Introduction

In the rapidly growing industrial setting the industrial systems require updated techniques for maintenance (Algabroun et al., 2022). The maintenance structures are important as they are responsible for guaranteeing operational effectiveness and improving the life of industry equipment. They further minimize downtime through effective maintenance tactics. Conventionally, the maintenance techniques are preventive and reactive, which leads to unexpected failure and extensive costs (Hardt et al., 2021). The issue of increased costs and failure serve as the challenges in the maintenance methods, therefore, there is a significant need to resolve these challenges through the predictive and prescriptive maintenance processes. Both these methods addressed particular issues in the maintenance methodologies, for instance, predictive maintenance utilizes real-time data to predict the lifespan of the equipment in order to identify the failure time of the equipment before it actually does (Lambán et al. 2022). On the other hand, prescriptive maintenance suggests actionable measures to overcome the issues highlighted by the predictive techniques.

Despite the cost-saving benefits, these advanced maintenance strategies still present several challenges, for instance, the outcomes of predictive and prescriptive analytics are based on advanced data analytics. According to (Ucar et al. 2024), it becomes challenging for these methods to handle excessive data generated by the industrial equipment, this data comprises the performance of the equipment. The Unified Namespace (UNS) in this regard provides an opportunity for a centralized data structure to act as a uniform piece of information for the entire operational data in the system (Péter and Werner, 2024). It enables real-time communication among the different devices, apps and systems. In order to enhance efficiency and overcome the data-related challenges UNS is incorporated in the prescriptive and predictive maintenance methods. Enterprises can now optimize information flow, enhance selection and streamline maintenance operations.

Concerning the effectiveness and usability of UNS in the maintenance systems, this article explores how UNS can be used to improve revamping strategies in an organizational setting, and studies its effectiveness in regard to record accessibility, interoperability, and method automation (Lazic et al., 2022). In addition, the facility examines the impact of UNS on reducing preservation costs, growing the reliability of the equipment and promoting a proactive maintenance culture. Consequently, the integration of UNS into predictive and prescriptive retention represents a huge advance in industrial asset management that leverages higher performance and sustainability in system maintenance. The aim of this article is to explore predictive and prescriptive maintenance techniques with a focus on UNS systems to optimize the performance of industrial equipment. In this regard, the following objectives are designed for this research article.

1.To explore the effectiveness of predictive and prescriptive maintenance methods using UNS for analyzing the lifespan of industrial equipment.

2. To study the existing prescriptive and predictive techniques for the maintenance of Industrial equipment.

3. To recommend strategies to optimize the applications of predictive and prescriptive maintenance techniques integrating UNS for industrial equipment.

2. Literature Review

2.1. Introduction to Maintenance Strategies

Maintenance strategies have evolved drastically, transitioning from basic reactive functions to advanced predictive and prescriptive processes. A reactive form of maintenance is additionally called "run-to-failure," which is the conventional method of addressing equipment malfunctions only after a breakdown happens. Although it involves minimal premature planning, it regularly leads to unplanned downtime and better restoration charges. Preventive maintenance also represents a proactive technique, scheduling recurring examinations and servicing to minimize the hazard of device failure (Lee et al., 2020). While it reduces the probability of unexpected breakdowns, it can result in unrequired maintenance and extended costs.

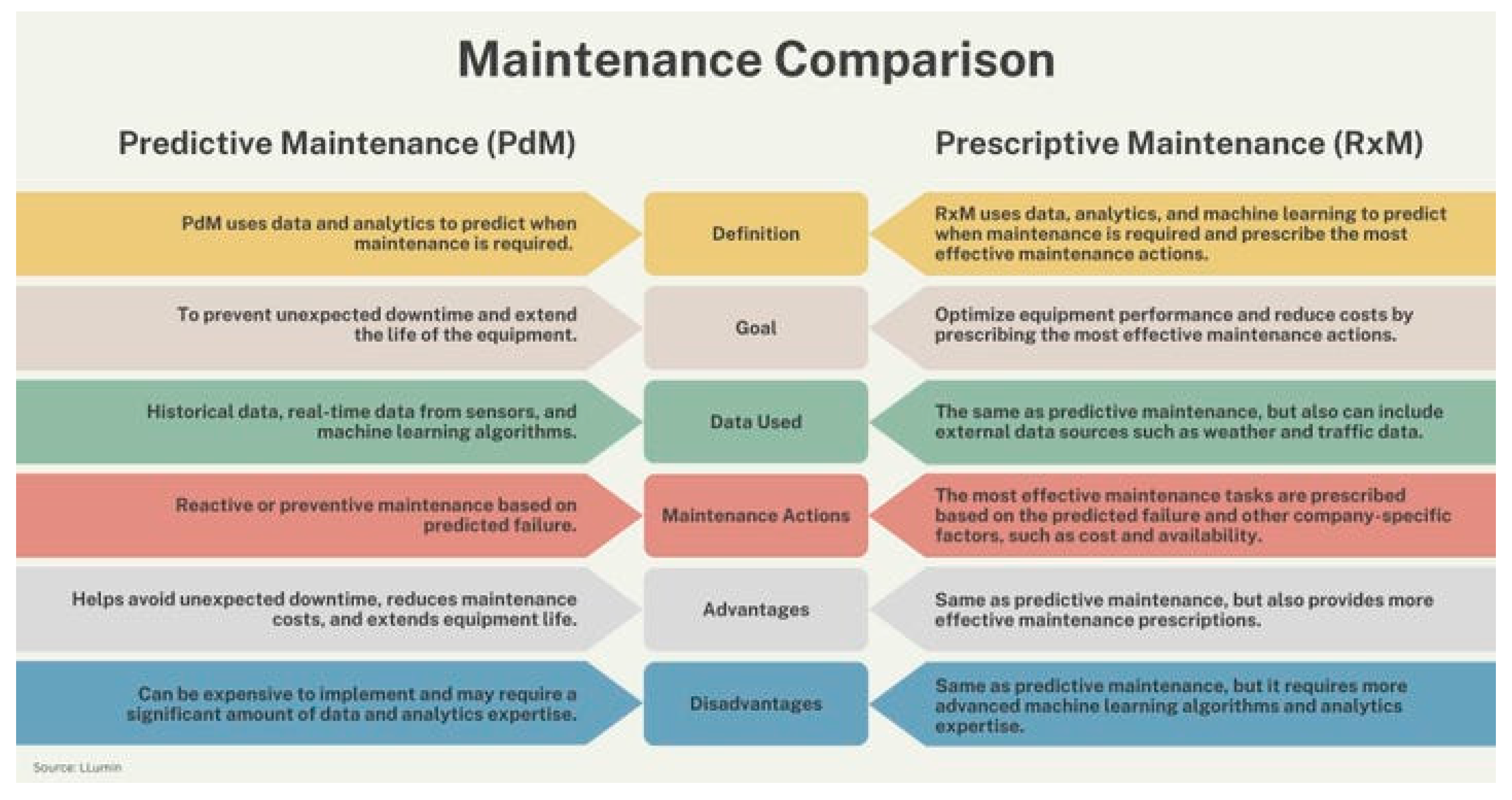

Predictive maintenance has emerged as leveraging actual-time records, sensor generation, and device studying to predict when equipment is likely to fail. This permits preservation groups to interfere best when important, decreasing downtime and optimizing costs. Building on this, prescriptive processes go beyond prediction by presenting actionable tips on how to save equipment from disasters and optimize device performance (Kabir, 2021). In modern business settings, where efficiency and reliability are paramount, superior protection strategies like predictive and prescriptive maintenance are essential. These strategies help lessen downtime, enhance asset lifespan and reduce costs while also enabling greener use of sources. Integrating those strategies is essential to accomplishing high ranges of operational performance, specifically in Industry 4.0 environments.

