Submitted:

08 December 2024

Posted:

10 December 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

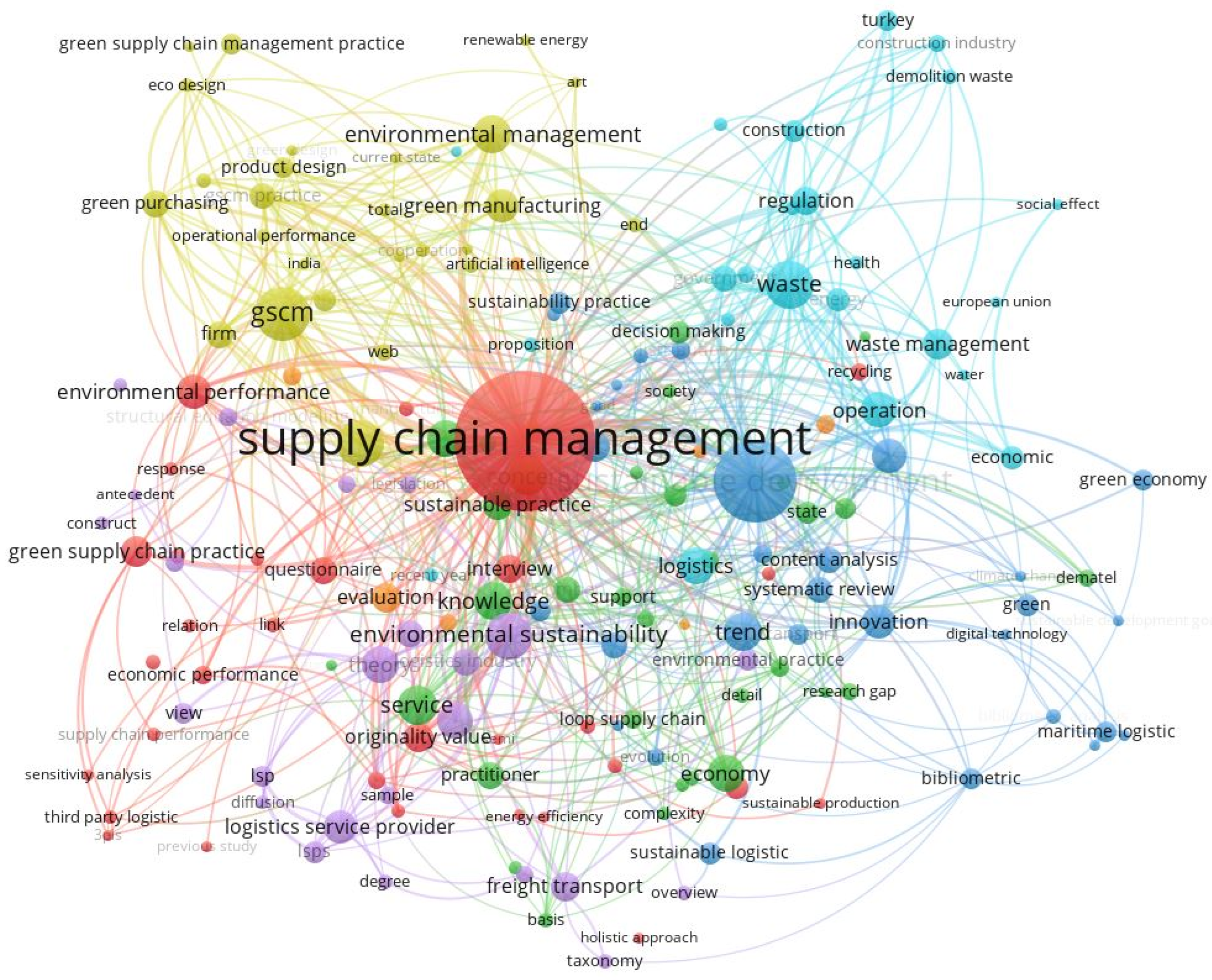

2. Literature Review

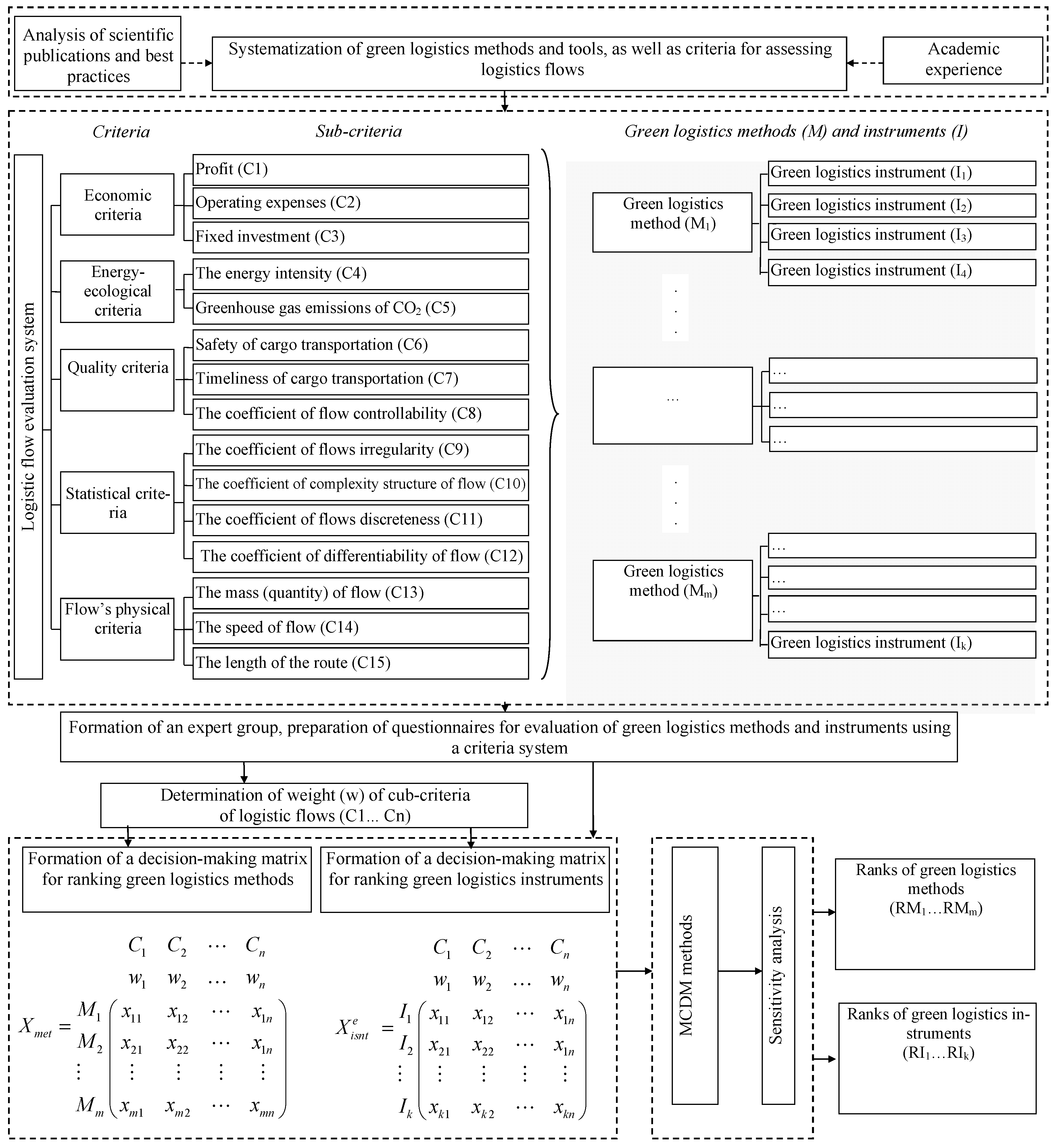

3. Methodology for Systematization and Ranking of Green Logistics Methods and Instruments

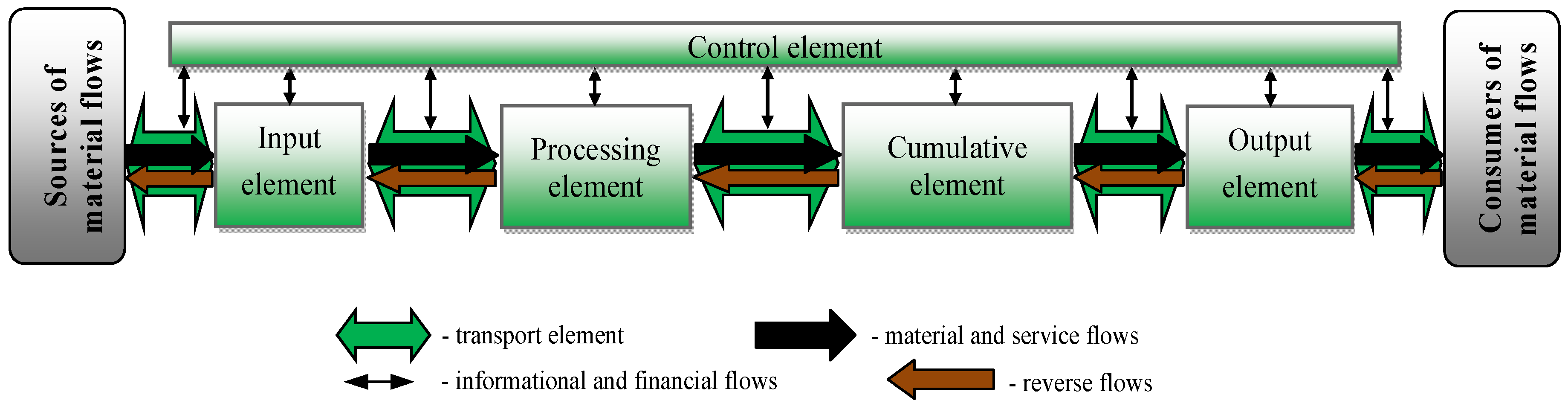

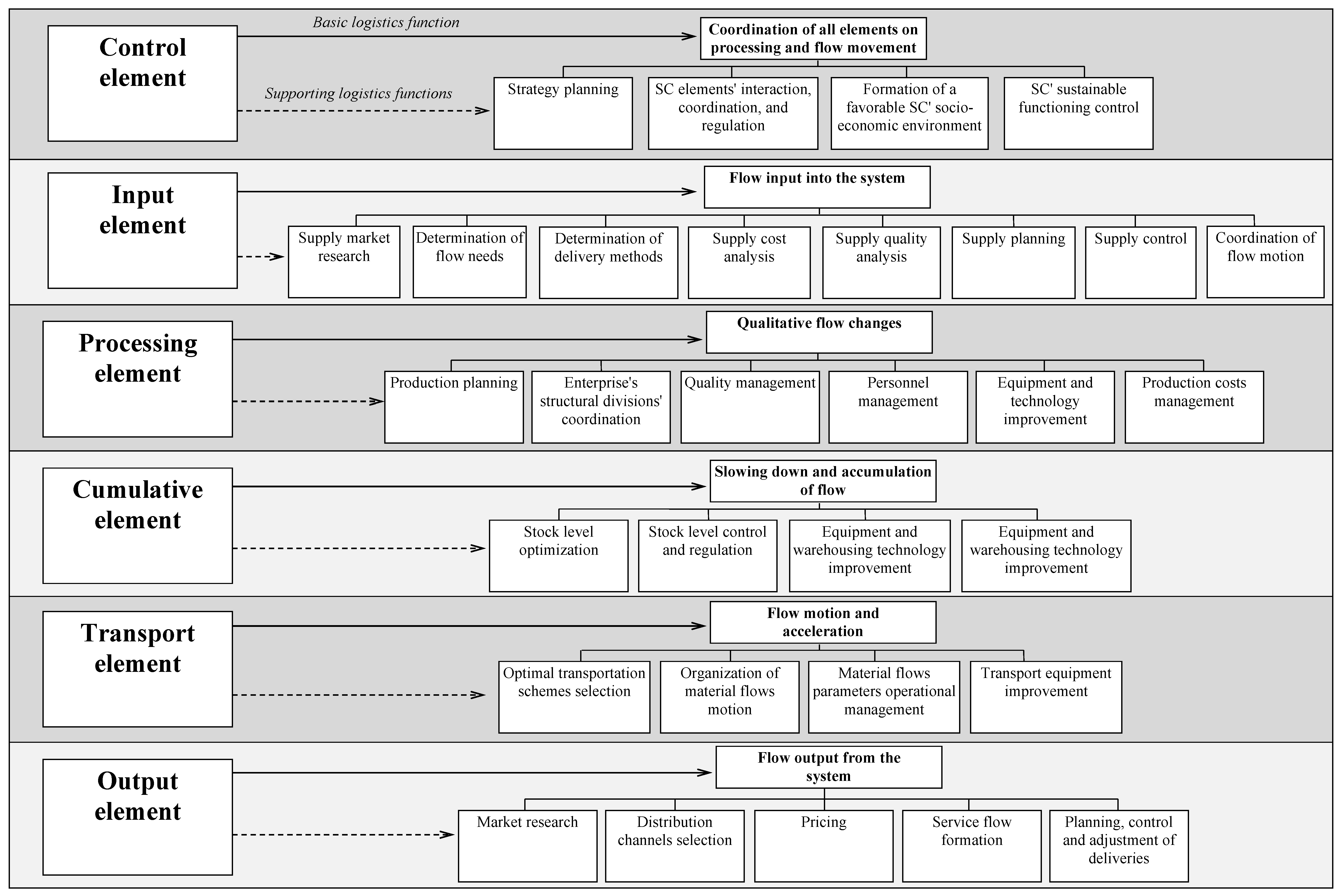

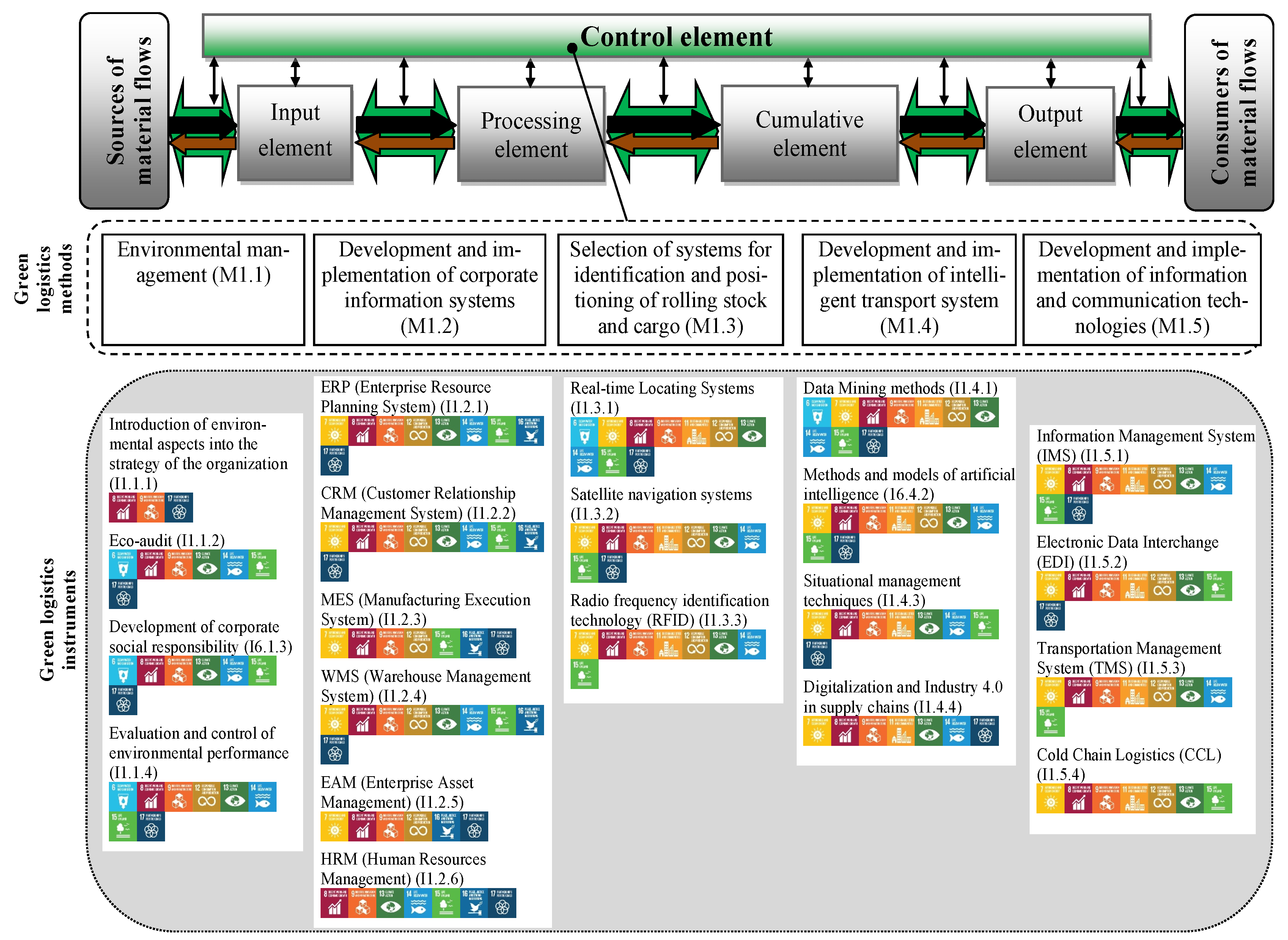

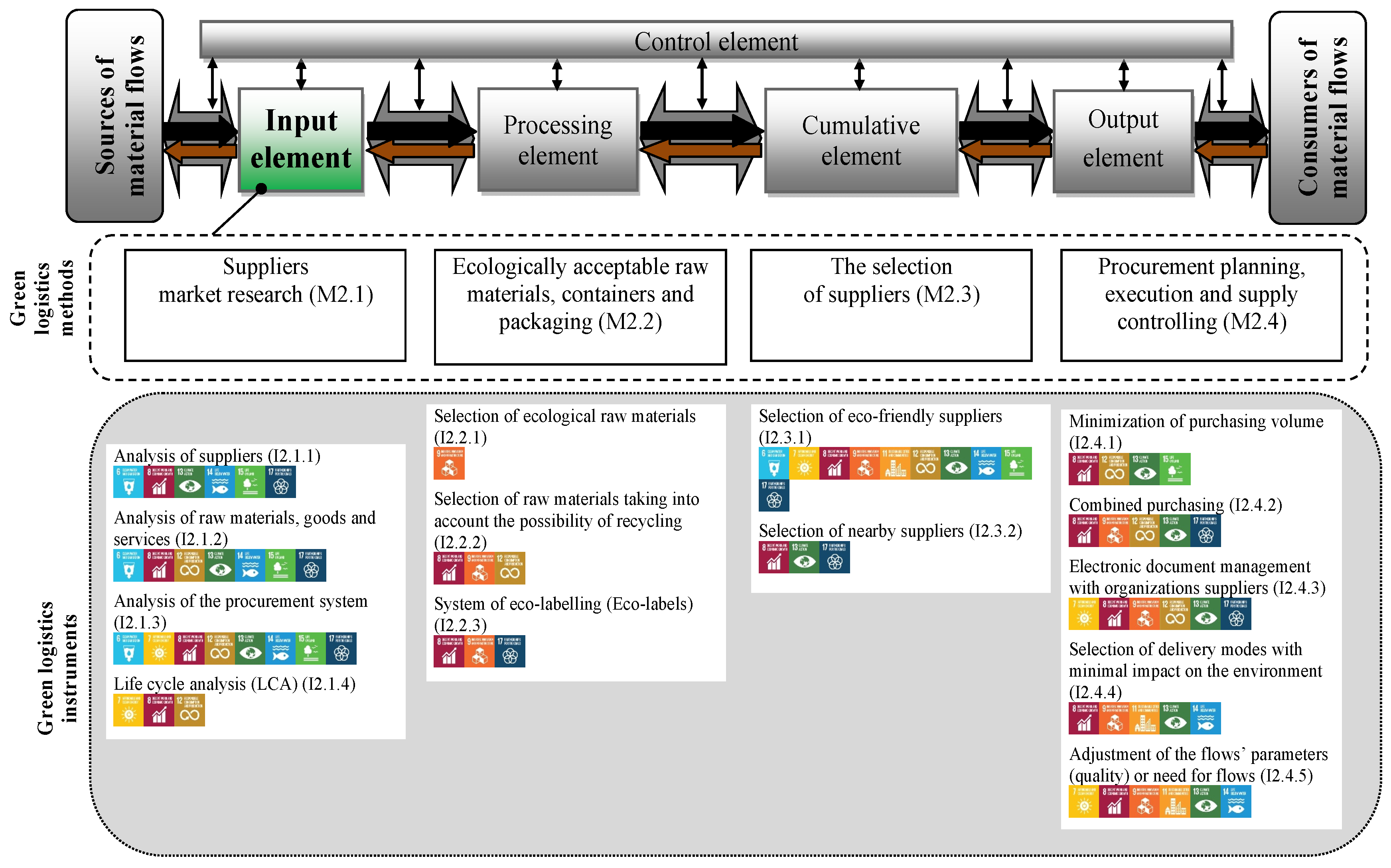

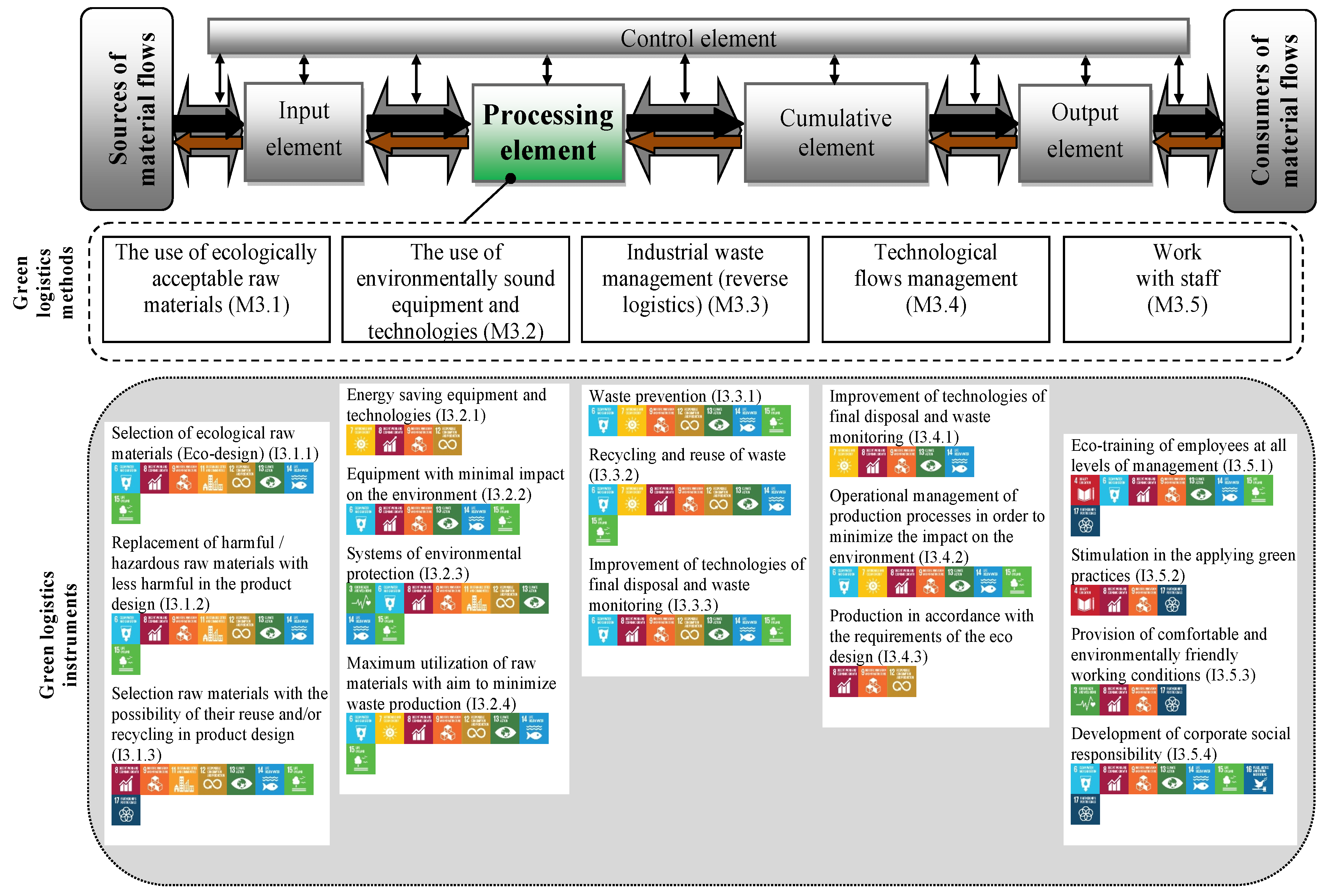

