1. Introduction

China’s global contract engineering company has achieved notable growth through its "Going Global" and "Belt and Road" initiatives. The EPC (Engineering-Procurement-Construction) model is increasingly favored for its efficient resource allocation, significantly impacting project costs, timing, and quality. Effective procurement, supported by integrated supply chain management, enables multinational EPC contractors to enhance operations and streamline processes through stakeholder alliances.

Recognizing the complexity and importance of procurement in international EPC projects, contractors are exploring innovative strategies to improve management standards. Traditional practices often treat relationships among supply chain participants, contractors, suppliers, owners, and consulting engineers—as temporary contracts, which can lead to inefficiencies, lack of cooperation, and increased costs [

1]. Such challenges necessitate novel approaches to procurement.

Researchers advocate for integrated supply chain management to consolidate fragmented processes, reduce costs, and save time [

2,

3,

4]. While supply chain integration has shown success in various industries, its application in construction remains largely theoretical, with limited real-world implementation [

1]. Proposed strategies for effective supply chain management include fostering long-term partnerships [

5], consolidating suppliers [

6] and enhancing information exchange [

7].

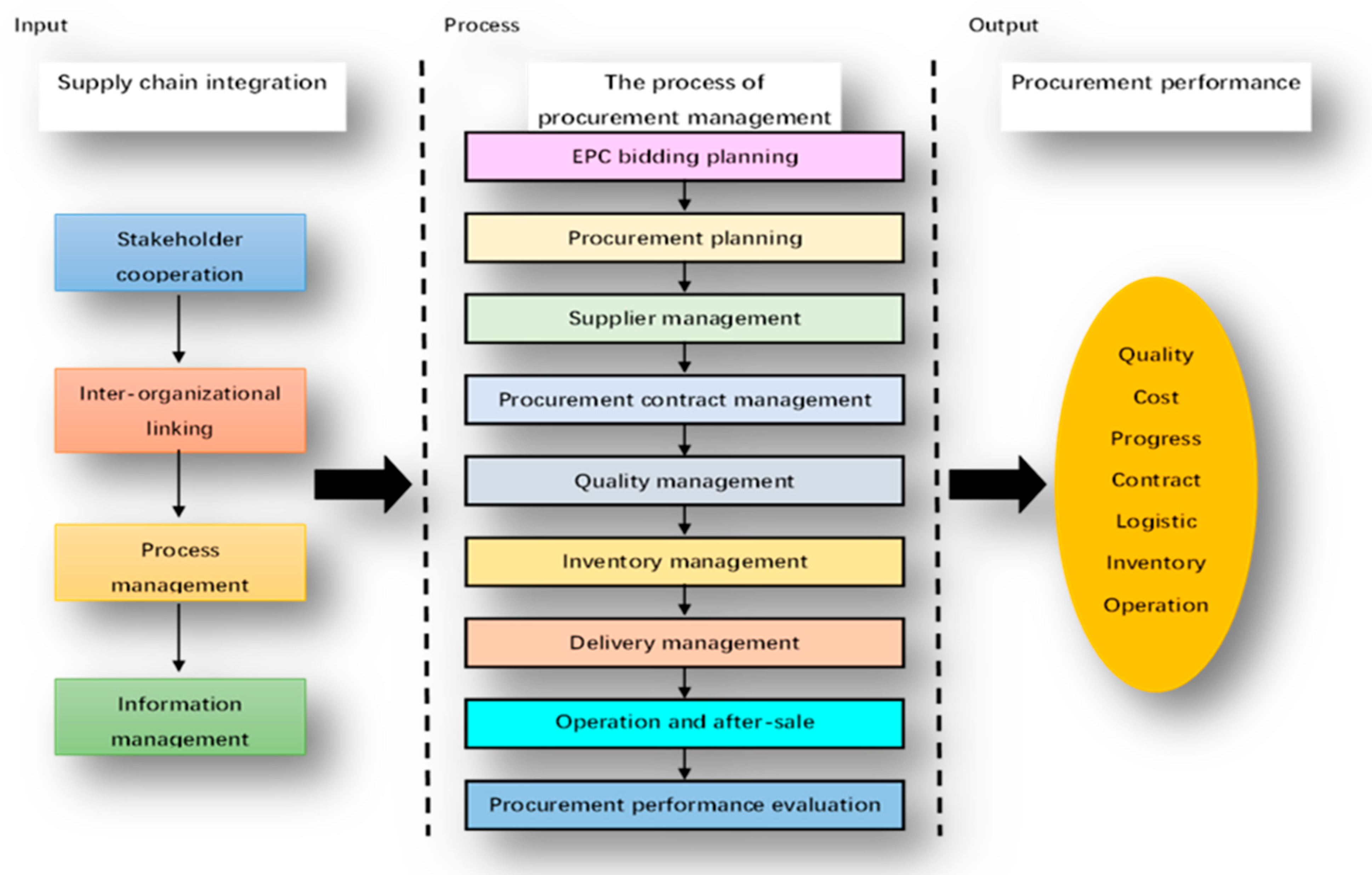

This paper aims to analyze the impact of integrated supply chain management on procurement processes and the overall performance of international EPC projects. By employing a framework that integrates statistical data analysis, and model validation, the research will assess the cooperation between general contractors and stakeholders, focusing on how collaboration, detailed planning, and operational performance contribute to project success. The findings will provide empirical data and strategic insights, enriching academic discourse on EPC supply chain integration and guiding industry professionals in refining procurement practices.

The expected contributions of this study include:

Intellectual Enhancement: Improving the understanding of supply chain management in multinational EPC projects by analyzing integration’s effects on efficiency, costs, risks, and resource allocation.

Bridging Research Gaps: Addressing gaps in EPC project management through rigorous analysis and discussions, offering new perspectives on the unique challenges and solutions within supply chain management.

Advancing Theory and Practice: Contributing to both the theoretical framework and practical strategies for enhancing project efficiency and management protocols.

Overall, this research aims to significantly advance international engineering project management by combining theoretical insights with practical relevance, thus improving performance and success in EPC projects through effective supply chain strategies.

2. Literature Reviews

2.1. The Concept of Supply Chain Integration

According to Goldratt (1990) [

8], the Theory of Constraints, which maintains that a system’s production is constrained by its bottlenecks, has an influence on supply chain management. The responsibility of management is to recognize and mitigate these restrictions, as additional enhancements may not substantially increase overall performance. As supply chains consist of numerous interconnected components, maximizing individual pieces alone is inadequate; a comprehensive, integrated strategy is essential. Research on supply chain integration often focuses on four principal domains [

9].

2.2. Collaborative Supply Chain Alliance

Dyer et al. (1993) [

10] credited Japan’s effective supply chain to lasting supplier relationships, but Blanchard (2021) [

11] emphasized the need of managing these intri-cate connections. Tait (1998) [

12] associated robust alliances with improved financial results and customer happiness, highlighting that companies frequently overlook the initial selection of strategic allies. The Cooperation Model underscores the need for in-formation exchange and shared objectives in complex supply chains [

13,

14]. Autry and Moon (2016) [

15] promoted a collaborative integrative strategy within teams. Channel collaboration entails mutual goals and transparent communication, cultivating part-nerships that facilitate the interchange of information, resources, and risks [

16,

17]. Trust and commitment are crucial for integration [

18,

19], whereas Titus et al. (2005) [

20] suggested a networked model for managing material flows facilitated by re-source-providing enterprises.

2.3. The Benefits of a Cohesive Supply Chain

Research has demonstrated a favorable correlation between supply chain integration and improved performance [

21,

22,

23,

24,

25], extending previous investigations [

26,

27,

28,

29,

30,

31]. Wood (1997) [

32] posited that a 10% enhancement in supply chain integration may potentially result in a twofold increase in earnings. Ragatz et al. (1997) [

33] discovered that integration in product development resulted in performance enhancements in U.S. companies. Fohlich et al. (2001) [

25] delineated five integration strategies associated with performance, however Olhager et al. (2003) [

34] observed a disparity between recognizing the significance of collaboration and actual performance outcomes. Bagchi et al. (2005) [

35] highlighted those levels of integration influence operational performance and cost efficiency.

Supply chain integration is essential for establishing competitive advantages, offering strategic gains over competitors (Jap 2001) [

36]. Vangen et al. (2003) [

37] ascribed these advantages to synergistic behaviors, while Ralston et al. (2015) [

38] contended that integration amplifies cooperative benefits. In addition to cost reductions, integration enhances competence, adaptability, decision-making, and promotes creativity through the exchange of ideas, potentially resulting in enduring strategic advantages (Min et al. 2005) [

39]. Cao et al. (2011) [

40] delineated five principal advantages: efficiency, flexibility, synergy, quality, and innovation.