2.2. Predictive Maintenance: Concepts and Applications

Predictive maintenance is a data-oriented approach that aims to anticipate that equipment may fail, allowing for just-in-time maintenance to prevent failures. Unlike reactive maintenance, which deals with failures when they happen, or preventive maintenance (Erbiyik, 2022). It schedules recurring service based primarily on time or usage, predictive maintenance uses up-to-the-minute statistics from sensors into equipment to monitor performance and detect early signs and symptoms of ability problems. This method minimizes unplanned downtime and reduces costs associated with reconditioning. The evolution of predictive maintenance has been fueled by advances in data analytics, machine learning (ML) and the Internet of Things (IoT). IoT enables continuous monitoring with connected machines and sensors with respect to a series of real-time statistics on various parameters along with temperature, vibration, pressure and load (Chamorro et al., 2022). Data analytics and ML algorithms then process these statistics to identify patterns and anomalies that signify capacity limitations (Ariyaluran Habeeb et al. 2022). Over time, the learning models can increase their accuracy by becoming familiar with the older statistics, making predictions more reliable.

Some of the case studies also highlight the successful use of predictive maintenance in the industrial environment. For example, General Electric (GE) performs PdM throughout its commercial system, such as jet engines and windmills (Wesendrup and Hellingrath, 2020). Powered by IoT and AI, GE's predictive analytics platform enables you to reduce downtime, optimize maintenance plans and lower costs. Similarly, Siemens uses predictive maintenance for its enterprise equipment, using sensor facts to anticipate component failures in critical structures, thereby minimizing operational disruptions (Rojek et al. 2023). Another prime example is SKF, a bearing manufacturer that uses predictive maintenance to monitor the condition of a rotating system in industries such as manufacturing and transportation. By detecting early signs and symptoms of wear and tear, SKF helps its clients prevent catastrophic breakdowns and extend the lives of their assets (Abuelenin, 2020). These examples reveal how predictive refurbishment can greatly enhance the reliability and performance of equipment in many commercial sectors.

2.3. Prescriptive Maintenance: Advancing Beyond Prediction

Prescriptive Maintenance is the subsequent step in the development of maintenance techniques, advancing the previous predictive conservation by not only predicting equipment failures but also recommending actions to save or mitigate them (Molęda et al., 2023). While predictive maintenance uses real-time information and analytics that can be expected, while failures may additionally occur, prescriptive maintenance proceeds similarly by suggesting the most efficient path of movement whether it's scheduling repairs, adjusting operating parameters, or converting parts (Fox et al., 2022). This approach enables maintenance teams to make fact-based decisions, optimize overall system performance, and extend the life of the equipment in the industries. Key technologies and frameworks enable normative maintenance. Like predictive maintenance, prescriptive maintenance is based on IoT sensors and machine learning algorithms to acquire and explore system information. However, prescriptive maintenance includes optimization algorithms, simulation tools, and selection frameworks that offer useful insights (Koops, 2020). For example, digital twins, and virtual replicas of physical assets can simulate single maintenance scenarios and consequences that provide certain indicators for superior intervention. In addition, advanced analytics frameworks use prescriptive ways to offer ranked solutions entirely based on costs, time, and operational impact.

The advantages of prescriptive maintenance in commercial applications are numerous. Thus, by providing actionable insights, it enables you to reduce unplanned downtime, increase productivity and improve operational equipment effectiveness (Hermans and Péter Tamás, 2024). In addition, prescriptive maintenance can increase safety by addressing problems before they spread while optimizing resources such as spare parts and effort. For example, oil and gas organizations have adopted prescriptive refurbishment to reduce costly downtime and ensure the safe operation of critical equipment. However, several challenges remain in implementing normative protection on a massive scale. The data and integration present extensive obstacles, as prescriptive methods require correct and complete records from various assets. Additionally, organizational resistance and the need for qualified personnel to interpret and act on advice are not uncommon constraints. Despite these challenging situations, as Industry 4.0 technology continues to improve, prescriptive maintenance is becoming increasingly possible and valued in the commercial environment.

