1. Introduction

The amount of freshwater available has drastically decreased due to rapid population growth, industrialization, and recurring dry extremes. Merely 3% of freshwater comprises all of Earth’s water resources, with saline water making up the other 97% [

1]. One-fifth of the world’s population, according to the World Health Organization (WHO), resides in nations where freshwater is scarce [

2]. Therefore, more attention is paid to alternatives to natural freshwater sources [

3]. One of the primary methods for potable water production is water desalination, which is the process of extracting salts and minerals from brackish or salty water to create pure potable water. For this reason, desalination of seawater (SW) or brackish water (BW) is one of the essential solutions to the worldwide problem of water scarcity [

4]. The process of desalination is quite effective approach for potable water production [

5,

6].

According to [

7] about 1% of the world’s drinking water comes from desalination, this amount is rising annually. A new production capacity of 5.7x10

6 cubic meters per day would be added with an anticipated US

$10 billion investment over the following five years. By 2030, this capacity is anticipated to double. Around 18,000 desalination facilities with a combined gross output of 86.55 million m

3/day, or 22,870 million gallons per day (MGD), were in operation as of the end of 2015. Since then, the total number of desalination units reached almost 21,000 in 2022 [

8]. The total amount of freshwater production from desalination plants worldwide is approximately 35×10

9 cubic meters per year [

9]. Approximately 44% of this capacity, or 37.32 million m

3/day or 9,860 MGD, is found in North Africa and the Middle East. The “hot spots” for faster desalination growth over the next ten years are anticipated to be Asia, the US, and Latin America, even if desalination within that region is predicted to increase steadily at a pace of 7 to 9 percent annually.

The majority of EU desalination plants are found in the Mediterranean region, where demand for them is expected to be highest in the future. However, the main barriers to the general adoption of desalination systems are the substantial upfront technology costs and the large amount of energy that is needed for the technological processes. The production of brine, a hyper-saline byproduct, and the desalination process’s relatively high energy consumption are its principal downsides. Furthermore, the emissions of greenhouse gases (GHGs) from fossil fuel-powered desalination plants have a detrimental effect on the environment and contribute to global warming by emission of CO2. As mentioned, among the main drawbacks of desalination is that it uses a lot of energy, which contributes to global warming [

10].

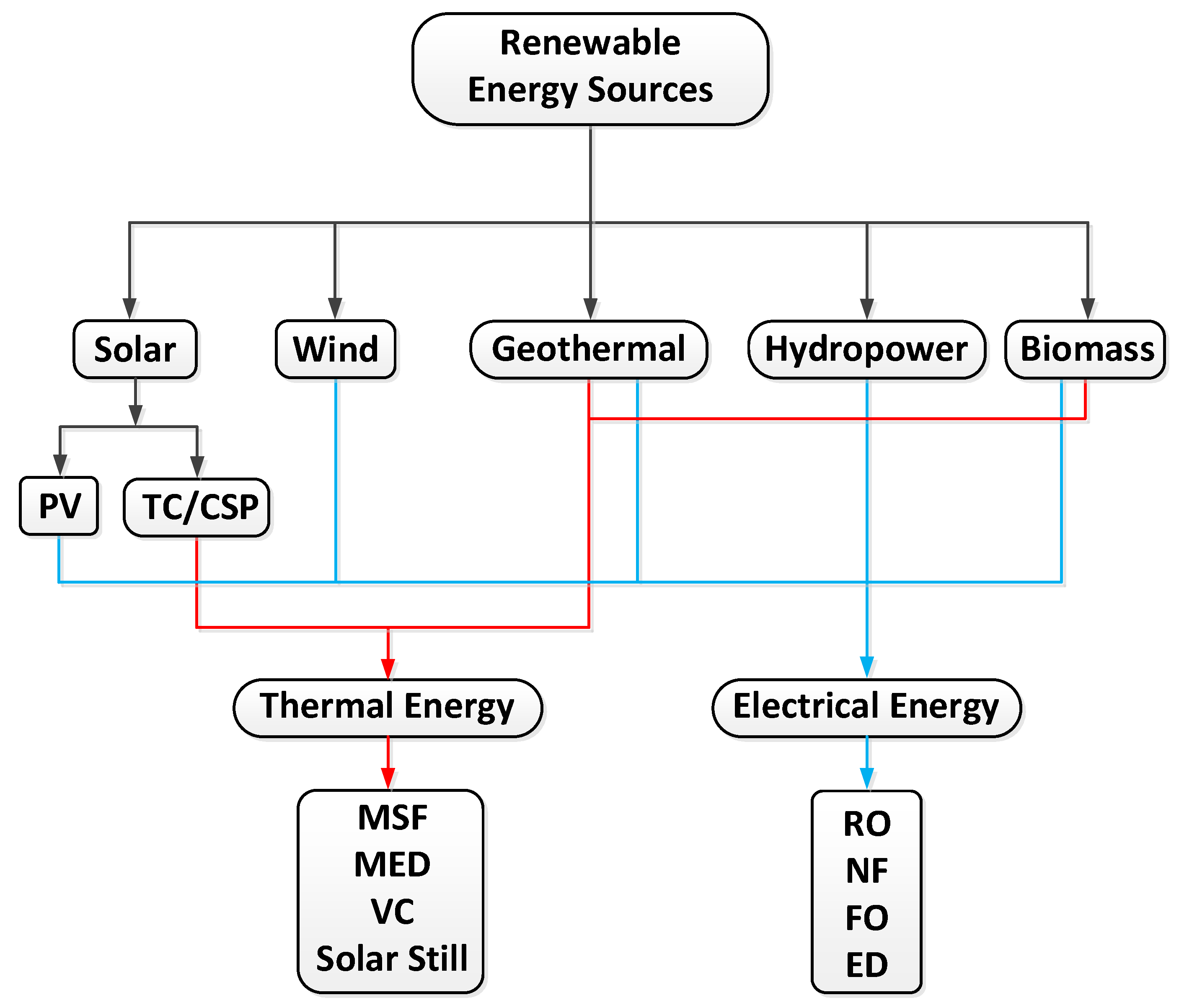

Renewable energy is a viable substitute for fossil fuels because it is clean and abundant, making it a good option for running desalination plants. For this reason, addressing the water-energy linkage is essential to moving towards a sustainable future. Consequently, it is crucial to incorporate renewable energy sources (RES) into the desalination process. Integrating RES into desalination systems can significantly improve sustainability. Renewable energy sources, such as solar, wind, and geothermal, offer promising solutions to mitigate these challenges related to GHG emissions and potentially can provide sustainable alternatives for desalination [

11]. The transition to desalination techniques that are both affordable and ecologically benign is being made easier by technological advancements. The increasing demand for clean water around the world requires the use of renewable energy. Over the past decade, renewable energy sources based desalination has primarily been carried out in areas like the Middle East that are known for having significant wind power and an abundance of sun radiation. However, there is now more interest in this area due to a combination of recent price reductions and technological breakthroughs in renewable energy.

Solar energy stands out as a particularly effective resource for desalination. Technologies like solar stills and solar-powered reverse osmosis systems harness sunlight to generate the heat or electricity needed for the desalination process. For instance, solar stills use the natural evaporation of water, which is then condensed and collected, effectively transforming seawater into potable water with minimal carbon footprint [

12,

13]. Additionally, concentrated solar power (CSP) systems can generate high temperatures necessary for thermal desalination processes, making them a viable option in arid regions where sunlight is abundant [

14]. Moreover, integrating renewable energy with desalination technologies enhances resilience against fluctuating energy prices and supply disruptions. By investing in renewable energy-powered desalination systems, countries can achieve greater energy independence and ensure a stable supply of freshwater. The versatility of solar energy in desalination extends beyond just traditional solar stills. Advanced technologies like photovoltaic (PV) panels can power reverse osmosis systems, offering a more scalable solution to meet larger water demands. Innovations such as solar-powered desalination plants have been successfully implemented in various regions, demonstrating their effectiveness in providing potable water while significantly reducing operational costs.