Although supply chain integration offers substantial potential for return on investment, the literature presents inconclusive results. Mackelprang et al. (2014) [

21] and Leuschner et al. (2013) [

22] employed stringent approaches but arrived at divergent conclusions—one underscoring restricted advantage centered on content, while the other accentuated enhanced benefits from a stakeholder-oriented perspective [

41]. Contemporary research frequently neglects the comprehensive aspect of integration, resulting in variable outcomes. A thorough understanding of supply chain integration is crucial for the progression of this significant theoretical topic [

23,

24].

2.4. Importance of Integrating Procurement Management Throughout the Supply Chain for Multinational Engineering EPC Projects

Supply chain activities are being streamlined by transnational firms as a result of global economic integration. Organizations such as IBM and Walmart have thrived due to proficient supply chain management [

42,

43]. Global EPC projects have distinct procurement issues because of their extensive and non-standardized characteristics [

44]. Although supply chain integration is firmly established in manufacturing, the construction sector is still in the process of adaptation [

45,

46].

At present, supply chain integration remains predominantly an academic notion within the construction industry [

1]. Essential tactics encompass partnering with a limited number of suppliers, cultivating enduring relationships, and exchanging information [

42,

47]. Nonetheless, manufacturing tools may not align with the project-oriented characteristics of construction [

45,

48].

Project managers frequently make supply chain decisions without formally acknowledging their participation [

11,

49,

50]. Although real-time information enhances accountability, the management of enormous data quantities can be daunting [

51]. The construction industry requires adaptable supply chain management to address its specific issues [

20].

In an unpredictable global context, EPC contractors must consolidate supply chains to optimize stakeholder resources [

52,

53]. This study examines how contractors may efficiently integrate supplier chains, identify procurement bottlenecks, and optimize procurement management to maximize project efficiency and economic advantages [

54].

3. Methods

3.1. Project Demographics and Survey Scope

This research refined metrics for integrated supply chain management, procurement processes, and procurement performance through expert consultations, leading to a detailed questionnaire. It comprised four sections: demographics, procurement processes, supply chain integration, and procurement performance, with the latter three rated on a 5-point Likert scale.

Data was collected through field surveys, including face-to-face and online responses from overseas personnel. The study focused on top Chinese contractors from the 2023 ENR250 list, engaging management from four major EPC contractors. Out of 180 questionnaires distributed, 117 valid responses were received, resulting in a 65% response rate.

From

Table 1, the findings demonstrate a satisfactory distribution of professional experience years among the research participants, with over 29% possessing more than 15 years of experience. This enhances the likelihood of achieving unbiased and precise research results.

Table 2 displays the allocation of roles among the research participants.

The findings suggest that the research subjects in EPC projects mostly engage in procurement responsibilities. More precisely, a total of 34% of the research participants are actively engaged in procurement tasks. The average number of international engineering EPC projects that each individual has engaged in during the past five years is roughly 1.79. The findings indicate a fair allocation of responsibilities among the research participants and a broad range of expertise in managing multinational engineering EPC projects.

The findings indicate that the study encompassed a collective of 45 EPC projects distributed over 23 nations in Africa, Asia, Latin America, the Middle East, and Oceania. These projects are mainly situated in strategic growth regions that are specifically focused on by China’s "Going Global" and "Belt and Road" initiatives. As a result, they serve as typical and exemplary examples of Chinese enterprises carrying out international engineering EPC projects. The allocation of business among the projects included in the research is specified in

Table 4.

The findings show that hydropower projects account for 62.23% of the total surveyed, with additional projects in thermal power, municipal engineering, and mineral resources.

In summary, the sample selection minimized biases by considering ENR rankings, respondents’ experience, and project types and locations. The data is representative, offering a comprehensive view of Chinese contractors’ capabilities in managing multinational engineering EPC projects.

3.2. Reliability and Validity Analysis

Reliability and validity of the quantitative data were assessed using Cronbach’s alpha and factor analysis. Alpha values indicated scale consistency: acceptable (0.7-0.8), good (0.8-0.9), and excellent (>0.9). The KMO test measured fitness for factor analysis, with values <0.5 indicating poor correlation and >0.8 and >0.9 indicating high suitability. Valid factor structures explained over 70% of the variance for clear construct interpretation.

3.2.1. Supply Chain Integration

Reliability test by Cronbach’s α, the result is shown as follows in

Table 5.

The Cronbach’s alpha for the supply chain integration scale presented in

Table 5 exceeds 0.900, indicating excellent internal consistency reliability. A factor analysis conducted on the scale yielded a KMO value of 0.957, affirming its appropriateness for factor analysis. Four factors were designated for extraction, with the interpretable results of the total variance shown in

Table 6.

The findings show that four factors explain 73.00% of the variance in the items, confirming the scale’s robust validity for assessing supply chain integration.

3.2.2. The Process of Procurement Management

Reliability test by Cronbach’s α, the result is shown as follows in

Table 7.

Cronbach’s alpha values for the procurement management process scale exceeded 0.800, signifying strong internal consistency. Factor analysis of this scale yielded a KMO of 0.915, indicating its aptness for factor analysis. With ten factors extracted, the explained total variance is detailed in

Table 8.

The findings reveal that ten factors explain 78.032% of the variance in the items, suggesting that the procurement management process scale has strong validity.

3.2.3. Procurement Performance

Reliability test by Cronbach’s α, the result is shown as follows in

Table 9.

The procurement performance scale’s Cronbach’s alpha stands at 0.961, reflecting superior internal consistency reliability. Factor analysis on this scale produced a KMO of 0.941, denoting excellent appropriateness for factor analysis. The extraction of one factor explains the total variance as detailed in

Table 10.

The findings indicate that one factor explains 81.753% of the variance in the items, demonstrating the procurement performance scale’s strong validity.

3.3. Data Analysis Methods

This paper employs sophisticated analytical techniques facilitated by SPSS software to rigorously examine the quantitative data collected through the survey. The integrated data analysis approach encompasses a suite of complementary methods, each contributing uniquely to the comprehensive understanding of the relationships and dynamics within the study:

Pearson Correlation Analysis [

55]: This tool assesses linear correlations between variables, highlighting interdependencies within and between supply chain integration, procurement management, and performance.

Typicality Analysis [

56]: Using Pearson correlation coefficients, this analysis identifies representative indicators in variable clusters, pinpointing key factors that account for variance in thematic constructs.

Hierarchical Cluster Analysis [

57]: This method classifies variables into homogeneous groups, revealing similarities and differences among supply chain integration, procurement management, and performance.

Canonical Correlation Analysis [

57]: This technique explores correlations between sets of interrelated variables, offering a holistic view of the study’s main constructs.

Regression Analysis [

57]: This analysis establishes causal relationships and quantifies effects among supply chain integration, procurement management processes, and performance.

By integrating these methods, the study achieves a nuanced analysis that not only identifies statistical associations but also unravels the complex web of causality and influence among the key variables, thereby providing a robust empirical foundation for the research hypotheses and contributing to the field’s theoretical and practical development.

4. Results

The survey data underwent Pearson correlation analysis, typicality analysis, and cluster analysis to depict the correlations within the components of supply chain integration, procurement management processes, and procurement performance. The outcomes are as stated.

4.1. An Analysis of the Correlations Between Supply Chain Integration Factors

To uncover the relationships within supply chain integration elements, Pearson correlation coefficients and their significance levels were computed.

Table 11 displays these results, offering a clearer view of the interactions and mutual influences among the components of supply chain integration.

The study reveals strong correlation coefficients among supply chain integration elements, all at or above 0.637**, indicating that total performance is driven by their synergistic interplay. A factor analysis confirmed this, showing that a single extracted factor explained 81.044% of the variance, highlighting the cohesive structure among the aspects listed in

Table 11.

Based on the strong connections observed, the study utilized typicality analysis, as suggested by [

56], to choose a representative element that could effectively capture the entire variability within the concept of supply chain integration. The formula used to get the typicality coefficient, which measures the representativeness of each element, is

. The formula utilizes the correlation coefficient, denoted by r, and the number of components or factors being analyzed, denoted by

. The outcomes of the typicality coefficient calculations are specified in

Table 12.

The typicality coefficient identifies the most prominent element within supply chain integration. Its high typicality score serves as a proxy for the combined impact of all elements, simplifying the study of the construction. By prioritizing this key representative element, academics and practitioners can gain clearer insights into the dynamics of supply chain integration, which is essential for strategic decision-making and improving operational efficiency.

The typicality analysis identifies stakeholder cooperation as the most crucial element of supply chain integration, reflected in its highest typicality coefficient. This highlights its role as a key indicator of overall performance, as strong stakeholder connections are essential for effective integration.

Stakeholder cooperation encompasses vital collaborations, including information exchange, synchronized planning, and coordinated execution, fostering trust and aligned objectives necessary for advancing integration.

Wang et al. (2013) [

58] emphasize that these collaborative ties are essential for implementing integrated supply chain processes, enabling firms to leverage shared knowledge and navigate challenges in multinational EPC projects.

