Submitted:

25 November 2024

Posted:

27 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Devise a mathematical model to predict the performance of solar chimney systems in different locations with varying dimensions.

- Compare and analyse results of the systems in different locations and for different energy requirements.

- Discuss the feasibility and practical implementation of the domestic application in different locations.

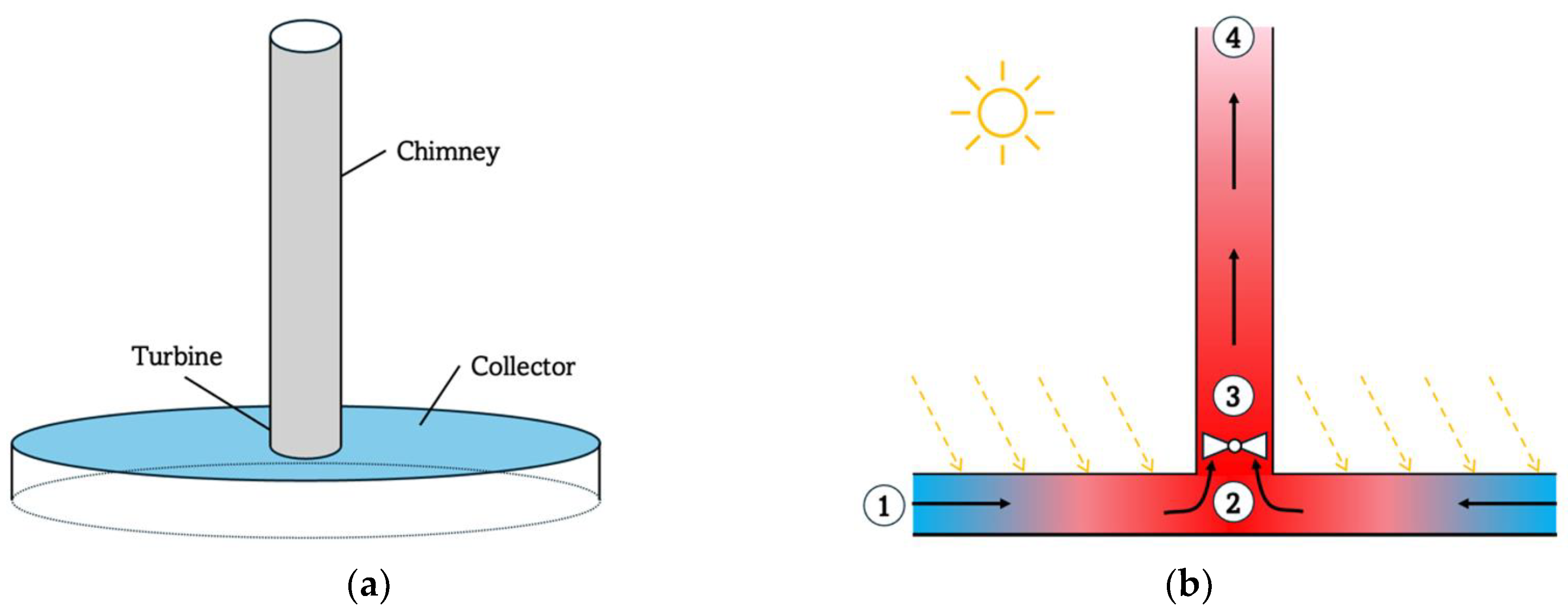

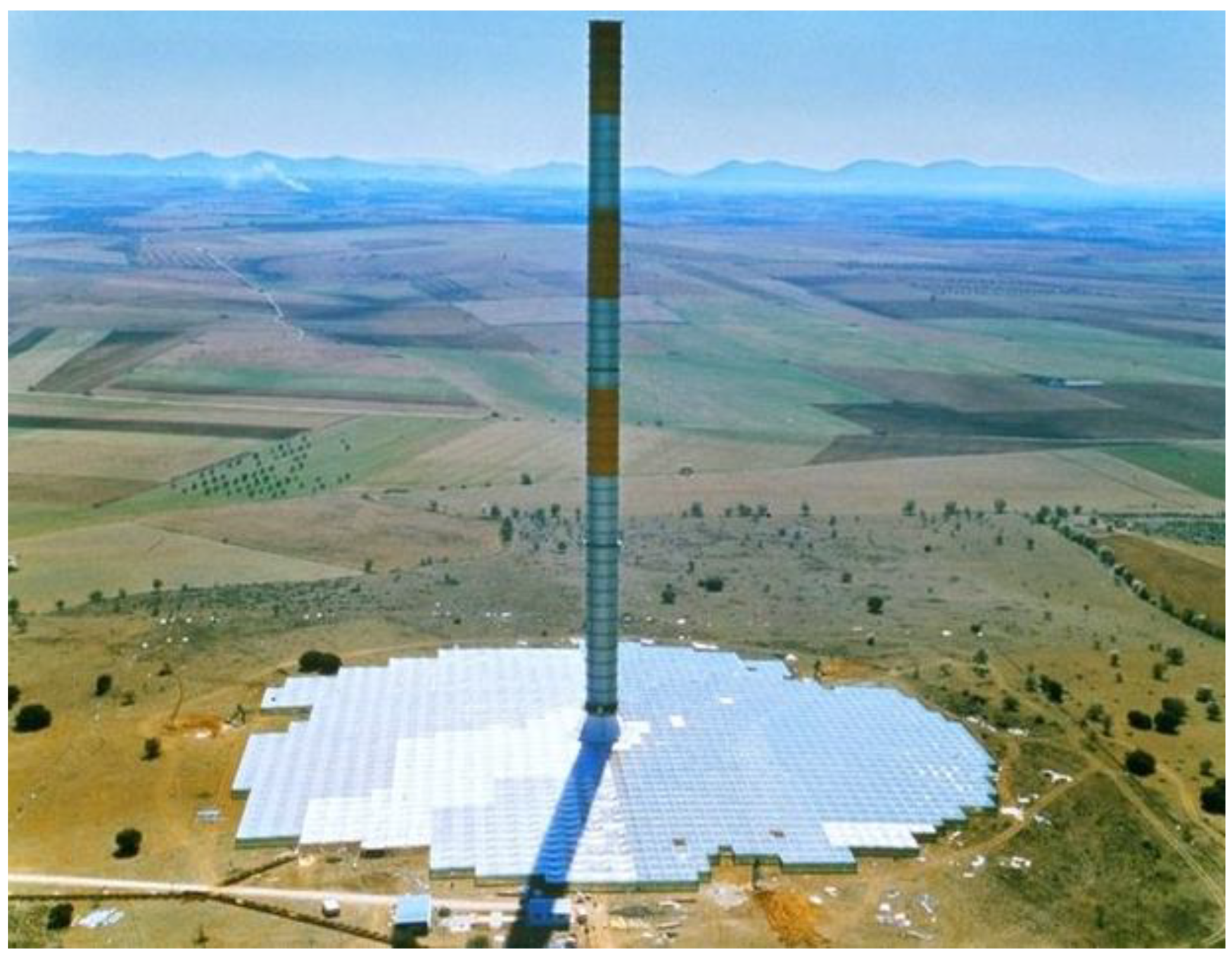