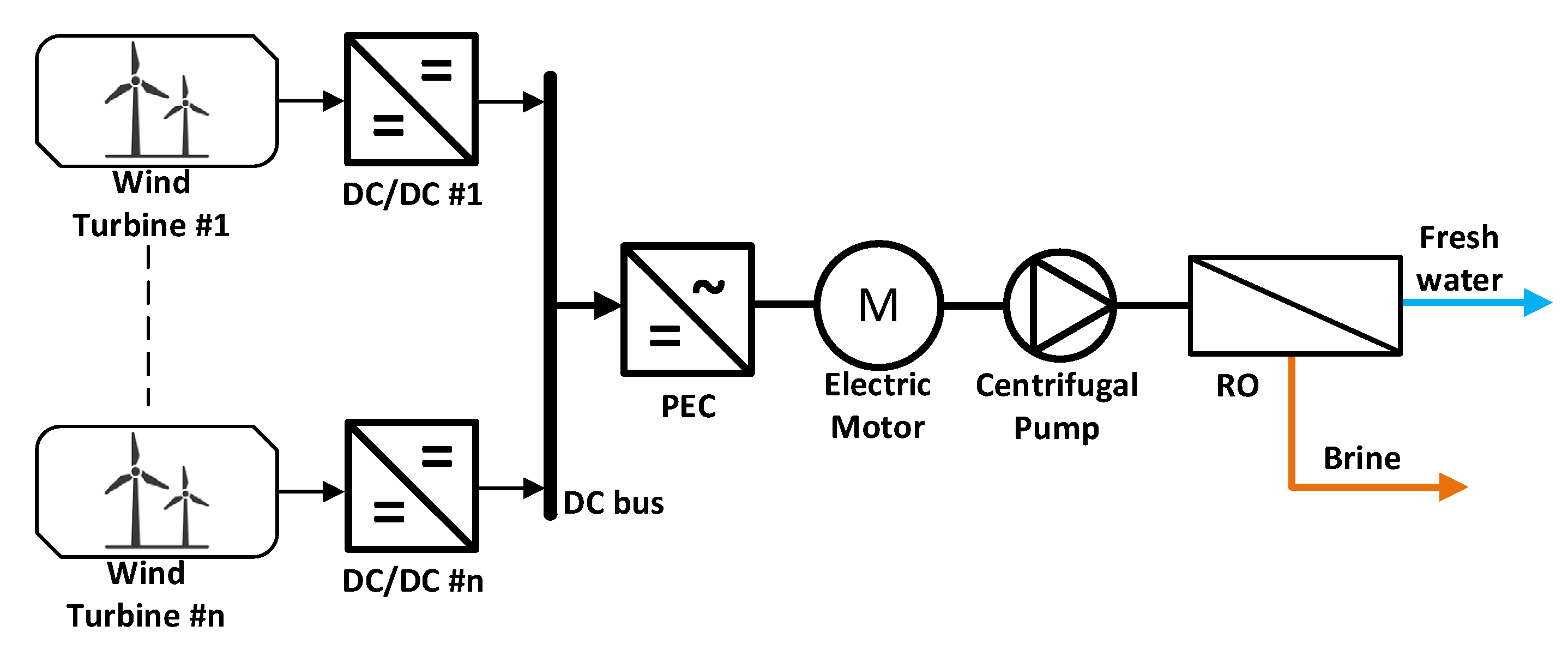

Wind energy is another renewable source that can significantly contribute to sustainable desalination. Wind turbines can generate electricity to power desalination plants, reducing reliance on fossil fuels [

15,

16]. In coastal areas where both wind and seawater are readily available, combining wind energy with desalination technologies can create a synergistic approach to addressing freshwater scarcity. This method not only lowers operational costs but also minimizes greenhouse gas emissions associated with traditional energy sources [

17]. Offshore and onshore wind farms can generate substantial amounts of electricity, which can be directly utilized to power desalination plants [

18,

19].

Geothermal energy, which utilizes heat from the Earth’s interior, can also be harnessed for desalination. The ability to harness heat from deep within the Earth allows for efficient thermal desalination processes that can operate at lower temperatures compared to conventional methods [

20,

21]. This not only reduces energy consumption but also enhances the overall sustainability of the system. It offers a unique advantage for desalination, particularly in regions with significant geothermal resources. In regions with substantial geothermal resources, this energy can be used in various desalination processes, including multi-effect distillation (MED) and multi-stage flash (MSF) distillation. These methods can operate efficiently at lower temperatures, making geothermal a sustainable option for producing freshwater while leveraging local resources.

However, even though RES powered desalination plant systems are attractive options to address the global freshwater deficit there are some challenges and obstacles that slow down the adoption of the technology. In fact, these systems are mostly either part of the national power grid or should have a reliable long-term energy storage system to guarantee a steady and uninterrupted supply of power. Since the significant amount of electricity needed by the entire desalination plant comes from the electrical power grid, under the grid connection scenario, these systems could overload the grid, particularly in places with inadequate infrastructure for the delivery of electricity, at nighttime and on cloudy days. Moreover, the intermittency of renewable energy sources like solar and wind can pose operational challenges for desalination plants, affecting their efficiency and reliability. Furthermore, integrating complex treatment for seawater, filtration, and wastewater treatment technologies into RES powered desalination systems requires careful planning and innovative engineering solutions. Several renewable energy sources, including solar, wind, and geothermal, are combined with various desalination techniques in hybrid RES desalination systems. This is a growing practice. These hybrid systems are designed to reduce the intermittent character of individual renewable sources, increase reliability, and maximize energy efficiency [

22].

The fluctuation of RES during electricity production poses a threat to the safety and reliability of the power grid and can negatively impact the desalination process. Energy storage systems (ESS) are becoming crucial for the broad integration of renewable energy sources into power generation, preserving the electrical grid’s security, and facilitating the energy system’s transition to a more environmentally friendly state [

23]. Recent developments have incorporated advanced energy storage technologies like batteries and thermal storage devices to address the unpredictability of RES. By helping to keep the supply of energy for desalination processes stable, these systems ensure a steady flow of water. Based on how a particular type of energy is used for storage, the different types of ESS can be categorized. Mechanical technologies, such as flywheels (FESS), compressed air (CAESS), hydro-pumped (HPESS), and thermal technologies, such as high-temperature storage (HTESS) and latent heat storage (LHESS), are among the most utilized. One important part of energy storage systems is battery storage systems or BESS. For instance, a battery energy storage system in conjunction with RES can be a cost-effective solution for powering a desalination plant. According to the Statista Research Department, 57 GW of battery energy storage devices will be constructed by 2030, only in Europe [

24].

Another issue is that desalination systems need a lot of energy to operate. The energy-intensive nature of desalination processes necessitates a focus on optimizing energy use, particularly when integrating RES such as solar and wind power.

Numerous studies have examined the integration of renewable energy sources primarily concentrating on specific energy sources or desalination methods. This has resulted in a fragmented understanding of how various renewable energy technologies could be combined in a synergistic way to improve desalination sustainability and efficiency. Furthermore, when adopting these combined structures on a larger scale, most research studies usually omit a comprehensive analysis of their advantages and disadvantages.

This paper aims to provide a comprehensive analysis of the current state of energy efficiency in desalination systems, highlighting the importance of renewable energy sources hybridization. In addition, this study offers a fresh perspective on desalination’s future, focusing on the use of diverse renewable energy sources to improve economic viability, sustainability, and efficiency.