In summary, the significance of stakeholder cooperation underscores its central role in enhancing supply chain integration. Managing these relationships effectively can improve integration capabilities, leading to greater efficiency, reduced costs, and better project outcomes, which is vital for general contractors optimizing their supply chain strategies in international EPC contexts.

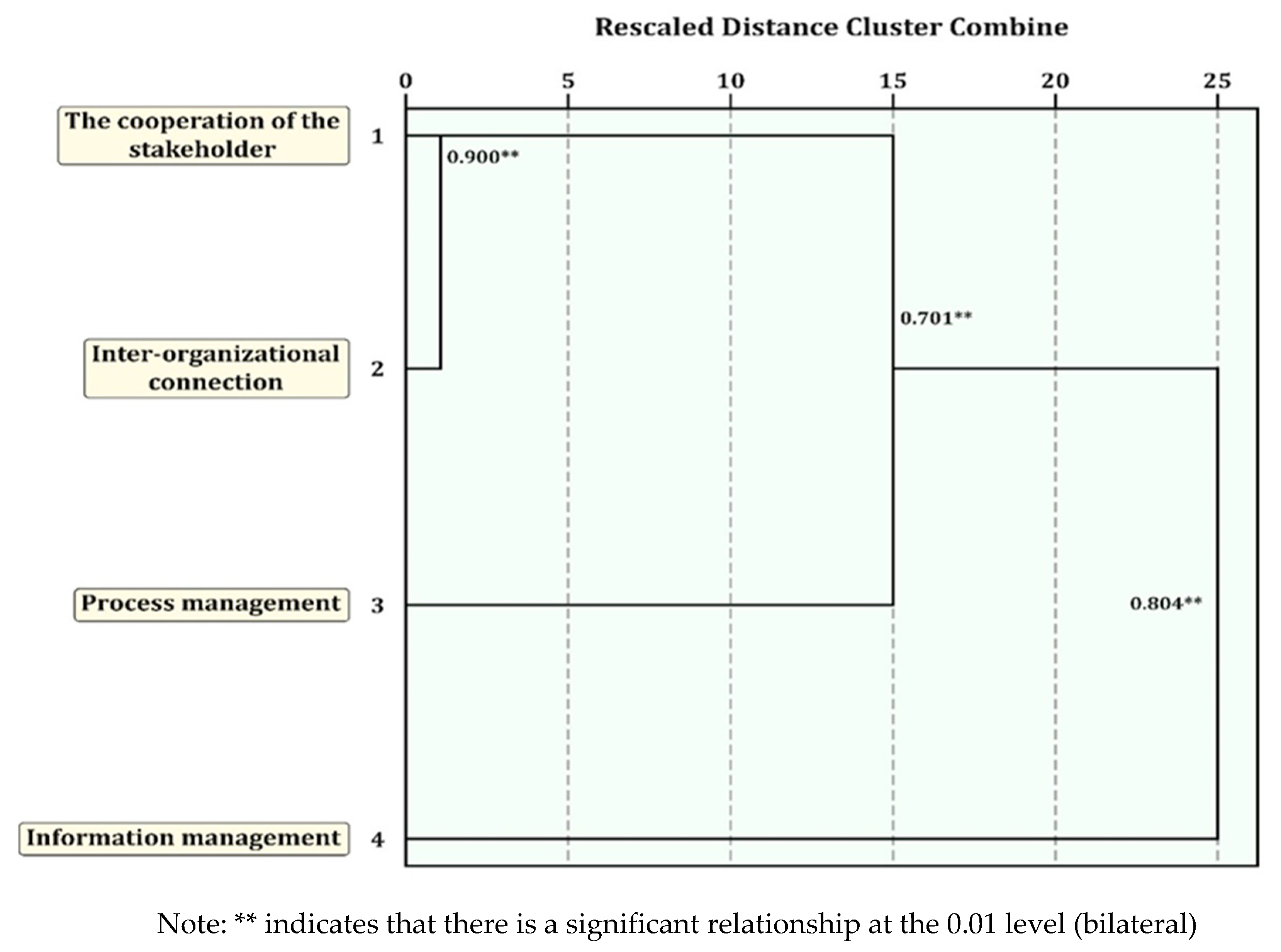

Cluster analysis illustrates the linkages and clustering of supply chain integration elements.

Figure 7 presents the dendrogram from the analysis, with a scale from 0 to 25 representing distances or correlations between elements. Higher values indicate longer distances or weaker correlations, visually depicting interdependence within the supply chain integration framework

From

Figure 7, the cluster analysis reveals a complex correlation among supply chain integration components. Initially, stakeholder cooperation and inter-organizational links merge, underscoring the importance of strong ties between the general contractor and stakeholders for effective information and resource transfer.

This interdependence is highlighted by how effective communication enhances collaboration, forming a cohesive network that supports supply chain goals.

As the analysis progresses, all four elements converge into a unified cluster, with a high correlation coefficient of 0.804** indicating their close interplay and interdependence in enhancing overall supply chain effectiveness.

The analysis provides valuable insights for general contractors, emphasizing the need for an integrated approach to supply chain management. By identifying interdependencies and prioritizing collaboration, they can improve the resilience and responsiveness of their supply chains, especially in complex multinational EPC projects.

4.2. A Correlation Analysis of the Elements of the Procurement Management Process

In order to determine the relationships between the components of the procurement management process, Pearson correlation coefficients were computed for each pair of components, along with the corresponding significance levels. The results are displayed in

Table 13. This analysis quantitatively assesses the relationships between different components of the procurement management process. It identifies areas of strong interconnectivity and possible areas that may need greater alignment.

Analyzing the components of the procurement management process provides a thorough understanding of how they are connected, as indicated by Pearson correlation coefficients of 0.425** and above. This high level of correlation suggests a closely interconnected framework where the pieces do not operate alone but instead work together, with each element adding to the overall effectiveness of the procurement management process.

In order to further explore the structure of these associations, a factor analysis was performed with the objective of determining if a single underlying factor explains the observed correlations. The study results are highly informative: by extracting just one factor, a significant 62.891% of the total variation is explained. This substantial percentage highlights the interdependence of the many components of the procurement management process, as outlined in

Table 13, and implies that they are integral parts of a unified entity.

These findings have significant implications for the field of procurement management. Through the application of typicality analysis, one can extract the fundamental nature of the procurement management process into a solitary representative component that encompasses the whole variation. This simplifies the intricacy of overseeing numerous interconnected elements and provides a strategic focus point for improving procurement processes. The typicality analysis results, presented in

Table 14, not only identify the most prominent aspect in the process but also offer a quantitative foundation for prioritizing efforts to enhance the procurement management system as a whole.

The detailed insights gained from this analysis are invaluable for organizations seeking to optimize their procurement management practices. By understanding which elements are most central to the process and how they interact with one another, procurement managers can make informed decisions that align with the strategic objectives of the organization and drive improvements in efficiency, cost-effectiveness, and overall project success.

The results show that the typicality coefficient for procurement contract management is the highest, making it the most representative aspect of the procurement management process. This suggests that contract management significantly reflects the effectiveness of the other nine components. A procurement manager emphasized its critical role in the overall process during interviews.

International engineering EPC projects often occur in regions with underdeveloped supply markets and limited equipment suppliers. General contractors in these areas must develop comprehensive contract management strategies to source materials globally, addressing constraints like production cycles, material shelf life, transportation, customs clearance, and market fluctuations. Effective contract management is vital for ensuring timely and cost-effective resource acquisition, which is essential for project success.

