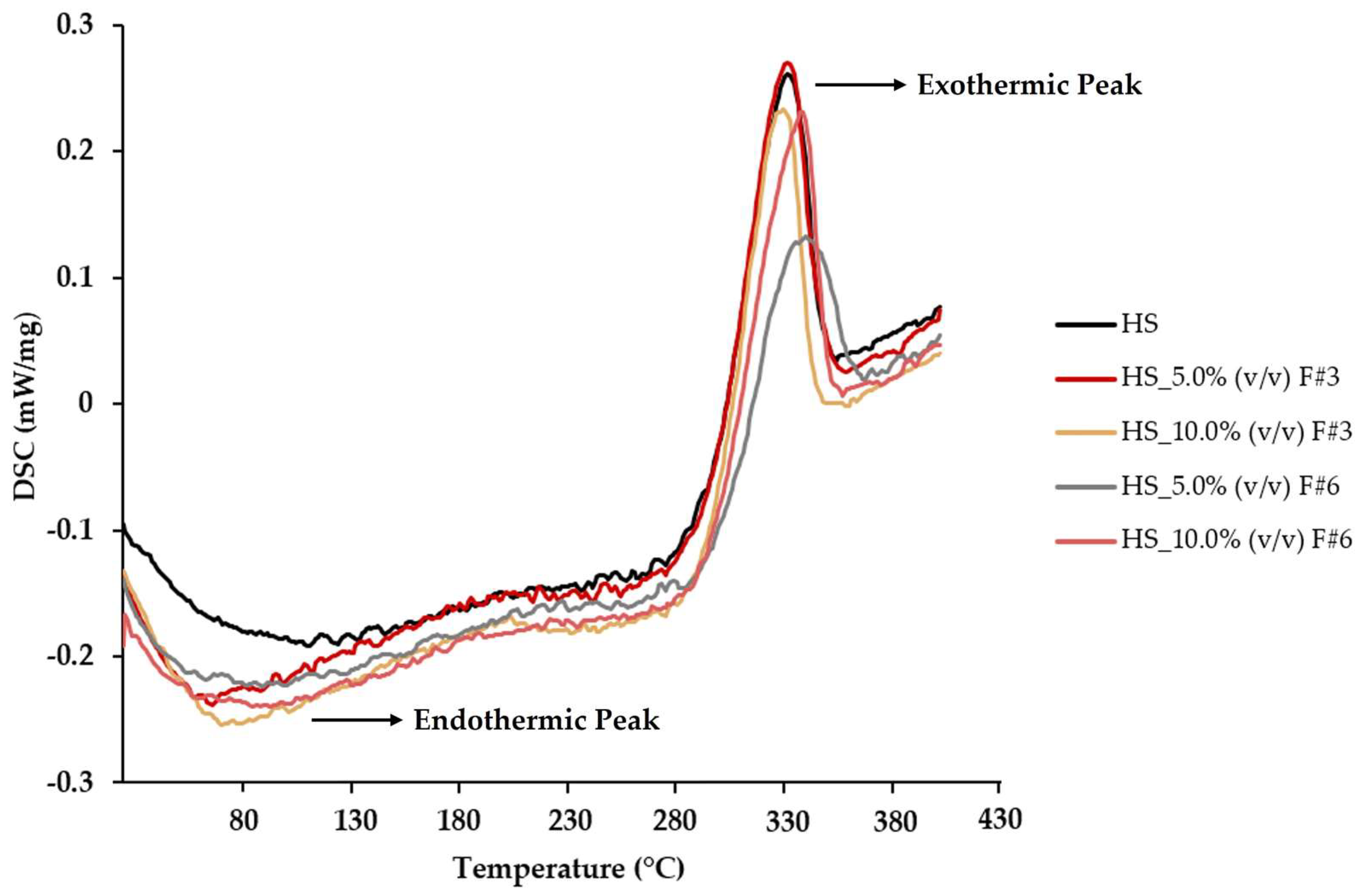

3.3.5. Differential Scanning Calorimetry (DSC) Measurements

3.3.6. Mechanical Properties

3.3.7. Water Holding Capacity (WHC)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramírez Tapias, Y.A.; Di Monte, M.V.; Peltzer, M.A.; Salvay, A.G. Bacterial Cellulose Films Production by Kombucha Symbiotic Community Cultured on Different Herbal Infusions. Food Chem 2022, 372, 131346. [CrossRef]