2. Overview of Desalination Technologies

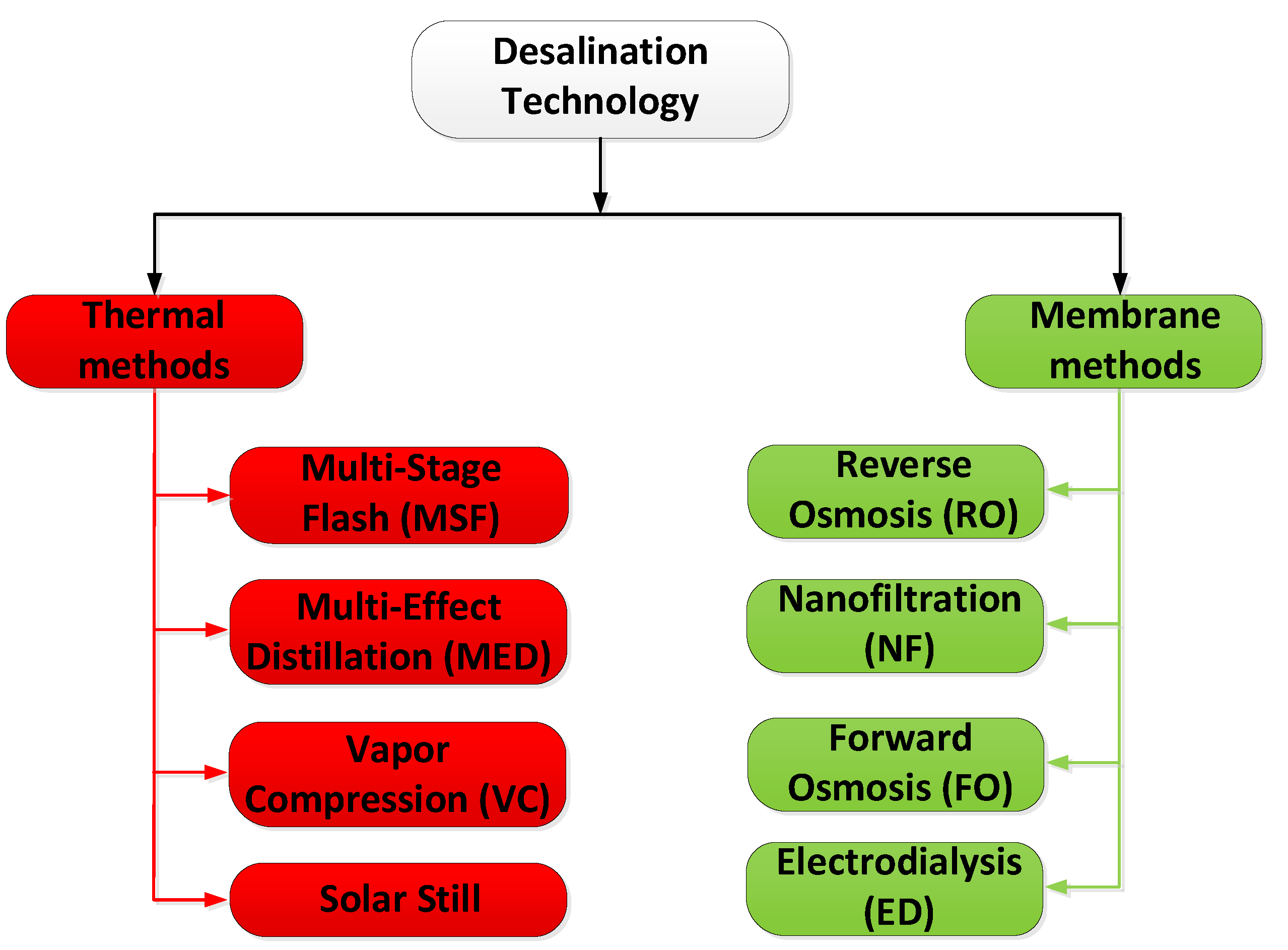

Depending on the separation method used, the technologies for water desalination can be broadly divided into thermal and membrane desalination approaches,

Figure 1. A heat source is used to bring the supply seawater, to the proper temperature during thermal operations. Conventional fossil fuels, nuclear electricity, and RES can all provide heat.

2.1. Thermal-Based Methods

Multi-Stage Flash (MSF) desalination is a widely used thermal process that converts seawater into fresh water through a series of stages. In MSF, seawater is preheated and then introduced into a series of chambers, or stages, where the pressure is progressively reduced. This reduction in pressure causes a portion of the seawater to “flash” or vaporize rapidly [

25]. The vapor produced in each stage is collected and condensed, resulting in freshwater. The remaining brine is then directed to the next stage for further processing. One of the key advantages of MSF is its ability to produce large volumes of freshwater, making it suitable for coastal regions with high water demand [

26]. MSF plants are often designed for high efficiency, utilizing waste heat from power generation or industrial processes to minimize energy consumption. However, the initial capital investment and operational costs can be significant. Additionally, MSF systems require careful management to handle scaling and corrosion issues due to the saline environment. MSF remains a vital technology for addressing water scarcity in arid regions and supporting agricultural and urban needs.

Multi-Effect Distillation (MED) is an efficient thermal desalination method that leverages the principle of using vapor from one stage to heat the next. In this process, seawater is heated in a series of evaporators known as “effects.” Each effect operates at a lower pressure than the previous one, allowing the vapor generated from boiling seawater in one effect to be used to heat the incoming seawater in the subsequent effect [

27]. This cascading effect minimizes energy consumption and maximizes the use of available heat. MED systems are known for their energy efficiency and lower operational costs compared to other thermal desalination methods. They can be designed to operate with both low-grade heat sources, such as waste heat from power plants, and renewable energy sources. The modular design of MED units allows for scalability, making them suitable for various applications, from small communities to large industrial operations [

28]. Despite its advantages, MED does have some limitations, such as sensitivity to scaling and fouling, which require regular maintenance and monitoring. Nevertheless, MED continues to be an important option for sustainable water production in many regions facing freshwater shortages.

Vapor Compression (VC) is a desalination technique that utilizes mechanical or thermal energy to compress vapor, raising its temperature and pressure for the purpose of producing fresh water. In VC systems, seawater is heated to generate vapor, which is then compressed using either mechanical compressors or steam ejectors. The compression process increases the temperature of the vapor, allowing it to be condensed on a heat exchanger where it transforms back into liquid water [

29,

30]. This results in freshwater while leaving behind concentrated brine. One of the significant advantages of VC technology is its high energy efficiency, particularly in smaller-scale desalination applications. VC systems can operate effectively with lower energy inputs compared to traditional thermal processes, making them suitable for regions with limited energy resources. Additionally, VC units have a smaller footprint and can be easily integrated into existing facilities. Among the disadvantages is that they may have higher initial capital costs due to the complexity of the equipment involved. Despite these challenges, Vapor Compression remains a promising technology for providing potable water in areas where conventional desalination methods may not be feasible.

Solar stills are simple yet effective devices that harness solar energy to desalinate seawater or brackish water. The basic principle involves placing a shallow basin filled with saline water under a transparent cover. As sunlight heats the water, it evaporates, creating vapor that rises and condenses on the cooler underside of the cover [

31,

32]. The condensed droplets then collect and can be harvested as fresh water. This passive method relies solely on solar energy, making it particularly suitable for remote areas with abundant sunlight. The advantages of solar stills include low operational costs and minimal environmental impact. They require no external power source and have low maintenance needs, making them accessible for communities in developing countries facing water scarcity. While solar stills are relatively easy to construct and operate, their production capacity tends to be lower compared to other desalination technologies, limiting their use for larger populations or industrial applications. Thanks to advancements in design and materials are improving their efficiency and output. Solar stills represent a sustainable solution for addressing water shortages in arid regions.

For thermal-based desalination systems to support the evaporation and hydraulic conveyance of several streams, both heat and electrical energy must be used. In comparison to membrane-based techniques, thermal-based technologies offer a number of advantages. The dependability of thermal methods is guaranteed by their widespread recognition and validation. Because of the improved quality of the product, less strict observing.

A comparison table with some characteristics for various thermal-based desalination technologies is given below,

Table 1.

2.2. Membrane-Based Methods

Reverse Osmosis (RO) is a widely used water purification technology that employs a semipermeable membrane to remove impurities from water. While the trapped concentrated brine is either released or processed for possible reuse, the water molecules that flow across the semipermeable membrane are captured as freshwater. To meet certain water quality requirements, the freshwater generated by a RO system is subjected to further treatment. The process involves applying pressure to overcome osmotic pressure, forcing water through the membrane while leaving contaminants behind [

33,

34]. RO is effective in removing a variety of substances, including salts, bacteria, viruses, and organic compounds, making it a popular choice for desalination and wastewater treatment. The technology is particularly valuable in desalination, where it can convert seawater into potable water. In desalination applications, RO systems provide several advantages. These include lower energy and capital costs, less physical space needed, greater recovery ratios, and less vulnerability to corrosion and scale, because the membrane can withstand microbial contamination and operates at room temperature. Despite its effectiveness, RO has some limitations, such as the need for pre-treatment to prevent membrane fouling and the generation of concentrated waste streams. Additionally, RO systems can be energy-intensive due to the pressure required for operation. RO is the most popular desalination technology at the moment for seawater desalination because of its greater recovery rate, lower energy usage, and cheaper water production costs. Recent advancements focus on improving membrane materials and configurations to enhance efficiency and reduce costs.

