Submitted:

24 November 2024

Posted:

25 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

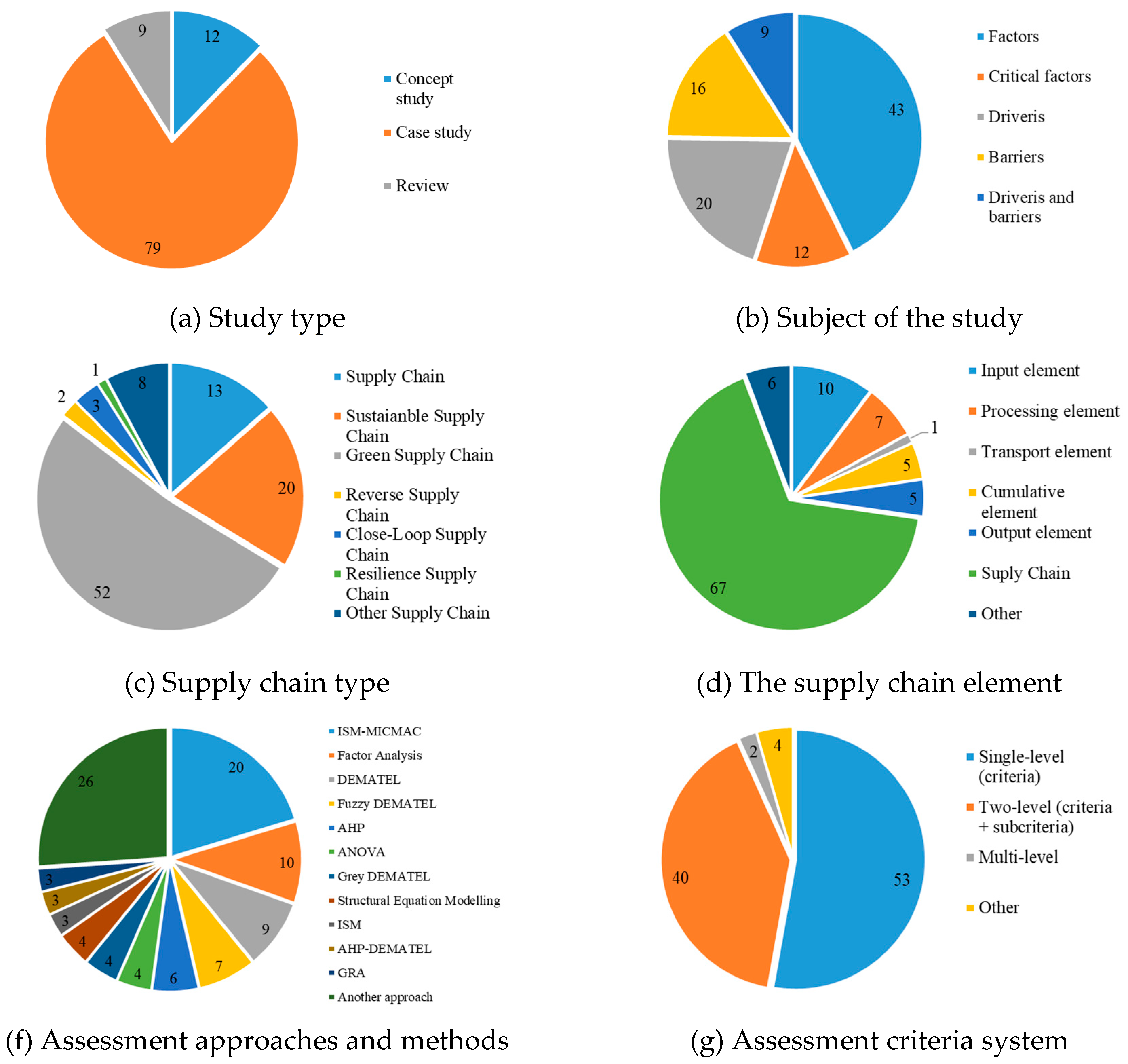

2. Literature Review

- factors, drivers, and barriers of supply chain sustainability, as well as indicators of their assessment.

- models and methods for assessing the performance and sustainability of different types of supply chains.

- case studies of supply chains of different types and structures.

2.1. Review Papers

2.2. Conceptual Studies

2.3. Case Studies

| № | Supply Chain Type | Object of Assessment | Number of Factors, Drivers, and Barriers | Methods and Models** | Reference |

|---|---|---|---|---|---|

| 1 | Supply Chain | Other | 7 factors | — | [8] |

| 2 | Green Supply Chain | Supply Chain | 7 factors | DEMATEL | [19] |

| 3 | Green Supply Chain | Other | 13 factors | ISM | [20] |

| 4 | Sustainable Supply Chain | Supply Chain | 7 drivers / 40 sub-drivers | SLR | [9] |

| 5 | Green Supply Chain | Supply Chain | 8 factors | ISM-MICMAC | [10] |

| 6 | Green Supply Chain | Other | 8 factors | FQFD | [22] |

| 7 | Sustainable Supply Chain | Supply Chain | 8 factors | SLR/Survey | [23] |

| 8 | Green Supply Chain | Supply Chain | 16 factors | DEMATEL | [4] |

| 9 | Green Supply Chain | Supply Chain | 5 factors / 24 sub-factors | AHP-DEMATEL | [47] |

| 10 | Other Supply Chain | Other | 6 factors | ANOVA | [48] |

| 11 | Green Supply Chain | Supply Chain | 11 drivers | ISM-MICMAC | [49] |

| 12 | Green Supply Chain | Supply Chain | 4 critical factors / 20 sub-factors | Factor Analysis | [50] |

| 13 | Other Supply Chain | Other | 3 factors / 20 sub-factors | ANOVA | [51] |

| 14 | Reverse Supply Chain | Supply Chain | 5 factors / 25 sub-factors | AHP-DEMATEL | [30] |

| 15 | Close-Loop Supply Chain | Other | 3 drivers | — | [52] |

| 16 | Supply Chain | Supply Chain | 3 drivers | AHP | [53] |

| 17 | Green Supply Chain | Processing element* | 12 drivers | Fuzzy AHP | [35] |

| 18 | Sustainable Supply Chain | Supply Chain | 13 factors | Hesitant Fuzzy DEMATEL | [54] |

| 19 | Sustainable Supply Chain | Supply Chain | 14 critical factors / 62 sub-factors | SLR | [12] |

| 20 | Sustainable Supply Chain | Supply Chain | 4 critical factors / 20 sub-factors | Factor Analysis | [55] |

| 21 | Resilience Supply Chain | Supply Chain | 15 factors | Data Analysis | [29] |

| 22 | Sustainable Supply Chain | Supply Chain | 15 factors | SLR | [15] |

| 23 | Supply Chain | Supply Chain | 4 factors / 43 sub-factors | SLR | [11] |

| 24 | Supply Chain | Supply Chain | 4 barriers | Cross-case Analysis | [3] |

| 25 | Green Supply Chain | Supply Chain | 5 barriers / 22 sub-barriers | AHP | [56] |

| 26 | Reverse Supply Chain | Supply Chain | 7 drivers / 37 sub-drivers 7 barriers / 36 sub-barriers |

SLR | [16] |

| 27 | Green Supply Chain | Supply Chain | 2 drivers / 10 sub-drivers 2 barriers / 15 sub-barriers |

SLR | [17] |

| 28 | Green Supply Chain | Supply Chain | 19 factors | ISM-MICMAC | [57] |

| 29 | Green Supply Chain | Supply Chain | 26 critical factors | ISM-MICMAC | [58] |

| 30 | Sustainable Supply Chain | Supply Chain | 7 critical factors / 32 sub-factors | ISM-MICMAC | [59] |

| 31 | Green Supply Chain | Input element* | 7 drivers / 26 sub-drivers | Structural Equation Modelling | [31] |

| 32 | Sustainable Supply Chain | Input element* | 7 drivers / 17 sub-drivers | Hierarchical Linear Modelling | [32] |

| 33 | Green Supply Chain | Supply Chain | 8 drivers | ISM-MICMAC | [60] |

| 34 | Green Supply Chain | Input element* | 5 factors / 15 sub-factors | Fuzzy DEMATEL | [61] |

| 35 | Green Supply Chain | Processing element* | 13 drivers | ISM-MICMAC | [36] |

| 36 | Other Supply Chain | Output element* | 8 barriers | Grey DEMATEL | [43] |

| 37 | Sustainable Supply Chain | Supply Chain | 7 factors | GRA | [62] |

| 38 | Green Supply Chain | Supply Chain | 18 barriers | ISM | [63] |

| 39 | Green Supply Chain | Output element* | 13 factors | DEMATEL | [44] |

| 40 | Green Supply Chain | Supply Chain | 5 factors / 28 sub-factors | Factor Analysis | [64] |

| 41 | Green Supply Chain | Supply Chain | 15 barriers | Hierarchical Clustering Analysis | [65] |

| 42 | Green Supply Chain | Supply Chain | 4 critical factors / 25 sub-factors | DEMATEL | [66] |

| 43 | Green Supply Chain | Supply Chain | 10 factors | Fuzzy DEMATEL | [67] |

| 44 | Green Supply Chain | Transport element* | 10 factors | Statistical Analysis | [41] |

| 45 | Green Supply Chain | Supply Chain | 5 drivers / 18 sub-drivers | ANOVA | [68] |

| 46 | Green Supply Chain | Transport element* | 8 drivers | Structural Equation Modelling | [42] |

| 47 | Green Supply Chain | Supply Chain | 3 drivers | Survey | [69] |

| 48 | Sustainable Supply Chain | Input element* | 17 drivers and 16 barriers | Delphi method | [33] |

| 49 | Supply Chain | Supply Chain | 32 drivers | Structural Equation Modelling | [70] |

| 50 | Green Supply Chain | Supply Chain | 26 barriers | ISM-MICMAC | [71] |

| 51 | Green Supply Chain | Supply Chain | 14 barriers | ISM-MICMAC | [72] |

| 52 | Green Supply Chain | Input element* | 10 barriers | ISM-MICMAC | [45] |

| 53 | Sustainable Supply Chain | Supply Chain | 13 barriers | ISM-MICMAC | [73] |

| 54 | Supply Chain | Processing element* | 10 drivers and 4 barriers | — | [37] |

| 55 | Green Supply Chain | Supply Chain | 7 drivers and 10 barriers | Semi-structured interviews | [74] |

| 56 | Sustainable Supply Chain | Supply Chain | 11 drivers | Fuzzy TISM-MICMAC | [75] |

| 57 | Sustainable Supply Chain | Supply Chain | 3 drivers / 11 sub-drivers 2 barriers / 11 sub-barriers |

— | [76] |

| 58 | Green Supply Chain | Supply Chain | 5 barriers / 22 sub-barriers | DEMATEL-Fuzzy EDAS-Fuzzy COPRAS | [77] |

| 59 | Supply Chain | Supply Chain | 14 barriers | Fuzzy TISM-MICMAC | [78] |

| 60 | Close-Loop Supply Chain | Supply Chain | 4 drivers / 21 sub-drivers | Grey DEMATEL | [27] |

| 61 | Close-Loop Supply Chain | Supply Chain | 6 barriers / 35 sub-barriers | Pythagorean Fuzzy AHP-DEMATEL | [28] |

| 62 | Green Supply Chain | Supply Chain | 9 critical factors | Fuzzy DEMATEL | [79] |

| 63 | Green Supply Chain | Output element* | 25 critical factors | Factor Analysis | [46] |

| 64 | Other Supply Chain | Supply Chain | 6 factors | GRA | [80] |

| 65 | Supply Chain | Supply Chain | 6 factors / 13 sub-factors | AHP | [81] |

| 66 | Supply Chain | Supply Chain | 2 factors / 10 sub-factors | — | [24] |

| 67 | Other Supply Chain | Transport element* | 7 critical factors | — | [21] |

| 68 | Sustainable Supply Chain | Supply Chain | 15 factors | ISM-MICMAC | [18] |

| 69 | Sustainable Supply Chain | Supply Chain | 7 drivers and 6 barriers | AHP-TOPSIS, AHP-COPRAS | [82] |

| 70 | Green Supply Chain | Input element* | 11 factors | SWARA-TOPSIS | [83] |

| 71 | Green Supply Chain | Supply Chain | 3 critical factors / 12 sub-factors | DEMATEL | [84] |

| 72 | Green Supply Chain | Supply Chain | 12 factors | ISM-MICMAC | [85] |

| 73 | Green Supply Chain | Input element* | 5 factors / 17 sub-factors | ANP-TOPSIS | [86] |

| 74 | Green Supply Chain | Supply Chain | 5 drivers | SEM | [87] |

| 75 | Other Supply Chain | Supply Chain | 3 factors / 8 sub-factors | ANP-AHP-BOCR | [25] |

| 76 | Green Supply Chain | Processing element* | 5 factors / 21 sub-factors | Confirmatory factor analysis | [88] |

| 77 | Sustainable Supply Chain | Processing element* | 4 factors / 14 sub-factors | Factor Analysis | [38] |

| 78 | Supply Chain | Processing element* | 3 barriers / 15 sub-barriers | Grey DEMATEL | [39] |

| 79 | Supply Chain | Cumulative element* | 15 factors | ISM-MICMAC | [40] |

| 80 | Other Supply Chain | Transport element* | 8 factors | — | [89] |

| 81 | Green Supply Chain | Supply Chain | 5 drivers / 17 sub-drivers | Fuzzy DEMATEL-Fuzzy ANP-Fuzzy TOPSIS | [90] |

| 82 | Green Supply Chain | Supply Chain | 3 barriers / 13 sub-barriers | AHP-ELECTRE I | [91] |

| 83 | Sustainable Supply Chain | Input element* | 3 factors / 10 sub-factors | DEMATEL | [92] |

| 84 | Green Supply Chain | Input element* | 5 factors / 21 sub-factors | AHP | [34] |

| 85 | Green Supply Chain | Input element* | 15 factors | Fuzzy DEMATEL | [26] |

| 86 | Supply Chain | Supply Chain | 10 factors | Grey system theory | [1] |

| 87 | Sustainable Supply Chain | Supply Chain | 22 drivers and 19 barriers | SLR | [5] |

| 88 | Green Supply Chain | Supply Chain | 2 drivers / 6 sub-drivers | — | [7] |

| 89 | Green Supply Chain | Supply Chain | 7 factors / 47 sub-factors | Factor Analysis | [93] |