Figure 1 shows Comparison od Predictive and Prescriptive manitenance

2.4. Unified Namespace (UNS): A Data Architecture for Industry 4.0

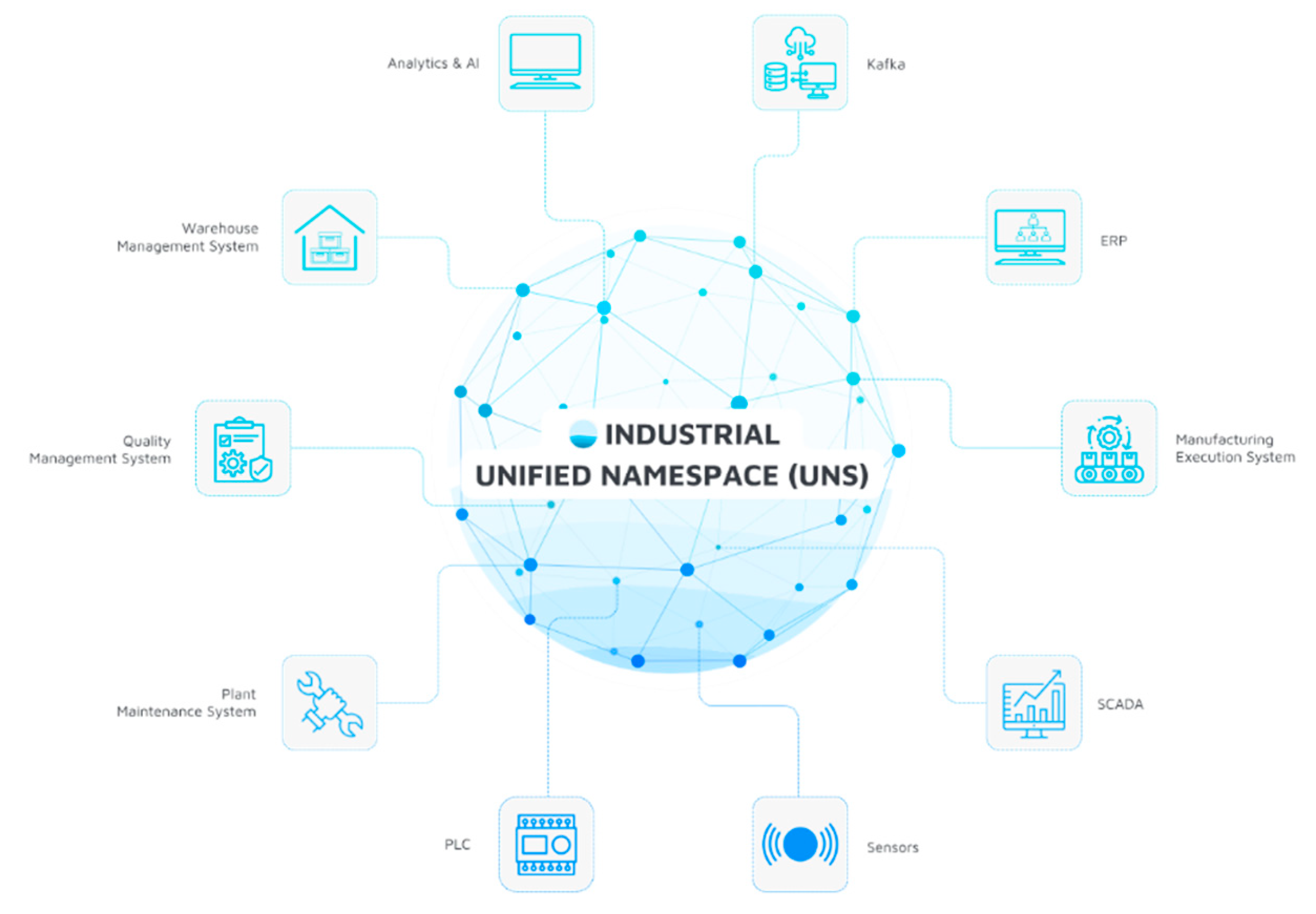

Unified Namespace is a data-based architecture idea that is valuable for the virtual transformation of business operations under Industry 4.0.

