Submitted:

04 November 2024

Posted:

05 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results and Discussion

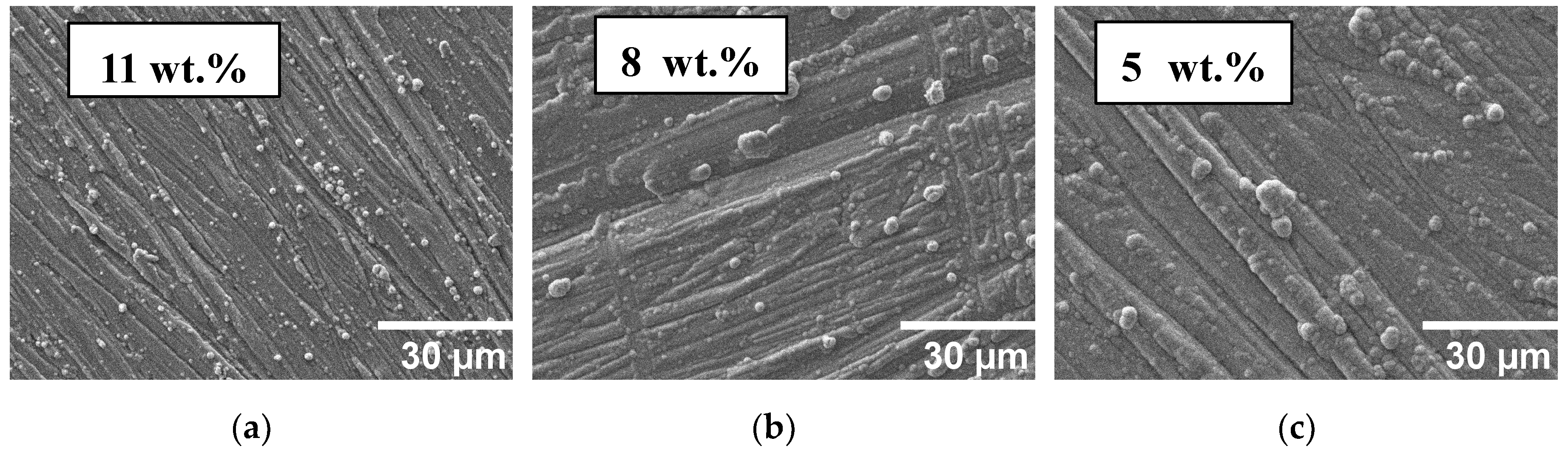

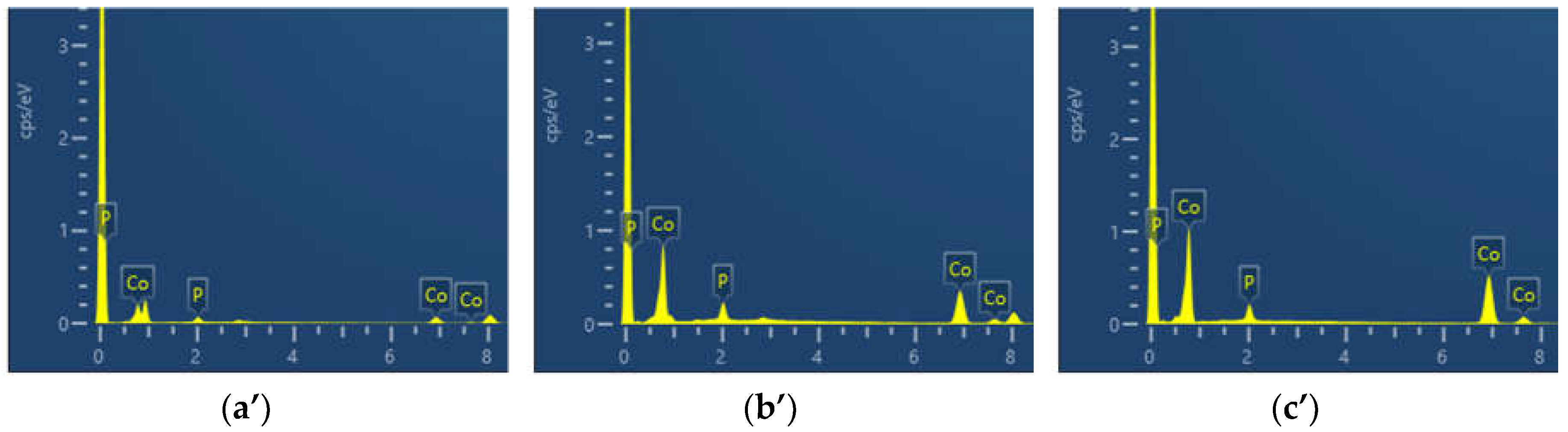

