Submitted:

16 December 2024

Posted:

16 December 2024

You are already at the latest version

Abstract

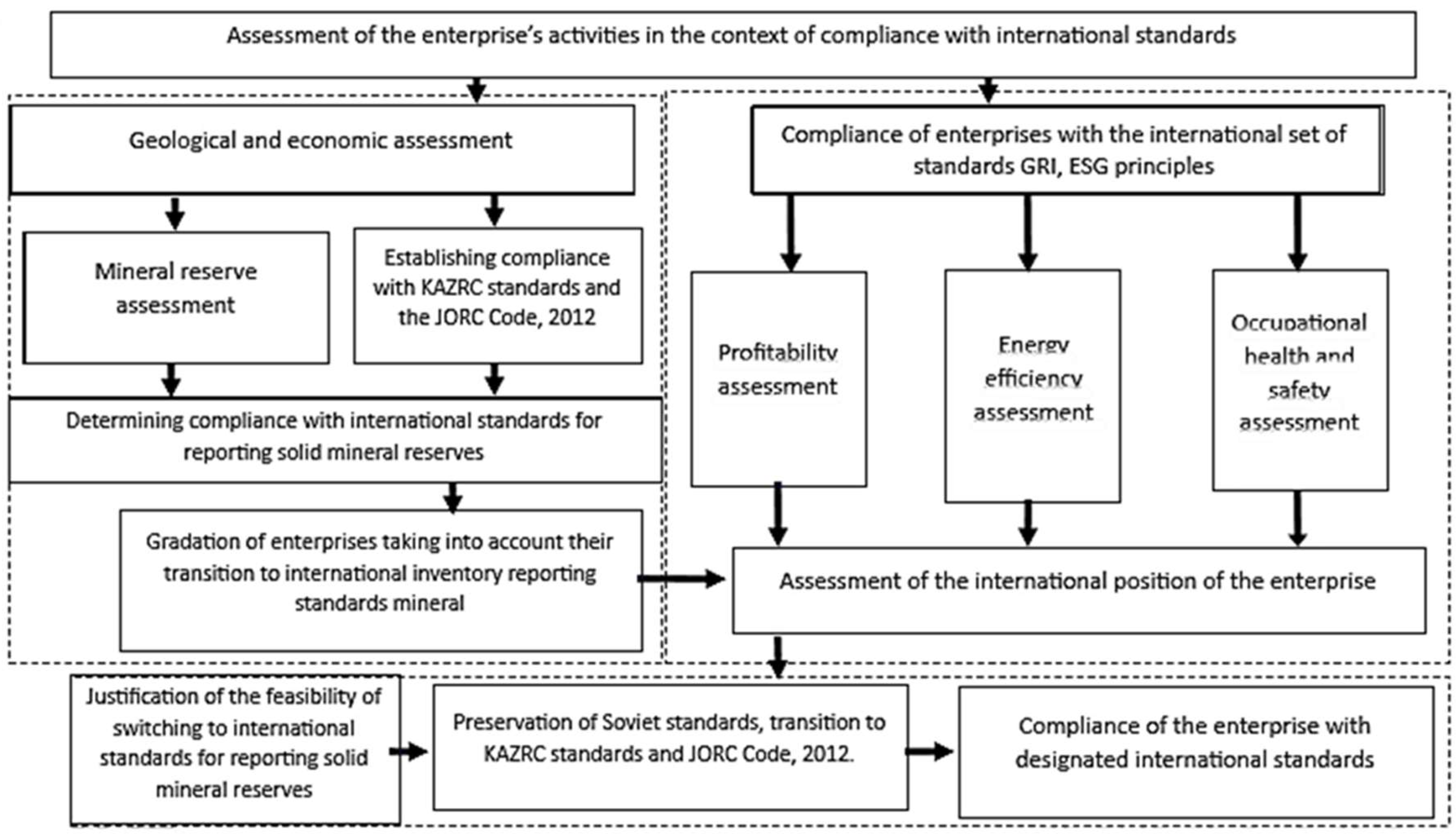

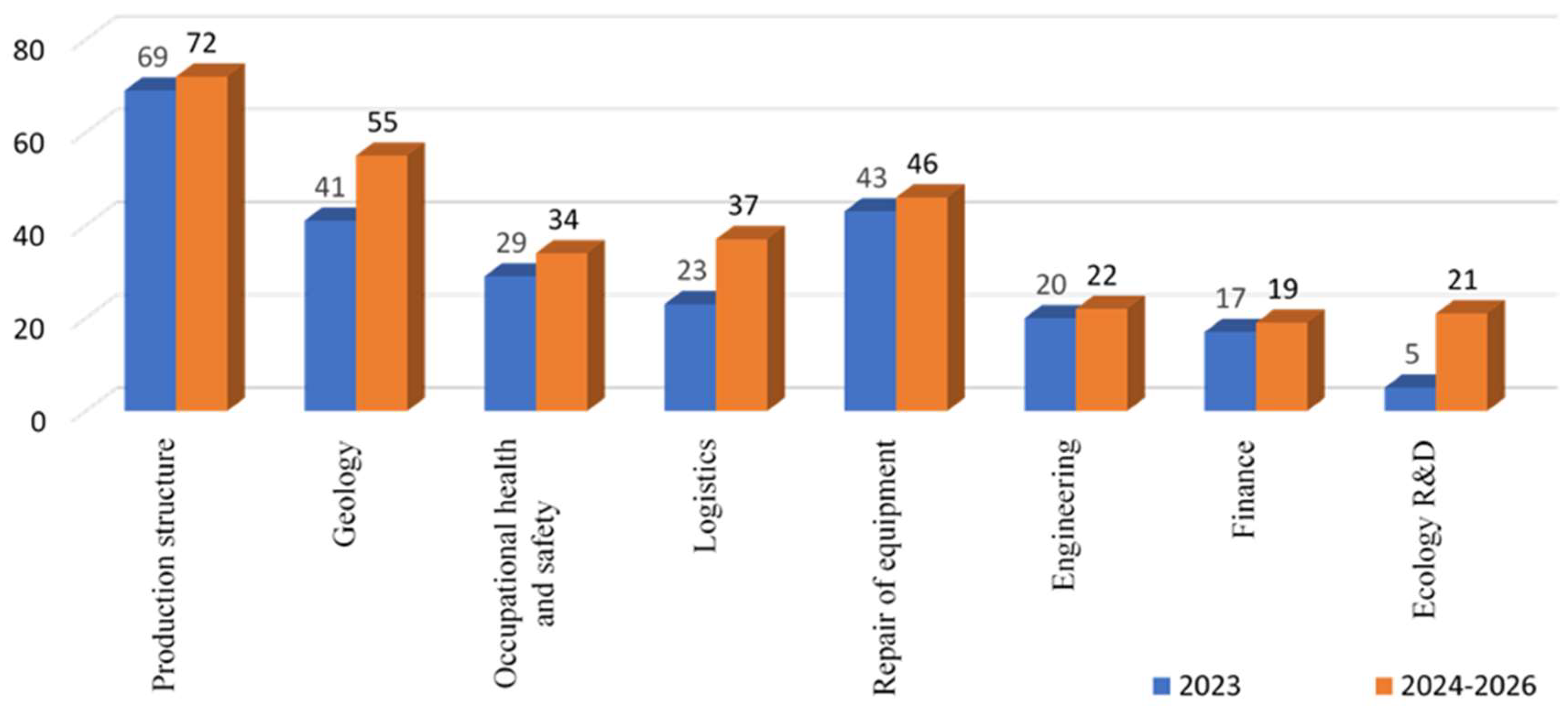

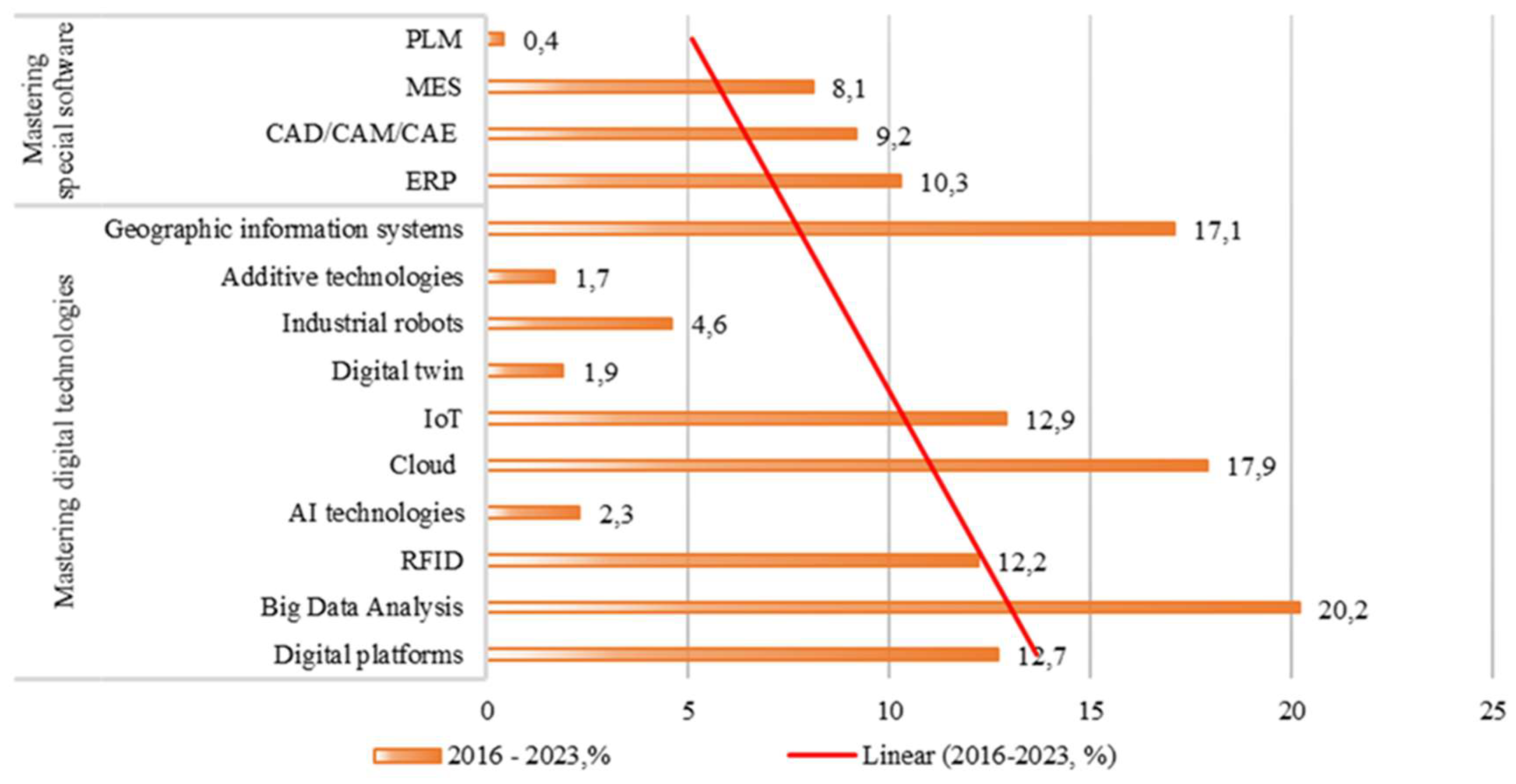

The study critically analyzes the innovation challenges faced by mining enterprises in Kazakhstan, focusing on key issues and potential opportunities related to the adoption of Industry 4.0 technologies. The research highlights that the strategic goal of Kazakhstan's mining sector is its integration into the global economy through digitalization, which aims to address the sector’s limited production of high-value goods. Despite the potential of digital transformation, the current level of digitalization across enterprises remains insufficient, requiring more structured implementation of engineering and economic processes. A statistical analysis using PESTEL, regression, and factor analysis, alongside a questionnaire survey, revealed low capital productivity as a major issue. The findings suggest that the complexity of mining operations necessitates improved innovation strategies tailored to specific resource extraction conditions. Furthermore, the digitalization focus is gradually shifting from production to areas like geology, ecology, and industrial safety. The study offers a framework for evaluating mining enterprises against international standards and serves as a valuable reference for both domestic and international investors interested in the evolving IT landscape of Kazakhstan's mining sector.

Keywords:

1. Introduction

2. Materials and Methods

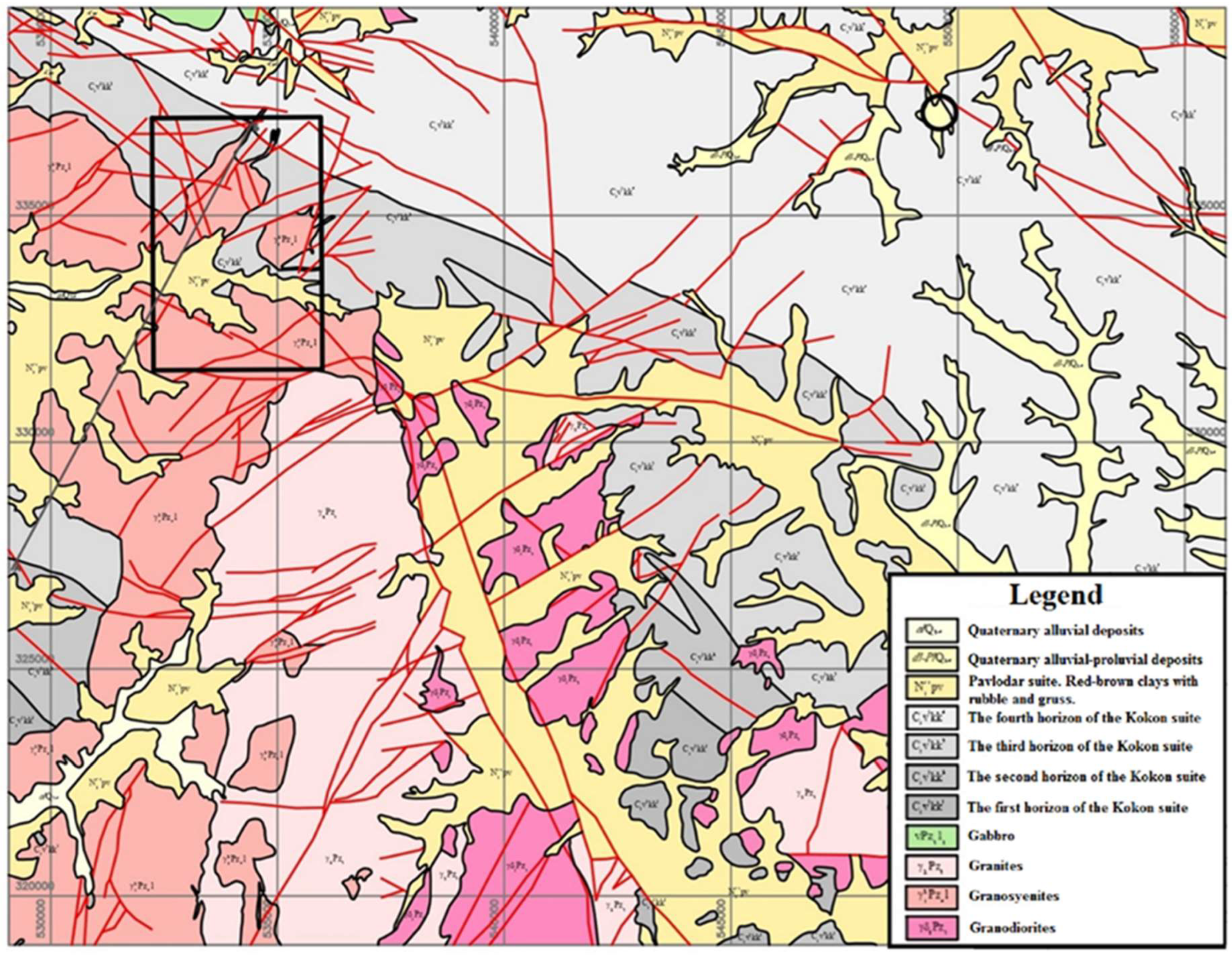

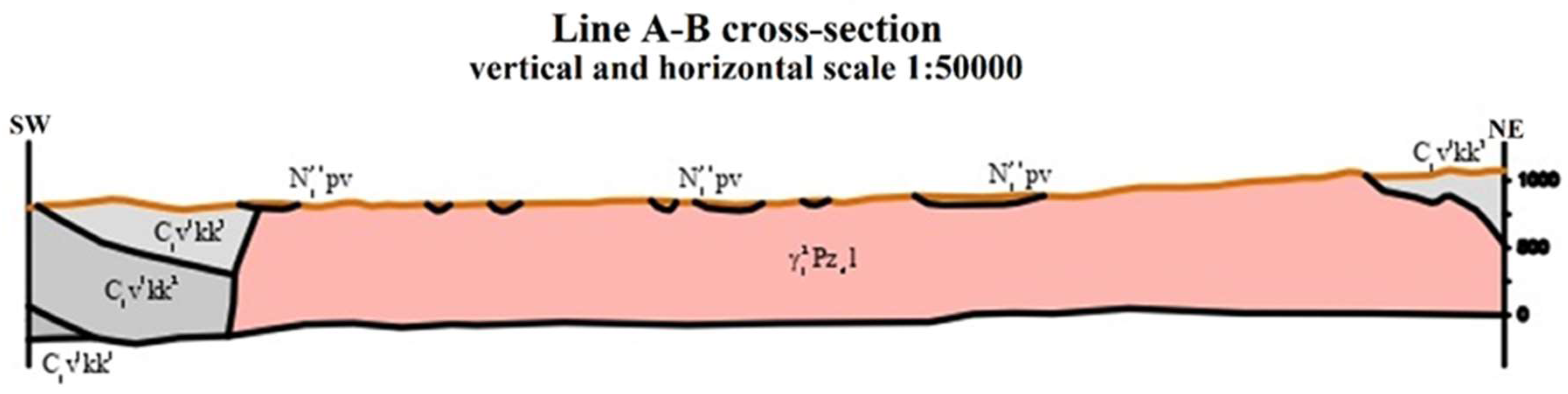

3. Results

| Category/Ore Body № | Ore, thousand tons | Nb₂O₅ | Ta₂O₅ | REE | ZrO₂ |

| C2/1 | 21 520 | 0.0481 | 0.0062 | 0.0915 | 0.1994 |

| C2/2 | 45 626 | 0.0512 | 0.0088 | 0.0634 | 0.1059 |

| C2/3 | 21 178 | 0.0271 | 0.0032 | 0.0440 | 0.0748 |

| C2/4 | 11 725 | 0.0370 | 0.0053 | 0.0724 | 0.0641 |

| C2/zh | 1 633 | 0.0727 | 0.0146 | 0.0251 | 0.1178 |

| Total for Category C2 | 101 682 | 0.0472 | 0.0076 | 0.0593 | 0.1124 |

| Р1/1 | 20 478 | 0.0432 | 0.0055 | 0.0867 | 0.2156 |

| Р1/2 | 10 832 | 0.0368 | 0.0053 | 0.0885 | 0.0378 |

| P1/3 | 35 524 | 0.0222 | 0.0070 | 0.0693 | 0.0549 |

| P1/4 | 22 983 | 0.0276 | 0.0046 | 0.1109 | 0.0117 |

| Total Forecast Resources | 89 817 | 0.0325 | 0.0056 | 0.0889 | 0.0800 |

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Top 10 business risks and opportunities for mining and metals in 2023. EYGM Limited, 2022. https://assets.ey.com/content/dam/ey-sites/ey-com/en_gl/topics/mining-metals/ ey-top-10-business-risks-and-opportunities-for-mining-and-metals-in-2023.pdf.

- Sekerin, V., Dudin, M., Gorokhova, A., Bank, S., & Bank, O. (2019). Mineral resources and national economic security: current features. Mining of mineral deposits. 13(1), 72-79. [CrossRef]

- Beauchamp, E., da Silva Bernardo, C., & Bueno, M. (2021). Progressing the Global Goal on Adaptation - key issues. London: International Institute for Environment and Development. pubs.iied.org. Retrieved from https://pubs.iied.org/17773iied .

- Garschagen, M., Doshi, D., Moure, M., James, H. & Shekhar H. (2021). The consideration of future risk trends in national adaptation planning: Conceptual gaps and empirical lessons. Climate Risk Management, 34, 100357. [CrossRef]

- Jia, F., Li, G., Lu, X. & Xie, S. (2021). CEO given names and corporate green investment. Emerging Markets Review, 48(2):100808. [CrossRef]

- Goudy, S. A. (2022). Made in America” Supply Chain for Critical Minerals. Environmental, Mining & Natural Resources, Rulemaking & Policy Development. March 7, Available: https://www.freshlawblog.com/2022/03/07/a-made-in-america-supply-chain-for-critical-minerals/.