- Pedersen, G.B.; Blaschek, L.; Frandsen, K.E.H.; Noack, L.C.; Persson, S. Cellulose Synthesis in Land Plants. Mol Plant 2023, 16, 206–231. [CrossRef]

- Cheng, W.; Zhu, Y.; Jiang, G.; Cao, K.; Zeng, S.; Chen, W.; Zhao, D.; Yu, H. Sustainable Cellulose and Its Derivatives for Promising Biomedical Applications. Prog Mater Sci 2023, 138, 101152. [CrossRef]

- Li, Z.Y.; Azi, F.; Ge, Z.W.; Liu, Y.F.; Yin, X.T.; Dong, M.S. Bio-Conversion of Kitchen Waste into Bacterial Cellulose Using a New Multiple Carbon Utilizing Komagataeibacter Rhaeticus: Fermentation Profiles and Genome-Wide Analysis. Int J Biol Macromol 2021, 191, 211–221. [CrossRef]

- Ghozali, M.; Meliana, Y.; Chalid, M. Synthesis and Characterization of Bacterial Cellulose by Acetobacter Xylinum Using Liquid Tapioca Waste. Mater Today Proc 2021, 44, 2131–2134. [CrossRef]

- Greser, A.B.; Avcioglu, N.H. Optimization and Physicochemical Characterization of Bacterial Cellulose by Komagataeibacter Nataicola and Komagataeibacter Maltaceti Strains Isolated from Grape, Thorn Apple and Apple Vinegars. Arch Microbiol 2022, 204. [CrossRef]

- Costa, A.F.S.; Almeida, F.C.G.; Vinhas, G.M.; Sarubbo, L.A. Production of Bacterial Cellulose by Gluconacetobacter Hansenii Using Corn Steep Liquor as Nutrient Sources. Front Microbiol 2017, 8, 282716. [CrossRef]

- Martirani-VonAbercron, S.M.; Pacheco-Sánchez, D. Bacterial Cellulose: A Highly Versatile Nanomaterial. Microb Biotechnol 2023, 16, 1174. [CrossRef]

- Poddar, M.K.; Dikshit, P.K. Recent Development in Bacterial Cellulose Production and Synthesis of Cellulose Based Conductive Polymer Nanocomposites. Nano Select 2021, 2, 1605–1628. [CrossRef]

- Salama, A.; Saleh, A.K.; Cruz-Maya, I.; Guarino, V. Bacterial Cellulose/Cellulose Imidazolium Bio-Hybrid Membranes for In Vitro and Antimicrobial Applications. J Funct Biomater 2023, 14. [CrossRef]

- Zhong, C. Industrial-Scale Production and Applications of Bacterial Cellulose. Front Bioeng Biotechnol 2020, 8, 605374. [CrossRef]

- Potočnik, V.; Gorgieva, S.; Trček, J. From Nature to Lab: Sustainable Bacterial Cellulose Production and Modification with Synthetic Biology. Polymers 2023, 15, 3466. [CrossRef]

- Girard, V.D.; Chaussé, J.; Vermette, P. Bacterial Cellulose: A Comprehensive Review. J Appl Polym Sci 2024, 141, e55163. [CrossRef]

- Amorim, L.F.A.; Li, L.; Gomes, A.P.; Fangueiro, R.; Gouveia, I.C. Sustainable Bacterial Cellulose Production by Low Cost Feedstock: Evaluation of Apple and Tea by-Products as Alternative Sources of Nutrients. Cellulose 2023, 30, 5589–5606. [CrossRef]