Nanofiltration (NF) is a membrane filtration process that operates between microfiltration and reverse osmosis, effectively removing divalent ions and larger organic molecules while allowing monovalent ions to pass through. The NF membranes have pore sizes typically ranging from 1 to 10 nanometers, making them suitable for applications that require selective separation without the energy-intensive processes associated with RO. NF is particularly effective in desalination and softening hard water by removing calcium and magnesium ions, making it valuable in both municipal water treatment and industrial processes [

35,

36]. It is also employed in wastewater treatment to recover valuable resources and reduce environmental impact. One of the advantages of NF over RO is its lower operational pressure requirement, which can lead to reduced energy consumption. However, NF membranes are still susceptible to fouling, necessitating effective cleaning protocols and pre-treatment methods. Overall, nanofiltration presents a versatile solution for diverse separation challenges while contributing to sustainable water management practices.

Forward Osmosis (FO) is an emerging water treatment technology that utilizes the natural osmotic pressure gradient between two solutions to draw water through a semipermeable membrane. The FO system has a low osmotic pressure feed solution on one side and a high osmotic pressure draw solution (DS) on the other. There is an osmotic pressure differential between the two solutions because the solute concentration in the draw solution is significantly larger compared to the one in the feed solution. Water molecules migrate over the FO membrane from the feed solution to the draw solution due to this osmotic pressure differential. Unlike reverse osmosis, FO does not require high pressure; instead, it relies on a more concentrated solution to pull water from a less concentrated feed solution [

37,

38]. This characteristic makes FO an attractive option for applications where energy efficiency is crucial. FO has garnered attention for its potential in desalination and wastewater treatment. The process is advantageous because it minimizes fouling issues commonly associated with other membrane technologies. Additionally, FO can operate under low hydraulic pressures, reducing energy costs significantly compared to traditional methods like RO. There are still challenges that remain regarding the selection of suitable draw solutions and the recovery of clean water from the draw solution after processing. Research is ongoing to develop more effective membranes and optimize operational parameters. As technology advances, forward osmosis holds promise for sustainable water management solutions, particularly in regions facing water scarcity or requiring innovative approaches to wastewater reuse.

Electrodialysis (ED) is an electrochemical separation process that uses an electric field to drive the movement of ions through selective ion-exchange membranes. This technology is primarily employed for desalination and the treatment of brackish water but can also be used for various industrial applications, including the recovery of valuable byproducts from wastewater. In ED systems, cation-exchange membranes allow positively charged ions (cations) to pass through while blocking negatively charged ions (anions), and vice versa for anion-exchange membranes. This selective ion transport creates a flow of fresh water on one side while concentrating salts on the other. One of the main advantages of electrodialysis is its lower energy consumption compared to reverse osmosis, especially when treating low-salinity feedwater. Additionally, ED systems can be easily scaled up or down depending on the specific application needs. A number of variables affect the functioning of ED systems, such as the voltage curve, the electrolyte concentration, the feed seawater concentration, and the particular working circumstances. Recent research has shown that raising the voltage gradient, raising the concentration of the electrolyte and feed saltwater, and lowering the system’s flow rate can all greatly improve the desalination functionality of the ED system. Among the challenges are membrane fouling and the need for regular maintenance to ensure optimal performance. Recent advancements focus on improving membrane materials and configurations to enhance efficiency and longevity. Electrodialysis presents a promising alternative for sustainable desalination and resource recovery efforts in various sectors.

There are several advantages to membrane-based desalination techniques. Since membrane-based technologies do not lose energy through evaporation and condensation, they consume less energy than thermal-based technologies. These include lower energy and capital costs, less physical space needed, greater recovery ratios, less vulnerability to corrosion and scale because the membrane operates at room temperature, and the membrane’s capacity to reject microbial contamination. The total dissolved solids (TDS) concentration of brackish and saltwater can be treated using any of the above-mentioned technologies. In addition, the maximum salinity of the feed water threshold for membrane-based technologies is lower than that of thermal-based technologies. It is crucial to establish pertinent criteria in order to select the best membrane-based desalination technique among a variety of possibilities. Energy consumption is one important consideration when choosing a desalination method. Among other important criteria are technology maturity level, fouling potential, and water recovery rate. Because the sustainability of the desalination industry depends on the environmental aspects it is necessary to improve membrane-based methods taking into account environmental footprint, process integration, waste recycling, and integration of renewable energy sources.

A comparison table with some characteristics for various membrane-based desalination technologies is given below,

Table 2.

4. Energy Storage Systems

However, despite the fact that RES powered desalination plant systems are attractive options to address the global freshwater deficit there are some challenges and obstacles that slow down the adoption of the technology. In fact, these systems are mostly either part of the electric power grid or should have a reliable long-term energy storage system to guarantee a steady and uninterrupted supply of power to a desalination plant. Since the significant amount of electricity needed by the entire desalination plant comes from the conventional power grid, under the grid connection scenario, these systems could overload the grid, particularly in places with inadequate infrastructure for the delivery of electricity, at nighttime and on cloudy days [

52]. Effective energy storage and management systems are required to provide a consistent and reliable power supply and satisfy the varying energy needs of desalination operations because solar and wind energy are discontinuous [

53]. Finding affordable and workable energy storage solutions for wastewater treatment facilities remains a challenge in this respect, particularly for large-scale applications.

In addition to reducing power output variations, energy storage systems may also enhance supply quality, adjust frequency, and provide voltage dependability. Power can be stored using a variety of techniques, such as pumped hydro storage (PHS), compressed air energy storage (CAES), and battery energy storage systems (BESS). When there is excess generating capacity, energy storage devices are used to store the energy generated by renewable energy sources and release it to supply peak load demands [

54]. Another advantage of ESS is that it allows the power distribution system to accommodate more RES [

55,

56]. The storage capacities of battery systems normally range from 1 to 30 kWh for home use to MWh for commercial battery systems [

57]. The charging and discharging operations also cause battery degradation, which shortens the battery’s lifespan. The battery degradation process results in varying battery lifetimes, performance decreases, and cost losses under different operating situations. Therefore, in order to assess battery performance, the health prognostics must be examined. There are already many review papers available that cover different facets of battery energy storage devices.