- Issatayeva, F.M.; Aubakirova, G.M.; Maussymbayeva, AD; Togaibayeva, LI; Biryukov, V.V.; Vechkinzova, E. Fuel and Energy Complex of Kazakhstan: Geological and Economic Assessment of Enterprises in the Context of Digital Transformation. Energies 2023, 16, 6002. [CrossRef]

- Kesselring M, Wagner F, Kirsch M, Ajjabou L, Gloaguen R. Development of Sustainable Test Sites for Mineral Exploration and Knowledge Spillover for Industry. Sustainability. 2020; 12(5):2016. [CrossRef]

- Raj, A., Dwivedi, G., Sharma, A., Lopes de Sousa Jabbour, A. B. L. & Rajak, S. (2020). Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: an inter-country comparative perspective. International Journal of Production Economics, 224(C). 107546. [CrossRef]

- Hinings, B., Gegenhuber, T. & Greenwood, R. (2018) Digital innovation and transformation: an institutional perspective. Information and Organization, 28(1):52-61. [CrossRef]

- Delera, M., Pietrobelli, C., Calza, E., Lavopa, A. (2022). Does value chain participation facilitate the adoption of Industry 4.0 technologies in developing countries? World Development,152, 10578. [CrossRef]

- Abramovitz, M. (1986). Catching up, forging ahead, and falling behind. The Journal of Economic History 46: 385-406 https://www.jstor.org/stable/2122171.

- Young, A., & Rogers, P. (2019). A Review of Digital Transformation in Mining. Mining, Metallurgy & Exploration, 36, 683-699. [CrossRef]

- Menzel, T., & Teubner, T. (2021). Green Energy Platform Economics - Understanding Platformisation and Sustainabiliz ation in the Energy Sector. International Journal of Energy Sector Management, 15(3), 456-475. [CrossRef]

- Zhironkin S., & Cehlár M. (2021). Coal Mining Sustainable Development: Economics and Technological Outlook. Energies, 14(16): 5029. [CrossRef]

- Klippel, A. F., Petter, C., & Antunes, J. (2008). Management Innovation, a way for mining companies to survive in a globalized world. Utilities Policy, 16(4), 332-333. [CrossRef]

- Kouhizadeh, M., Zhu, Q. & Sarkis, J. (2020). Blockchain and the circular economy: Potential tensions and critical reflections from practice. Production Planning & Control, 31, 950-966. [CrossRef]

- Cagno, E., Neri, A., Negri, M., Bassani, C. A. & Lampertico. T. (2021). The Role of Digital Technologies in Operationalizing the Circular Economy Transition: A Systematic Literature Review. Applied Sciences. 11(8):3328. [CrossRef]

- Arjune, V., Singh, R., Desai, P. N. & Tripathi, K. (2021). A Scientometric Analysis of the Evolution and Changing Structure in Systems of Innovation Approaches. Journal of Scientometric Research, 10,2, 212-224. [CrossRef]

- Pietrobelli, C., Marin, A., & Olivari, J. (2018). Innovation in mining value chains: new evidence from Latin America. Resources Policy, 58, 1-10. [CrossRef]

- Aydin, H., & Tilton, J. E. (2000). Mineral endowment, labor productivity, and comparative advantage in mining. Resource and Energy Economics, 22(4), 281–293. [CrossRef]

- Dai J., Vasarhelyi MA (2017) Toward blockchain-based accounting and assurance. Journal Information Systems, 31(3), 5–21. [CrossRef]

- Benlian A., Kettinger WJ, Sunyaev A., Winkler TJ (2018) Introduction to Special Section: The Transformative Value of Cloud Computing – A Decoupling, Platformization, and Recombination Theoretical Framework. Journal of Management Information Systems, 35(3), 719–739. [CrossRef]

- Fahlevia M., Vional V., Pramesti R. M. (2022). Blockchain technology in corporate governance and future potential solution for agency problems in Indonesia. International Journal of Data and Network Science, 6, 721–726. [CrossRef]

- Lufin, M., & Soto-Díaz J. (2022). Technology, geography, and diversification in a small mineral economy. The Extractive Industries and Society. 11, September, 10108. [CrossRef]

- Di Vaio, A., Palladino, R., Pezzi, A. & Kalisz, D. E. (2021). The role of digital innovation in knowledge management systems: A systematic literature review. Journal of Business Research, 123, 220–231. [CrossRef]

- Howells, J., James, A. D., & Malik, K. (2004). Sourcing external technological knowledge: A decision support framework for firms. International Journal of Technology Management, 27(2/3), 143. [CrossRef]

- Shashi, S., Centobelli, P., Cerchione, R. & Ertz, M. (2020). Agile supply chain management: Where did it come from and where will it go in the era of digital transformation? Industrial Marketing Management, 90, 324–345. [CrossRef]

- Zaheer, H., Breyer, Y., & Dumay, J. (2019). Digital entrepreneurship: An interdisciplinary structured literature review and research agenda. Technological Forecasting and Social Change, 148, 119735. [CrossRef]

- Vial, G. (2019). Understanding digital transformation: a review and a research agenda. The Journal of Strategic Information Systems, 28(2), 118-144. [CrossRef]

- Elsamani Y., Mejia C., Kajikawa Y. (2023). Employee well-being and innovativeness: A multi-level conceptual framework based on citation network analysis and data mining techniques. PLoS ONE 18(1): e0280005. [CrossRef]

- Batterham, R. J. (2017). The mine of the future - Even more sustainable. Minerals Engineering, 107, 2-7. [CrossRef]

- Asr, E. T., Kakaie, R., Ataei, M. & Tavakoli Mohammadi, M. R. (2019). A review of studies on sustainable development in mining life cycle. Journal of Cleaner Production, 229, 213- 231. [CrossRef]

- Cioacă, S.I., Cristache, S.E., Vuță, M., Marin, E. & Vuță, M. (2020). Assessing the Impact of the ICT Sector on Sustainable Development in the European Union: An Empirical Analysis Using Panel Data. Sustainability, 12(2):592. [CrossRef]