3.1. Structural-Functional Approach to the Green Supply Chain Formalization

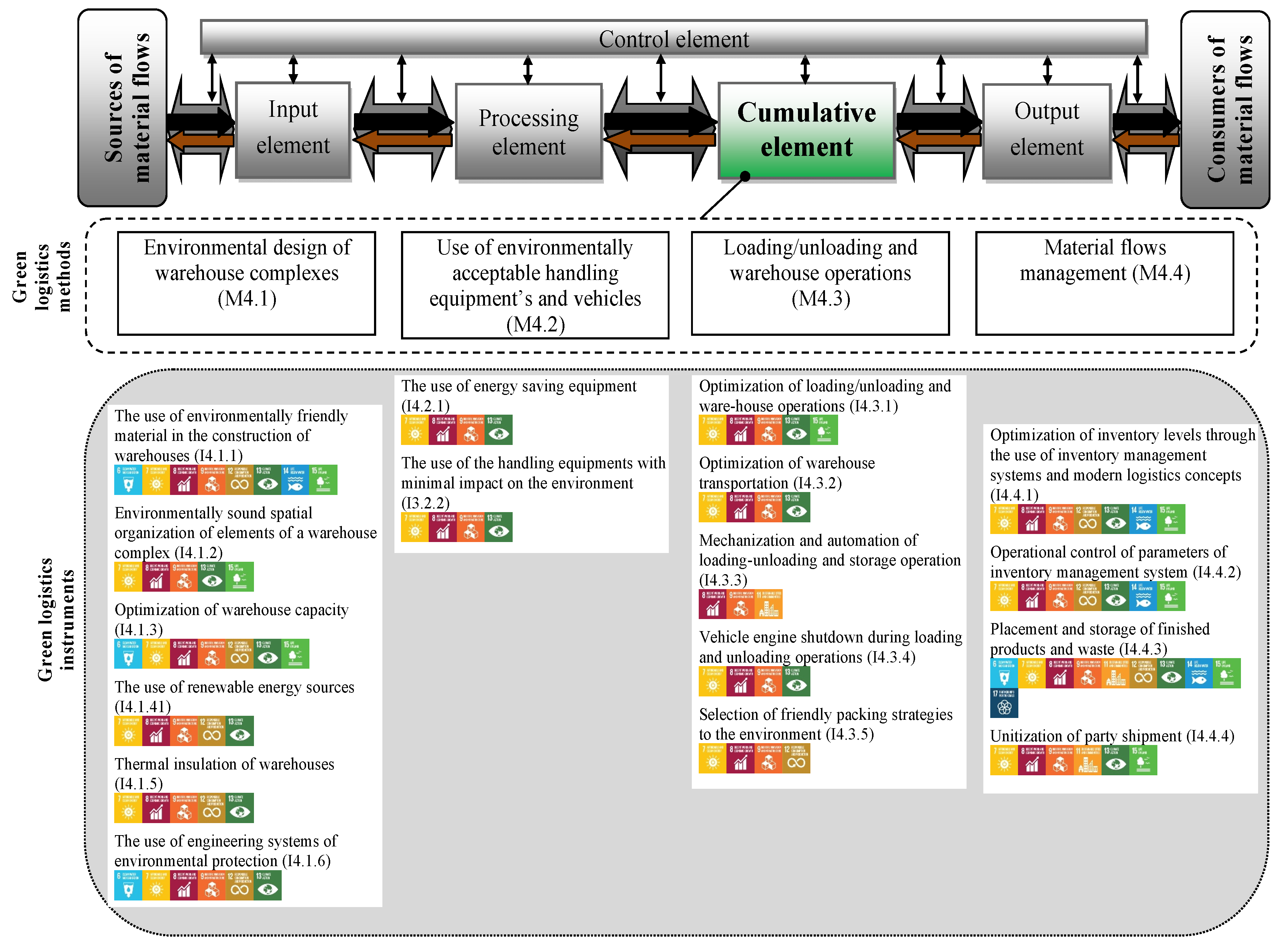

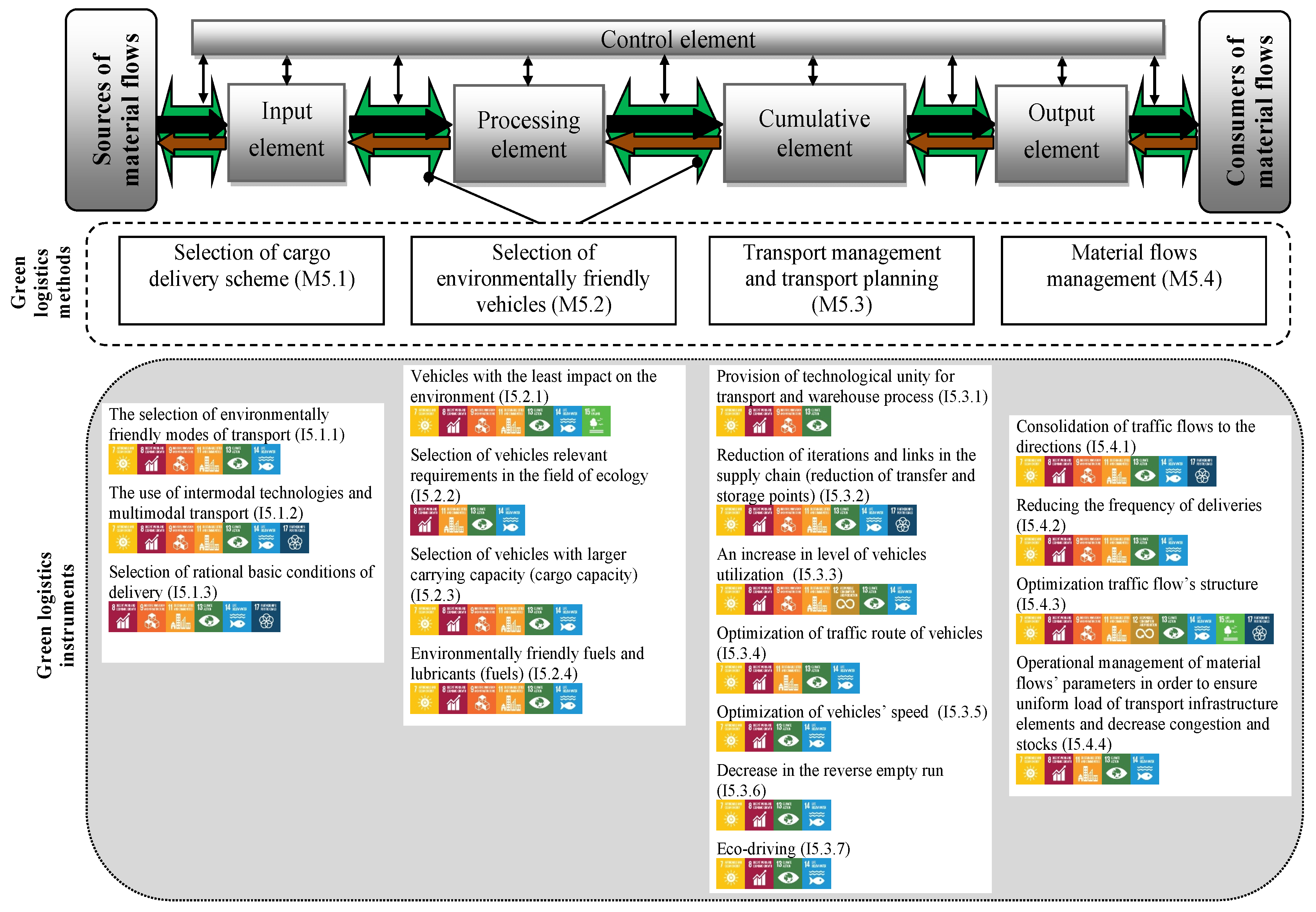

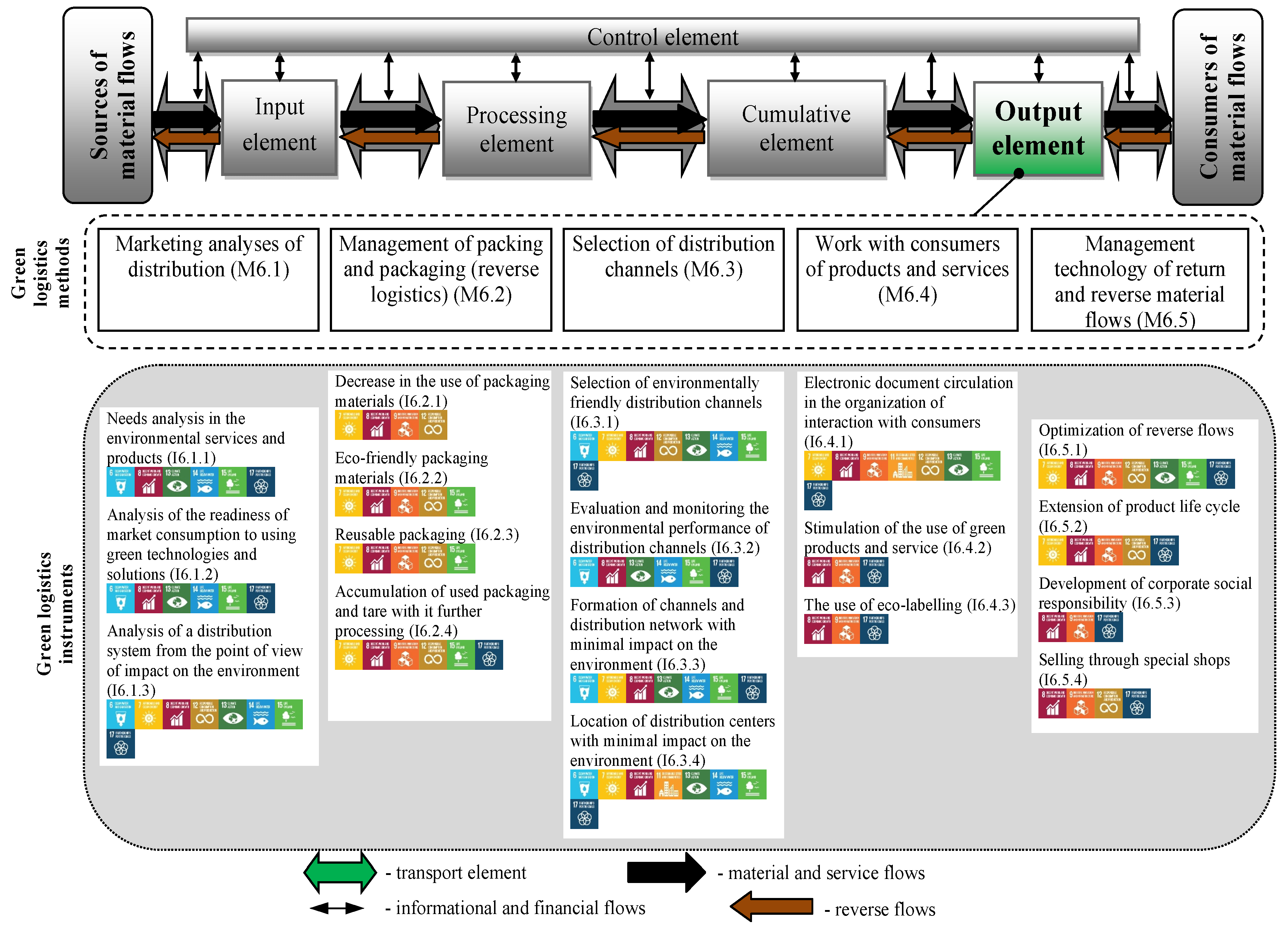

3.2. Classification of Green Logistics Methods and Instruments

- Correspondence to the elements of the supply chain to avoid duplication of methods and instruments at different stages of the logistics process, as well as to identify missing and promising methods and instruments.