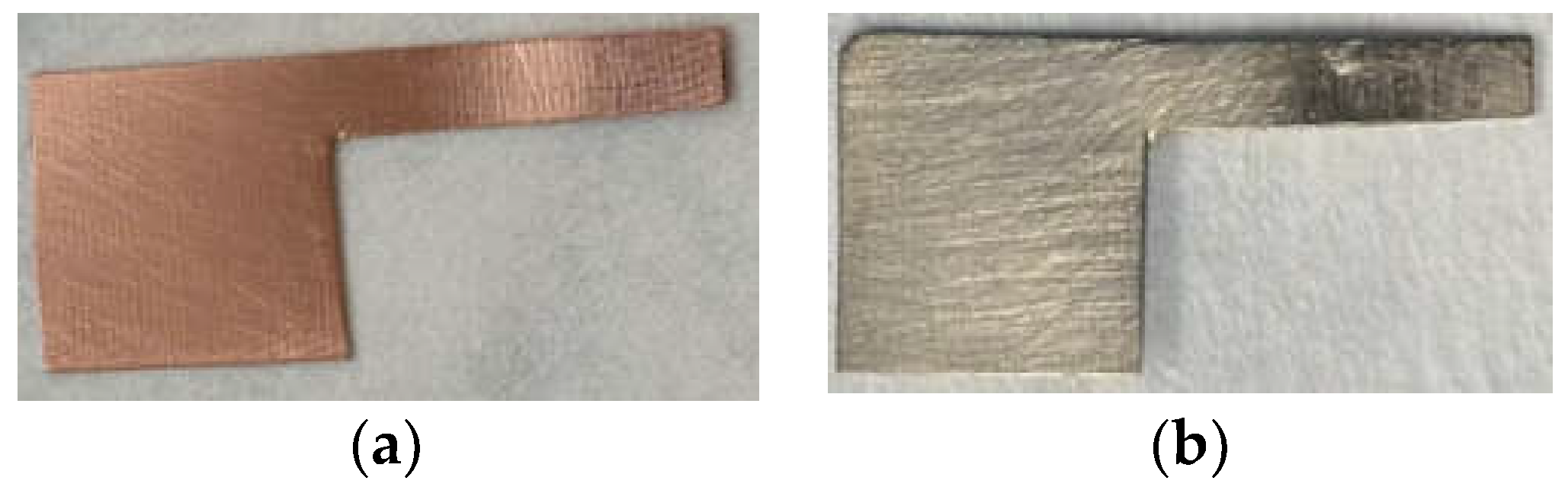

2.1. Coatings, Microstructure and Morphology Studies

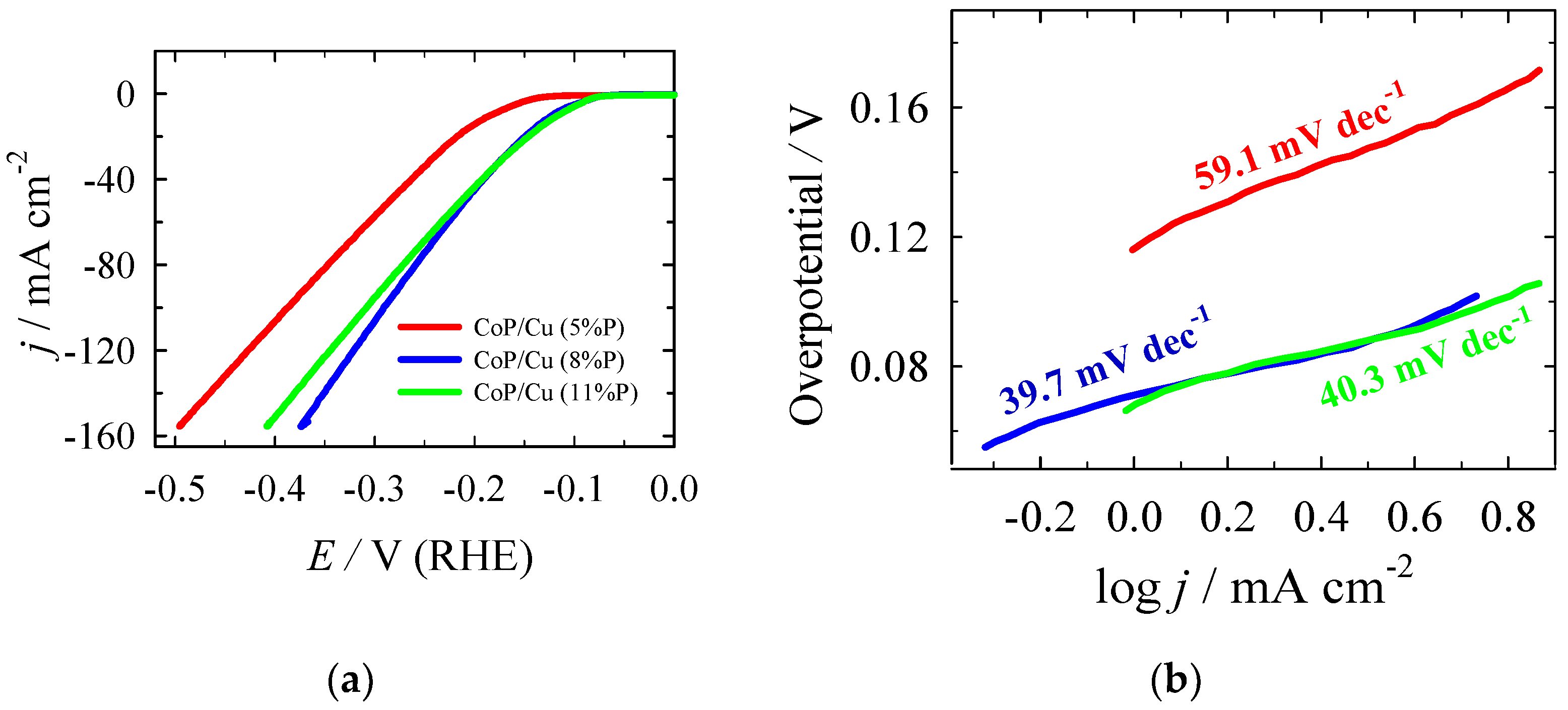

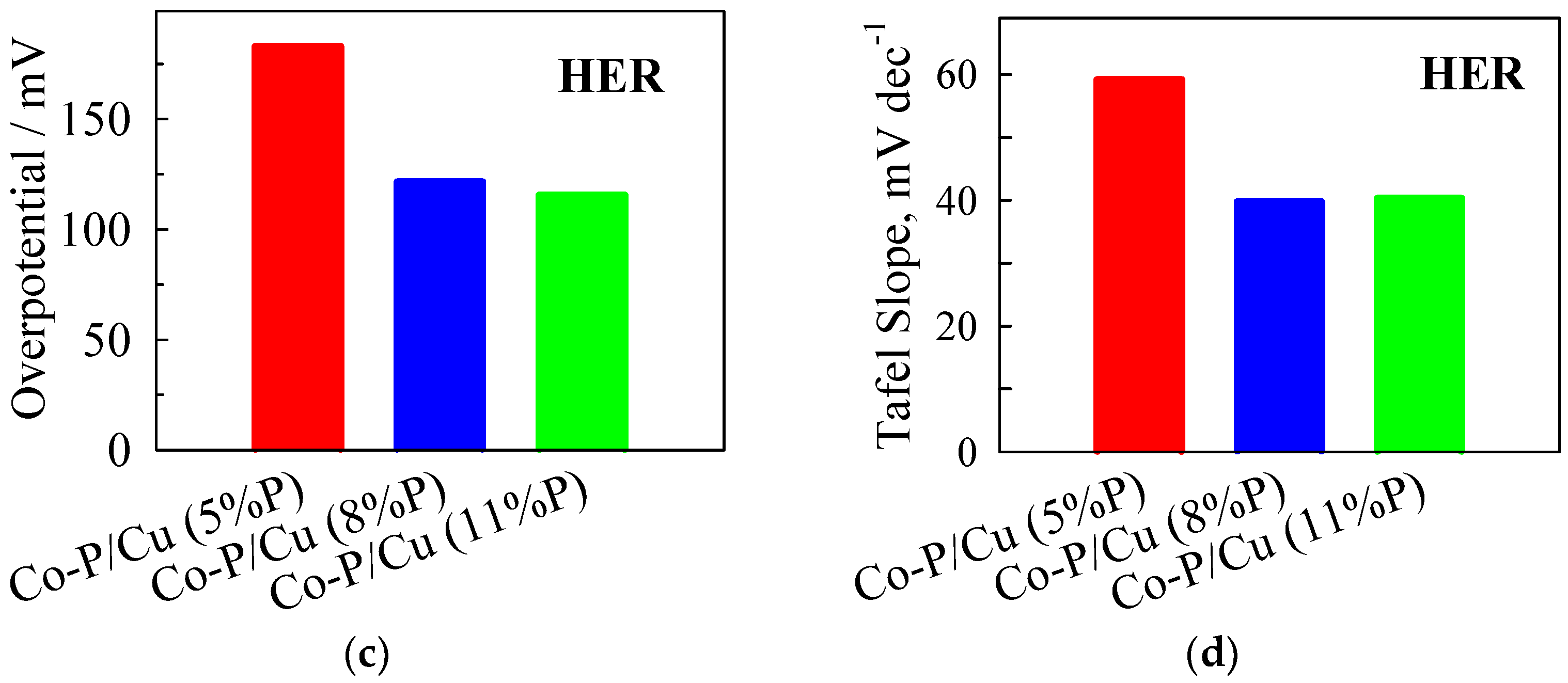