- Al Rawashdeh, R., & Campbell, G. (2022). Mineral policy in the Gulf Cooperation Council (GCC) countries: The case of Saudi Arabia. The Extractive Industries and Society, 9, March, 10104. [CrossRef]

- Cong Y., Du H., Vasarhelyi MA Cloud Computing Start-ups and Emerging Technologies: From Private Investors’ Perspectives. Journal of Information Systems (2021) 35(1): 47-64. [CrossRef]

- He, Y., Liao, N., Rao, J., Fu, F., & Chen, Z. (2019). The optimization of investment strategy for resource utilization and energy conservation in iron mines based on Monte Carlo and intelligent computation. Journal of Cleaner Production, 232, 672-691. [CrossRef]

- Inklaar, R., Timmer, M. P. (2009). Productivity convergence across industries and countries: The importance of theory-based measurement. Macroeconomic Dynamics, 13(S2), 218-240. [CrossRef]

- Brandt N., Schreyer P., Zipperer V. (2017). Productivity Measurement with Natural Capital // Review of Income and Wealth. 63(s1), S7–S21. [CrossRef]

- Menzel, T. & Teubner, T. (2021). How Regional Trust Cues Could Drive Decentralization in the Energy Sector-An Exploratory Approach. Sustainability. 13(6):3010. [CrossRef]

- Rakic, S., Pero, M., Sianesi, A., & Marjanovic, U. (2022). Digital Servitization and Firm Performance: Technology Intensity Approach. Inzinerine Ekonomika-Engineering Economics, 2022, 33(4), 398-413. [CrossRef]

- Moore, J. F. (1993) Predators and Prey: A New Ecology of Competition. Harvard Business Review, 71, 75-86.

- Cusumano M. A., Gawer A., Yoffie D. B. The Business of Platforms: Strategy in the Age of Digital Competition, Innovation, and Power. Harper Business, 2019. RUR 320.

- Nambisan, S., Wright, M., & Feldman, M. (2019). The digital transformation of innovation and entrepreneurship: Progress, challenges and key themes. Research Policy, 48(8), 103773. [CrossRef]

- Nambisan, S., Zahra, S. A. & Luo, Y. (2019). Global platforms and ecosystems: Implications for international business theories. Journal of International Business Studies, 50(9), 1464-1486. [CrossRef]

- Setiawan, A. D., Singh, R., & Romijn, H. A. (2019). Responsible innovation: moving towards a culturally sensitive approach. Studies in Asian Social Science, 6(2), 46-65. [CrossRef]

- Chanias, S., Myers, M. D., & Hess, T. (2019). Digital transformation strategy making in pre-digital organizations: The case of a financial services provider. The Journal of Strategic Information Systems, 28(1), 17-33. [CrossRef]

- Bolton, R., McColl-Kennedy, J. R., Cheung, L., Gallan, A., Orsingher, C., Witell, L., & Zaki, M. (2018). Customer experience challenges: bringing together digital, physical and social realms. Journal of Service Management, 29(5), 776-808. [CrossRef]

- Skog DA, Wimelius H, Sandberg J (2018) Digital Disruption. Business & Information Systems Engineering, 60(5), 431–437. [CrossRef]

- Zaki M. (2019) Digital transformation: Harnessing digital technologies for the next generation of services. Journal of Services Marketing, vol. 33, iss. 4, pp. 429–435. [CrossRef]

- Carayannis, E., Giudice, M. D. & Peruta, M. R. D. (2014). Managing the intellectual capital within government-university-industry R&D partnerships: a framework for the engineering research centers. Journal of Intellectual Capital, 15(4), 611- 630. [CrossRef]

- Abbate, T., Codini, A., Aquilani, B. & Vrontis, D. (2022). From knowledge ecosystems to capabilities ecosystems: When open innovation digital platforms lead to value cocreation. Journal of the Knowledge Economy, 13(1), 290–304. [CrossRef]

- Abbate, T., Codini, A.P. & Aquilani, B. (2019), Knowledge co-creation in Open Innovation Digital Platforms: processes, tools and services, Journal of Business & Industrial Marketing, Vol. 34 No. 7, pp. 1434-1447. [CrossRef]

- Young, A., & Rogers, P. (2019). A Review of Digital Transformation in Mining. Mining, Metallurgy & Exploration, 36, 683–699. [CrossRef]

- Sanguankaew, P., & Vathanophas Ractham, V. (2019). Bibliometric review of research on knowledge management and sustainability, 1994–2018. Sustainability, 11(16), 4388. [CrossRef]

- Banson, A. (2020). The Effect of Mechanization on Safety and Productivity of a Gold Mine. Journal of Environments, 6(1), 14–20. [CrossRef]

- Boulter, A. & Hall, R. (2015). Wireless network requirements for the successful implementation of automation and other innovative technologies in open-pit mining. International Journal of Mining, Reclamation and Environment. 29(5), 368-379. [CrossRef]

- Gellweiler, C. & Krishnamurthi, L. (2020). How Digital Innovators Achieve Customer Value. Journal of theoretical and applied electronic commerce research, 15 (1). Talca Jan. [CrossRef]

- Pozzi, R., Rossi, T. & Secchi, R. (2021). Industry 4.0 technologies: critical success factors for implementation and improvements in manufacturing companies. Production Planning & Control, Published online: 08 Mar. [CrossRef]

- Xie, C., Nguyen, H., Bui, X.-N., Choi, Y., Zhou, J., Nguyen-Trang, T. Predicting rock size distribution in mine blasting using various novel soft computing models based on meta-heuristics and machine learning algorithms. Geoscience Frontiers. 2021. Vol. 12(3). 101108. [CrossRef]

- Official website of the Kazakhmys Corporation LLP http://www.kazakhmys.kz (accessed 01/12/2023).