- Revin, V.; Liyaskina, E.; Nazarkina, M.; Bogatyreva, A.; Shchankin, M. Cost-Effective Production of Bacterial Cellulose Using Acidic Food Industry by-Products. Braz J Microbiol 2018, 49, 151–159. [CrossRef]

- Quijano, L.; Rodrigues, R.; Fischer, D.; Tovar-Castro, J.D.; Payne, A.; Navone, L.; Hu, Y.; Yan, H.; Pinmanee, P.; Poon, E.; et al. Bacterial Cellulose Cookbook: A Systematic Review on Sustainable and Cost-Effective Substrates. J Bioresour Bioprod 2024. [CrossRef]

- Akintunde, M.O.; Adebayo-Tayo, B.C.; Ishola, M.M.; Zamani, A.; Horváth, I.S. Bacterial Cellulose Production from Agricultural Residues by Two Komagataeibacter Sp. Strains. Bioengineered 2022, 13, 10010. [CrossRef]

- Öz, Y.E.; Kalender, M. A Novel Static Cultivation of Bacterial Cellulose Production from Sugar Beet Molasses: Series Static Culture (SSC) System. Int J Biol Macromol 2023, 225, 1306–1314. [CrossRef]

- Tyagi, N.; Suresh, S. Production of Cellulose from Sugarcane Molasses Using Gluconacetobacter Intermedius SNT-1: Optimization & Characterization. J Clean Prod 2016, 112, 71–80. [CrossRef]

- Gomes, F.P.; Silva, N.H.C.S.; Trovatti, E.; Serafim, L.S.; Duarte, M.F.; Silvestre, A.J.D.; Neto, C.P.; Freire, C.S.R. Production of Bacterial Cellulose by Gluconacetobacter Sacchari Using Dry Olive Mill Residue. Biomass Bioenergy 2013, 55, 205–211. [CrossRef]

- Tsouko, E.; Pilafidis, S.; Dimopoulou, M.; Kourmentza, K.; Sarris, D. Bioconversion of Underutilized Brewing By-Products into Bacterial Cellulose by a Newly Isolated Komagataeibacter Rhaeticus Strain: A Preliminary Evaluation of the Bioprocess Environmental Impact. Bioresour Technol 2023, 387, 129667. [CrossRef]

- Hasanin, M.S.; Abdelraof, M.; Hashem, A.H.; El Saied, H. Sustainable Bacterial Cellulose Production by Achromobacter Using Mango Peel Waste. Microb Cell Fact 2023, 22. [CrossRef]

- Zhao, H.; Xia, J.; Wang, J.; Yan, X.; Wang, C.; Lei, T.; Xian, M.; Zhang, H. Production of Bacterial Cellulose Using Polysaccharide Fermentation Wastewater as Inexpensive Nutrient Sources. Biotechnol Biotechnol Equip 2018, 32, 350–356. [CrossRef]

- Leonarski, E.; Cesca, K.; Pinto, C.C.; González, S.Y.G.; de Oliveira, D.; Poletto, P. Bacterial Cellulose Production from Acerola Industrial Waste Using Isolated Kombucha Strain. Cellulose 2022, 29, 7613–7627. [CrossRef]

- Ye, J.; Zheng, S.; Zhang, Z.; Yang, F.; Ma, K.; Feng, Y.; Zheng, J.; Mao, D.; Yang, X. Bacterial Cellulose Production by Acetobacter Xylinum ATCC 23767 Using Tobacco Waste Extract as Culture Medium. Bioresour Technol 2019, 274, 518–524. [CrossRef]

- Hong, F.; Guo, X.; Zhang, S.; Han, S. fen; Yang, G.; Jönsson, L.J. Bacterial Cellulose Production from Cotton-Based Waste Textiles: Enzymatic Saccharification Enhanced by Ionic Liquid Pretreatment. Bioresour Technol 2012, 104, 503–508. [CrossRef]