- Correspondence to supporting functions of supply chain elements. Traditionally, logistics functional areas are focused on cost reduction and quality improvement. Specialization of green logistics methods and instruments by supporting functions is necessary to achieve social and environmental goals additionally.

- Correspondence of instruments to the green logistics methods, i.e., realization of a certain method by a set of instruments.

- Consideration of green logistics methods and instruments as a unified system for achieving SDGs. The object of management is logistics flows in the supply chain.

- Using the best green practices, eco-programs and projects with the participation of political, social and economic institutions, scientific organizations, international unions and organizations to form and improve the system of green logistics methods and instruments.

- Green Logistics Method (GLM) – a set of solutions to achieve the SDGs by realizing the basic and supporting logistics functions of a certain element of the logistics system or supply chain.

- Green Logistics Instruments (GLI) – a specific solution for changing the parameters of logistics flows to implement the corresponding green logistics method.

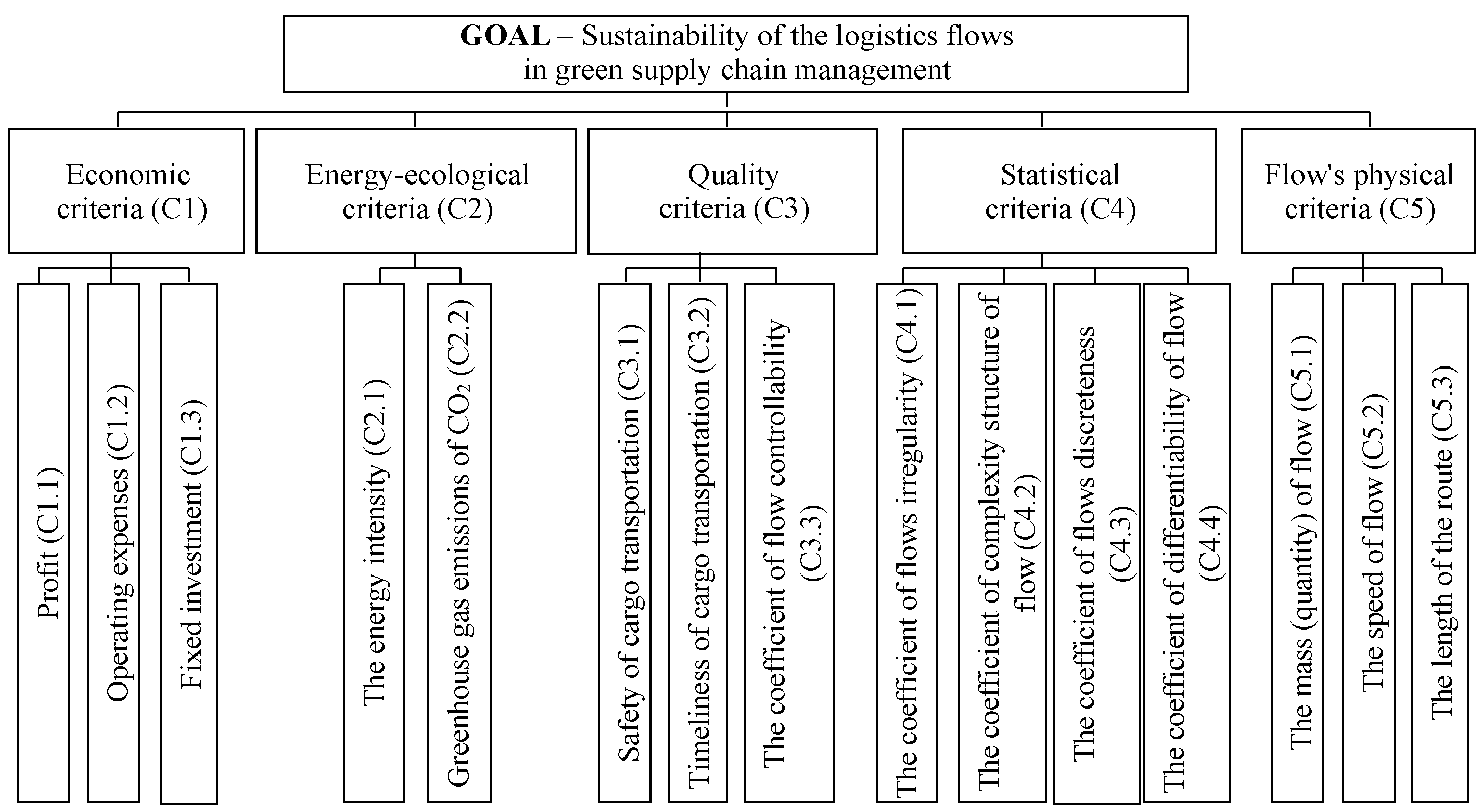

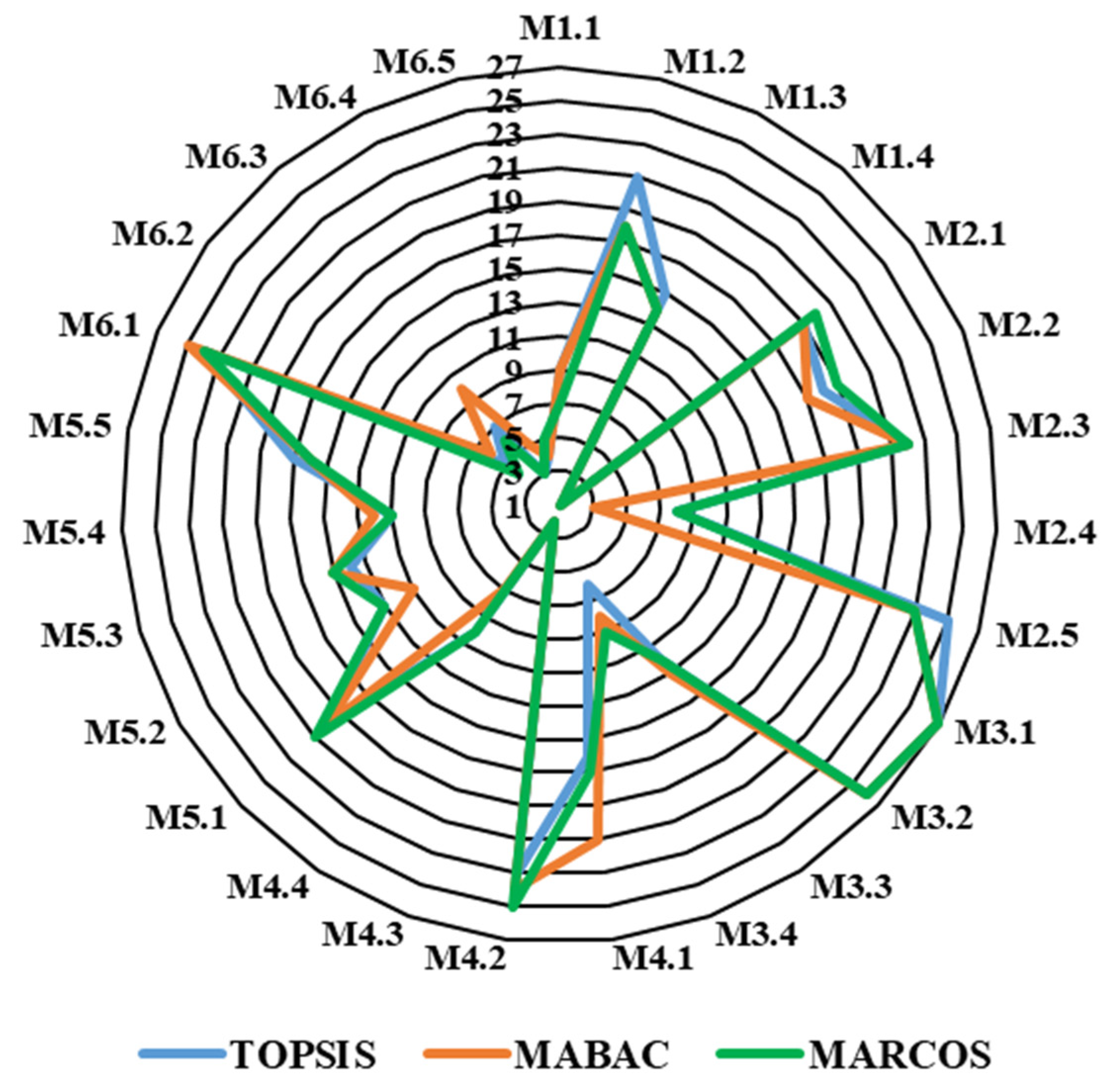

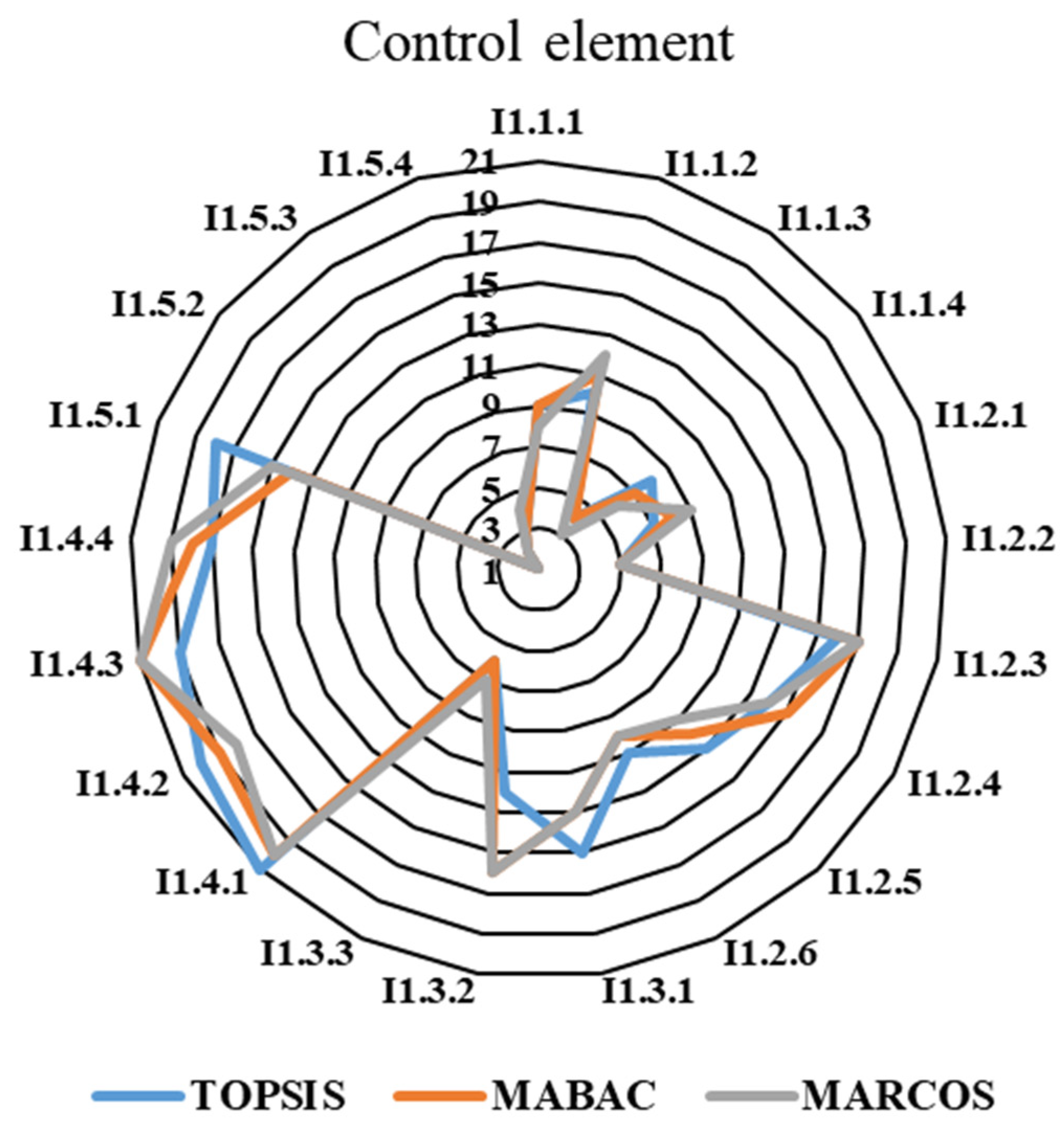

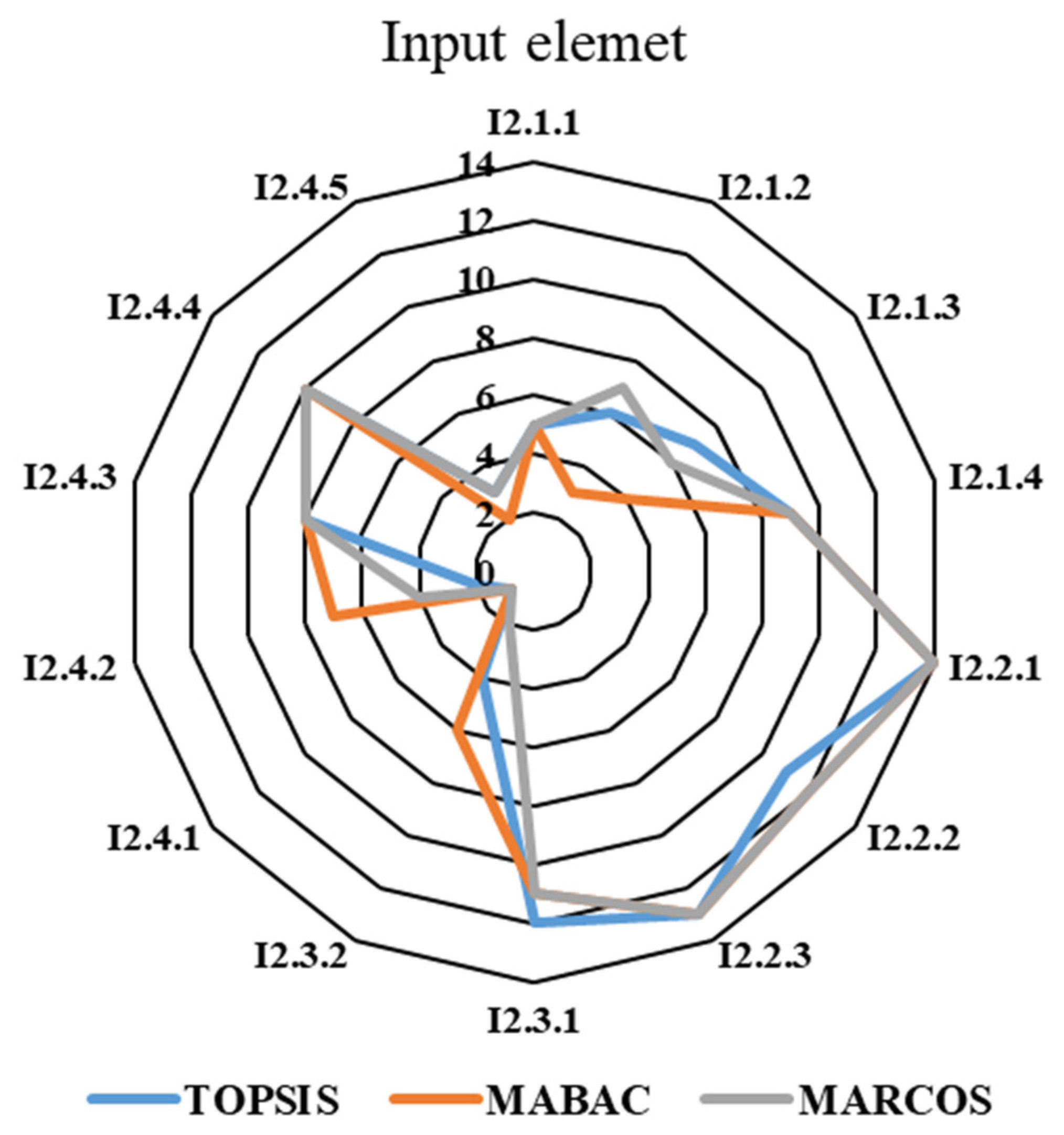

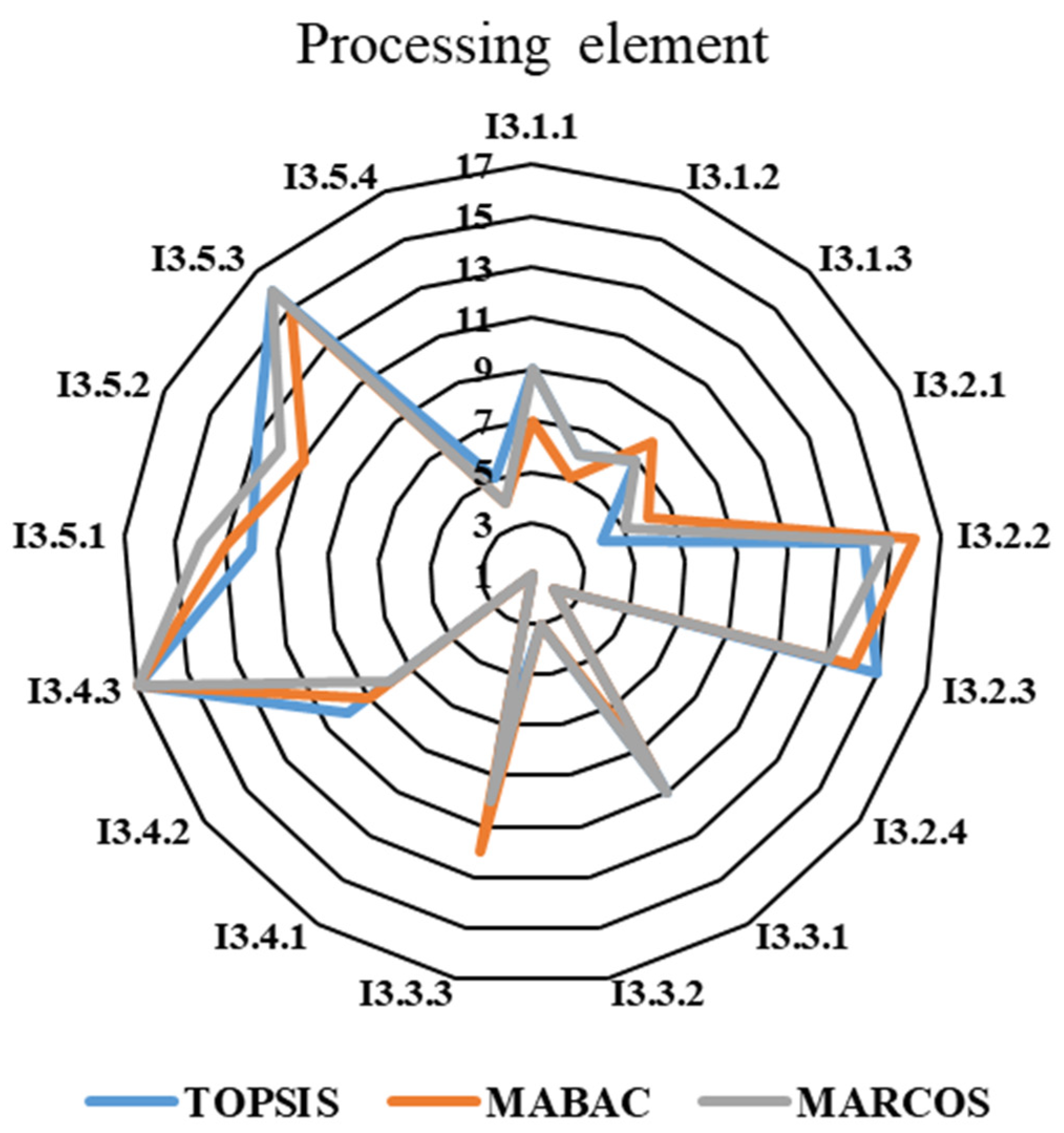

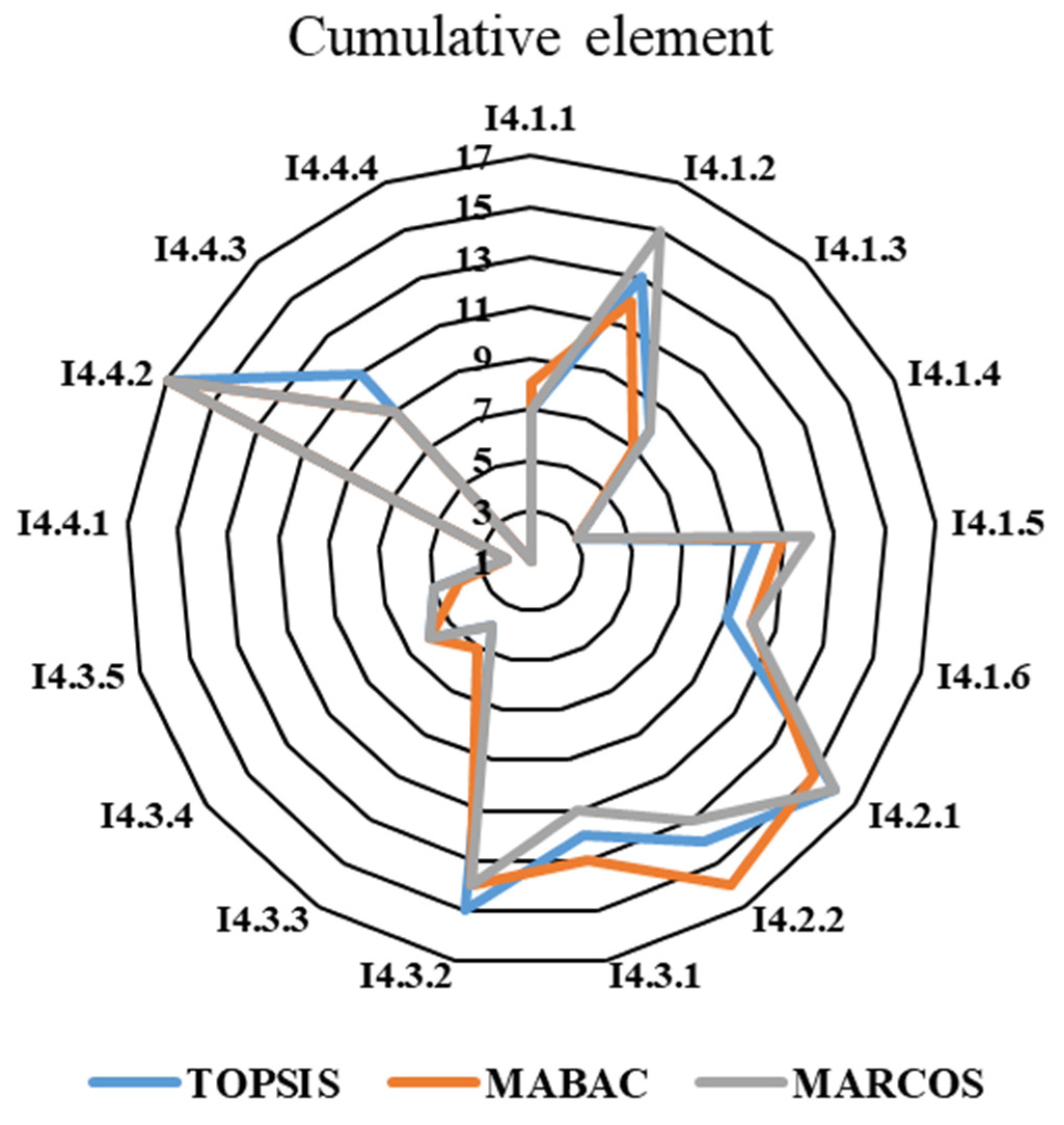

3.3. Multi-Criteria Ranking of Green Logistics Methods and Instruments

4. Case Study

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sergeev, V. Supply Chain Management; Publishing House Yurait: Moscow, 2023; ISBN 978-5-534-01356-6. [Google Scholar]

- Chakraborty, A.; Al Amin, M.; Baldacci, R. Analysis of internal factors of green supply chain management: An interpretive structural modeling approach. Cleaner Logistics and Supply Chain 2023, 7, 100099. [Google Scholar] [CrossRef]

- Tetteh, F.K.; Owusu Kwateng, K.; Mensah, J. Green logistics practices: A bibliometric and systematic methodological review and future research opportunities. Journal of Cleaner Production 2024, 476, 143735. [Google Scholar] [CrossRef]

- Bhatia, M.S.; Gangwani, K.K. Green supply chain management: Scientometric review and analysis of empirical research. Journal of Cleaner Production 2021, 284, 124722. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Islam, M.S.; Karia, N.; Fauzi, F.A.; Afrin, S. A literature review on green supply chain management: Trends and future challenges. Resources, Conservation and Recycling 2019, 141, 145–162. [Google Scholar] [CrossRef]

- Lazar, S.; Klimecka-Tatar, D.; Obrecht, M. Sustainability orientation and focus in logistics and supply chains. Sustainability 2021, 13, 3280. [Google Scholar] [CrossRef]

- Tozanli, O.; Duman, G.; Kongar, E.; Gupta, S. Environmentally concerned logistics operations in fuzzy environment: A literature survey. Logistics 2017, 1, 1–42. [Google Scholar] [CrossRef]

- Zhang, L.-J.; Liu, R.; Liu, H.-C.; Shi, H. Green supplier evaluation and selections: A state-of-the-art literature review of models, methods, and applications. Mathematical Problems in Engineering 2020, 2020, 1–25. [Google Scholar] [CrossRef]

- Zimmer, K.; Fröhling, M.; Schultmann, F. Sustainable supplier management – a review of models supporting sustainable supplier selection, monitoring and development. International Journal of Production Research 2016, 54, 1412–1442. [Google Scholar] [CrossRef]

- Malek, J.; Desai, T.N. A systematic literature review to map literature focus of sustainable manufacturing. Journal of Cleaner Production 2020, 256, 120345. [Google Scholar] [CrossRef]

- Roy, V.; Singh, S. Mapping the business focus in sustainable production and consumption literature: Review and research framework. Journal of Cleaner Production 2017, 150, 224–236. [Google Scholar] [CrossRef]

- Becerra, P.; Mula, J.; Sanchis, R. Green supply chain quantitative models for sustainable inventory management: A review. Journal of Cleaner Production 2021, 52, 129544. [Google Scholar] [CrossRef]

- Bartolini, M.; Bottani, E.; Grosse, E.H. Green warehousing: Systematic literature review and bibliometric analysis. Journal of Cleaner Production 2019, 226, 242–258. [Google Scholar] [CrossRef]

- Aloui, A.; Hamani, N.; Derrouiche, R.; Delahoche, L. Systematic literature review on collaborative sustainable transportation: Overview, analysis and perspectives. Transportation Research Interdisciplinary Perspectives 2021, 9, 100291. [Google Scholar] [CrossRef]