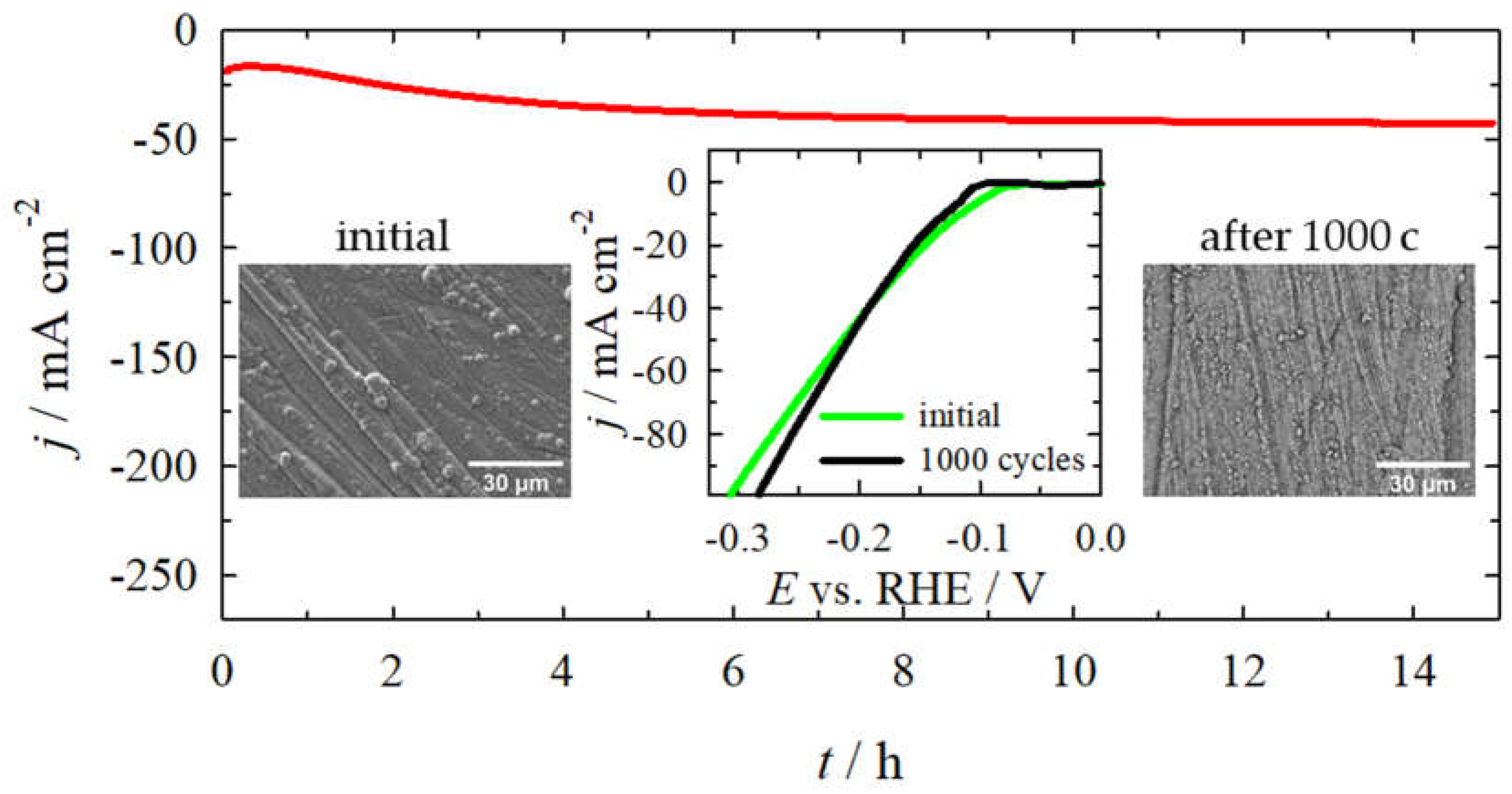

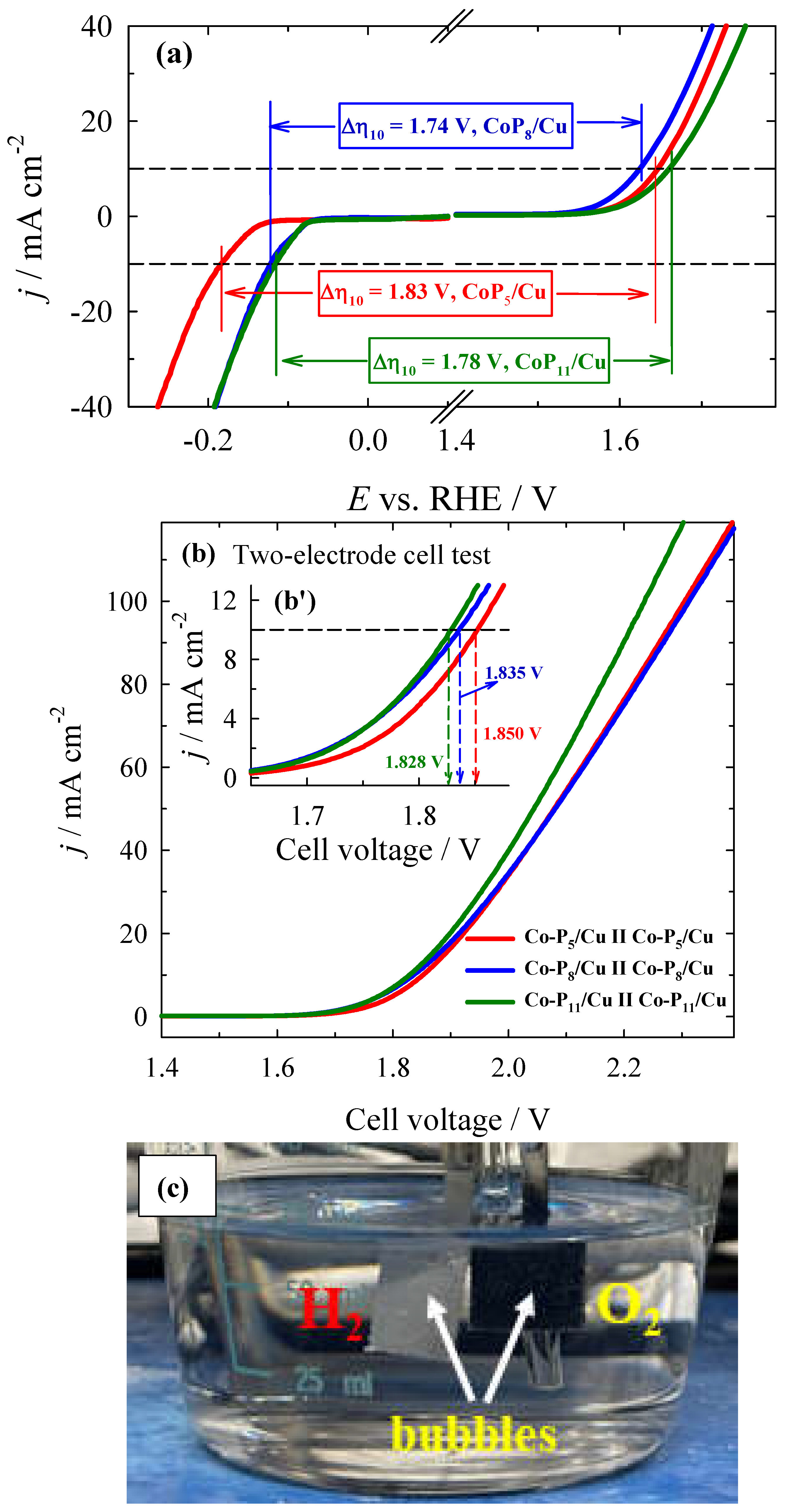

2.2. Electrocatalytic Activity towards HER

| Sample | Eonset, V at j = 1 mA cm−2 | η10*, mV | Tafel slope, mV dec−1 |