- Asgharnejad, H.; Khorshidi Nazloo, E.; Madani Larijani, M.; Hajinajaf, N.; Rashidi, H. Comprehensive Review of Water Management and Wastewater Treatment in Food Processing Industries in the Framework of Water-Food-Environment Nexus. Compr Rev Food Sci Food Saf 2021, 20, 4779–4815. [CrossRef]

- Shrivastava, V.; Ali, I.; Marjub, M.M.; Rene, E.R.; Soto, A.M.F. Wastewater in the Food Industry: Treatment Technologies and Reuse Potential. Chemosphere 2022, 293, 133553. [CrossRef]

- Blyashyna, M.; Zhukova, V.; Sabliy, L. Processes of Biological Wastewater Treatment for Nitrogen, Phosphorus Removal by Immobilized Microorganisms. East-Eur J Enterp Technol 2018, 2, 30–37. [CrossRef]

- Howard, I.; Espigares, E.; Lardelli, P.; Martín, J.L.; Espigares, M. Evaluation of Microbiological and Physicochemical Indicators for Wastewater Treatment. Environ Toxicol 2004, 19, 241–249. [CrossRef]

- Nishat, A.; Yusuf, M.; Qadir, A.; Ezaier, Y.; Vambol, V.; Ijaz Khan, M.; Ben Moussa, S.; Kamyab, H.; Sehgal, S.S.; Prakash, C.; et al. Wastewater Treatment: A Short Assessment on Available Techniques. Alex Eng J 2023, 76, 505–516. [CrossRef]

- Iqbal, A.; Zan, F.; Siddiqui, M.A.; Nizamuddin, S.; Chen, G. Integrated Treatment of Food Waste with Wastewater and Sewage Sludge: Energy and Carbon Footprint Analysis with Economic Implications. Sci Total Environ 2022, 825, 154052. [CrossRef]

- Jayaseelan, M.; Usman, M.; Somanathan, A.; Palani, S.; Muniappan, G.; Jeyakumar, R.B. Microalgal Production of Biofuels Integrated with Wastewater Treatment. Sustainability 2021, 13, 8797. [CrossRef]

- Singh, J.; Kumar, S.; Sharma, S. Biopolymer in Wastewater Treatment. 2022, Biopolymers Springer Series on Polymer and Composite Materials, 323–351. [CrossRef]

- Velmozhina, K.; Shinkevich, P.; Zhazhkov, V.; Politaeva, N.; Korablev, V.; Vladimirov, I.; Morales, T.C. Production of Biohydrogen from Microalgae Biomass after Wastewater Treatment and Air Purification from CO2. Processes 2023, 11, 2978. [CrossRef]

- Ezugbe, E.O.; Rathilal, S. Membrane Technologies in Wastewater Treatment: A Review. Membranes (Basel) 2020, 10. [CrossRef]

- Al-Tayawi, A.N.; Sisay, E.J.; Beszédes, S.; Kertész, S. Wastewater Treatment in the Dairy Industry from Classical Treatment to Promising Technologies: An Overview. Processes 2023, 11, 2133. [CrossRef]

- Lee, S.Y.; Stuckey, D.C. Separation and Biosynthesis of Value-Added Compounds from Food-Processing Wastewater: Towards Sustainable Wastewater Resource Recovery. J Clean Prod 2022, 357, 131975. [CrossRef]

- Chollangi, A.; Hossain, M.M. Separation of Proteins and Lactose from Dairy Wastewater. Chemical Engineering and Processing: Process Intensification 2007, 46, 398–404. [CrossRef]

- Brans, G.; Schroën, C.G.P.H.; Van Der Sman, R.G.M.; Boom, R.M. Membrane Fractionation of Milk: State of the Art and Challenges. J Memb Sci 2004, 243, 263–272. [CrossRef]

- Keskin, B.; Ersahin, M.E.; Ozgun, H.; Koyuncu, I. Pilot and Full-Scale Applications of Membrane Processes for Textile Wastewater Treatment: A Critical Review. J Water Process Engi 2021, 42, 102172. [CrossRef]