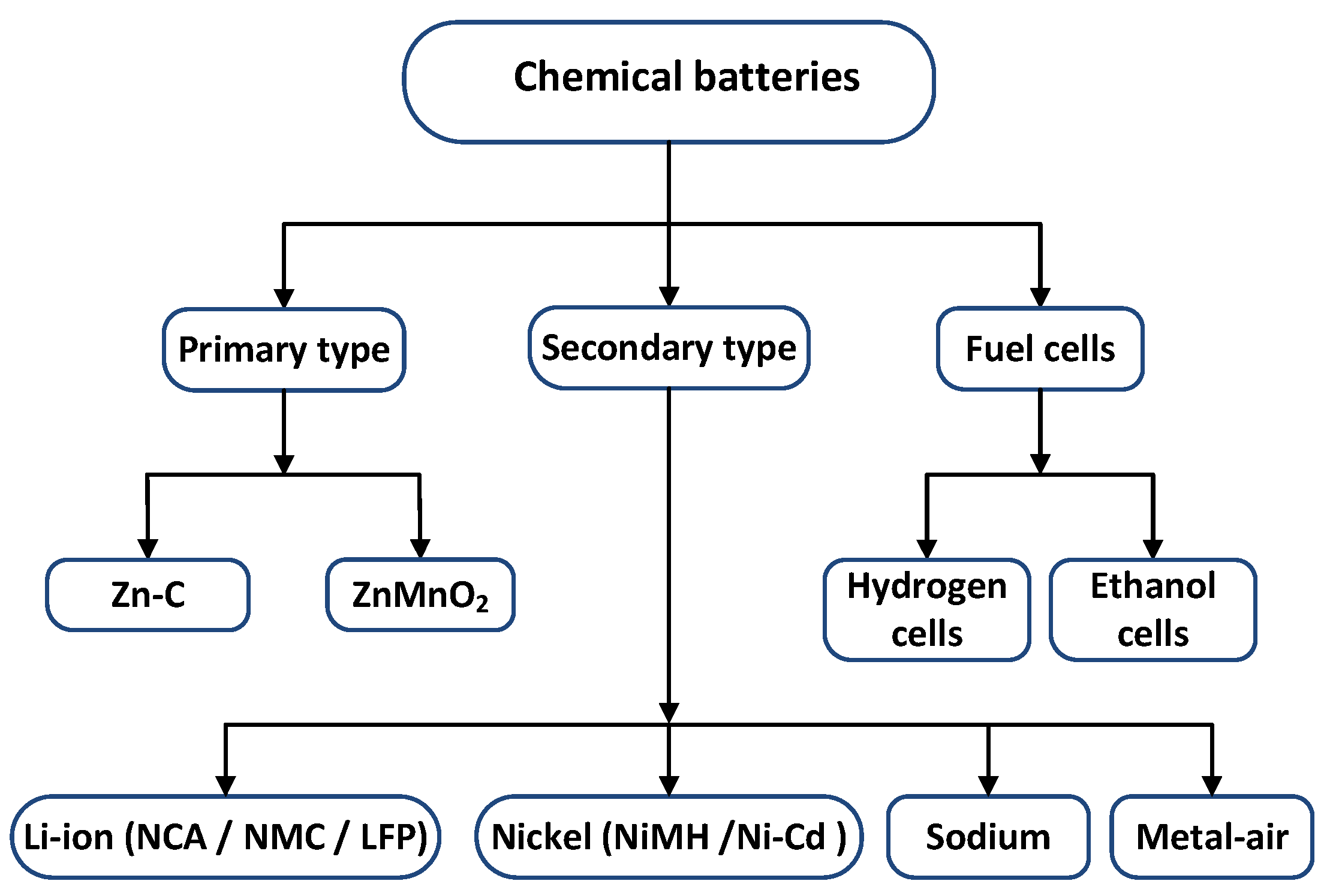

Stacks of cells that transform chemical energy into electrical energy makeup batteries. Different chemistries and series and parallel cell connections are used to select desired properties. There is currently a significant amount of study and investment in this area. The primary battery chemistries utilized in battery energy storage systems are illustrated in

Figure 5.

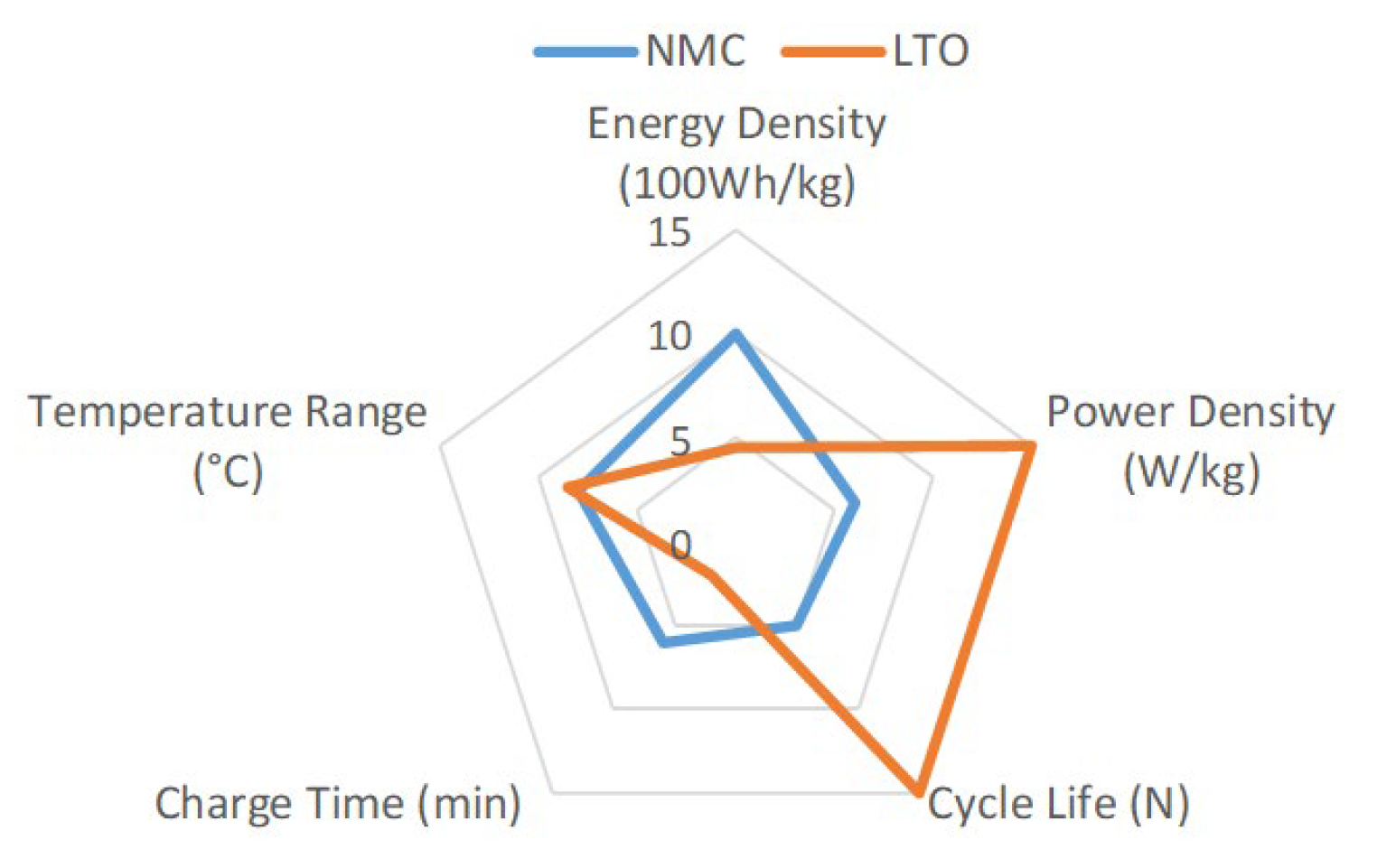

The hybrid energy storage systems consisting of different electrochemically composed batteries form hybrid energy storage systems (HESS). This type of ESS is one of the most promising energy storage systems. It combines the benefits of various chemistry batteries because some batteries are known for their high power density and rapid charging and discharging periods, but other batteries provide a higher energy density and longer cycle life [

58]. Therefore, for the high performance of desalination plants powered by renewable energy sources, a hybrid energy storage system that combines several kinds of electrochemical batteries may be a better choice than regular ones. Authors in [

59] showed that to create a more dependable and effective energy storage solution, a hybrid energy storage system that integrates multiple electrochemical energy storage technologies is a good choice. Simultaneously, sophisticated control techniques are needed to integrate several energy storage systems into a HESS in order to guarantee the system’s longevity and peak performance. Among the main conclusions is that the utilization of machine learning methods like deep reinforcement learning (DRL) or genetic algorithms (GA), as well as other recent advancements in HESS control systems, are very perspective for hybrid energy storage systems for both small-scale and large-scale desalination plants.

Figure 6, shows how the different Li-ion battery technologies such as Lithium-Titanium-Oxide (LTO) and Nickel Manganese Cobalt (NMC) can complement each other in HESS.

Hybrid energy storage systems are especially useful for large desalination facilities because maintaining continuous operation requires the simultaneous long and short-term storage of energy to overcome the intermittency of renewable energy sources. One of the main advantages of energy storage in desalination is that it ensures that desalination plants will continue to run even in the event that RES is not available, increasing their dependability. Optimizing energy utilization allows for more efficient management of energy resources, which lowers operating costs and boosts system performance overall. Application of HESS for desalination processes can help to lower carbon emissions because they increase penetration of RES in the desalination sector thus lessening reliance on fossil fuels.