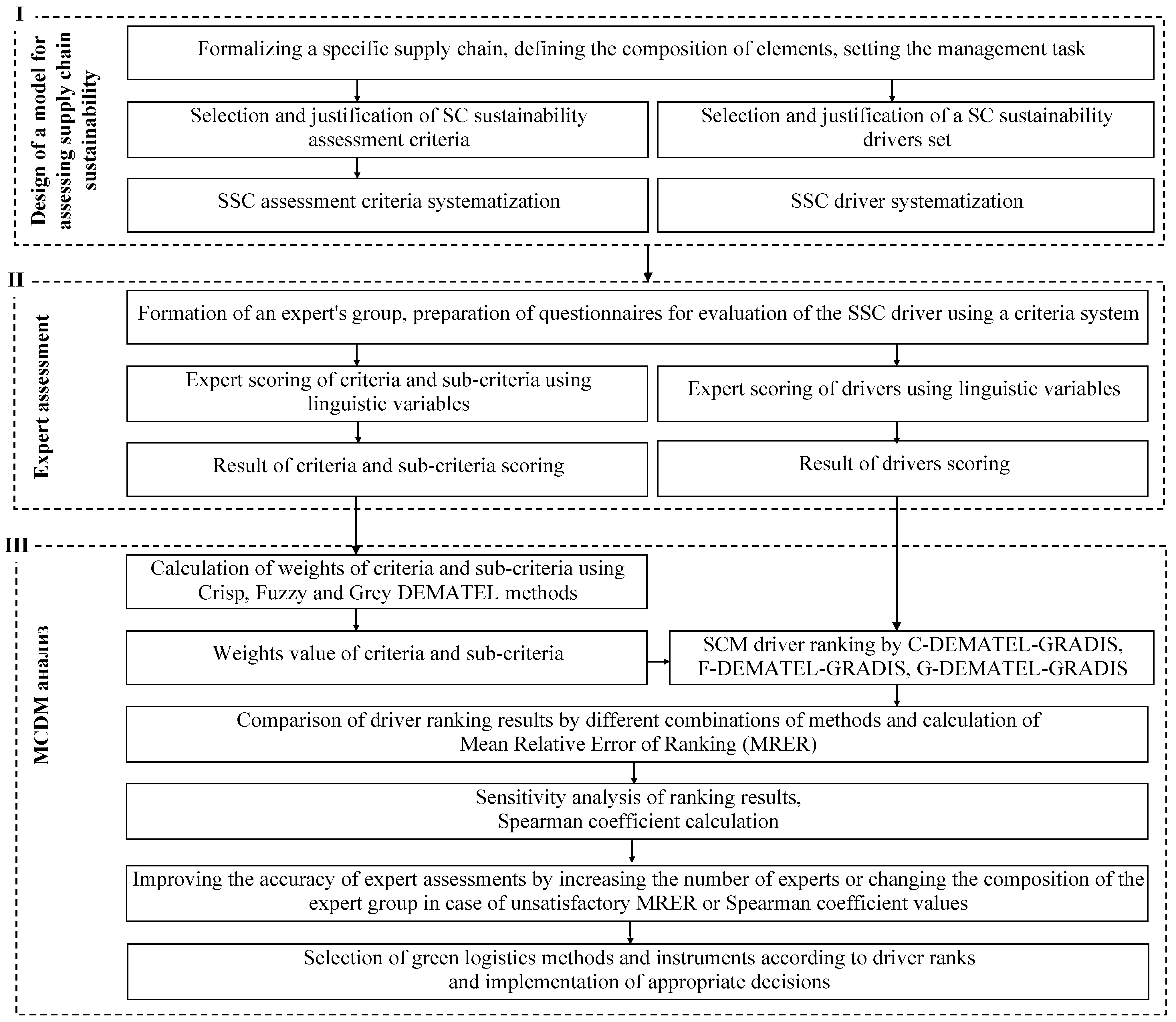

3. Methodology for Assessing Sustainable Supply Chain Drivers

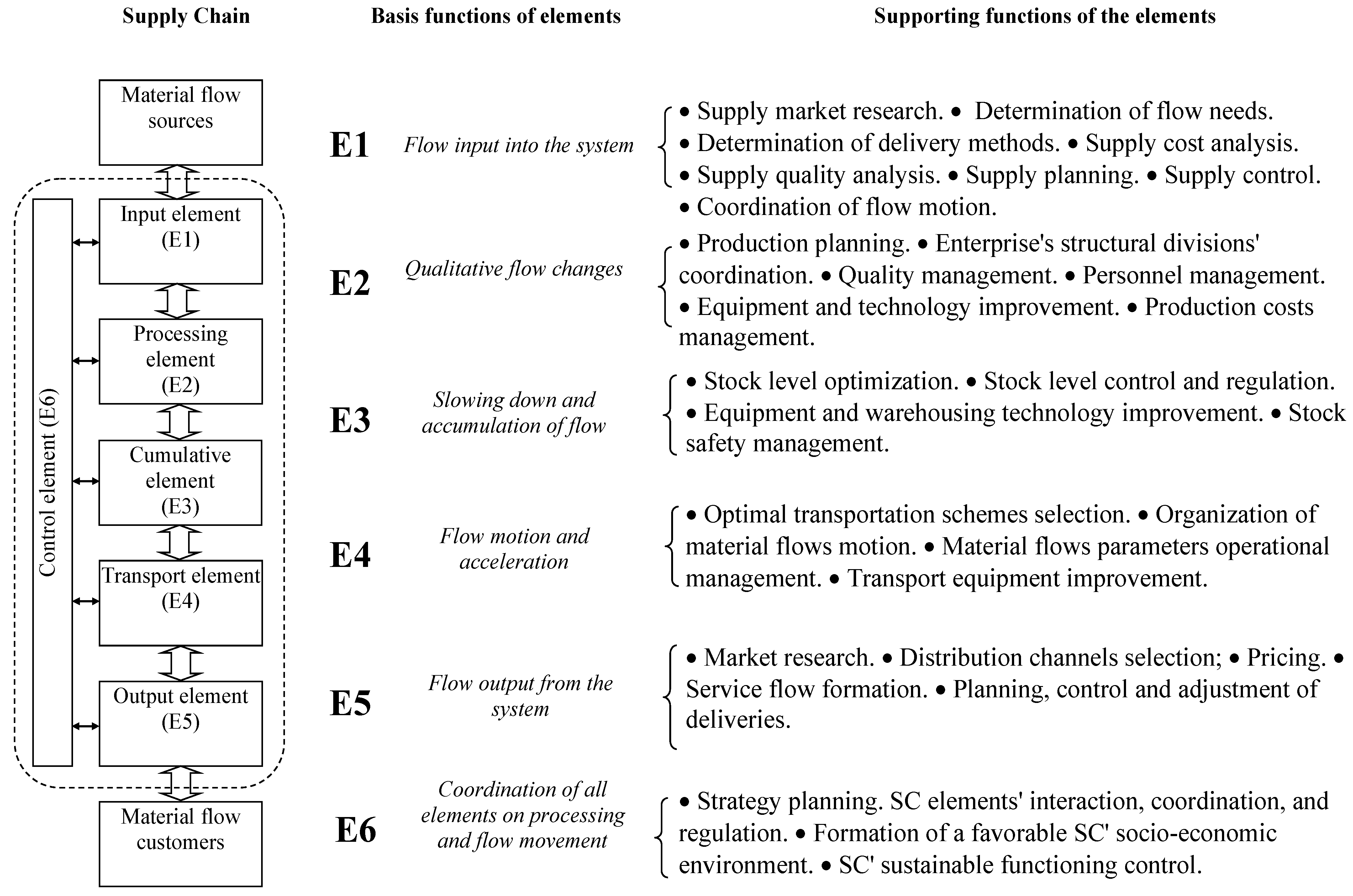

3.1. Sustainable Supply Chain Structure and Functions

- Input element (E1) the entry of material flows into the system, i.e., the purchase of necessary raw materials, supplies, or services.

- Processing element (E2) changes the qualitative properties of material flows, their transformation from raw materials into finished products.

- Cumulative element (E3) regulation of the speed of material flows as a result of their inhibition, accumulation, and storage.

- Transport element (E4) acceleration and movement of material flows.

- Output element (E5) withdrawal of material flow from the system, marketing, and distribution of finished products and services.

- Control element (E6) providing information and financial connection between other LS elements, controlling their functions and operations, regulating the promotion of information and financial flows in the SC.

3.2. Sustainable Supply Chain Driver System

| Supply chain elements | Sustainable supply chain drivers | References |

|---|---|---|

| Input element | D1.1 – Environmentally friendly raw materials (at supplier) | [19,31,43,50,55,56,59,60,61,64,66,67,68,69,72,77] |

| D1.2 – Raw materials able to reuse or recycle | [12,16,19,27,31,33,44,46,49,56,64] | |

| D1.3 – Raw materials procurement system | [30,31,36,50,52,53,57,59,60,64,66,67,81] | |

| D1.4 – Eco-friendly suppliers | [4,10,11,17,22,28,32,33,42,47,48,49,50,55,57,58,60,61,63,64,66,67,68,72,75,76,77] | |

| D1.5 – Delivery distance of raw materials | [31,32,64] | |

| D1.6 – Type of packaging for raw materials | [10,16,36,46,52,53,60,61,64,68,73] | |

| D1.7 – Raw material eco-labeling | [16,46,59] | |

| D1.8 – E-commerce with supplier | [62,75] | |

| Processing element | D2.1 – Eco-friendly raw materials from the manufacturer | [10,12,19,43,51,56,59,60,64,66,68,69,72,77] |

| D2.2 – Reusable or recyclable raw materials | [16,27,44,46,56,64,77] | |

| D2.3 – Eco-friendly equipment | [9,19,33,44,51,59,64,69] | |

| D2.4 – Energy and resource saving technologies | [4,22,33,35,36,44,47,49,69,72] | |

| D2.5 – Eco-friendly production technologies | [4,9,19,22,33,35,36,44,47,51,56,57,58,61,63,64,65,69,70,71,72,73,77,78,81] | |

| D2.6 – Environmental protection systems | [20,32,35,51,61,64] | |

| D2.7 – Industrial waste | [10,12,16,20,28,30,31,36,41,44,50,52,58,64,66,67,72,73,77] | |

| D2.8 – Labor conditions | [51,55,58,59] | |

| D2.9 – Eco-learning | [4,9,12,16,19,23,28,30,31,32,36,47,48,54,56,57,58,59,62,64,65,72,73,74,77,78,79,81] | |

| Transport element | D3.1 – Transport type | [19,51,61,69,81] |

| D3.2 – Transport links type | [51] | |

| D3.3 – Route of transportation | [64] | |

| D3.4 – Cargo flow structure | [81] | |

| D3.5 – Frequency and size of shipments | [31,36,50,52,53,57,59,60,81] | |

| D3.6 – Compliance of transportation vehicles with legal regulations | [19,35,44,51,61,64,69] | |

| D3.7 – Fuel type | [51,64] | |

| D3.8 – Technical condition of vehicle fleet | [64] | |

| D3.9 – Vehicle type and model | [61,64] | |

| D3.10 – Vehicles loading degree | [64] | |

| D3.11 – Equipment of rolling stock with navigation and telecommunication systems | [11] | |

| D3.12 – Eco-driving | [41,89] | |

| Cumulative element | D4.1 – Eco raw materials and materials for warehouse construction | [72] |

| D4.2 – Warehouse type | [40,83,86] | |

| D4.3 – Spatial organization of warehouse facilities | [44] | |

| D4.4 – Energy-saving technologies | [4,22,33,36,44,47,49,69,72,73] | |

| D4.5 – Environment protection systems | [20,35,61,64] | |

| D4.6 – Eco-friendly loading and unloading equipment | [19,35,44,64] | |

| D4.7 – Mechanization and automation of loading and unloading operations | [15,29,44] | |

| D4.8 – Inventory management system | [8,10,32] | |

| D4.9 – Placement and storage of products and waste | [10,12,16,20,36,44,47,50,52,53,58,66,72] | |

| D4.10 – Type of packaging for products | [36,46,52,53,61,64,68,73] | |

| D4.11 – Labor conditions | [19,59] | |

| Output element | D5.1 – Eco-marketing | [4,16,20,22,27,28,30,33,35,36,41,43,46,47,48,49,58,59,63,64,65,67,68,69,72,75,76,77,81] |

| D5.2 – Eco-friendly sales channels | [11,12,16,17,22,27,33,46,48,50,51,55,57,58,59,64,72,75,76] | |

| D5.3 – Tare and packaging return system | [10,16,27,36,50,60,61,64] | |

| D5.4 – Type of packaging for products | [10,16,36,46,52,53,61,64,68,73] | |

| D5.5 – Eco-labeling of products | [15,29,46,58,59,60] | |

| D5.6 – E-commerce with consumer | [62,75] | |

| Control element | D6.1 – Environment strategy | [4,9,11,12,16,19,20,22,23,27,28,30,31,32,33,35,36,41,42,46,47,48,49,50,52,53,55,56,57,58,61,63,65,66,68,70,71,73,74,75,76,77,78,79,80,81] |

| D6.2 – Environmental audit | [16,20,22,36,48,50,59,66] | |

| D6.3 – Corporate Information Systems | [9,11,12,15,16,17,23,29,31,33,43,47,50,54,56,59,62,63,65,66,70,71,74,75,76,79,80,81] | |

| D6.4 – Information and communication technologies | [3,8,10,11,15,23,27,29,30,33,35,42,46,50,57,58,59,62,63,66,70,71,72,73,75,76,78,79,80,81] | |

| D6.5 – Intelligent Transportation Systems | [21,83,89] | |

| D6.6 – Corporate social responsibility | [3,4,9,12,15,17,19,20,22,23,28,29,32,35,36,41,46,47,50,51,52,53,54,55,56,58,59,63,64,65,66,72,74,76,78,79] | |

| D6.7 – Return and reverse flow management systems | [4,10,16,27,28,36,46,47,49,52,53,56,60,61,65,73,77] | |

| D6.8 – Recycling processes for waste, packaging, finished products | [10,12,16,20,22,27,28,30,31,41,44,46,47,50,52,53,58,61,64,66,67,68,69,72,77] |

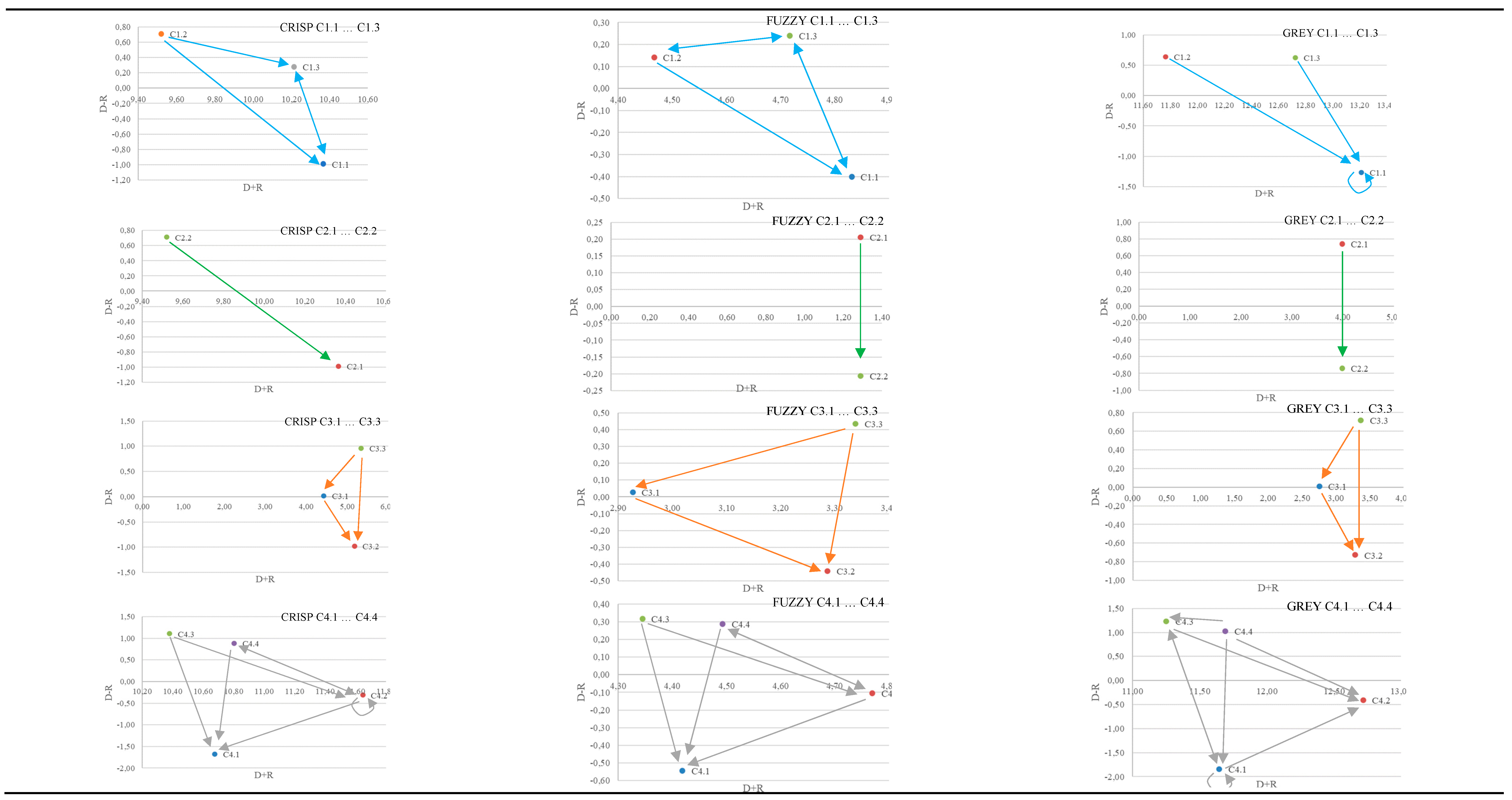

3.3. Sustainable supply Chain Drivers’ Assessment Criteria System

| Criteria | Characteristic | Sub-criteria | Characteristic |

|---|---|---|---|

| Economic criteria (С1) | The efficiency of using all types of resources in the SSC | Profit (C1.1) | Difference between total revenue and operating costs |