- Official website of the “ArcelorMittal Temirtau” JSC https://www.arcelormittal.kz/company/(accessed 13/12/2023).

- Aubakirova, G. M. & Isatayeva, F. M. (2021). New Approaches to the Construction of a Diversified Economy: the Experience of Kazakhstan. Studies on Russian Economic Development. 32(6), 712-718. [CrossRef]

- Diagnostics of the mining sector - Kazakhstan. World Bank Report 2023. -123p. https://documents1.worldbank.org/curated/en/099081823001511076/pdf/P176745032752e020ab830aca3807b2afc.pdf.

- Hilkevics, S., Semakina, V. (2019). The classification and comparison of business ratios analysis methods, Insights into Regional Development 1(1): 48-57. [CrossRef]

- Sanchis, R., Duran-Heras, A., Poler, R. (2020). Optimizing the Preparedness Capacity of Enterprise Resilience Using Mathematical Programming. Mathematics, 8(9), 1596. [CrossRef]

- Aubakirova, G., Rudko, G. & Isataeva, F. (2021). Assessment of metallurgical enterprises activities in Kazakhstan in the context of international trends. Economic Annals-XXI, 187(1-2), 121-130. [CrossRef]

- Habib, S. M., Hussain, H., Al-Faryan, M. A. S., Hussain, R. Y., & Mcmillan, D. (Ed.) (2022). Impact of firm characteristics and ownership structure on firm efficiency: evidence from non-financial firms of Pakistan. Cogent Economics & Finance, 10:1, 2106628. [CrossRef]

- Code of the Republic of Kazakhstan dated December 27, 2017 125-VI “On subsoil and subsoil use” (as amended and supplemented as of 01/12/2023). https://online.zakon.kz/Document/?doc_id=31764592 (date of access: 01/12/2023).

- Statistics of education, science and innovation: time series. https://stat.gov.kz/ru/ industries/social-statistics/stat-edu-science-inno/dynamic-tables/ (access date: 01/27/2024).

- Recommendations for solving problems using digital projects (solutions) and increasing the efficiency of enterprises. JSC Kazakhstan Center for Industry and Export “Qazindustry”, Nur-Sultan, 2020. URL: https://qazindustry.gov.kz/docs/otchety/1597038508.pdf (access date 12/13/2021).

- Official website of the Taldau Information and Analytical System https://taldau.stat.gov.kz/kk/Search/SearchByKeyWord (accessed November 10, 2023).

- Official website of the Autonomous Cluster Fund “Park of Innovative Technologies”. https://techgarden.kz/about_fund (access date 11/17/2023).

- Anderson, R. A. (2015). A model for data-driven knowledge creation and improved accountability in jamaican public schools through ICTs. The International Journal of Educational Organization and Leadership, 21(2), 1–7. [CrossRef]

- Rawashdeh, R. A. & Campbell, G. (2022). Mineral policy in the Gulf Cooperation Council (GCC) countries: The case of Saudi Arabia. The Extractive Industries and Society, 9, March, 10104. [CrossRef]

- Ansong, E., & Boateng, R. (2019). Surviving in the digital era – business models of digital enterprises in a developing economy. Digital Policy, Regulation and Governance, 21, 2, 164-178. [CrossRef]

| Model of the influence of production resources | Coefficient of determination | Coefficient significance F | F- critical | |||||||||||||||||

| 2005 | 2010 | 2015 | 2023 | 2005 | 2010 | 2015 | 2023 | 2005 | 2010 | 2015 | 2023 | |||||||||

| Energy plant JSC “ QARMET” | ||||||||||||||||||||

| 3-factor by production resources Y =0.3817* X1 2 +0.1936* X2 -1.0282* X3 | 0.8915 | 0.8703 | 0.8612 | 0.8740 | 413 | 407 | 409 | 411 | 213 | 215 | 193 | 197 | ||||||||

| 2-factor for factors of reproduction of labor and capital Y =0.0013* X2 2 +0.2045* X3 | 0.8113 | 0.7814 | 0.7217 | 0.7746 | 62 | 57 | 64 | 63 | 205 | 211 | 216 | 210 | ||||||||

| 1-factor: material costs Y =0.0025* X1 2 +0.2838 | 0.8003 | 0.7915 | 0.7993 | 0.8052 | 383 | 375 | 377 | 381 | 217 | 215 | 209 | 213 | ||||||||

| Plant KLMZ JSC “ QARMET” | ||||||||||||||||||||

| 3-factor by production resources Y =0.0721* X1 2 +1.1283* X2-0.0391* X3 | 0.9003 | 0.9314 | 0.9015 | 0.9117 | 427 | 431 | 435 | 429 | 227 | 239 | 237 | 249 | ||||||||

| 2-factor for factors of reproduction of labor and capital Y =0.1036* X2 2 +0.0313* X3 | 0.9115 | 0.8815 | 0.8798 | 0.9003 | 413 | 411 | 404 | 421 | 85 | 117 | 94 | 125 | ||||||||

| 1-factor: material costs Y =0.0384* X1 2 +0.0481 | 0.7815 | 0.8303 | 0.8172 | 0.7918 | 285 | 291 | 288 | 296 | 233 | 215 | 227 | 216 | ||||||||