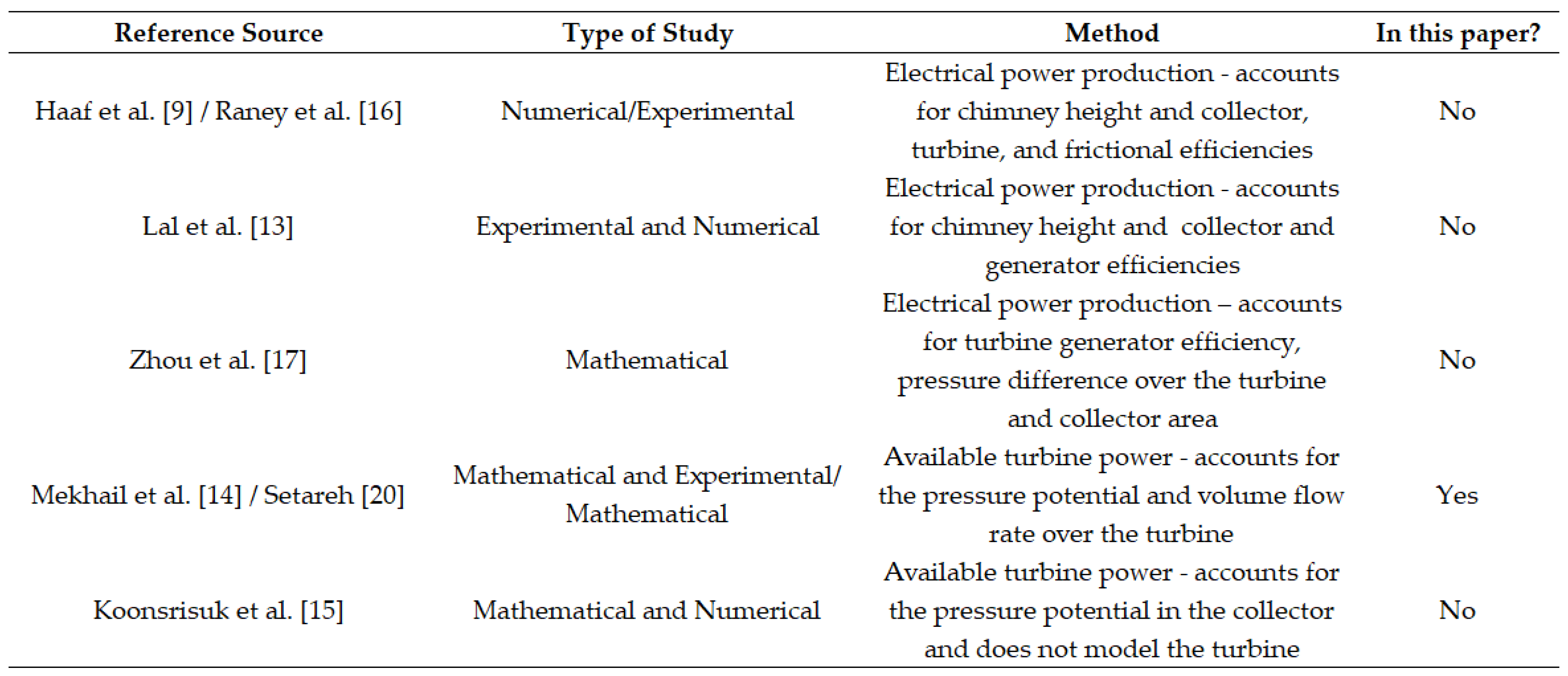

2. A Review of the Solar Chimney Power Plant (SCPP)

3. Methodology

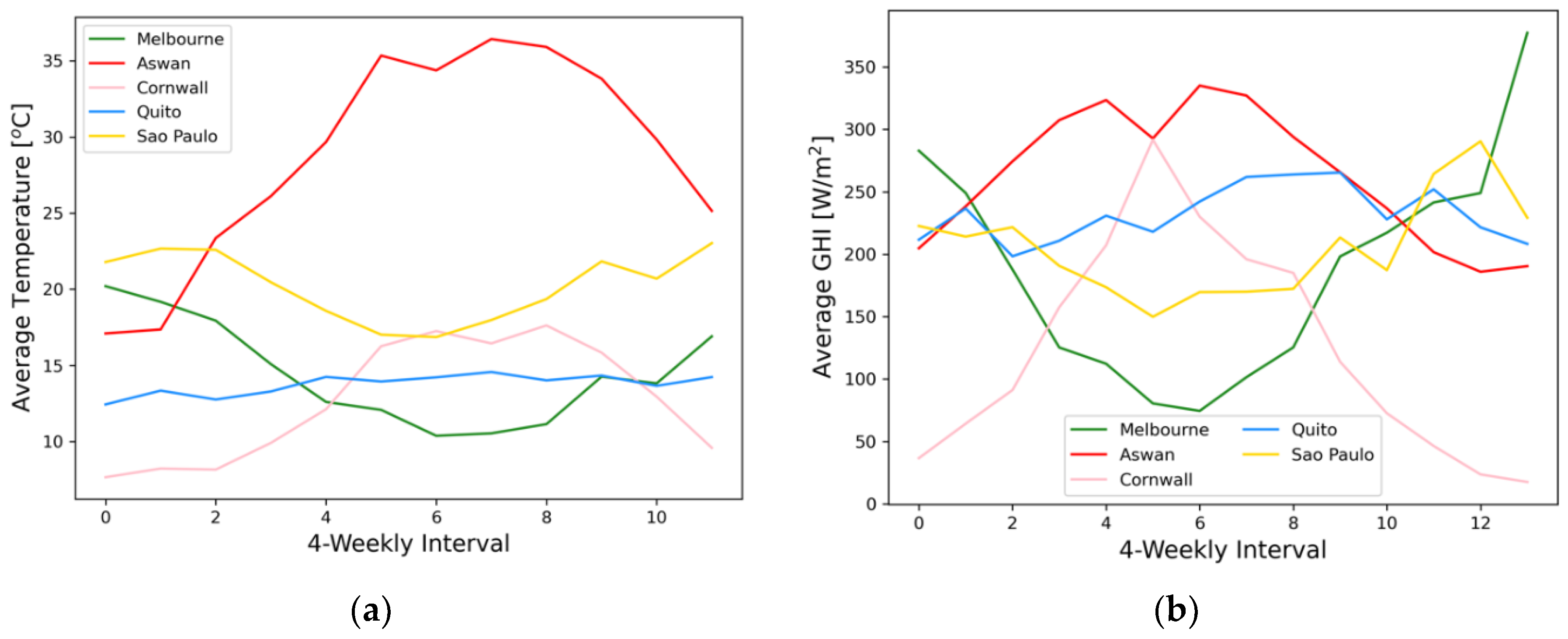

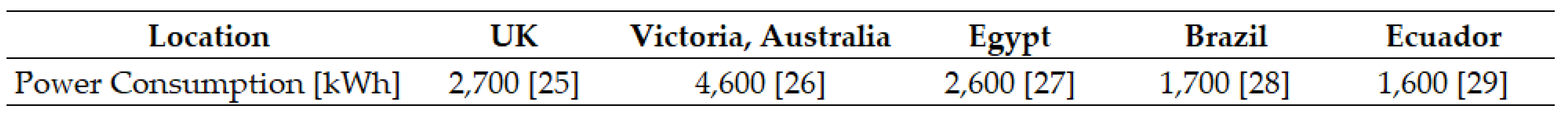

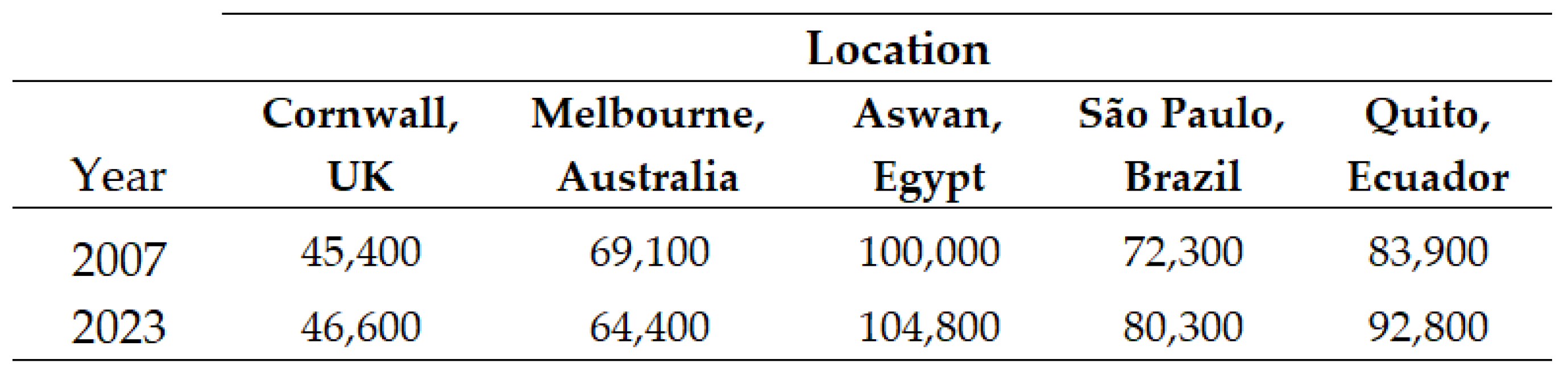

3.1. Location

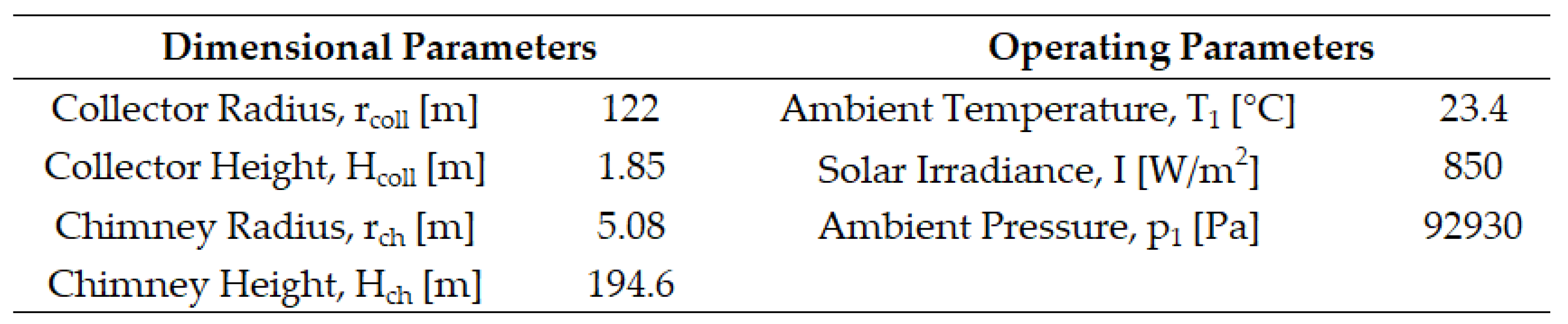

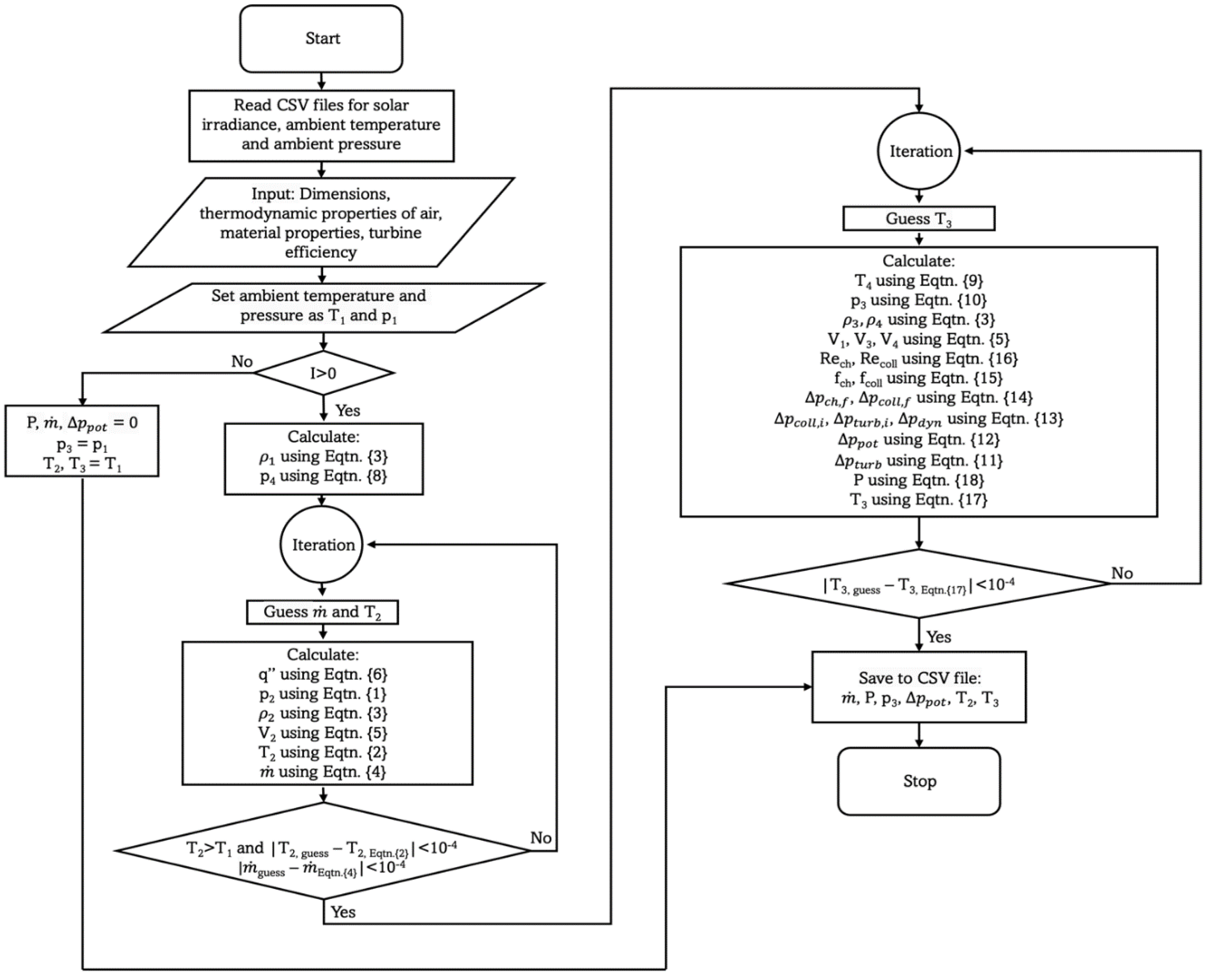

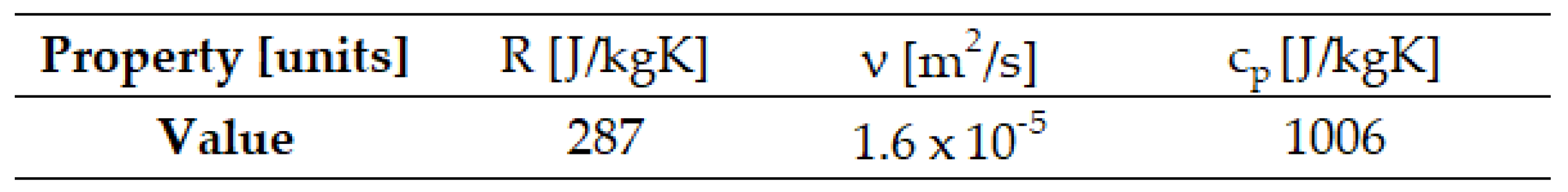

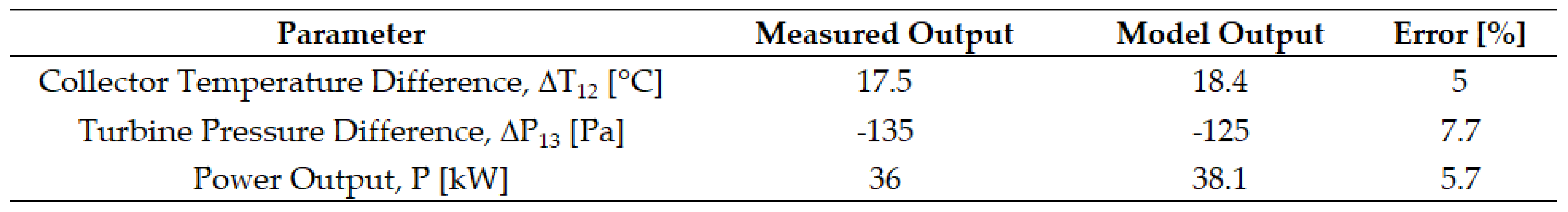

3.3. Modelling

- Air acts as an ideal gas, allowing for the application of the Ideal Gas Law (IGL).