| Operating expenses (C1.2) | The sum of all costs associated with converting investments into profits | ||

| Fixed investment (C1.3) | Cash flow for the formation of fixed assets | ||

| Energy-ecological criteria (С2) | The efficiency of energy use during the movement of logistics flows and their impact on the environment | The energy intensity (C2.1) | The amount of energy spent on the movement of the logistics flow |

| Greenhouse gas emissions of CO2 (C2.2) | The total volume of greenhouse gas emissions from all sources involved in the movement of the logistics flow | ||

| Quality criteria (С3) | The safety and timeliness of movement and processing of logistics flows, as well as the quality of their management | Safety of cargo transportation (C3.1) | Comprehensive indicator of the material flow movement without damage, pollution, and loss |

| Timeliness of cargo transportation (C3.2) | Comprehensive indicator of the material flow movement by the appointed date, regularly, or at the required speed | ||

| The coefficient of flow controllability (C3.3) | The ratio of the number of information messages on compliance with the indicators of safety and timeliness of transportation to the total number of management decisions | ||

| Statistical criteria (С4) | The patterns of change in the controlled sub-criteria of logistics flows | The coefficient of flows irregularity (C4.1) | Deviation of the logistics flows physical parameters of from their average values |

| The coefficient of complexity structure of flow (C4.2) | The number of streams within the logistic flow | ||

| The coefficient of flows discreteness (C.4.3) | The number of elements of the logistic flow in the stream | ||

| The coefficient of differentiability of flow (C4.4) | Changing the structure of the logistics flow (number of streams) in the process of movement | ||

| Flow’s physical criteria (С5) | The intensity of logistics flows and their spatio-temporal changes | The mass (quantity) of flow (C5.1) | The total number of elements in the logistics flow |

| The speed of flow (C5.2) | The speed of movement of the logistics flow elements | ||

| The length of the route (C5.3) | Distance traveled by a logistic flow element while moving along a route |

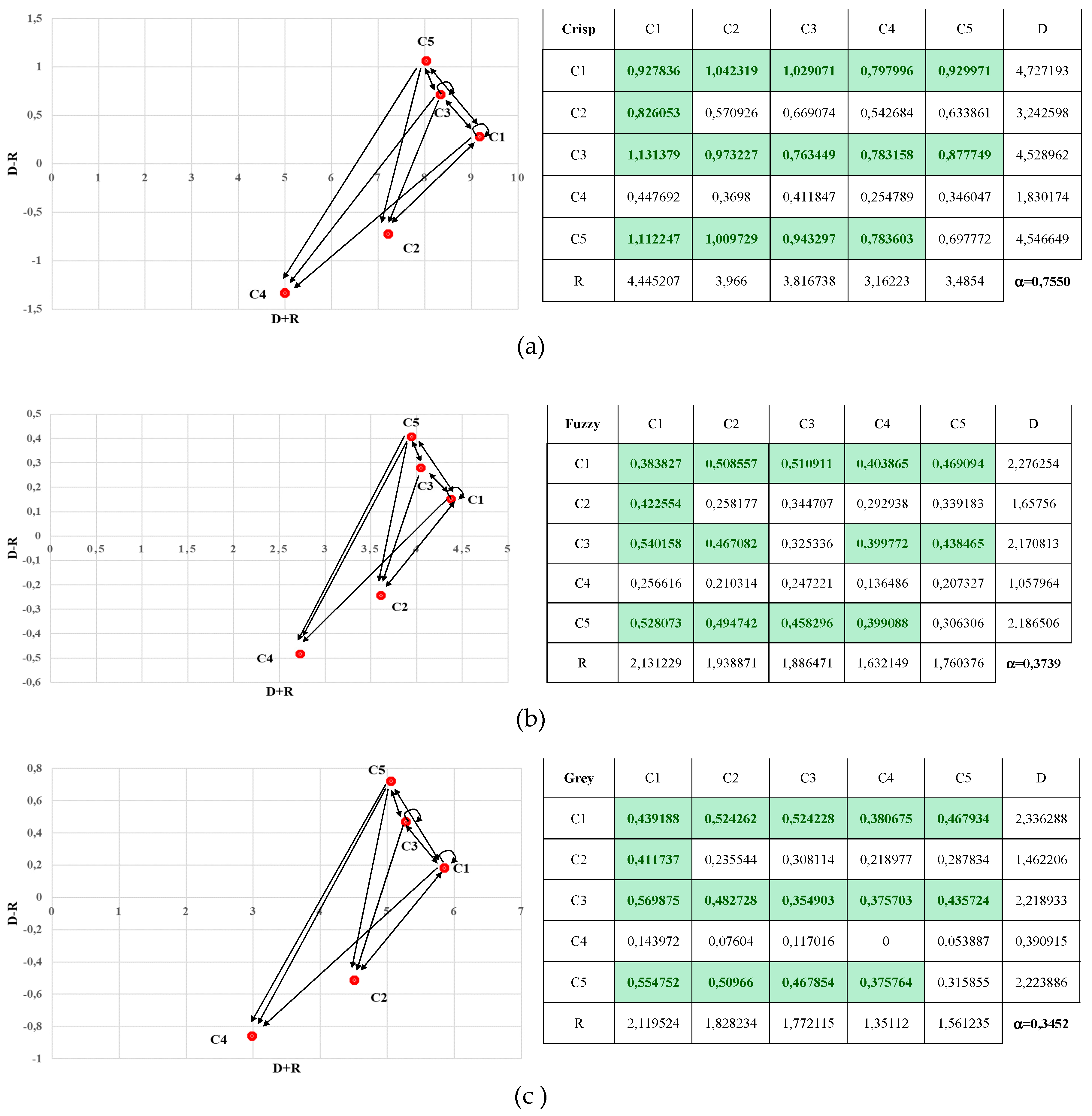

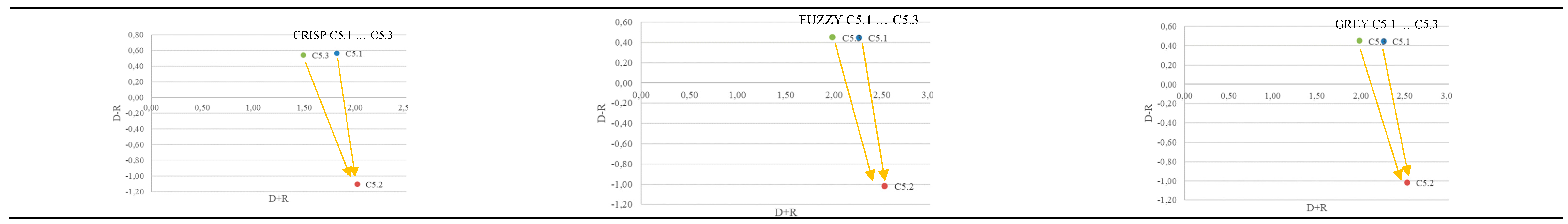

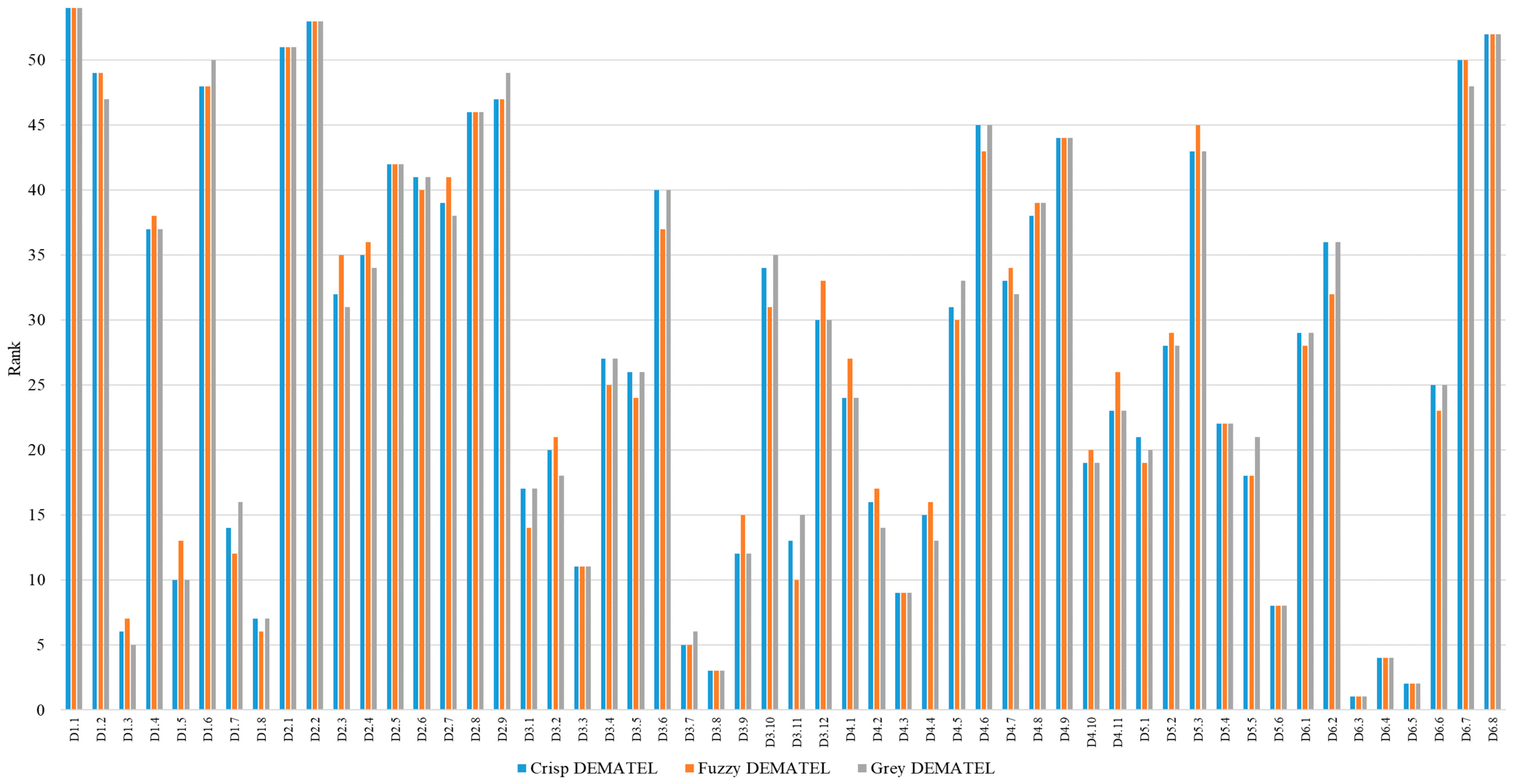

3.4. A Framework for Sustainable Supply Chain Drivers’ Multi-Criteria Assessment

4. Numerical Example

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alfaro-Saiz, J.-J.; Bas, M.C.; Giner-Bosch, V.; Rodríguez-Rodríguez, R.; Verdecho, M.-J. An evaluation of the environmental factors for supply chain strategy decisions using grey systems and composite indicators. Applied Mathematical Modelling 2020, 79, 490–505. [CrossRef]

- Guterres, A. Carbon neutrality by 2050: the world’s most urgent mission. Available online: https://www.un.org/sg/en/content/sg/articles/2020-12-11/carbon-neutrality-2050-the-world%E2%80%99s-most-urgent-mission (accessed on 11 December 2020).

- Zhang, A.; Alvi, M.F.; Gong, Y.; Wang, J.X. Overcoming barriers to supply chain decarbonization: Case studies of first movers. Resources, Conservation and Recycling 2022, 186, 106536. [CrossRef]

- Gandhi, S.; Mangla, S.K.; Kumar, P.; Kumar, D. Evaluating factors in implementation of successful green supply chain management using DEMATEL: A case study. International Strategic Management Review 2015, 3, 96–109. [CrossRef]

- Rehman Khan, S.A.; Yu, Z.; Golpîra, H.; Sharif, A.; Mardani, A. A state-of-the-art review and meta-analysis on sustainable supply chain management: Future research directions. Journal of Cleaner Production 2021, 278, 123357. [CrossRef]

- Lazar, S.; Klimecka-Tatar, D.; Obrecht, M. Sustainability orientation and focus in logistics and supply chains. Sustainability 2021, 13, 3280. [CrossRef]

- Schrettle, S.; Hinz, A.; Scherrer-Rathje, M.; Friedli, T. Turning sustainability into action: Explaining firms’ sustainability efforts and their impact on firm performance. International Journal of Production Economics 2014, 147, 73–84. [CrossRef]

- George, J.; Pillai, V.M. A study of factors affecting supply chain performance. Journal of Physics: Conference Series 2019, 1355, 12018. [CrossRef]

- Saeed, M.; Kersten, W. Drivers of sustainable supply chain management: Identification and classification. Sustainability 2019, 11, 1137. [CrossRef]

- Chakraborty, A.; Al Amin, M.; Baldacci, R. Analysis of internal factors of green supply chain management: An interpretive structural modeling approach. Cleaner Logistics and Supply Chain 2023, 7, 100099. [CrossRef]

- Kalaiarasan, R.; Olhager, J.; Agrawal, T.K.; Wiktorsson, M. The ABCDE of supply chain visibility: A systematic literature review and framework. International Journal of Production Economics 2022, 248, 108464. [CrossRef]

- Nilsson, F.; Göransson, M. Critical factors for the realization of sustainable supply chain innovations - Model development based on a systematic literature review. Journal of Cleaner Production 2021, 296, 126471. [CrossRef]

- Ahi, P.; Searcy, C. An analysis of metrics used to measure performance in green and sustainable supply chains. Journal of Cleaner Production 2015, 86, 360–377. [CrossRef]

- Paul, A.; Shukla, N.; Paul, S.K.; Trianni, A. Sustainable supply chain management and multi-criteria decision-making methods: A systematic review. Sustainability 2021, 13, 7104. [CrossRef]

- Apeji, U.D.; Sunmola, F.T. Principles and factors influencing visibility in sustainable supply chains. Procedia Computer Science 2022, 200, 1516–1527. [CrossRef]

- Govindan, K.; Bouzon, M. From a literature review to a multi-perspective framework for reverse logistics barriers and drivers. Journal of Cleaner Production 2018, 187, 318–337. [CrossRef]

- Walker, H.; Di Sisto, L.; McBain, D. Drivers and barriers to environmental supply chain management practices: Lessons from the public and private sectors. Journal of Purchasing and Supply Management 2008, 14, 69–85. [CrossRef]