|---|---|---|---|

| −0.118 | 182.9 | 182.9 | |

| Co-P/Cu (8 wt% P) | −0.072 | 121.1 | 39.7 |

| Co-P/Cu (11 wt% P) | −0.068 | 115.4 | 40.3 |

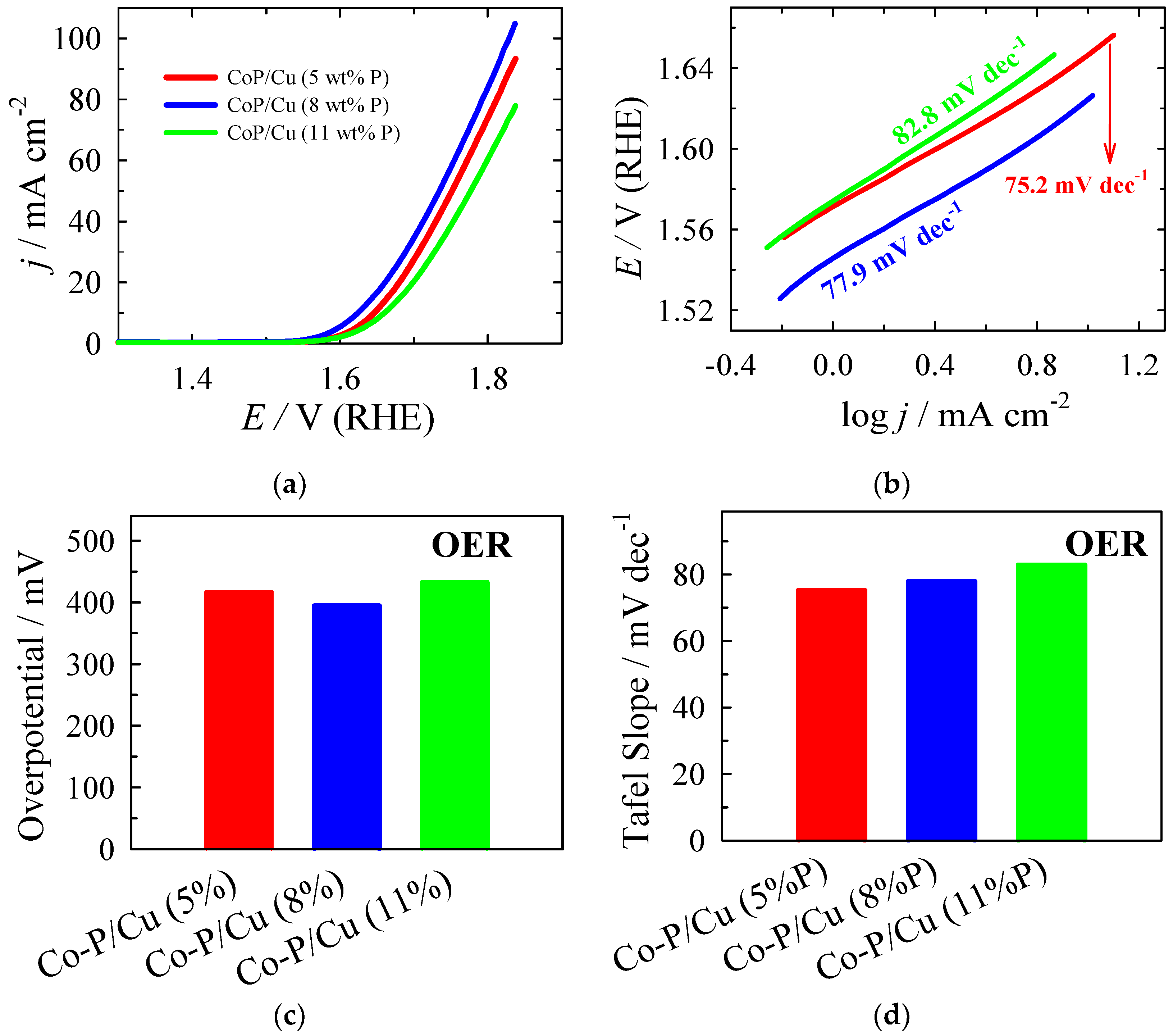