- Air has the properties listed in Table 4.

- One-dimensional, steady-state airflow in order to simplify the continuity, energy, and momentum equations.

- Only Global Horizontal Irradiance (GHI) is considered in the model as it is the sum of the direct and diffuse irradiance received on a horizontal surface.

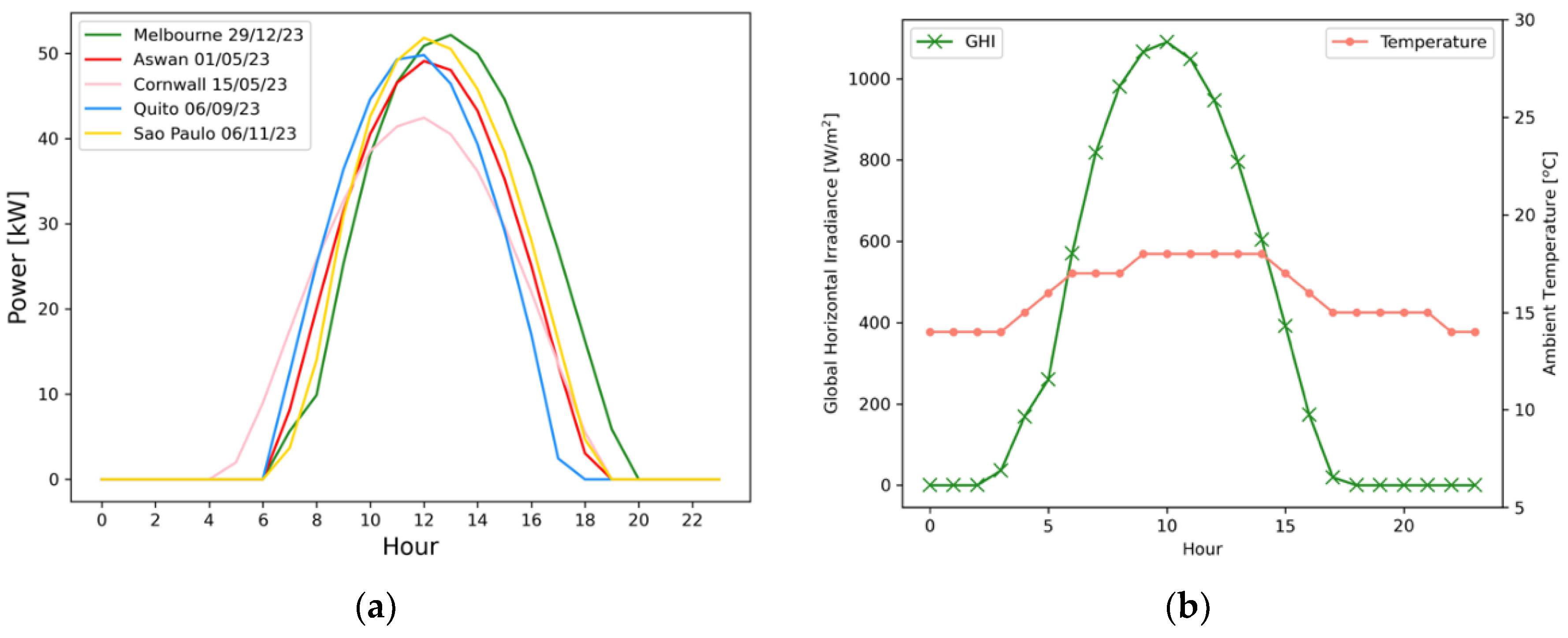

4. Results Analysis

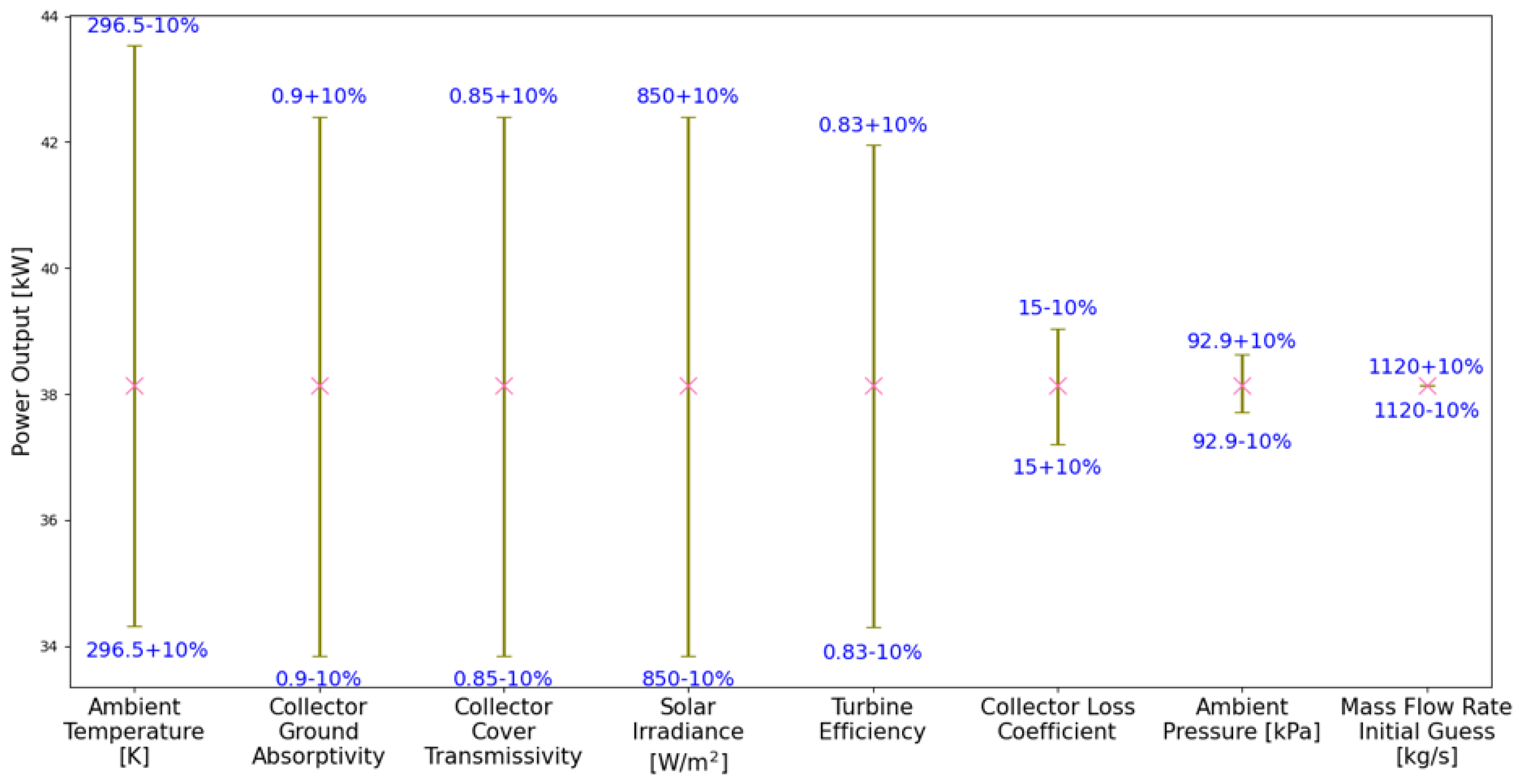

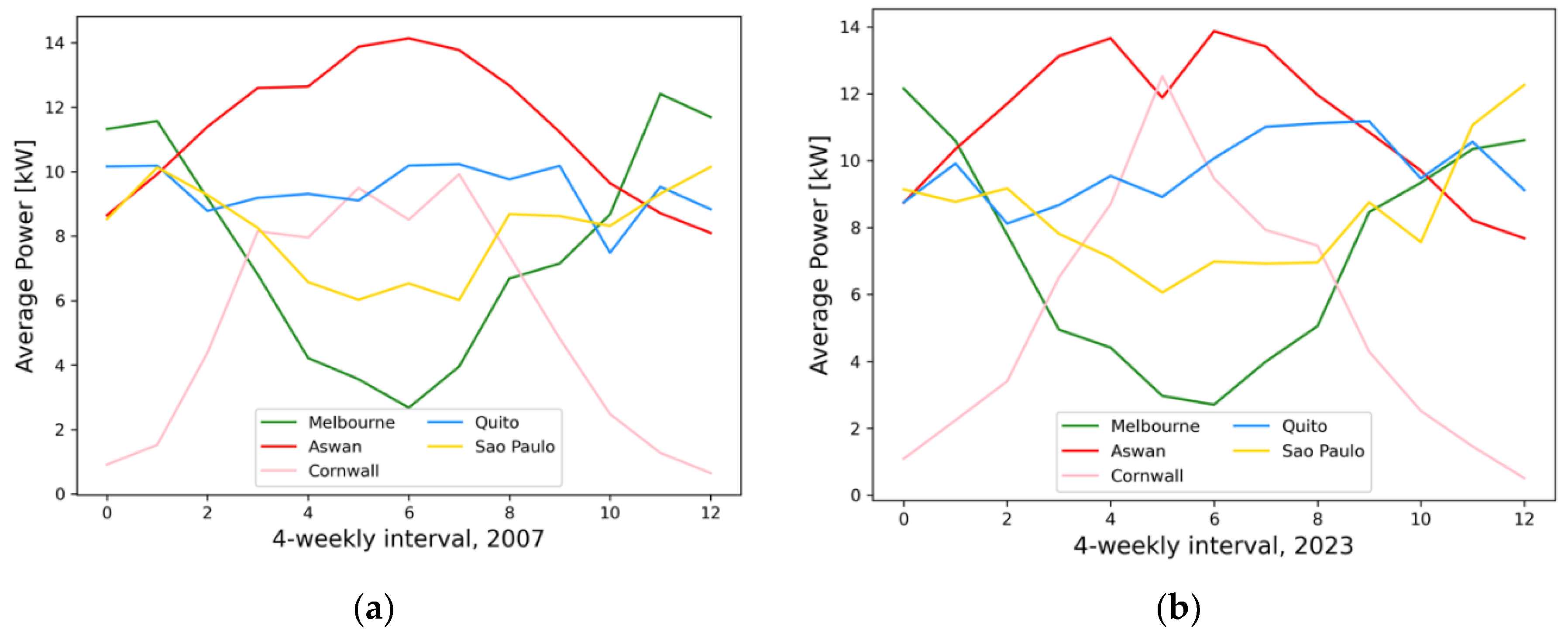

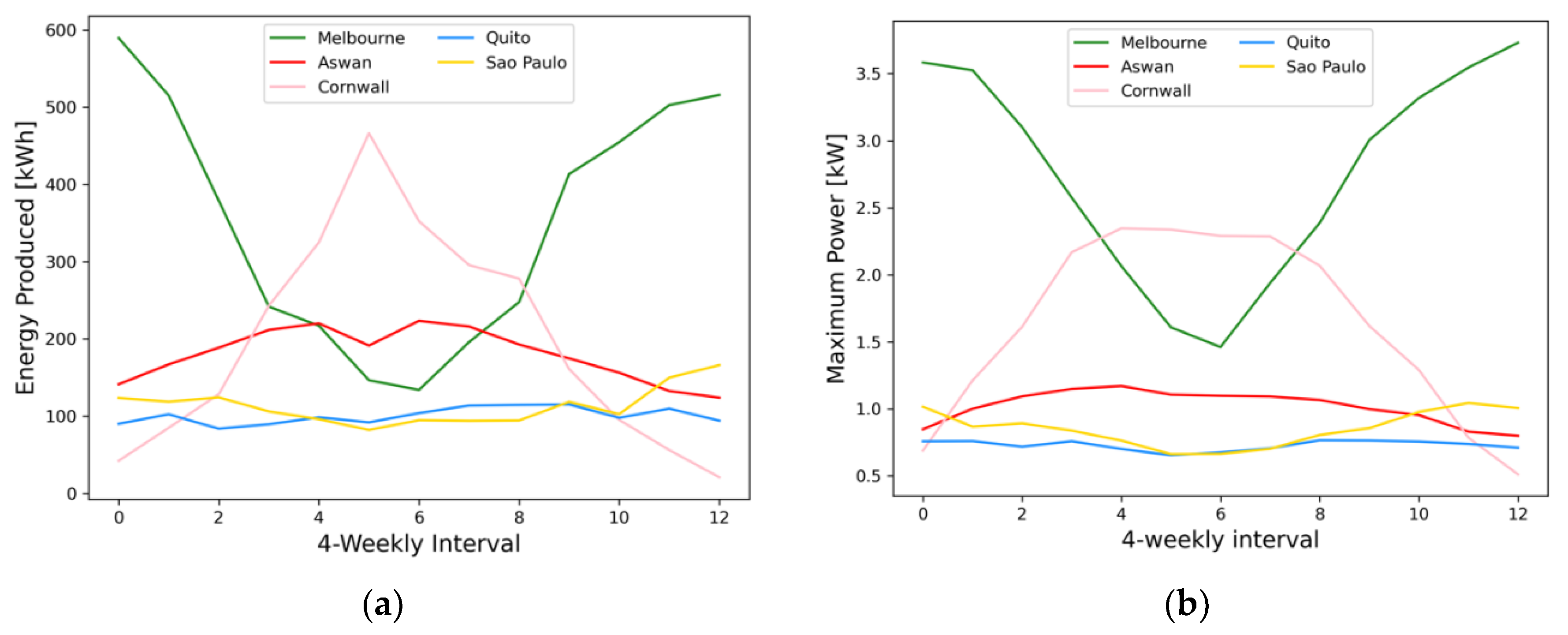

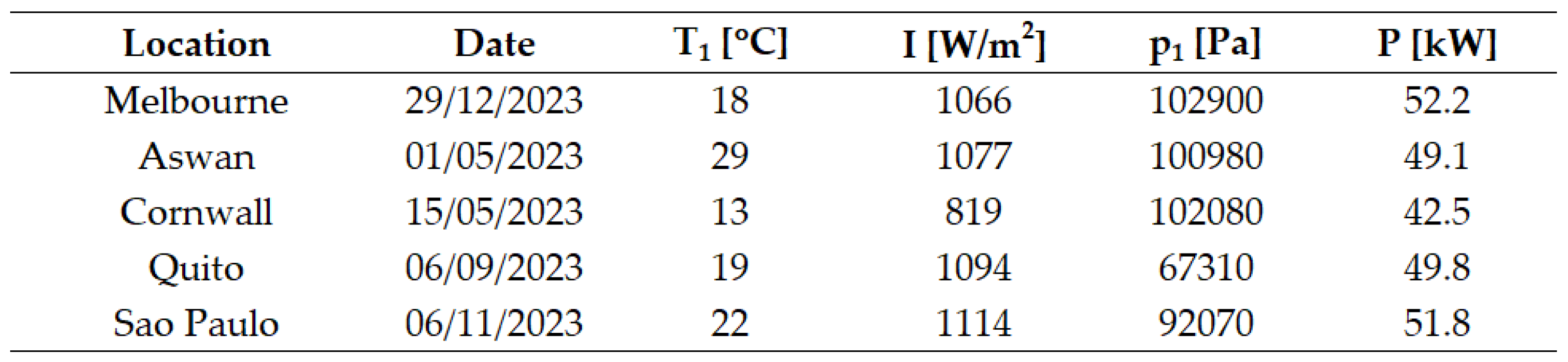

4.1. Power Output

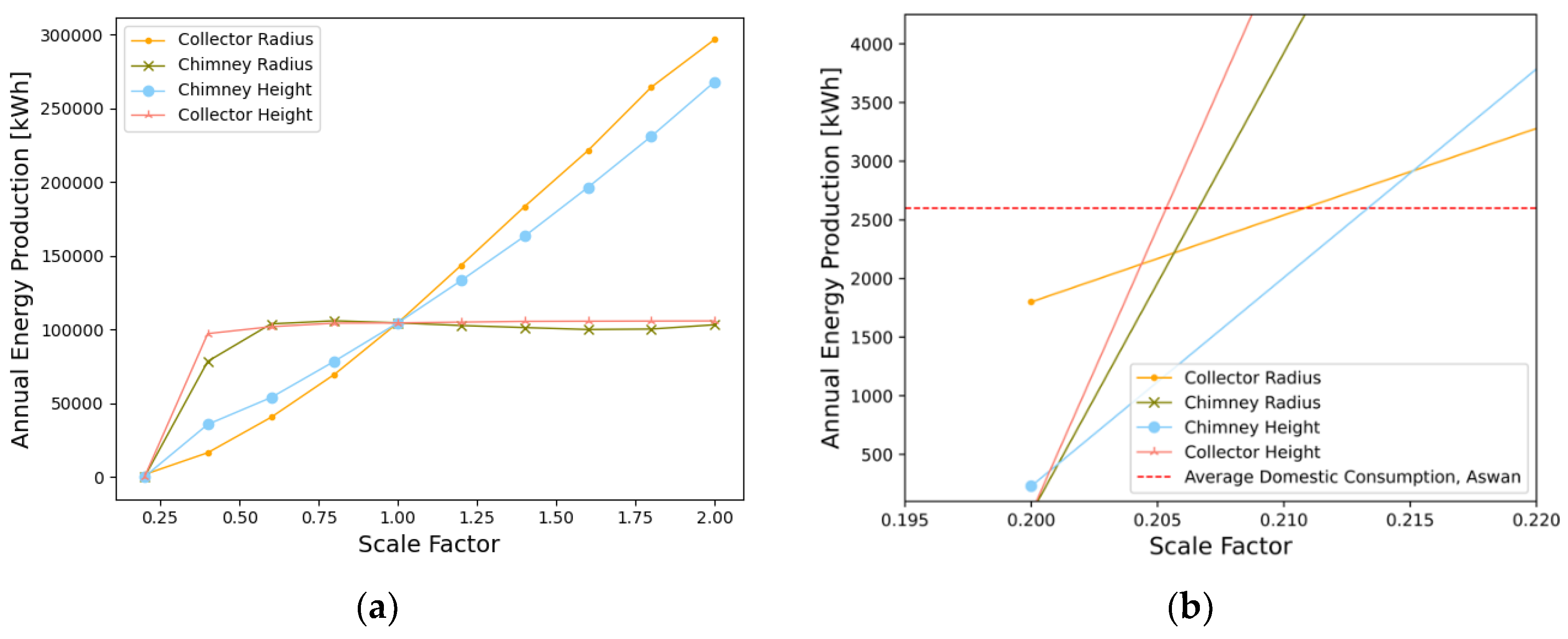

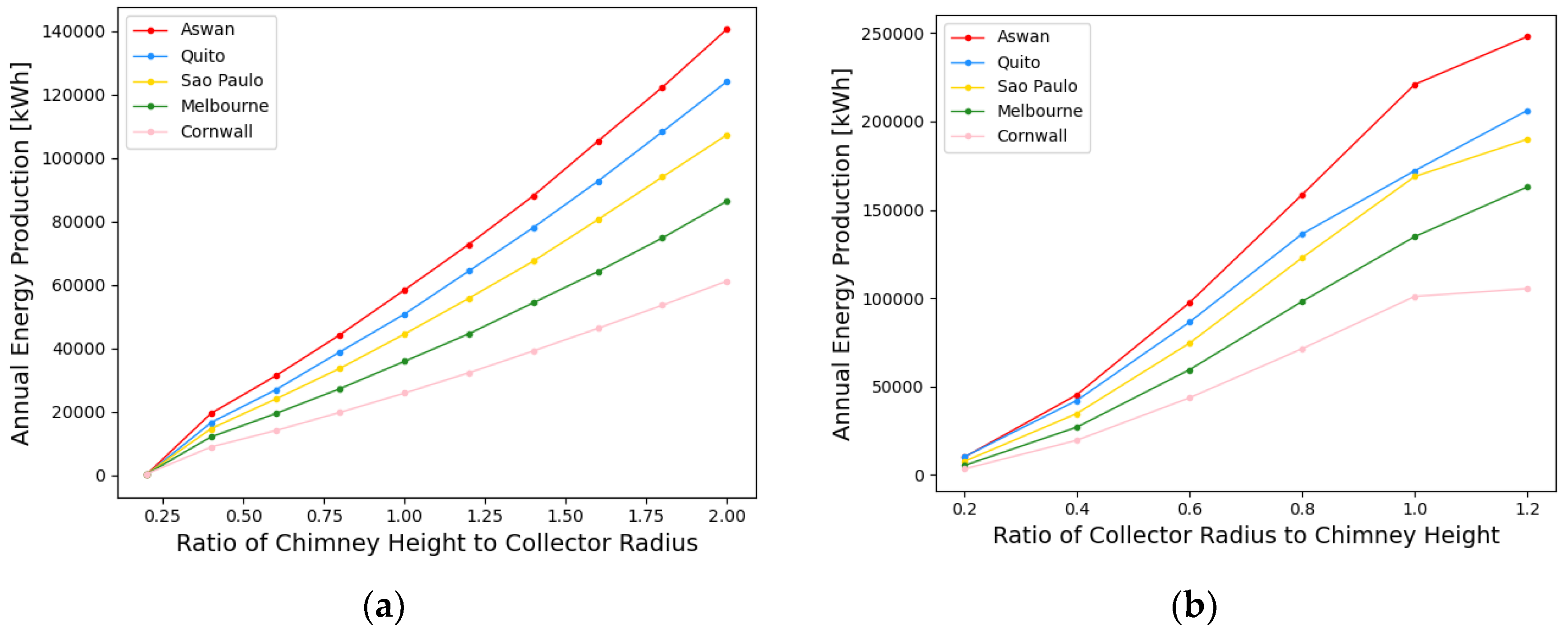

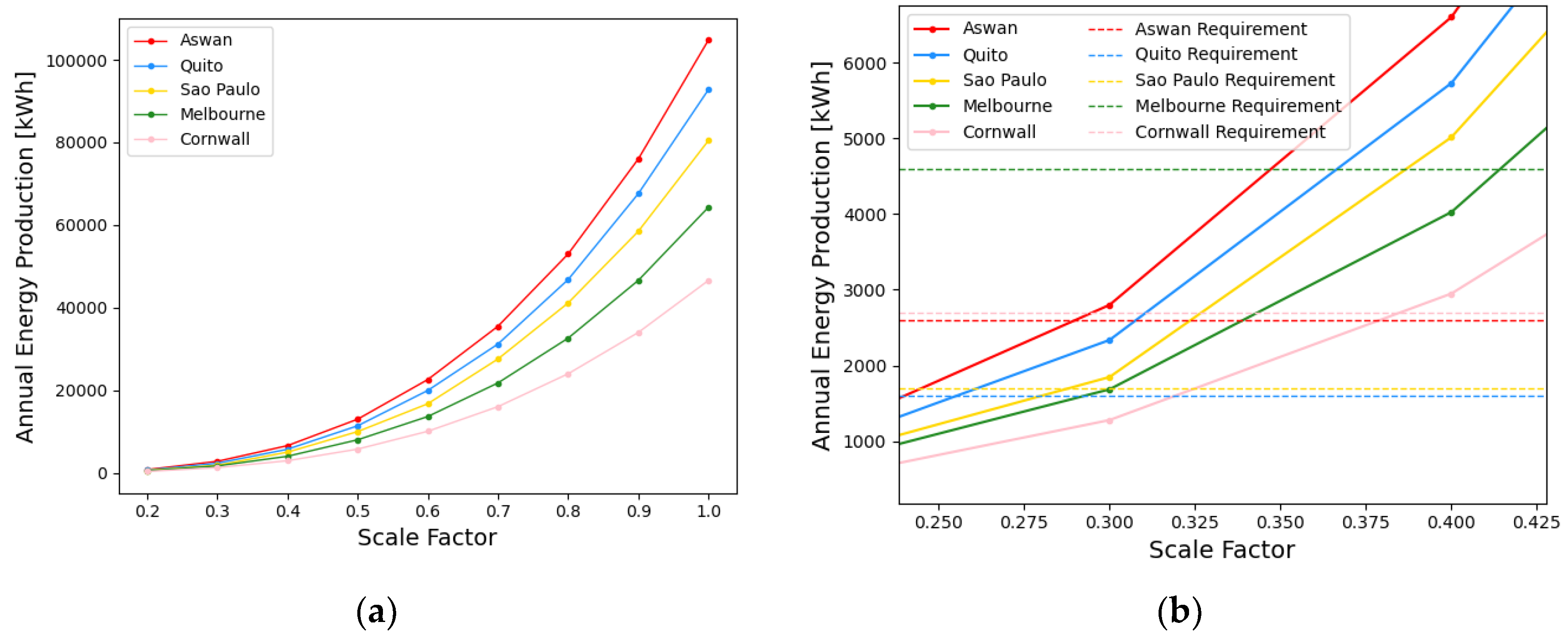

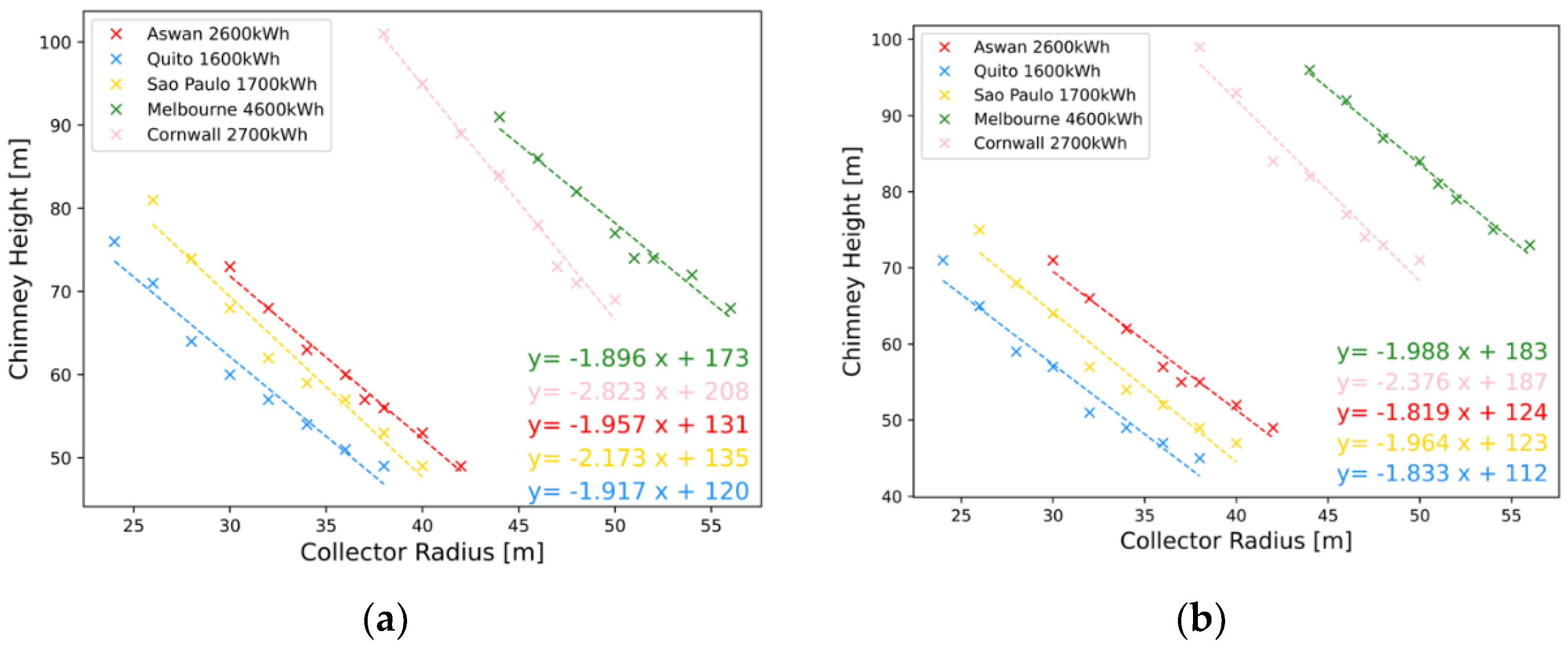

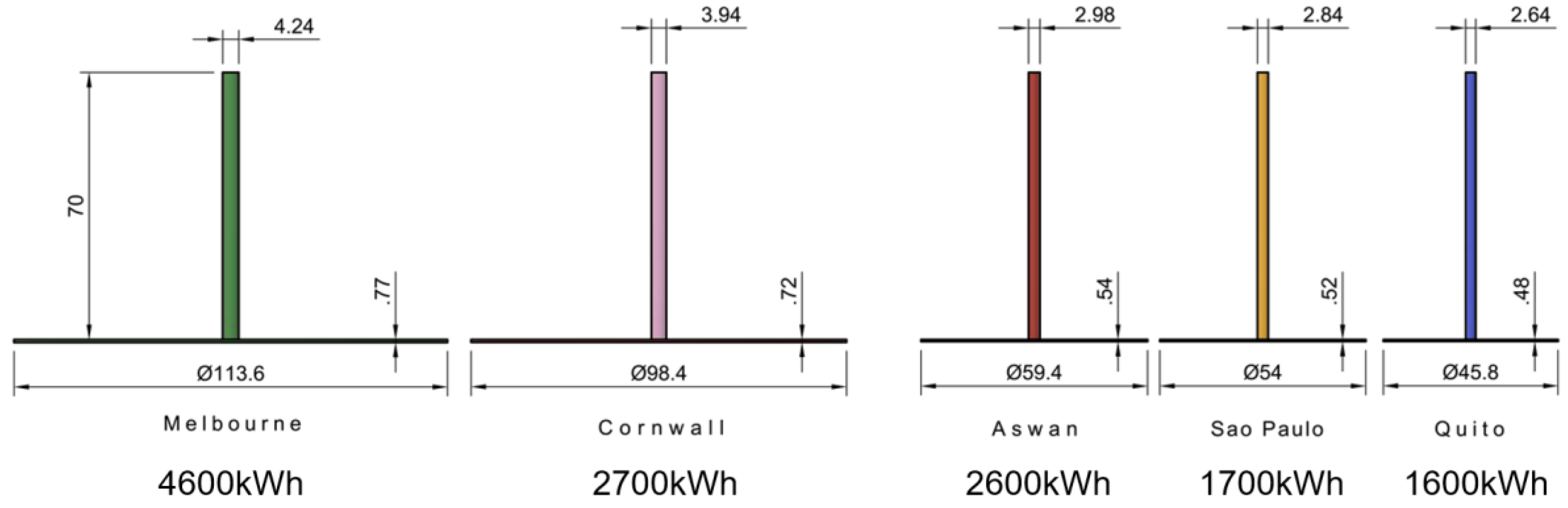

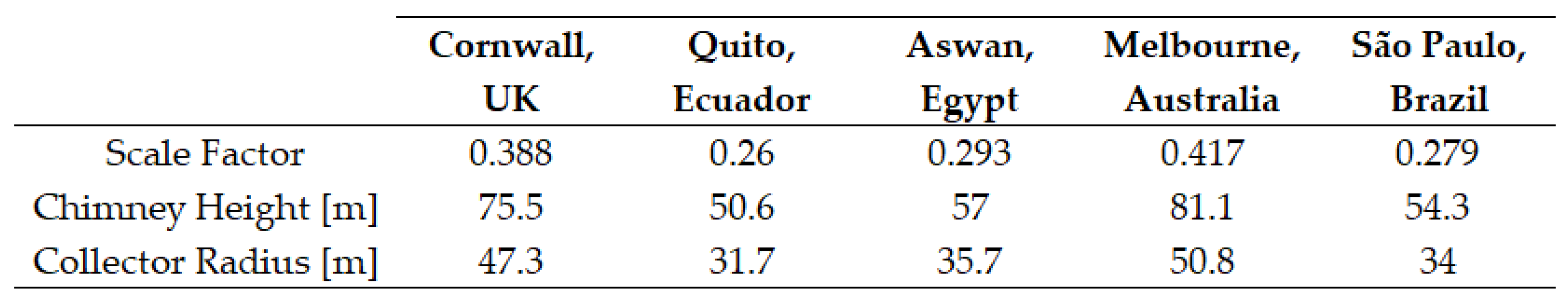

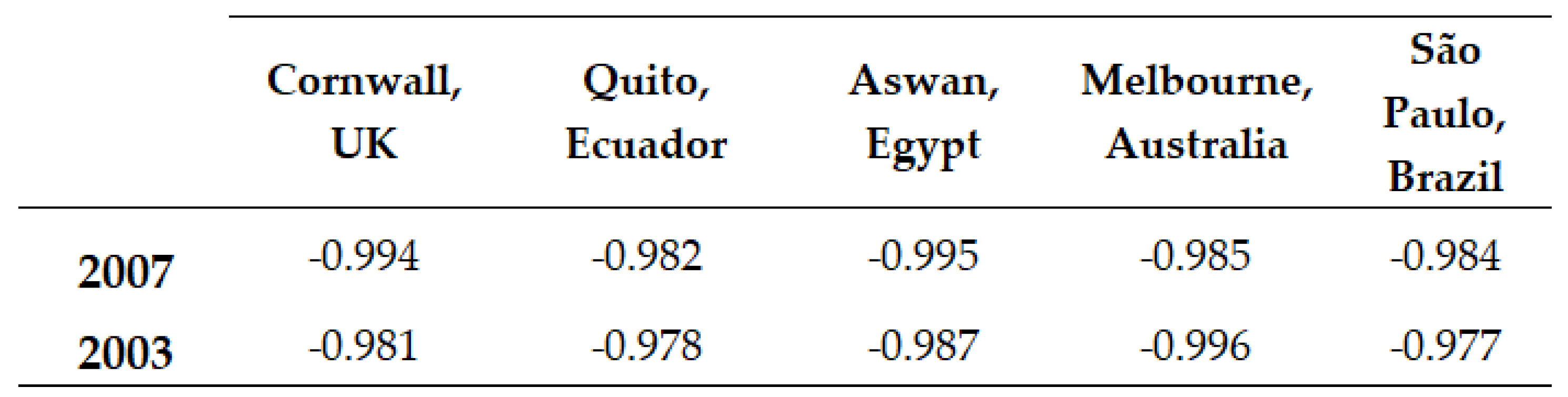

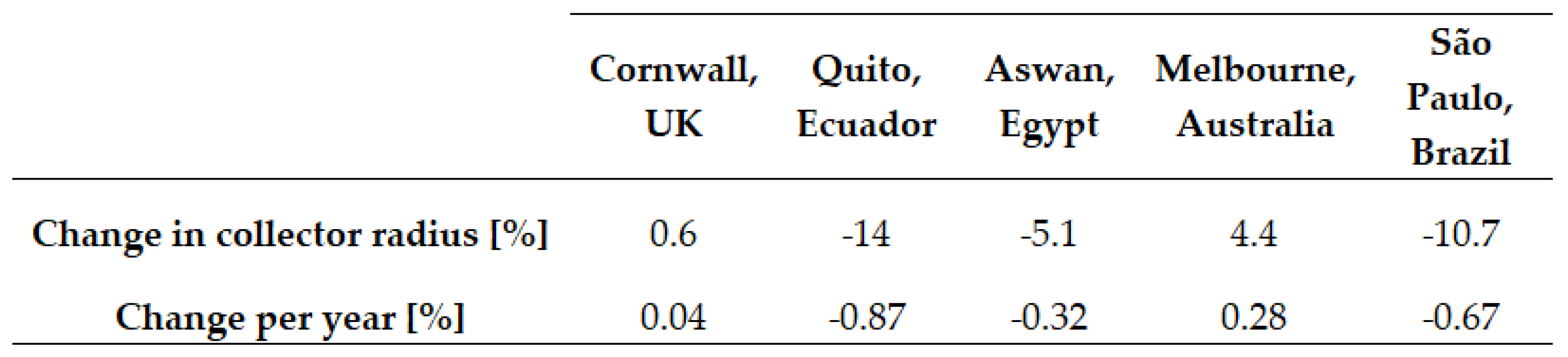

4.2. Dimensional Study

5. Hybridization and Lifecycle Analyses

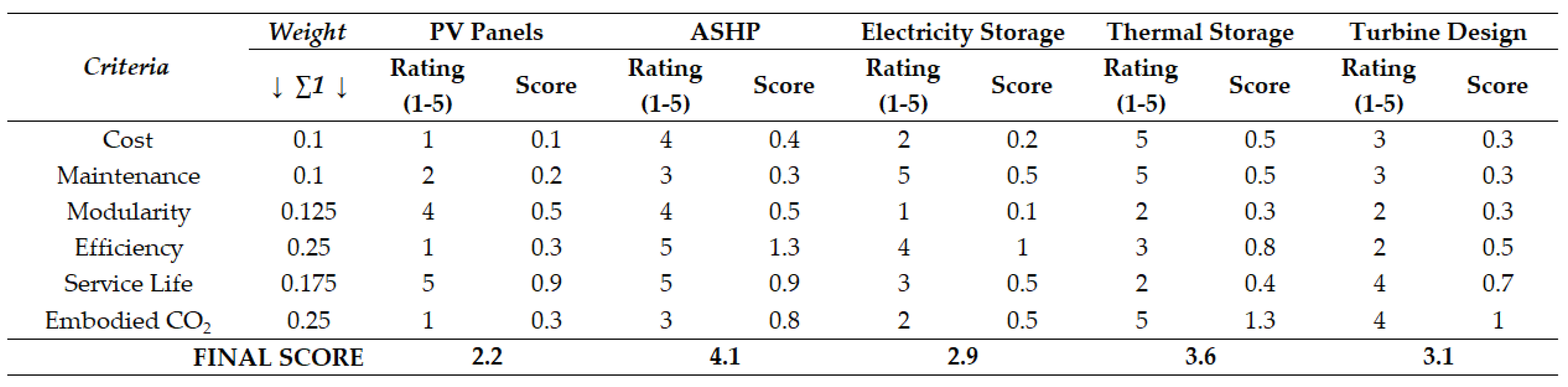

5.1. Hybrid Options and Selection