- Zhao, X.; Ke, Y.; Zuo, J.; Xiong, W.; Wu, P. Evaluation of sustainable transport research in 2000–2019. Journal of Cleaner Production 2020, 256, 120404. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Papadopoulos, T.; Childe, S.J. Green supply chain management enablers: Mixed methods research. Sustainable Production and Consumption 2015, 4, 72–88. [Google Scholar] [CrossRef]

- Carvalho, H.; Garrido Azevedo, S.; Cruz-Machado, V. Supply chain performance management: Lean and green paradigms. International Journal of Business Performance and Supply Chain Modelling 2010, 2, 304–333. [Google Scholar] [CrossRef]

- Hasan, M.M.; Nekmahmud, M.; Yajuan, L.; Patwary, M.A. Green business value chain: A systematic review. Sustainable Production and Consumption 2019, 326–339. [Google Scholar] [CrossRef]

- Zhang, S.; Lee, C.; Chan, H.K.; Choy, K.L.; Wu, Z. Swarm intelligence applied in green logistics: A literature review. Engineering Applications of Artificial Intelligence 2015, 37, 154–169. [Google Scholar] [CrossRef]

- Bülent Sezen; Sibel Yildiz Çankaya. Green supply chain management theory and practices. In Ethics and sustainability in global supply chain management; Akkucuk, U., Ed.; IGI Global: Hershey PA, 2017; pp 92– 114, ISBN 978-1-5225-2036-8.

- Islam, S.; Karia, N.; Fauzi, F.; Soliman, M. A review on green supply chain aspects and practices. Management and Marketing. Challenges for the Knowledge Society 2017, 12, 12–36. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R.; Shankar, R. Circular supply chain management: A state-of-art review and future opportunities. Journal of Cleaner Production 2020, 258, 120859. [Google Scholar] [CrossRef]

- Evangelista, P.; Santoro, L.; Thomas, A. Environmental sustainability in third-party logistics service providers: A systematic literature review from 2000-2016. Sustainability 2018, 10, 1627. [Google Scholar] [CrossRef]

- Bilek, G.M.; Calvi, R.; Erhel, D.; Mechouar, Y. Towards green transportation practices using a buyer/supplier perspective: A systematic literature review. Logistics 2024, 8, 68. [Google Scholar] [CrossRef]

- Balon, V. Green supply chain management: Pressures, practices, and performance - An integrative literature review. Business Strategy and Development 2019, 3. [Google Scholar] [CrossRef]

- Ahmed, T.; Yousaf, A.; Clavijo, R.C.; Sanders, K. Entrepreneurial pathways to sustainability: A theoretical paper on green human resource management, green supply chain management, and entrepreneurial orientation. Sustainability 2024, 16, 6357. [Google Scholar] [CrossRef]

- Morella, P.; Lambán, M.P.; Royo, J.; Sánchez, J.C.; Latapia, J. Technologies associated with Industry 4. 0 in green supply chains: A systematic literature review. Sustainability 2023, 15, 9784. [Google Scholar] [CrossRef]

- Villanueva-Ponce, R.; Avelar-Sosa, L.; Alvarado-Iniesta, A.; Cruz-Sánchez, V.G. The green supplier selection as a key element in a supply chain: A review of cases studies. DYNA 2015, 82, 36–45. [Google Scholar] [CrossRef]

- Khalil, N.; Che Abdullah, S.N.; Haron, S.N.; Hamid, M.Y. A review of green practices and initiatives from stakeholder’s perspectives towards sustainable hotel operations and performance impact. Journal of Facilities Management 2024, 22, 653–682. [Google Scholar] [CrossRef]

- Sharma, V.K.; Chandna, P.; Bhardwaj, A. Green supply chain management related performance indicators in agro industry: a review. Journal of Cleaner Production 2017, 141, 1194–1208. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. Manavalan, E.; Jayakrishna, K. A review of internet of things (IoT) embedded sustainable supply chain for Industry 4.0 requirements. Computers & Industrial Engineering 2018. [CrossRef]

- Osintsev, N.; Rakhmangulov, A.; Sładkowski, A.; Dyorina, N. Logistic flow control system in green supply chains. In Ecology in Transport: Problems and Solutions; Sładkowski, A., Ed.; Springer International Publishing: Cham, 2020; pp 311–380; ISBN 978-3-030-42322-3. [Google Scholar]

- Rakhmangulov, A.; Sladkowski, A.; Osintsev, N.; Muravev, D. Green logistics: A system of methods and instruments - Part 2. Naše more 2018, 65, 49–55. [Google Scholar] [CrossRef]

- Osintsev, N.A.; Tsyganov, A.V.; Rakhmangulov, A.N. Mathematical model for optimization of a range of tools for «green» logistics. Herald of the Ural State University of Railway Transport 2023, 98–112. [Google Scholar] [CrossRef]