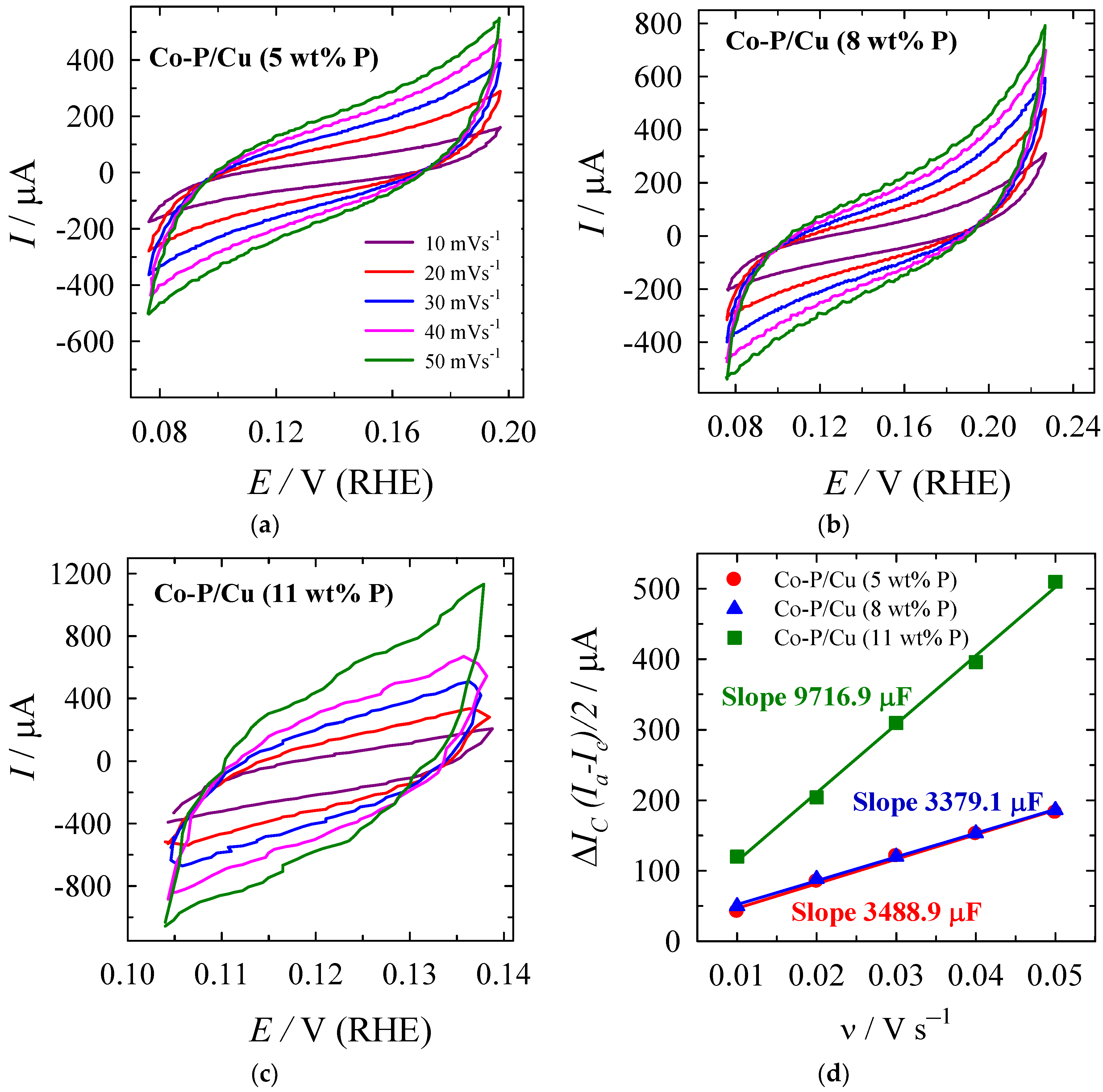

2.3. Electrocatalytic Activity towards OER

| Sample | Eonset, V at j = 1 mA cm−2 | ηonset, mV | E, V at j = 10 mA cm−2 | η10*, mV | Tafel slope, mV dec−1 |