- Photovoltaic (PV) panels – Located under the collector cover. Crystalline silicon PV panels become 0.2 – 0.5% less efficient for each 1°C rise in temperature. The convective air flow through the SCPP would maintain a lower surface temperature of the PV panels and therefore increase the efficiency. However, the heat absorbed by the PV panels would alter the collector properties and consequently reduce the power output of the SCPP [37].

- Air Source Heat Pump (ASHP) – Located between points 3 and 4 in the chimney tower. ASHPs are used to provide a more sustainable option for heating buildings by absorbing heat from the outside air and transferring it to an indoor space.

- Electricity storage – As an SCPP does not constantly generate power, energy storage such as large batteries could be incorporated into the design to harness the available energy. This would introduce more inefficiencies in the system; however, it could help to minimise the size of the plant to ensure the annual energy demand can be met.

- Thermal storage – As discussed in Ref. [21], this would include the use of a material to absorb some of the solar energy to be slowly released throughout the night or other periods where the plant would otherwise be inactive to allow for constant power generation. This would however decrease the peak power output as the convection induced airflow during sunlight hours would be reduced.

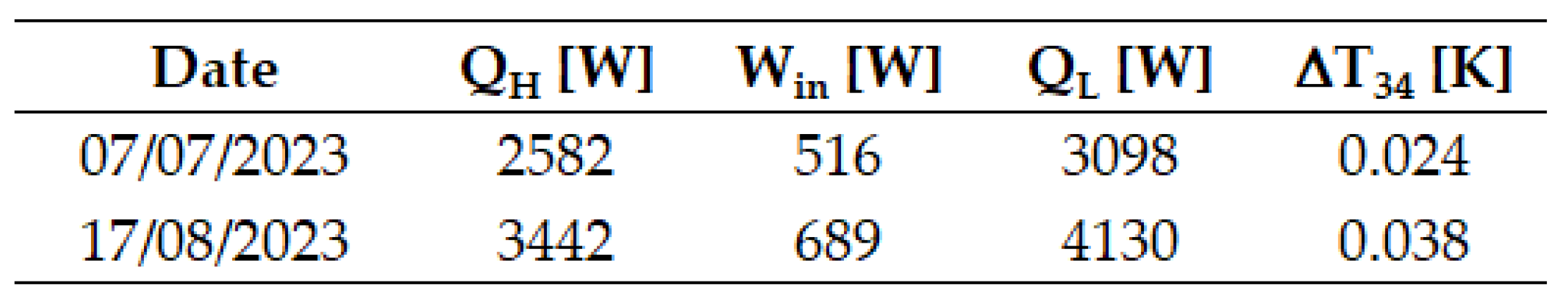

5.2. Analysis of a SCPP/ASHP Hybrid Plant

- Compressor - isentropic compression requiring work input.

- Condenser – isobaric heat rejection to maintain domestic temperature.

- Expansion valve – throttling.

- Evaporator – isobaric heat absorption from hot chimney air.

- The desired room temperature is 20°C and it takes 30 minutes (1800 seconds) to reach this temperature from ambient when the heating is turned on.

- The average size of a one-storey Melbourne house is 593m3 [38].

- The density of air is 1.3kg/m3, making the mass of the air inside the house equal to 770kg [39].