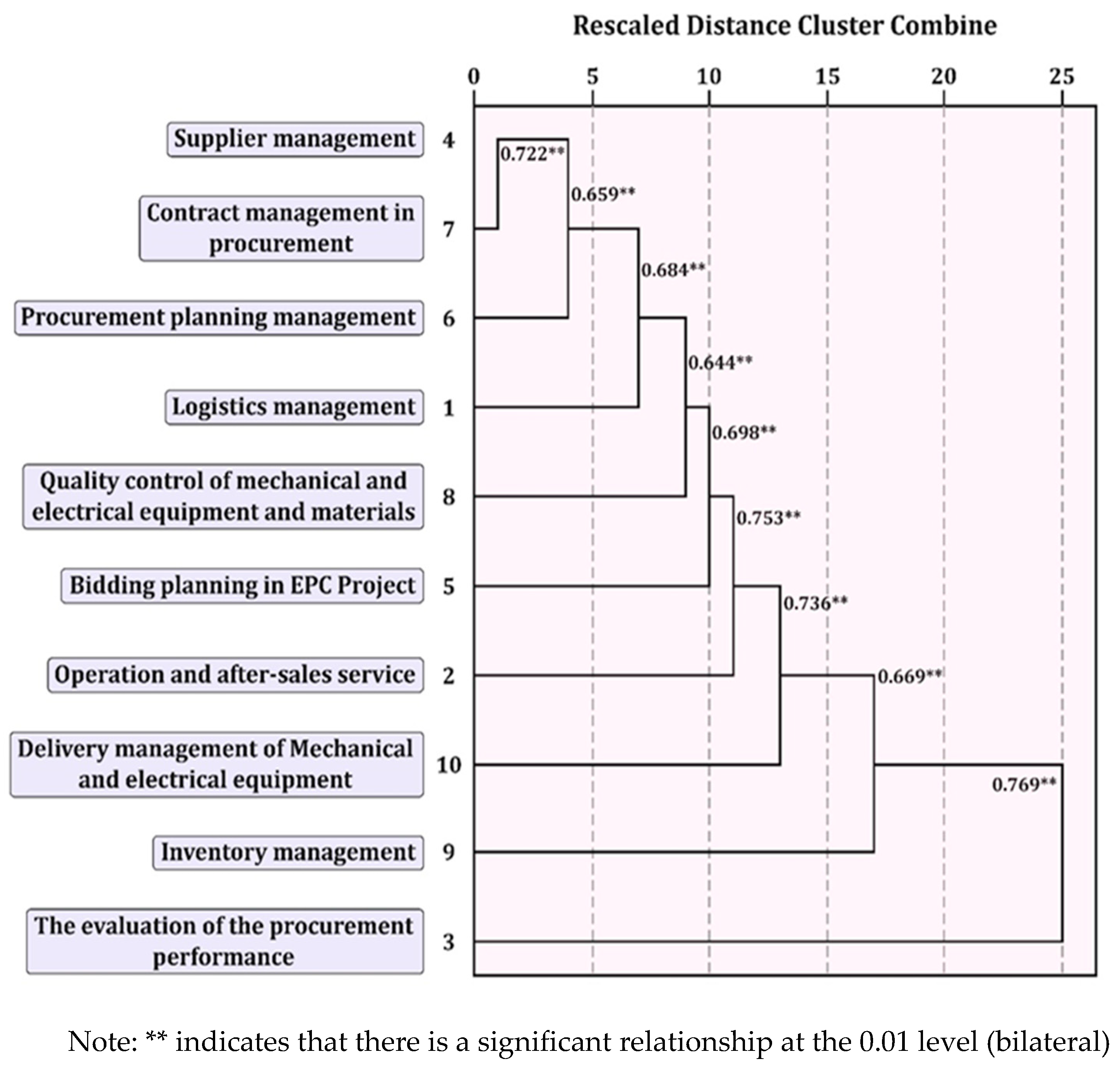

As is shown in

Figure 8, the cluster analysis shows that supplier management and procurement contract management are closely linked, highlighting their role in supplier selection. Procurement contracts support the general contractor’s management by governing relationships, performance terms, and compliance.

In summary, the ten aspects of procurement management form a single cluster with a correlation coefficient of 0.769**, confirming their strong interconnectedness. This underscores the importance of viewing procurement management as a cohesive entity where each component is vital for overall success.

These insights can help general contractors streamline procurement strategies, ensuring alignment for efficient operations, which is essential for enhancing effectiveness and supporting successful international EPC projects.

4.3. Correlation Analysis of Procurement Performance Factors

To determine relationships among procurement performance aspects, Pearson correlation coefficients and significance levels were calculated for each factor combination, as shown in

Table 15. This research provides a quantitative assessment of the strength and direction of links between procurement performance components, aiming to understand their interactions and impact on overall success.

The analysis of procurement performance elements shows correlation coefficients of 0.680** or higher, indicating that overall performance stems from the synergy among the seven identified elements.

A factor analysis reveals that a single factor accounts for 81.753% of total variance, explaining the strong correlations, as shown in

Table 15.

Typicality analysis identifies a representative factor that encapsulates procurement performance, crucial for understanding success.

Results in

Table 16 highlight the most impactful element, providing strategic insights for managers. Focusing on this key factor can optimize efforts to enhance overall performance, leading to better project outcomes and increased organizational efficiency.

The typicality analysis identifies the operational element as having the highest typicality coefficient, making it the most representative factor of procurement performance and a benchmark for the other six elements.

This operational aspect reflects stakeholders’ collective goals, including technical specifications, performance characteristics, and key financial indicators vital to project value. Its successful transition into operations indicates project benefits and overall lifecycle effectiveness.

In essence, the operational element integrates various procurement performance factors, showing how strategies contribute to success. Achieving operational excellence means meeting quality standards, staying within budget, and adhering to timelines.

The high typicality coefficient emphasizes the operational element’s role in enhancing procurement performance. Optimizing this factor allows managers to align activities with project goals for better outcomes.

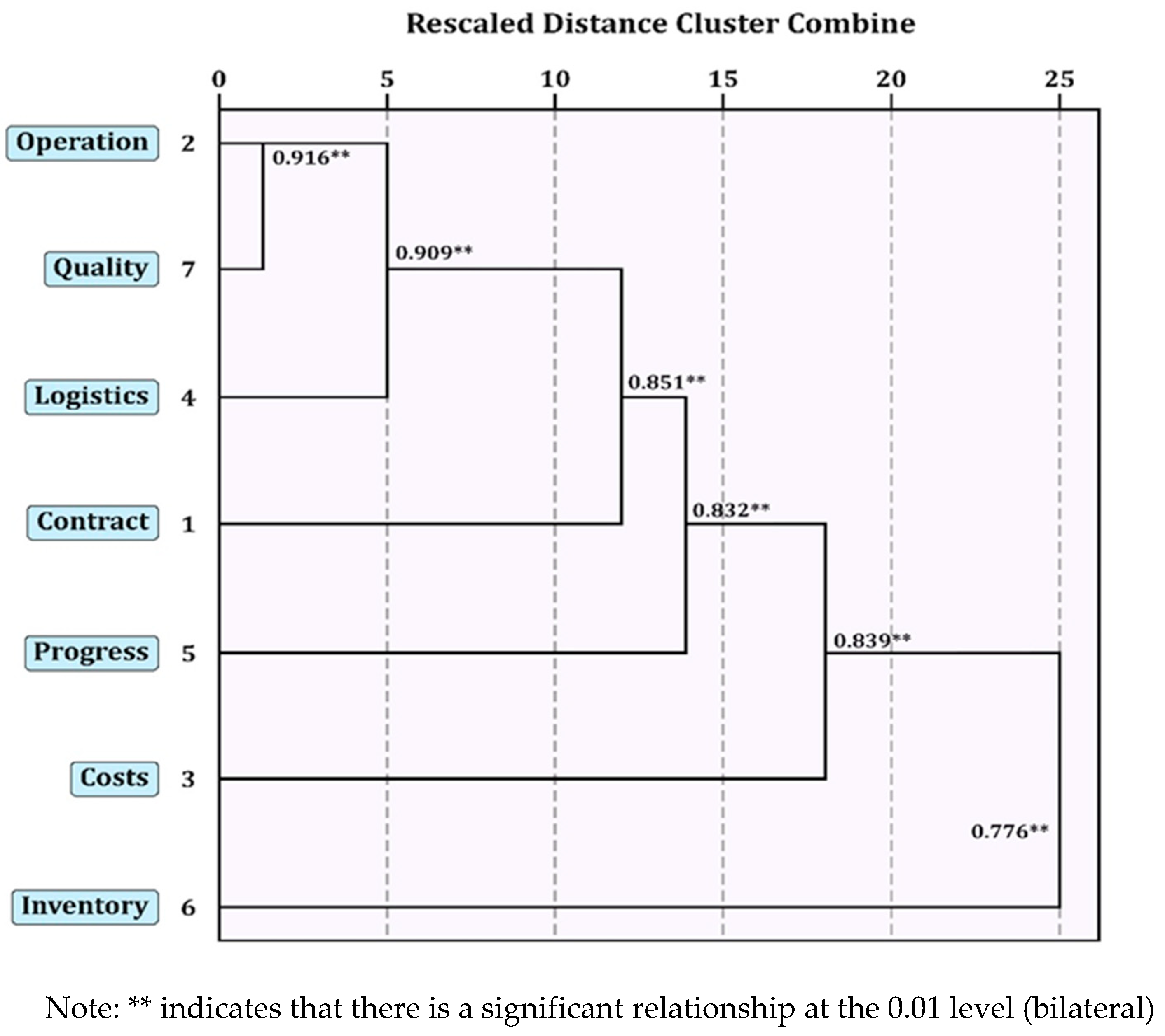

Figure 9 presents a cluster analysis of procurement performance elements, illustrating their hierarchical relationships and highlighting closely connected elements for strategic focus and improvement.

Cluster analysis of procurement performance aspects reveals interconnections, with quality and operations merging first into a cluster. This highlights the correlation between equipment quality and project operational efficiency, crucial for functionality and return on investment [

59].

As the general contractor, focusing on quality and operations is essential for meeting specifications and user needs [

60]. Their success impacts on owner satisfaction and the contractor’s reputation.