- Osintsev, N.A.; Rakhmangulov, A.N.; Sladkovski, A.V. A fuzzy AHP-TOPSIS approach for green logistics instruments ranking. Transport of the Urals 2020, 64, 3–14. [Google Scholar] [CrossRef]

- Osintsev, N.A.; Rakhmangulov, A.N. Supply сhain sustainability assessment based on gray relational analysis. Vestnik of Nosov Magnitogorsk State Technical University 2023, 21, 180–196. [Google Scholar] [CrossRef]

- Osintsev, N. Multi-criteria decision-making methods in green logistics. World of Transport and Transportation 2021, 19, 231–240. [Google Scholar] [CrossRef]

- Osintsev, N.; Rakhmangulov, A. Sustainable development of supply chains; INFRA-M: Moscow, 2025; ISBN 978-5-16-019680-0. [Google Scholar]

- Osintsev, N.; Rakhmangulov, A.; Baginova, V. Evaluation of logistic flows in green supply chains based on the combined DEMATEL-ANP method. Facta Universitatis, Series: Mechanical Engineering 2021, 19, 473–498. [Google Scholar] [CrossRef]

- Aliakbari Nouri, F.; Shafiei Nikabadi, M.; OLFAT, L. Sustainable service supply chain practices (SSSCPs): A framework development. International Journal of Productivity and Performance Management 2019, 69, 813–833. [Google Scholar] [CrossRef]

- Behdioglu, S.; Koca, G. Green supply chain initiatives in Turkish automotive main industry. Journal of Strategic Research in Social Science 2017, 3. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Mohapatra, P.; Kumar, V.; Dey, P.K.; Brady, M.; Tiwari, M.K.; Nudurupati, S.S. Green supply chain performance measurement using fuzzy ANP-based balanced scorecard: a collaborative decision-making approach. Production Planning & Control 2014, 25, 698–714. [Google Scholar] [CrossRef]

- Boutkhoum, O.; Hanine, M.; Boukhriss, H.; Agouti, T.; Tikniouine, A. Multi-criteria decision support framework for sustainable implementation of effective green supply chain management practices. Springerplus 2016, 5, 664. [Google Scholar] [CrossRef]

- Brandenburg, M.; Gruchmann, T.; Oelze, N. Sustainable supply chain management - A conceptual framework and future research perspectives. Sustainability 2019, 11, 7239. [Google Scholar] [CrossRef]

- Akman, G.; Pışkın, H. Evaluating green performance of suppliers via analytic network process and TOPSIS. Journal of Industrial Engineering 2013, 2013, 1–13. [Google Scholar] [CrossRef]

- Akcan, S.; Taş, M.A. Green supplier evaluation with SWARA-TOPSIS integrated method to reduce ecological risk factors. Environmental Monitoring and Assessment 2019, 191, 226. [Google Scholar] [CrossRef] [PubMed]

- Anand, K.R.; Ramalingaiah; Parthiban, P. Evaluation of green supply chain factors using DEMATEL. Applied Mechanics and Materials 2014, 592-594, 2619–2627. [CrossRef]

- Awasthi, A.; Chauhan, S.S.; Goyal, S.K. A fuzzy multicriteria approach for evaluating environmental performance of suppliers. International Journal of Production Economics 2010, 126, 370–378. [Google Scholar] [CrossRef]

- Baah, C.; Jin, Z.; Tang, L. Organizational and regulatory stakeholder pressures friends or foes to green logistics practices and financial performance: Investigating corporate reputation as a missing link. Journal of Cleaner Production 2020, 247, 119125. [Google Scholar] [CrossRef]

- Bai, C.; Kusi-Sarpong, S.; Sarkis, J. An implementation path for green information technology systems in the Ghanaian mining industry. Journal of Cleaner Production 2017, 164, 1105–1123. [Google Scholar] [CrossRef]

- Carvalho, H.; Govindan, K.; Azevedo, S.G.; Cruz-Machado, V. Modelling green and lean supply chains: An eco-efficiency perspective. Resources, Conservation and Recycling 2017, 120, 75–87. [Google Scholar] [CrossRef]

- Chin, T.A.; Tat, H.H.; Sulaiman, Z. Green supply chain management, environmental collaboration and sustainability performance. Procedia CIRP 2015, 26, 695–699. [Google Scholar] [CrossRef]

- Chou, Y.-C.; Yang, C.-H.; Lu, C.-H. ; van Dang; Yang, P. -A. Building criteria for evaluating green project management: An integrated approach of DEMATEL and ANP. Sustainability 2017, 9, 740. [Google Scholar] [CrossRef]

- Colicchia, C.; Marchet, G.; Melacini, M.; Perotti, S. Building environmental sustainability: empirical evidence from logistics service providers. Journal of Cleaner Production 2013, 59, 197–209. [Google Scholar] [CrossRef]

- Đalić, I.; Stević, Ž.; Karamasa, C.; Puška, A. A novel integrated fuzzy PIPRECIA – interval rough SAW model green supplier selection. Decision Making: Applications in Management and Engineering 2020, 3, 126–145. [Google Scholar] [CrossRef]

- Darnall, N.; Jolley, G.J.; Handfield, R. Environmental management systems and green supply chain management: Complements for sustainability? Business Strategy and the Environment 2008, 17, 30–45. [Google Scholar] [CrossRef]

- Deshmukh, A.J.; Vasudevan, H. Emerging supplier selection criteria in the context of traditional VS green supply chain management. International Journal of Managing Value and Supply Chains 2014, 5, 19–33. [Google Scholar] [CrossRef]

- Diabat, A.; Govindan, K. An analysis of the drivers affecting the implementation of green supply chain management. Resources, Conservation and Recycling 2011, 55, 659–667. [Google Scholar] [CrossRef]

- Drohomeretski, E.; Gouvea da Costa, S.; Pinheiro de Lima, E. Green supply chain management: drivers, barriers and practices within the Brazilian automotive industry. Journal of Manufacturing Technology Management 2014, 25, 1105–1134. [Google Scholar] [CrossRef]

- El Jaouhari, A.; Arif, J.; Samadhiya, A.; Kumar, A. Net zero supply chain performance and industry 4. 0 technologies: Past review and present introspective analysis for future research directions. Heliyon 2023, 9, e21525. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Sarkis, J.; Lewis, K.; Behdad, S. Blockchain for the future of sustainable supply chain management in Industry 4. 0. Resources, Conservation and Recycling 2020, 163, 105064. [Google Scholar] [CrossRef]

- Falatoonitoosi, E.; Ahmed, S.; Sorooshian, S. A multicriteria framework to evaluate supplier’s greenness. Abstract and Applied Analysis 2014, 2014. [Google Scholar] [CrossRef]

- Fu, X.; Zhu, Q.; Sarkis, J. Evaluating green supplier development programs at a telecommunications systems provider. International Journal of Production Economics 2012, 140, 357–367. [Google Scholar] [CrossRef]

- Gupta, S.; Soni, U.; Kumar, G. Green supplier selection using multi-criterion decision making under fuzzy environment: A case study in automotive industry. Computers & Industrial Engineering 2019, 136, 663–680. [Google Scholar] [CrossRef]

- Gurel, O.; Acar, A.Z.; Onden, I.; Gumus, I. Determinants of the green supplier selection. Procedia - Social and Behavioral Sciences 2015, 181, 131–139. [Google Scholar] [CrossRef]

- Haeri, S.A.S.; Rezaei, J. A grey-based green supplier selection model for uncertain environments. Journal of Cleaner Production 2019, 221, 768–784. [Google Scholar] [CrossRef]

- Hashemi, S.H.; Karimi, A.; Tavana, M. An integrated green supplier selection approach with analytic network process and improved Grey relational analysis. International Journal of Production Economics 2015, 159, 178–191. [Google Scholar] [CrossRef]

- Hsu, C.-W.; Kuo, T.-C.; Chen, S.-H.; Hu, A.H. Using DEMATEL to develop a carbon management model of supplier selection in green supply chain management. Journal of Cleaner Production 2013, 56, 164–172. [Google Scholar] [CrossRef]

- Hu, A.H.; Hsu, C.-W. Critical factors for implementing green supply chain management practice. Management Research Review 2010, 33, 586–608. [Google Scholar] [CrossRef]

- Husáková, N. A new approach to eco-logistics. Applied Mechanics and Materials 2014, 708, 99–104. [Google Scholar] [CrossRef]

- Hussain, M.; Khan, M.; Al-Aomar, R. A framework for supply chain sustainability in service industry with confirmatory factor analysis. Renewable and Sustainable Energy Reviews 2016, 55, 1301–1312. [Google Scholar] [CrossRef]

- Jalali Naini, S.G.; Aliahmadi, A.R.; Jafari-Eskandari, M. Designing a mixed performance measurement system for environmental supply chain management using evolutionary game theory and balanced scorecard: A case study of an auto industry supply chain. Resources, Conservation and Recycling 2011, 55, 593–603. [Google Scholar] [CrossRef]

- Jasmi, M.F.A.; Fernando, Y. Drivers of maritime green supply chain management. Sustainable Cities and Society 2018, 43, 366–383. [Google Scholar] [CrossRef]

- Jayant, A.; Azhar, M. Analysis of the barriers for implementing green supply chain management (GSCM) practices: an interpretive structural modeling (ISM) approach. Procedia Engineering 2014, 97, 2157–2166. [Google Scholar] [CrossRef]

- Jayant, A. ; Neeru; Agarwal, A. A novel hybrid MCDM approach based on DEMATEL, AHP and TOPSIS to evaluate green suppliers. Journal of Physics: Conference Series 2019, 1240, 12010. [Google Scholar] [CrossRef]

- Jo, D.; Kwon, C. Structure of green supply chain management for sustainability of small and medium enterprises. Sustainability 2022, 14, 50. [Google Scholar] [CrossRef]

- Jovanovic, N.; Zolfagharinia, H.; Peszynski, K. To green or not to treen trucking? Exploring the Canadian case. Transportation Research Part D: Transport and Environment 2020, 88, 102591. [Google Scholar] [CrossRef]

- Kannan, D.; Jabbour, A.B.L.d.S.; Jabbour, C.J.C. Selecting green suppliers based on GSCM practices: Using fuzzy TOPSIS applied to a Brazilian electronics company. European Journal of Operational Research 2014, 233, 432–447. [Google Scholar] [CrossRef]

- Karmaker, C.L.; Ahmed, T.; Ahmed, S.; Ali, S.M.; Moktadir, M.A.; Kabir, G. Improving supply chain sustainability in the context of COVID-19 pandemic in an emerging economy: Exploring drivers using an integrated model. Sustainable Production and Consumption 2021, 26, 411–427. [Google Scholar] [CrossRef]

- Kayikci, Y. Sustainability impact of digitization in logistics. Procedia Manufacturing 2018, 21, 782–789. [Google Scholar] [CrossRef]

- Keshavarz Ghorabaee, M.; Zavadskas, E.K.; Amiri, M.; Esmaeili, A. Multi-criteria evaluation of green suppliers using an extended WASPAS method with interval type-2 fuzzy sets. Journal of Cleaner Production 2016, 137, 213–229. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Dong, Q.L.; Yu, Z. Research on the measuring performance of green supply chain management: in the perspective of China. International Journal of Engineering Research in Africa 2016, 27, 167–178. [Google Scholar] [CrossRef]

- Khanal, G.; Shrestha, R.; Devkota, N.; Sakhakarmy, M.; Mahato, S.; Paudel, U.R.; Acharya, Y.; Khanal, C.K. An investigation of green supply chain management practices on organizational performance using multivariate statistical analysis. Supply Chain Analytics 2023, 3, 100034. [Google Scholar] [CrossRef]

- Kim, J.; Rhee, J. An empirical study on the impact of critical success factors on the balanced scorecard performance in Korean green supply chain management enterprises. International Journal of Production Research 2012, 50, 2465–2483. [Google Scholar] [CrossRef]

- Kumar, A.; Moktadir, M.A.; Khan, S.A.R.; Garza-Reyes, J.A.; Tyagi, M.; Kazançoğlu, Y. Behavioral factors on the adoption of sustainable supply chain practices. Resources, Conservation and Recycling 2020, 158, 104818. [Google Scholar] [CrossRef]

- Kumar, S.; Luthra, S.; Haleem, A. Customer involvement in greening the supply chain: An interpretive structural modeling methodology. Journal of Industrial Engineering International 2013, 9. [Google Scholar] [CrossRef]

- Kumar, S.; Luthra, S.; Haleem, A. Critical success factors of customer involvement in greening the supply chain: An empirical study. International Journal of Logistics Systems and Management 2014, 19, 283. [Google Scholar] [CrossRef]

- Kumar Shetty, S.; Subrahmanya Bhat, K. Green supply chain management practices implementation and sustainability – A review. Materials Today: Proceedings 2021, 19, 131. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Sarkis, J.; Wang, X. Assessing green supply chain practices in the Ghanaian mining industry: a framework and evaluation. International Journal of Production Economics 2016, 181, 325–341. [Google Scholar] [CrossRef]

- Lai, X.; Shi, Q. Green and low-carbon technology innovations. Innovation Strategies in Environmental Science; Elsevier, 2020; pp 209–253, ISBN 9780128173824.

- Lamba, N.; Thareja, P. Modelling of barriers pertaining to implementation of green supply chain management using ISM approach. Materials Today: Proceedings 2021, 43, 9–16. [Google Scholar] [CrossRef]

- Laosirihongthong, T.; Adebanjo, D.; Choon Tan, K. Green supply chain management practices and performance. Industrial Management & Data Systems 2013, 113, 1088–1109. [Google Scholar] [CrossRef]

- Large, R.O.; Gimenez Thomsen, C. Drivers of green supply management performance: Evidence from Germany. Journal of Purchasing and Supply Management 2011, 17, 176–184. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Q. Evaluating the green practice of food service supply chain management based on fuzzy DEMATEL-ANP model. In Seventh International Conference on Electronics and Information Engineering. Seventh International Conference on Electronics and Information Engineering, Nanjing, China, Saturday 17 September 2016; Chen, X., Ed.; SPIE, 2017; 103222J. 17 September.

- Lim, M.K.; Tseng, M.-L.; Tan, K.H.; Bui, T.D. Knowledge management in sustainable supply chain management: Improving performance through an interpretive structural modelling approach. Journal of Cleaner Production 2017, 162, 806–816. [Google Scholar] [CrossRef]

- Lin, K.-P.; Tseng, M.-L.; Pai, P.-F. Sustainable supply chain management using approximate fuzzy DEMATEL method. Resources, Conservation and Recycling 2018, 128, 134–142. [Google Scholar] [CrossRef]

- Lin, R.-J. Using fuzzy DEMATEL to evaluate the green supply chain management practices. Journal of Cleaner Production 2013, 40, 32–39. [Google Scholar] [CrossRef]

- Liou, J.J.; Tamošaitienė, J.; Zavadskas, E.K.; Tzeng, G.-H. New hybrid COPRAS-G MADM Model for improving and selecting suppliers in green supply chain management. International Journal of Production Research 2016, 54, 114–134. [Google Scholar] [CrossRef]

- Liu, P.; Gao, H.; Fujita, H. The new extension of the MULTIMOORA method for sustainable supplier selection with intuitionistic linguistic rough numbers. Applied Soft Computing 2021, 99, 106893. [Google Scholar] [CrossRef]

- Lorena, C.-M.; Leonardo, R.-U. Sustainable procurement with Coloured Petri Nets. Application and extension of the proposed model. Expert Systems with Applications 2018, 114, 467–478. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Identifying and ranking of strategies to implement green supply chain management in Indian manufacturing industry using Analytical Hierarchy Process. Journal of Industrial Engineering and Management 2013, 6. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4. 0 initiatives for supply chain sustainability in emerging economies. Process Safety and Environmental Protection 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Malviya, R.K.; Kant, R. Hybrid decision making approach to predict and measure the success possibility of green supply chain management implementation. Journal of Cleaner Production 2016, 135, 387–409. [Google Scholar] [CrossRef]

- Malviya, R.K.; Kant, R. Identifying critical success factors for green supply chain management implementation using fuzzy DEMATEL method. In 2014 IEEE International Conference on Industrial Engineering and Engineering Management. 2014 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Selangor Darul Ehsan, Malaysia, 09–12 Dec. 2014; IEEE, 122014; pp 214–218, ISBN 978-1-4799-6410-9.