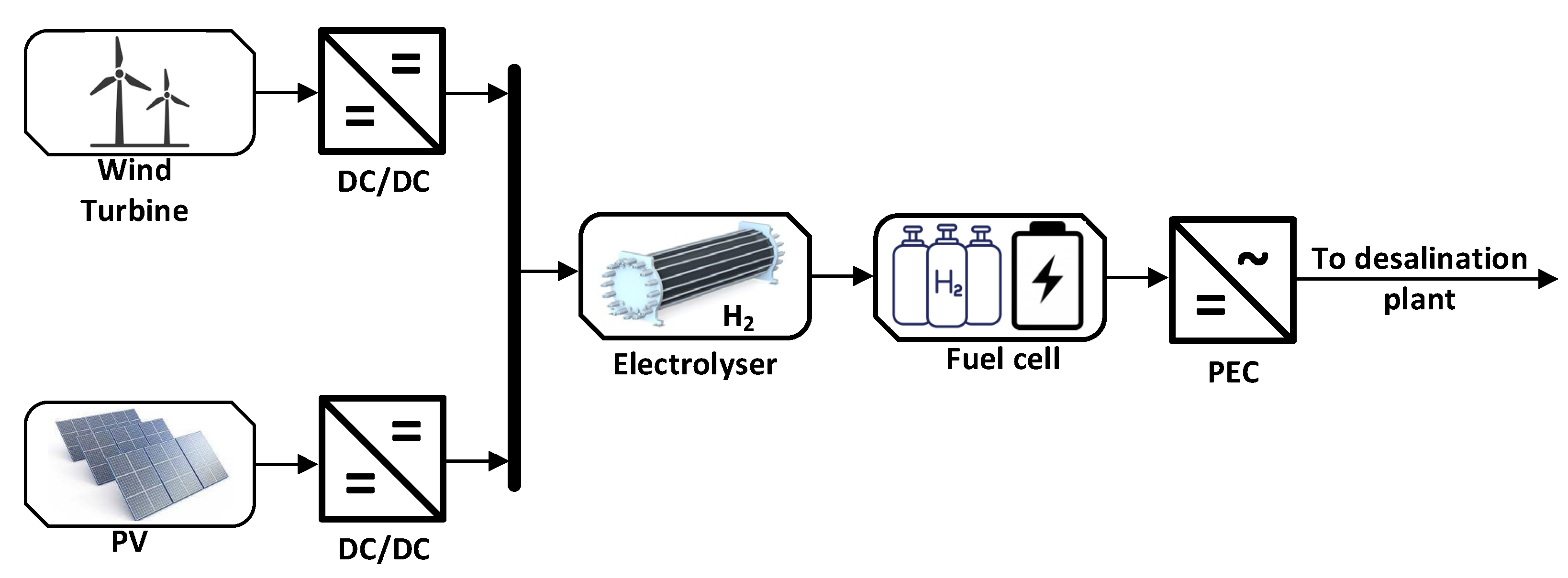

Hydrogen generated by electrolysis is another promising energy carrier and storage option for incorporating RES into the electrical grid that is presently being researched. Although it already has a number of uses, it may also make it possible to create hydrogen-based energy storage systems that consist mostly of fuel cells, electrolyzers, and hydrogen storage systems [

60,

61]. The technique of electrolyzing water to produce hydrogen using excess power from renewable sources is known as hydrogen storage. Hydrogen storage systems are emerging as a pivotal technology for enhancing the efficiency and sustainability of RES powered desalination facilities helping to ensure a consistent water supply in both island and grid-connected modes. By integrating hydrogen energy storage, it becomes possible to produce hydrogen during periods of excess energy generation, which can then be stored and converted back into electricity or used directly for desalination processes when renewable output is low.

In grid-connected scenarios, hydrogen energy storage offers similar benefits by facilitating load balancing and peak shaving. Desalination plants typically require substantial energy inputs, and hydrogen energy storage systems can help smooth out demand fluctuations by storing surplus energy during off-peak hours and releasing it during peak demand times [

62]. This flexibility can lead to lower operational costs and improved grid stability, making it easier to integrate higher shares of renewables into the energy mix,

Figure 7.

In [

63] authors proposed a novel synchronized sizing model for a solar or wind powered reverse osmosis desalination plant and used a follower-leader optimization framework to optimize the design both with and without demand-side water management (DSWM). The system was made up of PV panels and wind turbines to generate electricity, a battery bank to store extra power, an RO unit to produce freshwater and desalinate saltwater, and freshwater storage tanks. As a long-term storage solution, a hydrogen storage system was added to store extra electricity at the end of each day. The RO system was mostly powered by PV and WT, with any extra energy being stored in a battery-hydrogen storage (BHS) system.

5. Energy Efficient Operation of CPPs in Desalination

Centrifugal pumping plants (CPP) play a pivotal role in the desalination process, particularly in systems utilizing membrane technologies such as reverse osmosis, nanofiltration, and forward osmosis. CPPs are essential for ensuring that seawater or brackish water is effectively transported and pressurized to facilitate the desalination process. In reverse osmosis desalination, high-pressure centrifugal pumping plants are responsible for drawing water from its source and delivering it to the membrane units at high pressures necessary for overcoming osmotic pressure. The efficiency of these pumps directly influences the overall energy consumption of the desalination plant [

64]. Given that energy costs often represent a significant portion of operational expenses—sometimes accounting for up to 60%, the importance of energy-efficient pumping solutions cannot be overstated.

Energy efficiency in CPPs is crucial not only for cost savings but also for environmental sustainability. Traditional pumping systems can consume vast amounts of energy, contributing to greenhouse gas emissions and increasing the carbon footprint of desalination operations. By utilizing advanced pump designs, variable frequency drives (VFDs), and optimized control strategies, desalination plant operators can enhance the energy efficiency of CPPs. For instance, VFDs allow for real-time adjustments to pump speed based on demand, ensuring that energy is used only as needed. Moreover, the integration of energy recovery devices (ERDs) within the RO systems can further improve the overall energy efficiency of the desalination process. ERDs capture and reuse energy from the pressurized brine stream, significantly reducing the energy required by the CPPs to maintain optimal pressure levels. Energy efficiency, reliability, and maintenance of CPPs are critical factors in ensuring the uninterrupted operation of desalination plants.

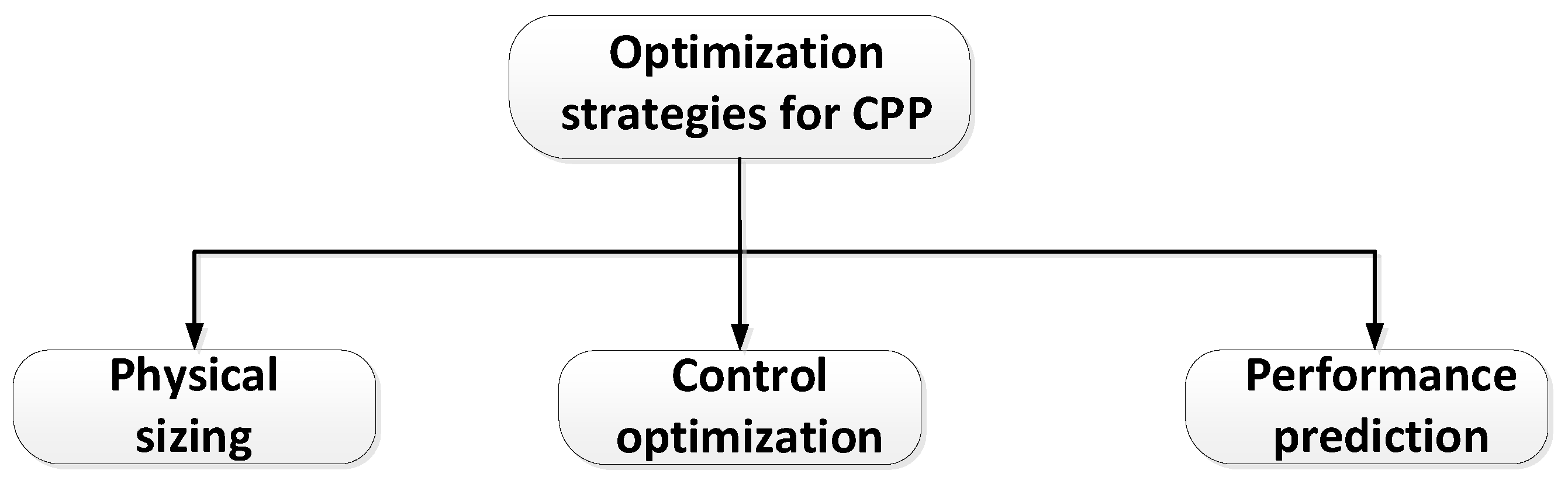

Enhancing centrifugal pumps’ energy efficiency and minimizing losses are essential for determining the optimal operation of the desalination system powered by RES. A system should be designed to be as productive as feasible in order to maximize its potential. Several researchers give some optimization strategies below. The three primary optimization strategies are shown in

Figure 8.