The correlation coefficient of 0.776 indicates a synergistic interaction among all seven procurement performance elements, suggesting they are interconnected and influence overall project success.

These insights encourage procurement managers to adopt a holistic approach, recognizing these interconnections to align procurement with project objectives, ultimately improving operational outcomes and achieving procurement excellence.

4.4. The Overall Model Validation

Path analysis, part of Structural Equation Modelling (SEM) [

61,

62] examines causal relationships and model fit. It validated connections between supply chain integration, procurement management processes, and procurement performance.

Figure 10 illustrates these relationships with arrows and coefficients indicating direction and strength.

This figure clarifies how supply chain integration impacts procurement processes and overall performance. Analyzing the coefficients helps identify key relationships and validate the model, guiding strategies to enhance supply chain and procurement efficiency.

The route analysis reveals strong links between supply chain integration, procurement management practices, and procurement performance. The path coefficient between supply chain integration and procurement management processes is significant at 0.872***, indicating a strong positive impact. Similarly, the correlation coefficient between procurement management processes and procurement performance is notable at 0.747***, both statistically significant (p < 0.001), indicating high reliability.

These findings show that supply chain integration is crucial for enhancing procurement management. An integrated supply chain improves coordination, communication, and collaboration, leading to a more efficient procurement process, resulting in lower costs, higher quality, and timely delivery.

The theoretical framework in

Figure 11 illustrates the interrelationship among supply chain integration, procurement management, and procurement performance, demonstrating their mutual influence.

For practitioners in international EPC projects, these insights emphasize the need for a cohesive supply chain to foster procurement excellence, essential for project success and client satisfaction. The validated model serves as a guide for continuous improvement in supply chain and procurement practices, helping organizations gain a competitive edge in complex projects.

Establishing strong collaborative relationships with stakeholders is crucial for general contractors in the global procurement landscape. These alliances provide access to vital resources, reduce transaction costs, and enhance competitiveness. A project manager from a leading EPC project in Vietnam emphasized the importance of effective supplier partnerships.

Acquiring key electromechanical equipment and materials is essential for project success. Open communication with suppliers fosters efficient production and timely delivery.

Efficient contract discussions streamline procurement, minimize conflicts, and ensure project milestones are met. These alliances enhance procurement effectiveness, allowing contractors to optimize schedules, reduce costs, and maintain quality.

Interviews reveal varying collaboration levels based on inter-organizational connections. Strong stakeholder collaboration improves resource transfer and communication. A procurement manager noted that good relationships with owners and suppliers are crucial for timely approvals and managing schedules.

These insights highlight the importance of strategic partnerships for effective procurement governance. By managing the procurement cycle, contractors can navigate the complexities of international EPC projects while aligning with timelines, budgets, and quality standards.

A procurement manager in Zambia discussed using full-cycle procurement management to mitigate risks and maintain momentum. Streamlining processes like purchase order approvals boosts productivity.

The interviews stress the importance of information flow in procurement. Effective communication enhances decision-making and innovation. Leading contractors recognize that managing information flows facilitates coordination and mitigates challenges.

Efficient information management reduces transaction costs and ensures transparency in procurement activities. Timely sharing enables informed decisions aligned with project goals, while proactive communication with suppliers streamlines schedules and manages costs.

The need for a comprehensive procurement information management system is emphasized, consolidating information streams and enabling cross-functional collaboration.

In summary, these insights underscore the need for an integrated approach to procurement information management, which supports successful international EPC projects. By leveraging advanced information systems and fostering transparency, general contractors can gain a competitive edge and deliver high-quality, efficient projects.

4.5. Case Study ---The Venezuelan Gas Power Plant Project

- 1)

A summary of the project

Located in Maracaibo, Araguá state, the Venezuela Gas Power Plant is intended to house two 190MW GE 7FA single cycle fuel units. The project is an EPC general con-tracting endeavor held by Venezuela’s national oil firm, PDVSA, with a total contract value of 533 million US dollars and a duration of 12 months.

- 2)

The key issues in procurement management

The Venezuelan gas power station project has the following key issues in terms of procurement:

The project has a short time limit and a small construction area. As a result, the construction conditions are difficult, which means more time should be spent on the design and procurement phase of the project.

The choice of suppliers is limited because the host models and standards specified by the owner are available only from a limited number of manufacturers in the world, so the selection of suppliers is limited. The host is a large-scale mechanical and electrical equipment with a long production cycle, which is easily limited by the supplier’s own production capacity and production plan.

- 3)

A strategy for procurement management

The subsequent are particular strategies for the procurement management of the Venezuela gas power plant project:

It is essential to uphold effective interface management with the group headquarters to facilitate information sharing and efficient decision-making. A comprehensive list of certified suppliers is available at the Group headquarters. Effective interface management with the Group headquarters revealed that only Siemens, GE, and Mitsubishi possess the capability to produce the host models and standards mandated by the owner globally, while another company within the Group headquarters has designated Siemens as the manufacturer, resulting in staggered production timelines. In this project, GE was designated as the primary supplier by the general contractor.

Establish strong collaborative relationships with major overseas electromechanical equipment providers. Owing to the effective collaboration between GE and the general contractor, two units manufactured for an unrelated company were allocated to the project, thereby considerably expediting the equipment production timeline.

The logistical oversight system must be enhanced across the entire process. Consequently, the cargo agency consistently relays logistics information, enabling the general contractor to efficiently oversee real-time logistics transportation.

5. Discussion

An advanced correlation study is necessary to achieve a deeper understanding of the relationships between supply chain integration, procurement management processes, and procurement performance. By employing rigorous statistical methods, this analysis will thoroughly investigate the interconnections among these factors and the extent to which they influence each other. The study aims to uncover both direct and indirect consequences, while also identifying opportunities for improvement [

64,

65,

66].

Building upon the empirical foundation established by the survey results, we will proceed with in-depth case studies of multinational engineering procurement and construction (EPC) projects. The primary goal of these case studies is to apply the theoretical concepts and models identified in the survey to real-world scenarios. These case studies will offer a detailed understanding of how experienced general contractors successfully manage procurement challenges in complex project settings. The research will specifically examine the pivotal role of supply chain integration in enhancing procurement processes, the strategic actions that lead to improved procurement performance, and the diverse challenges that emerge in such complex environments.

Through the integration of both quantitative and qualitative research approaches, this study will provide a comprehensive depiction of procurement management within the international EPC project domain. This dual-method approach not only aims to expand existing research but also seeks to derive practical strategies for professionals in the field. The insights gained from this research are expected to significantly contribute to the development of procurement management practices within the EPC sector, aligning with the high academic standards demanded by both the scholarly and professional communities.

Furthermore, this study points to several potential avenues for future research. These include examining the impact of digital transformation on procurement procedures, exploring the importance of sustainability factors in supply chain integration, and analyzing how geopolitical issues influence international procurement strategies. Longitudinal studies could provide dynamic perspectives on procurement processes over time, while comparative research across other industrial sectors or geographical regions might reveal both the commonalities and distinctions of procurement management practices in different contexts [

63].

Sustainability will be a key theme in future research stemming from this study. As global awareness of environmental and social responsibility grows, the integration of sustainability into procurement practices is becoming increasingly critical. This research emphasizes that supply chain integration not only improves procurement performance but also aligns with broader sustainability goals. By optimizing procurement processes, organizations can reduce waste, minimize environmental impacts, and promote socially responsible procurement practices. These findings underscore the growing importance of sustainability in the EPC sector and highlight the need for future studies to explore how sustainability can be systematically embedded in procurement strategies and supply chain management.

The intersection of digital transformation and sustainability presents new opportunities for enhancing procurement management. For instance, the adoption of intelligent technologies and renewable energy solutions can increase procurement transparency, improve efficiency, and reduce environmental footprints, thereby fostering a more sustainable approach to project management. Additionally, geopolitical factors and the uncertainties of global supply chains require procurement strategies to be increasingly adaptive and resilient. Understanding how these factors affect procurement decisions in international EPC projects will be crucial for developing more robust and flexible procurement systems in the face of global challenges.

In summary, this study provides valuable empirical data and theoretical insights into procurement management within multinational EPC projects. By linking supply chain integration with sustainability objectives, it contributes to the growing body of literature on sustainable procurement practices in large-scale international projects. Future research should continue to explore how these emerging trends—such as digitalization, sustainability, and geopolitical shifts—will shape the future of procurement management, ensuring that the EPC industry not only meets its economic goals but also contributes to a more sustainable and responsible global supply chain.

6. Conclusions

This study sheds light on the intricate network of inter-organizational relationships that underpin procurement success in global Engineering, Procurement, and Construction (EPC) projects. By leveraging advanced analytical methodologies, including Pearson correlation analysis, typicality analysis, and cluster analysis, we have elucidated the critical role of strategic collaborations between key stakeholders—such as general contractors, group headquarters, design teams, and material suppliers—in shaping an efficient procurement environment. These findings emphasize that effective procurement is not only a matter of operational excellence but also a strategic necessity that requires seamless coordination across various organizational boundaries.