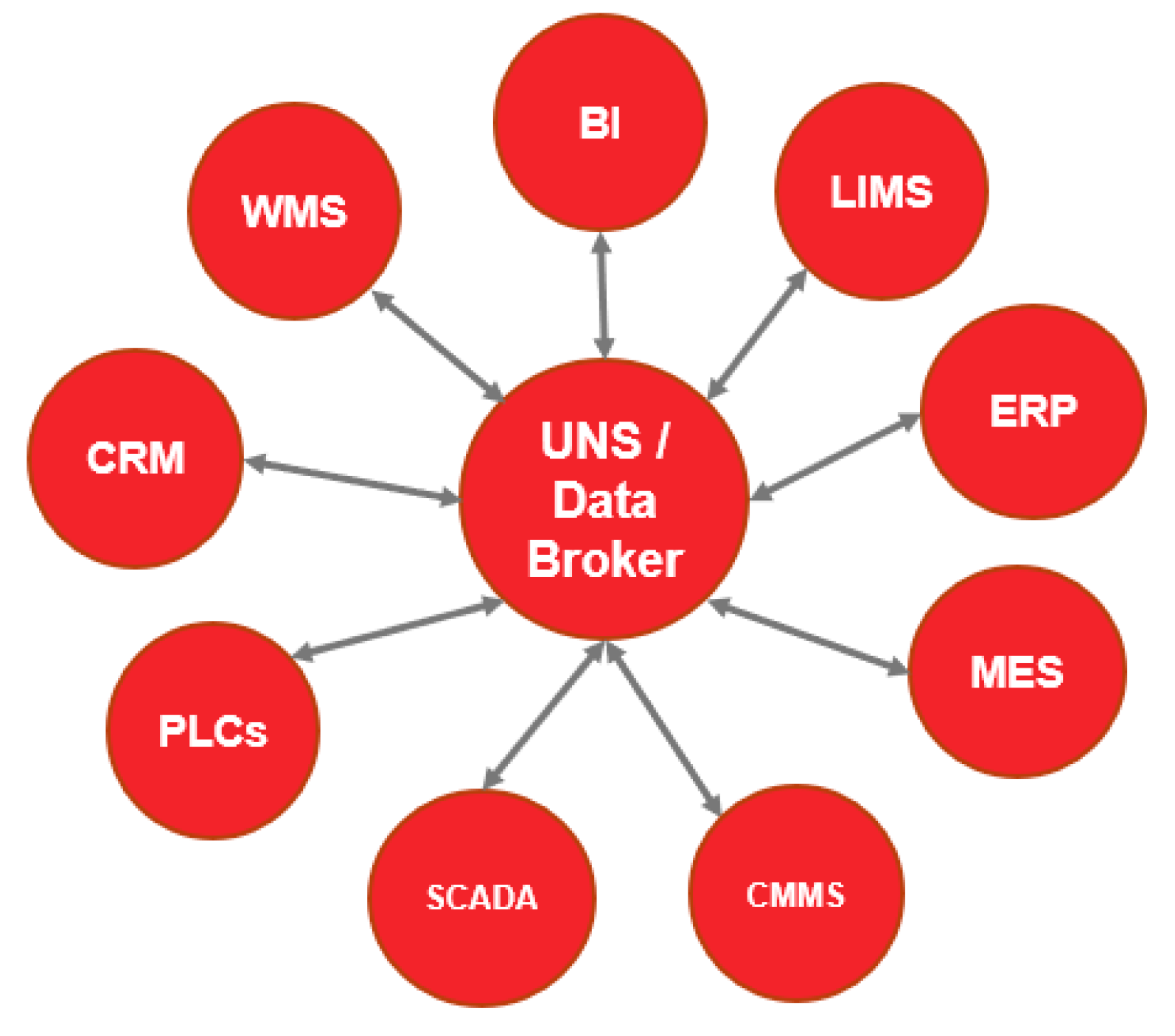

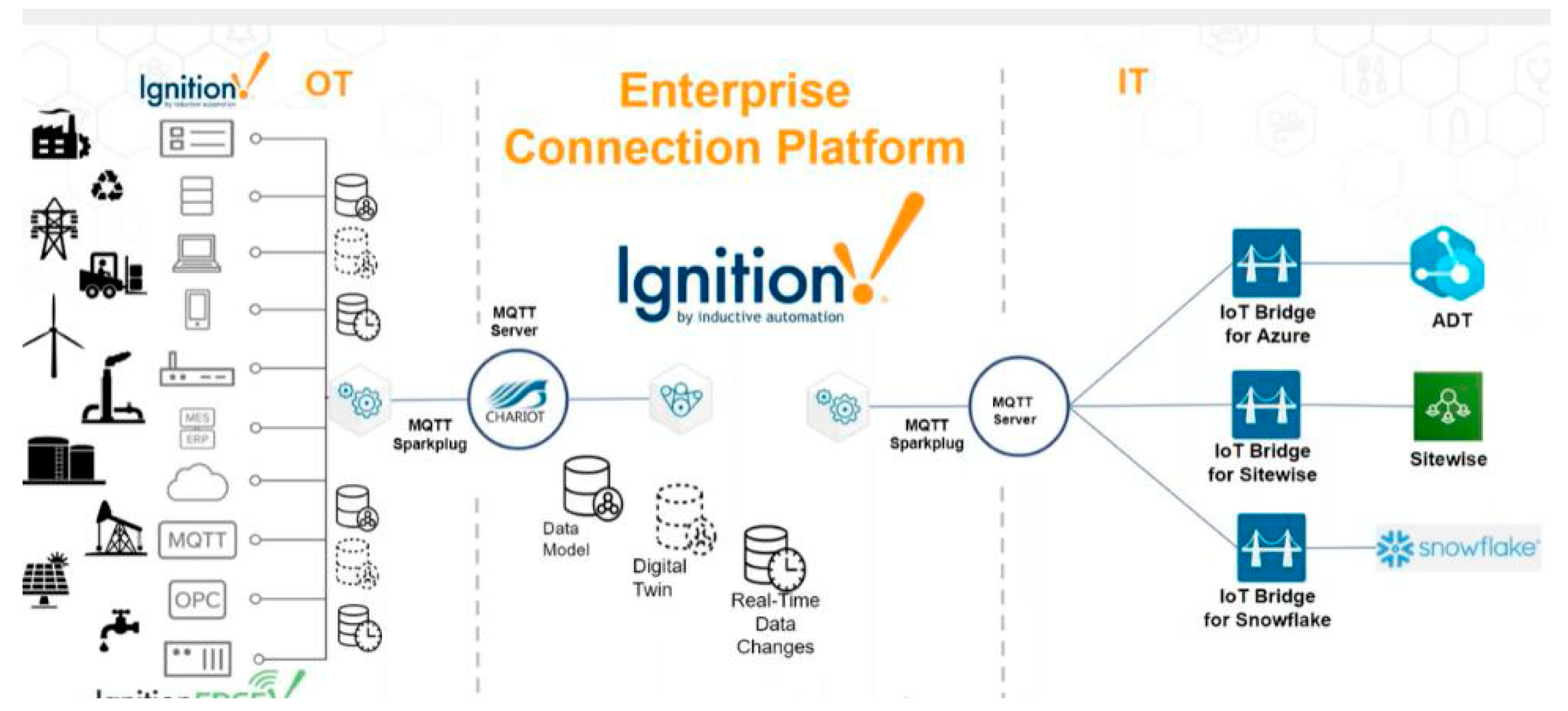

Figure 2 shows overall layout of UNS. Essentially, UNS serves as a centralized form of facts that integrates real-time statistics from multiple machines, devices and systems across the business environment. It works as a "single source of reality" in which all essential data streams consist of system popularity, procedure metrics and control data. These are consolidated and delivered to various stakeholders and systems, from cost-effective operators to employer-level analytics systems. One of the important roles of UNS is to facilitate seamless industrial verbal exchange. Traditionally, industrial systems have trusted infrastructures of classified records, where different machines or departments use their own protocols for verbal exchange (Winter et al., 2021), making it difficult to interpret statistics based on existing data. UNS addresses this by developing a unified data layer that guarantees real-time integration of facts (Eyeleko and Feng, 2023), regardless of the system or machine in use. This unification is key to maintaining a synchronized conversation between multiple devices and enables advanced applications such as predictive and prescriptive maintenance, virtual twins, and overall system effectiveness (OEE) monitoring.

Adopting UNS in an industrial environment offers significant benefits. For example, companies like Nestlé have rightly incorporated UNS to streamline operations in their manufacturing plants (Foley, 2020). By linking machines and up-to-date information into a disjointed namespace, Nestlé advanced production efficiency and reduced downtime through better predictive maintenance techniques likewise Procter.

2.5. The Intersection of UNS and Predictive/Prescriptive Maintenance

The Unified Namespace performs a crucial role in improving predictive and prescriptive maintenance strategies by developing a centralized, actual-time data hub that enables seamless conversation among diverse structures and devices. In industrial environments, powerful maintenance strategies require non-stop access to correct and up-to-date data from devices, sensors and managed structures. UNS addresses this requirement by unifying information streams from disparate assets, making them available in real-time for maintaining gear and analytics structures. These actual-time data records flow is important for predictive and prescriptive maintenance (Wennerström and Svensson, 2023), where timely and dependable information is essential for correct failure prediction and actionable insights.

UNS significantly improves the accessibility and visibility of operational information, which is a core requirement for each predictive and prescriptive protection. Traditional systems regularly be afflicted by data silos, in which crucial statistics are trapped within unique equipment or departments, making it tough to expand a holistic view of the operational environment (Péter and Werner, 2024). By presenting a single “source of truth,” UNS enables maintenance teams to get entry to and analyze information from across the complete system, ensuring more comprehensive and accurate predictions. Furthermore, due to the data, UNS helps actual-time data integration, it guarantees that predictive and prescriptive maintenance tools are usually operating with state-of-the-art information, minimizing the risk of incorrect predictions because of previous or incomplete data. The integration of UNS with predictive and prescriptive maintains and creates an effective framework for protection optimization (Elijah et al., 2021). Predictive renovation systems rely upon real-time statistics from UNS to monitor system situations, discover anomalies, and expect when screw-ups are in all likelihood to arise. With UNS, predictive models can get the right of entry to a non-stop stream of data from sensors and machines, improving the accuracy of predictions. Prescriptive maintenance takes this a step in addition via leveraging UNS to simulate one-of-a-kind maintenance scenarios and advise the only actions. UNS lets in prescriptive structures to get the right of entry to a broader dataset, which includes real-time device reputation, historical performance facts, and operational context, enabling accurate and actionable recommendations.

There are several case research that highlight the intersection of UNS with predictive and prescriptive maintenance. For example, Nestlé makes use of UNS to assist predictive maintenance throughout its manufacturing plant life. By integrating equipment data into a unified namespace, according to the study by Daniel Oluwasegun Uzoigwe (2024), Nestlé improved the accuracy of its predictive trends, lowering unplanned downtime and optimizing protection schedules. Similarly, Coca-Cola has applied UNS to connect its manufacturing line statistics with predictive maintenance tools, permitting actual time tracking and early detection of capability equipment failure. This integration has helped Coca-Cola appreciably reduce downtime and enhance production efficiency. Despite the effectiveness, several challenges remain in fully integrating UNS with preservation structures. Issues consisting of statistics standardization, legacy machine integration, and cybersecurity want to be addressed to completely recognise the capacity of UNS in upkeep optimization (Ayodeji et al., 2020). Nonetheless, as commercial environments hold to embrace virtual transformation, the combination of UNS with predictive and prescriptive maintenance is emerging as an effective approach to enhance operational efficiency and device reliability.