- Yang, M.; Movahedipour, M.; Zeng, J.; Xiaoguang, Z.; Wang, L. Analysis of success factors to implement sustainable supply chain management using interpretive structural modeling technique: A real case perspective. Mathematical Problems in Engineering 2017, 2017, 1–14. [CrossRef]

- Anand, K.R.; Ramalingaiah; Parthiban, P. Evaluation of green supply chain factors using DEMATEL. Applied Mechanics and Materials 2014, 592-594, 2619–2627. [CrossRef]

- Liu, M.; Fan, H.H.; Zhou, Y.W. Analysis of influencing factors to green supply chain based on ISM. Applied Mechanics and Materials 2012, 220-223, 309–314. [CrossRef]

- Giusti, R.; Manerba, D.; Bruno, G.; Tadei, R. Synchromodal logistics: An overview of critical success factors, enabling technologies, and open research issues. Transportation Research Part E: Logistics and Transportation Review 2019, 129, 92–110. [CrossRef]

- Anand, K.R.; Ramalingaiah; Parthiban, P. Fuzzy quantitative approach to prioritize green factors in supply chain. Applied Mechanics and Materials 2014, 592-594, 2645–2653. [CrossRef]

- Wittstruck, D.; Teuteberg, F. Understanding the success factors of sustainable supply chain management: Empirical evidence from the electrics and electronics industry. Corporate Social Responsibility and Environmental Management 2012, 19, 141–158. [CrossRef]

- Jiang, F. Analysis of the potential and influencing factors of regional logistics industry development from the perspective of supply chain. Advances in Multimedia 2022, 2022, 1–10. [CrossRef]

- Zhu, Q.; Shah, P.; Sarkis, J. Addition by subtraction: integrating product deletion with lean and sustainable supply chain management. International Journal of Production Economics 2018, 205, 201–214. [CrossRef]

- Hossain, M.I.; Al Amin, M.; Baldacci, R.; Rahman, M.H. Identification and prioritization of green lean supply chain management factors using fuzzy DEMATEL. Sustainability 2023, 15, 10523. [CrossRef]

- Nag, U.; Sharma, S.K.; Govindan, K. Investigating drivers of circular supply chain with product-service system in automotive firms of an emerging economy. Journal of Cleaner Production 2021, 319, 128629. [CrossRef]

- Lahane, S.; Kant, R. Evaluating the circular supply chain implementation barriers using Pythagorean fuzzy AHP-DEMATEL approach. Cleaner Logistics and Supply Chain 2021, 2, 100014. [CrossRef]

- Sunmola, F.; Burgess, P.; Tan, A.; Chanchaichujit, J.; Balasubramania, S.; Mahmud, M. Prioritising visibility influencing factors in supply chains for resilience. Procedia Computer Science 2023, 217, 1589–1598. [CrossRef]

- Mangla, S.K.; Govindan, K.; Luthra, S. Critical success factors for reverse logistics in Indian industries: a structural model. Journal of Cleaner Production 2016, 129, 608–621. [CrossRef]

- Large, R.O.; Gimenez Thomsen, C. Drivers of green supply management performance: Evidence from Germany. Journal of Purchasing and Supply Management 2011, 17, 176–184. [CrossRef]

- Sancha, C.; Longoni, A.; Giménez, C. Sustainable supplier development practices: Drivers and enablers in a global context. Journal of Purchasing and Supply Management 2015, 21, 95–102. [CrossRef]

- Giunipero, L.C.; Hooker, R.E.; Denslow, D. Purchasing and supply management sustainability: Drivers and barriers. Journal of Purchasing and Supply Management 2012, 18, 258–269. [CrossRef]

- Tsai, J.-F.; Wu, S.-C.; Pham, T.K.L.; Lin, M.-H. Analysis of key factors for green supplier selection: A case study of the electronics industry in Vietnam. Sustainability 2023, 15, 7885. [CrossRef]

- Govindan, K.; Diabat, A.; Madan Shankar, K. Analyzing the drivers of green manufacturing with fuzzy approach. Journal of Cleaner Production 2015, 96, 182–193. [CrossRef]

- Seth, D.; Rehman, M.A.A.; Shrivastava, R.L. Green manufacturing drivers and their relationships for small and medium (SME) and large industries. Journal of Cleaner Production 2018, 198, 1381–1405. [CrossRef]

- Olatunji, O.O.; Akinlabi, S.A.; Ayo, O.O.; Madushele, N.; Adedeji, P.A.; Fatoba, S.O. Drivers and barriers to competitive carbon footprint reduction in manufacturing supply chain: a brief review. Procedia Manufacturing 2019, 35, 992–1000. [CrossRef]

- Zailani, S.; Jeyaraman, K.; Vengadasan, G.; Premkumar, R. Sustainable supply chain management (SSCM) in Malaysia: A survey. International Journal of Production Economics 2012, 140, 330–340. [CrossRef]

- Xia, X.; Govindan, K.; Zhu, Q. Analyzing internal barriers for automotive parts remanufacturers in China using grey-DEMATEL approach. Journal of Cleaner Production 2015, 87, 811–825. [CrossRef]

- Verma, A.; Tripathy, S.; Singhal, D. The significance of warehouse management in supply chain: An ISM approach. Decision Making: Applications in Management and Engineering 2023, 6, 92–110. [CrossRef]

- Zhang, Y.; Thompson, R.G.; Bao, X.; Jiang, Y. Analyzing the promoting factors for adopting green logistics practices: a case study of road freight industry in Nanjing, China. Procedia - Social and Behavioral Sciences 2014, 125, 432–444. [CrossRef]

- Jasmi, M.F.A.; Fernando, Y. Drivers of maritime green supply chain management. Sustainable Cities and Society 2018, 43, 366–383. [CrossRef]

- Shao, J.; Taisch, M.; Ortega-Mier, M. A grey-DEcision-MAking Trial and Evaluation Laboratory (DEMATEL) analysis on the barriers between environmentally friendly products and consumers: Practitioners’ viewpoints on the European automobile industry. Journal of Cleaner Production 2016, 112, 3185–3194. [CrossRef]

- Shih-Hsiung Cheng; Shih Ming Ou; Su-Mei Lin. Using decision-making trial and evaluation laboratory (DEMATEL) to explore the key success factors for green logistics manufacturers. African Journal of Business Management 2018, 12, 58–65. [CrossRef]

- Kumar, S.; Luthra, S.; Haleem, A. Customer involvement in greening the supply chain: an interpretive structural modeling methodology. Journal of Industrial Engineering International 2013, 9. [CrossRef]

- Kumar, S.; Luthra, S.; Haleem, A. Critical success factors of customer involvement in greening the supply chain: an empirical study. International Journal of Logistics Systems and Management 2014, 19, 283. [CrossRef]

- Gandhi, S.; Mangla, S.K.; Kumar, P.; Kumar, D. A combined approach using AHP and DEMATEL for evaluating success factors in implementation of green supply chain management in Indian manufacturing industries. International Journal of Logistics Research and Applications 2016, 19, 537–561. [CrossRef]

- Sureeyatanapas, P.; Poophiukhok, P.; Pathumnakul, S. Green initiatives for logistics service providers: An investigation of antecedent factors and the contributions to corporate goals. Journal of Cleaner Production 2018, 191, 1–14. [CrossRef]

- Diabat, A.; Govindan, K. An analysis of the drivers affecting the implementation of green supply chain management. Resources, Conservation and Recycling 2011, 55, 659–667. [CrossRef]

- Hu, A.H.; Hsu, C.-W. Critical factors for implementing green supply chain management practice. Management Research Review 2010, 33, 586–608. [CrossRef]

- Wiśniewski, T.; Tundys, B. Comparative analysis of sustainability factors in supply chain links. Evidence of empirical research. Procedia Computer Science 2022, 207, 3358–3366. [CrossRef]

- Brito, M.P. de; Dekker, R. Reverse Logistics – a framework. In Reverse Logistics: Quantitative models for closed-loop supply chains; Dekker, R., Ed.; Springer-Verlag: Berlin, 2010; pp 3–27, ISBN 978-3-642-07380-9.

- Akdoğan, M.; Coşkun, A. Drivers of reverse logistics activities: An empirical investigation. Procedia - Social and Behavioral Sciences 2012, 58, 1640–1649. [CrossRef]

- Kumar, A.; Moktadir, M.A.; Khan, S.A.R.; Garza-Reyes, J.A.; Tyagi, M.; Kazançoğlu, Y. Behavioral factors on the adoption of sustainable supply chain practices. Resources, Conservation and Recycling 2020, 158, 104818. [CrossRef]

- Prasad, D.S.; Pradhan, R.P.; Gaurav, K.; Sabat, A.K. Critical success factors of sustainable supply chain management and organizational performance: An exploratory study. Transportation Research Procedia 2020, 48, 327–344. [CrossRef]

- Pradeep, C.C. Assessment and analysis of GSCM barriers using AHP. International Research Journal of Engineering and Technology 2017, 4, 1777-1782.

- Agi, M.A.N.; Nishant, R. Understanding influential factors on implementing green supply chain management practices: An interpretive structural modelling analysis. J. Environ. Manage. 2017, 188, 351–363. [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. An analysis of interactions among critical success factors to implement green supply chain management towards sustainability: An Indian perspective. Resources Policy 2015, 46, 37–50. [CrossRef]

- Raut, R.D.; Narkhede, B.; Gardas, B.B. To identify the critical success factors of sustainable supply chain management practices in the context of oil and gas industries: ISM approach. Renewable and Sustainable Energy Reviews 2017, 68, 33–47. [CrossRef]

- Refaie, A.A.; Momani, D. ISM approach for modelling drivers to practices of green supply chain management in Jordanian industrial firms. International Journal of Business Performance and Supply Chain Modelling 2018, 10, 91. [CrossRef]

- Reza Kiani Mavi; Sajad Kazemi; Ali Fallahian Najafabadi; Hosein Bemani Mousaabadi. Identification and assessment of logistical factors to evaluate a green supplier using the fuzzy logic DEMATEL method. Polish Journal of Environmental Studies 2013, 22, 445–455.

- Sharma, Y.K.; Sharma, S. IT success factors in sustainable food supply chain management. Materials Today: Proceedings 2022, 56, Part 1, 43–45. [CrossRef]

- Shibin, K.T.; Gunasekaran, A.; Papadopoulos, T.; Dubey, R.; Singh, M.; Wamba, S.F. Enablers and barriers of flexible green supply chain management: A total interpretive structural modeling approach. Global Journal of Flexible Systems Management 2016, 17, 171–188. [CrossRef]

- Tippayawong, K.; Niyomyat, N.; Sopadang, A.; Ramingwong, S. Factors affecting green supply chain operational performance of the Thai auto parts industry. Sustainability 2016, 8, 1161. [CrossRef]

- Tumpa, T.J.; Ali, S.M.; Rahman, M.H.; Paul, S.K.; Chowdhury, P.; Rehman Khan, S.A. Barriers to green supply chain management: An emerging economy context. Journal of Cleaner Production 2019, 236, 117617. [CrossRef]

- Wu, H.-H.; Chang, S.-Y. A case study of using DEMATEL method to identify critical factors in green supply chain management. Applied Mathematics and Computation 2015, 256, 394–403. [CrossRef]

- Wu, K.-J.; Liao, C.-J.; Tseng, M.-L.; Chiu, A.S. Exploring decisive factors in green supply chain practices under uncertainty. International Journal of Production Economics 2015, 159, 147–157. [CrossRef]

- Zhu, Q.; Sarkis, J. An inter-sectoral comparison of green supply chain management in China: drivers and practices. Journal of Cleaner Production 2006, 14, 472–486. [CrossRef]

- Drohomeretski, E.; Gouvea da Costa, S.; Pinheiro de Lima, E. Green supply chain management: drivers, barriers and practices within the Brazilian automotive industry. Journal of Manufacturing Technology Management 2014, 25, 1105–1134. [CrossRef]

- Attia, E.-A.; Alarjani, A.; Uddin, M.S.; Kineber, A.F. Examining the influence of sustainable construction supply chain drivers on sustainable building projects using mathematical structural equation modeling approach. Sustainability 2023, 15, 10671. [CrossRef]

- Mathiyazhagan, K.; Govindan, K.; NoorulHaq, A.; Geng, Y. An ISM approach for the barrier analysis in implementing green supply chain management. Journal of Cleaner Production 2013, 47, 283–297. [CrossRef]

- Kshitij Dashore, N.S. Green supply chain management: A hierarchical framework for barriers. International Journal of Engineering Trends and Technology 2013, 4, 2172–2182.

- Al Zaabi, S.; Al Dhaheri, N.; Diabat, A. Analysis of interaction between the barriers for the implementation of sustainable supply chain management. The International Journal of Advanced Manufacturing Technology 2013, 68, 895–905. [CrossRef]

- Meager, S.; Kumar, V.; Ekren, B.; Paddeu, D. Exploring the drivers and barriers to green supply chain management implementation: A study of independent UK restaurants. Procedia Manufacturing 2020, 51, 1642–1649. [CrossRef]

- Karmaker, C.L.; Ahmed, T.; Ahmed, S.; Ali, S.M.; Moktadir, M.A.; Kabir, G. Improving supply chain sustainability in the context of COVID-19 pandemic in an emerging economy: Exploring drivers using an integrated model. Sustainable Production and Consumption 2021, 26, 411–427. [CrossRef]

- Sajjad, A.; Eweje, G.; Tappin, D. Managerial perspectives on drivers for and barriers to sustainable supply chain management implementation: Evidence from New Zealand. Business Strategy and the Environment 2020, 29, 592–604. [CrossRef]

- Özaşkın, A.; Görener, A. An integrated multi-criteria decision-making approach for overcoming barriers to green supply chain management and prioritizing alternative solutions. Supply Chain Analytics 2023, 3, 100027. [CrossRef]

- Sumrit, D.; Jongprasittiphol, O. Exploring barriers in supply chain disaster management using fuzzy total interpretative structure modeling approach: Insight from Thai automotive industry. Asia Pacific Management Review 2023. [CrossRef]

- Malviya, R.K.; Kant, R. Identifying critical success factors for green supply chain management implementation using fuzzy DEMATEL method. In 2014 IEEE International Conference on Industrial Engineering and Engineering Management. 2014 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Selangor Darul Ehsan, Malaysia, 09–12 Dec. 2014; IEEE, 122014; pp 214–218, ISBN 978-1-4799-6410-9.