- Manimaran, A.; Muthuraman, V.; Jayakumar, V. A novel tolerance evaluation framework for green supply chain management implementation. International Journal of Mechanical Engineering and Technology 2018, 9, 152–159. [Google Scholar]

- Muasya, K.; Kihara, A. Role of green supply chain practices on the performance of government ministries in Kenya: A case of ministry of industrialization and enterprise development. Journal of International Business, Innovation and Strategic Management 2018, 1, 215–230. [Google Scholar]

- Matić, B.; Jovanović, S.; Das, D.K.; Zavadskas, E.K.; Stević, Ž.; Sremac, S.; Marinković, M. A new hybrid MCDM model: Sustainable supplier selection in a construction company. Symmetry 2019, 11, 353. [Google Scholar] [CrossRef]

- Mavi, R.K.; Goh, M.; Zarbakhshnia, N. Sustainable third-party reverse logistic provider selection with fuzzy SWARA and fuzzy MOORA in plastic industry. The International Journal of Advanced Manufacturing Technology 2017, 91, 2401–2418. [Google Scholar] [CrossRef]

- Mishra, A.R.; Rani, P.; Pardasani, K.R.; Mardani, A. A novel hesitant fuzzy WASPAS method for assessment of green supplier problem based on exponential information measures. Journal of Cleaner Production 2019, 238, 117901. [Google Scholar] [CrossRef]

- Mousakhani, S.; Nazari-Shirkouhi, S.; Bozorgi-Amiri, A. A novel interval type-2 fuzzy evaluation model based group decision analysis for green supplier selection problems: A case study of battery industry. Journal of Cleaner Production 2017, 168, 205–218. [Google Scholar] [CrossRef]

- Mubarik, M.S.; Kazmi, S.H.A.; Zaman, S.I. Application of gray DEMATEL-ANP in green-strategic sourcing. Technology in Society 2021, 64, 101524. [Google Scholar] [CrossRef]

- Muduli, K.; Govindan, K.; Barve, A.; Kannan, D.; Geng, Y. Role of behavioural factors in green supply chain management implementation in Indian mining industries. Resources, Conservation and Recycling 2013, 76, 50–60. [Google Scholar] [CrossRef]

- Mumtaz, U.; Ali, Y.; Petrillo, A.; Felice, F. de. Identifying the critical factors of green supply chain management: Environmental benefits in Pakistan. Sci. Total Environ. 2018, 640-641, 144–152. [CrossRef]

- Nag, U.; Sharma, S.K.; Govindan, K. Investigating drivers of circular supply chain with product-service system in automotive firms of an emerging economy. Journal of Cleaner Production 2021, 319, 128629. [Google Scholar] [CrossRef]

- Nikookar, H.; Takala, J.; Sahebi, D.; Kantola, J. A qualitative approach for assessing resiliency in supply chains. Management and Production Engineering Review 2014, 5, 36–45. [Google Scholar] [CrossRef]

- Olatunji, O.O.; Akinlabi, S.A.; Ayo, O.O.; Madushele, N.; Adedeji, P.A.; Fatoba, S.O. Drivers and barriers to competitive carbon footprint reduction in manufacturing supply chain: A brief review. Procedia Manufacturing 2019, 35, 992–1000. [Google Scholar] [CrossRef]

- Ortiz-Barrios, M.; La Miranda-De Hoz, C.; López-Meza, P.; Petrillo, A.; Felice, F. de. A case of food supply chain management with AHP, DEMATEL, and TOPSIS. Journal of Multi-Criteria Decision Analysis 2019, 27, 104–128. [Google Scholar] [CrossRef]

- Özaşkın, A.; Görener, A. An integrated multi-criteria decision-making approach for overcoming barriers to green supply chain management and prioritizing alternative solutions. Supply Chain Analytics 2023, 3, 100027. [Google Scholar] [CrossRef]

- Pimenta, H.C.; Ball, P.D. Analysis of environmental sustainability practices across upstream supply chain management. Procedia CIRP 2015, 26, 677–682. [Google Scholar] [CrossRef]

- Prakash, C.; Barua, M.K. Integration of AHP-TOPSIS method for prioritizing the solutions of reverse logistics adoption to overcome its barriers under fuzzy environment. Journal of Manufacturing Systems 2015, 37, 599–615. [Google Scholar] [CrossRef]

- Puška, A.; Božanić, D.; Nedeljković, M.; Janošević, M. Green supplier selection in an uncertain environment in agriculture using a hybrid MCDM model: Z-Numbers–Fuzzy LMAW–Fuzzy CRADIS model. Axioms 2022, 11, 427. [Google Scholar] [CrossRef]

- Puška, A.; Nedeljković, M.; Hashemkhani Zolfani, S.; Pamučar, D. Application of interval fuzzy logic in selecting a sustainable supplier on the example of agricultural production. Symmetry 2021, 13, 774. [Google Scholar] [CrossRef]

- Rajesh, R.; Ravi, V. Supplier selection in resilient supply chains: a grey relational analysis approach. Journal of Cleaner Production 2015, 86, 343–359. [Google Scholar] [CrossRef]

- Raut, R.D.; Narkhede, B.; Gardas, B.B. To identify the critical success factors of sustainable supply chain management practices in the context of oil and gas industries: ISM approach. Renewable and Sustainable Energy Reviews 2017, 68, 33–47. [Google Scholar] [CrossRef]

- Refaie, A.A.; Momani, D. ISM approach for modelling drivers to practices of green supply chain management in Jordanian industrial firms. International Journal of Business Performance and Supply Chain Modelling 2018, 10, 91. [Google Scholar] [CrossRef]

- Rostamzadeh, R.; Govindan, K.; Esmaeili, A.; Sabaghi, M. Application of fuzzy VIKOR for evaluation of green supply chain management practices. Ecological Indicators 2015, 49, 188–203. [Google Scholar] [CrossRef]

- Sancha, C.; Longoni, A.; Giménez, C. Sustainable supplier development practices: Drivers and enablers in a global context. Journal of Purchasing and Supply Management 2015, 21, 95–102. [Google Scholar] [CrossRef]

- Sauer, P.C.; Seuring, S. Sustainable supply chain management for minerals. Journal of Cleaner Production 2017, 151, 235–249. [Google Scholar] [CrossRef]

- SHAHRYARI NIA, A.; OLFAT, L.; Esmaeili, A.; Rostamzadeh, R.; ANTUCHEVIČIENĖ, J. Using fuzzy choquet integral operator for supplier selection with environmental considerations. Journal of Business Economics and Management 2016, 17, 503–526. [Google Scholar] [CrossRef]

- Shao, J.; Taisch, M.; Ortega-Mier, M. A grey-DEcision-MAking Trial and Evaluation Laboratory (DEMATEL) analysis on the barriers between environmentally friendly products and consumers: Practitioners’ viewpoints on the European automobile industry. Journal of Cleaner Production 2016, 112, 3185–3194. [Google Scholar] [CrossRef]

- Shen, L.; Muduli, K.; Barve, A. Developing a sustainable development framework in the context of mining industries: AHP approach. Resources Policy 2015, 46, 15–26. [Google Scholar] [CrossRef]

- Sharma, Y.K.; Sharma, S. IT success factors in sustainable food supply chain management. Materials Today: Proceedings 2022, 56, 43–45. [Google Scholar] [CrossRef]

- Shibin, K.T.; Gunasekaran, A.; Dubey, R. Explaining sustainable supply chain performance using a total interpretive structural modeling approach. Sustainable Production and Consumption 2017, 12, 104–118. [Google Scholar] [CrossRef]

- Shih-Hsiung Cheng; Shih Ming Ou; Su-Mei Lin. Using decision-making trial and evaluation laboratory (DEMATEL) to explore the key success factors for green logistics manufacturers. African Journal of Business Management 2018, 12, 58–65. [CrossRef]

- Soltanmohammadi, A.; Andalib Ardakani, D.; Dion, P.A.; Hettiarachchi, B.D. Employing total quality practices in sustainable supply chain management. Sustainable Production and Consumption 2021, 28, 953–968. [Google Scholar] [CrossRef]

- Staš, D.; Lenort, R.; Wicher, P.; Holman, D. Сonceptual framework for assessing the green transport level in industrial companies and supply chains. Applied Mechanics and Materials 2014, 708, 87–92. [Google Scholar] [CrossRef]

- Stević, Ž.; Durmić, E.; Gajić, M.; Pamučar, D.; Puška, A. A novel multi-criteria decision-making model: interval rough SAW method for sustainable supplier selection. Information 2019, 292. [Google Scholar] [CrossRef]

- Su, C.-M.; Horng, D.-J.; Tseng, M.-L.; Chiu, A.S.; Wu, K.-J.; Chen, H.-P. Improving sustainable supply chain management using a novel hierarchical grey-DEMATEL approach. Journal of Cleaner Production 2016, 134, 469–481. [Google Scholar] [CrossRef]

- Sugandini, D.; Muafi, M.; Susilowati, C.; Siswanti, Y.; Syafri, W. Green supply management and green marketing strategy on green purchase intention: SMEs cases. Journal of Industrial Engineering and Management 2020, 13, 79. [Google Scholar] [CrossRef]

- Thakker, S.V.; Rane, S.B. Implementation of green supplier development process model in Indian automobile industry. Management of Environmental Quality: An International Journal 2018, 29, 938–960. [Google Scholar] [CrossRef]

- Thiell, M.; Zuluaga, J.P.S.; Montañez, J.P.M.; van Hoof, B. Green logistics: Global practices and their implementation in emerging markets. In Green finance and sustainability: Environmentally-aware business models and technologies; Luo, Z., Ed.; Business Science Reference; London: Hershey, Pa, 2011; ISBN 1609605322. [Google Scholar]

- Tippayawong, K.Y.; Tiwaratreewit, T.; Sopadang, A. Positive influence of green supply chain operations on Thai electronic firms’ financial performance. Procedia Engineering 2015, 118, 683–690. [Google Scholar] [CrossRef]

- Tippayawong, K.; Niyomyat, N.; Sopadang, A.; Ramingwong, S. Factors affecting green supply chain operational performance of the Thai auto parts industry. Sustainability 2016, 8, 1161. [Google Scholar] [CrossRef]

- Tsai, J.-F.; Shen, S.-P.; Lin, M.-H. Applying a hybrid MCDM model to evaluate green supply chain management practices. Sustainability 2023, 15, 2148. [Google Scholar] [CrossRef]

- Tsai, J.-F.; Wu, S.-C.; Pham, T.K.L.; Lin, M.-H. Analysis of key factors for green supplier selection: A case study of the electronics industry in Vietnam. Sustainability 2023, 15, 7885. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Chiu, S.F.; Tan, R.R.; Siriban-Manalang, A.B. Sustainable consumption and production for Asia: sustainability through green design and practice. Journal of Cleaner Production 2013, 40, 1–5. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Lim, M.; Wu, K.-J.; ZHOU, L.; Bui, D.T.D. A novel approach for enhancing green supply chain management using converged interval-valued triangular fuzzy numbers-grey relation analysis. Resources, Conservation and Recycling 2018, 128, 122–133. [Google Scholar] [CrossRef]

- Uddin, S.; Ali, S.M.; Kabir, G.; Suhi, S.A.; Enayet, R.; Haque, T. An AHP-ELECTRE framework to evaluate barriers to green supply chain management in the leather industry. International Journal of Sustainable Development & World Ecology 2019, 26, 732–751. [Google Scholar] [CrossRef]

- Ulutaş, A.; Topal, A.; Pamučar, D.; Stević, Ž.; Karabašević, D.; Popović, G. A new integrated multi-criteria decision-making model for sustainable supplier selection based on a novel grey WISP and grey BWM methods. Sustainability 2022, 14, 16921. [Google Scholar] [CrossRef]

- Uygun, Ö.; Dede, A. Performance evaluation of green supply chain management using integrated fuzzy multi-criteria decision making techniques. Computers & Industrial Engineering 2016, 102, 502–511. [Google Scholar] [CrossRef]

- Vijayvargy, L.; Thakkar, J.; Agarwal, G. Green supply chain management practices and performance. Journal of Manufacturing Technology Management 2017, 28, 299–323. [Google Scholar] [CrossRef]

- Vila, C.; Abellán-Nebot, J.V.; Albiñana, J.C.; Hernández, G. An approach to sustainable product lifecycle management (Green PLM). Procedia Engineering 2015, 132, 585–592. [Google Scholar] [CrossRef]

- Murphy, P.R.; Poist, R.F. Green perspectives and practices: a “comparative logistics” study. Supp Chain Mnagmnt 2003, 8, 122–131. [Google Scholar] [CrossRef]

- Sarkis, J.; Meade, L.M.; Talluri, S. E-logistics and the natural environment. Supp Chain Mnagmnt 2004, 9, 303–312. [Google Scholar] [CrossRef]

- Walker, H.; Di Sisto, L.; McBain, D. Drivers and barriers to environmental supply chain management practices: Lessons from the public and private sectors. Journal of Purchasing and Supply Management 2008, 14, 69–85. [Google Scholar] [CrossRef]

- Wan Hasrulnizzam Wan Mahmood. Manufacturing performance in green supply chain management. World Applied Sciences Journal 2013, 21. [CrossRef]

- Wu, K.-J.; Liao, C.-J.; Tseng, M.-L.; Chiu, A.S. Exploring decisive factors in green supply chain practices under uncertainty. International Journal of Production Economics 2015, 159, 147–157. [Google Scholar] [CrossRef]

- Wu, K.-J.; Tseng, M.-L.; Vy, T. Evaluation the drivers of green supply chain management practices in uncertainty. Procedia - Social and Behavioral Sciences 2011, 25, 384–397. [Google Scholar] [CrossRef]

- Yunlin, C. Awareness of green logistics technology, certification, and standards by logistics practitioners at Chinese e-commerce company, Jing Dong. The Asian Journal of Shipping and Logistics 2023, 39, 37–46. [Google Scholar] [CrossRef]

- Zhang, Y.; Thompson, R.G.; Bao, X.; Jiang, Y. Analyzing the promoting factors for adopting green logistics practices: a case study of road freight industry in Nanjing, China. Procedia - Social and Behavioral Sciences 2014, 125, 432–444. [Google Scholar] [CrossRef]

- Zhou, L.; Zhu, J.; Guo, J. Research on construction of the green logistics evaluation index system and determination of index weight. American Journal of Theoretical and Applied Statistics 2014, 3, 96–99. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. Journal of Operations Management 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. An inter-sectoral comparison of green supply chain management in China: Drivers and practices. Journal of Cleaner Production 2006, 14, 472–486. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Confirmation of a measurement model for green supply chain management practices implementation. International Journal of Production Economics 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Jayarathna, C.P.; Agdas, D.; Dawes, L. Exploring sustainable logistics practices toward a circular economy: A value creation perspective. Business Strategy and the Environment 2023, 32, 704–720. [Google Scholar] [CrossRef]

- Kumar, K.M.; Rahman, A.A.; Jayaraman, K.; Rahim, S.A. Conceptualization of a research model for sustainable logistics practices and logistics transport performance. Jurnal Pengurusan 2017, 51, 1–12. [Google Scholar] [CrossRef]

- Souza, E.D. de; Kerber, J.C.; Bouzon, M.; Rodriguez, C. Performance evaluation of green logistics: Paving the way towards circular economy. Cleaner Logistics and Supply Chain 2022, 3, 100019. [Google Scholar] [CrossRef]

- Kim, S.-T.; Han, C.-H. Measuring environmental logistics practices. The Asian Journal of Shipping and Logistics 2011, 27, 237–258. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Pimentel, C.M.O.; Alves, A.C.; Matias, J.C.O. Support of advanced technologies in supply chain processes and sustainability impact. Applied Sciences 2021, 11, 3026. [Google Scholar] [CrossRef]

- Banasik, A.; Bloemhof-Ruwaard, J.M.; Kanellopoulos, A.; Claassen, G.D.H.; van der Vorst, J.G.A.J. Multi-criteria decision making approaches for green supply chains: A review. Flexible Services and Manufacturing Journal 2018, 30, 366–396. [Google Scholar] [CrossRef]

- Dekker, R.; Bloemhof, J.; Mallidis, I. Operations research for green logistics – an overview of aspects, issues, contributions and challenges. European Journal of Operational Research 2012, 219, 671–679. [Google Scholar] [CrossRef]

- Popović, V.; Kilibarda, M.; Andrejić, M.; Jereb, B.; Dragan, D. A new sustainable warehouse management approach for workforce and activities scheduling. Sustainability 2021, 13, 2021. [Google Scholar] [CrossRef]

- Rachih, H.; Mhada, F.Z.; Chiheb, R. Meta-heuristics for reverse logistics: A literature review and perspectives. Computers & Industrial Engineering 2019, 127, 45–62. [Google Scholar] [CrossRef]

- Vasiliauskas, A.V.; Zinkevičiūtė, V.; Šimonytė, E. Implementation of the concept of green logistics reffering to it applications for road freight transport enterprises. Business: Theory and Practice 2013, 14, 43–50. [Google Scholar] [CrossRef]

- Balouei Jamkhaneh, H.; Shahin, R.; Tortorella, G.L. Analysis of Logistics 4. 0 service quality and its sustainability enabler scenarios in emerging economy. Cleaner Logistics and Supply Chain 2022, 4, 100053. [Google Scholar] [CrossRef]

- Pålsson, H.; Lundquist, K.-J.; Olander, L.-O.; Larsson, F.E.; Hiselius, L. Target: Low-carbon goods transportation: A growth-dynamics perspective on logistics and goods transportation until 2050. International Transport Forum Discussion Papers, 2014.

- Geroliminis, N.; Daganzo, C.F. A review of green logistics schemes used in cities around the world. Available online: https://escholarship.org/uc/item/4x89p485.

