1. Introduction

With the rapid development of computer-aided design technology, parametric design has become a research focus in the industrial manufacturing field due to its efficiency and flexibility[

1,

2].For example, the newly registered "Xidian Component Surface Heat Sink Parametric Design Software V1.0" in China demonstrates the application of parametric design in power equipment design, optimizing the design process through intelligent means to improve design efficiency and product quality. This paper is based on Python-based ceramic parametric design research, addressing the growing diversity development needs of the traditional ceramic industry. By integrating physiological human-machine testing and ergonomics experimental analysis, it deeply explores the role mechanism of ceramic shape parametric design in human-computer interaction, aiming to achieve more efficient and personalized design processes. As a time-honored intangible cultural heritage in China, ceramic culture is widely loved by the masses and enjoys a prestigious reputation both domestically and internationally. Its unique artistic characteristics and exquisite ceramic-making techniques make Chinese ceramics a treasure of world civilization[

3]. With the increasing demand for personalized customization, computer-aided design that can quickly generate designs based on the preferences of the customizers is gradually entering the consumer market[

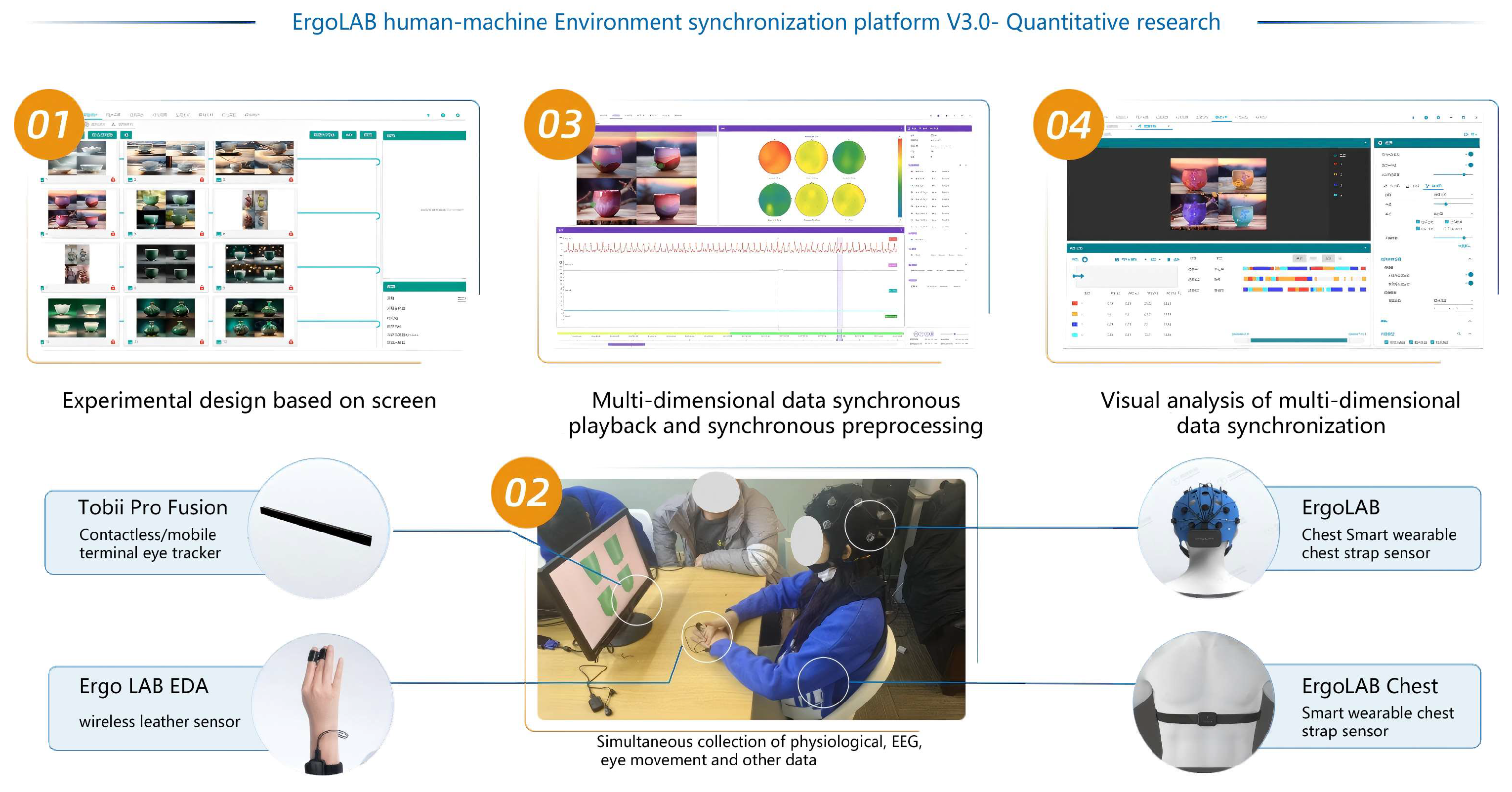

4]. To optimize design solutions and enhance user experience, this study innovatively introduces the ErgoLAB human-computer environment synchronization platform for collecting ceramic product shape dataThe study involves multimodal data related to the user, including electroencephalography (EEG) for recording the users mental activities, eye-tracking technology to display the distribution of visual focus, and electrocardiogram (ECG) and skin conductance response (GSR) to show the users emotional state and stress response, comprehensively and deeply assessing the users cognitive load[

5], operational efficiency, and comfort perception in the parametric design process, providing a scientific basis for design optimization. Subsequently, combining ceramic 3D printing layer-by-layer technology[

6,

7], this study achieves a complete closed loop from design to manufacturing of parametric ceramic models, not only successfully verifying the manufacturability of the design but also fully demonstrating the great potential and broad prospects of parametric design in promoting the intelligent, personalized, and diversified development of ceramic manufacturing. This study not only deepens the understanding of parametric design for ceramic modeling but also provides strong support for the diverse development of the ceramic industry, while offering valuable references for parametric design in other industrial design fields. Its foresight, practicality, and academic value are significant, playing a crucial role in promoting the integration and innovation of industrial design and manufacturing technologies.