Our empirical evidence reveals that the strength and quality of inter-organizational ties, especially those with construction parties and key suppliers, are foundational to procurement performance. This study highlights the significance of these alliances in achieving procurement success, demonstrating that synchronized activities and strong communication channels among owners, consultants, and authorities are essential for optimizing procurement outcomes. Furthermore, the identified correlations between supply chain integration, procurement management, and performance elements underscore their interdependent roles in enhancing the procurement ecosystem.

In the context of sustainable development, these findings offer an important perspective on how procurement management can contribute to the long-term success of international EPC projects. The emphasis on supply chain integration as a means to optimize procurement processes aligns with broader sustainability goals by fostering efficient resource utilization, reducing waste, and enhancing project delivery timelines. As global construction projects increasingly face pressure to meet environmental, social, and governance (ESG) criteria, our theoretical model offers a framework that can support the integration of sustainability principles into procurement strategies. By promoting collaborative relationships and aligning procurement goals with sustainability objectives, contractors and project managers can drive both economic and environmental performance.

While this study provides valuable insights into the role of inter-organizational ties in procurement management, it is important to acknowledge several limitations. First, the scope of our empirical analysis was constrained by the availability of data from selected EPC projects, which may not fully capture the diverse challenges and dynamics faced across all types of international projects. As a result, future research could expand the scope to include a broader range of projects from different regions and industries to further validate the findings and explore the applicability of our theoretical model in varying contexts.

Another limitation lies in the cross-sectional nature of the study, which only captures the relationships and procurement performance at a single point in time. Longitudinal studies that track the evolution of procurement management practices and inter-organizational relationships over time would offer deeper insights into how these dynamics change and adapt in response to market conditions, technological advancements, and shifts in sustainability priorities.

Future research could also investigate the integration of emerging technologies such as digital procurement platforms, artificial intelligence, and blockchain in the procurement process. These innovations have the potential to enhance supply chain transparency, reduce costs, and improve procurement efficiency, contributing to both project performance and sustainability goals. Additionally, exploring the impact of digitalization on inter-organizational collaboration could provide new perspectives on optimizing procurement strategies in an increasingly interconnected and technology-driven world.

Furthermore, future studies could explore the long-term effects of evolving inter-organizational relationships on procurement performance, particularly in projects with diverse international stakeholders. This would help in understanding how these relationships mature and how their strategic importance shifts as projects progress and external factors evolve.

In conclusion, this paper contributes both to academic knowledge and practical application, offering a comprehensive understanding of the determinants of procurement success in international EPC projects. By integrating theoretical models with real-world evidence, it lays the groundwork for enhancing procurement strategies that are not only cost-effective and efficient but also aligned with the principles of sustainable development. This study underscores the importance of collaborative relationships in optimizing procurement outcomes, ensuring the long-term viability of global projects, and advancing sustainability goals. By addressing the limitations and suggesting avenues for future research, we hope to inspire continued exploration into the evolving nature of procurement management and its critical role in driving sustainable development in the global construction industry.

Author Contributions

Conceptualization, J.H and S.M.L.; J.H, software, J.H.; validation, J.H.; formal analysis, J.H.; data curation, J.H..; writing—original draft preparation, J.H.; writing—review and editing, J.H.; supervision, S.M.L.; project administration, J.H. Both authors have read and agreed to the published version of the manuscript.

Funding

This research received financial support from the Hong Kong Polytechnic University (Project P0050863 / 1-CDK5).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this article are available on request from the corresponding author.

Acknowledgments

The authors would like to express their gratitude to the Faculty of Engineering at The Hong Kong Polytechnic University. Special thanks are extended to Shui Ming Li for his invaluable support of this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- He Bosen. International Engineering Contracting (2nd Edition). China Construction Industry Press 2007.

- Schoenherr, T.; Swink, M. Revisiting the arcs of integration: Cross-validations and extensions. Journal of Operations Management 2012, 30, 99–115. [Google Scholar] [CrossRef]

- Lau, H.S.; Lau AH, L. The newsstand problem: A capacitated multiple-product single-period inventory problem. European Journal of Operational Research, 1996, 94, 29–42. [Google Scholar] [CrossRef]

- Sahin, F.; Robinson, E.P. Flow coordination and information sharing in supply chains: review, implications, and directions for future research. Decision sciences 2002, 33, 505–536. [Google Scholar] [CrossRef]

- Shin, H.; Collier, D.A.; Wilson, D.D. Partnership-based supply chain collaboration: Impact on commitment, innovation, and firm performance. Journal of Business Logistics 2019, 40, 137–152. [Google Scholar] [CrossRef]

- Lv, Y.; Shang, Y. Investigation of industry 4.0 technologies mediating effect on the supply chain performance and supply chain management practices. Environmental Science & Pollution Research 2023.

- Lee, H.L.; Padmanabhan, V.; Whang, S. Information distortion in a supply chain: The bullwhip effect. Management science 2004, 50, 1875–1886. [Google Scholar] [CrossRef]

- Goldratt, E.M. Theory of Constraints. NewYork: North River Press, 1990.

- Koc, K.; Gurgun, A.P. Stakeholder-associated life cycle risks in construction supply chain. Journal of Management in Engineering 2021, 37, 04020107. [Google Scholar] [CrossRef]

- Dyer, J.H.; Sing, H. The relational view: Cooperative strategy and sources of interorganizational competitive advantage. Academy of management review, 1998, 23, 660–679. [Google Scholar] [CrossRef]

- Blanchard, D. Supply chain management best practices. New Jersey: John Wiley & Sons, 2021.

- Tait, D. Make strong relationships a priority. Canadian Manager, 1998, 23, 21–28. [Google Scholar]

- Kaufmann, L.; Carter, C.R. International supply relationships and non-financial performance-a comparison of US and German practices. Journal of Operations Management 2006, 24, 653–675. [Google Scholar] [CrossRef]

- Brinkhoff, A. , Özer, Ö. , Sargut, G. All you need is trust? An examination of inter-organizational supply chain projects. Production and Operations Management 2015, 24, 181–200. [Google Scholar]

- Autry, C.W.; Moon, M.A. Achieving supply chain integration: Connecting the supply chain inside and out for competitive advantage. Upper Saddle River, NJ: FT Press, 2016.

- Mattessich, P.W.; Johnson, K.M. Collaboration: What makes it work. St. Paul, MN: Fieldstone Alliance, 2018.

- Golicic, S.L.; Foggin, J.H.; Mentzer, J.T. Relationship magnitude and its role in interorganizational relationship structure. Journal of business logistics 2003, 24, 57–75. [Google Scholar] [CrossRef]

- Kaufmann, L.; Carter, C.R. International supply relationships and non-financial performance-a comparison of US and German practices. Journal of Operations Management 2006, 24, 653–675. [Google Scholar] [CrossRef]

- Benton, W.C.; Maloni, M. The influence of power driven buyer/seller relationships on supply chain satisfaction. Journal of Operations Management 2005, 23, 1–22. [Google Scholar] [CrossRef]

- Titus, S.; Brochner, J. Managing information flow in construction supply chains. Construction Innovation Information Process Management 2005, 5, 71–82. [Google Scholar] [CrossRef]

- Mackelprang A W, Robinson J L, Bernardes, E. , et al.The Relationship Between Strategic Supply Chain Integration and Performance: A Meta-Analytic Evaluation and Implications for Supply Chain Management Research. Journal of Business Logistics 2014, 35, 71–96.

- Leuschner, R.; Rogers, D.S.; Charvet, F.F. A Meta-Analysis of Supply Chain Integration and Firm Performance. Journal of Supply Chain Management 2013, 29, 32–56. [Google Scholar] [CrossRef]

- Flynn, B.B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. Journal of operations management 2010, 28, 58–71. [Google Scholar] [CrossRef]

- Van der Vaart, T.; Van Donk, D.P. A critical review of survey-based research in supply chain integration. International Journal of Production Economics 2008, 111, 42–55. [Google Scholar] [CrossRef]

- Frohlich, M.T.; Westbrook, R. Arcs of integration: an international study of supply chain strategies. Journal of operations management 2001, 19, 185–200. [Google Scholar] [CrossRef]

- Stock, G.N.; Greis, N.P.; Kasarda, J.D. Logistics, strategy and structure: a conceptual framework. International Journal of Operations & Production Management, 1998, 18, 37–52. [Google Scholar]

- Gustin, C.M.; Stank, T.P.; Daugherty, P.J. Computerization: supporting integration. International Journal of Physical Distribution & Logistics Management, 1994, 24, 11–16. [Google Scholar]

- Ellram, L.M.; Cooper, M.C. The relationship between supply chain management and Keiretsu. The International Journal of Logistics Management, 1993, 4, 1–12. [Google Scholar] [CrossRef]

- Byrne, S.M.; Javad, S. Integrated logistics information systems (ILIS): Competitive advantage or increased cost? //Annual Conference, Council of Logistics Management, 1992.