| Balkhash Mining and Metallurgical Plant Kazakhmys Corporation LLP | ||||||||||||||||||||

| 3-factor by production resources Y =0.9252* X1 2 +0.02816* X2-0.9184* X3 | 0.1785 | 0.8405 | 0.8611 | 0.8810 | 371 | 344 | 358 | 305 | 197 | 201 | 195 | 198 | ||||||||

| 2-factor for factors of reproduction of labor and capital Y =0.0141* X2 2 +0.5036* X3 | 0.7915 | 0.7785 | 0.7845 | 0.7703 | 43 | 59 | 61 | 57 | 196 | 199 | 213 | 207 | ||||||||

| 1-factor: material costs Y =0.0259* X1 2 +0.0305 | 0.8505 | 0.8747 | 0.8605 | 0.8503 | 211 | 241 | 238 | 229 | 173 | 184 | 178 | 182 | ||||||||

| “Maker “ Kazakhmys Corporation LLP | ||||||||||||||||||||

| 3-factor by production resources Y =0.0813* X1 2 +0.0581* X2-0.0692* X3 | 0.8451 | 0.8003 | 0.7914 | 0.8351 | 382 | 361 | 357 | 375 | 221 | 205 | 200 | 213 | ||||||||

| 2-factor for factors of reproduction of labor and capital Y =0.0395* X2 2 +0.0293* X3 | 0.7845 | 0.7313 | 0.7003 | 0.7499 | 261 | 314 | 322 | 294 | 103 | 127 | 110 | 125 | ||||||||

| 1-factor: material costs Y =0.0134* X1 2 +0.0492 | 0.8113 | 0.8051 | 0.7915 | 0.7803 | 200 | 211 | 235 | 215 | 195 | 189 | 197 | 199 | ||||||||

| Political | Economic |

| – international positioning, degree of globalization and openness of Kazakhstan; - diversification of energy supplies to world markets, search for alternative routes and new markets; – stimulating private investment and developing public-private partnerships to attract global geological exploration and mining companies to cooperation on the basis of state geological exploration of subsurface resources; – establishment of the National geological survey to declassify and provide investors with open access to geological data. |

– Kazakhstan’s commitment to combat climate change; - difficulties in creating conditions for new investment in exploration and production, including by foreign junior exploration companies; - dependence on foreign equipment suppliers; - tax policy (tariffs and incentives); - completion of the transition to the CRIRSCO international system of certification of mineral reserves and introduction of KAZRC; –-– - depletion and non - recovery of some high-quality reserves, low operating efficiency; - legacy unprofitable fields and obsolete facilities; - high concentration of large state-affiliated enterprises in the industry; - few new geological discoveries; - shortage of experienced professionals.data |

| Social | Technological |

| - development of model agreements on social support for persons affected by the Ministry of Mineral Resources; – preparation of rules for resettlement of persons affected by mining enterprise; – compensation and redress for damage to private lands caused by exploration activities. |

– technological changes in the industry, taking into account the availability and transfer of exploration, extraction and processing technologies; inter-industry co-operation; collaborations with scientific and educational institutions; – degree of use, implementation and transfer of geological survey technologies and expansion of the mineral resource base; R&D expenditure; - production capacity and readiness of enterprises to integrate external digital solutions; - dependence on foreign software against the background of lack of effective Kazakhstani developments comparable to Western technologies, difficulties in adapting standard software solutions to the needs of the enterprise; - lack of unified standards of work with mining and geological-economic information for detailed exploration and commercial exploitation of deposits, - lack of a unified information and analytical industry platform. |

| Environmental | Legal |

| - complexity of the procedure for obtaining environmental permits for exploration; - transition to environmentally friendly alternative energy sources; - the environmental situation in the regions where the mining company operates; - implementation of the decarbonization strategy; - development of ESG standards for the mining industry. - transition to the principles of the best available technologies (Best Available Techniques, BAT). |

- legislative regulation of research and development (R&D) of practical orientation (BAT) [70]; - Regulatory and legal regulation of information disclosure in the mining sector. |

| Factor | Expert judgment with weight adjustment |

| Technological sectoral changes, taking into account the availability and transfer of exploration, extraction and processing technologies; inter-industry co-operation; collaboration with scientific and educational institutions; | 0.093 |

| Extent of use, implementation and transfer of geological survey technologies and expansion of the mineral resource base | 0.071 |

| Research and development expenses (R&D) | 0.062 |

| Production capacity and readiness of enterprises to integrate external digital solutions | 0.053 |

| Dependence on foreign software and difficulties in adapting standard software solutions to the needs of the enterprise | 0.046 |

| Lack of unified standards work with mining and geological-economic information for detailed exploration and commercial exploitation of deposits | 0.034 |

| Lack of a unified information and analytical industry platform | 0.026 |

| Index | Change |

| Reducing the cost of the final product | 10-40 |

| Energy optimization | 25-65 |

| Reducing waste | 8-20 |

| Reduce inventory and warehouse losses | 7-15 |

| Reduced maintenance and support costs | 20-65 |

| Reduced diagnostic time | 25-50 |

| Improving specification accuracy | 30-70 |

| Increased supply chain agility | 20-60 |

| Reduced space | 15-40 |

| Capacity utilization | 15-50 |

| Accelerate time to market | 10-75 |

| Increased sales | 15-50 |

| Increased profitability | 25-50 |

| Increased profitability | 20-50 |

| Increased profitability | 20-50 |

| Improving planning | 10-70 |

| Pricing accuracy | 30-65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).