2.6. Challenges and Limitations of UNS in Maintenance Systems

Technical, operational, and organizational barriers to UNS implementation.

Data privacy and security concerns.

Possible solutions and ongoing research to address these limitations.

2.7. Future Trends and Innovations in Predictive and Prescriptive Maintenance

Emerging technologies and methodologies influencing future maintenance practices.

The role of AI, machine learning, and edge computing.

UNS in the context of Industry 4.0 and its future potential for maintenance.

2.8. Gaps in current research and areas for future exploration

UNS in industrial equipment optimization as related to predictive and prescriptive maintenance provides quite a few gaps in the current research opportunities to explore more about it:

Integration with Legacy Systems: Often, industrial setups still rely on relatively old equipment that doesn't support compatibility with UNS, which requires middleware solutions for retrofitting these systems.

Real-Time Analytics: Very few research articles are in the literature related to optimizing edge-based analytics in UNS for predictive maintenance. Thus, there are possibilities for future work to be developed that can enhance the machine-learning models with greater speed and accuracy.

Cybersecurity Concerns: UNS is also susceptible to cyber threats. Strong cyber security techniques must be developed for handling real-time data.

Scalability and Interoperability: Many current studies focus on specific types of equipment that limit the scalability of their resulting applications. Research should be directed toward developing UNS implementations across different industrial systems with standardized interoperability protocols.

Environmental Impacts: UNS-based strategies are applicable in meeting some sustainability goals. Further work could be done to show whether UNS can further improve resource efficiency and waste minimization.

Through such gaps, UNS's scalability and efficiency in its maintenance practices will improve, considering cybersecurity, cost implications, and human factors.

3. Methods

The Unified Namespace architecture defines the methodology that optimizes predictive and prescriptive maintenance for equipment within industrial facilities. This methodology describes the processes of collecting, processing, and analyzing real-time industrial data and extracting actionable insights for maintenance decisions from that data. The subsequent sections deal with research design, data collection tools, and implementation of predictive and prescriptive maintenance strategies.

3.1. Research Design

A study based on a quantitative research design will be offered to the focus audience, consisting of data on industrial equipment collected and analyzed by integrating sensors and systems into a Unified Namespace. The maintenance processes will be optimized by applying predictive and prescriptive models for maintenance upon the availability of real-time data.

This methodology forms a case study of how the UNS system will affect equipment efficiency and the impact of cutting downtime in an industrial setting. Some of the core components of research are given below:

A UNS system for integrating data.

Predictive maintenance models for failure prediction.

Prescriptive maintenance to give optimal actions.

This approach provides a broader view of how UNS can impact processes to streamline maintenance and increase efficiency in industrial operations.

3.2. Implementation of UNS

Embedding the data communication framework into information on industrial equipment will be real-time. In the context of this research, UNS was implemented for integration purposes on various data sources, communication protocols, and equipment under one unified digital umbrella. UNS will:

Enable communication between predictive and prescriptive maintenance processes. The UNS system supports inter-device real-time data exchange that enhances the effectiveness of both predictive and prescriptive models, illustrated in

Figure 3

3.3. Data Mining

Industrial data is collected from several sources. Some of the data collection sources include:

Sensors are placed on crucial industrial equipment to measure important parameters such as temperature, pressure, vibrations, and energy consumption.

PLC (Programmable Logic Controllers): enables real-time control data coming from equipment

SCADA (Supervisory Control and Data Acquisition): collects and tracks process data to facilitate a high-performance system.

Industrial Internet of Things Devices: Since they are taken to provide real-time information, they thus ensure the development of a digital twin of physical assets that are used to enhance the maintenance process.

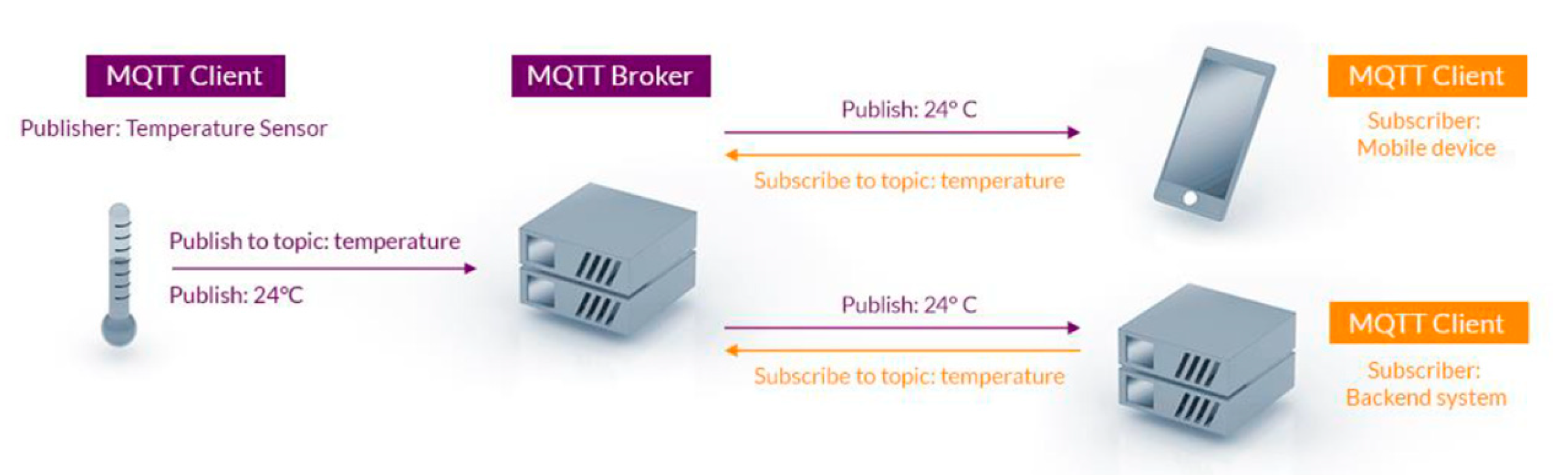

Data transmission protocols that feature in this study include:

OPC-UA (Open Platform Communications - Unified Architecture) and OPC-DA (Data Access): Specifications for industrial real-time communication.

3.4. Data Processing and Analysis

These are the steps taken in the processing of data as collected by the UNS:

Real-Time Data Integration: Sensors, PLCs, and SCADA systems collect data normalized and integrated using the UNS. This helps normalize data so all devices can talk to each other equally, regardless of the protocol.

Predictive Maintenance Model: The predictive maintenance model elaborates on both historical and on-time data. Regression analysis and anomaly detection of machine learning algorithms find tendencies showing probable equipment degradation or failures.

Deviations in temperature, pressure, and vibrations from normal operational conditions.

Higher energy input with probable inefficiency in the system.