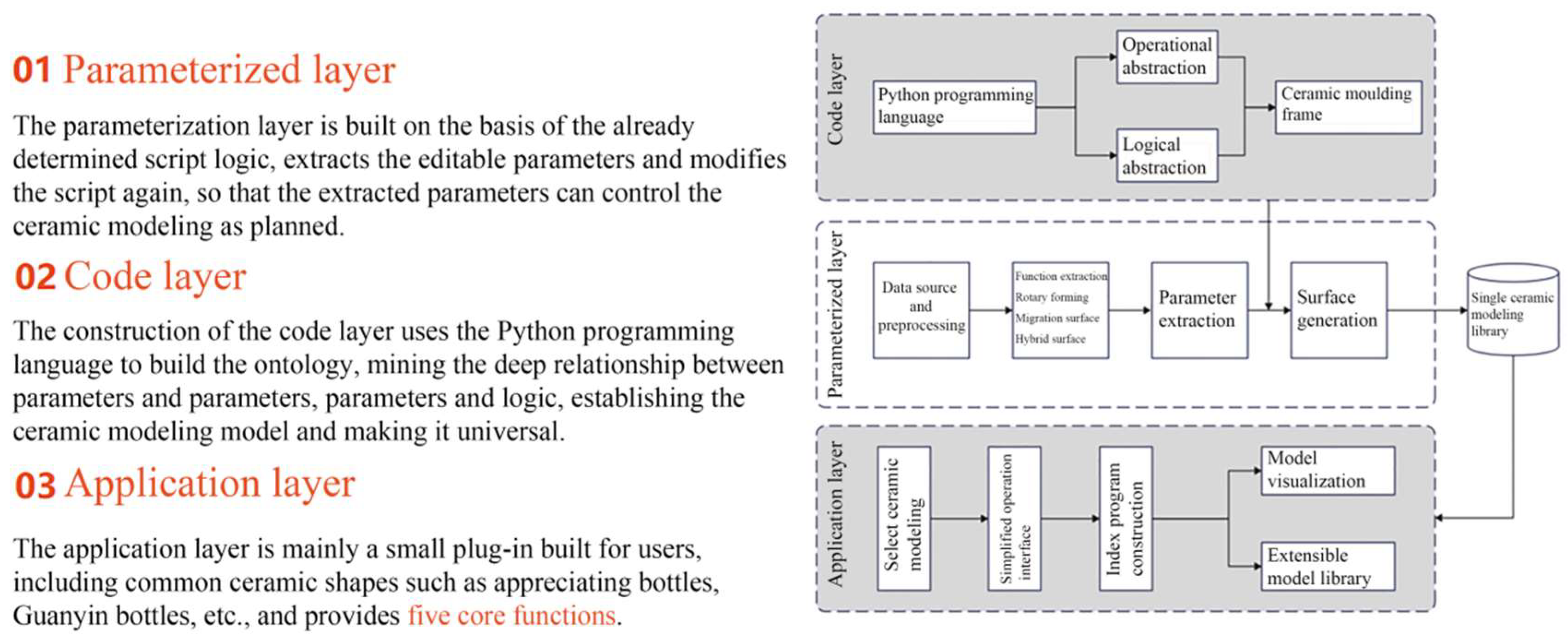

3. Parametric Design Practice

3.1. Determination of Parametric Design Factors

With the continuous improvement of peoples living standards and aesthetic requirements, ceramic products are no longer limited to traditional practical functions; their artistic value and personalized characteristics are increasingly valued. The artistic value of ceramic artworks is mainly reflected in the profound artistic cultivation and unique artistic style presentation. Moreover, the strong plasticity of ceramic crafts allows artists to transform them into various unique forms through creativity and imagination, making them more visually appealing and artistic. In the design process of ceramic products, the selection and combination of modeling elements are directly related to the overall effect and user experience of the product. Therefore, how to scientifically and reasonably determine the modeling elements of ceramic products and optimize design based on user needs has become an important topic in ceramic product innovation design. In the design process of ceramic products, the selection and optimization of modeling elements hold a pivotal position. This is because modeling directly affects the visual appeal of the product and profoundly influences the user experience. To systematically and thoroughly study how ceramic product modeling elements specifically impact user experience, this research adopts principles of human factors engineering and utilizes the ErgoLAB Human-Machine Environment Synchronization Platform V3.0, carefully planning experiments and comprehensively collecting data, aiming to rigorously conduct human factors engineering experiments.This paper analyzes the role of ceramic product shaping elements on user experience, focusing on the core elements such as the shape, volume, material, mouthpiece, handle and bottom design of ceramic products[

13].Advanced measurement technology and data analysis methods are used to summarize the shaping elements of ceramic products, and then carry out parameterization design on this basis

This paper adopted the ErgoLAB Human-Machine Environment Synchronization Platform V3.0 for experimental design and data collection. The platform can synchronously collect multi-modal data from participants, including physiological signals (such as electroencephalography, electrocardiography, heart rate variability, etc.), eye movement data, etc., providing strong support for a comprehensive analysis of participants behaviors and reactions when observing and using ceramic products. To ensure the reliability and representativeness of the experimental results, we carefully recruited fifty representative participants to ensure the diversity of the sample source and took measures to balance the distribution of the sample to avoid the impact of data skewness and outliers. The participants covered different age, gender, occupational, and educational backgrounds to ensure that the experimental results can fully reflect the needs and preferences of different user groups. During the experiment, we showed the participants samples of ceramic products with various design elements and set observation times, employing a series of advanced physiological measurement techniques, such as electroencephalography (EEG) technology to capture users cognitive processing, eye movement tracking technology to reveal patterns of visual attention distribution, and electrocardiography (ECG) and galvanic skin response (GSR) technology to reflect users emotional changes and stress responses (see

Figure 2, which shows a photo of an actual experimental scene). To accurately capture the behavior of the participants. In the paradigm of solicitation and response, we designed a variety of task scenarios including product browsing, preference selection, and use simulation. In addition, we adjusted the experimental parameters such as lighting conditions and observation angles to study the variability of participants responses under different conditions