- Ma, R.; Li, J.; Zeng, P.; Duan, L.; Dong, J.; Ma, Y.; Yang, L. The Application of Membrane Separation Technology in the Pharmaceutical Industry. Membranes 2024, 14, 24. [CrossRef]

- Birniwa, A.H.; Habibu, S.; Abdullahi, S.S. ad; Mohammad, R.E.A.; Hussaini, A.; Magaji, H.; Al-dhawi, B.N.S.; Noor, A.; Jagaba, A.H. Membrane Technologies for Heavy Metals Removal from Water and Wastewater: A Mini Review. Case Stud Chem Environ Eng 2024, 9, 100538. [CrossRef]

- Gomes, A.C.; Gonçalves, I.C.; De Pinho, M.N. The Role of Adsorption on Nanofiltration of Azo Dyes. J Memb Sci 2005, 255, 157–165. [CrossRef]

- APHA. Standard Methods for the Examination of Water & Wastewater. 2005, 21st Edition, American Public Health Association/American Water Works Association/Water Environment Federation, Washington DC.

- Teixeira, G.G.; Santos, P.M. Simple and Cost-Effective Approaches for Quantification of Reducing Sugar Exploiting Digital Image Analysis. J Food Compos Anal 2022, 113, 104719. [CrossRef]

- Miller, G.L. Use of Dinitrosalicylic Acid Reagent for Determination of Reducing Sugar. Anal Chem 1959, 31, 426–428. [CrossRef]

- Han, J.H.; Floros, J.D. Casting Antimicrobial Packaging Films and Measuring Their Physical Properties and Antimicrobial Activity. J Plast Film Sheeting 1997, 13, 287–298. [CrossRef]

- Salari, M.; Sowti Khiabani, M.; Rezaei Mokarram, R.; Ghanbarzadeh, B.; Samadi Kafil, H. Development and Evaluation of Chitosan Based Active Nanocomposite Films Containing Bacterial Cellulose Nanocrystals and Silver Nanoparticles. Food Hydrocoll 2018, 84, 414–423. [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text Res J 1959, 29, 786–794. [CrossRef]

- Ul-Islam, M.; Khan, T.; Park, J.K. Water Holding and Release Properties of Bacterial Cellulose Obtained by in Situ and Ex Situ Modification. Carbohydr Polym 2012, 88, 596–603. [CrossRef]

- Barshan, S.; Rezazadeh-Bari, M.; Almasi, H.; Amiri, S. Optimization and Characterization of Bacterial Cellulose Produced by Komagatacibacter Xylinus PTCC 1734 Using Vinasse as a Cheap Cultivation Medium. Int J Biol Macromol 2019, 136, 1188–1195. [CrossRef]

- Dulekgurgen, E.; Doǧruel, S.; Karahan, Ö.; Orhon, D. Size Distribution of Wastewater COD Fractions as an Index for Biodegradability. Water Res 2006, 40, 273–282. [CrossRef]

- Fiorentino, A.; Gentili, A.; Isidori, M.; Monaco, P.; Nardelli, A.; Parrella, A.; Temussi, F. Environmental Effects Caused by Olive Mill Wastewaters: Toxicity Comparison of Low-Molecular-Weight Phenol Components. J Agric Food Chem 2003, 51, 1005–1009. [CrossRef]

- Wang, F.; Smith, D.W.; Gamal El-Din, M. Aged Raw Landfill Leachate: Membrane Fractionation, O3 Only and O3/H2O2 Oxidation, and Molecular Size Distribution Analysis. Water Res 2006, 40, 463–474. [CrossRef]

- Rodrigues, A.S.; Souiad, F.; Fernandes, A.; Baía, A.; Pacheco, M.J.; Ciríaco, L.; Bendaoud-Boulahlib, Y.; Lopes, A. Treatment of Fruit Processing Wastewater by Electrochemical and Activated Persulfate Processes: Toxicological and Energetic Evaluation. Environ Res 2022, 209, 112868. [CrossRef]