In [

65] authors found out that certain high-speed centrifugal pumps show signs of instability in their cavitation and hydraulic performance. Using the orthogonal experimental design approach, the turbulence model was developed in order to examine the effects of these parameters on the net positive suction head (NPSH). Rotating cavitation was observed at part-load in a visual high-speed photography test setup. A numerical model that closely resembles the experimental cavitation characteristics was developed by comparing the cavitation and pressure counters with high-speed photographic photos. This simulation approach helps to identify the optimal sizing of the CPP to avoid cavitation and increase the efficiency of the pumping unit.

In order to maximize the capacity sizes of various CPPs’ components employing water tank storage, authors in [

66] suggest an ideal sizing approach. The suggested model considers the pumping system’s submodels and employs two optimization criteria: the life cycle cost (LCC) for the economic assessment and the loss of power supply probability (LPSP) model for reliability. In [

67] a technique for figuring out the size of a PV array that supplies electricity to a drip irrigation pumping system in a southwestern Spanish olive tree orchard is explained. The total yield of the photovoltaic-pump-irrigation system is taken into consideration when calculating the peak photovoltaic power needed for irrigation purposes.

A very important role in the energy efficiency of CPP plays the control approach. Most of the centrifugal pump systems are driven by induction motors (IM). In RES powered pumping systems, there are two primary methods for controlling the IM. Scalar control is the first, and vector control is the second. The authors in [

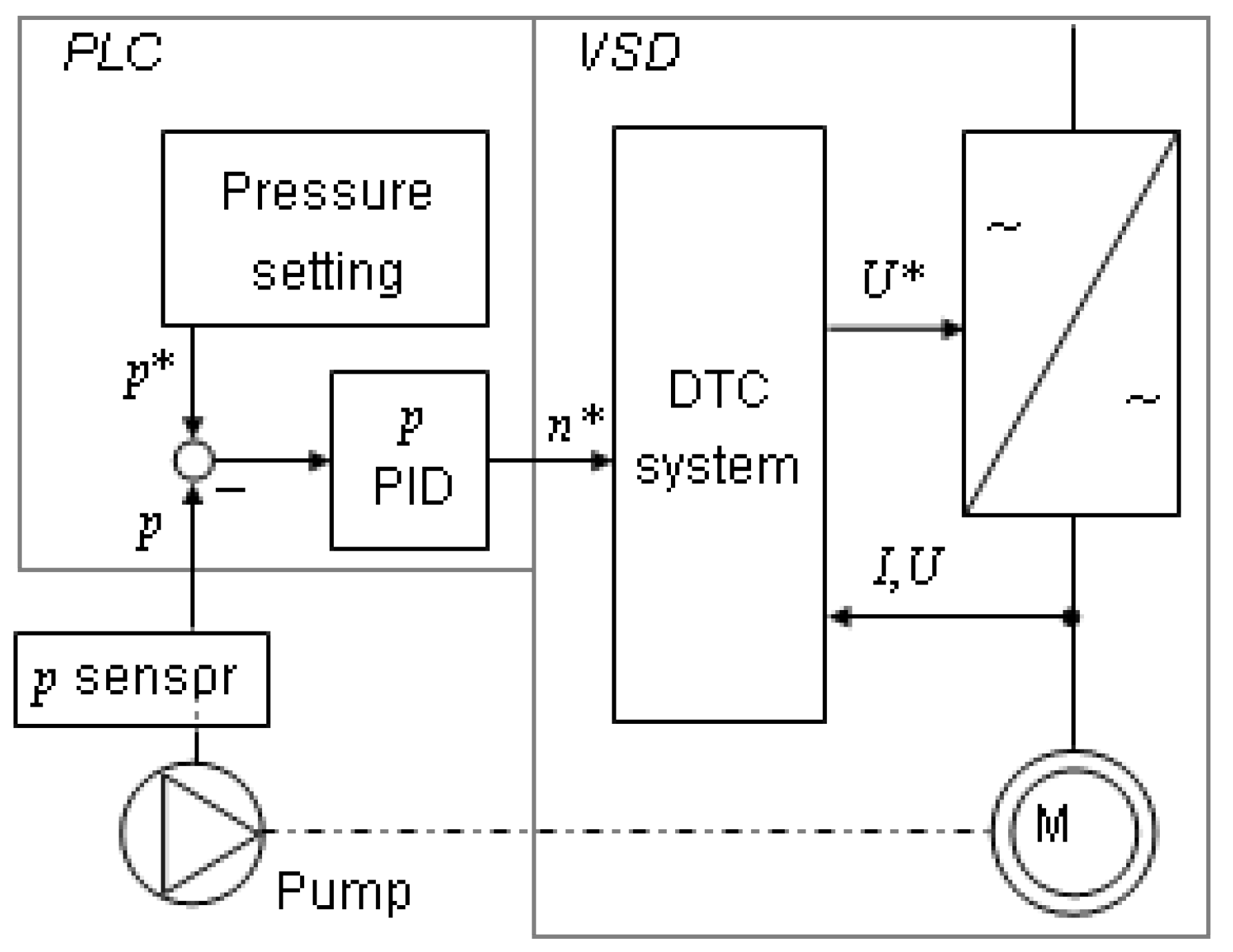

68] suggested using direct torque control (DTC) in conjunction with a hybrid control algorithm that was developed for pressure maintenance,

Figure 9. The suggested hybrid method is used to operate the DTC-based control system using a programmable logic controller.

In [

69] the perturb and observe (P&O) control method and the incremental conductance (INC) maximum power point tracking (MPPT) control method with an automatically adjustable variable step size are compared. As an example, a PV powered centrifugal pumping system with an induction motor in a stand-alone application without energy storage was taken. Studying these two methods makes it easier to determine which one, may provide a system with less oscillation and higher efficiency. This MPPT operates on the boost converter’s working duty cycle. The converter then transforms DC electricity into AC power with the help of a voltage source inverter (VSI). The authors also employed indirect field-oriented control (IFOC), which operates the centrifugal pump by sequentially driving the three phases of an induction motor. The application of high-efficiency electrical motors can help to achieve better performance and energy-efficiency as shown in [

70]. The author’s primary focus is on the productivity of pumping plants that are driven by two different types of electrical machines called synchronous reluctance motors and induction motors. A centrifugal pumping plant efficiency prediction simulation approach for flow regulation is suggested. The Simulink/Matlab simulation method that has been proposed is quite useful for confirming efficiency when it comes to pumping plants that are equipped with different kinds of electrical machinery.

Another hybrid control approach was proposed in [

71]. A model based on Simulink/DriveSize is suggested for the hybrid throttle and speed operation of a CPP with a variable speed drive. Input power estimation for speed control and mutual throttling is made possible by the model. With the aid of a hybrid speed and throttle control technique, the proposed model enables the selection of the most optimal valve position and pumping system rotational speed. The model is divided into two primary sections: one for simulating speed control and the other for simulating throttle position.

As mentioned before, centrifugal pumps play a vital role in desalination processes, including not only reverse osmosis but also multi-stage flash distillation, where they are responsible for transporting seawater and brine. Accurate performance prediction of these pumps is essential for optimizing system efficiency, reducing operational costs, and ensuring reliability. Various methods exist for predicting pump performance, including empirical models, computational fluid dynamics (CFD), and machine learning approaches. However, the effectiveness and applicability of these methods can vary significantly based on factors such as pump design, operating conditions, and fluid properties.

Table 3.

Comparison of various performance prediction methods.

Table 3.