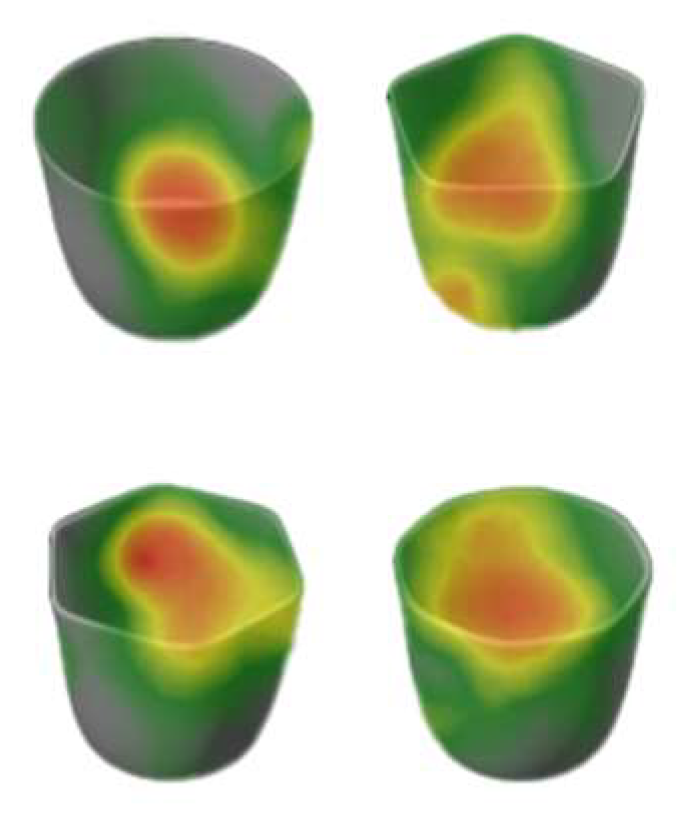

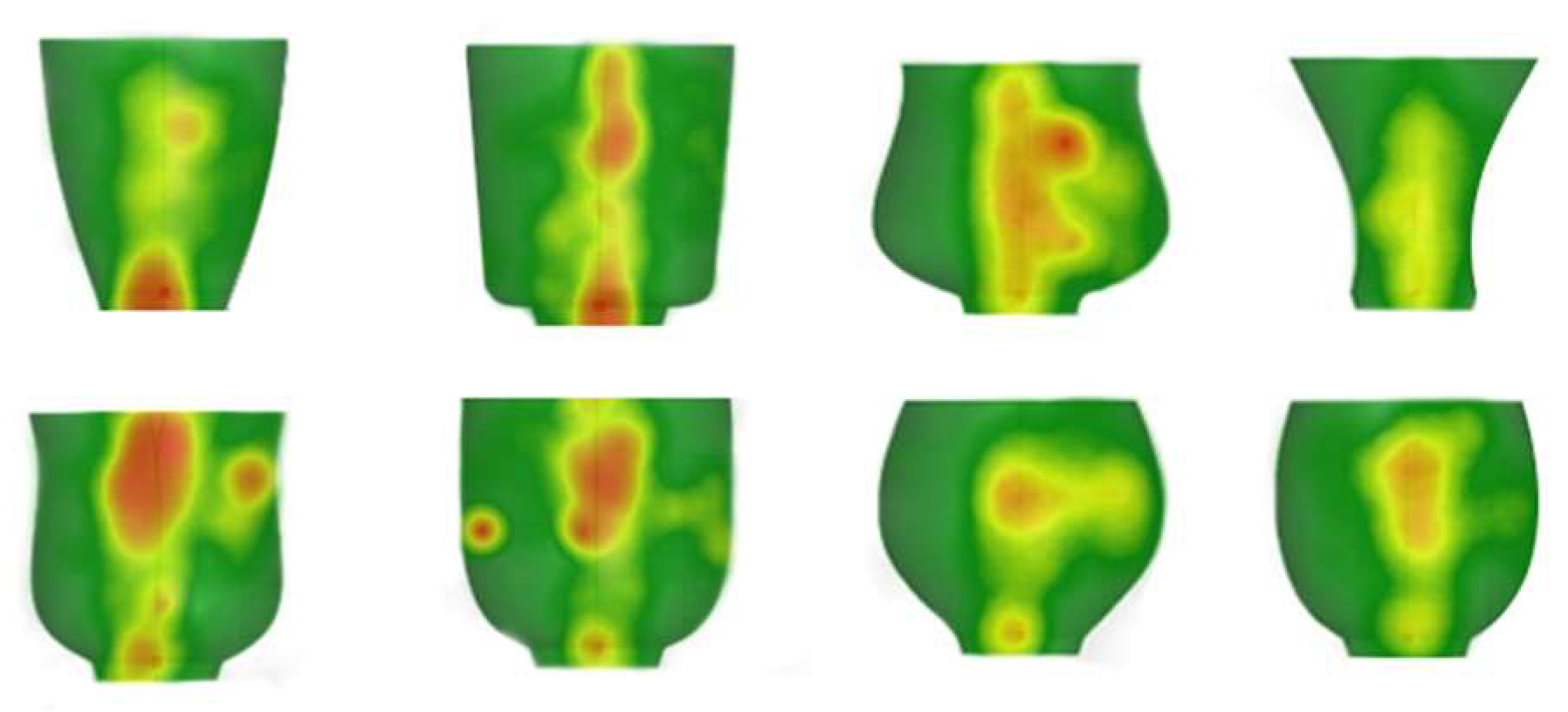

During the human experiment, based on the obtained thermographic information, it was found that when the subject viewed the ceramic product from below, their visual attention was mainly focused on the cup rim shape; while at an oblique viewing angle, the changes in the outer contour curves corresponding to the axis of the ceramic product became the focal point of attention (see

Figure 3 and

Figure 4).

Based on the results of eye movement hotspots, gaze trajectory, gaze duration and brain wave analysis of ErgoLAB platform, several key factors in ceramic product shape design are established:(1)Final radius and starting radius; (2)Number of segments; (3)Starting Angle and Ending Angle and (4)End height and start height.

Among them, about the (1)Final radius and starting radius,these two parameters in geometry respectively define the curvature characteristics of the terminal and initial points of a shaping curve or contour. The final radius, as a key indicator of the products top shape, is directly related to the width and smoothness of the cup rim or top opening, significantly impacting the overall proportion and visual focus of the product. The starting radius, on the other hand, lays the foundation for the products form, closely associated with the stability of the product and the design of the bottom support structure, while also visually establishing the "foundation" of the product. By precisely controlling these two radius values, designers can create various forms that transition smoothly from soft to sharp edges or maintain uniform curvature, thus meeting different aesthetic preferences and functional requirements.

And (2)number of segments, the number of segments plays a crucial role in parametric design, determining the degree of subdivision of shapes or surfaces, which in turn affects the fineness and complexity of the forms presentation. Increasing the number of segments means introducing more control points on the curve or surface, allowing designers to more accurately manipulate local changes in form, such as subtle indentations, ripples, or transitions, thereby enriching the visual hierarchy and tactile experience of the product, enhancing its overall refinement and artistry.

And (3)starting angle and ending angle, these two parameters define the starting and ending directions of the shaping curve or outline, which are crucial elements for creating the dynamism, symmetry, and stability of a product. The selection of the starting angle determines the position and direction of the forms beginning, while the ending angle dictates the manner in which the form concludes. By skillfully adjusting these two key angles, designers can create a myriad of forms, from smooth transitions to sharp turns, all accurately guiding the users visual flow, thereby significantly enhancing the products visual impact and spatial hierarchy.