- Beškovnik, B.; Twrdy, E. Green logistics strategy for South East Europe: to improve intermodality and establish green transport corridors. Transport 2012, 27, 25–33. [Google Scholar] [CrossRef]

- Hossain, M.I.; Al Amin, M.; Baldacci, R.; Rahman, M.H. Identification and prioritization of green lean supply chain management factors using fuzzy DEMATEL. Sustainability 2023, 15, 10523. [Google Scholar] [CrossRef]

- Keshavarz-Ghorabaee, M. Using SWARA II for subjective evaluation of transport emissions reduction policies. The Open Transportation Journal 2023, 17. [Google Scholar] [CrossRef]

- Assis, T.F. de; Marujo, L.G.; Abreu, V.H.S. de; Da Costa, M.G.; Rodrigues, L.M.; D’Agosto, M.d.A. Best practices to support the transition towards sustainable logistics from the perspective of Brazilian carriers. Sustainability 2023, 15, 13434. [Google Scholar] [CrossRef]

- Cherrafi, A.; Garza-Reyes, J.A.; Kumar, V.; Mishra, N.; Ghobadian, A.; Elfezazi, S. Lean, green practices and process innovation: A model for green supply chain performance. International Journal of Production Economics 2018, 206, 79–92. [Google Scholar] [CrossRef]

- Gruchmann, T. Advanced green logistics strategies and technologies. In Operations, Logistics and Supply Chain Management; Zijm, H., Klumpp, M., Regattieri, A., Heragu, S., Eds.; Springer: Cham, Switzerland, 2019; 663-686; ISBN 978-3-319-92446-5. [Google Scholar]

- Reza Kiani Mavi; Sajad Kazemi; Ali Fallahian Najafabadi; Hosein Bemani Mousaabadi. Identification and assessment of logistical factors to evaluate a green supplier using the fuzzy logic DEMATEL method. Polish Journal of Environmental Studies 2013, 22, 445–455.

- Ouyang, C.Y.; Nie, X.L. An investigation into green logistics and packaging design. Applied Mechanics and Materials 2013, 448-453, 4552–4556. [CrossRef]

- Pourjavad, E.; Shahin, A. Green supplier development programmes selection: a hybrid fuzzy multi-criteria decision-making approach. International Journal of Sustainable Engineering 2020, 13, 463–472. [Google Scholar] [CrossRef]

- Sarkar, A.N. Green supply chain management: a potent tool for sustainable green marketing. Asia-Pacific Journal of Management Research and Innovation 2012, 8, 491–507. [Google Scholar] [CrossRef]

- van Hoek, R.I. From reversed logistics to green supply chains. Supply Chain Management: An International Journal 1999, 4, 129–135. [Google Scholar] [CrossRef]

- Waltho, C.; Elhedhli, S.; Gzara, F. Green supply chain network design: A review focused on policy adoption and emission quantification. International Journal of Production Economics 2019, 208, 305–318. [Google Scholar] [CrossRef]

- Björklund, M.; Forslund, H. A framework for classifying sustainable logistics innovations. Logistics Research 2018, 11. [Google Scholar] [CrossRef]

- Abu Seman, N.A.; Zakuan, N.; Jusoh, A.; Md Arif, M.S.; Mat Saman, M.Z. Green supply chain management: a review and research direction. International Journal of Managing Value and Supply Chains 2012, 3, 1–18. [Google Scholar] [CrossRef]

- Aslam, H.; Rashid, K.; Wahla, A.R.; Tahira, U. Drivers of green supply chain management practices and their impact on firm performance: A developing country perspective. Journal of Quantitative Methods 2018, 2, 87–113. [Google Scholar] [CrossRef]

- Masoumik, S.M.; Abdul-Rashid, S.H.; Olugu, E.U.; Raja Ghazilla, R.A. Sustainable supply chain design: a configurational approach. The Scientific World Journal 2014, 2014, 897121. [Google Scholar] [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [Google Scholar] [CrossRef]

- Lakshmi, P.; Visalakshmi, S. Managing green supply chain: initiatives and outcomes. International Journal of Managing Value and Supply Chains 2012, 3, 55–63. [Google Scholar] [CrossRef]

- Sureeyatanapas, P.; Poophiukhok, P.; Pathumnakul, S. Green initiatives for logistics service providers: An investigation of antecedent factors and the contributions to corporate goals. Journal of Cleaner Production 2018, 191, 1–14. [Google Scholar] [CrossRef]

- Zou, X.; Zhao, W.; Zhang, T.T. Study of green logistics technology to manufacturing based on green supply chain Theory. Advanced Materials Research 2014, 1073-1076, 2438–2442. [CrossRef]

- Maji, I.K.; Mohd Saudi, N.S.; Yusuf, M. An assessment of green logistics and environmental sustainability: Evidence from Bauchi. Cleaner Logistics and Supply Chain 2023, 6, 100097. [Google Scholar] [CrossRef]

- Modica, T.; Perotti, S.; Melacini, M. Green warehousing: Exploration of organisational variables fostering the adoption of energy-efficient material handling equipment. Sustainability 2021, 13, 13237. [Google Scholar] [CrossRef]

- Juan, A.; Mendez, C.; Faulin, J.; Armas, J. de; Grasman, S. Electric vehicles in logistics and transportation: a survey on emerging environmental, strategic, and operational challenges. Energies 2016, 9, 86. [Google Scholar] [CrossRef]

- Dubisz, D.; Golinska-Dawson, P.; Zawodny, P. Measuring CO2 emissions in E-Commerce deliveries: From empirical studies to a new calculation approach. Sustainability 2022, 14, 16085. [Google Scholar] [CrossRef]

- Noor Aslinda, A.S.; Norhayati Mohmad, Z.; Jusoh, A.; Arif, M.S.M.; Bahari, A.Z.; Zaidin, N.; Saman, M.Z.M. The development of green innovation measurement based on inter rater agreement approach: a preliminary study. Advanced Materials Research 2014, 903, 347–352. [Google Scholar] [CrossRef]

- Chen, Z.-S.; Zhang, X.; Govindan, K.; Wang, X.-J.; Chin, K.-S. Third-party reverse logistics provider selection: A computational semantic analysis-based multi-perspective multi-attribute decision-making approach. Expert Systems with Applications 2021, 166, 114051. [Google Scholar] [CrossRef]

- The Sustainable Development. Available online: https://sustainabledevelopment.un.org/ (accessed on 8 February 2024).

- Osintsev, N.; Rakhmangulov, A.; Sladkowski, A. A fuzzy AHP-TOPSIS approach for green logistics instruments ranking. Transport of the Urals 2020, 64, 3–14. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Masud, A.S.M. Multiple Objective Decision Making - Methods and Applications: A state-of-the-art survey; Springer Berlin Heidelberg: Berlin, Heidelberg, 1979; ISBN 978-3-642-45511-7. [Google Scholar]

- Pamučar, D.; Ćirović, G. The selection of transport and handling resources in logistics centers using multi-attributive border approximation area comparison (MABAC). Expert Systems with Applications 2015, 42, 3016–3028. [Google Scholar] [CrossRef]

- Stević, Ž.; Pamučar, D.; Puška, A.; Chatterjee, P. Sustainable supplier selection in healthcare industries using a new MCDM method: Measurement of alternatives and ranking according to COmpromise solution (MARCOS). Computers & Industrial Engineering 2020, 140, 106231. [Google Scholar] [CrossRef]

| № | Green logistics instrument | Description | |

|---|---|---|---|

| I1.1.1 | 1.1. Introduction of environmental aspects into the strategy of the organization | Development of the organization's environmental strategy based on the goals and principles of sustainable development and its integration into the business strategy (ESG-strategy) | |

| I1.1.2 | 1.2. Eco-audit | Independent assessment of compliance with regulatory and legal requirements in the field of environmental protection and preparation of recommendations in the field of environmental activities | |

| I1.1.3 | 1.3. Development of corporate social responsibility | Design and implementation of the strategy for developing the concept of Corporate Social Responsibility (CSR), taking responsibility for external and internal stakeholders, the environment, and society as a whole | |

| I1.1.4 | 1.4. Evaluation and control of environmental performance | Design standards for the process of selecting indicators, collecting and evaluating data and information to provide an ongoing assessment of environmental performance and its trends over time, consistent with the organization's environmental goals (ISO 14031:2013) | |

| I1.2.1 | Enterprise Resource Planning System (ERP) | Implementation of the enterprise resource management and planning system based on the integration and automation of data required to perform business processes — production, financial, personnel management, service provision, etc. | |

| I1.2.2 | Customer Relationship Management System (CRM) | Implementation of Customer Relationship Management (CRM) based on the use of advanced management and information technologies to interact with customers to increase the efficiency of customer service and improve business processes | |

| I1.2.3 | Manufacturing Execution System (MES) | Implementation of Manufacturing Execution System (MES) based on data integration and automation to manage manufacturing activities | |

| I1.2.4 | Warehouse Management System (WMS) | Implementation of Warehouse Management System (WMS) based on data integration and automation for planning and execution of a set of tasks and functions of warehouse business processes | |

| I1.2.5 | Enterprise Asset Management (EAM) | Implementation of Enterprise Asset Management (EAM) based on automation of business processes for managing physical assets and their modes of operation, risks, and costs throughout the asset lifecycle | |

| I1.2.6 | Human Resources Management (HRM) | Implementation of Human Resources Management (HRM) based on the integration of data required to effectively manage the organization's workforce | |

| I1.3.1 | Real-time Locating Systems (RTLS) | Implementation of Real-time Locating Systems (RTLS) based on the use of methods and technologies of identification and location of controlled objects (UWB, RFID, Wi-Fi, Bluetooth, ZigBee, NFER, etc.) within the territory for the purpose of monitoring transportation, logistics and business processes | |

| I1.3.2 | Satellite navigation systems | Implementation of satellite navigation systems (GPS, GLONAS, BeiDou, Galileo, QZSS and IRNSS) to determine the location of objects and movement parameters (vehicles, cargoes, etc.) to monitor the performance of logistics functions and supply chain operations | |

| I1.3.3 | Radio frequency identification technology (RFID) | Implementation of Radio Frequency Identification (RFID) technology in transportation and logistics processes for automatic identification, transmission, and storage of information about elements of the material flow throughout the life cycle from production to retail trade | |

| I1.4.1 | Data Mining methods | Use of Data Mining methods and systems for intellectual analysis of the data array and identification of patterns for the purpose of making managerial decisions (Board, SAS Revenue Optimization, SAS Enterprise Miner, etc.). | |

| I1.4.2 | Methods and models of artificial intelligence | Integration of systems, technologies or intelligent machines capable of mimicking human behavior in performing logistics functions in the supply chain | |

| I1.4.3 | Situational management techniques | The use of a set of techniques and methods of managerial decision-making in the operational management of supply chains under the influence of external and internal changes. This set includes system, situational and factor analysis, expert methods, simulation modeling, multi-criteria decision-making methods, heuristic methods and others | |

| I1.4.4 | Digitalization and Industry 4.0 in supply chains | Control and optimization of logistics flows based on the implementation of principles and technologies of Industry 4.0 concept and digitalization of supply chains (cloud technologies, Internet of Things, blockchain, artificial intelligence and machine learning, virtual reality, 3D printing, etc.) | |

| I1.5.1 | Management Information System (MIS) | Implementation of Management Information System (MIS) for decision-making, coordination, control, analysis, and visualization of information in supply chains by integrating the links between chain members, processes, and technologies required to perform business processes | |

| I1.5.2 | Electronic Data Interchange (EDI) | Implementation of Electronic Data Interchange (EDI) transfer of structured digital information between organizations – elements of the supply chain, based on regulations and formats of transmitted messages. | |

| I1.5.3 | Transportation Management System (TMS) | Implementation of the Transportation Management System (TSM) for complex automation of transportation and logistics operations | |

| I1.5.4 | Cold Chain Logistics (CCL) | Utilizing Cold Chain Logistics (CCL) technologies and techniques to ensure consistent temperature of goods in the supply chain from production to consumption |

| № | Green logistics instrument | Description | |

|---|---|---|---|

| I2.1.1 | Analysis of suppliers | Assessment of suppliers' and contractors' performance for the purpose of further cooperation by analyzing previous activities, as well as compliance with the requirements and principles of the customer's work, including in achieving SDGs | |

| I2.1.2 | Analysis of raw materials, goods and services | Assessing products and services for compliance with customer and supply chain requirements | |

| I2.1.3 | Analysis of the procurement system | Evaluate the management of logistics processes in procurement to effectively utilize logistics resources and achieve the SDGs | |

| I2.1.4 | Life cycle analysis (LCA) | Comprehensive assessment of the environmental impact of a logistics material or work flow at all stages of its life cycle | |

| I2.2.1 | Selection of ecological raw materials | Selection of environmentally friendly and safe raw materials in logistics processes, ensuring the least impact on the environment and human health | |

| I2.2.2 | Selection of raw materials taking into account the possibility of recycling | Selection of raw materials and materials considering the possibility of their reuse and recycling | |

| I2.2.3 | System of eco-labelling (eco-labels) | Use of eco-labeling system to identify products and services for compliance with environmental standards and requirements, inform consumers about environmental properties of products or services | |

| I2.3.1 | Selection of eco-friendly suppliers | Evaluate and select suppliers that have environmental policies and incorporate environmentally friendly mechanisms into their operations | |

| I2.3.2 | Selection of nearby suppliers | Assessing and selecting the nearest suppliers to reduce logistics costs and environmental impact | |

| I2.4.1 | Minimization of purchasing volume | Analysis of cargo flow parameters and optimization of purchasing volumes to minimize inventories and reduce logistics costs | |

| I2.4.2 | Combined purchasing | Consolidation of procurement and collective tendering to reduce logistics costs and environmental footprints | |

| I2.4.3 | Electronic document management with organizations suppliers | Implementation of the electronic document management system and refusal to use paper carriers | |

| I2.4.4 | Selection of delivery modes with minimal impact on the environment | Assessing and selecting methods of raw material delivery with minimal environmental impact | |

| I2.4.5 | Adjustment of the flows’ parameters (quality) or need for flows | Analysis of statistical parameters of logistics flows to assess the need for them, as well as to optimize their parameters and indicators |

| № | Green logistics instrument | Description | |

|---|---|---|---|

| I3.1.1 | Selection of ecological raw materials (Eco-design) | Consideration of environmental parameters in the process of creating products (services) when selecting raw materials and materials used in production processes to improve the natural, social, cultural and physical environment of certain areas | |

| I3.1.2 | Replacement of harmful/hazardous raw materials with less harmful in the product design | Replacing harmful and hazardous raw materials in the process of creating products (services) with environmentally friendly ones that ensure the least impact on the environment and human health | |

| I3.1.3 | Selection raw materials with the possibility of their reuse and/or recycling in product design | Considering the possibility of reusing and recycling raw materials in the process of creating products (services) | |

| I3.2.1 | Energy saving equipment and technologies | Application of energy-saving equipment and resource-saving technologies to rationally utilize logistics resources and improve production efficiency | |

| I3.2.2 | Equipment with minimal impact on the environment | Selection and application of equipment and technologies with minimal environmental impact in production processes | |

| I3.2.3 | Systems of environmental protection | Use of environmental safety methods and technical systems (air protection systems, water protection systems, waste management systems, etc.) to reduce the negative impact on the environment | |

| I3.2.4 | Maximum utilization of raw materials with aim to minimize waste production | Analysis of production process parameters and implementation of methods that maximize the use of raw material components to minimize production and service waste | |

| I3.3.1 | Waste prevention | Selection and application of ways to prevent waste generation in the process of production of products (services) | |

| I3.3.2 | Recycling and reuse of waste | Selection and application of waste treatment methods to ensure its reuse in logistics processes and to obtain raw materials, energy, products, and supplies | |

| I3.3.3 | Improvement of technologies of final disposal and waste monitoring | Evaluate and select ways to control and improve technologies for the utilization of waste generated during production, operation and after decommissioning | |

| I3.4.1 | Optimization of technological flows’ parameters | Analyzing the parameters of production processes and operations and making decisions to adjust the parameters of industrial logistics flows to reduce logistics costs and achieve the SDGs | |

| I3.4.2 | Operational management of production processes in order to minimize the impact on the environment | Operational management of production processes to control product quality and reduce the negative environmental impact of the industry | |

| I3.4.3 | Production in accordance with the requirements of the eco design | Designing and manufacturing products and services with consideration of their environmental impact throughout their life cycle | |

| I3.5.1 | Eco-training of employees at all levels of management | Training in the field of environmental protection and ecological safety for managers and specialists responsible for decision-making in the implementation of activities that have a negative impact on the environment | |

| I3.5.2 | Stimulation in the applying green practices | Stimulating supply chain participants' activities and personnel behavior in implementing “green” principles and technologies to reduce the negative impact on the environment | |

| I3.5.3 | Provision of comfortable and environmentally friendly working conditions | Creation of favorable conditions of the production environment and labor process, which have an impact on personnel health, working capacity and labor productivity, labor satisfaction, efficiency, and safety of work | |

| I3.5.4 | Development of corporate social responsibility | Incentivizing personnel in implementing the CSR strategy |

| № | Green logistics instrument | Description | |

|---|---|---|---|

| I4.1.1 | The use of environmentally friendly material in the construction of warehouses | The use of modern environmentally friendly and safe building materials and technologies in the construction of warehouses in accordance with ISO 14024:1999, LEED, BREEAM, DGNB, Green Globes, CASBEE, BEAM and other standards | |