- Fan, L.; Yi, H. The influence factors analysis on response speed of agile supply chain. Advanced Materials Research 2012, 472-475, 3269–3272. [CrossRef]

- Guritno, A.D.; Fujianti, R.; Kusumasari, D. Assessment of the supply chain factors and classification of inventory management in suppliers’ level of fresh vegetables. Agriculture and Agricultural Science Procedia 2015, 3, 51–55. [CrossRef]

- Mohseni, S.; Baghizadeh, K.; Pahl, J. Evaluating barriers and drivers to sustainable food supply chains. Mathematical Problems in Engineering 2022, 2022, 1–24. [CrossRef]

- Akcan, S.; Taş, M.A. Green supplier evaluation with SWARA-TOPSIS integrated method to reduce ecological risk factors. Environmental Monitoring and Assessment 2019, 191, 226. [CrossRef]

- Mumtaz, U.; Ali, Y.; Petrillo, A.; Felice, F. de. Identifying the critical factors of green supply chain management: Environmental benefits in Pakistan. Sci. Total Environ. 2018, 640-641, 144–152. [CrossRef]

- Muduli, K.; Govindan, K.; Barve, A.; Kannan, D.; Geng, Y. Role of behavioural factors in green supply chain management implementation in Indian mining industries. Resources, Conservation and Recycling 2013, 76, 50–60. [CrossRef]

- Akman, G.; Pışkın, H. Evaluating green performance of suppliers via analytic network process and TOPSIS. Journal of Industrial Engineering 2013, 2013, 1–13. [CrossRef]

- Aslam, H.; Rashid, K.; Wahla, A.R.; Tahira, U. Drivers of green supply chain management practices and their impact on firm Performance: A developing country perspective. Journal of Quantitative Methods 2018, 2, 87–113. [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Confirmation of a measurement model for green supply chain management practices implementation. International Journal of Production Economics 2008, 111, 261–273. [CrossRef]

- Vasiliauskas, A.V.; Zinkevičiūtė, V.; Šimonytė, E. Implementation of the concept of green logistics reffering to it applications for road freight transport enterprises. Business: Theory and Practice 2013, 14, 43–50. [CrossRef]

- Uygun, Ö.; Dede, A. Performance evaluation of green supply chain management using integrated fuzzy multi-criteria decision making techniques. Computers & Industrial Engineering 2016, 102, 502–511. [CrossRef]

- Uddin, S.; Ali, S.M.; Kabir, G.; Suhi, S.A.; Enayet, R.; Haque, T. An AHP-ELECTRE framework to evaluate barriers to green supply chain management in the leather industry. International Journal of Sustainable Development & World Ecology 2019, 26, 732–751. [CrossRef]

- Song, W.; Xu, Z.; Liu, H.-C. Developing sustainable supplier selection criteria for solar air-conditioner manufacturer: An integrated approach. Renewable and Sustainable Energy Reviews 2017, 79, 1461–1471. [CrossRef]

- Kim, J.; Rhee, J. An empirical study on the impact of critical success factors on the balanced scorecard performance in Korean green supply chain management enterprises. International Journal of Production Research 2012, 50, 2465–2483. [CrossRef]

- Osintsev, N.; Rakhmangulov, A.; Sładkowski, A.; Dyorina, N. Logistic flow control system in green supply chains. In Ecology in Transport: Problems and Solutions; Sładkowski, A., Ed.; Springer International Publishing: Cham, 2020; pp 311–380, ISBN 978-3-030-42322-3.

- Kornilov, S.; Rakhmangulov, A.; Shaulsky, B. Logistics Basics. Moscow: FGBOU "Uchebno-metodicheskii tsentr po obrazovaniiu na zheleznodorozhnom transporte, 2016, ISBN 978-5-89035-918-6.

- Rakhmangulov, A.; Sladkowski, A.; Osintsev, N.; Muravev, D. Green logistics: a system of methods and instruments - Part 2. Naše more 2018, 65, 49–55. [CrossRef]

- Rakhmangulov, A.; Sładkowski, A.; Osintsev, N. Design of an ITS for industrial enterprises. In Intelligent Transportation Systems – Problems and Perspectives; Sładkowski, A., Pamuła, W., Eds.; Springer International Publishing: Cham, 2016; pp 161–215, ISBN 978-3-319-19149-2.

- Osintsev, N.; Kazarmshchikova, E. Factors of sustainable development of transport and logistics systems. Modern Problems of Russian Transport Complex 2017, 7, 13–21. [CrossRef]

- Osintsev, N.; Rakhmangulov, A.; Baginova, V. Evaluation of logistic flows in green supply chains based on the combined DEMATEL-ANP method. Facta Universitatis, Series: Mechanical Engineering 2021, 19, 473–498. [CrossRef]

- Gabus, A.; Fontela, E. World problems, an invitation to further thought within the framework of DEMATEL; Battelle Geneva Research Centre: Geneva, Switzerland, 1972.

- Puška, A.; Stević, Ž.; Pamučar, D. Evaluation and selection of healthcare waste incinerators using extended sustainability criteria and multi-criteria analysis methods. Environment, Development and Sustainability 2021, 32, 688. [CrossRef]

- Hwang, C.-L.; Yoon, K. Multiple attribute decision making: Methods and applications: a state-of-the-art survey; Springer Berlin Heidelberg: Berlin, Heidelberg, 1981, ISBN 3642483186.

- Zavadskas, E.K.; Turskis, Z. A new additive ratio assessment (ARAS) method in multicriteria decision-making. Technological and Economic Development of Economy 2010, 16, 159–172. [CrossRef]

- Stević, Ž.; Pamučar, D.; Puška, A.; Chatterjee, P. Sustainable supplier selection in healthcare industries using a new MCDM method: Measurement of alternatives and ranking according to COmpromise solution (MARCOS). Computers & Industrial Engineering 2020, 140, 106231. [CrossRef]

| Linguistic variables | Scale numbers | ||

|---|---|---|---|

| Crisp | Fuzzy | Grey | |

| No influence (N) | 0 | [0,0,0] | [0,0] |

| Low influence (L) | 1 | [0,1,2] | [0,1] |

| Medium influence (M) | 2 | [1,2,3] | [1,2] |

| High influence (H) | 3 | [2,3,4] | [2,3] |

| Very high influence (VH) | 4 | [3,4,4] | [3,4] |

| Steps | C-DEMATEL | F-DEMATEL | G-DEMATEL |

|---|---|---|---|

| III.1. Construction of the initial matrix of direct links between the criteria |

where C – initial matrix of direct relations, aij - degree of influence of i-th criterion on j-th criterion |

where – initial fuzzy matrix of direct relations, – degree of influence of i-th criterion on j-th criterion, represented by triangular fuzzy numbers |

where G – the initial gray matrix of direct relations, ⊗gij – the gray number showing the degree of influence of the i-th criterion on the j-th criterion. If is the upper boundary of the gray number and is its lower boundary, then |

| III.2. Normalization of the direct relations matrix |

, where – normalized matrix of direct relations |

where – normalized fuzzy matrix of direct relations, It is considered that there is at least one value i such that where 3 – number of values defining the fuzzy number |

where – normalized matrix of direct relations, – respectively, the lower and upper limits of the gray number, n - criteria number |

| III.3. Calculation of the total matrix of direct relations |

where – total matrix of direct relations between criteria |

тoгда где – total fuzzy matrix of direct relations between criteria; – fuzzy numbers of the total relational matrix, , |

где – total matrix of direct relations between criteria, I – single matrix |

| III.4. Calculation of the number of relationships (Di+Ri) and forces of influence (Di–Ri) between criteria | The sum of rows and the sum of columns are denoted, respectively, as vectors D and R in the total relation matrix T and are calculated by the following formulas |

Compute and , where and is the sum of the rows and the sum of the columns in the overall fuzzy relations matrix . Then the fuzzy numbers are converted to absolute values | The sums of rows ⊗Ri and the sums of columns ⊗Di in the total relation matrix Tg is calculated by the following formulas |

| III.5. Building a network relationship map of the criteria. Ranking of criteria according to the values of weighting coefficients calculated based on the results of the assessment of the number of interrelationships (Di + Ri) and the strength of influence (Di – Ri) between the criteria | |||

| № | Academic degree | Number of experts | Expert science interests | Work experience in the field of research |

|---|---|---|---|---|

| 1 | Professor, Doctor (Technical Science) | 1 | Supply chain management, Transport systems | 41 |

| 1 | Supply chain management, Logistics | 34 | ||

| 1 | Transport systems, Logistics | 18 | ||

| 2 | Assistant Professor (PhD) | 1 | Supply chain management | 17 |

| 1 | Transport systems, Warehouse systems | 17 |

| Criteria | C1 | C2 | C3 | C4 | C5 | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Experts | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | |

| Criteria | C1 | N | N | N | N | N | H | H | VH | H | H | H | H | VH | VH | VH | L | VH | M | M | M | VH | H | H | M | H |

| C2 | VH | H | L | VH | M | N | N | N | N | N | M | M | L | H | N | L | M | N | H | N | M | H | M | M | N | |

| C3 | VH | VH | VH | VH | H | H | VH | M | M | M | N | N | N | N | N | H | H | L | M | M | H | VH | H | L | M | |

| C4 | L | N | L | M | M | N | N | N | M | L | L | N | N | M | VH | N | N | N | N | N | L | N | N | M | L | |

| C5 | VH | VH | H | H | H | H | VH | M | H | VH | H | VH | H | M | L | H | VH | L | M | L | N | N | N | N | N | |

| Sub-criteria | C1.1 | C1.2 | C1.3 | C2.1 | C2.2 | |||||||||||||||||||||

| Experts | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | |

| Sub-criteria | C1.1 | N | N | N | N | N | M | M | VH | H | N | VH | VH | VH | VH | L | M | M | VH | L | N | L | H | VH | L | N |

| C1.2 | VH | VH | VH | H | VH | N | N | N | N | N | L | H | VH | H | N | M | H | VH | H | L | L | M | M | L | L | |

| C1.3 | H | H | VH | VH | VH | H | M | VH | H | H | N | N | N | N | N | L | VH | VH | H | H | L | H | VH | H | H | |

| C2.1 | H | VH | VH | H | L | VH | VH | VH | H | M | M | L | H | M | L | N | N | N | N | N | VH | VH | H | H | M | |

| C2.2 | M | H | L | L | N | H | H | L | L | H | M | L | H | M | H | H | VH | N | L | L | N | N | N | N | N | |

| C3.1 | VH | VH | H | H | VH | M | VH | M | H | H | L | L | N | L | M | L | H | VH | L | N | L | M | N | N | N | |

| C3.2 | H | H | H | H | VH | H | H | M | H | H | L | L | N | M | L | H | VH | L | M | N | M | M | N | L | N | |

| C3.3 | M | VH | L | L | M | H | VH | L | M | H | L | L | N | L | H | L | VH | M | L | L | M | M | N | L | M | |

| C4.1 | M | VH | L | L | M | H | VH | L | M | H | L | L | N | L | L | L | VH | M | M | M | L | VH | N | L | N | |

| C4.2 | L | VH | N | M | L | M | VH | M | H | M | L | L | N | L | M | M | H | M | H | L | M | H | N | M | N | |

| C4.3 | L | VH | L | L | M | M | VH | L | M | H | L | L | N | L | M | M | VH | L | M | N | H | H | N | L | N | |

| C4.4 | L | M | N | L | M | M | M | M | M | H | L | L | N | L | M | M | H | L | M | N | M | H | N | L | N | |

| C5.1 | H | VH | VH | VH | VH | H | VH | VH | VH | VH | H | H | N | M | M | VH | VH | VH | H | M | VH | VH | L | VH | H | |

| C5.2 | M | VH | VH | H | M | H | VH | L | VH | VH | M | M | N | M | VH | H | VH | M | VH | VH | M | VH | N | M | M | |

| C5.3 | M | L | M | H | L | M | VH | M | VH | L | L | H | N | L | L | H | VH | H | VH | L | M | VH | N | H | M | |

| Sub-criteria | C3.1 | C3.2 | C3.3 | C4.1 | C4.2 | |||||||||||||||||||||

| Experts | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | |

| Sub-criteria | C1.1 | M | H | VH | M | N | M | H | M | M | N | M | H | M | M | N | L | H | L | M | N | L | H | N | L | N |

| C1.2 | H | H | M | M | M | H | H | L | H | M | L | M | L | L | L | L | L | N | M | L | L | L | N | M | N | |

| C1.3 | M | M | H | M | VH | M | M | L | M | H | M | H | L | M | M | L | L | M | L | M | L | L | M | M | M | |

| C2.1 | L | L | M | L | N | L | L | L | H | N | L | H | L | M | N | L | VH | N | M | N | L | H | N | H | N | |

| C2.2 | L | N | N | L | N | L | N | N | L | N | L | N | N | L | N | L | N | N | L | N | L | N | N | L | N | |

| C3.1 | N | N | N | N | N | M | H | N | VH | L | M | H | N | L | L | L | L | L | M | L | M | N | N | H | N | |

| C3.2 | L | H | N | M | N | N | N | N | N | N | M | H | L | M | L | M | VH | L | H | M | L | VH | N | H | N | |

| C3.3 | M | H | H | L | M | VH | VH | H | M | H | N | N | N | N | N | L | VH | VH | M | M | L | VH | H | H | M | |

| C4.1 | L | H | L | M | L | H | VH | H | H | H | H | VH | L | H | L | N | N | N | N | N | M | VH | N | H | N | |

| C4.2 | H | H | H | M | M | M | VH | H | H | H | M | VH | M | H | VH | M | VH | M | M | H | N | N | N | N | N | |

| C4.3 | M | H | N | M | N | M | VH | L | H | N | M | VH | L | H | M | M | VH | VH | H | M | M | VH | L | H | H | |

| C4.4 | M | M | H | L | N | M | VH | H | M | N | M | VH | M | M | M | M | VH | M | M | L | H | VH | H | M | VH | |

| C5.1 | H | H | L | H | L | M | VH | H | H | L | H | H | L | H | L | M | VH | L | M | M | L | VH | N | VH | M | |

| C5.2 | M | VH | N | M | N | VH | VH | VH | VH | N | H | H | M | H | M | M | H | L | M | VH | L | M | N | H | L | |

| C5.3 | M | H | N | H | M | H | VH | VH | H | H | M | VH | L | H | N | M | VH | L | M | L | L | H | N | M | L | |

| Sub-criteria | C4.3 | C4.4 | C5.1 | C5.2 | C5.3 | |||||||||||||||||||||

| Experts | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | Ex1 | Ex2 | Ex3 | Ex4 | Ex5 | |

| Sub-criteria | C1.1 | L | H | N | L | N | L | H | N | L | N | M | VH | H | M | M | L | H | L | M | M | L | L | N | L | N |

| C1.2 | L | L | N | L | L | L | L | N | L | L | L | L | H | H | N | L | L | L | H | L | L | L | N | L | N | |

| C1.3 | M | M | L | L | M | L | L | N | L | M | L | L | H | M | H | M | M | M | H | H | L | L | L | M | L | |

| C2.1 | M | VH | N | H | N | M | H | L | H | N | H | L | VH | M | N | M | L | H | M | N | M | L | L | L | N | |

| C2.2 | L | N | N | L | N | L | N | N | L | N | L | N | N | L | N | L | N | N | L | N | L | N | N | L | N | |

| C3.1 | L | L | L | M | L | L | L | L | M | L | M | M | L | L | N | L | H | L | M | N | L | H | N | M | N | |

| C3.2 | L | VH | N | H | N | L | VH | N | H | N | L | L | L | L | N | H | M | VH | L | N | M | M | VH | L | N | |

| C3.3 | L | VH | VH | M | L | L | VH | H | M | L | L | L | M | L | N | M | H | VH | L | H | M | L | M | L | N | |

| C4.1 | M | VH | N | M | N | L | H | L | H | L | L | L | H | L | N | M | L | M | H | L | L | N | N | L | N | |

| C4.2 | L | H | L | H | M | M | VH | L | H | M | L | H | N | M | L | L | M | L | H | M | L | L | L | M | N | |

| C4.3 | N | N | N | N | N | L | M | L | H | L | L | L | H | H | N | H | M | L | H | M | M | M | N | L | N | |

| C4.4 | L | M | M | M | M | N | N | N | N | N | L | L | L | M | L | L | H | M | M | L | M | M | L | L | N | |

| C5.1 | H | VH | L | M | M | M | H | L | H | M | N | N | N | N | N | VH | H | M | H | VH | L | N | N | L | H | |

| C5.2 | H | M | M | M | L | L | H | M | H | L | L | N | N | H | N | N | N | N | N | N | L | N | N | L | N | |

| C5.3 | M | M | N | M | N | M | M | N | M | N | L | N | N | M | M | VH | M | M | H | L | N | N | N | N | N | |

| Supply chain elements | Drivers | Sub-criteria | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1.1 | C1.2 | C1.3 | C2.1 | C2.2 | C3.1 | C3.2 | C3.3 | C4.1 | C4.2 | C4.3 | C4.4 | C5.1 | C5.2 | C5.3 | ||