The last key factor (4)end height and start height, the height parameter defines the vertical dimension and spatial positioning of a product in three-dimensional space. The endpoint height, which is the highest point on the top of the product, not only determines the overall height of the product but also influences the visual focus and spatial proportion relationship. The starting point height is closely related to the bottom or support surface of the product, serving as the foundation for ensuring stable placement and visual balance. A reasonable height design must comprehensively consider the actual application scenarios of the product, the scientific principles of ergonomics, and the aesthetic requirements of visual aesthetics, aiming to achieve a harmonious unity between functionality and aesthetics.

Based on the above data analysis results, we carry out parametric design and optimization of the shaping elements of ceramic products (see

Figure 5).

3.2. Parametrically Adjusted Battery Pack

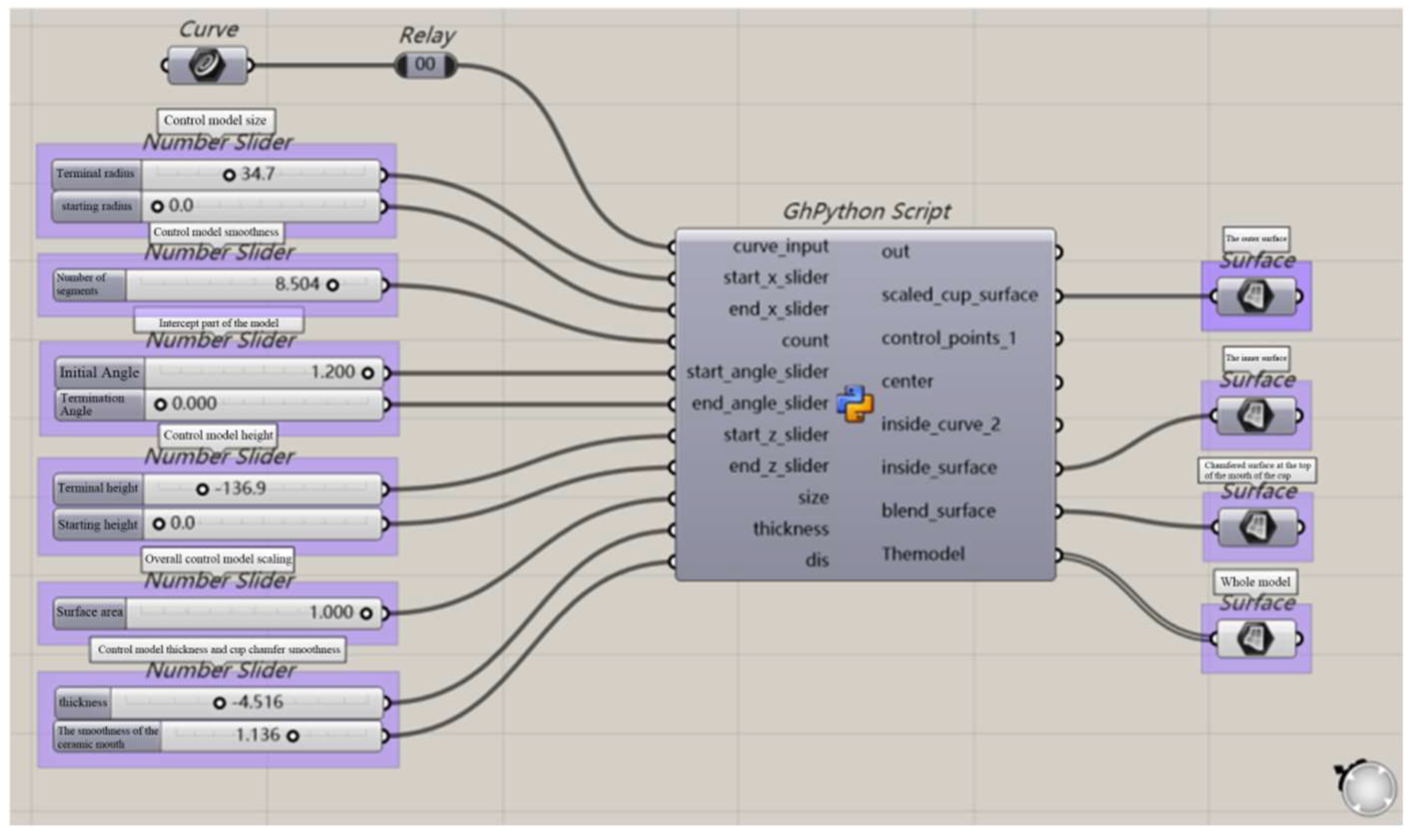

Within the complex framework of parametric design, parametrically adjustable battery packs play a crucial role, serving not only as a bridge between designers and computer algorithms but also as the key to seamlessly integrating creative precision with technical implementation. Leveraging Grasshopper, an excellent parametric design platform, we have developed a highly integrated, flexible, and real-time feedback parametric adjustable battery pack, aiming to drive the infinite possibilities of ceramic product shaping through precise parameter control.

According to the logical flow of parametric design, the battery pack is divided into multiple levels, including the basic parameter input layer, computational processing layer, shape generation layer, and feedback optimization layer. Each level bears specific functions, progressively deepening to form a closed design cycle process. Within the battery pack, we have established logical chains between parameters to ensure that any adjustment is accurately transmitted to every stage of shape generation. Through advanced programming techniques such as conditional judgment and iterative loops, we have achieved mutual dependence and constraints between parameters, enhancing the flexibility and controllability of the design. For key parameters (such as curve radius, angle, height, number of segments), we have specifically designed input components that support various input methods, including numerical input, slider drag, and preset value selection, aiming to meet diverse design requirements. Leveraging Grasshoppers instant update mechanism, we have achieved real-time dynamic parameter adjustments. Whenever a parameter changes, the battery pack immediately recalculates and updates the shape, ensuring designers can see the adjustment effects in real-time, thus achieving more precise personalized choices.

This article integrates Rhinos 3D view function to display the parametrically generated ceramic product shapes in real-time for designers. This intuitive visual feedback significantly improves design efficiency, enabling designers to rapidly iterate and optimize their design solutions. In addition to real-time visual previews, we have introduced a performance evaluation module to assess the structural strength, material consumption, and other aspects of the generated shapes, providing designers with intuitive feedback on the evaluation results. This data-driven feedback mechanism helps designers find the optimal balance between creativity and practicality. We have optimized the battery pack algorithm, effectively reducing redundant calculations and thus enhancing overall operational efficiency. At the same time, we have modularized the battery pack for easier maintenance and upgrades in the future. To meet the future expansion needs of parametric design, we have meticulously designed multiple expansion interfaces for the battery pack. This means that designers can easily add new parameters, computational components, or shape generation methods according to actual needs, continuously expanding the boundaries of parametric design.