| I4.1.2 | Environmentally sound spatial organization of elements of a warehouse complex | Warehouse design, warehouse space planning and placement of main elements considering the requirements of environmental standards and the use of modern safety equipment, as well as the efficiency of loading and unloading and storage operations | |

| I4.1.3 | Optimization of warehouse capacity | Analysis of statistical parameters of cargo flows to optimize warehouse capacity and ensure the quality of inventory storage | |

| I4.1.4 | The use of renewable energy sources | Utilization of renewable energy sources in the warehouse to reduce greenhouse gas emissions (bioenergy, photovoltaics, concentrated solar energy, geothermal energy, hydropower, ocean energy, wind energy) | |

| I4.1.5 | Thermal insulation of warehouses | Use of special materials and technologies to insulate warehouses to ensure comfortable working conditions for the personnel and reduce the costs of heating the warehouse | |

| I4.1.6 | The use of engineering systems of environmental protection | Use of autonomous and centralized engineering systems ensuring maintenance of specified environmental parameters (air conditioning systems, ventilation systems, heating systems, water environment protection systems, energy saving systems, physical security systems, etc.) | |

| I4.2.1 | The use of energy saving equipment | Application of energy-saving equipment and resource-saving technologies to rationally utilize logistics resources and improve warehouse efficiency | |

| I4.2.2 | The use of the handling equipment’s with minimal impact on the environment | Use of loading and unloading means and devices with minimal environmental impact in the warehouse | |

| I4.3.1 | Optimization of loading/unloading and warehouse operations | Regulating the parameters of loading, unloading and warehousing processes to reduce logistics costs and achieve the SDGs | |

| I4.3.2 | Optimization of warehouse transportation | Use of progressive organization of cargo movement between different storage areas in the warehouse to minimize transshipment and optimize intro-warehouse routes | |

| I4.3.3 | Mechanization and automation of loading-unloading and storage operation | Mechanization and automation of loading and unloading and warehousing operations to reduce the share of manual processes and operations and increase labor productivity in warehousing operations | |

| I4.3.4 | Vehicle engine shutdown during loading and unloading operations | Disabling the vehicle engine during loading and unloading operations to reduce fuel consumption and CO2 emissions | |

| I4.3.5 | Selection of friendly packing strategies to the environment | Developing and using a packaging strategy to prevent damage and loss of goods, efficiently utilize resources, and reduce environmental impact (ISO 18601-06: 2013) | |

| I4.4.1 | Optimization of inventory levels through the use of inventory management systems and modern logistics concepts | Optimization of inventory levels based on the Inventory Management Systems and modern logistics concepts (Just-in-Time, Kanban, Lean Production, etc.) | |

| I4.4.2 | Operational control of parameters of inventory management system | Operational control of deviations of the actual parameters of the inventory management system from the optimal ones and decision-making to regulate these parameters | |

| I4.4.3 | Placement and storage of finished products and waste | Optimal filling of storage space, safe and efficient handling and warehousing services | |

| I4.4.4 | Unitization of party shipment | Consolidation of cargo consignments for efficient use of vehicles, reduction of transportation expenses and harmful emissions into the environment |

| № | Green logistics instrument | Description | |

|---|---|---|---|

| I5.1.1 | The selection of environmentally friendly modes of transport | Assessment and selection of transport modes and transport planning systems for efficient transport of goods and reduction of negative environmental impacts | |

| I5.1.2 | The use of intermodal technologies and multimodal transport | Use in supply chains of multimodal delivery systems with intermodal technologies based on sequential or parallel advancement of cargo flows by several modes of transportation, and elimination of transshipment operations when transferring cargo from one mode of transportation to another | |

| I5.1.3 | Selection of rational basic conditions of delivery | Selection of basic terms of delivery of goods that define the duties, place of transfer of goods, cost, and risks arising in the delivery of goods from sellers to buyers, considering the least negative impact on the environment | |

| I5.2.1 | Vehicles with the least impact on the environment | Selection and use of vehicles with the least negative environmental impact throughout the life cycle, including zero emission vehicles — ZEVs | |

| I5.2.2 | Selection of vehicles relevant requirements in the field of ecology | Evaluating and selecting vehicles that comply with established environmental regulations and requirements (Euro 1-6) | |

| I5.2.3 | Selection of vehicles with larger carrying capacity (cargo capacity) | Selecting a vehicle with a larger payload (cargo capacity) to increase productivity and reduce CO2 emissions | |

| I5.2.4 | Environmentally friendly fuels and lubricants (fuels) | Selection and use of fuels, lubricants and special fluids with improved environmental properties, ensuring reliability and efficiency of vehicle operation | |

| I5.3.1 | Provision of technological unity for transport and warehouse process | Ensuring the technological unity of the transportation and warehousing process by unifying the parameters of vehicles, tare, loading and unloading means and devices, places of cargo storage in the warehouse | |

| I5.3.2 | Reduction of iterations and links in the supply chain (reduction of transfer and storage points) | Minimize iterations and links in the supply chain (transshipment and storage points) to reduce logistics costs | |

| I5.3.3 | An increase in level of vehicles utilization | Selection of the best ways to load vehicles to optimize the use of vehicle load capacity | |

| I5.3.4 | Optimization of traffic route of vehicles movement | Optimization of vehicle routes to reduce mileage, fuel consumption, save engine life, and reduce pollutant emissions | |

| I5.3.5 | Optimization of vehicles’ speed | Selecting vehicle speeds that reduce fuel consumption, emissions, and safety | |

| I5.3.6 | Decrease in the reverse empty run | Reducing empty vehicle miles traveled to improve vehicle efficiency, reduce fuel consumption and carbon dioxide emissions | |

| I5.3.7 | Eco-driving | Training drivers in vehicle driving techniques that optimize fuel consumption, reduce emissions and improve safety | |

| I5.4.1 | Consolidation of traffic flows to the directions | Consolidation of small jets of material flow (cargo flow) into a powerful jet to increase the efficiency of its transportation using the system of main modes of transportation | |

| I5.4.2 | Reducing the frequency of deliveries | Optimization of the frequency and size of deliveries based on the inventory management strategy adopted within the boundaries of a particular logistics system | |

| I5.4.3 | Optimization traffic flow’s structure | Changing the structure of material flow (cargo flow) during transportation, considering the needs of supply chain elements in material flow | |

| I5.4.4 | Operational management of material flows’ parameters in order to ensure uniform load of transport infrastructure elements and decrease congestion and stocks | Use of various methods of continuous assessment of material flow parameters and their correction in case of deviation from normative values |

| № | Green logistics instrument | Description | |

|---|---|---|---|

| I6.1.1 | Needs analysis in the environmental services and products | Using the principles and methods of green marketing to study the market, demand for goods (services), consumer behavior and competitors to meet consumer demand for environmentally friendly products and services | |

| I6.1.2 | Analysis of the readiness of market consumption to using green technologies and solutions | Utilizing a range of different activities to communicate the merits of “green” goods or services to potential consumers and stimulate the consumption of “green” goods or services | |

| I6.1.3 | Analysis of a distribution system from the point of view of impact on the environment | Assessment of the distributional system for compliance with the principles of building sustainable supply chains and achieving the SDGs | |

| I6.2.1 | Decrease in the use of packaging materials | Rational use of packaging to reduce logistics costs and packaging material volumes | |

| I6.2.2 | Eco-friendly packaging materials | Use of eco-friendly packaging materials composed of natural ingredients, as well as materials with ingredients that accelerate their decomposition | |

| I6.2.3 | Reusable packaging | Use of reusable and reusable containers and packaging to reduce waste and packaging procurement costs, and to improve the security of cargo delivery | |

| I6.2.4 | Accumulation of used packaging and tare with it further processing | Collection of used containers and packaging for recycling by own forces or under contract with specialized organizations | |

| I6.3.1 | Selection of environmentally friendly distribution channels | Assessment and selection of distribution channels that implement environmental policies and incorporate environmentally friendly mechanisms in their operations | |

| I6.3.2 | Evaluation and monitoring the environmental performance of distribution channels | Operational elimination of the distributional system parameters deviations from those set in accordance with the SDGs or ESG strategy | |

| I6.3.3 | Formation of channels and distribution network with minimal impact on the environment | Use of strategy and methods for the formation of the distribution network with minimal environmental impact | |

| I6.3.4 | Location of distribution center’s with minimal impact on the environment | Green field analysis for distribution centers to reduce logistics costs and reduce negative environmental impact | |

| I6.4.1 | Electronic document circulation in the organization of interaction with consumers | Using the system and EDI operator to organize work with documents by forming them electronically, without using paper carriers | |

| I6.4.2 | Stimulation of the use of green products and service | Stimulating consumers of products or services whose behavior is based on the concepts of sustainable development, responsible, ethical, “green” consumption | |

| I6.4.3 | The use of eco-labelling | Use of eco-labeling system to inform consumers about the environmental properties of products or services | |

| I6.5.1 | Optimization of reverse flows | Use of methods of handling return material flows, i.e., reuse, recycling, utilization of goods, materials, and wastes | |

| I6.5.2 | Extension of product life cycle | Extension of product life cycle based on the use of principles and methods of closed-loop economy and Closed-loop Supply Chain, including defect elimination, repair, restoration, refurbishment, modernization of products | |

| I6.5.3 | Development of corporate social responsibility | Cooperation with various charitable, environmental, volunteer organizations, animal shelters, etc. for donation of products | |

| I6.5.4 | Selling through special shops | Sale of goods and services through specialized stores, including Zero waste stores, online stores, second hand stores, eco-markets, food sharing, etc. |

| Criteria | Weight | Sub criteria |

Weight | Global weight |

| Economic criteria (С1) | 0.2538 | C1.1 | 0.75726 | 0.19216 |

| C1.2 | 0.01508 | 0.00383 | ||

| C1.3 | 0.22766 | 0.05777 | ||

| Energy-ecological criteria (С2) | 0.2220 | C2.1 | 0.98622 | 0.21890 |

| C2.2 | 0.01378 | 0.00306 | ||

| Quality criteria (С3) | 0.2474 | C3.1 | 0.44784 | 0.11080 |

| C3.2 | 0.30491 | 0.07544 | ||

| C3.3 | 0.24725 | 0.06117 | ||

| Statistical criteria (С4) | 0.0005 | C4.1 | 0.41160 | 0.00020 |

| C4.2 | 0.32903 | 0.00016 | ||

| C4.3 | 0.17474 | 0.00009 | ||

| C4.4 | 0.08463 | 0.00004 | ||

| Flow’s physical criteria (С5) | 0.2764 | C1.1 | 0.45068 | 0.12456 |

| C2.2 | 0.54476 | 0.15056 | ||

| C3.3 | 0.00456 | 0.00126 |

| Element | GLM / GLI | С11 | С12 | С13 | С21 | С22 | С31 | С32 | С33 | С41 | С42 | С43 | С44 | С51 | С52 | С53 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control element | M1.1 | 2.35 | 2.93 | 2.17 | 3.03 | 3.90 | 1.64 | 1.52 | 1.78 | 1.32 | 1.15 | 1.15 | 1.32 | 1.64 | 1.43 | 1.64 |

| I1.1.1 | 3.064 | 3.245 | 2.297 | 3.776 | 4.129 | 2.825 | 3.178 | 3.519 | 2.352 | 2.221 | 2.297 | 2.297 | 1.516 | 2.551 | 3.366 | |

| I1.1.2 | 2.169 | 2.000 | 1.741 | 2.930 | 3.519 | 2.702 | 2.702 | 2.993 | 2.491 | 2.551 | 2.702 | 2.702 | 1.516 | 2.352 | 2.048 | |

| I1.1.3 | 2.993 | 3.519 | 3.594 | 3.245 | 4.317 | 2.825 | 2.825 | 3.519 | 2.702 | 2.930 | 2.862 | 2.862 | 2.169 | 3.104 | 3.438 | |

| I1.1.4 | 2.702 | 2.862 | 3.981 | 3.594 | 4.317 | 2.605 | 2.825 | 3.641 | 2.862 | 3.031 | 2.639 | 2.639 | 1.644 | 2.862 | 4.076 | |

| M1.2 | 3.52 | 3.25 | 3.73 | 3.10 | 2.49 | 2.83 | 3.52 | 3.98 | 3.44 | 2.70 | 2.55 | 2.70 | 2.70 | 3.37 | 1.89 | |

| I1.2.1 | 2.825 | 3.288 | 2.169 | 2.551 | 2.930 | 2.048 | 2.702 | 2.605 | 2.352 | 2.048 | 2.048 | 2.048 | 1.644 | 2.460 | 1.783 | |

| I1.2.2 | 2.551 | 2.639 | 2.352 | 2.702 | 2.491 | 2.352 | 3.565 | 3.807 | 2.352 | 2.551 | 2.048 | 1.888 | 1.516 | 3.129 | 1.888 | |

| I1.2.3 | 2.169 | 2.702 | 1.741 | 2.352 | 3.245 | 1.149 | 1.320 | 1.783 | 1.320 | 1.320 | 1.320 | 1.320 | 1.888 | 1.783 | 1.644 | |

| I1.2.4 | 1.888 | 2.169 | 1.888 | 2.048 | 3.680 | 1.644 | 1.516 | 1.516 | 1.320 | 1.320 | 1.320 | 1.320 | 1.644 | 1.888 | 1.516 | |

| I1.2.5 | 2.862 | 3.565 | 2.352 | 3.641 | 3.438 | 2.169 | 1.516 | 2.702 | 2.352 | 2.605 | 1.888 | 2.000 | 2.639 | 2.048 | 2.605 | |

| I1.2.6 | 3.519 | 3.728 | 2.639 | 3.807 | 4.129 | 1.516 | 1.320 | 2.221 | 2.268 | 2.402 | 1.974 | 2.091 | 2.993 | 1.783 | 2.268 | |

| M1.3 | 2.70 | 3.10 | 3.90 | 2.40 | 2.17 | 3.13 | 3.59 | 3.59 | 3.29 | 2.22 | 2.30 | 2.17 | 1.52 | 3.10 | 1.74 | |

| I1.3.1 | 2.825 | 3.104 | 2.551 | 3.438 | 3.594 | 2.000 | 1.320 | 2.766 | 1.974 | 2.091 | 1.974 | 2.091 | 2.402 | 1.783 | 1.974 | |

| I1.3.2 | 1.888 | 2.048 | 1.149 | 1.741 | 1.888 | 1.149 | 1.149 | 1.741 | 1.320 | 1.516 | 1.431 | 1.516 | 2.000 | 1.644 | 2.169 | |

| I1.3.3 | 2.766 | 2.702 | 1.888 | 1.516 | 2.048 | 1.888 | 1.516 | 2.221 | 1.644 | 2.491 | 2.048 | 2.169 | 2.048 | 1.888 | 2.491 | |

| M1.4 | 3.73 | 3.68 | 4.13 | 3.73 | 3.29 | 3.73 | 4.13 | 4.32 | 3.59 | 3.13 | 3.17 | 3.17 | 2.35 | 4.32 | 3.73 | |

| I1.4.1 | 2.352 | 2.930 | 2.169 | 3.031 | 3.898 | 1.644 | 1.516 | 1.783 | 1.320 | 1.149 | 1.149 | 1.320 | 1.644 | 1.431 | 1.644 | |

| I1.4.2 | 2.352 | 2.297 | 2.141 | 3.031 | 3.807 | 1.644 | 1.516 | 1.933 | 1.320 | 1.246 | 1.149 | 1.320 | 1.783 | 1.552 | 1.888 | |

| I1.4.3 | 2.048 | 2.766 | 1.644 | 2.639 | 3.594 | 1.644 | 1.516 | 1.888 | 1.320 | 1.149 | 1.149 | 1.320 | 1.644 | 1.431 | 1.644 | |

| I1.4.4 | 2.352 | 2.352 | 1.320 | 2.169 | 2.930 | 1.888 | 1.741 | 1.644 | 1.516 | 1.431 | 1.431 | 1.431 | 1.149 | 1.149 | 1.149 | |

| M1.5 | 3.44 | 3.73 | 4.08 | 3.29 | 3.29 | 3.52 | 3.73 | 3.76 | 3.59 | 3.44 | 3.03 | 3.03 | 2.55 | 3.90 | 2.86 | |

| I1.5.1 | 2.460 | 2.402 | 2.268 | 2.491 | 2.993 | 2.091 | 1.821 | 1.974 | 1.741 | 1.431 | 1.431 | 1.431 | 1.320 | 1.320 | 1.149 | |

| I1.5.2 | 3.519 | 3.245 | 3.728 | 3.104 | 2.491 | 2.825 | 3.519 | 3.981 | 3.438 | 2.702 | 2.551 | 2.702 | 2.702 | 3.366 | 1.888 | |

| I1.5.3 | 3.519 | 2.993 | 3.438 | 2.825 | 2.551 | 2.825 | 3.323 | 4.317 | 3.438 | 3.064 | 2.551 | 2.551 | 2.402 | 2.491 | 1.888 | |