|---|---|---|---|---|---|

| Co-P/Cu (5 wt% P) | 1.571 | 341 | 1.646 | 416 | 75.2 |

| Co-P/Cu (8 wt% P) | 1.546 | 316 | 1.624 | 394 | 77.9 |

| Co-P/Cu (11 wt% P) | 1.576 | 346 | 1.662 | 432 | 82.8 |

3. Materials and Methods

3.1. Chemical Reagents

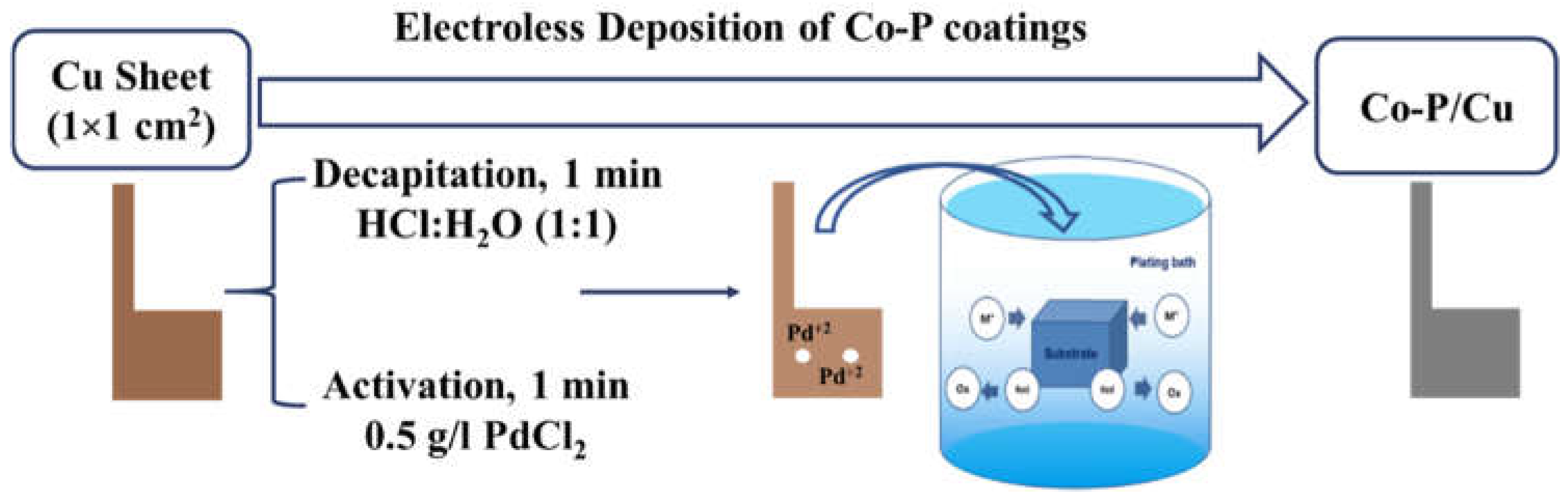

3.2. Preparation of Co-P/Cu Catalysts

3.3. Characterization of Catalysts

3.4. Evaluation of Catalysts Activity for HER and OER

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zai, S.F.; Zhou, Y.T.; Yang, C.C.; Jiang, Q. Al, Fe-codoped CoP nanoparticles anchored on reduced graphene oxide as bifunctional catalysts to enhance overall water splitting. Chemical Engineering Journal 2021, 421, 127856. [Google Scholar] [CrossRef]

- Liu, M.; Li, J. Cobalt phosphide hollow polyhedron as efficient bifunctional electrocatalysts for the evolution reaction of hydrogen and oxygen. ACS Applied Materials & Interfaces 2016, 8, 2158–2165. [Google Scholar]

- Younas, M.; Shafique, S.; Hafeez, A.; Javed, F.; Rehman, F. (2022). An overview of hydrogen production: current status, potential, and challenges. Fuel 2022, 316, 123317. [Google Scholar] [CrossRef]

- Yoon, S.; Kim, J.; Lim, J. H.; Yoo, B. Cobalt iron-phosphorus synthesized by electrodeposition as highly active and stable bifunctional catalyst for full water splitting. Journal of The Electrochemical Society 2018, 165, H271. [Google Scholar] [CrossRef]

- Zhang, W.; Cui, L.; Liu, J. Recent advances in cobalt-based electrocatalysts for hydrogen and oxygen evolution reactions. Journal of alloys and compounds 2020, 821, 153542. [Google Scholar] [CrossRef]

- Vilekar, S.A.; Fishtik, I.; Datta, R. Kinetics of the hydrogen electrode reaction. Journal of the electrochemical society 2010, 157(7), B1040. [Google Scholar] [CrossRef]

- Li, X.; Hao, X.; Abudula,, A.; Guan, G. Nanostructured catalysts for electrochemical water splitting: current state and prospects. Journal of Materials Chemistry A 2016, 4, 11973–12000. [Google Scholar] [CrossRef]

- Greeley, J.; Jaramillo, T.F.; Bonde, J.; Chorkendorff, I.B.; Nørskov, J.K. Computational high-throughput screening of electrocatalytic materials for hydrogen evolution. Nature materials 2006, 5, 909–913. [Google Scholar] [CrossRef]

- Sun, H.; Xu, X.; Yan, Z.; Chen, X.; Jiao, L.; Cheng, F.; Chen, J. Superhydrophilic amorphous Co–B–P nanosheet electrocatalysts with Pt-like activity and durability for the hydrogen evolution reaction. Journal of Materials Chemistry A 2018, 6, 22062–22069. [Google Scholar] [CrossRef]

- Lv, Y.; Wang, X. Nonprecious metal phosphides as catalysts for hydrogen evolution, oxygen reduction and evolution reactions. Catalysis Science & Technology 2017, 7, 3676–3691. [Google Scholar]

- Bose, R.; Jothi, V.R.; Karuppasamy, K.; Alfantazi, A.; Yi, S.C. High performance multicomponent bifunctional catalysts for overall water splitting. Journal of Materials Chemistry A 2020, 8, 13795–13805. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Li, C.; Pham, B.T.; Zhang, D. Electrodeposition of Ni–Fe–Mn ternary nanosheets as affordable and efficient electrocatalyst for both hydrogen and oxygen evolution reactions. International Journal of Hydrogen Energy 2020, 56, 24670–24683. [Google Scholar] [CrossRef]

- Ma, J.; Wei, H.; Liu, Y.; Ren, X.; Li, Y.; Wang, F.; Wei, S. Application of Co3O4-based materials in electrocatalytic hydrogen evolution reaction: a review. International Journal of Hydrogen Energy 2020, 45, 21205–21220. [Google Scholar] [CrossRef]

- Xie, L.; Qu, F.; Liu, Z.; Ren, X.; Hao, S.; Ge, R.; Chen, L. In situ formation of a 3D core/shell structured Ni3N@ Ni–Bi nanosheet array: an efficient non-noble-metal bifunctional electrocatalyst toward full water splitting under near-neutral conditions. Journal of Materials Chemistry A 2017, 5, 7806–7810. [Google Scholar] [CrossRef]

- Ma, J.; Cai, A.; Guan, X.; Li, K.; Peng, W.; Fan, X.; Li, Y. Preparation of ultrathin molybdenum disulfide dispersed on graphene via cobalt doping: a bifunctional catalyst for hydrogen and oxygen evolution reaction. International Journal of Hydrogen Energy 2020, 45, 9583–9591. [Google Scholar] [CrossRef]

- Hu, G.; Tang, Q.; Jiang, D.E. CoP for hydrogen evolution: implications from hydrogen adsorption. Physical Chemistry Chemical Physics 2016, 18, 23864–23871. [Google Scholar] [CrossRef]

- Gerken, J.B.; McAlpin, J.G.; Chen, J.Y.; Rigsby, M.L.; Casey, W.H.; Britt, R.D.; Stahl, S.S. Electrochemical water oxidation with cobalt-based electrocatalysts from pH 0–14: the thermodynamic basis for catalyst structure, stability, and activity. Journal of the American Chemical Society 2011, 133, 14431–14442. [Google Scholar] [CrossRef]

- Rosen, J.; Hutchings, G.S.; Jiao, F. Ordered mesoporous cobalt oxide as highly efficient oxygen evolution catalyst. Journal of the American Chemical Society 2013, 135(11), 4516–4521. [Google Scholar] [CrossRef]