In summary, the parametric adjustment battery pack we built not only realizes the fine control and dynamic adjustment of ceramic product shape, but also provides designers with an efficient, flexible and easy to iterate parametric design environment through real-time preview and feedback mechanism, performance optimization and scalability considerations and other design details.

Figure 6.

Battery pack display.

Figure 6.

Battery pack display.

3.3. Python Code Control Manufacturing Generation

In the field of parametric design and manufacturing, Python code serves as a powerful programming tool whose role in the ceramic modeling generation process is indispensable, especially in the two core aspects of curve rotation and forming, as well as the creation of wall thickness and blended surfaces. Adopting Python code plays a crucial controlling role in these two key steps, facilitating subsequent 3D model generation.

The primary task of the Python code is to receive the rotation parameters transmitted by the Grasshopper plugin, including the direction vector of the rotation axis, starting and ending angles, and the coordinates of the two-dimensional contour control points, among other core information. Subsequently, the code needs to preprocess these input parameters, such as verifying the legality of the parameters, converting angles to radians (if necessary), and calculating the rotation matrix, etc. Based on the user-defined rotation axis and angle, the Python code employs linear algebra theory of rotation matrices to accurately construct a three-dimensional matrix describing the curves rotation. This matrix will be used to spatially rotate each control point of the two-dimensional contour curve. Using the rotation matrix, the Python code performs spatial coordinate transformations on each control point to achieve three-dimensional rotation of the curve. Subsequently, using these rotated control points, combined with Rhinos API functions (such as AddRevSrf or AddNurbsSurface), an accurate three-dimensional surface model is constructed. During this process, to ensure the smoothness and continuity of the surface, the code also needs to appropriately adjust and refine the control points to meet design requirements.

Thereafter, the Python code receives the wall thickness value set by the user, which directly determines the spatial distance between the inner and outer surfaces of the ceramic shape. The code must ensure that this parameter is within a reasonable range and perform necessary verification and conversion. Based on the outer surface (i.e., the curved surface generated by rotation) and wall thickness parameters, the Python code uses offset algorithms (such as OffsetSurface) to generate the inner surface. This process requires precise calculation of the offset amount for each curved surface point and ensuring that the geometric properties of the inner surface are consistent with those of the outer surface. Subsequently, the code must also perform necessary optimization processing on the inner surface, such as adjusting control points and increasing the number of subdivision segments to improve smoothness, to meet design requirements.

Python codes utilize complex geometric algorithms and mathematical theories (such as interpolation, approximation, surface subdivision, etc.) to calculate the blended surfaces ensuring the integrity and aesthetics of ceramic modeling. This process requires ensuring that the connections between the blended surfaces and internal and external surfaces are smooth and seamless, meeting specific geometric continuity requirements. The codes also need to make necessary adjustments and optimizations to the blended surfaces to achieve the best design outcomes.

Finally, the Python code is responsible for correctly closing the inner and outer surfaces as well as the blended surfaces to form a complete ceramic shape. This includes handling the matching of surface boundaries, adjusting normal vectors, and verifying the overall geometric characteristics. The code must comprehensively verify and inspect the generated ceramic shape to ensure it meets design requirements while also being feasible for actual production, covering multiple aspects such as surface continuity, smoothness, wall thickness uniformity, and overall shape accuracy.

In summary, Python code plays a core controlling role in the process of parametric ceramic shape generation. Through precise calculation of rotation matrices, construction of three-dimensional surfaces, generation of inner surfaces and blended surfaces, and overall verification, Python code ensures that ceramic shape generation is both rapid and accurate, laying a solid technical foundation for subsequent manufacturing and production. For example, NURBS-based modeling methods demonstrate their advantages in constructing vivid ceramic shapes[

14], while Python, as an advanced programming language, is widely used for rapid development and prototyping due to its concise syntax and rich libraries, which have been widely applied in the architectural field; however, it has not yet seen reasonable application in traditional ceramics industries. This paper presents the first use of Python programming to achieve simple to moderately complex ceramic shape designs. Its powerful computational capabilities and flexible programming features make parametric design possible, significantly improving the efficiency and quality of ceramic shape design.