| Input element | D1.1 | 3.10 | 4.00 | 1.78 | 2.70 | 3.76 | 1.00 | 1.00 | 1.15 | 1.15 | 2.70 | 2.05 | 2.64 | 2.17 | 1.89 | 2.76 |

| D1.2 | 3.81 | 4.32 | 2.05 | 3.59 | 4.32 | 1.52 | 1.52 | 1.43 | 1.32 | 2.70 | 2.17 | 2.49 | 3.29 | 2.55 | 2.72 | |

| D1.3 | 4.13 | 4.37 | 2.41 | 3.29 | 3.10 | 3.90 | 4.32 | 4.32 | 4.13 | 3.37 | 3.57 | 3.57 | 2.86 | 3.10 | 2.86 | |

| D1.4 | 2.55 | 2.70 | 1.74 | 2.22 | 3.64 | 2.35 | 2.40 | 2.09 | 1.89 | 2.22 | 2.05 | 2.17 | 1.64 | 2.17 | 4.18 | |

| D1.5 | 3.90 | 4.32 | 1.74 | 3.52 | 3.13 | 3.57 | 4.32 | 4.18 | 3.81 | 2.86 | 3.37 | 3.00 | 2.17 | 2.76 | 4.78 | |

| D1.6 | 3.10 | 4.00 | 2.35 | 2.70 | 4.13 | 1.64 | 1.32 | 1.64 | 1.52 | 2.70 | 2.49 | 2.49 | 2.55 | 2.35 | 2.14 | |

| D1.7 | 2.05 | 2.55 | 1.89 | 2.00 | 1.82 | 1.89 | 1.43 | 1.52 | 1.43 | 1.93 | 1.32 | 1.32 | 1.32 | 1.43 | 1.55 | |

| D1.8 | 2.70 | 3.10 | 2.70 | 2.35 | 2.05 | 2.93 | 3.29 | 2.95 | 2.40 | 2.17 | 1.89 | 2.05 | 1.52 | 2.14 | 1.43 | |

| Processing element | D2.1 | 3.39 | 4.57 | 2.61 | 3.47 | 3.31 | 1.38 | 1.15 | 1.15 | 1.52 | 2.35 | 1.93 | 2.05 | 2.05 | 2.17 | 1.89 |

| D2.2 | 3.13 | 4.32 | 2.35 | 3.39 | 4.32 | 1.15 | 1.32 | 1.32 | 1.64 | 2.22 | 2.05 | 2.05 | 2.76 | 2.05 | 2.27 | |

| D2.3 | 3.10 | 3.57 | 3.98 | 3.59 | 4.78 | 1.74 | 1.74 | 1.78 | 1.89 | 1.78 | 1.78 | 1.64 | 2.35 | 2.22 | 2.05 | |

| D2.4 | 3.29 | 3.95 | 3.98 | 3.98 | 4.32 | 1.52 | 1.52 | 1.43 | 1.64 | 1.52 | 1.43 | 1.64 | 2.49 | 2.17 | 2.05 | |

| D2.5 | 2.86 | 3.18 | 3.98 | 3.59 | 5.00 | 1.15 | 1.32 | 1.32 | 1.32 | 1.43 | 1.32 | 1.32 | 1.52 | 1.89 | 1.89 | |

| D2.6 | 2.55 | 3.18 | 3.64 | 3.39 | 4.51 | 1.52 | 1.15 | 1.64 | 1.52 | 1.32 | 1.15 | 1.52 | 1.64 | 1.74 | 1.74 | |

| D2.7 | 3.68 | 3.90 | 3.18 | 3.44 | 4.08 | 1.15 | 1.32 | 2.55 | 2.22 | 2.70 | 2.22 | 2.70 | 3.29 | 2.49 | 2.76 | |

| D2.8 | 2.35 | 3.95 | 2.83 | 3.10 | 2.86 | 1.52 | 1.52 | 1.78 | 1.78 | 1.74 | 1.64 | 1.64 | 1.52 | 1.52 | 1.52 | |

| D2.9 | 2.70 | 3.57 | 1.32 | 2.83 | 3.13 | 1.32 | 1.32 | 2.00 | 1.74 | 1.52 | 1.52 | 1.64 | 1.52 | 1.64 | 1.32 | |

| Transport element | D3.1 | 1.74 | 3.10 | 4.37 | 2.72 | 2.40 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.32 | 1.15 | 1.15 |

| D3.2 | 2.49 | 3.95 | 4.57 | 3.81 | 3.39 | 2.27 | 2.05 | 2.09 | 2.00 | 1.89 | 1.78 | 1.64 | 2.35 | 2.35 | 1.78 | |

| D3.3 | 1.74 | 2.70 | 4.08 | 2.46 | 2.83 | 1.43 | 1.74 | 1.74 | 1.52 | 1.52 | 1.52 | 1.52 | 2.17 | 2.49 | 1.82 | |

| D3.4 | 3.25 | 3.68 | 4.13 | 4.37 | 4.32 | 1.52 | 1.32 | 1.43 | 1.15 | 1.15 | 1.15 | 1.15 | 1.43 | 1.32 | 1.15 | |

| D3.5 | 2.00 | 2.83 | 3.95 | 3.37 | 3.95 | 1.74 | 1.43 | 1.74 | 1.32 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | 1.15 | |

| D3.6 | 2.35 | 3.06 | 3.95 | 3.73 | 4.78 | 1.58 | 1.52 | 1.52 | 1.43 | 1.52 | 1.32 | 1.32 | 1.43 | 1.43 | 1.32 | |

| D3.7 | 3.59 | 4.08 | 4.37 | 3.18 | 3.10 | 3.13 | 3.25 | 3.13 | 2.99 | 2.22 | 2.35 | 2.05 | 1.74 | 3.59 | 1.82 | |

| D3.8 | 4.32 | 3.90 | 2.40 | 4.13 | 3.13 | 3.44 | 3.98 | 3.98 | 3.98 | 3.81 | 3.81 | 3.44 | 3.73 | 3.98 | 2.40 | |

| D3.9 | 2.49 | 2.86 | 2.35 | 2.49 | 2.40 | 3.17 | 2.61 | 2.27 | 2.61 | 2.61 | 2.46 | 2.61 | 2.35 | 2.30 | 2.17 | |

| D3.10 | 2.09 | 2.67 | 1.78 | 2.70 | 3.64 | 1.52 | 1.64 | 1.74 | 1.32 | 1.32 | 1.32 | 1.32 | 1.32 | 1.32 | 1.15 | |

| D3.11 | 2.49 | 2.83 | 3.68 | 3.95 | 3.39 | 3.68 | 1.32 | 1.32 | 1.52 | 1.15 | 1.15 | 1.15 | 1.32 | 1.32 | 1.15 | |

| D3.12 | 3.39 | 3.68 | 3.39 | 4.32 | 4.51 | 2.55 | 2.70 | 2.86 | 2.49 | 2.49 | 2.30 | 2.17 | 1.89 | 2.55 | 2.72 | |

| Cumulate element | D4.1 | 2.99 | 2.99 | 2.61 | 3.17 | 3.44 | 2.64 | 2.55 | 2.83 | 2.22 | 2.49 | 2.35 | 2.17 | 1.52 | 2.93 | 2.67 |

| D4.2 | 3.25 | 3.52 | 1.89 | 3.52 | 3.73 | 2.67 | 3.90 | 3.44 | 3.44 | 2.27 | 2.61 | 2.37 | 1.78 | 4.13 | 3.98 | |

| D4.3 | 2.99 | 3.64 | 2.41 | 3.29 | 2.86 | 2.22 | 3.44 | 4.08 | 3.31 | 3.47 | 3.31 | 3.47 | 3.31 | 3.47 | 3.10 | |

| D4.4 | 2.17 | 3.59 | 2.05 | 3.57 | 3.10 | 1.89 | 3.73 | 3.10 | 3.59 | 3.25 | 3.17 | 2.70 | 3.57 | 3.81 | 2.00 | |

| D4.5 | 2.35 | 2.70 | 3.02 | 3.31 | 3.90 | 1.64 | 1.64 | 1.32 | 1.32 | 1.43 | 1.32 | 1.32 | 1.15 | 1.89 | 1.32 | |

| D4.6 | 3.31 | 4.08 | 2.27 | 3.39 | 3.59 | 1.58 | 1.58 | 1.82 | 1.58 | 1.52 | 1.52 | 1.52 | 1.32 | 1.82 | 1.58 | |

| D4.7 | 2.86 | 3.25 | 3.31 | 4.08 | 4.57 | 2.17 | 2.35 | 1.89 | 2.00 | 1.74 | 2.00 | 1.89 | 1.74 | 2.35 | 1.52 | |

| D4.8 | 2.35 | 2.70 | 3.31 | 3.59 | 4.51 | 1.64 | 1.78 | 1.74 | 1.74 | 1.89 | 1.74 | 1.52 | 1.52 | 2.55 | 1.64 | |

| D4.9 | 3.29 | 3.44 | 2.51 | 3.90 | 4.32 | 1.97 | 1.97 | 1.64 | 2.30 | 2.27 | 2.17 | 1.78 | 2.40 | 2.14 | 1.64 | |

| D4.10 | 2.35 | 2.99 | 1.64 | 3.18 | 3.10 | 1.74 | 2.70 | 3.17 | 2.35 | 2.00 | 1.52 | 1.89 | 1.52 | 3.31 | 1.58 | |

| D4.11 | 2.40 | 3.10 | 2.05 | 3.44 | 3.52 | 2.00 | 2.49 | 3.03 | 2.17 | 2.14 | 1.82 | 1.82 | 1.58 | 3.44 | 1.55 | |

| Output element | D5.1 | 2.46 | 2.70 | 1.55 | 2.22 | 1.89 | 1.32 | 1.32 | 2.05 | 1.78 | 1.64 | 1.55 | 1.43 | 1.52 | 1.89 | 1.74 |

| D5.2 | 3.06 | 3.25 | 2.30 | 3.78 | 4.13 | 2.83 | 3.18 | 3.52 | 2.35 | 2.22 | 2.30 | 2.30 | 1.52 | 2.55 | 3.37 | |

| D5.3 | 2.86 | 3.57 | 2.35 | 3.64 | 3.44 | 2.17 | 1.52 | 2.70 | 2.35 | 2.61 | 1.89 | 2.00 | 2.64 | 2.05 | 2.61 | |

| D5.4 | 2.86 | 3.52 | 2.17 | 3.29 | 3.90 | 2.99 | 2.05 | 2.35 | 1.89 | 2.00 | 1.64 | 1.74 | 2.86 | 1.89 | 1.43 | |

| D5.5 | 1.89 | 2.17 | 1.89 | 2.05 | 3.68 | 1.64 | 1.52 | 1.52 | 1.32 | 1.32 | 1.32 | 1.32 | 1.64 | 1.89 | 1.52 | |

| D5.6 | 2.55 | 2.64 | 2.35 | 2.70 | 2.49 | 2.35 | 3.57 | 3.81 | 2.35 | 2.55 | 2.05 | 1.89 | 1.52 | 3.13 | 1.89 | |

| Control element | D6.1 | 2.35 | 2.30 | 2.14 | 3.03 | 3.81 | 1.64 | 1.52 | 1.93 | 1.32 | 1.25 | 1.15 | 1.32 | 1.78 | 1.55 | 1.89 |

| D6.2 | 2.05 | 2.77 | 1.64 | 2.64 | 3.59 | 1.64 | 1.52 | 1.89 | 1.32 | 1.15 | 1.15 | 1.32 | 1.64 | 1.43 | 1.64 | |

| D6.3 | 3.52 | 3.25 | 3.73 | 3.10 | 2.49 | 2.83 | 3.52 | 3.98 | 3.44 | 2.70 | 2.55 | 2.70 | 2.70 | 3.37 | 1.89 | |

| D6.4 | 3.44 | 3.73 | 4.08 | 3.29 | 3.29 | 3.52 | 3.73 | 3.76 | 3.59 | 3.44 | 3.03 | 3.03 | 2.55 | 3.90 | 2.86 | |

| D6.5 | 3.73 | 3.68 | 4.13 | 3.73 | 3.29 | 3.73 | 4.13 | 4.32 | 3.59 | 3.13 | 3.17 | 3.17 | 2.35 | 4.32 | 3.73 | |

| D6.6 | 2.35 | 2.35 | 1.32 | 2.17 | 2.93 | 1.89 | 1.74 | 1.64 | 1.52 | 1.43 | 1.43 | 1.43 | 1.15 | 1.15 | 1.15 | |

| D6.7 | 3.52 | 3.73 | 2.64 | 3.81 | 4.13 | 1.52 | 1.32 | 2.22 | 2.27 | 2.40 | 1.97 | 2.09 | 2.99 | 1.78 | 2.27 | |

| D6.8 | 3.10 | 3.95 | 2.30 | 3.48 | 3.90 | 1.64 | 1.32 | 1.78 | 2.05 | 2.40 | 2.17 | 2.00 | 2.61 | 2.05 | 2.35 | |

| Criteria | Sub-criteria | Local weight | Global weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Crisp | Fuzzy | Grey | Crisp | Fuzzy | Grey | ||||||

| Economic (С1) | Profit (C1.1) | 0.241 | 0.345 | 0.233 | 0.345 | 0.244 | 0.351 | 0.083 | 0.081 | 0.086 | |

| Operating expenses (C1.2) | 0.316 | 0.318 | 0.311 | 0.076 | 0.074 | 0.076 | |||||

| Fixed investment (C1.3) | 0.338 | 0.336 | 0.337 | 0.082 | 0.078 | 0.083 | |||||

| Energy-ecological (С2) | The energy intensity (C2.1) | 0.190 | 0.521 | 0.192 | 0.500 | 0.189 | 0.500 | 0.099 | 0.096 | 0.095 | |

| Greenhouse gas emissions of CO2 (C2.2) | 0.478 | 0.500 | 0.500 | 0.091 | 0.096 | 0.095 | |||||

| Quality (С3) | Safety of cargo transportation (C3.1) | 0.220 | 0.292 | 0.215 | 0.304 | 0.221 | 0.288 | 0.064 | 0.066 | 0.064 | |

| Timeliness of cargo transportation (C3.2) | 0.348 | 0.345 | 0.351 | 0.077 | 0.075 | 0.078 | |||||

| The coefficient of flow controllability (C3.3) | 0.358 | 0.350 | 0.360 | 0.079 | 0.076 | 0.080 | |||||

| Statistical (С4) | The coefficient of flows irregularity (C4.1) | 0.135 | 0.247 | 0.147 | 0.246 | 0.130 | 0.247 | 0.034 | 0.036 | 0.032 | |

| The coefficient of complexity structure of flow (C4.2) | 0.266 | 0.263 | 0.267 | 0.036 | 0.039 | 0.035 | |||||

| The coefficient of flows discreteness (C.4.3) | 0.238 | 0.240 | 0.237 | 0.032 | 0.036 | 0.031 | |||||

| The coefficient of differentiability of flow (C4.4) | 0.247 | 0.249 | 0.246 | 0.034 | 0.037 | 0.032 | |||||

| Flow physical (С5) |

The mass (quantity) of flow (C5.1) | 0.212 | 0.329 | 0.211 | 0.326 | 0.213 | 0.330 | 0.070 | 0.069 | 0.071 | |

| The speed of flow (C5.2) | 0.397 | 0.385 | 0.404 | 0.085 | 0.081 | 0.086 | |||||

| The length of the route (C5.3) | 0.273 | 0.288 | 0.264 | 0.058 | 0.061 | 0.057 | |||||