Digital Twin Building: This is a digital twin of the equipment to be developed for simulating real conditions in the operating environment. This digital model follows the equipment's performance and helps detect its deviation from the predicted output. Thus, it creates a test platform for strategies before implementing them in real operations.

Prescriptive Maintenance Model: Given the output of a predictive maintenance system, prescriptive algorithms recommend optimal actions. These include:

Replacement of the part to be repaired.

We are changing the operational parameters to avoid impending failure.

Critical threshold is reached, it automatically triggers an alarm signal or machine shutdown.

3.5. Predictive and Prescriptive Support for Maintenance

Predictive Maintenance: This model type predicts equipment failure by analyzing trends and anomalies in data. The UNS continually monitors the health of equipment by providing data. Predictive maintenance does away with unannounced downtimes since they provide precursory warnings of probable failures, and maintenance teams intervene beforehand.

Prescriptive Maintenance: The prescriptive maintenance system offers the best alternatives to be carried out in real-time based on the anticipated troubles highlighted by the predictive model. Such actions as scheduling maintenance, resource mobilization, or re-structuring equipment to prevent shutdowns highlighted by the model are followed through machine learning.

3.6. Tools and Software

The following tools were utilized for processing the data and modeling as well as integration into the UNS system:

MQTT Broker enables industrial devices to communicate with the UNS and carry out high-fidelity rapid data transfer.

Splunk Cloud aggregates and analyzes Big Data from large industrial plants, using machine learning techniques to perform predictive modeling.

3.7. Lifecycle Phases of the Maintenance Strategy

The maintenance strategy goes through the following stages.

Perceived Plan: The maintenance plan is run by perceived needs, mostly based on some form of time-based methodology.

Conceived Plan: Having installed core digital infrastructure, at least a degree of analysis can be undertaken of that data.

Predictive Plan: Predictive maintenance models are again led by real-time data and then making a prediction of when those failures might happen.

Adaptive Plan: At this stage, prescriptive maintenance needs to be considered, where the system recommends prescriptive action or advice upon gaining predictive insight.

3.8. Data Security and Integrity

As a part of the process, ensure data while in transit by the UNS is safe and integrity has been taken with the following steps:

Encryption: All data sent using MQTT and OPC-UA is encrypted so that no unauthorized access is allowed.

Access Control: To secure the system, authorized personnel are granted access to sensitive data and operational controls.

Audit Trails: All communications with the system are logged in full traceability in case of system failure or anomaly.

3.9. Evaluation and Testing

The following performance metrics were used to evaluate the effectiveness of the developed predictive and prescriptive maintenance models:

Reduction in Downtime: It is measured by the decreased rate of unplanned equipment.

Cost saving: It is calculated due to the lower maintenance cost from proper timing intervention.

Improvement Efficiency: It appears as a general increase in system efficiency caused by optimized maintenance schedules and fewer machine failures.

The predictive and prescriptive models have been tested in a controlled industrial setting that simulates several failure conditions. The results show how well and how often the models' predictions and recommendations are correct.

4. Findings

These new insights, derived from an analysis of how real-time information and the strategies imposed over maintenance can be combined, reveal how a single data architecture can help enhance efficiency or decrease time-variant downtime within an industrial setting. New insights into the optimization of industrial equipment based on analyses of predictive and prescriptive UNS-based maintenance systems:

4.1. Better Flow and Interaction Between Data

It achieved this by effectively centralizing all data communication in the industrial ecosystem and making data exchange from different protocols to different devices entirely seamless (Ali and Sofi, 2021). This consolidation of diverse types of sensors, PLCs, SCADA systems, and IIoT devices eliminated traditional industrial data silos by bringing things to a more holistic capability for monitoring and maintenance (Wu, et al., 2020). This standard data architecture allowed for high accuracy in monitoring in real-time, thus allowing predictive models to rely on it, and it also reduced latency in answering possible cases of equipment failure.

4.2. Optimization of Predictive Maintenance

Real-time UNS-driven data predictive maintenance models built and powered have provided insight into the process of deterioration of equipment. Applications of machine learning algorithms and anomaly detection indicated possible performance deviations, especially concerning temperature, vibration, and energy consumption, all before it happened (Herrero and Zorrilla, 2022). Predictions for failures were accurate; therefore, potential failures were resolved in due time so that the unscheduled downtime could be minimized. Of crucial importance was the integration of a digital twin in the UNS, which made possible the continuous virtual monitoring and pre-emptive testing of maintenance strategies (Werner et al. 2023).

4.3. Smarter Maintenance Decision

Based on predictive insights, this prescriptive maintenance framework precisely targeted recommendations for optimizing equipment performance. Prescriptive models proved effective in predicting specific maintenance actions, such as scheduling repairs, changing machine settings, or ordering an immediate shutdown to avoid a catastrophic failure, based on real-time data and the system's conditions (Gordon, et al., 2020). Such proactive maintenance was highly effective in decisions: operators leveraged data-driven prescriptions to implement appropriate interventions quickly. The authoritarian actions also leveraged the operating parameters, thus improving the overall lifetime of the equipment and wasting minimal resources (Rodríguez et al. 2024).

4.4. Seamless Integration with IIoT Data with their equipment

The connection of IIoT (Industrial Internet of Things) to the UNS enabled it to expand the scope of its real-time data capture. Also, the devices of IIoT enabled continuous monitoring of critical parameters such as pressure, speed, and operational status at different locations and systems. Real-time data easily enables the creation of a digital shadow that mirrors the physical assets, thus enabling continuous performance calculation. The UNS fits into other industrial sources of data besides devices on IIoT, hence creating stronger and more comprehensive models for both predictive and prescriptive maintenance (Javaid, et al., 2021).

4.5 Scalability and Flexibility of UNS

The key findings that make the UNS system standout are its scalability, making it deployable across various scales of industrial operations. Whether it was a simple data integration,

Figure 5, from one site or a multi-location enterprise of significance, the UNS always maintained its efficiency and reliability (Kocot et al. 2023). The system demonstrated robustness along with such flexibility in allowing different data formats and communication protocols from OPC-UA to MQTT and legacy systems like Modbus and BACnet. This characteristic makes UNS the long-term solution for companies wanting to implement advance-maintenance strategies yet retaining any available infrastructure (Silva et al. 2021).

4.6. Cost Efficiency through Optimised Maintenance

They were directly transferring predictive and prescriptive models into UNS translated to great cost-saving measures. The system improved the unscheduled downtimes in terms of retaining the continuity of operations and reducing the financial impact of emergency repairs. Moreover, the optimized schedules in maintenance allocated resources only when required. That means there was neither an over-maintenance scenario nor an under-maintenance scenario. Optimized schedules in terms of maintenance strategies went on to translate into more efficient usage of labor and materials to be translated into the overall cost efficiency of the system (Pinciroli et al. 2023)

4.7. Smooth Integration of Digital Shadow and Data Hub

The predictive and prescriptive maintenance potentiality was revealed through a digital shadow-the real-time digital replica of the physical equipment. The digital shadow and the data hub would provide real-time visualization of equipment performance with the opportunity to compare current conditions against historical data to make the predictions of failures much better. At this stage, the maintenance decisions were based on the most current integrated data to ensure effectiveness toward prolonging equipment life besides ensuring operational efficiency.