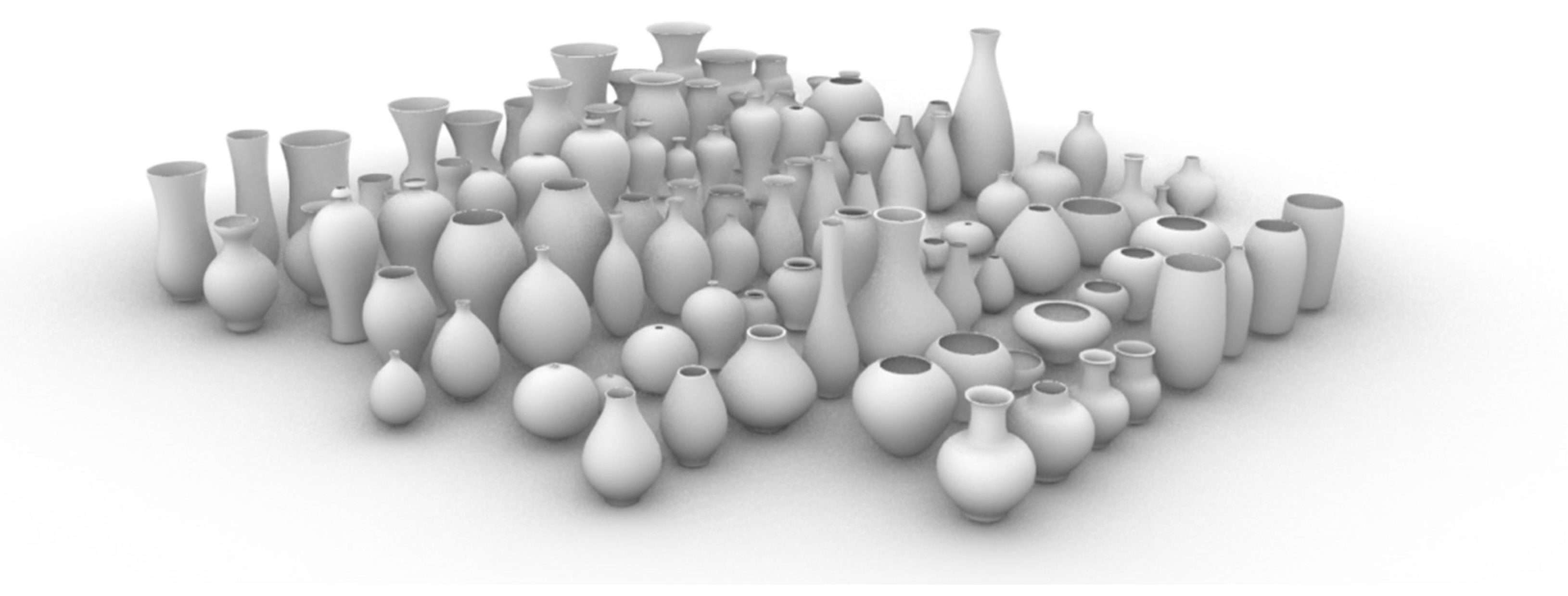

3.4. Application of Parametric Design

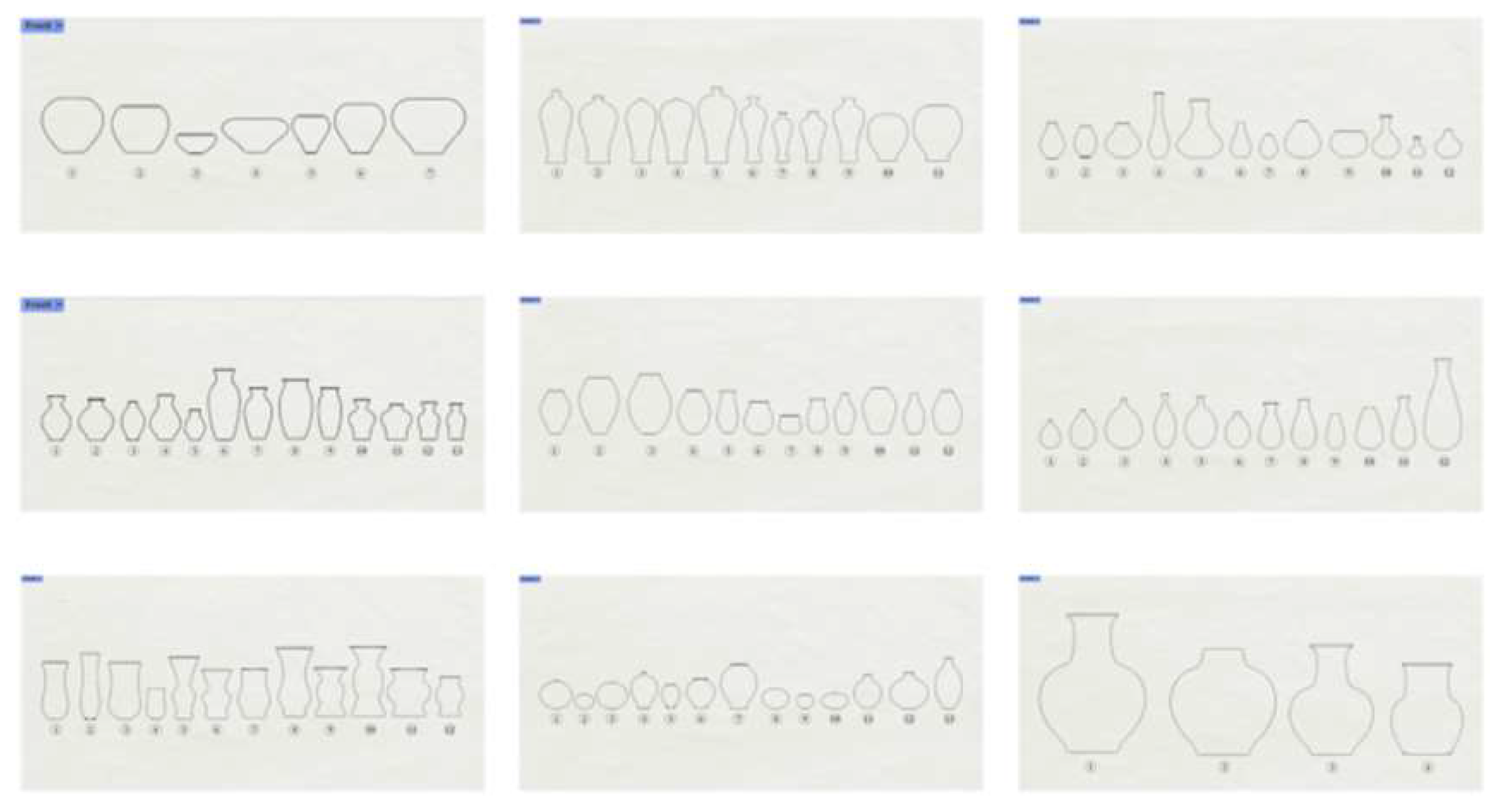

Figure 7.

Parametric batch production of ceramic shapes.

Figure 7.

Parametric batch production of ceramic shapes.