| Drivers | Method | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C-DEMATEL-CRADIS | F-DEMATEL-CRADIS | G-DEMATEL-CRADIS | ||||||||||||||||

| s+ | s- | K+ | K- | Q | Rank | s+ | s- | K+ | K- | Q | Rank | s+ | s- | K+ | K- | Q | Rank | |

| D1.1 | 0.995 | 0.348 | 0.487 | 0.405 | 0.446 | 54 | 0.953 | 0.339 | 0.466 | 0.400 | 0.433 | 54 | 0.937 | 0.355 | 0.453 | 0.409 | 0.431 | 54 |

| D1.2 | 0.951 | 0.392 | 0.510 | 0.456 | 0.483 | 49 | 0.911 | 0.381 | 0.487 | 0.449 | 0.468 | 49 | 0.891 | 0.401 | 0.476 | 0.462 | 0.469 | 47 |

| D1.3 | 0.810 | 0.533 | 0.599 | 0.621 | 0.610 | 6 | 0.775 | 0.517 | 0.572 | 0.609 | 0.591 | 7 | 0.745 | 0.546 | 0.569 | 0.629 | 0.599 | 5 |

| D1.4 | 0.925 | 0.419 | 0.525 | 0.488 | 0.506 | 37 | 0.885 | 0.408 | 0.502 | 0.480 | 0.491 | 38 | 0.866 | 0.426 | 0.490 | 0.491 | 0.490 | 37 |

| D1.5 | 0.862 | 0.481 | 0.563 | 0.561 | 0.562 | 10 | 0.826 | 0.466 | 0.537 | 0.550 | 0.543 | 13 | 0.798 | 0.494 | 0.531 | 0.569 | 0.550 | 10 |

| D1.6 | 0.951 | 0.392 | 0.510 | 0.457 | 0.483 | 48 | 0.911 | 0.381 | 0.487 | 0.449 | 0.468 | 48 | 0.892 | 0.400 | 0.476 | 0.461 | 0.468 | 50 |

| D1.7 | 0.871 | 0.472 | 0.557 | 0.550 | 0.554 | 14 | 0.823 | 0.469 | 0.539 | 0.553 | 0.546 | 12 | 0.813 | 0.478 | 0.521 | 0.551 | 0.536 | 16 |

| D1.8 | 0.815 | 0.529 | 0.595 | 0.616 | 0.606 | 7 | 0.773 | 0.520 | 0.574 | 0.613 | 0.594 | 6 | 0.754 | 0.538 | 0.563 | 0.620 | 0.591 | 7 |

| D2.1 | 0.968 | 0.375 | 0.501 | 0.437 | 0.469 | 51 | 0.925 | 0.367 | 0.480 | 0.433 | 0.456 | 51 | 0.908 | 0.384 | 0.467 | 0.442 | 0.455 | 51 |

| D2.2 | 0.980 | 0.363 | 0.495 | 0.423 | 0.459 | 53 | 0.939 | 0.353 | 0.473 | 0.417 | 0.445 | 53 | 0.921 | 0.371 | 0.461 | 0.428 | 0.444 | 53 |

| D2.3 | 0.917 | 0.426 | 0.529 | 0.497 | 0.513 | 32 | 0.877 | 0.416 | 0.506 | 0.490 | 0.498 | 35 | 0.857 | 0.434 | 0.495 | 0.501 | 0.498 | 31 |

| D2.4 | 0.920 | 0.423 | 0.527 | 0.493 | 0.510 | 35 | 0.878 | 0.415 | 0.506 | 0.489 | 0.497 | 36 | 0.860 | 0.431 | 0.493 | 0.497 | 0.495 | 34 |

| D2.5 | 0.935 | 0.408 | 0.519 | 0.475 | 0.497 | 42 | 0.891 | 0.401 | 0.498 | 0.473 | 0.485 | 42 | 0.877 | 0.414 | 0.483 | 0.477 | 0.480 | 42 |

| D2.6 | 0.930 | 0.413 | 0.521 | 0.481 | 0.501 | 41 | 0.885 | 0.407 | 0.501 | 0.480 | 0.490 | 40 | 0.872 | 0.419 | 0.486 | 0.483 | 0.485 | 41 |

| D2.7 | 0.929 | 0.414 | 0.522 | 0.483 | 0.502 | 39 | 0.891 | 0.401 | 0.498 | 0.473 | 0.485 | 41 | 0.867 | 0.424 | 0.489 | 0.489 | 0.489 | 38 |

| D2.8 | 0.947 | 0.396 | 0.512 | 0.461 | 0.487 | 46 | 0.902 | 0.390 | 0.492 | 0.460 | 0.476 | 46 | 0.888 | 0.403 | 0.477 | 0.465 | 0.471 | 46 |

| D2.9 | 0.949 | 0.394 | 0.511 | 0.459 | 0.485 | 47 | 0.904 | 0.389 | 0.491 | 0.458 | 0.475 | 47 | 0.891 | 0.400 | 0.476 | 0.461 | 0.469 | 49 |

| D3.1 | 0.877 | 0.467 | 0.553 | 0.544 | 0.548 | 17 | 0.827 | 0.465 | 0.537 | 0.548 | 0.542 | 14 | 0.820 | 0.471 | 0.517 | 0.543 | 0.530 | 17 |

| D3.2 | 0.887 | 0.456 | 0.547 | 0.532 | 0.539 | 20 | 0.846 | 0.447 | 0.525 | 0.526 | 0.526 | 21 | 0.826 | 0.465 | 0.513 | 0.536 | 0.525 | 18 |

| D3.3 | 0.862 | 0.481 | 0.562 | 0.560 | 0.561 | 11 | 0.820 | 0.473 | 0.541 | 0.557 | 0.549 | 10 | 0.804 | 0.487 | 0.527 | 0.562 | 0.544 | 11 |

| D3.4 | 0.899 | 0.444 | 0.540 | 0.518 | 0.529 | 27 | 0.851 | 0.441 | 0.521 | 0.520 | 0.521 | 25 | 0.841 | 0.450 | 0.504 | 0.519 | 0.511 | 27 |

| D3.5 | 0.897 | 0.446 | 0.541 | 0.520 | 0.530 | 26 | 0.849 | 0.443 | 0.523 | 0.522 | 0.522 | 24 | 0.841 | 0.451 | 0.504 | 0.520 | 0.512 | 26 |

| D3.6 | 0.929 | 0.414 | 0.522 | 0.483 | 0.502 | 40 | 0.884 | 0.408 | 0.502 | 0.481 | 0.492 | 37 | 0.872 | 0.420 | 0.486 | 0.484 | 0.485 | 40 |

| D3.7 | 0.808 | 0.535 | 0.600 | 0.623 | 0.612 | 5 | 0.771 | 0.521 | 0.575 | 0.614 | 0.595 | 5 | 0.746 | 0.546 | 0.568 | 0.629 | 0.599 | 6 |

| D3.8 | 0.798 | 0.545 | 0.608 | 0.636 | 0.622 | 3 | 0.764 | 0.529 | 0.581 | 0.623 | 0.602 | 3 | 0.732 | 0.559 | 0.579 | 0.645 | 0.612 | 3 |

| D3.9 | 0.868 | 0.475 | 0.559 | 0.554 | 0.556 | 12 | 0.828 | 0.465 | 0.536 | 0.548 | 0.542 | 15 | 0.807 | 0.485 | 0.526 | 0.559 | 0.542 | 12 |

| D3.10 | 0.919 | 0.424 | 0.528 | 0.494 | 0.511 | 34 | 0.872 | 0.421 | 0.509 | 0.496 | 0.502 | 31 | 0.863 | 0.429 | 0.491 | 0.494 | 0.493 | 35 |

| D3.11 | 0.869 | 0.474 | 0.558 | 0.552 | 0.555 | 13 | 0.820 | 0.472 | 0.541 | 0.556 | 0.549 | 11 | 0.812 | 0.480 | 0.522 | 0.553 | 0.538 | 15 |

| D3.12 | 0.913 | 0.430 | 0.531 | 0.502 | 0.516 | 30 | 0.875 | 0.417 | 0.507 | 0.492 | 0.500 | 33 | 0.851 | 0.441 | 0.498 | 0.508 | 0.503 | 30 |

| D4.1 | 0.896 | 0.448 | 0.542 | 0.522 | 0.532 | 24 | 0.857 | 0.435 | 0.518 | 0.513 | 0.516 | 27 | 0.834 | 0.457 | 0.508 | 0.527 | 0.517 | 24 |

| D4.2 | 0.873 | 0.470 | 0.555 | 0.547 | 0.551 | 16 | 0.837 | 0.455 | 0.530 | 0.536 | 0.533 | 17 | 0.811 | 0.481 | 0.523 | 0.554 | 0.539 | 14 |

| D4.3 | 0.851 | 0.493 | 0.570 | 0.574 | 0.572 | 9 | 0.816 | 0.477 | 0.544 | 0.562 | 0.553 | 9 | 0.787 | 0.505 | 0.539 | 0.582 | 0.560 | 9 |

| D4.4 | 0.873 | 0.470 | 0.556 | 0.548 | 0.552 | 15 | 0.836 | 0.456 | 0.531 | 0.538 | 0.534 | 16 | 0.810 | 0.482 | 0.523 | 0.555 | 0.539 | 13 |

| D4.5 | 0.917 | 0.426 | 0.529 | 0.497 | 0.513 | 31 | 0.871 | 0.421 | 0.510 | 0.497 | 0.503 | 30 | 0.860 | 0.432 | 0.493 | 0.498 | 0.496 | 33 |

| D4.6 | 0.944 | 0.400 | 0.514 | 0.466 | 0.490 | 45 | 0.899 | 0.393 | 0.494 | 0.464 | 0.479 | 43 | 0.885 | 0.407 | 0.479 | 0.469 | 0.474 | 45 |

| D4.7 | 0.918 | 0.426 | 0.529 | 0.496 | 0.512 | 33 | 0.876 | 0.416 | 0.506 | 0.490 | 0.498 | 34 | 0.858 | 0.434 | 0.494 | 0.500 | 0.497 | 32 |

| D4.8 | 0.926 | 0.417 | 0.523 | 0.486 | 0.504 | 38 | 0.885 | 0.408 | 0.502 | 0.480 | 0.491 | 39 | 0.868 | 0.424 | 0.489 | 0.488 | 0.489 | 39 |

| D4.9 | 0.940 | 0.403 | 0.516 | 0.470 | 0.493 | 44 | 0.899 | 0.393 | 0.494 | 0.464 | 0.479 | 44 | 0.880 | 0.412 | 0.482 | 0.475 | 0.478 | 44 |

| D4.10 | 0.887 | 0.456 | 0.547 | 0.532 | 0.539 | 19 | 0.846 | 0.447 | 0.525 | 0.527 | 0.526 | 20 | 0.827 | 0.465 | 0.513 | 0.536 | 0.524 | 19 |

| D4.11 | 0.892 | 0.451 | 0.544 | 0.525 | 0.534 | 23 | 0.852 | 0.441 | 0.521 | 0.519 | 0.520 | 26 | 0.832 | 0.459 | 0.510 | 0.530 | 0.520 | 23 |

| D5.1 | 0.887 | 0.456 | 0.547 | 0.531 | 0.539 | 21 | 0.841 | 0.451 | 0.528 | 0.532 | 0.530 | 19 | 0.828 | 0.463 | 0.512 | 0.534 | 0.523 | 20 |

| D5.2 | 0.907 | 0.436 | 0.534 | 0.508 | 0.521 | 28 | 0.869 | 0.423 | 0.511 | 0.499 | 0.505 | 29 | 0.846 | 0.446 | 0.501 | 0.514 | 0.507 | 28 |

| D5.3 | 0.940 | 0.403 | 0.516 | 0.470 | 0.493 | 43 | 0.899 | 0.393 | 0.494 | 0.463 | 0.478 | 45 | 0.879 | 0.412 | 0.482 | 0.475 | 0.479 | 43 |

| D5.4 | 0.889 | 0.454 | 0.545 | 0.529 | 0.537 | 22 | 0.846 | 0.446 | 0.524 | 0.526 | 0.525 | 22 | 0.830 | 0.462 | 0.511 | 0.532 | 0.522 | 22 |

| D5.5 | 0.885 | 0.458 | 0.548 | 0.534 | 0.541 | 18 | 0.840 | 0.453 | 0.529 | 0.534 | 0.531 | 18 | 0.830 | 0.462 | 0.511 | 0.532 | 0.522 | 21 |

| D5.6 | 0.823 | 0.520 | 0.589 | 0.606 | 0.598 | 8 | 0.784 | 0.508 | 0.566 | 0.599 | 0.583 | 8 | 0.762 | 0.530 | 0.557 | 0.611 | 0.584 | 8 |

| D6.1 | 0.908 | 0.435 | 0.534 | 0.507 | 0.521 | 29 | 0.862 | 0.431 | 0.515 | 0.507 | 0.511 | 28 | 0.851 | 0.441 | 0.498 | 0.508 | 0.503 | 29 |

| D6.2 | 0.920 | 0.423 | 0.527 | 0.493 | 0.510 | 36 | 0.873 | 0.420 | 0.509 | 0.494 | 0.501 | 32 | 0.864 | 0.428 | 0.491 | 0.493 | 0.492 | 36 |

| D6.3 | 0.780 | 0.564 | 0.622 | 0.657 | 0.639 | 1 | 0.744 | 0.549 | 0.597 | 0.647 | 0.622 | 1 | 0.716 | 0.576 | 0.592 | 0.664 | 0.628 | 1 |

| D6.4 | 0.802 | 0.541 | 0.605 | 0.630 | 0.618 | 4 | 0.768 | 0.524 | 0.578 | 0.618 | 0.598 | 4 | 0.738 | 0.553 | 0.574 | 0.638 | 0.606 | 4 |

| D6.5 | 0.782 | 0.561 | 0.620 | 0.654 | 0.637 | 2 | 0.749 | 0.543 | 0.592 | 0.640 | 0.616 | 2 | 0.717 | 0.574 | 0.591 | 0.662 | 0.626 | 2 |

| D6.6 | 0.896 | 0.447 | 0.541 | 0.521 | 0.531 | 25 | 0.849 | 0.443 | 0.523 | 0.522 | 0.522 | 23 | 0.840 | 0.452 | 0.505 | 0.521 | 0.513 | 25 |

| D6.7 | 0.952 | 0.391 | 0.509 | 0.456 | 0.482 | 50 | 0.912 | 0.380 | 0.487 | 0.448 | 0.467 | 50 | 0.891 | 0.400 | 0.476 | 0.461 | 0.469 | 48 |

| D6.8 | 0.970 | 0.374 | 0.500 | 0.435 | 0.468 | 52 | 0.929 | 0.364 | 0.478 | 0.429 | 0.453 | 52 | 0.909 | 0.382 | 0.466 | 0.441 | 0.453 | 52 |