- Scott, B. Partnering in Europe: Incentive based alliancing for projects. London:Thomas Telford, 2001.

- Shapiro, R.D. Get leverage from logistics. Harvard Business Review, 1984, 62, 119–126. [Google Scholar]

- Wood, A. Extending the supply chain: strengthening links with IT. Chemical Week, 1997, 159, 25–26. [Google Scholar]

- Ragatz, G.L.; Handfield, R.B.; Scannell, T.V. Success factors for integrating suppliers into new product development. Journal of product innovation management, 1997, 14, 190–202. [Google Scholar] [CrossRef]

- Olhager, J.; Selldin, E. Enterprise resource planning survey of Swedish manufacturing firms. European Journal of Operational Research 2003, 146, 365–373. [Google Scholar] [CrossRef]

- Bagchi P K, Chun Ha B, Skjoett-Larsen, T. , et al. Supply chain integration: a European survey. The International Journal of Logistics Management 2005, 16, 275–294.

- Jap, S.D. Perspectives on joint competitive advantages in buyer-supplier relationships. International Journal of Research in Marketing 2001, 18, 19–35. [Google Scholar] [CrossRef]

- Vangen, S.; Huxham, C. Enacting Leadership for Collaborative Advantage: Dilemmas of Ideology and Pragmatism in the Activities of Partnership Managers. British Journal of Management 2003, 14, S61–S76. [Google Scholar] [CrossRef]

- Ralston, P.M.; Blackhurst, J.; Cantor, D.E.; Crum, M.R. A structure–conduct–performance perspective of how strategic supply chain integration affects firm performance. Journal of Supply Chain Management 2015, 51, 47–64. [Google Scholar] [CrossRef]

- Min S, Roath A S, Daugherty, P. J., et al. Supply chain collaboration: what’s happening?. The international journal of logistics management 2005, 16, 237–256.

- Cao, M.; Zhang, Q. Supply chain collaboration: Impact on collaborative advantage and firm performance. Journal of Operations Management 2011, 29, 163–180. [Google Scholar] [CrossRef]

- Autry, C.W.; Rose, W.J.; Bell, J.E. Reconsidering the Supply Chain Integration-Performance Relationship: In Search of Theoretical Consistency and Clarity. Journal of Business Logistics 2014, 35, 275–276. [Google Scholar] [CrossRef]

- Davis, T. Effective supply chain management. Sloan Management Review, 1993, 2, 35–46. [Google Scholar]

- Quinn Francis, J. Reengineering the supply chain: An interview with Michael Hammer. Supply Chain Management Review, 1999, 1, 20–26. [Google Scholar]

- Whyte, J.; Stasis, A.; Lindkvist, C. Managing change in the delivery of complex projects: Configuration management, asset information and ‘big data’. International Journal of Project Management 2016, 34, 339–351. [Google Scholar] [CrossRef]

- Briscoe, G.; Dainty, A. Construction supply chain integration: an elusive goal? Supply chain Management 2005, 10, 319–326. [Google Scholar] [CrossRef]

- Tookey J E, Murray M, Hardcastle, C. , et al. Construction procurement routes: re-defining the contours of construction procurement. Engineering Construction & Architectural Management in Engineering, 1998, 14, 73–78.

- Lee, H.L.; Whang, S. Information sharing in a supply chain. International Journal of Manufacturing Technology and Management, 2000.

- VrijhoefR.; KoskelaL Roles of supply chain management in construction. 7th Annual Conference of the International Group for Lean Construction (IGLC-7), Berkeley, USA, 1999.

- Hugos, M.H. Essentials of supply chain management. New Jersey: John Wiley & Sons, 2024.

- Love P E D, Davis P R, Chevis, R. , et al. Risk/reward compensation model for civil engineering infrastructure alliance projects. Journal of Construction Engineering and Management 2011, 137, 127–136.

- Shokri S, Ahn S, Lee S, et al. Current Status of Interface Management in Construction: Drivers and Effects of Systematic Interface Management. Journal of Construction Engineering and Management 2015: 04015070.

- Du L, Tang W, Liu C, Wang S, Wang T, Shen W, et al. Enhancing engineer–procure–construct project performance by partnering in international markets: Perspective from Chinese construction companies. International Journal of Project Management 2016, 34, 30–43.

- Amirtash, P.; Parchami Jalal, M.; Jelodar, M.B. Integration of project management services for International Engineering, Procurement and Construction projects. Built Environment Project and Asset Management 2021, 11, 330–349. [Google Scholar] [CrossRef]

- Huang, J.; Fu, X.; Chen, X.; Wen, X. Supply Chain Management for the Engineering Procurement and Construction (EPC) Model: A Review and Bibliometric Analysis. Sustainability 2024, 16, 9748. [Google Scholar] [CrossRef]

- Jaccard, J.; BeckerMA Statistics for the behavioral sciences.Melbourne:International Thomson Publishing Incorporated, 1997.

- HuangZ Factor analysis in medical application.Changsha:Hunan Science and Technology Press, 1995.

- SPSS Incorporated. SPSS base 7.5 for Windows User’s guide. Chicago: Statistical Package for Social Science Incorporated, 1997.

- Wang, S.; Tang, W.; Li, Y. Relationship between owners’ capabilities and project performance on development of hydropower projects in China. Journal of Construction Engineering and Management 2013, 139, 1168–1178. [Google Scholar] [CrossRef]

- Chan AP, C.; Scott, D.; Lam EW, M. Framework of success criteria for design/build projects. Journal of Management in Engineering 2002, 18, 120–128. [Google Scholar] [CrossRef]

- Chan, A.P. ; C Evaluation of enhanced design and build system-a case study of a hospital project. Construction Management & Economics 2000, 18, 863–871. [Google Scholar]

- Come Zebra, E.I.; van der Windt, H.J.; Nhambiu JO, P.; Golinucci, N.; Gandiglio, M.; Bianco, I.; Faaij AP, C. The integration of economic, environmental, and social aspects by developing and demonstrating an analytical framework that combines methods and indicators using Mavumira Village as a case study. Sustainability 2024, 16(22), 9829. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, D. A study on the rational decision-making process of vessel organization—Focusing on cases of vessel accidents. Sustainability 2024, 16, 9820. [Google Scholar] [CrossRef]

- Huang, J.; Li, S.M. Adaptive strategies and sustainable innovations of Chinese contractors in the Belt and Road Initiative: A social network and supply chain integration perspective. Sustainability 2024, 16, 8927. [Google Scholar] [CrossRef]

- Petridi, A.; Fragkouli, D.-N.; Mejias, L.; Paredes, L.; Bistue, M.; Boukouvalas, C.; Kekes, T.; Krokida, M.; Papadaki, S. Assessing the overall sustainability performance of the meat processing industry before and after wastewater valorization interventions: A comparative analysis. Sustainability, 2024, 16, 9811. [Google Scholar] [CrossRef]

- Waduge, S.; Sugathadasa, R.; Piyatilake, A.; Nanayakkara, S. A process analysis framework to adopt intelligent robotic process automation (IRPA) in supply chains. Sustainability, 2024, 16, 9753. [Google Scholar] [CrossRef]

- Safaei, M.; Al Dawsari, S.; Yahya, K. Optimizing multi-channel green supply chain dynamics with renewable energy integration and emissions reduction. Sustainability, 2024, 16, 9710. [Google Scholar] [CrossRef]

Figure 7.

Cluster analysis results for supply chain integration.

Figure 7.

Cluster analysis results for supply chain integration.

Figure 8.

Cluster analysis results for procurement management.

Figure 8.

Cluster analysis results for procurement management.

Figure 9.

Analyses of procurement performance clusters.

Figure 9.

Analyses of procurement performance clusters.

Figure 10.

Integration of the supply chain, procurement management process and procurement performance.

Figure 10.

Integration of the supply chain, procurement management process and procurement performance.

Figure 11.

Procurement management model of internal EPC Project based on supply chain integration [

63].

Figure 11.

Procurement management model of internal EPC Project based on supply chain integration [

63].

Figure 12.

The gas power plant project in Venezuela.

Figure 12.

The gas power plant project in Venezuela.

Table 1.

The Research object’s company and the number of years of their employment.

Table 1.

The Research object’s company and the number of years of their employment.

| The employment of the year |

A company |

B company |

C company |

D company |

The total number |

The percentage (%) |

| 0-5 |

11 |

2 |

10 |

2 |

25 |

21.36 |

| 6-10 |

18 |

5 |

6 |

16 |

45 |

38.46 |

| 11-15 |

6 |

5 |

1 |

1 |

13 |

11.11 |

| Above 15 |

14 |

4 |

13 |

3 |

34 |

29.06 |

| The total number |

49 |

16 |

30 |

22 |

117 |

100 |

Table 2.

The role distribution of research objects.