4.8. Data Security and Integrity in Maintenance Operation

The UNS framework ensured the utmost security and integrity of data through the system. It utilized encrypted protocols such as MQTT and OPC-UA, which prevented unauthorized access to sensitive industrial data. Strict access controls and audit trails ensured the system's integrity was maintained by applying correct and reliable data points on predictive and prescriptive models. The security framework provided here not only had an important function to make operators accept and sustain strategies over long periods based on recommendations offered but also proved crucial in earning operator confidence for recommended actions by the system (Mathew et al. 2023).

4.9. Integrated Maintenance Framework: From Predictive to Prescriptive

This led to a shift from predictive to prescriptive maintenance. The UNS produced a comprehensive framework for maintenance that was variant with the operational circumstances. Predictive models helped point out possible issues before they became big problems. Prescriptive models furnished recommendations that could be put into action to avoid those problems. Thus, the two types of maintenance described above allowed the dynamic system not only to predict failures but also to work efficaciously in preventing failures, making the maintenance process effective (Zhao et al. 2023)

4.10. Overall Impact on Efficiency of Operations

With UNS, overall productive time in the industrial environment improved significantly upon implementing predictive and prescriptive maintenance models. Equipment uptime and process reliability improved due to efficient maintenance scheduling and the uneventful nature of breakdowns that caught people off guard. Quicker responses and efficient use of existing resources are more important in bringing much-needed, productive operations into the industry through real-time, actionable insights.

5. Conclusions

The integration of UNS in the maintenance of industrial equipment may significantly improve strategies such as predictive and prescriptive. Its ability to centralize real-time data emanating from various sources, combined with integrated machine learning models, provides early detection for possible equipment failure, optimizes the maintenance arrangement schedule, and gives actionable recommendations. Improved operational efficiency, with potential savings in reduced downtime and costs, occurs without compromising scalability and flexibility within diverse industrial environments. This digital shadow with integrated secure communication protocols ensures that the maintenance decision is always based on available data and is thus reliable, strengthening the long-term viability of this unified maintenance framework. In addition, the seamless integration of the UNS framework with IIoT devices gives it a powerful ability of continuous monitoring of critical parameters, and provides a complete digital shadow of physical assets. By visualizing it in real time, the predictions are more accurate, and the interventions can respond faster, keeping equipment in good shape and boosting operational efficiency. Secure industrial data is protected by the system’s robust security measures including encrypted protocols and tight access controls, which build up trust and confidence among operators. As a result, the UNS framework goes beyond predicting potential problems to prescribing the much more effective actions to prevent them, leading to maximum equipment uptime and reliability. The holistic approach in the end enables for the development of a more sustainable and high effective industrial maintenance strategy that is long run successful.

References

- Abuelenin, M.H. (2020). Risk-Based Maintenance Management System Achieving Operational Excellence. Day 1 Mon, November 09, 2020. [CrossRef]

- Algabroun, H., Bokrantz, J., Al-Najjar, B. and Skoogh, A., (2022). Development of digitalised maintenance–a concept. Journal of Quality in Maintenance Engineering, 28(2), pp.367-390. [CrossRef]

- Ali, J. and Sofi, S., 2021. Ensuring security and transparency in distributed communication in iot ecosystems using blockchain technology: Protocols, applications and challenges. International Journal of Computing and Digital System.

- Ariyaluran Habeeb, R.A., Nasaruddin, F., Gani, A., Amanullah, M.A., Abaker Targio Hashem, I., Ahmed, E., and Imran, M. (2022) ‘Clustering-based real-time anomaly detection—A breakthrough in big data technologies’, Transactions on Emerging Telecommunications Technologies, 33(8), e3647.

- Ayodeji, A., Liu, Y., Chao, N. and Yang, L. (2020). A new perspective towards the development of robust data-driven intrusion detection for industrial control systems. Nuclear Engineering and Technology. [CrossRef]

- Chamorro, J., Vallejo, L., Maynard, C., Guevara, S., Solorio, J.A., Soto, N., Singh, K.V., Bhate, U., G.V.V., R.K., Garcia, J. and Newell, B. (2022). Health monitoring of a conveyor belt system using machine vision and real-time sensor data. CIRP Journal of Manufacturing Science and Technology, 38, pp.38–50. [CrossRef]

- Daniel Oluwasegun Uzoigwe (2024). Evaluating the Effectiveness of Reliability-Centered Maintenance Programs in Food and Beverage Manufacturing Facilities; A Review. International journal of research and innovation in applied science, IX(II), pp.204–232. [CrossRef]

- Elijah, O., Ling, P.A., Abdul Rahim, S.K., Geok, T.K., Arsad, A., Kadir, E.A., Abdurrahman, M., Junin, R., Agi, A. and Abdulfatah, M.Y. (2021). A Survey on Industry 4.0 for the Oil and Gas Industry: Upstream Sector. IEEE Access, 9, pp.144438–144468. [CrossRef]

- Erbiyik, H. (2022). Definition of Maintenance and Maintenance Types with Due Care on Preventive Maintenance. [online] www.intechopen.com. Available at: https://www.intechopen.com/chapters/83444.

- Eyeleko, A.H. and Feng, T. (2023). A Critical Overview of Industrial Internet of Things Security and Privacy Issues Using a Layer-Based Hacking Scenario | IEEE Journals & Magazine | IEEE Xplore. [online] ieeexplore.ieee.org. Available at: https://ieeexplore.ieee.org/abstract/document/10229166/.

- Foley, M.E. (2020). Digital Disruption: Exploring Effects on the Manufacturing Environment - ProQuest. [online] Proquest.com. Available at: https://www.proquest.com/openview/ddb3b3a9aa820abb992b0974c8e1cd7a/1.pdf?pq-origsite=gscholar&cbl=51922&diss=y [Accessed 5 Oct. 2024].

- Fox, H., Pillai, A.C., Friedrich, D., Collu, M., Dawood, T. and Johanning, L. (2022). A Review of Predictive and Prescriptive Offshore Wind Farm Operation and Maintenance. Energies, 15(2), p.504. [CrossRef]

- Gordon, C.A.K., Burnak, B., Onel, M. and Pistikopoulos, E.N., 2020. Data-driven prescriptive maintenance: Failure prediction using ensemble support vector classification for optimal process and maintenance scheduling. Industrial & Engineering Chemistry Research, 59(44), pp.19607-19622.