- Leonarski, E.; Cesca, K.; Zanella, E.; Stambuk, B.U.; de Oliveira, D.; Poletto, P. Production of Kombucha-like Beverage and Bacterial Cellulose by Acerola Byproduct as Raw Material. LWT 2021, 135, 110075. [CrossRef]

- Jittaut, P.; Hongsachart, P.; Audtarat, S.; Dasri, T. Production and Characterization of Bacterial Cellulose Produced by Gluconacetobacter Xylinus BNKC 19 Using Agricultural Waste Products as Nutrient Source. Arab J Basic Appl Sci 2023, 30, 221–230. [CrossRef]

- Ramírez Tapias, Y.A.; Peltzer, M.A.; Delgado, J.F.; Salvay, A.G. Kombucha Tea By-Product as Source of Novel Materials: Formulation and Characterization of Films. Food Bioproc Tech 2020, 13, 1166–1180. [CrossRef]

- Tsouko, E.; Pilafidis, S.; Kourmentza, K.; Gomes, H.I.; Sarris, G.; Koralli, P.; Papagiannopoulos, A.; Pispas, S.; Sarris, D. A Sustainable Bioprocess to Produce Bacterial Cellulose (BC) Using Waste Streams from Wine Distilleries and the Biodiesel Industry: Evaluation of BC for Adsorption of Phenolic Compounds, Dyes and Metals. Biotechnology for Biofuels and Bioproducts 2024, 17, 1–17. [CrossRef]

- Zhang, X.; Wang, D.; Liu, S.; Tang, J. Bacterial Cellulose Nanofibril-Based Pickering Emulsions: Recent Trends and Applications in the Food Industry. Foods 2022, 11, 4064. [CrossRef]

- Güzel, M. Valorisation of Bread Wastes via the Bacterial Cellulose Production. Biomass Convers Biorefin 2024, 1–14. [CrossRef]

- Revin, V. V.; Dolganov, A. V.; Liyaskina, E. V.; Nazarova, N.B.; Balandina, A. V.; Devyataeva, A.A.; Revin, V.D. Characterizing Bacterial Cellulose Produced ByKomagataeibacter Sucrofermentans H-110 on Molasses Medium and Obtaining a Biocomposite Based on It for the Adsorption of Fluoride. Polymers 2021, 13, 1422. [CrossRef]

- Gomes, R.J.; Ida, E.I.; Spinosa, W.A. Nutritional Supplementation with Amino Acids on Bacterial Cellulose Production by Komagataeibacter Intermedius: Effect Analysis and Application of Response Surface Methodology. Appl Biochem Biotechnol 2022, 194, 5017–5036. [CrossRef]

- Uğurel, C.; Öğüt, H. Optimization of Bacterial Cellulose Production by Komagataeibacter Rhaeticus K23. Fibers 2024, 12, 29. [CrossRef]

| Process | Designation | Selectivity (1) | Hydraulic permeability (L/m2/h) | Operation limits |

|---|---|---|---|---|

| MF | MFP5 | 0.5 µm | 264 | pH: 1–11 Pressure: 1–3 bar Temperature: 5–60 °C |

| UF | GR40PP | 100 kDa | 91 | pH: 2–12 Pressure: 1–10 bar Temperature: 5–75 °C |

| GR60PP | 25 kDa | 36 | ||

| GR90PP | 5 kDa | 29 | ||

| NF | NFT | > 99% | 7 | pH: 3–9 Pressure: 15–35 bar Temperature: 5–50 °C |

| Media designation | Carbon and Nitrogen sources |

|---|---|

| HS | 2.0% (w/v) Glucose |

| HS_5.0% (v/v) F#1 | 2.0% (w/v) Glucose 0.5% (w/v) Peptone 0.5% (w/v) Yeast extract 5.0% (v/v) F#1 |