- Faber, M.S.; Dziedzic, R.; Lukowski, M.A.; Kaiser, N.S.; Ding, Q.; Jin, S. High-performance electrocatalysis using metallic cobalt pyrite (CoS2) micro-and nanostructures. 2014, 136, 10053–10061. [Google Scholar] [CrossRef]

- Popczun, E.J.; Read, C.G.; Roske, C.W.; Lewis, N.S.; Schaak, R.E. Highly active electrocatalysis of the hydrogen evolution reaction by cobalt phosphide nanoparticles. Angewandte Chemie International Edition 2014, 53(21), 5427–5430. [Google Scholar] [CrossRef]

- Chen, P.; Xu, K.; Fang, Z.; Tong, Y.; Wu, J.; Lu, X.; Xie, Y. Metallic Co4N porous nanowire arrays activated by surface oxidation as electrocatalysts for the oxygen evolution reaction. Angewandte Chemie 2015, 127(49), 14923–14927. [Google Scholar] [CrossRef]

- Zhang, Y.; Ouyang, B.; Xu, J.; Jia, G.; Chen, S.; Rawat, R.S.; Fan, H.J. Rapid synthesis of cobalt nitride nanowires: highly efficient and low-cost catalysts for oxygen evolution. Angewandte Chemie 2016, 128, 8812–8816. [Google Scholar] [CrossRef]

- Suntivich, J.; May, K.J.; Gasteiger, H.A.; Goodenough, J.B.; Shao-Horn, Y. A perovskite oxide optimized for oxygen evolution catalysis from molecular orbital principles. Science 2011, 334, 1383–1385. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.; Cha, J.J.; Wang, H.; Lee, H.R.; Cui, Y. First-row transition metal dichalcogenide catalysts for hydrogen evolution reaction. Energy & Environmental Science 2013, 6, 3553–3558. [Google Scholar]

- Xu, J.; Li, J.; Xiong, D.; Zhang, B.; Liu, Y.; Wu, K.H.; Liu, L. Trends in activity for the oxygen evolution reaction on transition metal (M= Fe, Co, Ni) phosphide pre-catalysts. Chemical science 2018, 9, 3470–3476. [Google Scholar] [CrossRef]

- Kumaravel, S.; Karthick, K.; Sam Sankar, S.; Karmakar, A.; Madhu, R.; Bera, K.; Kundu, S. Recent advances in engineering of Ni and Co based phosphides for effective Electrocatalytic water splitting. ChemElectroChem 2021, 8(24), 4638–4685. [Google Scholar] [CrossRef]

- Chen, Z.; Wei, W.; Ni, B.J. Cost-effective catalysts for renewable hydrogen production via electrochemical water splitting: Recent advances. Current Opinion in Green and Sustainable Chemistry 2021, 27, 100398. [Google Scholar] [CrossRef]

- Liu, C.; Su, F.; Liang, J. Producing cobalt–graphene composite coating by pulse electrodeposition with excellent wear and corrosion resistance. Applied Surface Science 2015, 351, 889–896. [Google Scholar] [CrossRef]

- Kouotou, P.M.; Tian, Z.Y. CVD synthesis of cobalt spinel for bio-butanol combustion. Surface and Coatings Technology 2017, 326, 11–17. [Google Scholar] [CrossRef]

- Pandey, N.; Gupta, M.; Gupta, R.; Chakravarty, S.; Shukla, N.; Devishvili, A. Structural and magnetic properties of Co-N thin films deposited using magnetron sputtering at 523 K. Journal of Alloys and Compounds 2017, 694, 1209–1213. [Google Scholar] [CrossRef]

- Cho, J.; Moon, J.; Jeong, K.; Cho, G. Application of PU-sealing into Cu/Ni electroless plated polyester fabrics for e-textiles. Fibers and Polymers 2007, 8, 330–334. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F.; Zhou, Y.; Liang, A.; Zhang, J. Aluminum-induced direct electroless deposition of Co and Co-P coatings on copper and their catalytic performance for electrochemical water splitting. Surface and Coatings Technology 2018, 352, 42–48. [Google Scholar] [CrossRef]

- Brenner, A.; Riddell, G.E. Deposition of nickel and cobalt by chemical reduction. Journal of Research of the National Bureau of Standards 1947, 39, 385–395. [Google Scholar] [CrossRef]

- Stankevičienė, I.; Jagminiene, A.; Tamasauskaite-Tamasiunaite, L.; Norkus, E. Electroless Co-B Deposition Using Dimethylamine Borane as Reducing Agent in the Presence of Different Amines. ECS Transactions 2015, 64, 17. [Google Scholar] [CrossRef]

- Yu, Y.; Song, Z.; Ge, H.; Wei, G. Preparation of CoP films by ultrasonic electroless deposition at low initial temperature. Progress in Natural Science: Materials International 2014, 24, 232–238. [Google Scholar] [CrossRef]

- Vitry, V.; Bonin, L. Increase of boron content in electroless nickel-boron coating by modification of plating conditions. Surface and Coatings Technology 2017, 311, 164–171. [Google Scholar] [CrossRef]

- Liang, M.W.; Yen, H.T.; Hsieh, T.E. Investigation of electroless cobalt-phosphorous layer and its diffusion barrier properties of Pb-Sn solder. Journal of Electronic materials 2006, 35, 1593–1599. [Google Scholar] [CrossRef]

- Luo, W.; Wang, Y.; Cheng, C. Ru-based electrocatalysts for hydrogen evolution reaction: Recent research advances and perspectives. Materials Today Physics 15, 100274. [CrossRef]

- Gong, Y.; Yao, J.; Wang, P.; Li, Z.; Zhou, H.; Xu, C. Perspective of hydrogen energy and recent progress in electrocatalytic water splitting. Chinese Journal of Chemical Engineering 2022, 43, 282–296. [Google Scholar] [CrossRef]

- Li, R.; Zhou, D.; Luo, J.; Xu, W.; Li, J.; Li, S.; Yuan, D. The urchin-like sphere arrays Co3O4 as a bifunctional catalyst for hydrogen evolution reaction and oxygen evolution reaction. Journal of Power Sources 2017, 341, 250–256. [Google Scholar] [CrossRef]

- Bai, C.; Wei, S.; Deng, D.; Lin, X.; Zheng, M.; Dong, Q. A nitrogen-doped nano carbon dodecahedron with Co@ Co3O4 implants as a bi-functional electrocatalyst for efficient overall water splitting. Journal of Materials Chemistry A 2017, 5, 9533–9536. [Google Scholar] [CrossRef]