- Hardt, F., Kotyrba, M., Volna, E. and Jarusek, R. (2021). Innovative Approach to Preventive Maintenance of Production Equipment Based on a Modified TPM Methodology for Industry 4.0. Applied Sciences, [online] 11(15), p.6953. [CrossRef]

- Hermans, M. and Péter Tamás (2024). OEE as a Tool for Stability and Continuity. Lecture notes in logistics, pp.15–40. [CrossRef]

- Herrero, R.D. and Zorrilla, M., 2022. An I4. 0 data intensive platform suitable for the deployment of machine learning models: a predictive maintenance service case study. Procedia Computer Science, 200, pp.1014-1023.

- Javaid, M., Haleem, A., Singh, R.P., Rab, S. and Suman, R., 2021. Upgrading the manufacturing sector via applications of Industrial Internet of Things (IIoT). Sensors International, 2, p.100129.

- Kabir, E. (2021). Predictive and Prescriptive Analytics for Managing the Impact of Hazards on Power Systems. Deep Blue (University of Michigan). [CrossRef]

- Kocot, B., Czarnul, P., and Proficz, J. (2023) ‘Energy-aware scheduling for high-performance computing systems: A survey’, Energies, 16(2), 890.

- Koops, L.G., 2020, July. Optimized maintenance decision-making—A simulation-supported prescriptive analytics approach based on probabilistic cost-benefit analysis. In PHM Soc. Eur. Conf (Vol. 5, p. 14). Accessed on 5th Oct 2024 available at: https://www.researchgate.net/profile/Lily-Koops/publication/344025081_Optimized_Maintenance_Decision-Making_-A_Simulation-supported_Prescriptive_Analytics_Approach_based_on_Probabilistic_Cost-Benefit_Analysis/links/5f4e4f33458515e96d1f0646/Optimized-Maintenance-Decision-Making-A-Simulation-supported-Prescriptive-Analytics-Approach-based-on-Probabilistic-Cost-Benefit-Analysis.pdf.

- Lambán, M.P., Morella, P., Royo, J., and Sánchez, J.C. (2022) ‘Using industry 4.0 to face the challenges of predictive maintenance: A key performance indicators development in a cyber physical system’, Computers & Industrial Engineering, 171, 108400.

- Lazic, I., Ferran Agullo, Aussó, S., José, B., Barelle, C., Josep Ll. Berral, Paschalis Bizopoulos, Oana Bunduc, Ioanna Chouvarda, Dominguez, D., Dimitrios Filos, Gutierrez-Torre, A., Iman Hesso, Nikša Jakovljević, Kayyali, R., Kogut-Czarkowska, M., Kosvyra, A., Lalas, A., Lavdaniti, M. and Tatjana Lončar-Turukalo (2022). The Holistic Perspective of the INCISIVE Project—Artificial Intelligence in Screening Mammography. Applied sciences, 12(17), pp.8755–8755. [CrossRef]

- Lee, J., Ni, J., Singh, J., Jiang, B., Azamfar, M. and Feng, J., (2020). Intelligent maintenance systems and predictive manufacturing. Journal of Manufacturing Science and Engineering, 142(11), p.110805. Accessed on 5th Oct 2024 available at: https://www.researchgate.net/profile/Moslem-Azamfar-2/publication/343121327_Intelligent_Maintenance_Systems_and_Predictive_Manufacturing/links/5fbd099fa6fdcc6cc65f2f12/Intelligent-Maintenance-Systems-and-Predictive-Manufacturing.pdf.

- Mathew, D., Brintha, N., and Jappes, J.W. (2023) ‘Artificial intelligence powered automation for industry 4.0’, in New Horizons for Industry 4.0 in Modern Business, Springer, 1–28.

- Molęda, M., Małysiak-Mrozek, B., Ding, W., Sunderam, V. and Mrozek, D. (2023). From Corrective to Predictive Maintenance—A Review of Maintenance Approaches for the Power Industry. Sensors, [online] 23(13), p.5970. [CrossRef]

- Péter, Á. and Werner, S., (2024). The Impact of Unified Namespace in Industry 4.0. [Online] Accessed on 5th Oct 2024 available at: https://lup.lub.lu.se/luur/download?func=downloadFile&recordOId=9174552&fileOId=9174561.

- Pinciroli, L., Baraldi, P., and Zio, E. (2023) ‘Maintenance optimization in industry 4.0’, Reliability Engineering & System Safety, 234, 109204.

- Rodríguez, M., Crespo, A., and González-Prida, V. (2024) ‘Enhancing Prescriptive Capabilities in Electrical Substations: A Systemic Impact Factor Approach for Failure Impact Analysis’, Energies, 17(4), 770.

- Rojek, I., Jasiulewicz-Kaczmarek, M., Piechowski, M., and Mikołajewski, D. (2023) ‘An artificial intelligence approach for improving maintenance to supervise machine failures and support their repair’, Applied Sciences, 13(8), 4971.

- Ucar, A., Karakose, M., and Kırımça, N. (2024) ‘Artificial intelligence for predictive maintenance applications: key components, trustworthiness, and future trends’, Applied Sciences, 14(2), 898.

- Wennerström, K. and Svensson, A. (2023). Predictive Maintenance in Production Robots in a Real World Industrial Setting. [online] Chalmers.se. Available at: http://odr.chalmers.se/items/d765b833-987b-48d4-b611-c104a908c506 [Accessed 5 Oct. 2024].

- Werner, A., Mendez-Rial, R., Salvo, P., Charisi, V., Piccini, J., Mousavi, A., Civardi, C., Monios, N., Espinosa, D.B., Hildebrand, M., and others (2023) ‘Architecture for Predictive Maintenance Based on Integrated Models, Methods and Technologies’, in Intelligent and Transformative Production in Pandemic Times: Proceedings of the 26th International Conference on Production Research, Springer, 259–274.

- Wesendrup, K. and Hellingrath, B., 2020, July. A process-based review of post-prognostics decision-making. In A. Bregon & K. Medjaher (Chairs), 5th European Conference of the PHM Society, Virtual. Accessed on 5th Oct 2024 available at: https://www.researchgate.net/profile/Kevin-Wesendrup-2/publication/343305494_A_Process-based_Review_of_Post-Prognostics_Decision-Making/links/5f227854458515b729f3352a/A-Process-based-Review-of-Post-Prognostics-Decision-Making.pdf.

- Winter, P.M., Eder, S., Weissenböck, J., Schwald, C., Doms, T., Vogt, T., Hochreiter, S. and Nessler, B. (2021). Trusted Artificial Intelligence: Towards Certification of Machine Learning Applications. arXiv (Cornell University). [CrossRef]

- Wu, Y., Dai, H.N. and Wang, H., 2020. Convergence of blockchain and edge computing for secure and scalable IIoT critical infrastructures in industry 4.0. IEEE Internet of Things Journal, 8(4), pp.2300-2317.

- Zhao, D., Xia, Z., Zhu, Y.-A., and Duan, J.-H. (2023) ‘Overview of predictive maintenance based on digital twin technology’, Heliyon, available: https://. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).