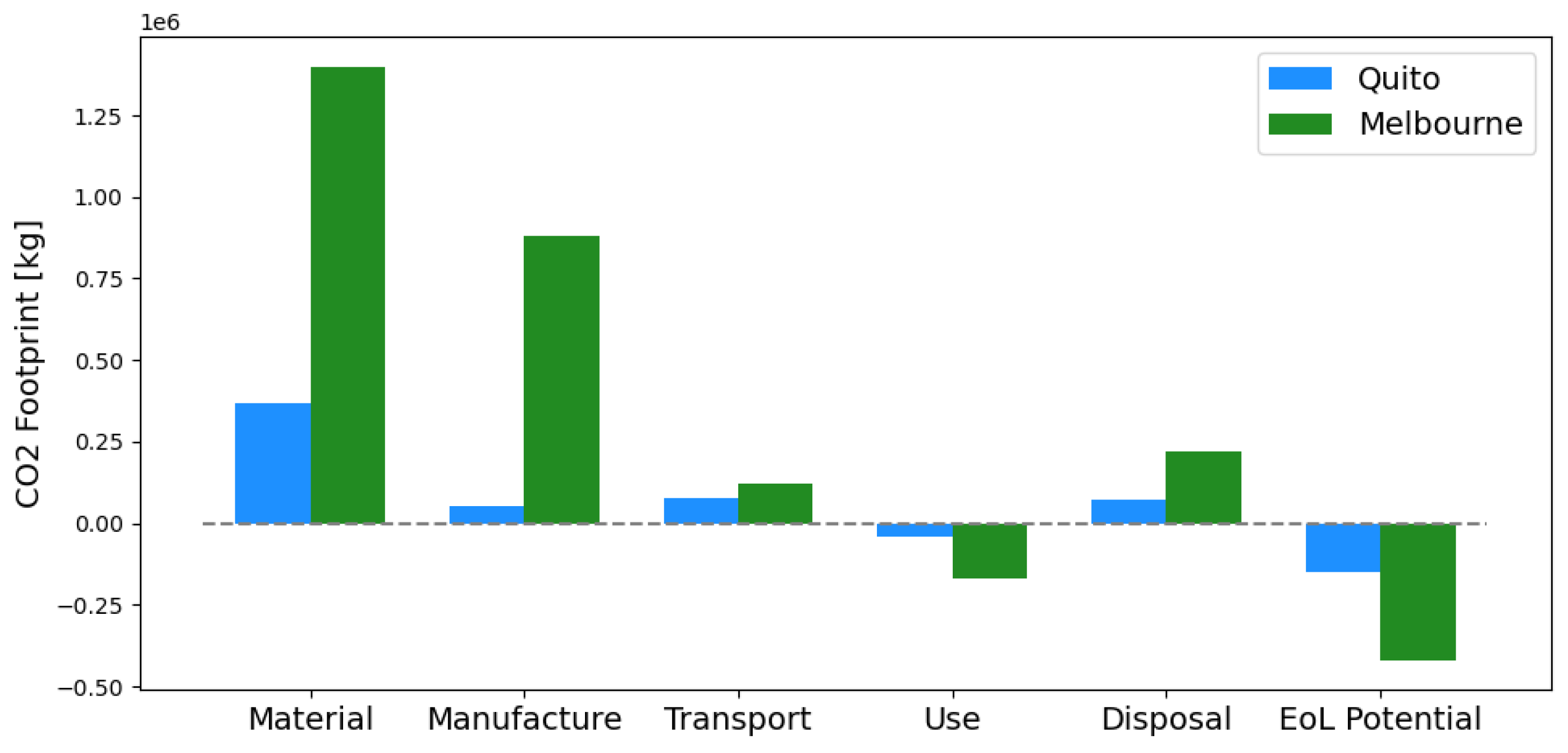

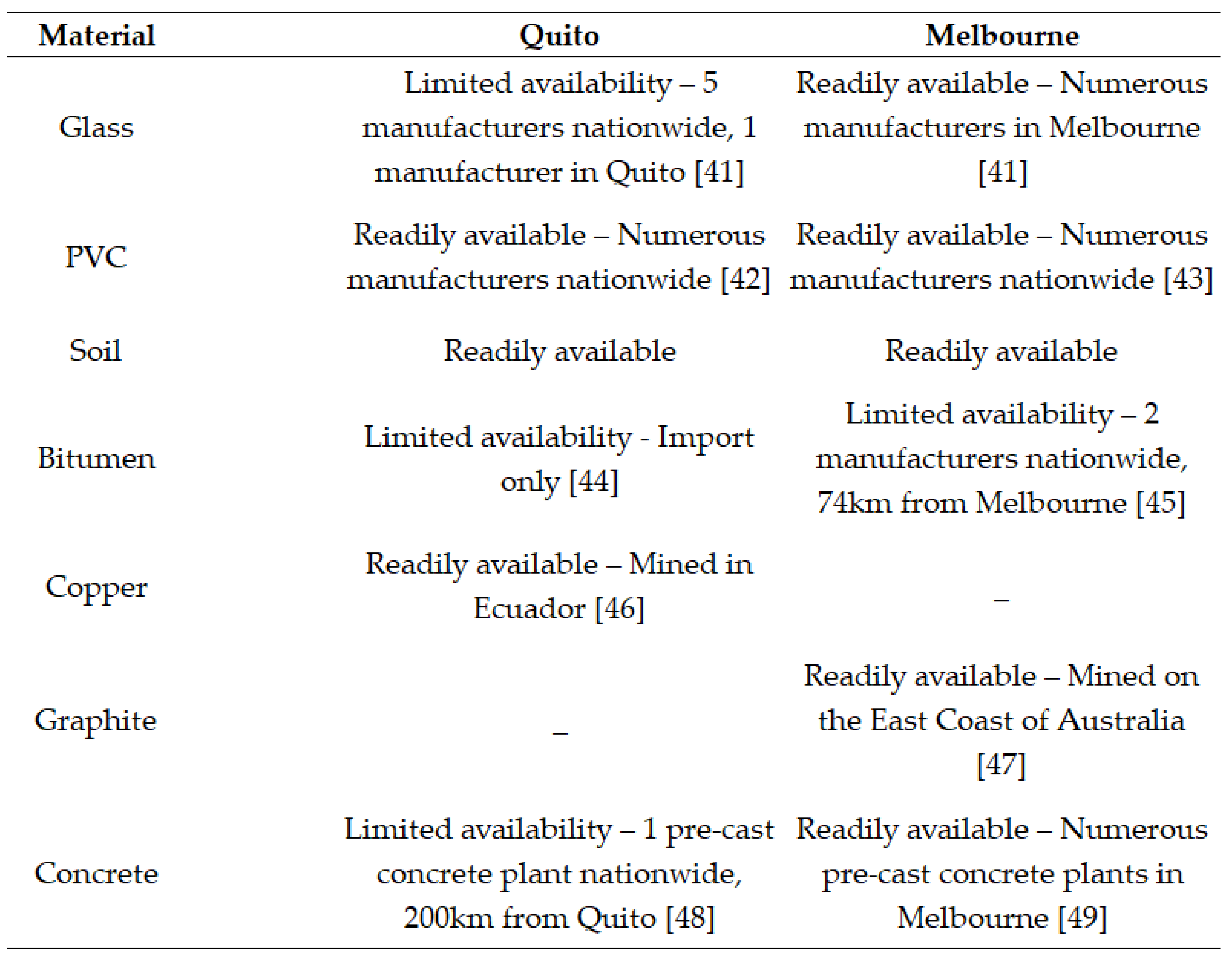

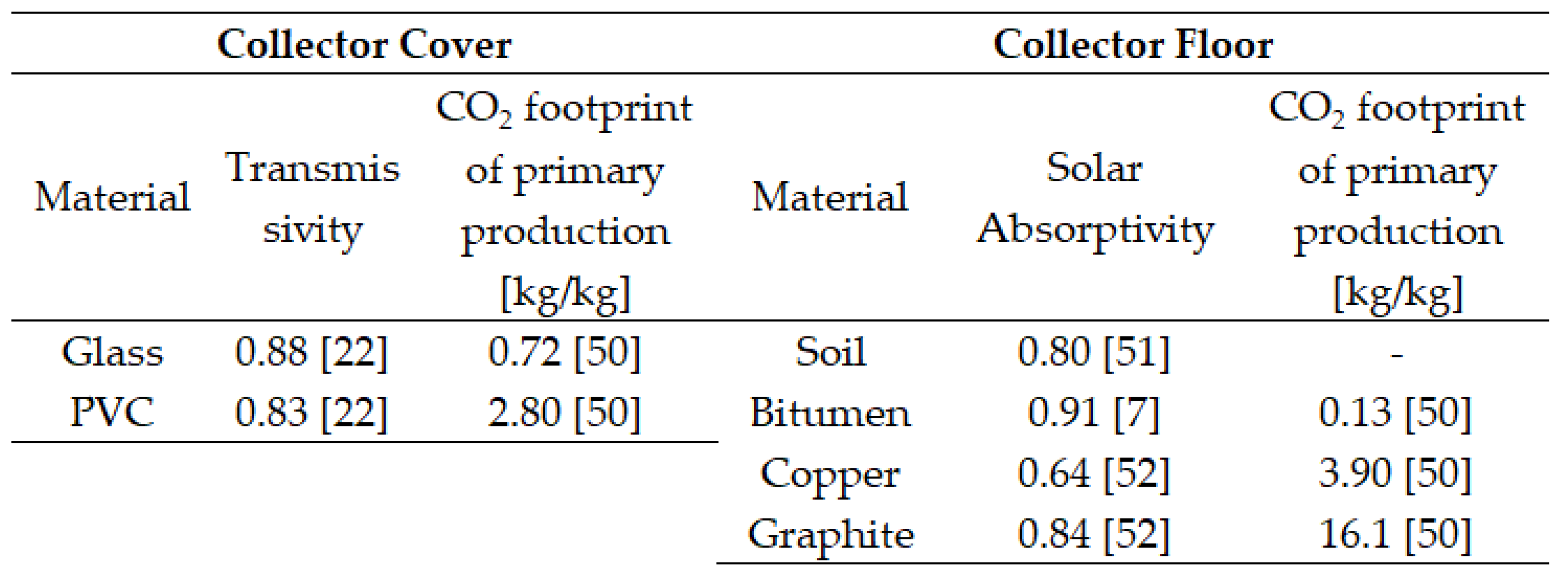

5.3. Lifecycle Considerations

- Quito – PVC collector cover, soil collector floor and concrete chimney.

- Melbourne – Glass collector cover, bitumen collector floor and concrete chimney.

6. Conclusions

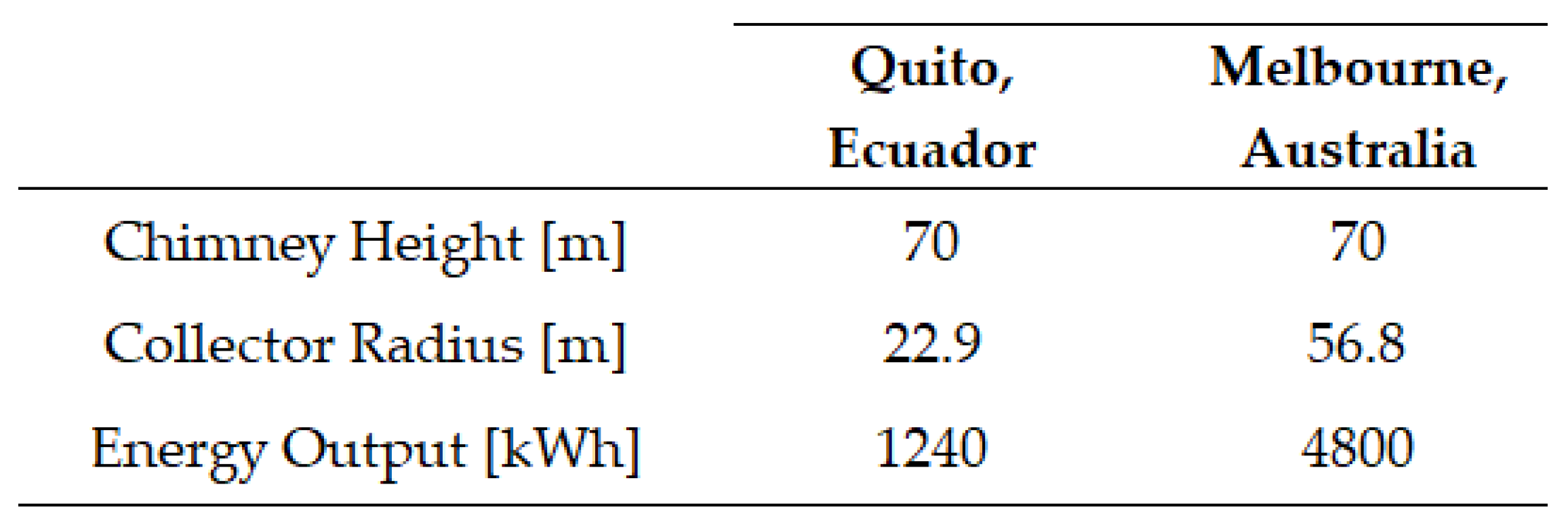

- The smallest collector radius of all the plants in this report is in Quito and is approximately 25m, corresponding to a chimney height of approximately 70m. Decreasing the radius more than this would lead to an increase in chimney height because of the strong negative correlation between the two dimensions.

- Aswan, Quito, and São Paulo can reliably produce year-round power; however, Cornwall and Melbourne may need a supplementary energy supply in the winter months.