- Guo, M.; Liu, Y.; Dong, S.; Jiao, X.; Wang, T.; Chen, D. Co9S8-Catalyzed Growth of Thin-Walled Graphite Microtubes for Robust, Efficient Overall Water Splitting. ChemSusChem 2018, 11, 4150–4155. [Google Scholar] [CrossRef]

- Chen, X.; Zhen, X.; Gong, H.; Li, L.; Xiao, J.; Xu, Z.; Yang, R. Cobalt and nitrogen codoped porous carbon as superior bifunctional electrocatalyst for oxygen reduction and hydrogen evolution reaction in alkaline medium. Chinese Chemical Letters 2019, 30(3), 681–685. [Google Scholar] [CrossRef]

- Gao, W.; Yan, M.; Cheung, H.Y.; Xia, Z.; Zhou, X.; Qin, Y.; Qu, Y. Modulating electronic structure of CoP electrocatalysts towards enhanced hydrogen evolution by Ce chemical doping in both acidic and basic media. Modulating electronic structure of CoP electrocatalysts towards enhanced hydrogen evolution by Ce chemical doping in both acidic and basic media 2017, 38, 290–296. [Google Scholar] [CrossRef]

- Al-Naggar, A.H.; Shinde, N.M.; Kim, J.S.; Mane, R.S. Water splitting performance of metal and non-metal-doped transition metal oxide electrocatalysts. Coordination Chemistry Reviews 2023, 474, 214864. [Google Scholar] [CrossRef]

- Ha, D.H.; Han, B.; Risch, M.; Giordano, L.; Yao, K.P.; Karayaylali, P.; Shao-Horn, Y. Activity and stability of cobalt phosphides for hydrogen evolution upon water splitting. Nano Energy 2016, 29, 37–45. [Google Scholar] [CrossRef]

- Wang, J.; Cui, W.; Liu, Q.; Xing, Z.; Asiri, A.M.; Sun, X. Recent progress in cobalt-based heterogeneous catalysts for electrochemical water splitting. Advanced materials 2016, 28, 215–230. [Google Scholar] [CrossRef]

- Ma, J.; Wei, H.; Liu, Y.; Ren, X.; Li, Y.; Wang, F.; Wei, S. Application of Co3O4-based materials in electrocatalytic hydrogen evolution reaction: a review. International Journal of Hydrogen Energy 2020, 45, 21205–21220. [Google Scholar] [CrossRef]

- Li, X.; Zhang, R.; Luo, Y.; Liu, Q.; Lu, S.; Chen, G.; Sun, X. A cobalt–phosphorus nanoparticle decorated N-doped carbon nanosheet array for efficient and durable hydrogen evolution at alkaline pH. Sustainable Energy & Fuels 2020, 4, 3884–3887. [Google Scholar]

- Liu, T.; Xie, L.; Yang, J.; Kong, R.; Du, G.; Asiri, A.M.; Chen, L. Self-standing CoP nanosheets array: a three-dimensional bifunctional catalyst electrode for overall water splitting in both neutral and alkaline media. ChemElectroChem 2017, 4, 1840–1845. [Google Scholar] [CrossRef]

- Li, Z.; Sui, J.; Zhang, Q.; Yu, J.; Yu, L.; Dong, L. CoP@NC electrocatalyst promotes hydrogen and oxygen productions for overall water splitting in alkaline media. International Journal of Hydrogen Energy 2021, 46, 2095–2102. [Google Scholar] [CrossRef]

- Xie, Y.; Chen, M.; Cai, M.; Teng, J.; Huang, H.; Fan, Y.; Su, C.Y. Hollow cobalt phosphide with N-doped carbon skeleton as bifunctional electrocatalyst for overall water splitting. Inorganic Chemistry 2019, 58, 14652–14659. [Google Scholar] [CrossRef] [PubMed]

- Ji, L.; Wang, J.; Teng, X.; Meyer, T.J.; Chen, Z. CoP nanoframes as bifunctional electrocatalysts for efficient overall water splitting. ACS Catalysis 2019, 10(1), 412–419. [Google Scholar] [CrossRef]

- Beltrán-Suito, R.; Menezes, P.W.; Driess, M. Amorphous outperforms crystalline nanomaterials: surface modifications of molecularly derived CoP electro (pre) catalysts for efficient water-splitting. Journal of Materials Chemistry A 2019, 7, 15749–15756. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, Y.; Hu, F.; Wang, Q. Urchin-like CoP nanocrystals as hydrogen evolution reaction and oxygen reduction reaction dual-electrocatalyst with superior stability. Nano letters 2015, 15, 7616–7620. [Google Scholar] [CrossRef]

- Jiao, L.; Zhou, Y.X.; Jiang, H.L. Metal-organic framework-based CoP/reduced graphene oxide: high-performance bifunctional electrocatalyst for overall water splitting. Chem. Sci. 2016, 7, 1690–1695. [Google Scholar] [CrossRef]

- Liu, X.; Dong, J.; You, B.; Sun, Y. Competent overall water-splitting electrocatalysts derived from ZIF-67 grown on carbon cloth. RSC Adv. 2016, 73336–73342. [Google Scholar] [CrossRef]

- Zhu, G.X.; Lu, T.L.; Han, L.; Zhan, Y.Z. Graphitic carbon nitride (g–C3N4) as an efficient metal-free Fenton-like catalyst for degrading organic pollutants: The overlooked non-photocatalytic activity. Water Sci. Technol. 2020, 81, 518–528. [Google Scholar] [CrossRef]

- Anantharaj, S.; Ede, S.R.; Karthick, K.; Sam Sankar, S.; Sangeetha, K.; Karthik, P.E.; Subrata, K. Precision and correctness in the evaluation of electrocatalytic water splitting: Revisiting activity parameters with a critical assessment. Energy Environ. Sci. 2018, 11, 744–771. [Google Scholar] [CrossRef]

- Cossar, E.; Houache, M.S.E.; Zhang, Z.; Baranova, E.A. Comparison of electrochemical active surface area methods for various nickel nanostructures. J. Electroanal. Chem. 2020, 870, 114246. [Google Scholar] [CrossRef]

- Niyitanga, T.; Kim, H. Time-dependent oxidation of graphite and cobalt oxide nanoparticles as electrocatalysts for the oxygen evolution reaction. J. Electroanal. Chem. 2022, 914, 116297. [Google Scholar] [CrossRef]

| Sample | Element, wt% | |

|---|---|---|

| Co | P | |

| CoP5/Cu | 95.13 | 4.87 |

| CoP8/Cu | 92.02 | 7.98 |

| CoP11/Cu | 88.87 | 11.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).