Comparison of various performance prediction methods.

| Method |

Accuracy (%) |

Computational Time (hrs) |

Ease of Implementation |

Applicability Range |

| Empirical Scaled Models |

85-90 |

up to 0.5 |

High |

Limited to specific designs |

| CFD |

90-95 |

10-20 |

Moderate |

Wide range of conditions |

| Machine Learning (ML) |

80-95 |

1-5 |

Moderate to High |

Data-dependent |

| Analytical Methods |

75-85 |

0.1-0.5 |

Very High |

Basic designs only |

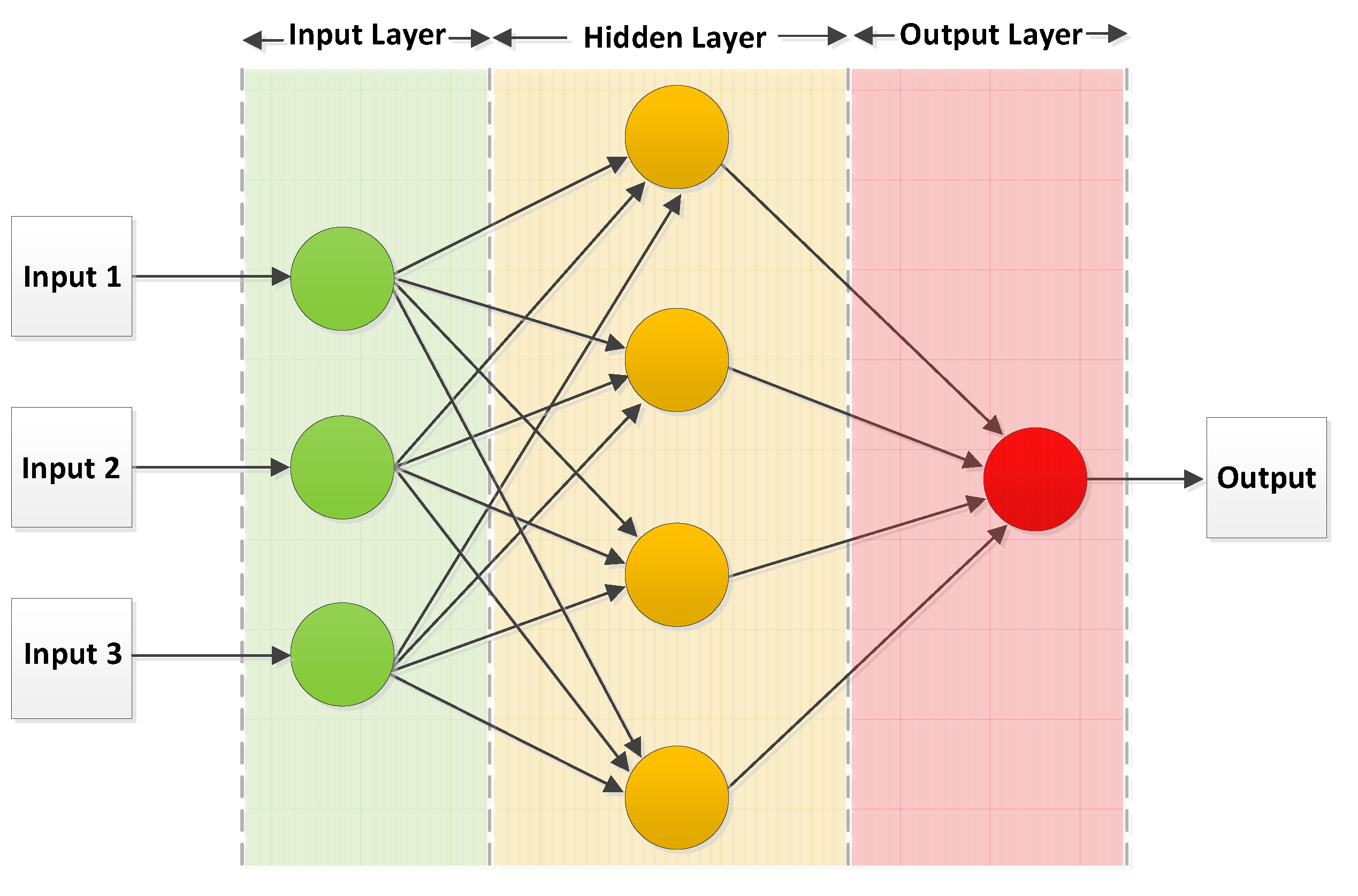

The application of Artificial Neural Networks (ANN) has started to play an important role in recent periods for the performance prediction of CPPs. ANNs are a subset of machine learning methods that employ the principles of neural organization. They are primarily composed of units or nodes connected by edges that specify the connections between each node. Generally, mathematical functions are used to calculate the various outputs, and all edges and nodes have a weight that is modified as learning progresses,

Figure 10.

The prediction of centrifugal pumps’ energy performance is crucial for the advancement of pump design and energy efficiency. However, the performance forecast of centrifugal pumps is always impacted by the intricate internal flow, especially when running at low flow rates. In [

72] authors propose a multi-condition performance prediction method for centrifugal pumps with variable speeds is proposed, based on the data-fitting method. The prediction model is improved by automatically meeting the performance constraints, and the performance relationship is integrated into the particle swarm optimization algorithm. By adding performance restrictions, the performance under various operating situations is accurately predicted in comparison to the experimental data. The results show mean absolute relative error (MARE) for head, power, and efficiency is 0.85%, 1.53%, and 1.15 percent, respectively. In [

73] authors suggest a single-objective optimization design approach founded on the non-hierarchical response surface methodology (RSM) and the multi-island genetic algorithm (MIGA) to enhance the operation performance of the multi-stage double-suction centrifugal pump and lower the internal energy loss of the pump. Efficiency under design conditions was the optimization goal, and nine parameters, including the blade outlet width and blade wrap angle, were used as design variables. Using the Latin hypercube sampling method (LHS), 99 sets of valid data were retrieved out of 149 pieces of data, with the associated efficiency and head criteria set. Based on non-hierarchical RSM, a cross-validation study of the sieved data was conducted, and the efficiency was globally optimized.

For the modeling of hydraulic transient phenomena that occur in pipe systems, the full set of centrifugal pump characteristics is essential. However, pump manufacturers usually only provide minimal information because of the work necessary to get these curves, especially when the pump is operating normally. In [

74] the authors propose a machine learning model to predict full, complete Suter curves using a pump’s particular speed with the known parts of the Suter curve in order to obtain the entire characteristic curves based on the manufacturer’s general performance curve. The Suter curves that are available from lab tests serve as the model’s training data. In order to determine the most accurate forecast in terms of the root mean, the suggested machine learning model then integrates many regression model types.

Even though modern pumping systems are dependable, unplanned malfunctions could endanger public safety or result in large financial losses. As a result, early defect diagnosis, detection, and predictive monitoring systems are highly sought after. The majority of earlier research on machine learning-based centrifugal pump failure detection relies on either simulations, synthetic data, or data from test rigs operating under carefully monitored laboratory circumstances. In [

75] the authors worked with a specialized pump engineering business to gather data from actual functioning pumps placed in several locations in an effort to identify centrifugal pump defects with the help of convolutional neural network transfer learning.

7. Conclusions

A review of desalination systems driven by renewable energy sources is provided, outlining the status of available and emerging technologies, study findings, and the use of both traditional and innovative approaches in the desalination sector. Numerous studies were reviewed, with a particular emphasis on the application of solar and wind energy. This analysis examined over seventy research papers and articles devoted to the study of the performance and operation of desalination technologies, renewable energy sources, energy storage technologies, and pumping systems that were published between 1982 and 2024.

The primary conclusions of this study emphasize the advantages of the application of hybrid energy storage systems, particularly hybrid battery storage systems, which offer a coordinated approach to reduce the influence of the intermittent nature of renewable energy sources, maximize desalination effectiveness, and reduce environmental impacts. The need to use cutting-edge performance prediction control strategies is also emphasized in this paper. According to several recent research publications, the pumping system can achieve improved controllability based on energy management criteria and predictive control techniques. This contributes to the optimal operation of the desalination plants. New developments and evaluations of control systems based on artificial neural networks have been covered.

Finally, combining advanced desalination technologies with renewable energy is an essential step toward achieving sustainable water management. By utilizing the combined potential of hybrid energy storage systems with the advanced machine learning based energy management technology for centrifugal pumping units, desalination systems can demonstrate improved energy efficiency, environmental sustainability, and economic viability.