- Hybridising the system with an ASHP could enhance the overall performance of the plant. However. There are days when the power generated by the plant is insufficient to power the ASHP compressor, suggesting that there are optimum environmental conditions for this technology.

- The material selection for the construction of the SCPP influences the plant performance and is the greatest contributor to the carbon footprint. From the data in Section 6, the net annual CO2 footprint is 10,430kg for Quito and 48,750kg for Melbourne, the smallest and largest plant, respectively.

Author Contributions

Funding

Conflicts of Interest

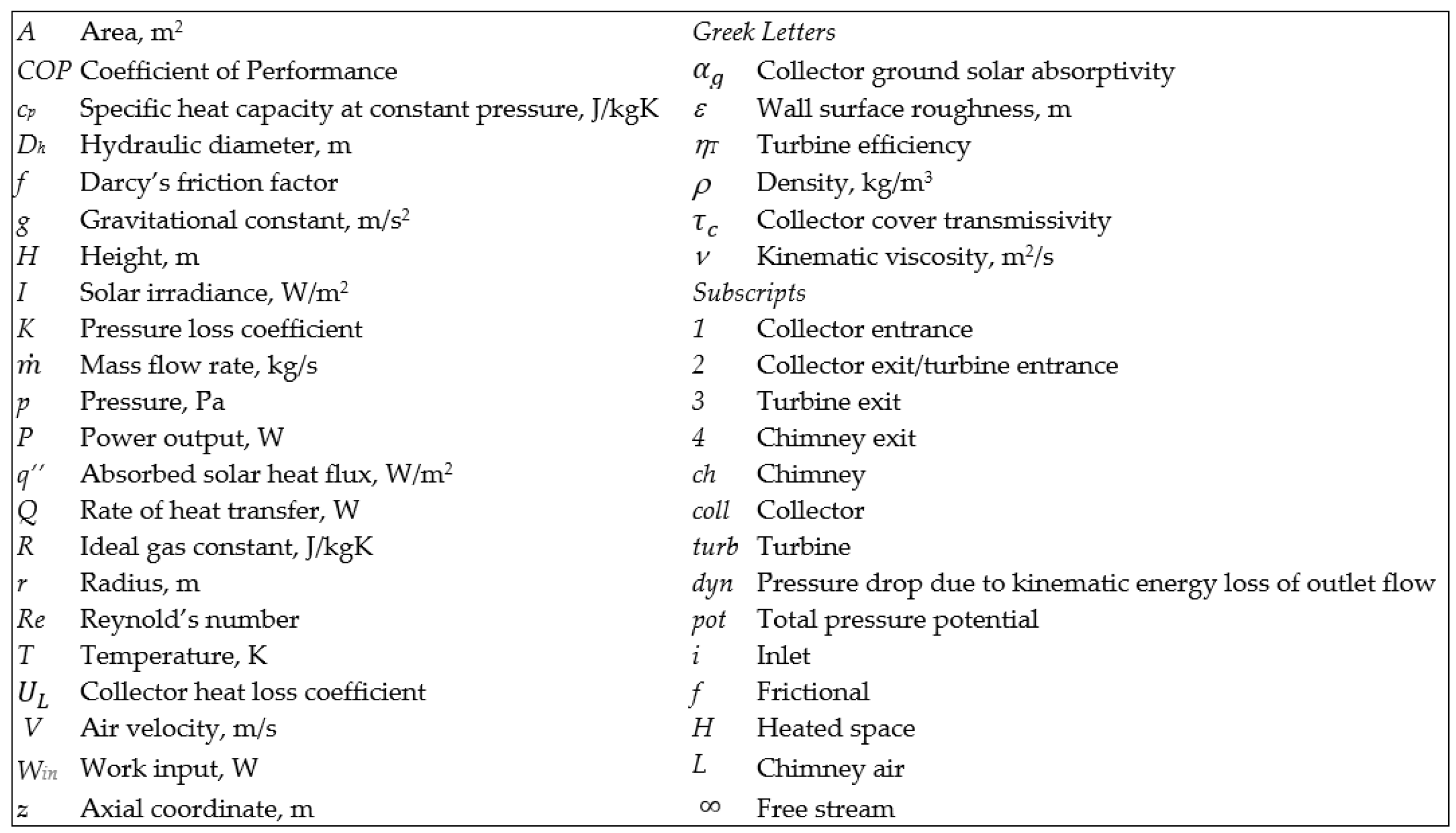

Nomenclature

References

- Yohe, G.; Toth, F.L. Adaptation and the Guardrail Approach to Tolerable Climate Change. Clim. Chang. 2000, 45, 103–128. [CrossRef]

- UNFCCC, “The Paris Agreement,” in Paris Climate Change Conference, Paris, 2015.