Table 2.

The role distribution of research objects.

| The role of the research object |

The number of people |

The percentage (%) |

| Procurement |

40 |

34.19 |

| Construction |

21 |

17.94 |

| Project manager/ Chief engineer |

15 |

12.82 |

| Department manager |

23 |

19.66 |

| Others (Business, contract management) |

19 |

16.24 |

| The total |

117 |

100 |

| The number of being participant in international EPC projects in the past five years |

1.79 |

Table 3.

The distribution of countries.

Table 3.

The distribution of countries.

| The area of the project |

The country of the project |

The number of the projects |

| Africa |

Zambia |

5 |

| Angola |

2 |

| Zimbabwe |

2 |

| Sultan |

2 |

| Nepal |

1 |

| Ghana |

1 |

| Uganda |

1 |

| Botswana |

1 |

| Lesotho |

1 |

| Asia |

Vietnam |

5 |

| The Philippines |

4 |

| Malaysia |

3 |

| Nepal |

1 |

| Pakistan |

1 |

| Latin America |

Venezuela |

5 |

| Costa Rica |

1 |

| Honduras |

1 |

| The Middle East |

Iraq |

1 |

| Iran |

2 |

| Saudi Arabia |

1 |

| Oman |

1 |

| Oceania |

Fiji |

2 |

| The total |

23 |

45 |

Table 4.

Business Distribution of Projects Involved in the Survey.

Table 4.

Business Distribution of Projects Involved in the Survey.

| Types of Project Business |

Number of Projects |

Percentage of Total (%) |

| Hydropower |

28 |

62.23 |

| Thermal Power |

9 |

20.00 |

| Municipal Engineering |

3 |

6.67 |

| Mineral Resources |

3 |

6.67 |

| Others |

2 |

4.44 |

Table 5.

The analysis results of supply chain integration scale.

Table 5.

The analysis results of supply chain integration scale.

| The target |

Cronbach’s α |

|

| Stakeholder cooperation |

0.961 |

|

| Inter-organizational connection (Partnership) |

0.975 |

0.985 |

| Process management |

0.946 |

|

| Information management |

0.959 |

|

Table 6.

The factor analysis of supply chain integration scale explains the total variance.

Table 6.

The factor analysis of supply chain integration scale explains the total variance.

| Ingredient |

Initial eigenvalue |

| The total |

Variance (%) |

Accumulation (%) |

| 1 |

26.991 |

59.979 |

59.979 |

| 2 |

2.824 |

6.277 |

66.256 |

| 3 |

2.021 |

4.491 |

70.747 |

| 4 |

1.014 |

2.253 |

73.000 |

Table 7.

The reliability analysis results of procurement management process scale.

Table 7.

The reliability analysis results of procurement management process scale.

| The target |

Cronbach’s α |

|

| Bidding planning for EPC project |

0.905 |

|

| Schedule management in procurement |

0.839 |

|

| Supplier management |

0.930 |

|

| Procurement contract management |

0.958 |

|

| Electromechanical device & material quality management |

0.937 |

0.978 |

| Logistic management |

0.943 |

|

| Inventory management |

0.949 |

|

| Mechanical and electrical equipment delivery management |

0.925 |

|

| Operation and after-sales service |

0.868 |

|

| The evaluation of procurement management |

0.940 |

|

Table 8.

The factor analysis of procurement process scale explains the total variance.

Table 8.

The factor analysis of procurement process scale explains the total variance.

| Ingredient |

Initial eigenvalue |

| The total |

Variance (%) |

Accumulation (%) |

| 1 |

26.606 |

45.872 |

45.872 |

| 2 |

3.078 |

5.306 |

51.179 |

| 3 |

2.964 |

5.110 |

56.289 |

| 4 |

2.709 |

4.671 |

60.960 |

| 5 |

2.079 |

3.585 |

64.545 |

| 6 |

2.013 |

3.471 |

68.016 |

| 7 |

1.882 |

3.245 |

71.262 |

| 8 |

1.581 |

2.725 |

73.987 |

| 9 |

1.301 |

2.244 |

76.231 |

| 10 |

1.045 |

1.801 |

78.032 |

Table 9.

The factor analysis of procurement performance scale.

Table 9.

The factor analysis of procurement performance scale.

| The target |

Cronbach’s α |

| Procurement performance |

0.961 |

Table 10.

The factor analysis of procurement process scale explains the total variance.

Table 10.

The factor analysis of procurement process scale explains the total variance.

| Ingredient |

Initial eigenvalue |

| The total |

Variance (%) |

Accumulation (%) |

| 1 |

5.723 |

81.753 |

81.753 |

Table 11.

Correlation between elements of supply chain integration according to Pearson’s formula.

Table 11.

Correlation between elements of supply chain integration according to Pearson’s formula.

| |

The cooperation of the stakeholder |

Inter-organizational connection |

Process management |

Information management |

| The cooperation of the stakeholder |

1 |

|

|

|

| Inter-organizational connection |

.900** |

1 |

|

|

| Process management |

.698** |

.672** |

1 |

|

| Information management |

.753** |

.810** |

.637** |

1 |

Table 12.

The typicality coefficient of the supply chain integration factor.

Table 12.

The typicality coefficient of the supply chain integration factor.

| Indicator |

The typicality coefficient |

| The cooperation of the stakeholder |

0.688 |

| Inter-organizational connection |

0.459 |

| Process management |

0.254 |

| Information management |

0.122 |

Table 13.

An analysis of the Pearson correlation between procurement management process elements.

Table 13.

An analysis of the Pearson correlation between procurement management process elements.

| |

Logistics management |

Operation and after-sales service |

The evaluation of the procurement performance |

Supplier management |

Bidding planning in EPC Project |

Procurement planning management |

Contract management in procurement |

Quality control of mechanical and electrical equipment and materials |

Inventory management |

Delivery management of Mechanical and electrical equipment |

| Logistics management |

1 |

|

|

|

|

|

|

|

|

|

| Operation and after-sales service |

.608** |

1 |

|

|

|

|

|

|

|

|

| The evaluation of the procurement performance |

.631** |

.692** |

1 |

|

|

|

|

|

|

|

| Supplier management |

.603** |

.638** |

.653** |

1 |

|

|

|

|

|

|

| Bidding planning in EPC Project |

.600** |

.586** |

.582** |

.585** |

1 |

|

|

|

|

|

| Procurement planning management |

.523** |

.614** |

.622** |

.616** |

.509** |

1 |

|

|

|

|

| Contract management in procurement |

.665** |

.677** |

.637** |

.722** |

.628** |

.607** |

1 |

|

|

|

| Quality control of mechanical and electrical equipment and materials |

.568** |

.548** |

.553** |

.530** |

.546** |

.516** |

.576** |

1 |

|

|

| Inventory management |

.523** |

.612** |

.546** |

.536** |

.462** |

.513** |

.584** |

.531** |

1 |

|

| Delivery management of Mechanical and electrical equipment |

.592** |

.554** |

.568** |

.658** |

.623** |

.495** |

.624** |

.589** |

.535** |

1 |

Table 14.

A typicality coefficient for the elements of the purchasing management process.

Table 14.

A typicality coefficient for the elements of the purchasing management process.

| Indicator |

Typicality coefficient |

| Bidding planning in EPC Project |

0.127 |

| Procurement planning management |

0.126 |

| Supplier management |

0.164 |

| Contract management in procurement |

0.346 |

| Quality control of mechanical and electrical equipment and materials |

0.161 |

| Logistics management |

0.228 |

| Inventory management |

0.19 |

| Delivery management of Mechanical and electrical equipment |

0.162 |

| Operation and after-sales service |

0.126 |

| The evaluation of the procurement performance |

0.015 |

Table 15.

Factors associated with procurement performance according to Pearson’s correlation.

Table 15.

Factors associated with procurement performance according to Pearson’s correlation.

| |

Procurement contract |

Operation |

Procurement costs |

Logistic |

Procurement progress |

Inventory |

Procurement quality |

| Procurement contract |

1 |

|

|

|

|

|

|

| Operation |

.839** |

1 |

|

|

|

|

|

| Procurement costs |

.704** |

.816** |

1 |

|

|

|

|

| Logistic |

.812** |

.870** |

.811** |

1 |

|

|

|

| Procurement progress |

.756** |

.813** |

.730** |

.775** |

1 |

|

|

| Inventory |

.680** |

.738** |

.693** |

.721** |

.691** |

1 |

|

| Procurement quality |

.815** |

.916** |

.838** |

.909** |

.805** |

.757** |

1 |

Table 16.

Typicality coefficient of procurement performance.

Table 16.

Typicality coefficient of procurement performance.

| Indicator |

Typicality coefficient |

| Quality |

0.446 |

| Costs |

0.124 |

| Progress |

0.005 |

| Contract |

0.198 |

| Logistic |

0.18 |

| Inventory |

0.258 |

| Operation |

0.92 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).