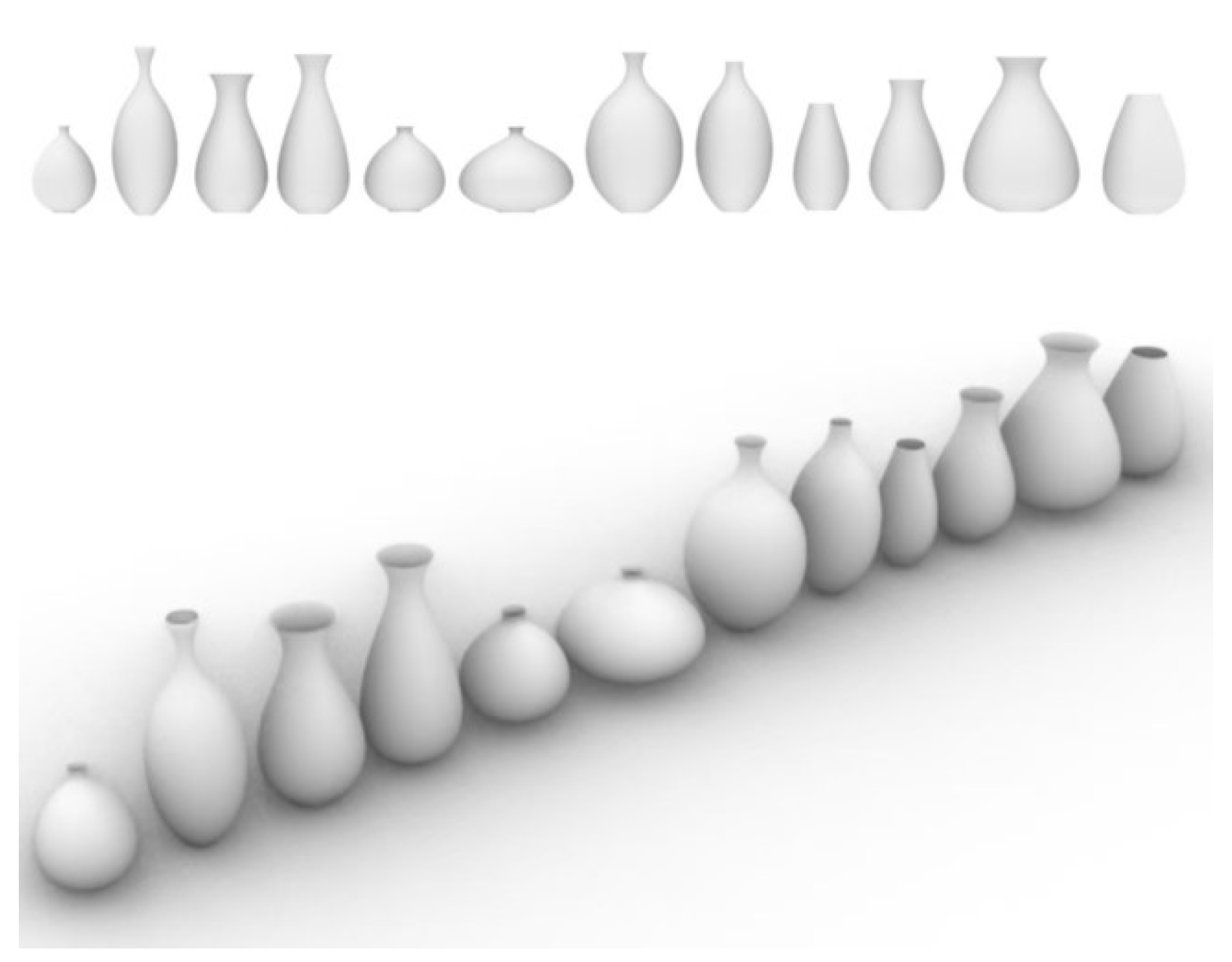

To verify and demonstrate the practical application effects and advantages of the Python-based ceramic shape parametric design system, this section particularly selects the traditional Chinese bottle named by Yuhuchun as a representative case for in-depth discussion. The Yuhuchun bottle, as a typical form in Chinese porcelain design, evolved from the water purification bottles found in Tang Dynasty temples, featuring a basic shape of flared mouth, slender neck, hanging abdomen, and ring foot, along with aesthetically pleasing lines formed by symmetrical "S" -shaped curves on both sides. Throughout the Song, Yuan, Ming, Qing dynasties, the Republic of China era, and up to modern times, the Yuhuchun bottle has not only been widely used in practical applications but has also been highly esteemed in artistic appreciation. As a masterpiece of traditional Chinese ceramic art, the Yuhuchun bottle is renowned for its unique shape, elegant lines, and rich cultural heritage, demanding extremely high standards for design precision and detail processing, making it an ideal subject for testing the performance of parametric design systems[

15].

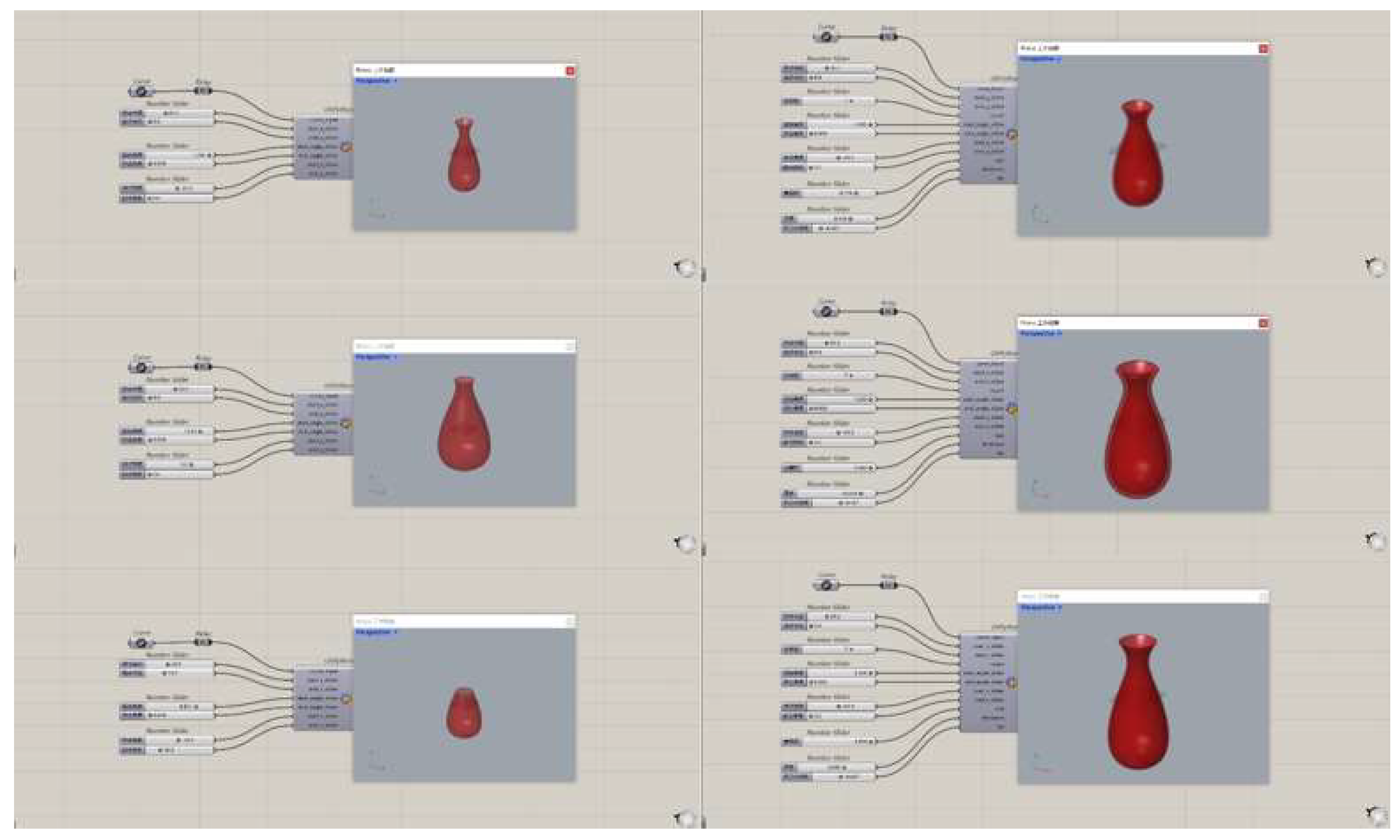

In the parametric design process of the Yuhuchun bottle, we strictly adhered to the parametric design procedures and technical details previously outlined. Firstly, through an in-depth analysis of the Yuhuchun bottles shape, we identified and defined the key parameters that influence its form, such as the bottles radius, the length and angle of the neck, and the diameter of the base. Subsequently, using Python programming language in conjunction with Rhino and Grasshopper plugins, we constructed a parametric model (see

figure 8)[

16]. Through Python code, we precisely controlled key parameters such as curve rotation, surface generation, and wall thickness adjustments. By adjusting these core parameters, we rapidly generated and optimized the shape of the Yuhuchun bottle, ensuring the accuracy and aesthetics of the final design.