- Energy Institute, “Statistical Review of World Energy,” Energy Institute, London, 2023.

- U. N. E. Programme, “Emissions Gap Report,” United Nations Environment Programme, Nairobi, 2023.

- L. D. Vinci, Artist, Design for an airscrew operated smoke-jack. [Art]. Science & Society Picture Library, 1480-1482.

- M. A. d. S. Bernardes, “Solar Chimney Power Plants – Developments and Advancements,” in Solar Energy, Rijeka, InTech, 2010, p. Chapter 9.

- W. Haaf, “Solar Chimneys - Part II: Preliminary Test Results from the Manzanares Pilot Plant,” Harwood Academic Publishers, Reading, 1984.

- J. Schlaich and W. Schiel, “The Solar Chimney: Electricity from the sun,” Schlaich Bergermann und Partner, Stuttgart, Germany, 1995.

- Haaf, W.; Friedrich, K.; Mayr, G.; Schlaich, J. Solar Chimneys Part I: Principle and Construction of the Pilot Plant in Manzanares. Int. J. Sustain. Energy 1983, 2, 3–20. [CrossRef]

- T. K. Grose, “Solar Chimneys Can Convert Hot Air to Energy, But Is Funding a Mirage?,” National Geographic, 17 April 2014.

- N. P. Stoianoff, L. Kreiser, B. Butcher, J. E. Milne and H. Ashiabor, Green Fiscal Reform for a Sustainable Future: Reform, Innovation and Renewable Energy, Cheltenham: Edward Elgar Publishing, 2016.

- Ghalamchi, M.; Kasaeian, A.; Mirzahosseini, A.H. An experimental study on the thermal performance of a solar chimney with different dimensional parameters. Renew. Energy 2016, 91, 477–483. [CrossRef]

- Lal, S.; Kaushik, S.; Hans, R. Experimental investigation and CFD simulation studies of a laboratory scale solar chimney for power generation. Sustain. Energy Technol. Assessments 2016, 13, 13–22. [CrossRef]

- the Faculty of Energy Engineering; Mekhail, T.; Rekaby, A.; Fathy, M.; Bassily, M.; Harte, R. Experimental and Theoretical Performance of Mini Solar Chimney Power Plant. J. Clean Energy Technol. 2017, 5, 294–298. [CrossRef]

- Koonsrisuk, S. Lorente and A. Bejan, “Constructal solar chimney configuration,” International Journal of Heat and Mass Transfer, vol. 53, pp. 327-333, 2010.

- Raney, S.M.; Brooks, J.R.; Schaffer, J.P.; French, J.J. Experimental Validation of Solar Chimney Performance Models and Operational Characteristics for Small Scale Remote Applications. ASME 2012 6th International Conference on Energy Sustainability collocated with the ASME 2012 10th International Conference on Fuel Cell Science, Engineering and Technology, United States; pp. 27–32.

- Zhou, X.; Yang, J.; Xiao, B.; Hou, G.; Xing, F. Analysis of chimney height for solar chimney power plant. Appl. Therm. Eng. 2008, 29, 178–185. [CrossRef]

- Cuce, E.; Cuce, P.M.; Sen, H. A thorough performance assessment of solar chimney power plants: Case study for Manzanares. Clean. Eng. Technol. 2020, 1, 100026. [CrossRef]

- Koonsrisuk, A.; Chitsomboon, T. Mathematical modeling of solar chimney power plants. Energy 2013, 51, 314–322. [CrossRef]

- Setareh, M. Comprehensive mathematical study on solar chimney powerplant. Renew. Energy 2021, 175, 470–485. [CrossRef]

- H. Kreetz, “Theoretische Untersuchungen und Auslegung eines temporären Wasserspeichers für das Aufwindkraftwerk,” Energien-EVUR, Technical University Berlin, Berling, 1997.

- D. Pritam and V. Chandramohan, “A review on solar updraft tower plant technology: Thermodynamic analysis, worldwide status, recent advances, major challenges and opportunities,” Sustainable Energy Technologies and Assessments, vol. 52, 2022.

- Strobel, C.S.; Moura, L.M.; Catapan, M.F. Technical feasibility analysis of the use of solar chimneys in Brazil. Rev. Bras. de Planej. e Desenvolv. 2020, 9, 450–467. [CrossRef]

- Dhimish, M.; Mather, P. Exploratory evaluation of solar radiation and ambient temperature in twenty locations distributed in United Kingdom. Urban Clim. 2018, 27, 179–192. [CrossRef]

- British Gas, “What is the average energy bill in Great Britain?,” April 2024. [Online]. Available: https://www.britishgas.co.uk/energy/guides/average-bill. [Accessed 20 November 2024].

- D. Crismale, “How much energy does the average home use?,” Finder, 19 January 2024. [Online]. Available: https://www.finder.com.au/energy/how-much-energy-does-the-average-home-use. [Accessed 20 November 2024].

- Tiedemann, K. Performance standards and residential energy efficiency in Egypt. WASTE MANAGEMENT 2006.

- Statista, “Residential electricity consumption in Brazil from 2013 to 2022,” 12 July 2023. [Online]. Available: https://www.statista.com/statistics/985975/brazil-residential-electricity-consumption/#:~:text=In%202022%2C%20the%20residential%20electricity,percent%20of%20Brazil's%20electricity%20consumption. [Accessed 20 November 2024].

- M. Zambrano-Monserrate and M. Ruano, “Sociodemographic drivers and interconnected energy-saving practices: insights from Ecuador's household sector,” Management of Environmental Quality, vol. 35, no. 4, pp. 885-902, 2024.

- Solcast, “Historical Time Series,” DNV Company, 2024. [Online]. Available: https://solcast.com. [Accessed 20 November 2024].

- Cuce, P.M.; Cuce, E.; Sen, H. Improving Electricity Production in Solar Chimney Power Plants with Sloping Ground Design: An Extensive CFD Research. J. Sol. Energy Res. Updat. 2020, 7, 122–131. [CrossRef]

- Fluri, T.; von Backström, T. Comparison of modelling approaches and layouts for solar chimney turbines. Sol. Energy 2008, 82, 239–246. [CrossRef]

- Pretorius, J.P.; Kröger, D.G. Solar Chimney Power Plant Performance. J. Sol. Energy Eng. 2006, 128, 302–311. [CrossRef]

- Haaland, S.E. Simple and Explicit Formulas for the Friction Factor in Turbulent Pipe Flow. J. Fluids Eng. 1983, 105, 89–90. [CrossRef]

- Dawood, A.O.; Sangoor, A.J.; Al-Rkaby, A.H. Behavior of tall masonry chimneys under wind loadings using CFD technique. Case Stud. Constr. Mater. 2020, 13, e00451. [CrossRef]

- H. Sharon, “ A detailed review on sole and hybrid solar chimney based sustainable ventilation, power generation, and potable water production systems,” Energy Nexus, vol. 10, 2023.

- P. Singh, A. Kumar, Akshayveer and O. Singh, “Performance enhancement strategies of a hybrid solar chimney power plant T integrated with photovoltaic panel,” Energy Conversion and Management, vol. 218, 2020.

- Australian Bureau of Statistics, “New houses being built on smaller blocks.,” 7 June 2022. [Online]. Available: https://www.abs.gov.au/articles/new-houses-being-built-smaller-blocks#cite-window1. [Accessed 20 November 2024.

- The Engineering Toolbox, “ir - Density, Specific Weight and Thermal Expansion Coefficient vs. Temperature and Pressure,” 2003. [Online]. Available: https://www.engineeringtoolbox.com/air-density-specific-weight-d_600.html. [Accessed 20 November 2024].

- Green Match, “Best Air Source Heat Pump Manufacturers UK 2024,” 3 April 2024. [Online]. Available: https://www.greenmatch.co.uk/heat-pumps/manufacturers. [Accessed 20 November 2024].

- glassglobal, “Glass Directory,” 2024. [Online]. Available: https://www.glassglobal.com/directory/glass/. [Accessed 20 November 2024].

- The Trade Vision, “Ecuador Suppliers of plastic sheets,” 2024. [Online]. Available: https://www.thetradevision.com/global/plastic-sheets-suppliers-in-ecuador. [Accessed 20 November 2024].

- Volza Grow Global, “Pvc sheet export data of Australia,” 2024. [Online]. Available: https://www.volza.com/p/pvc-sheet/export/export-from-australia/. [Accessed 20 November 2024].

- OEC, “Bitumen and asphalt,” 2022. [Online]. Available: https://oec.world/en/profile/hs/bitumen-and-asphalt. [Accessed 20 November 2024].

- Viva Energy, “Geelong Refinery,” 2024. [Online]. Available: https://www.vivaenergy.com.au/operations/geelong. [Accessed 20 November 2024].

- International Trade Administration, “Ecuador - Country Commercial Guide,” 8 February 2024. [Online]. Available: https://www.trade.gov/country-commercial-guides/ecuador-mining#:~:text=Ecuador%20enjoys%20excellent%20mineral%20resources,increasing%2033%20percent%20in%20mining. [Accessed 20 November 2024].

- Australian Government: Geoscience Australia, “Australian mineral facts,” 19 April 2024. [Online]. Available: https://www.ga.gov.au/education/minerals-energy/australian-mineral-facts. [Accessed 20 November 2024].

- Echo Precast Engineering, “Uncharted territory for precast technology – first precast concrete plant opened in Ecuador,” Concrete Plant International, vol. 5, pp. 184-186, 2016.

- National Precast, “Find-a-master precaster,” 2024. [Online]. Available: https://nationalprecast.com.au/tools/find-a-master-precaster/. [Accessed 20 November 2024].

- ANSYS Granta EduPack, GRANTA EduPack software, Cambridge: ANSYS, 2022.

- Krishnan, A.R.; D, K. Influence of heat absorber materials sand, soil and paraffin wax in solar still on sustainable water distillation. Case Stud. Chem. Environ. Eng. 2023, 8. [CrossRef]

- The Engineering Toolbox, “Absorbed Solar Radiation,” 2009. [Online]. Available: https://www.engineeringtoolbox.com/solar-radiation-absorbed-materials-d_1568.html. [Accessed 20 November 2024].

- Adedeji, J. Aweda and O. Lasode, “Estimation of Service Life for a Solar Chimney-Collector System,” Lecture Notes in Engineering and Computer Science., 2010.

- EPA. United States Environmental Protection Agency. Greenhouse Gas Equivalencies Calculator. Available online https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator (accessed on 2 February 2018).

- Z. Xinping, Y. Jiakuan, X. Bo and H. Guoxiang, “Experimental study of temperature field in a solar chimney power setup,” Applied Thermal Engineering, vol. 27, no. 11-12, pp. 2044-2050, 2007.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).