| HS_10.0% (v/v) F#1 | 2.0% (w/v) Glucose 0.5% (w/v) Peptone 0.5% (w/v) Yeast extract 10.0% (v/v) F#1 |

| HS_5.0% (v/v) F#3 | 2.0% (w/v) Glucose 0.5% (w/v) Peptone 0.5% (w/v) Yeast extract 5.0% (v/v) F#3 |

| HS_10.0% (v/v) F#3 | 2.0% (w/v) Glucose 0.5% (w/v) Peptone 0.5% (w/v) Yeast extract 10.0% (v/v) F#3 |

| HS_5.0% (v/v) F#6 | 2.0% (w/v) Glucose 0.5% (w/v) Peptone 0.5% (w/v) Yeast extract 5.0% (v/v) F#6 |

| HS_10.0% (v/v) F#6 | 2.0% (w/v) Glucose 0.5% (w/v) Peptone 0.5% (w/v) Yeast extract 10.0% (v/v) F#6 |

| Parameter (units) | (Mean ± Standard Deviation) |

|---|---|

| pH | 11.5 ± 0.8 |

| Electrical conductivity (mS/cm) | 1.80 ± 0.07 |

| Total Suspended Solids (g/L) | 2.52 ± 0.09 |

| Chemical Oxygen Demand (COD) (g/L) | 12.85 ± 0.60 |

| Total dissolved nitrogen (N) (mg/L) | 6.44 ± 0.31 |

| Parameter (units) | F#1 (> 0.50 µm) |

F#3 (5–25 kDa) |

F#6 (< 0.50 kDa) |

|---|---|---|---|

| pH | 6.08 ± 0.27 | 5.98 ± 0.16 | 6.70 ± 0.23 |

| Chemical oxygen demand (g/L) | 23.32 ± 1.64 | 15.26 ± 0.51 | 0.76 ± 0.03 |

| Reducing sugars (g/L) | 0.78 ± 0.09 | 0.85 ± 0.11 | 0.74 ± 0.06 |

| Total dissolved nitrogen (mg/L) | n.d. | 6.18 ± 0.15 | 2.70 ± 0.07 |

| Samples | Thickness (mm) | Opacity (Abs 600 nm mm-1) | Whiteness Index (WI) | Color Change (ΔE) |

|---|---|---|---|---|

| HS | 0.424 ± 0.050 | 6.892 ± 0.042 | 71.080 ± 3.622 | - |

| HS_5.0% (v/v) F#3 | 0.326 ± 0.040 | 7.862 ± 0.063 | 75.382 ± 1.475 | 4.705 ± 1.528 |

| HS_10.0% (v/v) F#3 | 0.439 ± 0.195 | 6.933 ± 0.116 | 75.859 ± 1.552 | 5.630 ± 1.051 |

| HS_5.0% (v/v) F#6 | 0.871 ± 0.234 | 3.049 ± 0.017 | 75.506 ± 1.729 | 4.505 ± 1.502 |

| HS_10.0% (v/v) F#6 | 0.908 ± 0.181 | 3.527 ± 0.094 | 73.307 ± 2.501 | 3.132 ± 1.603 |

| Tensile Strength (MPa) | Young’s Modulus (MPa) | Elongation at Break (%) | |

|---|---|---|---|

| HS | 12.771 ± 4.445 | 837.633 ± 269.340 | 1.514 ± 0.181 |

| HS_5.0% (v/v) F#3 | 20.132 ± 5.656 | 3706.835 ± 1420.495 | 0.647 ± 0.413 |

| HS_10.0% (v/v) F#3 | 19.221 ± 7.099 | 1986.560 ± 1019.253 | 1.099 ± 0.605 |

| HS_5.0% (v/v) F#6 | 23.149 ± 4.041 | 4827.031 ± 2171.323 | 0.545 ± 0.225 |

| HS_10.0% (v/v) F#6 | 22.755 ± 8.449 | 1645.328 ± 870.893 | 1.182 ± 0.185 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).