Figure 8.

Parametric generation and display of Yuhu Chun bottle shape.

Figure 8.

Parametric generation and display of Yuhu Chun bottle shape.

Figure 9.

Python code parameterization generation display.

Figure 9.

Python code parameterization generation display.

Through the aforementioned parametric design system, we successfully generated multiple jade pot spring vase designs in different styles and converted them into physical models using 3D printing technology (see

Figure 10). Compared with traditional manual design, parametric design combined with 3D printing takes about 1 hour to print a model approximately 25 cm tall, which not only meets the personalized rapid customization needs of the cultural tourism industry at tourist attractions but also significantly improves design efficiency, allowing designers to easily explore more diverse design solutions[

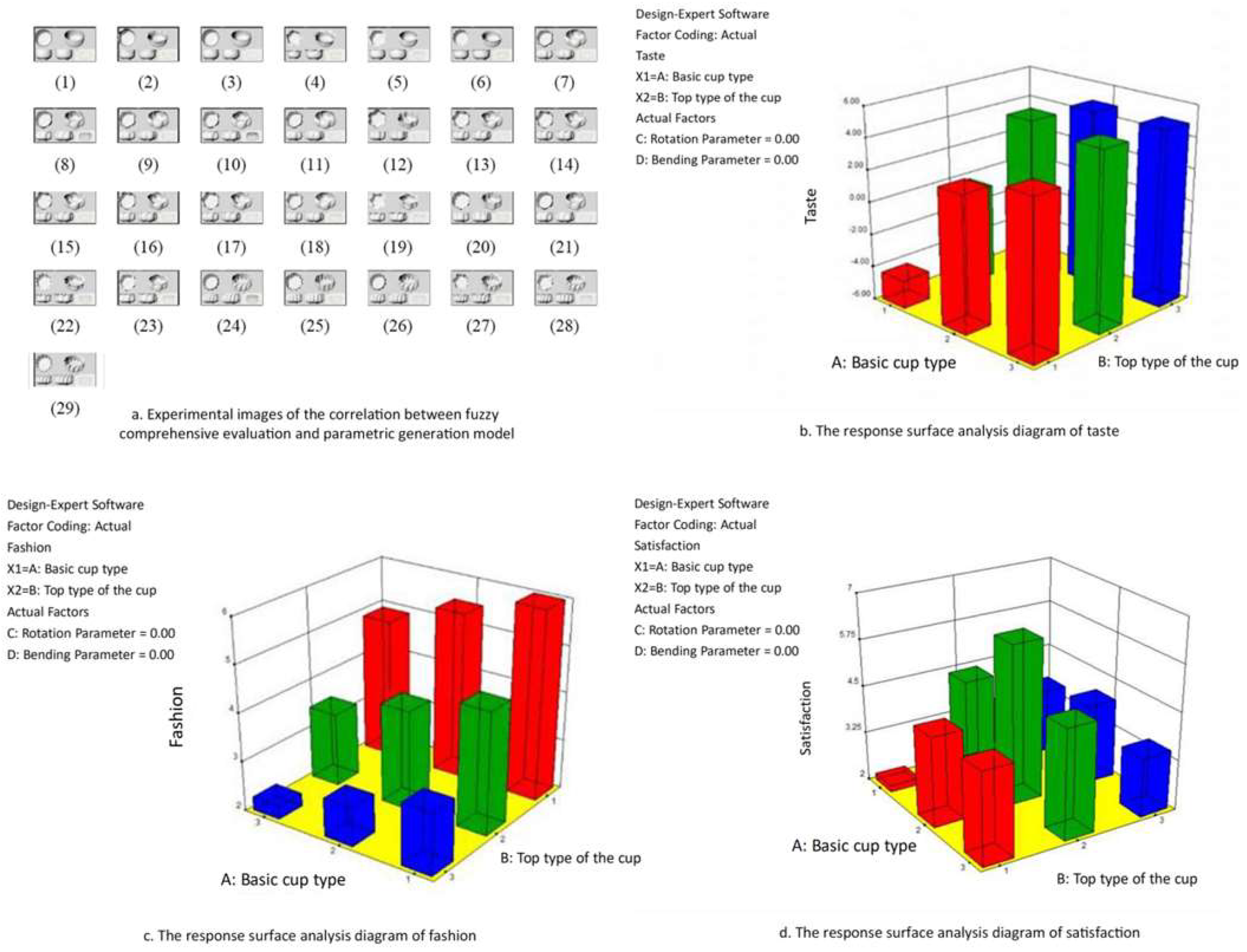

17]. Meanwhile, we analyzed the generated models using fuzzy comprehensive evaluation[

18], and the results showed that parametric design has significant advantages in enhancing the aesthetic characteristics of product shapes (see

Figure 11).

In summary, through the parametric design practice of the classic Yuhuchun vase shape, we have fully verified the practicality and effectiveness of the ceramic shape parametric design system based on the Python platform. This system not only provides ceramic designers with powerful design tools but also offers strong support for the diversified and personalized development of the ceramic industry. In the future, we will continue to deepen our research and application of parametric design, promoting the deep integration of ceramic art and modern technology.

4. Conclusions and Future Outlook

This study, for the first time, establishes the design parameters of ceramic shapes based on scientific experimental research grounded in ergonomics, achieving exploratory results in the field of Python ceramic shape parameterization design and application. It explores the human-computer interaction mechanism of ceramic shape parameterization design, adopting a parametric design method to conveniently and quickly construct a model library containing various classic ceramic shapes, and achieves a complete closed loop from design to manufacturing through 3D printing technology, verifying the manufacturability of the design. These research findings not only deepen our understanding of ceramic shape parameterization design but also inject strong momentum into the diversified development of the ceramic industry. However, we also recognize that current research faces challenges such as high technical barriers and the need to improve software compatibility and stability. Looking ahead, we plan to adopt parametric design methods, such as the reconstruction technology of Yagizhi peony patterns, to further enhance the aesthetic appeal and texture of ceramic products. At the same time, we will strive to reduce technical barriers by developing more intuitive and user-friendly design tools and interfaces, enabling more designers and even ordinary consumers to easily master parametric design technology, thereby promoting the popularization and deep innovation of ceramic design, enhancing the inclusiveness and originality of design, and contributing to the inheritance and prosperity of ceramic art.