| s0 | 0.485 | 0.858 | 0.444 | 0.849 | 0.424 | 0.867 | ||||||||||||

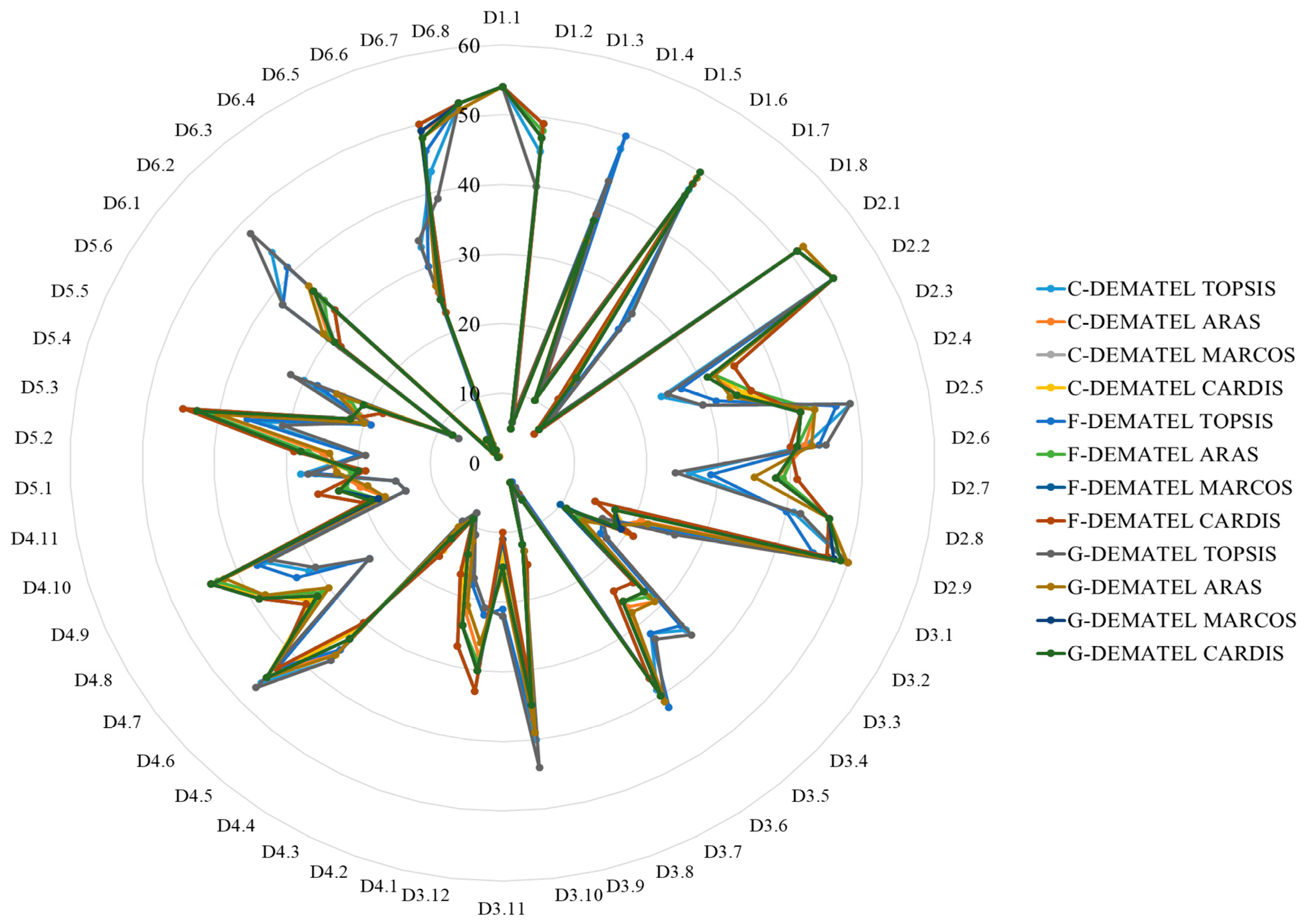

| Supply chain elements |

Drivers | C-DEMATEL TOPSIS | C-DEMATEL ARAS | C-DEMATEL MARCOS | C-DEMATEL CARDIS | F-DEMATEL TOPSIS | F-DEMATEL ARAS | F-DEMATEL MARCOS | F-DEMATEL CARDIS | G-DEMATEL TOPSIS | G-DEMATEL ARAS | G-DEMATEL MARCOS | G-DEMATEL CARDIS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Input element | D1.1 | 54 | 54 | 54 | 54 | 54 | 54 | 54 | 54 | 54 | 54 | 54 | 54 |

| D1.2 | 45 | 47 | 49 | 49 | 49 | 48 | 49 | 49 | 40 | 47 | 47 | 47 | |

| D1.3 | 6 | 5 | 6 | 6 | 6 | 5 | 7 | 7 | 6 | 5 | 5 | 5 | |

| D1.4 | 48 | 33 | 37 | 37 | 50 | 37 | 38 | 38 | 43 | 34 | 37 | 37 | |

| D1.5 | 12 | 10 | 10 | 10 | 13 | 10 | 13 | 13 | 12 | 10 | 10 | 10 | |

| D1.6 | 47 | 48 | 48 | 48 | 48 | 49 | 48 | 48 | 46 | 49 | 50 | 50 | |

| D1.7 | 27 | 16 | 14 | 14 | 25 | 16 | 12 | 12 | 28 | 15 | 16 | 16 | |

| D1.8 | 9 | 7 | 7 | 7 | 8 | 7 | 6 | 6 | 9 | 7 | 7 | 7 | |

| Processing element | D2.1 | 51 | 52 | 51 | 51 | 51 | 51 | 51 | 51 | 51 | 52 | 51 | 51 |

| D2.2 | 53 | 53 | 53 | 53 | 53 | 53 | 53 | 53 | 53 | 53 | 53 | 53 | |

| D2.3 | 24 | 32 | 32 | 32 | 27 | 32 | 35 | 35 | 25 | 32 | 31 | 31 | |

| D2.4 | 29 | 34 | 36 | 35 | 31 | 36 | 36 | 36 | 29 | 33 | 34 | 34 | |

| D2.5 | 49 | 44 | 42 | 42 | 47 | 44 | 42 | 42 | 49 | 44 | 42 | 42 | |

| D2.6 | 42 | 42 | 41 | 41 | 44 | 41 | 40 | 40 | 45 | 43 | 41 | 41 | |

| D2.7 | 26 | 38 | 39 | 39 | 29 | 39 | 41 | 41 | 24 | 35 | 38 | 38 | |

| D2.8 | 41 | 46 | 46 | 46 | 40 | 46 | 46 | 46 | 42 | 46 | 46 | 46 | |

| D2.9 | 50 | 50 | 47 | 47 | 45 | 47 | 47 | 47 | 50 | 50 | 48 | 49 | |

| Transport element | D3.1 | 25 | 21 | 17 | 17 | 24 | 17 | 14 | 14 | 26 | 22 | 17 | 17 |

| D3.2 | 16 | 18 | 20 | 20 | 16 | 19 | 21 | 21 | 16 | 18 | 19 | 18 | |

| D3.3 | 18 | 14 | 11 | 11 | 17 | 13 | 10 | 11 | 18 | 14 | 11 | 11 | |

| D3.4 | 35 | 29 | 27 | 27 | 34 | 28 | 25 | 25 | 36 | 29 | 27 | 27 | |

| D3.5 | 32 | 27 | 26 | 26 | 32 | 26 | 24 | 24 | 33 | 28 | 26 | 26 | |

| D3.6 | 39 | 41 | 40 | 40 | 42 | 40 | 37 | 37 | 41 | 41 | 40 | 40 | |

| D3.7 | 4 | 6 | 5 | 5 | 3 | 6 | 5 | 5 | 4 | 6 | 6 | 6 | |

| D3.8 | 5 | 3 | 3 | 3 | 5 | 3 | 3 | 3 | 5 | 3 | 3 | 3 | |

| D3.9 | 13 | 13 | 12 | 12 | 12 | 12 | 15 | 15 | 13 | 13 | 12 | 12 | |

| D3.10 | 40 | 37 | 34 | 34 | 39 | 35 | 31 | 31 | 44 | 39 | 35 | 35 | |

| D3.11 | 22 | 15 | 13 | 13 | 21 | 15 | 11 | 10 | 22 | 16 | 15 | 15 | |

| D3.12 | 21 | 28 | 30 | 30 | 22 | 29 | 33 | 33 | 21 | 26 | 30 | 30 | |

| Cumulate element | D4.1 | 17 | 22 | 24 | 24 | 18 | 24 | 27 | 27 | 17 | 21 | 24 | 24 |

| D4.2 | 11 | 12 | 16 | 16 | 11 | 14 | 17 | 17 | 11 | 12 | 14 | 14 | |

| D4.3 | 8 | 9 | 9 | 9 | 9 | 9 | 9 | 9 | 8 | 9 | 9 | 9 | |

| D4.4 | 10 | 11 | 15 | 15 | 10 | 11 | 16 | 16 | 10 | 11 | 13 | 13 | |

| D4.5 | 37 | 35 | 31 | 31 | 35 | 33 | 30 | 30 | 37 | 36 | 33 | 33 | |

| D4.6 | 46 | 45 | 45 | 45 | 43 | 45 | 43 | 43 | 47 | 45 | 45 | 45 | |

| D4.7 | 23 | 31 | 33 | 33 | 23 | 31 | 34 | 34 | 23 | 30 | 32 | 32 | |

| D4.8 | 31 | 39 | 38 | 38 | 33 | 38 | 39 | 39 | 30 | 38 | 39 | 39 | |

| D4.9 | 36 | 43 | 44 | 44 | 37 | 43 | 44 | 44 | 35 | 42 | 44 | 44 | |

| D4.10 | 14 | 17 | 19 | 19 | 14 | 18 | 20 | 20 | 14 | 17 | 18 | 19 | |

| D4.11 | 15 | 20 | 23 | 23 | 15 | 22 | 26 | 26 | 15 | 19 | 23 | 23 | |

| Output element | D5.1 | 28 | 23 | 21 | 21 | 26 | 21 | 19 | 19 | 27 | 23 | 20 | 20 |

| D5.2 | 20 | 25 | 28 | 28 | 20 | 27 | 29 | 29 | 19 | 24 | 28 | 28 | |

| D5.3 | 34 | 40 | 43 | 43 | 36 | 42 | 45 | 45 | 31 | 40 | 43 | 43 | |

| D5.4 | 19 | 19 | 22 | 22 | 19 | 20 | 22 | 22 | 20 | 20 | 22 | 22 | |

| D5.5 | 30 | 24 | 18 | 18 | 28 | 23 | 18 | 18 | 32 | 25 | 21 | 21 | |

| D5.6 | 7 | 8 | 8 | 8 | 7 | 8 | 8 | 8 | 7 | 8 | 8 | 8 | |

| Control element | D6.1 | 38 | 30 | 29 | 29 | 38 | 30 | 28 | 28 | 38 | 31 | 29 | 29 |

| D6.2 | 44 | 36 | 35 | 36 | 41 | 34 | 32 | 32 | 48 | 37 | 36 | 36 | |

| D6.3 | 1 | 2 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 1 | 1 | |

| D6.4 | 2 | 4 | 4 | 4 | 2 | 4 | 4 | 4 | 2 | 4 | 4 | 4 | |

| D6.5 | 3 | 1 | 2 | 2 | 4 | 2 | 2 | 2 | 3 | 1 | 2 | 2 | |

| D6.6 | 33 | 26 | 25 | 25 | 30 | 25 | 23 | 23 | 34 | 27 | 25 | 25 | |

| D6.7 | 43 | 49 | 50 | 50 | 46 | 50 | 50 | 50 | 39 | 48 | 49 | 48 | |

| D6.8 | 52 | 51 | 52 | 52 | 52 | 52 | 52 | 52 | 52 | 51 | 52 | 52 |

| MCDM model | C-DEMATEL TOPSIS | C-DEMATEL ARAS | C-DEMATEL MARCOS | C-DEMATEL CARDIS | F-DEMATEL TOPSIS | F-DEMATEL ARAS | F-DEMATEL MARCOS | F-DEMATEL CARDIS | G-DEMATEL TOPSIS | G-DEMATEL ARAS | G-DEMATEL MARCOS | G-DEMATEL CARDIS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C-DEMATEL TOPSIS | 1.000 | 0.945 | 0.917 | 0.918 | 0.994 | 0.934 | 0.884 | 0.884 | 0.995 | 0.955 | 0.929 | 0.929 |

| C-DEMATEL ARAS | 0.945 | 1.000 | 0.991 | 0.991 | 0.957 | 0.996 | 0.978 | 0.977 | 0.932 | 0.999 | 0.994 | 0.994 |

| C-DEMATEL MARCOS | 0.917 | 0.991 | 1.000 | 1.000 | 0.937 | 0.997 | 0.995 | 0.995 | 0.898 | 0.986 | 0.998 | 0.998 |

| C-DEMATEL CARDIS | 0.918 | 0.991 | 1.000 | 1.000 | 0.938 | 0.996 | 0.994 | 0.994 | 0.899 | 0.987 | 0.998 | 0.998 |

| F-DEMATEL TOPSIS | 0.994 | 0.957 | 0.937 | 0.938 | 1.000 | 0.951 | 0.909 | 0.908 | 0.983 | 0.965 | 0.945 | 0.945 |

| F-DEMATEL ARAS | 0.934 | 0.996 | 0.997 | 0.996 | 0.951 | 1.000 | 0.989 | 0.988 | 0.917 | 0.993 | 0.998 | 0.998 |

| F-DEMATEL MARCOS | 0.884 | 0.978 | 0.995 | 0.994 | 0.909 | 0.989 | 1.000 | 1.000 | 0.861 | 0.970 | 0.991 | 0.990 |

| F-DEMATEL CARDIS | 0.884 | 0.977 | 0.995 | 0.994 | 0.908 | 0.988 | 1.000 | 1.000 | 0.861 | 0.970 | 0.990 | 0.990 |

| G-DEMATEL TOPSIS | 0.995 | 0.932 | 0.898 | 0.899 | 0.983 | 0.917 | 0.861 | 0.861 | 1.000 | 0.945 | 0.912 | 0.913 |

| G-DEMATEL ARAS | 0.955 | 0.999 | 0.986 | 0.987 | 0.965 | 0.993 | 0.970 | 0.970 | 0.945 | 1.000 | 0.991 | 0.991 |

| G-DEMATEL MARCOS | 0.929 | 0.994 | 0.998 | 0.998 | 0.945 | 0.998 | 0.991 | 0.990 | 0.912 | 0.991 | 1.000 | 1.000 |

| G-DEMATEL CARDIS | 0.929 | 0.994 | 0.998 | 0.998 | 0.945 | 0.998 | 0.990 | 0.990 | 0.913 | 0.991 | 1.000 | 1.000 |

| Supply chain elements | Highest-ranked drivers | Solutions for the implementation of green logistics methods and instruments [96] |

|

|---|---|---|---|

| Green logistics method | Green logistics instrument | ||

| Input element | D1.8 – E-commerce with supplier | Procurement planning, execution and supply controlling | Electronic document management with organizations-suppliers |

| Processing element |

D2.3 – Eco-friendly equipment | The use of Eco-friendly equipment and technologies | Equipment with minimal impact on the environment |

| Transport element |

D3.8 – Technical condition of vehicle fleet | Selection of Eco-friendly vehicles | Vehicles with the least impact on the environment |

| Selection of vehicles relevant requirements in the field of ecology | |||

| Transport management and transport planning | Provision of technological unity for transport and warehouse process | ||

| Cumulative element |

D4.3 – Spatial organization of warehouse facilities | Environmental design of warehouse complexes | Environmentally sound spatial organization of elements of a warehouse complex |

| Output element | D5.6 – E-commerce with consumer | Work with consumers of products and services | Electronic document circulation in the organization of interaction with consumers |

| Control element | D6.3 – Corporate Information Systems | Development and implementation of corporate information systems | ERP (Enterprise Resource Planning System) |

| CRM (Customer Relationship Management System) | |||

| MES (Manufacturing Execution System) | |||

| WMS (Warehouse Management System) | |||

| EAM (Enterprise Asset Management) | |||

| HRM (Human Resources Management) | |||

| D6.5 – Intelligent Transportation Systems | Development and implementation of intelligent transport systems | Implementation of advanced information technologies (RFID, GPS, GIS, EDI, GPRS, GSM) |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).